Digital Equipment VAX 6000 XMI-1, VAX 6000 XMI Series, VAX 6000 XMI-2 Conversion Manual

VAX 6000 XMI Conversion Manual

Order Number EK–650EB–UP–002

This manual details the procedure for the full power

and packaging upgrade from a VAX 6000 Model 200,

300, or 400 system with an XMI-1 card cage to a

system with an XMI-2 card cage.

digital equipment corporation

maynard, massachusetts

First Printing, December 1990

Revised, July 1991

The information in this document is subject to change without notice and should not be

construed as a commitment by Digital Equipment Corporation.

Digital Equipment Corporation assumes no responsibility for any errors that may appear in

this document.

The software, if any, described in this document is furnished under a license and may be used

or copied only in accordance with the terms of such license. No responsibility is assumed

for the use or reliability of software or equipment that is not supplied by Digital Equipment

Corporation or its affiliated companies.

Copyright ©1991 by Digital Equipment Corporation.

All Rights Reserved.

Printed in U.S.A.

The following are trademarks of Digital Equipment Corporation:

DEC PDP VAXcluster

DEC LANcontroller ULTRIX VAXELN

DECnet UNIBUS VMS

DECUS VAX XMI

DWMVA VAXBI

FCC NOTICE: The equipment described in this manual generates, uses, and may emit

radio frequency energy. The equipment has been type tested and found to comply with the

limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such radio frequency interference when

operated in a commercial environment. Operation of this equipment in a residential area

may cause interference, in which case the user at his own expense may be required to take

measures to correct the interference.

Contents

Preface vii

Chapter 1 Specifications and Preparation

1.1 Upgrade Kit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2 Battery Backup Kit Specifications . . . . . . . . . . . . . . . . . . . . . 1–4

1.3 Save EEPROM Contents to TK Tape . . . . . . . . . . . . . . . . . . . 1–6

1.4 Record System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1.5 Prepare Area, Kits, and Tools . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1.6 Unpacking Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

Chapter 2 XMI-1 to XMI-2 Conversion

2.1 Full Upgrade Procedure Overview . . . . . . . . . . . . . . . . . . . . . 2–2

2.2 Step 1, Remove the XMI-1 Card Cage . . . . . . . . . . . . . . . . . . 2–4

2.2.1 Prepare for Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

2.2.2 Remove the XMI-1 Card Cage from the Cabinet . . . . . . . . 2–8

2.3 Step 2, Remove the H7214 Power Regulator(s) . . . . . . . . . . . 2–10

2.3.1 Replace the H7214 in Position 2, if Necessary . . . . . . . . . . 2–12

2.3.2 Remove the H7214 in Position 3 . . . . . . . . . . . . . . . . . . . . 2–14

2.4 Step 3, Install the H7242 Power Regulator . . . . . . . . . . . . . . 2–16

2.5 Step 4, Install the XMI-2 Card Cage . . . . . . . . . . . . . . . . . . . 2–18

2.5.1 Attach the Daughter Card and Install the Card Cage . . . . 2–19

2.5.2 Attach XMI-2 Card Cage Cables . . . . . . . . . . . . . . . . . . . . 2–20

2.5.3 Complete XMI-2 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

2.6 Step 5, Replace the XTC Power Sequencer . . . . . . . . . . . . . . 2–26

2.7 Step 6, Remove the H7231-N Battery Backup Unit . . . . . . . . 2–28

2.8 Step 7, Replace the Power and Logic Unit . . . . . . . . . . . . . . . 2–30

2.8.1 Remove the H7206-A Power and Logic Unit . . . . . . . . . . . 2–31

2.8.2 Replace the Power and Logic Unit Mounting Plate . . . . . . 2–32

iii

2.8.3 Install the H7206-B Power and Logic Unit . . . . . . . . . . . . 2–34

2.8.4 Apply Power to Check Conversion . . . . . . . . . . . . . . . . . . . 2–36

Chapter 3 Wrap-Up and Troubleshooting

3.1 Insert XMI Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3.2 Install DWMBB Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.3 Reattach Doors, Change System Number, and Attach Product

Conversion Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.4 Restore Power to System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.5 H7206-B Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3.6 H7206-B LEDs During Normal Power-Up . . . . . . . . . . . . . . . 3–12

3.7 Sample Self-Test Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–14

3.8 Pack Up and Return Replaced Items . . . . . . . . . . . . . . . . . . . 3–16

Appendix A Module Handling

A.1 Handling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

A.2 Inserting Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Appendix B Power-Up Troubleshooting Procedures

B.1 Power-Up with Inhibit Cable and XMI-1 Modules Installed . . B–2

B.2 Normal Operation with Model 500 CPUs and No Inhibit

Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

Index

Examples

1–1 SAVE EEPROM Command . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1–2 Show All System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

3–1 Sample Self-Test Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–14

iv

Figures

1–1 Overview of Full Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1–2 Battery Backup Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–3 System Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

2–1 Upgrade Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2–2 XMI-1 Backplane Cables and Power Connections . . . . . . . . . 2–4

2–3 XMI-1 Backplane Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2–4 Power Control/Status Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2–5 XMI-1 Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

2–6 Remove the H7214 Power Regulator(s) . . . . . . . . . . . . . . . . . 2–10

2–7 Replace the H7214 in Position 2 . . . . . . . . . . . . . . . . . . . . . . 2–12

2–8 Bulk Power Cable to Power Regulators . . . . . . . . . . . . . . . . . 2–13

2–9 Remove the H7214 in Position 3 . . . . . . . . . . . . . . . . . . . . . . 2–14

2–10 H7242 Power Regulator Installation . . . . . . . . . . . . . . . . . . . 2–16

2–11 XMI Backplane and Daughter Card . . . . . . . . . . . . . . . . . . . . 2–18

2–12 XMI-2 Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

2–13 XMI-2 Bus Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–21

2–14 Power Control/Status Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

2–15 Complete XMI-2 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

2–16 Replace the XTC Power Sequencer Module . . . . . . . . . . . . . . 2–26

2–17 H7231-N Battery Backup Unit Removal . . . . . . . . . . . . . . . . 2–28

2–18 H7206-A Power and Logic Unit Removal (Top View) . . . . . . . 2–30

2–19 Attaching BeCu Clips to New Mounting Plate . . . . . . . . . . . . 2–32

2–20 H7206-B Power and Logic Unit (Top View) . . . . . . . . . . . . . . 2–34

2–21 H7242 Inhibit Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–36

3–1 Module Utilization Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–2 VAX 6000 Series Slot Numbers . . . . . . . . . . . . . . . . . . . . . . . 3–4

3–3 Front Door (Inside View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3–4 Product Conversion Label . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3–5 AC Power Controller Circuit Breaker . . . . . . . . . . . . . . . . . . 3–8

3–6 Power-Up Troubleshooting Flowchart . . . . . . . . . . . . . . . . . . 3–9

3–7 H7206-B Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3–8 H7206-B LEDs During Normal Power-Up . . . . . . . . . . . . . . . 3–12

A–1 Holding 6000 Series Processor Modules . . . . . . . . . . . . . . . . . A–2

A–2 Inserting the Scalar Processor in an XMI Card Cage . . . . . . . A–4

A–3 Inserting the Vector Processor in an XMI Card Cage . . . . . . . A–4

v

Tables

1 VAX 6000 Series Documentation . . . . . . . . . . . . . . . . . . . . . . viii

2 VAX 6000 Model Level Documentation . . . . . . . . . . . . . . . . . ix

3 Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1–1 Components to Be Replaced . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1–2 Battery Backup Kit H7236-A . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–3 Tools and Supplies Required . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

1–4 H9657-CU Platform Upgrade Components. . . . . . . . . . . . . . . 1–12

B–1 H7206-B Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

vi

Preface

Intended Audience

This manual is written for the Digital customer service engineer who is

upgrading a VAX 6000 Model 200, 300, or 400 system with a +5V XMI-1

card cage to a +3.3V XMI-2 card cage.

Document Structure

This manual uses a structured documentation design. There are many

topics, organized into small sections for efficient reference. Each topic

begins with an abstract. You can gain an overview by reading only the

abstracts. Next is an illustration or example, which also provides quick

reference. Last in the structure is descriptive text.

This manual has three chapters and two appendixes, as follows:

• Chapter 1, Specifications and Preparation, gives an overview of

the power upgrade and conversion described in this manual.

• Chapter 2, XMI-1 to XMI-2 Conversion, gives the details of the XMI

and power upgrade.

• Chapter 3, Wrap-Up and Troubleshooting, explains how to verify

the system and what to do if something goes wrong.

• Appendix A describes the proper handling of modules.

• Appendix B describes power-up troubleshooting procedures.

vii

Conventions Used in This Document

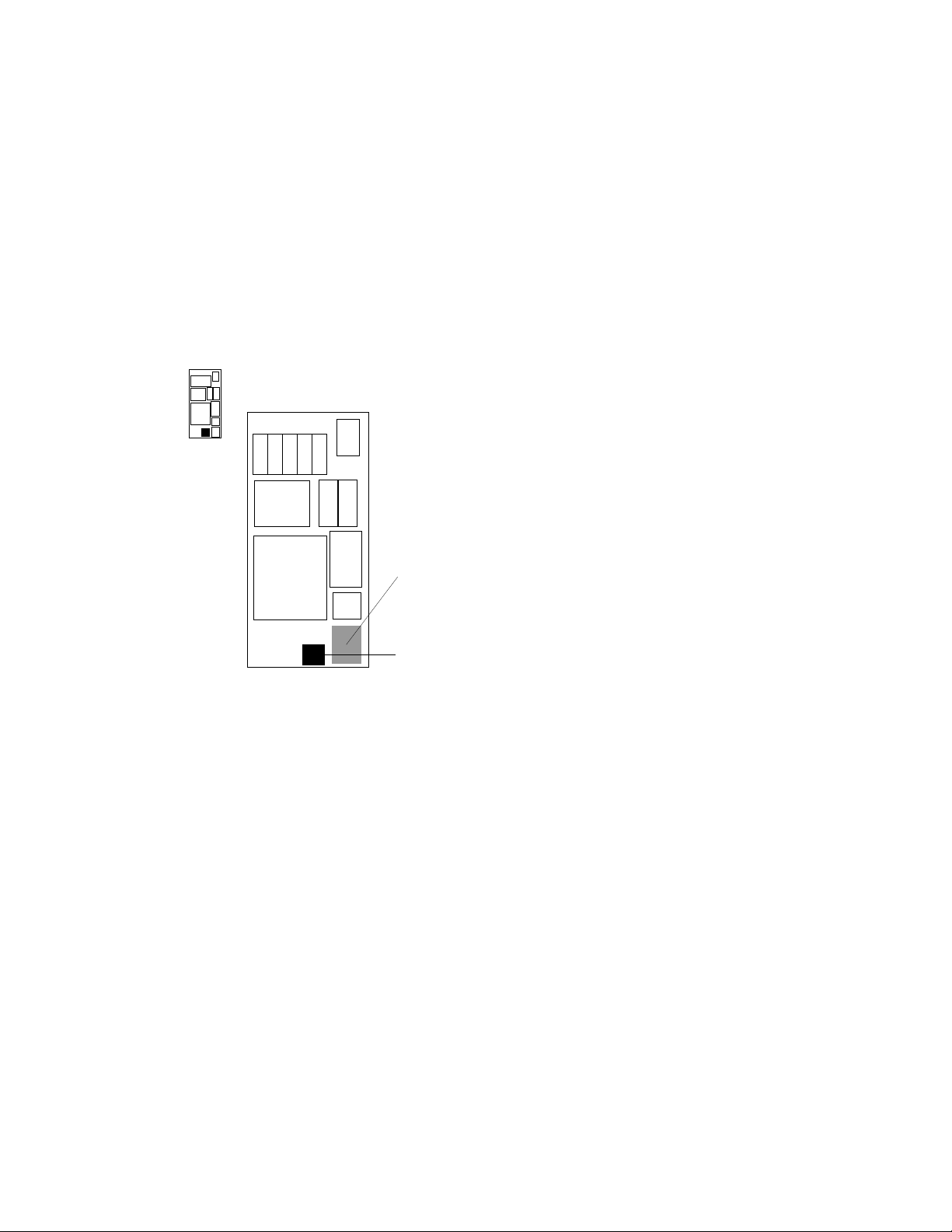

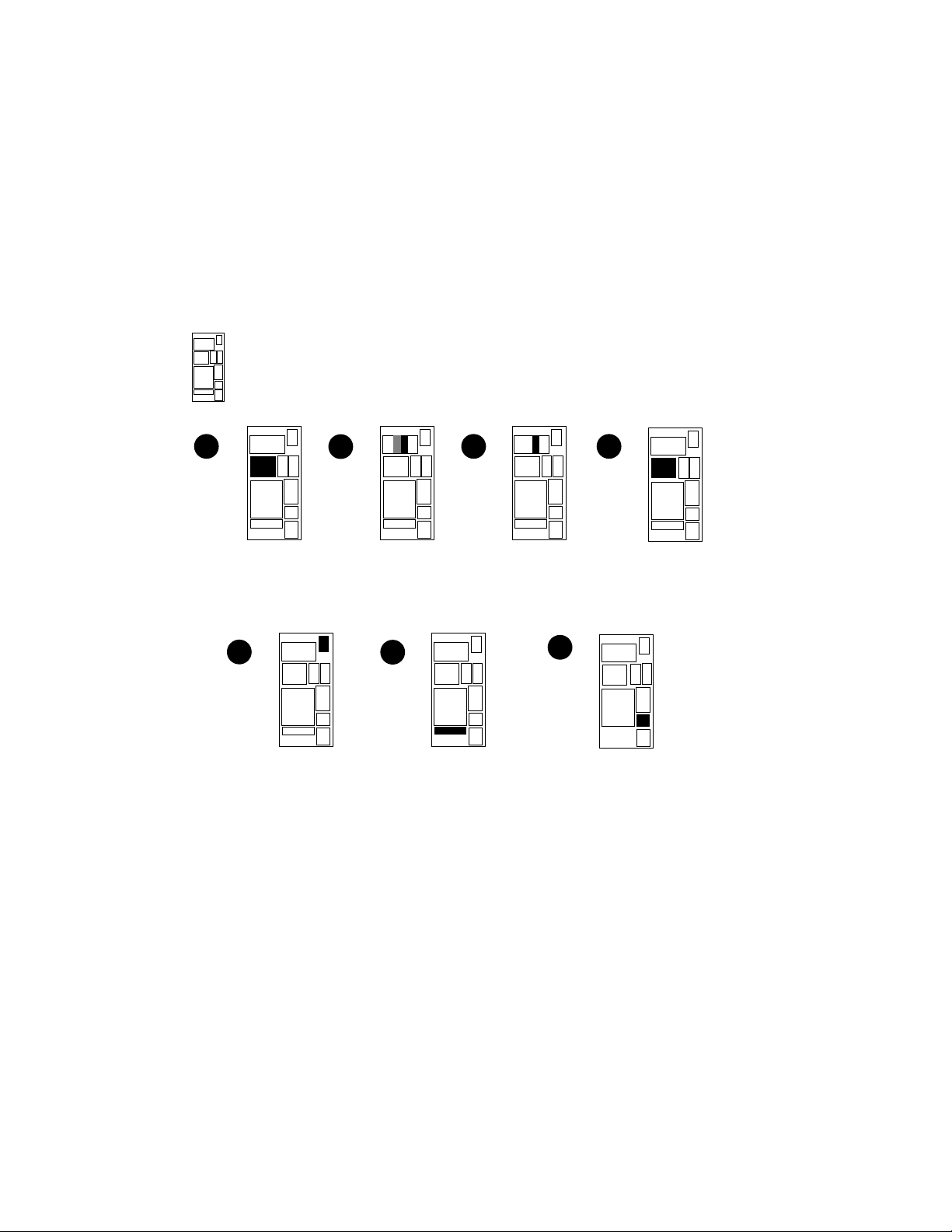

The icons shown below are used in illustrations for designating part

placement in VAX 6000 systems. A shaded area in the icon shows the

location of the component or part being discussed.

FRONT

REAR

VAX 6000 Series Documents

There are two sets of documentation: manuals that apply to all VAX 6000

series systems and manuals that are specific to one VAX 6000 model.

Table 1 lists the manuals in the VAX 6000 series documentation set.

Table 1: VAX 6000 Series Documentation

Title Order Number

Operation

VAX 6000 Series Owner ’s Manual EK–600EA–OM

VAX 6000 Series Vector Processor Owner ’s Manual EK–60VAA–OM

VAX 6000 Vector Processor Programmer’s Guide EK–60VAA–PG

Service and Installation

VAX 6000 Platform Technical User’s Guide EK–600EA–TM

VAX 6000 Series Installation Guide EK–600EA–IN

VAX 6000 Installationsanleitung EK–600GA–IN

VAX 6000 Guide d’installation EK–600FA–IN

VAX 6000 Guia de instalacion EK–600SA–IN

viii

Table 1 (Cont.): VAX 6000 Series Documentation

Title Order Number

Service and Installation

VAX 6000 Platform Service Manual EK–600EA–MG

Options and Upgrades

VAX 6000: XMI Conversion Manual EK–650EB–UP

VAX 6000: Installing MS65A Memories EK–MS65A–UP

VAX 6000: Installing the H7236-A Battery Backup Option EK–60BBA–IN

VAX 6000: Installing the FV64A Vector Option EK–60VEA–IN

VAX 6000: Installing the VAXBI Option EK–60BIA–IN

Manuals specific to models are listed in Table 2.

Table 2: VAX 6000 Model Level Documentation

Title Order Number

Models 200/300/400

VAX 6000 Model 300 and 400 Service Manual EK–624EA–MG

VAX 6000: Installing Model 200/300/400 Processors EK–6234A–UP

Model 500

VAX 6000 Model 500 Mini-Reference EK–650EA–HR

VAX 6000 Model 500 Service Manual EK–650EA–MG

VAX 6000 Model 500 System Technical User’s Guide EK–650EA–TM

VAX 6000: Installing Model 500 Processors EK–KA65A–UP

Associated Documents

Table 3 lists other documents that you may find useful.

ix

Table 3: Associated Documents

Title Order Number

System Hardware Options

VAXBI Expander Cabinet Installation Guide EK–VBIEA–IN

VAXBI Options Handbook EB–32255–46

System I/O Options

CIBCA User Guide EK–CIBCA–UG

CIXCD Interface User Guide EK–CIXCD–UG

DEC LANcontroller 200 Installation Guide EK–DEBNI–IN

DEC LANcontroller 400 Installation Guide EK–DEMNA–IN

InfoServer 100 Installation and Owners Guide EK–DIS1K–IN

KDB50 Disk Controller User’s Guide EK–KDB50–UG

KDM70 Controller User Guide EK–KDM70–UG

RRD40 Disc Drive Owner’s Manual EK–RRD40–OM

RA90/RA92 Disk Drive User Guide EK–ORA90–UG

SA70 Enclosure User Guide EK–SA70E–UG

Operating System Manuals

Guide to Maintaining a VMS System AA–LA34A–TE

Guide to Setting Up a VMS System AA–LA25A–TE

Introduction to VMS System Management AA–LA24A–TE

ULTRIX–32 Guide to System Exercisers AA–KS95B–TE

VMS Upgrade and Installation Supplement: VAX 6000 Series AA–LB36C–TE

VMS Networking Manual AA–LA48A–TE

VMS System Manager’s Manual AA–LA00A–TE

VMS VAXcluster Manual AA–LA27B–TE

x

Table 3 (Cont.): Associated Documents

Title Order Number

Peripherals

HSC Installation Manual EK–HSCMN–IN

H4000 DIGITAL Ethernet Transceiver Installation Manual EK–H4000–IN

Installing and Using the VT320 Video Terminal EK–VT320–UG

RV20 Optical Disk Owner ’s Manual EK–ORV20–OM

SC008 Star Coupler User’s Guide EK–SC008–UG

TA78 Magnetic Tape Drive User’s Guide EK–OTA78–UG

TA90 Magnetic Tape Subsystem Owner’s Manual EK–OTA90–OM

TK70 Streaming Tape Drive Owner ’s Manual EK–OTK70–OM

TU81/TA81 and TU/81 PLUS Subsystem User’s Guide EK–TUA81–UG

VAX Manuals

VAX Architecture Reference Manual EY–3459E–DP

VAX Systems Hardware Handbook — VAXBI Systems EB–31692–46

VAX Vector Processing Handbook EC–H0739–46

xi

Chapter 1

Specifications and Preparation

This chapter describes the preliminary steps to be performed in upgrading

a VAX 6000 XMI-1 platform to an XMI-2 platform. This upgrade converts

an older Model 200, 300, or 400 system to a Model 500.

If the Model 500 does not need more than four processors, more than 12 XMI

slots, or require battery backup, a simpler upgrade is possible as described

in the VAX 6000: Installing Model 500 Processors manual.

Sections in this chapter include:

• Upgrade Kit Overview

• Battery Backup Kit Specifications

• Save EEPROM Contents to TK Tape

• Record System Parameters

• Prepare Area, Kits, and Tools

• Unpacking Checklist

Specifications and Preparation 1–1

1.1 Upgrade Kit Overview

Upgrade order number H9657–CU takes a VAX 6000 Model

200, 300, or 400 system with an XMI-1 power system and

upgrades it to a VAX 6000 Model 500 with an XMI-2 power

system. The upgrade adds +3.3 volt power, an XMI-2

backplane preassembled with bus bars and cables, and an

H7206-B power and logic unit.

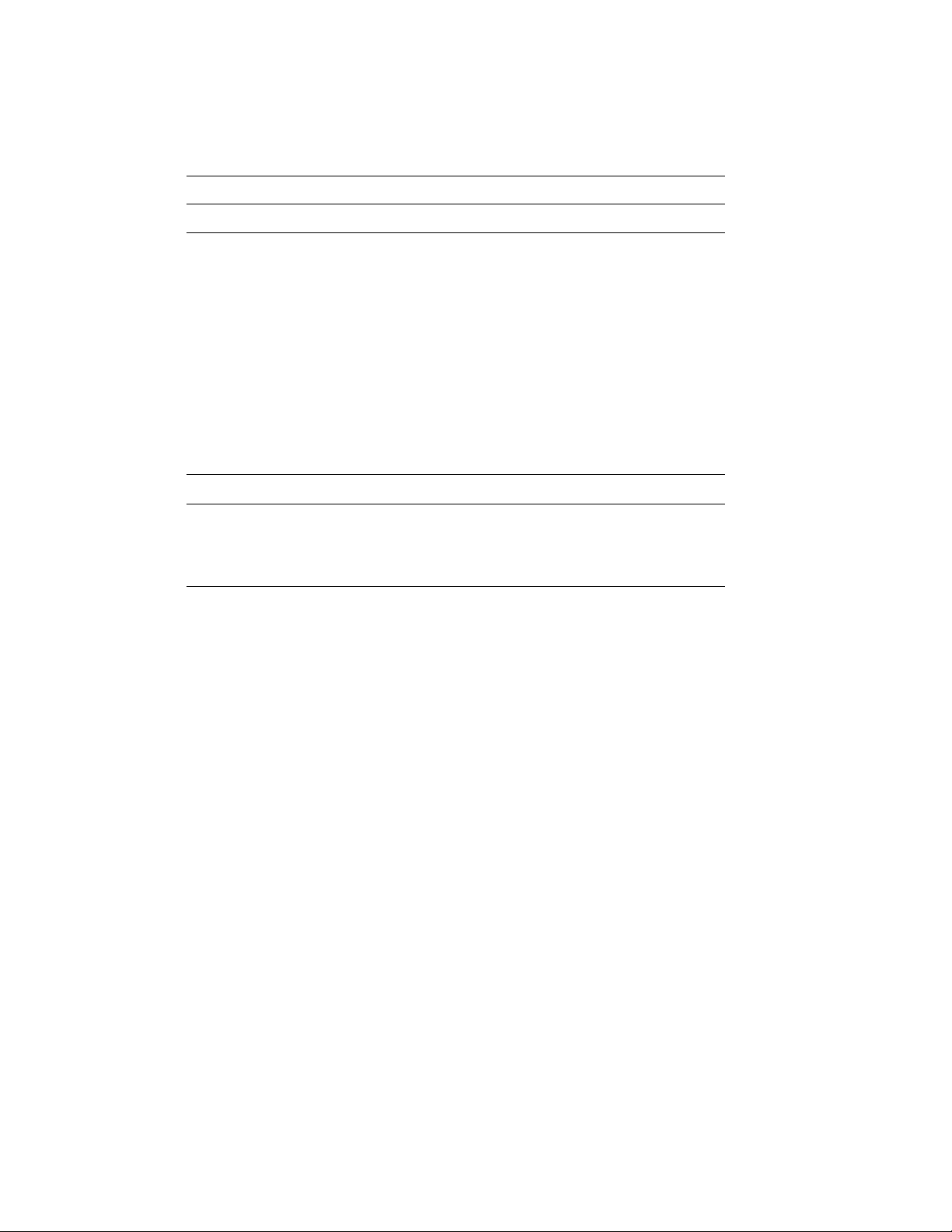

Figure 1–1: Overview of Full Upgrade

REAR

POSSIBLE

UPGRADE TO

H7214

REMOVE H7231

BATTERY BACKUP

UNIT

REPLACE H7214

WITH AN H7242

REPLACE XTC

POWER SEQUENCER

MODULE

REPLACE XMI

CARD CAGE

ASSEMBLY

REPLACE H7206

POWER AND LOGIC

UNIT

msb-0379-90

1–2 VAX 6000 XMI Conversion Manual

Table 1–1 lists the components you will remove. See Table 1–4 for the

listing of components in the upgrade kit. See Chapter 2 for the full upgrade

procedures.

NOTE: Before you start, make sure you have enough ESD boxes for

all processor, DWMBA, and memory modules from the system you are

upgrading.

Table 1–1: Components to Be Replaced

Part Number Description

H7206-A Power and logic unit

70-24902-01 XMI-1 card cage assembly

H7214 +5V regulator, located in position 3

H7214 The second XMI +5V regulator, if at A or B revision level

20-29176-01 XTC power sequencer module

17-01833-01 H405 fail safe enable cable

KA64A/KA62A/KA62B Processors

MS62A Memories

74-39700-XX Old system name plate mounted on the door

17-01549-01 H7206 to H405 DEC power bus cable

H7231-N Battery backup unit, if present

Specifications and Preparation 1–3

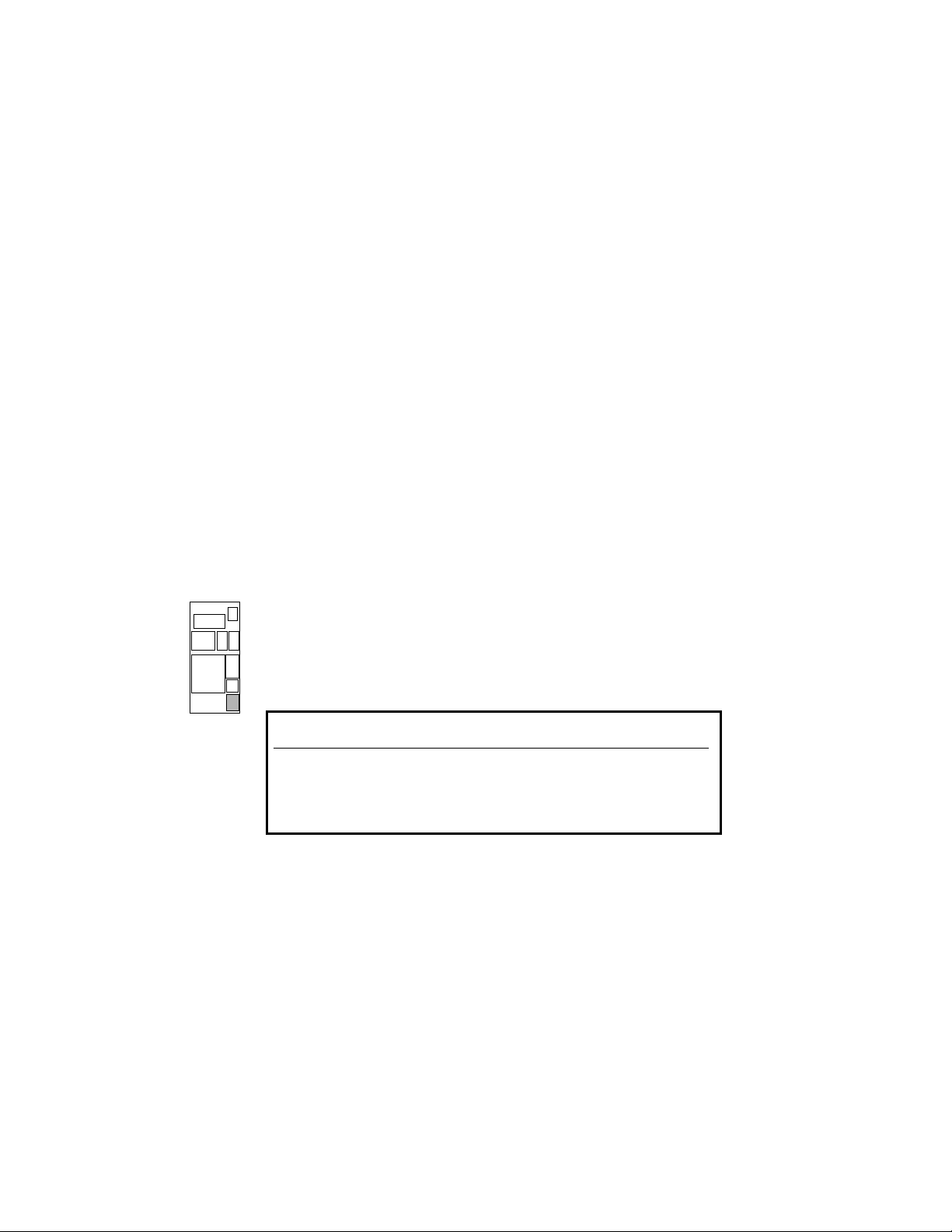

1.2 Battery Backup Kit Specifications

If the VAX 6000 system that you are upgrading has or

requires battery backup, you must install the battery

backup option kit order number H7236-A.

Figure 1–2: Battery Backup Installation

REAR

REPLACE THE H405

AC POWER CONTROLLER,

IF NECESSARY

INSTALL BATTERY

BACKUP UNIT

1–4 VAX 6000 XMI Conversion Manual

msb-0380-90

See VAX 6000: Installing the H7236-A Battery Backup Option, which

ships with the battery backup unit (BBU), for a description of the BBU

installation procedures. Table 1–2 lists the major components in the BBU

kit.

Table 1–2: Battery Backup Kit H7236-A

Part Number Description

30-31264-01 Battery backup unit

17-02975-01 Battery backup signal cable

17-02485-01 Battery backup DC power cable

17-00442-27 Battery backup AC power cable

If the H405-E AC power controller is below revision level F, it must be

replaced. If an H405-F AC power controller is below revision level H, it

must be replaced when an H7236-A battery backup unit is installed.

Specifications and Preparation 1–5

1.3 Save EEPROM Contents to TK Tape

Begin preparation for the upgrade by saving the EEPROM

contents to a TK tape. With a blank cartridge in the tape

drive, use the SAVE EEPROM command to copy the contents

of the boot processor’s EEPROM to tape.

Example 1–1: SAVE EEPROM Command

! A blank TK tape is in the tape drive. With the upper

! key switch at Enable and the lower key switch at Halt,

! press the Restart button.

#123456789 0123456789 0123456789 01234567#

F E D C B A 9 8 7 6 5 4 3 2 1 0 NODE #

A A . . M M . . . . . . P P TYP

o o . . + + . . . . . . + + STF

. . . . . . . . . . . . E B BPD

. . . . . . . . . . . . + + ETF

. . . . . . . . . . . . E B BPD

. . . . . . . . . + . + . . + . XBI D +

. . . . . . . . . + . + . . + . XBI E +

. . . . A2 A1 . . . . . . . . ILV

. . . . 32 32 . . . . . . . . 64 Mb

ROM0 = V1.00 ROM1 = V1.00 EEPROM = 1.00/1.00

>>> SAVE EEPROM

Proceed with save to tape? (Y or N) >>> Y

?6B EEPROM saved to tape successfully.

7

>>>

4

! Enter SAVE command.

! System prompts user to proceed.

! Enter a Y to continue.

! System confirms SAVE is complete.

2

3

SN = SG01234567

5

6

1

Before doing an upgrade you should save the contents of the boot processor’s

EEPROM by copying the image to a TK cartridge. Earlier VAX 6000

systems have TK50 tape drives; later models have TK70 tape drives. The

operation of the TK50 differs slightly from the TK70. See Appendix A of

the Owner’s Manual for your system for more information on the TK tape

drive.

1–6 VAX 6000 XMI Conversion Manual

Example 1–1 shows the steps to save the EEPROM contents:

1

Put a blank TK cartridge in the tape drive. Put the control panel’s

upper key switch in the Enable position and the lower key switch in

the Halt position, and then press the Restart button to generate self-test

results. See the Owner’s Manual for your system for a full explanation

of self-test results.

2

These numbers appear for Model 400 systems and indicate the progress

of self-test. The progress trace line is displayed by the processor in slot

1.

3

Note the values here for the EEPROM. The second number indicates if

any patches have been installed. Whenever you do an upgrade, make

sure that the boot processor has the latest patches installed on its

EEPROM before you perform the save operation.

4

Following self-test, the console prompt appears. At the prompt, enter

SAVE EEPROM. This operation saves the information from the boot

processor and overwrites any existing information on the TK cartridge.

5

The console program queries you, requiring your confirmation to

proceed with the SAVE EEPROM operation. Enter Y. The save process

takes less than a minute to complete.

6

The console program confirms that the save operation has completed

successfully. When the console prompt returns, the save operation is

complete. Saved information includes:

System serial number

Systemwide console parameters (baud rate, interleave, terminal

characteristics)

Saved boot specifications

Diagnostic patches

Console patches

Boot primitives

7

Rewind the tape and remove the cartridge from the drive. Label and

write-protect the tape.

NOTE: This tape should be used only on this system. Each system

has its own identifying information stored in the processor EEPROMs.

Furthermore, tapes written by a TK50 tape drive are formatted differently

from those written by a TK70 tape drive. The TK70 can read data from a

tape written by a TK50, but it cannot overwrite a tape originally written by

a TK50. A TK50, however, cannot read data from a tape written by a TK70.

Specifications and Preparation 1–7

1.4 Record System Parameters

Save a printout of the system parameters, which you’ll want

to restore after the power conversion and installation of the

KA65A modules.

Example 1–2: Show All System Parameters

>>> SHOW ALL

Type Rev ! Lists all system parameters,

1+ KA64A (8082) 0006 ! beginning with the system

2+ KA64A (8082) 0006 ! configuration

9+ MS62A (4001) 0002

A+ MS62A (4001) 0002

D+ DWMBA/A (2001) 0002

E+ DWMBA/A (2001) 0002

XBI D

1+ DWMBA/B (2017) 0007

4+ KDB50 (010E) 0F1C

6+ DEBNI (0118) 0100

XBI E

1+ DWMBA/A (2017) 0007

4+ CIBCA (0108) 41C1

6+ TBK70 (410B) 0307

Current Primary: 1 ! Shows the status of CPUs

/NOENABLED/NOVECTOR_ENABLED/NOPRIMARY- 2

F E D C B A 9 8 7 6 5 4 3 2 1 0 NODE #

. . . . A2 A1 . . . . . . . . ILV

. . . . 32 32 . . . . . . . . 64 Mb

/INTERLEAVE:DEFAULT

/SCOPE /SPEED: 1200 /BREAK ! Shows the terminal characteristics

English ! Shows the language mode

XMI:D 08-00-2B-08-3D-64 ! Shows the Ethernet address

DEFAULT /XMI:E /BI:4 DU0 ! Shows Boot specs saved

DIAG /R5:00000010 XMI:E /BI:5 DU1

HSC /R5:40000000 XMI:D /BI:2 /NODE:00000405 DU0

>>>

1

! Shows the memory interleave

2

! Print the console display for reference.

1–8 VAX 6000 XMI Conversion Manual

To direct the console terminal output to a printer, use the Print Screen key

(the second key at the top left of the keyboard) on the VT320 terminal,

or you can select from four printing modes. See Installing and Using

the VT320 Video Terminal. Initialize to reset the entire system. The

self-test results are displayed. These should also be saved as they show

the processor and memory configurations, adapters installed, and other

important information.

Example 1–2 shows the steps to produce a record of the system parameters.

1

Following self-test, the console prompt appears. At the prompt, enter

SHOW ALL.

2

If you have not selected one of the printing modes, use the Print Screen

key to print this screen.

NOTE: Store these two printouts in the Site Management Guide for later

reference.

Specifications and Preparation 1–9

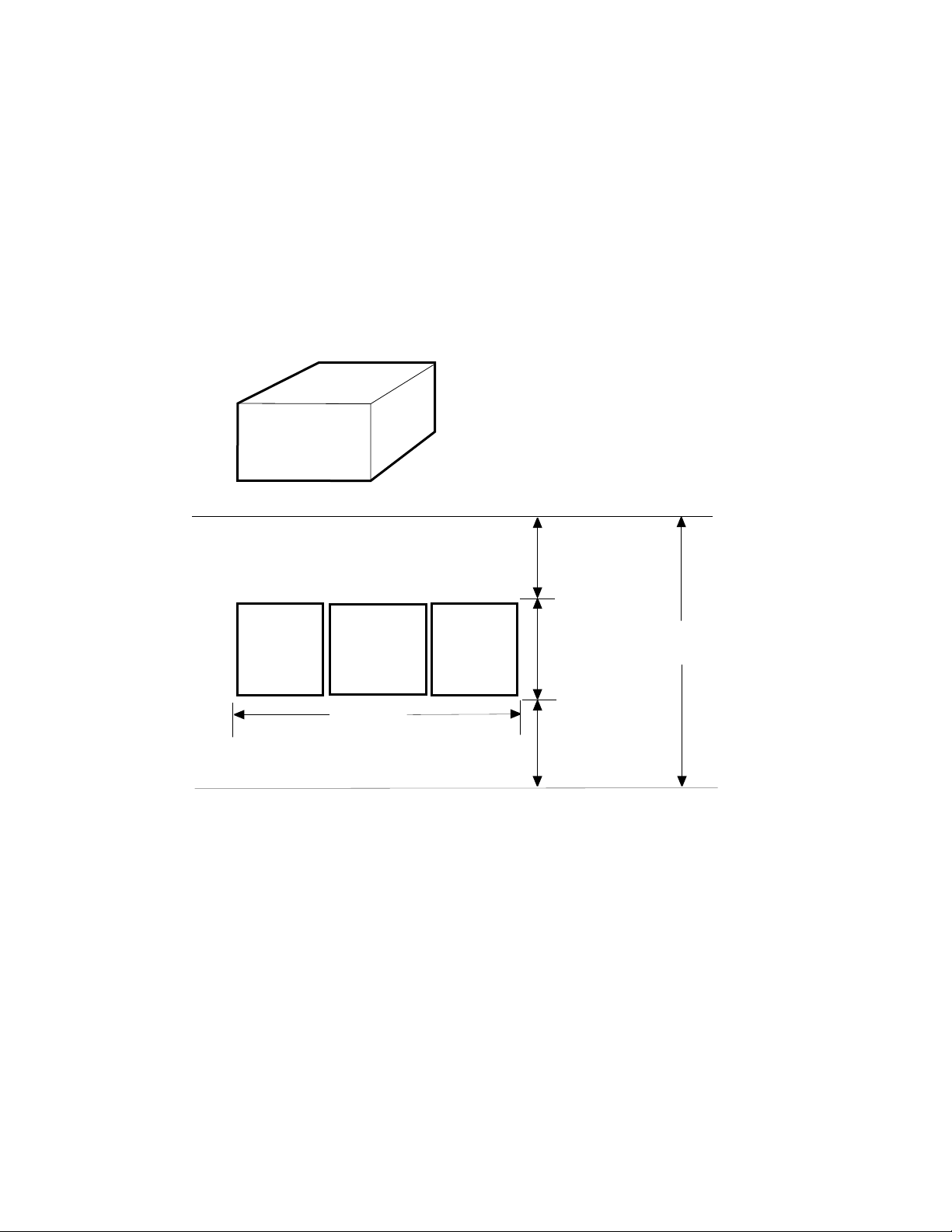

1.5 Prepare Area, Kits, and Tools

Set up a work space near the system where you can store

components, upgrade kits, and modules while you work on

the system upgrade. Prepare the system for shutdown.

Figure 1–3: System Space Requirements

H9657-CU

UPGRADE KIT

46.2 CM (18.5 IN)

68.8 CM (27.5 IN)

70 CM (28.0 IN)

REAR

CLEARANCE

1 M (39 IN)

TAPE

CABINET

SYSTEM

CABINET

WIDTH

1.9 M (74 IN)

DISK

CABINET

1–10 VAX 6000 XMI Conversion Manual

.9 M

(36 IN)

FRONT

CLEARANCE

1 M (39 IN)

DEPTH

2.9 M (114 IN)

msb-0119A-90

1. Prepare an area near the system where you can place system

components during the upgrade.

2. Perform an orderly shutdown of the system.

3. Turn the upper key switch on the front control panel to the Off (0)

position.

4. Pull the circuit breaker on the AC power controller to the Off position.

The AC power controller is at the bottom rear of the cabinet.

5. Unplug system power cord; wait 2 minutes for capacitors to discharge.

6. Using a Phillips screwdriver, remove the ground straps from the doors.

Remove the doors from the cabinet and set them aside.

7. Remove the screws and drop the I/O bulkhead tray to expose the card

cages.

8. As you work, save all screws that you remove.

Table 1–3: Tools and Supplies Required

Item Description

VAXBI tool kit

A2-M1094-10

Other tools 3/8", 5/16", and 11/32" nutdrivers, pliers, 7/16" socket wrench, flash-

ESD boxes Antistatic boxes; correct box for each module to be removed from the

Torque screwdriver, 11/32" nutdriver, large Phillips and flat screwdrivers, small Phillips screwdriver with magnetic tip

light

XMI-1 card cage

Specifications and Preparation 1–11

1.6 Unpacking Checklist

Carefully unpack the full power and packaging upgrade kit

(H9657-CU). Check the contents against Table 1–4. If any

components are missing, note items on the bill of lading and

do not start installation until you receive all components.

Table 1–4: H9657-CU Platform Upgrade Components

Part Number Description

70-24902-02 14-slot XMI-2 card cage assembly

H7242-00 +3V regulator

H7206-B Power and logic unit

DWMBB-AB XMI-2 adapters for VAXBI; 2 required

20-29176-02 XTC module

17-02500-01 Power supply enable cable

17-02521-01 XMI-2 card cage to H405 cable

74-40932-01 Mounting plate for H7206 power and logic unit

12-28686-07 Shield, RFI (BeCU spring clips)

12-28686-10 Shield, RFI (BeCU spring clips)

12-28686-11 Shield, RFI (BeCU spring clips)

36-33598-01 XMI module utilization label

17-02522-01 H7242 inhibit cable

36-15946-01 Product change label

17-02759-01 Fail safe enable cable

1–12 VAX 6000 XMI Conversion Manual

Chapter 2

XMI-1 to XMI-2 Conversion

This chapter describes how to upgrade a VAX 6000 XMI-1 platform to a

VAX 6000 XMI-2 platform.

Sections include:

• Full Upgrade Procedure Overview

• Step 1, Remove the XMI-1 Card Cage

Prepare for Removal

Remove the XMI-1 Card Cage from the Cabinet

• Step 2, Remove the H7214 Power Regulator(s)

Replace the H7214 in Position 2, if Necessary

Remove the H7214 in Position 3

• Step 3, Install the H7242 Power Regulator

• Step 4, Install the XMI-2 Card Cage

Attach the Daughter Card and Install the Card Cage

Attach the XMI-2 Card Cage Cables

Complete XMI Cabling

• Step 5, Replace the XTC Power Sequencer

• Step 6, Remove the H7231-N Battery Backup Unit

• Step 7, Replace the Power and Logic Unit

Remove the H7206-A Power and Logic Unit

Replace the Power and Logic Unit Mounting Plate

Install the H7206-B Power and Logic Unit

Apply Power to Check Conversion

XMI-1 to XMI-2 Conversion 2–1

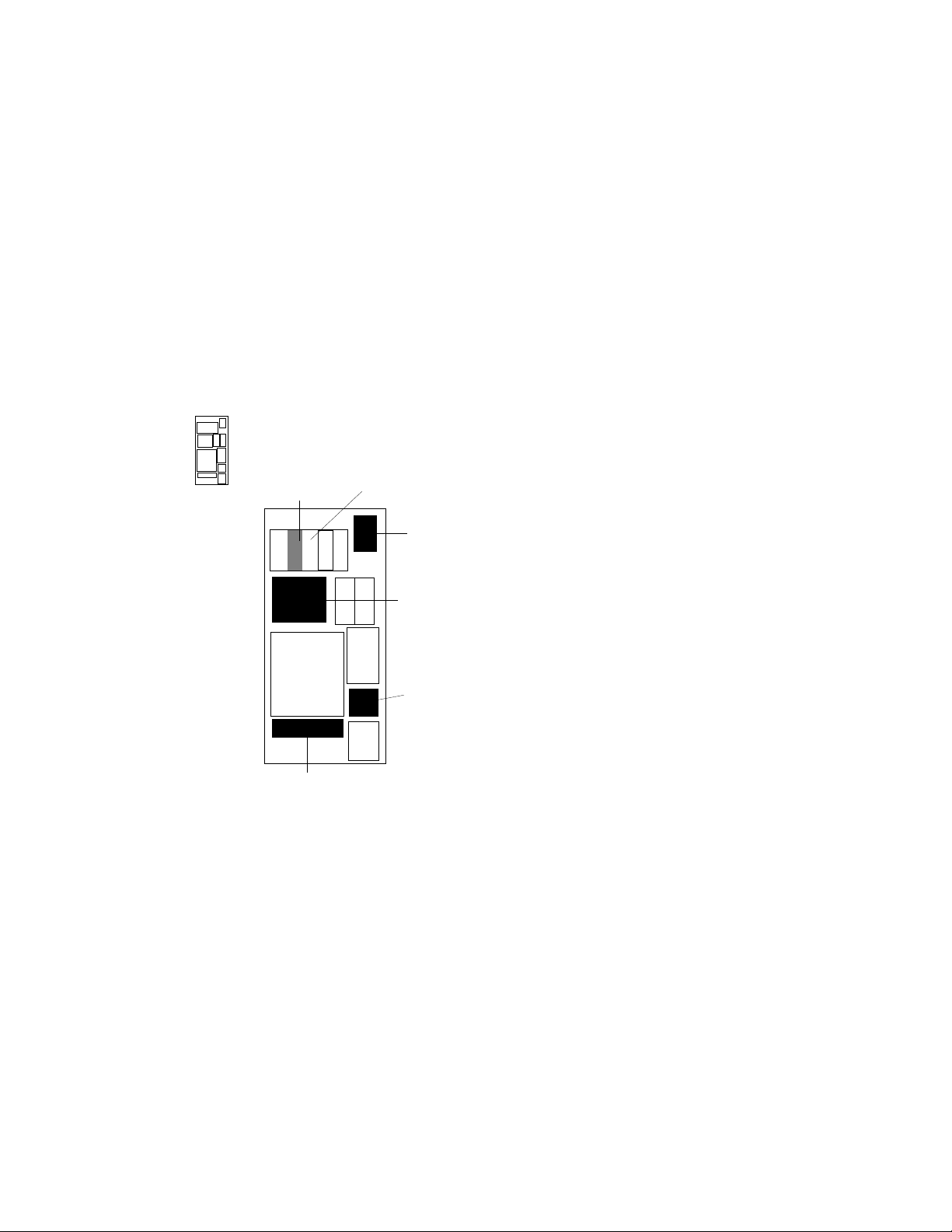

2.1 Full Upgrade Procedure Overview

Figure 2–1 shows the order of the upgrade procedure.

Detailed instructions follow.

Figure 2–1: Upgrade Overview

REAR

1

REMOVE THE

XMI CARD CAGE

5

REPLACE THE

XTC POWER

SEQUENCER

MODULE

2

REMOVE THE

H7214(s) POWER

REGULATOR(s)

6

3

INSTALL THE

H7242 POWER

REGULATOR

REMOVE BATTERY

BACKUP UNIT, IF

PRESENT

4

XMI CARD CAGE

7

INSTALL THE NEW

H7206-B POWER

AND LOGIC UNIT

INSTALL THE

3.3 VOLT

msb-0370-90

2–2 VAX 6000 XMI Conversion Manual

Figure 2–1 shows the optimal order for the full upgrade. The steps include:

1

The XMI-1 card cage must be removed first. This step requires two

people to guide the unit from the front and the back at the same time.

The daughter card from the XMI-1 card cage will be used on the XMI-2

card cage.

2

The H7214 power regulator above and to the right of the XMI card

cage is removed next. If the other XMI H7214 regulator is at A or B

revision level (120 amps), you also need to exchange this H7214 with a

C revision level or above (130 amps).

3

Install the H7242 +3.3V power regulator.

4

Install the XMI-2 card cage, after the daughter card from the XMI-1

card cage has been attached. This unit comes with preassembled bus

bars.

5

Replace the XTC power sequencer module, which is mounted on the

back of the system control assembly.

6

Remove the battery backup unit, if the system has one. To replace

the battery backup unit, follow the procedures described in VAX 6000:

Installing the H7236-A Battery Backup Option.

7

Replace the H7206-A power and logic unit with an H7206-B unit.

Three new cables are installed in the steps above. For cable information,

see Section 1.6.

XMI-1 to XMI-2 Conversion 2–3

2.2 Step 1, Remove the XMI-1 Card Cage

The XMI-1 card cage is removed from the front of the cabinet

after you disconnect cables from the backplane.

2.2.1 Prepare for Removal

Prepare the system for shutdown. Set up a work space

nearby where you can store the modules and work on the

XMI-1 card cage. Label and disconnect the signal and power

connections.

Figure 2–2: XMI-1 Backplane Cables and Power Connections

REAR

2–4 VAX 6000 XMI Conversion Manual

Product Conversion

From:

To: H9657-CU

By: Date:

DEC

36-15946-06-A01

msb-0686B-91

1. Perform an orderly shutdown of the system.

2. Turn the upper key switch on the front control panel to the Off position.

3. Pull the circuit breaker on the AC power controller to the Off position.

The AC power controller is at the bottom rear of the cabinet.

4. Unplug the system.

5. Open the rear cabinet door.

6. Remove the screws and drop the I/O bulkhead tray to expose the card

cages.

NOTE: Figure 2–2 shows the end to disconnect for each of the following

cables.

7. Disconnect all I/O adapter cables from the XMI-1 card cage. See7in

Figure 2–2.

8. Loosen the 5/16 inch nut on the H7215 cable retainer bracket. Swing

the bracket to one side.

9. Disconnect the power supply cable (17-01566-01) from J3 of the H7215

power regulator. See9.

10. If present, remove the plastic covers over the power connections on the

H7214 power regulators. To do this, remove the three 5/16 inch nuts

that connect each cover to the back of a regulator.

11. Disconnect the power connections from the H7214 power regulators.

(On each regulator, remove the four screws from the leads.) See11.

12. Disconnect the remote sense wires (17-01525-01) from the H7214 power

regulators. (Remove connector J4 from the regulator.) See12.

XMI-1 to XMI-2 Conversion 2–5

Loading...

Loading...