Page 1

EK-OLASO-UG-001

.

Installing

and. Using

the

LASO

Printer

mamaama

.

Page 2

Page 3

EK-0

LASO-UG-001

Installing

and

Using

the

LASO

Printer

Prepared

by

Educational

Services

of

Digital

Equipment

Corporation

Page 4

1st

Edition, August

1982

Copyright©

1982

by Digital Equipment Corporation

All Rights Reserved

The reproduction of this

material, in part

or

whole, is strictly prohibited. For

copy information, contact the

Educational Services Department, Digital

Equipment Corporation, Maynard, Massachusetts

01754.

The information in this document is subject

to

change without notice. Digital

Equipment Corporation assumes no responsibility for any errors that may

appear in this document.

Notice: This equipment generates and uses radio frequency energy.

It

has

been type tested and found

to

comply with

the

limits for a Class B computing

device in accordance with the specifications in

Subpart J

of

Part

15

of FCC

Rules,

which are designed

to

provide reasonable protection against radio and

television interference in a residential installation. However, there is no

guarantee that interference

will not occur in a particular installation. If this

equipment does cause interference to radio or

television reception, the user is

encouraged

to

try

to

correct the interference.

Printed in Japan.

The

following are trademarks of Digital Equipment Corporation, Maynard,

Massachusetts.

DEC

DEC

US

DIGITAL

Digital

Logo

PDP

UNIBUS

VAX

OS/8

DECnet

DECsystem-1

O

DECSYSTEM-20

DECwriter

DIBOL

EduSystem

OMNIBUS

IAS

MASS BUS

PDT

RSTS

RSX

VMS

VT

Page 5

---------------------------iii

CONTENTS

Introduction

Installing Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Packing

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installing Ribbon

Cartridge........................................

2

Installing Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inserting Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inserting Pinfeed Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inserting Single Sheet Paper

.....................................

1 O

Self-Test Procedure

....................................................

12

Installing System Cable

................................................

14

Front Panel Indicators and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Printer

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintaining Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting Printer

.. ..

. . .

..

.. . ..

. . .

..

.. . .. . ..

. .

.. ..

. .

.. . ..

. .

..

. . . .

18

Operator Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

Replacing Printhead

..............................................

20

Replacing

Fuse

...................................................

24

Printer Configuration

...................................................

26

Configuration Switches

...........................................

26

National Character Set Switches

..

. . . . .

..

. .

..

. .

.. .. ..

.. . .. . ..

. . . . . 28

Graphics Aspect Ratio Switch

.....................................

29

XON/XOFF and Ready/Busy Protocol Switches

...................

29

Right Margin Switch

..............................................

30

Baud Rate Select Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

Data Format Switches . .

.. . ..

. . . . . . .

.. . ..

. . .

.. . .. . .. . ..

. . . . . .

..

.. . 31

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

Field Service Information .

.. . ..

..

. . . .

..

. .

.. . .. ..

. . .

.. . ..

..

. .

..

. . . .

..

. .

..

34

Page 6

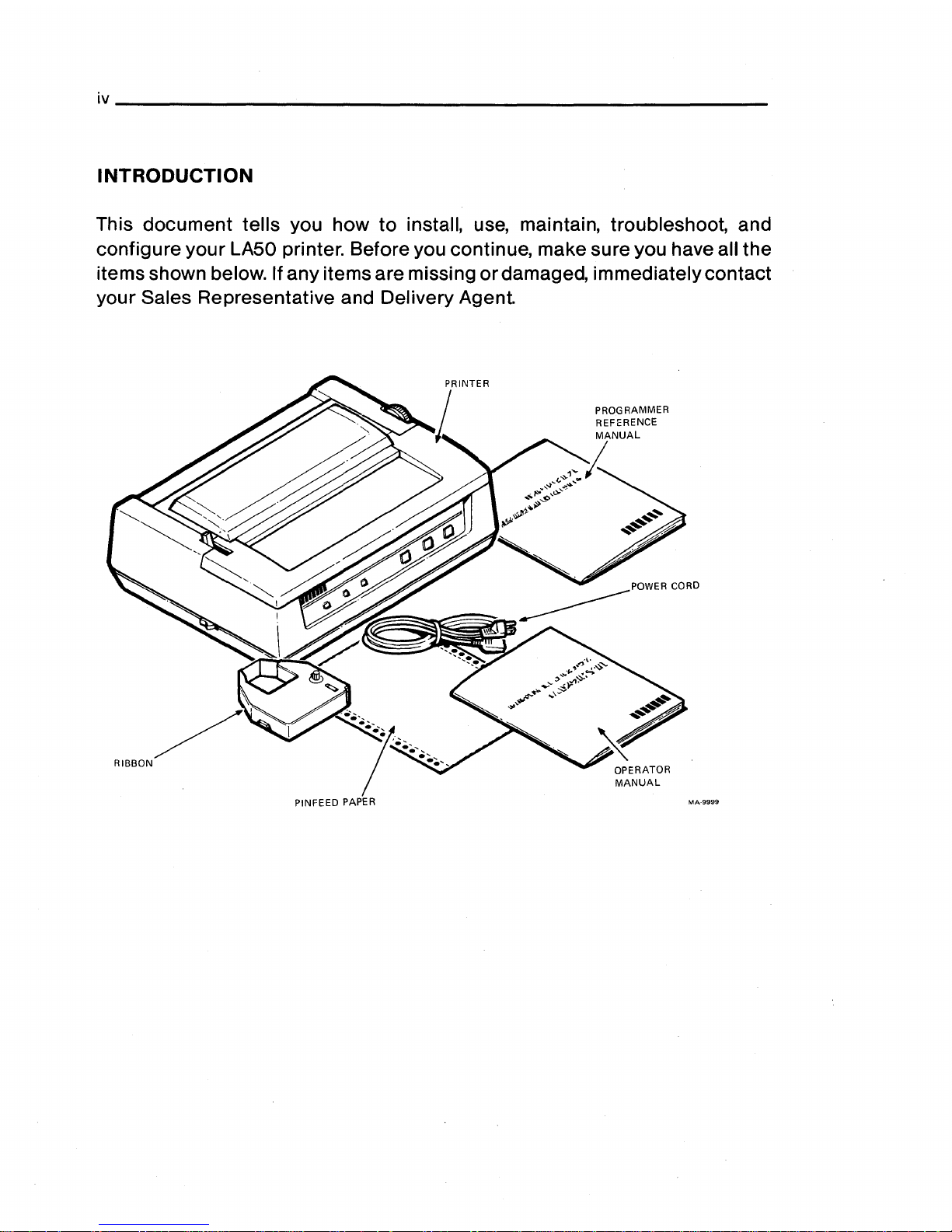

INTRODUCTION

This

document

tells you how

to

install, use, maintain, troubleshoot, and

configure

your

LA50 printer. Before you continue, make sure you have all the

items shown below. If any items are missing

or

damaged, immediately contact

your Sales Representative and Delivery Agent.

OPERATOR

MANUAL

Page 7

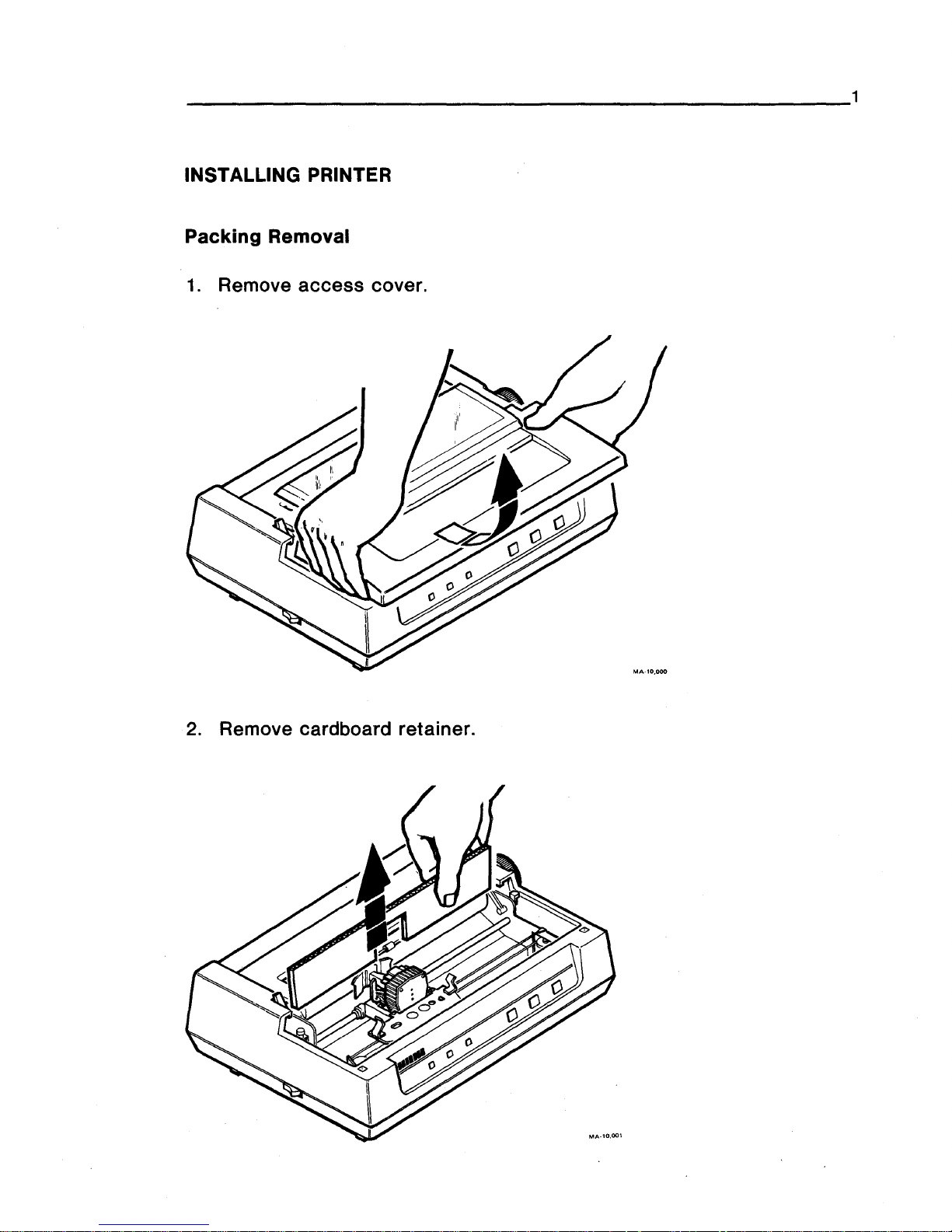

INSTALLING PRINTER

Packing

Removal

1.

Remove

access

cover.

2. Remove c d

ar board ret .

a mer.

Page 8

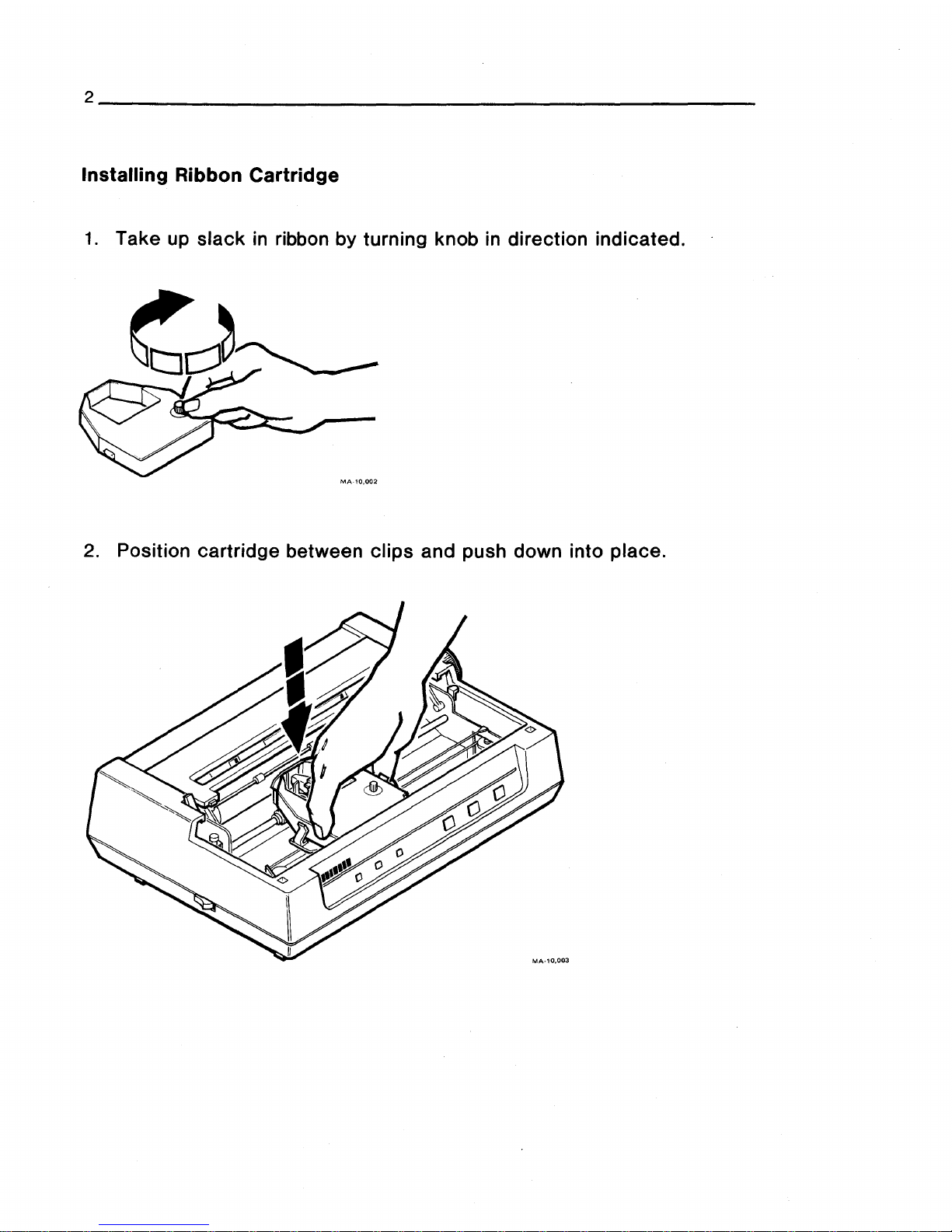

Installing

Ribbon

Cartridge

1.

Take up slack

in

ribbon by turning knob in direction indicated.

2.

Position cartridge between

clips

and push down into place.

Page 9

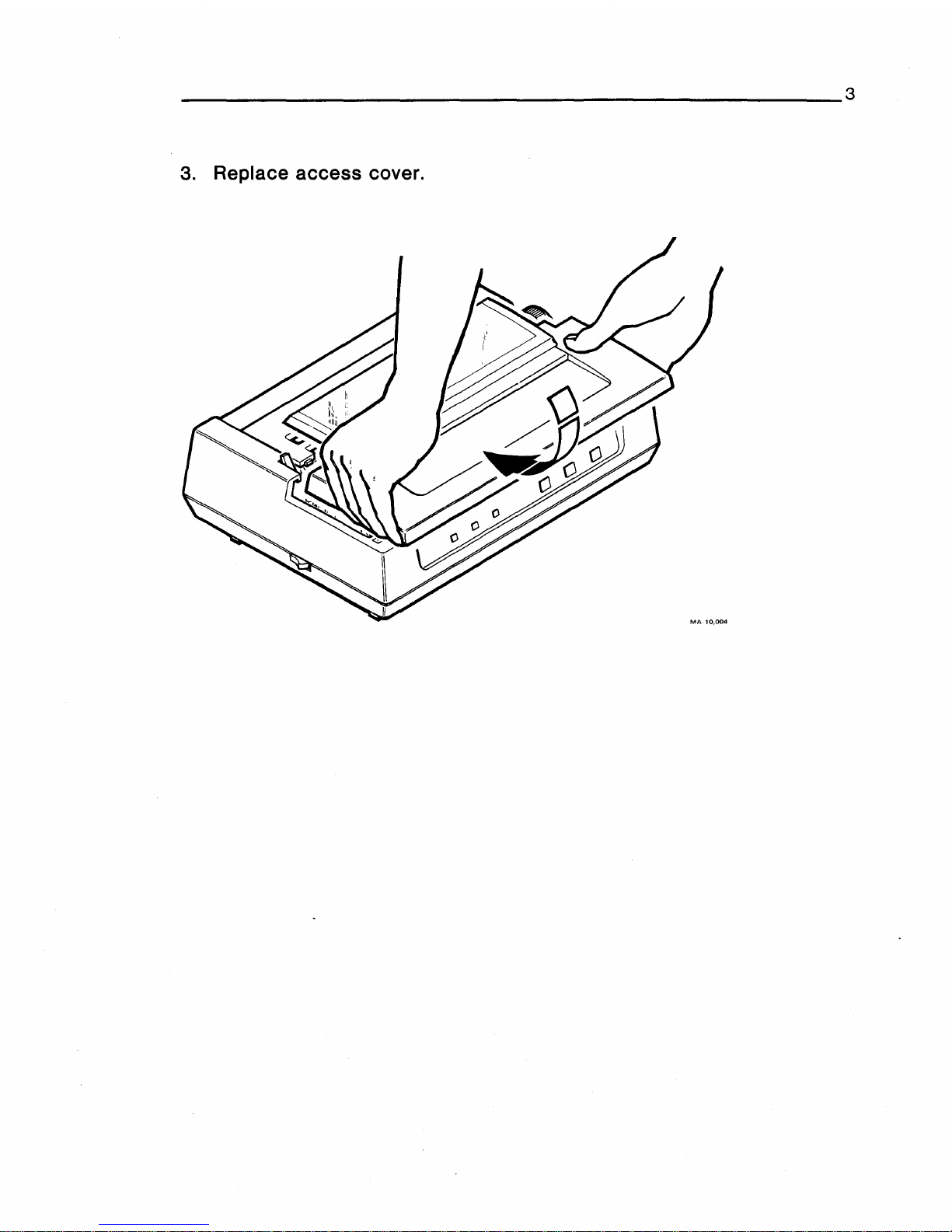

3

3

· Repla

ce access

cover.

Page 10

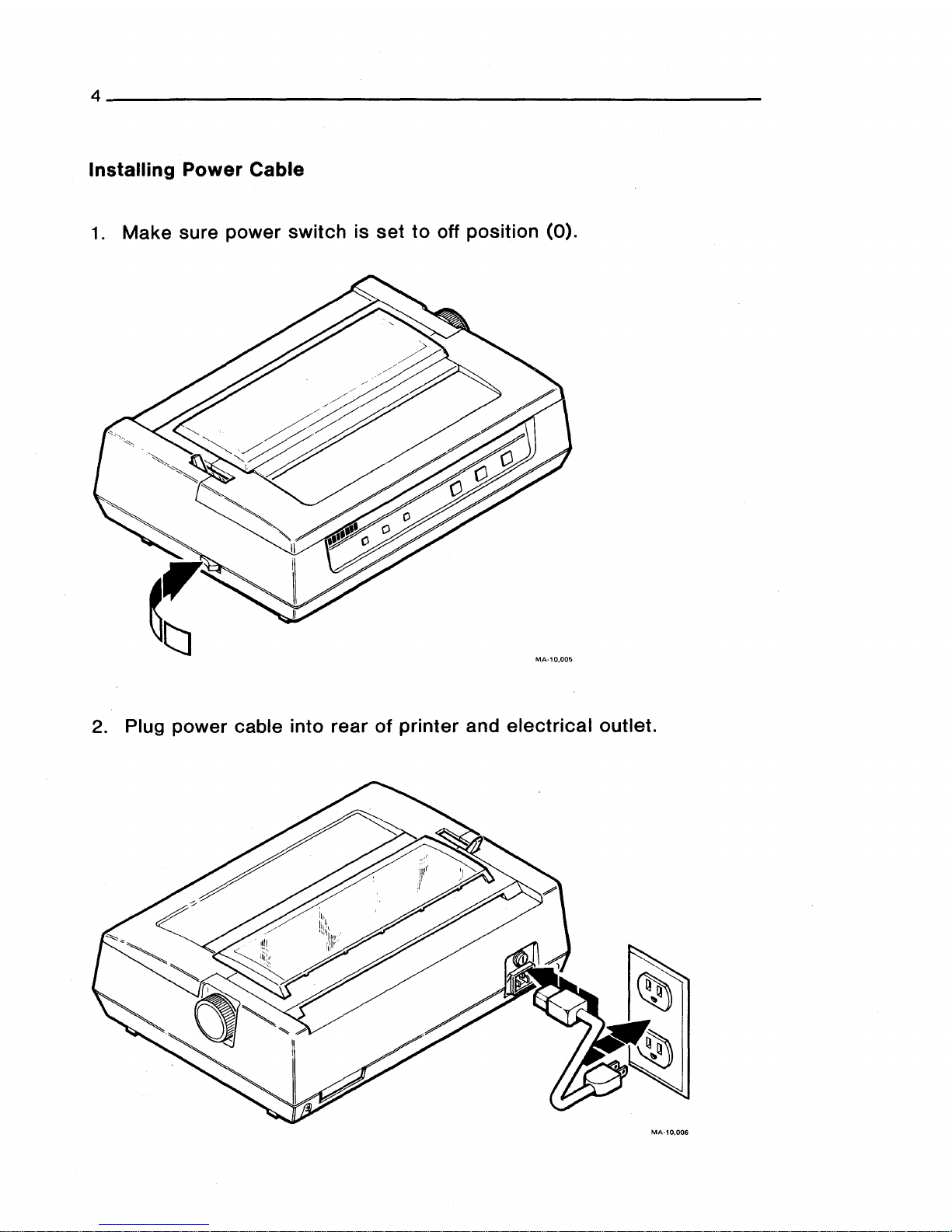

Installing

Power

Cable

1.

Make

sure

power

switch

is

set

to

off

position

(0).

2. Plug

power

cable into

rear

of

printer

and

electrical

outlet.

MA·10,006

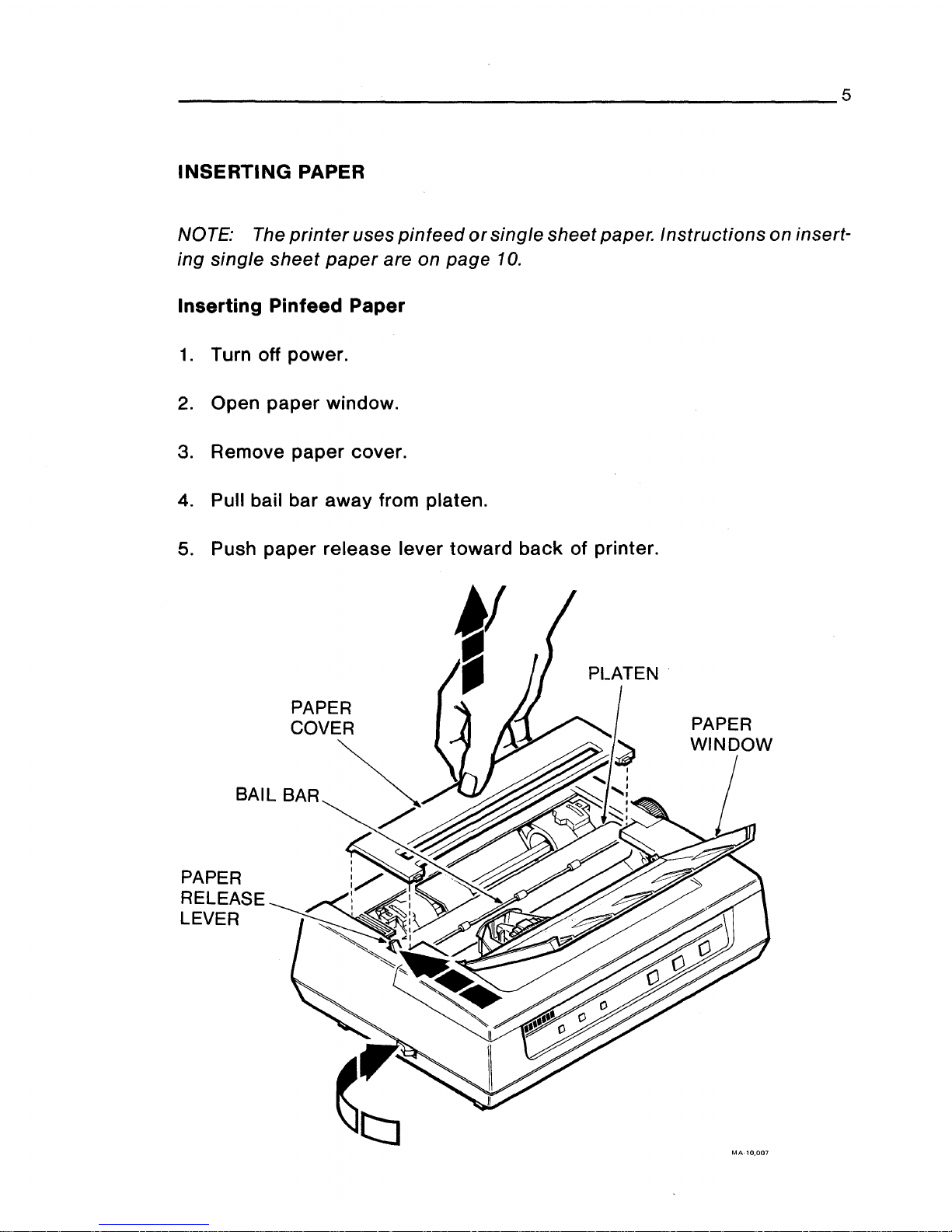

Page 11

INSERTING

PAPER

NOTE: The

printer

uses

pinfeed

or

single sheet paper. Instructions on insert-

ing single

sheet

paper

are on page

10.

Inserting Pinfeed Paper

1.

Turn off power.

2.

Open

paper

window.

3. Remove

paper

cover.

4. Pull bail bar away from platen.

5. Push

paper

release lever

toward

back

of printer.

MA-10,007

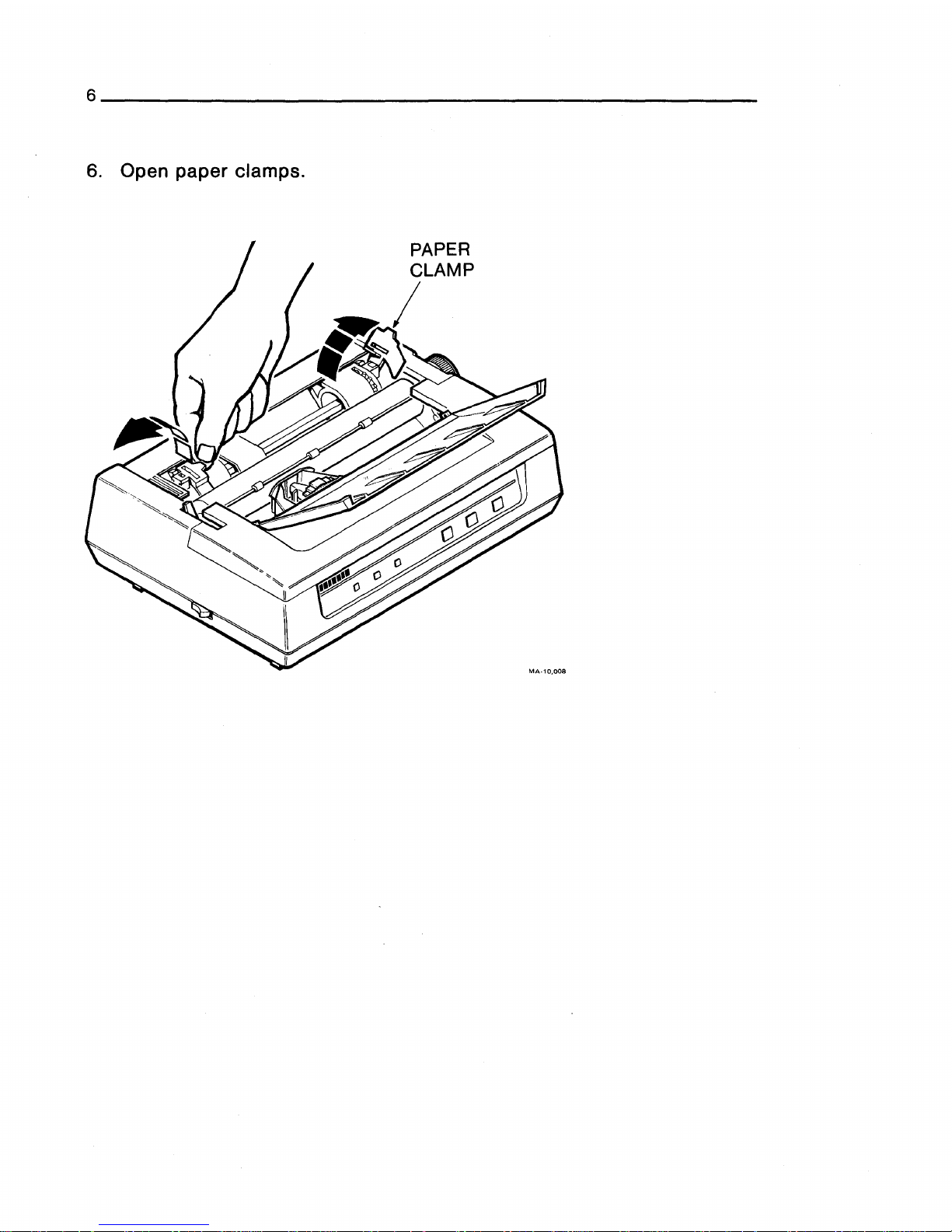

Page 12

6. Open paper clamps.

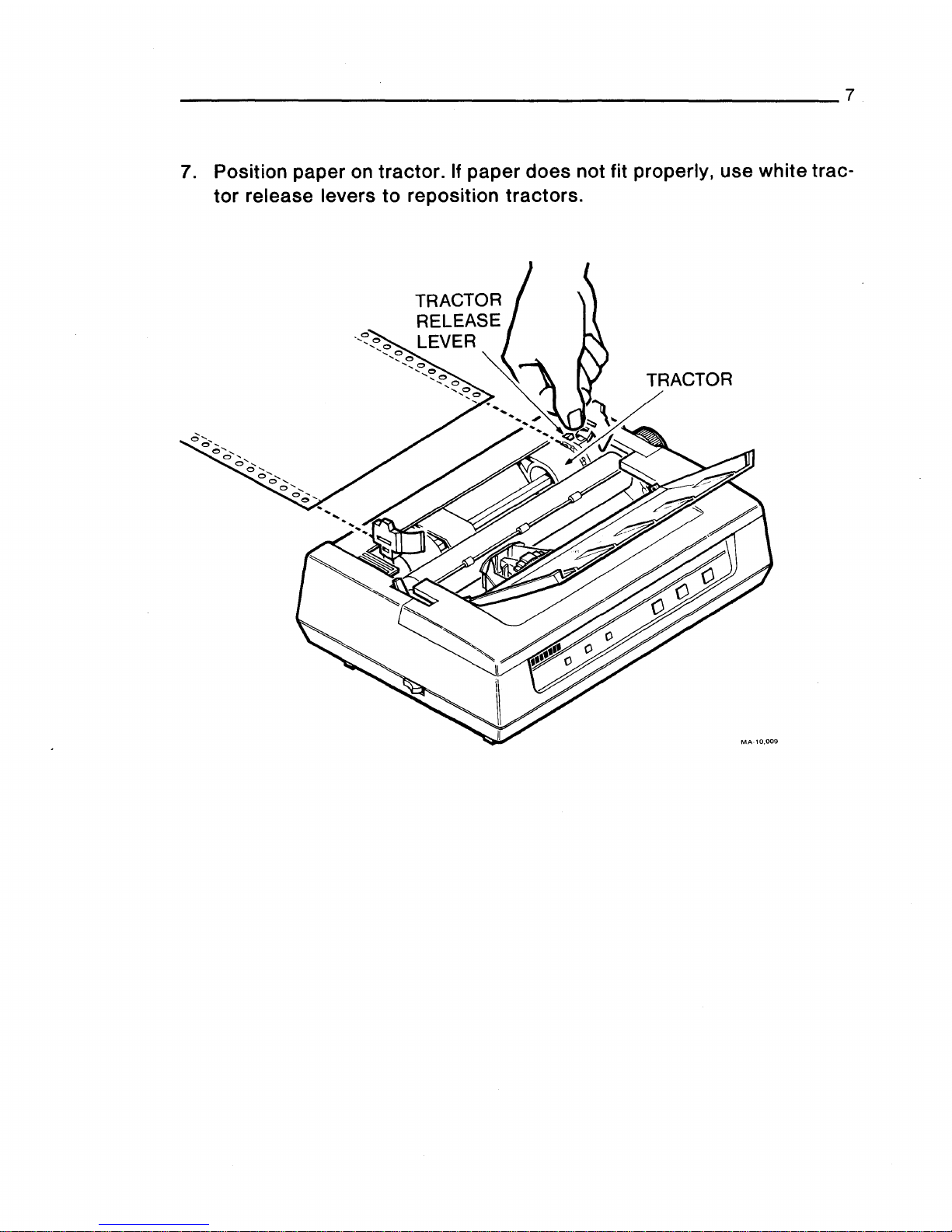

Page 13

7. Position paper on tractor.

If

paper does not fit properly, use white trac-

tor

release levers

to

reposition tractors.

Page 14

8. Close paper clamps.

9. Turn platen knob and guide

paper

behind platen.

10. Advance paper until

top

of

paper

is

behind bail bar.

BAIL BAR

PLATEN

,KNOB

I

MA·10,010

Page 15

9

11.

Push bail ba .

r

against platen.

12. Close

paper window.

13.

Replace paper cover.

Page 16

Inserting Single Sheet Paper

1.

Turn off power.

2. Open paper window.

3.

Pull bail bar away from platen.

4.

Push

paper

release lever

toward

back

of

printer.

PAPER

WINDOW

\

MA-10,012

Page 17

5. Push

paper

through slot in

paper

cover

and guide it

to

front of platen.

Align paper.

6. Pull

paper

release lever

toward

front of printer.

7. Push bail bar against platen.

8. Close

paper

window.

9. Turn platen knob

to

reposition paper.

SLOT

PLATEN

KNOB

/

Page 18

SELF-TEST PROCEDURE

NOTE: The

cover

must

be

on to run self-test.

1.

Push and hold down FORM FEED button.

2.

Turn the

power

on.

3. Release FORM FEED button.

Page 19

You should get the following printout.

ABCDEFGHI

JKLMNOPQRSTUVWXYZ

[\.J

A_'

abcdefgh

i j K 1

mnopqr·s.tuvwxyz

(:

)~·

!

"tt$X&'

<)

*+,

-

./01

BCDEFGHIJKLMNOPQRSTUVWXYZC\.JA_'abcdefghijKlmnopqrstuvwxyz{:}~

!"tt$X&'<>*+,-./012

CDEFGHI JKLMNOPQRSTUVWXYZ

[\.J

A-'

abcdefgh

i j K 1

mnopqrstuvwxyz

<:

}~·

!

"tt$X&'

( >

*+,

-

./0123

DEFGHI

JKLMNOPQRSTUVWXYZ C\.J

''-'

abcdefgh

i j K 1

mnopqrstuvwxyz

<:

}~

!

"tt$X&'

<)

*+,

-./01234

EFGHI

JKLMNOPQRSTUVWXYZ

[\.J

"_'

abcdefgh i jK 1 mnopqrstuvwxyz

(:

)~

'"

tt$X&'

< >

*+,

-

./012345

FGHI

JKLMNOPQRSTUVWXYZ

['\J

"-'

abcdefgh i jKl

mnopqrstuvwxyz

<:

)~

'"

tt$X&-·

()

*+, -./0123456

GHI

~TKLMNOPQRSTUVWXYZ

[\.J "-'abcdefgh

i

_i

K 1

mnopqrs.tuvwxyz

<:

)~

'"

tt$X&'

<)

*+,

-

./01234567

HIJKLMNOPQRSTUVWXYZC\.l"-'abcdefghijKlmnopqrstuvwxyz{:}~

!"tt$X&'()*+

1

-./012345678

I

JKLMNOPQRSTWWXYZ

['\J

"_'

abtdefgh

i j K 1

mnopqrstuvwxyz

<:

}~·

'"

#$%&·'

()

*+,

-

./0123456789

JKLMNOPQRSTUVWXYZC\.l"-'abcdefghijKlmnopqrstuvwxyz{I}~

!"#$%&'<>*+,-./0123456789:

KLMNOPQRSTUVWXYZ

[\.J

"-'

abcdef

gh

i j K 1

mnopqrstuvwxyz

<:

}~

'"

tt$X&'

<)

*+,

-

./0123456789:;

LMNOPQRSTUVWXYZC\.l"-'abcdefghijKlmnopqrstuvwxyz<:

}~

1

"#$%&'<>*+,-./0123456789:;<

MNOPQRSTWWXYZ

[\.J

"-'

abcdefgh

i j K 1

mnopqrstuvwxyz

{I}~

!

"#$%&'

()

*+, -./0123456789:;

<=

NOPQRSTUVWXYZ

[\.J "-·,

abcdefgh

i j k 1

mnopqrstuvwxyz

<:

}~

'"

#$%&'

<)

*+, -./0123456789:;

<=>

OPQRSTUVWXYZ

[\.J

"-'

abcdefgh

i j K 1

mnopqrstuvwxyz

<I)~·

!

"tt$X&'

<)

*+,

- •

/0123456789:;

<=>?

PQRSTUVWXYZ

[\.]

"-'

abcdefgh

i j K 1

mnopqrstuvwxyz

<:

}~

!

"#$X&'

<)

*+ ,-./0123456789:

; <=>?Gl

MA·l0,016

4. After a few lines print out, turn off power to stop printer.

Followup

If

printer passes self-test, continue to next instruction.

If

printer does not

pass

self-test,

or

FAULT light blinks, refer to Troubleshooting section.

Page 20

INST ALLING SYSTEM CABLE

1.

Plug system cable into

back

of printer, and

tighten

two

retaining

screws by turning them

clockwise.

2. Install other end of cable

as

described in

your

system

installation man-

ual.

~

RETAINING

SCREW

MA-10,015

3. Installation is now complete. Please fill

out

and return

the

enclosed

installation card.

A Customer Identification Number is

located

on

the

rear

of

the top

cover. If

you are capitalizing

this

equipment,

use

this

number in

your

records

as

identification of

the

printer, and

place

your

asset

tag

on

the

top

cover.

Become familiar with

the

information in

the

next

section

before you oper-

ate

the printer with

your

system.

Page 21

FRONT PANEL INDICATORS AND SWITCHES

1111111

READY D FAUL

TD

POWERD

READY

Indicator

The green READY light

indicates

the

printer's

operating state. The light is

on when

the

printer is ready

to

print,

or

is printing. If

the

light is off,

the

printer is not ready and will not start.

FAULT

Indicator

The red FAULT light blinks when the

printer

detects

an

electronic

fault.

The light

stays

on when the printer is out

of

paper.

POWER

Indicator

The green POWER light is on when you

apply

power

to

the

printer.

READY

Switch

The READY switch

controls

the

printer's

operating

state. Pressing

the

switch puts

the

printer

in

either

the

ready

or

not

ready state. Watch

the

READY light

to

determine

the

operating

state.

LINE FEED

Switch

Pressing the LINE FEED

switch

advances

the

paper

one line.

FORM FEED

Switch

Pressing the FORM FEED switch

advances

the

paper

one full sheet.

Page 22

PRINTER CONTROLS

MA-10,018

Paper Bail

The

paper

bail

holds

the

paper

against

the

platen. Red

etch

marks

on

the

bail help you position

paper

on the

platen

and

locate

the horizontal print-

ing position.

Paper Thickness Lever

The

paper

thickness

lever

adjusts

the

printhead

position

to

allow for dif-

ferent printing form thickness. Keep

the

lever

close

to

the

platen

for

nor-

mal printing

..

Move the lever away from

the

platen

for

thicker

sheets

and

multicopy forms.

Paper Release Lever

The

paper

release

lever

controls

paper

holding tension.

In

the

forward po-

sition,

paper

is held

tightly

against

the

platen.

In

the

backward

position,

the paper is free

for

positioning

or

removal.

Platen Knob

The platen knob

allows

manual

control

of

the

platen for

paper

insertion,

and for changing

the

paper's

vertical

position.

Page 23

MAINTAINING PRINTER

The printer does not need preventive maintenance. Clean

its

surfaces

and platen with a damp

cloth

only. Do not use

cleaners

with solvents or

excessive

water.

Office Area

To help maintain proper

operating

temperatures, keep the printer away

from extreme temperature,

such

as

direct

sunlight, room heaters, and air

conditioners.

Keep paper clips, coffee,

matches,

cold drinks, and

other

small objects

and liquids away from

the

printer.

Paper

Select

the right paper for

the

job. Always make sure

to

position

paper

squarely and

set

it

tightly

around the platen. Also make sure

the

paper

thickness

lever is in

correct

position. To remove

paper

from

the

printer,

use the form feed switch,

or

turn

the

platen knob.

Printhead and Ribbon Cartridge

Keep samples of early

printouts

to

help you know when

to

replace

the

printhead and ribbon cartridge. Use only DIGITAL-approved ribbon car-

tridges

in

the printer.

Other

cartridges

may not give

the

same perform-

ance and may damage

your

printer. Store

printheads

and ribbon car-

tridges

in

their

containers, in

the

same environment as

the

printer. (Refer

to

specifications

at the

back

of

this

document.)

Page 24

TROUBLESHOOTING THE PRINTER

Operator

Checklist

Try

to

correct

the trouble

as

listed

below.

CAUTION:

Always

turn

off

the

printer

before

you

attempt

to

correct

a

problem.

If you

cannot

correct

the

trouble:

Turn off the

printer

and

contact

your

dealer

or

the

nearest

DIGITAL

service

technician.

Trouble

Printer does not

start when power

is

turned

on.

No printout. FAULT

light is

on.

Pressing

the READY button

causes printer

to

print one line.

Probable

Cause

Power cord not

connected,

or

broken

Power source

fault

Fuse open

Printer

out

of

paper

No printout. Access cover open

FAULT light is

on.

READY light is out

and pressing the READY

button does not start

printer.

Corrective

Action

Check power cord

connections;

check

power

cord

for

damage.

Check power

at

power

receptacle.

Make sure fuse is in

place. Replace fuse if

blown. Refer

to

Fuse

Replacement.

Reload paper and press

the READY button.

Close cover and press

the READY button.

Page 25

Trouble

Probable Cause

Corrective Action

Light print. Paper thickness

Reset paper thickness

lever set incorrectly

lever

to

a position

closer

to

the

platen.

Ribbon worn

Replace ribbon cartridge.

Carriage moves, but Paper thickness Reset paper thickness

no printout

lever set

incorrectly

lever to a position

closer

to

the platen.

Printhead fault

Replace

the

printhead.

Refer

to

Printhead

Replacement.

Missing dots

in

print; Printhead fault Replace

the

printhead.

always in same row. Refer

to

Printhead

Replacement.

Paper jams. Paper path

obstructed

Clear paper path.

Paper thickness

lever Reset paper thickness

set

incorrectly

lever

to a position away

from

the

platen.

Pinfeed

paper

jams.

Tractors positioned

Release and reposition

incorrectly

for

paper

the

tractors. Avoid

width

pulling

or

compressing

paper.

Page 26

20

Replacing Printhead

1.

Turn off

power.

2. Remove

access

cover.

3. Remove

"bb

n on

cartridge.

Page 27

21

4

·

Push

pr"

mthead ret .

amer

clips away from head.

MA·10,021

5.

Page 28

6.

Plug

in

replacement head.

Make

sure it is fully seated.

7.

Return printhead retainer

clips

to

their

original positions.

Page 29

23

8. Replace

"b

n bon

cart

"d

n ge.

9.

Replace

acces

s cover.

Page 30

Replacing

Fuse

1.

Turn off power.

MA-10,005

2. Unplug

power

cord from

power

outlet.

Page 31

3. Turn fuse retainer

counterclockwise.

FUSE RETAINER

MA-10,026

4.

Remove retainer.

5. Replace fuse with one of equal value.

Page 32

PRINTER CONFIGURATION

Configuration Switches

The configuration

switches

are

set

for printer

use

with DIGITAL

systems

in

the United States. (The illustration

shows

factory

settings.)

The

switches

are under the

access

cover.

CAUTION: Turn

off

power

before

you

reset

the

switches.

N3d0

8L9St>£<:~

N3d0

NOTE

SW2-7, SW2-8 NOT USED

MA-10,027

Page 33

You can change

the

switch

positions

by sliding

the

switch tabs with a ball

point pen

or

equivalent. Never

use

a lead pencil.

MA-10,028

Page 34

The following tables show the switch positions for various system configurations.

National Character

Set

Switches SW1-1 through SW1-4

Switch SW

1-1

through SW 1-4 change

the

characters

for multinational ap-

plications.

Switch Positions

Nation

SW1-1 SW1-2

United

States

Open Open

Britain

Closed Open

Finland Open Closed

France Closed Closed

French Canada Open Open

Germany Closed Open

Italy Open Closed

Japan

Closed Closed

Norway I Denmark Open Open

Spain Closed Open

Sweden Open Closed

CHARACTER

SET

SWITCHES

SW1-1

THROUGH SW1-4

N3d0

8 L 9 S v £ G

~

N3d0

SW1-3

Open

Open

Open

Open

Closed

Closed

Closed

Closed

Open

Open

Open

MA·10,029

SW1-4

Open

(factory

setting)

Open

Open

Open

Open

Open

Open

Open

Closed

Closed

Closed

Page 35

Graphics

Aspect

Ratio

Switch

SW1-5

Switch SW 1-5

changes

the

horizontal

to

vertical

dot

ratio in graphic mode

by changing

the

number of horizontat

dots

per

inch. The number of

vertical

dots

are kept

constant

at

72

dots

per

inch.

Horizontal

Ratio

Dots/Inch

Switch

Position

2

to

1

2.5

to

1

144

Open

(factory

setting)

180

Closed

PROTOCOL SWITCHES

SW1-6,

SW1-7 GRAPHICS

SWITCH

\

/sw1-s

s'T"9'9

17

£ G

~

N3d0

8 L 9 9

17

£ G

~

N3d0

MA-10,030

XON/XOFF and

Ready/Busy

Protocol

Switches

SW1-6

and

SW1-7

DIGITAL systems use XON I XOFF

protocol.

Other

systems

may require

Ready

/Busy

protocol. Switch SW 1-6

selects

the

protocol.

Switch SW 1-7

selects

the ready and busy signal levels.

Protocol

SW 1-6

Position

XON I XOFF Open

(factory

setting)

Ready I Busy Closed

Signal Level SW 1-7

Position

Busy = High Open

(factory

setting)

Ready=

Low

Busy = Low Closed

Ready=

High

Page 36

Right Margin Switch SW1-8

Switch SW 1-8

selects

the method

of

controlling a line of

characters

that

exceed

the eight inch line of print. If

set

to

truncate,

the

printer

prints

only

the first eight inches of

characters

and

drops

the

remaining

characters.

If

set

to

wrap, the printer prints

the

remaining

characters

on

the

next

line.

Selection

Truncate

Wrap

SW1-8 Switch Position

Open

(factory

setting)

Closed

RIGHT MARGIN

SWITCH

SW1-8

\

8 L 9 S v 8 Z

~

OPEN~~~~~~~~~

N3d0

8 L 9 S v 8 Z

~

N3d0~

BAUD

RATE

SWITCHES

SW2-1

THROUGH SW2-3

MA-10,031

Baud Rate Select Switches SW2-1, SW2-2, SW2-3

These

switches

select

the

speed

(bits

per

second)

at

which

the

printer

communicates with

the

computer.

Switch Positions

Baud Rate SW2-1

SW2-2 SW2-3

4800

Open Open Open

(factory

setting)

2400

Open

Closed Open

1200

Open

Closed Closed

600

Closed Open Open

300

Closed Open

Closed

200

Closed

Closed Open

110

Closed Closed Closed

Page 37

Data Format Switches SW2·4, SW2-5, SW2·6

These

switches

select

the

data

format

to

enable communication with the

computer.

9 L 9 S v £ l

~

N3d0

9 L 9 S v £ l

~

N3d0

DATA FORMAT SWITCHES

SW2-4 THROUGH SW2-6

MA-10,032

Switch Position

Data Format

SW2·4

SW2·5

7 bits plus odd

parity

Open Closed

7 bits plus even

parity

Closed Closed

7 bits plus 8th bit mark Open Open

7 bits plus 8th bit

space

Closed Open

8 bits plus odd parity

Open Closed

8 bits plus even

parity

Closed Closed

8 bits, no

parity

Open Open

SW2·6

Closed

Closed

Closed

Closed

Open

Open

Open

(factory

setting)

Page 38

SPECIFICATIONS

Weight

Dimensions

Width

Depth

Height

Environment

Temperature

Relative Humidity

Power requirements

Power consumption

Data interface

Ribbon

Paper

Type

Dimensions

Thickness

Print method

Print density

8.S Kg (18.7 lb)

400

mm

(16 in)

29S mm (11.8 in)

142 mm (S.6 in)

10° C

to

40°

C

so° F to

104° F

10%

to

90%

LASO-RA 100

or

120 Vac,

SO

or

60

Hz

LASO-RB

220

or

240

Vac,

SO

or

60

Hz

Less

than 180 W

Serial RS232-C and RS423 EIA

standard

Disposable

cartridge

Two million

characters

life

expectancy

(average

use)

Single

sheet

or

sprocket

Single sheets: 3

to 9 inches

wide

Sprocket

paper: 4.S

to

10

inches

wide

Sprocket

holes: 4

to

9.S

inches

on

center

O.SO

+I - 0.01 inch

spacing

0.011 inches maximum

Incremental with

bidirectional

lookahead

7 by 9

matrix

(normal)

13 by 9 matrix

(enhanced)

Page 39

Print speed

Character features

Graphic mode

Characters

Character pitch

Compressed font

Double width

Elite pitch

Double width

Pica pitch

Double width

Line spacing

Line feed speed

100 CPS (7 by 9 matrix printing)

44

LPM

(80

characters per line)

Enhanced density

Bold

Underlined

Doublewidth

144

or 180

dots

I inch horizontal

72

dots

I inch vertical

2:

1 or 2.5: 1

aspect

ratio

94

ASCII

81

Multinational

63 JIS Katakana

27

VT

100 Special Graphics

1 error

indicator

16.5 CPI, 132 characters I line

8.25 CPI, 66

characters

I line

12

CPI,

96

characters

I line

6 CPI,

48

characters

I line

10

CPI,

80

characters

I line

5 CPI,

40

characters/line

12, 8, 6, 4, 3 or 2 lines I inch

Partial line up and down,

1I12

inch

100 ms I line

at

6 lines I inch

Page 40

FIELD SERVICE INFORMATION

DIGIT AL SERVICES

DIGIT AL

provides a wide

range

of

maintenance

programs

that

cover

small

systems

and

terminals.

These

include

on-site,

carry-in,

and

mail-in main-

tenance

services.

You

can

use

these

programs

to

select a plan

that

meets

your

service

needs,

from

complete

DIGITAL

support,

to

self-mainte-

nance.

ON-SITE SERVICE

DIGIT AL offers fast,

low

cost,

quality

maintenance

performed

at

your

site

by DIGITAL-trained

Service

Specialists.

Whether

you

take

advantage

of

our

DECservice

or

Basic

Service

Agreements,

or

choose

our

Time

and

Materials

service,

you

can

be

sure

that

your

small

system

or

terminal

is

getting

the

best

possible

maintenance.

CARRY-IN SERVICE

There

are

several

hundred

DIGIT AL

service

centers

in

major

cities

world-

wide,

which

offer

convenient,

fast,

and

dependable

''return-to"

mainte-

nance,

at a savings

over

on-site

service.

DECMAILER

If

you

are

capable

of

self-maintenance,

you

should

use

our

fast

turnaround

module

and

sub-assembly

repair

service

- DECmailer.

For

more information on

any

of.DIGITAL's

Maintenance

Services,

call

the

DIGIT AL

Field

Service

information

number

in

your

area

during

normal

busi-

ness

hours

United

States

(800)

554-3333

Canada

(800)

267-5251

United Kingdom

(0256)

57122

Belgium

(02)

242-6790

West

Germany

(089)

95

91

66

44

Italy

(02)

617-5381

/2

Japan

(03)

989-

7161

Page 41

Printed

in Japan

E1-1668

830210000@

Page 42

Digital

Equipment

Corporation

• Maynard,

MA

01754

Loading...

Loading...