Page 1

RA7x/SA7x Pocket

ReferenceGuide

Order Number EK–RSA7X–PG–002

This guide contains quick-reference information for RA7x

disk drives (RA70, RA71, RA72, and RA73) and SA7x

enclosures.

Digital Equipment Corporation

Page 2

August 1992

The information in this document is subject to change

without notice and should not be construed as a

commitment by Digital Equipment Corporation. Digital

Equipment Corporation assumes no responsibility for any

errors that may appear in this document.

Possession, use, duplication, or dissemination of the

software described in this documentation is authorized

only pursuant to a valid written license from Digital or the

third-party owner of the software copyright.

No responsibility is assumed for the use or reliability of

software on equipment that is not supplied by Digital

Equipment Corporation.

Copyright © Digital Equipment Corporation 1991, 1992

All Rights Reserved.

Printed in U.S.A.

FCC NOTICE: The equipment described in this manual

generates, uses, and may emit radio frequency energy.

The equipment has been type tested and found to comply

with the limits for a Class A computing device pursuant to

Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such radio frequency

interference when operated in a commercial environment.

Operation of this equipment in a residential area may cause

interference, in which case the user at his own expense may

be required to take measures to correct the interference.

The following are trademarks of Digital Equipment

Corporation: DEC, DSA, DSDF, HSC, HSC50, HSC70,

KDA, KDA50, KDB50, KDM, MicroVAX, PDP-11, RA, SA,

SDI, UDA, UNIBUS, VAXsimPLUS, and the DIGITAL logo.

Page 3

Contents

Introduction and Related

Documentation . . . . . . . . . . . . . . . 1

RA7x Characteristics . . . . . . . . . . . 2

Thermal Stabilization Specifications . . 3

Setting Capacity Indicator Switch . . . 4

Troubleshooting . . . . . . . . . . . . . . . 6

RA7x Parts . . . . . . . . . . . . . . . . . . 10

SA7x Parts . . . . . . . . . . . . . . . . . . 13

RA7x Electronics Block Diagrams . . . 15

RA71-RA73 Support . . . . . . . . . . . . 16

RA7x Drive Status Information . . . . . 19

OCP Error Codes . . . . . . . . . . . . . . 30

Drive Error Codes and Fault Numbers 34

iii

Page 4

iv Contents

Figures

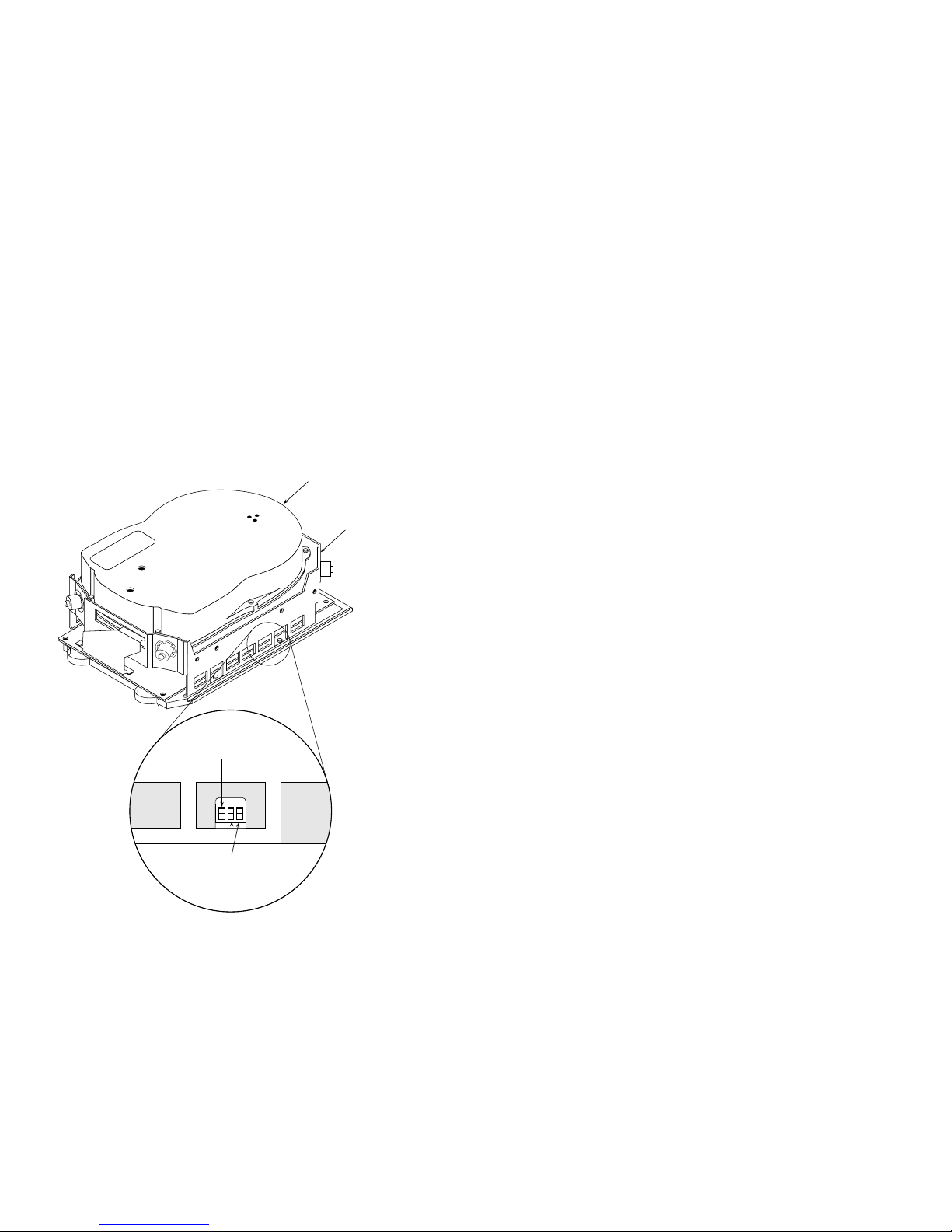

1 RA71/RA72 Capacity Indicator Switch 5

2 Drive Internal Error Log . . . . . . . . . . 7

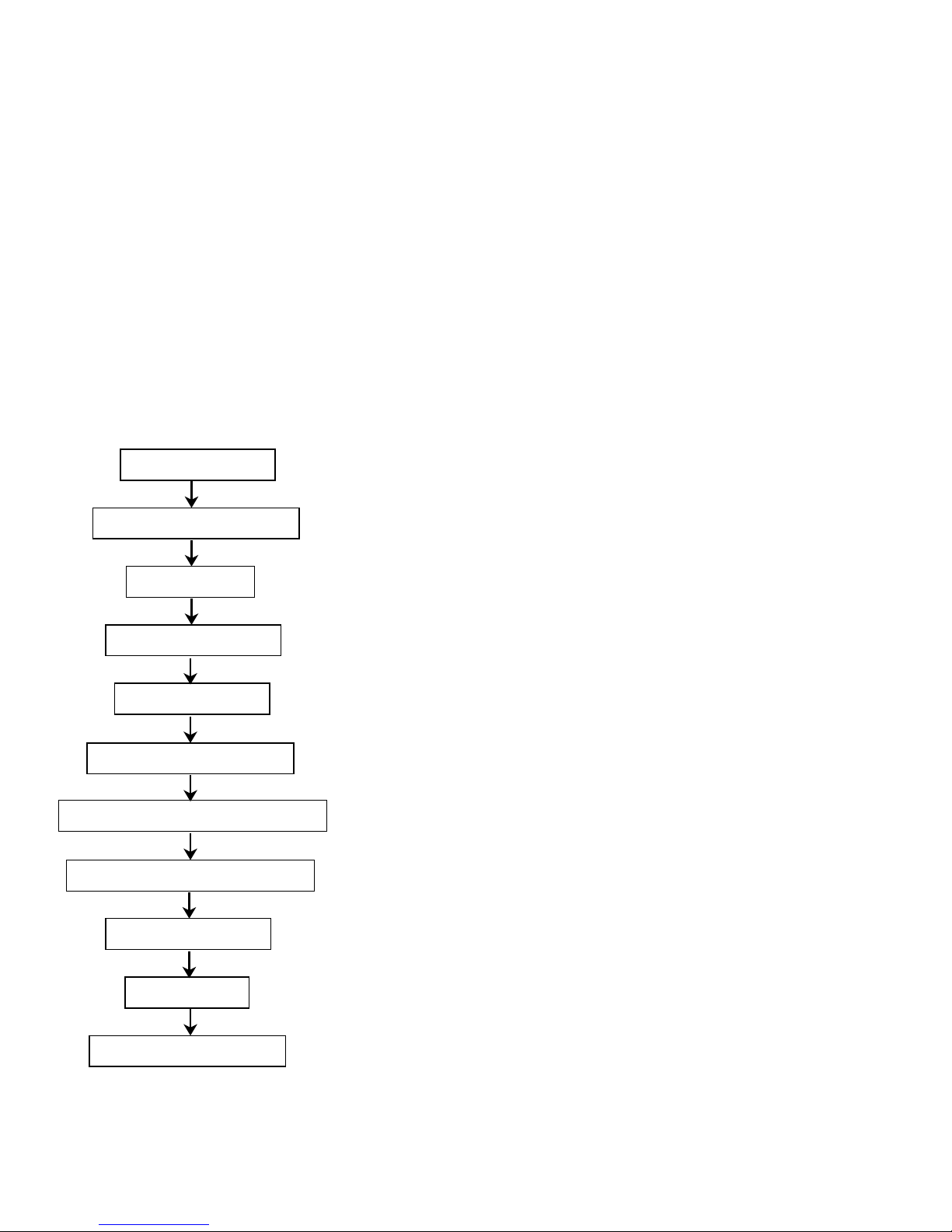

3 Troubleshooting Flowchart . . . . . . . . 9

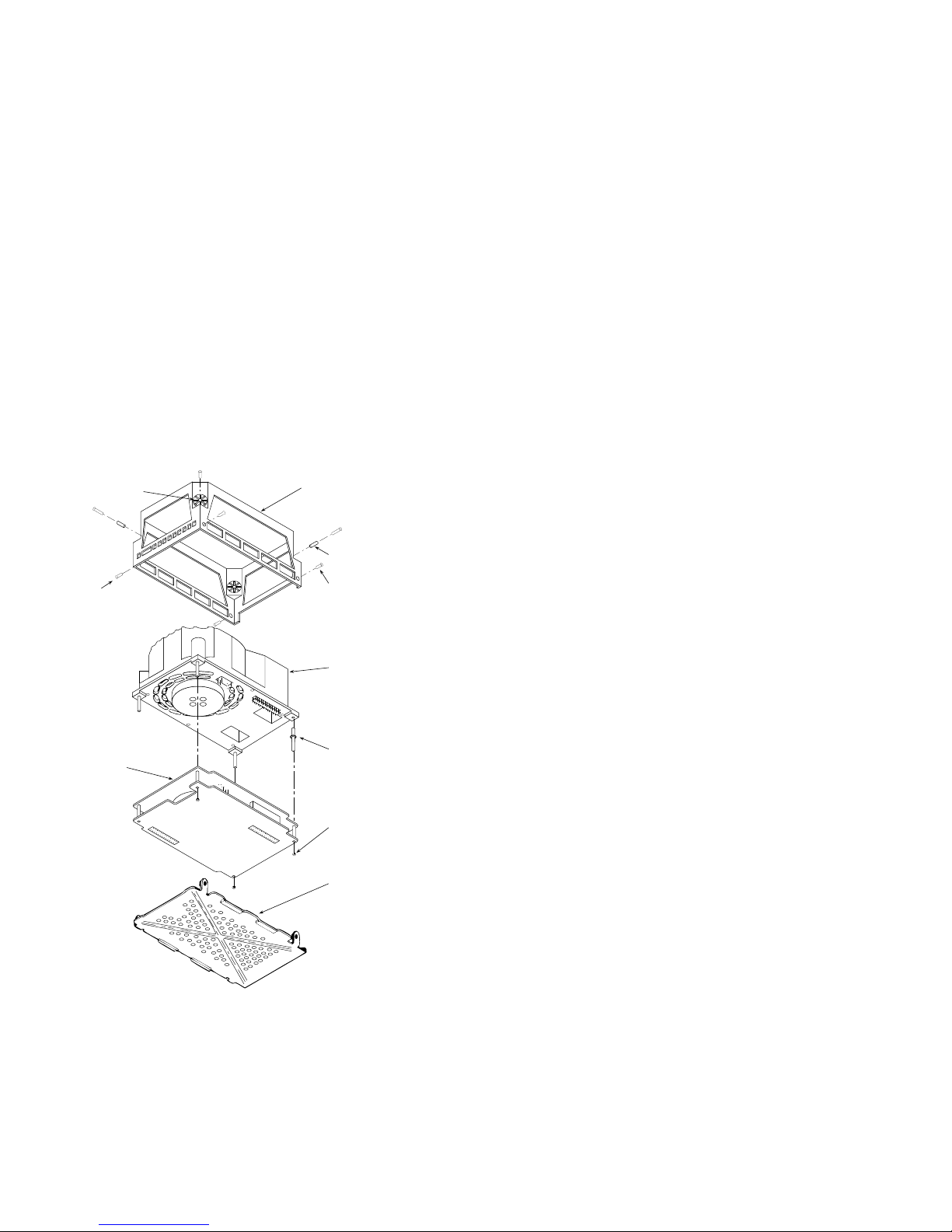

4 RA70 Exploded View . . . . . . . . . . . 11

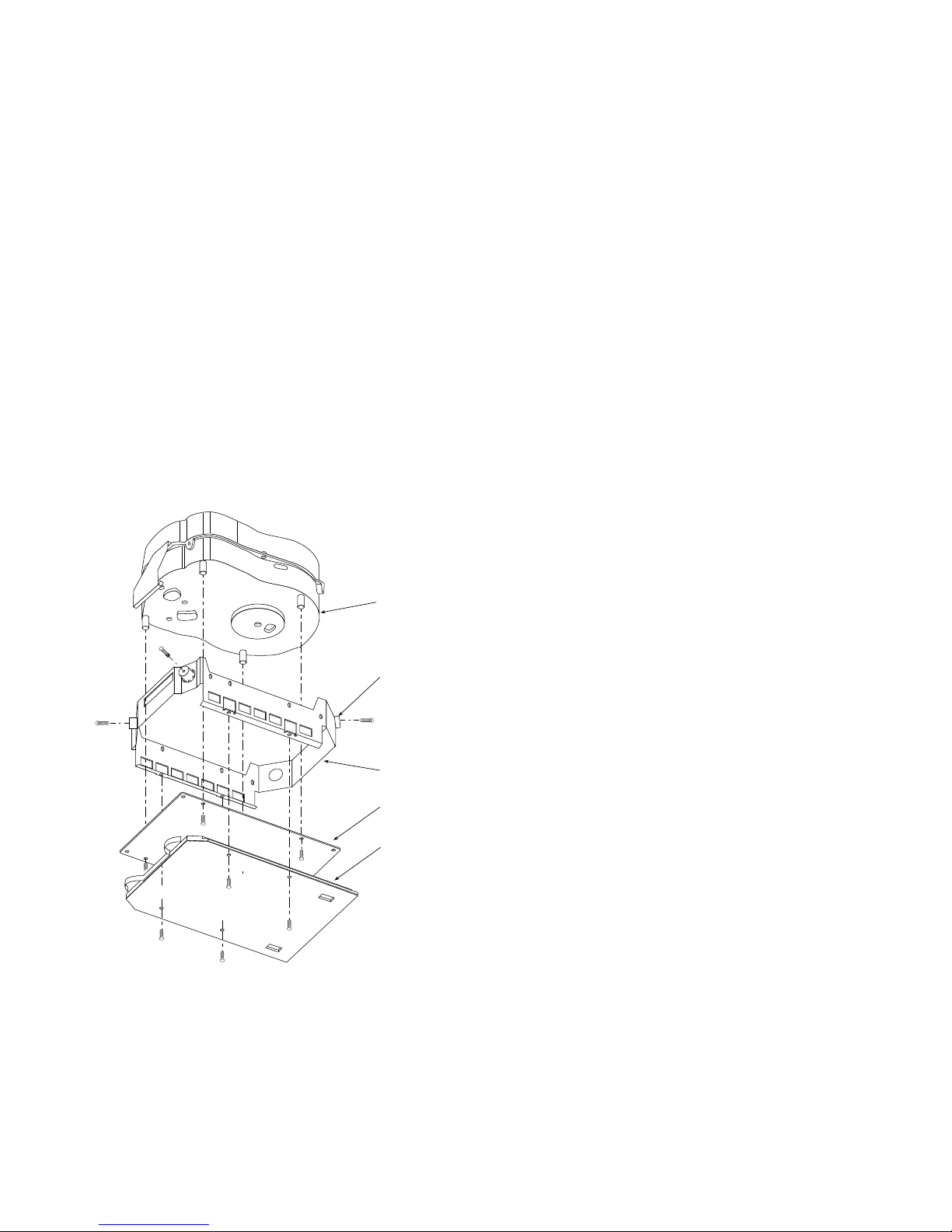

5 RA71-RA73 Exploded View . . . . . . . 12

6 SA7x Enclosure Exploded View . . . . 14

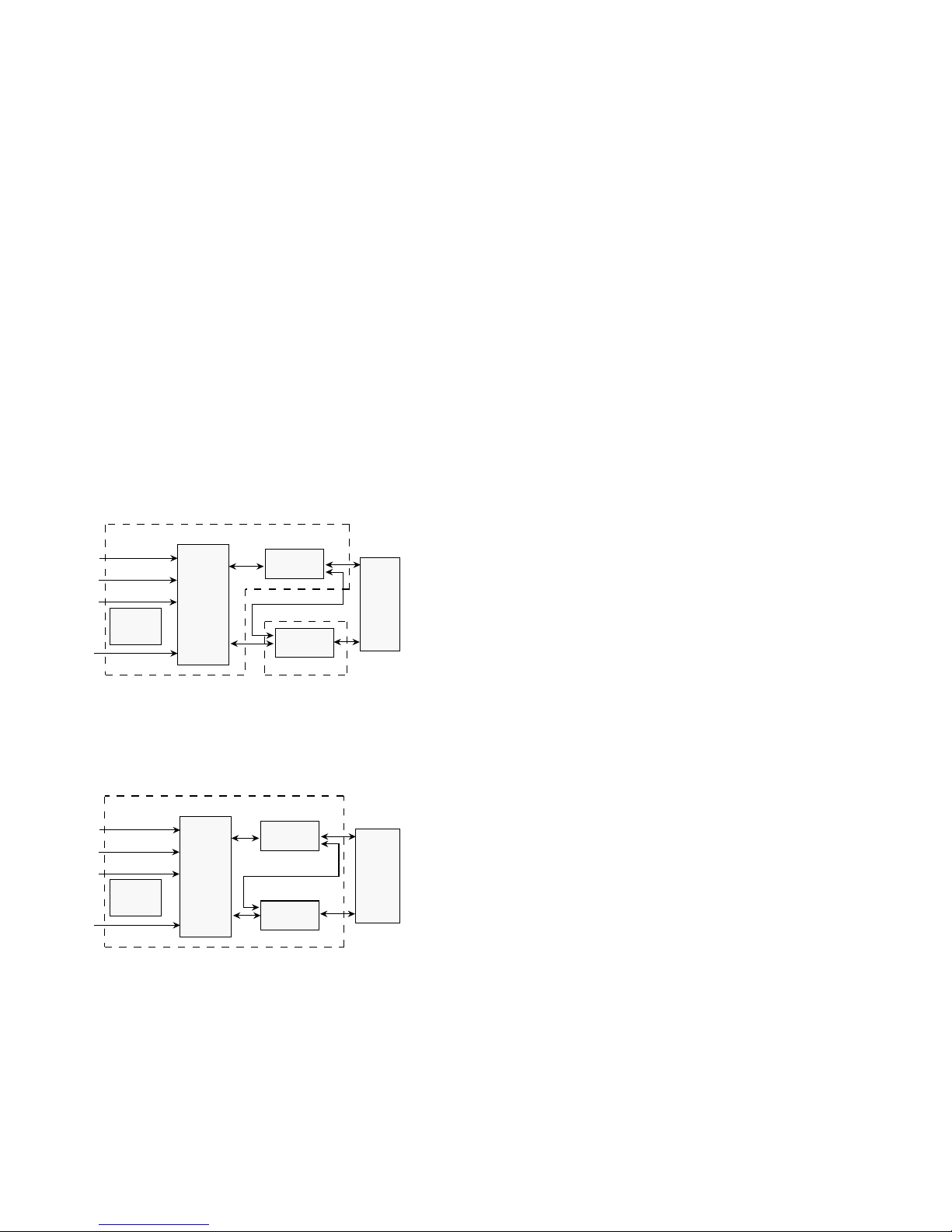

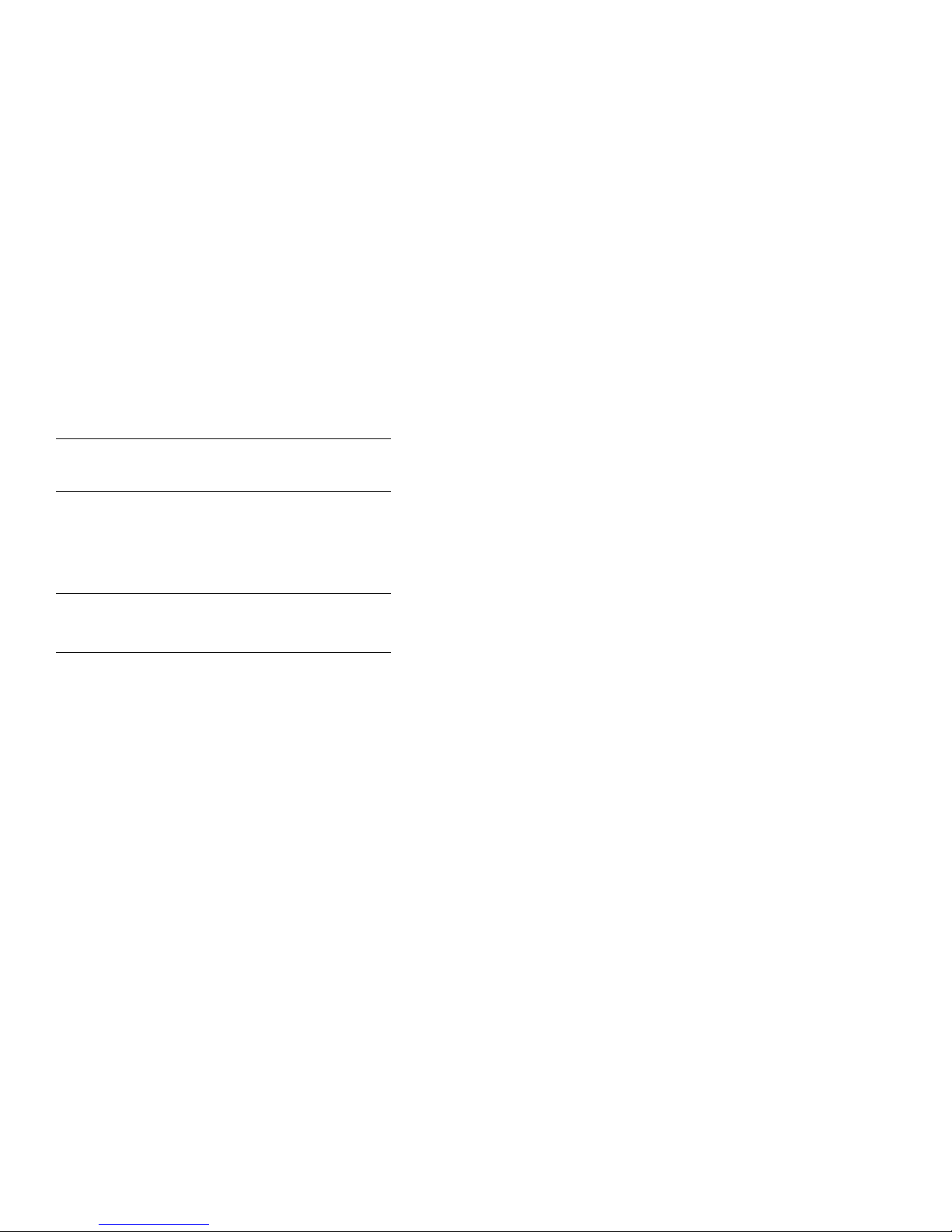

7 RA70 Electronics—Simplified Block

Diagram . . . . . . . . . . . . . . . . . . . . 15

8 RA71-RA73 Electronics—Simplified

Block Diagram . . . . . . . . . . . . . . . . 15

9 RA7x Drive Status . . . . . . . . . . . . . 20

10 RA7x Response Opcode (Byte 1) . . . 21

11 RA7x Lower Unit (Byte 2) and High

Unit and Subunit Mask (Byte 3) . . . . 21

12 RA7x Request Byte (Byte 4) . . . . . . . 22

13 RA7x Mode Byte (Byte 5) . . . . . . . . 23

14 RA7x Error Byte (Byte 6) . . . . . . . . . 24

15 RA7x Controller Byte (Byte 7) and

Retry Count (Byte 8) . . . . . . . . . . . . 25

16 RA7x Previous Command Opcode

(Byte 9) . . . . . . . . . . . . . . . . . . . . 26

17 RA7x Drive State Byte (Byte 10) . . . . 27

18 RA7x Current Cylinder Address (Bytes

11 and 12) . . . . . . . . . . . . . . . . . . 27

19 RA7x Current Group (Byte 13) . . . . . 28

20 RA7x Drive Error Code (Byte 14) . . . . 28

21 RA70 OCP Code Byte; RA71-RA73

Fault Number Byte (Byte 15) . . . . . . 28

22 SA7x OCP . . . . . . . . . . . . . . . . . . 29

Page 5

Contents v

Tables

1 Related Documentation . . . . . . . . . . 1

2 RA7x Characteristics . . . . . . . . . . . 2

3 Thermal Stabilization Times . . . . . . . 3

4 RA7x Part Numbers . . . . . . . . . . . . 10

5 SA7x Part Numbers . . . . . . . . . . . . 13

6 VAX Diagnostics for RA71-RA73 . . . . 16

7 Operating Systems for RA71-RA73 . . 17

8 SDI Controllers for RA71-RA73 . . . . . 18

9 Retired VAX Supervisor Programs . . . 18

10 OCP Error Codes . . . . . . . . . . . . . . 30

Page 6

Page 7

RA7x/SA7x Pocket Reference Guide 1

Introduction and Related Documentation

This guide contains quick-reference information for RA7x

disk drives (RA70, RA71, RA72, and RA73) and SA7x

enclosures.

For more complete information about RA7x disk drives and

SA7x enclosures, see the related documentation listed in

Table 1.

Table 1 Related Documentation

Document Title Order number

RA70 Disk Drive Technical

Description Manual EK–ORA70–TD

DSA Troubleshooting Flowchart EK–DSATF–TM

BA27 Field Maintenance Print Set MP–01429

SA7x Support Print Set EM–01435

SA7x Field Maintenance Print Set MP–01435

SAxxx Storage Array Configuration

Guide EK–SAXXX-CG

SA7x Enclosure User Guide EK–OSA7X–UG

SA7x Enclosure Service Manual EK–OSA7X-SM

RA7x Disk Drive Service Manual EK–ORA7X-SM

RA70 Field Maintenance Print Set MP–01428

RA71/RA72 Support Print Set EM–01434

RA71/RA72 Field Maintenance Print

Set MP–01434

RA73 Field Maintenance Print Set MP–01439

RA73 Support Print Set EM–01439

Page 8

2 RA7x/SA7x Pocket Reference Guide

RA7x Characteristics

Table 2 lists the characteristics of RA70 and RA71-RA73

disk drives.

Table 2 RA7x Characteristics

Characteristics RA70 RA71 RA72 RA73

Total Number of Heads

12 15 21 22

Number of Data Heads

11 14 20 21

Number of Dedicated Servo Heads

1 1 1 1

Surfaces Containing Data and Embedded Servo

Information

11 14 20 21

Formatted Data Storage Capacity

280

MB

700

MB

1.0

GB

2.0

GB

Although RA70 and RA71-RA73 disk drives are very similar

in appearance, they differ structurally and electronically.

The RA70 shoe plate is not interchangeable with those for

the RA71-RA73 disk drives. None of the RA7x HDAs or

ECMs are interchangeable.

Page 9

RA7x/SA7x Pocket Reference Guide 3

Thermal Stabilization Specifications

When condensation is visible on the enclosure or the disk

drive, stabilize the unit in the operating environment for six

hours, or until the condensation is no longer visible.

When condensation is not visible on the enclosure or

disk drive or enclosure, see Table 3 for correct thermal

stabilization times.

Table 3 Thermal Stabilization Times

Temperature

Range Degrees

C

60 to 66 140 to 151 3 hours

50 to 59 122 to 139 2 hours

40 to 49 104 to 121 1 hour

30 to 39 86 to 103 30 minutes

18 to 29 65 to 85 No stabilization

10 to 17 50 to 64 30 minutes

0 to 9 32 to 49 1 hour

–10 to –1 14 to 31 2 hours

–20 to –11 –4 to 13 3 hours

–30 to –21 –22 to –5 4 hours

–40 to –31 –40 to –21 5 hours

Temperature

Range Degrees

F

Minimum

Stabilization

Time

required

Page 10

4 RA7x/SA7x Pocket Reference Guide

Setting Capacity Indicator Switch

Set the Capacity Indicator switch on the RA71 and RA72

disk drives, shown in Figure 1, as follows:

NOTE

The capacity indicator switch has no function on an

RA73.

• RA71 (700 MB)

Capacity Indicator switch should be up (on).

• RA72 (1 GB)

Capacity Indicator switch should be down (off).

Page 11

RA7x/SA7x Pocket Reference Guide 5

UNIT SELECT SWITCHES

CAPACITY INDICATOR SWITCH

Figure 1 RA71/RA72 Capacity Indicator Switch

TOP COVER HDA

CHASSIS

COM-R002

Page 12

6 RA7x/SA7x Pocket Reference Guide

Troubleshooting

This section includes troubleshooting tips, an example of

a drive internal error log (Figure 2), and a troubleshooting

flowchart (Figure 3).

Tips for DSA Troubleshooting

Observe the following tips when troubleshooting DSA

products:

• Avoid formatting new HDA units.

• Note that EDC errors are not drive problems.

• Note that forced errors are not necessarily HDA

problems.

• Avoid running standalone diagnostics unless drive

or system error logs are unavailable and all other

troubleshooting techniques have failed.

• Ensure that equipment is thermally stabilized before

attempting to power up.

• Use proper ESD grounding methods. Equipment is

highly susceptible to static damage.

• Adhere to the service delivery strategy as outlined in

specific component service manuals.

Page 13

RA7x/SA7x Pocket Reference Guide 7

Figure 2 Drive Internal Error Log

Error Log Entries for Drive 0

Select starting entry location [(7), 1-191] ? 8

Enter how many error log entries to display [(191), 0-191] ? 30

Pause and prompt after every 10 error log entries [(Y), N] ? Y

Drive

Max#Entries

Type

RA70 191 580 125000

Entry

Entry

Count

Loctn

(D)

(D)

8

7

6

5

4

3

2

1

191

(D) = decimal, (A) = ASCII, (H) = hex

Seeks/Power-on

(D)

Err

Typ

(A)

2 00

DE

3

DE

3

DE

3

3

3

3

3

2

Err

Code

(H)

39

E7

E9

00

00

00

00

00

(D)

Seek

Count

(D)

453122

452446

452446

451699

451699

451616

451616

MFG

Code

(H)

0

0

Cum. Seeks

00 00 00 00 00 00 00 00 00 00 00 passed.test

32

33

34

00

00

00

00

00

Cum. Power-on

(D)

Drive-Specific Hex Data

Byte 0-9, right to left

00 00 09 0A 00 00 00 04 32 58

00 00 09 04 FF FB 0B 05 42 75

00 00 09 03 FF FB 0B 05 12 9D

00 00 09 02 02 F6 05 04 79 A0

00 00 09 01 02 F6 05 04 7A BB

00 00 09 00 00 00 00 00 42 A0

00 00 09 00 00 00 00 00 40 C0

00 00 00 00 00 00 00 00 00 00

(D)

7200

(H)

Minutes

(H)

00001C20

Drive Err

Message

(A)

wrg&off.trk

inc.lhd.sek

exp.sek.tmr

drv.sys.ini

exp.onl.atn

drv.sys.ini

drv.pwr.rst

passed.test

1 2 3 4 5 6

1. Drive error code—see “Drive error codes and fault numbers” in this guide for an explanation of

these codes

2. Manufacturing code (OCP code)—see the OCP error codes table in this guide for an expla-

nation of these codes

3. Logic Processor Number of Minutes (bytes 9, 8, 7, and 6)

4. Servo Processor Destination Cylinder (bytes 5 and 4)

7 8 9

5. Servo Processor Destination Logical Head Number (byte 3)

6. Servo Processor Physical State Number (byte 2)—see the following page for a list of physical

state numbers

7. Logic Processor Logical State Bit Flags (byte 1)—see the following page for a list of logical

state bit numbers

8. Logic Processor Fault Number (byte 0)

9. Drive error message—see "Drive error codes and fault numbers" in this guide for a translation

of these error messages

COM-0211

Page 14

8 RA7x/SA7x Pocket Reference Guide

Servo Processor Physical State Numbers (Byte 2)

00–reset

01–retract (unload heads)

02–spin-up motor

03–spin-down motor

04–detent (track follow)

05–seek to cylinder

06–return to cylinder zero (load heads)

07–recalibrate

08–diagnostic

The following State Numbers apply only to the

RA73:

09–fault

0A–PLL lock

Logic Processor Logical State Bit Flags (Byte 1)

Bit 07–hard error

Bit 06–soft fault

Bit 05–internal read/write ready

Bit 04–drive timing enabled

Bit 03–logical attention

Bit 02–logical topology state

Bit 01–logical available state

Bit 00–logical available state

NOTE

For more information about the physical state numbers

and logical state bit flags, see the RA7x Disk Drive

Service Manual.

Page 15

RA7x/SA7x Pocket Reference Guide 9

Figure 3 Troubleshooting Flowchart

Talk to the system operator.

Check the OCP for fault indications.

Run VAXsimPLUS.

Analyze the HSC Console Log.

Analyze the Host Error Log.

Analyze the Drive Internal Error Log.

Correlate error codes to the probable failing FRU.

Use host-based diagnostics as a last resort.

Identify prime suspect FRU.

Replace failing FRU.

Verify that the drive is operational.

COM-R080

Page 16

10 RA7x/SA7x Pocket Reference Guide

RA7x Parts

Table 4 lists RA7x part numbers. Figures 4 and 5 shows

exploded views for RA70 and RA71-RA73 disk drives.

Table 4 RA7x Part Numbers

Part Part Number

RA70 Disk Drive

ECM

HDA

Shoe plate

RA71 Disk Drive

ECM

HDA

Shoe plate

RA72 Disk Drive

ECM

HDA

Shoe plate

RA73 Disk Drive

ECM 54-21396-01

HDA 70-28699-01

Shoe plate 70-29408-01

70-22494-01

70-21946-01

70-22474-01

54-20826-01

70-28492-01

70-29408-01

54-20826-01

70-28492-02

70-29408-01

RA7x Disk Drive

Electronically conductive field

service grounding kit

29-11762

Page 17

RA7x/SA7x Pocket Reference Guide 11

Figure 4 RA70 Exploded View

SHOCK

ISOLATOR

SCREW

ELECTRONIC

CONTROL

MODULE

CHASSIS

GROMMET

BUSHING

SCREW

FOR SHOE

PLATE

ATTACHMENT

TOP

COVER/HDA

BASEPLATE

CORNER

POSTS

MODULE

RETENTION

KEP NUT

SHOE

PLATE

COM-R004

Page 18

12 RA7x/SA7x Pocket Reference Guide

Figure 5 RA71-RA73 Exploded View

HDA

ASSEMBLY

SHOCK

ISOLATOR

CHASSIS

ECM

SHOE

PLATE

CXO-3519A-MC_R

Page 19

RA7x/SA7x Pocket Reference Guide 13

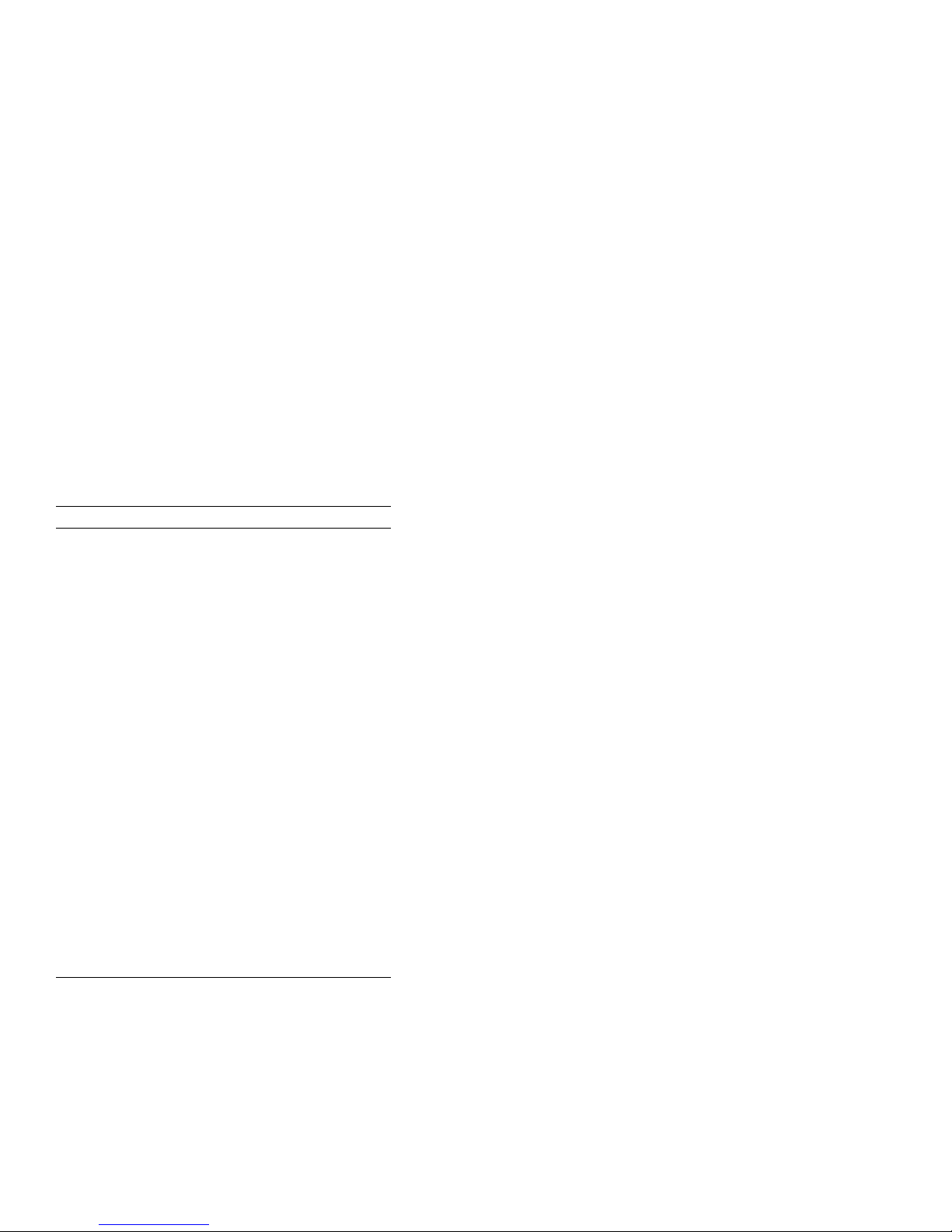

SA7x Parts

Table 5 contains a list of part numbers. Figure 6 shows an

exploded view of an SA7x enclosure.

Table 5 SA7x Part Numbers

Part Part Number

Chassis (enclosure assembly) 70-23901-01

Drive position filler 70-23970-01

Fan assembly 70-24440-01

Frame assembly 70-23913-01

OCP

assembly

cable, long 80 cm (31.5 in)

cable, short 35.6 cm (14 in)

Power cord 17-00442-19

Power harness 70-26255-01

Power supply H7869-AK

Pushbutton switch

with green LED 12-12717-13

Pushbutton switch cap

left front

left rear

right front

right rear

SDI Cables

External cable assembly

Internal cable assembly

Internal SDI cable harness

Transition board

Board 1

Board 2

Transition interface cables 17-02147-01

70-25696-01

70-26254-02

70-26254-01

12-14027-14

12-14027-15

12-14027-13

12-14027-12

70-26257-01

70-26256-01

17-01699-01

54-19171-01

54-19015-01

Page 20

14 RA7x/SA7x Pocket Reference Guide

Figure 6 SA7x Enclosure Exploded View

RIGHT REAR

DISK DRIVE

LEFT REAR

POSITION

DISK DRIVE

POSITION

REAR

COVER

(NOT

SHOWN)

POWER

SUPPLY

CHASSIS

FAN

TRANSITION

BOARD 2

TRANSITION

BOARD 1

OPERATOR

CONTROL

PANEL

RA70 DISK

DRIVE SHOWN

MOUNTING

SCREWS

FRAME

DRIVE POWER

SWITCH PANEL

LEFT FRONT

DISK DRIVE

POSITION

RIGHT FRONT

DISK DRIVE

POSITION

FRONT

COVER

CXO-1845D_S_R

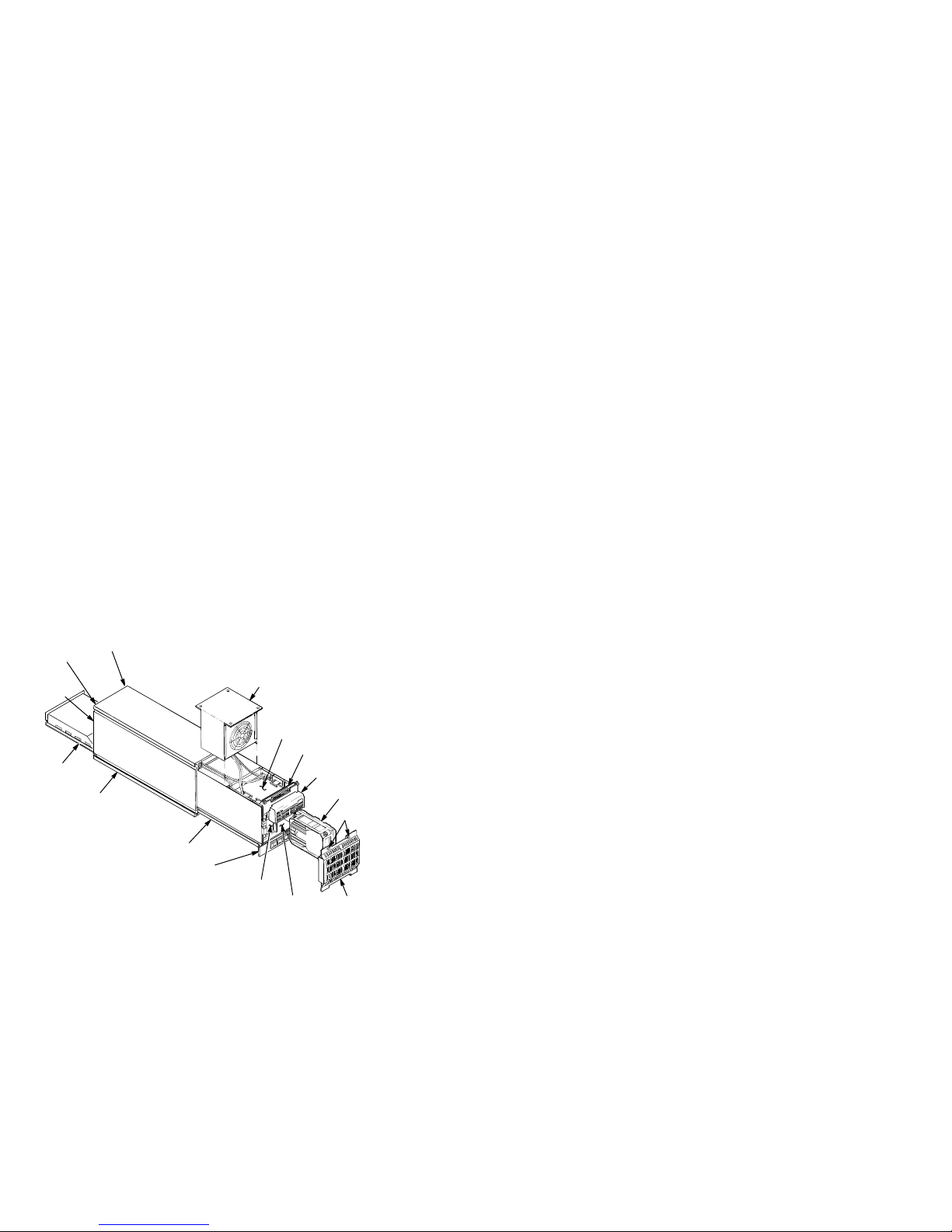

Page 21

RA7x/SA7x Pocket Reference Guide 15

RA7x Electronics Block Diagrams

Figures 7 and 8 are electronics block diagrams for RA70

and RA71-RA73 disk drives.

Figure 7 RA70 Electronics—Simplified Block Diagram

Logic Read/Write Module

Power J4

Port B J2

Port A J1

Remote

OCP J3

I/O Logic

Local OCP

Read/Write

HDA

Servo/Spindle

Servo/Spindle Module

COM-R082

Figure 8 RA71-RA73 Electronics—Simplified Block

Diagram

Electronic Control Module

Power J4

Port B J2

Port A J1

Remote

OCP J3

I/O Logic

Local OCP

Read/Write

Servo/Spindle

HDA

COM-R081

Page 22

16 RA7x/SA7x Pocket Reference Guide

RA71-RA73 Support

Tables 6, 7, and 8 list the minimum versions of operating

systems, diagnostics, and SDI controllers that support

RA71-RA73 disk drives in Release 43.

The diagnostics and VAX supervisor programs in Table 6

all recognize RA71-RA73 disk drives. The retired VAX

Supervisor programs in Table 9 do not recognize RA71RA73 disks drives. However, they will properly test and

operate the RA71-RA73 disk drives with the above disk

drive diagnostics when the disk drives are "attached as

RA70 disk drives" during program setup.

Table 6 VAX Diagnostics for RA71-RA73

Diagnostic

Supervisor Description Version

EVRAE Generic MSCP Exerciser 4.3

EVRLB UDA/KDB50 Basic Disk

Formatter

EVRLF UDA/KDB50 Basic

Subsystem Diagnostic

EVRLG UDA/KDB50 Disk Drive

Exerciser

EVRLJ VAX UDA/KDB50/KDM70

Exerciser

EVRLK VAX Bad Block Replace

Utility

EVRLL VAX Disk Resident Error

Log Utility

EVRLM KDM70 EEPROM Update

Utility

EVRLN DUP Control Program 1.6

EBSAA Supervisor, 8200, 8250,

8300, 8550 (Bereta)

ELSAA Supervisor, 5800, 6000-2xx,

6000-3xx

EMSAA Supervisor, 6000-5xx 14.4-PT1

ERSAA Supervisor, 6000-4xx 14.4-PAT1

EVSBA VAX Diagnostic Autosizer 7.5

EVSBB VAX Online Autosizer 4.0

8.3

10.4

10.3

4.3

4.3

3.3

1.6

14.4-PAT1

14.4-PAT1

Page 23

RA7x/SA7x Pocket Reference Guide 17

Table 7 Operating Systems for RA71-RA73

Operating

Systems

Software

RA71/RA72

Minimum

Version

VMS 5.4-2

1

RA73

Minimum

Version

5.5-2

VAXsimPLUS 1.6 2.0

ULTRIX-32 4.2 4.3

VAXELN 4.3 4.3-x

VAX System V 3.2.1 Not planned

1

The Error Log Formatter (ERF) Version 5.4-2 must be

upgraded to Version 5.4-2 (0001) to support RA71-RA72.

Version 5.5-2 is required to support the RA73 disk drive.

Page 24

18 RA7x/SA7x Pocket Reference Guide

Table 8 SDI Controllers for RA71-RA73

SDI

Controller

HSC40

(CRONIC)

HSC50

(CRONIC)

HSC60

(CRONIC)

HSC70

(CRONIC)

HSC90

(CRONIC)

KDM70 SW Version 30 (3.0)

KDA50 SW Version 8

KDB50 SW Version 20

UDA50A SW Version 6

Minimum

Version

V600

V410

V600

V600

V600

K.SI Interface SW Version 12

K.SDI Interface SW Version 39/40

HW Version 17

HW Version 4

HW Version 28

HW Version 0

Table 9 Retired VAX Supervisor Programs

Supervisor

Program Description

ECSAA Supervisor, 750

EDSAA Supervisor, 8600, 8650

EJSAA Supervisor, 8820/30/40

ENSAA Supervisor, 725, 730

ESSAA Supervisor, 780, 785

EWSAA Supervisor, 9000

EBSAA Supervisor, 8530, 8550, 8700, 8800,

8820N

Page 25

RA7x/SA7x Pocket Reference Guide 19

RA7x Drive Status Information

Figures 9 through 22 disk drive status information diagrams

for the RA7x disk drives. These drives format the drive

status bytes as shown in Figure 9. Note that Byte 15

contains different data for RA70 and RA71-RA73 disk

drives. Byte 15 contains the OCP code for an RA70 disk

drive; for RA71-RA73 drives, byte 15 contains the fault

number.

NOTE

Unless specifically stated otherwise, the status

information diagrams apply to the same bytes for all

RA7x drives.

Page 26

20 RA7x/SA7x Pocket Reference Guide

Figure 9 RA7x Drive Status

MSB

BYTE 1

BYTE 2

BYTE 3

BYTE 4

BYTE 5

BYTE 6

BYTE 7

BYTE 8

BYTE 9

BYTE 10

BYTE 11

BYTE 12

BYTE 13

BYTE 14

BYTE 15

NOTE: IF DRIVE IS RA70, BYTE 15 CONTAINS OCP CODE. IF DRIVE IS

RA71/RA72/RA73, BYTE 15 CONTAINS FAULT NUMBER.

RESPONSE CODE

UNIT NO.

SUBUNIT MASK

OA

RR

W4 W3 W2W1DD FO

DE

RE

S4

S3 S2 S1 C1 C2

PREVIOUS COMMAND CODE

LOW CYLINDER ADDRESS

HIGH CYLINDER ADDRESS

DRIVE ERROR CODE

EL

DR SR

PE

DF

WE

RETRY COUNT

DRIVE STATE

CURRENT GROUP

SEE NOTE

HI UNIT NO.

PS

DB S7

C3

LSB

REQUEST BYTE

RU

MODE BYTE

ERROR BYTE

CONTROLLER BYTE

C4

SEEK AND RECALL

GENERIC

STATUS BITS

EXTENDED DRIVE

STATUS BYTES

CXO-3521A-TI_R

Page 27

RA7x/SA7x Pocket Reference Guide 21

Figure 10 RA7x Response Opcode (Byte 1)

X X X X X X X X

Byte 1 — Response Opcode

COM-R055

Figure 11 RA7x Lower Unit (Byte 2) and High Unit and

Subunit Mask (Byte 3)

Byte 3

0 0 0 1 X X X X

Byte 2

X X X X X X X X

Drive select unit number

Subunit 0 mask (subunit 0 reporting this status)

Subunit 1 mask (not used)

Subunit 2 mask (not used)

Subunit 3 mask (not used)

COM-R056

Page 28

22 RA7x/SA7x Pocket Reference Guide

Figure 12 RA7x Request Byte (Byte 4)

X X X X X X X X

Byte 4

(RU) 0 = Run/Stop switch out

1 = Run/Stop switch in

(PS) 0 = Port switch out

1 = Port switch in

(PB) 0 = Port A receivers enabled

1 = Port B receivers enabled

(EL) 0 = No loggable information in extended status area

1 = Loggable information in extended status area

(SR) 0 = Spindle not ready (not up to speed)

1 = Spindle ready

(DR) 0 = No diagnostic is being requested from the host

1 = There is a request for a diagnostic to be loaded into

the drive microprocessor memory

(RR) 0 = Drive requires no recalibrated command

1 = Drive request recalibrated command

(OA) 0 = Drive on-line or available to current controller

1 = Drive unavailable (it is already on-line to another

controller)

Request Byte

COM-R057

Page 29

RA7x/SA7x Pocket Reference Guide 23

Figure 13 RA7x Mode Byte (Byte 5)

X X 0 X

X X X X

Byte 5 Mode Byte

(S7) 0 = 512-Byte sector format (16 bit)

1 = 576-Byte sector format (18 bit)

(no current plan to implement 18 bit)

(DB) 0 = DBN area access disabled

1 = DBN area access enabled

(FO) 0 = Formatting operations disabled

1 = Formatting operations enabled

(DD) 0 =Drive enabled by controller error routine or diagnostic

1 = Drive disabled by controller error routine or diagnostic

(Fault Light = ON)

(W1) 0 = Write Protect switch for subunit 0 is out

1 = Write Protect switch for subunit 0 is ON

(W2) Not implemented

(ED1) Error log disable (set by 2-board controller diagnostics)

(ED0) Error log disable (set by 2-board controller diagnostics)

COM-R058

Page 30

24 RA7x/SA7x Pocket Reference Guide

Figure 14 RA7x Error Byte (Byte 6)

X X X X

X 0 0 0

Byte 6 Error Byte

(WE) 0 = No error

1 = Write lock error (attempt to write while

write protected)

(DF) 0 = No error

1 = Drive failure during initialization

(PE) 0 = No error

1 = Level 2 protocol error (improper command

codes or parameters issued to drive)

(RE) 0 = No error

1 = SDI receive error on SDI transmission

line(s) from controller

(DE) 0 = No error

1 = Drive error (drive Fault light may be on

—possibly clearable via DRIVE CLEAR

command)

COM-R059

Page 31

RA7x/SA7x Pocket Reference Guide 25

Figure 15 RA7x Controller Byte (Byte 7) and Retry

Count (Byte 8)

0 0 0 1 X X X X

X X X X X X X X Byte 8 Retry Count/Failure Code

Byte 7 Controller Byte

0000 = Normal drive operation

1000 = Drive off-line (under control of a diagnostic)

1001 = Drive off-line (another drive has same unit select

identifier)

(S1) 1 (not used)

(S2) 1 (not used)

(S3) 1 (not used)

(S4) 1 (not used)

COM-R060

Page 32

26 RA7x/SA7x Pocket Reference Guide

Figure 16 RA7x Previous Command Opcode (Byte 9)

X X X X X X X X Byte 9 Last Opcode

(Extended drive status byte)

Opcode of the last previous level 2 drive command

decoded by the drive (received from the SDI controller)

COM-R061

Last Level 2 Drive Commands

The following is a list of the last level 2 drive commands

decoded by the drive (received from the SDI controller).

81—change mode

82—change controller flags

03—diagnose

84—disconnect (drive)

05—drive clear

06—error recovery

87—get common characteristics

88—get subunit characteristics

0A—initiate seek

8B—on line

0C—run

8D—read memory

8E—recalibrate

90—topology

0F—write memory

FF—select group (level 1 command, processed by

firmware seek head select subroutines)

Page 33

RA7x/SA7x Pocket Reference Guide 27

Figure 17 RA7x Drive State Byte (Byte 10)

X X X X X X X X

Byte 10

AV 1 = Available asserted

OL 1 = Drive in on-line status

TP 1 = Drive executing level 2 topology command

AT 1 = Attention asserted

TG 1 = Sector + index timing enabled for transmission

via RTDS line

RW 1 = Drive is internal read/write ready

SF 1 = Soft fault detected; possibly clearable via

level 2 clear command

HE 1 = Hard error; drive must be power-cycled to attempt

to clear this error

Drive State Bit Flags

Contains a number representing state

of drive at time of error

COM-R062

Figure 18 RA7x Current Cylinder Address (Bytes 11

and 12)

Byte 11Byte 12

X X X X X X X X

X X X X X X X X

Cylinder requested during last seek command

COM-R063

Page 34

28 RA7x/SA7x Pocket Reference Guide

Figure 19 RA7x Current Group (Byte 13)

X X X X X X X X

Byte 13

Group number currently selected

(will be read/write head number in

an RA7x)

COM-R064

Figure 20 RA7x Drive Error Code (Byte 14)

X X X X X X X X

Byte 14 Drive Error Code

COM-R065

Figure 21 RA70 OCP Code Byte; RA71-RA73 Fault

Number Byte (Byte 15)

X X X X X X X X

Byte 15 OCP/fault number code indicates to

module repair centers (as close as

possible) area of logic specifically in

question

COM-R066

Page 35

RA7x/SA7x Pocket Reference Guide 29

Figure 22 SA7x OCP

d i g i t a l

LEFT

REAR

Run Fault

O O

/Set No.

Ready

O

Unit No. Write

000

Protect

O O

PORT SWITCHES

A B

O

LEFT

FRONT

O O

Run Fault

/Set No.

O O

O O

SERIAL NO.

LABEL FOR

LEFT REAR

DISK POSITION

SERIAL NO.

LABEL FOR

LEFT FRONT

DISK POSITION

O

002

Unit No. Write

Ready

O

001

O

003

O O

Protect

O O

O O

PORT SWITCHES

Unit Select

A B

O

O

O

SERIAL NO.

LABEL FOR

RIGHT REAR

DISK POSITION

SERIAL NO.

LABEL FOR

RIGHT FRONT

DISK POSITION

FRONT

COVER

PC DRIVE

POWER SWITCHES

RIGHT

REAR

RIGHT

FRONT

LEFT

LEFT

REAR

FRONT

RIGHT

REAR

RIGHT

FRONT

COM-0204

Page 36

30 RA7x/SA7x Pocket Reference Guide

OCP Error Codes

Table 10 lists the error codes displayed by the OCP lights.

The next section, "Drive Error Codes and Fault Numbers,"

describes each error code and the most probable cause of

the error.

Table 10 OCP Error Codes

Description

and

FRUs

00–No error

01–Logic input/output module

Note1– – – – – On

02–SDI PSID interface

ECM – – – – On –

SDI

controller

SDI

cable

03–SDI gate array

ECM – – – – On On

04–MC 6803 microcomputer

ECM – – – On – –

05–27264 UVPROM

ECM – – – On – On

06–2716 static RAM

ECM – – – On On –

07–X2816A EEPROM

ECM – – – On On On

08–Bus decoders and drivers

Note1– – On – – –

09–ZXENDEC

ECM – – On – – On

Run

Stop Fault Ready

– – – – – –

– – – – On –

– – – – On –

Write

Protect

PortAPort

B

1

Obtain the drive error code from the host error log, the

internal drive error log, or the HSC console. Refer to the

next section "Drive Error Codes and Fault Numbers."

Page 37

RA7x/SA7x Pocket Reference Guide 31

Table 10 (Continued) OCP Error Codes

Description

and

FRUs

SDI

Run

Stop Fault Ready

Write

Protect

PortAPort

B

– – On – – On

controller

0A–Analog signal processor

ECM – – On – On –

HDA – – On – On –

0B–Detector qualifier

Note1– – On – On On

11–Servo module digital circuits

ECM – On – – – On

HDA – On – – – On

12–Servo gate array

ECM – On – – On –

13–TMS 32020 processor

ECM – On – – On On

14–Static RAM

ECM – On – On – –

15–Servo analog

ECM – On – On – On

HDA – On – On – On

16–Voltage controlled oscillator (VCOO)

ECM – On – On On –

HDA – On – On On –

17–Spindle motor control chip

ECM – On – On On On

HDA – On – On On On

18–Spindle power amp

ECM – On On – – –

HDA – On On – – –

19–Actuator power amp

1

Obtain the drive error code from the host error log, the

internal drive error log, or the HSC console. Refer to the

next section "Drive Error Codes and Fault Numbers."

Page 38

32 RA7x/SA7x Pocket Reference Guide

Table 10 (Continued) OCP Error Codes

Description

and

FRUs

Run

Stop Fault Ready

Write

Protect

PortAPort

B

ECM – On On – – On

HDA – On On – – On

1A–Actuator analog

ECM – On On – On –

HDA – On On – On –

1B–A-D and D-A converters

ECM – On On – On On

HDA – On On – On On

1C–Analog MUXs

ECM – On On On – –

HDA – On On On – –

1E–HDA Capacity Indicator switch setting

ECM – On On On On –

HDA – On On On On –

Note2– On On On On –

1F–Head/disk assembly

HDA – On On On On On

ECM – On On On On On

30–Microprocessor module

ECM On On – – – –

31–OCP module

ECM On On – – – On

Note1On On – – – On

32–Fault module

Note1On On – – On –

33–Spindle motor control module

Note1On On – – On On

1

Obtain the drive error code from the host error log, the

internal drive error log, or the HSC console. Refer to the

next section "Drive Error Codes and Fault Numbers."

2

Verify that the HDA Capacity Switch setting is as described

in "Setting the Capacitor Indicator Switch" section.

Page 39

RA7x/SA7x Pocket Reference Guide 33

Table 10 (Continued) OCP Error Codes

Description

and

FRUs

Run

Stop Fault Ready

Write

Protect

PortAPort

B

34–Digital signal processor module

ECM On On – On – –

HDA On On – On – –

35–SDI module

ECM On On – On – On

SDI

On On – On – On

cable

SDI

On On – On – On

controller

36–Microprocessor unit module

Note1On On – On On –

37–Diagnostic module

ECM On On – On On On

HDA On On – On On On

3E–Debug error trap

Note1On On On On On –

3F–Power supply

ECM On On On On On On

Power

On On On On On On

supply

Note1On On On On On On

1

Obtain the drive error code from the host error log, the

internal drive error log, or the HSC console. Refer to the

next section "Drive Error Codes and Fault Numbers."

Page 40

34 RA7x/SA7x Pocket Reference Guide

Drive Error Codes and Fault Numbers

00—Internal Error Log Events

Error Description: The following fault numbers (FNs)

may appear in the drive internal error log with a drive

error code of "00" (not a drive error):

FN: 00—passed.test.—no drive detected fault

FN: 20—drv.sys.rst.—valid drive system reset

FN: 3E—rdg.off.trk.—read gate and off track

The drive will not post a recoverable read-and-off-track

error to prevent interruption to the controller. This

allows the controller to execute all of its available

retry/error recovery sequences to the drive and if

necessary, retrieve user data during a recoverable

error.

FN: A0—drv.sys.ini.—valid drive system initialize.

The drive received an INIT pulse from the controller via

the SDI RTCS line.

FN: BB—exp.onl.atn.—expired on-line timer with

attention.

While in the on-line state, the drive timed out the

controller and raised attention. A second timeout

occurred and the drive performed a disconnect to the

SDI and went to the available state. This is usually the

result of a host failure, a controller failure, or SDI cable

disconnection.

FN: BC—inv.sys.ini.—invalid or spurious SDI INIT.

The drive received a SDI initialize pulse (via RTCS

line) and discontinued the drive clock (per SDI

specification), but the controller did not clear SDI INIT

after the drive responded with discontinued clocks.

FN: C0—drv.pwr.rst.—drive power reset

FN: 28—int.brt.ers.—initiate burst write erase

FN: 29—ini.brt.wrt.—initiate burst write

FN: 2A—passed.brwt.—burst write complete

Most Probable Cause: Refer to specific Fault Number

(FN) above.

03—Spin-Up Timeout

Error Description: The I/O processor has instructed

the spindle subsystem to spin up, but the spindle

subsystem has not indicated up to speed within 15

seconds.

FN: 70—exp.sup.tmr.—expired spinup timer

Page 41

RA7x/SA7x Pocket Reference Guide 35

FN: 72—exp.pur.tmr.—expired purge cycle timer)

Most Probable Cause: ECM, HDA

04—Spin-Up Actuator Fault

Error Description: Prior to a spinup operation, the

drive firmware performs some actuator tests. A failure

during this test will result in this error and the drive will

abort any further attempts to spin up the disks.

FN: 6F—sup.svo.dgn.—spinup servo diagnostic fault)

Most Probable Cause: HDA, ECM

05—Power Supply

Error Description: The drive has detected changes

in PWR OK resulting from the detection of ACOK or

changes detected by the on board +12v and +5v dc

sensor circuits. This may cause all of the operator

control panel (OCP) indicators to stay on.

FN: 3F—inv.drv.pwr.—invalid or spurious drive power

Most Probable Cause: SA7x Power Supply, Internal

SA7x cables, ECM, site power problems

06—Microcode Fault

Error Description: The I/O processor tried to access

an unused ROM location due to a hardware problem

or a software error internal to the drive.

FN: Not Appropriate

Most Probable Cause: ECM

Page 42

36 RA7x/SA7x Pocket Reference Guide

07—Frame Sequence Error

Error Description: There are three transmission error

types that are reported as sequence errors:

• A message continuation frame or message end

frame was decoded before a message start

frame.

• Two message start frames were decoded in a

row.

• Less than two frames, a message start frame

and a message end frame, or more than 63

frames have been decoded before a message

end frame.

FN: A1—grp.frm.seq.—group select frame sequence

error

FN: AB—str.frm.seq.—start frame sequence error

FN: AC—con.frm.seq.—continue frame sequence error

FN: AD—end.frm.seq.—end frame sequence error

Most Probable Cause: ECM, SDI controller, SDI

cable

08—Level 2 Message Checksum Error

Error Description: The last level 1 frame transmitted

as a result of a level 2 command is the message end

frame. The lower eight bits of the end frame contain

a checksum for the entire level 2 message. This error

occurs if the checksum calculated by the drive does

not match the checksum transmitted as part of the

message end frame.

FN: A5—inc.cmd.cksm—incorrect command packet

checksum

Most Probable Cause: ECM, SDI controller, SDI

cable

09—SDI Message Framing Error

Error Description: The upper eight bits of the control

frame did not match one of the nine possible framing

codes as defined in the SDI specification.

FN: A4—inv.frm.code.—invalid frame code

Most Probable Cause: ECM, SDI controller, SDI

cable

Page 43

RA7x/SA7x Pocket Reference Guide 37

0A—SDI Command Opcode Parity Error

Error Description: The opcode in a level 2 SDI

command was received with incorrect parity. The

opcode byte must be even parity.

FN: B3—inc.opc.prty—incorrect command opcode

parity

Most Probable Cause: ECM, SDI controller, SDI

cable

0B—Invalid Opcodes

Error Description: One of two conditions have been

detected:

• The opcode received in the level 2 command was

not one of the 16 possible opcodes.

• The opcode received in the level 2 command was

one of the 16 possible opcodes, but the opcode

parity was wrong.

FN: B2—inv.cmd.opcd.—invalid command packet

opcode

FN: B7—inv.lv1.opcd.—invalid level 1 command

opcode

Most Probable Cause: ECM, SDI controller, SDI

cable

0C—Command Length Error

Error Description: The byte count for any given level

2 command is incorrect.

FN: A3—inv.cmd.byct.—invalid command packet byte

count

FN: B1—inv.cmd.byct.—invalid command packet byte

count

FN: B6—inc.lv1.byct.—invalid level 1 command packet

byte count

Most Probable Cause: ECM, SDI controller, SDI

cable

Page 44

38 RA7x/SA7x Pocket Reference Guide

0E—Real-Time Command Contains Invalid Head

Address

Error Description: A real-time command is one of the

SDI level 1 data transfer commands. If the low byte of

any of these commands indicates an invalid head, this

error occurs.

FN: A2—inv.grp.num.—invalid group select (head)

number

Most Probable Cause: ECM, SDI controller, SDI

cable

13—Spindle Fault

Error Description: The motor control circuit has

detected a condition that could prevent the spindle

from spinning at a safe speed.

FN: 63—ast.smc.flt.—asserted spindle motor control

fault

Most Probable Cause: ECM, HDA

14—Spindle Over Current

Error Description: The current being used by the

spindle motor is too high.

FN: 61—ast.smc.pwr.—asserted spindle motor control

power

FN: 62—neg.smc.pwr.—negated spindle motor control

power

Most Probable Cause: ECM, HDA, SA7x power

supply

Page 45

RA7x/SA7x Pocket Reference Guide 39

16—Guard Band Error

Error Description: During normal operation, the

heads have moved into the inner or the outer guard

band area. If the servo system is in the process

of loading or unloading heads (for example: the

positioner is moving from the landing zone or to the

landing zone), the I/O processor will mask out the

guard band signals internal to the GASP gate array

and thus prevent a servo fault from occurring.

FN: 46—out.grd.bnd.—outer guard band fault

FN: 47—inn.grd.bnd.—inner guard band fault

Most Probable Cause: ECM, HDA

Page 46

40 RA7x/SA7x Pocket Reference Guide

17—Invalid or Inconsistent Parameters

Error Description: One or more of the parameters

sent by the controller as part of the level 2 command is

invalid or inconsistent.

FN: 18—inv.gbd.cyl.—invalid guard band cylinder

access

FN: AE—inc.sct.fmt.—incorrect drive sector format

FN: B8—inv.lv1.grp.—invalid level 1 group select

(head) number

FN: C2—inv.sct.fmt.—invalid drive sector format

FN: C3—inv.dmr.num.—invalid diagnose memory

region number

FN: C4—inc.dmr.num.—incorrect diagnose memory

region number

FN: C6—inv.top.disc.—invalid topology disconnect

FN: C7—err.flg.astd.—generic error bit flag asserted

FN: C9—inv.lv1.num.—invalid error recovery level

number

FN: CB—inv.grp.num.—invalid group select (head)

number level 2

FN: CC—inv.cyl.adr.—invalid cylinder address number

level 2

FN: CD—inv.dgn.cyl.—invalid diagnostic cylinder

access

FN: D0—inv.rmr.num.—invalid read memory region

number

FN: D1—inv.rmr.ofst.—invalid read memory region

offset

FN: D3—inv.wmr.byct.—invalid write memory region

byte count

FN: D4—inv.wmr.num.—invalid write memory region

number

FN: D5—inv.wmr.ofst.—invalid write memory region

offset

FN: D6—inv.wmr.siz.—invalid write memory region size

Most Probable Cause: ECM, SDI controller, SDI

cable

Page 47

RA7x/SA7x Pocket Reference Guide 41

18—Opcode/Parameter Invalid/Inconsistent with Drive

State

Error Description: The level 2 command received

from the controller is valid, but the command itself or

a parameter contained in the command is inconsistent

with the drive’s current state or physical status.

FN: 68—asup.bkd.ctrl.—spinup blocked by the

controller

FN: 69—sup.bkd.dgn.—spinup blocked by diagnostic

FN: B4—inc.cmd.flt.—incorrect command drive fault

state

FN: B5—inc.cmd.lsn.—incorrect command drive logical

state number

FN: B9—inv.svo.hsw.—invalid level 1 servo head

switch

FN: C1—drv.wrt.prtd.—drive write protected

FN: C5—inc.drst.top.—incorrect drive state—NOT

topology

FN: C8—flt.not.negd.—fault or error not cleared

FN: CA—inv.svo.rcv.—invalid servo error recovery

FN: CE—inv.svo.sek.—invalid servo seek

FN: CF—run.sw.stop.—run switch in ’STOP’ position

FN: D2—inv.run.lsn.—invalid run logical state number

Most Probable Cause: ECM, SDI controller, SDI

cable

1D—Actuator Over Speed Error

Error Description: During course positioning mode

the positioner velocity was greater than design

specifications.

FN: 4B—act.ovr.spd.—actuator over speed

Most Probable Cause: ECM, HDA

1E—Actuator Over Current Error

Error Description: The current being used by the

read/write head actuator is too high.

FN: 4C—act.ovr.cur.—actuator over current

Most Probable Cause: ECM, HDA

Page 48

42 RA7x/SA7x Pocket Reference Guide

1F—Sector Overrun Error

Error Description: The internal read gate or write

gate was asserted and a sector pulse or an index

pulse occurred.

FN: 51—sct.ovr.run.—sector over run

Most Probable Cause: ECM, SDI controller, SDI

cable, HDA

25—Off Track Error

Error Description: During track following mode, the

DSP processor determined that the read/write heads

are not within track center line tolerances.

FN: 4D—svo.off.trk.—servo off track error

Most Probable Cause: HDA, ECM

26—Spindle Speed Error

Error Description: The spindle speed is not operating

within design specifications. The nominal spindle

speed is 4000 r/min for the RA70 and 3600 r/min for

the RA71/RA73 disk drives.

FN: 6E—inc.sup.svo.—incorrect spinup servo state

number

FN: 71—inc.sup.psn.—incorrect spinup physical state

number

FN: 73—inc.pur.psn.—incorrect purge cycle physical

state number

FN: 77—inc.run.psn.—incorrect run physical state

number

Most Probable Cause: ECM, HDA

27—HDA Over Temperature

Error Description: The temperature inside the HDA

has exceeded the maximum allowed for safe operation.

FN: 4F—hda.ovr.tmp.—head disk assembly over

temperature

Most Probable Cause: SA7x fan, HDA, ECM.

Be sure the disk is operating within the environmental

specifications.

Page 49

RA7x/SA7x Pocket Reference Guide 43

28—Module Over Temperature Error

Error Description: Sensing circuits on the ECM have

detected temperatures that exceed the maximum

allowed for safe and reliable operation.

FN: 4E—snk.ovr.tmp.—heat sink assembly over

temperature

FN: 3C—xep.ovr.tmp.—module exception over

temperature error

FN: 3D—com.ovr.tmp.—module common over

temperature error

Most Probable Cause: SA7x fan, ECM, HDA. Be

sure that the disk is operating within the environmental

specifications.

31—Read Gate and Write Gate Error

Error Description: The SDI gate array detected both

internal read gate and write gate at the same time.

FN: 5A—rdg&wrs.ast.—read state and write state both

asserted

Most Probable Cause: ECM, SDI controller, SDI

cable

32—Read/Write While Faulted

Error Description: Even though the drive is in a

faulted condition, the drive detected either RTCS read

gate or RTCS write gate.

FN: 52—flt&rdg.wrg.—fault and read gate or write gate

both asserted

Most Probable Cause: ECM, SDI controller, SDI

cable

Page 50

44 RA7x/SA7x Pocket Reference Guide

33—Attempt to Write Through Bursts

Error Description: The read/write heads were over

the embedded burst area of the sector, and the internal

write gate was asserted.

FN: 53—wrg&brt.prt.—write gate and burst protection

both asserted

Most Probable Cause: SDI controller, ECM, SDI

cable

NOTE

See Table 9 and verify the minimum controller revision.

34—Data Encoder/Decoder Error

Error Description: A failure of the data

encoder/decoder custom chip or some of its associated

circuitry.

FN: 5C—enc.pls.flt.—encoder pulse fault (RWENDEC)

Most Probable Cause: ECM

35—Write Unsafe

Error Description: A condition exists with the write

data path (for example: read/write heads, preamp

chips, flex circuit, etc.) which would prevent the drive

from correctly writing data to the disk surface.

FN: 5B—wrg&wrt.uns.—write gate and write unsafe

both asserted

Most Probable Cause: ECM, HDA

39—Write and Off Track

Error Description: While write gate was asserted, the

read/write heads moved off track.

FN: 58—wrg&off.trk.—write gate and off track both

asserted

Most Probable Cause: ECM, HDA

Page 51

RA7x/SA7x Pocket Reference Guide 45

3A—Write and Write Protected

Error Description: The drive was write protected and

detected the assertion of the internal write gate.

FN: 59—wrg&wrt.prt.—write gate and write protection

both asserted

Most Probable Cause: ECM, SDI controller, SDI

cable

3B—AGC Fault

Error Description: Either the automatic gain control

(AGC) circuit has failed or read signal amplitude

variations have far exceeded the capability of the AGC

circuit to maintain a proper signal lock. The latter of

these may be caused by a severe signal degradation

ratio (SDR, erasure) from a defective HDA.

FN: 5D—agc.lck.flt.—automatic gain control lock fault

Most Probable Cause: ECM, HDA

3C—Servo Faults

Error Description: There are hardware-detected

inconsistencies with the servo system. These are

divided into two categories: actuator faults and servo

faults.

FN: 57—hrd.svo.flt.—hard servo fault

Most Probable Cause: ECM, HDA

41—SDI Command/Response Timeout

Error Description: The drive detected the start of an

incoming SDI command or the transmission of an SDI

response, but the operation did not complete within a

specified time period.

FN: A8—exp.rsp.tmr.—expired response packet timer

FN: A9—exp.cmd.tmr.—expired command packet timer

Most Probable Cause: ECM, SDI controller, SDI

cable

Page 52

46 RA7x/SA7x Pocket Reference Guide

43—TCR and R/W Ready Out L

Error Description: Transfer command received (TCR)

and read/write ready out L indicates the drive received

a data transfer command and read/write ready was not

asserted.

FN: 50—tcr&r/w.rdy.—TCR and NOT read/write ready

both asserted

Most Probable Cause: ECM, SDI controller, SDI

cable

44—Format Command and Format Not Enabled

Error Description: An SDI level 1 select track and

format on index or format on sector or index command

was decoded by the SDI gate array, but the enable

format bit was not set.

FN: 55—fmt.w/o.ena.—format command without format

enabled error

Most Probable Cause: ECM, SDI controller, SDI

cable

4B—Index Error

Error Description: Index was detected when it should

not have been or was not detected when it should

have been.

FN: 56—idx.pls.flt.—index pulse fault

Most Probable Cause: HDA, ECM

4C—External Hardware Fault

Error Description: The gate array or the ground

connection on the ECM is broken.

FN: 5E—ext.hrd.flt.—external hardware fault

Most Probable Cause: ECM

Page 53

RA7x/SA7x Pocket Reference Guide 47

4D—Write and Bad Embedded

Error Description: The drive internal write gate is

asserted and embedded bursts are not valid.

FN: 54—wrg&emb.bad.—write gate and embedded

NOT OK both asserted

Most Probable Cause: ECM, HDA

4F—SDI Transmit Error—Pulse Error

Error Description: Extra or missing pulses on the SDI

write command line (data pulse error) or the RTCS line

(control pulse error) were detected.

FN: 5F—tcr&pls.err.—TCR and pulse error both

asserted (PSID)

Most Probable Cause: ECM, SDI controller, SDI

cable

50—DSP Diagnostic Timeout

Error Description: There is not a specific error code

for a failure during the initialization section of the DSP

diagnostic. However, if the DSP fails to execute the

basic initialization, it is most likely hung (or lost) and

is not able to pass an error code to the I/O processor.

It is possible that the initialization completed and the

problem is with the analog loop test. Realize that the

effect is the same: the I/O processor detects diagnostic

timeout due to the fact the DSP does not respond with

diagnostic complete or error detected.

FN: 84—exp.exc.tmr.—expired servo (DSP) execute

timer

Most Probable Cause: ECM

51—Byte/Sector Counter Failure

Error Description: Reported any time the counter is

checked and is incorrect.

FN: E5—inv.sct.ctr.—invalid sector counter

Most Probable Cause: ECM

Page 54

48 RA7x/SA7x Pocket Reference Guide

60—Read/Write Head Select Failure

Error Description: One of two conditions occurred.

While trying to select a specific head to read or write,

the DSP detected a soft servo fault and as such could

not complete the head switch operation, or the I/O

processor timed out waiting for the DSP to complete

the head switch operation. Realize that if the drive

detects any other faults, these faults are reported with

the real-time error code associated with the error.

FN: F2—inv.dgn.cnt.—invalid diagnostic (head) bit

error count

FN: F3—inc.dgn.cnt.—incorrect diagnostic (track) bit

error count

FN: F5—exp.dgn.sct.—expired diagnostic sector timer

FN: FA—exp.dgn.rws.—expired diagnostic read/write

sector timer

FN: FE—inc.dgn.rdy.—incorrect diagnostic ready

Most Probable Cause: ECM, HDA

Page 55

RA7x/SA7x Pocket Reference Guide 49

61—Drive Capacity Configuration Error

Error Description: One of two conditions occurred.

Either the HDA capacity indicator switch on the

RA71/RA72 disk drive was set incorrectly, or the

ECM logic cannot determine whether the HDA is an

RA71 disk drive (700 MB storage capacity) or an RA72

disk drive (1 GB storage capacity).

If the HDA capacity indicator switch was set incorrectly,

the drive will spin down and you will be unable to spin

it up again until you set the switch correctly. You will

receive fault number 19. Verify the switch setting.

If the HDA is an RA71, the switch should be in the

on position (up). If the HDA is an RA72, the switch

should be in the off position (down). See the section

on setting RA71/RA72 capacity indicator switch and

refer to Figure 1.

If the capacity indicator switch is set correctly and you

obtain fault number 1A, this indicates that the head

table, which defines whether the drive is an RA71 or

an RA72, cannot be read from the HDA. The problem

may be related to the ECM or HDA.

FN: 19—inc.hda.swi.—incorrect HDA capacity switch

setting

FN: 1A—inv.hda.type—invalid HDA type (can’t

determine HDA type)

Most Probable Cause: ECM, HDA

Page 56

50 RA7x/SA7x Pocket Reference Guide

62—Read Failure

Error Description: One of six possible conditions

occurred during the diagnostic read section of the test.

The six conditions are:

• Invalid sector number

• Expired sector timer

• Expired read sector timer

• Incorrect read sector

• Read diagnostic failure

• Incorrect sector error count

FN: F4—inv.dgn.sct.—invalid diagnostic read sector

number

FN: F6—inv.dgn.rsf.—invalid diagnostic read sector

fault

FN: F7—exp.dgn.rds.—expired diagnostic read sector

timer

FN: F8—inc.dgn.rds.—incorrect diagnostic read sector

number

Most Probable Cause: ECM, HDA

Page 57

RA7x/SA7x Pocket Reference Guide 51

67—Write Failure

Error Description: One of five possible conditions

occurred during the diagnostic write section of the test.

The five conditions are:

• Invalid sector number

• Expired sector timer

• Expired write sector timer

• Incorrect write sector

• Write diagnostic failure

FN: F9—inv.dgn.wsn.—invalid diagnostic write sector

number

FN: FB—inv.dgn.wsf.—invalid diagnostic write sector

fault

FN: FC—exp.dgn.wrs.—expired diagnostic write sector

timer

FN: FD—inc.dgn.wrs.—incorrect diagnostic write sector

number

Most Probable Cause: ECM, HDA

85—External RAM Failure

Error Description: If, during any data verification

process, the data stored in the processor external

RAM location does not match the data that was written

to that location, the test is terminated and this error is

reported.

FN: E3—inv.dat.mem.—invalid external static RAM

memory

Most Probable Cause: ECM

Page 58

52 RA7x/SA7x Pocket Reference Guide

86—Internal RAM Failure

Error Description: If during any data verification

process the data stored in the processor internal RAM

location does not match the data that was written to

that location, the test is terminated and this error is

reported.

FN: E4—inv.ram.mem.—invalid internal static RAM

memory

Most Probable Cause: ECM

87—UVPROM Checksum Failure

Error Description: This test calculates a checksum by

adding, without carry, all the locations of the UVPROM.

The sum is then compared to a stored value. If the

computed sum and the stored sum do not match, this

error will result.

FN: E2—inv.rom.sum.—invalid UVPROM checksum

Most Probable Cause: ECM

88—I/O Processor Sanity Failure

Error Description: This test verifies the I/O

processor’s ability to execute basic processor functions

including branch instructions, verifying interrupts, and

one of the general timers. Indications of this failure

are:

• The basic processor functions fail.

• The interrupt/timer test fails.

FN: E0—ins.mcu.dgn.—insane microprocessor

diagnostic

FN: E1—inv.ctr.int.—invalid counter over flow interrupt

Most Probable Cause: ECM

Page 59

RA7x/SA7x Pocket Reference Guide 53

89—EEPROM Failure

Error Description: The I/O processor has detected a

failure with the EEPROM memory used to store drive

internal error log entries.

FN: 41—inv.log.fmt.—invalid EEPROM error log format

FN: 42—exp.pwc.tmr.—expired EEPROM page write

cycle timer

FN: 43—inc.pwc.dat.—incorrect EEPROM write page

cycle data

FN: 44—exp.bwc.tmr.—expired EEPROM byte write

cycle timer

Most Probable Cause: ECM

8A—GASP Mailbox Failure

Error Description: The I/O processor address and

data path lines to the GASP gate array are verified

in both normal mode and register mode, and the

hardware protocol (flags) and the data integrity of the

mailboxes is verified in register mode.

FN: EC—inv.dsp.bus.—invalid DSP bus test

FN: ED—inv.dsp.mbx.—invalid DSP mailbox test

Most Probable Cause: ECM

8B—DSP External RAM Failure

Error Description: During the data verification

process, the data stored in the DSP external RAM

location does not match the data that was written to

that location.

FN: EE—inv.dsp.mem.—invalid DSP memory test

Most Probable Cause: ECM

8C—Sector Pulse Failure

Error Description: A sector pulse error is reported if

the signal sector pulse H should be asserted and it is

not, or if the signal should not be asserted and it is.

FN: E6—inv.sct.pls.—invalid sector pulse

Most Probable Cause: ECM

Page 60

54 RA7x/SA7x Pocket Reference Guide

8D—External Loop Back Failure

Error Description: External loop back failure occurs if

the signal Init Req H should be asserted and it is not,

or if it should not be asserted and it is.

FN: EA—ext.lop.tst.—invalid external loop back test

Most Probable Cause: ECM

94—Loop Back Frame Not Received

Error Description: Non-transfer command received

(NTCR) did not become asserted after an SDI frame

was sent.

FN: E7—int.lop.tst.—invalid internal SDI loop back test

Most Probable Cause: ECM

95—Loop Back Frame Code Incorrect

Error Description: The frame was received, but it is

not the same frame as was sent.

FN: E8—inv.frm.cod.—invalid response frame code

Most Probable Cause: ECM

96—Loop Back Frame Data Incorrect

Error Description: The frame was received correctly

and the frame code was correct, but the data that was

received did not match the data that was sent.

FN: E9—inv.frm.byt.—invalid response frame byte

Most Probable Cause: ECM

Page 61

RA7x/SA7x Pocket Reference Guide 55

9A—Read and Off Track

Error Description: The heads were not fine-

positioned or locked on track (relative to the embedded

servo information) at the time a read operation was

ready to start. The drive took the necessary actions to

establish the on-track condition.

The drive will not post a recoverable read-and-off-track

error to prevent interruption to the controller. This

allows the controller to execute all of its available

retry/error recovery sequences to the drive and if

necessary, retrieve user data during a recoverable

error.

FN: 09—rdg&off.trk.—read gate and off track both

asserted

Most Probable Cause: HDA, ECM

9B—Write and Off Track

Error Description: While write gate was asserted, the

read/write heads moved off track.

FN: 58—wrg&off.trk.—write gate and off track both

asserted

Most Probable Cause: ECM, HDA

A0 Illegal Diagnostic Sequence

Error Description: The controller issued an SDI

DIAGNOSE command to the drive. The drive

determined that the requested diagnostics tests were

not in correct sequence or out of context with the

current state of the drive (for instance, seek test while

drive spun down). It also indicates that one of the

diagnose error commands was executed without the

error log being in the correct state. This could be an

operator error if special controller diagnostics were

manually invoked and the user inadvertently entered

incorrect parameters.

FN: D9—ill.dgn.seq—illegal diagnostic sequence

Most Probable Cause: Operator error, ECM, SDI

controller

Page 62

56 RA7x/SA7x Pocket Reference Guide

C6—PLO Failure

Error Description: The VCO clock is not in sync or

has fallen out of sync with the rotating disk.

FN: 48—plo.lck.flt.—PLO lock failure

Most Probable Cause: HDA, ECM

C9—Analog Loop Failure

Error Description: There are three possible

conditions that result in analog loop failure:

• The I/O processor could not complete a write to

the GASP gate array mailbox.

• The I/O processor could not complete a read of

the GASP gate array mailbox.

• The DSP could not complete the analog test or it

completed the test but with incorrect results. This

consists of three possible conditions:

– The DSP timed out waiting for the A/D

convert to complete.

– The DSP received an unexpected interrupt.

– The DSP found one or more of the

conversions were out of tolerance.

FN: 85—inc.exc.rsp.—incorrect DSP execute response

FN: EF—inv.dsp.dgn.—invalid DSP diagnose response

Most Probable Cause: ECM

CD—Track Count Error

Error Description: While in the course positioning

mode, both gray codes (gray code X and gray code

Y) changed during the same servo frame or one gray

code changed on two consecutive frames.

FN: 49—trk.ctr.flt.—track counter—gray codes out of

quad.

Most Probable Cause: ECM, HDA

Page 63

RA7x/SA7x Pocket Reference Guide 57

E0—Firmware Detected Fault - microprocessor Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the microprocessor driver

(MCUDRV). The MCUDRV provides the interface to

the firmware timer functions and controls and monitors

the I/O processor hardware timer.

FN: 01—inc.opr.mode.—incorrect operating mode

FN: 02—inv.pwr.rst.—invalid power on reset

FN: 03—ctr/tmr.flt.—counter/timer test failure

FN: 04—int.ram.flt.—internal RAM test failure

FN: 05—inv.ctr.intr.—invalid or spurious counter

interrupt

FN: 06—inv.tmr.intr.—invalid or spurious timer interrupt

FN: 07—inv.cap.intr.—invalid or spurious input capture

interrupt

FN: 08—opn.tmr.num.—invalid open timer number

FN: 09—act.tmr.flt.—can’t open timer (already active)

FN: 0A—cls.tmr.num.—invalid close timer number

FN: 0B—chk.tmr.num.—invalid check timer number

FN: 0C—get.tmr.num.—invalid get timer number

FN: 0D—mcu.und.flt.—mcudrv module undefined fault

FN: 0E—mcu.und.flt.—mcudrv module undefined fault

FN: 0F—mcu.und.flt.—mcudrv module undefined fault

Most Probable Cause: ECM

Page 64

58 RA7x/SA7x Pocket Reference Guide

E1—Firmware Detected Fault - Test Handler

Error Description: The I/O processor firmware

has detected an inconsistency in the test handler

(TSTHDR). The TSTHDR controls the drive when and

only when it is connected to the test device at the

manufacturing plant or a repair center.

FN: 10—inv.tsts.adr.—invalid test memory address

number

FN: 11—exp.tst.tmr.—expired test command received

timer

FN: 12—inv.tst.byct.—invalid test command packet

byte count

FN: 13—inv.tst.opcd.—invalid test command packet

opcode

FN: 14—inv.rdm.ofst.—invalid read memory address

offset

FN: 15—inv.rdm.byct.—invalid read memory data

count

FN: 16—inv.wrm.ofst.—invalid write memory address

offset

FN: 17—inv.wrm.byct.—invalid write memory data

count

FN: 18—inv.wrm.data.—invalid write memory data

(RAM didn’t change)

FN: 19—inv.exc.ofst.—invalid execute memory address

offset

FN: 1A—inv.exc.byct.—invalid execute memory data

count

FN: 1B—emp.exc.buf.—empty execute command

buffer (no arguments)

FN: 1C—ful.exc.buf.—full execute response buffer

FN: 1D—inv.fnc.num.—invalid SWI "trap" function

number

FN: 1E—tst.und.flt.—tsthdr module undefined fault

FN: 1F—tst.und.flt.—tsthdr module undefined fault

Most Probable Cause: ECM

Page 65

RA7x/SA7x Pocket Reference Guide 59

E2—Firmware Detected Fault - OCP Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the OCP driver. This

driver provides the interface to the operator control

functions and determines what type of device is

connected to the drive’s remote front panel connector.

FN: 21—rxp.seq.err.—receive packet sequence error

FN: 22—rxp.ovr.run.—receive packet overrun error

FN: 23—inv.syn.byt.—invalid ’sync’ byte

FN: 24—inv.rxp.cnt.—invalid receive packet count

FN: 25—rxp.byt.ovr.—receive packet byte overrun

FN: 26—inv.rxp.sum.—invalid receive packet

checksum

FN: 27—inv.txp.cnt.—invalid transmit packet byte count

FN: 28—exp.txb.tmr.—expired transmit byte timer

FN: 29—exp.rxb.tmr.—expired receive byte timer

FN: 2A—rxb.frm.err.—receive byte framing error

FN: 2B—rxb.ovr.run.—receive byte over run error

FN: 2C—ocp.und.flt.—ocpdrv module undefined fault

FN: 2D—ocp.und.flt.—ocpdrv module undefined fault

FN: 2E—inv.fls.ers.—invalid flash memory erase

FN: 2F—inv.fls.pgm.—invalid flash memory program

Most Probable Cause: ECM, OCP, SA7x logic

Page 66

60 RA7x/SA7x Pocket Reference Guide

E3—Firmware Detected Fault - OCP Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the OCP driver. This

driver provides the interface to the operator control

functions and determines what type of device is

connected to the drive’s remote front panel connector.

FN: 30—ocp.flt.num.—invalid OCP logical state

FN: 31—inv.cmd.opc.—invalid command opcode

FN: 32—exp.rxp.tmr.—expired response packet timer

FN: 33—rtx.lst.rsp.—retransmit last response

FN: 34—inv.rsp.cnt.—invalid response packet byte

count

FN: 35—inc.rsp.opc.—incorrect response packet

opcode

FN: 36—inv.rsp.opc.—invalid response packet opcode

FN: 37—inv.ocp.lck.—invalid OCP interlock

FN: 38—exp.rsp.tmr.—expired response packet timer

FN: 39—rtx.lst.rsp.—retransmit last response

FN: 3A—ocp.und.flt.—ocphdr module undefined fault

FN: 3B—ocp.und.flt.—ocphdr module undefined fault

FN: 3C—ocp.und.flt.—ocphdr module undefined fault

FN: 3D—ocp.und.flt.—ocphdr module undefined fault

Most Probable Cause: ECM, OCP, or SA7x logic

Page 67

RA7x/SA7x Pocket Reference Guide 61

E4—Firmware Detected Fault - Fault Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the fault handler. This

handler monitors and controls the drive’s error logging

functions, both internal and external.

FN: 40—inv.drv.flt.—invalid or spurious drive fault

FN: 45—sft.svo.flt.—soft servo fault

Most Probable Cause: ECM

E6—Firmware Detected Fault - Spindle Motor Control

Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the spindle motor control

(SMC) driver. The SMC provides the interface to the

drive’s spindle motor.

FN: 60—smc.flt.num.—smcdrv module undefined fault

FN: 64—inv.smc.lsn.—invalid spindle motor control

logical state number

FN: 65—inv.smc.num.—invalid spindle motor control

function number

FN: 66—inv.smc.lck.—invalid spindle motor control

lock

FN: 67—inv.smc.flt.—invalid spindle motor control fault

FN: 6A—sup.bkd.flt.—spinup blocked by drive hard or

soft fault

FN: 6B—sup.bkd.lsn.—spinup blocked by spin logical

state number

FN: 6C—smc.und.flt.—smcdrv module undefined fault

FN: 6D—smc.und.flt.—smcdrv module undefined fault

FN: 6E—smc.und.flt.—smcdrv module undefined fault

Most Probable Cause: ECM, HDA

Page 68

62 RA7x/SA7x Pocket Reference Guide

E7—Firmware Detected Fault - Spindle Motor Control

Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the spindle motor control

(SMC) handler. The SMC controls and monitors the

spindle motor functions via the driver.

FN: 74—inc.lhd.rtz.—incorrect load heads return to

zero state

FN: 75—inc.lhd.sek.—incorrect load heads seek state

FN: 76—inc.lhd.rcl.—incorrect load heads recalibrate

state

FN: 78—exp.spn.tmr.—expired spin timer

FN: 79—inc.spn.psn.—incorrect spin physical state

number

FN: 7A—exp.uhd.tmr.—expired unload heads timer

FN: 7B—inc.uhd.psn.—incorrect unloads heads

physical state number

FN: 7C—exp.sdn.tmr.—expired spindown timer

FN: 7D—inc.sdn.psn.—incorrect spindown physical

state number

FN: 7E—exp.idl.tmr.—expired idle timer

FN: 7F—inc.idl.psn.—incorrect idle physical state

number

Most Probable Cause: ECM, HDA

NOTE

If this error occurs on an RA70 disk drive with FN = 7C

when the drive is spun down, be sure the ECM revision

is J6 or higher (firmware revision 79 or higher).

Page 69

RA7x/SA7x Pocket Reference Guide 63

E8—Firmware Detected Fault - DSP Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the DSP driver. This

driver provides the interface to the DSP processor via

the servo gate array.

FN: 80—dsp.flt.num.—servo detected fault

FN: 86—exp.rmb.tmr.—expired read mailbox timer

FN: 87—inv.rmb.rsp.—invalid read mailbox response

opcode

FN: 88—exp.wmb.tmr.—expired write mailbox timer

FN: 89—une.wmb.rsp.—unaccepted write mailbox

response

FN: 8A—inc.dma.mode.—incorrect DSP memory mode

FN: 8B—vrf.dsp.mem.—verify DSP memory data

FN: 8C—inc.dsp.bus.—incorrect data bus pattern

FN: 8D—inc.dsp.mbx.—incorrect DSP mailbox pattern

FN: 8E—inc.h/c.num.—incorrect head/cylinder number

FN: 8F—svo.rwr.ast.—servo read/write ready asserted

Most Probable Cause: ECM, HDA

Page 70

64 RA7x/SA7x Pocket Reference Guide

E9—Firmware Detected Fault - DSP Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the DSP handler. This

handler controls and monitors the servo functions via

the driver.

FN: 90—inc.dst.grp.—incorrect destination group

(head) number

FN: 91—inv.dsp.lsn.—invalid DSP logical state number

FN: 92—exp.dsp.tmr.—expired DSP state timer

FN: 93—inc.dsp.psn.—incorrect DSP physical state

number

FN: 94—inc.dsp.rsp.—incorrect DSP response opcode

FN: 95—inc.dsp.lsn.—incorrect DSP logical state

number

FN: 96—inv.svo.head—invalid servo head number

FN: 97—exp.dtn.tmr.—expired detent state timer

FN: 98—inc.dtn.psn.—incorrect detent physical state

number

FN: 99—inv.svo.cyl.—invalid servo cylinder number

FN: 9A—exp.rtz.tmr.—expired return to zero state

timer

FN: 9B—inc.rtz.psn.—incorrect return to zero physical

state number

FN: 9C—inc.rtz.cyl.—incorrect return to zero cylinder

number

FN: 9D—exp.sek.tmr.—expired seek state timer

FN: 9E—inc.sek.psn.—incorrect seek physical state

number

FN: 9F—inc.sek.cyl.—incorrect seek cylinder number

Most Probable Cause: ECM, HDA

EA—Firmware Detected Fault - SDI Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the SDI driver. This

driver provides the interface to the controller and the

read/write hardware via the SDI gate array.

FN: A6—aut.snd.flt.—auto send mode fault

FN: A7—inv.rsp.byct.—invalid response packet byte

count

FN: AA—drv.not.rwr.—drive NOT read/write ready

FN: AF—inc.sct.num.—incorrect/invalid sector number

Most Probable Cause: ECM

Page 71

RA7x/SA7x Pocket Reference Guide 65

EB—Firmware Detected Fault - SDI Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the SDI driver. This

driver provides the interface to the controller and the

read/write hardware via the SDI gate array.

FN: 10—exp.idx.hsw.—expired index/sector pulse timer

(head switch)

FN: 11—inv.head.hsw—invalid physical head switch

(head switch)

FN: B0—inv.sdi.lsn.—invalid SDI logical state number

FN: BA—exp.idx.tmr.—expired index/sector timer

FN: BD—inv.spu.IRQ.—invalid or spurious IRQ

interrupt

FN: BE—inv.head.adr.—invalid physical head address

FN: BF—inv.head.num.—invalid logical head number

Most Probable Cause: ECM

ED—Firmware Detected Fault - SDI Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the SDI handler. This

handler processes and performs SDI level 2 command

packets provided by the SDI driver. In addition, it

provides the SDI level 2 response packets to the SDI

driver.

FN: D7—inv.cpy.byct.—invalid buffer copy byte count

FN: D8—inc.sub.unt.—incorrect subunit mask bit

FN: DA—drv.hrd.flt.—drive hard fault—CANNOT be

cleared

Most Probable Cause: ECM

EE—Firmware Detected Fault - Diagnostic Driver

Error Description: The I/O processor firmware has

detected an inconsistency in the diagnostic driver. This

driver performs the drive’s power on reset diagnostics.

FN: EB—inv.dsp.drv.—invalid DSP driver response

Most Probable Cause: ECM

Page 72

66 RA7x/SA7x Pocket Reference Guide

EF—Firmware Detected Fault - Diagnostic Handler

Error Description: The I/O processor firmware has

detected an inconsistency in the Diagnostic handler.

This handler performs the drive’s spinup diagnostics.

FN: 28—exp.dgn.bwd.—expired diagnostic drive burst

write timer

FN: 29—exp.dgn.bwh.—expired diagnostic head burst

write timer

FN: 2A—exp.dgn.bwk.—expired diagnostic seek burst

write timer

FN: 2B—exp.dgn.erd.—expired diagnostic drive burst

write erase timer

FN: 2C—exp.dgn.erh.—expired diagnostic head burst

write erase timer

FN: 2D—brt&off.trk— burst write and offtrack

FN: 2F—inv. head.tbl—invalid head table data (on the

head track)

FN: DB—exp.dgn.rnd.—expired diagnostic random

cylinder state timer

FN: DC—exp.dgn.sng.—expired diagnostic single

cylinder state timer

FN: DD—exp.dgn.avg.—expired diagnostic average

cylinder state timer

FN: DE—exp.dgn.ful.—expired diagnostic full cylinder

state timer

FN: DF—exp.dgn.hsw.—expired diagnostic head

switch state timer

FN: F0—inv.dgn.psn.—invalid diagnostic physical state

number

FN: F1—inc.dgn.lsn.—incorrect diagnostic logical state

number

Most Probable Cause: ECM

Page 73

RA7x/SA7x Pocket Reference Guide 67

F2—Soft Servo Fault

Error Description: The DSP firmware has detected

an error.

FN: 4A—svo.grd.bnd.—soft servo fault or inner or

outer guard band

Most Probable Cause: ECM, HDA