Page 1

EK-ORAS1-UG-

001

RA81

User

. Disk Drive

Guide

Page 2

EK-ORA81-UG-

001

RA81

User

Disk Drive

Guide

Prepared

Digital Equipment Corporation

by

Educational Services

of

Page 3

Copyright © 1982

All Rights Reserved

by

Digital Equipment Corporation

The

material

in

this manual is for informational purposes and is subject to change

without notice.

Digital Equipment Corporation assumes no responsibility for any errors which

may appear

in

this manual.

Printed

in

U.S.A.

This document was set on DIGITAL's computerized type-setting system.

• Class A Computing Devices:

Notice:

The equipment has been type tested and found to

Class A computing device pursuant to Subpart J

are designed to provide

terference when operated

ment

own expense may be required

This equipment generates, uses, and may emit radio frequency energy.

comply with the limits for a

of

Part 15

of

FCC Rules

..

reasonable protection against such radio frequency

in

a commercial environment. Operation

in

a residential area may cause interference

to

take measures

in

which case the user

to

correct the interference.

of

this equip-

which

in-

at

his

following are trademarks

The

chusetts:

DEC

DECUS

DIGITAL

Digital

Logo

PDP

UNIBUS

VAX

of

Digital Equipment Corporation, Maynard, Massa-

DECnet

DECsystem-10

DECSYSTEM-20

DECwriter

DIBOL

EduSystem

lAS

OMNIBUS

OS/8

PDT

RSTS

RSX

VMS

VT

MASSBUS

11

Page 4

CONTENTS

Page

CHAPTER 1

1.1

1.2

1.3

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

1.4

1.5

1.6

CHAPTER 2

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.2

2.2.1

2.2.2

2.2.3

2.3

2.3.1

2.3.2

2.3.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4.9

INTRODUCTION

PURPOSE AND SCOPE

GENERAL INFORMATION

DRIVE DESCRIPTION

Head Disk Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Internal Drive Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-Drive and

Recording Features

Media Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RELATED

RA81

RA81

INSTALLATION

SITE PREPARATION AND PLANNING

Environmental Considerations

Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floor Loading

Heat Dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC

EQUIPMENT UNPACKING AND EXTERNAL INSPECTION. . . . . . . . . . . . . 2-2

Unpacking the System on a Shipping

Installing the Cabinet Levelers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Removing Internal Shipping Brackets and

RA81

Connecting Cabinets

External SDI Cabling Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Programming the Drive Unit Address Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

RA81

Remove the Front Trim Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Install the Slide Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove the Internal Shipping Brackets and

Mount the RA81 on the

Program the Drive

Connect the Electrostatic Discharge

Install the Internal SDI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Mount the

Install the Drive Sequence Cables

DOCUMENTATION

SPECIFICATIONS

OPTIONS

Power Wiring

Packing Material

INSTALLATION.

ADD-ON INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Packing Material

...................................................

I/O

Bulkhead.

............................................

... " .. " ..............

.............................................

Dual-Port Capability

.............................................

... , ...............

...........................

..................

.................................................

..............................................

...........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

............................................

...........................................

Slides.

Unit Address Plug

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

..............................

.............

Pallet

. . . . . . . . . . . . . . . . . . . . . .

Bracket.

.................................

.........................

...................

. . . . . . . . . . . . . . . . . . . . . . . . 2-30

"

....... , '"

, "

.. " ........

'.

. . . . . . . . . . . . . . . . 1-9

~

................

;<

. . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . 2-25

. . . . . . . . . . . 2-30

. " . .

'"

1-1

1-1

1-2

11-5

11-

. 1-8

1-12

,

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-2

2-6

2-10

2-

21

2-

25

2-33

2

7

7

1II

Page 5

Page

QHAPTER 2

2.4.10

204.11

2.S

2.S.1

2.S.2

2.S.3

CHAPTER 3

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.S

3.2

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

304.3

INSTALLATION (Cont)

Connect AC Power

Route and Clamp the Cables

RA81 DRIVE

The Diagnostic Terminal

Applying

Checkout

OPERA TING INSTRUCTIONS

CONTROL

RUN/STOP

FA

UL

UNIT/READY

WRITE

A and B

CIRCUIT BREAKERS

DRIVE

Spin-Up

Spin-Down

Removing RA81

CUSTOMER

Air-Filter

Cleaning

Replacement

DIAGNOSTIC

Power to the Drive

....................................................

PANEL SWITCHES AND INDICATORS

Switch and Indicator

T Switch and Indicator

PROT

Port Select Switches

OPERATION

.....................................................

.......

CARE

....................................................

.....................................................

..................................................

.. , .........................................

CHECKOUT

........................................

................................................

................................................

.........................................

........

"

......

Power

.....................

...............................................

.....................................

............................

....................................

..........

.................................

....................................

....................................

,

............................

"

.....................

'

....................

,

...

,

....... , ...

'"

"

..

.,

"

, .

.

2-36

.

2-36

.

2-38

.

2-38

.

2-39

.

2-39

.

3-1

.

3-2

.

3-3

.

3-S

.

3-S

.

3-6

3-6

.

3-6

3-6

.

3-6

3-6

.

3-6

.

3-6

.

.

3-7

.

3-7

APPENDIX A

A.l

A.2

A.3

AA

A.S

A.6

A.7

A.8

A.9

A.I0

FIGURES

1-1

1-2

1-3

1-4

1-5

1-6

1-7

2-1

2-2

2-3

2-4

2-5

2-6

DIAGNOSTIC TERMINAL INSTRUCTIONS

INTRODUCTION

SHIFf

CONTROL

CONTINUE (CONT) AND

X-ON, X-OFF KEYS

DELETE

DISPLAY

BREAK

CR

ESCAPE

The RA81 Disk Drive

Basic RA81 Disk-Subsystem Block Diagram

Hinged Circuit-Module Arrangement

Bingle-Port, Multi-Drive Configuration

Dual-Port Configuration

HDA

RA81

RA81 Electrical

Unpacking a

Building the Ramp

Shipping Bracket Removal

Cabinet Leveler Installation

Leveler Adjustment

KEyS

CHARACTERS

KEy

SCROLL SWITCH

KEy

KEY (CARRIAGE RETURN)

KEy

Head Arrangement

Sector Format

..................................

.....................................................

.........................................

CLEAR

.... , ....... , .................................

....................................................

.....................................................

....................................................

..............................................

............................................

..................

...............................................

Plugs and Receptacles

System

on

a Shipping Pallet

.................................................

..........................................

.........................................

................................................

(CLR) KEYS

.......................................

....................................

...........................

..................................

................................

................................

..............................

,

'

...............

......................

.........................

.

A-I

.

A-2

A-2

.

.

A-2

A-2

.

A-2

.

A-2

.

.

A-3

.

A-3

.

A-3

.

1-3

.

1-4

.

I-S

.

1-6

.

1-6

.

1-7

.

1-7

.

2-2

.

2-3

.

2:-4

.

2-S

.

2-S

.

2-6

iv

Page 6

Page

FIGURES

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

2-25

2-26

2-27

2-28

2-29

2-30

2-31

2-32

2-33

2-34

2-35

2-36

2-37

2-38

2-39

2-40

2-41

2-42

2-43

2-44

2-45

3-1

3-2

3-3

A-I

(Cont)

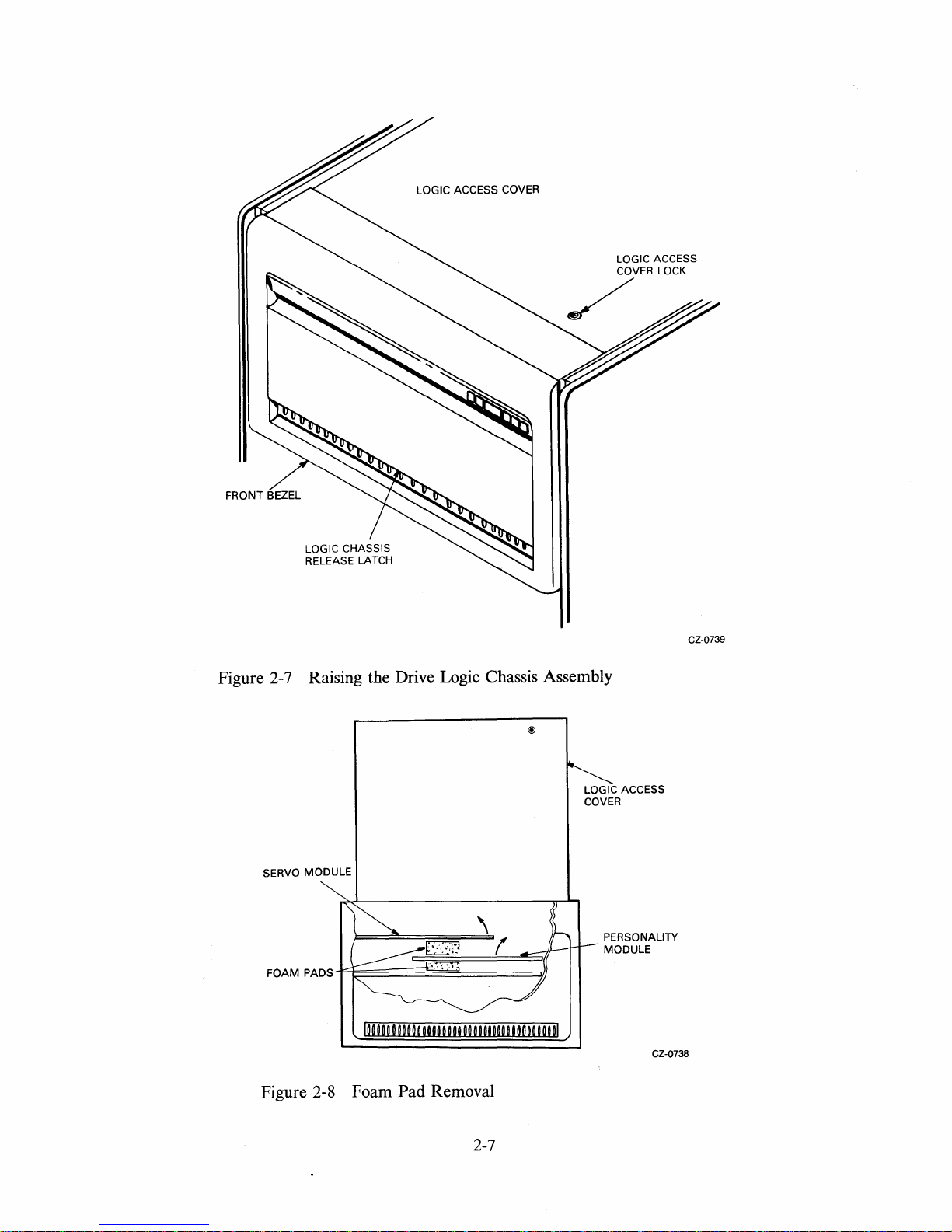

Raising the Drive Logic Chassis Assembly

Foam

Pad Removal

HDA

Details

Belt Tension Lever

Belt tension

End

Panels

Opening the

Back

Door

End-Panel

Connecting the Cabinets

Removing the

Installing the Front Locking Bracket

Installing the

SOl

Cable Shield Terminator Installation

Single Drive External

Drive

Removing Cabinet

Chassis

Mounting Chassis

Mounting Chassis

Mounting the Electrostatic Discharge Bracket

Installation

Installation

Installation

Removal

HDA

Positioner

Extending

Extending the Chassis

Pivot

Wing

Electrostatic Discharge Bracket Details

Cabling for a Two-Drive

Cabling for a Three- and Four-Drive

Connecting

Mounting the

Drive Sequence Cable Installation

Power

Connecting Cable Clamps to Uprights

Cable Routing and Clamping

Diagnostic Terminal Connections

Panel Controls and Indicators

Front Cam-Coded

Air

Filter Removal

Field Service Diagnostic Terminal

Lever

and

Back

and

and

Back

Unit Address Plug

Slide Bracket Installation

of

of

of

of

HDA

Cabinet

Assembly

SOl

I/O

Controller

Swlich

................................................

.....................................................

................................................

and Interlock Switch

Joiner Panels

Door

End-Panel Lock Removal

Bottom Key-Button Removal

Trim

Panel Brackets

Locking Brackets

SOl

Trim

Slide to Front Upright

Slide to Back Upright

Cable Retainer Springs

Drive Detent Latch

Drive Mounting Rails

Cable Connections

Lock

..............................................

Stabilizer

Slides

..............................................

Cable Shield Terminators

Bulkhead Assembly

AC

Receptacles

Cover

.................................................

........................................

.............................................

............................................

Cables

............................................

Panels

System

......................................

.....................................

.........................................

........................................

.....................................

........................................

.....................................

...........................................

.............................

...............................

..............................

............................

...................................

..................................

..................................

..............................

....................................

...............................

...............................

...........................

.................................

....................................

..................................

..................................

................................

System

.................................

....................................

....................................

.................................

...................................

....................................

...........................

.............................

.

2-7

.

2-7

.

2-8

.

2-9

.

2-10

.

2-11

.

2-11

2-12

.

2-13

.

2-14

.

2-15

.

2-16

.

2-17

.

.

2-18

.

2-19

.

2-19

.

2-20

.

2-21

.

2-22

.

2-22

.

2-23

.

2-24

.

2-24

.

2-25

.

2-26

.

2-27

.

2-28

.

2-28

.

2-29

2-30

.

.

2-31

.

2-32

.

2-33

.

2-34

.

2-35

.

2-36

2-37

.

.

2-38

.

2-40

.

3-1

.

3-5

.

3-7

.

A-I

TABLES

1-1

1-2

1-3

3-1

3-2

Related Documentation

RA81 Specifications

RA81 Options

Indicator Conditions

Drive

Front-Panel Fault Identification

.............................................

...............................................

....................................................

...............................................

Codes

v

............................

1-8

.

.

1-9

1-13

.

3-2

.

3-3

.

Page 7

CHAPTER 1

INTRODUCTION

1.1

PURPOSE AND SCOPE

This manual describes the RA81 Disk Drive and tells

is

This manual

written primarily for the RA81 user except for Chapter 2 which

service personnel.

1.2 GENERAL INFORMATION

The RA81

is

a random-access, moving-head disk drive with non-removable media using a head/disk assembly (HDA). The HDA, a key feature of this drive, protects data and improves hardware dependability.

The RA81 has a data storage capacity of 456 megabytes in 16-bit word format. The RA81 connects to the

controller via the Standard Disk Interconnect

(SDI) bus and may be used with any controller implementing

this bus. Additional disk drives can be connected to a controller to increase the data storage capacity. The

RA81 can also be connected

in

a dual-port arrangement permitting time-shared access by two controllers.

Performance Features

• 17.4 megabit per second peak transfer rate

how

to install, checkout, and operate the equipment.

is

only for qualified field

•

28

ms average positioning rate

• 8.3 ms average rotational latency

Data Integrity

• Protected media

• Microprocessor-controlled servo

• Automatic error correction

Hardware Features

• Simple modular construction

• Rugged design

• Extensive microcode diagnostics

]

-]

Page 8

NOTE

Like other fixed-media devices, some method

backup should be used to prevent loss

event

of

a failure. The following methods are recom-

of

data in the

of

mended.

File Duplication-Important files should be duplicated often. Usually, this

will

involve

copying the

data on a removable medium such as magnetic tape.

Journaling-The use

of

journaling is recommended in

transaction processing applications. This method allows reconstruction

of

files

up

to the last checkpoint

or backup.

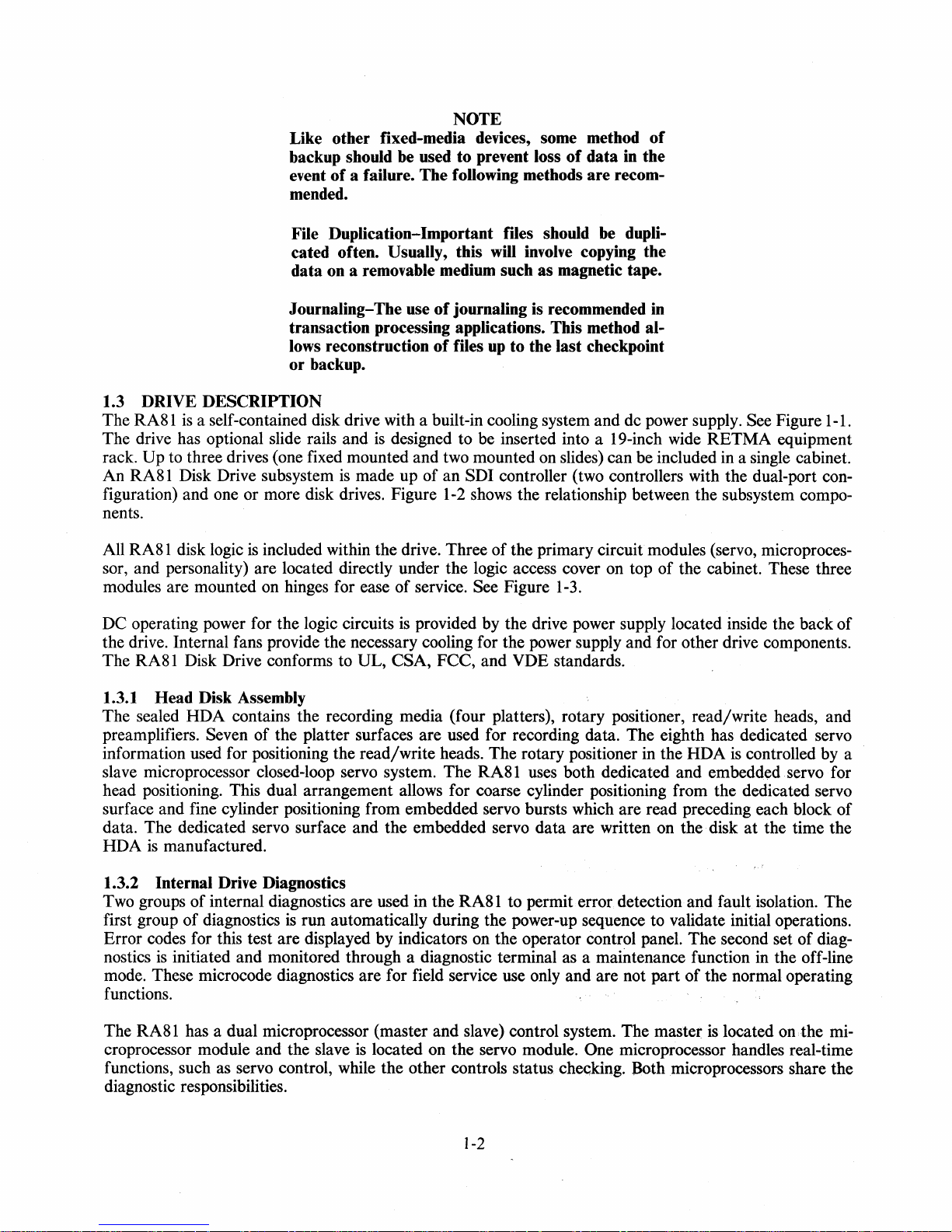

1.3 DRIVE DESCRIPTION

The RA81

The drive has optional slide rails and

rack.

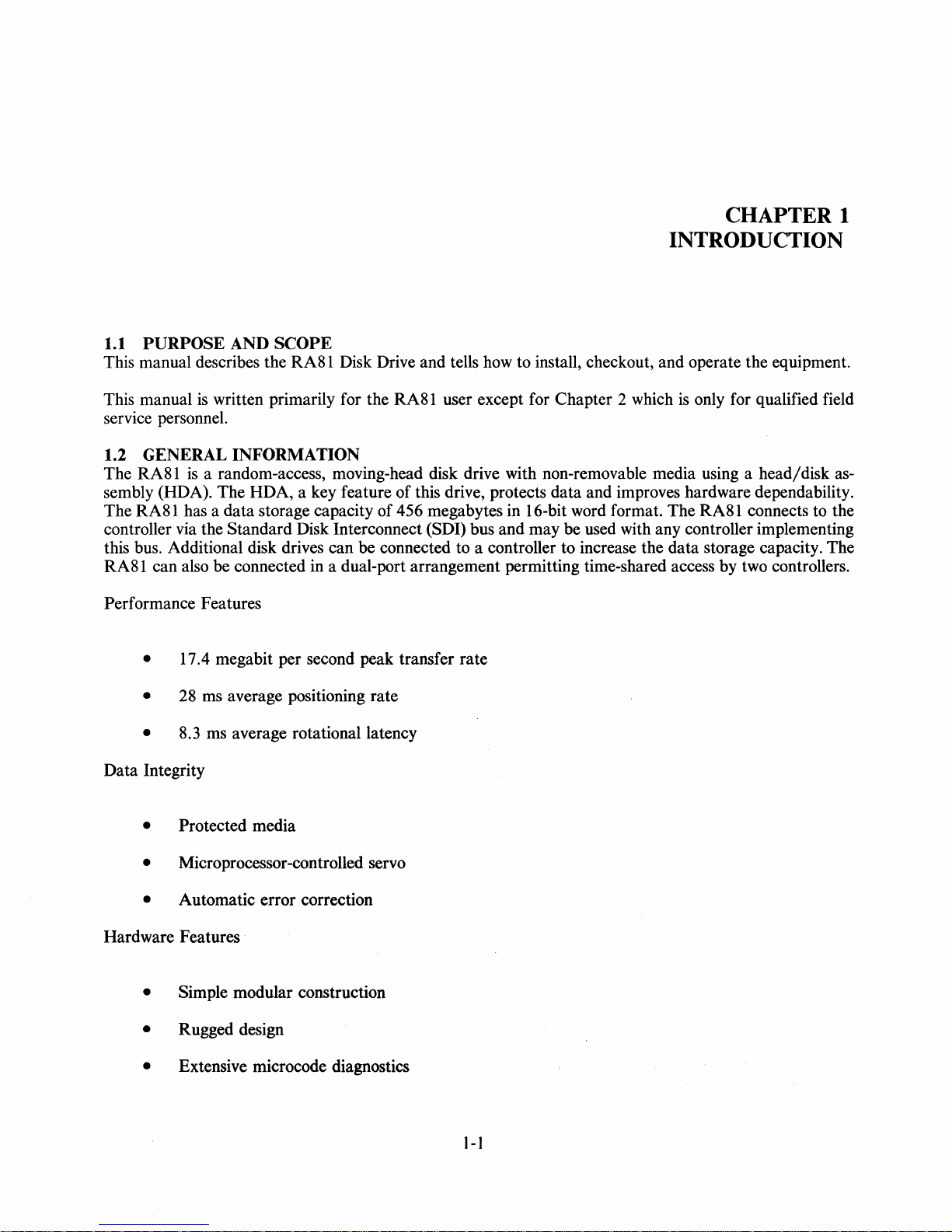

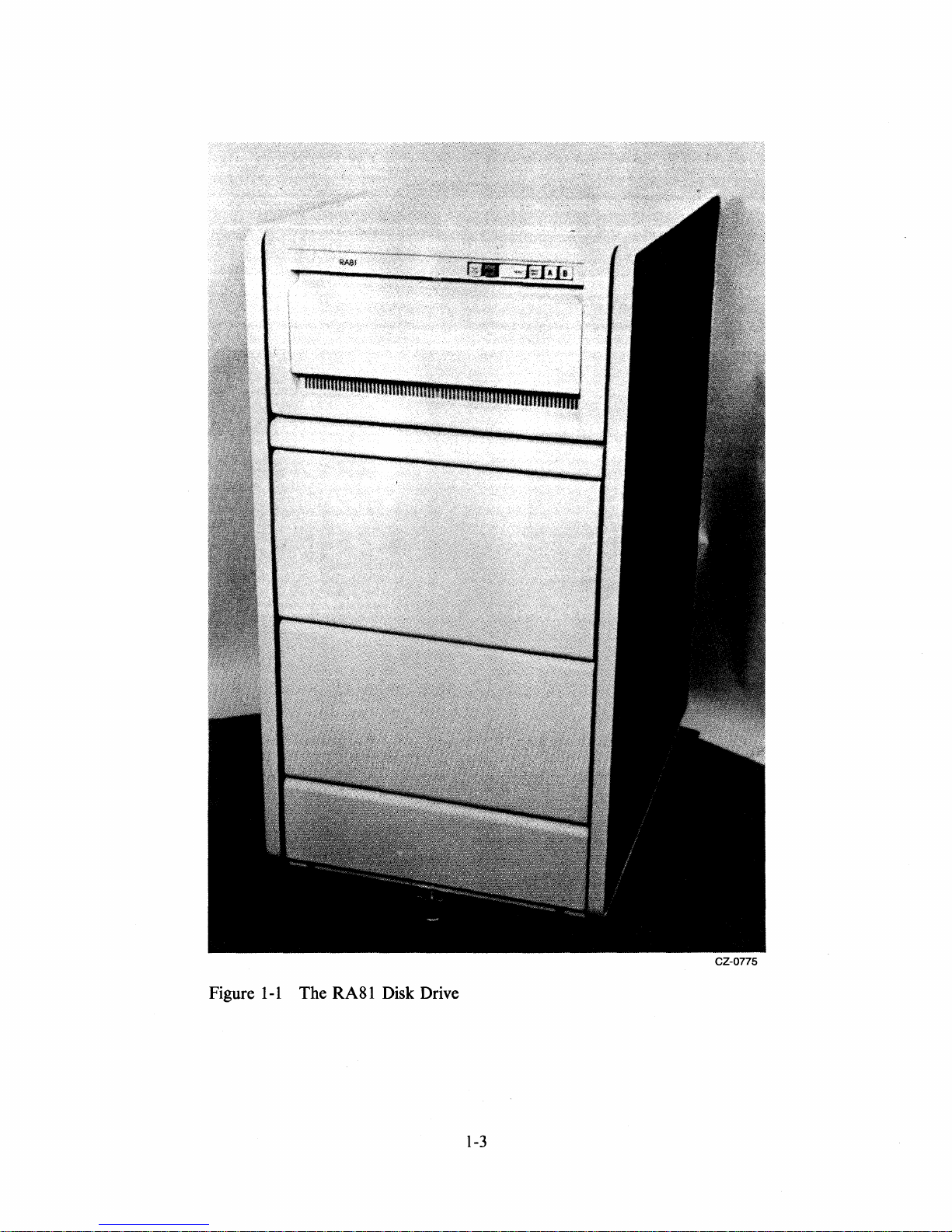

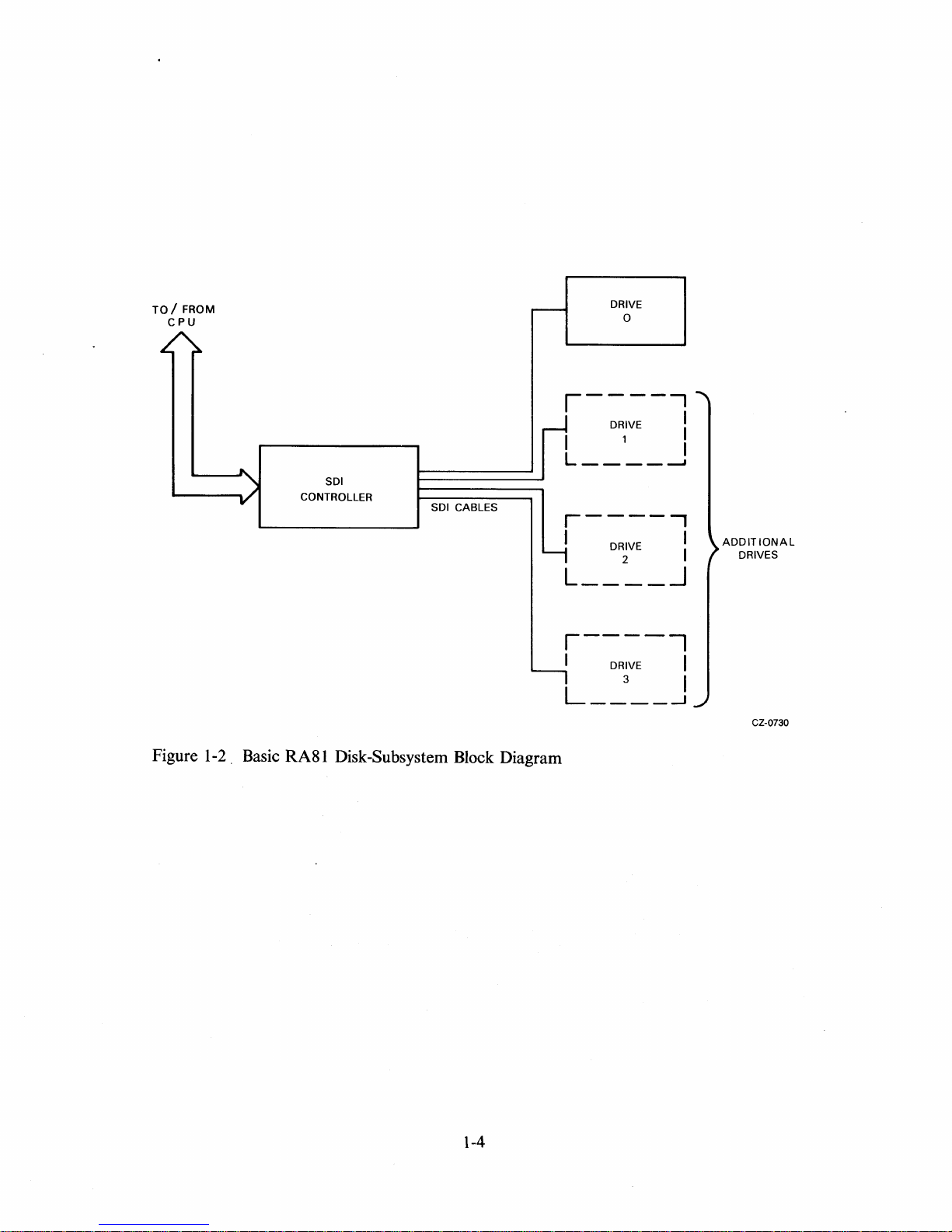

An RA81 Disk Drive subsystem

figuration) and one or more disk drives. Figure

is

a self-contained disk drive with a built-in cooling system and dc power supply. See Figure

is

designed to be inserted into a 19-inch wide RETMA equipment

Up to three drives (one fixed mounted and two mounted

is

made up of an SDI controller (two controllers with the dual-port con-

1-2

shows the relationship between the subsystem compo-

on

slides) can be included in a single cabinet.

1-1.

nents.

All RA81 disk logic

is

included within the drive. Three of the primary circuit modules (servo, microprocessor, and personality) are located directly under the logic access cover on top of the cabinet. These three

modules are mounted

DC operating power for the logic circuits

on

hinges for ease of service. See Figure

is

provided by the drive power supply located inside the back of

1-3.

the drive. Internal fans provide the necessary cooling for the power supply and for other drive components.

The RA81 Disk Drive conforms to UL,

CSA, FCC, and VDE standards.

1.3.1 Head Disk Assembly

The sealed HDA contains the recording media (four platters), rotary positioner, read/write heads, and

preamplifiers.

information used for positioning the read/write heads. The rotary positioner in the HDA

Seven of the platter surfaces are used for recording data. The eighth has dedicated servo

is

controlled by a

slave microprocessor closed-loop servo system. The RA81 uses both dedicated and embedded servo for

head positioning. This dual arrangement allows for coarse cylinder positioning from the dedicated servo

surface and fine cylinder positioning from embedded servo bursts which are read preceding each block of

data. The dedicated servo surface and the embedded servo data are written on the disk

HDA

is

manufactured.

at

the time the

1.3.2 Internal Drive Diagnostics

Two groups of internal diagnostics are used in the RA81 to permit error detection and fault isolation. The

first group of diagnostics

is

run automatically during the power-up sequence to validate initial operations.

Error codes for this test are displayed by indicators

nostics

is

initiated and monitored through a diagnostic terminal as a maintenance function in the off-line

mode. These microcode diagnostics are for field service use only and are not part of the normal operating

functions.

The RA81 has a dual microprocessor (master and slave) control system. The master

croprocessor module and the slave

functions, such

as

servo control, while the other controls status checking. Both microprocessors share the

diagnostic responsibilities.

on

the operator control panel. The second set of diag-

is

located

is

located on the servo module. One microprocessor handles real-time

on

the

1-2

mi-

Page 9

CZ-0775

Figure

1·1

The RA81 Disk Drive

Page 10

TO/

FROM

CPU

SDI

CONTROLLER

SDI CABLES

DRIVE

o

r------,

DRIVE :

I 1 I

L

____

---J

r----.

I DRIVE I

L

2 I

____

-.1

r------,

I DRIVE I

L

3 I

____

-1

ADDITIONAL

DRIVES

CZ-0730

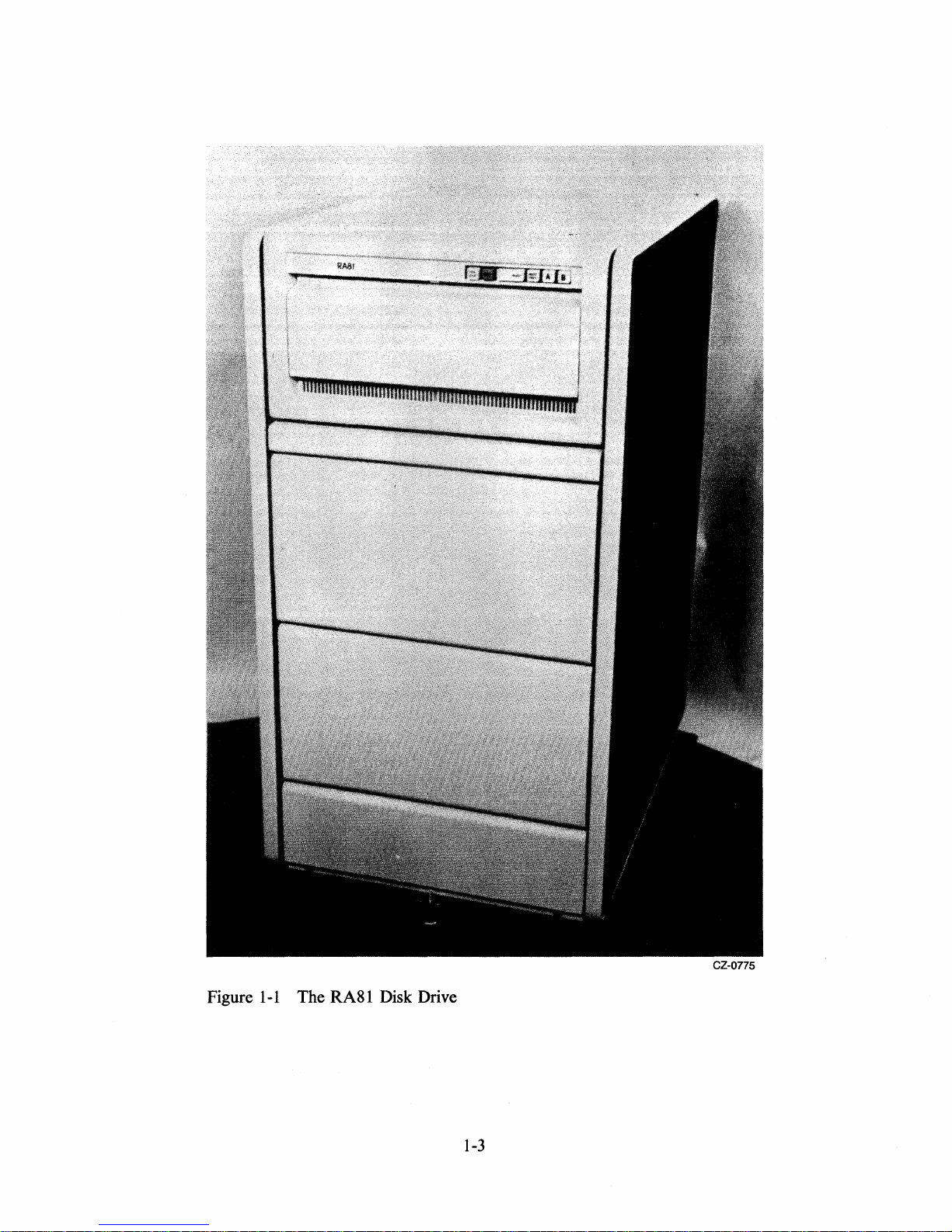

Figure 1-2. Basic RA81 Disk-Subsystem Block Diagram

1-4

Page 11

CHAPTER 1

INTRODUCTION

1.1

PURPOSE AND SCOPE

This manual describes the RA81 Disk Drive and tells

is

This manual

service personnel.

written primarily for the RA81 user except for Chapter 2 which

1.2 GENERAL INFORMATION

The RA81

sembly (HDA). The HDA, a key feature of this drive, protects data and improves hardware dependability.

The RA81 has a data storage capacity of 456 megabytes

controller via the Standard Disk Interconnect

this bus. Additional disk drives can be connected to a controller to increase the data storage capacity. The

RA81 can also be connected in a dual-port arrangement permitting time-shared access by two controllers.

Performance Features

is

a random-access, moving-head disk drive with non-removable media using a head/disk

(SDI) bus and may be used with any controller implementing

• 17.4 megabit per second peak transfer rate

how

to install, checkout, and operate the equipment.

is

only for qualified field

in

16-bit word format. The RA81 connects to the

as-

•

28

ms

average positioning rate

• 8.3

Data Integrity

• Protected media

• Microprocessor-controlled servo

• Automatic error correction

Hardware Features

• Simple modular construction

• Rugged design

• Extensive microcode diagnostics

ms

average rotational latency

I-I

Page 12

NOTE

Like other fixed-media devices, some method

backup should be used to prevent loss

event

of

a failure. The following methods

of

data in the

are

recom-

mended.

of

File Duplication-Important files should

cated often. Usually, this

will

involve

be

dupli-

copying the

data on a removable medium such as magnetic tape.

Journaling-The use

of

journaling is recommended in

transaction processing applications. This method allows reconstruction

of

files

up

to the last checkpoint

or backup.

1.3 DRIVE DESCRIPTION

The RA81

The drive has optional slide rails and

rack.

An RA81 Disk Drive subsystem

figuration) and one or more disk drives. Figure

is

a self-contained disk drive with a built-in cooling system and dc power supply. See Figure

is

designed to be inserted into a 19-inch wide

RETMA

Up to three drives (one fixed mounted and two mounted on slides) can be included

is

made up of an SDI controller (two controllers with the dual-port con-

1-2

shows the relationship between the subsystem compo-

equipment

in

a single cabinet.

I-I.

nents.

All RA81 disk logic

sor, and personality) are located directly under the logic access cover

modules are mounted

DC operating power for the logic circuits

is

included within the drive. Three of the primary circuit modules (servo, microproces-

on

top of the cabinet. These three

on

hinges for ease of service. See Figure

is

provided by the drive power supply located inside the back of

1-3.

the drive. Internal fans provide the necessary cooling for the power supply and for other drive components.

The RA81 Disk Drive conforms to

UL, CSA, FCC, and VDE standards.

1.3.1 Head Disk Assembly

The sealed HDA contains the recording media (four platters), rotary positioner, read/write heads, and

preamplifiers. Seven of the platter surfaces are used for recording data. The eighth has dedicated servo

information used for positioning the read/write heads. The rotary positioner in the HDA

is

controlled by a

slave microprocessor closed-loop servo system. The RA81 uses both dedicated and embedded servo for

head positioning. This dual arrangement allows for coarse cylinder positioning from the dedicated servo

surface and fine cylinder positioning from embedded servo bursts which are read preceding each block of

data. The dedicated servo surface and the embedded servo data are written

HDA

is

manufactured.

on

the disk

at

the time the

1.3.2 Internal Drive Diagnostics

Two groups of internal diagnostics are used in the RA81 to permit error detection'and

first group of diagnostics

Error codes for this test are displayed by indicators

nostics

is

initiated and monitored through a diagnostic terminal as a maintenance function in the off-line

is

run automatically during the power-up sequence to validate initial operations.

on

the operator control panel. The second set of diag-

fault isolation. The

mode. These microcode diagnostics are for field service use only and are not part of the normal operating

functions.

The RA81 has a dual microprocessor (master and slave) control system. The niaster

croprocessor module and the slave

functions, such

as

servo control, while the other controls status checking; Both microprocessors share the

is

located on the servo module. One microprocessor handles real-time

'located on

the

mi-

is

diagnostic responsibilities.

1-2

Page 13

"

IIliiiIiIIiIiii.UHlliUiIIIlifiiRiUliilM9f1

~

........

uHdinii

.1.

I

!

Figure

1-1

The RA81 Disk Drive

CZ-0775

1-3

Page 14

TO/

FROM

CPU

SDI

CONTROLLER

SDI CABLES

DRIVE

o

,------,

DRIVE I

I 1 I

L

____

---J

r-----,

I DRIVE I

L

2 I

____

--1

,----,

I DRIVE I

L

3 I

____

--1

ADDITIONAL

DRIVES

CZ-0730

Figure 1-2. Basic RA81 Disk-Subsystem Block Diagram

1-4

Page 15

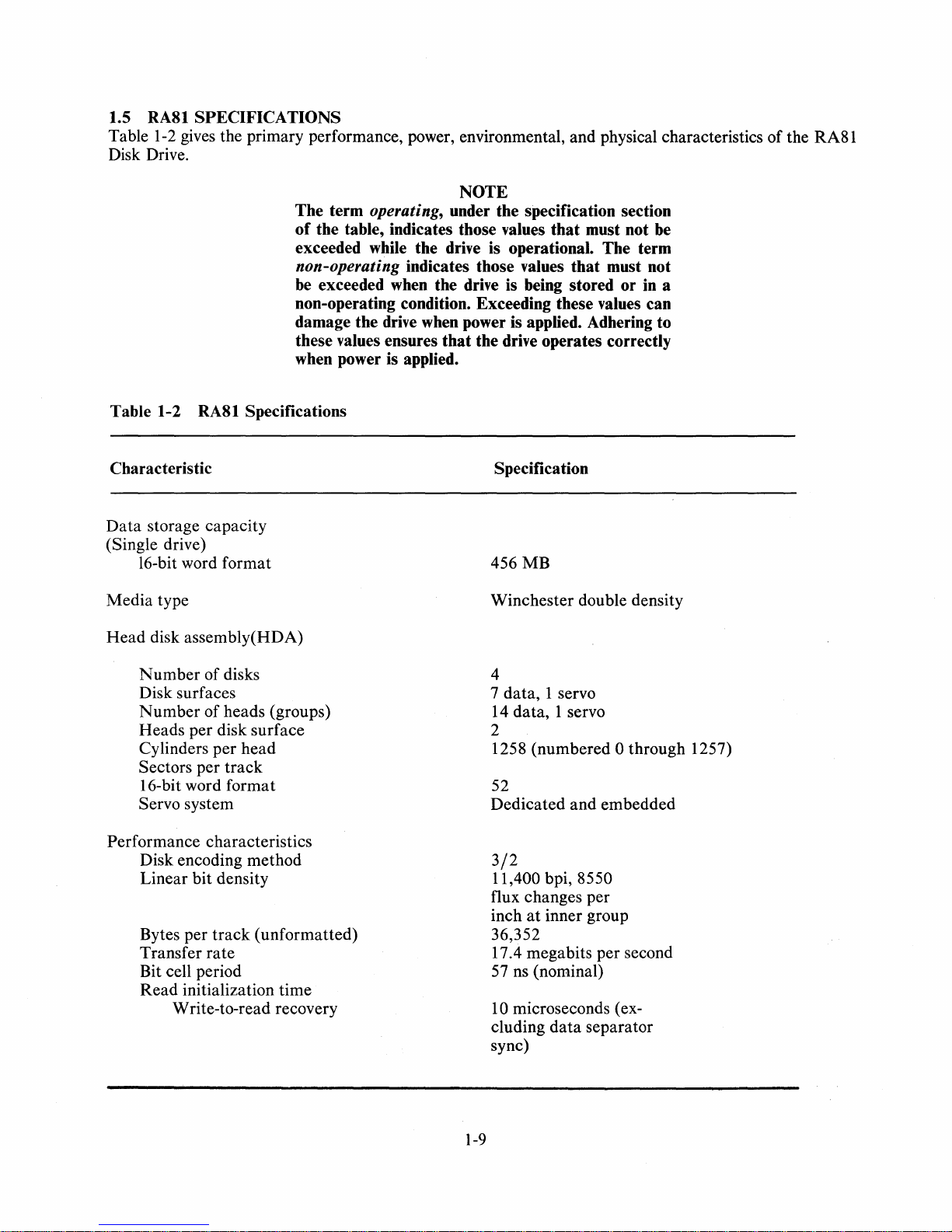

1.5 RA81

SPECIFICATIONS

Table 1-2 gives the primary performance, power, environmental, and physical characteristics

Disk Drive.

NOTE

The term operating, under the specification section

of

the table, indicates those values

that

must not be

exceeded while the drive is operational. The term

non-operating indicates those values

be exceeded when the drive is being stored

that

must not

or

in a

non-operating condition. Exceeding these values can

damage the drive when power is applied. Adhering to

that

these values ensures

the drive operates correctly

when power is applied.

Table 1-2 RA81 Specifications

of

the RA81

Characteristic

Data

storage capacity

(Single drive)

16-bit word format

Media

Head

type

disk assembly(HDA)

Number

of disks

Disk surfaces

Number

of

heads (groups)

Heads per disk surface

Cylinders per

Sectors per

head

track

16-bit word format

Servo system

Performance characteristics

Disk encoding method

Linear bit density

Bytes per

Transfer

track

rate

(unformatted)

Bit cell period

Read

initialization time

Write-to-read recovery

Specification

456

MB

Winchester double density

4

7 data, 1 servo

14 data, 1 servo

2

1258 (numbered 0 through 1257)

52

Dedicated

and

embedded

3/2

11,400 bpi, 8550

flux changes per

inch

at

inner group

36,352

17.4 megabits per second

57 ns (nominal)

10 microseconds (ex-

data

cluding

separator

sync)

1-9

Page 16

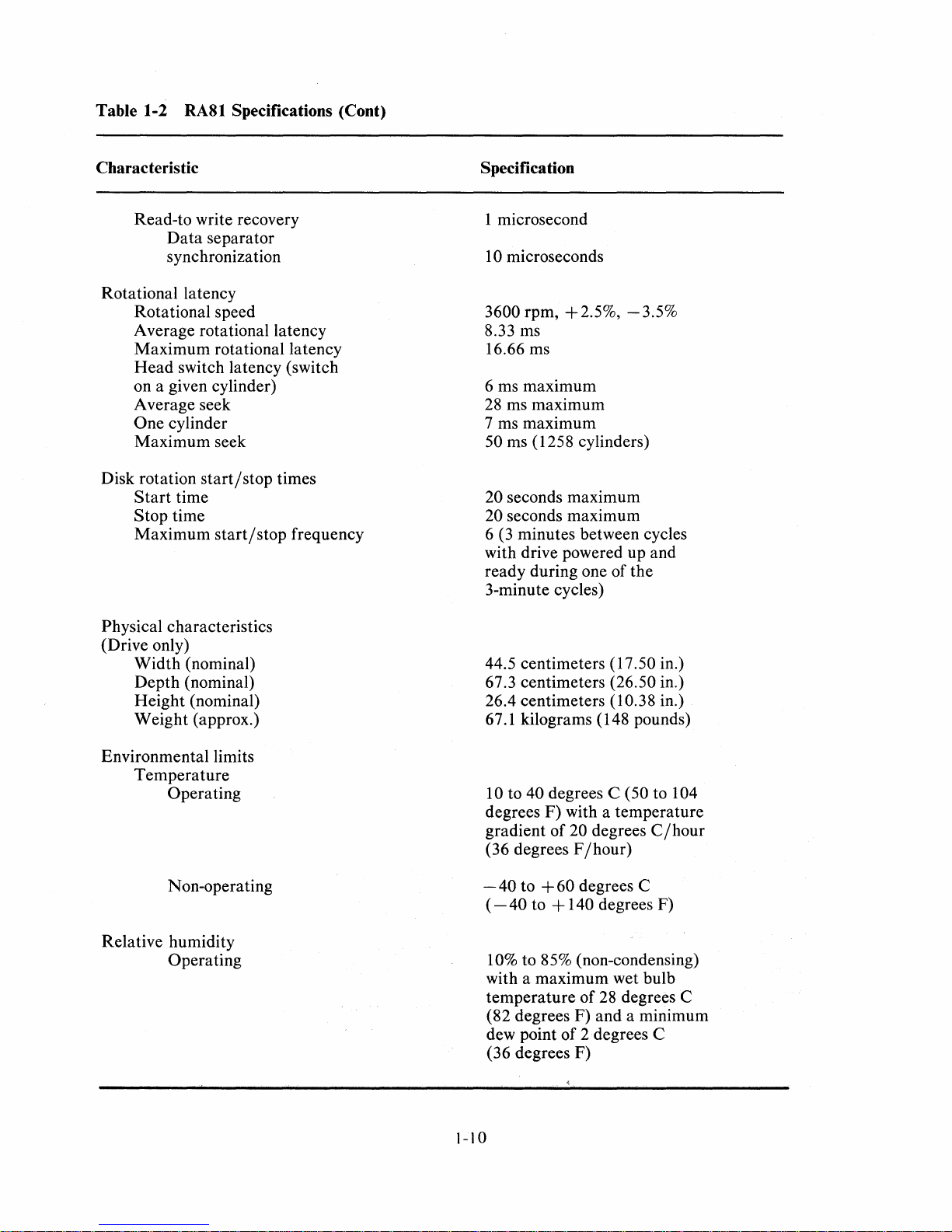

Table 1-2 RA81 Specifications (Cont)

Characteristic

Read-to write recovery

Data

separator

synchronization

Rotational latency

Rotational speed

Average rotational latency

Maximum rotational latency

Head

switch latency (switch

on a given cylinder)

Average seek

One cylinder

Maximum seek

Disk rotation

Start

start/stop

time

Stop time

Maximum

start/stop

times

frequency

Specification

1 microsecond

10

microseconds

3600 rpm, + 2.5%, - 3.5%

8.33 ms

16.66 ms

6 ms maximum

28

ms maximum

7 ms maximum

50 ms (1258 cylinders)

20 seconds maximum

20 seconds maximum

6

(3

minutes between cycles

with drive powered up and

ready during one of the

3-minute cycles)

Physical characteristics

(Drive only)

Width (nominal)

Depth (nominal)

Height (nominal)

Weight (approx.)

Environmental limits

Temperature

Operating

Non-opera ting

Relative humidity

Operating

44.5 centimeters (17.50 in.)

67.3 centimeters

(26.50 in.)

26.4 centimeters (10.38 in.)

67.1 kilograms (148 pounds)

10 to 40 degrees C (50 to 104

degrees F) with a temperature

gradient of

(36 degrees F

20 degrees

/hour)

C/hour

- 40 to + 60 degrees C

( - 40 to + 140 degrees F)

10%

to 85% (non-condensing)

with a maximum wet bulb

temperature of

28

degrees C

(82 degrees F) and a minimum

dew point of 2 degrees C

(36 degrees F)

1-10

Page 17

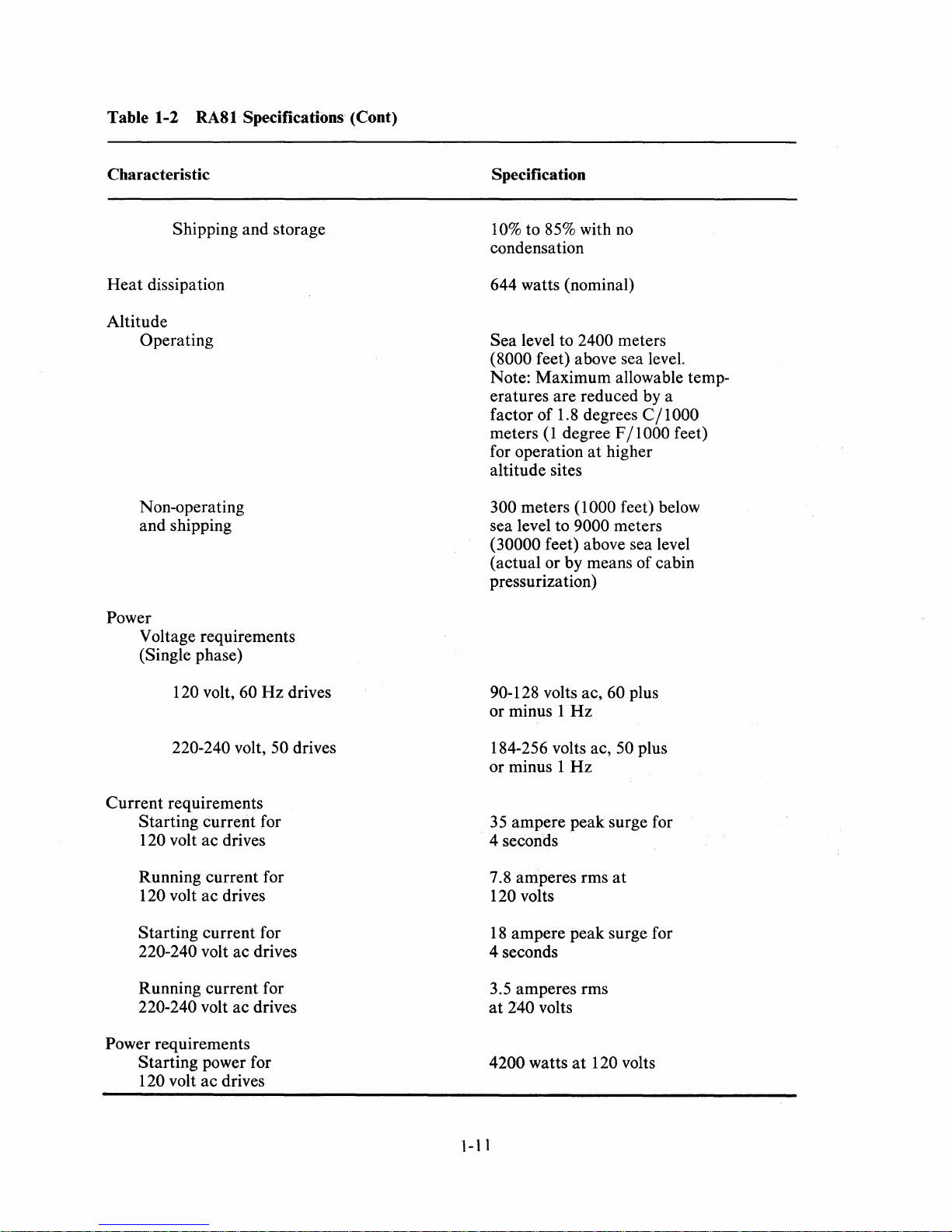

Table 1-2 RA81 Specifications (Cont)

Characteristic

Shipping and storage

Heat

dissipation

Altitude

Operating

Non-opera ting

and shipping

Power

Voltage requirements

(Single phase)

Specification

10%

to

85%

with

no

condensation

644 watts (nominal)

Sea level to 2400 meters

(8000 feet) above sea level.

Note: Maximum allowable temperatures are reduced by a

factor of 1.8 degrees

meters

for operation

(1

degree F /1000 feet)

at

C/1000

higher

altitude sites

300 meters (1000 feet) below

sea level to

9000 meters

(30000 feet) above sea level

(actual or by means of cabin

pressurization)

120 volt, 60

220-240 volt, 50 drives

Current requirements

Starting current for

120 volt ac drives

Running current for

120 volt ac drives

Starting current for

220-240 volt ac drives

Running current for

220-240 volt ac drives

Power requirements

Starting power for

120 volt ac drives

Hz

drives

90-128 volts ac, 60 plus

or minus 1

Hz

184-256 volts ac, 50 plus

or minus 1

35

ampere peak surge for

Hz

4 seconds

7.8 amperes rms

at

120 volts

18

ampere peak surge for

4 seconds

3.5 amperes rms

at

240 volts

4200 watts

at

120 volts

I-I

I

Page 18

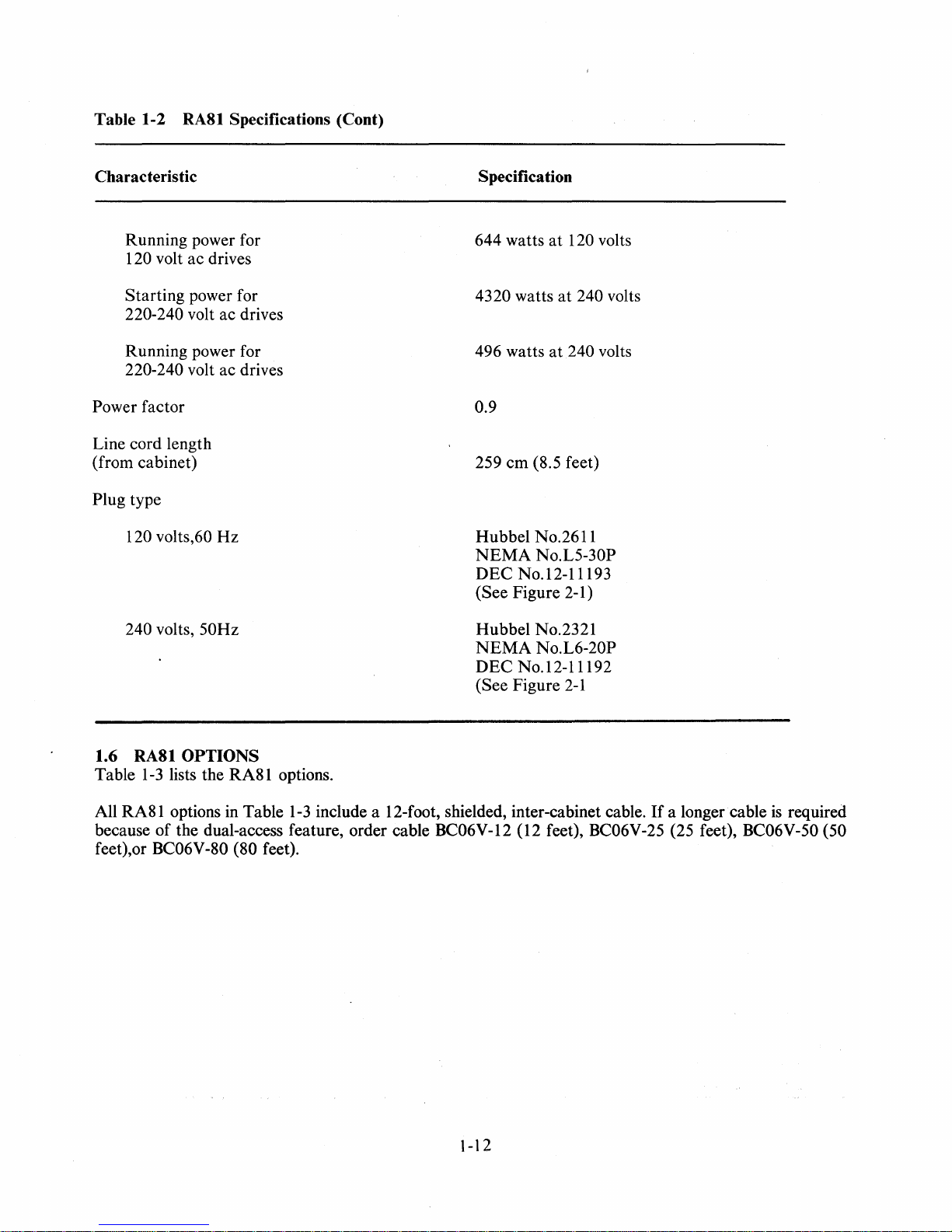

Table 1-2 RA81 Specifications (Cont)

Characteristic

Running power for

120 volt ac drives

Starting power for

220-240 volt ac drives

Running power for

220-240 volt ac drives

Power factor

Line cord length

(from cabinet)

Plug type

120 volts,60 Hz

Specification

644 watts

4320 watts

496 watts

at

120 volts

at

240 volts

at

240 volts

0.9

259 cm (8.5 feet)

Hubbe1 No.2611

NEMA

DEC

No.L5-30P

No.12-11193

(See Figure 2-1)

240 volts, 50Hz

1.6 RA81 OPTIONS

Table

All RA81 options

1-3

lists the RA81 options.

in

Table

1-3

include a 12-foot, shielded, inter-cabinet cable.

because of the dual-access feature, order cable

feet),or BC06V-80 (80 feet).

Hubbel No.2321

NEMA

DEC

(See Figure

No.L6-20P

No.12-11192

2-1

If

a longer cable

is

required

BC06V-12 (12 feet), BC06V-25 (25 feet), BC06V-50 (50

1-12

Page 19

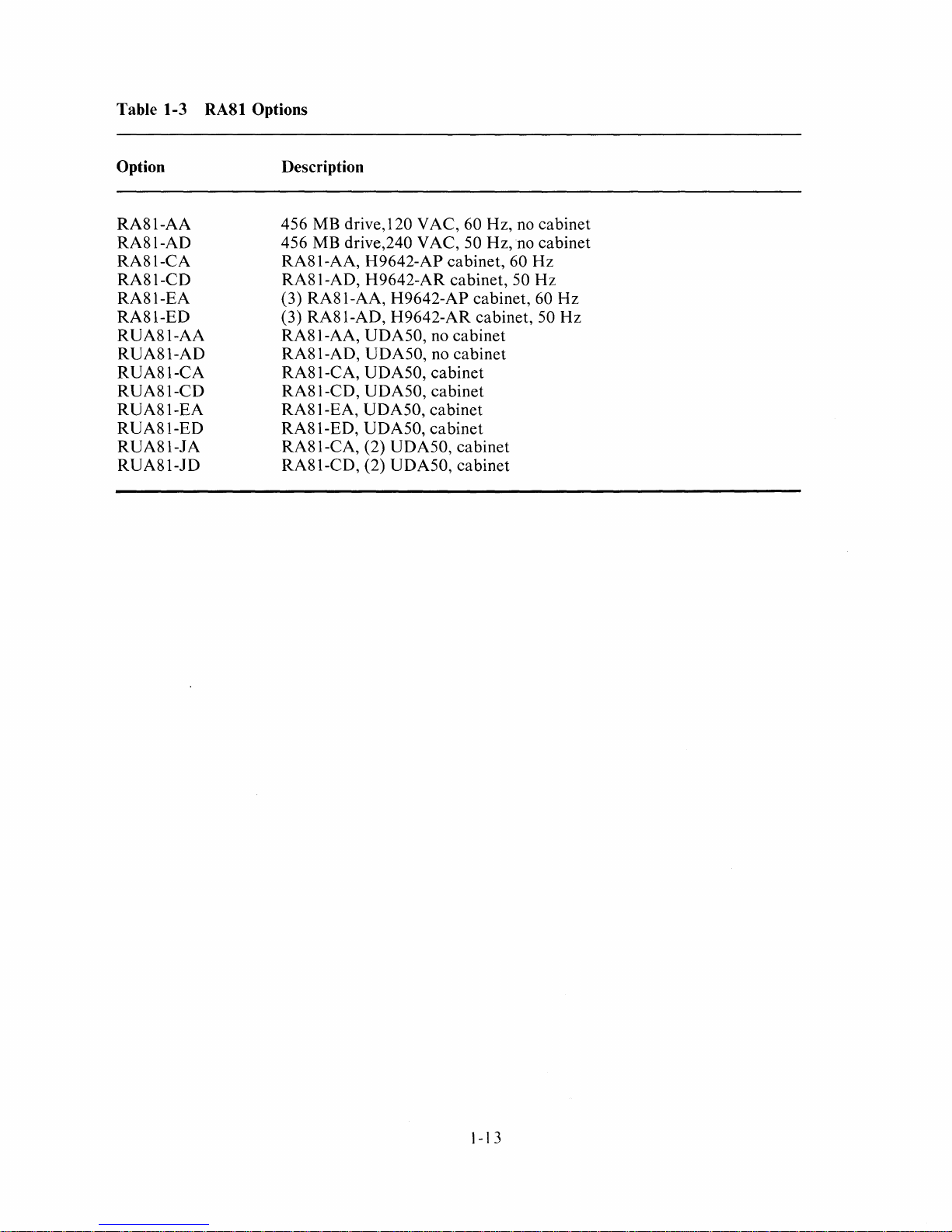

Table 1-3 RA81 Options

Option

RA81-AA

RA81-AD

RA81-CA

RA81-CD

RA81-EA

RA81-ED

RUA81-AA

RUA81-AD

RUA81-CA

RUA81-CD

RUA81-EA

RUA81-ED

RUA81-JA

RUA81-JD

Description

456 MB drive, 120 V AC, 60 Hz,

456 MB drive,240 VAC,

50

RA81-AA, H9642-AP cabinet,

RA81-AD, H9642-AR cabinet, 50

no

HZ,no

60

cabinet

cabinet

Hz

Hz

(3) RA81-AA, H9642-AP cabinet, 60

(3) RA81-AD, H9642-AR cabinet, 50

RA81-AA,

RA81-AD,

RA81-CA,

RA81-CD,

RA81-EA,

RA81-ED,

RA81-CA, (2)

RA81-CD, (2)

UDA50,

no cabinet

UDA50, no cabinet

UDA50, cabinet

UDA50, cabinet

UDA50, cabinet

UDA50, cabinet

UDA50, cabinet

UDA50, cabinet

Hz

Hz

1-13

Page 20

Page 21

CHAPTER 2

INSTALLATION

2.1

SITE

PREPARATION AND PLANNING

A certain amount of preparation and planning

paragraphs that follow discuss some of the points that should be considered.

2.1.1 Environmental Considerations

The RA81

altitude limits must be considered before the drive

mental characteristics.

2.1.2 Cleanliness

Because the RA81 has a sealed HDA, dust particles should not be able to enter the area where the recording media

ment possible.

2.1.3 Floor Loading

The weight of one RA81 cabinet and disk drive

drive weighing approximately 67.1 Kg (148Ibs). A completely loaded RA81 cabinet (approximately 283

Kg or 6241bs) should not place any abnormal stress on a raised computer room floor. However, the weight

of existing equipment should be considered before installing additional drives.

is

designed to operate in a business or light industrial environment. Temperature, humidity, and

is

located. However, it

is

still desirable that the equipment be operated in the cleanest environ-

is

necessary before installing the RA81 Disk Drive. The

is

installed. Refer to Table 1-2 for figures

is

approximately 148.8 Kg (328 lb) with each additional

on

environ-

2.1.4

The heat dissipation

requirements for the complete system can be computed by multiplying this figure by the number of drives,

adding the heat dissipation figures of the other system components, and then adjusting the total figure to

allow for cooling system efficiency and any other factors.

2.1.5 Power and

The RA81

wiring

for future expansion. The circuit breaker on the back of the power controller regulates the power to every

drive within the cabinet.

Heat

Dissipation

of

each RA81 may reach approximately 2200 Btu/hour. The approximate cooling

Safety Precautions

WARNING

Hazardous voltages

ment. Installation and servicing should be performed

by

a qualified and trained service person. Bodily in-

jury

or

equipment damage may result from incorrect

servicing. Refer to the RA81 Service Manual for

proper instructions.

will

not cause any unusual fire or safety hazards to other computer equipment. The ac power

in

the computer system should be carefully checked, however, to be sure there

are

present inside this equip-

2-1

is

adequate capacity

Page 22

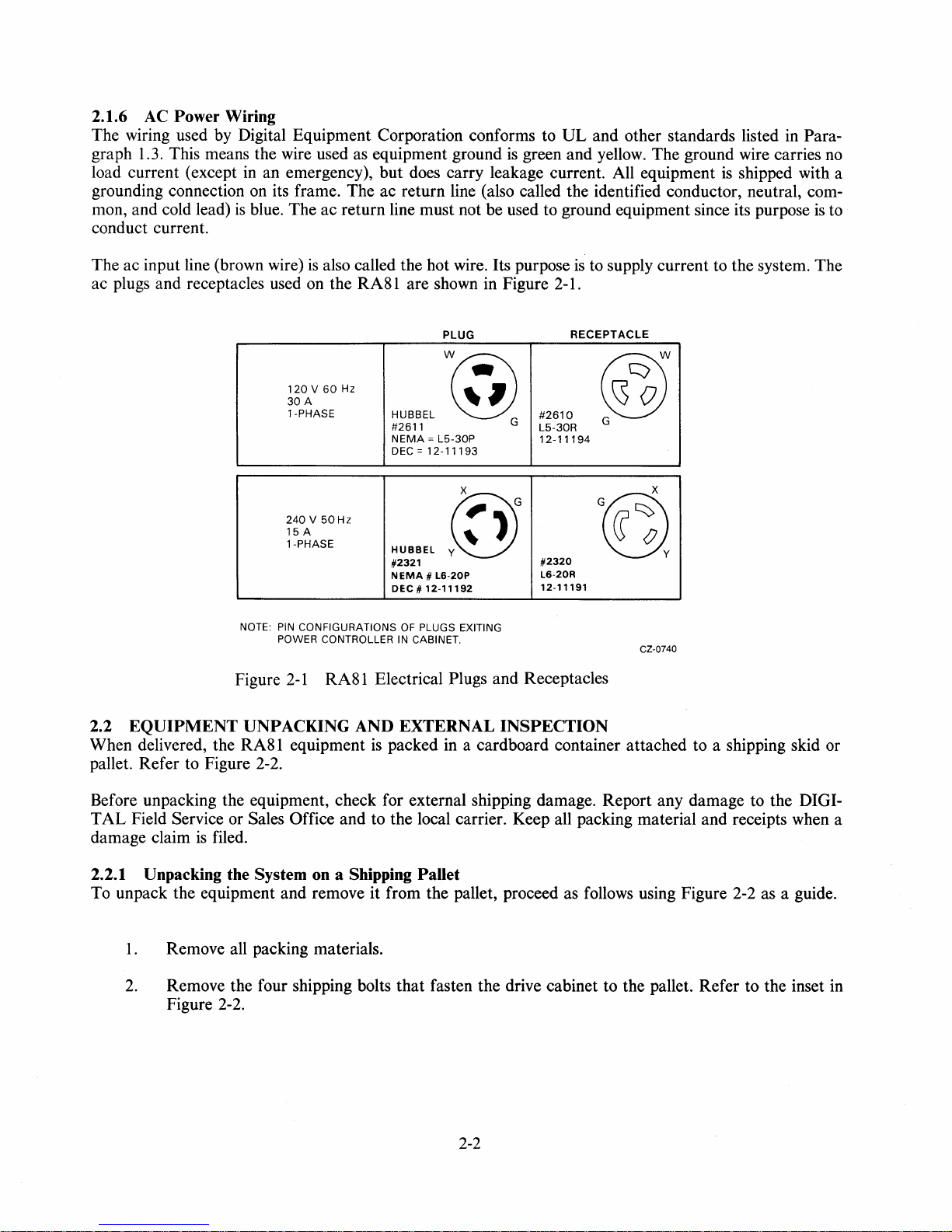

2.1.6

The wiring used by Digital Equipment Corporation conforms to

graph 1.3. This means the wire used

load current (except

AC

Power Wiring

UL

and other standards listed in Para-

as

equipment ground

in

an emergency), but does carry leakage current. All equipment

is

green and yellow. The ground wire carries

is

shipped with a

no

grounding connection on its frame. The ac return line (also called the identified conductor, neutral, common, and cold lead)

is

blue. The ac return line must not be used to ground equipment since its purpose

is

to

conduct current.

The ac input line (brown wire)

ac plugs and receptacles used

120V

30

1-PHASE

240 V 50Hz

15

1-PHASE

NOTE:

PIN

POWER CONTROLLER

Figure

2-1

is

also called the hot wire. Its purpose

on

the RA81 are shown in Figure 2-1.

PLUG

60

Hz

A

A

CONFIGURATIONS

HUBBEL

#2611

NEMA = L5-30P

DEC = 12-11193

HUBBEL

#2321

N

DEC#12-11192

w~

@

EMA # L6-20P

OF

PLUGS EXITING

IN

CABINET.

#2610

L5-30R

12-11194

#2320

L6-20R

12-11191

RA81 Electrical Plugs and Receptacles

is

to supply current to the system. The

RECEPTACLE

@

G

X

@

CZ-0740

2.2

EQUIPMENT

When delivered, the RA81 equipment

UNPACKING AND EXTERNAL

is

packed in a cardboard container attached to a shipping skid or

INSPECTION

pallet. Refer to Figure 2-2.

Before unpacking the equipment, check for external shipping damage. Report any damage to the DIGI-

TAL

Field Service or Sales Office and to the local carrier. Keep all packing material and receipts when a

damage claim

is

filed.

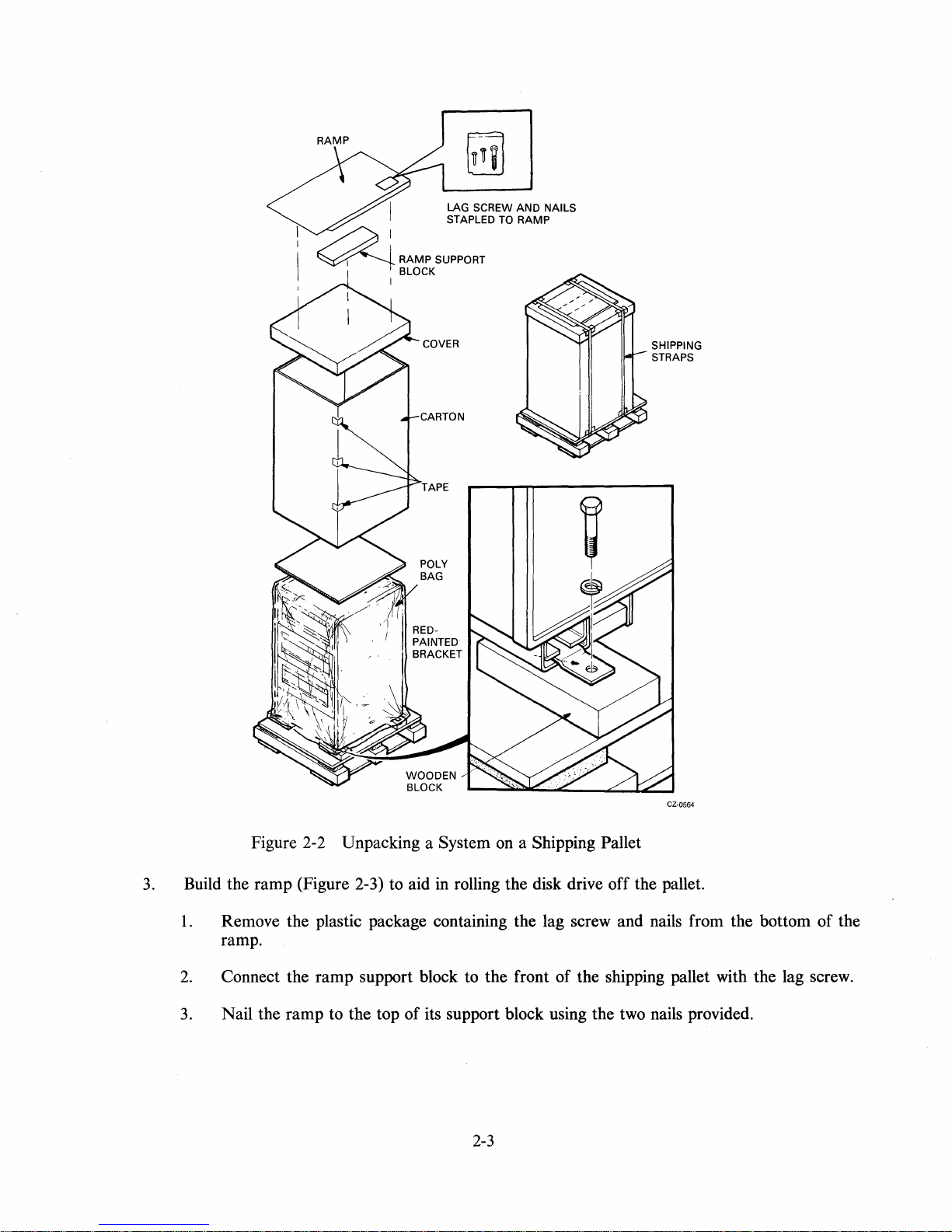

2.2.1 Unpacking the System on a Shipping Pallet

To unpack the equipment and remove it from the pallet, proceed

1.

Remove all packing materials.

2.

Remove the four shipping bolts that fasten the drive cabinet to the pallet. Refer to the inset

as

follows using Figure 2-2 as a guide.

Figure 2-2.

2-2

in

Page 23

SHIPPING

STRAPS

Figure 2-2 Unpacking a System

3.

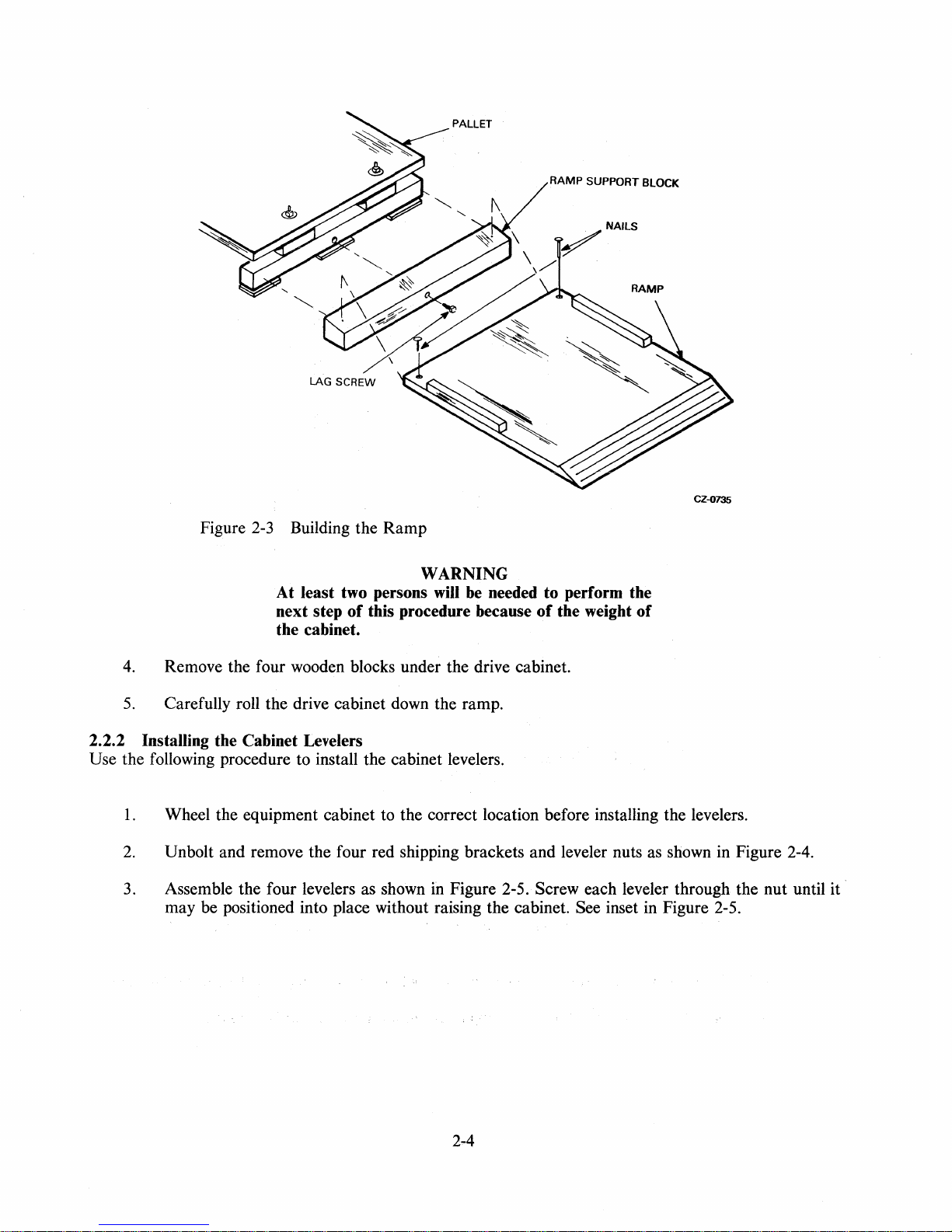

Build the ramp (Figure 2-3) to aid in rolling the disk drive off the pallet.

1.

Remove the plastic package containing the lag screw and nails from the bottom of the

ramp.

2.

Connect the ramp support block to the front of the shipping pallet with the lag screw.

3.

Nail the ramp to the top of its support block using the two nails provided.

on

a Shipping Pallet

2-3

CZ-0564

Page 24

LAG SCREW

PALLET

RAMP

SUPPORT BLOCK

CZ-Q735

Figure

2-3

Building the Ramp

WARNING

will

be

At least two persons

next step

of

this procedure because

needed to perform the

the cabinet.

4.

Remove the four wooden blocks under the drive cabinet.

5.

Carefully roll the drive cabinet down the ramp.

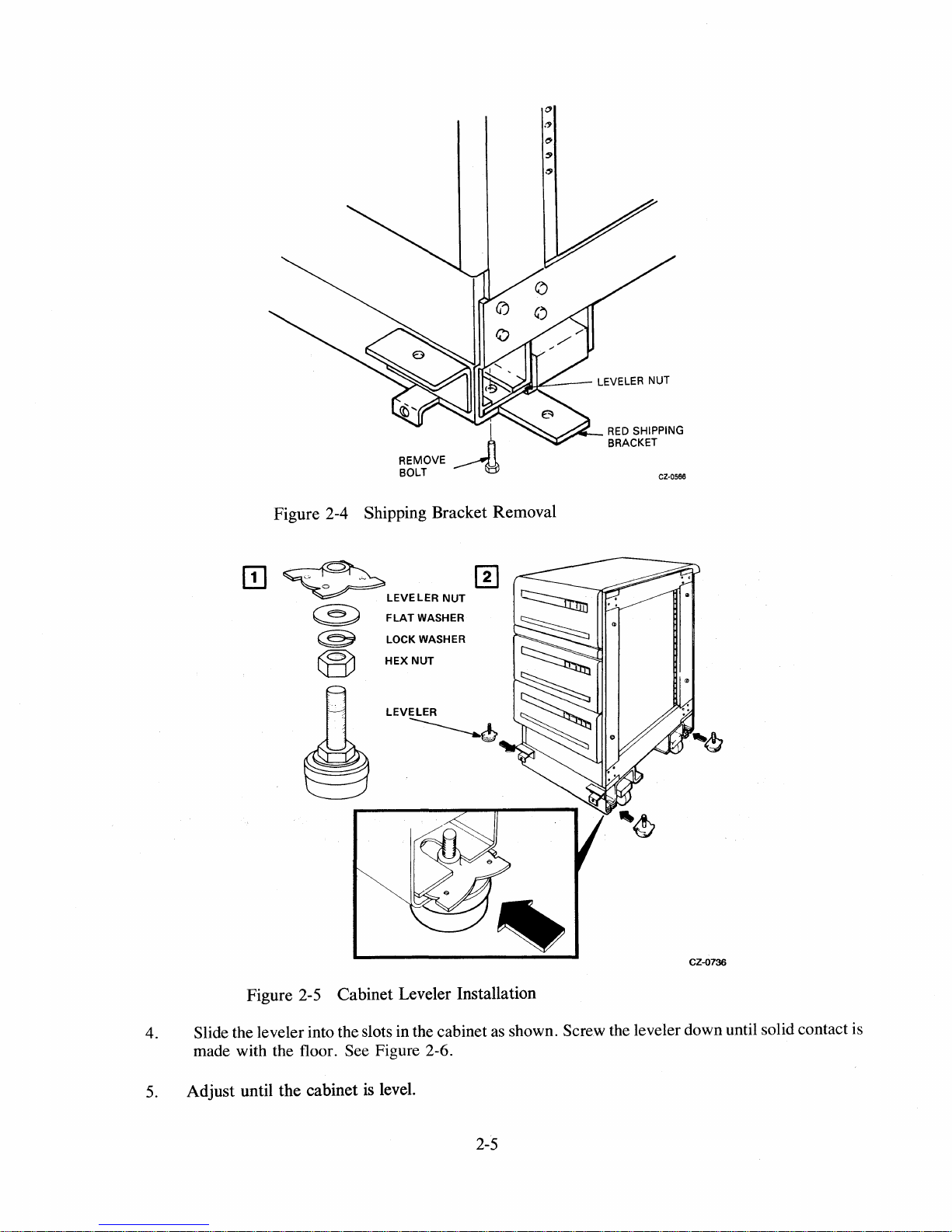

2.2.2 Installing the Cabinet Levelers

Use the following procedure to install the cabinet levelers.

1.

Wheel the equipment cabinet to the correct location before installing the levelers.

2.

Unbolt and remove the four red shipping brackets and leveler nuts

3.

Assemble the four levelers as shown

in

Figure 2-5. Screw each leveler through the nut until it .

may be positioned into place without raising the cabinet. See inset

of

the weight of

as

shown in Figure 2-4.

in

Figure 2-5.

2-4

Page 25

..h~:....---

................

LEVELER NUT

~.J>~-

RED

SHIPPING

BRACKET

Figure 2-4 Shipping Bracket Removal

ill

~LEVELERNUT

®

FLAT

WASHER

[!]

@ LOCK WASHER

®

HEX

NUT

CZ·OS88

Figure 2-5 Cabinet Leveler Installation

4. Slide the leveler into the slots in the cabinet

made with the floor.

5.

Adjust until the cabinet

See Figure 2-6.

is

level.

CZ-0736

as

shown. Screw the leveler down until solid contact is

2-5

Page 26

"'------_d'

CZ-0737

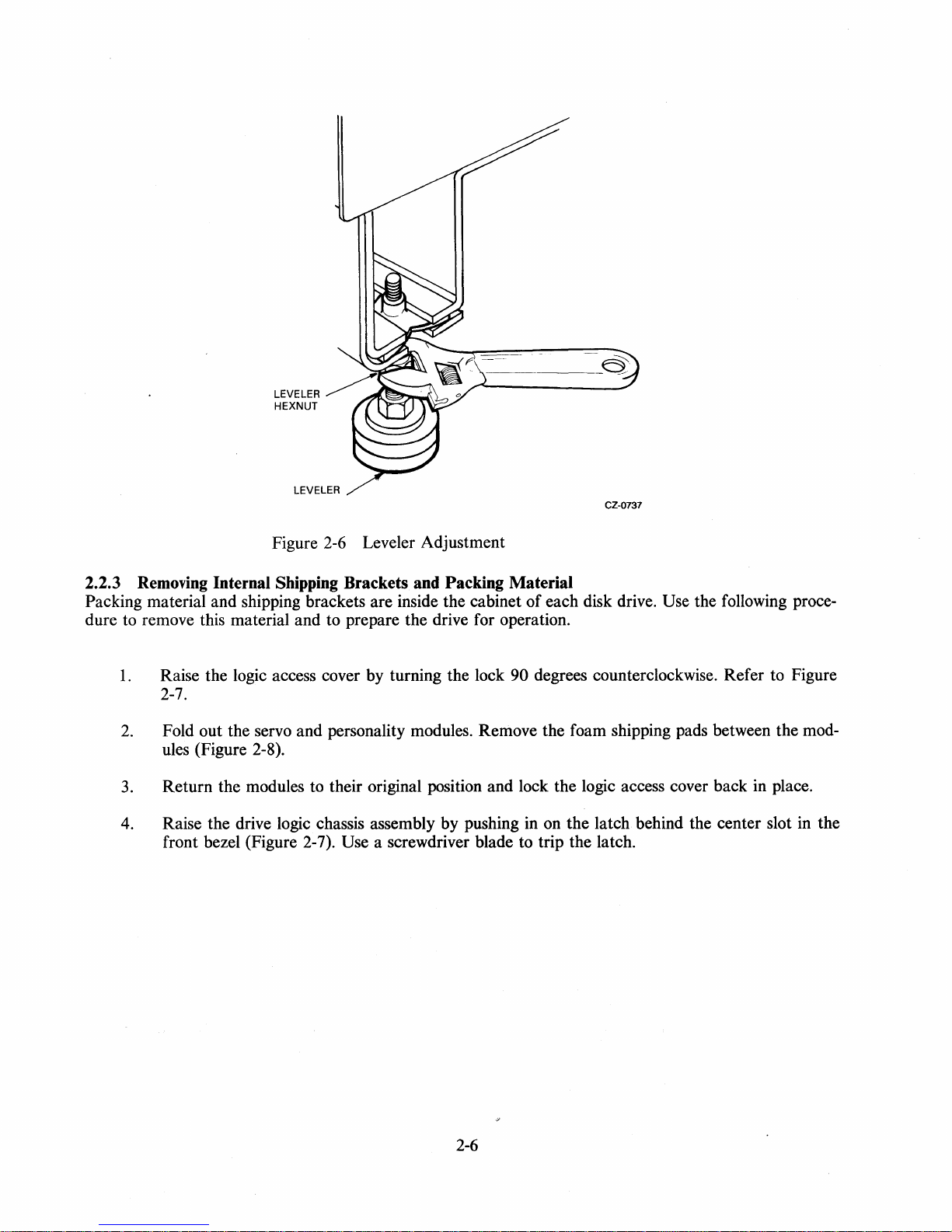

2.2.3

Figure

Removing Internal Shipping Brackets and Packing Material

2-6

Leveler Adjustment

Packing material and shipping brackets are inside the cabinet of each disk drive. Use the following procedure to remove this material and to prepare the drive for operation.

1.

Raise the logic access cover by turning the lock 90 degrees counterclockwise. Refer to Figure

2-7.

2.

Fold out the servo and personality modules. Remove the foam shipping pads between the modules (Figure 2-8).

3.

Return the modules to their original position and lock the logic access cover back in place.

4.

Raise the drive logic chassis assembly by pushing in

front bezel (Figure 2-7).

Use a screwdriver blade to trip the latch.

on

the latch behind the center slot in the

2-6

Page 27

LOGIC ACCESS

COVER

/

LOGIC ACCESS

COVER LOCK

CZ-0739

Figure 2-7 Raising the Drive Logic Chassis Assembly

LOGIC ACCESS

COVER

SERVO

MODULE

PERSONALITY

MODULE

FOAMPADS14~======~~========~)

U~

m 0

moo

00100

all

00

ooooom

00000

00001

Figure 2-8 Foam Pad Removal

CZ-0738

2-7

Page 28

5.

Remove the four red shipping brackets that fasten the HDA to its mountings. See Figure 2-9.

The bracket next to the spindle motor requires special attention and should be removed last. To

remove the other three shipping brackets, loosen the three HDA mounting nuts. Also, completely remove the 5/16-inch hex-head bolts that hold the shipping brackets in place. Slide the

three shipping brackets out from under the HDA mounting nuts.

6.

Remove the shipping bracket next to the spindle motor by loosening the remaining HDA mount-

jam

ing nut and detaching the bolt and

nuts. See Figure 2-9. Slide the shipping bracket out from

under the HDA mounting nut.

TOP

VIEW

SPINDLE

MOTOR

~

..........

.r

POSITIONER

LOCK

LEVER

1c5l):::!!~'!!!!!:.~~E!~~~~~--

11'

LOCK

WASHER

SHIPPING BOLT

AND

JAM

NUTS

SHIPPING

BRACKET

5/16

BOLT

HEX HEAD

Figure

2-9

HDA Details

2-8

SHOCK

MOUNT

SHIPPING

BRACKET

FRONT VIEW

CZ-0741

Page 29

NOTE

Save all shipping brackets and hardware for future

use when moving equipment.

7.

Tighten all four HDA mounting nuts.

8.

Ensure that the belt-tension lever

9.

Place the positioner lock lever on the HDA in the UNLOCK position (Figure 2-9).

is

in the engaged position as shown in Figure 2-10.

READ/WRITE

MODULE

HDA

RELEASED

POSITION

BELT

TENSION

LEVER

Figure 2-10 Belt Tension Lever

An interlock switch prevents the spindle motor from

operating while the belt tension is released. See Figure 2-11. The belt-tension lever must be in the en-

gaged position for spin-up.

CZ-0742

NOTE

2-9

Page 30

CZ-0743

10.

Figure

Lower the logic chassis assembly until it latches.

2-11

Belt Tension Lever and Interlock Switch

2.3 RA8l INSTALLATION

An RA81 Disk Subsystem consists of an SDI disk controller and

the subsystem, it

net, install the

is

necessary to join two drive cabinets together.

is

necessary to connect the disk drive cabinet to the Central Processing Unit (CPU) cabi-

SDI cables, and program the unit address plug.

at

least one RA81 Disk Drive. To install

If

the system has more than three RA81s, it

2.3.1 Connecting Cabinets

The H9642

end panels for stand-alone use.

to the first. The H9642 BP

AP/AR

(120/240 volt) cabinet

If

more than three drives are required, a second drive cabinet may be joined

/BR

(120/240 volt) expansion cabinet comes with a joiner panel but

will

hold up to three disk drives.

It

comes equipped with two

no

end

panels. The two cabinets may be joined by removing one of the end panels of the first cabinet and placing it

on

the the outside edge of the expansion cabinet. Figure 2-12 shows the end and joiner panel locations.

Use the following procedure to join disk cabinets.

1.

Open the back door

on

the cabinet with the end panels by turning the hex lock counterclockwise.

Refer to Figure 2-13.

2-10

Page 31

JOINER PANEL

END PANELS

Figure 2-12 End Panels and Joiner Panels

Figure 2-13 Opening the Back Door

2-11

Page 32

2.

Remove the back cabinet door by unscrewing the ground wire and pulling down

latch. See Figure 2-14.

on

the top door

PULL DOWN

ON

DOOR

LATCH

CZ-07B1

Figure 2-14 Back Door and End-Panel Lock Removal

3.

Lift the door off the bottom end panel lock.

4.

Loosen the two hex screws and remove the end panel lock from the base of the cabinet.

5.

Lift the end panel vertically to disengage it from the four key buttons on the side of the cabinet

frame. Refer to Figure 2-15.

6.

Unscrew the ground wire attached to the end panel.

7.

Remove the back end-panel lock from the expansion cabinet.

8.

Attach the ground wire just removed from the first cabinet to the exposed side frame of the

expansion cabinet.

9.

Attach the other end of the ground wire to the end panel just removed from the first cabinet.

2-12

Page 33

TOP KEY BUTTONS

10.

11.

12.

13.

REMOVE CENTER SCREW

CZ-0774

Figure 2-15 End-Panel Bottom Key-Button Removal

Lower the end panel over the keyhole buttons on the expansion cabinet.

Secure the end panel by replacing the back end-panel lock.

Remove the screws in the center

of

the two lower key buttons from the first drive cabinet.

Engage the top two key buttons on the first drive cabinet (Figure 2-16) into the keyhole slots

the expansion cabinet joiner panel.

on

2-13

Page 34

DRIVE

CABINETS

DRIVE

CABINETS

TOP VIEWS:

KEY

BUnONS

CABINET

EXPANSION

JOINER

PANEL

CABINET

EXPANSION

14.

15.

DRIVE

CABINETS

CABINET

EXPANSION

CZ-0744

Figure 2-16 Connecting the Cabinets

Adjust the cabinets until their fronts are flush.

Remove the bottom trim panels from the front of the cabinets by removing the two screws

their base. Refer to Figure 2-17.

at

2-14

Page 35

Figure

2-1

7 Removing the Trim Panel Brackets

16.

Remove the two screws that hold the two retainer trim brackets nearest the side where the two

cabinets are joined. Refer to Figure 2-18.

17.

18.

19.

Place the front locking bracket over the retainer trim brackets.

Bolt the two cabinets together with the four bolts, as shown.

Replace the two bottom trim panels.

20. Open the back door of the cabinets.

21. Loosen the screws that hold the two back end-panel locks nearest the side where the two cabinets

are joined.

2-15

Page 36

RETAINER

TRIM

BRACKET

FRONT LOCKING BRACKET

FRONT LEFT

END-PANEL

LOCK

CZ-0760

22.

Figure

Slide the back locking bracket over the end panel locks and tighten the four

2-18

Installing the Front Locking Bracket

Figure 2-19.

23.

24.

25.

Replace the back door and any end panel locks removed

Lower the levelers until the cabinets are raised off their casters.

Adjust the levelers.

2-16

in

this procedure.

screws.

Refer to

Page 37

CPU

CABINET

==--

111111

111111

111111

111111

111111,

111111

111111

11111'

111111

111111

111111

111111

11

1111

1111111111111

=-----

''ill

111111.

1111

IlIlIi

11111

111111

11111

JlJII

,

11111

1111111

BACK LOCKING BRACKET

11111

11111

11111111111

'1111

11111

111111

111111

'11111

111111

11111

11111

",Ii

111111

11111

lill

DRIVE CABINET

CZ-0746

Figure 2-19 Installing the Back Locking Brackets

2.3.2 External SDI Cabling Procedure

Both internal and external SDI cables are mounted in the

I/O

bulkhead assembly. Internal SDI cables

connect to the top of the bulkhead and external cables connect to the bottom. Refer to Figures

2-21. The procedure for connecting the internal

The external

head connector, and the drive cabinet

have already been installed.

ler user guide. When the

SDI cables must be installed between the central processing unit (CPU) cabinet,

I/O

If

not, refer to the installation procedure

CPU

cabinet

I/O

the appropriate disk controller user guide to install the

procedure to install the external

1.

Plug the external SDI cable into the Port A receptacle

SDI cables.

SDI cables

bulkhead connector. The CPU

is

discussed in Paragraph 2.4.7.

I/O

bulkhead connector should

in

the appropriate disk drive control-

bulkhead connector has been installed,

SDI cables

at

the

CPU

cabinet. Use the following

on

the bulkhead. External SDI cables

follow

the instructions in

enter from the bottom.

2.

Install the two screws that hold the SDI cable shield terminator in place and tighten them. Refer

to Figure

2-20.

2-20 and

I/O

bulk-

2-17

Page 38

--------

-- i :

: -

MO~::-~

SCREWS

I/O

BULKHEAD

FOR

SECOND

ADD-ON

EXTERNAL

SDI

CABLES

Figure 2-20 SDI Cable Shield Terminator Installation

3.

Clamp the external SDI cables to the cable entry retainers below the

hose clamp or tie wrap. Refer to Figure 2-21.

4.

If

more than one drive

the

RA8!

add-on installation procedure (Paragraph 2.4) for instructions.

is

mounted in the cabinet, more SDI cables must be installed. Refer to

--

~

rl----

I/O

FOR

ADD-ON

_________

BULKHEAD

FIRST

I/O

bulkheads with either a

--

CZ-0764

2-18

Page 39

DRIVE

CIRCUIT

BREAKER

POWER

CORD

AC

OUTLET FOR

DRIVE POWER ON FRONT

OF

POWER CONTROLLER

DISK DRIVE

2.3.3

Figure

Programming the Drive Unit Address Plug

2-21

Single Drive External SDI Cables

The READY cover on the operator control panel

between

0 and

251

must be programmed into this plug. The plug comes

~~==O=~~~_POWER

LOCAL/REMOTE

is

also the drive unit address plug. The drive unit numbers

SWITCH CZ-0765

LAMP

as

"Unit 0". To set up a drive unit

number other than zero, remove the READY switch cover from the control panel and cut off the tabs that

add up to the required number. Figure 2-22 shows the binary value represented by each tab.

REAR

PIN

CONFIGURATION

Figure 2-22 Drive

16

Unit

2-19

CZ-0747

Address Plug

Page 40

For example,

switch cap.

number 0

if

unit number 7 is required for a specific drive, tabs

If

unit number 113

is

required.

is

required, tabs

64,32,

1,

2, and 4 would have to be

cut

16, and 1 must be removed. Leave all tabs on

off

the

ifunit

After the drive unit number has been selected, place the gummed label with the corresponding number in

the recessed area on the front

of

the switch cover. Replace the switch cover on the operator control panel.

2.4 RA81 ADD-ON INSTALLATION

Use the following procedure to install additional drives in a cabinet.

CAUTION

Do not try to complete the add-on instalhition with-

of

out the help

of

the drives.

a second person because

of

the weight

2.4.1 Remove the

The first add-on drive should be placed in the center bay

bay. Remove the trim panel

Front

Trim

Panel

of

the RA81 cabinet and the second in the bottom

at

the proper location by unscrewing the four 10-32 hex nuts

panel to the cabinet frame. These nuts can be reached through the back

2-23.

HEX

NUT

10-32

(4

PL)

TRIM

PANEL

/~

~

,/

8

that

hold the

of

the cabinet. Refer to Figure

Figure 2-23 Removing Cabinet Trim Panel

CZ-OS77

2-20

Page 41

2.4.2 Install

the

Slide Assembly

Each RA81 add-on drive must be mounted

to install the slides in the drive cabinet.

1.

Screw a chassis slide bracket

5/16

inch phillips head sems screws (screws with star washers attached) to mount each. Refer to

on

Figure 2-24.

2.

Set aside the following hardware:

in

the cabinet on a slide assembly. Use the following procedure

to each end of the left and right chassis slides. Use two 8-32 x

• Four phillips head screws - 10-32 x

5/8

inch

• Four lock washers - 0.380 inch O.D. x 0.200 inch I.D.

• Two slide mount spacers (two holes)

• Four phillips head sems screws - 10-32 x

1/2

inch

• Four nut bars (four holes)

3.

Mount the chassis slides to the front vertical upright as shown

add-on drive (center bay), use mounting holes

27

and 31, counting from the bottom. Notice that

in

Figure 2-25.

If

this installation to the front vertical upright needs both a slide mount spacer and a nut bar.

RIGHT

CHASSIS

SLIDE

this

is

a first

NOTE

1.

REPEAT

Figure 2-24 Chassis Slide Bracket Installation

FOR

LEFT

CHASSIS SLIDE.

2-21

CHASSIS

SLIDE

BRACKETS

CZ·0578

Page 42

VIEWED FROM FRONT

CABINET FRONT

LEFT UPRIGHT

LOCK

OF

,.

CABINET

SLIDE

SPACER

MOUNT

Whttps://manualmachine.com/

NUT

BAR

CHASSIS SLIDE

BRACKET

< PHILLIPS HEAD SCREWS

NOTE

1. REPEAT FOR FRONT RIGHT UPRIGHT.

10-32

X

5/8"

Figure 2-25 Mounting Chassis Slide to Front Upright

4.

Mount the chassis slides to the back vertical uprights

nut bar

is

used here with sem screws. Use the same mounting holes as specified in Step 3 above.

VIEWED FROM FRONT

NUT

BAR

OF

CABINET

CHASSIS

SLIDE

BRACKET

as

shown

PHILLIPS HEAD

SEM

10-32 X 1/2"

CZ·OS79

in

Figure 2-26. Note that only a

SCREWS

NOTE

1. REPEAT

Figure 2-26 Mounting Chassis Slide to Back Upright

FOR

RIGHT

LEFT

VERTICAL UPRIGHT

BACK

VERTICAL UPRIGHT.

2-22

BACK

CZ-0749

Page 43

5.

Mount the electrostatic discharge bracket over the chassis slide bracket on the back left vertical

upright. Pass the two sem screws through the two center holes of the chassis slide bracket and

fasten them to the nut bar inside. Refer to Figure 2-27.

bay), use mounting holes

ing holes

10

and 12.

28

and 30.

If

this

is

the second add-on drive (bottom bay), use mount-

If

this

is

the first add-on drive (center

VIEWED FROM BACK

LEFT

VIEWED FROM

LEFT

CHASSIS

SLIDE

BRACKET

OF

CABINET

VERTICAL UPRIGHT

ELECTROSTATIC

DISCHARGE

BRACKET

BACK

"-

"-

"-

"~

PHILLIPS HEAD

SEM SCREWS

10-32 X 1/2"

CZ-0750

Figure 2-27 Mounting the Electrostatic Discharge Bracket

6.

Insert the two cable retainer springs in to the back of the left and right chassis slides as shown in

Figure 2-28. Push the cable retainer springs until they latch into place.

7.

Mount an

11/

16-inch cable clamp on to each cable retainer spring,

as

shown. Each cable clamp

should be mounted on inside (drive side) of the cable retainer spring.

8.

Install the drive detent latch on the left vertical upright (back

that the drive detent latch will not move freely but

If

this

is

a first add-on drive (center bay), use mounting holes 36 and 37.

add-on drive (bottom bay), use mounting. holes

is

loose enough that it can be adjusted later.

18

and 19.

view).

See Figure 2-29. Ensure

If

this

is

a second

2-23

Page 44

VIEWED FROM FRONT

OF

CABINET

PHILLIPS

SEM SCREW

10-32 X 1/2"

HEAD

CABLE

RETAINER

SPRING

CABINET

SLIDE

MEMBER

~_

"

FLAT WASHER /

0.500

INTERMEDIATE

SLIDE

MEMBER

NOTE

1. REPEAT

FOR

CHASSIS SLIDE

ON

RIGHT SIDE.

Figure 2-28 Installation of Cable Retainer Springs

VIEWED FROM RIGHT SIDE

CABINET

OF

SPACER

/ CABLE CLAMP

11/161NCH

~

/"~

aD

X 0.281

ID

PHILLIPS HEAD SCREW

10-32

X

5/8"

CZ-0751

PHILLIPS HEAD

SEM SCREWS

10-32 X 1/2"

~

"

'-

"

'-

.......

.......

......

.......

'-

DRIVE

DETENT

LATCH

"

CABINET BACK

LEFT

VERTICAL

UPRIGHT

Figure 2-29 Installation of Drive Detent Latch

CZ-0752

2-24

Page 45

2.4.3 Remove the Internal Shipping Brackets and Packing Material

Remove the shipping brackets and packing material from inside the drive using the procedure described

previously in Paragraph 2.2.3.

2.4.4 Mount the RA81 on the Slides

Use the following procedure to mount the drive on its slides.

1.

Install the left and right mounting rails onto the sides of the disk drive as shown in Figure 2-30

using ten 6-32 kep nuts.

RIGHT

NOTES

1.

REPEAT

MOUNTING

RAIL

FOR

LEFT MOUNTING RAIL.

-_-'/n

.......

KEP

NUT

6-32 X 5/16"

(5

PL

EACH SIDE)

CZ-0584

Figure 2-30 Installation of Drive Mounting Rails

2.

Remove the HDA to reduce the weight of the drive using the following procedure. Refer to

Figures

1.

2.

3.

4.

2-31

and 2-32.

Raise the drive logic chassis. Refer to Paragraph 2.2.3, Step

4.

Unplug connector P502 from the read/write module. See Figure 2-31.

Unplug connectors P602 and P603 from the preamplifier module. Refer to Figure 2-31.

Place the belt tension lever in the release position. Refer to Figure

2-31

2-25

Page 46

READ/WRITE

MODULE

HDA

RELEASED

BELT

TENSION

LEVER

POSITION

"'@-

ENGAGED POSITION

HDA HOLDDOWN

NUTS

(4)

Figure

2-31

5.

6.

7.

8.

-----.

~.

~

CZ-0770

Removal of HDA Cable Connections

Remove the four HDA retaining nuts.

Place the positioner lock

in

the LOCK position. Refer to Figure 2-32.

CAUTION

The HDA could

be

damaged

if

the previous step is

not performed.

Remove the HDA from the drive by lifting from diagonally opposite corners. Refer to

Figure 2-32.

Place the HDA on a level surface in the vertical position only. Feet are provided

on

the

front cover of the HDA for this purpose.

2-26

Page 47

CAUTION

Do not place

the

UDA in a horizontal position (on

the pulley). The speed and temperature transducers

mounted on the bottom

of

the UDA could

be

dam-

aged.

If

the UDA is going to

tape the

movement

UDA spindle pulley in place to prevent

of

the spindle. Any movement

be

moved

to another location,

of

the spin-

dle could damage the heads.

It

is important to use a good nylon reinforced pack-

ing tape. Masking tape should never

be

used

as

it

not strong enough.

is

Figure 2-32 HDA Positioner Lock.

3.

Extend the cabinet stabilizer as shown in Figure 2-33.

4.

Extend each chassis slide all the way forward until it locks. See Figure 2-34.

A second person is needed to place the drive on the

chassis slides because

PLASTIC

BULKHEAD

WARNING

of

the weight

2-27

FEET

of

the disk drive.

CZ-8021

Page 48

Figure 2-33 Extending Cabinet Stabilizer

DRIVE

CABINET

SLIDE

ASSEMBLY

PHILLIPS HEAD

SEM SCREWS

8-32 X 5/16

(2 EACH SIDE)

Figure 2-34 Extending the Chassis Slides

CZ-0753

RA81

DISK

DRIVE

•

CZ-0754

5.

With the help of a second person, lift the drive and place it on top of the chassis slides

in Figure 2-34. Push the drive toward the back of the cabinet until its mounting rails touch the

stop.

2-28

as

shown

Page 49

6.

Fasten the drive to the chassis slides using four 8-32 x

shown.

7.

Extend the drive forward

8.

Replace the HDA using the following procedure.

1.

Ensure that the drive belt

on

the slides.

is

centered on the motor pulley. The other end of the belt should

be even with the top of the nylon rollers on the wing pivot assembly.

5/16

inch phillips head sem screws,

See Figure 2-35.

as

CZ-0767

Figure 2-35 Wing Pivot Assembly

CAUTION

Damage to the HDA,

could result

2.

Lift the HDA by grasping two diagonally opposite corners, then lower the HDA over the

if

the

drive

belt, or nylon rollers

drive

belt is not aligned correctly.

four mounting bolts.

3.

Replace the four nuts and washers on the HDA.

4. Connect P602 and P603 to the read preamplifier module on the front of the HDA.

5.

Connect P502 to the read/write module.

6.

Place the belt tension lever in the engaged position. See Figure 2-10.

2-29

Page 50

7.

Turn the HDA positioner lock counterclockwise to the unlocked position.

9.

Slide the drive back into the cabinet.

10.

Adjust the drive detent latch

so

that it prevents the drive from sliding forward and tighten the

la tch screws.

2.4.5 Program the Drive

Unit Address Plug

Program the drive unit address plug using the procedure described previously in Paragraph 2.3.3.

2.4.6 Connect the Electrostatic Discharge Bracket

The electrostatic discharge bracket grounds the disk drive to the cabinet. To complete this ground path, the

bottom left screw

on

the drive power supply should be removed. This same screw should then be inserted

through the electrostatic discharge bracket and screwed back into place as shown in Figure 2-36.

~

<tl

<tl

<tl

<tl

<tl

cg

ELECTROSTATIC

DISCHARGE

BRACKET

<tl

cg

cg

NOTE

1.

Figure 2-36 Electrostatic Discharge Bracket Details

This ground connection must always

the drive is operated.

To slide the drive forward, remove the screw that holds the electrostatic discharge bracket to the power

supply and push on the drive detent latch. Remember to reconnect the electrostatic discharge bracket each

time the drive

is

pushed back into the cabinet.

LEFT

DISK DRIVE

REMOVE POWER SUPPLY SCREW TO

SLIDE DRIVE

THROUGH

IS SLID BACK INTO CABINET.

FORWARD. REPLACE SCREW

BRACKET EACH TIME THE DRIVE

CAUTION

2-30

BACK

OF

CZ-0755

be

made before

Page 51

2.4.7 Install the Internal SDI Cables

The two internal SDI cables that exit from the back of the add-on drive must be connected to the top of the

I/O

bulkhead assembly. The external SDI cable that connects the drive cabinet to the disk controller must

be mounted on the bottom of the

tion), a second external SDI cable must be installed. The SDI cables must be connected to the

head before the bulkhead

wiring for add-on disk drives.

I/O

bulkhead assembly.

is

connected to the drive cabinet. Figures 2-37 and 2-38 show the electrical

Use the following procedure to install the SDI cables.

If

two disk controllers are used (dual-port opera-

I/O

bulk-

AC

LIN

POWE

CONT

./

ES

~"

R

ROllER

I/O

BULKHEAD

_OUT

c=J

c=J

1

.OUTl~

B

1--

I

I

L-

•

____

I

~~~~

SDI CABLES

!

i I B

110UT

~

ApN'

DRIVE 0

A"rlr-

DRIVE 1

--l

~

?N

I

I

I

DRIVE

SEQUENCE

TERMINAT

OR

CONTROllER

SDI

PORT 0

1

PORT

Figure 2-37 Cabling for a Two-Drive System

SDI

B

NOTES

1. HEAVY LINE INDICATES THE DRIVE

SEQUENCE CABLE.

2-31

CONTROllE

RA

PORT 0

PORT

CZ-0758

1

Page 52

•

OUTl

AI

B"r

IN

.OUT1~

~NT

AC

LIN

~

WER

PO

NTROLLER

CO

f-o

1'--'-..

c:::J

c:::J

.OUT1~

c:::J

CJ

.OUT1~

15

n

R

~~

SDI CABLES

DRIVE 0

A"r~-

DRIVE 1

A"rIN~

DRIVE 2

~

~

!

1/0

BULKHEAD

0

.0.1 0 []

A B A B A

B

NO

TES

1.

ALL

PORT

CONTROLLER

GO

2. HEAVY LINE INDICATES DRIVE SEQUENCE

CABLE.

A CONNECTIONS GO TO SDI

A.

TO

SDI CONTROLLER

ALL

I D

PORT B CONNECTIONS

B.

I I

D

0 0

OUT

lU-

DRIVE SEQUENCE

IN

TERMINATOR

r--

I

I

I

AC

I

I

,

L1\

,--

I

I

L

•

POWER

CONTROLLER

I

!

EXTERNAL DRIVE /

SEQUENCE CABLE

c::J

~

--

__

I

,

I/O

BULKHEAD

DRIVE 3

--,.

__

J

---1

__.J

CbttJCb

J6

J5 J4

l~

J3

SDI CABLES

I I

o 0

0

A OUT

IN

I

I

I

I

CZ-0759

Figure 2-38 Cabling for a Three- and Four-Drive System

1.

Locate the Port A SDI cable where it exits the back of the disk drive. Find the end of the cable

and plug the connector into Port A on the top of the

tion key.

2.

Screw the Port A SDI cable shield terminator into the

will

the disk drive

captive hardware. Refer to Figure 2-39.

3.

Repeat Steps 1 and 2 for the Port B SDI cable.

4.

Plug the SDI cable from the first disk controller into the Port A connector on the bottom of the

I/O

bulkhead assembly. Note the orientation key.

need separate screws to mount the shield terminator. Later versions

2-32

I/O

bulkhead assembly. Note the orienta-

I/O

bulkhead assembly. Early versions of

will

have

Page 53

EXTERNAL

SOl CABLES

Figure 2-39 Connecting SDI Cable Shield Terminators

5.

Screw the shield terminator of this cable into the

6.

If

a second disk controller

is

used, mount its SDI cable into Port B

bly.

M~;;:NG~

SCREWS

1/0

BULKHEAD

FOR

SECOND

ADD-ON

1/0

BULKHEAD

FOR

FIRST

ADD-ON

I/O

bulkhead assembly

on

the

CZ-0764

as

in

I/O

bulkhead assem-

Step

2.

2.4.8 Mount the

An

I/O

bulkhead assembly must be installed

Screw the

I/O

I/O

Bulkhead

on

the back base of the drive cabinet for each add-on drive.

bulkhead assembly on to the back of the cabinet as shown in Figure 2-40. Mount the

bulkhead assembly in the drive 1 location for the first add-on drive. Mount the

the drive 2 location for the second add-on drive.

2.4.9 Install the Drive Sequence Cables

Figures 2-37 and 2-38 show the electrical wiring diagrams for add-on drives.

Use them

installing drive sequence cables, as follows.

1.

Unplug the drive sequence cable from the output connector on drive 0 (top drive) done by raising the back cover and removing

2.

Plug the drive sequence cable described in Step 1 into the output connector

it

from the cable clamp. Refer to Figure 2-41.

add-on, or into the output connector on drive 2 for two add-ons.

3.

Install the new 8-foot cable between the output connector of drive 0 and the input connector on

drive

1.

If

a second add-on drive has been installed, connect another 8-foot drive sequence cable

between the output connector of drive

1 and the input connector of drive

2-33

I/O

bulkhead assembly in

as

a reference when

on

drive 1 for one

2.

I/O

Page 54

•

./

....

~~-I/O

1/0

BULKHEAD

FOR

SECOND

ADD-ON

DRIVE SEQUENCE

CABLE BULKHEAD

BULKHEAD

FOR FIRST

ADD-ON

CZ-0772

Figure 2-40 Mounting the

I/O

Bulkhead Assembly

2-34

Page 55

DRIVE SEQUENCE

CABLES

DRIVE SEQUENCE

CABLES

Figure

4.

Tie-wrap the drive sequence cable to the existing SDI cable clamps.

5.

Add a cable between the drive sequence bulkheads

is

used. Refer to Figures 2-38 and 2-41.

2-41

Drive Sequence Cable Installation

on

each drive cabinet when a second cabinet

2-35

CZ-0769

Page 56

2.4.10 Connect AC Power

Plug the ac power cord from each add-on into the ac receptical on the power controller

cabinet. Refer to Figure 2-42.

J6

at

the base of the

AC PLUG

DRIVE 1

Figure 2-42 Power Controller AC Receptacles

2.4.11 Route and Clamp the Cables

The cables from the add-on drives must

now

the slide rails. Route and clamp the cables

1.

Mount the spacers and cable clamps into the back vertical uprights

this

is

the first add-on drive (center bay), mount the cable clamps in hole 44 of the left and right

vertical uprights.

mounting hole

If

this

is

the second add-on drive (bottom bay), mount the cable clamps in

23

of the left and right vertical uprights.

CZ-07S7

be routed and clamped to allow the drive to be extended

as

follows.

as

shown in Figure 2-43.

2-36

on

If

Page 57

KEP

NUT

10-32 X 3/8"

STANDOFF

10-32,6-32

FLAT WASHER

0.375

OD X 0.156

ID

CABLE CLAMP

3/8"

Figure 2-43 Connecting Cable Clamps to Uprights

2.

Use the

15

cable ties provided with each add-on to route and tie the cables where indicated in

Figure 2-44. Three cable ties are used on the ac power cord and seven ties are

and drive sequence cables.

CZ-0771

used on the SDI

3.

Tie wrap the cables to the clamp mounted previously on the back of the chassis slides.

4.

Form a service loop approximately eight inches in diameter in the cables as shown in Figure

2-44. Fasten the output of the service loop with the cable clamps installed

uprights in Step 1 above.

5.

Tie wrap the cables

at

the bottom of the cabinet to the cable clamp