Page 1

VAX 4000 Model 300

•

Operation

Order Number:

EK~36AB-OP-O02

Page 2

VAX 4000 Model 300

Operation

Order Number EK-336AB-OP-O02

Digital Equipment Corporation

Maynard, Massachusetts

Page 3

March

1990,

July

1990

The information

construed

Digital

Equipment

this document.

The

software,

or

copied only

for

the

use

Corporation or

Restricted Rights:

restrictions

Software clause

Copyright

Printed

The Reader's Comments form

assist

The following

CompacTape

DDCMP

DEC

DEC

DECnet

DECserver

DECsystem

DECUS

DECwriter

in

in

direct

preparing

DELNI

DELQA

in

this

as

a commitment

if

any, described

in

or reliability of software or

its

as

set

forth

at

@1990.

U.S.A.

are

5400

document

Corporation

accordance

affiliated companies.

Use, duplication or disclosure

in

subparagraph

DFARS 252.227-7013.

Digital

Equipment

future

documentation.

trademarks

DEQNA

DESTA

DSSI

IVI8

MicroVAX

PDP

Professional

Q-bus

ReGIS

RQDX

ThinWire

by

in

with

at

of

is

subject to change

Digital

Equipment

assumes

this

document

the

terms

equipment

(c)(1Xii)

Corporation All

the

end

Digital

Equipment

Corporation.

no

responsibility for

is

furnished

of

such

that

of

the

of

this

document

Corporation.

ULTRIX

UNIBUS

VAX

VAX

VAXcluster

VAX

VAXELN

VAXlab

VM8

VT

the

without

license. No responsibility

is

not

by

the

Rights

rights

requests

4000

DOCUMENT

Digital Logo

notice

and

any

errors

that

under

a license

supplied

U.S. Government

in

reserved.

by

Digital

Technical

Data

your critical evaluation to

should

may

and

is

and

not

appear

may

be

used

is

assumed

Equipment

subject to

Computer

be

in

X Window System

FCC NOTICE:

frequency energy. The

a Class A

computing device

to provide reasonable protection

a commercial environment. Operation

interference,

correct

the

This document

is a trademark

The

equipment described

in

which case

interference.

was

prepared

equipment

pursuant

the

user

using

of

Massachusetts

has

been

to

against

at

VAX.

Institute

in

this

manual

type tested

Subpart J of

such

of

this

his

own

DOCUMENT, Version 1.2.

Part

radio frequency interference

equipment

expense

of

generates, uses,

and

found to comply

15

of

in a residential

may

be

Technology.

and

may

emit

the

limits for

operated

may

cause

measures

81466

radio

in

to

to

with

when

area

take

FCC Rules, which are designed

required

Page 4

Contents

Preface

Chapter 1 System Overview

1.1

Front

View

and

1.1.1

1.1.1.1

1.1.1.2

1.1.1.3

1.1.1.4

1.1.1.5

1.1.1.6

1.2

1.2.1

1.2.1.1

1.2.1.2

1.2.1.3

1.2.1.4

1.2.1.5

1.2.2

1.2.2.1

1.2.2.2

1.2.2.3

1.2.2.4

1.2.2.5

1.2.2.6

1.2.2.7

1.3

The

BA440

Mass

Card

Console Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSSI Connector (DSSI

Power

Fans

Functional Description

Base

System

Central

Console

Main

Network

Embedded DSSI

Optional

Mass

Mass

Mass

Communications Controllers

Real-Time Controllers

Printer

Other

Dual-Host Capability (VMS

Physical

Enclosure.

Storage

Cage

..........................

Supply

........................................

Components

Processing

Serial

Memory.

Controller

Components.

Storage

Storage

Storage

Interfaces.

Available

Description.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shelf

Devices

Subsystems.

Expanders

.....

Controls

of

Base

Unit

Line

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................

Host

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Options.

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

Bus

0)

..

. . . . . . . . . . . . . . . .

and

Indicators.

System

.........................

(CPU)

(SLU) . . . . . . . . . . . . . . . . .

Adapters.

and

..........................

Systems

...................

. . . . . . . . . . . . . . . .

Controllers.

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

.....................

. . . . . . . . . . . . . . . . . . . . . .

Only) . . . . . . . . . . . .

. . . . . . . . . . .

......

. . . . . . . . . . .

. . . . . . . . .

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

ix

1-1

1-6

1-8

1-9

1-11

1-14

1-15

1-18

1-19

1-19

1-20

1-20

1-20

1-20

1-21

1-21

1-21

1-22

1-22

1-23

1-24

1-25

1-25

1-25

iii

Page 5

Chapter 2 Operating the System

2.1

2.2

2.2.1

2.2.2

2.3

2.4

2.4.1

2.4.2

2.5

2.6

2.7

2.8

2.9

Before

Switch Settings

Turning

Booting the

Using

Halting

Restarting

Turning

Recovering from

You

Operate

..................................

Normal Operation

Special Operation

On

the

System

System

Autobooting

Booting

the

the

Off

the

System

the

System from Console Mode

System

the

.................................

System

System

the

System

an

the

System

..............................

...............................

............................

...............................

...............................

.............................

............................

Over Temperature Condition

......................

..........................

..............

........

Chapter 3 Operating the System Options

3.1 Mass Storage Options

3.1.1 RF-Series Integrated Storage Assemblies

3.1.2 TK70 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2.1 Design

3.1.2.2 Labeling a Tape Cartridge . . . . . . . . . . . . . . . . . . . . .

3.1.2.3 Write-Protecting a Tape

3.1.2.4 Tape Cartridge Handling

3.1.2.5 Inserting a Tape Cartridge. . . . . . . . . . . . . . . . . . . . .

3.1.2.6 Removing a Tape Cartridge . . . . . . . . . . . . . . . . . . . .

3.1.2.7 Summary ofTK70 Tape Drive Controls

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 TLZ04 Tape Drive

3.1.3.1 Proper Handling of Cassette Tapes

3.1.3.2 Setting the Write-Protect Tab on

3.1.3.3 Inserting a Cassette Tape into

3.1.3.4 System Software

3.1.3.5 Cleaning the

3.1.4

3.1.5 RRD40 Digital Disk Subsystem

RV20

of

the Drive

Optical Disk Subsystem

..............................

............................

Cartridge.

and

Storage

...............................

..............................

Heads.

. . . . . . . . . . . . . . . . . .

......................

.....................

.............

. . . . . . . . . . . . . . . .

Guidelines.

and

................

the

Cassette Tape. .

the

Drive.

. . . . . . . . .

. .

Indicator

..

. . . . .

..

..

..

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

2-1

2-1

2-1

2-2

2-4

2-6

2-6

2-11

2-12

2-12

2-13

2-13

2-14

3-1

3-2

3-6

3-7

3-8

3-9

3-11

3-11

3-14

3-16

3-17

3-19

3-20

3-21

3-22

3-23

3-24

3-25

Iv

Page 6

3.1.6

3.1.7

3.2

3.2.1

3.2.1.1

3.2.1.2

3.2.2

3.2.3

3.3

3.4

3.5

TVS05 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TU81-Plus

Communications Controller Options

Asynchronous

Without Modem

With Modem

Synchronous Controllers

Network Controllers

Real-Time

Printer

Adding

Options

Options

Tape

Drive.

Serial

Options

..................................

..................................

Controllers.

Support

Support

.............................

................................

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

...........................

.........................

Appendix A Related Documentation

...................

. . . . . . . . . . . . . . . . .

..

..

..

..

.

.

.

.

.

3-25

3-25

3-25

3-25

3-26

3-27

3-28

3-28

3-29

3-30

3-30

Appendix B Programming Parameters for RF-Series

Appendix C Backup Procedures

C.1

C.1.1

C.1.2

C.1.3

C.1.4

C.2

C.2.1

C.2.2

Overview

Installing

Booting

Installing

Booting

Backing

Backing

Restoring

of

Standalone

Standalone BACKUP on System

Standalone

Standalone

Standalone

Up

the

System

Up

the

the

System

BACKUP

BACKUP from

BACKUP on a Tape Cartridge

BACKUP from a Tape Cartridge

Disk

System

Disk

Disk

....................

........................

......................

........................

the

Disk

System

.......

Disk

Appendix D Removing Unwanted VMS Files

D.1

Using

VMSTAILOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary

ISAs

....

....

...

..

C--1

.

.

C--2

.

C--2

.

C-3

.

C-5

.

~

.

C--7

.

C--9

0-1

v

Page 7

Index

Examples

B-1

SHOW DSSI Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-2

B-4

B-5

B-6

B-7

Starting

B-3

Setting

Setting a Unit

Changing a Node

Exiting

SHOW DSSI Display

the

DUP

Driver Utility

......................

Allocation Class for a Specified ISA . . . . . . . . . . . .

Number

the

DUP Driver Utility for a Specified ISA

for a Specified ISA

Name

for a Specified ISA . . . . . . . . . . . .

..

...............................

Figures

1-1

VAX.

4000

System.

1-2

Key

Positions.

1-3

Upper Door

1-4

Entire

1-5

Front

1-6

Mass Storage

1-7

1-8

1-9

1-10

Card Cage

Console Module Controls

Connector for

Power Supply Controls

Opened.

Door

Opened.

View

of

.......................................

1-11 Sample Power

1-12

System Air Circulation. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual-Host Configuration

1-13

2-1

2-2

2-3

2-4

2-5

2-6

3-1

Language Selection

Sample

Error

Successful Power-On

Successful Power-On to

Selecting a Bootable Device . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample SHOW DEVICE Display . . . . . . . . . . . . . . . . . . . .

2-7

Successful Power-On to Console

RF-Series ISA Controls

3-2

Inserting Bus Node ID

3-3

TK70 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

BA440

Shelf.

nSSI

Bus

Enclosure.

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and

Connectors

...............

Bus 0 ...........................

and

Indicators.

. . . . . . . . . . . . . . .

Configuration. . . . . . . . . . . . . . . . . . . .

............................

Menu.

Summary.

and

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Boot . . . . . . . . . . . . . . .

List

of Bootable Devices . . . . . . . . . .

and

Indicators

Plugs.

Mode.

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

.................

. . . . . . . . . .

........

..

..

..

..

..

..

..

..

..

B-5

B-6

B-7

B-8

B-9

B-10

B-10

1-2

1-3

1-4

1-5

1-7

1-8

1-10

1-12

1-15

1-16

1-18

1-19

1-26

2-3

2-6

2-7

2-7

2-8

2-10

2-11

3-3

3-5

3-7

vi

Page 8

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

B-1

B-2

Attaching a Unit

Tables

Labeling a Tape Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape

Cartridge

Inserting

Removing a Tape

TLZ04 Tape

Setting

the

Inserting a Cassette

Inserting

DSSI Busses for

Write-Protect

a Tape

Cartridge.

Cartridge.

Drive.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write-Protect Tab on

Tape into

the

Head Cleaning

an

Expanded

Number

Label to

Switch

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

the

Cassette

the

Drive.

Cassette.

VAX

4000

the

ISA

Tape.

. . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

System.

Front

. . . . . . .

Panel. . ..

..

..

..

..

..

..

..

..

3-8

3-10

3-13

3-15

3-18

3-21

3-22

3-24

B-4

B-8

2-1

2-2

3-1

3-2

3-3

3-4

3-5

C-1

Normal

Device

RF-Series Controls

TK70 Tape Drive Controls

TK70 Tape Drive

TLZ04 Drive Indicators (Normal Conditions)

Power-On Indications

Names

...................................

and

Indicators

Indicator

....................

..........................

Lights

....................

............

TLZ04 Drive Indicators (Abnormal Conditions) . . . . . . . . .

Standalone

BACKUP

Qualifiers.

. . . . . . . . . . . . . . . . . . . .

..

..

.

.

.

.

.

2-4

2-10

3-4

3-16

3-16

3-19

3-19

C-7

vII

Page 9

Page 10

This

manual

VAXserver 4000 Model 300

for each

system.

system.

or

VAXELN

full-function node

The

manual

•

Chapter

•

Chapter

•

Chapter

describes how to use

of

these

systems

The

VAX.

4000

The

VAXserver 4000 system

operating

on

is

structured

1 provides

2 describes how to use

3 describes how to use options

differs slightly, according to

is a multiuser

systems. Both systems can function

an

Ethernet

as

an

server

network.

follows:

overview

VAX.

4000 Model 300

systems.

system

is

a single-user system

of

the

each

The

that

systems.

system.

installed

hardware

uses

timesharing

the

the

in

the

Preface

and

and

software

function

VMS

that

as

systems.

of

operating

uses

VMS

an

end-

the

or

• Appendix A

• Appendix B describes how to

RF

-series ISAs.

Appendix C describes procedures for

•

• Appendix D describes how to

VMS files from

• A glossary explains key

NOTE: VAXserver systems are designed to offer

applications

in

this

manual

for server systems.

any

questions about whether use

server system.

lists

related

the

system disk.

that

do

not

require timesharing.

are designed for

Contact

documentation.

set

and

examine

creating

use

VMSTAILOR to remove

tenns.

Some

multiuser

your

Digital service representative

of

a specific device is appropriate for

systems

internal

backup

maximum

of

and

parameters

files.

performance for

the devices referred to

may

not

unwanted

be

suitable

if

you have

your

for

Ix

Page 11

Conventions

The following conventions

Convention

BOLD

NOTE

CAUTION

WARNING

Meaning

A symbol denoting a terminal key used

For example,

keypad.

keypad.

A symbol

Ckey.

This bold type indicates

»>BOOT

This line shows

prompt.

Provides general information about

Provides information to prevent damage to equipment or

Provides information to prevent personal

Return

indicatins

MUAO

are

used

Break

indicates

that

in

indicates

that

that

you hold down

user

the

user

this manual:

in

text

and

examples

that

you press

you press the Return key on your terminal

input.

must

the

the

For

example:

enter BOOT

the

CUlTent

Break key on your terminal

Ctrl key while you press

MUAO

topic.

in

this book.

at

the console

software.

iIUury.

the

x

Page 12

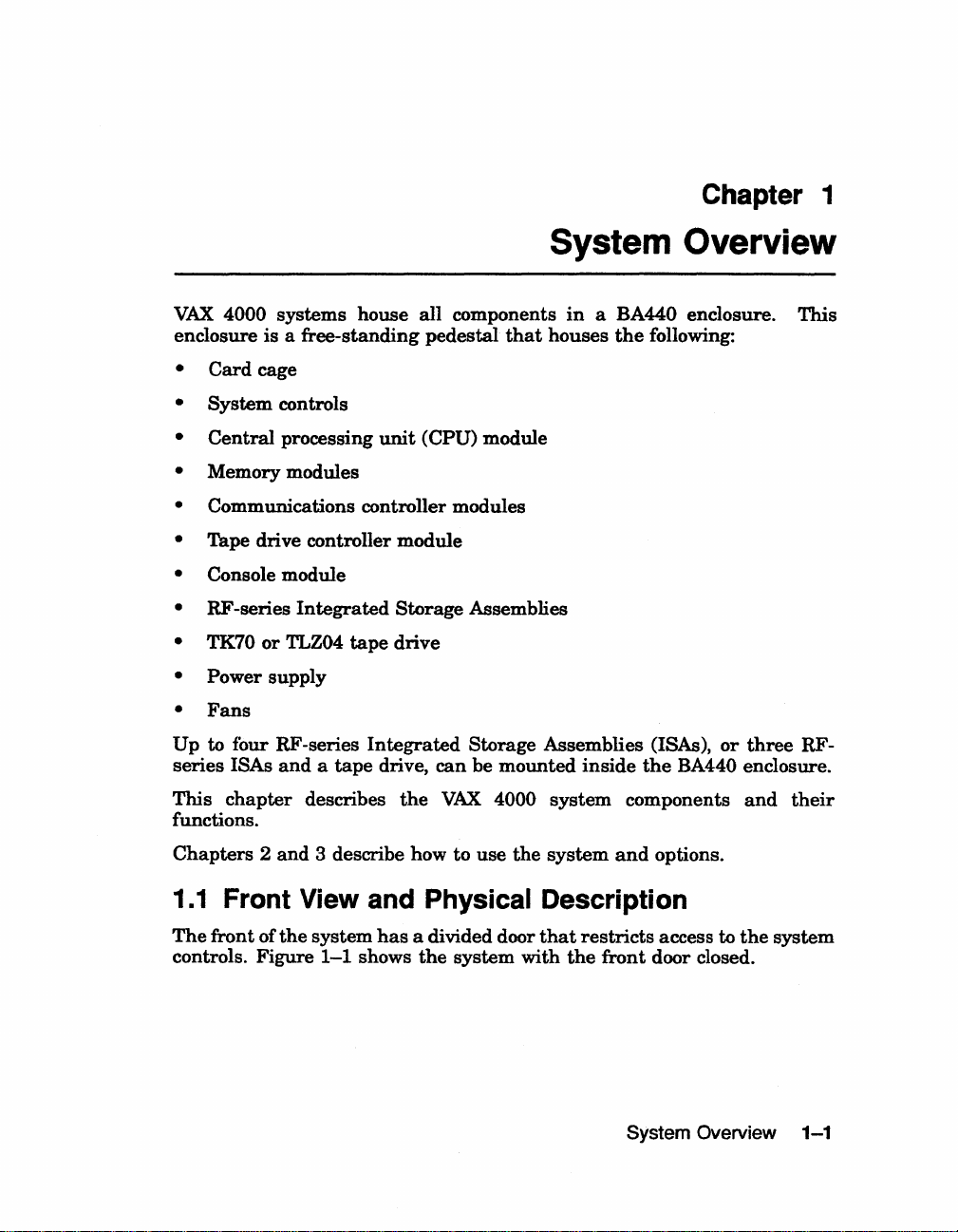

VAX

4000 systems house all components

enclosure is a free-standing

•

Card

cage

•

System

controls

pedestal

Chapter 1

System Overview

in

a BA440 enclosure. This

that

houses

the

following:

Central

•

Memory modules

•

Communications controller modules

•

Tape drive controller module

•

Console module

•

RF

•

TK70

•

Power supply

•

Fans

•

Up

to

series

This

chapter

functions.

Chapters 2 and

1.1

Front View and

The

front of

controls. Figure

-series

or

four

ISAs

processing

Integrated

TLZ04

RF-series

and a tape

describes

3 describe how to use

the

system

1-1

unit

Storage Assemblies

tape

drive

Integrated

drive,

the

has

a divided door

shows

(CPU) module

can

VAX

PhYSical

the

Storage Assemblies (ISAs),

be mounted

4000 system components

the

inside

system

and

the

options.

Description

that

system with

restricts

the

front

access to

door closed.

or

three

RF-

BA440 enclosure.

and

their

the

system

System Overview

1-1

Page 13

Figure 1-1:

VAX

4000

MLO-004032

System

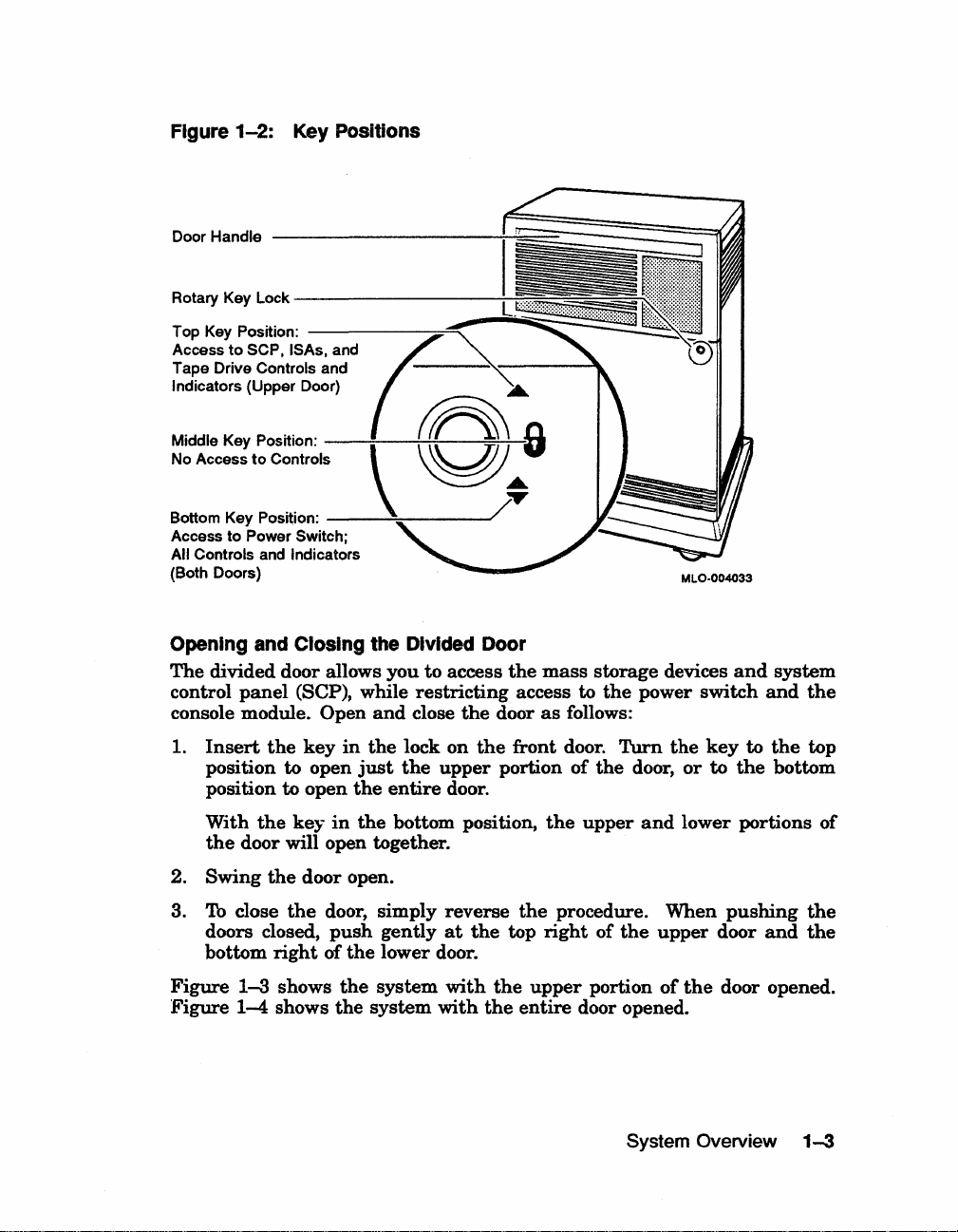

A three-position rotary lock allows you to lock both the upper and lower

doors, or to lock

you to access

(ISAs),

Opening

TK70

the

just

the

the

controls for

or

TLZ04

lower door. Opening

the

RF -series Integrated Storage Assemblies

tape drive,

and

the

the

upper door allows

System Control Panel (SCP).

entire door allows you to access all system controls

and

cable

connections.

Figure

position.

1-2

VAX

1-2 shows the three key positions

4000

Model

300 Operation

and

the controls accessible

in

each

Page 14

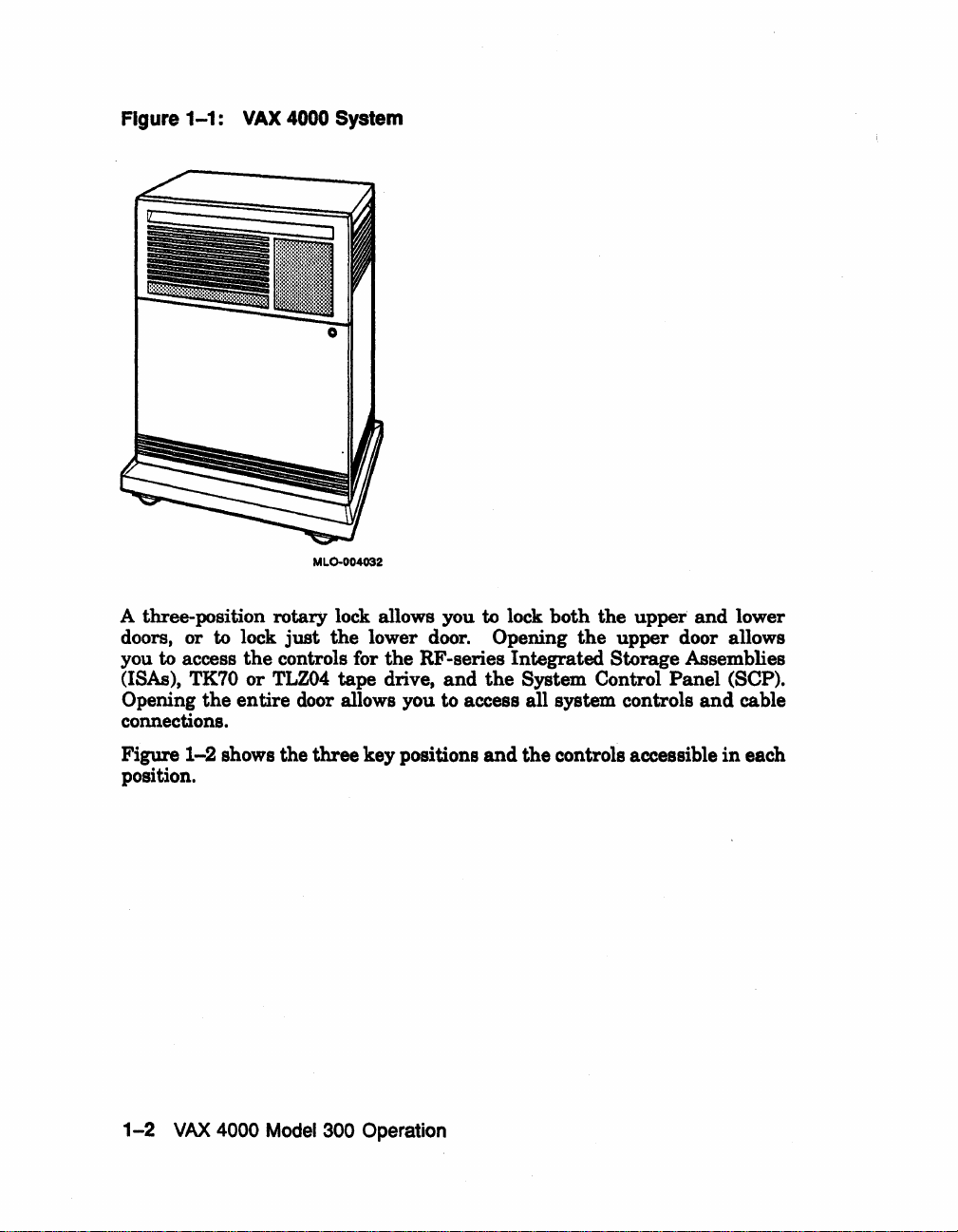

Figure

1-2:

Key

Positions

Door Handle

Rotary Key Lock

Top Key Position:

Access

Tape Drive

Indicators (Upper Door)

Middle Key Position:

No Access

Bottom Key Position:

Access to Power Switch;

All Controls and Indicators

(Both Doors)

Opening

The

divided door allows you

control

----------I~~~~;;~====~

--------=::I!!§§~I~

to

SCP, ISAs, and

to

-------:::==--

Controls and

---:--~;.---=~.::r1III

Controls

-----'==----../

and

Closing

panel

(SCP), while

console module. Open

1.

Insert

the

key

in

position to open

to

open

position

the

the

and

the

just

Divided

to

restricting

close

lock

the

upper

entire

Door

access

the

on

the

door.

the

mass

storage devices

access to

door

as

the

follows:

front door. Turn

portion

of

the

power

the

door,

switch

key

or

to

and

to

the

system

and

the

the

top

bottom

With

the

2.

Swing

3.

To

close

doors closed,

bottom

Figure

Figure

1-3

1-4

the

key

in

the

bottom position,

door will open together.

the

door open.

the

door, simply

push

gently

right

of

the

lower door.

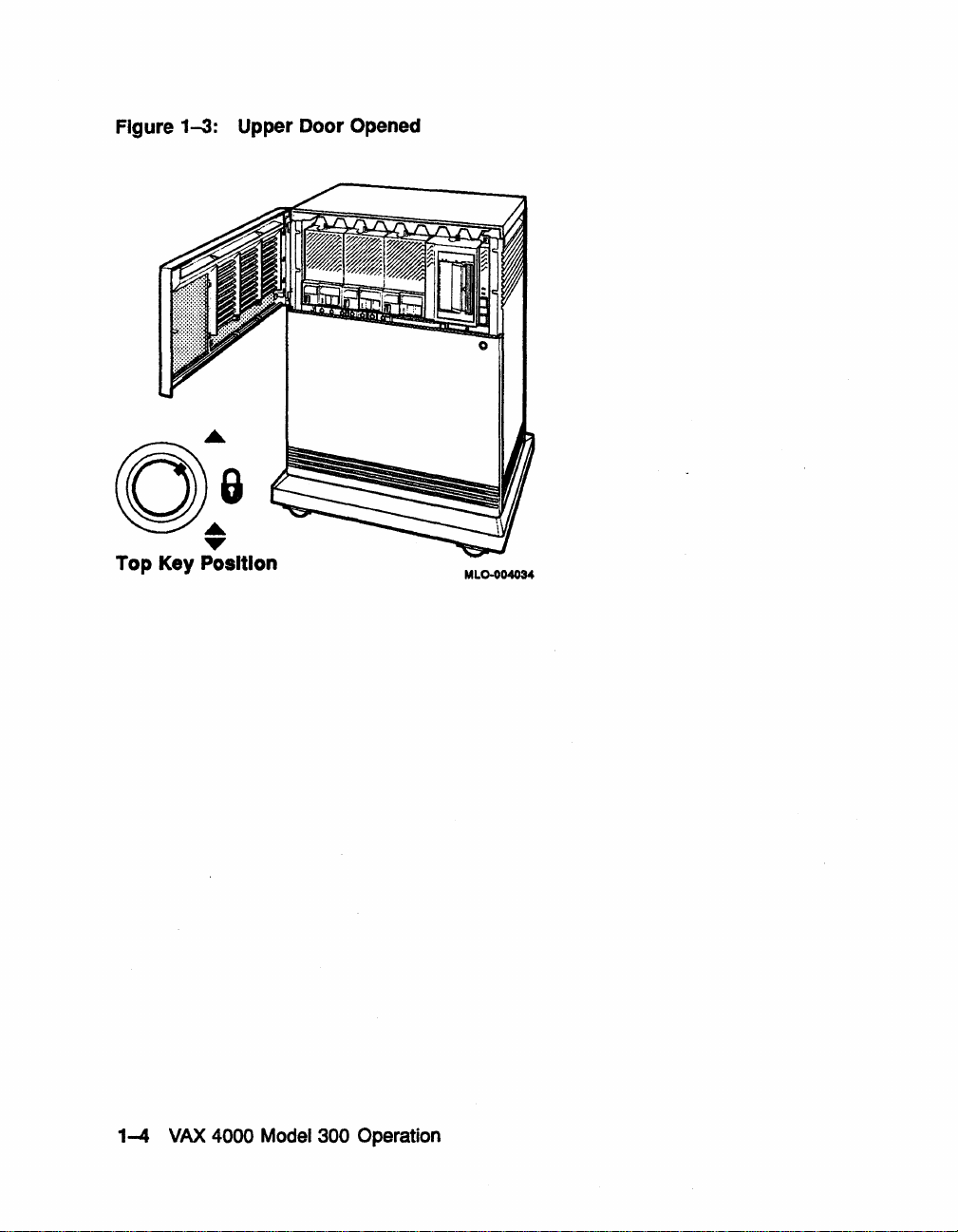

shows

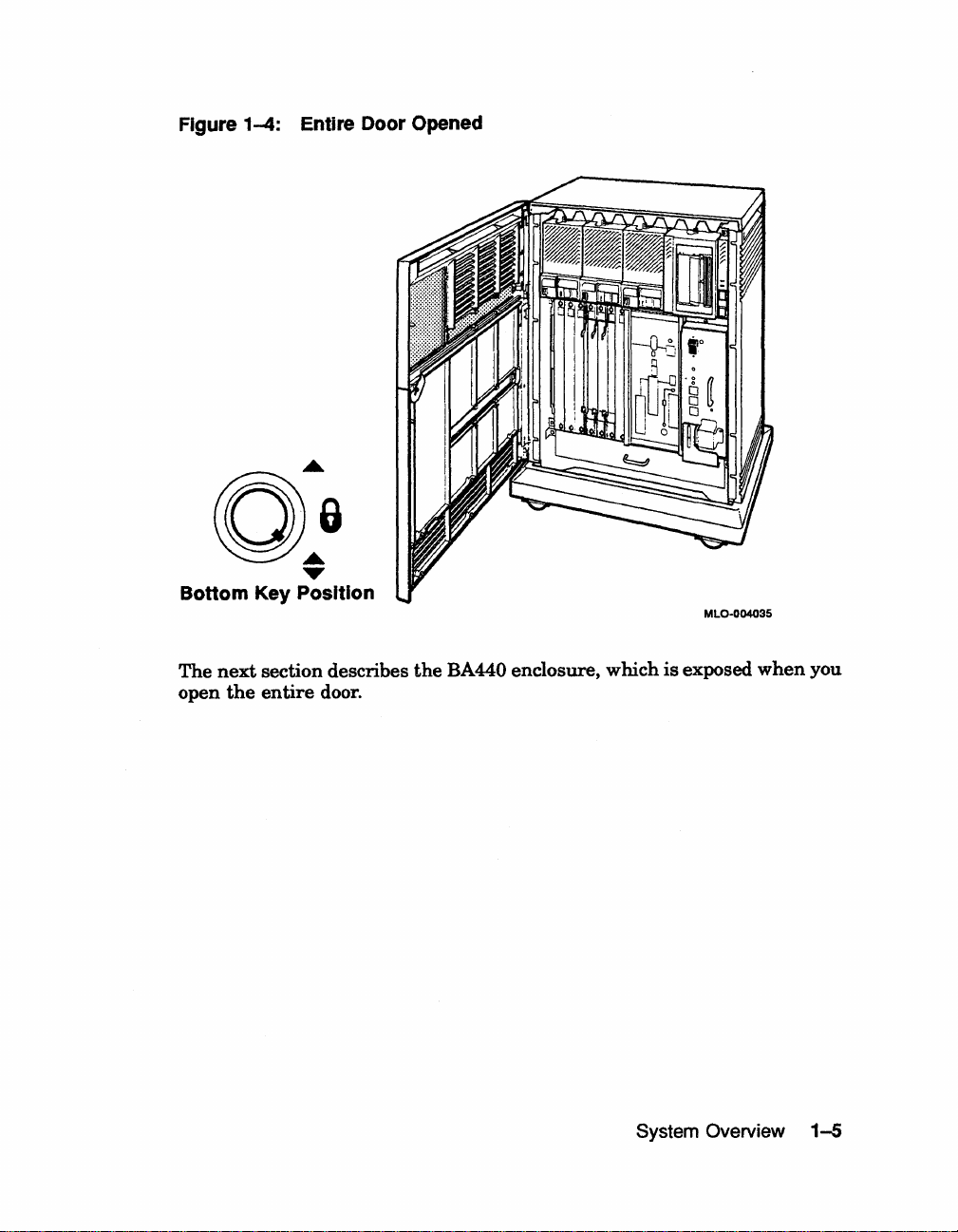

shows

the

the

system

system

with

reverse

at

the

with

the

the

the

top

upper

entire

the

upper

procedure.

right

of

portion

door opened.

and

lower portions of

When

the

upper

of

System Overview

pushing

door

the

door opened.

and

the

the

1-3

Page 15

Figure 1-3: Upper Door Opened

0

0:

~

Top Key Position

MLO-OO4034

1-4

VAX

4000

Model

300 Operation

Page 16

Figure 1-4: Entire Door Opened

O:a

...

Bottom Key Position

The

next

open

section describes

the

entire

door.

the

BA440 enclosure, which

MlO-004035

is

exposed

when

you

System Overview

1-5

Page 17

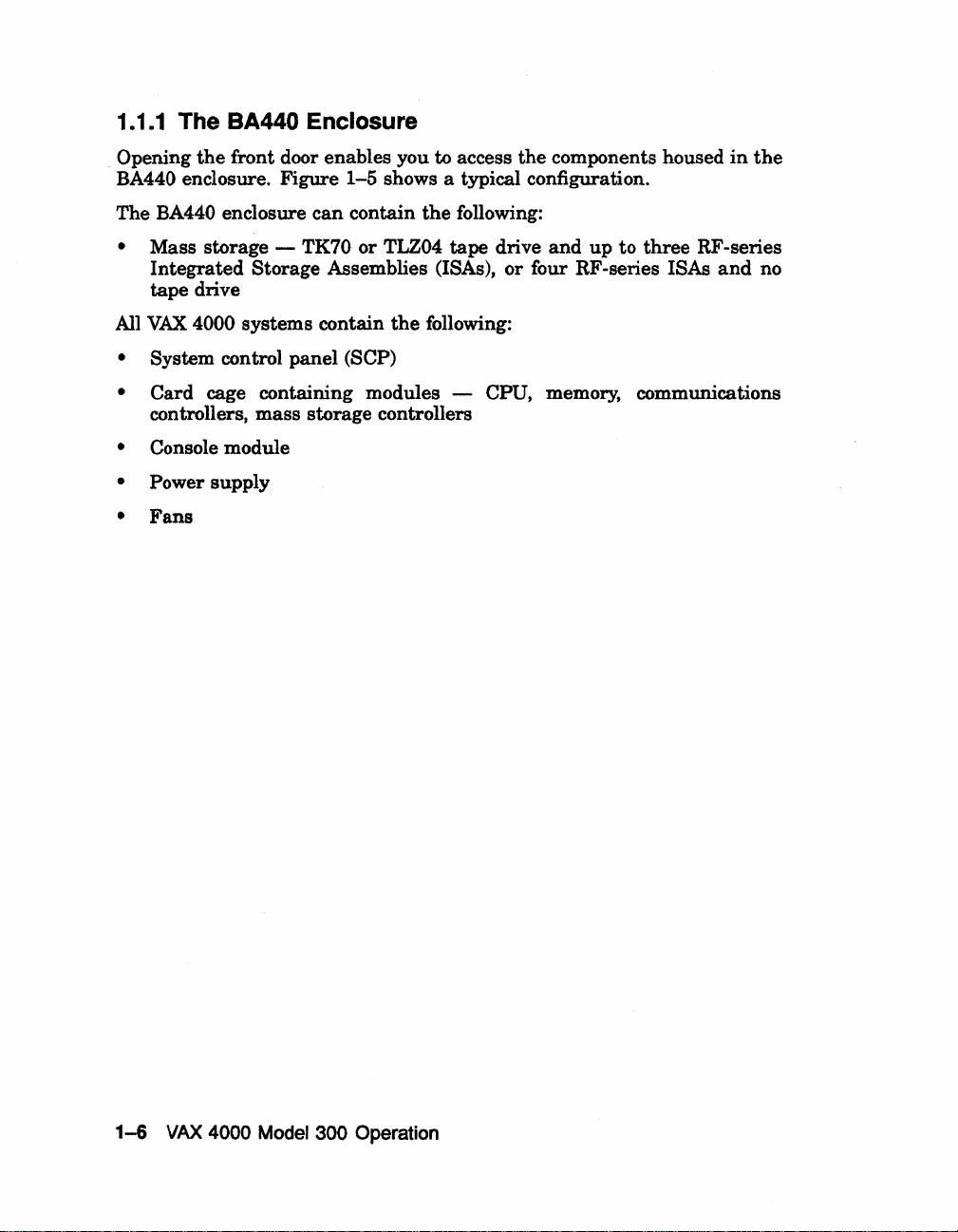

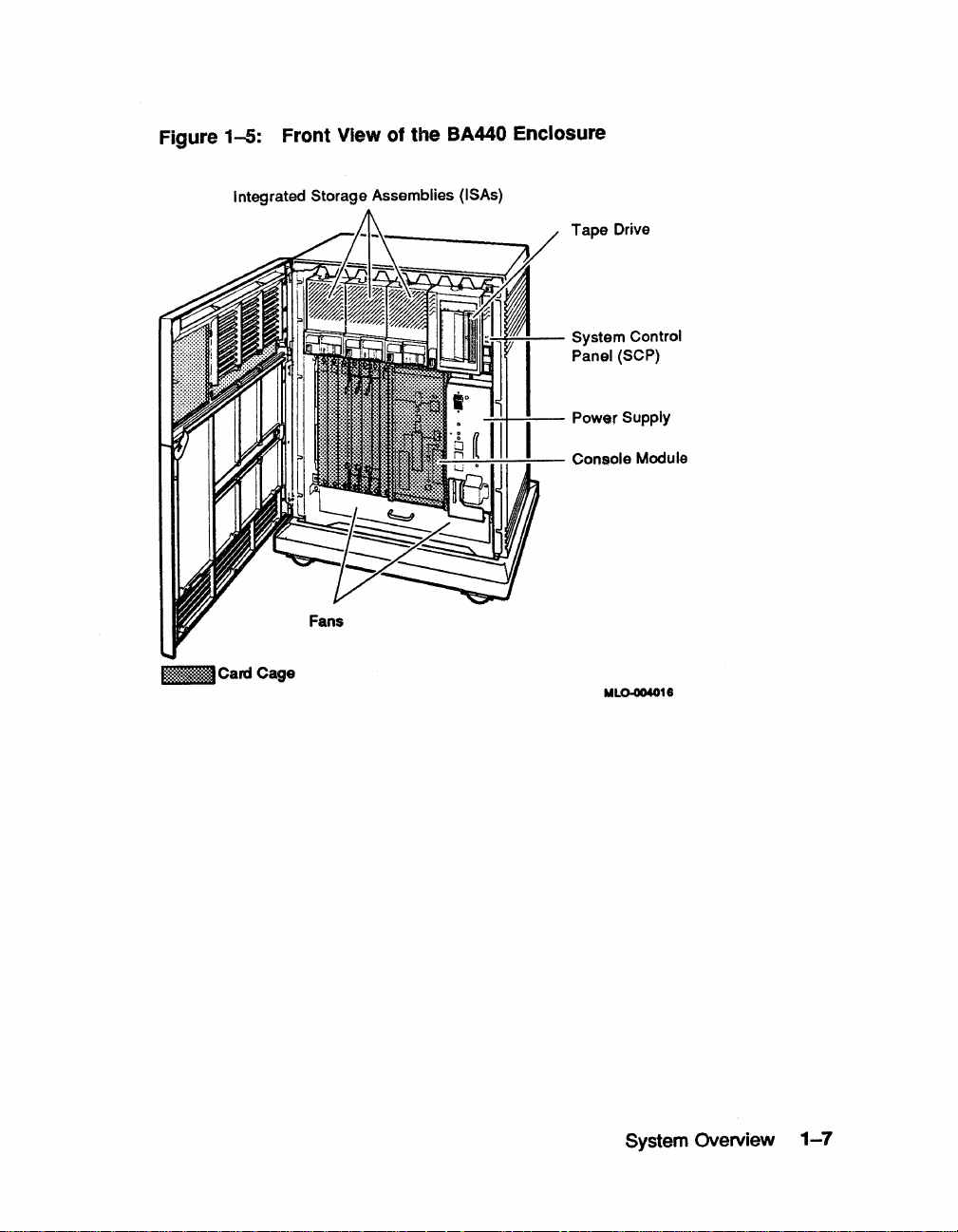

1.1.1

The BA440 Enclosure

. Opening

BA440 enclosure. Figure

The

• Mass storage - TK70 or TLZ04

the

front door enables you to access

BA440 enclosure

Integrated

Storage Assemblies (ISAs),

can

the

components housed

1-5

shows a typical configuration.

contain

the

following:

tape

drive

and

or

four RF-series ISAs

up

to

three

tape drive

VAX

All

4000 systems contain

the

following:

• System control panel (SCP)

•

Card cage containing modules CPU, memory, communications

mass

controllers,

storage controllers

• Console module

• Power supply

•

Fans

in

the

RF-series

and

no

1-6

VAX

4000

Model

300 Operation

Page 18

Figure

1-5:

Front View

Integrated Storage Assemblies (ISAs)

of

the

BA440 Enclosure

Tape Drive

i:§~:~::~.::i«.

Card Cage

I~!...!.i~~-

....!:-!..i-!~-

:....;....:......:.,:....-:~-=--

System Control

(SCP)

Panel

Power Supply

Console Module

ML0-004018

System Overview

1-7

Page 19

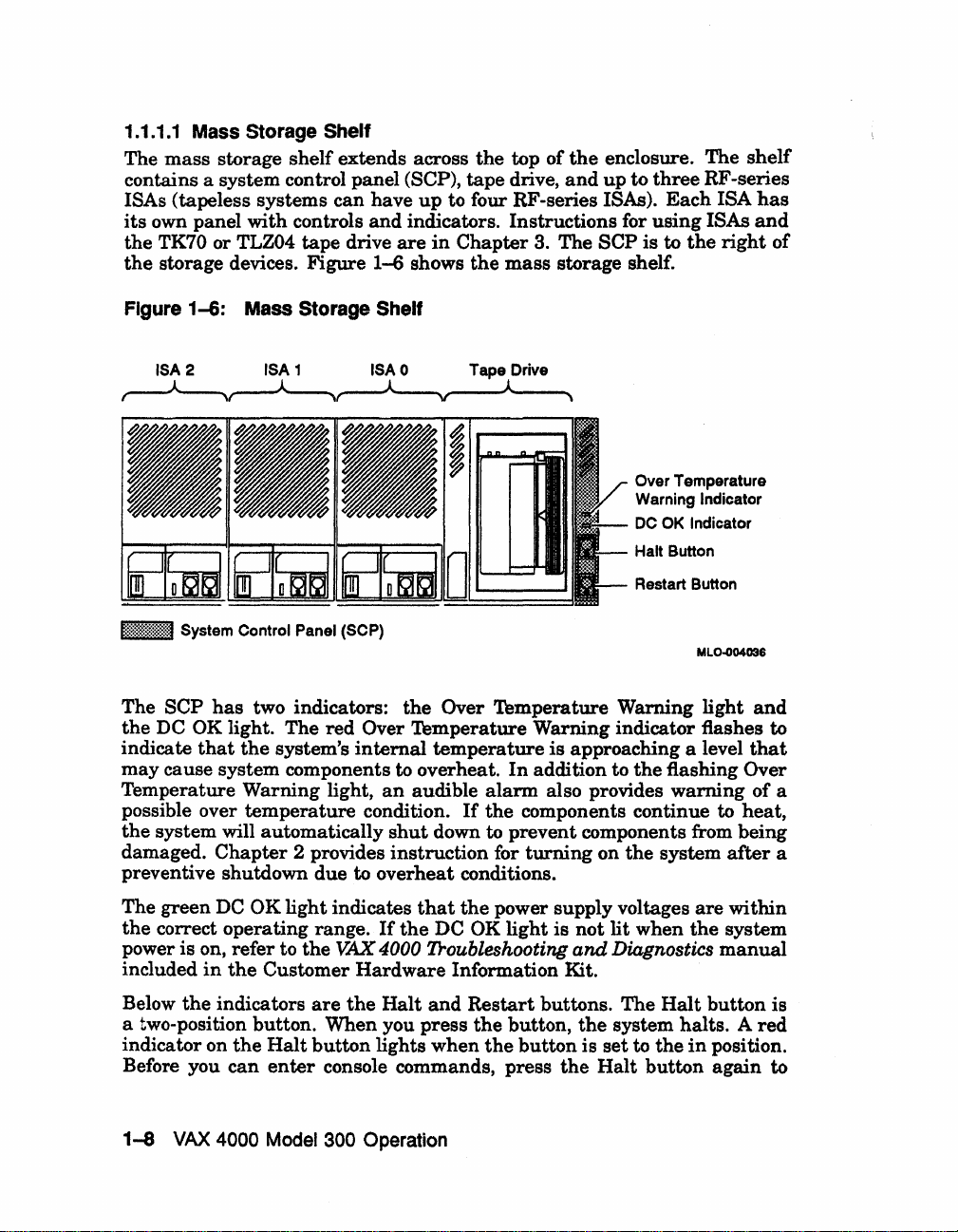

1.1.1.1 Mass Storage Shelf

The

mass

storage

shelf

extends across

contains a system control panel (SCP),

ISAs (tapeless systems can have

its

own panel

the

TK70 or TLZ04

the

storage devices. Figure

with

controls

tape

drive

up

to four RF-series ISAs).

and

indicators. Instructions for

are

in

1-6

shows

the

top of

tape

drive,

Chapter

the

mass

the

enclosure. The

and

up

3. The

SCP

storage shelf.

to

is

three

Each

using

to

the

shelf

RF -series

ISA

has

ISAs

and

right

of

Figure

1~:~~:~:~:i:~1:~1

The SCP

the

indicate

may

Temperature Warning light,

possible over

the

damaged.

preventive shutdown

1-6:

Mass Storage Shelf

ISA 0 Tape Drive

System Control Panel (SCP)

has

two indicators:

DC OK light. The

that

the

system's

red

the

Over

internal

cause system components to overheat.

an

temperature

system will automatically

Chapter

2 provides

condition.

shut

instruction

due

to overheat conditions.

Over Temperature Warning

Temperature

temperature

audible

If

down to

Warning indicator flashes to

is

approaching a level

In

addition to

alarm

the

also provides

components continue to

prevent

for

components from being

turning

on

Over Temperature

Warning

DC

Halt

Restart Button

Indicator

OK Indicator

Button

MLO"()04036

light

the

flashing Over

warning

the

system

after

and

that

of a

heat,

a

The green

the

correct operating range.

power

included

Below

DC

is

on, refer to

in

the

the

indicators

OK

light

the

Customer

are

indicates

If

the

VAX

4000 Troubleshooting

Hardware

the

Halt

a two-position button. When you

indicator on

Before you

1-8

VAX

the

Halt

button

can

enter

4000 Model 300 Operation

lights

console commands, press

that

the

power supply voltages

DC OK

light

Information Kit.

and

Restart

press

the

button,

when

the

is

buttons.

button

the

not

lit

and

Diagnostics

The

the

system

is

set

Halt

when

Halt

halts. A red

to

the

button

are

within

the

system

manual

button

in

position.

again

is

to

Page 20

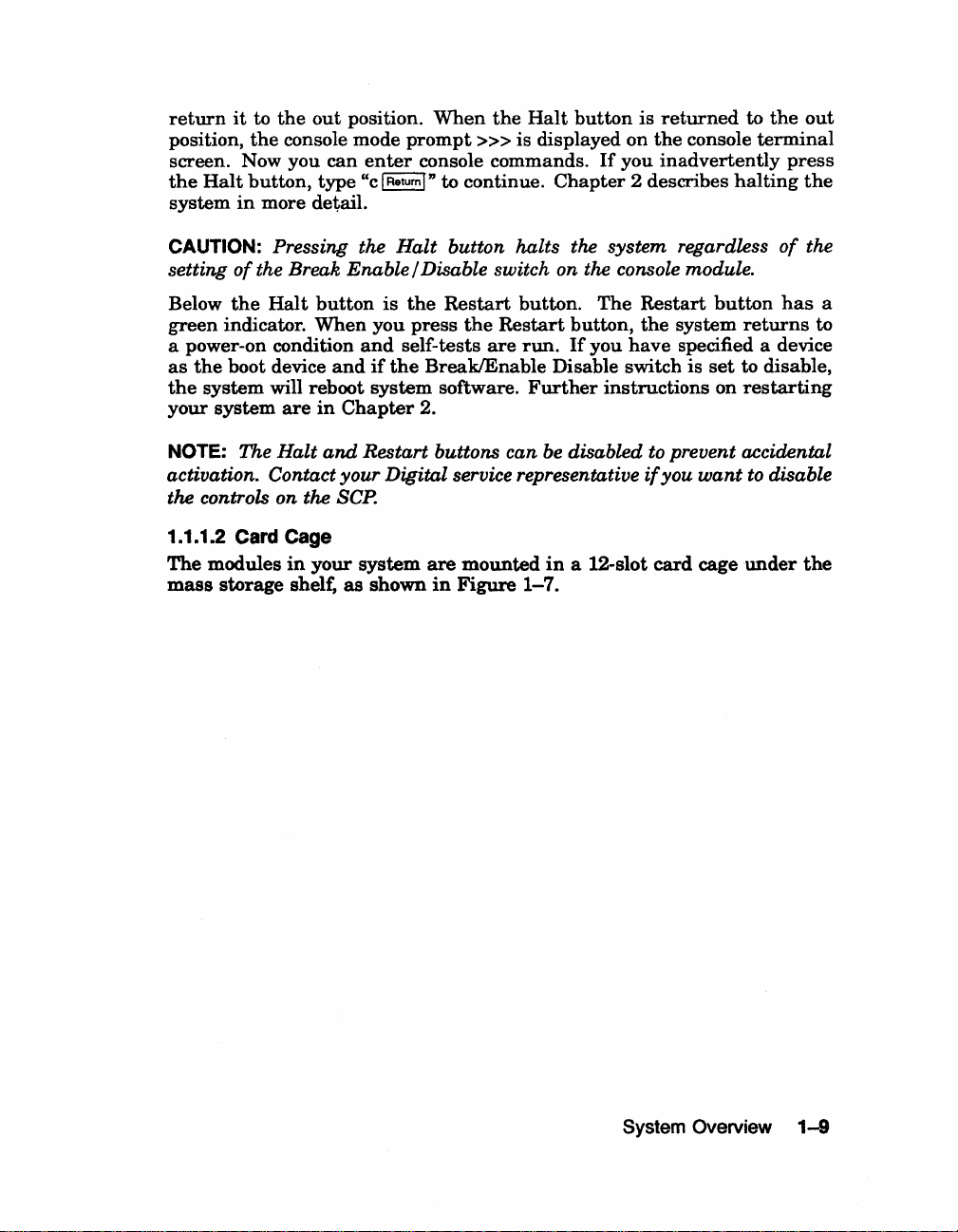

return

position,

screen. Now you

the

system

it

Halt

in

to

the

the

console mode

button,

more detail.

out

position.

can

enter

type "c I Return I " to continue.

When

prompt

console commands.

the

»>

is displayed on

Halt

Chapter

button

If

you

is

returned

the

console

inadvertently

2 describes

to

the

terminal

halting

out

press

the

CAUTION: Pressing the Halt button halts the system regardless

setting

Below

green

a power-on condition

as

the

your

NOTE: The Halt

activation. Contact your Digital service representative

the controls on the

1.1.1.2

The

mass

of

the

indicator.

the

boot device

system

system

Card

modules

storage

the Break Enable / Disable switch on the console module.

Halt

button

When

will reboot

are

in

and

is

the

Restart

you

press

the

and

self-tests

and

if

the

BreaklEnable

system

Chapter

software.

2.

Restart buttons can

button.

Restart

are

run.

Further

The

Restart

button,

If

Disable switch

be

disabled to prevent accidental

the

you

have

instructions

if

button

system

specified a device

is

set

on

returns

to disable,

restarting

you want

SCP.

Cage

in

your

shelf,

system

as

shown

are

in

Figure

mounted

1-7.

in

a 12-slot

card

cage

under

to

of

the

has

a

to

disable

the

System Overview

1-9

Page 21

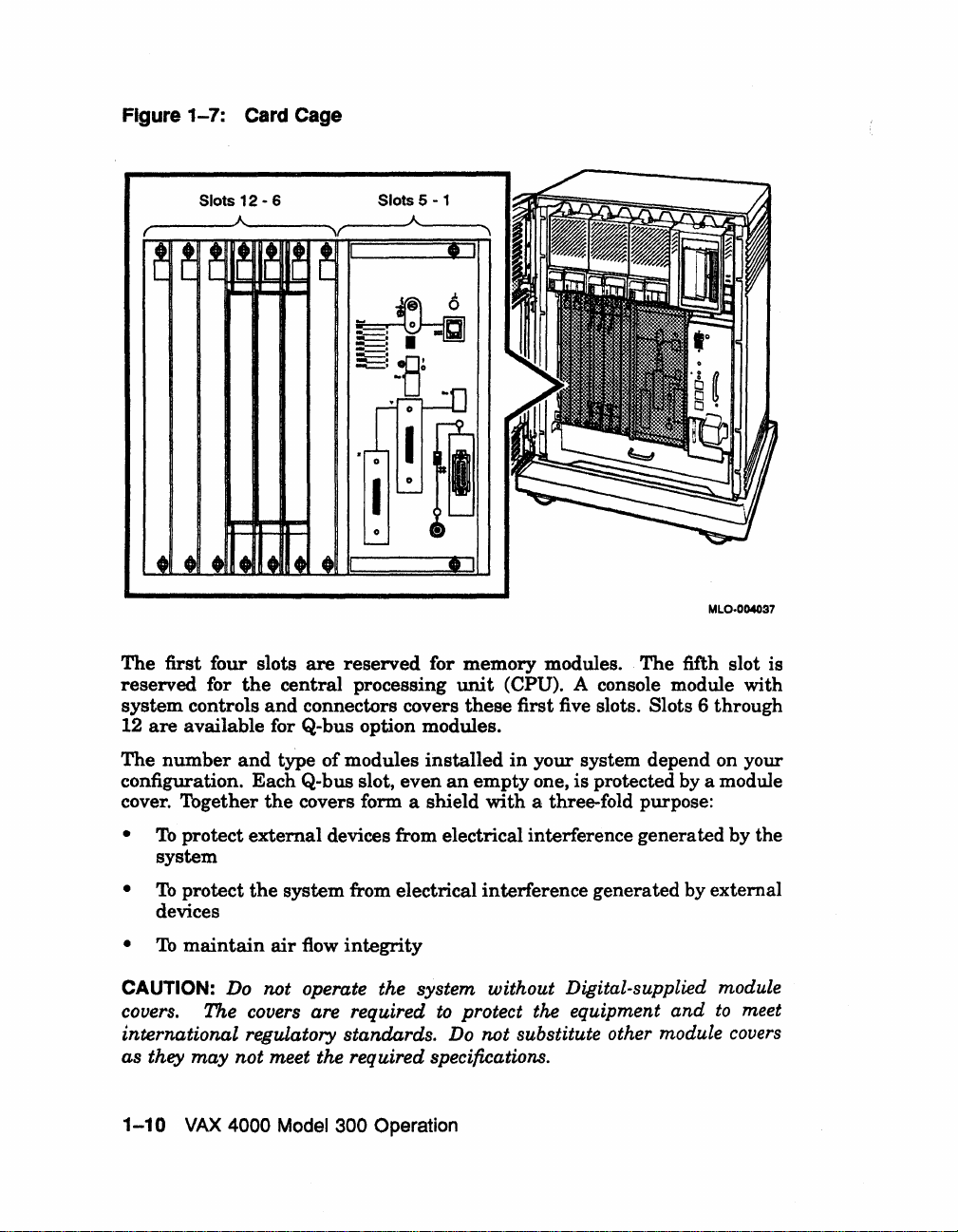

Figure 1-7: Card Cage

Slots 12 - 6

__

-----A------~~----~A~--

The first four slots

reserved for

system controls

12

are

the

available for Q-bus option modules.

are

central processing

and

connectors covers

Slots 5 - 1

reserved for memory modules.

__

\

•

The

unit

(CPU). A console module with

these

first five slots. Slots 6 through

MLO·004037

fifth slot is

The

number

configuration. Each Q-bus slot, even

cover. Together

To

•

system

To

•

devices

•

To

CAUTION: Do not operate the system without Digital-supplied module

covers. The covers are required

international regulatory standards.

and

type

of

modules

the

covers form a shield with a three-fold purpose:

protect external devices from electrical interference generated by the

protect

maintain

the

system from electrical interference generated by external

air

flow

integrity

installed

an

to

Do

in

your system depend on your

empty

one, is protected by a module

protect the equipment and

not substitute other module

to

meet

covers

as they may not meet the required specifications.

1-10

VAX

4000 Model 300 Operation

Page 22

Operating the system without the module covers has the following

consequences:

• The system

• The system will not comply with FCC

electrostatic shielding

may

overheat due

and

to

improper air circulation.

and

VDE requirements for

may

produce electrical interference

that

affects other equipment.

• The system is susceptible to electrical interference or damage from

external sources.

The

design

installed

communications controllers,

the

to

cables. Modules

storage

covered

except

installed

Cables connecting

modems,

cable

and

out

individual lines.

1.1.1.3 Console Module

Your

system

occupy

The

memory

the

first five slots.

system

of

the

in

the

slot. Modules

module.

controllers,

by

those

in

and

can

contain

the

the

controls

The

flush covers which

covering

the

slot.

printers)

back

Chapter

can

have

first four slots

and

and

module covers

recessed module covers allow space for connecting

requiring

are

covered

empty

your

system

are

multiple lines.

or

side

of

3 describes

up

to four

of

CPU

modules

The

console module, shown

connectors.

varies,

requiring

have

recessed covers

no

external

by

may

slots,

to

attached

The

the

enclosure,

memory

the

card

are

depending

external

cable connections,

flush

covers.

be

single

have a label

peripheral

to communications controllers.

cables

behind

these

cage

run

where

connections

modules.

and

the

on

the

type

cable connections,

that

are

riveted

such

Empty

or

double width. All covers,

identifying

devices (such

under

the

the

The

are

followed

console module

in

Figure

slots

the

as

BA440 enclosure

cables

are

in

more

memory

1-8,

by

that

has

of

terminals,

detail.

module

such

directly

as

mass

are

also

module

Each

split

into

modules

the

CPU.

covers

several

as

System Overview 1-11

Page 23

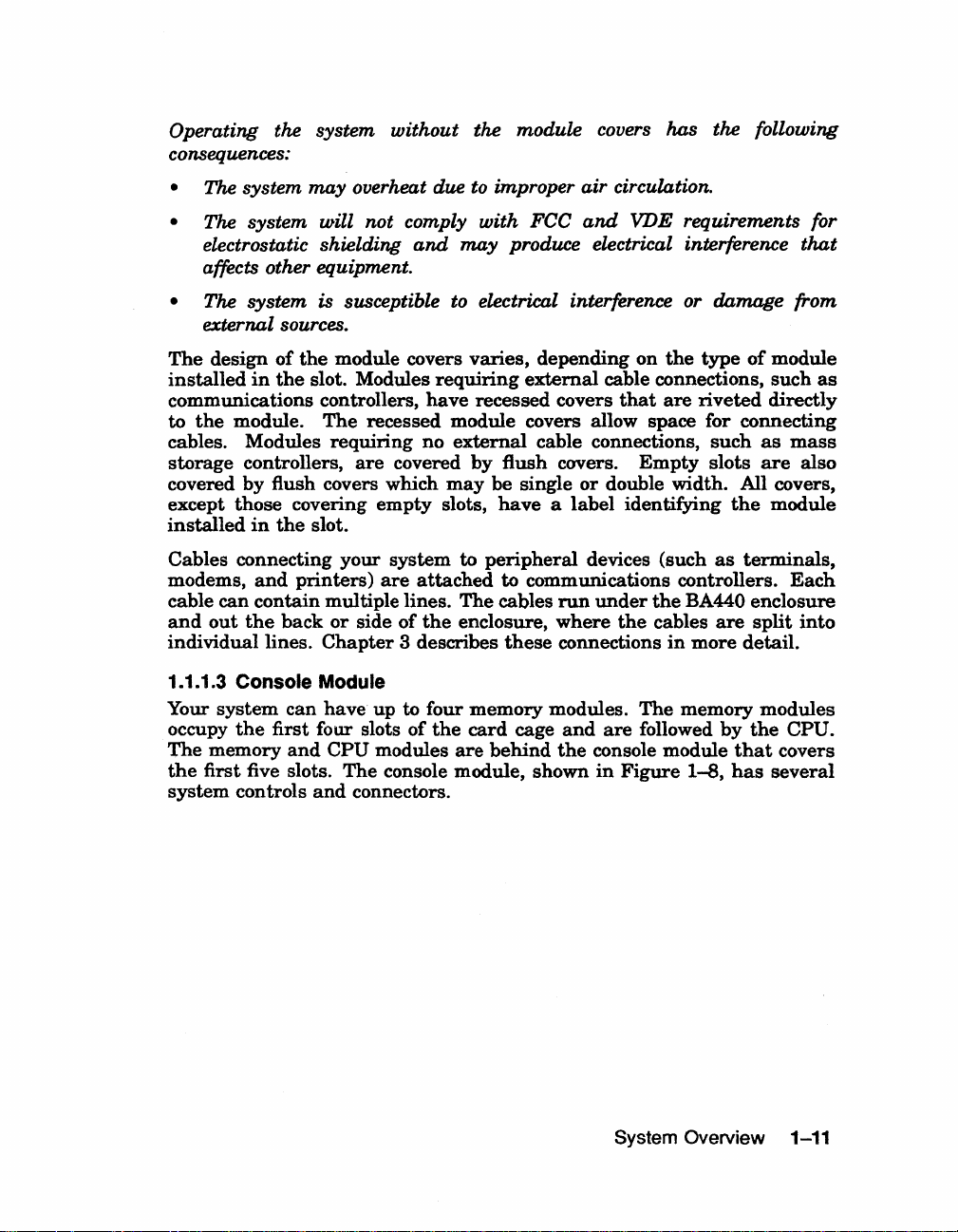

Figure

1-8:

Console Module

Power-On

Mode

Switch

Baud Rate

Select Switch

LED Display

DSSI

Connectors

Console Module Controls and Connectors

II"""Tr===

-';""':"---......

II

~I

IN;

II

==:::::;;;::::=,

~iJ

=:"

__

~

5d

I

=.

~§

~.pI

"'1!!J

~

..

, I I

t----t,;";,,I"i1

~Ethernet

y.

I L

0

=1

'--

I

0

'---

I

~

)

e

1

I

III

Modifiecj

II

Modular Jack

Break Enablel

"Disable

iY

Bus Node

10

~

I I Connector

Switch

Plugs

-,-;;;:

Connector

ThinWire

Ethernet

Connector

I

MLO-004038

The console module

Power-On Mode switch - This three-position rotary switch

•

1-12

determines how the system responds

Language Inquiry Mode (in the top position, indicated

by a profile of a face) causes

language selection menu

terminal supports multiple languages. Also,

boot device

system

to select a device from

the

it

VAX

4000

Model

has

the following components:

has

not been selected, this mode causes the

to

issue a list of bootable devices and prompts you

sY$tem

on.

autoboots from

300

Operation

at

power-on:

the

system

at

power-on

the

list. Once a device is selected,

that

device each time you

to

display a

if

your console

if

a default

turn

Page 24

-t>

Run

the

is

Mode (in

nonnal

the

middle

operating

position, indicated

setting.

by

an

arrow)

•

Loop Back Test Mode (in

in

a circle)

a T

the

console serial

specialloopback

Services use only.

Baud

Modified

The

(position

I Break I on

control to

I Break I

Rate

Select switch -

used

to

set

the

system's

terminal.

provides

sequence

Break

1),

CONTROLP, you

The

factory

modular

the

light-emitting diode (LED)

during

EnablelDisable switch -

0),

breaks

the

the

to

initiate a break

jack

connection for

power-on.

breaks

are

console

are

enabled.

terminal

console program.

can

specify

causes

line

connectors

baud

setting

(MMJ) -

the

disabled.

When

the

signal.

the

bottom position,

the

system

at

power-on. This

The

rate

is

position 5 (9600).

This

console

When

breaks

halts

Using

control character, I CtrllP

to

and

is

Baud

to

match

console

tenninal.

display

When

the

the

processor

the

run

loopback

setting

for Digital

Rate

Select switch

that

terminal

shows

the

switch

switch

are

enabled,

console command

indicated

requires

Customer

of

the

connector

the

is

is

up

(position

pressing

and

transfers

I,

rather

by

tests

on

console

testing

down

SET

than

is

•

The

Break

power-on. When

system

When

console mode (indicated

Using

RESTART_REBOOT, you

software

Bus

Digital

bus

node ID plugs, one for

one for

EnablelDisable switch also controls

breaks

attempts

breaks

the

after

node

Storage

the

console command,

ID

to

are

enabled

the

system

plugs -

System

external

automatically

can

bus,

are

disabled (down, position 0),

boot software

(up, position 1),

by

the

»>prompt)

SET

set

your

system

is

halted

VAX

Interconnect

the

Bus

due

4000

systems

internal

1, identify

what

happens

the

at

power-on.

the

system

at

power-on.

HALT REBOOT

to automatically boot

to pressing I Break

have

(DSSI) busses. 1\vo DSSI

DSSI bus,

the

System Overview

or

two

bus

SET

I.

separate

Bus

node

enters

HALT

0,

and

of

the

1-13

at

Page 25

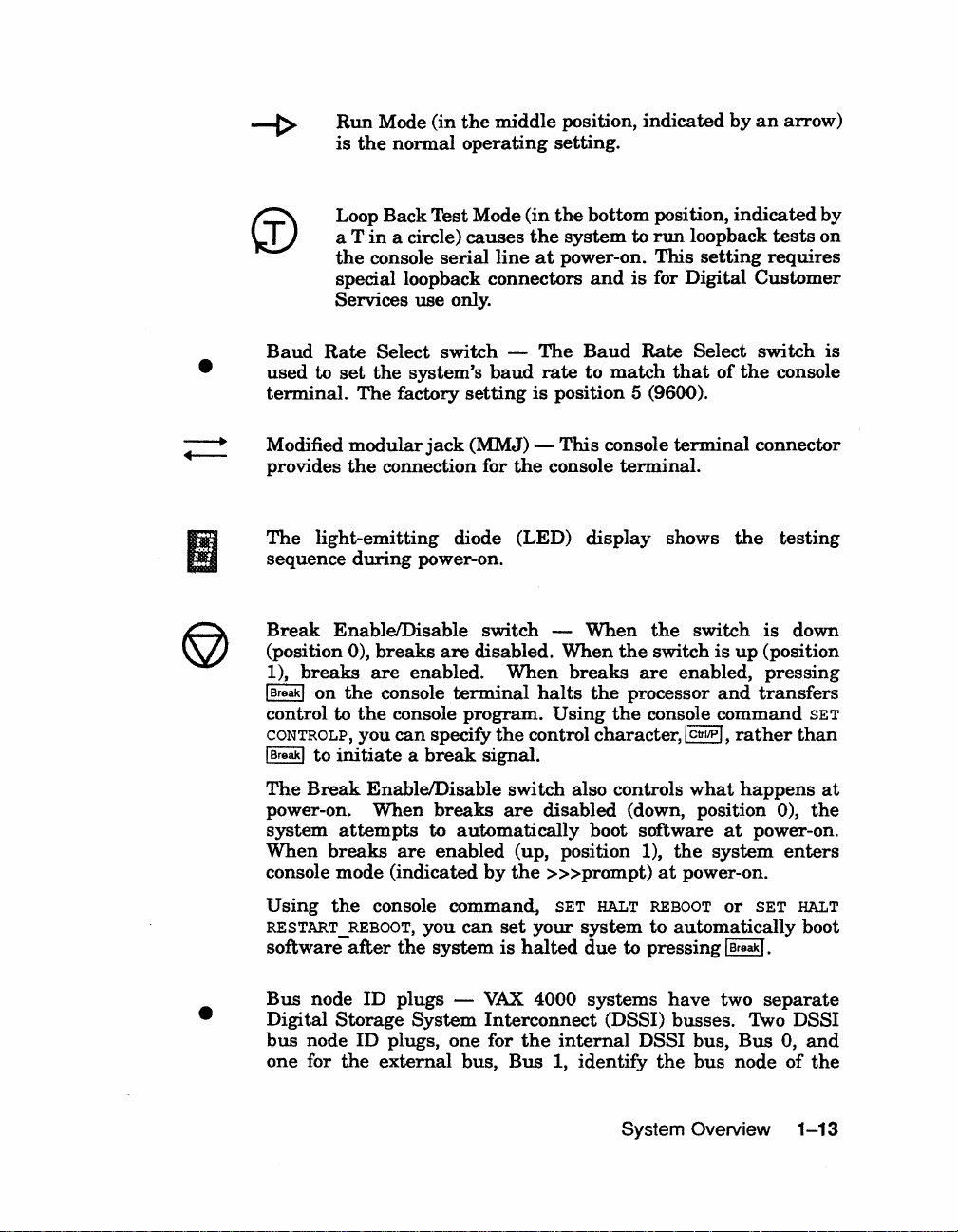

CPU. These plugs

systems, Bus

bus node

are

identified

are

identified

0 is identified

7;

for dual-host systems, both busses on

as

bus node

as

bus node 6.

are

configured

7,

at

the

factory.

as

bus

node 6, bus 1 is identified

and

both busses on the second host

For

the

single-host

as

first host

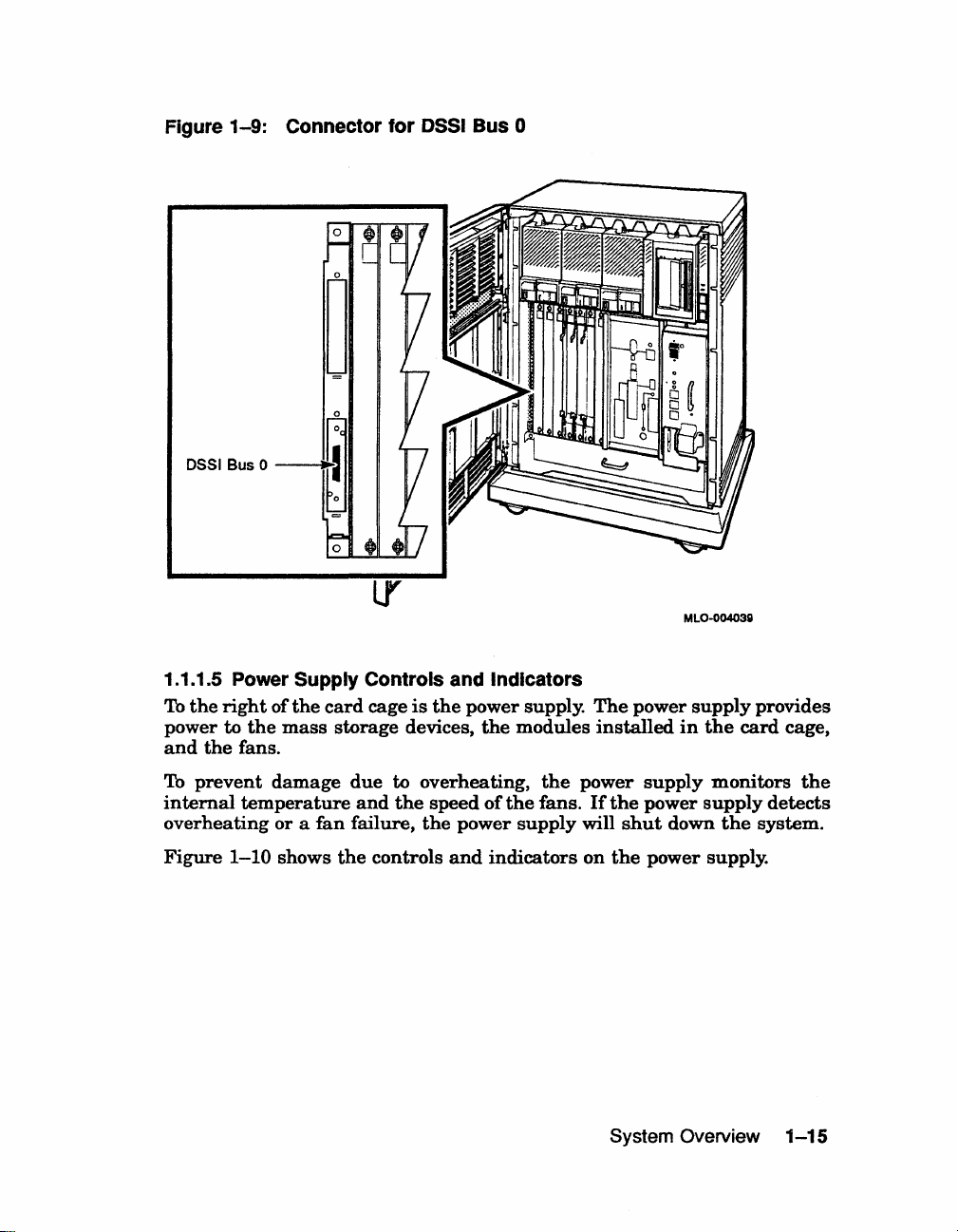

DSSI connectors (DSSI Bus

•

1.1.1.4

To

the left of

o provides

connector allows you to expand your system

storage devices to the bus.

second system by forming a dual-host configuration. Figure

location of

Interconnect (DSSI) connectors, labeled X

module allow you to expand your system by connecting additional

mass storage devices to

Ethernet

connectors: a BNe-type connector for Thin Wire Ethernet, and

a 15-pin connector for a

The

connection.

set

connection,

light (LED) for each connector indicates which connection is

active.

DSSI

Connector (DSSI Bus 0)

the

the

connectors - The console module has two

Ethernet

the switch

the

card cage is the

nSSI

nSSI

connector switch allows you

To

use

the

to

the

up

set

the

switch to the down position. A green indicator

bus for ISAs installed

You

can also

connector for

1) -Two

the

second DSSI bus. '

standard

standard

position.

nSSI

nSSI

Ethernet

transceiver cable connection,

To

connector for DSSI Bus

in

the

by

connecting additional

share

mass storage devices with a

Bus

O.

Digital Storage System

and

Y,

transceiver cable.

to

use the Thin Wire cable

system enclosure. The

on the console

Ethernet

set

the

type of

O.

Bus

mass

1-9

shows

the

1-14

VAX

4000

Model 300 Operation

Page 26

Figure

DSSI Bus 0

1-9:

Connector

for

DSSI

Bus 0

MLO-004039

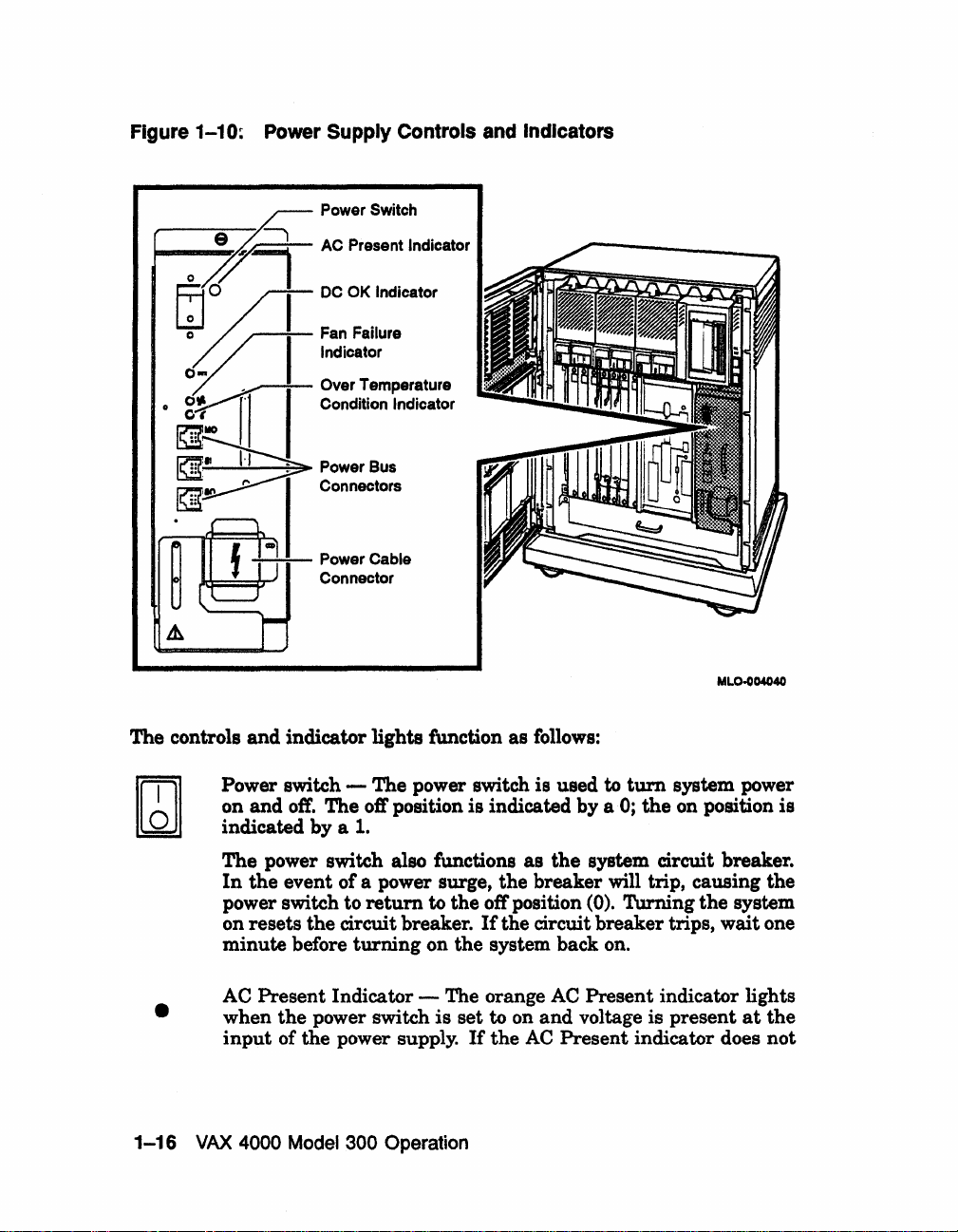

1.1.1.5 Power Supply Controls and Indicators

To

the

right

of

the

card

cage

is

the

power supply.

to

the

mass

power

and

the

fans.

To

prevent

internal

temperature

overheating

Figure

1-10

damage

or a fan

shows

storage devices,

due

to overheating,

and

the

failure,

the

the

controls

speed

power

and

the

modules

the

of

the

fans.

supply

indicators on

The

power

installed

power

If

the

will

the

System Overview

in

supply

power

shut

down

power supply.

supply

the

card

monitors

supply

the

provides

cage,

the

detects

system.

1-15

Page 27

Figure 1-10; Power Supply Controls and Indicators

---e--~

o

7'1

GJ~O

00.

o~

~

o

gYI

n'1

~MO

-:--:-:--

The controls and indicator lights function as follows:

Power Switch

AC Pr

....

nt Indicator

I

DC

OK

Indicator

Fan Failure

Indicator

OVer

Temperatur.

I I Condition Indicator

Power Cable

Connector

MLO-o04040

•

1-16

Power switch - The power switch is used

off.

on and

indicated by a

The power switch also functions as

In

the

power switch to

on resets the circuit breaker.

minute before turning on the system back on.

AC

Present Indicator - The orange

when the power switch

input

VAX

4000 Model 300 Operation

The off position is indicated by a

1.

the

event of a power surge, the breaker will trip, causing the

return

of the power supply.

to the off position

If

the circuit breaker trips, wait one

AC

is

set to on and voltage is present

If

the

AC

Present indicator does not

to

tum

system power

0;

the

on

position

system circuit breaker.

(0).

Turning the system

Present indicator lights

at

is

the

Page 28

light

when

the

Troubleshooting

power

and

switch

Diagnostics

is

set

to on,

manual.

refer

to

your

VAX

4000

+

t

•

DC OK -

supply voltages

DC

OK

to

on,

manual.

Fan

Failure

if

either

will automatically

measure

representative

Over

Temperature

down

instructions

Power

to configure a

or

B400X expander.

and

on

designated

can

control power for

illustrates

system.

When

are

indicator does

refer

to

your

indicator -The

of

the

two cooling fans stop working. The power

when a

Temperature

due

to

bus

off for

fan

if

a fan failure occurs.

Condition

an

over

on recovering from

connectors -

power

one

as

the

a possible power

the

green

within

VAX 4000 7roubleshooting

shut

failure

Condition indicator temperature

bus

The

or

more

main

an

DC

OK

the

correct

not

light

when

amber

down

indicator

Three

for systems

power supply:

the

is

detected. Call

lights

condition. Section 2.9 provides

an

power

power

expanders

entire

bus

expanded

bus

configuration for

over

indicator

operating

the

Fan

system

if

temperature

bus

expanded

allows you to

through

this

is lit,

power switch

Failure

as a precautionary

your

The

the

enclosure

connectors allow

the

way, one power switch

system.

the

range.

and

Diagnostics

indicator

Digital

amber

condition.

with

the

turn

power

Figure

an

expanded

power

If

is

lights

supply

service

has

R400X

power

supply

Over

shut

you

1-11

the

set

NOTE:

bus. Inadvertently

reliability

MO

81

Dual-host systems should not be configured

of

a dual-host system.

The

main

bus

signal to

cable is connected here,

secondary

The

secondary

control

bus

with

signal

connectors

shutting

out

in

(81) connector

signal

more

is

passed

as

off

a host system defeats the

(MO) connector sends

the

expander. One

the

other

end

of

an

expander

in

(81) connector receives

from

the

main

power supply.

than

one expander,

along,

shown

in

Figure

using

the

1-11.

System Overview

with

the

power control

end

of

a power

is connected to

power

the

In

the

power control

secondary

a power

supply.

power

a power

in

and

added

bus

the

bus

bus

out

1-17

Page 29

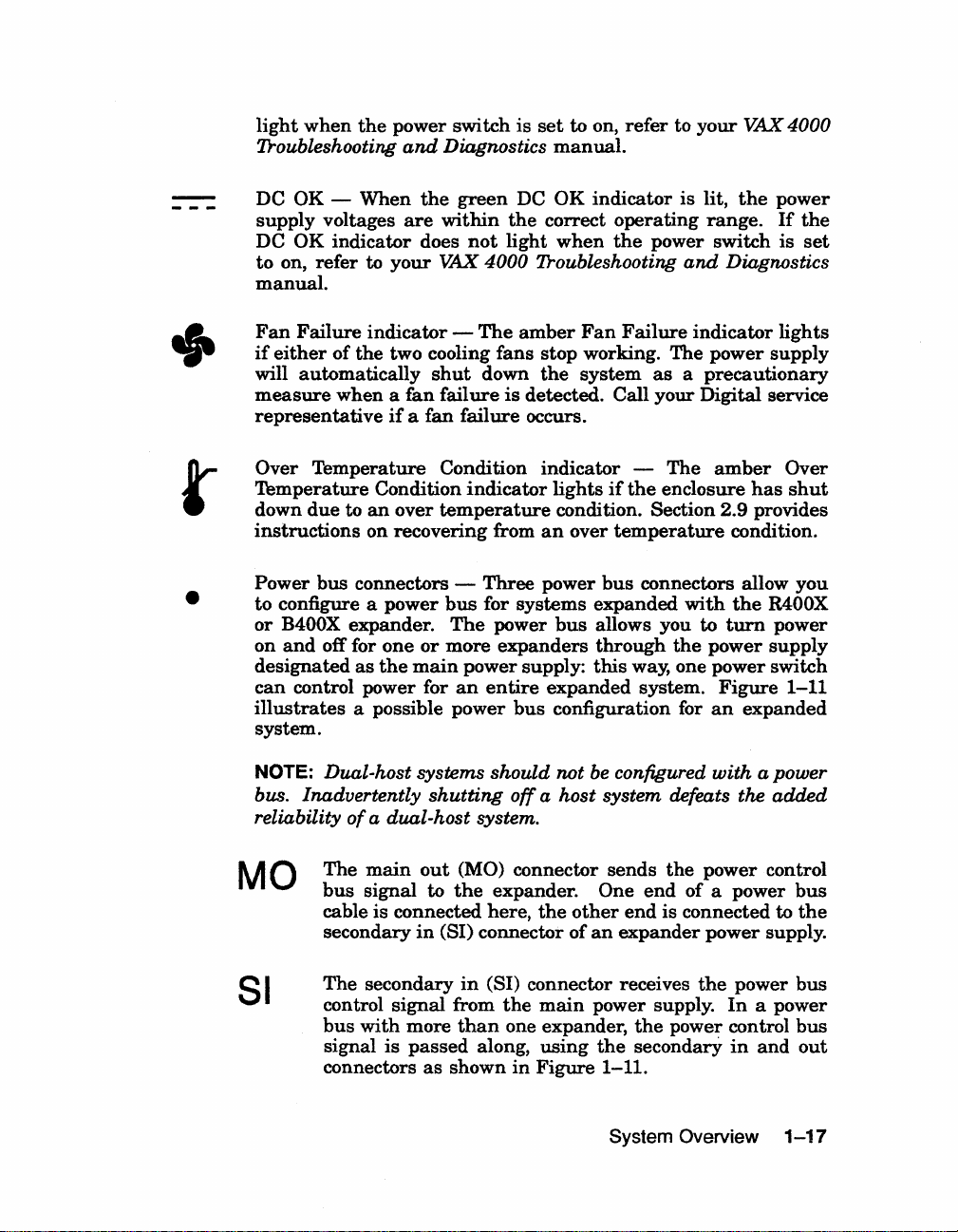

so

Figure 1-11: Sample Power Bus Configuration

The secondary

the power bus for configurations of more

expander.

out

(SO) connector sends

the

signal down

than

one

System

MO

Expander 1 Expander 2

gMO

gSI

gso

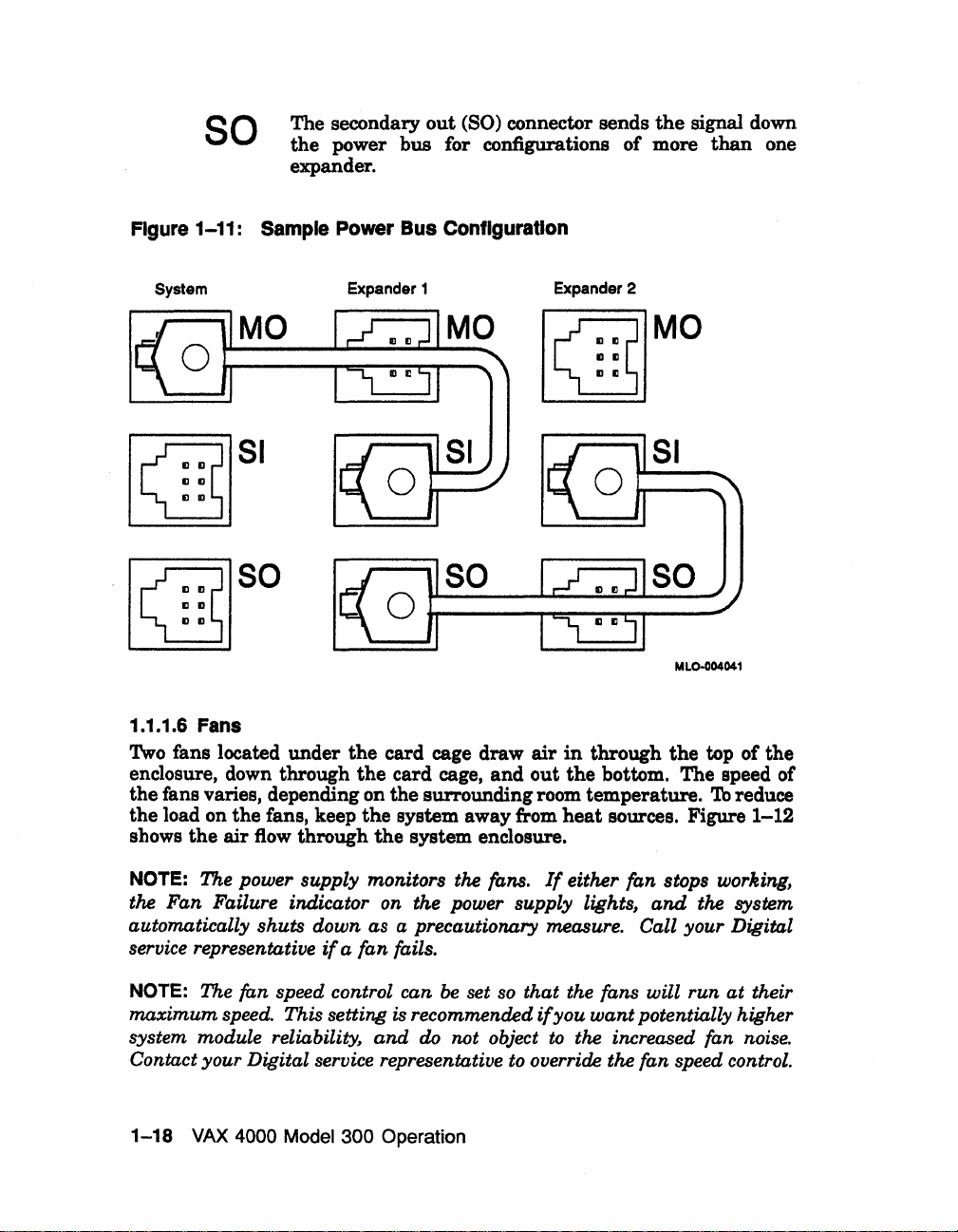

1.1.1.6 Fans

1\vo fans located under

enclosure, down through

the fans varies, depending on the surrounding room temperature.

the load on the fans, keep the system away from

shows

the

air

flow

the

the

through

card cage draw

the

so

card cage,

system enclosure.

and

air

out

MLO·004041

in

through

the

bottom. The speed of

heat

sources. Figure

the

top of the

To

reduce

1-12

NOTE: The power supply monitors the fans.

the Fan Failure indicator

automatically shuts down as a precautionary measure. Call your Digital

service representative

NOTE: The fan speed control can

maximum speed. This setting is recommended

system module

Contact your Digital service representative

1-18

VAX

4000 Model 300 Operation

if

reliability~

on

the power supply lights,

a fan fails.

and

do

be

set so that the fans will run at their

not object

If

either fan stops working,

and

the system

if

you

want

potentially higher

to

the increased fan noise.

to

override the fan speed control.

Page 30

Figure 1-12: System Air Circulation

•

MLO-G04042

1.2 Functional Description of Base System

Each

VAX

4000

systems. Your

was

configured

system

system

at

the

includes

may

have

factory,

base

system

optional components

based

on

your

components common to

order.

as

well. Your

all

system

The following sections describe

turn.

1.2.1

Base

•

•

•

•

• Embedded DSSI

Base System Components

system

Central

Console

Main

Network

components include

processing

serial

memory

controller

line

host

unit

unit

(CPU)

(SL U)

adapters

base

the

system

following:

components

System Overview

and

options,

1-19

in

Page 31

1.2.1.1

The central processing unit (CPU) controls

and

Centra~

Processing Unit

(CPU)

the

execution of all instructions

processes. The CPU circuits contain the logic, arithmetic, and control

functions used by the system.

1.2.1.2 Console Serial Line Unit (SLU)

Each system has a serial line unit connecting

system. The

SLU connector (a modified modular jack) is located on

the

console terminal to the

the

console module. The console serial line provides a means of communicating

with the CPU.

1.2.1.3 Main Memory

Main memory provides the electrical storage area for

used by the

CPU. When you

start

your system, the operating system is

data

and instructions

loaded into main memory. Application programs must also be loaded into

memory.

When the system cannot load everything into memory

in

units of data called pages (512 bytes of data) from disk. A large main

of

memory increases the efficiency

copied

to and from

the

disk. Each configuration comes with a standard

memory option. There is room

processing, since fewer pages must be

for

up to four memory modules.

at

once,

it

By

reads

adding

more main memory, you can increase efficiency.

The contents of memory are volatile.

you turn

off power to the system. Use mass storage devices, such

This means they are lost when

as

integrated storage assemblies and tape cartridges, to store software and

data

permanently.

1.2.1.4 Network Controller

Network communications controllers allow you to connect to

an

Ethemet

network. With a network connection and appropriate DECnet software, you

can use network services, such as mail; access

data

stored on other systems;

perform operations, such as editing and printing on remote systems; and

share resources, such as laser printers.

Ethemet

an

Ethernet network through either standard

Ethemet

controller

that

is

part

cable. Connectors for both types

Your

system comes with

an

onboard

of the CPU. The system can connect to

Ethemet

of

cables are

cable

on

or

Thin Wire

the console

module. .

1-20

VAX

4000

Model

300

Operation

Page 32

1.2.1.5 Embedded

Your system

built

into

the

(Bus 0

series ISAs.

The

to a second

and

DSSI

Bus

Each

host

host

extended to a second system,

Section 1.3 for

to

has

two Digital

CPU.

1)

through

nSSI

adapters

to form a

further

DSSI

Host Adapters

The

DSSI

bus

also allow

discussion

Storage

adapters

which

can

dual-host

both

1.2.2 Optional Components

System

Interconnect (DSSI)

provide two

the

CPU

can

communicate

support

seven RF-series ISAs.

you

to

link

configuration. When a

systems

of

can

share

dual-host systems.

separate

one

of

up

adapters

DSSI

busses

with

the

RF-

the

DSSI

busses

nSSI

bus

is

to six ISAs. Refer

System options

base

system (for example, additional

following kinds

•

Mass

storage devices

•

Mass

storage

•

Mass

storage

can

include

of

options:

subsystems

expanders

multiples

and

controllers

• Communications controllers

• Real-time controllers

•

Printer

1.2.2.1

Mass

not

lost

record over

permanently.

from

of

mass

!D.edia,

Integrated Storage Assemblies

Up to four RF-series ISAs

an

intelligent storage device

Special

interfaces

Mass Storage Devices and Controllers

storage devices record

when

you

turn

the

data.

Use

the

When

mass

the

storage device

storage devices

such

as

tape

cartridges

off

data

are

data

the

mass

or

the

can

that

mounting

bracketry

allows

BA400-series backplane.

of

components

memory

and

adapters

on

magnetic

system,

but

can

storage devices to

software

into

main

RF

-series ISAs

and

compact disks.

be

contains

is

needed,

memory.

installed

its

the

device to plug directly

that

modules

or

media. The

be

altered

store

data

the

The

two

and

devices

in

your

system.

own controller

are

ISAs)

data

or

erased

and

CPU

primary

with

part

of

the

and

the

recorded

if

you

software

transfers

types

removable

An

ISA is

and

server.

into

the

is

it

Devices with Removable Media

Devices

input

with

and

removable media,

output

devices.

In

such

as

tape

cartridges,

are

addition, compact optical disks

System Overview 1-21

used

are

as

both

used

as

Page 33

input

devices when you install software or copy

use tape cartridges

data

from your system.

can copy (back up)

to archive data.

used

Mass Storage Controllers and Adapters

and

tapes

You

the

contents of

as

output devices when you copy software or

can copy individual files or programs,

an

entire fixed disk. Tapes

data

All mass storage devices require a controller, a device

between the

for each RF-series

options require a controller module located

controller for the

for RA-series disk drives. Each

CPU

and

the

ISA is built into

TK70 tape drive is

mass storage devices. While

the

storage assembly,

in

your system's card cage. The

the

TQK70j

the

KDA50 controller supports up to four

series disk drives.

to your system.

are

that

controls activity

the

other

You

or

you

commonly

controller

storage

KDA50 is a controller

RA-

KZQSA

The

drive or

System Interface (SCSI). Each KZQSA

adapter allows

the

CPU to communicate with the TLZ04 tape

RRD40 digital compact disk drive through a Small Computer

adapter

can support up to three

drives.

The

CPU communicates with the ISAs through a Digital Storage System

Interconnect (DSSI) adapter, which is built into

system

has

two DSSI adapters,

and

hence, two separate DSSI busses. Each

the

CPU. Your

VAX

4000

DSSI bus is capable of supporting seven integrated storage assemblies. A

third

and fourth DSSI bus can be added to your system by using

KFQSA DSSI storage adapter modules. Each KFQSA storage

up

support

1.2.2.2 Mass Storage Subsystem.

Several optional

to seven RF -series ISAs.

mass

storage subsystems

are

available for

up

to two

adapter

VAX

can

4000

systems. Such subsystems include RRD40 Digital Disk Subsystems, the

RV20

Optical Disk Subsystem, TS05

Storage

an

manual

1.2.2.3 Mal.

You

Array (with

optional mass storage subsystem, refer to the user's guide or owner's

for

that

Storage

can expand

up

to eight RA90 disk drives).

subsystem for instructions on how to operate

Expander.

the

mass storage

and

TUB1

tape drives,

If

and

Q-bus capacity of your

and

the

SA600

your system includes

the

device.

VAX

4000

system by using expanders. The R400X mass storage expander provides

up

space for

you can

to seven additional RF-series ISAs. Using R400X expanders,

fill

both DSSI busses for a total of 14 ISAs.

The B400X expander provides

to four additional RF-series ISAs. Refer to

11

additional Q-bus slots

expander for more information.

1-22

VAX

4000 Model 300 Operation

the

addendum shipped

and

space for up

with

the

Page 34

1.2.2.4 Communications Controllers

Besides

tions controllers for connecting

ing

controllers provide

system.

data

The

• Asynchronous serial controllers

the

with

other

Many

lines.

following

console

serial

systems

standard

communications controllers provide

types

of

line,

most

additional

over telephone

interfaces

communications controllers

systems

or

between

have

additional communica-

terminals,

network lines. Communications

and

peripheral

support

are

available:

for communicat-

devices

for

and

the

multiple

• Synchronous

•

DECservers

•

Network

Serial

transmitting

end

controllers

assembles

serial

controllers

transmit

end

breaks

incoming

controllers

data

one

bytes

of

bits

into

character

data

bytes

into

bits. A device

of

data.

at

a time. A device

at

the

receiving

Asynchronous Serial Controllers

Asynchronous serial controllers provide low-speed connections

peripheral

the

system

and

stop bits,

Asynchronous

support

You

use

terminals

provides connections for

NOTE: Printers equipped with a microprocessor (intelligent printers)

require modem control signals to function correctly.

requiring modem control signals

Check your printer documentation

devices

and

and

serial

and

and

the

not

on a time

serial

those

with

controllers

printers

the

system. Asynchronous communication

peripheral

controllers

modem support.

to

interval.

without

your

up

to

depends'

16

on

recognition

may

be divided

modem

system.

serial

to

to

For

lines

a controller with no modem support.

determine the proper communications

into

support

example,

with

of a pattern

those

without

to connect additional

the

CXA16

no

modem

Do

not attach a printer

between

between

of

modem

module

support.

interface for your printer.

at

start

may

the

Communications controllers

over telephone lines. With a

access

terminal

Computers

exception

other

or

of

computers

computer.

transmit

digital

leased

with

and

digital signals, while telephone

modem

modem

you

can

lines)

support

connected to your system,

dial

into

transmit

allow you to communicate

your

system from a

analog

signals.

System Overview

you

lin~s

(with

When

can

remote

the

two

1-23

Page 35

computers communicate over telephone lines, a modem is required

the

transmitting

and

receiving ends of

the

line.

At

the

transmitting end, the

at

both

modem converts digital signals from the computer (or terminal) to analog

signals prior to transmission.

the

analog signals back into digital signals the computer can process.

The degree of modem support depends on

signals recognized by

the

standards) requires recognition of eleven signals. The

supports

Synchronous Serial Controllers

up

to eight serial lines with full modem support.

At

the receiving end, another modem converts

the

number of modem control

device. Full modem support (according to Digital

CXYOB

module

Synchronous serial controllers provide high-speed connections between

systems. Communication between synchronous devices depends on time

intervals

Synchronous devices

DECservers

DECservers

that

Ethernet

that

are

synchronized before transmission of

can

also have modem support.

are

terminal servers (a combination of hardware

allow you to connect multiple terminals

Local Area Network

(LAN).

or

printers to hosts

data

and

begins.

software)

in

an

Terminal servers perform

but

switches

multiplex

the

the

lines over

functions of traditional

the

Ethernet. Using a DECserver

data

offloads communications processing from the host system.

Network Controllers

Network communications controllers allow you to connect to

LAN or other network type. With a network connection

DECnet software, you can use network services, such

stored on other systems; perform operations, such

remote systems;

and

share

resources, such as

as

laser

controller function for your system is implemented on

a second network controller,

added

1.2.2.5 Re.I-Tlme Controllers

to your system.

Real-time controllers interface with devices

particular processes,

lor example, laboratory equipment

equipment connected to

parallel devices,

1-24

VAX

4000

not

serial devices.

Model

the

DESQA Ethernet,

adapter

that

the

system. Typically, real-time controllers

300 Operation

and

as

mail; access

editing

and

printers. The network

the

CPU module,

module can be

monitor or control

or

manufacturing

terminal

an

Ethernet

appropriate

data

printing on

but

are

Page 36

1.2.2.6 Printer Interfaces

Some

printers

For

example,

SA

interface module.

1.2.2.7 Other Available Options

Your

system

change,

advise you on

describes

provides

you

require

the

LGOl, LG02,

arrives

can

add

available

the

options

installation

specific interfaces to communicate

and

LP25-LP29

configured

more

options. VAX 4000 Model 300 Thchnical Information

currently

for additional options

with

the

options you ordered. As

options. Your Digital

available for

printers

VAX

that

sales

4000 systems. Digital

you order.

with

the

require

representative

the

your

1.3 Dual-Host Capability (VMS Systems Only)

system.

LPVll-

needs

can

A dual-host

ISAs via a Digital

can

have

shared

a

The

primary

The

simplest

system

disk

physically

access to

either

A

DSSI ISA,

allows

embedded

physically connecting

Using

connected to form a dual-host configuration.

host

configuration

NOTE: Dual-host capability

VMS

(version

VAXclus ter.

same

The

benefits

• VAXcluster

nodes.

system

direct

common

application for such a configuration

disk

to

the

enclosure.

it

to connect to two DSSI

in

an

external

5.3-2

of

consists

Storage

access to

system

dual-host

be

used

resides

system

such

the

with

a dual-host configuration are:

features

any

disk.

configuration, for example, is to configure one

as

in

one enclosure, however,

disk

as

the

system's CPU, allows you to

it

to a second system.

DSSI cable,

two

and

later) when the two systems are configured into the

such

of

two systems

System

the

and

RF71,

VAX

for

Interconnect

of

the

ISAs

in

system

to

host

disk

any

other

has

a built-in dual-host capability

adapters.

any

two DSSI-based

4000 systems.

VAX 4000 systems is only supported under

as

shared

data

in

a VAXcluster

(DSS!) bus.

either

system;

is

a VAXcluster system.

by

both

systems.

both

systems

DSSI

mass

The

DSSI storage

extend

Figure

across systems

1-13

sharing

Each

this

can

The

have

storage

a DSSI

systems

device

adapter,

shows a dual-

and

satellite

their

system

include

system

equal

in

that

bus

by

can

be

•

Higher

unavailable, for example,

system availability -

If

one of

due

to a system malfunction,

the

System Overview

DSSI-based

the

systems

satellites

1-25

is

Page 37

booted through

it

are

able to continue operating through the other

system .

.

If

one of the nSSI-based systems fails, all satellite nodes booted through

that

system lose connections to the system disk. Each satellite node knows,

that

the

however,

satellite nodes establish a new connection through

system disk is also available through a second path. The

the

other system and

continue operation.

To

increase system availability, a second system disk may be added to each

In

the

boot node.

disk would continue

booted through it.

event of one system disk failure,

to serve one nSSI-based system

As

with any VAXcluster, however, a second system disk

the

remaining system

and

the satellite nodes

improves availability while increasing system management tasks.

Figure 1-13: Dual-Host Configuration

MLO·OOo404S

VAX 4000 Dual·Host Systems provides more information on dual· host

configurations.

1-26

VAX

4000

Model

300 Operation

Page 38

Operating the System

This

chapter

the

system

procedures for factory-installed VMS.

2.1

Before

This

chapter

Installation

system

time

the

factory-installed VMS.

products, see

or

require

on

The

installed

been

and

startup

VAX 4000 Model 300 Installation

layered

you

the

console module.

remainder

completed.

describes how to

software

assumes

includes

installing

procedures for factory-installed VMS. Refer to Appendix A

the

product

to

open

and

first

has

You

of

Operate the System

that

running

the

To

install

instructions

installation

the

front

this

chapter

time

startup

been

base

operate

installed

your

the

diagnostic software

operating

other

in

your

manual.

door

of

assumes

procedures for factory-installed VMS

system

manual

operating

system

the

system

your

or

you

has

system,

for

instructions

software

Some

that

system

VAX

have

been

or

completing

system

installation

of

the

to

change

Chapter 2

4000

system

completed

properly

shipped

options

instructions

software

with

on

starting

or

switch

installed.

has

once

startup

your

the

first

of

up

layered

manual

may

settings

been

have

2.2 Switch Settings

Switch

two sections describe switch

Set

2.2.1 Normal Operation

Switch

•

settings

the

switches according

settings

The

Break

(down, position

disabled to

pressing

activity to stop.

vary, depending

for

EnablelDisable switch on

prevent

I Break I on

to

nonnal

0). Digital recommends you

the

the

operation

console

on

settings

your

user

from

terminal.

the

operation

for

normal

needs.

are

the

the

inadvertently

being

performed.

and

for special operations.

following:

console module

run

the

halting

Halting

the

Operating the System 2-1