Digital Equipment VT50, VT52 Service Manual

VT50/VT52

Pocket

Service

Guide

E

K-VT502-PG-001

VT50/VT52

Pocket Service Guide

digital

equipment

corporation • maynard.

massachusetts

1st Edition, January

1979

Copyright ©

1979

by Digital Equipment Corporation

The material in this manual

is

for informational

purposes and

is

subject to change without notice.

Digital Equipment Corporation assumes no re-

sponsibility for any errors which may appear

in

this manual.

Printed in U.S.A.

The following are trademarks

of

Digital Equipment

Corporation, Maynard, Massachusetts:

DEC DECtape

DECCOMM DECUS

DECsystem-lO DIGITAL

DECSYSTEM-20 MASSBUS

UNIBUS

PDP

RSTS

TYPESET-8

TYPESETcll

CONTENTS

1

INTRODt:CTION

1.1

Purpose

.....................................

.

1.2 Reference Documentation

.....................

.

2 TROUBLESHOOTING

2.1

Troubleshooting Philosophy. . . . . . . . . . . . . . . . . . . . 2

3 REMOVAL AND

REPLACEMENT

3.1 Removing and Replacing the

EIA

or 20

rnA

Adapter

Card.

. . . . . . . . . . . . . . . .

..

. .

..

15

3.2 Removing and Replacing the Power Supply/

Monitor Assembly

Heat

Sink Panel. . . . . . . . . . . . . 16

3.3 Removing and Replacing the Base

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Removing and Replacing the Character

Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 Removing and Replacing the

Printer

Interface Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 Removing and Replacing the

RUT

and

DP

Modules

....

. . . . . . . . . . . . . . . . . . . . . . . . . . .

..

20

3.7 Removing and Replacing the Anti-Static

Ground

Shield...

. .

..

. . . . . . . . . . . . . . . . . . . . . . . . .

21

3.8 Removing and Replacing the Keyboard. . . . . . . .

..

22

3.9 Removing and Replacing the

Power

Supply/Monitor Assembly. . . . . . . . . . . . . . . . . . .

..

23

3.10 Removing and Replacing the CRT

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

26

3.11 Removing and Replacing the CRT Yoke. .

..

. . .

..

27

3.12 Removing and Replacing the Electrolytic

Copier

Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

28

3.13 Removing and Replacing the Transformer

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

iii

iv CONTENTS

4 ALIGNMENT AND

ADJUSTMENTS

4.1

CRT

Yoke Alignment

........................

.

4.2 Display Adjustments

.........................

.

5 ACCEPTANCE

TEST

PROCEDURES

5.1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

33

5.2

Terminal

Tests.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3

Copier Option Tests. . . . . . . . . . . . . . . . . . . . . . . . .

..

36

5.4 Printer Interface Option

Tests.

. . . . . . . . . . . . . . .

..

36

6 INSTALLATION

A:"oID

OPERATION

6.1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 7

6.2

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 PMK04 OPERATION

APPENDIX

A CARE AND HANDLING

OF

CATHODE

RAY

TUBES

APPENDIX

B REPLACEABLE

:\10DULES

AND ASSEMBLIES PARTS LIST

FIGURES

2-1

Troubleshooting Procedures Index

..............

2-2

ROM

Chip Locations

.........................

2-3 Jumper

W7

Location

..........................

3-1

Removal and Replacement Guide

...............

3-2 Removing and Replacing the

EIA

or

20 rnA Adapter

Card

..........................

3-3 Removing and Replacing the Power

Supply/Monitor Assembly

Heat

Sink Panel

......

3-4 Removing and Replacing the Base

Assembly

....................................

3-5

Removing and Replacing the Character

Generator and Optional

Printer Interface

Module

......................................

3-6

Removing and Replacing the

RUT

and

DP

Modules

.................................

'

3-7

Removing and Replacing the Keyboard

.........

3

14

15

16

18

19

20

22

CONTENTS v

3-8 Removing and Replacing the Power

Supply/Monitor Assembly

.....................

23

,9

Discharging the

CRT

and Power Supply

Capacitors

...................................

24

3-10

Power Supply/Monitor Assembly

Capacitor Connections

........................

25

3-11

Installing the Power Supply /Monitor

Board Assembly

..............................

26

3-12 Removing and Replacing the CRT Assembly

.....

27

3-13 Removing and Replacing the Electrolytic

Copier

Option

................................

28

3-14

Copier

Power and Signal Connectors

............

29

3-15

Transformer Assembly Wiring Diagram

.........

30

4-1

Yoke Alignment

..............................

31

4-2 Display Adjustments

..........................

32

6-1

Function and Baud Rate Switch Settings

.........

38

6-2

Power

ON/OFF

Switch and Intensity Control

Locations

....................................

38

B-1

VT52 Replaceable Modules and

Assemblies/Parts List

.........................

46

C-l

Physical/Functional Block Diagram

.............

47

TABLES

2-1

Power on Troubleshooting Procedure. . . . . . . . . . . . 4

2-2 Character Display Troubleshooting

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3

Display Troubleshooting Procedure . . . . . . . . . . . . . 9

~-4

Copier Option Troubleshooting Procedure

..

. . . . .

11

l-5 Printer Interface Option Troubleshooting

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-6 Printer Interface

Option Baud Rate Selection. . . . .

13

7-2 7-Bit ASCII

Code.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

40

1 INTRODUCTION

1.1

PURPOSE

The purpose

of

this Pocket Service Guide

is

to provide Field Service engineers and technicians with a convenient

source

of

"memory

jogger"

reference

information for the VT50 and VT52 terminals. This in-

formation supplements detailed operation

and

mainte-

nance

information

contained

in

the

reference

documentation listed in Paragraph

1.2.

1.2 REFERENCE DOCUMENTATION

Document

VT52 DECscope Maintenance

Manual

DECscope User's Manual

PMK04 Operating and Service

Manual

Document No.

EK-VT52-MM-OOI

EK-

VT5X-OP-OOI

EK-PMK04-05-001

2 TROUBLESHOOTING

2.1

TROUBLESHOOTING

PHILOSOPHY

NOTE

Before attempting to troubleshoot the terminal ensure that

there actually

is

a malfunction by checking that the unit is

properly set

up

for operation with a host computer (Chap-

ter 6).

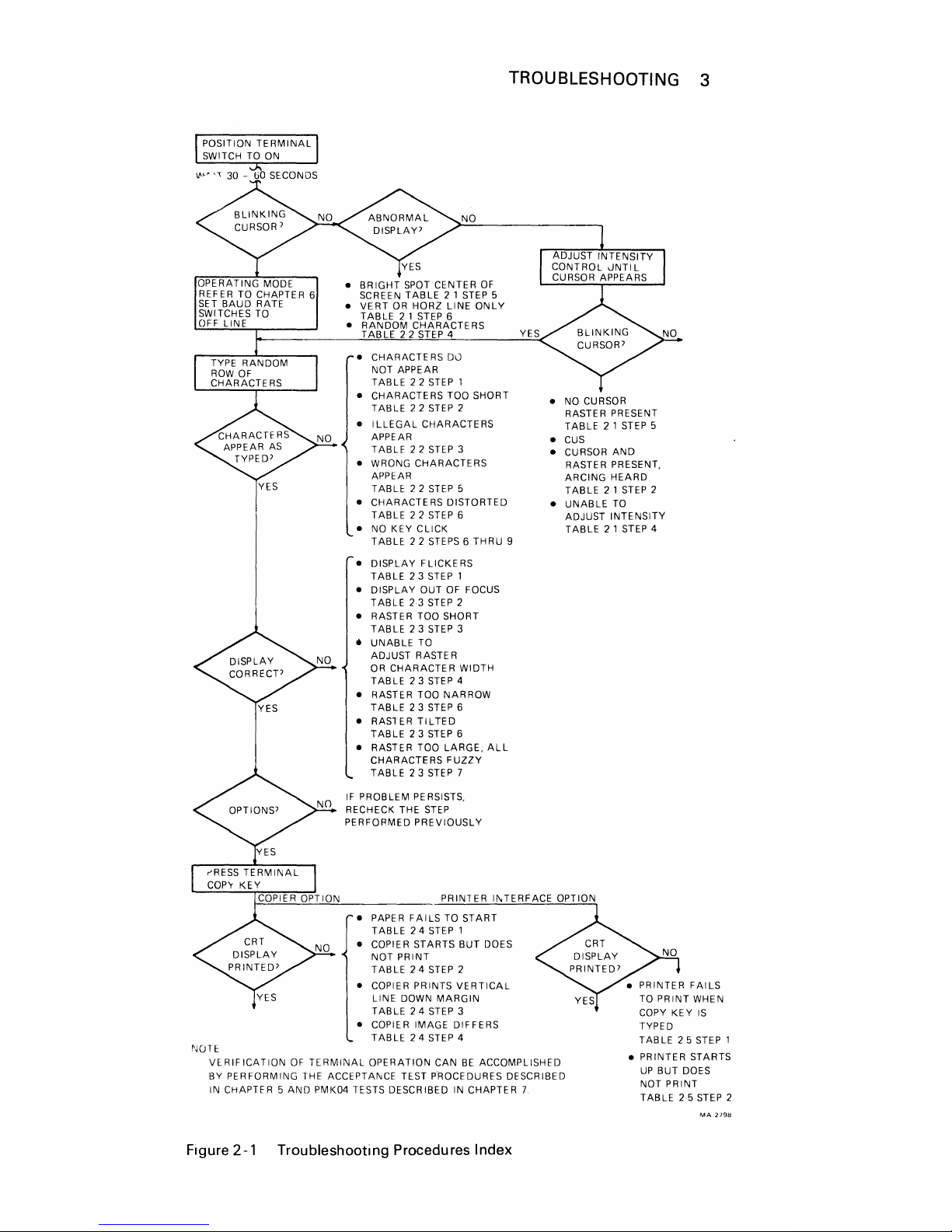

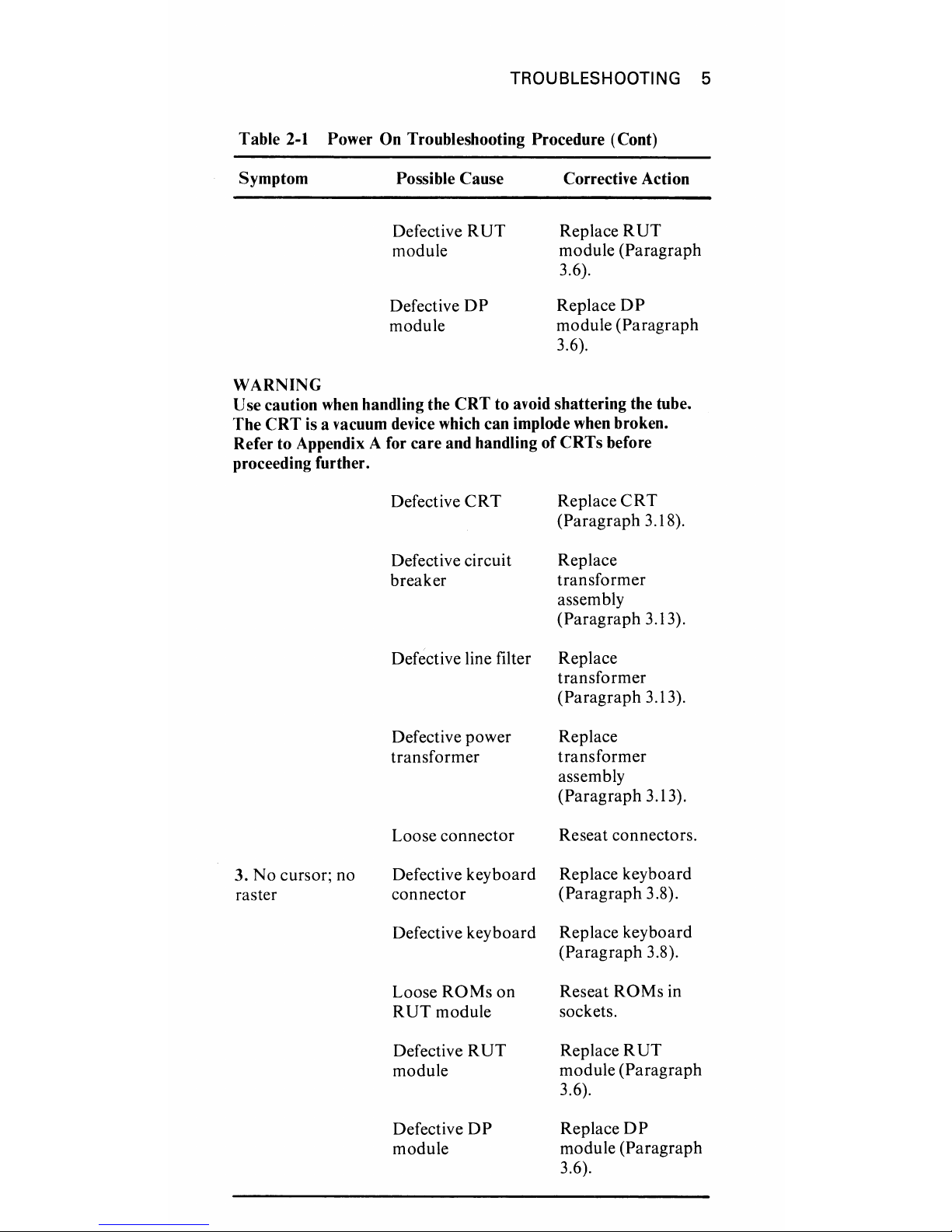

Figure

2-1

is

an index to the troubleshooting pro-

cedures contained in Tables

2-1

through 2-5. Step-by-

step turn-on

and

operating instructions are followed by

normal display indications.

If

these indications are ab-

sent

or

incorrect, refer

to

the corresponding tables for

troubleshooting information.

Possible equipment malfunctions are categorized by

abnormal symptoms. Corresponding causes are listed in

order

of

probability. Corrective actions are limited

mainly

to

the adjustments

and/or

substitutions

of

major

replaceable subassemblies suspected to be defective.

If after performing the off-line tests described

in

this

chapter the terminal functions properly

but

still does

not

operate correctly when connected to a host computer,

verify

that

portion

of

the terminal

not

checked by offline tests and the interface cabling with the PMK04

tester (Chapter

6).

2

TROUBLESHOOTING 3

YES

NOTE

NO

•

BRIGHT

SPOT

CENTER

OF

SCREEN

TABLE

21

STEP 5

•

VERT

OR

HORZ

LINE

ONLY

TABLE

21

STEP

6

•

RANDOM

CHARACTERS

TABLE

22

STEP 4

• CHARACTE

RS

Du

NOT

APPEAR

TABLE

22

STEP

1

•

CHARACTERS

TOO

SHORT

TABLE

22

STEP

2

• I

LLEGAL

CHARACTERS

APPEAR

TABLE

22

STEP

3

• WRONG

CHARACTERS

APPEAR

TABLE

22

STEP 5

•

CHARACTERS

DISTORTED

TABLE

22

STEP 6

• NO KEY

CLICK

TABLE

22

STEPS 6 THRU

9

• DISPLAY

FLICKERS

TABLE

23STEP

1

• DISPLAY OUT OF FOCUS

TABLE

2·3

STEP 2

•

RASTER

TOO

SHORT

TABLE

23

STEP 3

•

UNABLE

TO

ADJUST

RASTER

OR

CHARACTER

WIDTH

TABLE

23

STEP 4

• RASTE R

TOO

NAR

ROW

TABLE

23

STEP 6

•

RASTER

TILTED

TABLE

23

STEP

6

• RASTER

TOO

LARGE.

ALL

CHARACTERS

FUZZY

TABLE

23

STEP 7

IF PROBLEM PERSISTS,

RECHECK THE

STEP

PERFORMED

PREVIOUSLY

PAPER

FAILS

TO

START

TABLE

24

STEP

1

COPIER STARTS

BUT

DOES

NOT PRINT

TABLE

24

STEP

2

COPIER PRINTS

VERTICAL

LINE

DOWN

MARGIN

TABLE

24

STEP

3

COPIER IMAGE DIFFERS

TABLE

24

STEP 4

•

NO

CURSOR

RASTER

PRESENT

TABLE

21

STEP

5

• CUs

• CURSOR

AND

RASTER

PRESENT,

ARCING

HEARD

TABLE

2·'

STEP

2

•

UNABLE

TO

ADJUST INTENSITY

TABLE

2'

STEP

4

TYPED

TABLE

25

STEP'

VERIFICATION

OF

TERMINAL

OPERATION CAN

BE

ACCOMPLISHED

BY PERFORMING THE ACCEPTANCE TEST PROCEDURES DESCRIBED

IN

CHAPTER 5

AND

PMK04 TESTS DESCRIBED

IN

CHAPTER 7

• PRINTER STARTS

UP

BUT DOES

NOT

PRINT

TABLE

2·5

STEP

2

Figure 2-1 Troubleshooting Procedures Index

4 TROUBLESHOOTING

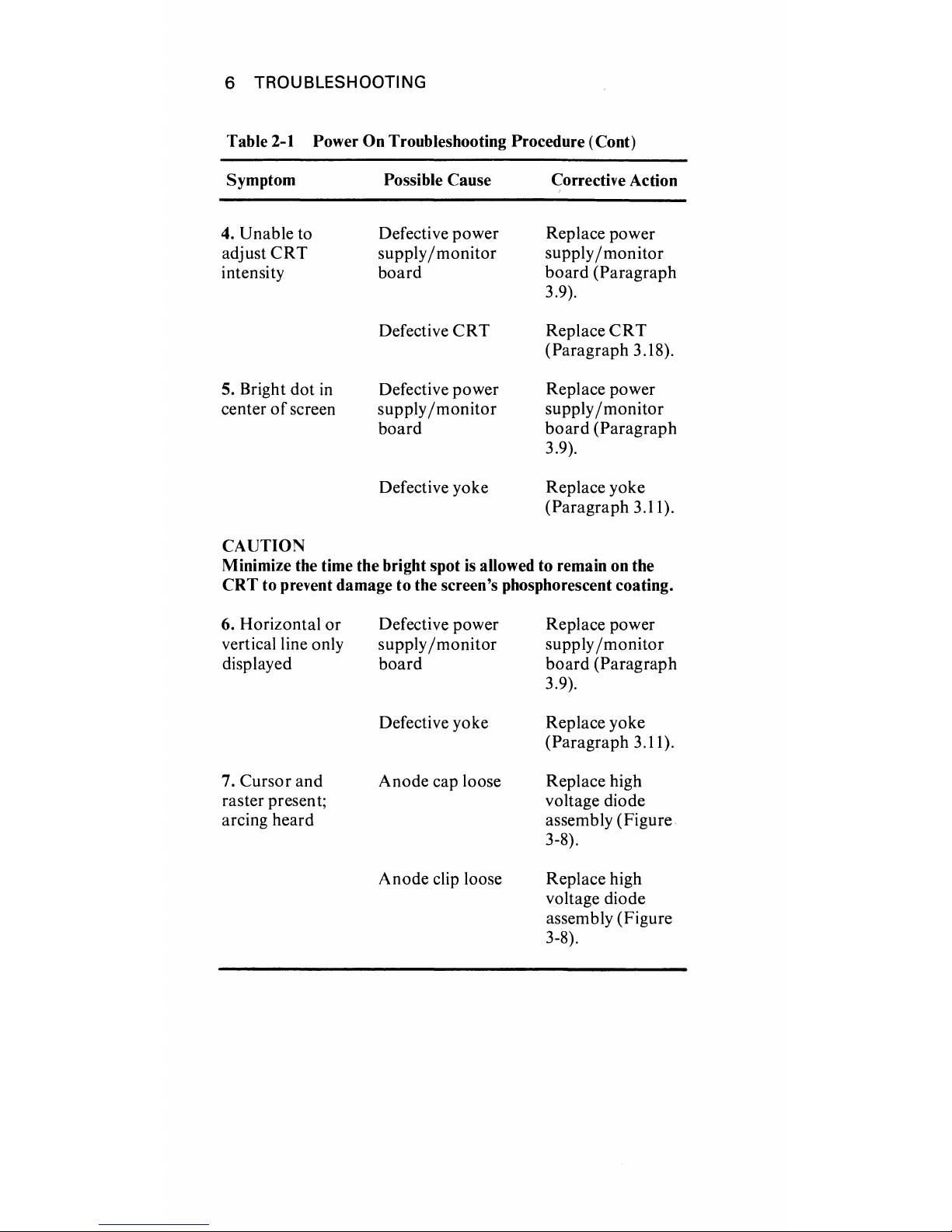

Table

2-1 Power

On

Troubleshooting Procedure

Symptom

I.

No

cursor

2.

No

cursor;

no

raster

WARNING

Possible

Cause

Unit

not

plugged

into

power

source

Intensity

control

turned

down

Blown fuse

or

tripped

circuit

breaker

Corrective Action

Plug

unit

into

appropriate

source

of

prime

power.

Adjust

intensity

control

(Paragraph

6.2).

Replace

fuse

or

reset

circuit

breaker.

No

prime

power

at

Restore

source

of

power

receptacle

prime

power.

There

are

high voltages present in the power supply and

CRT.

Ensure

that

the terminal power line is unplugged and the

CRT

and capacitors

are

discharged (Figure 3-9) before handling the

power supply

or

CRT

components. Ensure

that

ground connection

is made before discharging these points.

Defective

power

supply/monitor

assembly

Defective high

voltage

diode

assembly

Anode

cap

disconnected

Anode

clip

disconnected

Defective

ON/OFF

switch

Replace

power

supply

/monitor

assembly

(Paragraph

3.9).

Replace high

voltage

diode

assembly

(Figure

3-8).

Connect

anode

cap

at

power

supply

(Paragraph

3.2

and

Figure

3-8).

Connect

anode

clip

at

CRT

bell

(Paragraph

3.6

and

Figure

3-12).

Replace

transformer

assembly

(Paragraph

3.13).

TROUBLESHOOTING 5

Table

2-1 Power On Troubleshooting Procedure (Cont)

Symptom

WARNING

Possible Cause

Defective

RUT

module

Defective

DP

module

Corrective Action

Replace

RUT

module

(Paragraph

3.6).

ReplaceDP

module

(Paragraph

3.6).

Use caution when handling the

CRT

to avoid shattering the tube.

The

CRT

is a vacuum device which can implode when broken.

Refer to Appendix A for

care

and handling

of

CRTs

before

proceeding further.

Defective

CRT

Replace

CRT

(Paragraph

3.18).

Defective circuit Replace

breaker

transformer

assembly

(Paragraph

3.13).

Defective line filter

Replace

transformer

(Paragraph

3.13).

Defective

power

Replace

transformer

transformer

assembly

(Paragraph

3.13).

Loose

connector

Reseat connectors.

3.

No

cursor; no

Defective

keyboard

Replace

keyboard

raster

connector

(Paragraph

3.8).

Defective

keyboard

Replace

keyboard

(Paragraph

3.8).

Loose

ROMs

on

Reseat

ROMs

in

RUT

module

sockets.

Defective

RUT

Replace

RUT

module

module

(Paragraph

3.6).

Defective

DP

ReplaceDP

module

module

(Paragraph

3.6).

6 TROUBLESHOOTING

Table

2-1

Power On Troubleshooting Procedure (Cont)

Symptom Possible Cause

Corrective Action

4.

Unable to

Defective power Replace power

adjust

CRT

supply/monitor

supply

/monitor

intensity board board (Paragraph

3.9).

Defective

CRT

Replace

CRT

(Paragraph 3.18).

5. Bright dot

in

Defective power Replace power

center 0 f screen supply

/monitor

supply

/monitor

board

board

(Paragraph

3.9).

Defective yoke Replace yoke

(Paragraph 3.11).

CAlJTION

Minimize the time the bright spot

is

allowed to remain on the

CRT to prevent damage to the screen's phosphorescent coating.

6. Horizontal

or

vertical line only

displayed

7.

Cursor and

raster presen

t;

arcing heard

Defective power

supply

/monitor

board

Defective yoke

Anode cap loose

Anode clip loose

Replace power

supply

/monitor

board (Paragraph

3.9).

Replace yoke

(Paragraph 3.11).

Replace high

voltage diode

assembly (Figure

3-8).

Replace high

voltage diode

assembly (Figure

3-8).

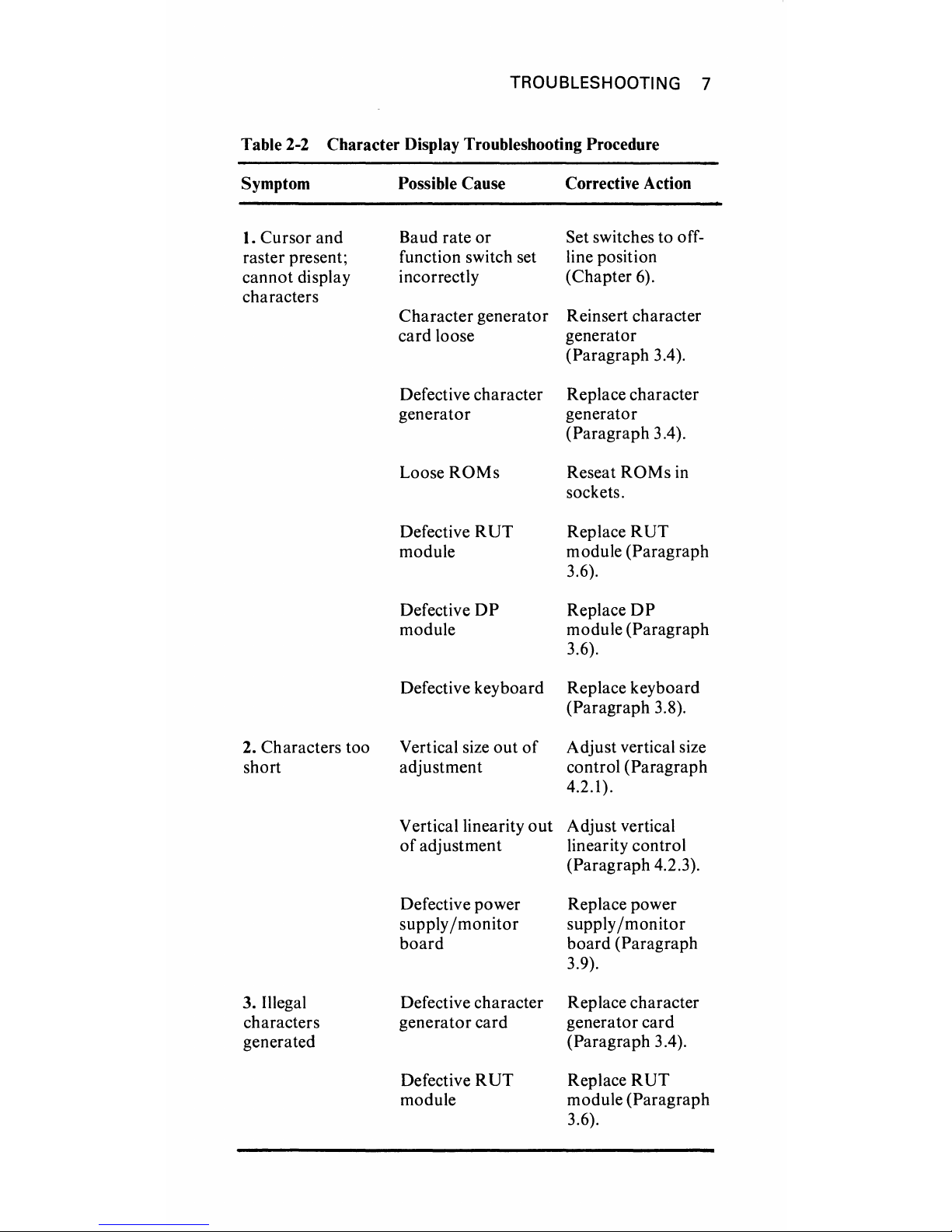

TROUBLESHOOTING

7

Table 2-2

Character Display Troubleshooting Procedure

Symptom Possible Cause Corrective Action

1. Cursor and

Baud rate

or

Set switches to off-

raster present; function switch set

line position

cannot display

incorrectly (Chapter 6).

characters

Character generator

Reinsert character

card loose

generator

(Paragraph 3.4).

Defective character Replace character

generator generator

(Paragraph 3.4).

Loose

ROMs

Reseat

ROMs

in

sockets.

Defective

RUT

Replace

RUT

module

module

(Paragraph

3.6).

Defective

DP

Replace

DP

module

module

(Paragraph

3.6).

Defective keyboard

Replace keyboard

(Paragraph 3.8).

2. Characters too Vertical size out

of

Adjust vertical size

short adjustment

control

(Paragraph

4.2.1).

V erticallinearity

out

Adjust vertical

of

adjustment linearity control

(Paragraph 4.2.3).

Defective power Replace power

supply

/monitor

supply

/monitor

board

board (Paragraph

3.9).

3. Illegal

Defective character

Replace character

characters generator card generator card

generated

(Paragraph 3.4).

Defective

RUT

Replace

RUT

module

module

(Paragraph

3.6).

8 TROUBLESHOOTING

Table 2-2

Character

Display Troubleshooting

Procedure (Cont)

Symptom

4.

Random

characters

fill

screen when first

turned

on

5.

Wrong

character

displayed when

typed

6.

No

key clicks;

characters

legal

but

distorted

7.

:-;0

key clicks;

cursor

present

8.

No

key clicks

or

cursor; raster

present

9.

No

key clicks;

characters

Possible Cause

RUT

/character

ROM/PROM

chips

are

incompatible

Defective

character

generator

card

Defective

DP

module

Defective

RUT

module

Defective

keyboard

Defective

character

generator

card

Defective

RUT

module

Defective

DP

module

Defective

keyboard

Defective

RUT

module

Defective interface

card

Corrective Action

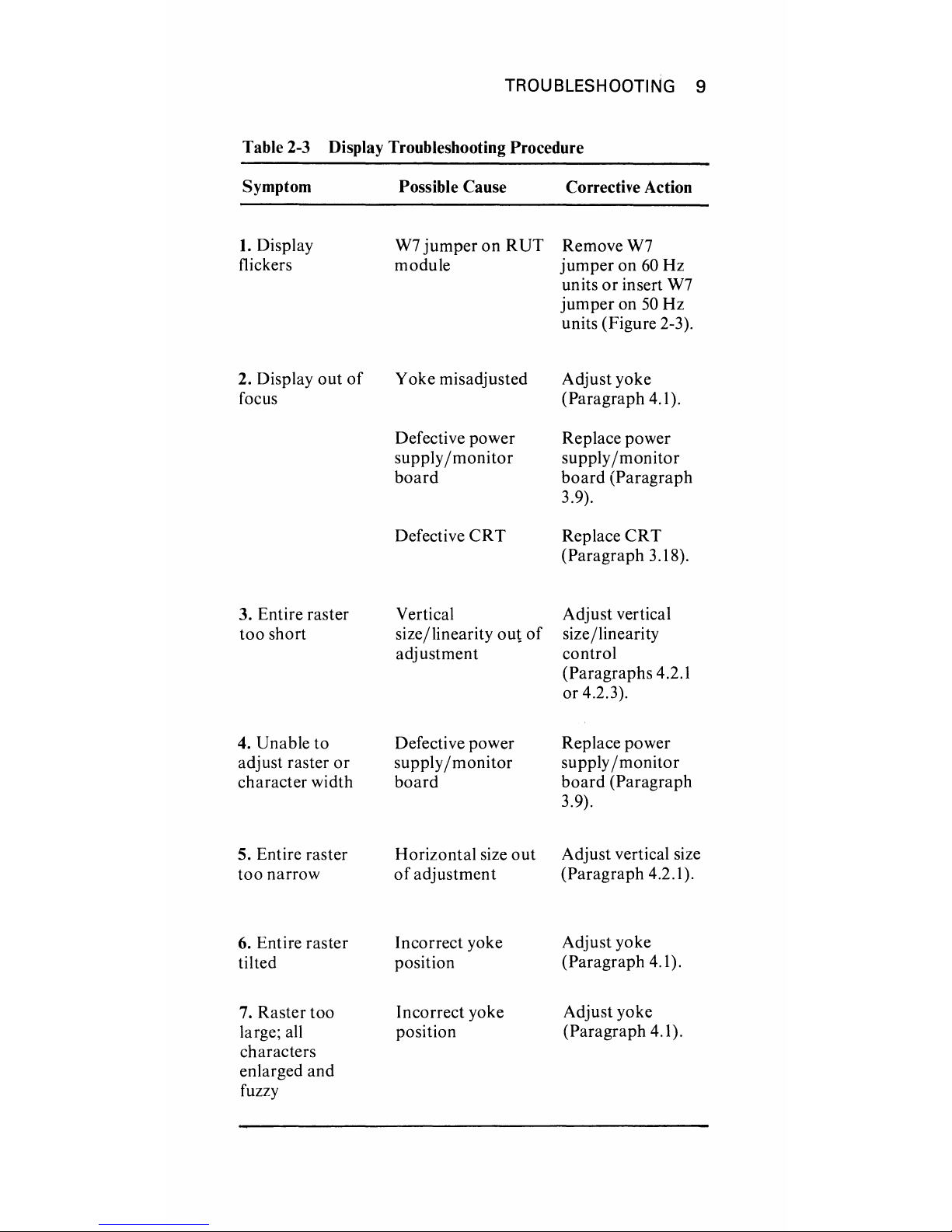

Ensure

that

ROM/PROM

chip

is

A23002B4 series

(Figure

2-2).

Replace

character

generator

card

(Paragraph

3.4).

Replace

DP

module

(Paragraph

3.6).

Replace

RUT

module

(Paragraph

3.6).

Replace

keyboard

(Paragraph

3.8).

Replace

character

generator

card

(Paragraph

3.4).

Replace defective

RUT

module

(Paragraph

3.6).

Replace defective

DPmodule

(Paragraph

3.6).

Replace defective

keyboard

(Paragraph

3.8).

Replace defective

RUT

module

(Paragraph

3.6).

Replace defective

interface

card

(Paragraph

3.5).

TROUBLESHOOTING

9

Table 2-3 Display Troubleshooting Procedure

Symptom

Possible Cause

Corrective Action

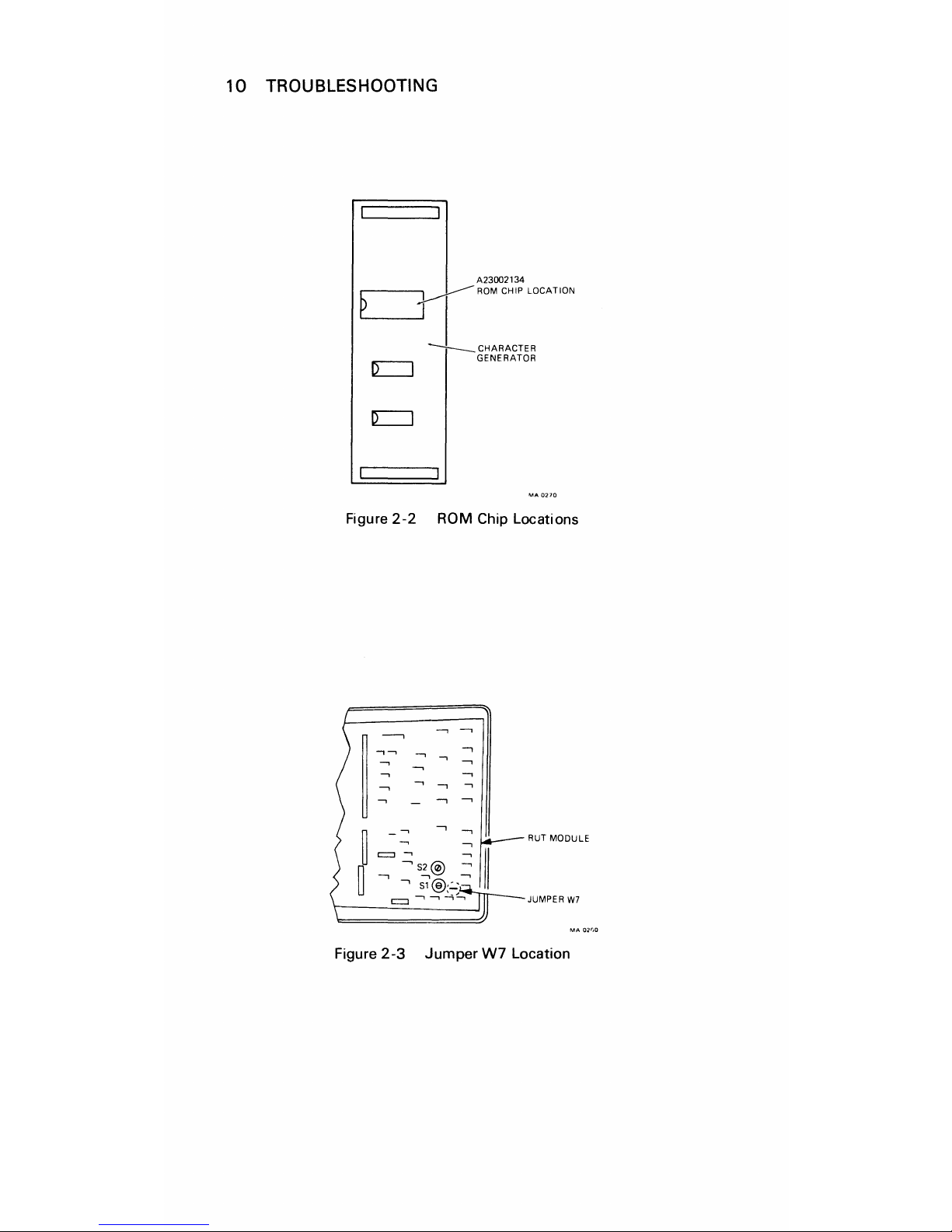

I.

Display

W7

jumper

on

RUT

RemoveW7

flickers module

jumper

on

60 Hz

units

or

insert W7

jumper

on

50

Hz

units (Figure 2-3).

2. Display

out

of

Yoke misadjusted Adjust yoke

focus

(Paragraph 4.1).

Defective power

Replace power

supply

/monitor

supply

/monitor

board

board

(Paragraph

3.9).

Defective

CRT

Replace

CRT

(Paragraph 3.18).

3. Entire raster Vertical Adjust vertical

too

short

size/linearity

out

of

size/linearity

adjustment

control

(Paragraphs 4.2.1

or 4.2.3).

4. Unable to Defective power Replace power

adjust raster

or

supply/monitor

supply

/monitor

character width

board board

(Paragraph

3.9).

5. Entire raster Horizontal size

out

Adjust vertical size

too narrow

of

adjustment (Paragraph 4.2.1).

6. Entire raster Incorrect yoke

Adjust yoke

tilted position

(Paragraph 4.1).

7. Raster too Incorrect yoke

Adjust yoke

large; all

position

(Paragraph 4.1).

characters

enlarged and

fULlY

10

TROUBLESHOOTING

A23002134

C=:3

------

ROM

CH"

LOCATIO'

~CHARACTER

GENERATOR

Figure

2-2

ROM

Chip Locations

Figure

2-3

Jumper

W7

Location

Loading...

Loading...