Page 1

EK-RL012-UG

-005

RL01/Rl02

User

Guide

Page 2

EK-Rl012-UG-005

Rl01/Rl02

User

Guide

Prepared

by

Educational Services

Digital Equipment Corporation

Page 3

1st Edition, December ]l978

2nd Printing (Rev), September ]l979

3rd Printing (Rev), June

]1980

4th Printing (Rev), October 1980

5th Printing (Rev), September 1981

Copyright @ 1981 by Digital Equipment Corporation

All Rights Reserved

The material

in

this manual is for informational purposes and is subject to change

without notice.

Digital Equipment Corporation assumes no responsibility for any errors which

may appear

in

this manual.

Printed

in

U.S.A.

This document was set on DIGITAL's DECset-8000 computeriized typesetting system.

• Class A Computing Devices:

Notice:

This equipment generates, uses, and may emit radio frequency energy.

The equipment has been type tested and found to comply with the limits for a

Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such radio frequency

in-

terference when operated

in

a commercial environment. Operation of this equip-

ment

in

a residential area may cause interference

in

which case the user at his

own expense may be required to take measures to correct the interference.

The following are trademarks of Digital Equipment Corporation, Maynard, Massachusetts:

DEC

DECUS

DIGITAL

Digital Logo

PDP

UNIBUS

VAX

DECnet

DECsystem-10

DECSYSTEM-20

DECwriter

DIBOL

EduSystem

lAS

MASSBUS

OMNIBUS

OS/8

PDT

RSTS

RSX

VMS

VT

Page 4

CHAPTER 1

1.1

1.2

1.3

1.3.1

1.3.2

1.3.2.1

1.3.2.2

1.3.2.3

1.3.2.4

1.3.3

1.3.3.1

1.3.3.2

1.4

1.5

1.6

CHAPTER 2

2.1

2.1.1

2.1.1.1

2.1.1.2

2.1.1.3

2.1.1.4

2.1.1.5

2.1.1.6

2.1.1.7

2.1.1.S

2.1.1.9

2.1.1.10

2.1.1.11

2.1.2

2.1.3

2.1.3.1

2.1.3.2

2.1.4

2.1.5

2.2

2.3

CONTENTS

Page

INTRODUCTION

PURPOSE

AND

SCOPE

........ ............. ......... ........................................................

1-1

REFERENCE

DOCUMENTS

.............................................................................

1-1

SUBSYSTEM

DESCRIPTION

............................................................................

1-1

RLO 1 /RL02

Disk Drive.... ......... ......... ....... ...... ............ ...... ............................

1-2

RLControllers ............. ; ..................................................................................

1-2

RLII

Controller Description..................................................................

1-2

RLVII

Controller Description...............................................................

1-3

RLSA Controller Description.................................................................

1-3

RLV12 Controller Description...............................................................

1-3

RLOIK/RL02K

Disk Cartridge.....................................................................

1-4

Interchangability ..... ................................................ ............ ...................

1-4

Sector Format.........................................................................................

1-4

SECTOR

LOCATION

..........................................................................................

1-7

BAD

SECTOR

FILE

.............................................................................................

1-8

RLOI/RL02

SPECIFICATIONS

......................................................................... 1-10

INSTALLATION

SITE

PREPARATION

AND

PLANNING

.........................................................

2-1

Environmental Considerations........................................................................

2-1

Cleanliness..............................................................................................

2-1

Space Requirements...............................................................................

2-1

Floor Loading.........................................................................................

2-1

Heat

Dissipation .....................................................................................

2-1

Acoustics... ............... ......... ......................................... ............................

2-2

Temperature ...........................................................................................

2-2

Relative Humidity ..................................................................................

2-2

Altitude..... ......... ........... ................. ............. ................... ...... ........ ........

...

2-2

Power and Safety Precautions ..................... ......... .............. ....................

2-2

Radiated Emissions ................................................................................

2-2

Attitude/Mechanical Shock...................................................................

2-3

Options............................................................................................................

2-3

AC Power Requirements. ...............................................................................

2-5

Standard Applications ...................................................... ..... ....... ..........

2-5

Optional Applications.............................................................................

2-5

Installation Constraints...................................................................................

2-7

Grounding Requirements ......... ....... ................................................ ....... ........

2-7

AC

CABLING

.......................................................................................................

2-8

INSTALLATION -GENERAL

.......................................................................... 2-10

111

Page 5

CHAPTER

2

2.4

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.6.5

2.6.6

2.6.7

2.6.8

2.6.9

2.7

2.7.1

2.7.2

2.7.3

2.8

2.8.1

2.8.2

2.8.3

2.8.4

2.9

2.9.1

2.9.2

2.9.3

2.10

CHAPTER 3

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.3

3.3.1

3.3.2

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.5

Page

INSTALLATION

(Cont)

RLII

CONTROLLER

INSTALLATION

...........................................................

2-11

RLV11

CONTROLLER

INSTALLATION

........................................................ 2-16

Bus Interface Module ..................................................................................... 2-16

Drive

..................................................................... ' .............................

2-18

Module Slot Location.....................................................................................

2-19

Module Installation.................................................................................. .......

2-20

RLV12

CONTROLLER

INSTALLATION

........................................................

2-21

Introduction ....................................................................................................

2-21

Device Address Selection ...............................................................................

2-21

Bus Selection...................... .................................................................... ........

2-26

Interrupt Vector.......................................................... ....................................

2-26

Interrupt Request Level .................................................................................

2-26

Memory Parity Error Abort Feature ...................................... , .................

,.

.....

2-26

Other Jumpers ................................................................................................

2-27

Installation..... ....... .............. ...................................................... ......................

2-27

Acceptance Testing........................................................................................

2-27

RL8A

CONTROLLER

INSTALLATION

...................................................

,.

.....

2-28

Introduction............ ........................................................................................

2-28

Module Slot Location .....................................................................................

2-28

Module Installation. ........................................................................................

2-28

RLOI/RL02

DISK

DRIVE

INSTALLATION

.................................................... 2-30

Unpacking and Inspection .......................................................................

,.

..... 2-30

RL01/RL02

Disk Drive Unit Mounting ........................................................ 2-32

Drive Prestartup Inspection ............................................................................

2-37

Drive Startup Operation Check ...................................................................... 2-39

CONFIDENCE

TESTING

................................................................................... 2-39

RLI1-Based Diagnostics .................................................................................

2-40

RLVI1-/RLVI2-Based Diagnostics ...............................................................

2-43

RL8A-Based Diagnostics ................................................................................

2-43

USE

OF

THE

M9312 BOOTSTRAP

WITH

AN

RLII

SUBSySTEM

.............. 2-46

OPERATOR'S GUIDE

INTRODUCTION.................................................................................................

3-1

CONTROLS

AND

INDICATIONS

....................................................................

3-1

Power

ON

/OFF

Circuit Breaker....................................................................

3-2

Run/Stop

Switch with LOAD Indicator ........................................................

3-2

UNIT

SELECT

Switch with READY Indicator ...........................................

3-3

FAULT Indicator .............................................................. .............................

3-3

WRITE

PROTECT

Switch and Indicator .....................................................

3-3

OPERATING

PROCEDURES.............................................................................

3-3

Cartridge Loading and Drive Startup Procedure ...........................................

3-4

Cartridge Unloading Procedure......................................................................

3-6

OPERATOR

MAINTENANCE...........................................................................

3-6

Introduction....................................................................................................

3-6

Professional Cartridge Cleaning.....................................................................

3-6

User Cartridge Cleaning.................................................................................

3-6

Spindle Assembly Cleaning ............................................................................

3-7

CARTRIDIGE

CARE

SUMMARy.....................................................................

3-7

lV

Page 6

CHAPTER 4

4.1

4.1.1

4.1.2

4.1.3

4.2

4.2.1

4.2.2

4.2.3

4.2.3.1

4.2.3.2

4.2.3.3

4.2.4

4.2.4.1

4.2.4.2

4.2.4.3

4.2.4.4

4.2.5

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.4

4.4.1

4.4.2

4.4.3

4.4.4

4.4.5

4.4.6

4.4.7

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.6

4.7

4.7.1

4.7.2

4.7.3

4.7.4

4.7.5

4.7.6

Page

II-FAMILY PROGRAMMING INFORMATION

GENERAL

DESCRIPTION

................................................................................

4-1

RL

11

Controller Description.. .................................... .............. ..... .................

4-1

RLVII

Controller Description .......................................................................

4-1

RL V 12

Controller Description ...................................... ...... ............... ............

4-1

ADDRESSABLE

REGISTERS............................................................................

4-1

Control Status Register ..................................................................................

4-2

Bus Address Register......................................................................................

4-5

Disk Address Register ....................................................................................

4-5

DA Register During a Seek Command ..................................................

4-5

DA Register During Read or Write Data Command.............................

4-6

DA Register During A Get Status Command........................................

4-7

Multipurpose Register ....................................................................................

4-8

MP

Register After a

Get

Status Command ...........................................

4-8

MP

Register After a Read Header Command ....................................... 4-10

MP

Register During

Read/Write

Data Commands ..............................

4-11

Bus Address Extension Register.............................................................

4-11

Register Summary ........................................................................................... 4-12

CONTROLLER

COMMANDS

........................................................................... 4-14

No-Op

(RLll)

or Maintenance

(RLVll)

- Function Code 0 ........................ 4-14

Write Check - Function Code 1 ..................................................................... 4-15

Get Status - Function Code 2 ......................................................................... 4-16

Seek - Function Code 3 ................................. .................................................. 4-16

Read Header - Function

Code 4 .................................................................... 4-16

Write

Data

- Function Code 5 ........................................................................ 4-16

Read Data - Function

Code 6 ........................................................................

4-1

7

Read Data Without Header

Check - Function Code 7 .................................. 4-17

CSR

ERROR

CODE

DEFINITIONS

.................................................................. 4-17

Operation Incomplete

(OPI) ........................................................................... 4-17

Data

CRC

(DCRC) or Write Check (WCE) ................................................. 4-17

Header

CRC

(HCRC)

.................................................................................... 4-17

Data

Late (DLT) ............................................................................................ 4-17

Header

Not

Found

(HNF)

.............................................................................. 4-18

Non-Existant Memory

(NXM)

....................................................................... 4-18

Memory Parity Error (MPE) .......................................................................... 4-18

OPERATIONAL

CONSIDERATIONS

.............................................................. 4-18

Interrupt ......................................................................................................... 4-18

Seek Operation.............. ......... ........ ................ ................................................ 4-18

Overlapped Seeks ........................................................................................... 4-18

Data Transfer .................................................................................................. 4-19

Recovery of

Data

with Bad Headers .............................................................. 4-19

Non-Interchangability of

RLOIK/RL02K

Disk Cartridges .......................... 4-19

ERROR

RECOVERY

........................................................................................... 4-19

DIFFERENCE

SUMMARY

(RK05

AND

RLOI

/RL02)

....................................

4-21

Spiral

Read/Write

or Mid-Transfer Seeks .....................................................

4-21

Implicit Seeks Versus Explicit Seeks .............................................................

4-21

Recalibrate ..................................................................................................... 4-22

Bad Sector File............................................................................................... 4-22

Reformatting .................................................................................................. 4-22

Seek Interrupt ................................................................................................. 4-22

v

Page 7

CHAPTER 5

5.1

5.2

5.2.1

5.2.1.1

5.2.1.2

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.7.1

5.2.7.2

5.2.8

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.3.9

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4

..

6

5.4

..

6.1

5.4.6.2

5.4

..

7

5.5

5.6

5.6

..

1

5.6

..

2

5.6

..

3

5.6.4

5.6.5

5.6.6

APPENDIX A

A.1

A.2

Page

RL8A PROGRAMMING INFORMATION

GENERAL

DESCRIPTION

................................................................................

5-1

ADDRESSABLE REGISTERS............................................................................

5-2

Command Register A .....................................................................................

5-2

Command Register A During a Seek Command ...................................

5-2

Command Register A During Read or Write Data Command ..............

5-3

Command Register B......................................................................................

5-4

Break Memory Address Register...................................................................

5-6

Word Count Register......................................................................................

5-6

Sector Address Register.................................................................................

5-6

Error Register.................................................................................................

5-7

Silo Data Buffer..............................................................................................

5-8

Data Buffer Contents Following a Get Status Command ......................

5-9

Silo Data Buffer Contents Following a Read Header

Command ...... ...... ....... ...... ...... .................. ..... .............

.........

........... .........

5-9

Register Summary..........................................................................................

5-9

CONTROLLER

COMM.ANDS ...........................................................................

5-9

Maintenance Command ................................................................................... 5-16

Reset Command ............................................................................................. 5-16

Get

Status Command ..................................................................................... 5-16

Seek Command................................................................................................

5-1

7

Read Header Command.................................................................................

5-17

Write Data Command ....................................................................................

5-17

Read Data Command .....................................................................................

5-18

Read Data without Header Check Command ................................................

5-18

Maintenance Bit ....... ........... .................................... ........................ ...............

5-18

OPERATIONAL

CONSIDERATIONS

.............................................................. 5-20

8-Bit Mode Versus 12-Bit Mode ..................................................................... 5-20

Interrupt ......................................................................................................... 5-20

Seek Operation ............................................................................................... 5-20

Overlapped

Seeks ........................................................................................... 5-20

Recovery of Data with Bad Headers .............................................................. 5-20

Non-Interchangability of Disk Cartridges ....................................................

:.

5-21

RLOIK/RL02K

.....................................................................................

5-21

RL8A/RL11/RLV11/RLV12

..............................................................

5-21

Use of Two RL8A Controllers....... ................ ....... .............. .......... ..................

5-21

ERROR

RECOVERY ............................................................................................

5-21

DIFFERENCE

SUMMARY

(RK05 AND RLOI

/RL02)

.................................... 5-22

Spiral

Read/Write

or Mid-Transfer Seeks ......................................................

5-23

Implicit Seeks Versus Explicit Seeks ..............................................................

5-23

Recalibrate

...

.................... ............................. ......... ..... .............................. .....

5-23

Bad Sector File.................................................. ........ .....................................

5-23

Reformatting... .................................................... ..... ............................. .........

5-23

Seek Interrupt .................................................................................................

5-23

RLll

CONFIGURATION AND INSTALLATION CONSIDERATIONS

SPC

CONSIDERATIONS

..................................................................................... A-I

CONFIGURATIONS

CONSIDERATIONS

...................................................... A-I

vi

Page 8

FIGURES

1-1

1-2

1-3

1-4

1-5

1-6

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23a

2-23b

2-24

2-25

2-26

2-27

3-1

3-2

3-3

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

5-1

5-2

Page

Typical

RLOI/RL02

Mass Storage Subsystem Configuration ..............................

1-2

RLO 1 /RL02

Disk Drive......... ............ .......... ....... ..... .......... .................... ................

1-3

RLOIK/RL02K

Disk Cartridge Format ................................................................

1-5

Access Method for Sequential Transfers ................................................................

1-7

Sector Relocation. .............. .....................................................................................

1-8

Bad Sector File Format...........................................................................................

1-9

RLOI/RL02

Disk Drive - Rear View.....................................................................

2-5

Approved Electrical Plugs and Receptacles........................................... ........ ........

2-6

Power Panel Grounded Building Frame.................................... .............. ......... ......

2-7

Power Panel Grounded To Metal Plate ..................................................................

2-8

Typical 60

Hz

Power System....... .......................................... ..................... ............

2-9

Typical 50

Hz

Power System.................. ................................................................. 2-10

Split Phase

(2-phase) Power System ....................................................................... 2-10

Three Phase Y Power System................................................................................. 2-10

RL

11

Component Layout ........ ............ ......... ........ ..... ............. ................................

2-11

RLll

Base and Vector Address Jumper Configuration .......................................... 2-13

RLll

Priority Jumper Assembly Connections ........................................................ 2-14

RL

11

Controller Installation.. ........... ......... ........ .................. ................................... 2-15

RLVll

Bus Interface Module (M8014) (Component Side) ................................... 2-17

RL V 11

Base Address Switch Settings .................................................................... 2-18

RL V 11

Vector Address Switch Settings ................................................................. 2-18

RLVll

Drive Module (M8013) .............................................................................. 2-19

H9273 Backplane Grant Priority Structure ............................................................ 2-20

RL V 12

J urn per Locations....................................................................................... 2-24

RLV12 Device Address Format. ............................................................................. 2-25

RLV12 Format Interrupt Vector ............................................................................ 2-26

RL8A Jumpers........................................................................................................ 2-29

H950 Shipping Package ..........................................................................................

2-31

RLOI/RL02

Cabinet Installation ........................................................................... 2-32

RLOI/RL02

Cabinet Installation ........................................................................... 2-33

RLO 1 /RL02

Disk Drive - Exposed Drive Logic Module ....................................... 2-34

RLOI

/RL02

- Covers Removed ............................................................................. 2-35

RLO 1 /RL02

Disk Drive - Rear View................ ...... .................. .............. ............... 2-36

RLOI/RL02

Disk Drive - Front View .................................................................... 2-37

RLOI/RL02

Disk Drive - Front View....................................................................

3-1

RLOI/02

Disk Drive - Rear View.......................................................................... 3-2

Cartridge Loading

Procedure..... .................. ................... ...... .................................

3-5

CS

Register ............................................................................................................. 4-2

BA Register.............................................................................................................

4-5

DAR

Contents to Execute a Seek Command .........................................................

4-5

DAR

Contents During a

Read/Write

Data Command .......................................... 4-6

DAR

Contents to Execute a Get Status Command................................................

4-7

MPR

- Following a Get Status Command........ ...... ......... .......................................

4-8

MPR

- Following a Read Header Command ......................................................... 4-10

MPR

- Used as a Word Counter ............................................................................

4-11

BAE Register .......................................................................................................... 4-12

Register Summary.................................................................................................. 4-12

Command Register A During a

Seek Command....... ......... .................. ...... ............ 5-3

Command Register A During a

Read/Write

Data

Command ...............................

5-4

Vll

Page 9

Page

FIGURES

(Coot)

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

TABLES

I-I

1-2

1-3

1-4

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

5-1

5-2

5-3

Command Register B..............................................................................................

5-4

Break Memory Address Register............................................................................

5-6

Word Count Register..............................................................................................

5-6

Sector Address Register... .......................................................................................

5-7

Error Register.........................................................................................................

5-7

Silo Buffer for Status Word I ......................................................... '........................

5-9

Silo Buffer for Status Word 2 .................................................................................

5-9

Silo Buffer for Header Words ................................................................................. 5-12

Register Summary..................................................................................................

5-13

Maintenance Mode Bit................................. ..... .............

...

........... ...... ...... ..... ......... 5-19

Reference Documents ............................................................................................. I-I

RLO I /RL02

Disk Drive Physical and Environmental

Specification ...........................................................................................................

1-10

RLO I /RL02

Disk Drive Operational Specifications...... ........... .... ................... ......

1-13

RLO I K/RL02K

Disk Cartridge Specifications ....... .......... ...... ......... ............ .........

1-14

Saleable RLOI

/RL02

Subsystem Options .............................................................

2-3

Saleable Cabinet Options: (Includes Skins, Doors, Covers,

Trim, and

Power Controllers) ......................................................... '........................

2-4

Address Selection............ ....... ........... ....... ................................ ............................... 2-22

Diagnostic Catalogs and Indexes ..... ...................... ...................... ..................... ......

2-40

RLII-Based Diagnostics ......................................................................................... 2-40

RLII

Diagnostic Kit Numbers ...............................................................................

2-41

RL

II

Diagnostic Components.................. ................. ..... .......... ..... ............ .... .........

2-41

User Documents...................................................................................................... 2-42

RLVII

/RLVI2

Diagnostic Kit Designations .........................................................

2-43

RL8/RLOI Diagnostic Kits ....................................................................................

2-43

RL8/RLOI Diagnostic Components ....................................................................... 2-44

RL8A Diagnostic

Kits.

....... ....................... ................. ............................................

2-45

RL8/RL02

Diagnostic Components .......................................................................

2-45

Controller Addressable Registers................... ........... ......... ................ ....... .... ......... 4-2

Control Status Register Bit Description .................................................................

4-3

Disk Address Register Bit Description for Seek Commands.................................. 4-6

Disk Address Register Bit Description for Data Transfer

Commands....... ........ ....... ....... ..... ...... .....

...

..... ......... ...... ..... ..... .... ..... ...... ..... ....... .....

4-7

Disk Address Register Bit Description for Get Status

Commands............. ....... ......... ...... ..... ...... ...... ...... ..... ..... .... ............... ..... ...... ....... .....

4-7

MP

Register Bit Description for Get Status Commands........................................

4-8

MP

Register Bit Description for Read Header Commands .................................... 4-10

MP

Register Bit Description for Data Transfer Commands ..................................

4-11

RLII

/RLVII

/RLVI2

Controller Commands ....................................................... 4-14

Errors.

...

........ ....... ............. ........ ..... ..... ...... ...... .... ..... .......... ...... .... ..... ........... ..... ...... 4-20

RL8A Instruction Set.............................................................................................

5-1

RL8A Controller Commands .......................................................... ,........................

5-2

Command Register A Bit Description for Seek Commands...................................

5-3

viii

Page 10

Page

TABLES

(Cont)

5-4

5-5

5-6

5-7

5-8

5-9

Command Register A Bit Description

for

Data Transfer

Commands............ ..... ........ ......... ................. ........ ........... ............... ................. ........

5-4

Command Register B Bit Description.....................................................................

5-5

Error

Register Bit Description........... .............................................................. .......

5-7

Silo Data Buffer

Word

1 of Get Status Command ................................................. 5-10

Silo

Data Buffer

Word

2 of Get Status Command .................................................

5-11

Errors

...................................................................................................................... 5-22

ix

Page 11

1.1

PURPOSE AND SCOPE

CHAPTER 1

INTRODUCTION

This manual provides information on the capabilities, installation, operation, and programming of the

RLOI/RL02

disk subsystem. A basic subsystem

is

comprised of one

RLll,

RLVll,

RLVI2,

or RLSA

controller and up to four RLOI or

RL02

disk drives.

This manual

is

intended primarily for operating and programming personnel. Service should be performed only by qualified Digital field engineering and maintenance personnel. A prerequisite for understanding this manual

is

a basic knowledge of PDP-S

and/or

PDP-II

processors and peripherals.

1.2 REFERENCE DOCUMENTS

Table

1-1

lists the documents

that

provide the information necessary for a complete understanding of

the function, theory, and maintenance of

the

RLO 1 /RL02

disk drives and the controllers. The

UNIBUS

and

LSI-II

Bus are described in the

PDP-II

Bus Handbook (EB-17525). The

OMNIBUS

is

described in the PDP-8A Miniprocessor User's Manual (EK-SA002-MM).

Table

1-1

Reference Documents

Title

RLOI/RL02

Disk Drive Technical Manual

RLOI Disk Drive Illustrated Parts Breakdown

RL02 Disk Drive Illustrated Parts Breakdown

RLOI/RL02

Disk Subsystem Preventive

Maintenance Manual

*

RLO 1 /RL02

Disk Drive Pocket Service Guide

RLII

Controller Technical Description Manual

RLVII

Controller Technical Description Manual

RLSA

OMNIBUS

Controller Technical Manual

RLV12 Disk Controller User's Guide

RL V 12

Controller Technical Description Manual

Document No.

EK-RLOI2-TM

EP-OOO

16-

IP

EP-OOO

16-

IP

EP-OOOOS-PM

EK-RLOI2-PG

EK-ORLII-TD

EK-RLVI1-TD

EK-ORLSA-TD

EK-RLVI2-UG

EK-RLVI2-TD

•

This document

is

only available to Digital Equipment Corporation Service personnel.

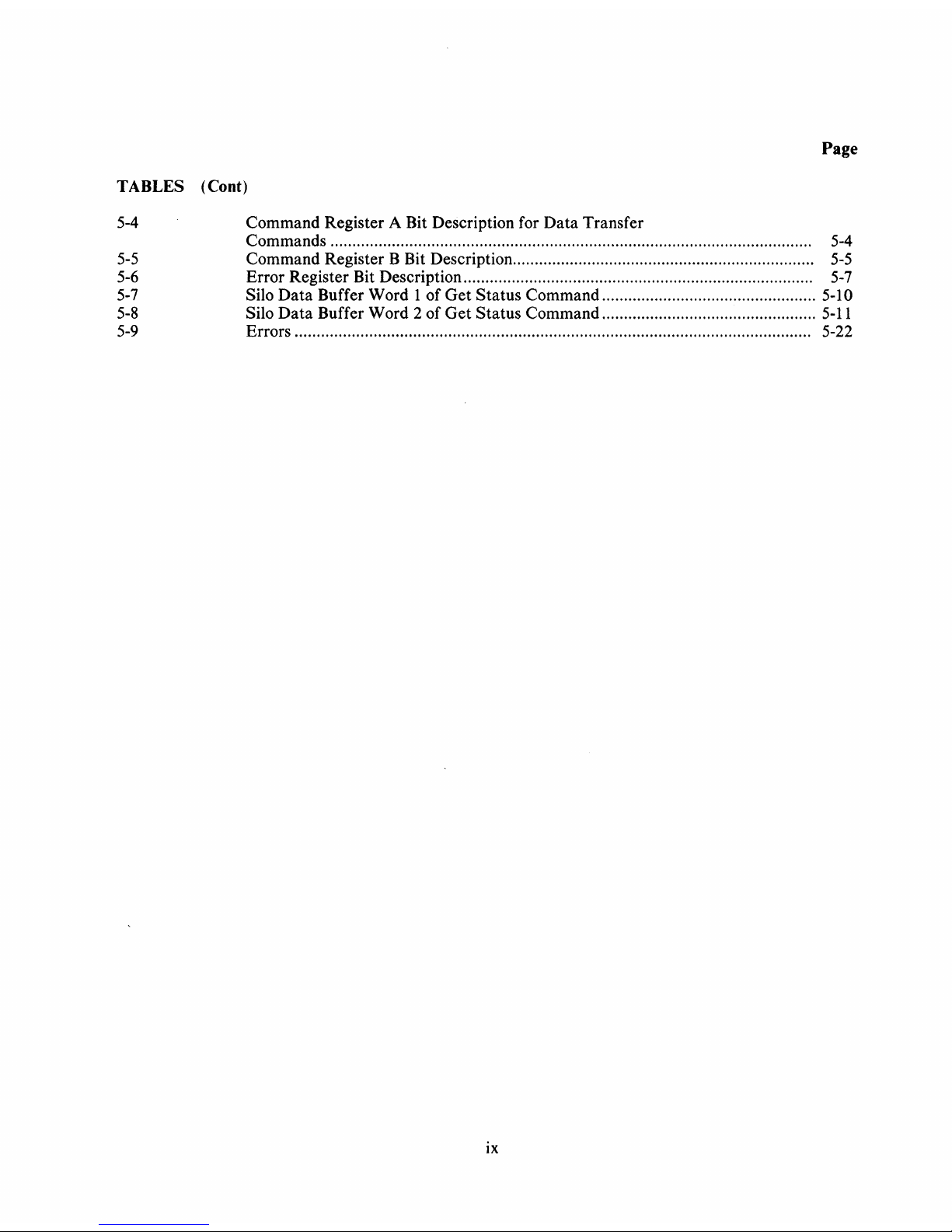

1.3 SUBSYSTEM DESCRIPTION

The

RLOI/RL02

mass storage subsystem

is

based on the

RLOIK/RL02K

disk cartridges, the

RLOI/RL02

drive unit(s), and an appropriate controller such as the

RLII

(PDP-II),

RLVII

or

RLV12

(LSI-II),

or

RL8A

(PDP-S). The basic subsystem

is

illustrated in Figure

1-1.

1-1

Page 12

•

UNIBUS

•

OMNIBUS

•

Q-BUS

CONTROLLER

RL11

CU/DRIVE

INTERFACE

RLV11

RLV12

RL8A

•

•

READ

DATA

•

STATUS

• SECTOR PULSES

• GET

STATUS

• SEEK

•

WRITE

DATA

Figure

1-1

Typical RLO]

/RL02

Mass

Storage

Subsystem

Configura tion

1.3.1 RLOljRL02 Disk Drive

(DRIVE

0)

o

(DRIVE 1)

01

(DRIVE

2)

01

(DRIVE

3)

0]

CZ-1007

The

RLOI

/RL02

drive unit

is

built into a chassis

that

slides

out

of

the

cabinet

to allow

operator

access

to

the

top cover for loading and unloading

of

the

disk cartridge.

If

the

stops on

the

slide

are

manually

released,

the

chassis

can

be

pulled

farther

out

so

that

the

rear

top cover

can

be

removed for servicing.

The

front panel contains.

operator

controls

and

indicators.

The

chassis contains a spindle, two

read/write

heads mounted on a positioner, logic modules, a power

supply with

an

ac

power cord and

circuit

breaker, a closed-loop clean

air

system, a cooling

air

syste:m,

appropriate

safety interlocks,

and

connectors for

the

I/O

cable(s).

The

drive

unit

is shown in Figure 1-2.

The

RL02

drive unit has a label reading

"RL02"

on

the

front panel.

The

RLOI drive

currently

does not

have a label identifying it as

an

RLO

1.

1.3.2 RL Controllers

There

are

four controllers available for

the

RLO 1

/RL02

subsystem. All

can

handle

up

to four drives

and

all feature

Direct

Memory

Access

(DMA)

operation.

1.3.2.1

RLl1

Controller Description -

The

RLII

controller consists

of

a single, hex-height

Small

Peri-

pheral Controller

(SPC)

module designated M7762.

It

is

used to interface

the

drive with

the

PDP-II

UNIBUS.

The

data

is

formatted

in 16-bit words.

1-2

Page 13

Figure

1-2

RLOI/RL02

Disk Drive

1.3.2.2 RLVII Controller Description - The

RLVII

controller consists of two quad-height modules

designated

M8013 and M8014. This controller interfaces the drive with the

LSI-II

Bus. The data

is

formatted in 16-bit words. The controller can handle any combination of up to four RLOI

/RL02

drives.

1.3.2.3 RL8A Controller Description - The RL8A controller consists of a single, hex-height module

designated M8433.

It

is

used to interface the drive with the PDP-8 OMNIBUS. The data can be formatted in either 8-bit bytes or 12-bit words. This controller has a jumper-determined choice of handling

RLOI or RL02 drives. However, in the RL02-jumpered configuration,

it

can handle any combination of

up to four

RLO 1 /RL02

drives.

1.3.2.4 RLV12 Controller Description - The RLV12 controller consists of a single, quad-height mod-

ule designated

M8061.

It

is

used to interface the drive with either the extended

LSI-II

Bus or the

standard

LSI-II

Bus. A jumper designates the 22-bit or 18-bit addressing scheme. The data

is

for-

matted in 16-bit words. This controller can handle any combination of up to four

RLO 1 /RL02

drives.

1-3

Page 14

1.3.3 RLOIK/RL02K Disk Cartridge

The

RLO

1 K or RL02K

is

a removable, top-loading 5440-type disk cartridge

that

is

formatted in a man-

ner unique to the

RL01/RL02

subsystem. Both cartridges contain a single platter. The RL01K cartridge has a capacity of 5.2 megabytes of user data, and the RL02K cartridge holds 10.4 megabytes of

data. Both sides of the platter are used for data. There are 256 tracks on each

RL01K platter surface

and 512 tracks on each

RL02K platter surface. Each track

is

divided into 40 sectors. Each sector

con-

tains 256 bytes of data. The last track of the last surface

is

reserved for the cartridge serial number and

bad sector information. Head positioning servo information and header information are prerecorded at

the factory and cannot be reformatted in the field. This information, along with the data,

is

read by

the:

read/write heads but the internal logic of the drive unit protects the servo and header information

from.

being overwritten.

1.3.3.1 Interchangability - The RL01K and RL02K disk cartridges are not functionally inter··

changable although they are physically interchangable.

It

is

possible to mount an RL01K cartridge

Ont

an RL02 drive, for example,

but

proper operation will not occur. An RL01K cartridge written on

an.

RL01 unit can be read on any other RLOI unit even if

that

unit

is

controlled by a different type of

controller. The limitation to this interchangeability

is

that

if an RL8A controller

is

used to write data.

and the cartridge

is

to be used by an II-Family controller, the RL8A must use the 8-bit byte mode of

operation.

An

RL02K cartridge written on an RL02 unit can be read

on

any other RL02 unit (assuming the

conditions mentioned above).

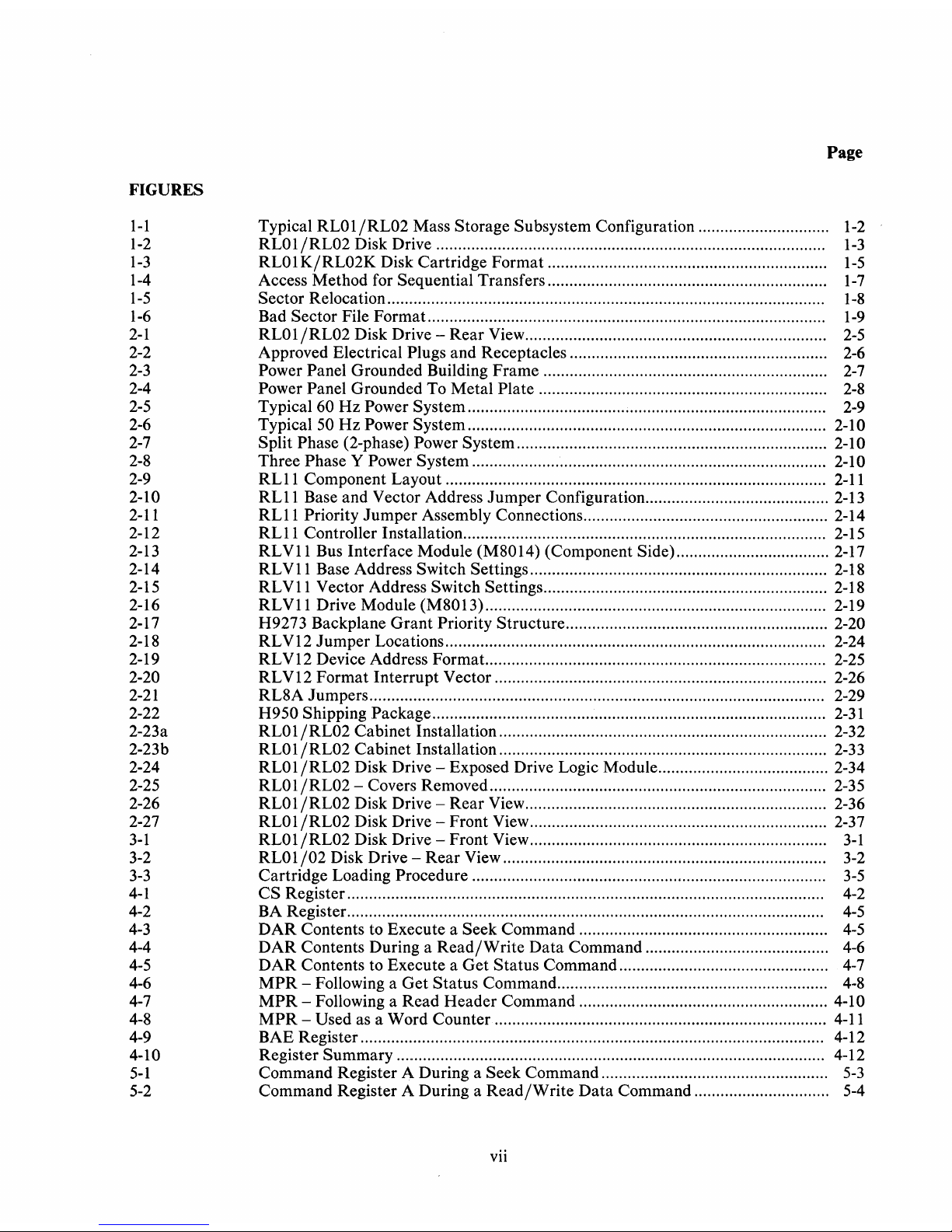

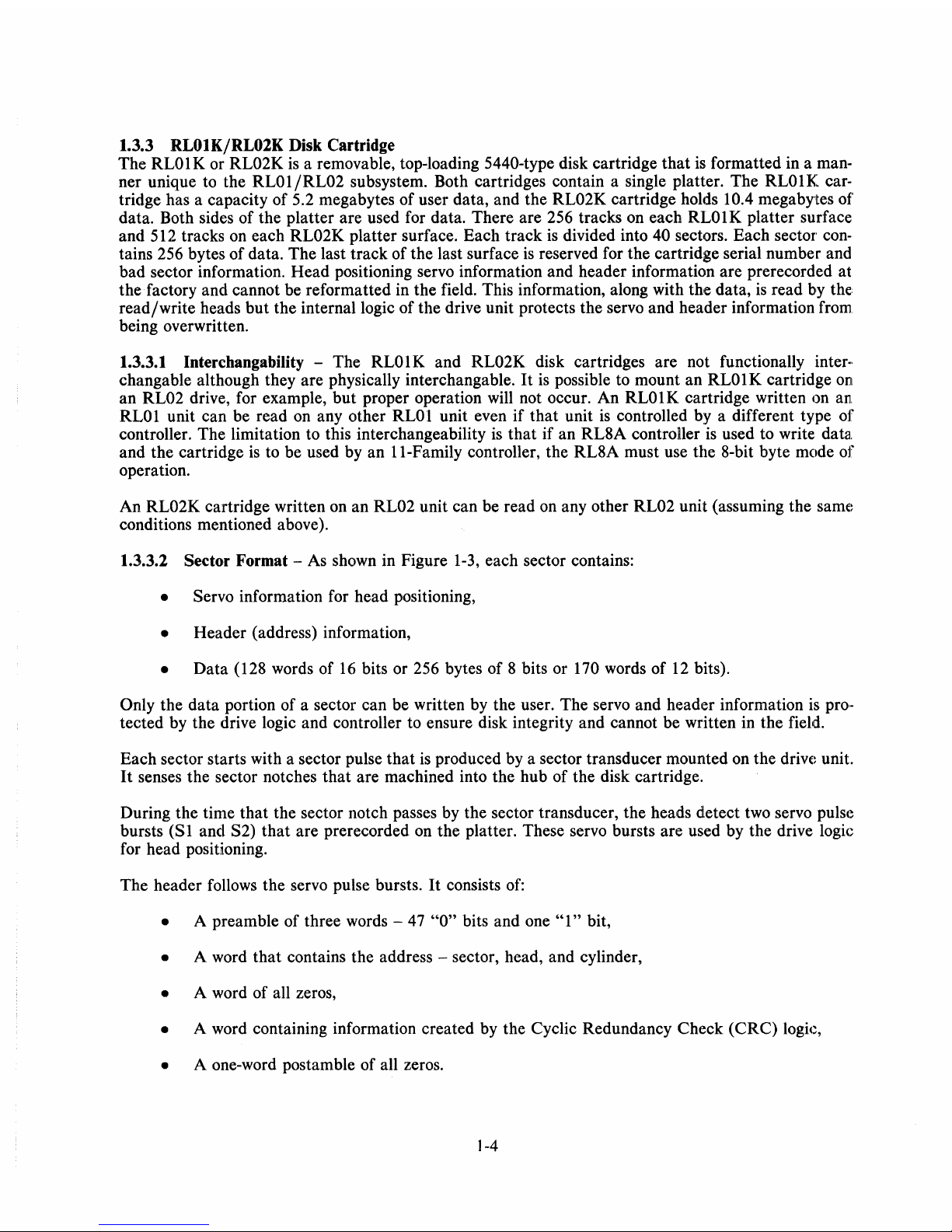

1.3.3.2 Sector Format - As shown in Figure 1-3, each sector contains:

• Servo information for head positioning,

• Header (address) information,

• Data (128 words of

16

bits or 256 bytes of 8 bits or 170 words of

12

bits).

Only the data portion of a sector can be written by the user. The servo and header information

is

pro.-

tected by the drive logic and controller to ensure disk integrity and cannot be written in the field.

Each sector starts with a sector pulse

that

is

produced by a sector transducer mounted on the unit.

It

senses the sector notches

that

are machined into the hub of the disk cartridge.

During the time

that

the sector notch passes by the sector transducer, the heads detect two servo pulse

bursts

(Sl

and S2)

that

are prerecorded

on

the platter. These servo bursts are used by the drive logic

for head positioning.

The header follows the servo pulse bursts.

It

consists

of:

• A preamble of three words -

47

"0"

bits and one

"1"

bit,

• A word that contains the address - sector, head, and cylinder,

• A word of all zeros,

• A word containing information created by the Cyclic Redundancy Check (CRC) logic,

• A one-word postamble of all zeros.

]-4

Page 15

-

I

V.

I

....

----------------

6251£5

---------------.-.11

I I

.-62.51£5

....

I

I 1 I

J

SECTOR I I

PULSE

I •

:.

I I

>0--

-----------------,

__

'

__________________

l

.;"/

--------

---

......

-

......

-

....

"

PREAMBLE

ADDRESS

47 ZERO BITS

11

16

BITS

./

./

SECTOR

HEAD

SIX BITS

ONE

BIT

L

lSB

ZEROES

16 ZERO BITS

.....

.......

CYLINDER

NINE BITS

CRC

16 BITS

--

POSTAMBlE

16 ZERO BITS

16

BITIWORD

MODE

S BIT/BYTE

MODE

12 BITIWORD

MODE

Figure

1-3

RLOIK/RL02K Disk Cartridge Format

-

PREAMBLE

47

ZERO BITS

--

---

-

WORD 0

WORD 1

16

BITS

16

BITS

BYTE BYTE

I

0

1

I

SBITS

SBITS

·.If

I

WORD

0 WORD 1

I

12 BITS

12 BITS

t

L

MSB

I

lSB

..

DATA

CRC

POSTAMBlE

11

..

16

BITS

16

ZERO BITS

2048 BITS

.IL

.

-

......

"'-

......

I

I

WORD 126

WORD 127

.1

S.

16 BITS

16

BITS

f

•

I

BYTE

BYTE

J

254 255

8

BITS

8

BITS

,

,

WORD

168

WORD

169

UN-

USED

I

12

BITS

12

BITS

8 BITS

f

CZ·2C127

Page 16

The user writeable data area

follows

the header.

It

consists

of:

• A preamble of three words -

47

"0"

bits and one

"1"

bit,

• Data (128 words of

16

bits or 256 bytes of 8 bits or

170

words of

12

bits),

• A word containing CRC-generated information,

• A one-word postamble of all zero bits.

Following each sector

is

a period of idle tirne that

is

simply a wait for the next sector pulse.

In addition to the data tracks, there are tracks both inside and outside of the data area that contain

unique servo signals that define those areas as guard bands.

If

the read/write heads attempt to enter

a.

guard band, the drive logic causes the positioner to retreat from the guard band and return to data

are:a.

The disk has a nominal rotational speed of 2400 rev/min. Therefore, the time for one revolution

is

25

milliseconds. Since the revolution

is

divided into

40

sectors, the duration of each sector

is

625

nlicro·,

seconds. This 625 microsecond period

is

divided into non-data (sector pulse,

headel!",

idle time) time

and.

data time. The data time period

is

500 microseconds. Thus, the data

is

transferred in 500

bursts that occur every 625 microseconds.

For 16-bit word mode there are

128

words of data in a sector

so

the peak transfer rate

is

3.9

n(licro··

seconds per word and the average transfer rate

is

4.9 microseconds per word.

For 8-bit bytes (256 bytes per sector), the peak transfer rate

is

1.9

microseconds per byte and the aver

..

age transfer rate

is

2.4 microseconds per byte.

For 12-bit word mode

(170 words per sector), the peak transfer rate

is

2.9 microseconds per word and

the average transfer rate

is

3.7

microseconds per word.

1-6

Page 17

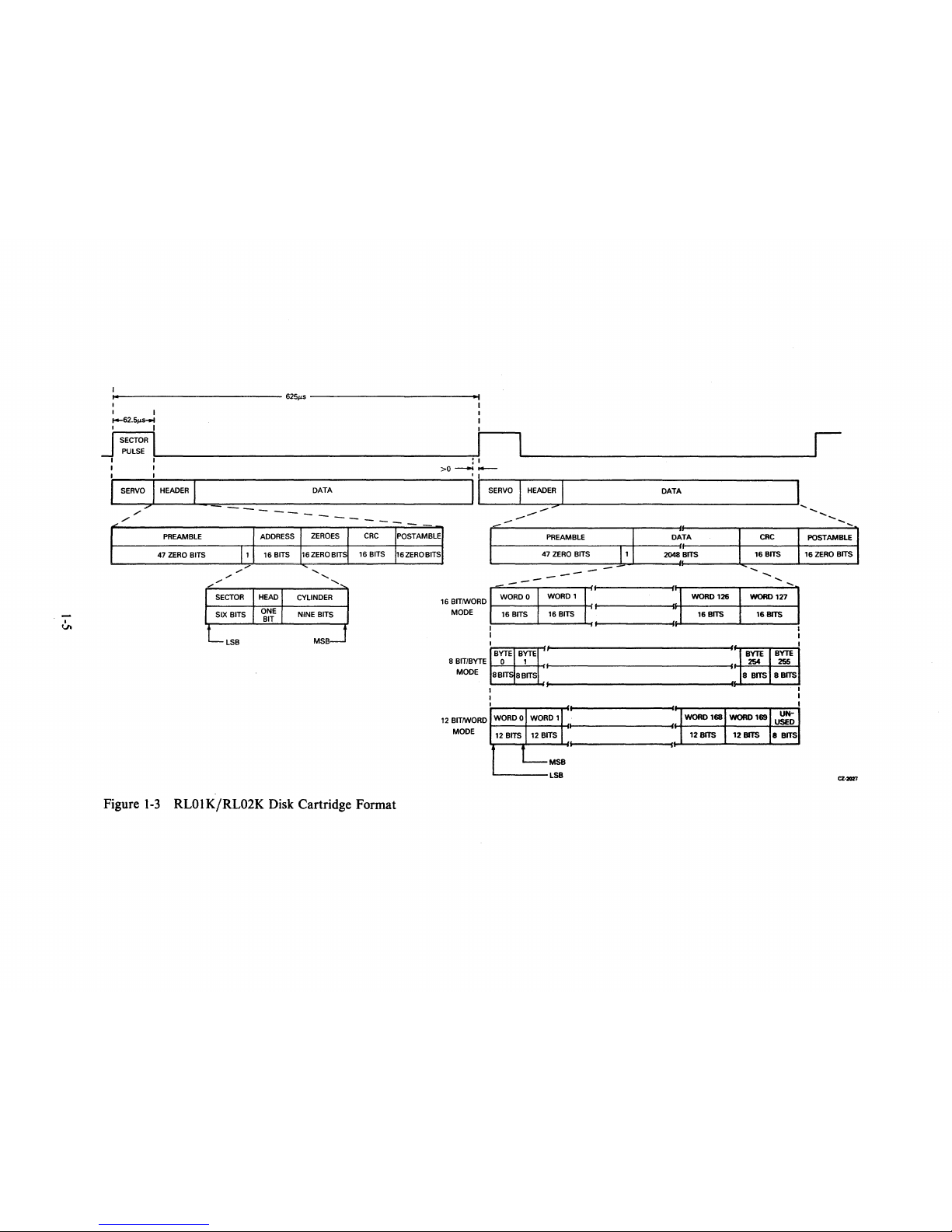

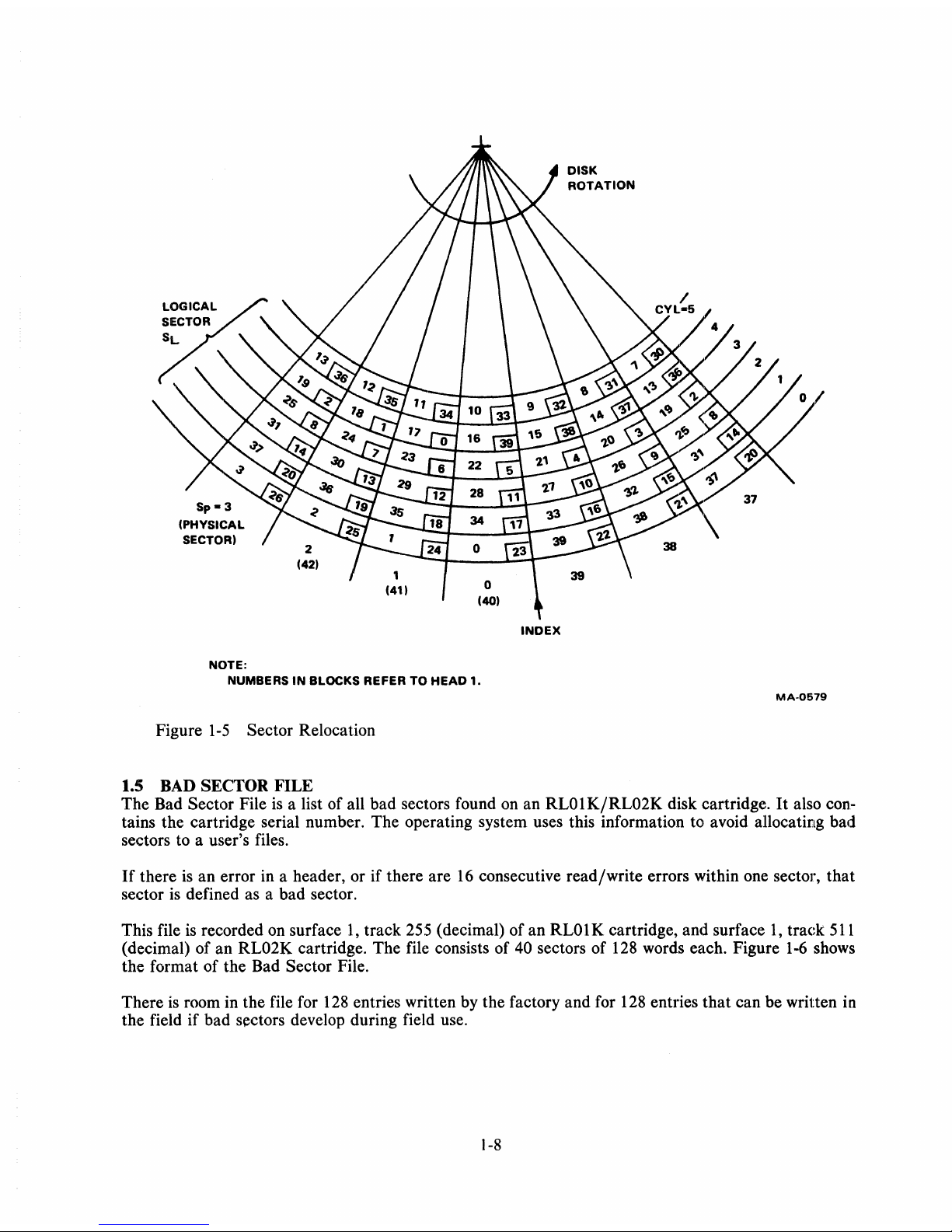

1.4 SECTOR LOCATION

The

RLOIK/RL02K

disk cartridges do not have a physical index notch (occurring once per revolution)

machined into the hub as some cartridges do.

The

controller determines the rotational position

of

the

disk cartridge by reading, from the header,

the

sector address as well as the head (surface) and cylinder

(track) addresses. Thus, the cartridge does not need a physical index.

The

sectors

are

relocated to opti-

mize the

data

transfer

rate

when it becomes necessary to perform a seek during a

data

transfer.

A head switch to the other surface is considered a seek because the

RLOI/RL02

subsystem uses servo

information

that

is

recorded on each track.

The

newly selected head will position itself over the center

of

the

track. There

is

no hardware-controlled implicit seek on the

RLOI/RL02

subsystem. All seeks,

including spiral (mid-transfer) seeks, must be programmed into the software.

The

correct head must be

selected and positioned over the correct

track

by a seek operation before the software

can

initiate a

data

transfer.

When

the end

of a track

is

reached and the

data

transfer has not been completed, the software must do

one

of

two things.

It

must switch to the head

that

is

over the corresponding

track

on

the

other surface

(6.5 milliseconds average, 8 milliseconds maximum) or the software must issue a seek to the next cylinder (15 milliseconds).

If

the head is to be switched also, the seek

and

the head switching are normally

combined.

Once the unit has completed

the

seek operation, the software

can

continue the

data

transfer.

To reduce

the

rotational latency following a head switch seek, surface one is offset by

17

sectors from

surface zero.

The

eight milliseconds head switch corresponds to

13

sectors

of

this offset and the addi-

tional four sectors allow for software overhead.

To reduce the rotational latency following a one cylinder seek (with head switch), surface 0

of

a cylin-

der is offset by 29 sectors from surface 1

of

the previous cylinder.

The

15

millisecond seek time takes

24 sectors

of

this offset

and

five more sector times are allowed for software overhead.

These two offset patterns are illustrated in Figures

1-4

and

1-5.

SURFACE

"0"

(HDS = 0)

SURFACE

"1"

(HDS

-1)

CYL

=0

I

1

2

I

Figure

1-4

Access Method for Sequential

Transfers

1-7

3

I

..

TO

SPINDLE

MA-0567

Page 18

Sp·

3

(PHYSICAL

SECTOR)

NOTE:

NUMBERS

IN

BLOCKS

REFER

TO

HEAD

1.

Figure

1-5

Sector Relocation

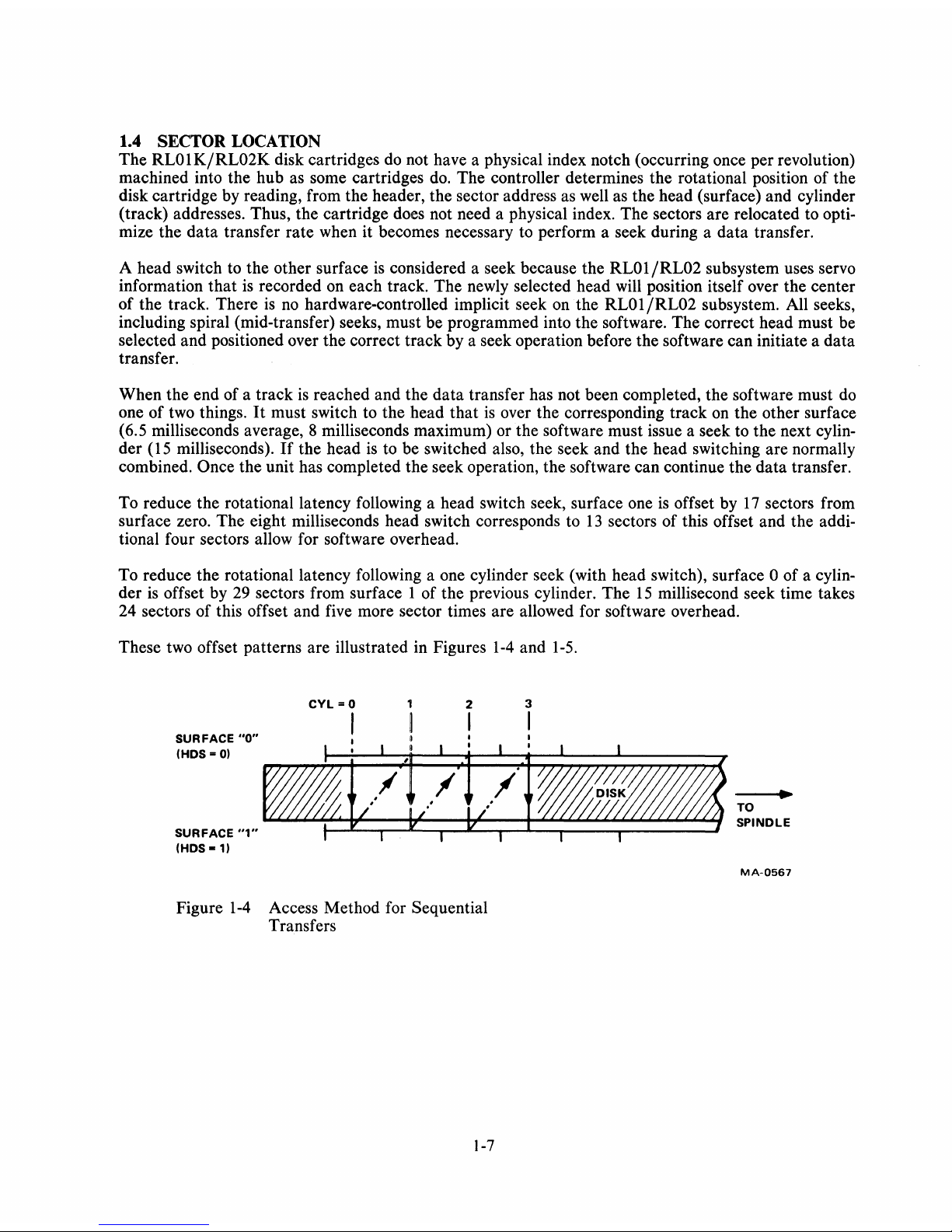

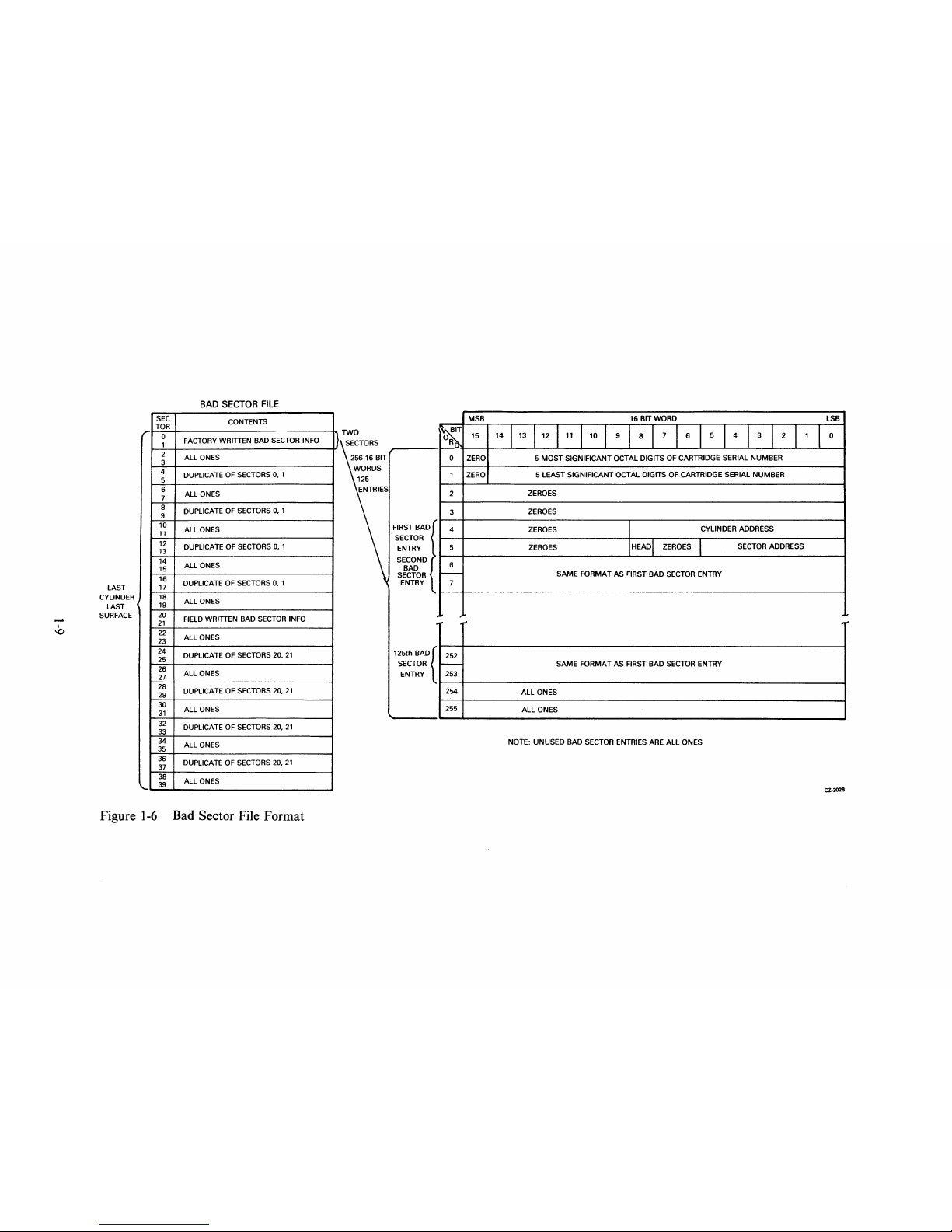

1.5

BAD

SECTOR FILE

INDEX

MA-0579

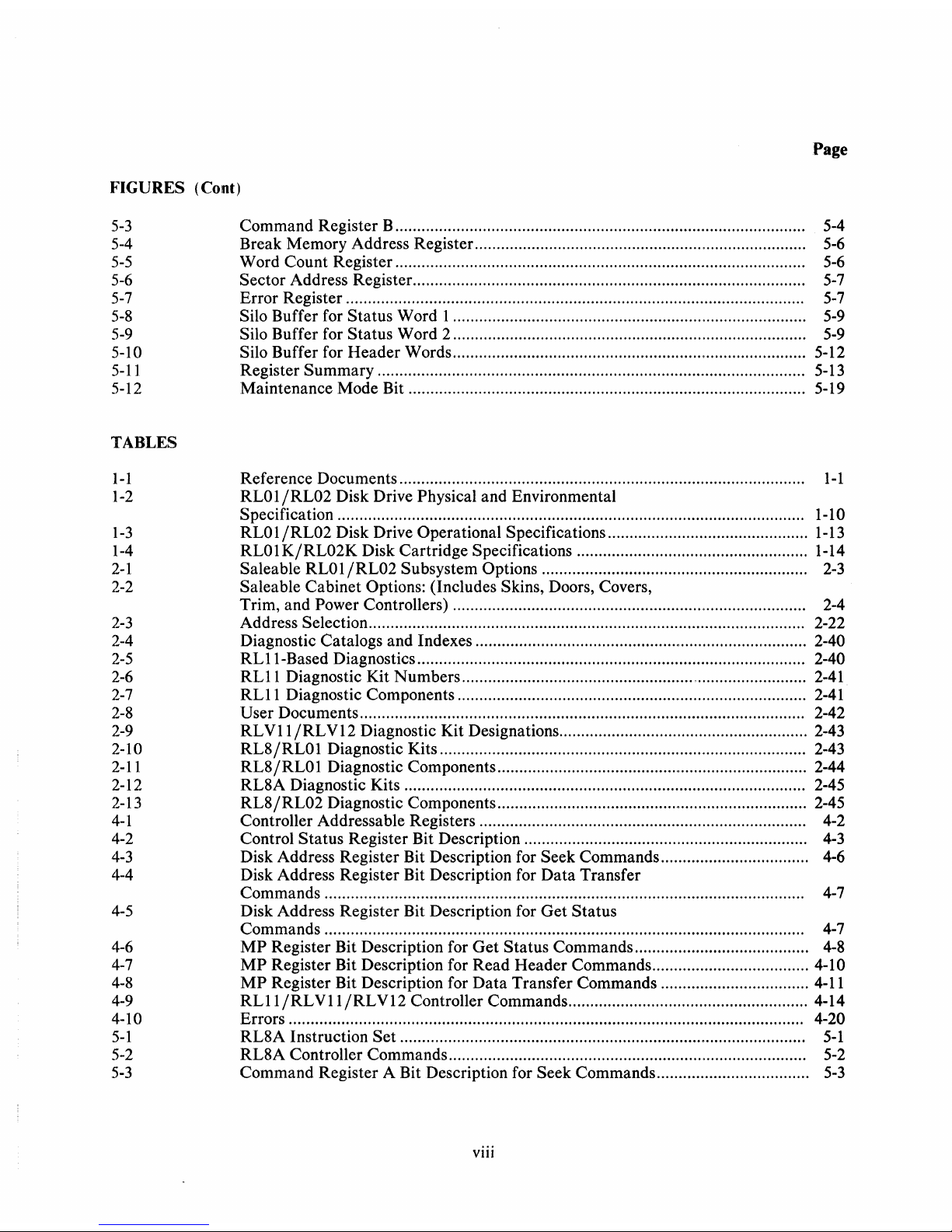

The Bad Sector File

is

a list of all bad sectors found

on

an

RLO 1 K/RL02K

disk cartridge.

It

also contains the cartridge serial number. The operating system uses this information to avoid allocating bad

sectors to a user's files.

If

there

is

an error in a header, or if there are

16

consecutive read/write errors within one sector, that

sector

is

defined as a bad sector.

This file

is

recorded

on

surface

1,

track

255

(decimal) of an RLOIK cartridge, and surface

1,

tra(!k

511

(decimal) of an RL02K cartridge. The file consists of

40

sectors of

128

words each. Figure

1-6

shows

the format of the Bad

Sector File.

There

is

room

in

the file for

128

entries written by the factory and for

128

entries that can be written

in

the field if bad sectors develop during field use.

1-8

Page 19

I

-.0

LAST

CYLINDER

LAST

SURFACE

SEC

TOR

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

BAD SECTOR FILE

CONTENTS

FACTORY

WRITTEN BAD SECTOR INFO

ALL ONES

DUPLICATE OF SECTORS 0, 1

ALL ONES

DUPLICATE OF SECTORS

0,1

ALL ONES

DUPLICATE OF SECTORS

0,1

ALL ONES

DUPLICATE OF SECTORS

0,1

ALL ONES

FIELD WRITTEN BAD SECTOR INFO

ALL ONES

DUPLICATE OF SECTORS 20,

21

ALL ONES

DUPLICATE OF SECTORS 20,

21

ALL ONES

DUPLICATE OF SECTORS 20,

21

ALL ONES

DUPLICATE OF SECTORS 20,

21

ALL ONES

Figure

1-6

Bad Sector File Format

TWO

SECTORS

25616

BIT

WORDS

125

ENTRIES

SECTOR

ENTRY

SECOND

BAD

SECTOR

ENTRY

.

125th BAD {

SECTOR

ENTRY

MSB

16

BIT

WORD

LSB

OR

15

14

113

112

1

11

1

10

1

9

8 1

7

1 6 1

5

1 4 1

3

1

2

11

1

0

0

ZERO

5

MOST

SIGNIFICANT OCTAL DIGITS OF CARTRIDGE SERIAL

NUMBER

1 ZERO

5 LEAST SIGNIFICANT

OCTAL

DIGITS OF CARTRIDGE SERIAL

NUMBER

2

ZEROES

3

ZEROES

4

ZEROES

CYLINDER ADDRESS

5 ZEROES

HEADl

ZEROES

I

SECTOR ADDRESS

6

f--

SAME

FORMAT

AS

"'IRST

BAD

SECTOR ENTRY

7

,

r'

,

.

252

f--

SAME

FORMAT

AS

FIRST BAD SECTOR ENTRY

253

254

ALL

ONES

255

ALL

ONES

NOTE:

UNUSED

BAD SECTOR ENTRIES ARE

ALL

ONES

CZ-2028

Page 20

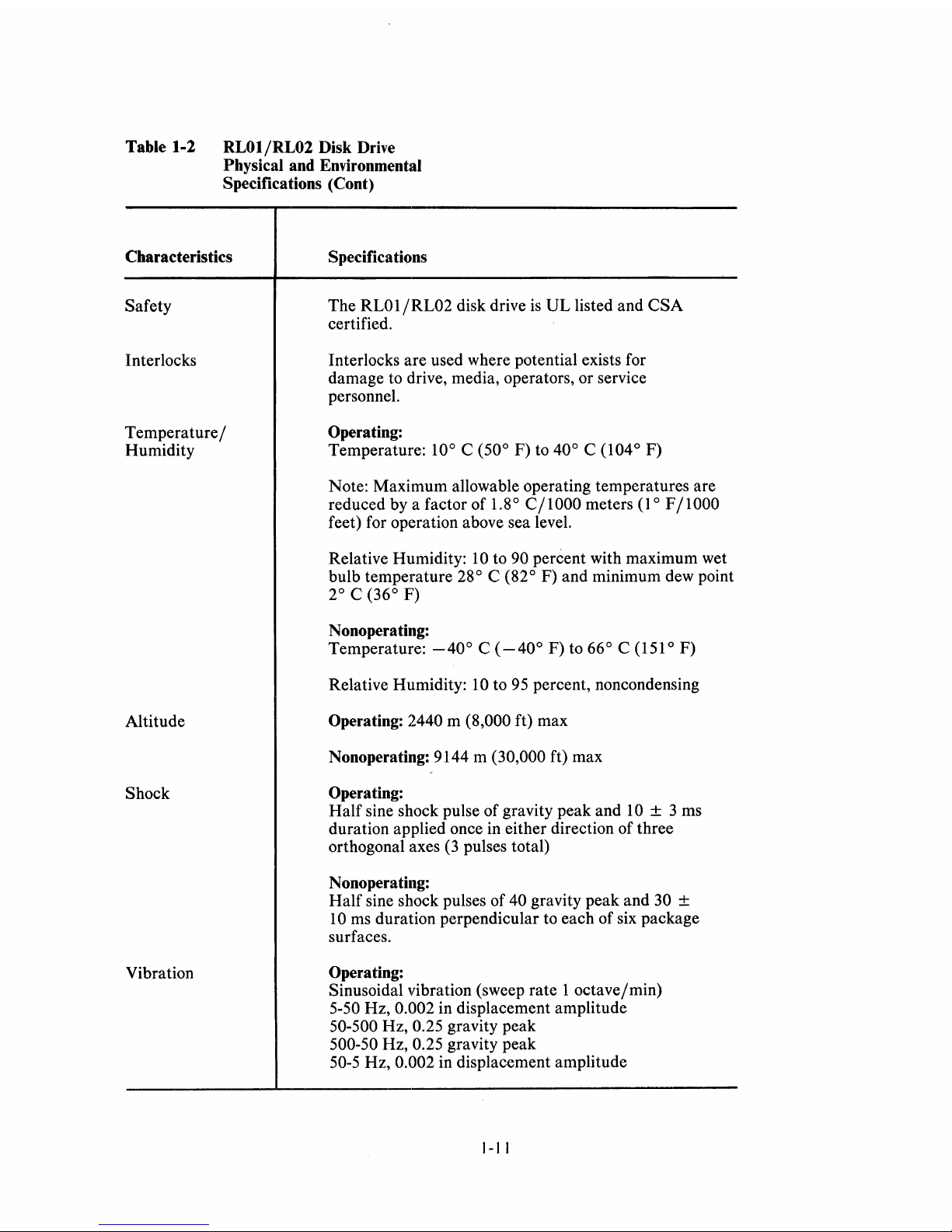

1.6 RLOI

jRL02

SPECIFICATIONS

The following tables list the specifications of the

RL01jRL02

drives and the

RL01KjRL02K

car-

tridges.

1.

Table

1-2

RL01jRL02

Disk Drive Physical and Environmental Specifications

2.

Table

1-3

RLO 1 KjRL02K

Disk Drive Operational Specifications

3.

Table

1-4

RL01K/RL02K

Disk Cartridge Specifications

Table 1-2 RLOljRL02 Disk Drive

Physical and Environmental

Specifications

Characteristics

Width

Depth

Height

Weight

Mounting

Power

Source

Input Power

Power Factor

Starting Current

Heat

Dissipation

Power Cord and

Connector

Specifications

Compatible with

19

inch

RETMA

rack

63.5 cm (25 in) behind bezel

26.52 cm (10.44 in)

34

kg

(75 lb)

The drive mounts

on

chassis slides

90-127 Vac (47.5-63 Hz)

180-256 Vac (47.5-63 Hz)

(Manually selectable)

160W

max

at

115 Vac, 60 Hz

Greater than 0.85

3.5A (rms) max

@ 90 Vacj47.5-63

Hz

5.0A (rms) max @

127

Vac/47.5-63 Hz

1.75A (rms) max

@ 180 Vac/47.5-63 Hz

2.5A (rms) max

@ 254 Vac/47.5-63 Hz

546

Btu/hr

max

A molded line cord compatible with the drive operating voltage and the

861

power control for 120

Vac

is

attached to the drive. The power cord

is

2.74 m

(9

ft)

long and the plug

is

NEMA

5-15P.

The

230 Vac plug to be attached to high voltage

drives

is

NEMA

6-15P.

1-10

Page 21

Table 1-2 RLOl/RL02 Disk Drive

Physical and Environmental

Specifications (Cont)

Characteristics

Safety

Interlocks

Temperature

/

Humidity

Altitude

Shock

Vibration

Specifications

The

RL01

/RL02

disk drive

is

UL

listed and

CSA

certified.

Interlocks are used where potential exists for

damage to drive, media, operators, or service

personnel.

Operating:

Temperature: 100 C (500 F) to 400 C (1040 F)

Note: Maximum allowable operating temperatures are

reduced by a factor

of

1.80 C/1000

meters (10 F

/1000

feet) for operation above sea level.

Relative Humidity:

10 to 90 percent with maximum wet

bulb

temperature

280 C (820 F) and minimum dew point

20 C (360 F)

Nonoperating:

Temperature:

-400 C

(-400 F) to 660 C (1510 F)

Relative Humidity: 10 to 95 percent, non condensing

Operating:

2440 m (8,000 ft) max

Nonoperating: 9144 m

(30,000

ft)

max

Operating:

Half

sine shock pulse

of

gravity peak and 10 ± 3 ms

duration applied once in either direction of three

orthogonal axes (3 pulses total)

Nonoperating:

Half

sine shock pulses of 40 gravity peak and 30 ±

10 ms duration perpendicular to each of six package

surfaces.

Operating:

Sinusoidal vibration (sweep

rate

1 octave/min)

5-50 Hz, 0.002 in displacement amplitude

50-500 Hz, 0.25 gravity peak

500-50 Hz, 0.25 gravity peak

50-5 Hz, 0.002 in displacement amplitude

I-I

I

Page 22

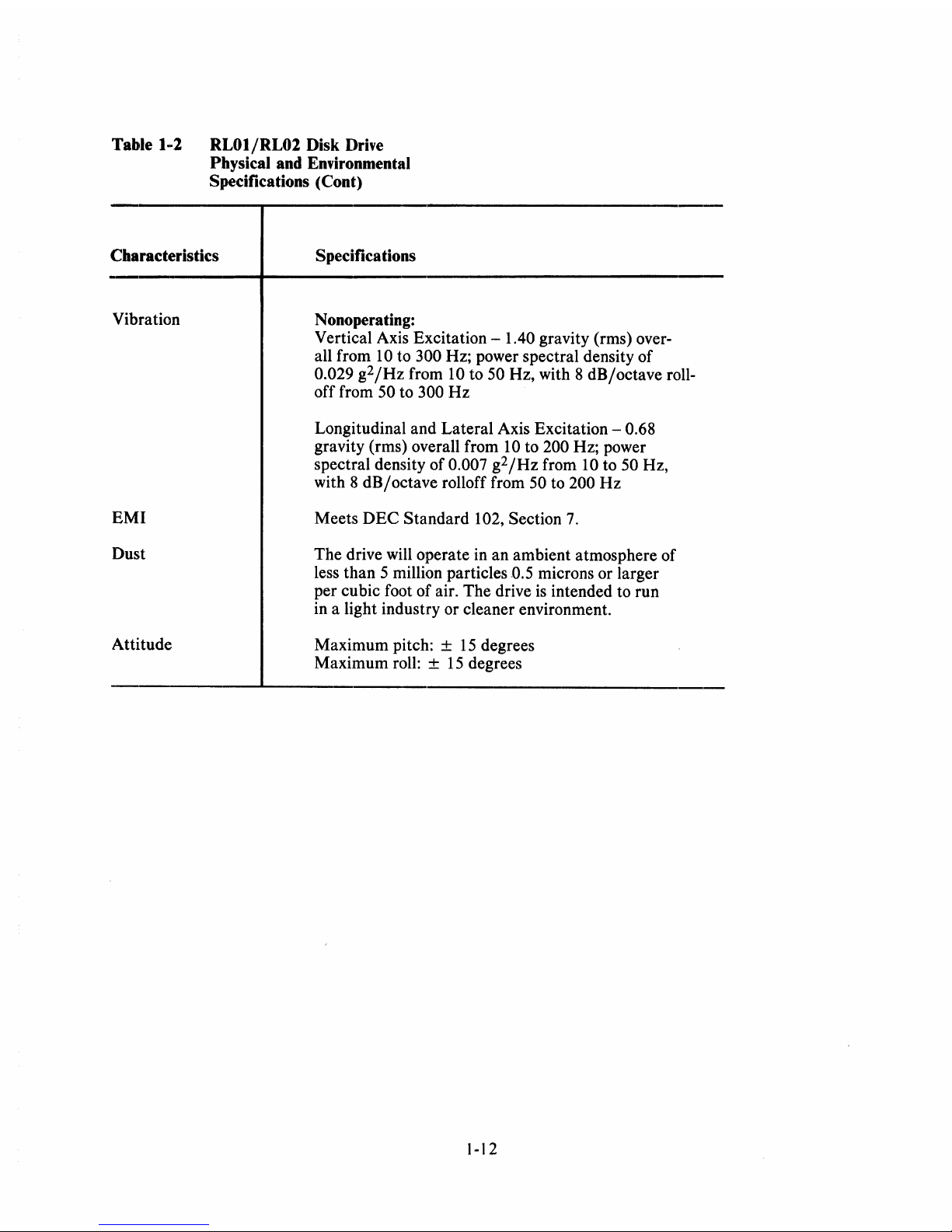

Table 1-2 RLOI/RL02 Disk Drive

Physical

and

Environmental

Specifications (Cont)

Characteristics

Vibration

EMI

Dust

Attitude

Specifications

Nonoperating:

Vertical Axis Excitation - 1.40 gravity (rms) overall from

10 to 300 Hz; power spectral density

of

0.029

g2/Hz

from 10 to 50 Hz, with 8

dB/octave

roll-

off from

50 to 300

Hz

Longitudinal and

Lateral

Axis Excitation - 0.68

gravity (rms) overall from

10 to 200 Hz; power

spectral density

of

0.007

g2/Hz

from 10 to 50 Hz,

with 8

dB/octave

rolloff from 50 to 200

Hz

Meets

DEC

Standard

102, Section

7.

The

drive will operate in

an

ambient atmosphere

of

less

than

5 million particles 0.5 microns or larger

per cubic foot

of

air.

The

drive is intended to run

in a light industry or cleaner environment.

Maximum

pitch: ±

15

degrees

Maximum

roll: ±

15

degrees

1-12

Page 23

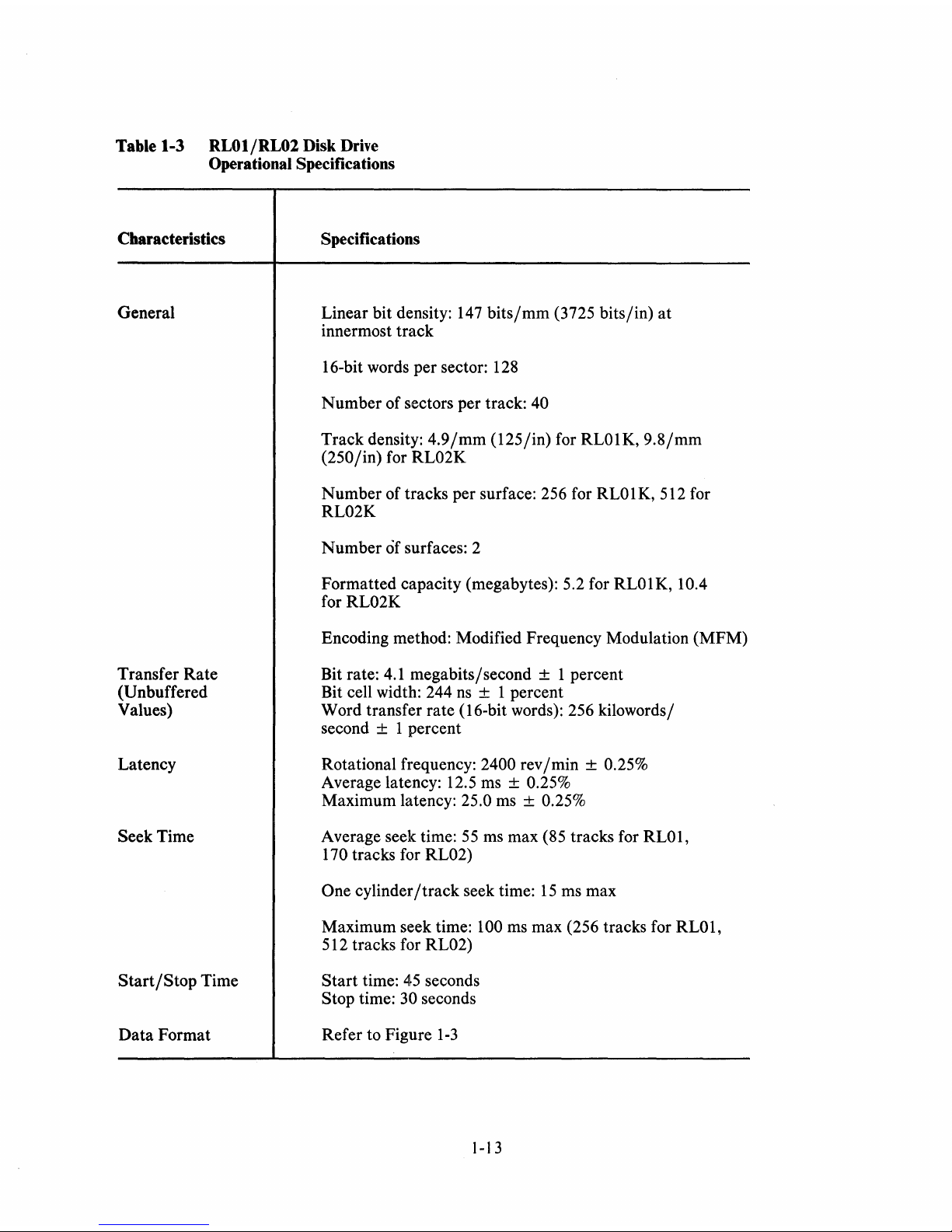

Table 1-3 RLOI/RL02 Disk Drive

Operational Specifications

Characteristics

General

Transfer

Rate

(Unbuffered

Values)

Latency

Seek Time

Start/Stop

Time

Data

Format

Specifications

Linear bit density: 147

bits/mm

(3725 bits/in)

at

innermost track

16-bit words per sector: 128

Number

of sectors per track: 40

Track density:

4.9/mm

(125/in) for RL01K,

9.8/mm

(250/in) for

RL02K

Number

of tracks per surface: 256 for RL01K, 512 for

RL02K

Number

of surfaces: 2

Formatted capacity (megabytes): 5.2 for

RL01K,

lOA

for RL02K

Encoding method: Modified Frequency Modulation (MFM)

Bit rate:

4.1

megabits/second ± 1 percent

Bit cell width: 244 ns

± 1 percent

Word transfer rate (16-bit words): 256 kilowords/

second ± 1 percent

Rotational frequency:

2400 rev/min ± 0.25%

Average latency: 12.5 ms ± 0.25%

Maximum latency: 25.0 ms ± 0.25%

Average seek time:

55

ms max (85 tracks for RL01,

170 tracks for RL02)

One cylinder/track seek time:

15

ms max

Maximum seek time:

100 ms max (256 tracks for RL01,

512 tracks for RL02)

Start

time:

45

seconds

Stop time: 30 seconds

Refer to Figure

1-3

1-13

Page 24

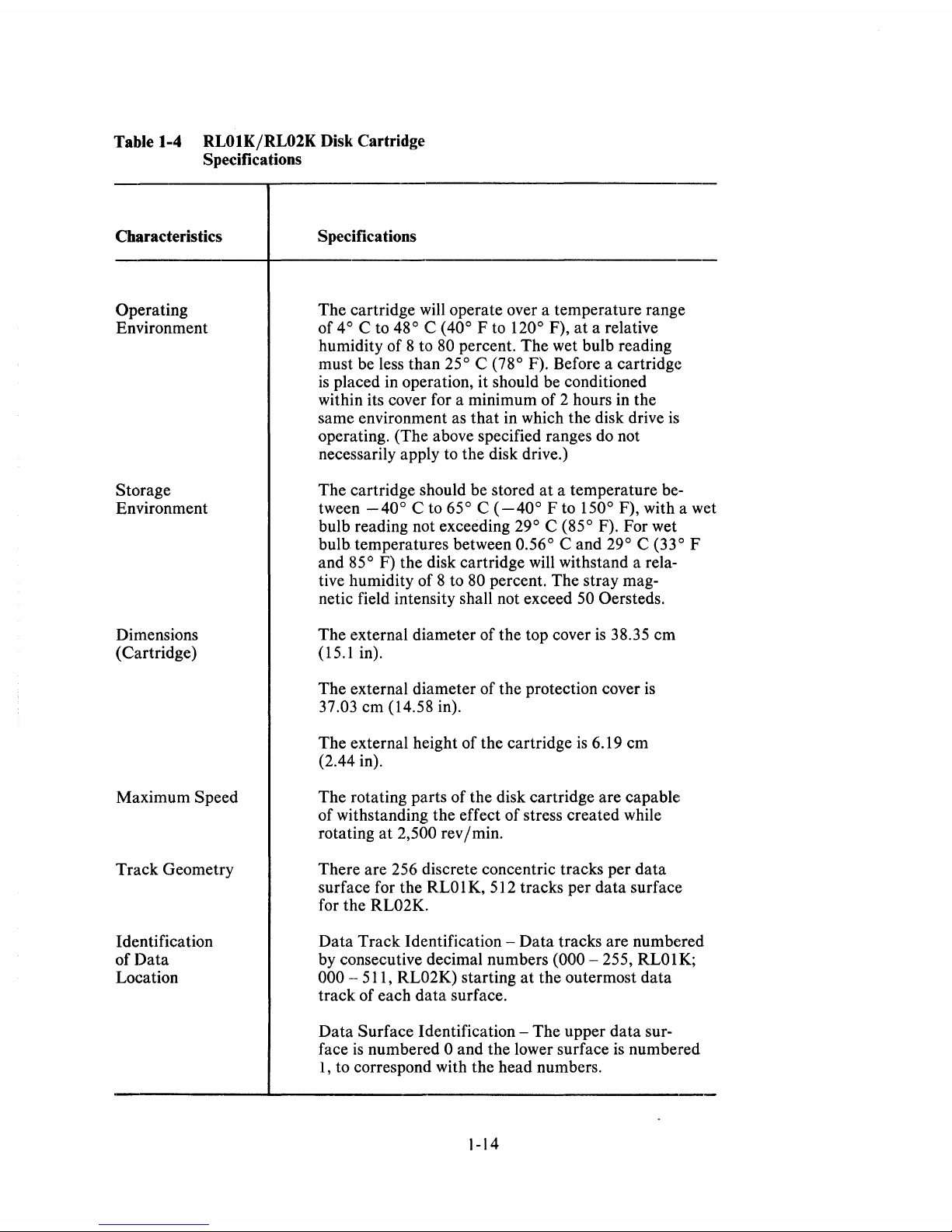

Table 1-4 RLOIKjRL02K Disk Cartridge

Specifications

Characteristics

Operating

Environment

Storage

Environment

Dirnensions

(Cartridge)

Maximum

Speed

Track Geometry

Identification

of Data

Location

Specifications

The cartridge

will

operate over a temperature range

of

4° C to 48° C (40° F to 120° F),

at

a relative

humidity of 8 to

80

percent. The wet bulb reading

must be less than

25° C (78° F). Before a cartridge

is

placed in operation, it should be conditioned

within its cover for a minimum of 2 hours in the

same environment as that in which the disk drive

is

operating. (The above specified ranges do not

necessarily apply to the disk drive.)

The cartridge should be stored

at

a temperature be-

tween

-400 C to

650 C

(-400 F to 150° F), with a wet

bulb reading not exceeding

29° C (85° F). For wet

bulb. temperatures between

0.56° C and

29

0

C (33

0

F

and

85° F) the disk cartridge will withstand a rela-

tive humidity of 8 to

80

percent. The stray mag-

netic field intensity shall not exceed

50 Oersteds.

The external diameter of the top cover

is

38.35 cm

(15.1 in).

The external diameter of the protection cover

is

37.03 cm (14.58 in).

The external height of the cartridge

is

6.19 cm

(2.44 in).

The rotating parts of the disk cartridge are capable

of withstanding the effect of stress created while

rotating

at

2,500 rev Imin.

There are 256 discrete concentric tracks per data

surface for the

RLO 1 K,

512 tracks per data surface

for the

RL02K.

Data Track Identification - Data tracks are numbered

by consecutive decimal numbers

(000 - 255, RLOIK;

000

- 511, RL02K) starting

at

the outermost data

track of each data surface.

Data Surface Identification - The upper data surface

is

numbered 0 and the lower surface

is

numbered

1, to correspond with the head numbers.

1-14

Page 25

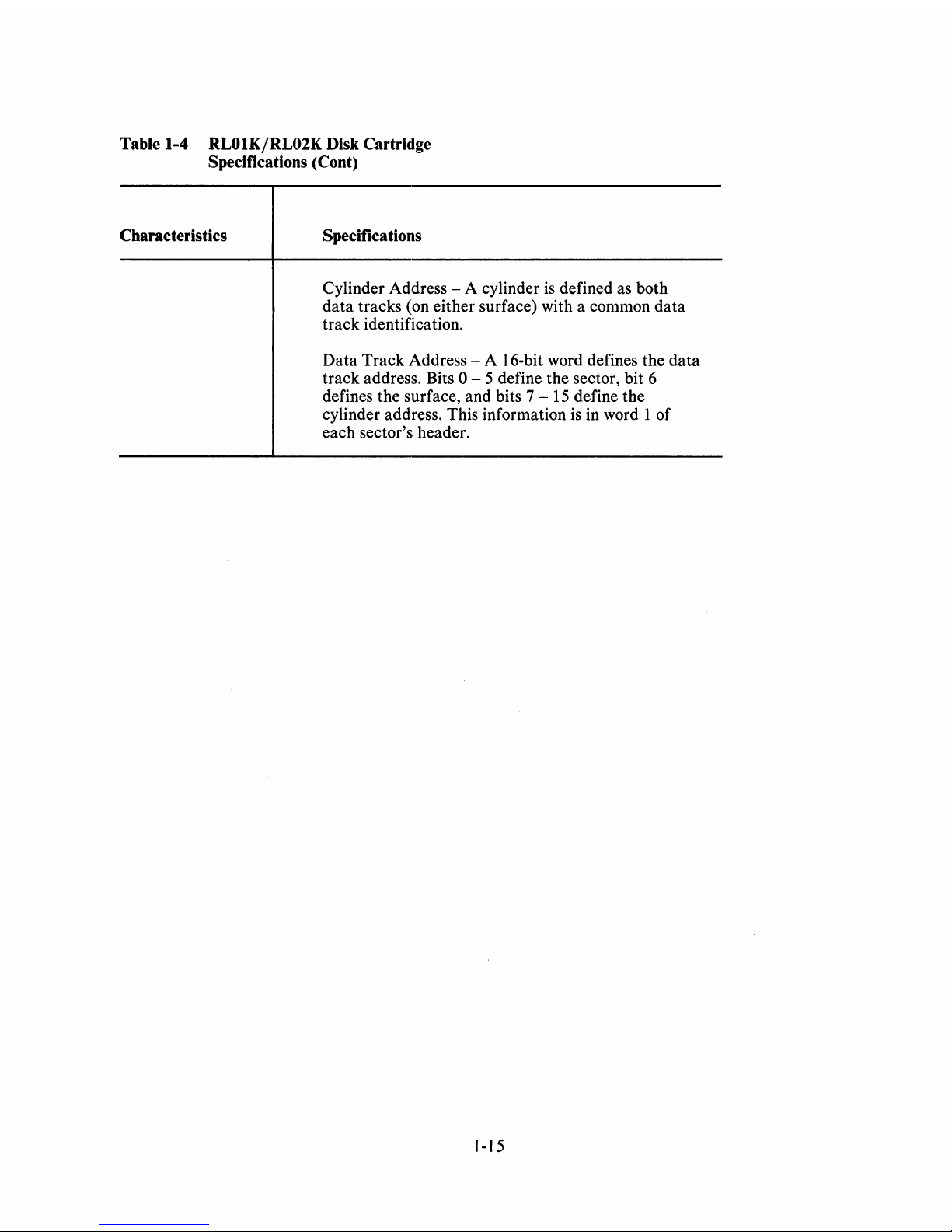

Table 1-4 RLOIKjRL02K Disk Cartridge

Specifications (Cont)

Characteristics Specifications

Cylinder Address - A cylinder

is

defined as both

data tracks (on either surface) with a common data

track identification.

Data Track Address - A 16-bit word defines the data

track address. Bits

0 - 5 define the sector, bit 6

defines the surface, and bits 7 -

15

define the

cylinder address. This information

is

in word 1 of

each sector's header.

1-15

Page 26

Page 27

2.1

SITE

PREPARATION

AND

PLANNING

CHAPTER 2

INSTALLATION

This

chapter

describes power, space, environmental, cabling, and safety requirements

that

must be con-

sidered before installation

of

the

RLOl/RL02

disk subsystem.

2.1.1 Environmental Considerations

The

RLOl/RL02

disk subsystem is designed to operate in a business or light industry environment.

Although cleanliness is

an

important consideration in the installation

of

any computer system, it is par-

ticularly crucial for proper operation

of

a disk drive.

The

RLO 1 K/RL02K

disk cartridge is not sealed

while being loaded and is therefore vulnerable to dust or smoke particles suspended in the air, as well as

to fingerprints, hair, lint, etc. These minute obstructions can cause head crashes, resulting in severe

damage to the

read/write

heads and disk surfaces.

2.1.1.1

Cleanliness -

The

RLOl/RL02

disk drives

can

operate in

an

ambient with less than five mil-

lion particles per cubic foot of air which are

0.5 micron or larger in diameter.

The

drive contains a filter

system which, under these conditions, maintains the particle count within the cartridge below 100 particles per cubic foot.

2.1.1.2 Space Requirements - Provision should be made for service clearances

of

1 m (39 in)

at

the

front

and

rear

of

the rack or cabinet in which the drive

is

mounted and 1 m (39 in)

at

either side.

Storage space for the

RLOIK/RL02K

cartridges should also be made available.

Each

cartridge has a

diameter

of

approximately 38

cm

(15 in) and a height

of

approximately 6

cm

(2.5 in).

CAUTION

RL01K/RL02K

disk cartridges must never be

stacked on top

of

each other. A designated shelf area

or

specially designed disk cartridge storage unit is

recommended (see the DIGITAL

Supplies and Ac-

cessories Catalog).

2.1.1.3

Floor Loading -

The

weight

of

the

RLOl/RL02

disk drive alone

is

34 kg (75 lb), which will

not place undue stress on most floors. However, the added weight

of

the rack or cabinet as well as the·

number

of

drives to be installed should be considered in relation to the weight

of

existing computer

systems. Possible future expansion should also be a consideration.

2.1.1.4

Heat

Dissipation -

The

heat

dissipation

of

each

RLOl/RL02

disk drive is 546

Btu/hour

max-

imum.

The

approximate cooling requirements for the entire system can be calculated by multiplying

this figure by the number

of

drives, adding the result to the total

heat

dissipation

of

the other system

components,

and

then adjusting

the

total figure to compensate for personnel, cooling system efficiency,

etc.

It

is advisable to allow a safety margin of

at

least

25

percent above the maximum estimated re-

quirements.

2-1

Page 28

2.1.1.5 Acoustics - Most computer sites require

at

least some degree of acoustical treatment. How-

ever, the

RLOl/RL02

disk subsystem should not contribute unduly to the overall system

leve:1.

Ensure

that

acoustical materials used do not produce or harbor dust.

2 . .1.1.6 Temperature - The

RLOl/RL02

disk subsystem operates over a temperature range of

10

0

C

(500 F) to 400 C (1040 F). The maximum temperature gradient

is

16.60 C (300 F) per hour. The non-

operating temperature range

is

from

-400 C

(-40

0

F) to 66

0

C (151

0

F).

2 . .1.1.7 Relative Humidity - Humidity control

is

important for proper operation of any computer system since static electricity may cause memory errors or even permanent danlage to logic components.

The

RLOI/RL02

disk subsystem

is

designed to operate within a relative humidity range of

10

to 90

percent with a maximum wet bulb temperature of

280 C (82

0

F) and a minimum dew point of 2

0

C

(36

0

F). The nonoperating relative humidity range

is

from

10

to 95 percent, with a maximum wet

bullb

temperature of 460 C (115

0

F).

2.1.1.8 Altitude - Computer systems operating

at

high altitudes may have heat dissipation problems.

Altitude also affects the flying height of

read/write

heads in disk drives. The maximum altitude speci-

fied for operating the

RLOI/RL02

disk subsystem

is

2440 m (8000 ft). Also, the maximum allowable

operating temperature

is

reduced by a factor of 1.80 C per 1000m

(l0

F per 1000 ft) above sea

level

Thus, the maximum allowable operating temperature

at

2440 m (8000 ft) would be reduced to 360 C

(96

0

F).

2.1.1.9 Power and Safety Precautions - The

RLOI/RL02

disk subsystem presents

no

unusual fire or

safety hazards to an existing cOlnputer system.

AC

power wiring should be checked carefully, however,

to ensure

that

its capacity

is

adequate for the added load as well as for any possible expansion. The

RLO 1 /RL02

disk drive

is

UL

listed and

CSA

certified.

2.1.1.10 Radiated Emissions - Any source of electromagnetic interference

(EMI)

that

is

near the

computer system may affect the operation of the processor and its related peripheral equipment

..

Conl-

m.on

EMI

sources

that

are known causes of failures include:

•

Thunderstorms,

•

Broadcast stations,

•

Radar,

•

Mobile communications,

•

High-voltage power lines,

•

Power tools,

•

Arc welders,

•

Vehicle ignition systems,

•

Static

electricity.

The effect of radiated

EMI

emissions on a computer system

is

unpredictable. Thus, grounding plays an

inlportant role in protecting the circuits used in disk drive subsystems.

To help reduce the effects of known high-intensity

EMI

emissions, perform the following actions:

• Ground window screens and other large metal surfaces,

• Ensure

that

the overall computer system

is

grounded properly (refer to Paragraph 2.1.5,

Grounding Requirements),

• Provide proper storage (metal cabinets with doors) for disk cartridges.

2-2

Page 29

2.1.1.11 Attitude/Mechanical Shock - Performance of the

RL01/RL02

disk subsystem will not be

affected by an attitude where maximum pitch and roll do not exceed

15

degrees.

The subsystem

is

designed to operate while a half-sine shock pulse of

10

gravity peak and

10

± 3 ms

duration

is

applied once in either direction of three orthogonal axes (three pulses total).

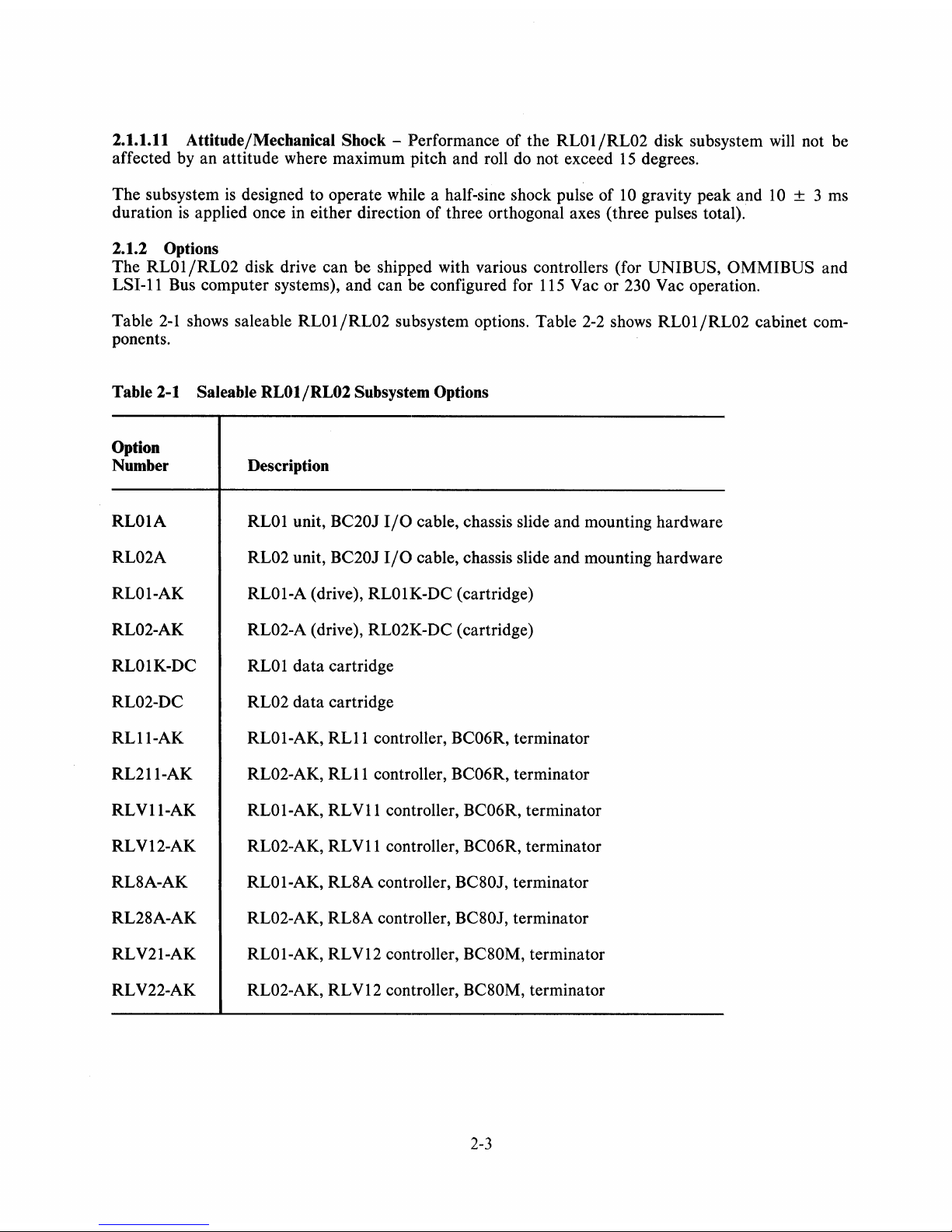

2.1.2 Options

The

RL01/RL02

disk drive can be shipped with various controllers (for UNIBUS,

OMMIBUS

and

LSI-II

Bus computer systems), and can be configured for

115

Vac or 230 Vac operation.

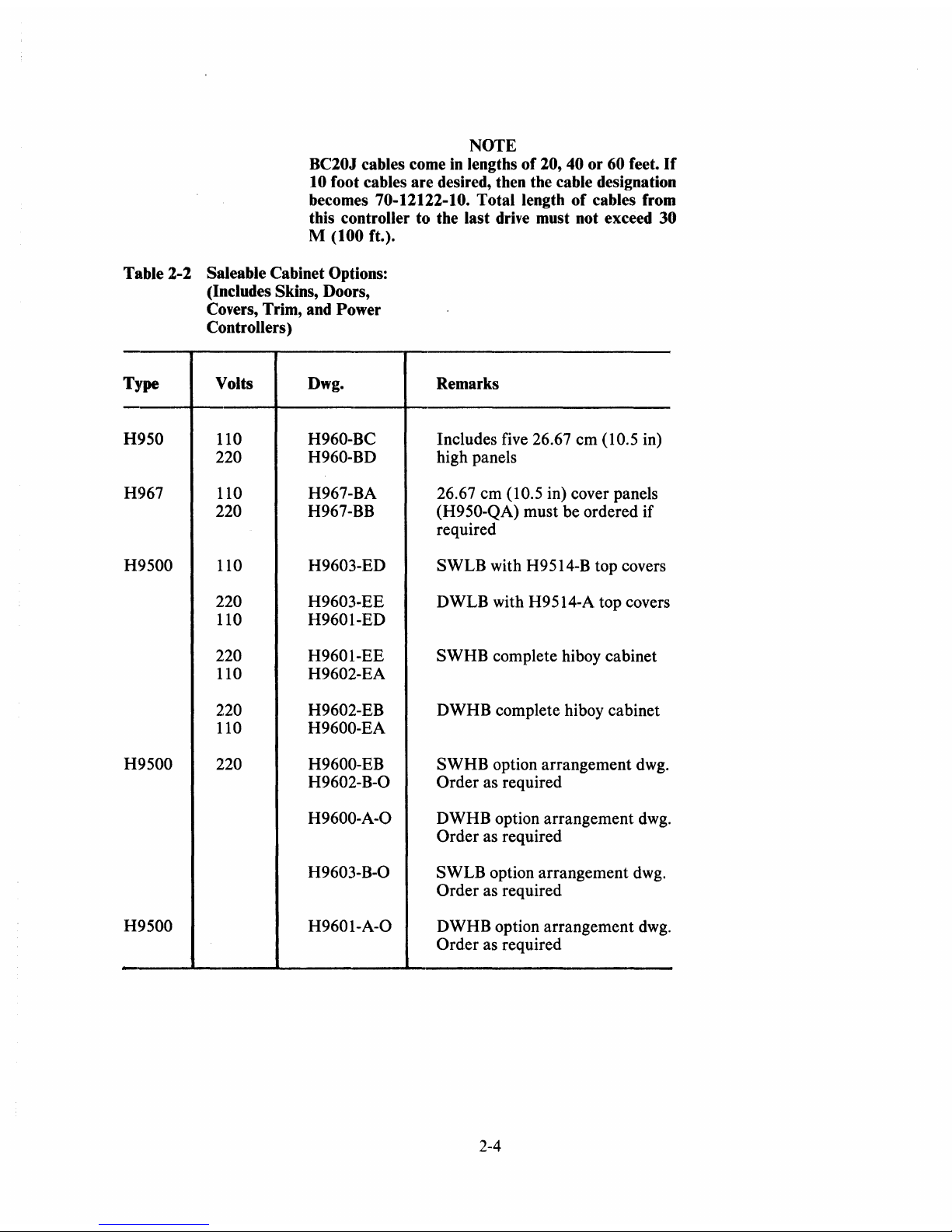

Table

2-1

shows saleable

RL01/RL02

subsystem options. Table

2-2

shows

RL01/RL02

cabinet com-

ponents.

Table 2-1 Saleable

RLOI/RL02 Subsystem Options

Option

Number

RL01A

RL02A

RL01-AK

RL02-AK

RL01K-DC

RL02-DC

RL11-AK

RL211-AK

RLV11-AK

RLV12-AK

RL8A-AK

RL28A-AK

RLV21-AK

RLV22-AK

Description