Page 1

EK-OTU58-UG-004

TUS8

DECtape

II

User

Guide

Page 2

,

EK·OTU58·UG·004

TUS8

DECtape

User

II

Guide

Prepared

Digital Equipment Corporation

by

Educational Services

of

Page 3

Copyright () 1978, 1981, 1982. 1983

by Digital Equipment Corporation

All Rights Reserved

1st Edition, October 1978

2nd Edition, June 1981

3rd Edition, October 1982

4th Edition, December 1983

The reproduction

strictly prohibited. For copy information, contact the Educational Services Department. Digital Equipment Corporation, Maynard, Massachusetts 01754.

The information in this document

without notice. Digital Equipment Corporation assumes

responsibility for any errors that may appear

document.

This equipment generates, ml.($, and may emit radio

quency. The equipment has been type tested and found to

comply with the limits for a Class A computing device

pursuant to Subpart J

designed to provide reasonable protection against such

radio frequency interference. Operation

in a residential area may cause interference

the user

whatever measures may

.interference.

The following are trademarks

poration, Maynard, Massachusetts.

at

of

this material, in part or whole,

Printed in U.S.A.

of

Part

his own expense

be

is

subject to change

in

15

of

FCC rules, which are

of

this equipment

in

which

case

will

be required to take

required to correct the

of

Digital Equipment Cor-

is

no

this

fre~

DEC

DECUS

DIGITAL

RIIID

UNIBUS

DECtape

DECtape

II

DECnet

DECsystem-l0

DECSYSTEM-20

DECwriter

DIooL

EduSystem

VAX

MASSBUS

OMNIBUS

OS/8

PDT

RSTS

RSX

VMS

lAS

VT

Page 4

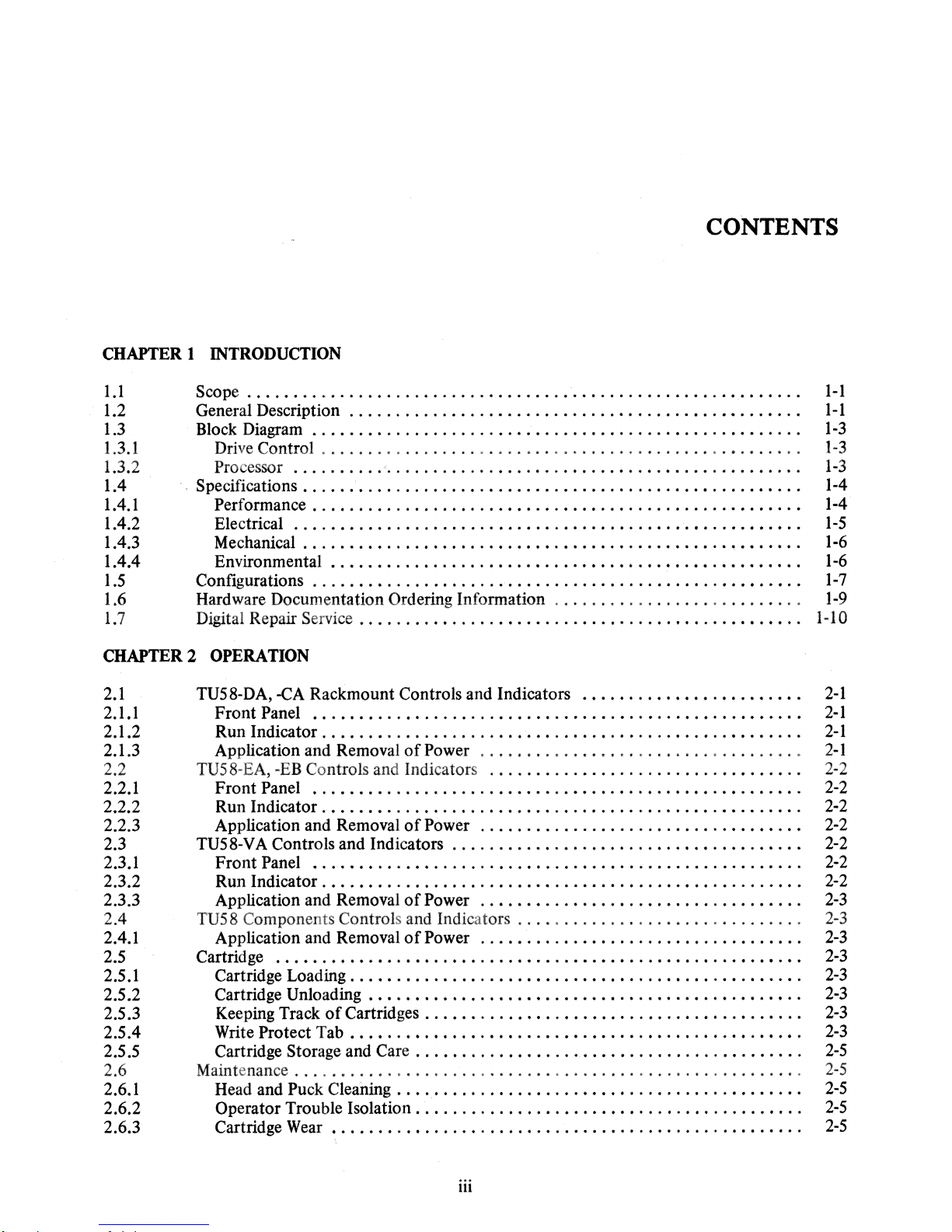

CHAPTER 1 INTRODUCTION

CONTENTS

1.1

1.2 General Description

1.3 Block Diagram

1.3.1 Drive Control

1.3.2 Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope

...

"'

...

........

"'

......

..............................•..........•.......

..........................

...

, ,

...

" . "

......

" . . . . .

" "

......

" "

......

.. . .. . .......

" "

"'

..

"'

.........

" .

"'

........... " ..

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

........

,

.... " .......

,.

1-1

1-1

1-3

1-

1-3

1.4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . 1-4

1.4.1 Performance . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 Electrical

1.4.3

Mechanical"

1.4.4 Environmental

1.S

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . .

1.6 Hardware Documentation Ordering Information '

1.

7 Digital Repair Service

...........................................•...........

..........

.................

" .......

"'"."

""

.... " ..

".,,"'

"'"'."

. . . . . . . . . . . • . . • . . • . • . . • . . . . . . . . . . .

........

........•.......•.......................•.•...

"""

..

"'''''"."'

"

........

..

,,"'

, ,

"'.,,"'

........

""'.

'"

'

" 1-10

1-5

1-6

1-6

1-7

1-9

CHAPTER 2 OPERATION

2.1 TU58-DA,

2.1.1

Front

2.1.2 Run

2.1.3 Application and Removal

2.2 TU58·EA,

2.2.1 Front

2.2.2

Run

2.2.3 Application and Removal

2.3

2.3.1

TU58-VA Controls and Indicators

Front

2.3.2 Run

2.3.3 Application and Removal

2.4

TU58 Components Controls and Indicators

2.4.1 Application and Removal

2.5

Cartridge

2.5.1 Cartridge Loading. . . . . . . . . . . . . . . . . . . • • . . . . . . . • • . . . . • • . . . . . . . . . . . . .

2.5.2 Cartridge Unloading • . . • . • . • • • • . . . . • . • • . . . . . . . • . . . . . . . . . . . . . . . . . . . .

2.5.3 Keeping Track

2.5.4 Write Protect

2.5.5 Cartridge Storage and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.Maintenance

2.6.1 Head and Puck Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Operator Trouble Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Cartridge Wear

-CA

Rackmount Controls and Indicators

Panel

.•..............................................•....

Indicator.

-EB

Controls and Indicators

Panel

".""""""1O"""""

Indicator"

Panel

Indicator.

•........................................•...........

.

it

it

it

'"

Tab.

.. , ,.

........•....•.....•....

. . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . • . . • . . . . . . . . . .

of

Power

...................................

...........................•......

..

""

..

.,,,,,,,,,,,,,,,

" " " " " " " " " " " " " " " " " " "

of

Power

...................................

..

...

,,,,,,,,,,

'"

" " " " "

..

" • "

,.

..

" " " "

,.

" "

" " " " . " " " " " " " " " " " " " ... " " " " " " " " " "

..

~

...............•......•..•.••.....•.•.

• . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • . • . • • • • . . . . . . . . . . 2-2

of

Power

of

Power

•••••••

of

it

Ii

•

it

••••

Cartridges. . . • . . . . . . • . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

..•.......•.•..•..•................

...•.........

.........•.........................

it

•

Ii

it

•••••

it • it

••

it

••••

'

...•... , ........

"

it

it

••••

it

...

it

••

.

it • ,. • it

. . • . . . • . • . . . . . • . . . . . . . . . . . . . . . . . . . . . . . • . . • . • . . . .

.......

•..

,.

........

,.

•.....

,. , ............

, . , . , . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-1

2-1

2-2

2-2

2",,2

2-2

2-2

2-2

2-3

2-3

2-3

2-3

2-3

2-3

2-S

2-5

2-S

2-S

2-S

3

iii

Page 5

· CHAPTER 3 PROGRAMMING

3.1

3.1.1

3.1.2

3.2

3.2.1

3.2.1.1

3.2.2

3.2.3

3.2.3.1

3.2.3.2

3.2.4

3.2.4.1

3.2.4.2

3.2.5

3.3

3.4

General

Radial Serial Protocol (RSP) and Modified

Instruction Set

PASCAL

Principles

.......................•.............•.............

Block Number, Byte Count, and Drive Number

Special Handler Functions

Packets

Break

Command

.......

Packet

Usage

and

Initialization

Packets

Maintenance

" " " " " " "

""."""""

..

Mode

Special Address Mode

Data

Packets" " ..

" "

..

Radial Serial Protocol

Modified Radial Serial Protocol

End

Packets

..

" ... "

.... " ..

.. " .. " ....

" "

....•...••.•.••.•...........•.............

RSP

(MRSP)

..

" " " " " " "

"."""."

"""".,,,.,,,,,,,,"

... " ..

..

" " " " " " " " " " " " " " " " "

""""

..

""".".""""""".,.""

..

".""

....

""".,,,

...

,,.,,,,,,

...........•............•.•...................

...•.•.•..........•••.....•••...........•...

" " " ,

.. " ....

" " " "

.... " .. " ......

.......................••..•......•......•..

...........•......•...••...•..•.•.••

to

...... " ... " .....................

.. " ....

" ....... " ......... " . " ...

TU58 Handler Algorithm Definitions

............••.•..•......•

......•.•...••..•..•.

.. " ..

" , " "

...

... ,,.,,

..

,,

..

,,.,,,,,,,,,,,,,

..

,,

..

,,.,,,,,,,,,,,,,,,,.,,

" " " "

...

" " . "

.. " ....

" "

"

..

" "

... " .... " .... " .. " .......

.,

" ....... " ..... "

.. " .. " ....

..

" . " . " " " "

"".,."

..

".,

....

,,,,,,,,.

...

,,

....

,,,,,,.,, ...

....

" "

..

" " " . " ,

" • " "

" ........ " ... " "

...

..

CHAPTER4 INSTALLATION

4.1 Introduction"

4.2 Rack Installation

4.2.1

Rackrnount

4.2.2 Unpacking

4.2.3

Power

4.2.4 Removing Bottom Plates for Controller Board Configuration

..

" , " " " " " , " " , , " " " " " " " " , " " " " "

..

"""""""""""""""

..

"""

Selection

..

(-DA

Version) . . . . . . . . . . . • • • . • . . . • . . . . . • .

....

,,

111

, , " , , , "

..

"""""".""."

""

..

""""""""

•. " ..

..

"."""

""""""".""

..

".".".""""

" " " " " " " " " " " " " " "

..

, , , , " , " , " , , , , " , " , , , • " , " • ,

..

,,

...

,,",,

....

..

,,""",,.,,"""",,

............•.•

.. " ""

•.

,,"",,

" " " " " " "

•• . • . . • . . . .

...

,,""""""

..

,,"",,.,,"

4.2.5 Rackmounting Procedure. . . . . . . . . . • . • . . . • . • • • • • • • . • • • . • • . . . . • . . . • • •

4.3 Rack Installation

4.3.1 Rackmount """."

4.3.2 Power Selection for the Rack Version

4.3.3 Removing Module from Chassis. • • . • . • . .

4.3.4 Reinstalling the Module

4.4 Installation

4.4.1 Tabletop Installation

4.4.2

Solid Mounting Installation

4.5 Installation

4.5.1 Tabletop Installation

4.5.2

Solid Mounting Installation

4.5.3 Mounting the

4.6 Components" ... , " " " " " " " , " " " " " " " " " " " " " "

4.7 Interface Standards Selection and Setup

4.7.1 Selecting Interface

4.7.2 Connecting Standards Jumpers

4.8 Operational Checkout

4.8.1 Checkout

4.8.2 Configuring Interface Modules

4.8.3 Checkout

(-EA

(-VA

of

Interface

of

Drive

(-CA

Version) . . • . . . . . . . . . . . . . . • . . • . . • . . • • • . . . • . • • • • • .

.. " ..

""."""""""".""."."""""""""" ... ""."""

.....•.....•••••.••.••..•.••..•..

..

. • • • •• • • . . • . • • . .

..••..•.............••••.•.•••••.••••.•••.•.

and

-EB

Versions)

.....................................

.....••..•.............•.•••.....•.••.••..••.•

.........................................

Version)

.•••..•.•....•.••..•...•......•••.••••.••.•.

.•........•••.•••••••....•.••••..•.••........•

.......•.•.•...............•...•...•..••.

TU58-VA

to

the

SBll

(or BAll-VA)

......................

e."

....

" .. " " " " " .. " " " " " " " " • " "

...•••..•.•..•.....•..•..........

Standards..

• . • . . • •• • . • . • . . . . • • . . • .

...

• • . •

..•..•.•......•..•••..••..•.•.....•....

.....••••.•......•......•.••..•..........••••.•

•.•......•••••••.•..•••.••...•••...•....•....

•• • • . • . . . . . . . . . . . . • . • • . • • . • . . • • . . . . • .

Command Function

...••...........••....••........

....

",,

..

. . .

.. . •. . •.

... ,,,,.... 4-7

..

. •

•.

......

.. " 4-13

.•

"

..

3-1

3-1

3-1

3-1

3-1

3-2

3-3

3-3

3-4

3-4

3-4

3-4

3-4

3-5

3-6

3-11

4-1

4-1

4-1

4-1

4-1

4-2

4-2

4-7

4-8

4-10

4-10

4-12

4-12

4-12

4-13

4-13

4-13

4-13

4-16

4-17

4-19

4-19

4-19

4-21

4-31

iv

Page 6

CHAPTER S OPTIONS

5.1 Run Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Installation . .

..

..

.. .. ..

..

.. .. .. .. .. .. ..

..

.. .. .. .. .. .. ..

..

.. .. .. ..

..

.. ..

..

.. .. ..

..

..

..

..

.. .. ..

..

.. ..

..

.. .. .. ..

..

5.2 Boot Switch.......................................... .....................................................................

5.2.1

5.2.2

S.2.3

General..............

................

Operation ......................................................

Installation~

.. . .. .. .. .. .. ..

.. .. . .. ..

..

..

..

.. .. .. . .. ..

..

..

.. ..

..........

e"

..................................

.. ..

.. ..

..

.. .. .. . ..

...........•.....

.. .. .. . .. ..

.. ..

if

................

.. .. ..

.. .. . .. ..

..

..

..

..

. . 5-2

5-1

5-1

5-2

5-2

-2

5

APPENDIX A TUS8/pDP-ll TOGGLE-IN BOOT

APPENDIX

APPENDIX

APPENDIX

APPENDIX

B RSP SEQUENCE

C SAMPLE DEVICE HANDLERS

D CARTRIDGE REPAIR

E FffiLD REPLACEABLE UNIT SPARES LIST

FIGURES

I-I Tape Cartridge Partially Inserted into Drive (Top View)

1-2

1-3

1-4

2-1

2-2 TU58-EA, -EB, and -VA

2-3

2-4 Write

2-5

3-1

An Exchange in Radial Serial

Protocol.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TU58 Block Diagram .........................................................................................

Block Locations

TU58-DA and

on

Tape

...........•........................•..•.....

-CA

Rackmount Front

Front

Panel

Panel.

• • • . . . . . . . . . . . . . . . . . . . . . . . . . . .

.............

Cartridge Loading. . . . . . • • . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . 2-4

Protect Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . 2-4

View Into Tape Drive Cartridge Slot

Read Command Packet Exchange

....................................

......................................

•.......•............

. . . . . . . . . . . . . . . . . . . . . . .

1-2

1-3

1-4

1-5

2-1

2-2

2-5

3-8

3-2 RSP Write Transaction . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . 3-9

3-3

4-1

4-2 Installing Support Brackets

4-3 Installing Mounting Brackets

MRSP

Write Transaction

TU58-DA Rear Panel

............................................•

................................................................................

..................................•...•....

••......•.......•.........................

3·10

4-2

4-3

4-4

4-4 Front Vertical Rail U-Nut Retainers. . . . . . . . . • . . . . . . . . . . . . . . . . . . • . • . . . . . . 4-4

4-5

4-6 Rear Vertical Support U-Nut Retainers

4-7 Fastening Support Bracket Extenders

4-8 Installing the Bezel .

4-9 Bezel and Ball Stud

4·10 Rackmounting the TU58-CA

4-11

4-12 Installing

4-13 Mounting the TU58-EA and

4-14 Mounting Choices for the

4-15 Interfacing the TU58-VA

4-16 Drive Outline Drawings . . .

4-17 Board

4-18

4-19 Data Rate and Cable Length for

4-20 Interface Selection Jumper Pin Locations

Rackmounting the TU58·DA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . .

..•.....•..........•...•..........

...•......................•........

• . • . . • . . . . . . • . . . • . • • • . • • • . . . . . . . • . • .

....................

'"

. • . . • • . • . . . • . • . . • . • • • . . . • • . • . . . . 4-8

...

• • • • .

...

• • .

...

. . 4-7

..........................................

TU58-CA Rear Panel

Cage

and Retainer

Outline Drawings

TU58 Drive Mounting Hardware

................

Bar.

• . . . . . . . . . .

-EB

.......................................

TU58· V A . • . . . .

..•...••..

• . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . .

•.

• . . .

...

. . • • . . • . • • . • . . • • • • . • . • . • • . . • . . • . . • . . .

.......................................

RS-423

".

. . . . . . . . . . . . . • • . • . . . . . . . . . . . .

..

. . . . • . . . . . . . . . . . • • . . . . . .

..

. . .

.. .. . .. ..

'.

........•...•••...•...............

. . . .

..

............••.......•.•.........

. . . . .

..

..

.. . ...

..

..

..•...............•.............

4-5

4-6

4-6

4-9

4-10

4-11

4-12

4-14

4·14

4-15

4-16

4-17

4-19

4-20

v

Page 7

4-21

4-22

4-23 OLVII-J Factory Conftguration Summary

Factory

TUS8

Wiring

Wiring " .. " ....... " ....

(9600 Baud)

............................................

" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

...............................

4-24 MXVII-A Jumper Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

D-l

0·2

0·3

D-4

0-5

Installation

Baseplate

Threading the Metal·Base Cartridge

of

Run Indicator

Screw

Locations

..........•...•.

.......

. . . . . . . . . . . . . . . . . . . . . . . . . .

" " . " " " " " "

...

" . "

..

" "

.......

•.•...•.....•........................

Head Gate and Spring. . . • . • . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stretch the Belt with the Floating Roller . . . . . . . . • . . . . . . . . . . . . . . . . . . . • . . . . 0-3

Threading the Plastic-Base Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . .

TABLES

4-21

4-21

4-25

• . . . . . . .

..

4-26

5-1

" . " . " . " . . . . 0-1

0-2

..

0-3

..

D-4

2-1

3-1

3-2

3-3

34

4-1

Operator Trouble Isolation. . • . . • . . . . . . . • . . . . . . . . . . . . • . • . . . . . . . . . . . . • . . 2·6

Command Packet Structure

Data

Packets"

.... " ...

" "

...

.. " ..

"."""

....

" "

... " ...... " ...... " ............

End Packet . • • . . . . . . . . . • • • . • . • . . . . . . . . . . .

Instruction

TU58 Module Connections

Set

""

" . " . " . . " " . " . " "

.....•.............................•........

..

" . "

4·2 MXVII-A Standard Factory Conftguration

""

...... " ... " ... " ...

""

..

".".,,

"

..

. • • . . . . . • • . . • . . . • . . . . . • • . 3·5

...

" . " " . " " . " . . . " . " " " . . " . " " . . . " " "

...............................

..

41

" . . .

• 3-3

3-5

3-7

4-18

4-27

vi

Page 8

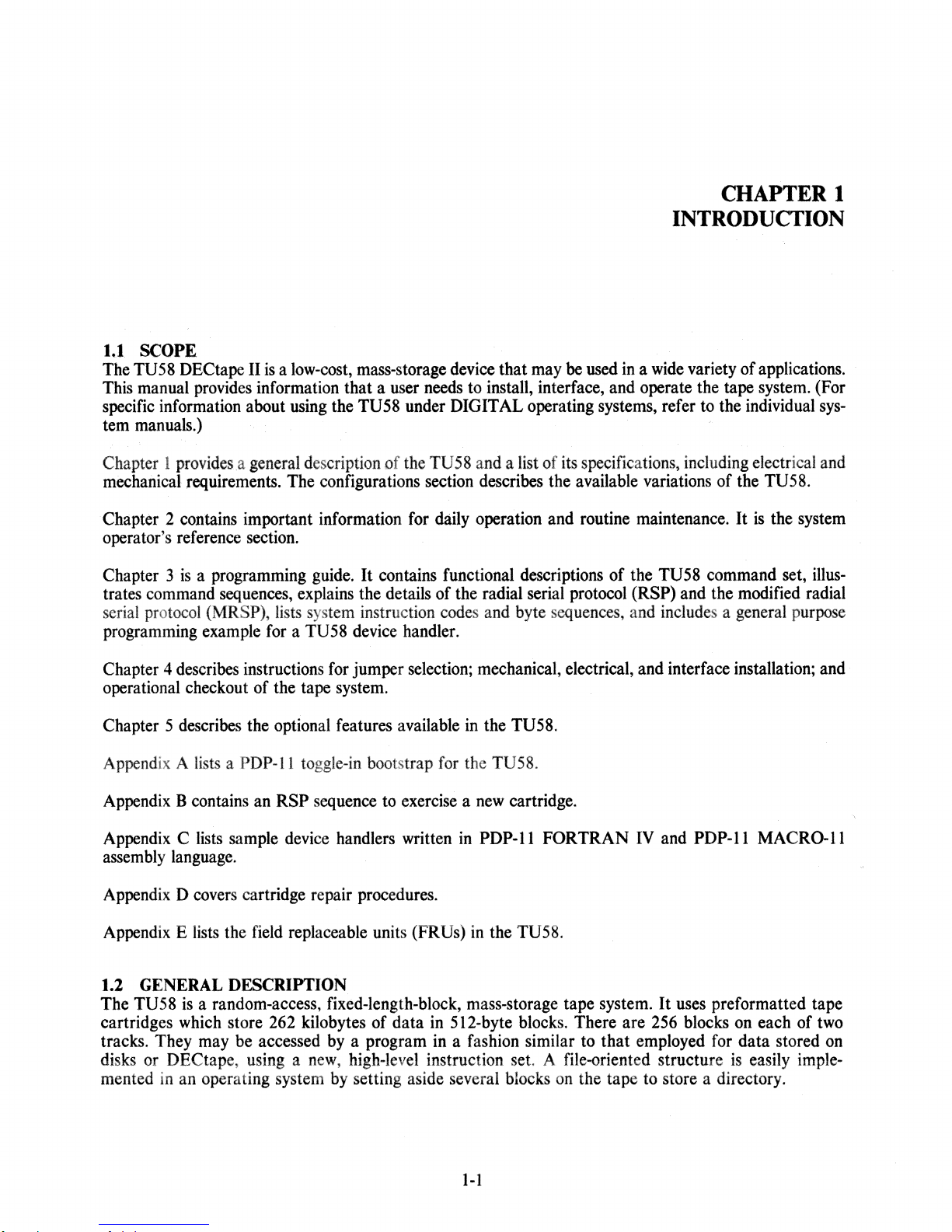

1.1

SCOPE

The

TU58

This

manual

specific

tem

manuals.)

DECtape

provides

information

II

is a low-cost,

information that a

about

using

the

mass-storage

user

needs

TU58

under

device

to

that

install,

may

be

interface,

DIGITAL operating

used

in a wide

and

systems,

CHAPTER 1

INTRODUCfION

variety of

operate the tape

refer

to

applications.

system.

the

individual

(For

sys-

Chapter 1

mechanical

Chapter 2

operator's

Chapter 3

trates

serial

programming

Chapter 4

operational

Chapter 5

Appendix A lists

provides a general

requirements.

contains

reference

is a programming

command

protocol

sequences,

(MRSP),

example

describes

checkout

describes

a PDP-II

Appendix B contains

Appendix C lists

assembly

language.

sample

Appendix 0 covers

description

of the TU58

The configurations

important information

section.

guide.

explains

lists

system

for a TU58

instructions

of

the tape

the

optional

toggle-in

an

RSP

sequence

device

cartridge repair

It

contains

the details of the radial

instruction

device

for

jumper

system.

features

bootstrap

to

handlers

procedures.

and a list

section

for

daily

describes

operation

functional

codes

and

handler.

selection;

available

for

in

the

mechanical,

the TU58.

exercise a new

written

in

POP-ll FORTRAN

descriptions

serial

byte

TU58.

cartridge.

of

its

specifications,

the

available

and

routine

protocol

sequences,

electrical,

variations

maintenance.

of the

TU58

(RSP)

and

includes a general

and

IV

and

including

electrical

of the TU58.

It

is

the

command

and

the

interface

installation;

set,

modified

PDP-ll MACRO-ll

and

system

illus-

radial

purpose

and

Appendix E lists

1.2 GENERAL DESCRIPTION

The TU58

cartridges

which

tracks. They

disks

or

DECtape,

mented

in

an

the

field

replaceable

is

a random-access, fixed-length-block, mass-storage tape

store

262

kilobytes of data

may

be

accessed

using a new,

operating system

units

(FRUs)

in

by

a program

high-level

by

setting aside several

in a fashion

instruction set. A file-oriented structure

in

the TU58.

5I2-byte

1-1

blocks.

similar

blocks

system.

There are

to

on

the tape

that

It

uses

preformatted tape

256

blocks

employed

to

store a directory.

for

on

each of

data stored

is

easily

two

on

imple-

Page 9

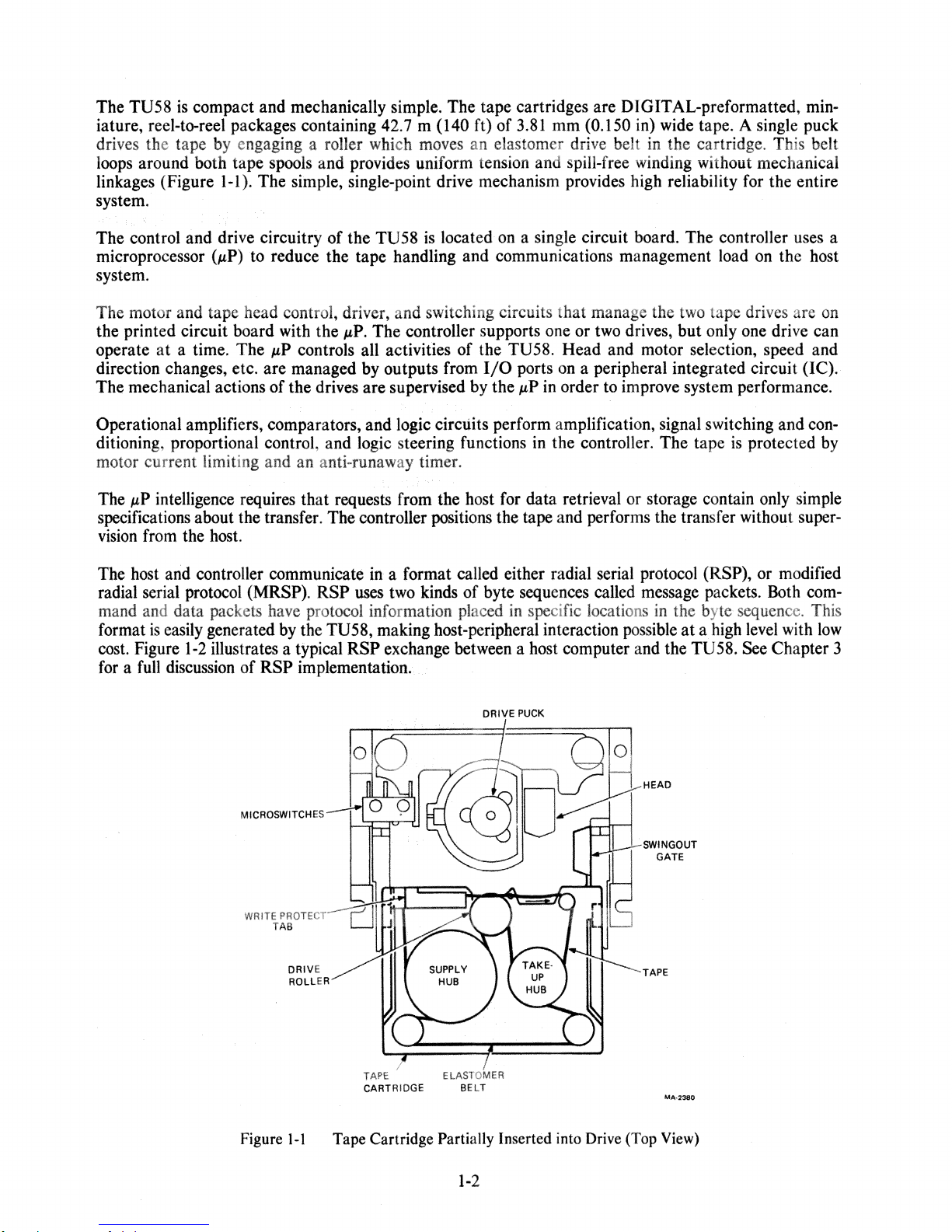

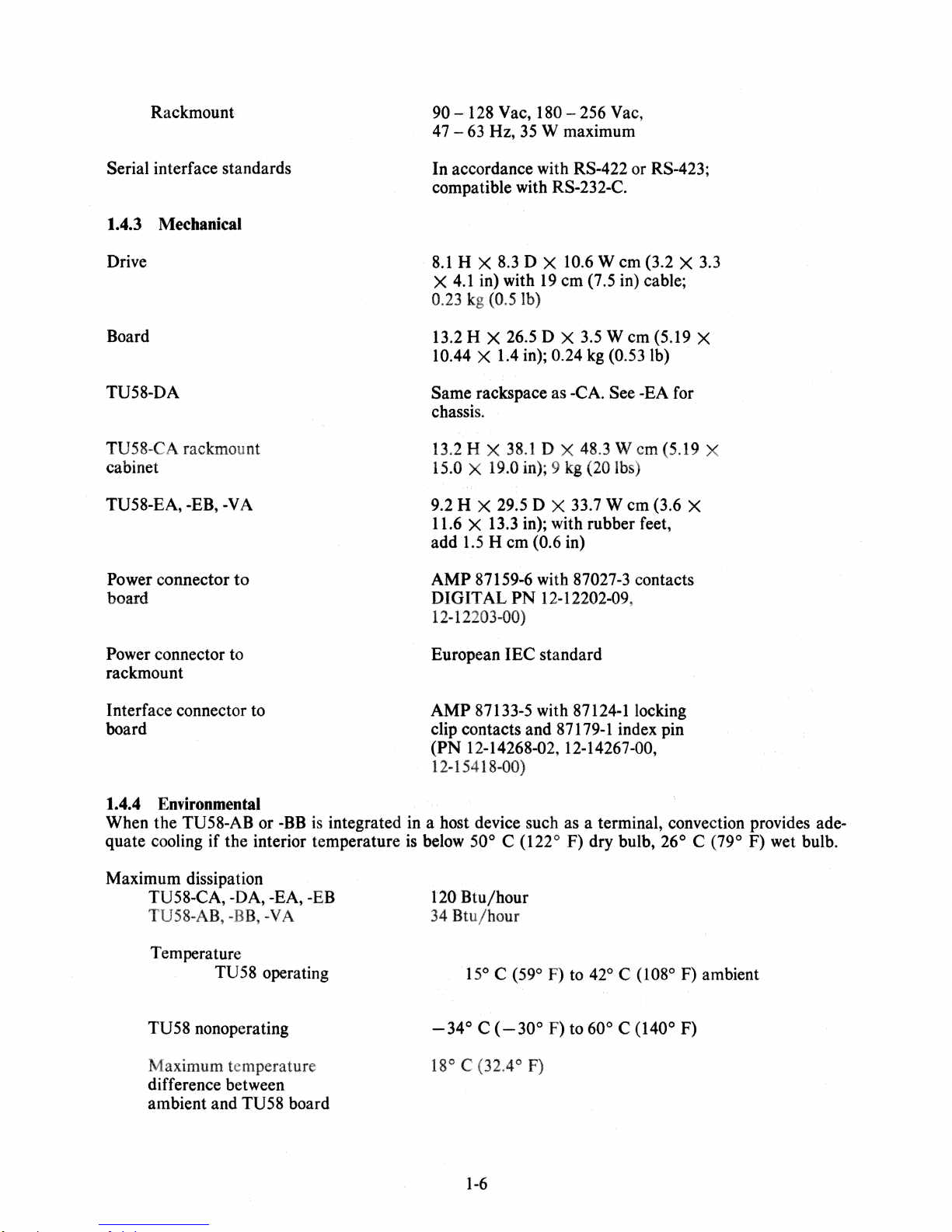

The TU58

iature, reel-to-reel packages containing 42.7 m (140 ft) of

is

compact and mechanically simple. The tape cartridges are DIGITAL-preformatted, min-

3.81

mm (0.150 in) wide tape. A single puck

drives the tape by engaging a roller which moves an elastomer drive belt in the cartridge. This belt

loops around both tape spools and provides uniform tension and spill-free winding without mechanical

linkages (Figure I-I). The simple, single-point drive mechanism provides high reliability for the entire

system.

The control and drive circuitry of the TU58

(p.P)

microprocessor

to reduce the tape handling and communications management load on the host

is

located

on

a single circuit board. The controller uses a

system.

The motor and tape head control, driver, and switching circuits that manage the two tape drives are

the printed circuit board with the

operate

a time. The

p.P

at

direction changes, etc. are managed by outputs from

The mechanical actions of the drives are supervised by the

p.P.

The controller supports one or two drives, but only one drive can

controls all activities of the TU58. Head and motor selection, speed and

I/O

ports on a peripheral integrated circuit (IC).

p.P

in order to improve system performance.

Operational amplifiers, comparators, and logic circuits perform amplification, signal switching and

ditioning, proportional control, and logic steering functions in the controller. The tape

is

protected by

on

con-

motor current limiting and an anti-runaway timer.

The

p.P

intelligence requires that requests from the host for data retrieval or storage contain only simple

specifications about the transfer. The controller positions the tape and performs the transfer without

vision

from the host.

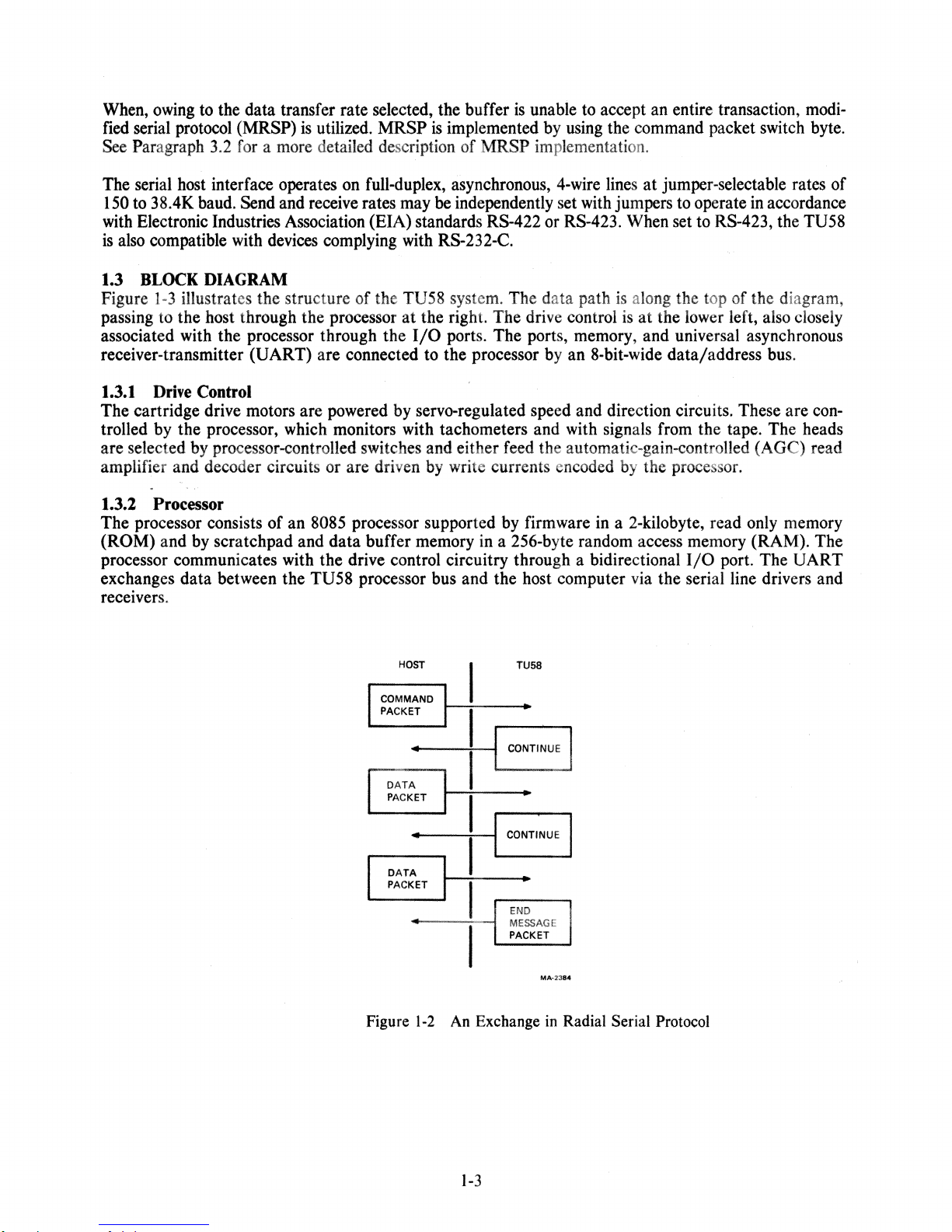

The host and controller communicate in a format called either radial serial protocol

(RSP), or modified

super-

radial serial protocol (MRSP). RSP uses two kinds of byte sequences called message packets. Both command and data packets have protocol information placed in specific locations in the byte sequence. This

is

format

cost. Figure

easily generated by the TU58, making host-peripheral interaction possible

1-2

illustrates a typical RSP exchange between a host computer and the TU58. See Chapter 3

for a full discussion of

RSP implementation

..

at

a high level with

low

DRIVE

PUCK

HEAD

MICROSWITCHES

SWINGOUT

WRITE PROTECT

TAB

DRIVE TAPE

ROLLER

TAPE ELASTOMER

CARTRIDGE

BELT

Figure I-I Tape Cartridge Partially Inserted into Drive (Top

GATE

MA·2380

View)

1-2

Page 10

When, owing to the data transfer rate selected, the buffer

fied serial protocol (MRSP)

See

Paragraph 3.2 for a more detailed description of MRSP implementation.

is

utilized.

MRSP

is

implemented by using the command packet switch byte.

is

unable to accept an entire transaction, modi-

The serial host interface operates on full-duplex, asynchronous, 4-wire lines

150 to 38.4K baud. Send and receive rates may

with Electronic Industries Association (EIA) standards

is

also compatible with devices complying with R8-232-C.

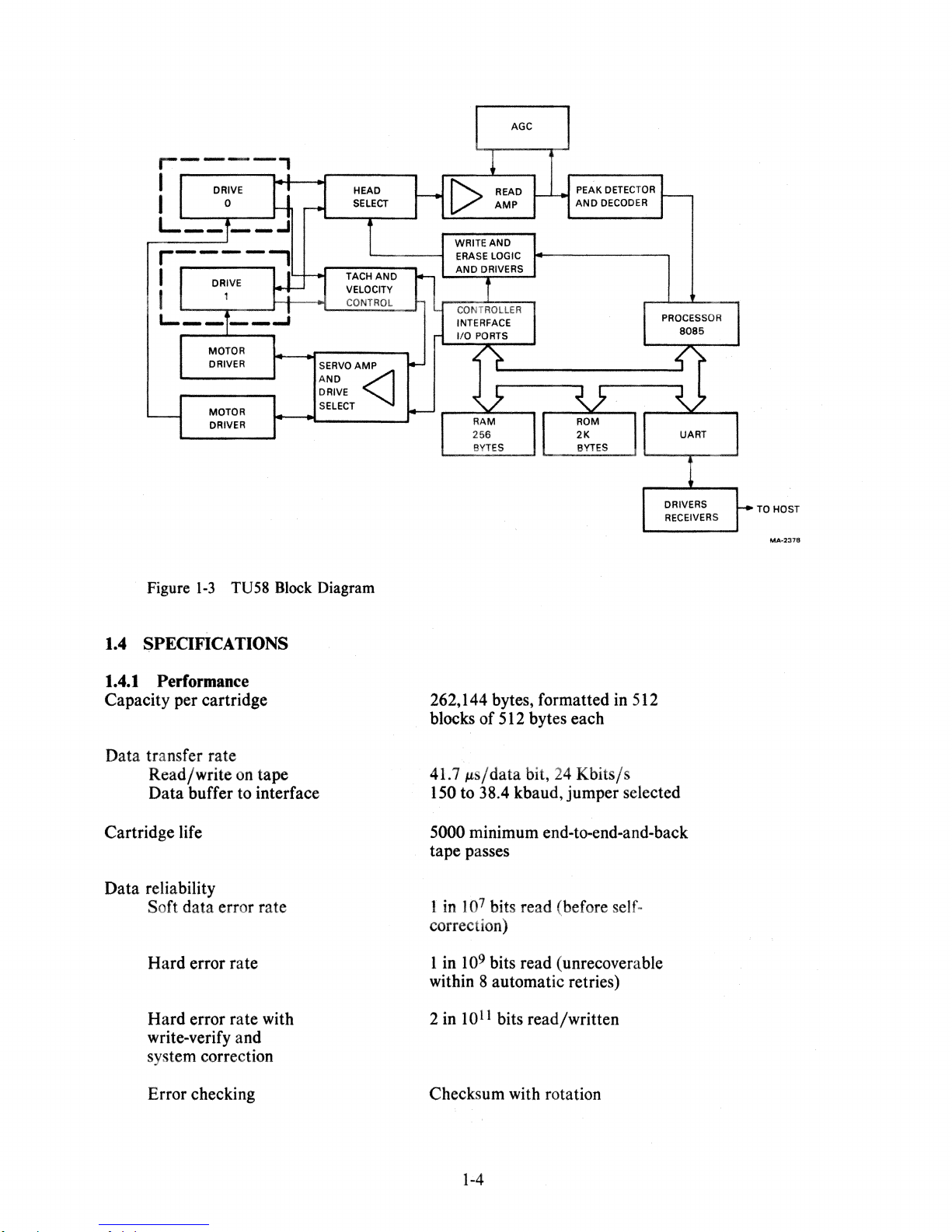

1.3

BLOCK

Figure

passing to the host through the processor

associated with the processor through the

receiver-transmitter

1.3.1

The cartridge drive motors are powered by servo-regulated speed and direction circuits. These are controlled by the processor, which monitors with tachometers and with signals from the tape. The heads

are selected by processor-controlled switches and either feed the automatic-gain-controlled

amplifier and decoder circuits or are driven by write currents encoded by the processor.

1.3.2 Processor

The processor consists

(ROM) and by scratchpad and

processor communicates with the drive control circuitry through a bidirectional

exchanges data between the TU58 processor bus and the host computer via the serial line drivers and

receivers.

1-3

Drive

DIAGRAM

illustrates the structure of the TU58 system. The data path is along the top of the diagram,

(UART) are connected to the processor by an 8·bit-wide data/address bus.

Control

of

an 8085 processor supported by firmware in a 2-kilobyte, read only memory

data

buffer memory in a 256-byte random access memory (RAM). The

be

independently set with jumpers to operate in accordance

R8-422 or RS-423. When set to R8-423, the TU58

at

the right. The drive control is

I/O

ports. The ports, memory, and universal asynchronous

at

jumper-selectable rates of

at

the lower left, also closely

(AGe)

I/O

port. The UART

read

HOST

I COMMAND

..

DATA

PACKET

..

DATA

PACKET

Figure

1-2

I

I

I

CONTINUE I

I

I

I

I

I

CONTI~UE

I

I

An Exchange

I

I

END

MESSAGE

PACKET

TU58

• PACKET

•

•

MA·2384

in

Radial Serial Protocol

1-3

Page 11

TO

HOST

Figure

1-3

TUS8

Block

1.4 SPEOFICATIONS

1.4.1

Performance

Capacity per cartridge

Data transfer rate

Read/write on tape

Data buffer to interface

Cartridge life

Data reliability

Soft data error rate

Hard error rate

Hard

error rate with

write-verify and

system correction

Diagram

262,144 bytes, formatted in 512

blocks of 512 bytes each

41.7

ps/data

bit,

24

Kbits/s

150 to 38.4 kbaud, jumper selected

5000 minimum end-to-end-and-back

tape passes

1 in

107 bits read (before self-

correction)

109 bits read (unrecoverable

1 in

within 8 automatic retries)

2 in

1011

bits read/written

Error checking

Checksum with rotation

1-4

Page 12

Average access

Maximmn

Read/write

Search

tape

time

access tirnc

tape

speed

speed

Bit density

Flux

reversal density

Recording method

9.3 seconds

28

seconds

76

cm/s

(30

152

cm/s

(60

315

bits/em

945

fr/cm

Ratio

encoding

in/s)

in/s)

(800

(2400

bits/in)

fr/in)

Medium

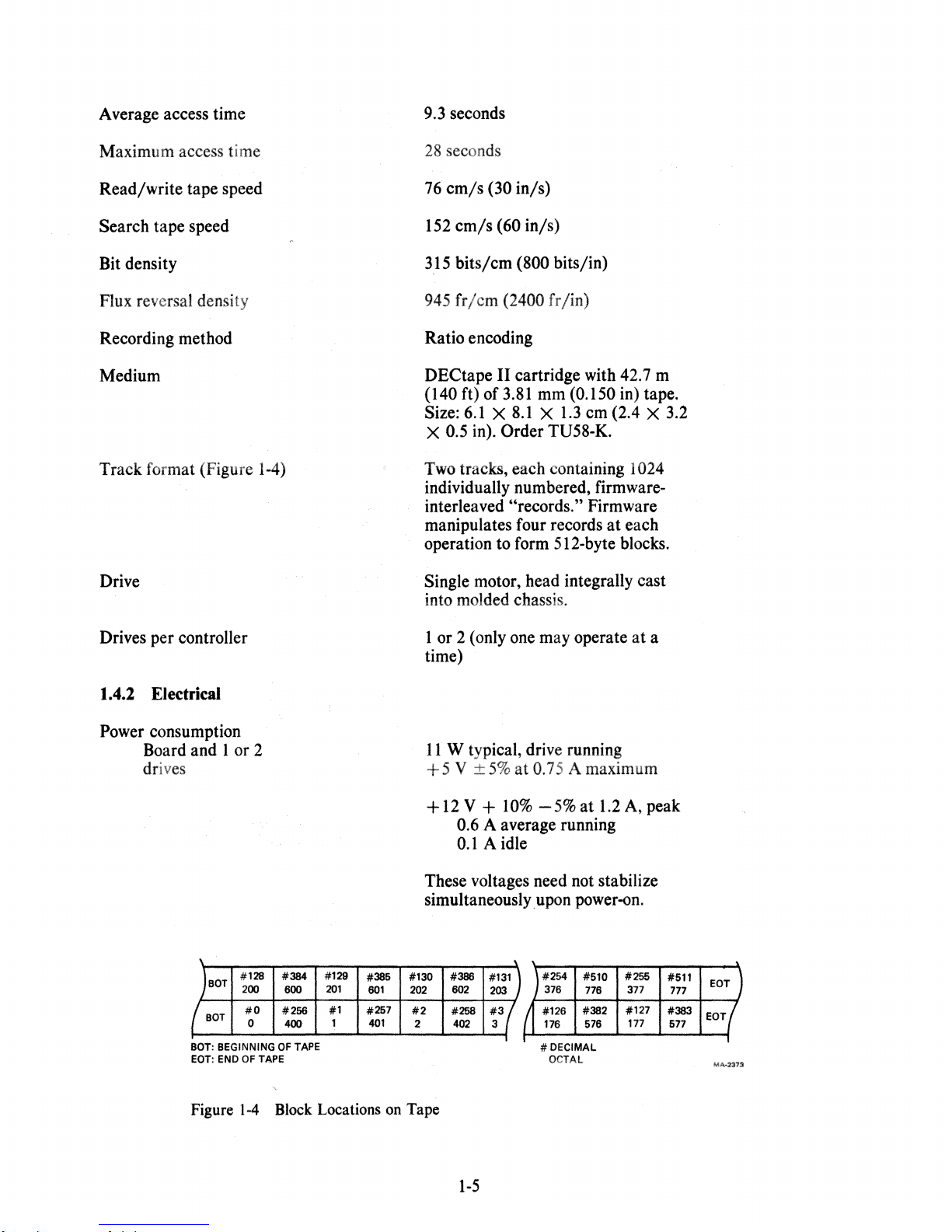

Track

format (Figure 1-4)

Drive

Drives

per

controller

1.4.2 Electrical

Power consumption

Board and

drives

1

or

2

DECtape

(140

Size: 6.1

X

0.5 in).

Two tracks,

II

ft)

of

3.81

X 8.1 X 1.3

Order

cartridge with 42.7 m

mm

(0.150 in) tape.

em

(2.4 X 3.2

TU58-K.

each

containing 1024

individually numbered, firmwareinterleaved

manipulates four records

operation

Single motor,

"records."

Firmware

at

to

form 512-byte blocks.

head

integrally cast

each

into molded chassis.

1

or

2 (only one may operate

at

a

time)

11

W typical, drive running

cor.

5 V

:t5%

at 0.75 A

+ 12 V + 10%

-5%

maximum

at

1.2

A,

peak

0.6 A average running

0.1 A idle

\

#128

JBOT

(

BOT

BOT:

BEGINNING

EDT:

END

Figure

#384

200

600

#0

#256

0

400

OF

OF

1-4

TAPE

TAPE

Block Locations on Tape

#129

201

#1

1

#385

601

#257

401

These voltages need not stabilize

simultaneously

#130 #386

602

202

#2

#256

2 402

upon

~lJ

~3(

#254

376

#126

176

#

DECIMAL

OCT.AL

power-on.

#510

776

#382

576

1-5

#255

377

#127

177

#511

777

#383

577

~1\~;a37""

Page 13

Rackmount

90-

128 Vac, 180 - 256 Vac,

47 -

63

Hz,

35

W maximum

Serial interface standards

1.4.3 Mechanical

Drive

Board

TU58-DA

TU58-CA

cabinet

TU58-EA, -EB, -VA

Power

board

rackmount

connector

to

In accordance with

RS-422 or RS-423;

compatible with RS-232-C.

8.1

H X 8.3 D X 10.6 W cm (3.2 X 3.3

X

4.1

in) with

19

cm

(7.5 in) cable;

0.23 kg (0.5Ib)

13.2 H X 26.5 D X 3.5 W

cm

(5.19 X

10.44 X 1.4 in); 0.24 kg (0.53Ib)

rackspace as -CA. See -EA for

Same

chassis.

13.2 H X 38.1 D X 48.3 W

15.0 X 19.0 in); 9

kg

(20 lbs)

9.2 H X 29.5 D X 33.7 W

cm

cm

(3.6 X

11.6 X 13.3 in); with rubber feet,

add

1.5 H cm

AMP

87159-6 with 87027-3 contacts

DIGITAL

(0.6 in)

PN

12-12202-09,

12-12203-00)

(5.19 X

Power connector to

rackmount

Interface connector to

board

1.4.4

When the

quate cooling

Environmental

TU58-AB

if

the interior temperature is below 50° C (122° F) dry bulb, 26° C (79° F) wet bulb.

Maximum dissipation

TU58-CA, -DA, -EA, -EB

TU58-AB, -BB, -VA

Temperature

TU58 operating

TU58 nonoperating

Maximum temperature

difference between

ambient and

TU58 board

or

European

AMP

IEC

standard

87133-5 with 87124-1 locking

clip contacts and 87179-1 index pin

(PN

12-14268-02, 12-14267-00,

12-

15418-00)

-BB

is integrated in a host device such as a terminal, convection provides ade-

120

Btu/hour

34

Btu/hour

15°

C (590 F) to 42° C (1080 F) ambient

-34° C (-30°

F) to 60° C (1400 F)

18° C (32.4° F)

1-6

Page 14

Relative humidity, noncondensing

TU58

TU

operating

Maximum dew point

Minimum dew point

Relative humidity

58 nonoperating .

If

imum

a cartridge bas

or

should

This

is

1.5 CONFIGURATIONS

The

TU58

is available in the following configurations with accompanying designations.

minimum

be

rewound

done

to

23° C (73.4°

2° C (36° F)

10%

to 90%

5%

to 98%

CAUTION

been

exposed

temperature extreme,

one

complete

bring

tbe tape

to

F)

to eitber tbe max-

tbe

cycle

before

tbe proper

using.

tension.

tape

TU58·CA

TU58-DA

TU58-EA

TU58-EB

TU58-VA

Rackmount, large chassis, two drives, serial interface controller board, power

supply

and

tenance

agnostic kit (ZJ287-RG).

Rackmount, tabletop chassis, two drives, serial interface controller board, power

V

ROM

Guide, Field Maintenance

Tabletop, two drives, serial interface controller board, power supply

switch-selectable, detachable line cord

hardware kit

(MPOlOI4).

Tabletop, two drives, serial interface controller board,' power supply

switch-selectable, detachable line cords and fuses for

tridges, two

accessory assembly hardware kit (70-16753-00), User Guide, Field Maintenance

Tabletop, two drives, serial interface controller board,

17569-1C),

User Guide, Configuration Guide, Field Maintenance Print

cessory assembly hardware kit

115/230

230 V, two cartridges, boot

Print

supply

and

230

for

Print

V switch-selectable, detachable line cords

Set

(MPOO747), two

115/230

V,

MRll-EA,

I/O

Set

I/O

V switch-selectable, detachable line cords

two cartridges, two

accessory assembly hardware kit (70-16753-00), User

(70-16753-00), User Guide, Field Maintenance

cables (BCI7A-18

(MPOlOI4).

cable (70-17568-1F), two cartridges,

ROM

I/O

I/O

Print

Sets (MPOlOI4

and

(70-16753-01).

for

MRII-EA,

cables (BC17A-18

cables (BCI7A-18

and

fuse for 115

BCI7B-18), boot

User Guide, Field Main-

and

MPOI063).

liS

MXVII-A-2

and

fuses for 115 V

and

BCI7B-18), di-

and

fuses for 115

and

BCI7B-18), boot

115/230

V,

accessory assembly

Print

115/230

V

and

230 V, two car-

ROM

for

MRll-EA,

dc

power cable (70-

boot

Set

(MPO 1 0 13), ac-

V

Set

V

ROM,

Additional

Supplies

BCllO-lO replaces BCl7A-l8

new

cable

ply

witb

8C220-lO

NOTE

and

BC17B-l8. The

has

an

improved

FCC

regulations.

Interface cable from TU58 to host.

1-7

shield

connection

to

com-

Page 15

BC17A-18

Interface cable from TU58 to

pin connector).

DL-ll

and

DLV-ll,

5.4 m (18 ft) (lO-pin-to-40-

BC17B-18

BC21B-05

TU58-K

TUC-OI

ru58-DB

TU58-EC

TU58-ED

TU58-VB

Interface cable from

100pin

connector).

Modem cable from

TU58 to

DLV-IlJ

and

MXV-ll,

TU58 to EIA connector,

1.5 m (5

5.4 m (18 ft) (to-pin-to-

ft) (lO-pin-to-DB25-P

male).

Preformatted tape cartridges, available singly or in packs of

Tape Drive Cleaning Kit.

Rackmount installation kit for tabletop versions -EA, -EB,

Accessory kit containing detachable line cord for 115

hardware kit

(70-16753-00), User Guide, Field Maintenance Print Set

V.

(MPOI014).

Accessory kit containing detachable line cords for

230

V,

two cartridges, two

MRII-EA,

for

Field Maintenance

accessory assembly hardware kit (70-16753-00), User Guide,

Print Set (MPOI014).

Accessory kit containing dc power cable

I/O

cables (BCI7A-18 and BCI7B-18), boot ROM

(70-17569-1C),

IF), two cartridges, MXVI1-A2 boot ROM,

Field Maintenance Print

Set (MPOlO13), accessory assembly hardware kit (70-

115

V and 230 V and fuse for

I/O

User Guide, Configuration Guide,

16753-01).

five.

-VA.

accessory assembly

cable (70-177568-

17-00090-00

70-16753-00

70-16753-01

23-126F3-O-O

MXVI1-A-2

23-765A9-OO

Line cord

250

V.

Accessory assembly hardware kit with brackets for mounting TU58 tabletop

versions to flat surface.

Accessory assembly hardware kit with brackets for mounting

TU58 tabletop

versions below a flat surface.

Boot ROM for BDVl1.

Boot ROM for

MXVII.

Boot ROM for MRII-EA.

Page 16

1.6 HARDWARE DOCUMENTATION ORDERING INFORMATION

The

following TU58 DECtape

DIGITAL's Accessory and Supplies Group.

II

Tape Subsystem hardware manuals can be purchased from

Part

No

EK-OTU58-UG

EK-OTU58-PS

EK-OTU58-TM

EK-OTU58-IP

MPOO747

MPOI014-00

MPO

1 0

13-00,

MPOI063

ORDERING

You

can

order supplies and accessories from one

Continental

Call 800-258-1710,

Digital Equipment Corporation

P.O.

Nashua,

New Hampshire

Call 603-884-6660, or mail order to:

USA

Box

CS2008

NH

Title

TU58

TU58 DECtape

TU58 DECtape

TU58 DECtape

TU58-C Field Maintenance Print

TU58-E Field Maintenance Print

TU58-V Field Maintenance Print

TU58-D Field Maintenance Print

or

mail order to:

03061

DECtape

II

User Guide

II

Pocket Service Guide

II

Technical Manual (microfiche or paper)

II

Illustrated Parts Breakdown

Set

Set

Set

Set

of

the

following addresses, according

to

your location.

Digital Equipment Corporation

P.O.

Box

CS2008

Nashua,

Alaska

Call

Canada

Call

or

408-7344915, or mail order to:

Digital Equipment Corporation

632 Caribbean Drive

Sunnyvale,

800-267-6146,

Digital Equipment

P.O.

Kanata, Ontario, Canada K2K 2A6

Au:

Telex:

NH

03061

Hawaii

CA

94086

or

mail order to:

of

Canada LTD.

Box

13000

A&SG Business Manager

610-562-8732

1-9

Page 17

1.7 DIGITAL

Digital Field Service offers a range

ON

SITE

REPAIR

SERVICE

SERVICE

of

flexible service plans. Choose the one that

offers the convenience

of

service

at

your site and insurance against unplanned repair

bills. For a small monthly fee you receive personal service from our Service

the specialist

is

dispatched to your site with all the equipment and parts needed to give you fast and

dependable maintenance.

is

right for you.

Specialists. Within a

few

hours

BASIC

available to extend your coverage to 12-, 16-, or 24-hour days, and to

DECsenice

maintenance. We don't leave until the problem

SERVICE

offers full coverage from 8 a.m. to 5 p.m., Monday through Friday. Options are

Saturdays, Sundays, and holidays.

offers a premium on-site service that guarantees extra-fast response and nonstop remedial

is

solved, which makes this service contract ideal for those

who need uninterrupted operations.

Under Basic Service and DECservice all parts, materials, and labor are covered in full.

CARRY

for a smaller monthly fee than

Servicenters worldwide,

service

Digital Servicenters are open during normal business hours, Monday through Friday. Call one

following numbers for the location

DECmailer offers expert repair

resources to troubleshoot, identify, and isolate the module causing the problem.

module to our Customer Returns Center where the module

-IN

SERVICE offers fast, personalized response and the ability to plan your maintenance costs

On-Site Service. When you bring your unit in to one

factory~trained

is

available on selected terminals and systems.

personnel repair your unit within two days (usually 24 hours). This

of

the office nearest you.

at

a per use charge. This service

is

for users who have the technical

of

You mail the faulty

is

repaired and mailed back to you within five

160 Digital

of

the

days.

PER

CALL SERVICE offers a maintenance program on a noncontractual, time-and-materials-cost basis.

is

This service

available with either On-Site or Carry-In service.

It

is

appropriate for customers who have

the expertise to perform first-line maintenance, but may occasionally need in-depth support from Field

Service.

Per Call Service

maintenance beyond their contracted coverage hours. There

is

also offered as s supplementary program for Basic Service customers who need

is no materials charge in this case.

On-Site Per Call Service is provided on a best effort basis, with a normal response time

three days.

Carry-In Per Call Service

It

is

available 24 hours a day, seven days a week.

is

available during normal business hours, with a two to three day

turnaround.

For more information on

of

one

the following numbers for the location

Digital

Service plans, prices,

of

the Digital Field Service office nearest you.

and

special rates for volume customers, call

these

Digital International Field Service Information Numbers

U.S.A.

Canada

United Kingdom

Belgium

West Germany

Italy

Japan

France

1-(800)-554-3333

(800)-267-5251

(0256)-57122

(02)-242-6790

(089)-9591-6644

(02)-617-5381/2

(03)-989-7161

1-6873152

Denmark

Spain

Finland

Holland

Switzerland

Sweden

Norway

1-10

of

two to

430-1005

91-7334370

90-423332

(01820)-34144

01-8105184

08-987350

2-256422

Page 18

Z.1

TU58-DA,

-CA

RACKMOUNT

CONTROlS

AND

INDICATORS

CHAPTER 1

OPERATION

%01.1

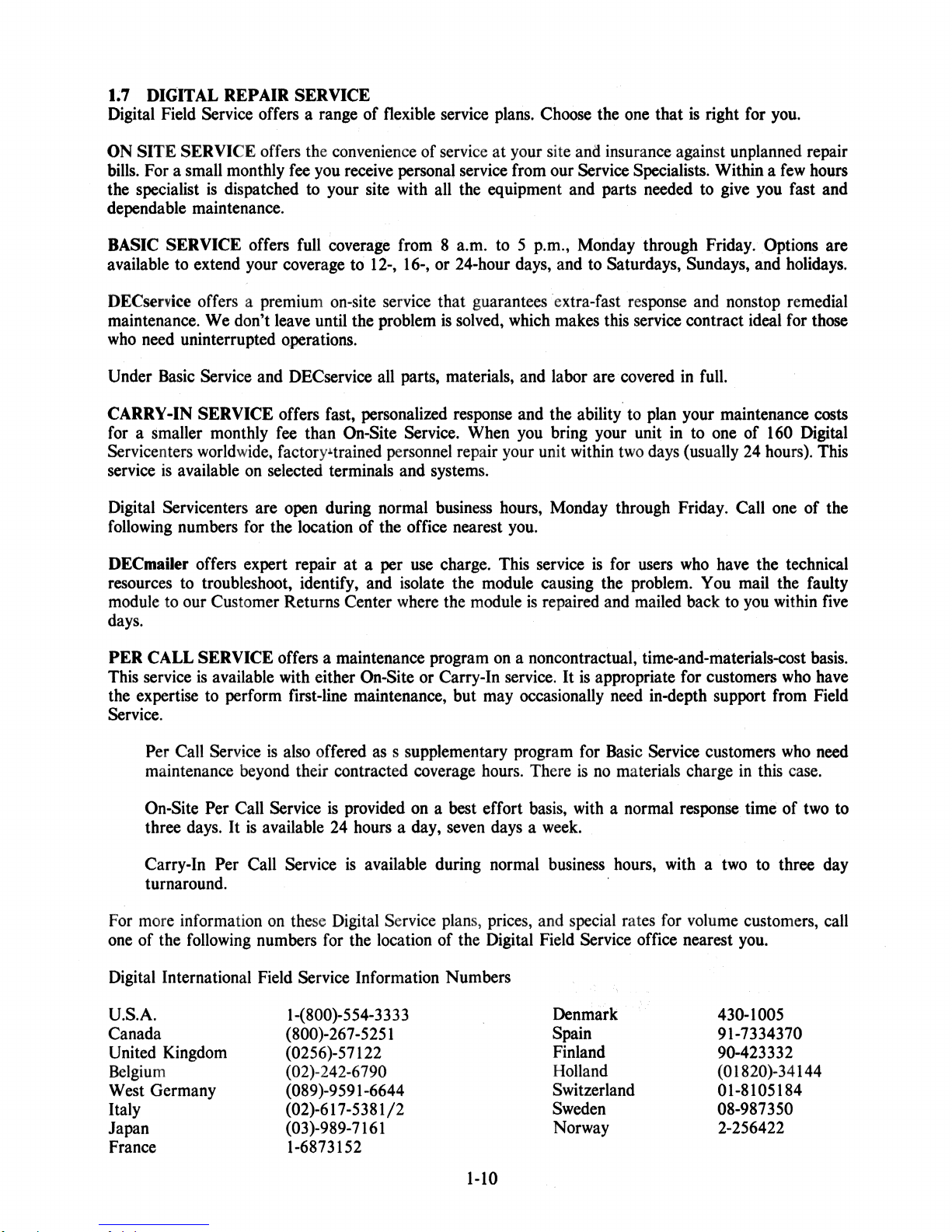

The front

drives.

(six

Front Panel

panel

(Figure

2-1)

In addition, the decorative

on

the

-CA)

in

their

boxes.

has

two

bezel

%o1.ZRua .Indicator

an

Each tape drive has

is

removed

Z.I.3

TUS8-DA

The

able

on a system

need

When

host

for

while

Application

has a power

to

be

turned

power

is

applied, the

an acknowledgement before it settles

indicator that lights

the tape

and

is

being

Removal

switch

power

controller, the TUS8

off.

Its idling

TU58

written, the cartridge

of Power

on

power

initializes itself, performs internal diagnostic tests,

description of the required exchange.

If

power

power

is

removed

removal.

while

a tape

is

being

slots

for

the tape cartridges and

has

a small compartment that can store

to

show

its backpanel,

may

consumption

down

written, data

tape

while

be

plugged

is

to

motion.

should

the

less

than

wait

for

may

two

tape

Since data

not

be

TUS8-CA

motion

loss

removed

does

not.

indicators

up

to

four

can

'occur

if a cartridge

if the indicator

If

an

outlet

into the controller. Otherwise, it

20

W.

and

then

instructions. See Paragraph

be

lost.

There are

no

other restrictions

for

the

cartridges

is

on.

is

avail-

does

not

asks

the

3.2.2

for

on

a

Figure

TAPE

STORAGE

AREA

2-1

TU58-DA and -CA Rackmount Front Panel

2-1

Page 19

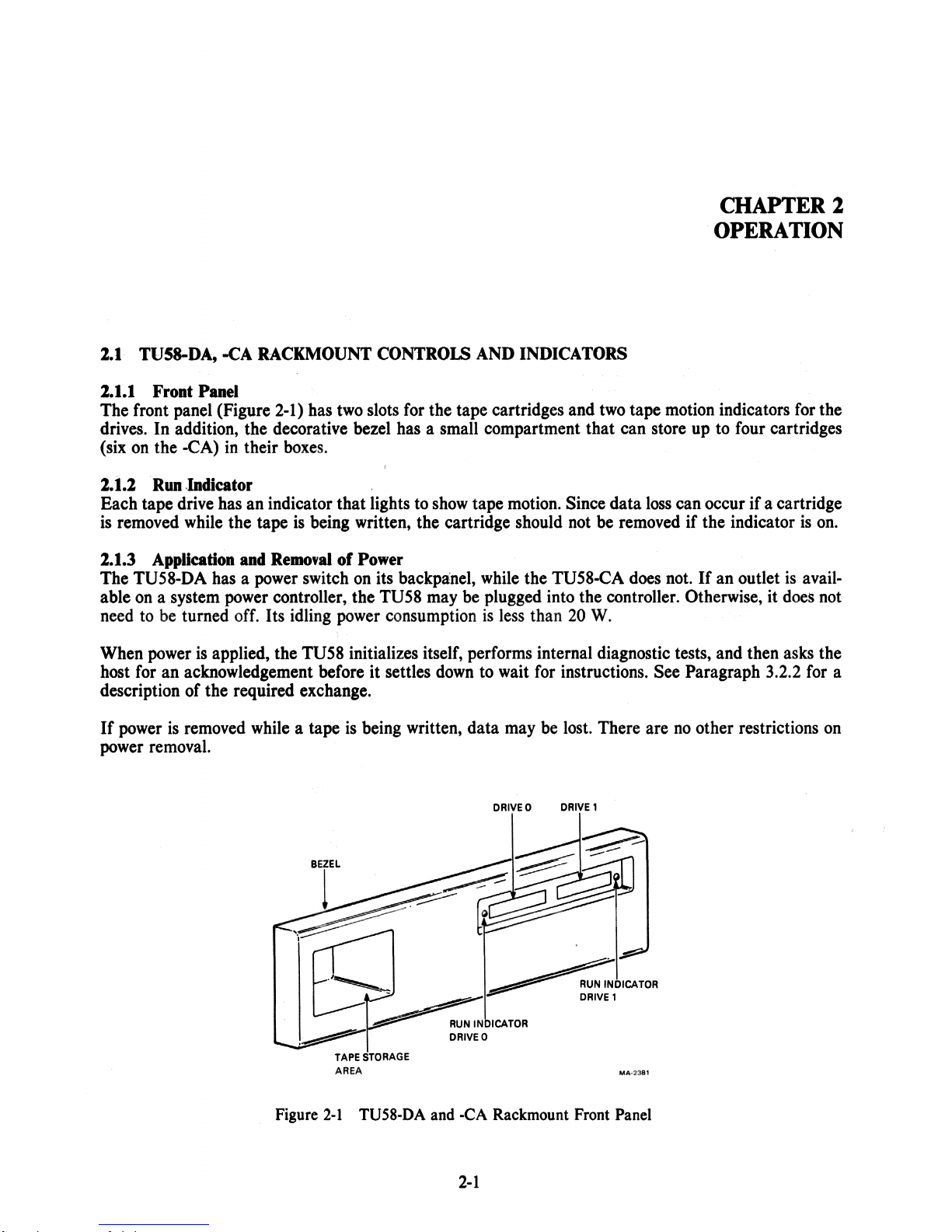

1.1 TU58-EA,

1.1.1 Front Panel

The front

panel

-ED

(Figure 2·2)

drives.

CONTROlS

has

two

AND

INDICATORS

slots

for

the tape cartridges and

two

tape

motion

indicators

for

the

1.1.1

Each tape drive

1.1.3

The

system

to

When

host

Run

Indicator

Application

TU58·EA and

power

be

turned

for

off.

power

is

an

acknowledgement before it settles

has

an

indicator that lights

and

Removal

-ED

versions

controller, these

Their idling

applied, the

TU58

of Power

have

versions

power

initializes itself, performs internal diagnostic tests, and then

description of the required exchange.

If

power

power

1.3 TU58-VA CONTROlS

1.3.1 Front Panel

The front panel (Figure

is

removed

removal.

while

2-2)

a tape

AND

has

is

INDICATORS

two

drives.

1.3.1

Each tape drive has

Run

Indicator

an

indicator that lights

to

power

may

switches

be

consumption

down

being

written, data

slots

for

the tape cartridges and

to

show

tape

on

plugged

is

less

to

show

tape

motion

their back

into

than

wait

may

motion

in

that

drive.

panels.

If

an

the controller. Otherwise, they

20

W.

for

instructions. See Paragraph 3.2.2

be

lost.

There are

two

tape

motion

in

that

drive.

outlet

is

available

do

no

other restrictions

indicators

not

asks

for

on

need

the

for

on

the

a

a

Figure

2-2

RUN

INDICATOR DRIVE 0

DRIVEO

TU58-EA,

-ED,

and -VA Front Panel

2-2

Page 20

2.3.3 Application and Removal

The

TU

58-VA requires + 5 V and +

fications in

ber of

Paragraph 1.4.2 for power requirements of a controller board and two drives. The part num-

dc

power cable supplied with the

mation.

of

Power

12

V from the device to which it connects. See the electrical speciTU

58-VA

is

70-17569-1 C. See Chapter 4 for installation infor-

When power is applied, the

host for an acknowledgement before it settles down to wait for instructions.

TUS8 initializes itself, performs internal diagnostic tests, and then asks the

See Paragraph 3.2.2 for a

description of the required exchange.

If

power is removed while a tape

is

being written, data may be lost. There are no other restrictions

on

power removal.

2.4 TUS8 COMPONENTS CONTROLS AND INDICATORS

See Chapter 5 for installation and operation of optional features.

2.4.1 Application and Removal

of

Power

The TU58 may be supplied with power from a host system. It is ready for operation within one second

of voltage stabilization.

is less than 5 W.

.

'.

It does not neep to be turned off when not in use; its idling power consumption

When power is applied, the TU58 initializes itself, performs internal diagnostic tests, and then asks the

host for an acknowledgment before it settles down to wait for instructions.

See Paragraph 3.2.2 for a

description of the required exchange.

If

power is removed while a tape is being written, data may be lost. There are

no

other restrictions on

power removal.

2.S CARTRIDGE

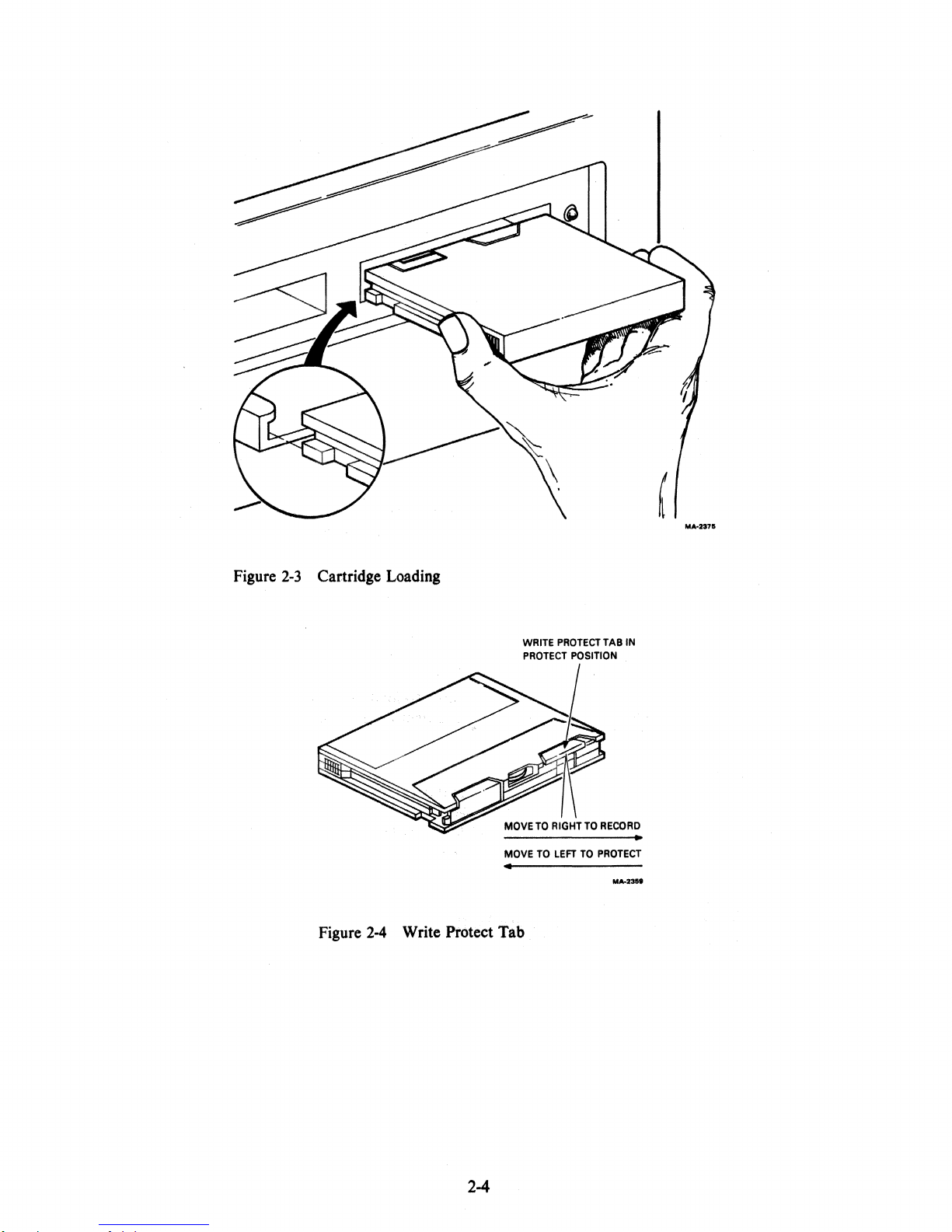

2.5.1 Cartridge Loading

The

TU58 drive is designed to make correct loading easy. To load the cartridge, hold it label-up, line it

up

with the grooves in the chassis, and slide it in with a firm push. Figure

2-3

illustrates the fit of the

cartridge into the drive chassis grooves.

2.5.2 Cartridge Unloading

Unloading the cartridge is as simple as loading. Just pull it straight out.

stop (run indicator turns off) before removing the cartridge. The mechanism cannot be damaged by

removing the cartridge while the tape

message

is

sent to the host

if

a command is interrupted by removal of a cartridge. The cartridge may be

left in the drive as long as needed.

2.5.3 Keeping Track

If

the TUS8

is

used in a non-file-structured system, the cartridge does not have an identifying number

of

Cartridges

or label recorded on the tape.

tridge was loaded; the operator must keep track of the contents of various cartridges.

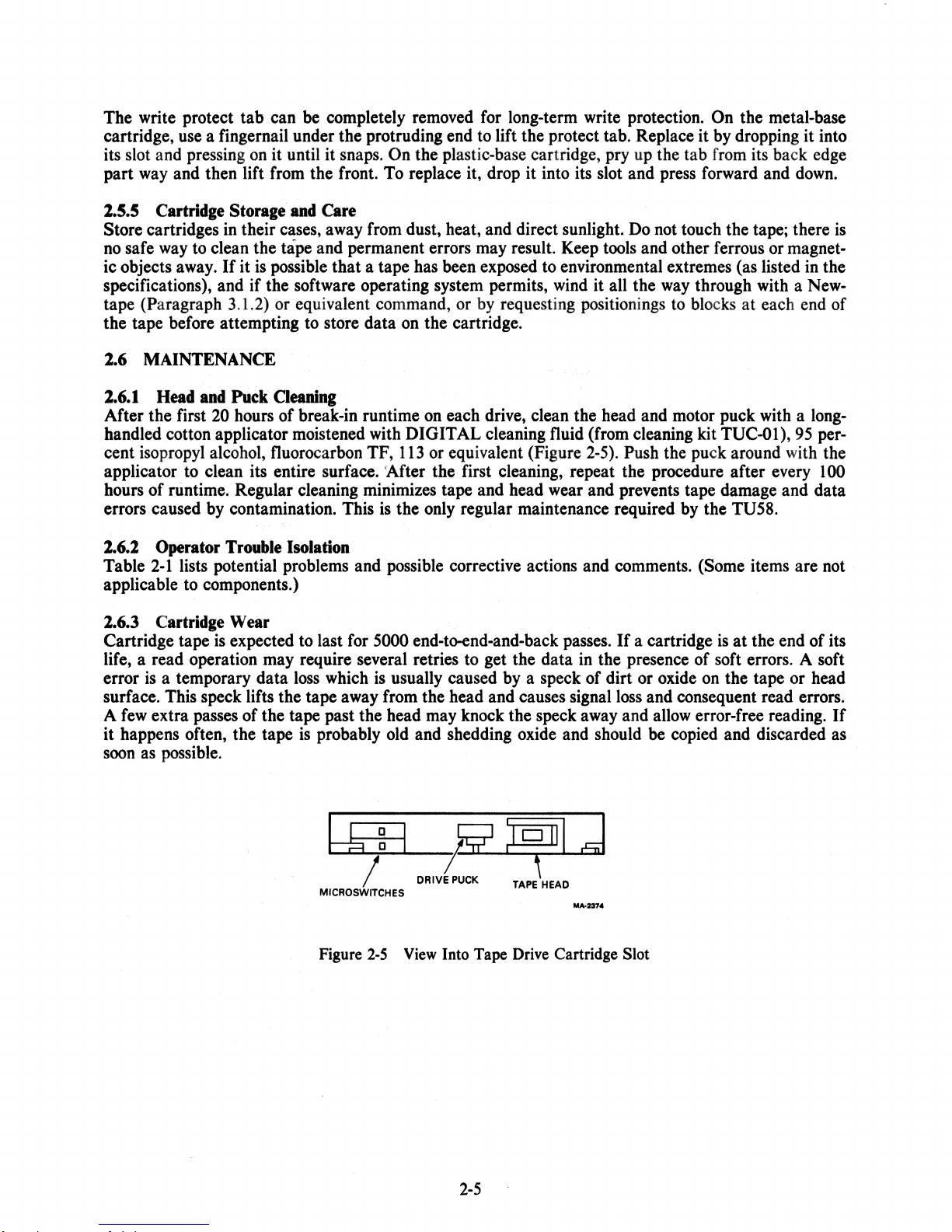

2.5.4 Write Protect Tab

Each tape cartridge has a movable tab which, when properly positioned, protects data on the tape from

unintended write operations. When this write protect tab (Figure 2-4)

the drive roller), it locks out the write circuitry.

When the write protect tab

is

troller to write when it is commanded. The operator should be sure

backed up with copies before loading them into the

It is best to wait for the tape to

is

moving, but

If

a cartridge is changed, the TUS8 does not know

in the outer position, it closes a switch in the chassis and allows the con-

if

a write is in progress, data may be lost. An error

that

a different car-

is

in the inner position (toward

that

system or program tapes are

TUS8 with their write protect tabs set to record.

2-3

Page 21

....

U71

Figure

2-3

Cartridge Loading

Figure

2-4

Write Protect Tab

WRITE

PROTECT

MOVE

..

TO

PROTECT

POSITION

LEFT

TO

TAB

IN

PROTECT

2-4

Page 22

The write protect tab can

cartridge, use a fingernail under the protruding end to lift the protect tab. Replace

its slot and pressing on it until it snaps.

part way and then lift from the front. To replace it, drop it into its slot and press forward and down.

2.S.S Cartridge Storage and Care

Store cartridges in their cases, away from dust, heat, and direct sunlight. Do not touch the tape; there

no

safe way to clean the tape and permanent errors may result. Keep tools and other ferrous or magnet-

If

ic objects away.

specifications), and if the software operating system permits, wind it all the way through with a New-

(Paragraph 3.1.2) or equivalent command. or by requesting positionings to blocks

tape

the tape before attempting to store data on the cartridge.

2.6 MAINTENANCE

it is possible

be

completely removed for long-term write protection. On the metal-base

it

by dropping it into

On

the plastic-base cartridge, pry up the tab from its back edge

that

a tape has been exposed to environmental extremes (as listed in the

at

each end of

is

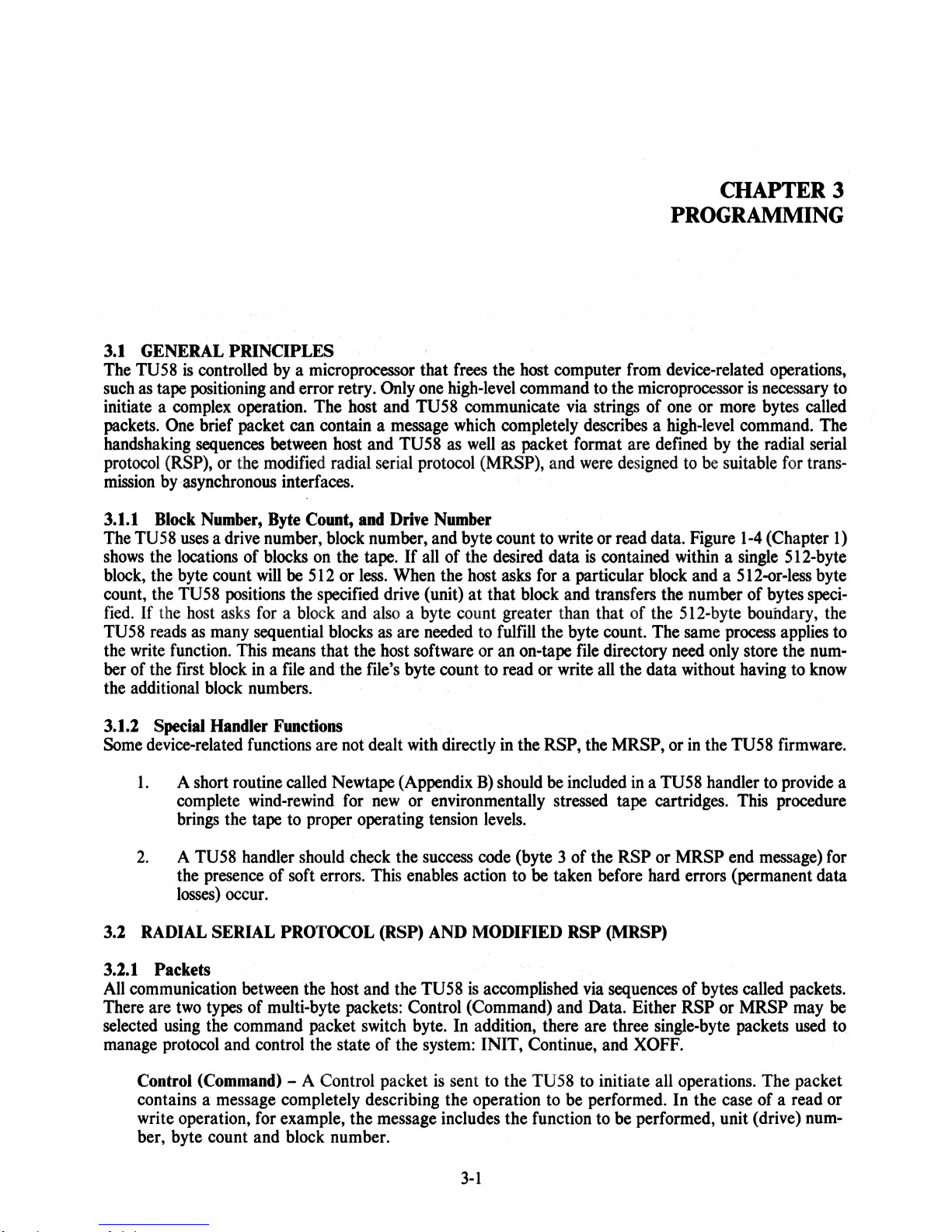

2.6.1

After the first 20 hours of break-in runtime on each drive. clean the head and motor puck with a longhandled cotton applicator moistened with DIGITAL cleaning fluid (from cleaning kit

cent isopropyl alcohol, fluorocarbon TF, 113 or equivalent (Figure 2-5). Push the puck around with the

applicator to clean its entire surface.

hours

errors caused by contamination. This is the only regular maintenance required by the

2.6.2 Operator Trouble Isoladon

Table

applicable to components.)

2.6.3 Cartridge Wear

Cartridge tape is expected to last for 5000 end-to-end-and-back passes.

life. a read operation may require several retries to get the data in the presence

error

surface. This speck lifts the tape away from the head and causes signal loss and consequent read errors.

A

it happens often. the tape is probably old and shedding oxide and should be copied and discarded as

soon as possible.

Head and Puck Oeanlng

TUC-Ol),

'After the first cleaning, repeat the procedure after every 100

of

runtime. Regular cleaning minimizes tape and head wear and prevents tape damage and data

TU58.

2-1

lists potential problems and possible corrective actions and comments. (Some items are not

If

a cartridge is

is

a temporary data loss which

few

extra passes of the tape past the head may knock the speck away and allow error-free reading.

is

w;

~

usually caused by a speck of dirt or oxide on the tape or head

I

f£

:1

0

111

J

at

the end of its

of

soft errors. A soft

95

per-

If

MICROSWITCHES

Figure

I DRIVE

2-5

View

PUCK

Into Tape Drive Cartridge Slot

2-5

TAP~HEAD

Page 23

Table 2-1 Operator Trouble Isolation

Symptom

TU58 does not respond

to host

TU58

does not write

(reads okay)

Action/Comments

1.

Ensure

socket (or proper dc source for -VA

2.

Check

3. Ensure

4.

Check

both

If

S.

Remove the bezel

the indicator should light for a

second, and then relight. This means the controller has passed its

automatic self-test and

off, there is some problem within the board or in the interface.

Check

serial interface is suspected

interface cable.

indicator from coming on.

1.

Check

(Figure 2-4).

that

the

TU58-CA, -DA, -EA, or -EB is plugged into a live

or

components).

that

the

voltage selection switch is properly set.

that

the

fuse and power cord are intact

that

the

baud

rates

and

interface standards are

the

TU58

and

the

host interface board (Paragraph 4.7).

possible, observe the self-test indicator on the controller board.

on

the rackmount version. When power

half second,

is ready for operation.

that

the

that

interface cable is intact

and

An

open wire in

Other

the

write protect

tab

the

and

standards are correct, try a new

the

line from

causes require servicing.

is

set correctly on

and

go

out for another half

If

the indicator remains

properly inserted.

the

properly inserted.

the

same for

is

applied,

If

host prevents

the

cartridge

the

ac

the

Read

errors (some host

operating systems may

provide this or a

similar message)

TU58

sends

motoNtopped

error messages

2.

The

trouble may be in a drive. Try writing on

the

problem except

1.

Clean

the

head.

The

tape

2.

poor condition

become a permanent

format problems will produce

cartridge.

3. Motor

This indicates

section and

should not

conditions without checking

is not getting near

may contain errors

or

head is reaching end

that

the

runaway timer has stopped the motor.

be

commanded

write protect

Dirt

or

if

data

a malfunction has occurred in

to

the

end where

tab

and

tape

oxide buildup

that

were written onto it.

is not verified

part

of

the

recording. A new cartridge with

the

same error message.

of

life. Replace drive.

move

tape

more than twice under these

the

cartridge. Make sure

it

might come free of

the

other drive. Any

setting requires service.

can

cause errors.

If

a

tape

at

write-time, errors may

Try

another

the

data

recovery

The

TU58

that

the tape

the

hub.

is in

2-6

Page 24

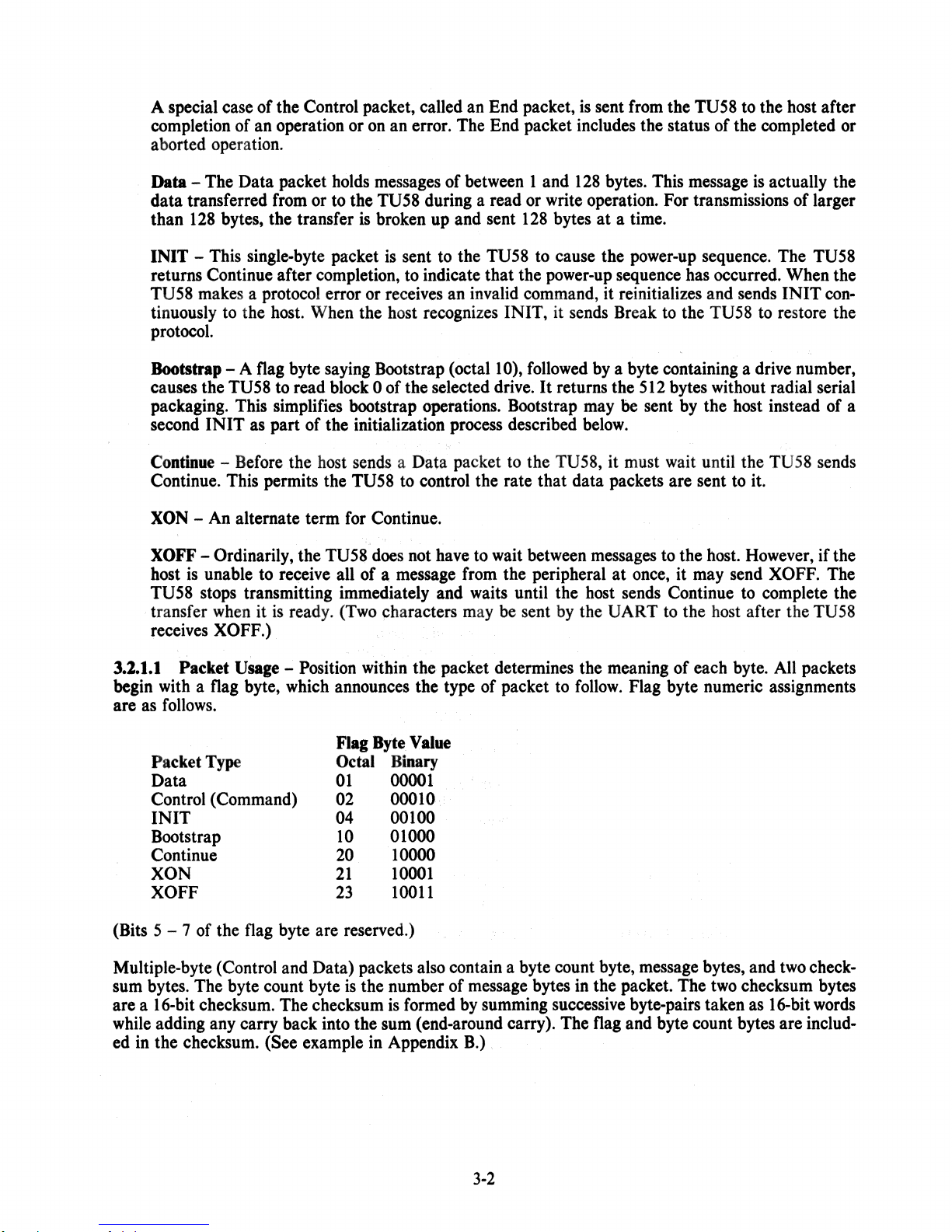

3.1 GENERAL PRINCIPLES

The

TU58

such

initiate a

packets.

handshaking

protocol

mission

as

tape

complex

One

(RSP),

by

is

controlled

positioning

and

operation.

brief packet

sequences

or

the

modified

asynchronous

by a microprocessor

error retry.

The

can

contain a message

between

interfaces.

host

host

radial

Only

and

and

serial

that

one

ru58

TU58

protocol

frees

the

high-level

communicate

which

completely

as

well

as

(MRSP),

host

computer

command

via

from

to

the

strings

describes a high-level

packet format are

and

were

designed

CHAPTER 3

PROGRAMMING

device-related

microprocessor

of

one

or

more

defined

to

by

be

operations,

is

necessary

bytes

command.

the

radial

suitable

for

to

called

The

serial

trans-

3.1.1

The

shows

block,

count,

fied.

TU58

the

ber

the

3.1.2

Some

3.2 RADIAL SERIAL PROTOCOL (RSP) AND MODIFIED RSP (MRSP)

3.2.1

All

There

selected

manage

Block

TU58

the

the

the

If

reads

write

of

the

additional

Special

Number,

uses a drive

locations

byte

TU58

the

host

as

many

function.

first

block

block

Handler

count

positions

asks

device-related

1.

A

short

complete

2.

brings

A

the

losses)

the

TU58

presence

occur.

Packets

communication

are

two

types

using

the

protocol

and

Byte

number,

of

blocks

will

be

the

for a block

sequential

This

means

in a file

numbers.

Functions

functions

routine

called

wind-rewind

tape

to

handler

of

should

soft

between

of

multi-byte

command

control

Count,

block

on

the

512

or

specified

and

blocks

that

and

the

are

not

Newtape

for

proper

errors.

the

host

packet

the

state of

and

Drive

number,

tape.

less.

When

drive

also

as

the

host

file's

dealt

new

operating

check

This

and

packets:

switch

Number

and

byte count

If

all

of the

the

host

(unit) at that

desired

asks

block

to

write

data

for

a particular

and

or

read data.

is

contained

transfers the

a byte count greater than that of the

are

needed

software

byte

with

(Appendix

or

environmentally

tension

the

success

enables

the

TU58

Control

byte.

the

system:

to

or

count

to

directly

B)

levels.

code

action

is

accomplished

(Command)

In

addition,

INIT,

fulfill

the

an

on-tape

read

or

in

the

RSP,

should

be

(byte 3 of

to

be

there are three

Continue,

byte

file

write

all

the

included

stressed

the

taken

before

via

and

Data.

count.

directory

the data

MRSP,

in a TU58

tape

RSP

sequences

Either RSP

and

XOFF.

block

The

cartridges.

or

hard errors (permanent data

single-byte

Figure

1-4

within a single

and a 512-or-Iess

number

512-byte

same

need

without

or

in

process

only

the

of

boundary,

store

having

ru58

handler

This

MRSP

of

end

bytes

or

called

MRSP

packets

(Chapter

512-byte

byte

bytes

speci-

applies

the

num-

to

know

firmware.

to

provide

procedure

message)

packets.

may

used

1)

the

to

a

for

be

to

Control

contains a

write operation,

ber, byte count

(Command)

message

for

and

- A Control packet

completely describing the operation

example, the

block

message

number.

is

sent

to

the

TU58

to

be

includes the function

3-1

to

initiate all operations. The packet

performed. In the case of a read

to

be

performed, unit (drive)

or

num-

Page 25

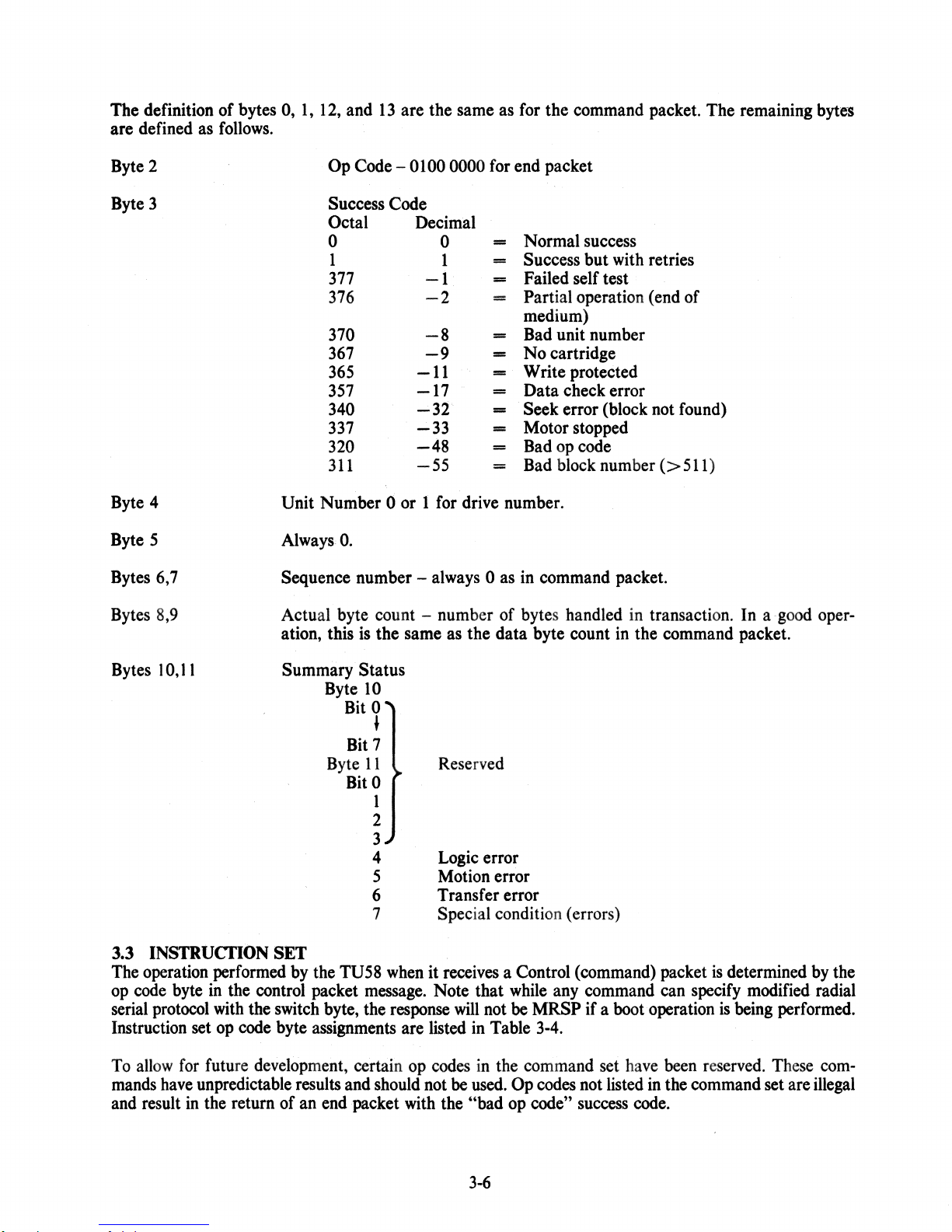

A special case

completion

aborted operation.

of

of

an operation or on an error. The End packet includes the status

the Control packet, called an End packet,

is

sent from the TU58 to the host after

of

the completed or

Data - The Data packet holds messages

data

transferred from

than 128 bytes, the transfer is broken up and sent 128 bytes

INIT

- This single-byte packet is sent to the TU58 to cause the power-up sequence. The TU58

returns Continue after completion, to indicate that the power-up sequence has occurred. When the

TU5S makes a protocol error or receives an invalid command, it reinitializes and sends

tinuously to the host. When the host recognizes

protocol.

Bootstrap - A flag byte saying Bootstrap (octal 10), followed by a byte containing a drive number,

causes the

packaging. This simplifies bootstrap operations. Bootstrap may be sent by the host instead

second

Continue

Continue. This permits the

XON

XOFF

host

TU58 stops transmitting immediately and waits until the host sends Continue to complete the

transfer when it

receives XOFF.)

TU58 to read block 0

INIT

as part

- Before the host sends a Data packet to the TU58, it must wait until the TUS8 sends

- An alternate term for Continue.

- Ordinarily, the TU58 does not have to wait between messages to the host. However,

is

unable to receive all

or

to the TU58 during a read or write operation. For transmissions

of

of

the initialization process described below.

TU58 to control the rate that data packets are sent to it.

of

a message from the peripheral

is

ready. (Two characters may be sent

of

between 1 and 128 bytes. This message is actually the

INIT,

the selected drive.

of

larger

at

a time.

INIT

it sends Break to the TU58

It

returns the 512 bytes without radial serial

at

once, it may send XOFF. The

by

the UART to the host after the TUS8

to

restore the

con-

of

if

a

the

3.2.1.1

begin with a flag byte, which announces the type

are as follows.

(Bits

Multiple-byte (Control and Data) packets also contain a byte count byte, message bytes, and two checksum bytes. The byte count byte

are a 16-bit checksum. The checksum

while adding any carry back into the sum (end-around carry), The flag and byte count bytes are included in the checksum.

Packet Usage - Position within the packet determines the meaning

of

packet to follow. Flag byte numeric assignments

Flag

Byte

Value

Packet

Data

Control (Command)

INIT

Bootstrap

Continue

XON

XOFF

5 - 7

Type

of

the

nag

byte are reserved.)

(See example in Appendix

Octal Binary

01

02 00010

04 00100

10

20 10000

21

23

00001

01000

10001

10011

is

the number

is

formed by summing successive byte-pairs taken as 16-bit words

of

message bytes in the packet. The two checksum bytes

8.)

of

each byte. All packets

3-2

Page 26

3.2.%

Break

of

the serial line, which normally switches between two logic states called mark and space,

space condition for

bit. The

If

Break and

Break and Initialization

is

a unique logic entity that can be interpreted by the TU58 and the host regardless

the protocol. This

is

the logical equivalent

at

least one character time. This causes the TU58's UART to set its framing error

of

a bus init or a master reset. Break

is

of

the state

transmitted when

is

kept in the

TU58 interprets the framing error as Break.

communications break· down, due to any transient problem, the host may restore order by sending

IN

IT

as outlined above. The faulty operations are cancelled, and the TU58 reinitializes it-

self, returns Continue, and waits for instructions.

With DIGITAL serial interfaces, the initialize sequence may be sent by the following sequence of oper-

Set

ations.

transmit ready flag

The second character

discarded by the TU58. The TU58 responds to the second

has been received, the initialize sequence

the Break bit in the transmit control status register, then send two null characters. When the

is

set again, remove the Break bit. This times Break to be one character time long.

is

discarded by the TU58controller. Next, send two

INIT

by sending Continue. When Continue

is

complete and any command packet may

INIT

characters. The first

follow.

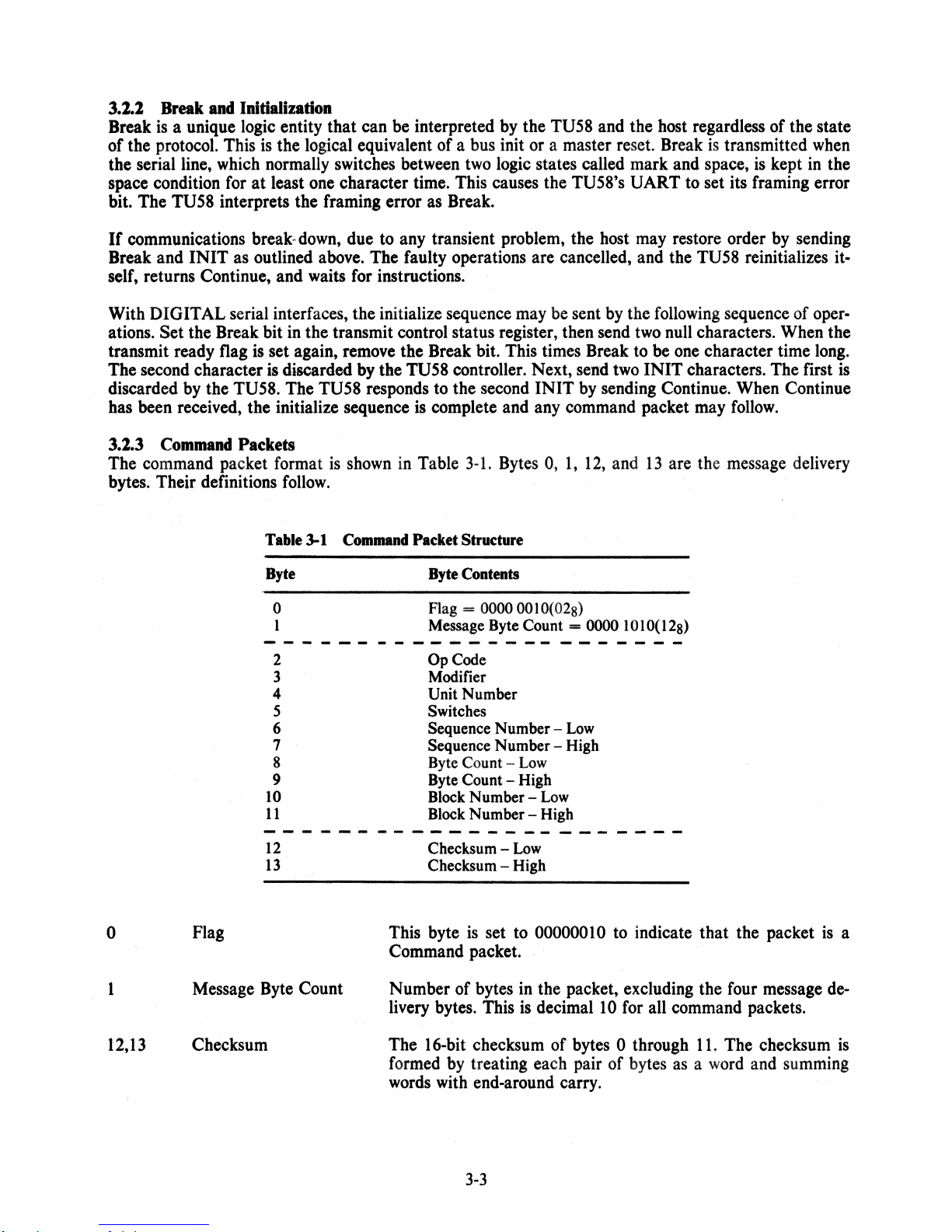

3.2.3 Command Packets

The command packet format is shown in Table

bytes. Their definitions

follow.

Table 3-1 Command Packet Structure

3-1.

Bytes 0,

1,

12, and

13

are the message delivery

is

o

1

Byte

o

1

2

3 Modifier

4 Unit Number

Byte Contents

Flag

= 0000 0010(028)

Message Byte Count = 0000

OpCode

101

O(

128)

5 Switches

Low

Low

is

Flag

6 Sequence Number 7 Sequence Number - High

8 Byte Count 9 Byte Count - High

10

11

12

13

Block Number Block Number - High

Checksum Checksum - High

This byte

is

Low

Low

set to 00000010 to indicate that the packet

Command packet.

Message Byte Count Number of bytes in the packet, excluding the four message de-

is

livery bytes. This

decimal

10

for all command packets.

a

12,13

Checksum The 16-bit checksum

of

bytes 0 through

formed by treating each pair

words with end-around carry.

3-3

11.

The checksum

of

bytes as a word and summing

is

Page 27

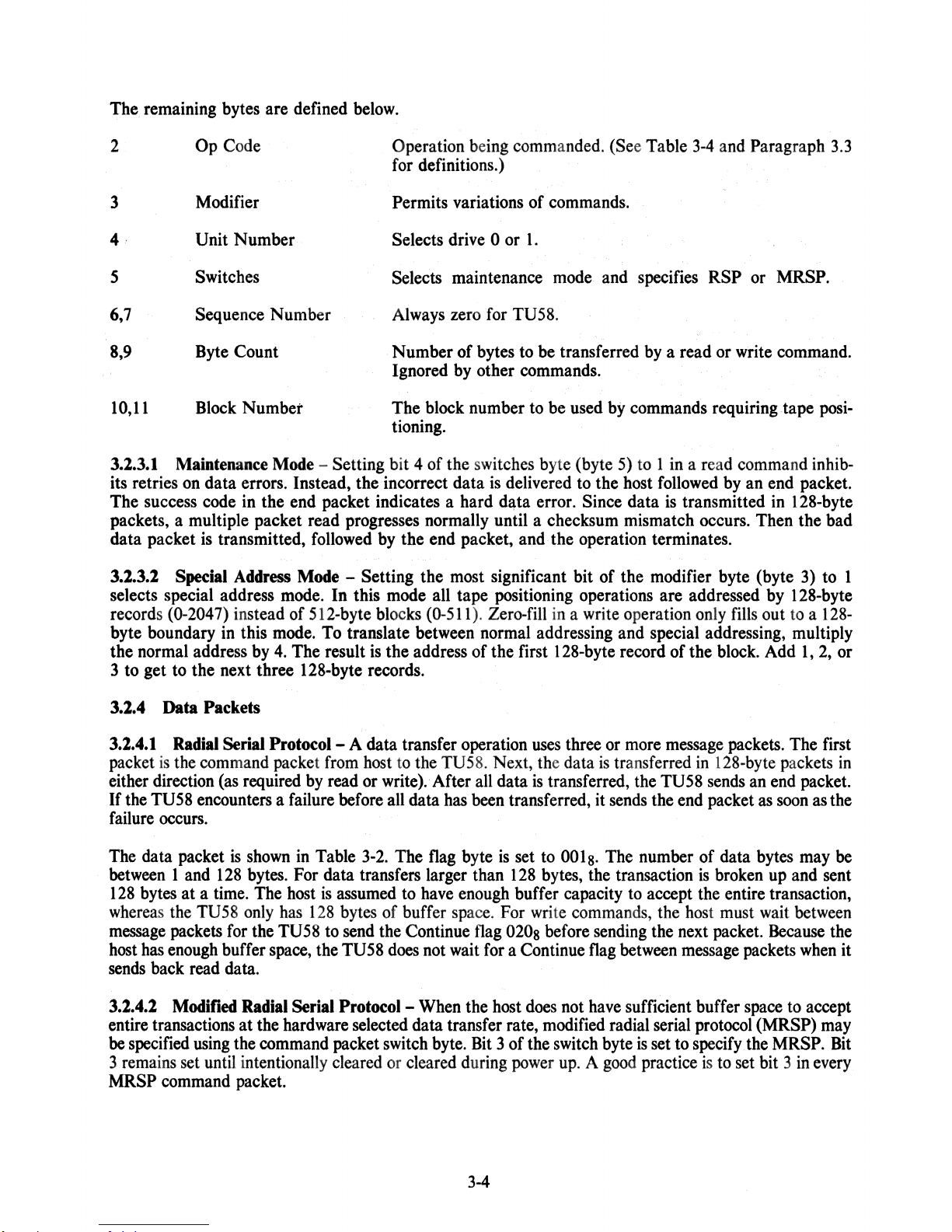

The remaining bytes are defined below.

Op

2

Code

Operation being commanded. (See Table

for definitions.)

34

and Paragraph 3.3

3

4·

5

6,7

8,9

Modifier

Unit Number

Switches

Sequence Number

Byte Count

Permits variations of commands.

Selects drive

Selects maintenance mode and specifies

Always zero for

0 or I.

TU58.

RSP

or MRSP.

Number of bytes to be transferred by a read or write command.

Ignored by other commands.

10,11

Block

Numbet

The block number to be used by commands requiring tape positioning.

3.1.3.1 Maintenance Mode - Setting bit 4 of the switches byte (byte 5) to I in a read command inhibits retries on data errors. Instead, the incorrect data

The success code in the end packet indicates a hard

is

delivered to the host followed by an end packet.

dt~.ta

error. Since data is transmitted in 128-byte

packets, a multiple packet read progresses normally until a checksum mismatch occurs. Then the bad

data packet is transmitted, followed by the end packet, and the operation terminates.

3.1.3.1 Special Address Mode - Setting the most significant bit of the modifier byte (byte 3) to 1

selects special address mode.

records

(0-2047) instead of 512-byte blocks (0-511). Zero-fill in a write operation only fills out to a 128-

In

this mode all tape positioning operations are addressed by 128-byte

byte boundary in this mode. To translate between normal addressing and special addressing, multiply

the normal address by

4.

The result is the address of the first I 28-byte record of the block. Add

I,

2, or

3 to get to the next three 128-byte records.

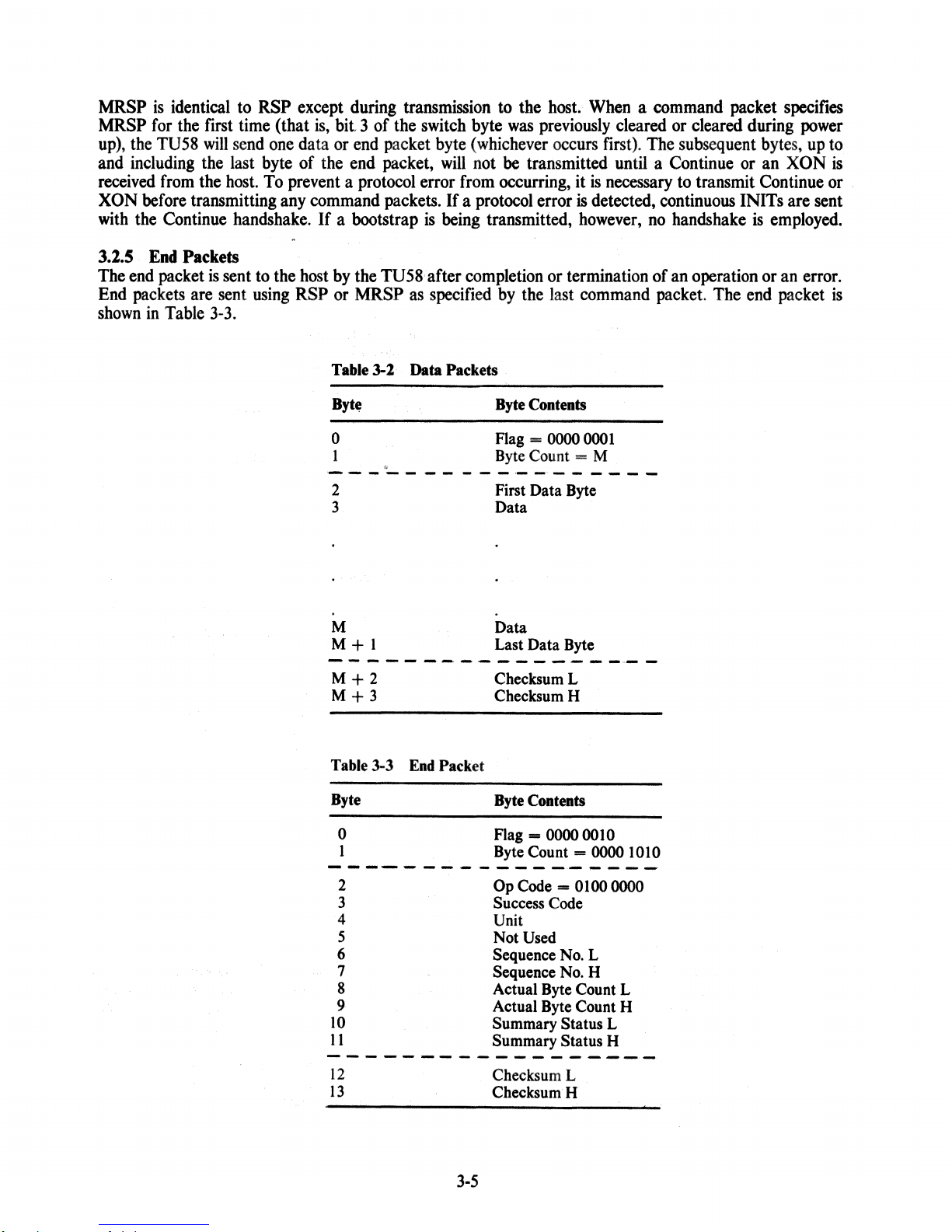

3.1.4 Data Packets

3.1.4.1 Radial Serial

is

packet

the command packet from host to the TU58. Next, the data

either direction (as required by read or write). After all data

If

the TUS8 encounters a failure before all data has been transferred, it sends the end packet as soon as the

Protocol-

A data transfer operation uses three or more message packets. The first

is

transferred in 128-byte packets in

is

transferred, the TU58 sends an end packet.

failure occurs.

The data packet

between

128

bytes

1 and

at

whereas the

message packets for the

host has enough buffer space, the

is

shown in Table 3-2. The flag byte

128

bytes. For data transfers larger than 128 bytes, the transaction

a time. The host

TU58 only

has

TU58 to send the Continue flag 0208 before sending the next packet. Because the

is

set to 0018. The number

is

assumed to have enough buffer capacity to accept the entire transaction,

128 bytes

of

buffer space. For write commands, the host must wait between

of

data bytes may be

is

broken up and sent