Page 1

FBS Slip & Passbook Printer

LB12/LB15

Field Support Manual

Part Number: EK-A0685-SV002

Page 2

FBS Slip & Passbook Printer

LB12/LB15

Field Support Manual

Page 3

Acknowledgments

IBM, PC, AT and ProPrinter are registered trademarks of International Business Machines

Corporation.

Related manuals

LB12/LB15 Field Support Manual (including MSF) EK-LB125-SM

LB12/LB15 User’s Guide EK-LB125-UG

APP 6390 HSI (Hardware Software Interface) Manual AA-PYSXB-TE

APP 6390 Application Programmer's Guide AA-PTGWB-TE

APP 6390 Available Emulations Reference Manual AA-PYSWB-TE

This is a publication of DIGITAL EQUIPMENT BCFI AB

Printers and Peripherals

S-175 29 JÄRFÄLLA, Sweden

© Digital Equipment BCFI AB, 1997

All rights reserved. Reproduction in whole or in parts is prohibited without written consent of

the copyright owner. We have taken great care to ensure that the information in this manual

is correct and complete. However, if you discover any errors or omissions, or if you wish to

make suggestions for improvements, you are welcome to send your comments to us. Digital

Equipment BCFI AB disclaims any liability resulting from the use of this information and

reserves the right to make changes without notice.

Publication number: EK-A0685-SV002

First edition, issued October 1997 (all pages marked 9710)

Page 4

CONTENTS LB12/LB15 FIELD SUPPORT MANUAL

Chapter 1 GENERAL DESCRIPTION

Chapter 2 FUNCTIONAL DESCRIPTION

Chapter 3 MAINTENANCE

Chapter 4 SITE PREPARATION

9710 LB12/LB15 Field Support Manual i

Page 5

WARNINGS, CAUTIONS AND NOTES

WARNING!

This type of safety instruction is used where there is potential danger of injury to personnel

and/or damage to the equipment or the environment. The symbol inside the triangle

indicates the type of danger.

CAUTION!

This type of safety instruction is used where injury to personnel and/or damage to the

equipment or the environment can occur, if related instructions are not followed.

NOTE!

Notes are used to provide important or explanatory information.

9710 LB12/LB15 Field Support Manual ii

Page 6

CHAPTER 1 GENERAL DESCRIPTION

Pages 1-1 through 1-20

Section 1.1 INTRODUCTION

1.1.1 Printing characteristics..............................................................................................................1-3

1.1.2 Information feedback.................................................................................................................1-4

1.1.3 Maintenance aspects................................................................................................................1-4

1.1.4 Power ON/OFF..........................................................................................................................1-4

1.2 REMOVING THE COVER

1.3 THE DESIGN CONCEPT

1.4 TECHNICAL DATA

1.4.1 General print characteristics ....................................................................................................1-7

1.4.2 Document station......................................................................................................................1-8

Print area on vouchers...................................................................................................1-9

Print area on passbooks..............................................................................................1-10

Book thickness.............................................................................................................1-15

1.4.3 Power supply ..........................................................................................................................1-15

1.4.4 Diagnostic tests.......................................................................................................................1-15

1.4.5 Environmental conditions........................................................................................................1-15

1.4.6 Miscellaneous .........................................................................................................................1-16

1.4.7 Position Detection Facility.......................................................................................................1-16

1.4.8 Communications interface.......................................................................................................1-16

1.5 MAGNETIC STRIPE FACILITY

1.5.1 Design ..........................................................................................................................1-17

1.5.2 Performance ..........................................................................................................................1-19

1.5.3 Encoding technique.................................................................................................................1-19

1.5.4 Specifications 1-19

MSF read/write.............................................................................................................1-19

Printer dimensions with MSF device installed..............................................................1-19

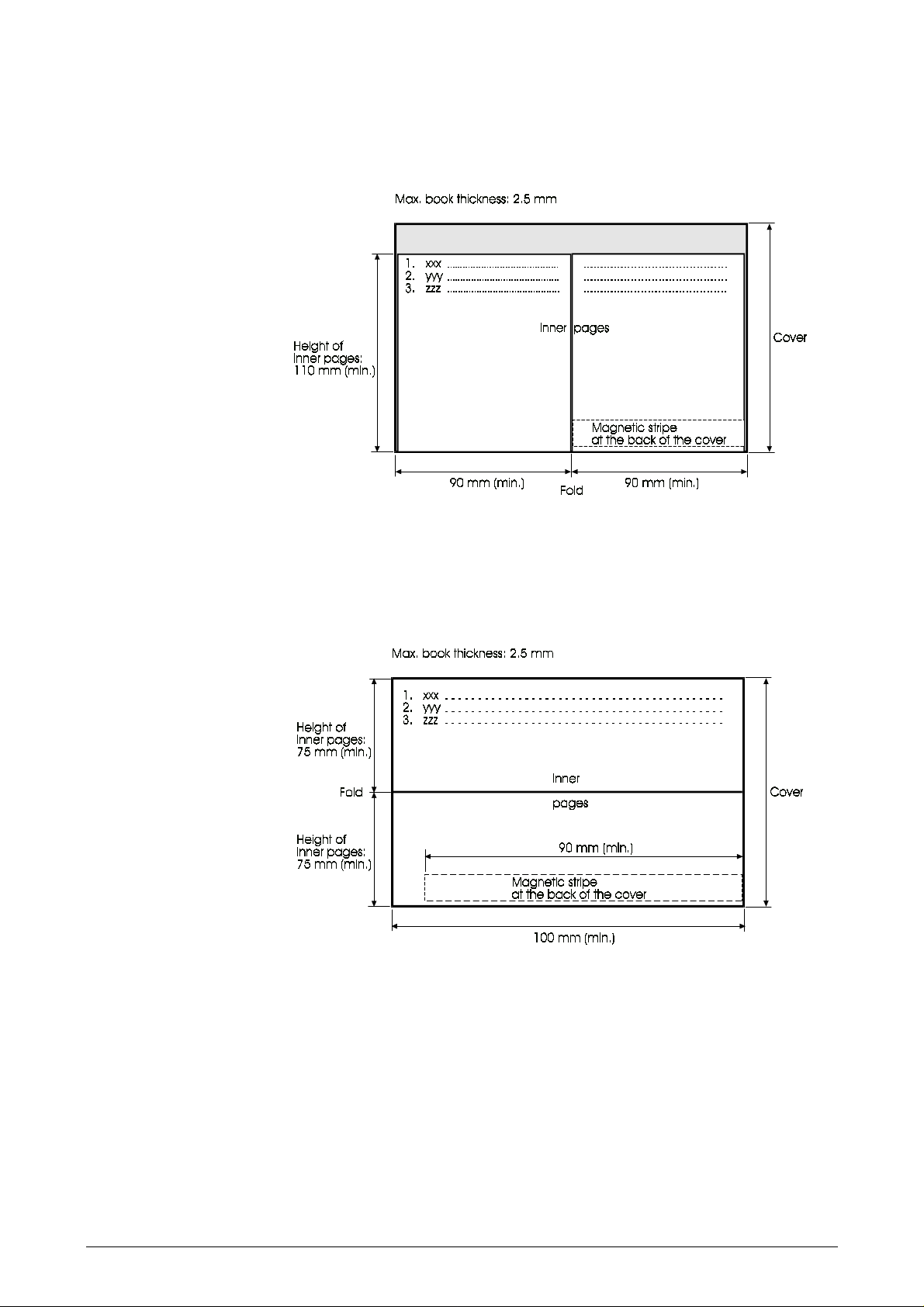

Vertically folded passbooks .........................................................................................1-20

Horizontally folded passbooks.....................................................................................1-20

.............................................................................................................Page 1-3

.........................................................................................................1-5

..........................................................................................................1-6

...................................................................................................................1-7

..............................................................................................1-17

Figure

Table

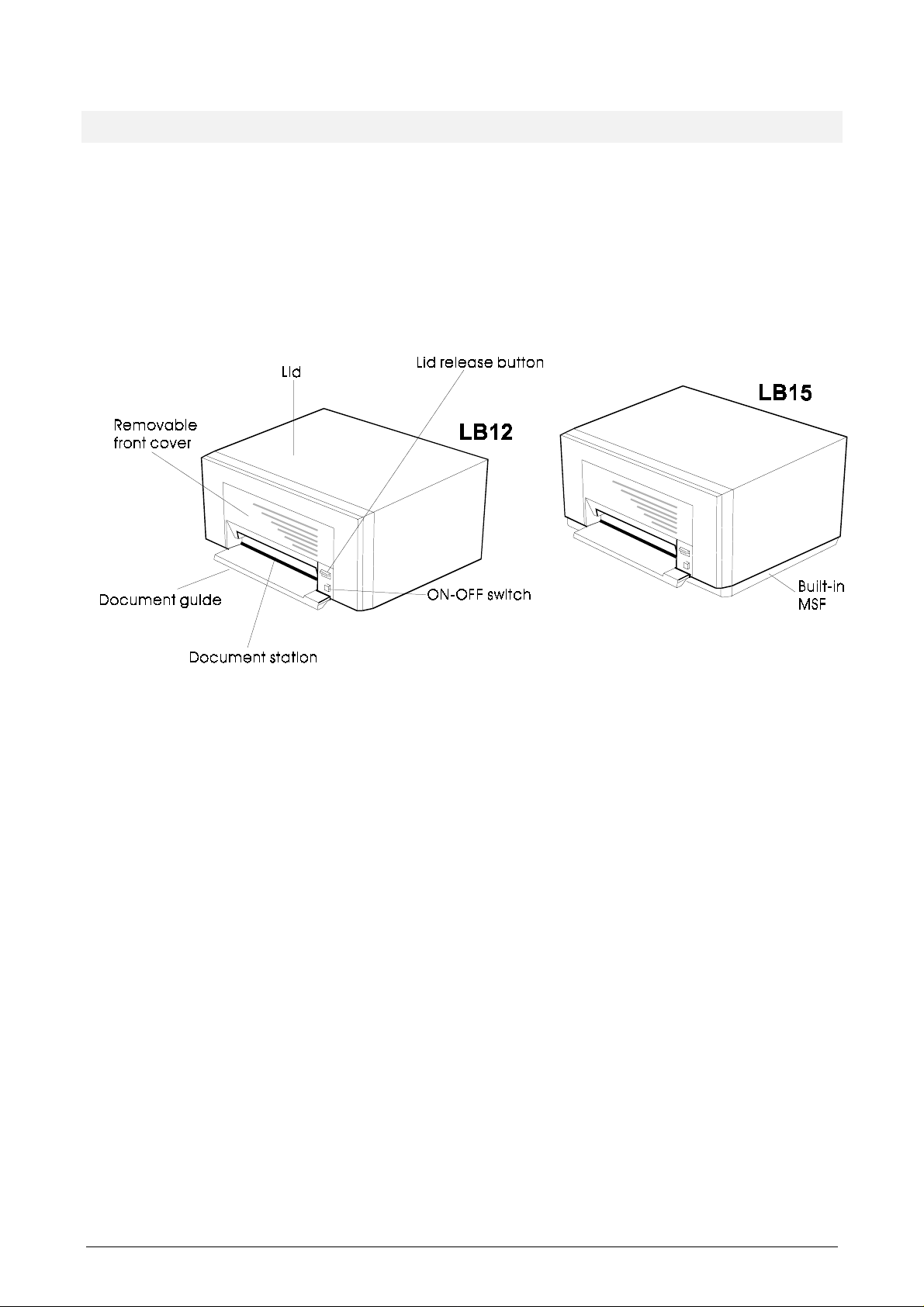

1-1 The LB12/LB15 printers, exterior ..............................................................................................1-3

1-2 Removing the cover ..................................................................................................................1-5

1-3 Printer modules.........................................................................................................................1-6

1-4 Print area on vouchers..............................................................................................................1-9

1-5 Print area on vertically folded

1-6 Print area on vertically folded

1-7 Print area on horizontally folded passbooks ...........................................................................1-14

1-8 Measuring passbook thickness...............................................................................................1-15

1-9 The main parts of the MSF device ..........................................................................................1-18

1-10 Dimensions of vertically folded passbooks .............................................................................1-20

1-10 Dimensions of horizontally folded passbooks.........................................................................1-20

1-1 Print measurements on vouchers .............................................................................................1-9

1-2 Print measurements on vertically folded type A passbooks....................................................1-11

1-3 Print measurements on vertically folded type B passbooks....................................................1-13

type A

passbooks....................................................................1-10

type B

passbooks....................................................................1-12

9710 LB12/LB15 Field Support Manual 1-1

Page 7

1-2 LB12/LB15 Field Support Manual 9710

Page 8

1.1 INTRODUCTION

The LB12 and LB15 Slip & Passbook Printers provide multi-functional document processing

in all-purpose workstations.

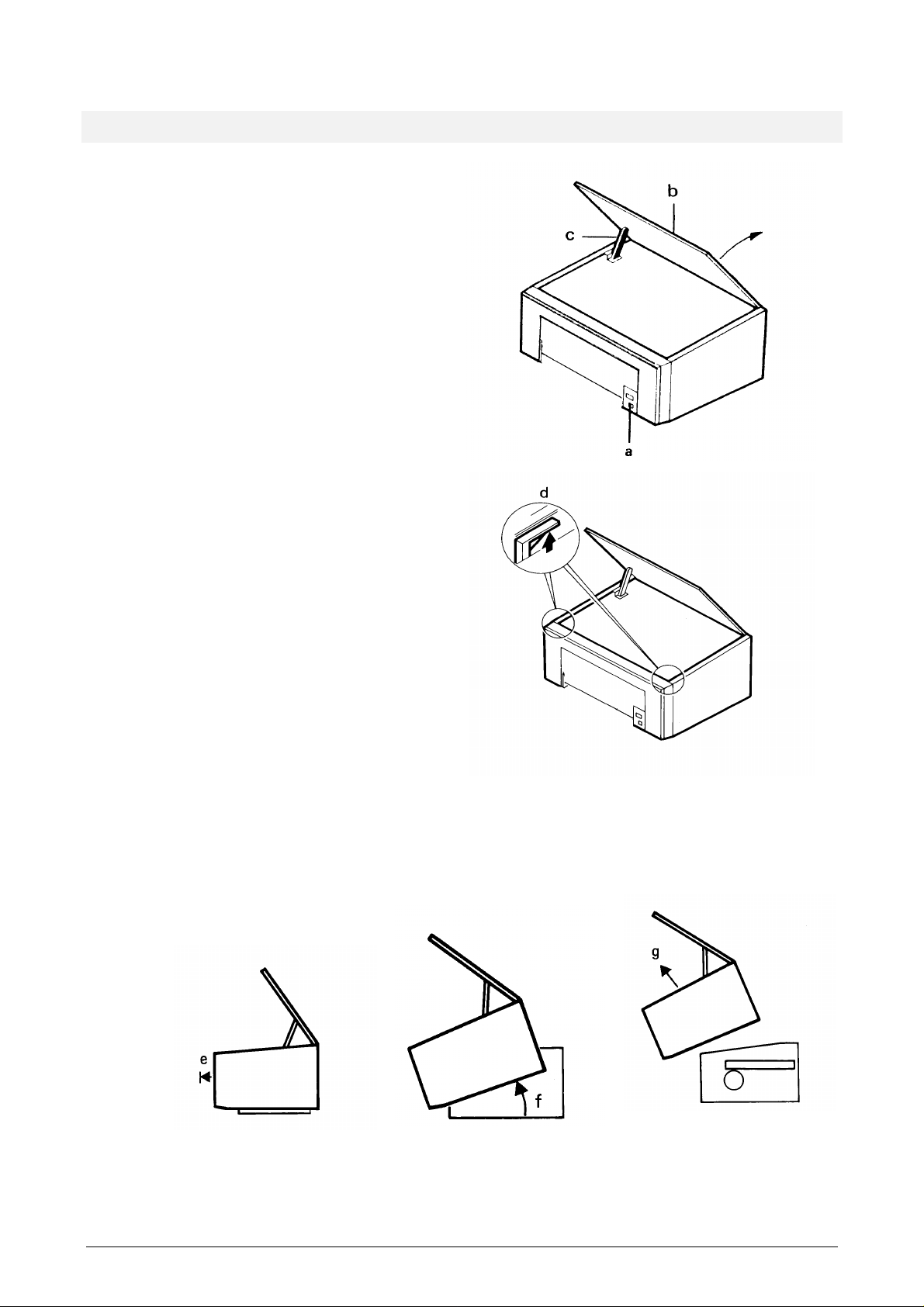

Figure 1-1 below shows the LB12/LB15. The printer is equipped with a

that can print on different types of documents such as single sheets, form sets, passbooks,

and passports, inserted horizontally through a slot at the front.

The document station can handle both vertically and horizontally folded passbooks or

passports. Printing is uni-directional or bi-directional and characters can be printed rotated

###

90

or upside down.

document station

1.1.1 Printing characteristics

On the LB12/LB15 printers, printing can take place at a speed of up to 300 characters per

second in both directions. The printer maintains the highest possible print speed by

automatically calculating the shortest possible route to the next print position. The position

of the 18-needle printhead can be controlled by the application program. The printer can

operate in its own Native mode or emulate an IBM ProPrinter III or IBM 4722.

When running in Native mode, the LB12/LB15 can use two character fonts and several

national character sets, including OCR-A and OCR-B fonts in PROMs. Other PROMs

providing logotypes and special character sets are optional. Additional character sets can

also be downloaded to the printer by the application program. When ProPrinter mode is

selected, the printer can use all the standard IBM ProPrinter III character generators.

A Position Detection Facility (PDF) can be used to find the left document edge.

Figure 1-1 The LB12/LB15 printers, exterior

9710 LB12/LB15 Field Support Manual 1-3

Page 9

1.1.2 Information feedback

The LB12/LB15 printers return a large amount of essential information to the application

program, including:

• printer configuration

• number of characters printed

• true status of execution

• error codes.

1.1.3 Maintenance aspects

The mechanical design is such that field replaceable modules can be replaced within five

minutes with no need for mechanical adjustments. The printers also have extensive built-in

test programs, significantly reducing the time spent on repairs.

1.1.4 Power ON/OFF

To reduce the amount of heat generated by the printer, the operator can switch the printer

from ON to STANDBY mode (and vice versa) by using the ON switch at the front of the

printer. The LB12/LB15 can also be switched OFF from the application program. The ON

switch, however, overrides software-controlled switching. The ON LED illuminates when the

printer is switched ON.

WARNING!

There is high voltage inside the PSU even when the printer is switched

off. REMOVE the power cable before you dismantle the PSU.

1-4 LB12/LB15 Field Support Manual 9710

Page 10

1.2 REMOVING THE COVER

1. Remove the front cover and the

document guide (see the

User's Guide

2. Press the lid release button (a).

3. Raise the lid (b) until the lid support

(c) snaps into the locked position.

4. Press the left side of the cover

backward whilst, at the same time,

lifting the cover latch (d) slightly,

using a screwdriver or similar tool.

With the latch lifted, pull the left side

of the cover forward a few

millimeters. Repeat on the right hand

side.

).

LB12/LB15

5. Pull the cover straight towards you as

far as possible (e).

6. Raise the cover as shown (f) and

remove it (g).

Figure 1-2 Removing the cover

9710 LB12/LB15 Field Support Manual 1-5

Page 11

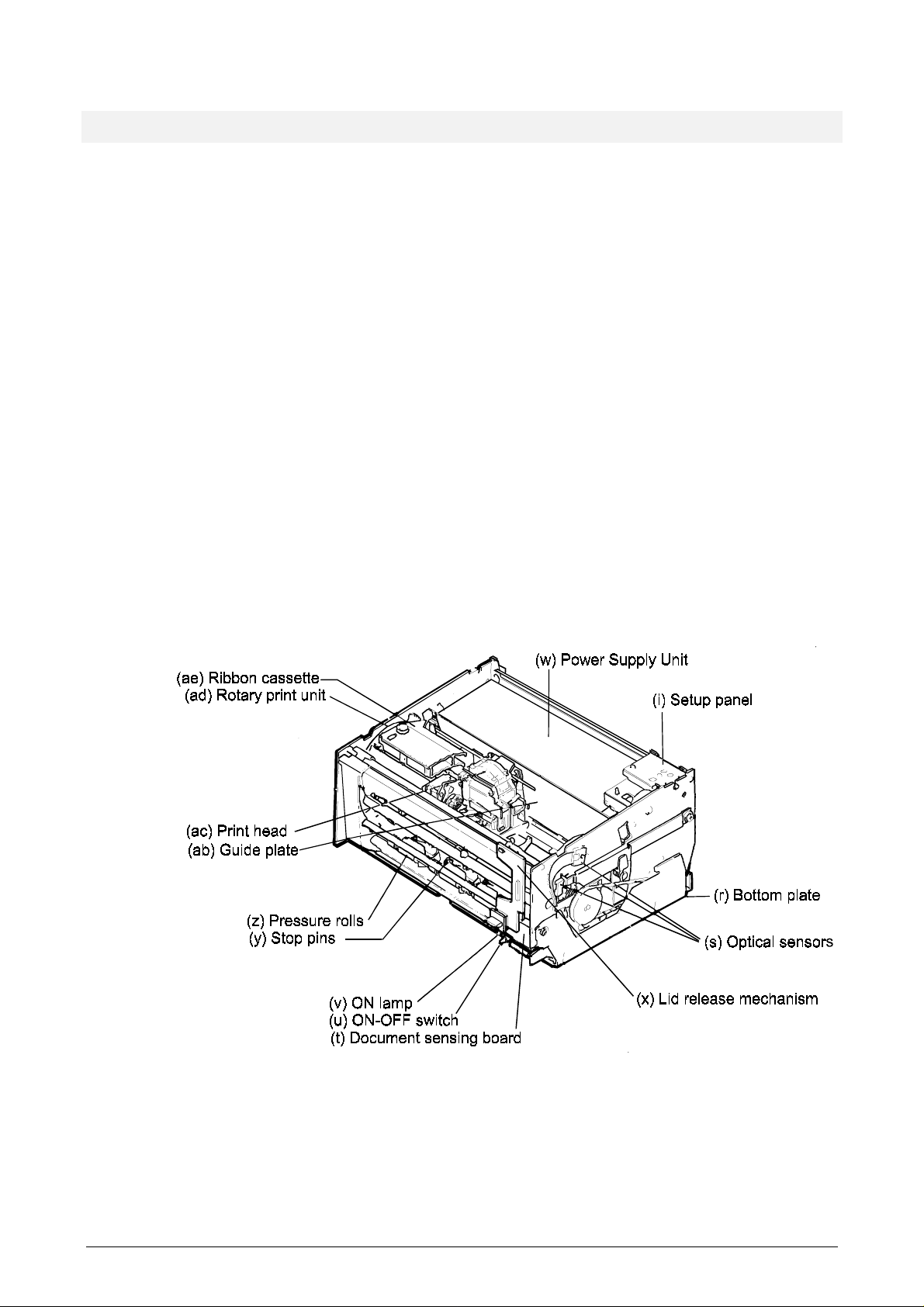

1.3 THE DESIGN CONCEPT

Each printer unit is built up between two side plates, joined by a base plate and various

bars and rods. The unit rests on a bottom plate (r) joined to the printer unit by means of two

screws. Rubber bushings and dampers reduce the transmission of vibrations to the bottom

plate and hence the printer cover.

The printhead (ac) is mounted on a carriage. The above parts and ink ribbon cassette (ae)

are all part of the rotary print unit (ad), which can rotate such that the printhead can be in

either a horizontal or a vertical position.

When a document is fed horizontally into the document station, the document stops against

a row of raised stop pins (y). Two optical sensors in the document station (t) detect that a

document is inserted and that it is in the correct position. The sensors are connected to the

document sensing board (t). A motor (not shown) lowers four pressure rolls (z) and removes

the stop pins. Four feed rolls, one under each pressure roll, feed the document into the print

position above a lower print bar (not shown).

Three optical sensors (s) are mounted on the outside of the right side plate. The upper

sensor senses when the rotary print unit is in the horizontal position. The middle sensor

detects when the printhead is in its extreme right position. The print unit cannot rotate

unless the printhead is in this position. The bottom sensor senses the position of the

pressure rolls and the stop pins. All sensors are connected to the document sensing board

(t) via optical fiber cables.

The ON lamp (v) and the ON-OFF switch (u) are mounted on the document sensing board

(t).

As a safety measure, printing cannot take place while the lid is open. An exception to this is

when the built-in tests are run.

Figure 1-3 Printer modules

The lid release mechanism (x) is mounted on the two shafts at the front. In addition to

raising the lid, this mechanism also handles the locking and release of the rotary print unit

in the LB12.

The main board (l) is mounted between the printer mechanism and the bottom plate (r). The

setup panel (i) can be replaced by an optional diagnostic panel.

1-6 LB12/LB15 Field Support Manual 9710

Page 12

1.4 TECHNICAL DATA

1.4.1 General print characteristics

Print method

Emulation

Print modes

Matrix

Resolution

Print speed Matrix Maximum print speed

Character pitches

(single-pass printing) Vertical 144 dots/inch.

Native mode Matrix Pitches

9x12 10, 12, 15, 16.5cpi

Impact dot matrix, 18-needle printhead.

IBM ProPrinter III

IBM 4722.

Alphanumeric, semi-graphics, graphics.

9x12, 18x36 (NLQ single pass), 18x72 (NLQ single pass, OCR)

Right character inclination (italic style) is available under software

control.

Horizontal 720 dots/inch.

Flash 514cps

Draft 300cps (Draft)

NLQ Up to 130cps

OCR-A, OCR-B 80cps

Fastfont 360cps

18x36 10, 12, 15, 16.5cpi, and proportional

18x72 10, 12, 15, 16.5cpi, and proportional

OCR-A 10cpi

OCR-B 10cpi

Flash 17.1cpi

ProPrinter and 4722 modes Matrix Pitches

9x12 10, 12, 17.1, 20cpi, and proportional

18x36 10, 12cpi, and proportional

Fastfont 12

Number of characters Pitch (cpi) Characters

per line

Input buffer

Standard character sets in PROM

Other character sets

(line length = 203mm) 10 80

12 96

15 120

16.5 132

5.5KB = approximately 5500 characters.

Native mode

ProPrinter and 4722 modes

Courier and Gothid type faces (NLQ 18x36 and DATA 9x12

qualities), always included in the printer.

ASCII Italian

German Swedish

British Norwegian/Danish

French Portuguese

Spanish Swiss

Code pages 437 and 850.

Other typefaces, fonts, logos etc. can be added as PROMs or

downloaded from the system.

9710 LB12/LB15 Field Support Manual 1-7

Page 13

1.4.2 Document station

Voucher dimensions

Passbook dimensions

Thickness

Paper weight

Width 90—235mm.

Height 67mm minumum (single sheet). The maximum

print height is 286mm, starting 4mm from the

upper edge.

Thickness 2mm maximum (original + 4 copies).

Width 100—235mm.

Height 75mm minimum. Maximum print height is

185mm from upper edge.

Quality 50—70 g/m², 0.08—0.16mm.

Other paper qualities must be tested.

OCR printing requires OCR specified paper

quality.

See description on Page 1-15.

Single voucher 45—110 g/m², 0.08—0.30mm

Voucher set 1 original: 45—90 g/m², 0.08—0.12mm.

4 copies: 40—60 g/m² each, 0.06—0.10mm.

4 carbons: 20-28 g/m² each.

Note If four copies are used, the lower

values must be followed. The binder

for the set can be placed on any side

or at the top.

Document feed

Single line (1/6”) 50ms.

Max. speed 0.4m/s = 95 lines/second.

1-8 LB12/LB15 Field Support Manual 9710

Page 14

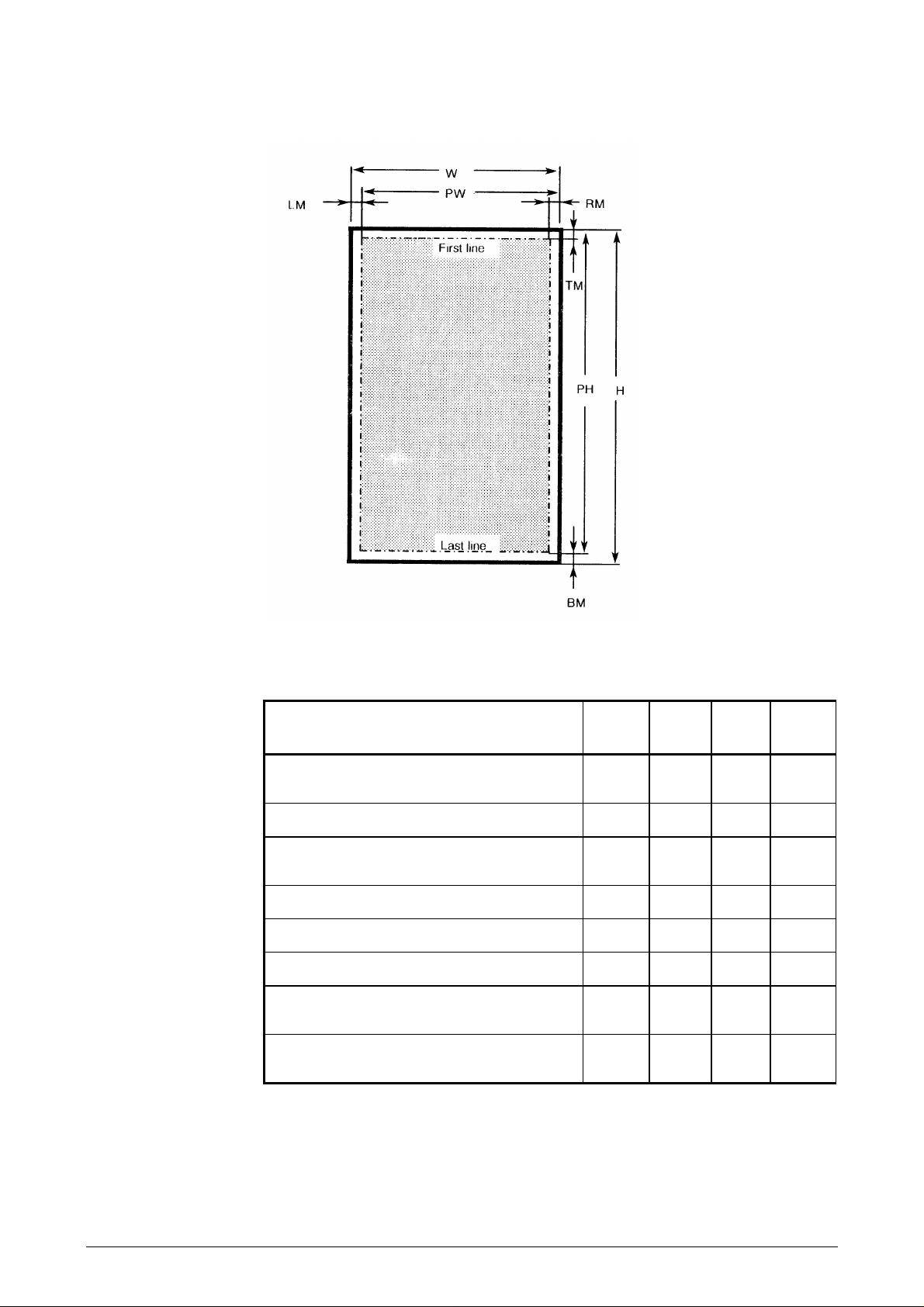

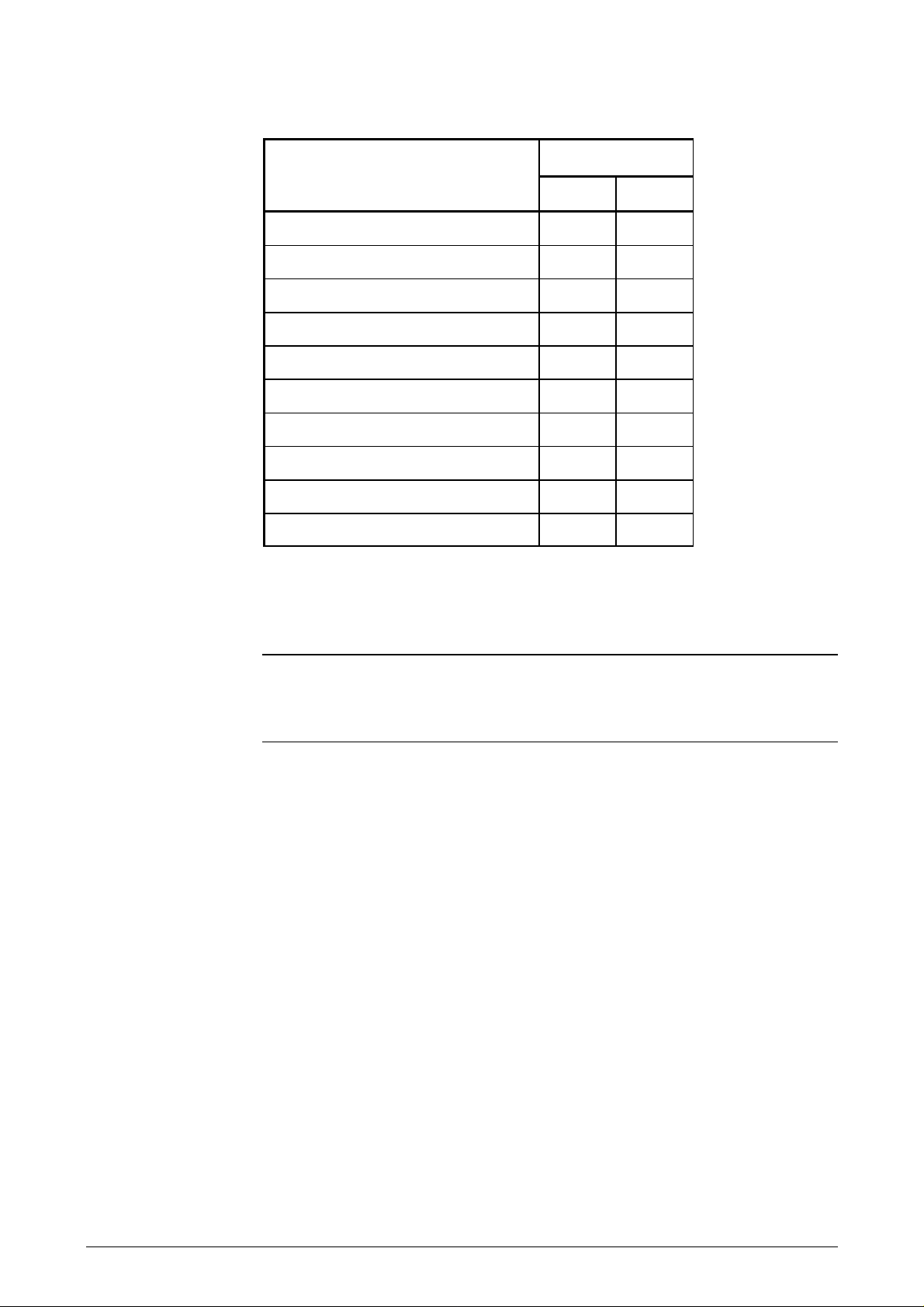

Print area on vouchers

H

W

PW

Document height 297 279 67 (See

Document width 210 216 90 235

Print width

(= leftmost print position)

RM

LM

PH

TM

Right margin 3 3 3 NA

Left margin 3 10 3 NA

Print height 287 269 61 291

Top margin (from top edge to top of

characters)

BM

Bottom margin (bottom edge to base of

characters)

NA = Not Applicable

Figure 1-4 Print area on vouchers

Measurement A4

(mm)

206 206 97 206

444NA

666NA

Letter

(mm)

Min.

(mm)

Max.

(mm)

Note)

Table 1-1 Print measurements on vouchers

The maximum document height is 318mm when using bottom synchronization, starting

4mm from the upper edge. The document height is infinite when using top synchronization

but PH is also maximized for top synchronization.

9710 LB12/LB15 Field Support Manual 1-9

Page 15

The above measurements include the binder (20mm wide) on either the short or long edge

in a form set. If the binder is placed on the right side, this reduces the line length. The

maximum number or lines is reduced if the binder is placed at the top.

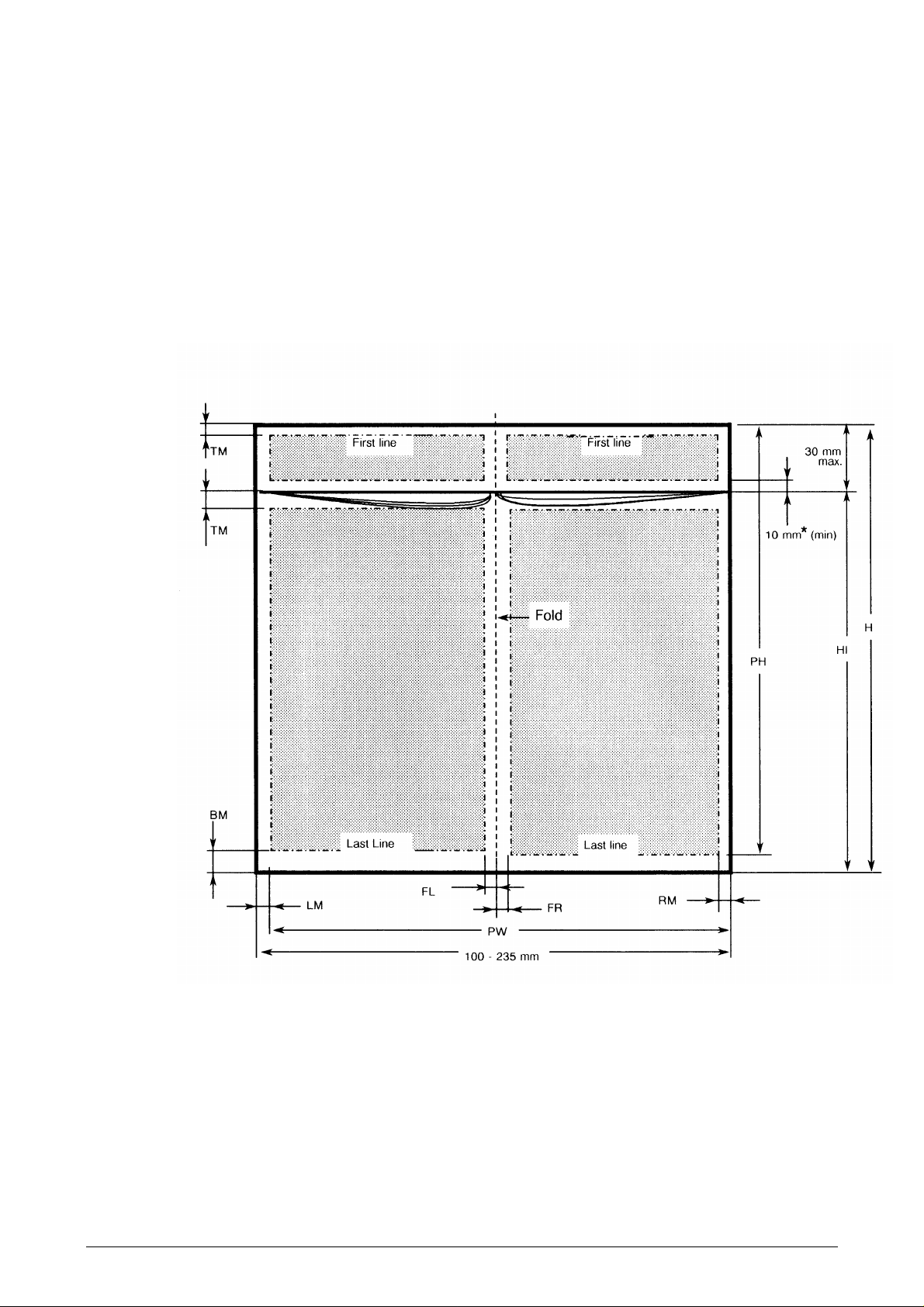

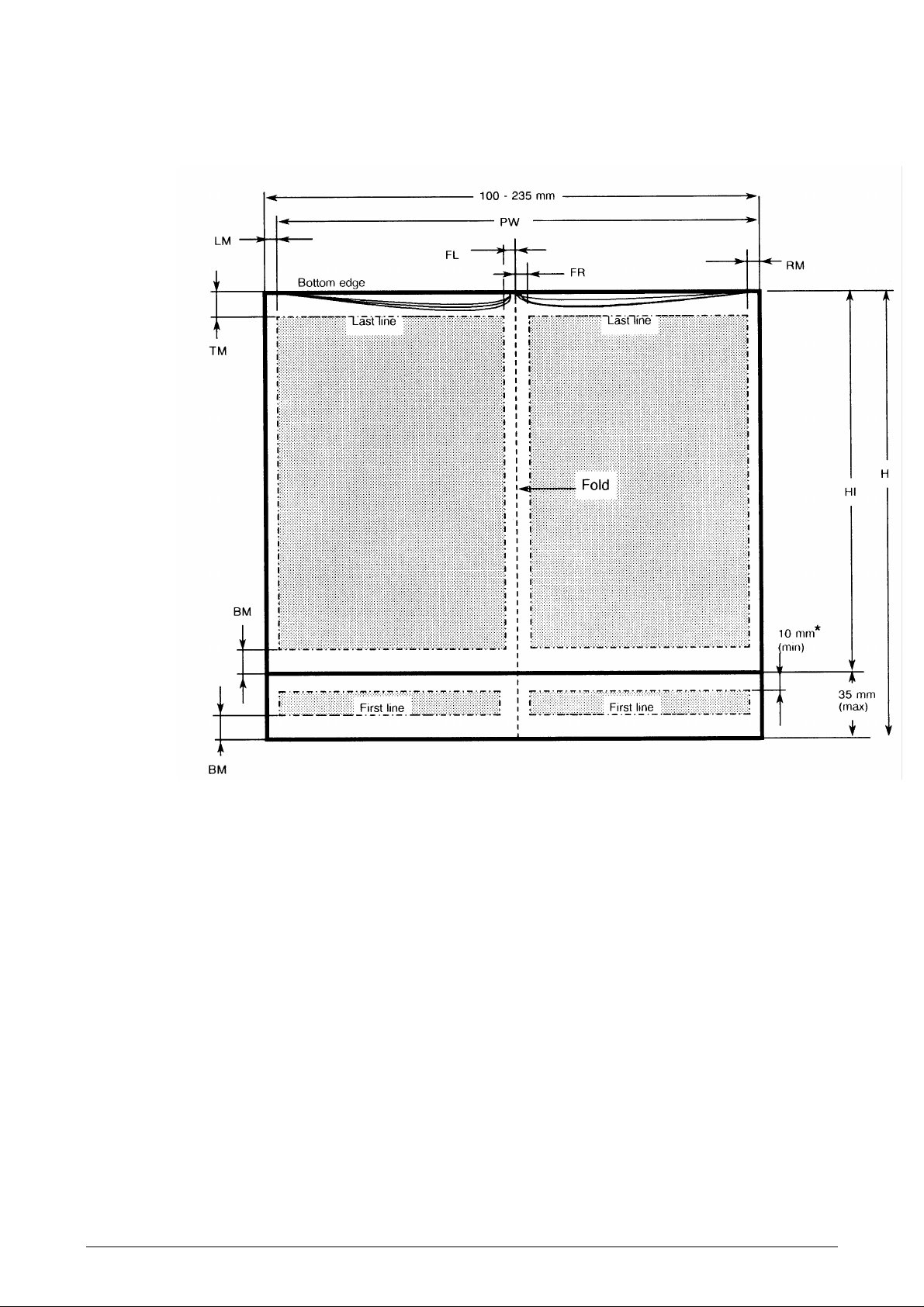

Print area on passbooks

Both vertically and horizontally folded books can be used. Two types of vertically folded

passbooks can be specified:

• Type A Height is 122mm or more. Upper edge to be inserted first.

• Type B Height is less than 122mm and the book has cut inner pages. Lower

edge to be inserted first.

* No restrictions if pages are flipped over.

Figure 1-5 Print area on vertically folded

type A

passbooks

See the measurement table on the next page.

1-10 LB12/LB15 Field Support Manual 9710

Page 16

Measurement Printing (mm)

Min. Max.

H

HI

PH

PW

RM

LM

TM

BM

FL + FR

Book thickness NA 3.2

NA Not applicable

Height (no cut inner pages) 75 NA

Height, inner pages 75 NA

Print height 4 185

Print width NA 206

Right margin 3 NA

Left margin 3 NA

Top margin 4 NA

Bottom margin 8 NA

Fold margins 6 + 6 NA

Table 1-2 Print measurements on vertically folded type A passbooks

IMPORTANT !

The function of the document feed mechanism must be verified before books of different

widths are used in the same printer.

See Chapter 3, Maintenance, for information about adjusting the pressure rolls.

9710 LB12/LB15 Field Support Manual 1-11

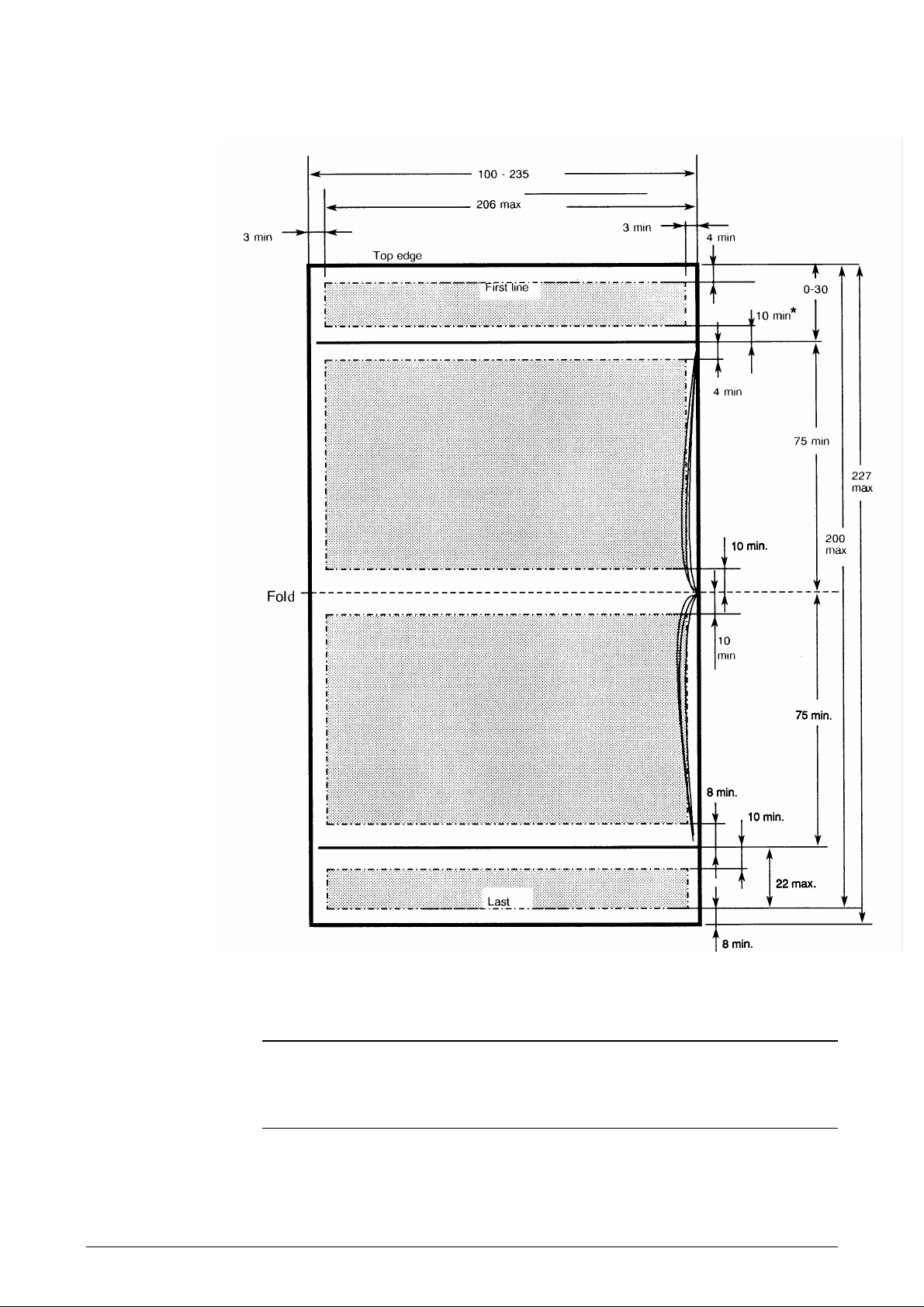

Page 17

The book is turned upside down to ease paper feeding. The text is rotated 180°.

* No restrictions if pages are flipped over.

Figure 1-6 Print area on vertically folded

type B

passbooks

See the measurement table on the next page.

1-12 LB12/LB15 Field Support Manual 9710

Page 18

Measurement Min

(mm)

Max.

(mm)

H

HI

PH

PW

RM

LM

TM

BM

FL + FR

Height 75 NA

Height, inner pages 75 NA

Print height NA NA

Print width NA 206

Right margin 3 NA

Left margin 3 NA

Top margin 4 NA

Bottom margin 8 NA

Fold margins 6 + 6 NA

Book thickness NA 2.5

NA Not applicable

Table 1-3 Print measurements on vertically folded type B passbooks

IMPORTANT !

The function of the document feed mechanism must be verified before books of different

widths are used in the same printer.

See Chapter 3, Maintenance, for information about adjusting the pressure rolls.

9710 LB12/LB15 Field Support Manual 1-13

Page 19

* No restriction if pages are flipped over.

Figure 1-7 Print area on horizontally folded passbooks

IMPORTANT !

The function of the document feed mechanism must be verified before passbooks of

differing widths are used in the same printer.

See Chapter 3, Maintenance, for information about adjusting the pressure rolls.

1-14 LB12/LB15 Field Support Manual 9710

Page 20

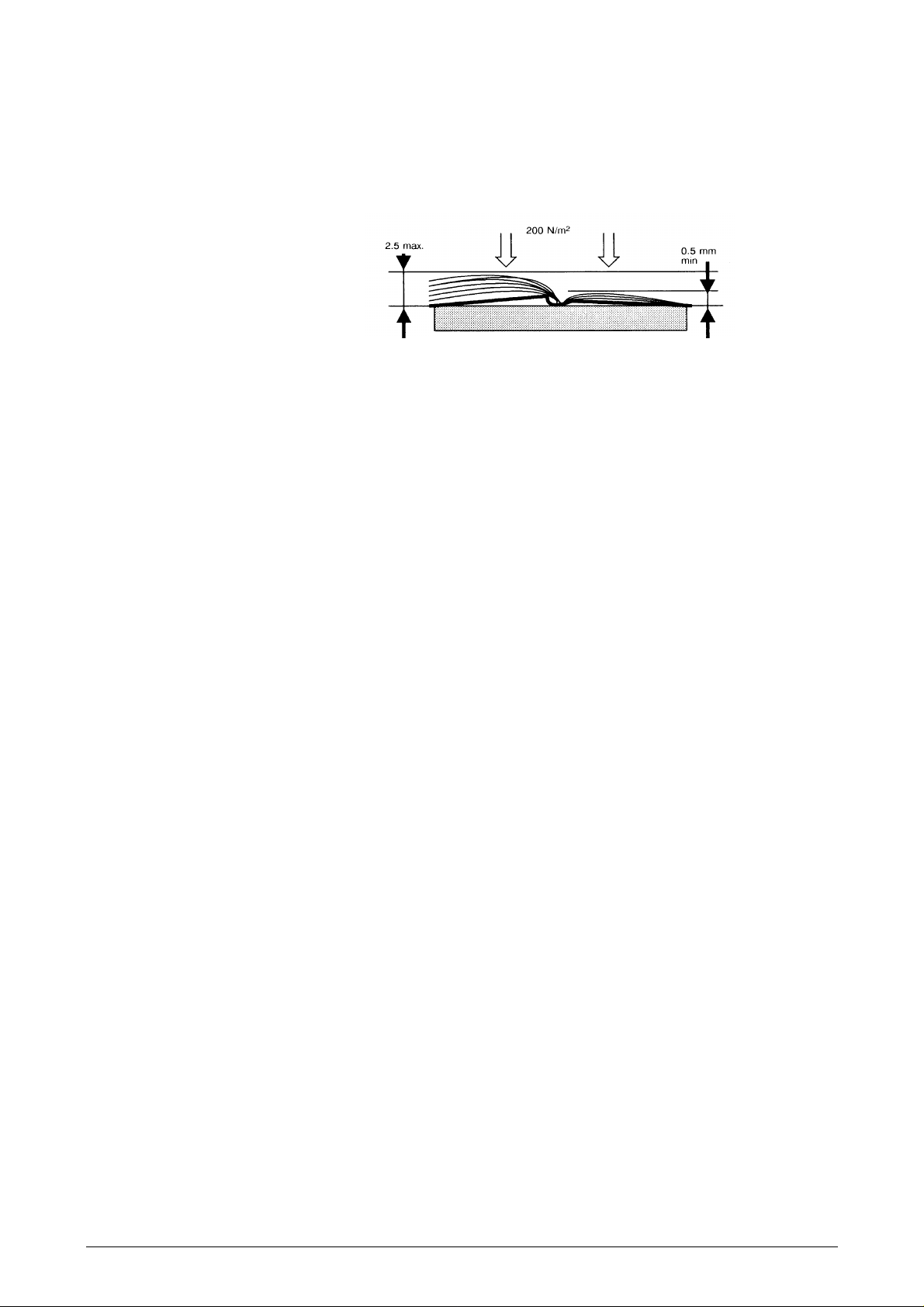

Book thickness

The thickness should be measured with a force of 200 N/m2 distributed over the passbook

surface.

1.4.3 Power supply

Figure 1-8 Measuring passbook thickness

Input voltage

Power dissipation

Power consumption

ON/OFF mode control

Input circuit fuse

Output voltage

1.4.4 Diagnostic tests

Automatic test

Other tests

1.4.5 Environmental conditions

87—132 V or 180—264 V, 50 or 60Hz auto ranging.

ON mode, not printing: 20 W

ON mode, printing: 150 W (peak load)

115 V 1.5 A

220 V 0.7 A

Manually, using switch on front panel.

One fast-acting, glass tube fuse, 6.3x32mm, 4 A.

+5.2 V, +36.5 V, and –12.5 V.

A power-ON test is performed at transition from standby to

ON mode. This test includes RAM and PROM tests,

movement of mechanical modules, checking of sensors, etc.

See Chapter 3,

Maintenance

.

Temperature

Operating +10— +35°C.

Storage –40— +70°C.

Humidity

Operating 20—80% RH, non-condensing.

Storage 20—90% RH, non-condensing.

9710 LB12/LB15 Field Support Manual 1-15

Page 21

1.4.6 Miscellaneous

Dimensions

Width 398mm.

Height, front LB12: 172mm; LB15: 192mm.

Height, back LB12: 195mm; LB15: 215mm.

Depth 300mm.

Weight

Acoustic noise

Operating Less than 60 dBA under any sound power level printing condition.

Standby Less than 40 dBA sound power level.

Ribbon

Type Cassette with endless loop. The ribbon is twisted 180° inside the

Length 2 x 28m (effective length).

Width 12.7mm.

Expected life More than 4x106 characters. With OCR printing, more than

1.4.7 Position Detection Facility

Detects the left document edge.

(See also Chapter 4,

LB12: 14kg.

LB15: 15kg.

cassette on each turn.

2.8 x 106 characters. The lower value is due to a higher degree of

inking.

Site Preparation

.)

1.4.8 Communications interface

See the

LB12/LB15 User's Guide

.

1-16 LB12/LB15 Field Support Manual 9710

Page 22

1.5 MAGNETIC STRIPE FACILITY

The MSF (Magnetic Stripe Facility) is a device in the LB15 printer. This device enables the

printer to read and write a track of magnetically encoded characters positioned on the back

cover of a passbook.

1.5.1 Design

The main part of the MSF device is a read/write (R/W) head that can be moved sideways in

a wide slot at the bottom of the document path. A black plastic panel covers the slot when

the head is in its home position on the right side. The panel moves away, exposing the head

during the read/write operation.

Passbooks must be inserted manually into the document station, aligned with the right side

of the insertion slot. The book must be open with the printable pages facing upward and the

outside of the cover downward. The magnetic stripe is then positioned as far as possible to

the right.

The MSF mechanics are built into the bottom plate assembly (see Figure 1-9).

The main MSF parts are:

• MSF logic board "piggy-back" mounted on the main board.

• Document guide with increased height (standard MSF version or MSF version with

operator panel).

• Printer bottom plate assembly with increased height compared to the bottom plate used

in the LB12

• Interconnecting cables between the MSF mechanics and the MSF logic board.

9710 LB12/LB15 Field Support Manual 1-17

Page 23

Figure 1-9 The main parts of the MSF device

1-18 LB12/LB15 Field Support Manual 9710

Page 24

1.5.2 Performance

Data recording is performed in accordance with the DIN 32744/ISO 8484 standards.

Usually, data recording is carried out in accordance with the DIN 32744 standard, which

means that a string of maximum 48 characters is written twice (i.e. the basic string followed

by a duplicate) in a single track on the magnetic stripe.

Recording in accordance with the ISO 8484 standard means either that a string of up to 108

characters is written or that a string of up to 48 characters is written twice (i.e. as defined by

the DIN 32744 standard).

Non-standard start and stop sentinels can be selected from the application.

Read after write is always performed to check that the string has been recorded correctly.

After a duplicate recording, both strings (or records) are read and compared to ensure that

they are equal.

Reading and writing is performed while the R/W head moves at constant speed. Writing is

performed when the R/W head moves from right to left whereas reading can be performed

in any direction.

1.5.3 Encoding technique

The encoding technique used is the F/2F encoding system, which allows serial recording of

self-clocking data. This means that the data string comprises both data bits and clock

signals. A flux transition occurring between clocks signifies a ONE, whereas the absence of

such a flux transition signifies a ZERO.

The data is recorded as a continuous sequence of characters with no inter-character gap.

The data string is both preceded and followed by at least 20 synchronizing ZERO bits. In

the event of of duplicate recording, the inter-record gap consists of at least 60 ZERO bits.

1.5.4 Specifications

MSF read/write

Packing density

Read/write speed

Return speed

Number of tracks

Number of characters

Character I/O format

Parity

Transaction time

Printer dimensions with MSF device installed

210 bits per inch ±5%.

8 inches per second.

8 inches per second.

1.

108 maximum (excluding pre- and post-amble).

5 bits (4 data + 1 parity bit), LSB first.

Odd.

2.5 s approx. (2 forward + 2 backward movements).

Height, front

Height, back

Document guide depth

9710 LB12/LB15 Field Support Manual 1-19

197mm.

215mm.

96 mm.

Page 25

Vertically folded passbooks

Inner pages can be shorter than the passbook cover.

Figure 1-10 Dimensions of vertically folded passbooks

Horizontally folded passbooks

Inner pages must not be smaller than the passbook cover.

Figure 1-11 Dimensions of horizontally folded passbooks

1-20 LB12/LB15 Field Support Manual 9710

Page 26

CHAPTER 2 FUNCTIONAL DESCRIPTION

Pages 1-1 through 1-40

Section 2.1 MAIN FUNCTIONAL PARTS

2.1.1 Document grasp and feed mechanisms....................................................................................2-3

Pressure rolls mechanism .............................................................................................2-4

Stop pin mechanism ......................................................................................................2-4

Home position................................................................................................................2-5

Inserting a document against the outer stop pins..........................................................2-5

2.1.2 Rotary print unit.........................................................................................................................2-8

2.1.3 Lateral carriage movement .......................................................................................................2-9

2.1.4 Ribbon feed ..........................................................................................................................2-10

2.1.5 Rotary print unit release and locking.......................................................................................2-11

2.1.6 Printhead-to-paper distance control (PDC) mechanism..........................................................2-12

Mechanism design.......................................................................................................2-12

Head attach and release..............................................................................................2-13

Auto calibration............................................................................................................2-15

Document printing........................................................................................................2-15

Passbook printing ........................................................................................................2-16

PDC cam wheel...........................................................................................................2-16

Sensor element............................................................................................................2-18

2.1.7 PDF - Position Detection Facility.............................................................................................2-19

2.1.8 Main board ..........................................................................................................................2-19

General........................................................................................................................2-19

Carriage motor drive circuits........................................................................................2-20

Stepper motor control and drive circuits ......................................................................2-20

Power ON/OFF logic....................................................................................................2-20

2.1.9 Capacitor board.......................................................................................................................2-20

2.1.10 Printhead board.......................................................................................................................2-20

2.1.11 Opto sensors ..........................................................................................................................2-20

General........................................................................................................................2-20

PDF sensor..................................................................................................................2-22

Sensor calibration........................................................................................................2-23

2.1.12 Joint board ..........................................................................................................................2-23

2.1.13 PSU and voltage Indicator......................................................................................................2-23

2.1.14 Diagnostic panel (optional)......................................................................................................2-24

2.1.15 Set-up panel ..........................................................................................................................2-24

..........................................................................................Page 2-3

2.2 PRINCIPLES OF PRINTING

2.2.1 Printhead ..........................................................................................................................2-27

2.2.2 Character formation ....................................................................................................... .........2-27

2.2.3 Character repertoires and character sets................................................................................2-28

2.2.4 Character sets.........................................................................................................................2-29

2.2.5 Character generation ...................................................................................................... ........2-29

2.2.6 Graphic character representation............................................................................................2-32

2.2.7 Logotypes ..........................................................................................................................2-32

2.2.8 IBM ProPrinter III emulation....................................................................................................2-32

2.3 STEPPER MOTOR DRIVE PRINCIPLES

2.3.1 General ..........................................................................................................................2-33

2.3.2 General motor drive principles................................................................................................2-33

2.3.3 Stepper motor drive in the LB12/LB15 printers.......................................................................2-35

2.4 NEEDLE FIRING PRINCIPLES

2.5 FIRMWARE STRUCTURE

2.6 MEMORY USAGE

..................................................................................................................2-36

...................................................................................................2-27

...............................................................................2-33

..............................................................................................2-35

......................................................................................................2-35

9710 LB12/LB15 Field Support Manual 2-1

Page 27

2.7 MAGNETIC STRIPE FACILITY ..............................................................................................2-37

2.7.1 Mechanics ..........................................................................................................................2-37

2.7.2 Electronics ..........................................................................................................................2-38

Reading........................................................................................................................2-38

Writing..........................................................................................................................2-39

Control register ............................................................................................................2-39

Configuration/status register........................................................................................2-39

Stepper motor control ..................................................................................................2-39

Figure 2-1 Document feed mechanism......................................................................................................2-3

2-2 Pressure rolls mechanism.........................................................................................................2-4

2-3 Stop pin mechanism..................................................................................................................2-4

2-4 Feed rolls and stop pins in home position.................................................................................2-5

2-5 The document being fed in........................................................................................................2-5

2-6 The feed motor starting to feed in the document ......................................................................2-6

2-7 Lowering the rear pressure rolls................................................................................................2-6

2-8 The front pressure rolls raised to let the document pass on its way out ...................................2-7

2-9 Front pressure rolls lowered to complete the document release ..............................................2-7

2-10 The document station ready for another document ..................................................................2-8

2-11 Print unit position sensor (V-H sensor) .....................................................................................2-9

2-12 Carriage drive mechanism ........................................................................................................2-9

2-13 Ribbon drive mechanism.........................................................................................................2-10

2-14 Carriage in its extreme right position releases the print unit ...................................................2-11

2-15 Printhead-to-paper distance mechanism in document position ..............................................2-12

2-16 Printhead-to-paper mechanism in book position.....................................................................2-13

2-17 Head attach position for passbook printing.............................................................................2-14

2-18 Head release short position ....................................................................................................2-14

2-19 Home position (= head release long)......................................................................................2-14

2-20 The PDC cam wheel ...............................................................................................................2-16

2-21 PDC sensor output voltage .....................................................................................................2-17

2-22 PDC sensor element...............................................................................................................2-18

2-23 Light-reflecting opto-sensor.....................................................................................................2-21

2-24a Light-breaking opto-sensors....................................................................................................2-21

2-24b Document edge opto-sensor...................................................................................................2-21

2-24c AIF opto-sensor........................................................................................................... ............2-21

2-25 Opto-sensor logic.................................................................................................................... 2-22

2-26 Diagnostic panel......................................................................................................................2-24

2-27 LB12/LB15 block diagram.......................................................................................................2-25

2-28 Printhead needle arrangement................................................................................................2-27

2-29 Character formation in high quality printing.............................................................................2-27

2-30 Character formation at 300cpi print speed..............................................................................2-28

2-31 Character repertoires and character sets................................................................................2-29

2-32 Character code table layout ....................................................................................................2-30

2-33 Code extension principles.......................................................................................................2-31

2-34 Selecting a character set......................................................................................................... 2-32

2-35 Simplified description of the stepper motor function ...............................................................2-34

2-36 MSF mechanics ......................................................................................................................2-37

2-37 Data read signal timing diagram .............................................................................................2-38

2-38 MSF block diagram .................................................................................................................2-40

Table 2-1 Printhead positions and related CPU commands ...................................................................2-13

2-2 Memory configuration..............................................................................................................2-19

2-3 Memory usage ........................................................................................................................2-36

2-2 LB12/LB15 Field Support Manual 9710

Page 28

2.1 MAIN FUNCTIONAL PARTS

This chapter starts with a description of the main mechanical and electromechanical

functions. This will give you a good understanding of the interface between the electromechanics on the one hand, and the electronics and the hardware-software interactions on

the other hand. This is followed by an overall description of the circuit board assemblies and

the connected devices. The chapter concludes with descriptions of the mechanical and

electronic functions of the Magnetic Stripe Facility.

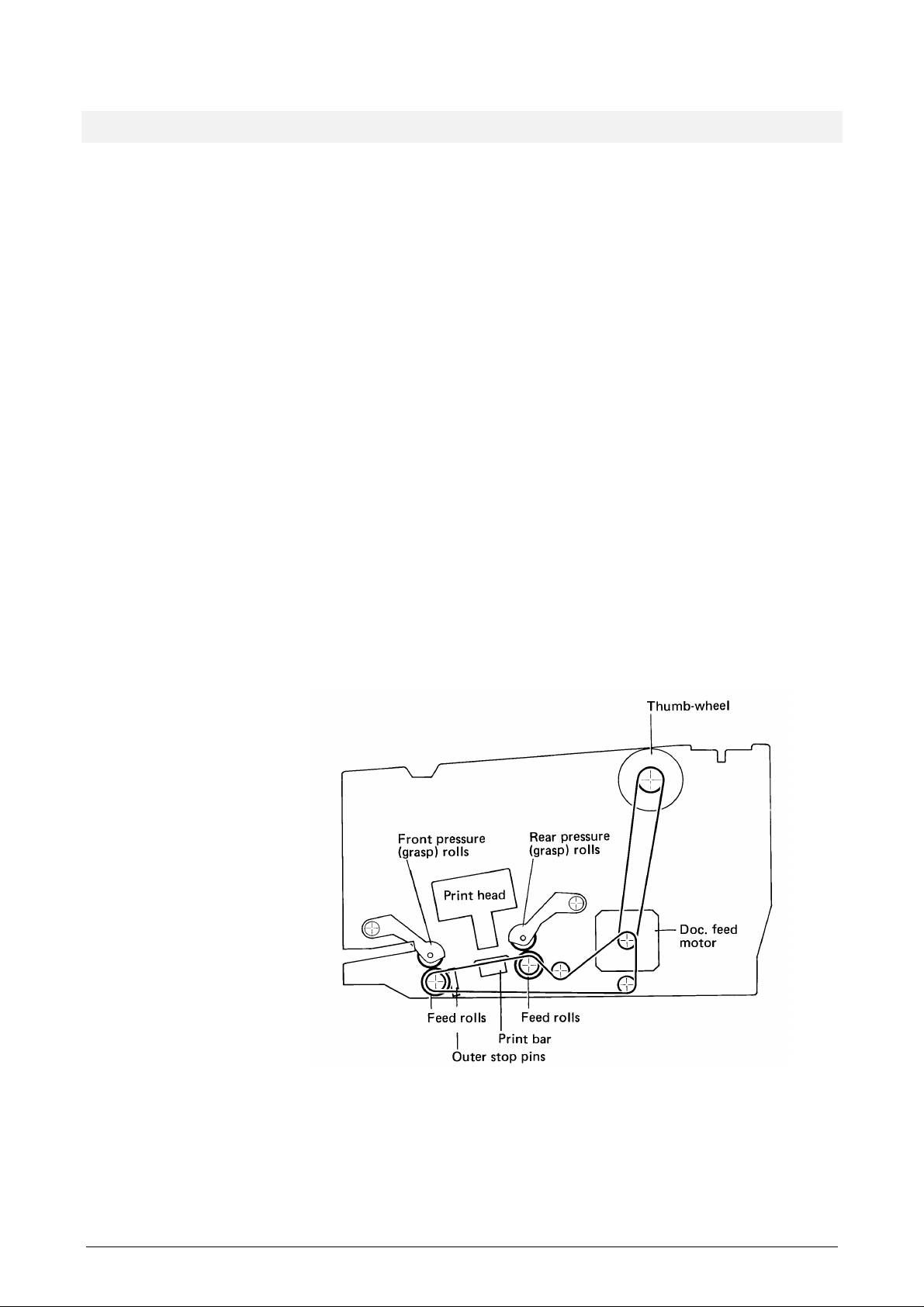

2.1.1 Document grasp and feed mechanisms

These mechanisms control the insertion, grasping, bi-directional transport, and release of

documents inserted into the document station.

The document feed motor drives the front and rear feed rolls. The front and rear pressure

rolls can be lowered to press the document against the feed rolls when the document is to

be grasped and fed in either direction. A line of stop pins helps the operator to align the

document. Both the pressure rolls and the stop pins are controlled by the grasp motor (not

shown). A sensor outside the printer's right side plate (not shown) senses the current

position of the stop pins.

The document station has the following document sensors (not shown) ensuring that the

document is in the correct position before document feeding starts:

• outer edge sensor positioned just outside the outer stop pins

• right-edge sensor

• Automatic Insertion Function (AIF) sensor.

Figure 2-1 Document feed mechanism

The thumbwheel near the setup/diagnostic panel can be used to retrieve a document that

has become trapped inside the printer.

9710 LB12/LB15 Field Support Manual 2-3

Page 29

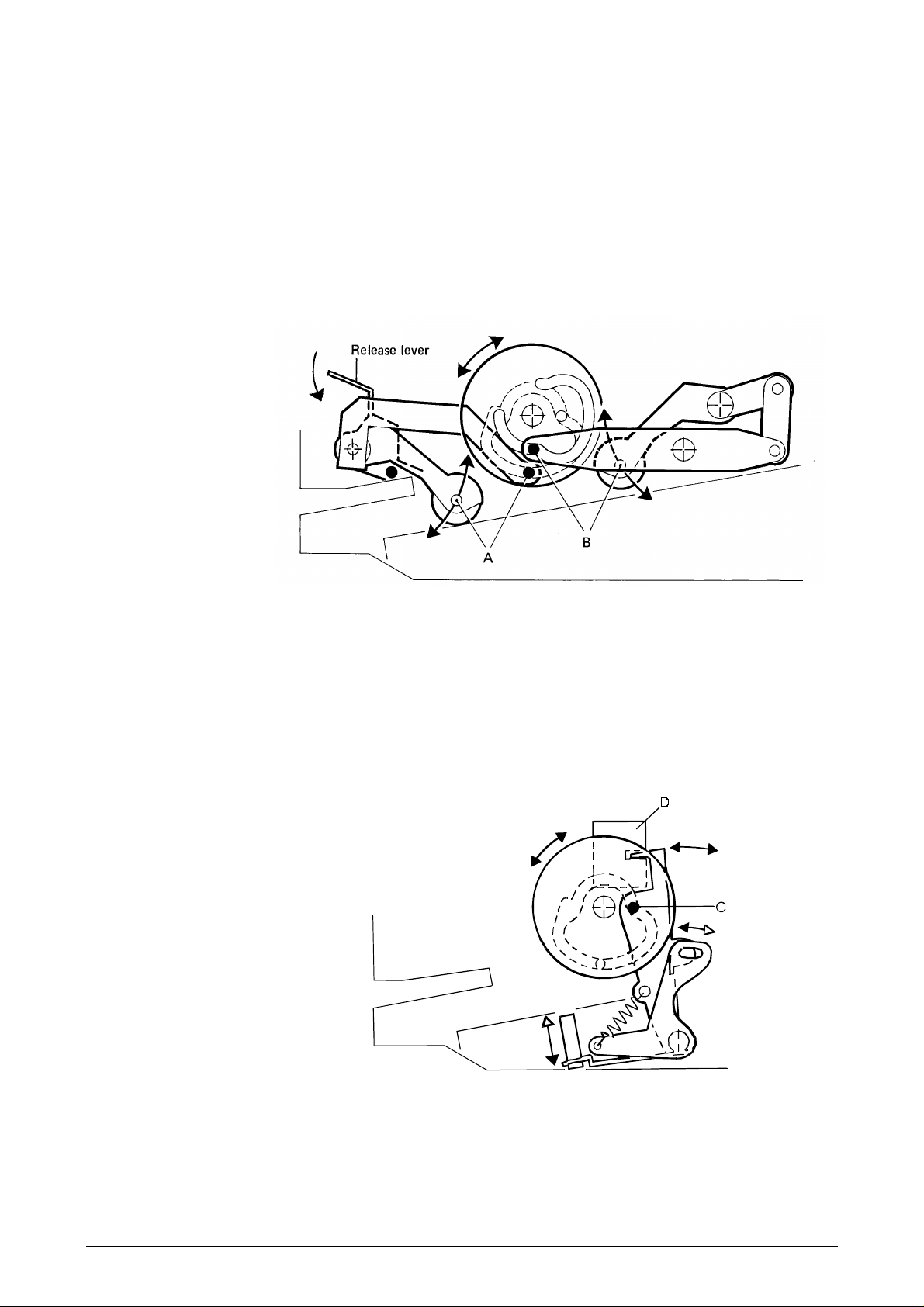

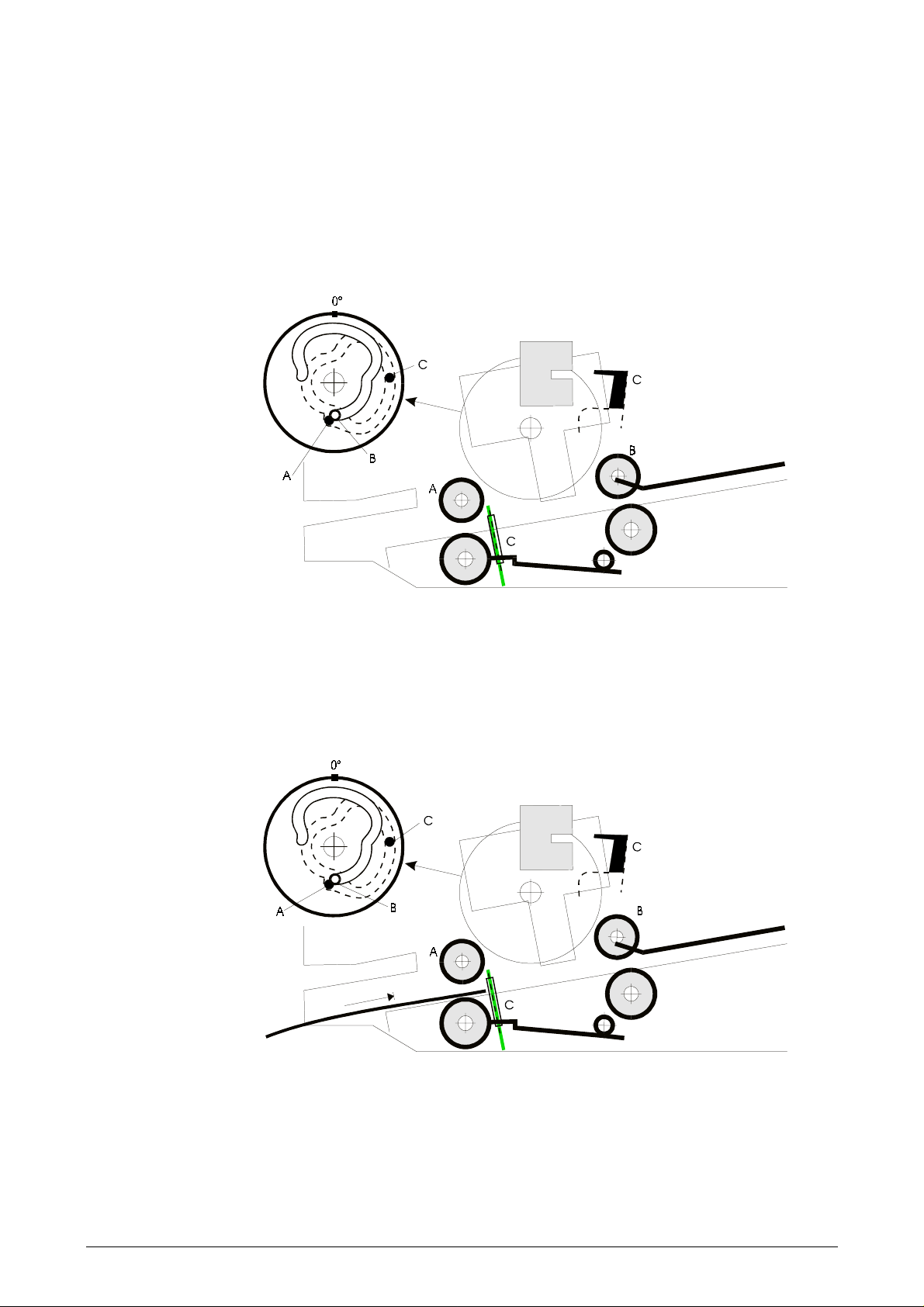

Pressure rolls mechanism

The mechanisms for the pressure rolls and the stop pins are shown in more detail in the

following two figures.

A cam wheel with two grooves controls both mechanisms. The grasp motor turns the cam

wheel, via a toothed belt, to six clearly-defined positions. One of the grooves moves the

outer pressure rolls (grasp rolls) up and down via an arm (A). The other groove controls the

inner pressure rolls via another arm (B). If you need to remove a jammed document, you

can lift the outer pressure rolls further by pressing the release lever down.

Stop pin mechanism

A third arm (C), which follows the same groove as arm (A), directly controls the movement

of the stop pins. This arm also controls the stop pins via a tension spring. When the stop

pins are lowered, the upper part of arm (C) interrupts the light in the opto-sensor (D) which

signals to the CPU that the document path is free.

Figure 2-2 Pressure rolls mechanism

Figure 2-3 Stop pin mechanism

2-4 LB12/LB15 Field Support Manual 9710

Page 30

Home position

The figure below shows the basic position of the relevant mechanisms. The pressure rolls

(A) and (B) are lifted, and both the outer and inner stop pins (C) are raised.

The application knows which type of document is to be inserted and may have informed the

operator by means of an on-screen message. Alternatively, the operator may have informed

the application, via the keyboard, regarding the type of document he or she is going to

insert.

Figure 2-4 Feed rolls and stop pins in home position

Inserting a document against the outer stop pins

Thin documents, such as forms and vertically folded passbooks, should be inserted against

the outer stop pins, as shown below.

Figure 2-5 The document being fed in

9710 LB12/LB15 Field Support Manual 2-5

Page 31

The document sensors are activated when the document is in the correct position. The cam

wheel turns 90 degrees, lowering the front feed rolls (A) grasping the document. The turning

of the cam wheel also lowers all the stop pins (C). The opto-sensor (C) is activated.

The feed motor starts and feeds the document into the printer.

The application program decides when the printhead is to be lowered to start printing.

Figure 2-6 The feed motor starting to feed in the document

The cam wheel turns a further 30 degrees, lowering the rear pressure rolls. The rear feed

rolls now take part in feeding the document.

Figure 2-7 Lowering the rear pressure rolls

2-6 LB12/LB15 Field Support Manual 9710

Page 32

When printing is complete, the cam wheel turns a further 80 degrees, lifting the front

pressure rolls to allow the bottom edge of the document to pass on its way out.

Figure 2-8 The front pressure rolls raised to let the document pass on its way out

When the bottom edge passes the outer edge sensor, the cam wheel returns to the 120

degrees position, thus lowering the front pressure rolls to achieve the complete release of

the document.

Figure 2-9 Front pressure rolls lowered to complete the document release

9710 LB12/LB15 Field Support Manual 2-7

Page 33

The cam wheel then returns to its home position, raising all feed rolls and stop pins. The

document station is now ready to receive another document.

Figure 2-10 The document station ready for another document

2.1.2 Rotary print unit

The rotary print unit is built up between two side plates interconnected by means of a front

and a rear guide shaft, along which the carriage moves.

The printhead is mounted on the carriage by means of metal leaf springs. A wire spring

pushes the printhead towards the print bar. A PDC mechanism, comprising a stepper motor

and a cam wheel can, via a tie-rod, pull the printhead away from the printbar to a number of

different positions.

The print unit can be turned to two fixed positions as follows:

Vertical position, used for:

• sensing the left paper edge, using the Position Detection Facility (PDF) in the

document station

• printing in the document station.

Horizontal position, used for:

• ink ribbon cassette replacement.

See Page 2-11 for information about the print unit release and locking mechanism.

2-8 LB12/LB15 Field Support Manual 9710

Page 34

An opto-sensor detects when the print unit is in its horizontal position.

Figure 2-11 Print unit position sensor (V-H sensor)

2.1.3 Lateral carriage movement

The carriage is driven laterally by a stepper motor via a toothed belt clamped to the carriage

with a belt clamp.

Figure 2-12 Carriage drive mechanism

9710 LB12/LB15 Field Support Manual 2-9

Page 35

The printer uses the carriage movement:

• to detect the left paper edge

• to print while the carriage moves

• to tabulate by moving the carriage to defined positions

• to move the carriage to a specific position during calibration of the automatic printhead-

• to change between book and document mode by moving the carriage to its extreme

• to feed the ink ribbon.

The CPU generates two 90 degree phase-shifted pulse trains, which move the carriage

motor. The frequency of the pulse trains increase or decrease according to tables stored in

memory during acceleration or decceleration or at constant speed.

2.1.4 Ribbon feed

The ribbon drive mechanism consists of a gear transmission, with a drive pin entering the

ink ribbon cassette. The gear is driven indirectly, via an O-ring, by the carriage motor, using

the same toothed belt used to drive the carriage. The drive pin rotates in the same direction

regardless of the direction of the carriage movement.

to-paper distance control function

right or left hand position

Figure 2-13 Ribbon drive mechanism

2-10 LB12/LB15 Field Support Manual 9710

Page 36

2.1.5 Rotary print unit release and locking

A pin (a), mounted on a spring-loaded locking arm (b), is pressed into a hole in the right

side plate of the print unit, to hold the print unit accurately in position during printing. The

conical-shaped end of the pin enters the hole only partly, thus eliminating any free play.

There is one hole each for the horizontal and the vertical position.

When the print unit is to rotate, the carriage moves as far as possible to the right side,

where it pushes a small rod (c) against the locking arm, thus disengaging the locking pin.

The front end of the locking arm then leaves the gap of an opto-sensor (d), signaling to the

CPU that the print unit can be rotated.

Figure 2-14 Carriage in its extreme right position releases the print unit

At the end of the rotation, the carriage moves slightly to the left to enable the locking pin to

lock the unit in its new position. Due to mechanical tolerances, the stepper motor may add

some extra motor steps until the latch pin enters the locking position. The opto-sensor

senses that the locking pin is engaged.

The locking pin locks the print unit in the vertical or horizontal position only.

When changing from the vertical to the horizontal position, pressing the

the carriage, releasing the locking pin for 10 seconds. A separate latch, controlled by the lid

release mechanism, locks the print unit in its vertical position. When the lid release button is

pressed within the 10 seconds, this latch unlocks and a tension spring pulls the print unit to

the horizontal position.

To return the print unit to the vertical position, press the

has released the locking pin, rotate the print unit manually until the latch snaps into the

locked position.

step switch

step switch

and, when the carriage

moves

9710 LB12/LB15 Field Support Manual 2-11

Page 37

2.1.6 Printhead-to-paper distance control (PDC) mechanism

Mechanism design

A wire spring, fitted under the carriage, pushes the printhead towards the print bar. The

PDC stepper motor, with its cam wheel, can pull the printhead away from the print bar to a

number of defined positions by means of the tie rod connected to the cam wheel.

A sensor arm with a nose wheel is fitted to the front of the printhead. The slide shown in the

figure decides how far the nose wheel can be pushed in. When the slide is in its left

position, called the

the nose. With the slide in the correct position, called the

extend 0.5—1.2mm. A sensor indicates the position of the nose wheel in relation to the

printhead nose. The sensor comprises a permanent magnet, fitted to the end of the sensor

arm, and a Hall element. The output voltage from this Hall element indirectly controls the

turning of the PDC motor and hence the position of the cam wheel and the printhead. The

sensor is called the

document position

distance sensor.

, the nose wheel can extend 0.3—1.2mm in front of

book position

, the nose wheel can

Figure 2-15 Printhead-to-paper distance mechanism in document position

2-12 LB12/LB15 Field Support Manual 9710

Page 38

To change the position of the slide, the application sends a command moving the carriage

either against the left print unit side plate, which moves the slide to its right position, or

against the right side plate to set the slide in its left position.

Head attach and release

A single step of the PDC motor moves the printhead approximately 50µm.

The printhead can be moved to the following positions on commands from the CPU:

Command Name Function

HAT Head attach 0.3mm from the printbar. Only used during

Figure 2-16 Printhead-to-paper mechanism in book position

calibration.

HAD Head attach

document

0.40mm from the paper surface. Used when

printing on all types of documents except passbooks.

HAB Head attach book 0.5mm from the page. The nose wheel rolls

against the book page. The PDC cam is turned

such that it cannot inhibit the printhead

movement.

HRS Head release short 2.0mm from the paper. Used while feeding thick

documents in and out.

HRB Head release book 5.0mm from the printbar. Used while feeding

passbooks in and out.

HRL Home or head

release long

5.25mm from the print bar. This is the home

position and also the position used when

rotating the print unit, when shifting between

book and document printing. The printhead is

mechanically locked.

TRP Head transport Range between Head Attach and Head Release

Long positions.

Table 2-1 Printhead positions and related CPU commands

9710 LB12/LB15 Field Support Manual 2-13

Page 39

The following figures show some of the printhead positions.

Fig 2-17 Head attach position for passbook printing

Figure 2-18 Head release short position

Figure 2-19 Home position (= head release long)

2-14 LB12/LB15 Field Support Manual 9710

Page 40

Auto calibration

µ

At printer reset, such as after Power ON, the printhead is first moved forwards and then

backwards while the processor measures and stores the corresponding distance sensor

output levels. If the values do not fall within the predetermined limits, an error code is

generated.

The carriage moves to the extreme right hand side. The slide is set in the document

position and the carriage moves back to its home position.

The printer executes autocalibration in the document station.

With the carriage in its home position (close to the right side plate), the printhead is moved

forwards. When the nose approaches the printbar, the nose wheel is pressed in, which

affects the distance sensor output level. During this movement, the sensor output signal is

measured and stored as a function of the number of steps by which the PDC motor has

rotated. The active part of the PDC cam wheel is thus tested and an error code is generated

if the position or movement cam is found to be incorrect.

The printhead is now moved to a calibration position. While moving the carriage slowly to

the left, the PDC function keeps the sensor output signal constant by stepping the PDC

motor back and forth. The number of steps used are stored in a deviation table. This

ensures that any slope of the printbar and any irregularity has been measured and

recorded. Both the printbar irregularity and the maximum/minimum distance between the

printbar and the HRL position are checked. If the measurements do not conform to preset

values, an error code is generated.

When the carriage reaches the left side plate, the slide is pushed into the book position.

The printhead is pulled back to HRL position, then advanced to HAB position, where the

distance sensor signal is again measured and recorded. The distance between the

printhead and the printbar is 0.5mm, which is the reference position for the calibration of the

PDC function.

Since it is known that a single motor step corresponds to 50

how many motor steps are required to move the printhead 0.4mm from the document, and

can maintain that distance during printing.

Finally the printhead is pulled back to the HRL position and the carriage is moved to the

right, to the center, and then to the home position close to the right side plate. The autocalibration process is now complete.

Document printing

The printhead is in its home (HRL) position and the nose wheel extends 1.2mm in front of

the printhead nose. A command is given to advance the printhead towards the document. A

change in the distance sensor output is detected when the nose wheel touches the surface

of the document. The printhead is advanced further until it is 0.4mm from the document.

The distance sensor output is then ignored

document is maintained.

The printhead nose wheel presses very lightly against the document during printing. The

printhead moves forward or backward to compensate for any slope or irregularity of the print

bar, according to the values stored in the calibration table.

If the printhead passes a sudden thickness change (e.g. a staple), the sensing arm hits the

slide and the printhead may be pushed backward. For this reason, the distance between

the paper and the printhead will never be less than 0.3mm, which prevents the paper from

being unintentionally colored by the ink ribbon.

m, the processor can calculate

, and the distance of the printhead from the

9710 LB12/LB15 Field Support Manual 2-15

Page 41

Passbook printing

Passbooks can have several pages and the thickness can vary slightly along the printed

line. The pages also need to be pressed together during printing. Before printing starts, the

application sets the mechanism in the book position by moving the slide to the right

position. The PDC motor turns, moving the printhead towards the book until the sensor arm

meets the slide. The nose wheel now presses hard against the page, forced by the wire

spring fitted between the printhead and the carriage. The cam wheel turns to a position

where the cam follower on the tie-rod separates from the cam wheel. During printing, the

nose wheel and the printhead now follow the book surface at the fixed printhead-to-paper

distance of 0.5mm.

The passbook method cannot be used when printing on form sets since the nose wheel

would cause stripes on the copies.

PDC cam wheel

The printhead moves forward and backward either controlled by the PDC cam wheel or

when printing in passbooks, with the cam wheel in the Head Attach Book position, guided

by the nose wheel. The figure below shows the number of motor steps required to move the

cam wheel to reach the various printhead positions. Each motor step moves the printhead

approximately 50µm:

• Head attach book (HAB) 6 mm (140 steps) forward from home position

• Head release, short (HRS) 2.0 mm (32 steps) from the paper

• Head release long (HRL), home pos. Reference position, 5.25 mm from the printbar

Figure 2-20 The PDC cam wheel

2-16 LB12/LB15 Field Support Manual 9710

Page 42

The distance sensor is disabled while the CPU counts the pulses to move the head into

position. The sensor is enabled again when the head approaches the Head Attach Book

position and the PDCPOS is sent to the CPU.

The figure below shows how the PDC sensor voltage changes as the printhead moves.

Figure 2-21 PDC sensor output voltage

9710 LB12/LB15 Field Support Manual 2-17

Page 43

Sensor element

The Hall-effect sensor is affected by a magnet fitted to the PDC sensing arm. A change in

the magnetic flux generates a linear change in the output voltage level.

The Hall IC includes the circuits shown in the block diagram below. An internal voltage

regulator supplies the Hall-effect generator and amplifier. An operator amplifier amplifies the

relatively small Hall-effect voltage.

Figure 2-22 PDC sensor element

2-18 LB12/LB15 Field Support Manual 9710

Page 44

2.1.7 PDF - Position Detection Facility

An opto-sensor fitted below the printhead can be used as a contrast sensor to search for

the left document edge.

2.1.8 Main board

General

(See Figure 2-27)

The main board has a 68000 CPU that controls all functions in the printer. The CPU

program (firmware) resides in EPROM. The EPROM also contains default parameters, fixed

character generators, stepper motor tables, etc.

The main board has connectors for the connection of motors, the sensor board, the

printhead board, etc. An optional interface board can also be mounted on top of the main

board in a “piggy-back” arrangement.

The main board, including CPU, DMA (Direct Memory Access) and other chips, controls all

the stepper motors. The EPROM holds the necessary program instructions and motor

control parameters.

Storage Size Chip

Main EPROM 128KB—2MB

Standard = 512KB

(2 x 256KB)

Main RAM 16KB—256KB

Standard = 64KB

2 x 64KB or

2 x 128KB or

2 x 256KB or

2 x 512KB or

2 x 1M8

2 x 8KB or

2 x 32KB or

2 x 128KB

2 x 512KB

EEPROM 128x8 1x128

Table 2-2 Memory configuration

The DMA function positions the carriage, and hence the printhead, using a number of step

pulses counted from the carriage home position.

A direct memory access controller (DMAC 8237) transfers needle data to the MPC interface

chip and pulse-width data to two programmable timers in the MPC timer chip that controls

all the stepper motors.

A parallel interface/timer (PI/T 68230) is used for various control signals transferred in both

directions between the main board and the other functional parts of the printer.

A dual asynchronous receiver transmitter (DUART 68681) handles serial asynchronous

communication with the host computer. The DUART also receives signals from:

• the ON-OFF switch on the document sensing board

• the setting switch on the diagnostic panel

• the host, when it issues a command for remote power OFF.

9710 LB12/LB15 Field Support Manual 2-19

Page 45

Carriage motor drive circuits

The direction and speed of the carriage motor are controlled by the DMA transfer of data

from memory to the timer-MPC. The signals are then transferred to the carriage motor drive

circuits via the decoder-MPC.

Stepper motor control and drive circuits

All motors in the printer are stepper motors, which are all driven in the same way. Pulses

are supplied by the programmable timers. Internal thermal protection circuits supervise the

drive circuits. If overheating occurs, the driver is automatically switched OFF.

The carriage motor is, however, driven by pulsed power transistors, and if the CPU detects

that the carriage is not moving according to the supplied pulses, it stops the pulses.

Power ON/OFF logic

The state of the power supply unit is affecting by:

• the ON/OFF switch

• interface signal 107 when this is used for remote power off control

• mains power supply interruptions.

If the remote power OFF control function has been selected (see Chapter 6 of the

LB12/LB15 User’s Guide

voltage required for RAM backup is supplied.

), a high signal level sets the PSU to standby mode, where only the

When the mains power supply is restored after a power interruption, the PSU is set to the

operating mode before the interruption occurred.

2.1.9 Capacitor board

This board contains two capacitors that buffer the +36 V, and act as a reservoir for the

current to the needle drive circuits.

2.1.10 Printhead board

The needle data is transferred sequentially to a serial-to-parallel converter register on a

printhead board mounted at the rear of the printhead. The needle drivers are also located

on this board. These drivers receive, via the DMAC, all the needle data required to ensure

that the appropriate needles are fired at the correct time, independent of the carriage

speed. The interface-MPC generates a strobe signal used to ensure that the needles are

fired in the correct positions.

2.1.11 Opto sensors

(See Figure 2-27)

(See Figure 2-27)

(See Figure 2-27)

General

The LB12/LB15 has seven opto-sensors, all connected to the document sensing board. The

board contains various circuits for measuring the threshold voltage level of each sensor.

The reading of a specific sensor is based on its current threshold level. The ON-OFF-switch

and the ON-lamp are also located on this board.

The opto-sensors are:

1. Grasp sensor (stop pin position).

2-20 LB12/LB15 Field Support Manual 9710

Page 46

2. Print unit rotation sensor (or V-H sensor, for Vertical-Horizontal).

3. Carriage extreme right position sensor (or carriage-HOME sensor).

4. Document right edge sensor (or EDGE sensor).

5. Document edge, outer sensor.

6. PDF sensor.

7. AIF sensor

The outer document sensor sends light against an adjustable polished metal reflector. The

reflector has a clearly-defined radius so the reflected light beam becomes very narrow,

resulting in very accurate document positioning.

The sensor is connected to the document sensing board via connectors P2, P3 and P4.

The reflector can be adjusted to reflect more or less light. This requires a special tool; see

Chapter 3 for adjustment instructions.

Figure 2-23 Light-reflecting opto-sensor

Each of the grasp, extreme right and V-H opto-sensors sends light, through an optical fiber,

via an air-gap, to a receiver. Small metal or plastic plates or "flags" can move into the gaps,

thus breaking the light beam.

Fig 2-24a Light-breaking opto-sensors

Fig 2-24b Document edge opto-sensor

Fig 2-24c AIF opto-sensor

9710 LB12/LB15 Field Support Manual 2-21

Page 47

The grasp sensor, the print unit rotation sensor (V-H sensor), and the carriage extreme right

sensor comprise light transmitters D2-D4 and receivers V1-V3. The output signals from

these sensors have a high amplification rate to compensate for the successive light

reduction that takes place in the optical fibers. The asserted SENSE signal tells the CPU

that the light passage is NOT interrupted by a paper edge or a metal "flag".

All sensor signals are amplified in a number of circuits, TLC274C and selected in a

multiplexor. The multiplexor output is the sensor output for the selected sensor. This sensor

level is compared to an individually set reference level.

Figure 2-25 Opto-sensor logic

PDF sensor

The position detection facility sensor can be used to detect the left edge of a document or

passbook. The sensor is connected to the main board via the printhead board.

The CPU actuates the PDF sensor by generating the signal CLEDON via the parallel

interface timer PI/T. After being negated on the main board, CLEDON-N actuates the light

transmitter in the opto-sensor. Its receiver output, CONSENSEB, becomes inverted in a

comparator producing a positive signal that is sent to the document sensing board.

2-22 LB12/LB15 Field Support Manual 9710

Page 48

Sensor calibration

The threshold values are calibrated for each opto-sensor at each power-ON to compensate

for component degradation and variations in component characteristics. A calibration

reference is made by running a special calibration function (see Chapter 3,

During calibration, all sensors are set to their WHITE or OPEN state. The sensor outputs

are then transferred, one at a time, to the comparator. For each sensor, the CPU changes

the threshold voltage until the SENSE signal changes to HIGH level. That threshold voltage

is then multiplied with a factor to obtain the calibrated threshold voltage to be used.

2.1.12 Joint board

The joint board connects the carriage motor to the main board. The joint board contains

only connectors.

Maintenance

).

2.1.13 PSU and voltage indicator

Voltage conversion is achieved in two steps on the PSU board. The first step is an AC/DC

conversion, which generates +36 V used for the motors and the needle drive circuits on the

printhead board.

The second step is a DC/DC conversion from +36 V to +5 V and –12 V. A +12 V voltage is

generated on the main board by a voltage regulator supplied from the +36 V. Only the +5 V

is provided with a LED indicator (ON lamp) located at the front of the printer.

(See Figure 2-27)

9710 LB12/LB15 Field Support Manual 2-23

Page 49

2.1.14 Diagnostic panel (optional)

When numeric characters are to be displayed, the CPU transfers the character data to the

two BCD-to-7-segment decoders on the diagnostic panel via the DBUS and the DBBUS.

The CPU also generates the chip select signal CSDA-N by addressing the chip select

decoder U42 on the main board via the ABUS. The selected display segments are switched

ON by CSDGNS-N.

The status of all switches on the diagnostic panel, except the setting switch, are transferred

to the parallel interface/timer U3 on the main board, where they are retrieved by the CPU.

The status of the setting switch is available to the CPU via the DUART.

Figure 2-26 Diagnostic panel

2.1.15 Set-up panel

The set-up panel is the same as the diagnostic panel, except that the printed board

assembly has only a lid switch and a step switch. These switches function in the same way

as the corresponding switches on the diagnostic panel.

2-24 LB12/LB15 Field Support Manual 9710

(See Figure 2-27)

Page 50

Figure 2-27 LB12/LB15 block diagram

9710 LB12/LB15 Field Support Manual 2-25

Page 51

2-26 LB12/LB15 Field Support Manual 9710

Page 52

2.2 PRINCIPLES OF PRINTING

2.2.1 Printhead

The printhead has 18 needles arranged in two rows. The rows are positioned 0.53mm (45 x

11.7µm) on either side of the center line of the printhead. Thus, the total needle row

separation is 1.06mm. The needles are numbered as shown below.

2.2.2 Character formation

When using low-speed high-quality printing, both needle rows can print in every column of

the character matrix. The needle rows are vertically positioned such that 18 partly

overlapping dots can be printed in one column.

Figure 2-28 Printhead needle arrangement

Figure 2-29 Character formation in high quality printing

When printing at 300cpi (9x12 matrix) only one needle row is used. A maximum of 9 nonoverlapping dots can be printed in one column.

9710 LB12/LB15 Field Support Manual 2-27

Page 53

Figure 2-30 Character formation at 300cpi print speed

2.2.3 Character repertoires and character sets

A "character repertoire" is a defined collection of characters with no coded representation.

A collection of characters defined together with its coded representation is called a "coded

character set", or simply, a "character set". Note that a character set does not define the

graphical representation of the characters, i.e. the type-face to be used.

The total character repertoire that can be used by the printer is divided into one basic and

several additional repertoires.

The basic repertoire consists of 190 characters, including 178 characters that form a subset

of the basic Teletex repertoire defined in CCITT recommendation T.61. The basic repertoire

is almost identical to that of EBCDIC.

The basic repertoire is represented by several pairs of 8-bit coded character sets. Each pair

contains a primary set of 94 characters and a supplementary set of 96 characters. Each

pair constitutes a national version and is defined in such a way that its primary set is

identical to the corresponding national version of the 7-bit code.

An additional repertoire consists of up to 192 characters and is represented by one or two

8-bit coded character sets. Each of these sets is unique, i.e. there are no national versions.

The EPROM part of the printer memory contains various character sets. Other character

sets, containing for example logotypes and graphics characters, can be added by

downloading them from the workstation controller into the printer's RAM area. This means

that the number of available graphic characters is theoretically unlimited.

2-28 LB12/LB15 Field Support Manual 9710

Page 54

2.2.4 Character sets

Figure 2-31 Character repertoires and character sets

For information about character sets, refer to the

Guide

.

APP 6390 Application Programmer's

2.2.5 Character generation

The character set handling used in the LB12/LB15 is based on the code extension

techniques defined in the ISO 2022 standard for code extension. This technique means that

the character repertoire is built up from a number of character sets and supplementary sets

consisting of code tables. A set of graphic characters is called a G set and can be mapped

into columns 02-07 or 10-15 of the 16 column character table.

9710 LB12/LB15 Field Support Manual 2-29

Page 55

Every character set is tied to an identifier, the Final (F) character, which must be used in the

designation sequence, a two-character escape sequence, Esc, I, F. The Intermediate (I)

character specifies the G set to which the selected character set is designated.

The application software specifies the standard character set to be used. Each standard

character set contains information on which character corresponds to a specific code. The

set contains only codes and does not describe the graphical layout of the characters. The

layout is defined in the graphic sets stored in the character generator PROM.

Selecting a character set to be used is achieved in two steps. First, the character set is

selected from the available sets and copied (designated) into one of four G sets. This is

then transferred (invoked) into columns 02-07 or 10-15 of the character table for the display.

Figure 2-32 Character code table layout

The method used to indicate the graphic sets to be selected from all available sets, is called

the Designation of G sets. Four sets, called G0, G1, G2, G3, can be designated at any

particular moment. The contents of the G1 set, for example, depend on the graphical set

designated to be a G1 set.

The G sets can either contain 94 codes or 96 codes.

• A 94-code position G set does not include code positions 02/00 and 07/15. When such

a set is designated as G0, these two positions have the meanings of SPACE and

DELETE.

• A 96-code position G set is one in which code positions 02/00 and 07/15 can have

other meanings than SPACE and DELETE.

Only two of the four G sets can be selected and used at any given time. This selection is

called Invocation. The primary and supplementary basic character sets contain national

versions and are, as standard, designated as G0 and G1 sets respectively. They are then

invoked to columns 02-07 and 10-15 of the 16-column character table.

2-30 LB12/LB15 Field Support Manual 9710

Page 56

G0 and G1 are, as standard, designated as ASCII primary set and ASCII supplementary set

respectively, while characters within G2 and G3 can be used, by element-wise invocation,

to set national version characters.

To replace the currently invoked G set by another G set, a “Shift Function” is used. There

are two types of shift functions:

• Locking Shift, LS, (the whole G set is invoked)

• Single Shift, SS, (only the following character is invoked).

The designation of another character set to an already invoked G set automatically invokes

the new set.

Figure 2-33 Code extension principles

9710 LB12/LB15 Field Support Manual 2-31

Page 57

Figure 2-34 Selecting a character set

2.2.6 Graphic character representation

The graphical representation of a particular 8-bit code depends on the selected:

•

character set

•

character generator (font, matrix, pitch)

•

transformation commands (if any).

2.2.7 Logotypes

Logotypes and other special graphical symbols can be printed if a special tailor-made

character generator is loaded (RAM or PROM). Since most graphical symbols need more

than one character position both horizontally and vertically, the symbol must be split up into

several segments, with each segment corresponding to a normal character position.

2.2.8 IBM ProPrinter III emulation

For information, refer to the

APP 6390 Available Emulations Reference Manual

.

2-32 LB12/LB15 Field Support Manual 9710

Page 58