Digital Equipment LG06 Maintenance Manual

LG06

Text and Graphics Printer

Maintenance Manual

latigid

Order Number: EK–ELG06–MG

LG06

Text and Graphics Printer

Maintenance Manual

Order Number: EK–ELG06–MG

Digital Equipment Corporation • Merrimack, NH 03054

2nd Edition, July 1992

Digital Equipment Corporation 1991, 1992

All Rights Reserved

The information in this document is subject to change without notice and should

not be construed as a commitment by Digital Equipment Corporation. Digital

Equipment Corporation assumes no responsibility for any errors that may appear

in this document.

Printed in U.S.A.

The following are trademarks of Digital Equipment Corporation:

DATATRIEVE

DEC

DECmate

DECset

DECsystem

DECUS

DECwriter

DECxpress

The DIGITAL logo

DIBOL

IVAX

MASSBUS

PDP

P/OS

Professional

Rainbow

RSTS

FCC USER STATEMENT

NOTICE:

This equipment generates, uses, and may emit radio frequency. The equipment has

been type tested and found to comply with the limits for a Class A computing device

pursuant to Subpart J of Part 15 of FCC rules, which are designed to provide reasonable

protection against such radio frequency interference. Operation of this equipment in a

residential area may cause interference in which case the user at his own expense will

be required to take whatever measures may be required to correct the interference.

RSX

Scholar

ULTRIX

UNIBUS

VAX

VMS

VT

Work Processor

Table of Contents

1 Maintenance Overview

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Special Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Conventions in This Manual 1–3. . . . . . . . . . . . . . . . . . . . . . . .

Controls and Indicators 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, Test Equipment, and Supplies 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Scheduled Maintenance

Preventive Maintenance Checks and Services (PMCS) 2–2. . . . . . . . . . . . .

Inspecting the Printer 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Troubleshooting

Introduction 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48 Volt Failed * 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic RAM Fault 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Bank Hot * 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Coil Open * 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Coil Short* 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Drv. Short * 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mech Driver Hot * 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mech Driver Link* 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Jam 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Out 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Ribbon Stall 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shttl Cover Open 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Jam 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Error 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptoms Not Indicated by Fault Messages 3–18. . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Aids 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Self–Tests 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Diagnostic Self–Tests 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Code Printout 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Adjustment Procedures

Preparing for Maintenance 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt, Paper Feed Timing, Adjustment 4–6. . . . . . . . . . . . . . . . . . . . . . . .

Belt, Platen Open, Adjustment 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Phasing 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Drive Motor Pulley Alignment 4–10. . . . . . . . . . . . . . . . . . . . . . . .

Paper Scale Alignment 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Angle Adjustment 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Gap Adjustment 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open Motor Pulley Alignment 4–12. . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Guide Alignment 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Splined Shaft Skew Adjustment 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Replacement Procedures

Replacement Procedures 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Printer for Maintenance 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt, Paper Feed Timing 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt, Platen Open 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Assembly W4, Hammer Bank 5–8. . . . . . . . . . . . . . . . . . . . . . . . .

Cable Assembly W5, Intermediate 5–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Assembly , Multi I/O 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Circuit Breaker 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Assembly 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Assembly , Hammer Bank 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Assembly , Shuttle 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Assembly , Card Cage 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Assembly , Cabinet Exhaust 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Assembly , Hammer Bank 5–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Spring Assembly 5–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Pick–up (MPU) Assembly 5–34. . . . . . . . . . . . . . . . . . . . . . . . .

Motor Assembly , Ribbon Drive 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Assembly, Paper Feed 5–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Assembly , Platen Open 5–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Guide Assembly 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Ironer 5–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCBA, Common Controller 5–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCBA, Mechanism Driver 5–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCBA, Power Supply 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROMs, Chips, and ICs on the CCB 5–52. . . . . . . . . . . . . . . . . . . . . . . . .

PROMs, Chips, and ICs on the Mechanism Driver 5–54. . . . . . . . . . . . . .

Resistors, Terminating 5–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Hub 5–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Guide Assembly (L/R) 5–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft, Splined 5–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft, Support 5–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Frame Assembly 5–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring Assembly, Gas 5–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring, Extension 5–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Assembly , Cover Open 5–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Assembly , Paper Detector 5–76. . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Assembly , Platen Interlock 5–78. . . . . . . . . . . . . . . . . . . . . . . . . .

Tractor (L/R) 5–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning the Printer to Normal Operation 5–80. . . . . . . . . . . . . . . . . . . . . . .

iii

Appendices

A: Printer Configuration

B: Printer Specifications

C: Torque Table

D: Cable Interconnections and Hammer Bank Wiring

E: Principles of Operation

F: Ferrite Noise Suppression Cores

Index

iv

1 Maintenance Overview

Chapter Contents

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Special Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Conventions in This Manual 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls and Indicators 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, Test Equipment, and Supplies 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1Maintenance Overview

About This Manual

This manual explains how to maintain and repair the LG06 printer at the field

service level of maintenance. This manual covers alignments and

adjustments, preventive and corrective maintenance, troubleshooting, and

basic principles of operation.

Related Documents

Information about operating the LG06 printer is in the User’s Manual.

How to Use This Manual

This manual is designed so you can quickly find the information you need to

maintain and repair the Encore printer. You can locate maintenance

information three ways:

• Use the Table of Contents at the front of the manual.

• Use the Chapter Contents list on the first page of each chapter.

• Use the Index at the back of the manual.

Read the entire procedure before beginning any maintenance task. Gather all

required tools and make sure you understand all warnings, cautions, and

notes before you begin working on the printer.

Warnings and Special Information

Always read and comply with information highlighted by special headings.

The headings reveal the nature of the information:

WARNING

Conditions that could harm you as well as damage the equipment.

CAUTION

Conditions that could damage the printer or related equipment.

IMPORTANT

Information vital to proper operation of the printer.

NOTE: Information considered important enough to emphasize.

1–2 Maintenance Overview

Printing Conventions in This Manual

Switches and indicators labeled on the printer are printed uppercase in this

manual. Example: “Press the ON LINE switch to take the printer off–line.”

If a control is not labeled on the printer, it is printed lowercase. Example:

“Set the forms thickness lever to the fully open position.”

Messages that appear on the control panel display are printed inside

quotation marks in lowercase with the first letter capitalized. Example: “Save

Config” appears on the message display.

1–3Maintenance Overview

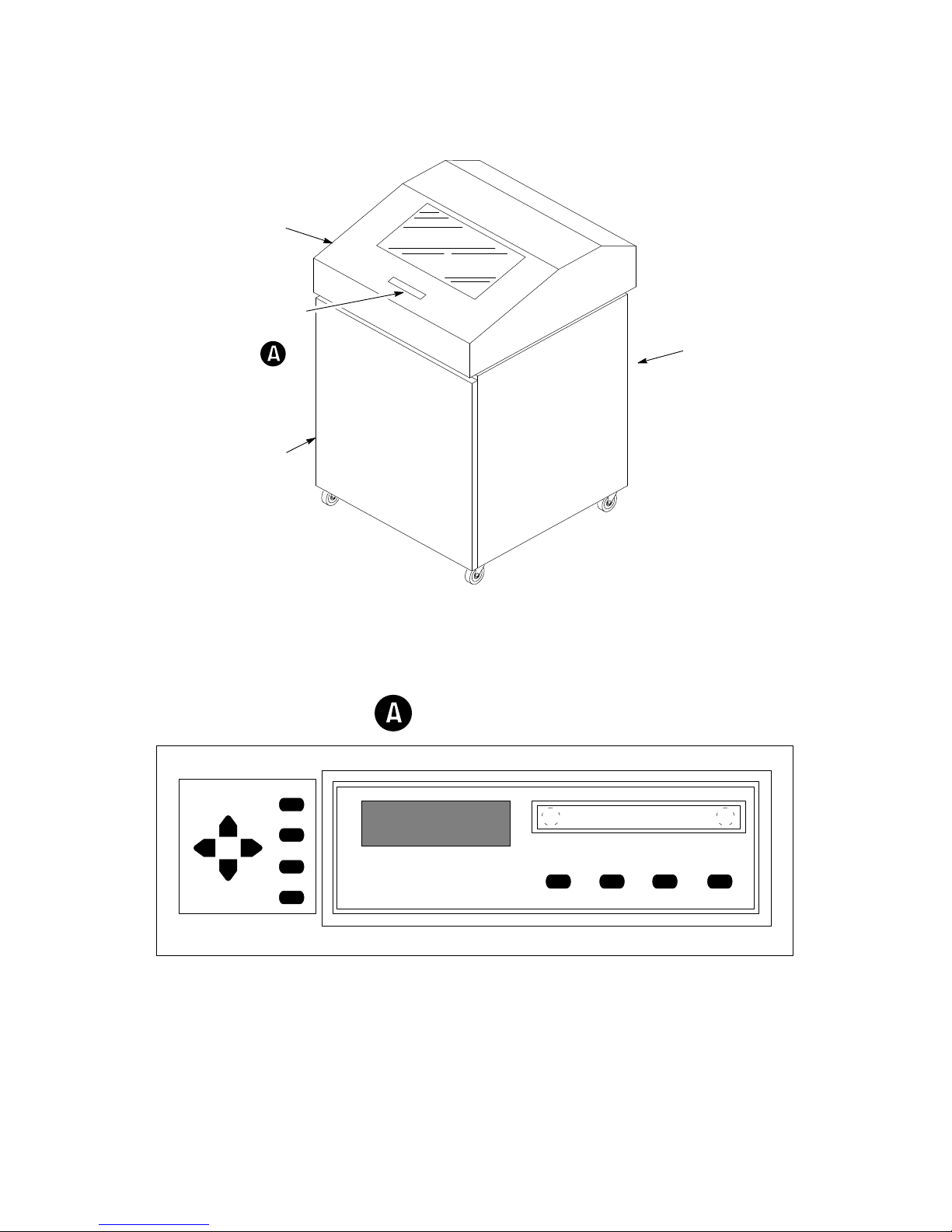

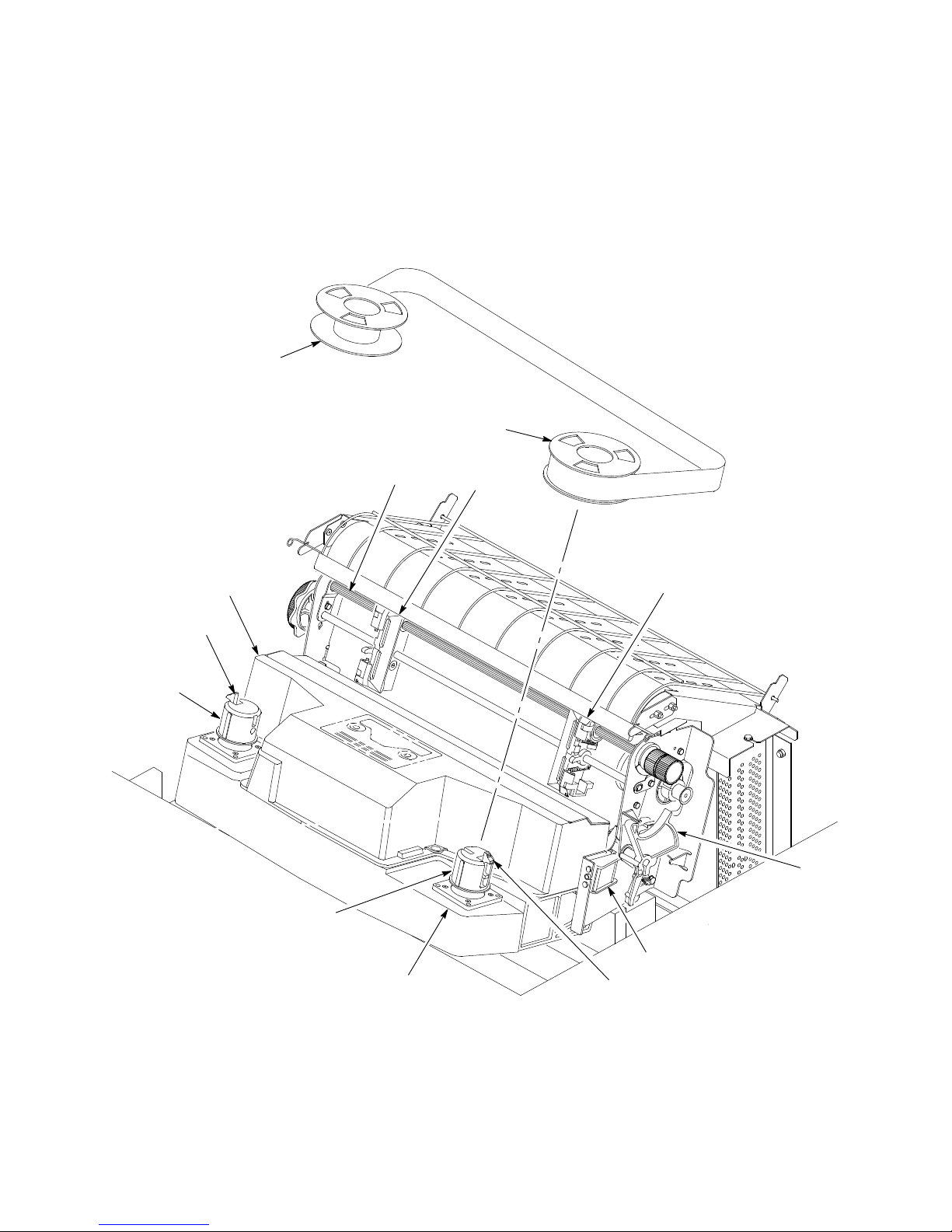

Controls and Indicators

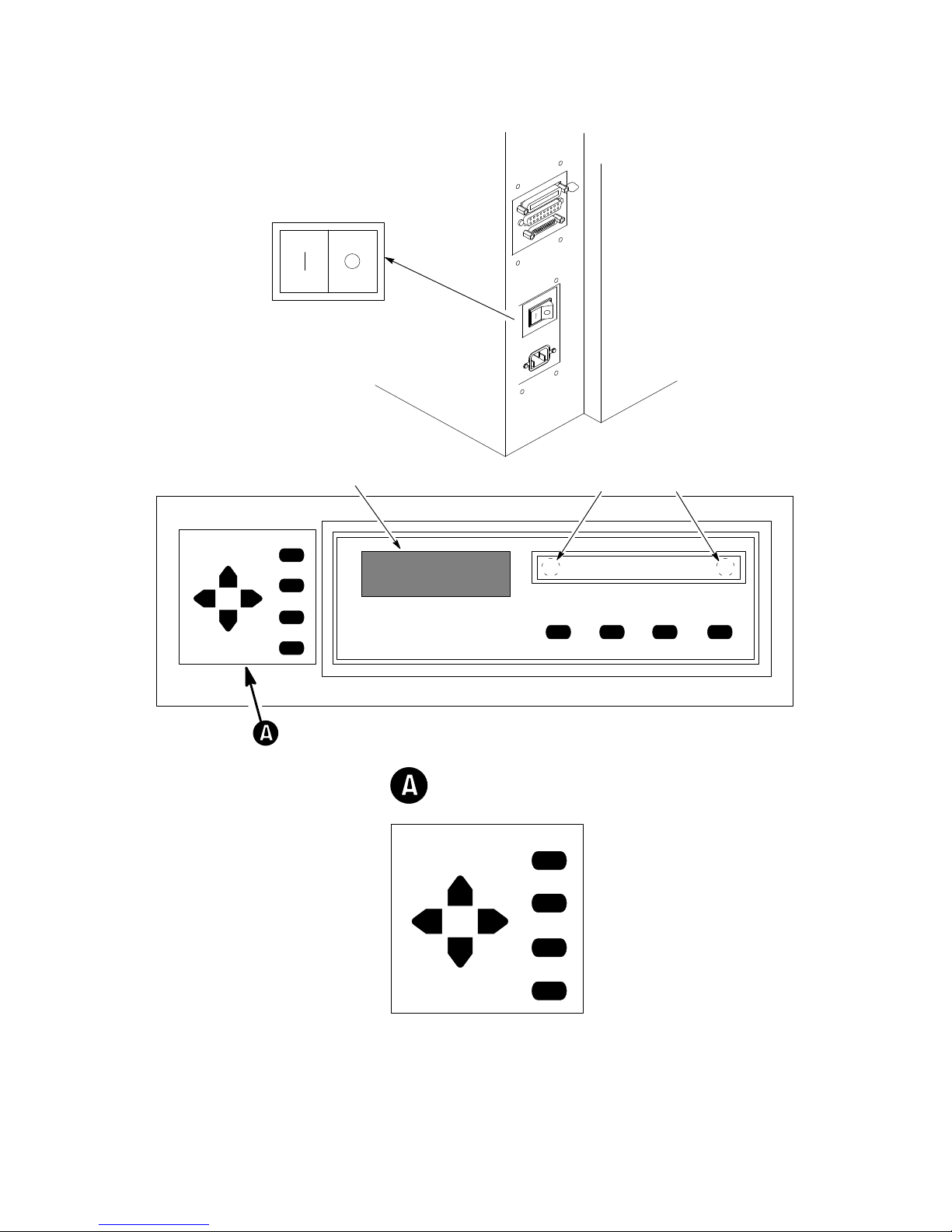

The locations of the printer cover, cabinet doors, and operator control panel

are shown in Figure 1–1.

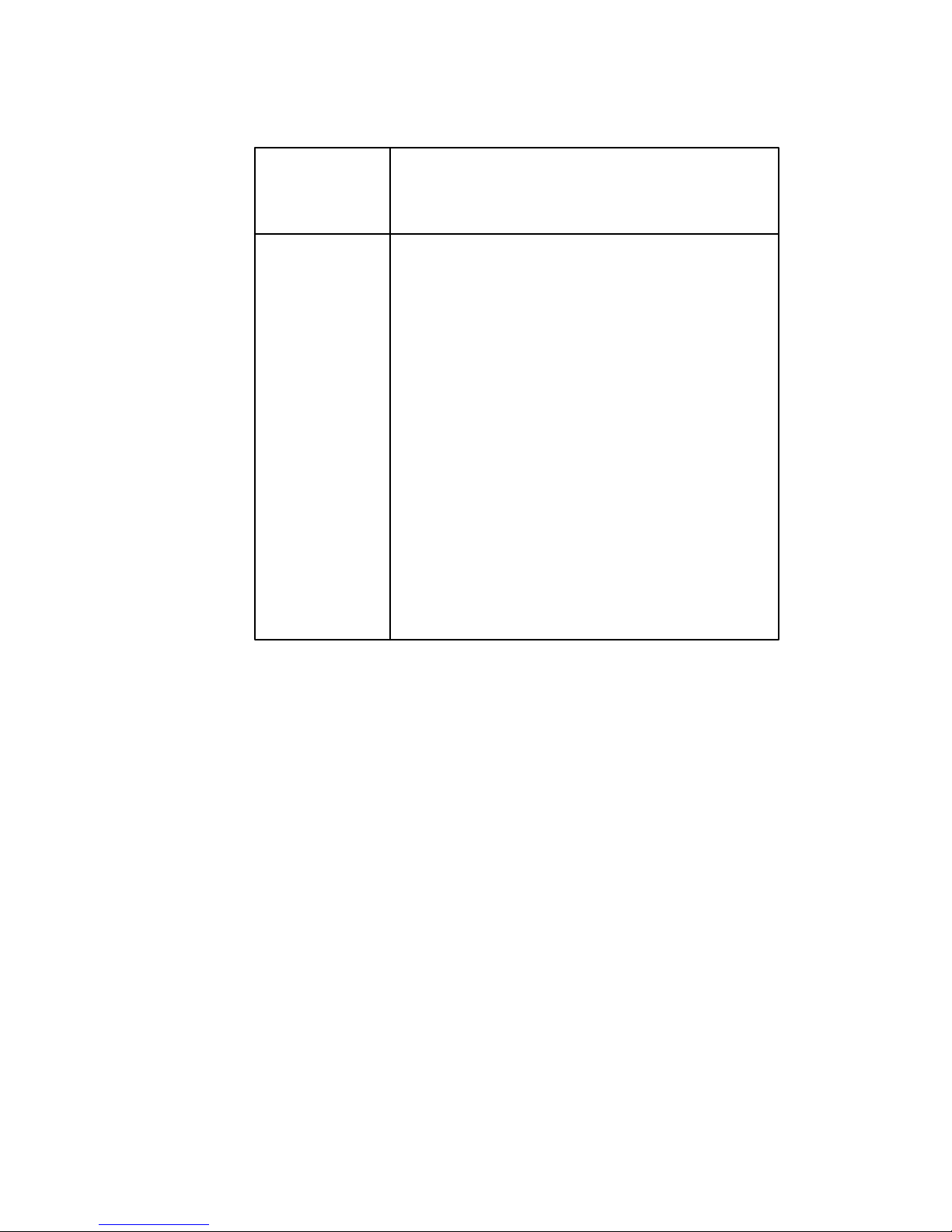

Electrical controls and indicators are described in Table 1–1 and illustrated in

Figure 1–2.

Mechanical controls and indicators are described in Table 1–2 and illustrated

in Figure 1–3.

1–4 Maintenance Overview

Printer Cover

Lift to open

Operator

Control

Panel

See Detail

Floor Cabinet

Front Door

Hinged on left.

Magnetic latch.

Open by pulling

right edge.

UP

NEXTPREV

SET TOF

DOWN

CLEAR

R/S

ENTER

Operator Control Panel

ON LINE FF VIEW

Rear Door

(Not shown)

Hinged on left.

Magnetic latch.

Open by pulling

right edge.

LF

Figure 1–1. Printer Cover, Door(s), and Operator Control Panel

1–5Maintenance Overview

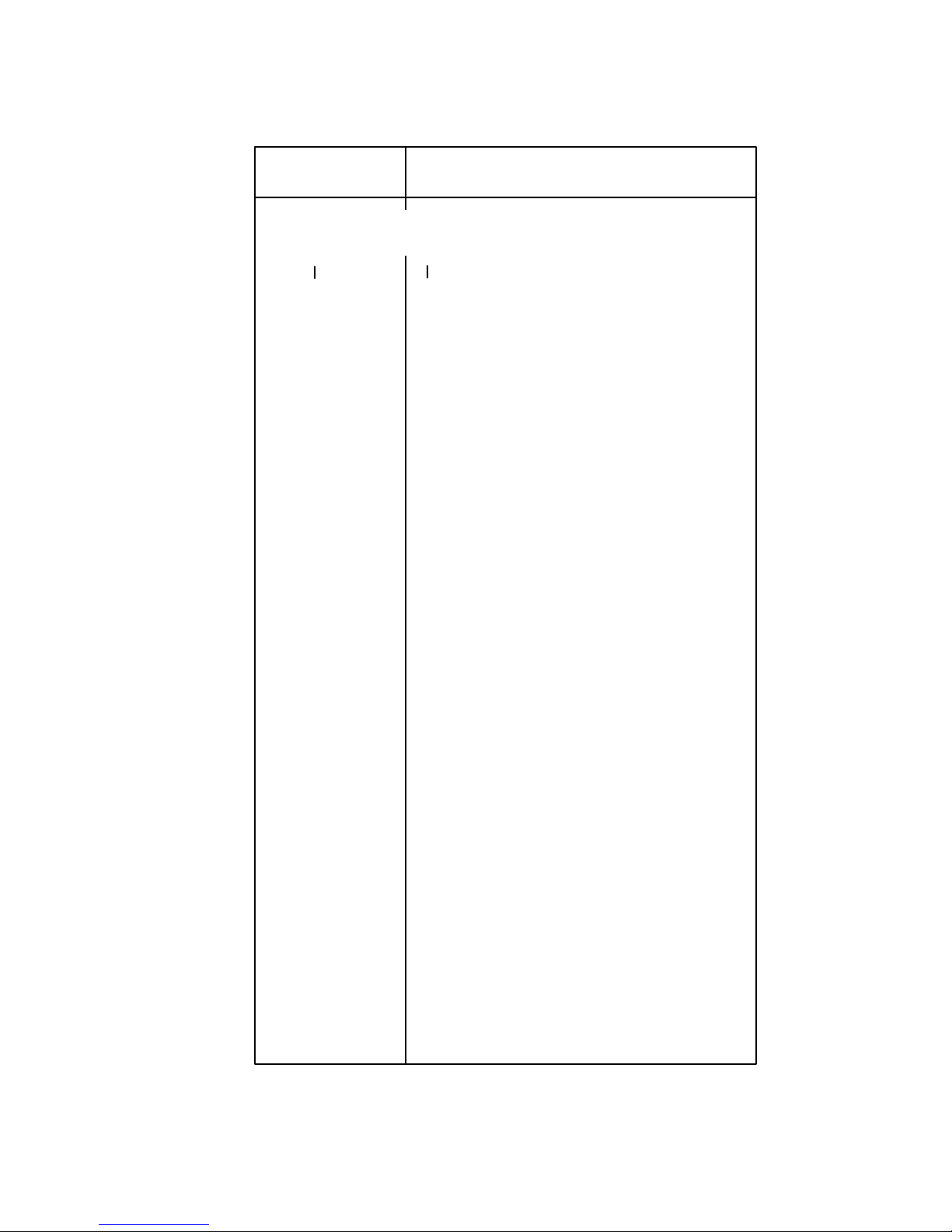

Table 1–1. Electrical Controls and Indicators

Switch or

Indicator

Function

NOTE: Only the ON LINE switch operates when the printer is on–line.

All other switches operate only in the off–line state.

/O

Status lamps

Message display

ON LINE

FF Advances paper to top of form on next page.

LF

VIEW

UP

= On O = Off Turns printer on and off. Switch is

also a circuit breaker.

Illuminate when printer is on–line. Flash alternate-

ly to indicate fault. Off when printer is off–line.

Displays printer status and error messages.

T oggles the printer on–line and off–line.

Advances paper to top of next print line.

Advances paper for viewing through cover window, then returns paper to print position.

Locks and unlocks ENTER switch when pressed

simultaneously with DOWN switch. Also causes

display of configuration menus, submenus, and

diagnostic tests.

DOWN See above.

PREV

NEXT

CLEAR

R/S

SET TOF

ENTER

Displays previous parameter in a configuration or

diagnostic test menu.

Displays next parameter in a configuration or

diagnostic test menu.

Clears printer after a fault is corrected. Returns

printer to off–line state from within a configuration menu. Resets printer when pressed simultaneously with R/S switch.

Runs and stops configuration and self tests. Runs

and stops hex dump. Resets printer when pressed

simultaneously with CLEAR switch.

Sets location of first line of print on a page.

Enters displayed parameter into printer nonvolatile

memory . Must be unlocked before using.

1–6 Maintenance Overview

Power Switch

UP

DOWN

(On) (Off)

Status LampsMessage Display

CLEAR

R/S

NEXTPREV

SET TOF

ENTER

ON LINE FF VIEW

LF

Raise Printer Cover to

Access These Switches

CLEAR

UP

R/S

NEXTPREV

SET TOF

ENTER

DOWN

Figure 1–2. Electrical Controls and Indicators

1–7Maintenance Overview

Table 1–2. Mechanical Controls and Indicators

Control or

(See Figure 1–3)

FunctionIndicator

Forms thickness

lever

Forms thickness

pointer and scale

Tractors (2)

Tractor locks (2)

Horizontal

adjustment knob

Vertical position

knob

Sets platen for paper and forms of different thicknesses. Must be fully opened (raised) to load paper.

Indicates relative thickness of forms or paper. Set the

forms thickness lever at A for thin (single–part) forms,

B for thicker forms, and so on.

Hold and feed paper. Used to set left margin. Left tractor moves about one inch. Right tractor moves full

range.

Lock tractors in position.

Allows fine positioning of left print margins. Moves

paper left or right.

Used to set top of form or first line to be printed. Rotate

to move paper vertically.

1–8 Maintenance Overview

Horizontal

Adjustment

Knob

Tractor

Lock

Left Tractor Door

Right Tractor Door

Tractor

Lock

Vertical

Position

Knob

Forms Thickness

Lever and Scale

Forms Thickness Pointer

Figure 1–3. Mechanical Controls and Indicators

1–9Maintenance Overview

Tools, Test Equipment, and Supplies

The tools, test equipment, and supplies required for field level maintenance

of LG06 printers are listed in Table 1–3.

Table 1–3. Tools, Test Equipment, and Supplies

Item Part No.

Adhesive, Loctite 101854–002

Alcohol, anhydrous (must contain no water)

RTV silicone sealant

Adjustable wrench

Diagonal cutters

Digital voltmeter

Extension 3 in., 3/8 in. drive

Feeler gauge set

Force gauge

Gauge, platen position 996083–200

Kimwipes

Lubricant, bearing 101805–001

Nut driver set

Oscilloscope and probes (35 MHz or better)

Pliers, grip ring

Pliers, chain nose

Ratchet, 3/8 in. drive

Rule, steel, 6 in.

Screwdriver, torque, Utica TS–35

Adapter, 1/4 in. hex to 1/4 in. square, Utica HW–18

Hex bit, 3/16 in., torque screwdriver 29–20995–00

Hex bit, 3/32 in., torque screwdriver

Hex bit, 5/32 in., torque screwdriver

(Chatillon NY, Gauge–R, 0–20 lb)

(adhesive, methacryl)

(Lubriko M–3, Master Lubricant Co.)

–

101537–001

–

–

–

–

–

CAT 719–20

–

–

–

–

–

–

–

29–17381–00

29–24723–00

29–18505–00

24–18504–00

Hex bit, 5/64 in., torque screwdriver –

Screwdriver, Allen hex (set), w/extension

Screwdriver, Phillips

Screwdriver, Phillips

Screwdriver, slot

Screwdriver, slot

Socket, 7/16 in., 3/8 in. drive

T weezers –

1–10 Maintenance Overview

–

–

–

–

–

–

2 Scheduled Maintenance

Chapter Contents

Preventive Maintenance Checks and Services (PMCS) 2–2. . . . . . . . . . . . . . . . . .

Inspecting the Printer 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1Scheduled Maintenance

Preventive Maintenance Checks and Services (PMCS)

Perform preventive maintenance checks and services (PMCS) every six

months or after every 1000 hours of operation, whichever comes first.

Do these checks more often if the printer is used for heavy–duty, continuous

printing or if is located in a dusty area.

PMCS are listed in Table 2–1.

WARNING

Disconnect the ac power cord before performing PMCS. Failure to do so

could result in injury to you or damage to equipment.

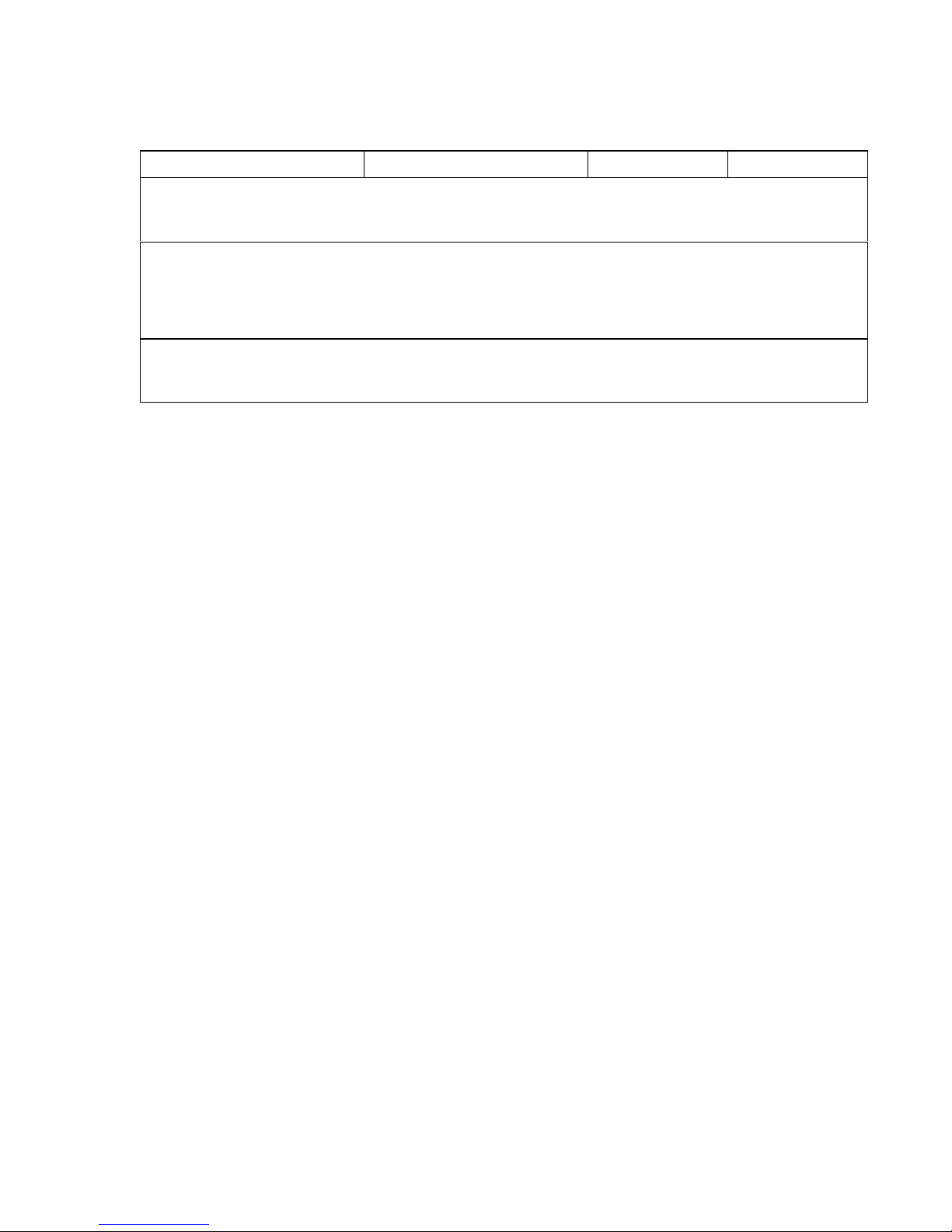

Table 2–1. Preventive Maintenance Checks and Services

Interval Procedure

Every 6 months or 1000

hours of operation,

whichever occurs first.

Inspect the printer.

Clean the printer.

Check and adjust

platen gap.

Page

2–3

2–4

4–18

2–2 Scheduled Maintenance

Inspecting the Printer

Correct any condition found during inspection that could affect printer

performance or reliability.

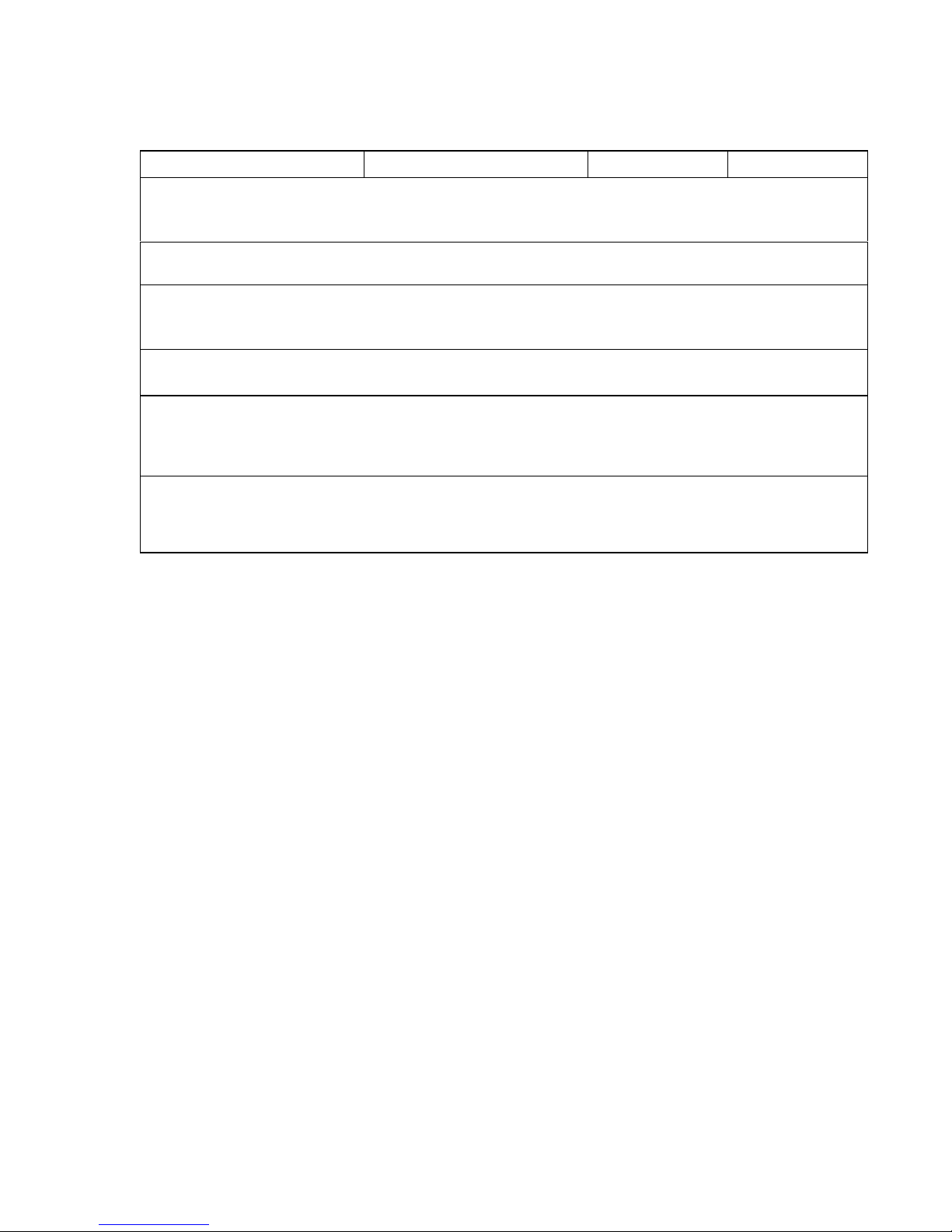

Table 2–2. Physical Inspection

Item(s) to Inspect

Cabinet, base,

frame

Attaching

hardware

Nameplates

Printer cover,

cabinet door(s),

gas spring

assemblies

Hinges

Electrical

connectors

Controls and

indicators

What to Look For

Check for damage, cracks, breaks, dents, gouges, scratches,

delamination, warping, corrosion, and proper finish.

Inspect fasteners for thread damage, corrosion.

Inspect for legibility and damage.

Inspect for damage and loose or missing hardware. Check

that door(s) open/close without binding and stay closed.

Check that printer cover opens/closes smoothly and the gas

spring assemblies hold the cover open.

Inspect for damage and loose or missing hardware.

Inspect for damage, bent or broken pins.

Inspect for damage.

Windows

Ribbon cables

Circuit boards

Fans and motors

Inspect for breaks, cracks, or discoloration.

Inspect for broken wires, damaged insulation, pinched

wiring, etc.

Inspect for breaks, warping, evidence of overheated

components.

Inspect for obvious damage.

2–3Scheduled Maintenance

Cleaning the Printer

Do not use abrasive cleaners, particularly on the window. Do not drip

water into the printer. Damage to the equipment will result. When using

spray solutions, do not spray directly onto the printer; spray the cloth,

then apply the dampened cloth to the printer.

Cleaning Outside the Cabinet

1. Wipe the cabinet with a clean, lint–free cloth dampened (not wet) with

water and mild detergent or window cleaning solution.

2. Dry the cabinet with a clean, lint–free cloth.

3. Clean the inside of the cabinet. (See below.)

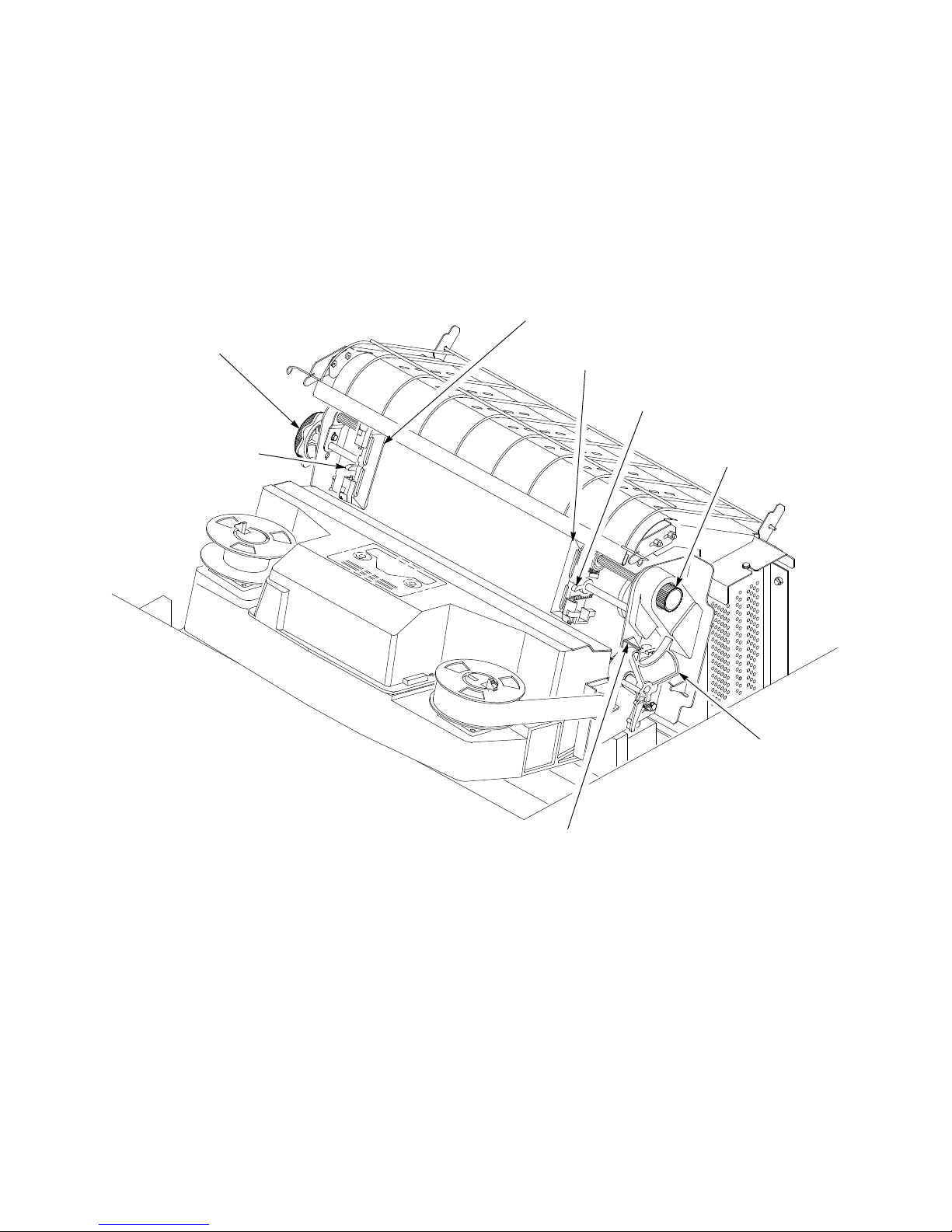

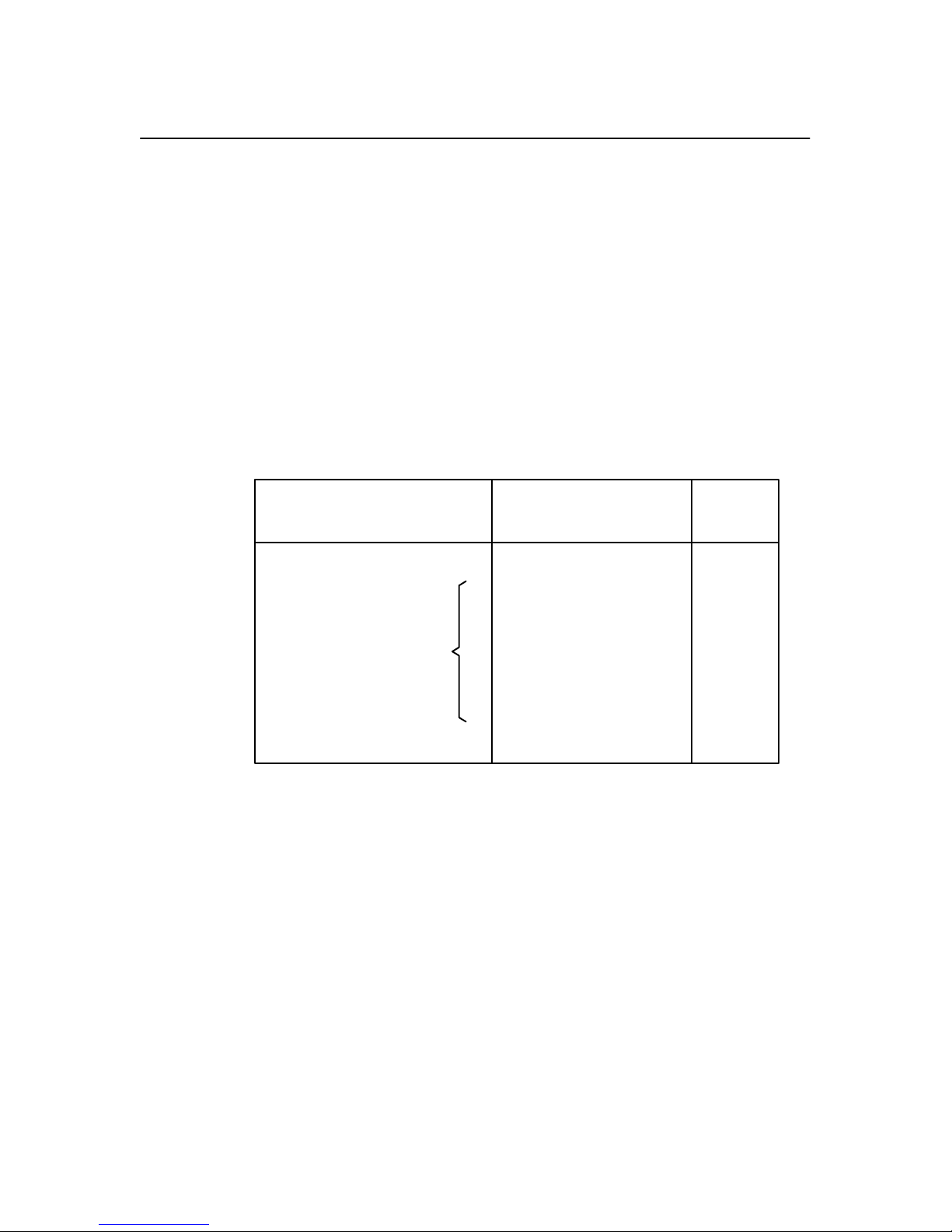

Cleaning Inside the Cabinet (Figure 2–1)

1. Set the power switch to the O (off) position.

CAUTION

2. Disconnect the ac power cord from the printer.

3. Open the printer cover.

4. Move the forms thickness adjustment lever (1) to the fully–open

position.

5. Remove paper from the printer.

6. Squeeze the locking latch (2) and lift the ribbon spools (3) from the

ribbon hubs (4).

7. Using a soft–bristled brush, wipe off paper dust and ribbon lint. Vacuum

up the residue. Pay particular attention to the tractors (5), shuttle cover

assembly (6), and base casting (7).

8. Wipe the splined shaft (8) with a soft cloth.

CAUTION

To avoid corrosion damage, use only anhydrous alcohol when cleaning

printer mechanical elements. The cleaning solution must contain no

water.

9. Using a cloth dampened with anhydrous alcohol, clean the ribbon guides

(9).

10. Vacuum up dust or residue that has accumulated inside the lower

cabinet.

2–4 Scheduled Maintenance

11. Wipe the lower cabinet interior with a clean, lint–free cloth dampened

with water and mild detergent or window cleaning solution.

12. Dry the cabinet interior with a clean, lint–free cloth.

13. Clean the shuttle assembly (page 2–6).

3

3

6

2

4

1. Forms Thickness Lever

2. Locking Latch (2)

3. Ribbon Spool (2)

4. Ribbon Hub (2)

5. Tractor (2)

6. Shuttle Cover Assembly

7. Base Casting

8. Splined Shaft

9. Ribbon Guide (2)

8

4

7

5

5

1

9

2

Figure 2–1. Cleaning Inside the Cabinet

2–5Scheduled Maintenance

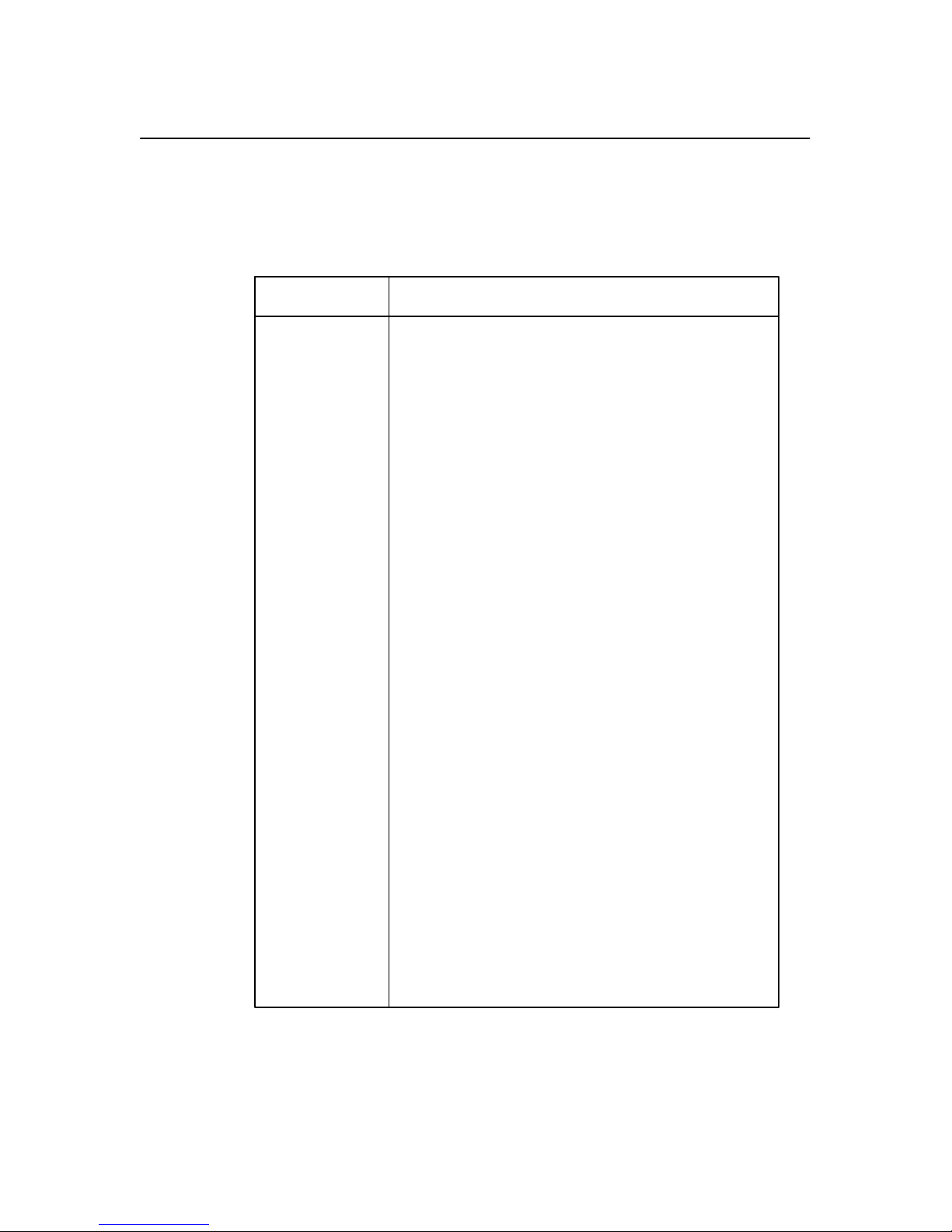

Cleaning the Shuttle Frame Assembly (Figure 2–2)

1. Remove the shuttle cover assembly (page 5–24).

2. Remove the shuttle frame assembly (page 5–66).

3. Remove the paper ironer (page 5–44).

WARNING

Over time, the upper edge of the paper ironer can become sharp. To

avoid cutting yourself, handle the paper ironer on the sides.

4. Moisten a clean, soft cloth with anhydrous alcohol. Wipe the paper

ironer to remove lint, ink, and paper residue.

5. Install the paper ironer (page 5–44).

6. Remove the hammer bank cover assembly (1).

7. Moisten a clean, soft cloth with anhydrous alcohol. Wipe the hammer

bank cover assembly to remove lint, ink, and paper residue. Clean the

holes in the cover strips.

CAUTION

Use of excessive force can chip hammer tips.

8. Using a stiff, non–metallic brush (such as a toothbrush) and anhydrous

alcohol, carefully brush the hammer tips (2) to remove lint and ink

accumulations. Vacuum up any residue.

CAUTION

The hammer bank contains a strong magnet. To prevent damage to the

hammer tips, do not let the hammer bank cover assembly snap into

place as the hammer bank magnet attracts it. Any impact of the cover

against the hammer bank can break hammer tips.

9. With the thick plate facing the hammer bank, engage the hammer bank

cover assembly (1) on the alignment pins (3).

10. Rotate the hammer bank cover assembly (1) until it lies flush on the

hammer bank.

11. Check that the hammer bank cover assembly is properly positioned over

the alignment pins (3) and hammer tips.

12. Install the shuttle frame assembly (page 5–66).

13. Install the shuttle cover assembly (page 5–24).

14. Clean the card cage fan assembly (page 2–8).

2–6 Scheduled Maintenance

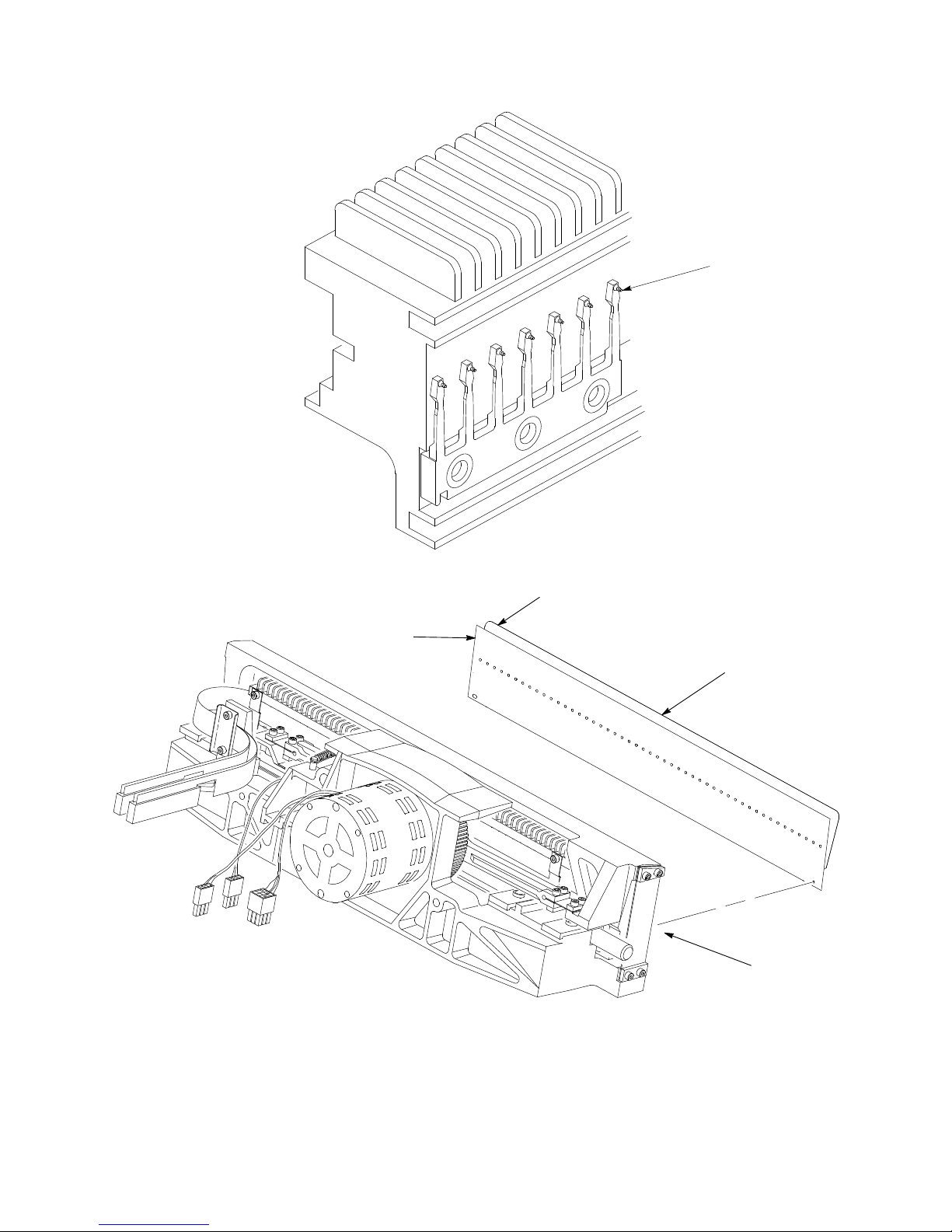

Thick plate

Thin plate

Hammer Tip

Hammer Bank

Cover Assembly

Roll pin (2)

(Not shown)

Figure 2–2. Cleaning the Shuttle Frame Assembly

2–7Scheduled Maintenance

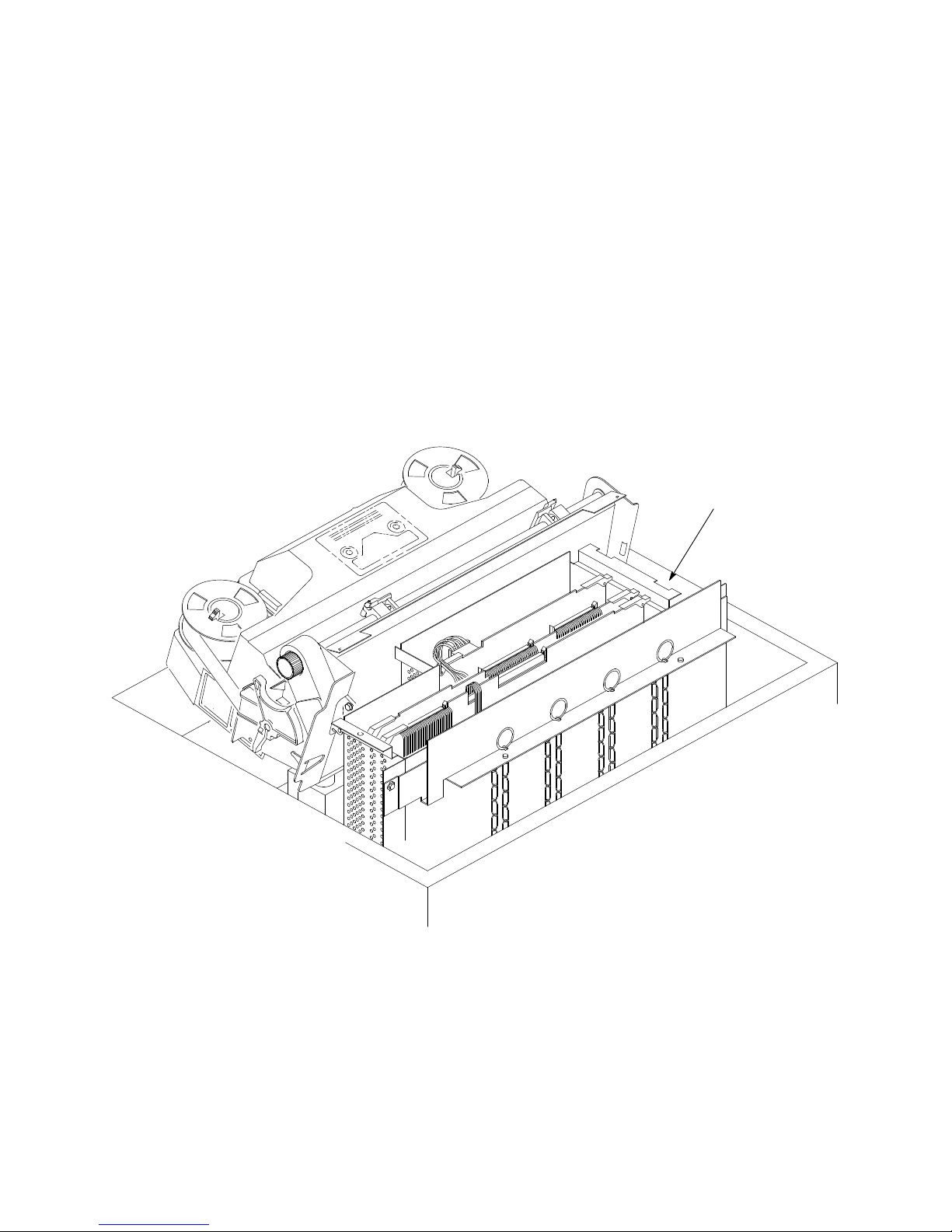

Cleaning the Card Cage Fan Assembly (Figure 2–3)

1. Open the printer cover.

2. Remove the paper guide assembly (page 5–42).

3. Vacuum the card cage fan assembly (1) and surrounding areas to remove

paper particles, dust, and lint.

4. Install the paper guide assembly (page 5–42).

5. Close the printer cover.

6. Connect the ac power cord to the printer.

Card Cage

Fan Assembly

2–8 Scheduled Maintenance

Figure 2–3. Cleaning the Card Cage Fan Assembly

3 Troubleshooting

Chapter Contents

Introduction 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48 Volt Failed * 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic RAM Fault 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Bank Hot * 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Coil Open * 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Coil Short * 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ham. Drv. Short * 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mech Driver Hot * 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mech Driver Link * 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Jam 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Out 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Stall 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shttl Cover Open 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Jam 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Error 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptoms Not Indicated by Fault Messages 3–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Aids 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Self–Tests 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Diagnostic Self–Tests 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Code Printout 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1Troubleshooting

Introduction

This chapter contains procedures for troubleshooting printer malfunctions.

You must operate the printer to check printer performance, so have the User’s

Manual at the printer site. Although diagnostic test procedures are covered in

this chapter, basic printer operation is not covered.

Fault Messages

This section lists the fault messages that can appear on the control panel

display. The messages are listed in alphabetical order, followed by a

troubleshooting table.

If a fault condition occurs in the printer, the status lamps on the control panel

flash on and off and the first line of the display indicates “Fault Condition.”

The second line of the display indicates the specific fault.

There are two types of displayed faults:

• Operator correctable

• Field–service required, indicated by an asterisk (*) next to the fault

message

Test the printer after each corrective action. Stop maintenance when the

symptom disappears. Always press the CLEAR switch after correcting a

fault indicated by a fault message.

48 Volt Failed *

Instruction

1. Set power switch to O (off).

Wait 15 seconds. Set power

switch to 1 (on).

2. Press the CLEAR switch.

3. Remove paper guide

assembly (page 5–42).

IMPORTANT

Indication Yes No

“48 Volt Failed * ” message. Step 2. Return printer to

normal operation.

“48 Volt Failed * ” message. Step 3. Return printer to

normal operation.

—

Step 4.

—

3–2 Troubleshooting

Instruction NoYesIndication

4. Disconnect cable assembly

W1, CCB/Mech Driver, from

connector J1 on the CCB and

connector J6 on the Mech

Driver board.

5. Power up the printer.

6. Pull the Mech Driver board

up so that it clears the bottom

edge connectors.

7. Disconnect +5Volt connector

PS5 (cable assembly W2)

from the power supply board

and put a 1K Ohm resistor

between pins 1 and 2.

8. Remove the Mech. Driver

board.

—

Card cage fan comes on. Replace the

—

—

—

Step 5.

common controller

PCBA (page

5–46).

Step 7.

Step 8.

Step 9.

—

Reattach cable

assembly W1,

CCB/Mech Driver,

to connector J1 on

the CCB and

connector J6 on

the Mech Driver

board, and go to

step 6.

9. Power up the printer. Check

for +48 V at power supply

cable W3 connector PS: pin 8

= +48 V, pin 15 = ground.

(See Appendix D for cable

interconnections.)

10. Cycle power and check for

the fault message.

11. Cycle power and check for

the fault message.

12. Cycle power and check for

the fault message.

+ 48 Volts at pin 8. Replace the

mechanism driver

PCBA (page

5–48) and go to

step 10.

“48 Volt Failed * ” message. Replace cable

assembly W2,

+5V. (See

Appendix D.) Go

to step 1 1.

“48 Volt Failed * ” message. Replace cable

assembly W3, Hi

Voltage. (See

Appendix D.) Go

to step 12.

“48 Volt Failed * ” message. Replace cable

assembly W6,

P4980A Main

Wire Harness.

(See Appendix D.)

Replace the

power supply

PCBA (page

5–50) and go to

step 10.

Return printer to

normal operation.

Return printer to

normal operation.

Return printer to

normal operation.

3–3Troubleshooting

Dynamic RAM Fault *

Instruction

1. Set power switch to O (off).

Wait 15 seconds. Set power

switch to 1 (on).

2. Disconnect the input data line

from the host computer. Set

power switch to O (off). Wait

15 seconds. Set power switch

to 1 (on).

3. Make a Diagnostic Check of

the Microprocessors (page

3–21).

Indication Yes No

“Dynamic RAM Fault * ”

message.

“Dynamic RAM Fault * ”

message.

— — —

Step 2. Return printer to

normal operation.

Step 3. Return printer to

normal operation.

3–4 Troubleshooting

Ham. Bank Hot *

Instruction

1. Set power switch to O (off).

Wait 15 seconds. Set power

switch to 1 (on).

2. Press the CLEAR switch.

3. Run diagnostic self–test “All

Black” for 1/4 page (page

3–26).

4. Remove the shuttle cover

(page 5–24).

5. Install a magnet across the

hole in the base casting

where the cover open sensor

is mounted.

6. Run a diagnostic self–test

(page 3–26).

Indication Yes No

“Ham. Bank Hot * ” message. Step 2. Return printer to

normal operation.

“Ham. Bank Hot * ” message. Step 3. Return printer to

normal operation.

“Ham. Bank Hot * ” message. Step 4. Return printer to

normal operation.

—

—

Hammer bank fan operates. Replace shuttle

Step 5.

Step 6.

frame assembly

(page 5–66).

—

—

Replace hammer

bank fan

assembly (page

5–30).

3–5Troubleshooting

Loading...

Loading...