Page 1

plus

LG

Series

Text and Graphics Printer

TM

Operator’s Guide

Order Number: EK–LGPLE–OG, Rev. A

Digital Equipment Corporation

Page 2

FCC Notice

This equipment has been tested and found to comply with the limits of a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide a reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense.

Any changes or modifications not expressly approved by the manufacturer could

void the user’s authority to operate the equipment.

Installing this equipment in an FCC Level B product results in an FCC Level A

Composite System as defined in the FCC Rules and Regulations.

Canadian Department of Communications compliance statement:

This equipment does not exceed Class A limits per radio noise emissions for

digital apparatus as set out in the Radio Interference Regulation of the Canadian

Department of Communications. Operation in a residential area may cause

unacceptable interference to radio and TV reception requiring the owner or

operator to take whatever steps are necessary to correct the interference.

Avis de conformite aux normes du ministere des

Communications du Canada:

Cet equipment ne depasse pas les limites de Classe A d’emission de bruits

radioelectriques pour les appareils numerriques tells que perscrites par le

Reglement sur le brouillage radioelectriques etabli par le ministere des

Communications du Canada. L’exploitation faite en milieu residentiel peut

entrainer le brouillage des receptions radio et tele, ce qui obligerait le proprietaire

ou l’operateur a prendre les dispositions necessarires pour en eliminer les cause.

Page 3

notices

European Directive.

This product is in conformity with the protection requirements of the EC Council

Directive 89/336/EEC on the approximation of the Laws of the Member States

relating to electromagnetic compatibility .

All Rights Reserved. December 1995.

Digital Equipment Corporation makes no representations that the use of its

products in the manner described in this publication will not infringe on existing or

future patent rights, nor do the descriptions contained in this publication imply the

granting of licenses to make, use, or sell equipment or software in accordance

with the description.

Possession, use, or copying of the software described in this publication is

authorized only pursuant to a valid written license from Digital or an authorized

sublicensor.

Digital Equipment Corporation 1995. Printed in U.S.A.

Page 4

Trademarks and Service Marks

The following are trademarks of Digital Equipment Corporation: DEClaser,

DECnet, DECserver, OpenVMS, PrintServer, ThinWire, ULTRIX, VAX, and the

DIGITAL logo.

PostScript

registered in certain jurisdictions. AppleTalk, LocalTalk, LaserWriter, and

Macintosh are registered trademarks of Apple Computer, Inc. Microsoft, MS,

MS–DOS, and Windows NT are registered trademarks of Microsoft Corporation.

Centronics is a trademark of Centronics Data Computer Corporation. IBM is a

registered trademark and IBM PC/A T is a trademark of International Business

Machines Corporation.

All other trademarks and registered trademarks are the property of their

respective holders.

TM

is a trademark of Adobe Systems Incorporated, which may be

Page 5

About this Operator's Guide

Digital wants you to feel comfortable

using the LG

guide. This book has been designed to

meet the needs of all users, from

beginners to those experienced with line

matrix printers.

Follow the directions in this guide along

with those in your

avoid injury to you and damage to the

printer.

This guide is divided into three sections:

Basic Operating Procedures — gives an

overview of the control panel and provides

procedures for loading paper and ribbon.

Configuration — provides procedures for

using the control panel to save, modify , and

delete configurations.

Troubleshooting — gives instructions

for clearing paper jams, cleaning

components, and troubleshooting.

plus

Series Printer and this

Setup Guide

in order to

LG

plus

Series Printer

Page 6

about this operator's guide

Conventions

Warnings, Cautions, and Notes

Warnings provide information about

conditions that could harm you or damage

the printer.

Cautions provide information about

conditions that could damage the printer.

Notes provide supplemental information

that could affect printer operation or use.

Message Display

These boxes show display messages as

they appear on the printer.

OFFLINE

CONFIG. CONTROL

Page 7

Table of Contents

BASIC OPERATING PROCEDURES

Powering On the Printer 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Control Panel 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Paper 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Top-of-Form 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reloading Paper 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading Paper 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Ribbon 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Canceling a Print Job 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONFIGURATION

Configurations and Parameters 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Configurations 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Configurations 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Configurations 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting Configurations 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Power–Up Configuration 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING

Clearing Paper Jams 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solving Print Quality Problems 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able of Contents

i

Page 8

ii T able of Contents

Page 9

BASIC OPERATING PROCEDURES

♦ Powering on the Printer 2

♦ Using the Control Panel 4

♦ Loading Paper 19

♦ Setting Top-of-Form 23

♦ Reloading Paper 26

♦ Unloading Paper 30

♦ Replacing the Ribbon 32

♦ Canceling a Print Job 36

1Operator’s Guide

Page 10

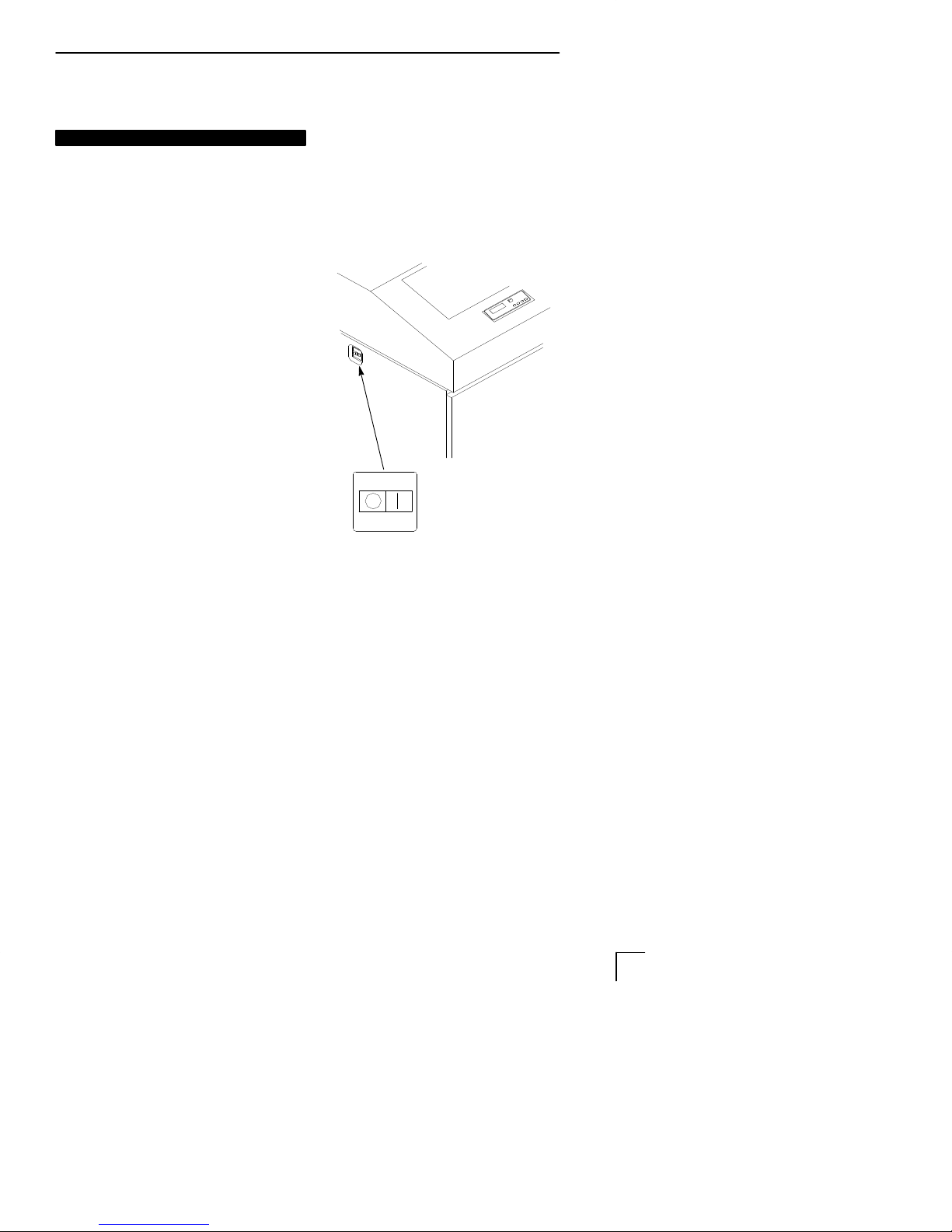

Powering On the Printer

warning

Before powering on the printer, make sure

it is plugged into the appropriate power

source.

Refer to the “Select a Site” section in

Chapter 2 of the Setup Guide for

information on proper power sources.

The power switch is located at the

top left side of the cabinet.

Push the On (|) switch to power on

the printer. Push the Off (O) switch

to power off the printer .

Off On

2 Operator’s Guide

Page 11

When you power on the printer,

the printer executes a

power-on self-test. The

message “Testing Hardware

Please Wait” displays. When

the self–test completes, the

message “Diagnostics Passed”

displays. Once the software

has initialized successfully, the

status indicator lights to

indicate the printer is online

and an online message

appears in the display , followed

by the name of the active

emulation (the default is LG).

If there is a fault during the

self-test, the status indicator

flashes and a specific fault

message appears on the

display (such as “LOAD

P APER”). See page 64 for

information on Fault Messages.

ONLINE

LG

LOAD PAPER

3Operator’s Guide

Page 12

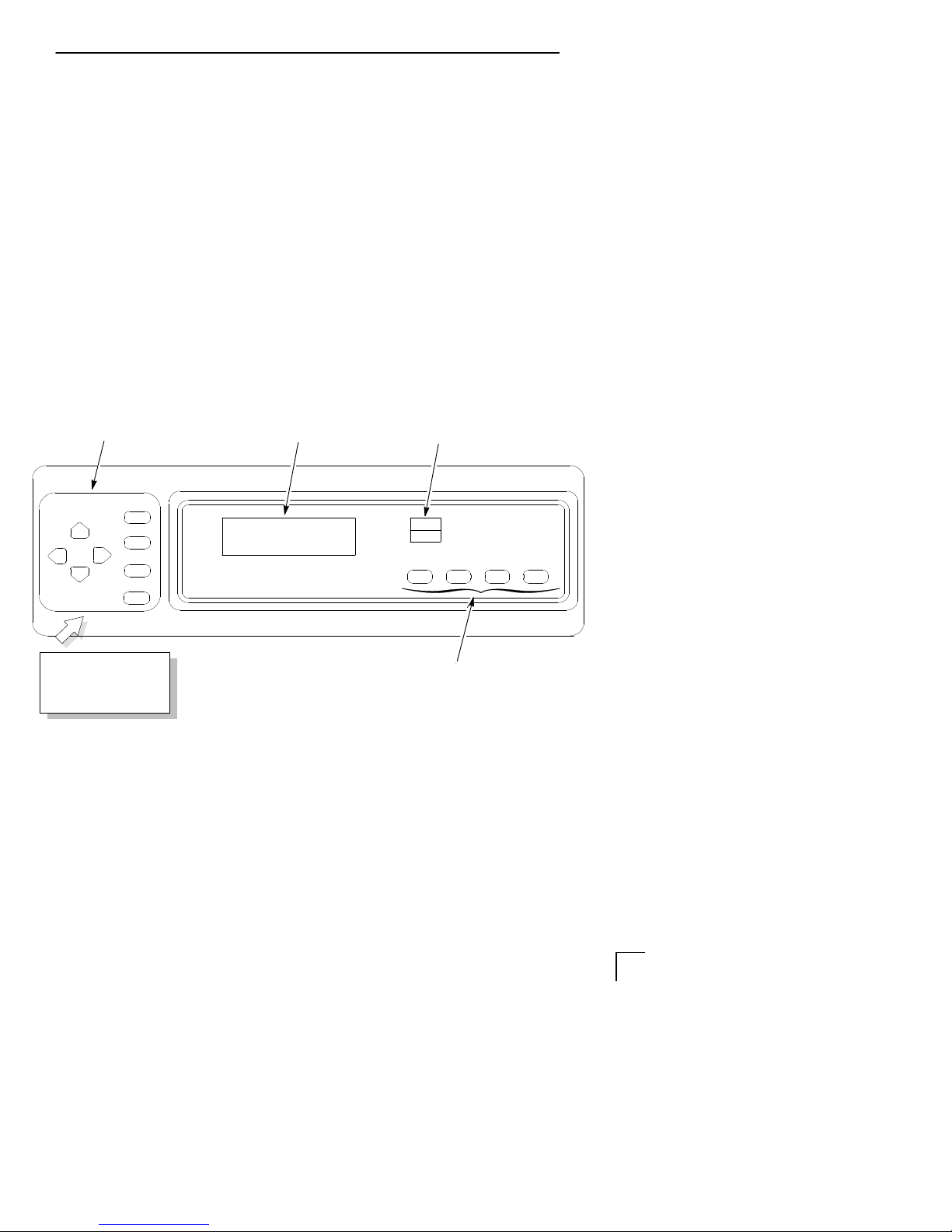

Using the Control Panel

Use the control panel to perform routine

operations such as:

• Placing the printer in the online or

offline mode

• Advancing or retracting the paper, and

setting the top–of–form

• Clearing fault conditions

• Configuring the printer

• Running printer self-tests

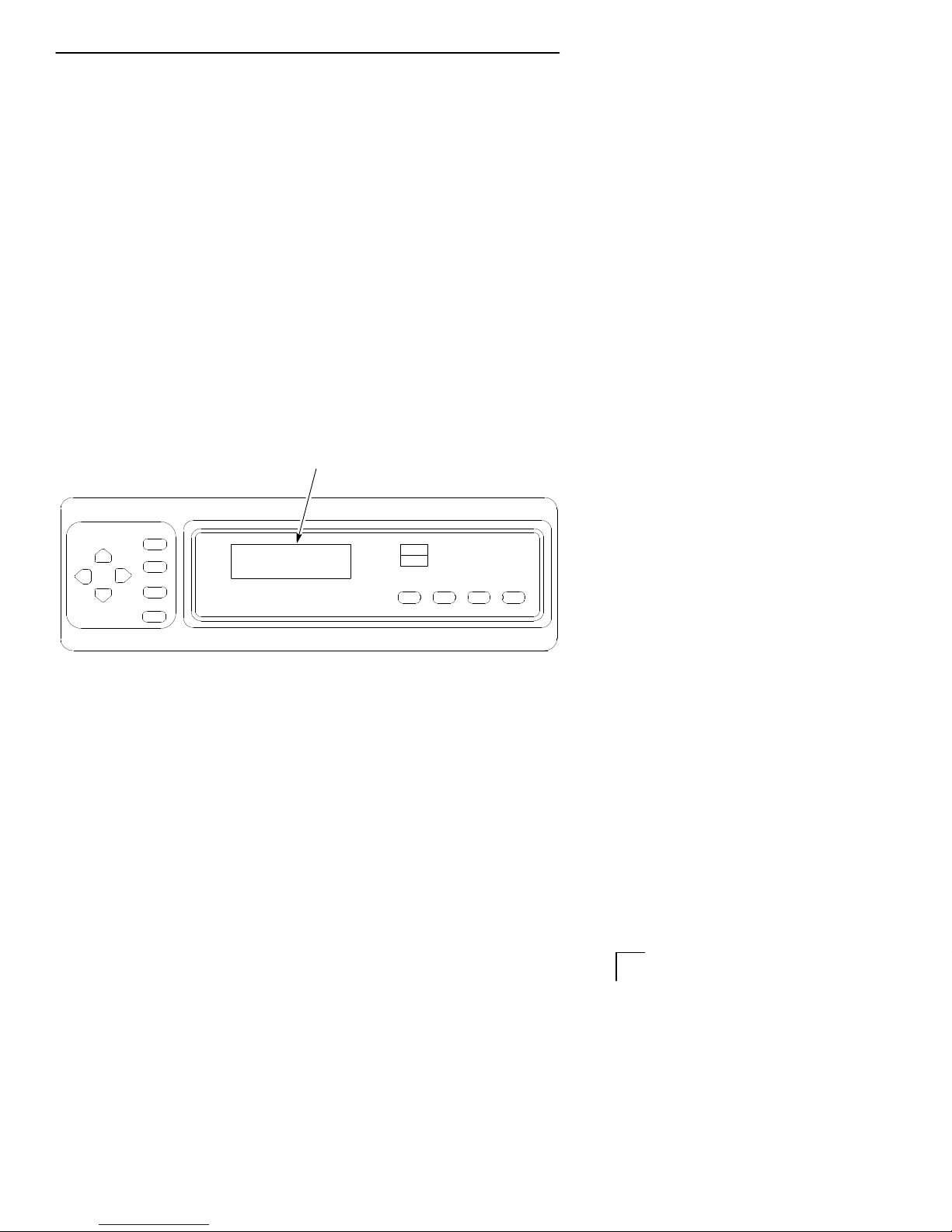

Control Panel Layout

Secondary Keys

UP

DOWN

RAISE PRINTER

COVER TO ACCESS

THESE SWITCHES

CLEAR

R/S

NEXTPREV

SET TOF

ENTER

Message Display

The printer’s operating modes, message

display , status indicator, and control panel

keys are described on the following pages.

Status Indicator

ON LINE FF VIEWLF

Primary Keys

4 Operator’s Guide

Page 13

Operating Modes

The printer operates in one of three modes,

as described below:

• Online Mode — In online mode, the printer

can receive and print data sent from the

host. Pressing the ON LINE key toggles

the printer from offline to online mode. The

status indicator is lit in online mode.

• Offline Mode — In offline mode, you may

perform operator functions, such as

loading paper and setting top-of-form. You

may also traverse the printer’s

configuration menus. Pressing the ON

LINE key toggles the printer from online to

offline mode. The status indicator is off in

offline mode.

• Fault Mode — a fault condition exists that

must be cleared before printing can

continue. In fault mode, the status indicator

is flashing, the alarm beeps three times,

and a descriptive fault message displays.

using the control panel

The current operating mode may be selected via

control panel keys, or may result from routine

operations such as powering on the printer. The

current operating mode is frequently indicated as

part of the printer display message.

5Operator’s Guide

Page 14

using the control panel

Format Conventions

Messages, keys, and indicators are shown

as they appear on the control panel. Key

combinations are indicated with the plus (+)

sign. For example, “Press CLEAR+ENTER”

means to press the CLEAR key and the

ENTER key at the same time.

Message Display

Function Displays operating modes,

menu options, and fault

messages.

Message Display

ONLINE

LG

6 Operator’s Guide

Page 15

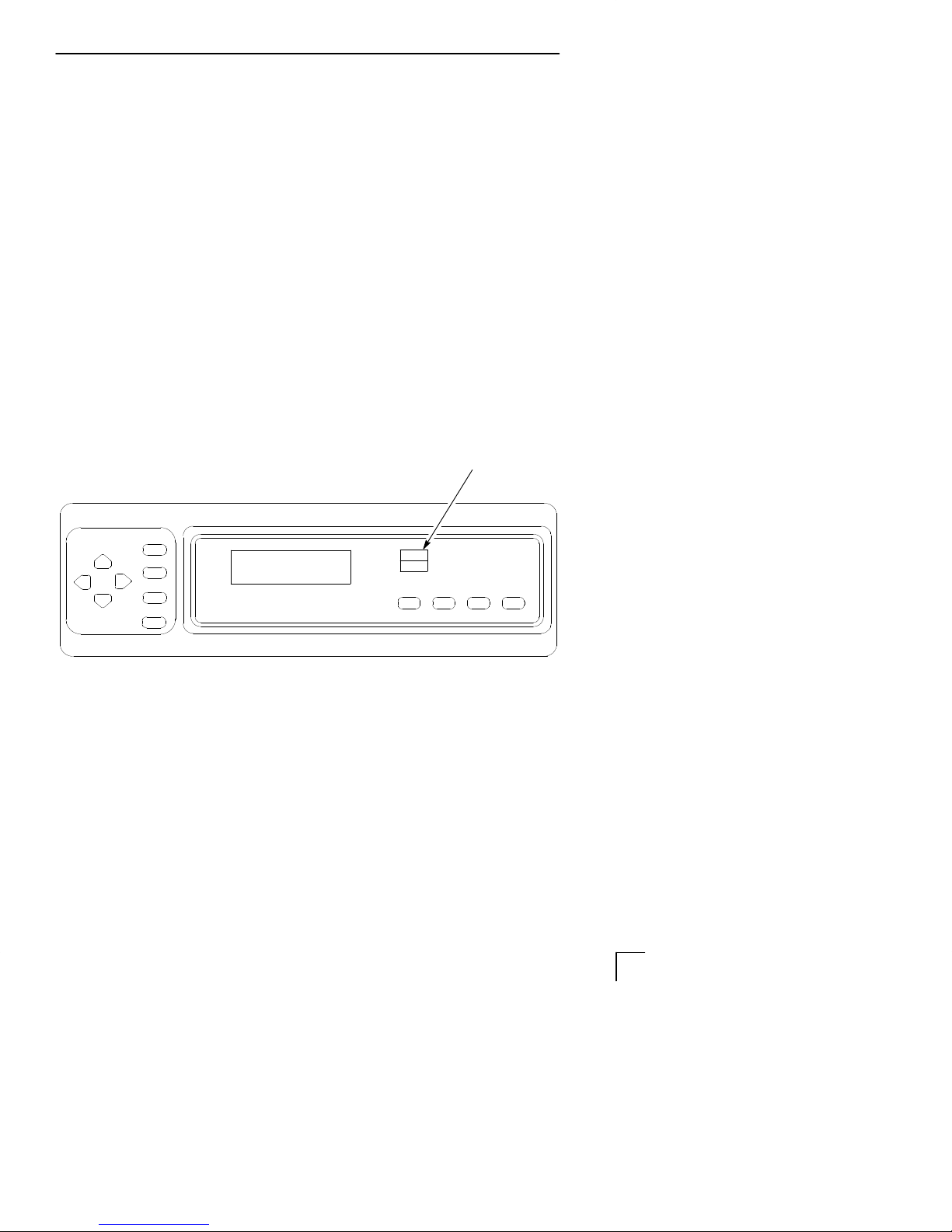

Status Indicator

The status indicator indicates the printer’s

operating mode, as follows:

•

On

— Status indicator illuminates

continuously when the printer is in

online mode.

•

Off

— Status indicator is off when the

printer is in offline mode.

•

Flashing —

fault condition exists and the printer is

in Fault mode. An error message will

generally display that describes the

error condition.

Status indicator flashes if a

using the control panel

Status Indicator

7Operator’s Guide

Page 16

using the control panel

ON LINE

Function Toggles the printer between

online and offline modes.

Action To place the printer in

online mode, press once.

The status indicator

remains continuously lit.

To place the printer in

offline mode, press once.

The status indicator is off.

Result When the printer is in online

mode, it is ready to receive

data and control commands

from the host computer,

and prints the data

immediately.

When the printer is in offline

mode, printing stops after

the current line finishes

printing. Communication

with the host stops, and you

may perform operator

functions such as setting the

top–of–form or configuring

the printer.

ON LINE

8 Operator’s Guide

Page 17

FF (Form Feed)

Function Causes the paper to

advance to the top–of–form

on the next page.

Action In online or offline mode,

press and release to

advance the paper to the

top–of–form on the next

page. If there is data in the

printer’s buffers, the data

will print and then the paper

will move to the next

top–of–form.

Other In the fault state FF does

not advance the paper to

the next top–of–form;

instead, it will slew the

paper 1 1 inches.

using the control panel

FF

9Operator’s Guide

Page 18

using the control panel

LF (Line Feed)

Function Advances the paper one

line at a time. Unprinted

data in the print buffer will

print before the paper

moves.

Action With the printer offline,

press and release to

advance the paper one line

at a time.

If there is data in the printer

buffer, the data will print

before the line feed occurs.

Press and hold to repeat

forward paper movement.

Other LF does not operate in the

fault or online states.

LF

10 Operator’s Guide

Page 19

VIEW (Forms Alignment)

Function In offline or online mode,

allows you to view and adjust

the placement of data on the

page, or to remove peel-off

labels.

using the control panel

Action In offline mode, press and

release to move the last data

printed to the tractor area for

viewing. Press VIEW a

second time to move the last

data printed back to the print

position.

To adjust fine vertical forms

alignment while the printer is

online and printing, press VIEW

to stop printing and move the

last data printed to the viewing

area; press Y or B to adjust

the paper up or down in 1/75”

increments; press VIEW a

second time to move the paper

back to its original print position

and return the printer to online.

Pressing ON LINE also moves the paper

back to its original print position and returns

the printer to online.

VIEW

11Operator’s Guide

Page 20

using the control panel

CLEAR

Function Clears a fault message and

returns the printer from fault

mode to offline mode.

Action After correcting a fault

condition, press and release.

Result The fault message is

cleared, and the printer

returns to offline mode.

Other 1) Press CLEAR+ENTER to

cancel a print job. The print job

must also be stopped from the

host system (see page 36).

2) Press CLEAR to move from

anywhere in the configuration

menus to the top menu

(“OFFLINE/CONFIG. CONTROL”)

CLEAR

12 Operator’s Guide

Page 21

R/S (Run/Stop)

Function Starts and stops diagnostic

tests, and generates a

configuration printout.

Action In the configuration

menus, when one of the

DIAGNOSTICS menu

Printer Tests displays

(such as Shift Recycle),

press R/S to start the test.

Press R/S again to stop

the test.

using the control panel

R/S

13Operator’s Guide

Page 22

using the control panel

SET TOF (Top–of–Form)

Function Sets the top–of–form on the

printer. This key is active

only when the printer is

offline and will not operate if

the printer is in a fault

condition.

Action Raise the forms thickness

lever; align the first print

line (directly below the

perforation) with the TOF

indicator on the tractor;

close the forms thickness

lever; then press SET TOF.

(See page 23 for a

complete procedure.)

Result The paper moves down to

the print position and aligns

to the top–of–form.

Other This key is not active during

a fault condition.

SET TOF

14 Operator’s Guide

Page 23

ENTER

Function In the menus, selects the

currently displayed option

value as the active value.

Action When the display shows the

desired configuration value,

press and release to select

that value as the active

value. An asterisk (*)

appears next to the active

value on the display .

(The ENTER key must be

unlocked before you can use

it to select option values. To

unlock the ENTER key,

press Y+B at the same

time from offline mode. To

relock the ENTER key, press

Y+B a second time.)

using the control panel

ENTER

Other Starts and stops printer tests,

and generates a configuration

printout. Press ENTER to start

a printer test (or configuration

printout). Press again to stop

the printer test.

15Operator’s Guide

Page 24

using the control panel

UP and DOWN ( Y and B )

Function Moves up and down between

levels in the configuration

menus.

In offline mode, press both

keys at the same time to

toggle the ENTER key

between locked and unlocked.

Action In the configuration menus,

press Y to move to a higher

level in the menu structure.

Press B to move to a lower

level in the menu structure.

In offline mode, press Y+B

at the same time to unlock

the ENTER key; press them

again to relock the ENTER

key.

Other After pressing VIEW, press Y

or B to adjust the paper up

or down in 1/75” increments

for fine vertical forms

alignment (see page 1 1).

UP

Y

B

DOWN

16 Operator’s Guide

Page 25

PREV and NEXT ( A and " )

Function Moves between the options

on the current level of the

configuration menu.

When both keys are

pressed simultaneously , the

printer will reset to the

power–up configuration and

reset its internal state.

Action In the configuration menu,

press A

or press " to scroll forward

through menu selections on

the same level.

to scroll backward

PREV

using the control panel

A

Press A +

printer by reloading the

power–up configuration and

resetting the printer’s

internal state.

" to reset the

"

NEXT

17Operator’s Guide

Page 26

18 Operator’s Guide

Page 27

Loading Paper

This procedure shows you how to load

paper into an empty printer or change the

paper supply to a different size.

To reload the paper after a “LOAD PAPER”

fault message, refer to page 26.

Press ON LINE to place the

printer in offline mode.

Open the printer cover.

Unload the current paper, if

necessary (page 30).

Tractor Door

Raise the forms thickness lever

as far as it will go.

Open both tractor doors.

Forms

Thickness

Lever

19Operator’s Guide

Page 28

loading paper

Open the cabinet front door.

Align the paper supply with

the label on the floor.

Ensure that the paper pulls

freely from the box.

Feed the paper up through the

paper slot inside the cabinet.

Hold the paper to prevent it

from slipping down through the

paper slot.

EDGE

OF

PAPER

BOX

Paper Slot

20 Operator’s Guide

Page 29

loading paper

Pull the paper above and behind

the ribbon mask. (The ribbon

mask location is shown on the

ribbon path diagram.)

Load the paper on the left

tractor and close the tractor

door.

Normally, you should not need

to adjust the position of the left

tractor.

If adjustment is necessary,

unlock the left tractor. Slide the

tractor until it is aligned directly

to the left of the number “1” on

the paper scale and lock it.

(You can also use the paper

scale to count columns.)

Tractor Door

Paper

Ribbon Path

Diagram

To avoid damage to the printer caused

by printing on the platen, always

position the left tractor unit directly to

the left of the “1” mark on the paper

scale.

Paper Scale

21Operator’s Guide

Page 30

loading paper

Unlock the right tractor.

Load the paper onto the

sprockets and close the

tractor door.

If necessary, slide the right

tractor to remove paper

slack or to adjust for

various paper widths. Then,

lock the tractor.

After both tractors are

secured, you may use the

horizontal adjustment knob

to make fine horizontal

paper adjustments.

Tractor Door

Tractor Lock

Close the cabinet front door.

Continue on to the next

section to set the

top–of–form.

22 Operator’s Guide

Horizontal

Adjustment Knob

Page 31

Setting Top-of-Form

The top-of-form setting determines where

the first line of print appears on a page.

Be sure to set the top–of–form under the

following conditions:

• Before each new print job

• After loading paper

• After clearing a paper jam

Follow this procedure to set the

top-of-form.

Make sure the printer is in offline

mode. (Press ON LINE to toggle

from online to offline mode.)

Press FF several times to make sure

the paper feeds properly beyond the

tractors and over the lower paper

guide. Feed sufficient paper to

ensure the paper stacks correctly.

Paper

Guide

Open the printer cover. Raise the

forms thickness lever as far as it

will go. ( If the cover and lever

are already raised, go directly to

Step 4.)

Forms

Thickness

Lever

23Operator’s Guide

Page 32

Align the top of the first print

line with the TOF indicator on

the tractor by rotating the

vertical position knob.

The first print line on the form

should be 1/2 inch or more from

the perforation for best print

quality.

Lower the forms thickness

lever. Set it to match the paper

thickness.

(The A–B–C scale corresponds

approximately to 1–, 3–, and

6–part paper thickness. Adjust

until you have the desired print

quality.)

TOF Indicator

Thin Paper

Medium Paper

Thick Paper

Perforation

Vertical

Position

Knob

Do not set the forms thickness lever too

tightly; excessive friction can cause paper

jams, ribbon jams with potential for ribbon

damage, smeared ink, or wavy print.

24 Operator’s Guide

Page 33

Press CLEAR to clear any fault

messages (such as “LOAD

P APER”) from the Liquid Crystal

Display.

Press SET TOF. The top–of–form

you have set moves down to the

print position. (If there is data in the

buffer, the paper moves back to the

last print position.)

Press ON LINE and close the

printer cover.

25Operator’s Guide

Page 34

Reloading Paper

Follow this procedure when “LOAD

PAPER” displays. (This message

occurs when the last sheet of paper

passes through the paper slot.) Use

this procedure to reload paper without

removing the last sheet of the old paper

supply.

If you are using multi-part paper and it is

too thick for the new paper to be loaded

over the existing paper, do not use this

procedure. Instead, remove the existing

paper and load new paper using the

loading paper procedure (page 19).

Raise the printer cover. Raise

the forms thickness lever as far

as it will go.

Do not open the tractor doors or

remove the existing paper.

Forms

Thickness

Lever

26 Operator’s Guide

Page 35

Open the cabinet front door.

Align the paper supply with the

label on the floor.

Ensure that the paper pulls

freely from the box.

Locate the paper slot inside

the cabinet and feed the

paper up through the slot.

It may be easier to feed one corner of the

new paper up through the slot first. When

this corner can be grasped from the top,

rotate the paper back to the normal

position. If necessary, gently press the

existing paper back.

reloading paper

EDGE

OF

PAPER

BOX

Hold the paper to prevent it

from slipping down and through

the paper slot.

Paper Slot

27Operator’s Guide

Page 36

reloading paper

Pull the new paper above and

behind the ribbon mask, but in

front of the existing paper. (The

ribbon mask location is shown on

the ribbon path diagram.)

If necessary, gently press the

existing paper back.

Align the top edge of the new

paper with the top perforation

of the existing paper.

New Paper

Existing

Paper

Load the new paper over the

existing paper.

Open and load the tractors one

at a time to prevent the paper

from slipping.

Ensure that the top edge of the new paper

lines up with the top perforation of the

existing paper.

Ribbon Path

Diagram

28 Operator’s Guide

Page 37

6 Lower the forms thickness lever. Set

it to match the paper thickness.

(The A–B–C scale corresponds

approximately to 1–, 3–, and 6–part

paper thickness. Adjust until you

have the desired print quality .)

caution

Do not set the forms thickness lever too

tightly; excessive friction can cause

paper jams, ribbon jams with potential

for ribbon damage, smeared ink, or

wavy print.

7 Press CLEAR to clear the

“LOAD PAPER” fault message

from the Liquid Crystal Display .

A

Thin Paper

B

Medium Paper

C

Thick Paper

reloading paper

8 Close the printer cover.

Close the cabinet front door.

9 Press ON LINE to place the

printer in online mode and

resume printing.

10 Open the cabinet back door

and ensure that the paper folds

in the stacker the same way it

does in the supply area, then

close the cabinet back door.

29Operator’s Guide

Page 38

Unloading Paper

To unload paper from the printer,

perform the following steps.

Press ON LINE to place the

printer in offline mode, and

open the printer cover.

Tear off the paper at the

perforation.

Allow the paper to fall to the

back of the printer and into

the paper stacking area.

Raise the forms thickness

lever as far as it will go.

Open both tractor doors.

Perforation

Tractor Door

Forms

Thickness

Lever

30 Operator’s Guide

Page 39

unloading paper

4 Remove the paper from the

tractors. Open the cabinet front

door.

Gently

pull the paper down

through the paper slot.

Do not let the paper

perforations or tractor holes

damage the ribbon mask. (The

ribbon mask location is shown

on the ribbon path diagram.)

Allow the paper to fall into the

paper supply area.

caution

Be careful when pulling any paper

backwards through the paper path,

especially when using label stock. If you

are not careful, labels can detach and

adhere to the printer within the paper

path, where only a Digital service

representative can remove them.

Tractor

Ribbon Path Diagram

Cabinet

Front

Door

5 Remove the stacked paper from

the cabinet floor.

6 Close the cabinet front door.

7 Close the printer cover.

31Operator’s Guide

Page 40

Replacing the Ribbon

When replacing ribbons, use only the

ribbons listed below:

Use of ribbons that do not meetDigital

specifications may void warranty.

Part Number Description

LGxxR–SR One OCR Application 60–yard ribbon (LG04 ribbon)

Length: 60 yards (54.84 m)

Width: 1 inch (2.54 cm)

Thickness: .0039 inches (.009906 cm)

LGxxR–LR One OCR Application 100–yard ribbon (LG04 ribbon)

Length: 100 yards (91.4 m)

Width: 1 inch (2.54 cm)

Thickness: .0039 inches (.009906 cm)

To order replacement ribbons, call

1–800–DIGITAL.

32 Operator’s Guide

Page 41

Press ON LINE to place the

printer in offline mode, and open

the printer cover.

Remove the old ribbon:

Raise the forms thickness

lever as far as it will go.

Press in on the hub latches

and lift the ribbon spools off

the hubs. Lift the ribbon out

of the ribbon path. (Refer to

the ribbon path diagram on

the shuttle cover.)

Discard the old ribbon.

If necessary, clean the interior

of the printer. (See page 59.)

replacing the ribbon

Hub Latch

Forms

Thickness

Lever

33Operator’s Guide

Page 42

replacing the ribbon

Install the new ribbon:

With the ribbon to the outside,

place the right spool on the

right hub. Press down on the

spool until the hub latch snaps

in place.

Thread the ribbon around

the ribbon guide and along

the ribbon path. (Refer to

the ribbon path diagram on

the shuttle cover.) Be sure

to thread the ribbon

between the hammer bank

cover and the ribbon mask.

The ribbon must not be twisted. A twisted

ribbon can lower print quality, shorten

ribbon life, or cause paper jams.

Hub

Latch

Hammer

Bank

Cover

Ribbon

Mask

Ribbon

Guide

Place the left spool on the left hub.

Press down on the spool until the

hub latch snaps into place.

Hand–turn the right spool to make

sure the ribbon tracks correctly in

the path and ribbon guides.

34 Operator’s Guide

Page 43

5 Lower the forms thickness

lever. Set it to match the paper

thickness you are using.

A

Thin Paper

replacing the ribbon

(The A–B–C scale

corresponds approximately to

1–, 3–, and 6–part paper

thickness. Adjust until you

have the desired print

quality.)

caution

Do not set the forms thickness lever too

tightly; excessive friction can cause paper

jams, ribbon jams with potential for ribbon

damage, smeared ink, or wavy print.

6 Close the printer cover.

7 Press ON LINE to return the

printer to online mode.

B

Medium Paper

C

Thick Paper

35Operator’s Guide

Page 44

Canceling a Print Job

The procedure to cancel a print job depends

on the printer emulation and your application

software. See your System Administrator for

additional information.

Place the printer offline.

From the host system, stop the

print job.

If the print job is not stopped from the host

system before pressing CLEAR + ENTER,

the print job will continue with data missing

when the printer returns to online.

Exercise caution to prevent unwanted data

loss occurrences as this function will delete

unprinted data in the printer. This function

is active only in an offline condition; the

purpose of this function is to eliminate the

necessity of printing unwanted data when

print jobs are canceled.

Press CLEAR + ENTER.

Set the top–of–form, as

described on page 23.

36 Operator’s Guide

Page 45

CONFIGURATION

♦ Configurations and Parameters 38

♦ Saving Configurations 44

♦ Printing Configurations 46

♦ Loading Configurations 48

♦ Deleting Configurations 50

♦ The Power–Up Configuration 52

37Operator’s Guide

Page 46

Configurations and Parameters

The following pages describe how to save,

print, load and delete entire configurations,

as well as how to select a power–on

configuration.

Configurations

A configuration is a group of parameter

settings. For example:

• 8 lpi

• 10 cpi

• Data processing typeface, etc.

Nine configurations are available. Your

printer has a preset factory configuration that

cannot be changed or deleted, configuration

0. Configurations 1 to 8 are provided so that

you can store custom configurations to meet

specific print job requirements.

To create a custom configuration, modify any

printer parameters as needed from the

default values, then save the modified

configuration (as number 1 to 8) using the

“Save Config.” menu option.

38 Operator’s Guide

Page 47

Once you have defined and saved a

configuration to nonvolatile memory , it will

not be lost if you power off the printer . You

can load or delete configurations; you can

also modify and overwrite (resave) them.

Configurations 1 to 8 are undefined until

you define them using the “Save Config.”

menu option.

configurations and parameters

39Operator’s Guide

Page 48

configurations and parameters

Parameters

Printer parameters are settings such as line

spacing (lpi), characters per inch (cpi), typeface,

etc. You can change a parameter by pressing

keys on the operator panel or by sending a

control code from the host computer.

A parameter such as 8 lpi is effective as long

as the printer is on. To save the 8 lpi

parameter, you must use the operator panel

and save it as part of a configuration.

To learn more about the configuration menus

and how to change individual parameters

such as line spacing, typeface, etc., refer to

plus

the

LG

Series Setup Guide

or the

programming reference manual for each

emulation.

Control Codes

Control codes override parameters that were

changed with the operator panel. For example, if

you set line spacing to 6 lpi with the operator

panel, and application software later changed

this to 8 lpi with a control code, then 8 lpi would

be the new, active parameter.

40 Operator’s Guide

Page 49

configurations and parameters

The Configuration Menus

The following two pages show a summary of the

entire set of configuration menus available with

plus

the LG

procedures for configuring particular menu

options from the Config. Control Menu.

Series

. Following this are several

Refer to the

descriptions of the configuration menu options.

plus

LG

Series Setup Guide

for

41Operator’s Guide

Page 50

configurations and parameters

OFFLINE

CONFIG.

CONTROL

Load Config.

0* – 8

Save Config.

1* – 8

Print Config.

Current*

Factory

Power–up

All

1 – 8

Delete Config.

1* – 8

Power–up Config.

0* – 8

Protect Configs.

Disable*

Enable

HOST

INTERFACE

(continued)

Dataproducts

Data Bit 8

Enable*/ Disable

PI Ignored

Enable*/ Disable

Data Polarity

Standard*/ Inverted

Data Request Pol.

Standard*/ Inverted

Strobe Polarity

Standard*/ Inverted

Buffer Size in K

8* (1–16)

Bidirectional

Buffer Size in K

8* (1–16)

ACTIVE

EMULATION

LG *

LinePrinter+

IGP/PGL & LP+

IGP/VGL & LP+

if installed

(see PGL or VGL

User’s Manual)

CONTROL

Unidirectional

Disable*

Enable

PMD Fault

Enable*

Disable

Slow Paper Slew

Disable*

Enable

Power Saver Time

15 min.*

(15–60)

PRINTER

EMULATION

LG *

Font

Font Style

DP 10 6*

(34 options)

Font Char. Set

U.S. ASCII*

(23 options)

Vert. Forms

Bot. Frm 66/6*

Top Mrg. 0/6*

(range 0–198 lines)

Horiz. Forms

Left Mrg. 0.0*

Right Mrg. 13.2*

(range 0–13.2 inches)

Autowrap

No*

Yes

CR

CR=CR * / CR=CR+LF

LF

LF=LF * / LF=CR+LF

Unsolicited Rpt.

No* / Small / Big

Print Mode Opt

Enable* / Disable

Plot Mode Opt

Enable* / Disable

LinePrinter+

SEE NEXT PAGE

Printer Tests

Test Width

Paper Out Dots

System Memory –

Print Statistics

1

MAINT / MISC

Hex Dump Mode

Disable*

Enable

Power–up State

Online*

Offline

Display Language

English*

German

French

Spanish

Italian

DIAGNOSTICS

Shift Recycle*, All E’s,

E’s + TOF, All H’s,

All Underlines, All Black,

Shuttle Slow, Shuttle Fast,

Shuttle Only, Phase Printer,

Paperout Adj., Burnin Test

Full Width*

80 col.

48 dots*

(Range 4–76)

X Megabytes

On X.X Hrs

Print: X.X Hrs

Print Strokes

Print Lines

11 inch Pages

HOST

INTERFACE

Serial*

Interface Type

RS 232* / RS 422

Data Protocol

XON/XOFF*, ETX/ACK,

ACK/NAK, DTR

Baud Rate

1200, 2400, 4800,

9600*, 19200, 38400,

57600, 115200 Baud

Word Length

8* or 7

Stop Bits

1* or 2

Parity

None*, Odd, Even,

Mark, Sense

Data Terminal Ready

True*

False

On-line and BNF

Off-line or BF

Request to Send

True*

False

On-line and BNF

Off-line or BF

Buffer Size in K

8* (1–16)

Parallel

Centronics

Data Bit 8

Enable*/ Disable

Data Polarity

Standard*/ Inverted

Strobe Polarity

Standard*/ Inverted

Resp. Polarity

Standard*/ Inverted

Busy On Strobe

Enable*/ Disable

Latch Data On

Leading*/Trailing

Prime Signal

Enable*/Disable

TOF Action

Reset*/Do Nothing

Buffer Size in K

8* (1–16)

(continued to left)

1

Only the current Active Emulation will display on the Emulation menu.

The default is LG.

42 Operator’s Guide

Page 51

configurations and parameters

LinePrinter+

Printer

Protocol

Define CR Code

CR=CR*

CR=CR+LF

Auto LF

Enable*

Disable

Define LF Code

LF=LF*

LF=CR+LF

FF Valid at TOF

Disable

Enable*

Character Set

Code Page 437*

Set 1*

Set 2

Code Page 850

Set 1*

Set 2

OCR–A

OCR–B

20 CPI Condensed

Enable*

Disable

CPI/LPI

Select

Select CPI

10.0 CPI*

12.0 CPI

15.0 CPI

17.1 CPI

20.0 CPI

Select LPI

6.0 LPI*

8.0 LPI

10.3 LPI

Epson FXProprinter XL*

Define CR Code

CR=CR*

CR=CR+LF

Auto LF

Enable*

Disable

Define LF Code

LF=LF*

LF=CR+LF

Printer Select

Disable*

Enable

Character Set

Epson Set*

ASCII (USA)*

(14 options)

OCR–A

OCR–B

IBM PC

20 CPI Condensed

Enable*

Disable

P–Series

Control Code 06

8.0 LPI*

10.3 LPI

6.0 LPI

Control Code 08

Elongated*

Backspace

Define CR Code

CR=CR*

CR=CR+LF

Auto LF

Disable*

Enable

Overstrike

Enable*

Disable

Define LF Code

LF=CR+LF*

LF=LF

Select SFCC

1B*

(Range 00–7F hex)

EVFU Select

Enable*

Disable

Alt. Set 80–9F

Control Code*

Printable

Character Set

IBM PC*

Primary/Extended

Multinational

ECMA Latin 1

Primary/Extended

DEC Mult.

OCR–A

OCR–B

Font

Attributes

Typeface

Data Processing*

NLQ

OCR A

OCR B

High Speed

NLQ Sans Serif

Prop. Spacing

Disable*/Enable

Bold Print

Disable*/Enable

Italic Print

Disable*

Forward Slant

Backward Slant

Slashed Zero

Disable*/Enable

To view options, press:

To select option value, press ENTER.

To return to main menu, press CLEAR.

To go to online mode, press ON LINE.

* = Factory Default

Margins

Perforation Skip

Form Length

Form Width

Page

Format

Left Margin

0 columns*

(range 0–369)

Right Margin

0 columns*

(range 0–369)

Bottom Margin

0 lines*

(range 0–451)

Disable*

1/2 inch

2/3 inch

5/6 inch

1 inch

Abs. Length IN

11 inches*

(range 1–24)

Abs.Length MM

279.4 mm*

(range .1–609.6)

Funct. of lines

66 lines*

(range 1–192)

Abs. Width IN

13.6 inches*

(range 1–13.6)

Function of CPI

136 Characters*

(range 1–264)

Abs. Width MM

345.4 mm*

(range 1–345.4)

Menu Function

B

Y

"

A

DOWN

UP

NEXT

PREV

43Operator’s Guide

Page 52

Saving Configurations

You can save up to eight unique

configurations. They are stored in

memory and will not be lost if you turn

off the printer .

Configuration 0 is the factory–preset

configuration and cannot be modified

or deleted.

Press ON LINE to place the

printer offline, and raise the

printer cover.

Press Y and B simultaneously

to unlock the control panel. The

message “UNLOCKED” displays

briefly.

Press B.

Press " repeatedly until you

reach the Save Config.

parameter.

Press B.

OFFLINE

CONFIG. CONTROL

ENTER SWITCH

UNLOCKED

CONFIG. CONTROL

Load Config.

CONFIG. CONTROL

Save Config.

Save Config.

1*

44 Operator’s Guide

Page 53

saving configurations

Press " or A until the desired

configuration number (1–8) displays.

Press ENTER to select the value.

An asterisk (*) appears next to the

value in the display . Your active

configuration is now saved as

configuration 2.

Press Y and B simultaneously to

lock the control panel. The

message “LOCKED” displays

briefly.

Press ON LINE. Close the printer

cover. The printer is ready to

resume printing.

Save Config.

2

Save Config.

2*

ENTER SWITCH

LOCKED

ONLINE

45Operator’s Guide

Page 54

Printing Configurations

The configuration printout lists the

stored configuration parameters (line

spacing, forms length, etc.). You can

print the following configurations:

current, factory, power–up, the

customized configurations (1–8), or all of

the configurations.

Press ON LINE to place the

printer offline, and raise the

printer cover.

Press Y and B simultaneously

to unlock the control panel. The

message “UNLOCKED” displays

briefly.

Press B.

Press " repeatedly until you

reach the Print Config.

parameter.

Press B.

OFFLINE

CONFIG. CONTROL

ENTER SWITCH

UNLOCKED

OFFLINE

Load Config.

CONFIG. CONTROL

Print Config.

Print Config.

Current*

Press " or A until the desired

option displays.

46 Operator’s Guide

Print Config.

Factory

Page 55

printing configurations

Press ENTER. The configuration

prints. Tear off the configuration

printout.

If a you try to print a configuration that does

not yet exist (i.e., you have not previously

saved values to that numbered

configuration), then the following fault

message will display:

“CONFIG. DOES NOT EXIST / Save First”

Press Y and B simultaneously to

lock the control panel. The message

“LOCKED” displays briefly.

Press ON LINE.Close the printer

cover. Save the printout in a safe

place. The printer is ready to resume

printing.

OFFLINE

CONFIG. CONTROL

ENTER SWITCH

LOCKED

ONLINE

47Operator’s Guide

Page 56

Loading Configurations

While the printer is on, you can load any

of the eight customized configurations or

the factory default configuration.

The configuration you load will remain in

effect as long as the printer is on. When

you turn the power off and then back on,

the designated power–up configuration

loads. See page 52.

Press ON LINE to place the

printer in offline mode, and open

the printer cover.

OFFLINE

CONFIG. CONTROL

Press Y and B simultaneously to

unlock the control panel. The

message “UNLOCKED” displays

briefly.

Press B.

Press B.

Press " or A until the

configuration you want to load

displays.

ENTER SWITCH

UNLOCKED

OFFLINE

Load Config.

LOAD CONFIG.

0*

LOAD CONFIG

2

48 Operator’s Guide

Page 57

loading configurations

Press ENTER.

If a you try to load a configuration that does

not yet exist (i.e., you have not previously

saved values to that numbered

configuration), then the following fault

message will display:

“CONFIG. DOES NOT EXIST / Save First”

Press Y and B simultaneously to

lock the control panel. The message

“LOCKED” displays briefly.

Press ON LINE and close the printer

cover. The printer is ready to resume

printing.

Loading Saved

Configuration

Load Config.

2*

ENTER SWITCH

LOCKED

ONLINE

49Operator’s Guide

Page 58

Deleting Configurations

You can delete any of your customized

configurations. The factory preset

configuration 0 cannot be deleted.

Press ON LINE to place the

printer offline, and open the

printer cover.

Press Y and B simultaneously to

unlock the control panel. The

message “UNLOCKED” displays

briefly.

OFFLINE

CONFIG. CONTROL

ENTER SWITCH

UNLOCKED

Press B.

Press " repeatedly until you

reach the Delete Config.

parameter.

Press B.

Press " or A until the

configuration you want to delete

displays.

CONFIG. CONTROL

Load Config.

CONFIG. CONTROL

Delete Config.

Delete Config.

1*

Delete Config.

3

50 Operator’s Guide

Page 59

deleting configurations

Press ENTER.

If a you try to delete a configuration that

does not yet exist (i.e., you have not

previously saved values to that numbered

configuration), then the following fault

message will display:

“CONFIG. DOES NOT EXIST / Save First”

Press Y and B simultaneously to

lock the control panel. The

message “LOCKED” displays

briefly.

Press ON LINE and close the

printer cover. The printer is ready

to resume printing.

Deleting

Configuration

Delete Config.

3*

ENTER SWITCH

LOCKED

ONLINE

51Operator’s Guide

Page 60

The PowerĆUp Configuration

When you power on the printer for the first

time, it loads configuration 0, the factory

default configuration.

If you save a configuration, such as

configuration 1, and turn the power off

and then back on, the printer will load

the designated power–up configuration,

not the last saved configuration.

For your convenience, you can specify

which configuration (0–8) should be the

power–up configuration.

Press ON LINE to place the printer

offline, and open the printer cover .

Press Y and B simultaneously to

unlock the control panel. The

message “UNLOCKED” displays

briefly.

Press B.

Press " repeatedly until you reach

the Power–up Config. parameter.

OFFLINE

CONFIG. CONTROL

ENTER SWITCH

UNLOCKED

CONFIG. CONTROL

Load Config.

CONFIG. CONTROL

Power–up Config.

52 Operator’s Guide

Page 61

the powerĆup configuration

Press B.

Press " or A until the

configuration you want displays.

Press ENTER.

If a you try to select a configuration that

does not yet exist (i.e., you have not

previously saved values to that numbered

configuration), then the following fault

message will display:

“CONFIG. DOES NOT EXIST / Save First”

Press Y and B simultaneously

to lock the control panel. The

message “LOCKED” displays

briefly.

Power–up Config.

0*

Power–up Config.

4

Loading Saved

Configuration

Power–up Config.

4*

ENTER SWITCH

LOCKED

Press ON LINE and close the

printer cover. The printer is ready

to resume printing.

ONLINE

53Operator’s Guide

Page 62

54 Operator’s Guide

Page 63

TROUBLESHOOTING

♦ Clearing Paper Jams 56

♦ Cleaning the Printer 59

♦ Solving Print Quality Problems 62

♦ Fault Messages 64

55Operator’s Guide

Page 64

Clearing Paper Jams

Perform the following steps to clear a

paper jam.

caution

Be careful when pulling any paper

backwards through the paper path,

especially when using label stock. If you

are not careful, labels may detach and

adhere to the printer within the paper

path, where only a Digital service

representative can remove them.

1 Open the printer cover.

2 Raise the forms thickness lever

as far as it will go.

3 Open both tractor doors.

4 Check the paper path and

tractors for jammed or torn

paper. Remove any pieces of

paper by turning the vertical

position knob.

Tractor Door

Forms

Thickness

Lever

Vertical

Position

Knob

56 Operator’s Guide

Page 65

Check that the ribbon mask has

not been deformed in such a way

as to block the paper path. (If the

ribbon mask is damaged or bent,

contact an authorized service

representative.)

Check the narrow paper path

between the face of the platen

and the ribbon mask for pieces of

torn paper and ribbon lint. Refer

to the ribbon path diagram on the

shuttle cover.

Reload the paper on the tractors.

If you need to load a new box of

paper, go to page 19. If you need

to set the top-of-form after

reloading paper, go to page 23 and

start at Step 2.

clearing paper jams

Tractor

Ribbon Path Diagram

57Operator’s Guide

Page 66

clearing paper jams

Lower the forms thickness lever.

Set it to match the paper

thickness.

The A–B–C scale corresponds

approximately to 1–, 3–, and

6–part paper thickness. Adjust

until you have the desired print

quality.

Do not set the forms thickness lever too

tightly; excessive friction can cause paper

jams, ribbon jams with potential for ribbon

damage, smeared ink, or wavy print.

Close the printer cover.

Press ON LINE to resume printing.

Thin Paper

Medium Paper

Thick Paper

58 Operator’s Guide

Page 67

Cleaning the Printer

Periodic cleaning ensures efficient

operation and clear print quality .

Disconnect the power source before

cleaning the printer.

Cleaning Exterior of Cabinet

Clean the outside of the cabinet with a

soft, lint-free cloth and mild detergent.

(Dishwashing liquid works well.) Do not

use abrasive powders or chemical

solvents. Clean the windows with plain

water or mild window cleaner.

Always apply the cleaning solution to

the cloth; never pour cleaning solution

directly onto the printer.

Cleaning Inside the Cabinet

Over time, it is normal for particles of

paper and ink to accumulate inside the

printer. Paper dust and ink build-up must

be removed periodically to avoid

degraded print quality . To clean the

interior of the printer, perform the

following steps.

59Operator’s Guide

Page 68

cleaning the printer

caution

To avoid damage to the printer, be

extremely careful when vacuuming and

dusting around the hammer bank and

surrounding areas.

1 Power off the printer and

unplug the power cord.

2 Unload the paper supply

(page 30).

3 Remove the ribbon

(step 2, page 33).

4 Using a soft-bristled,

non-metallic brush, remove

dust particles from the paper

path, ribbon guides, and

ribbon path. (Refer to the

ribbon path diagram on the

shuttle cover.)

Hammer Bank

(hidden)

Ribbon

Path

Diagram

Base

Pan

Splined

Shaft

Ribbon

Guide

5 Brush and vacuum

accumulated dust or residue,

especially in the tractor and

base pan areas, and around

the exterior of the hammer

bank.

60 Operator’s Guide

Page 69

Wipe the splined shaft with a soft

cloth.

Using a cloth dampened with

anhydrous (not diluted with water)

alcohol, clean the ribbon guides.

Do not let alcohol drip into the

hammer bank.

Brush and vacuum inside the

lower cabinet.

Wipe the lower cabinet interior

with a clean, lint-free cloth damp

(not wet) with water and mild

detergent.

Dry the interior with a dry , clean,

lint-free cloth.

cleaning the printer

Interior of

Lower

Cabinet

Load the paper (page 19) and

reinstall the ribbon (page 34).

61Operator’s Guide

Page 70

Solving Print Quality Problems

If you are having print quality problems, locate

your printer problem in the table below and do

the Corrective Action. If more than one

corrective action task is listed, test the printer

after each task. If the problem persists, contact

your authorized service representative.

Problem

Poor print quality:

dark print

light print

light print on half the page

missing dots or characters

smeared print

wavy vertical lines

Torn or damaged forms 1 Reset the forms thickness lever for

1 Adjust the forms thickness lever setting.

(Print quality can be affected if it is too

loose or too tight.)

2 Adjust the paper tension horizontally by

moving the right tractor (print quality can

be affected if the paper is too loose or

too tight).

3 Make sure the ribbon threads around the

ribbon guides and between the hammer

bank cover and ribbon mask, as shown

on the ribbon path diagram. Turn the

ribbon spools to ensure that the ribbon

tracks correctly in the ribbon path.

4 Clean the printer (see page 59).

5 Replace the ribbon (page 32) with an

approved ribbon.

thicker paper.

2 Adjust the paper tension horizontally by

moving the right tractor (print quality can

be affected if the paper is too loose or

too tight).

3 Check the paper slot for foreign material.

Corrective Action

continued next page

62 Operator’s Guide

Page 71

solving print quality problems

Problem Corrective Action

Loss of forms position 1 Set the forms thickness lever for

Asterisk does not appear

after you change a

configuration parameter with

the ENTER key.

The configuration printout

does not represent

configuration parameters

selected and changed.

Lost dots (incompletely

formed characters)

Horizontally or vertically

misaligned character

positions

Erratic character height

Vertically deformed print

thicker paper.

1 With the printer off–line, press UP and

DOWN simultaneously so that the

display reads “UNLOCKED”.

the configuration option you want to

change. Press ENTER when the option

is on the message display .

1 Verify that you have saved the current

configuration (see page 44).

1 Lower the forms thickness lever.

2 Clear the paper path of any

obstructions.

3 If problems persist, contact your Digital

Service Representative.

Display

63Operator’s Guide

Page 72

Fault Messages

When a fault condition occurs, the status lamps

flash, the alarm sounds, and a specific message

appears in the display . When this happens,

correct the fault immediately .

You can correct most faults by performing a

simple procedure, such as clearing a paper jam

or reloading paper. The following pages list

common fault messages and explain how to

correct the fault conditions.

For more serious faults, indicated by an asterisk

(*) following the fault message, a Digital

Customer Service Engineer may be needed.

Perform the following steps to clear a fault

message after you have corrected the fault

condition,

Service Engineer for the faults indicated by an

asterisk (*):

and

before you call a Digital Customer

Press CLEAR, then ON LINE to

continue printing.

If the fault message reappears, turn

the printer power off, wait 15 seconds,

then turn the printer back on. Run your

print job again. If the message does

not reappear during printing, no further

attention is required. If the fault

message reappears, go to step 3.

Press CLEAR, then ON LINE again

and resume printing. If the message

does not appear, no further attention is

required. If the message reappears,

call your Digital Customer Service

Engineer.

64 Operator’s Guide

Page 73

fault messages

8.5V PWR FAIL*

15V CTL FAIL*

23.5V CTL FAIL*

48V PWR FAIL*

ACCESS NULL PTR*

A TO D OVERUN*

8.5V PWR FAIL*

Internal power failure. Contact your

Digital Customer Service Engineer.

15V CTL FAIL*

Controller voltage failure. Contact your

Digital Customer Service Engineer.

23.5V CTL FAIL*

Controller voltage failure. Contact your

Digital Customer Service Engineer.

48V PWR FAIL*

Internal power failure. Contact your

Digital Customer Service Engineer.

ACCESS NULL PTR*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

A TO D OVERUN*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

BAD VFU CHANNEL

BUFFER OVERFLOW

BAD VFU CHANNEL

Error in channel assignment for a Vertical

Format Unit (VFU), for one of the

LinePrinter Plus emulations. Refer to the

LinePrinter Plus Programming Reference

Manual

for further information.

BUFFER OVERFLOW

Host sends data after the printer buffer is

full. (Serial interface.) Check your serial

host interface parameter settings; if

necessary, adjust them so that they

match the settings of the attached host.

65Operator’s Guide

Page 74

fault messages

CLEAR PAPER JAM

CLOSE PLATEN

COIL HOT

CTL VOLT FAIL*

DRVR CIR BAD*

ENERGY STAR

CLEAR PAPER JAM

Clear jam and reload paper (see page 56). If

this message recurs, contact your Digital

Customer Service Engineer.

CLOSE PLATEN

The forms thickness lever is open. Close

the forms thickness lever.

COIL HOT

One or more hammer coils are

overheating. Contact your Digital

Customer Service Engineer.

CTL VOLT FAIL*

Controller voltage failure. Contact your

Digital Customer Service Engineer.

DRVR CIR BAD*

Hammer coil count test failed. Contact

your Digital Customer Service Engineer.

ENERGY STAR

Status message: printer is in low–energy

idle state, all fans and higher voltages

are off, only+5Vdc logic circuits are

active. No action required.

EXHAUST FAN FLT

EXHAUST FAN FLT

Sensors cannot detect current in fan

circuit. Power off the printer and remove

the paper path. Check that the fan cable

connector is connected. Check for

obstruction of vents and fan airway , and

remove any obstructions. Check for items

beneath the printer blocking cabinet vents.

Power back on the printer. If this message

recurs, contact your Digital Customer

Service Engineer.

66 Operator’s Guide

Page 75

fault messages

FIRMWARE ERROR

FRAMING ERROR

HAM. COIL OPEN*

HB NOT INSTALLD*

FIRMWARE ERROR

Application software tried to perform an

illegal printer function or damaged memory

detected on CMX board.Contact your Digital

Customer Service Engineer.

FRAMING ERROR

Serial framing error (serial interface).

Check your serial host interface

parameter settings; if necessary , adjust

them so that they match the settings of

the attached host.

HAM. COIL OPEN*

Electrical malfunction of one or more

hammer coils. Contact your Digital

Customer Service Engineer.

HB NOT INSTALLED*

Self–test does not detect hammer coils.

Contact your Digital Customer Service

Engineer.

HMR BANK FAN FLT

ILL EXT BUS ACC*

HMR BANK FAN FLT

Sensors cannot detect current in fan

circuit. Power off printer and remove

paper path. Check that fan cable is

connected. Check for obstruction of vents

and fan airway; remove any obstructions.

Check for items beneath the printer

blocking cabinet vents. Power back on

the printer. If this message recurs,

contact your Digital Customer Service

Engineer.

ILL EXT BUS ACC*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

67Operator’s Guide

Page 76

fault messages

ILL INST ACCSS*

ILLGL OPR ACCSS*

INTAKE FAN FAULT

LO DRV. SHORT*

LOAD PAPER

ILL INST ACCSS*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

ILLGL OPR ACCSS*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

INTAKE FAN FAULT

Sensors cannot detect current in fan

circuit. See description for HMR BANK

FAN FLT.

LO DRV. SHORT*

Circuit(s) on the hammer bank or in the

hammer bank power cable shorted to

ground. Contact your Digital Customer

Service Engineer.

LOAD PAPER

Printer is out of paper. Load paper.

PAP BAD TABLE*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP BAD TABLE*

PAP BSY TOO LNG*

PAP BSY TOO LNG*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP FIFO OVERFL*

PAP FIFO OVERFL*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

68 Operator’s Guide

Page 77

fault messages

PAP FIFO UNDRFL*

PAP ILLGL ST*

PAP INCMPL ENER*

PAP INVLD CMD*

PAP INVLD PARM*

PAP FIFO UNDRFL*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP ILLGL ST*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP INCMPL ENER*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP INVLD CMD*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP INVLD PARM*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP NOT SCHED*

PAP NT AT SPEED*

PAP UNEXP INT*

PAP NOT SCHED*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP NT AT SPEED*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PAP UNEXP INT*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

69Operator’s Guide

Page 78

fault messages

PARITY ERROR

PLAT INV CMD*

PLAT INV PARM*

PLAT INV STATE*

POWER SUPPLY HOT

PARITY ERROR

Parity error (serial interface). Check your

serial host interface parameter settings; if

necessary, adjust them so that they

match the settings of the attached host.

PLAT INV CMD*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PLAT INV PARM*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PLAT INV STATE*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

POWER SUPPLY HOT

Circuits are overheating on the power

supply board. Contact your Digital

Customer Service Engineer.

PRINTER HOT

PRINTER HOT

Controller board sensors report high

temperatures on the board. Contact your

Digital Customer Service Engineer.

PROTECTED INSTR*

PROTECTED INSTR*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

PWR SUPP VOLT*

PWR SUPP VOLT*

Power supply failed. Replace power

supply board.

70 Operator’s Guide

Page 79

RIB INVLD CMD*

fault messages

RIB INVLD CMD*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

RIB INVLD STATE*

RIBBON DRIVE

SECURITY VIOLATION

SHUTL INV CMD*

SHUTL INV PARM*

RIB INVLD STATE*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

RIBBON DRIVE

CMX controller does not detect ribbon

drive motor. Contact your Digital

Customer Service Engineer.

SECURITY VIOLATION

Security code of P AL on controller board

does not match code of firmware on the

CMX controller board. Contact your

Digital Customer Service Engineer.

SHUTL INV CMD*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

SHUTL INV PARM*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

SHUTTLE JAM

SHUTTLE JAM

No shuttle movement or shuttle moving

at wrong speed. Check for obstruction to

shuttle, a twisted ribbon, or forms

thickness lever closed too tightly . If fault

source is not apparent, contact your

Digital Customer Service Engineer.

71Operator’s Guide

Page 80

fault messages

SOFTWARE ERROR*

Cycle power

STACK OVERFLOW*

STACK UNDERFLOW*

TCB CORRUPTED*

SOFTWARE ERROR*

Application software tried to perform

illegal printer function, or damaged logic

circuits found on controller board.

Contact your Digital Customer Service

Engineer.

STACK OVERFLOW*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

STACK UNDERFLOW*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

TCB CORRUPTED*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

UNDEF INTERRUPT*

UNDEF INTERRUPT*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

UNDFNED OPCODE*

UNDFNED OPCODE*

Fatal firmware error on CMX controller

board. Contact your Digital Customer

Service Engineer.

UP DRV. SHORT*

UP DRV. SHORT*

Hammer driver circuits on the CMX

boards shorted to ground. Contact your

Digital Customer Service Engineer.

72 Operator’s Guide

Loading...

Loading...