Page 1

Service Manual

Order Numb er: ER-LA400-SV

1

Page 2

Maintenance Manual Revision Record

_______________________________________________________________________________________

REVISION RECORD

Edition Date published Page Revised contents

001 June 1996 All First issue

Specification No. ER-LA400-SV

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright

1996 Digital Equipment Corporation. Printed in Ireland.

No part of this manual may be reproduced in any form without permission.

Address your comments and inquiries on this manual to:

____________________________________________________________________________________________

LA400 Multiprinter r. 1 ER-LA400-SV

Page 3

Maintenance Manual Contents

____________________________________________________________________________________________

Table of Contents

CHAPTER 1 GENERAL OVERVIEW

1.1 Introduction 1.2

1.1.1 Scope of the Products 1.2

1.1.2 Printers Features Summary 1.2

1.2 General Description 1.3

1.2.1 Physical Overview 1.3

1.2.2 Physical Dimension 1.5

1.2.3 Printer Structure 1.5

1.2.3.1 Mechanical Assy 1.6

1.2.3.1.1 Tractor Unit Assy 1.6

1.2.3.2 Print Head 1.6

1.2.3.3 Cabinet 1.6

1.2.3.4 Electronic Hardware 1.7

1.2.3.5 Inked Ribbon Cartridge 1.7

1.2.3.6 Mechanical Options 1.7

1.3 Printer Technical Specifications 1.8

CHAPTER 2 PAPER HANDLING OVERVIEW

2.1 Introduction 2.2

2.1.1 Paper Handling Architecture 2.2

2.1.2 Paper Path Configurations 2.5

2.1.2.1 Basic Configuration 2.5

2.1.2.2 Dual Fanfold Configurations 2.8

2.1.2.3 ASF Configuration 2.9

____________________________________________________________________________________________

LA400 Multiprinter i. 1 ER-LA400-SV

Page 4

Maintenance Manual Contents

____________________________________________________________________________________________

Table of Contents cont'd

CHAPTER 3 ELECTRONIC HARDWARE OVERVIEW

3.1 Hardware General Overview 3.2

3.1.1 Electronic Architecture 3.3

3.1.2 Controller Overview 3.4

3.1.2.1 V55PI µProcessor 3.4

3.1.2.1.1 V55PI Internal Block Architecture 3.5

3.1.2.1.2 V55PI Block Features 3.6

3.1.2.2 ASIC 3.8

3.1.2.3 Memories 3.9

3.1.2.4 Operator Panel 3.9

3.1.2.5 Serial Interface Board 3.9

3.1.2.6 Expansion Bus 3.10

3.1.3 Mechanical Drivers 3.10

3.1.3.1 DOE Block Features 3.11

3.1.4 Power Supply Board 3.18

3.1.5 Controller SW Overview 3.20

CHAPTER 4 REMOVAL AND REPLACEMENT

4.1 Overview 4.2

4.2 Recommended Hand Tools and Equipment 4.2

4.3 ORU Order of Access 4.3

4.3.1 Front Push-Pull Tractor Group 4.4

4.3.2 Operator Panel Boards 4.5

4.3.3 Print Head 4.6

4.3.4 Front Cover Parts 4.7

4.3.5 Rear Cover Parts 4.8

4.3.6 Serial I/F Board 4.9

4.3.7 Main Board 4.10

4.3.8 Power Supply Board 4.11

4.3.9 Ribbon Motor 4.12

4.3.10 AGA Motor 4.13

4.3.11 AGA Support and T/F Lever 4.14

4.3.12 Carriage Motor 4.15

4.3.13 Bail Assy 4.16

4.3.14 Cut Sheet Assy 4.17

4.3.15 Upper Feeder Assy 4.18

4.3.16 Platen Assy 4.19

4.3.17 Lower Feeder Assy 4.20

4.3.18 Carriage Assy 4.22

4.3.19 Sensor Assy 4.23

4.3.20 Mechanical Assy 4.24

4.3.21 Paper Motor 4.25

4.3.22 Friction Bar Assy 4.26

____________________________________________________________________________________________

LA400 Multiprinter i. 2 ER-LA400-SV

Page 5

Maintenance Manual Contents

____________________________________________________________________________________________

Table of Contents cont'd

CHAPTER 5 ADJUSTMENTS

5.1 Overview 5.2

5.1.1 Carriage Belt 5.2

5.1.2 Paper Belt 5.3

5.1.3 Print Head Gap 5.4

CHAPTER 6 SERVICE MAINTENANCE

6.1 Overview 6.2

6.2 Initial Ispection 6.2

6.2.1 Set-Up 6.2

6.2.2 Cleaning 6.3

6.2.3 Paper Specifications 6.3

6.2.4 Consumables 6.3

6.3 Troubleshooting Guide 6.4

6.3.1 Initializing Phase 6.4

6.3.2 Printer Errors 6.4

6.3.2.1 Status Errors 6.5

6.3.2.2 Recoverable Errors 6.5

6.3.2.3 Not Recoverable Errors 6.6

6.3.3 Power Malfunctions 6.8

6.3.3.1 P.S. Troubleshooting Guide 6.8

6.3.4 Self-Test 6.10

6.3.5 Hex-Dump 6.11

6.3.6 Faulty Probability Guide 6.12

6.4 Service Tests and Adjustments 6.16

6.4.1 Introduction 6.16

6.4.2 Loop-back Coonectors 6.16

6.4.3 Execution of the Service Adjustments 6.17

6.4.4 Execution of the Service Tests 6.19

____________________________________________________________________________________________

LA400 Multiprinter i. 3 ER-LA400-SV

Page 6

Maintenance Manual Contents

____________________________________________________________________________________________

Table of Contents cont'd

CHAPTER 7 ELECTROMECHANICAL DEVICES

7.1 Overview 7.2

7.1.1 Print Head 7.2

7.1.2 Motors 7.4

7.1.2.1 Carriage Motor 7.4

7.1.2.2 Paper Motor 7.5

7.1.2.3 AGA Motor 7.6

7.1.2.4 Ribbon Motor 7.7

7.1.2.5 Alternance Motor 7.8

7.1.2.6 ASF Motor 7.9

7.1.2.7 Color Motor 7.9

7.1.2.8 Stacker Motor 7.11

7.1.3 Cables 7.12

7.1.3.1 Sensors Cable 7.12

7.1.3.2 Alternance Cable 7.13

7.1.3.3 Paper Stacker Cable 7.13

7.1.3.4 Operator Panel Cable 7.14

CHAPTER 8 OPTIONS

8.1 Overview 8.2

8.1.1 Automatic Sheet Feeder 8.2

8.1.2 Color Motor 8.6

CHAPTER 9 HW SETTING & FW INSTALLATION

9.1 Overview 9.2

9.1.1 Hardware Setting 9.2

9.1.2 Firmware Installation 9.2

____________________________________________________________________________________________

LA400 Multiprinter i. 4 ER-LA400-SV

Page 7

Maintenance Manual Contents

____________________________________________________________________________________________

Figures

1.1 Basic Printer Parts Location (front view) 1.3

1.2 Basic Printer Parts Location (rear view) 1.4

1.3 Printer Internal Architecture 1.5

2.1 Paper Handling Architecture 2.4

2.2 Front Load Push-Mode 2.6

2.3 Rear Load Push-Mode 2.6

2.4 Rear (bottom) Load Pull-Mode 2.7

2.5 Front Load Push-mode and Rear Front Push-mode

with two tractors 2.7

2.6 Front Load Push-Pull with two tractors 2.8

2.7 Automatic Sheet Feeder 2.9

3.1 Electronics Structure 3.2

3.2 Electronics Architecture 3.3

3.3 Microprocessor Internal Block Diagram 3.5

3.4 DOE Blocks Diagram 3.10

3.5 Reset and Prefault Circuit 3.11

3.6 Reset and Prefault Waveforms 3.12

3.7 Color & Paper Stacker Motors Driving Circuit 3.12

3.8 Carriage and Paper Motors Driving Circuits 3.13

3.9 Ribbon and AGA Motors Driving Circuits 3.14

3.10 Color and Alternance Motors Driving Circuits 3.14

3.11 ASF Motor Driving Circuit 3.15

3.12 Sensors Driving Circuits 3.15

3.13a/b Print Head Behaviour 3.16

3.14 Print Head Needle Drivig Circuit 3.16

3.15 Print Head Needle Current Waveforms 3.17

3.16 Power Supply Major Block Diagram 3.19

3.17 Software Architecture 3.21

4.1 Front Push Tractor Group 4.4

4.2 Operator Panel Boards 4.5

4.3 Print Head 4.6

4.4 Front Cover Parts 4.7

4.5 Rear Cover Parts 4.8

4.6 Serial Interface Board 4.9

4.7 Main Board 4.10

4.8 Power Supply Board 4.11

4.9 Ribbon Motor 4.12

4.10 AGA Motor 4.13

4.11 AGA Support and T/F Lever 4.14

4.12 Carriage Motor 4.15

4.13 Bail Assy 4.16

4.14 Cut Sheet Assy 4.17

4.15 Upper Feeder Assy 4.18

4.16 Platen Assy 4.19

4.17 Lower Feeder Assy 4.21

4.18 Carriage Assy 4.22

4.19 Sensor Assy 4.23

4.20 Mechanical Assy 4.24

4.21 Paper Motor 4.25

4.22 Friction Bar Assy 4.26

____________________________________________________________________________________________

LA400 Multiprinter i. 5 ER-LA400-SV

Page 8

Maintenance Manual Contents

____________________________________________________________________________________________

Figures cont'd

5.1 Carriage Assy Belt Adjustment 5.2

5.2 Paper Belt Adjustment 5.3

5.3 Print Head Adjustment 5.5

6.1 Power Supply Test Points 6.9

6.2 Self-Test Printout 6.10

6.3 Hex-Dump Printout 6.11

6.4 Serial Interface Loop-back Diagram 6.16

6.5 Parallel Interface Loop-back Diagram 6.16

6.6 Service Test Fanfold Printout 6.21

7.1 Print Head pinout 7.3

7.2 Carriage motor pin connector assignment 7.4

7.3 Paper Motor pin connector assignment 7.5

7.4 AGA Motor pin connector assignment 7.6

7.5 Ribbon Motor pin connector assignment 7.7

7.6 Color Motor pin connector assignment 7.10

7.7 Stacker Motor pin connector assignment 7.11

7.8 Sensors Cable 7.12

7.9 Alternance Cable 7.13

7.10 Paper Stacker Cable 7.13

7.11 Operator Panel Cable 7.14

8.1 1st ASF Components 8.2

8.2 ASF and Stacker Blocks Diagram 8.3

8.3 ASF Installation (rear view) 8.4

8.4 Second Bin ASF Installation 8.5

8.5 Color Motor Installation 8.6

8.6 Color Ribbon Installation 8.7

Tables

2.1 Printer Path Configurations 2.4

4.1 ORU Order of Access 4.3

6.1 Unrecoverable Error Display Messages 6.7

7.1 Print Head Resistance/Temperature Characteristics 7.2

7.2 Print Head Pin assignment 7.3

____________________________________________________________________________________________

LA400 Multiprinter i. 6 ER-LA400-SV

Page 9

Maintenance Manual General Overview

_______________________________________________________________________________________

Chapter 1

General Overview

____________________________________________________________________________________________

LA400 Multiprinter 1. 1 ER-LA400-SV

Page 10

Maintenance Manual General Overview

_______________________________________________________________________________________

1.1 Introduction

This Manual describes the features and the maintenance procedures for the new Digital

LA400 Multiprinter and its options.

1.1.1 Scope of the Products

This printer is an advanced impact printer which give real and effi cient solutions to the

actual and future printer needs.

It is designed to be extremely flexible in paper handling and capable to manage different

paper types and formats, able to print on thick and multipart forms, specialized on dual

fanfold management in non-attended mode.

In the same time, these printers are intended to support EDP, Office and "Administrative"

environments applications requiring very high throughput, high level print quality and

graphic capabilities, either in black or in colors, in order to print listing, invoicing & billing,

spread sheets, diagrams, business or technical graphics and machine readable texts.

This printer enters the top segment of the SIDM pinter market and can be a valide and

convenient alternative to the low end line-printers.

1.1.2 Printers Features Summary

• 24 wire print head.

• Draft print at 400 cps and LQ print at 133 cps

• High resolution Graphics Printing at 360x360 dpi

• DEC ANSI Conformance Level 2, IBM Proprinter XL24E and Epson

LQ2550/LQ1170 (ESC P2) resident emulations

• Paper path switching selected by operator panel or SW commands.

• Easy print function selection and printer configuration via the operator panel or with

SW commands.

• Centronics Compatible Bidirectional (IEEE-1284) parallel interface

and Moduar 6-pin DECconnect type serial interface.

• Font styles in multiple international character sets.

• Optional second tractor assembly for dual fanfold operation.

• Optional Automatic Sheet Feeder that handles cut sheets, multicopies & envelopes.

• Optional color motor for color feature printing.

____________________________________________________________________________________________

LA400 Multiprinter 1. 2 ER-LA400-SV

Page 11

Maintenance Manual General Overview

_______________________________________________________________________________________

1.2 General Description

1.2.1 Physical Overview

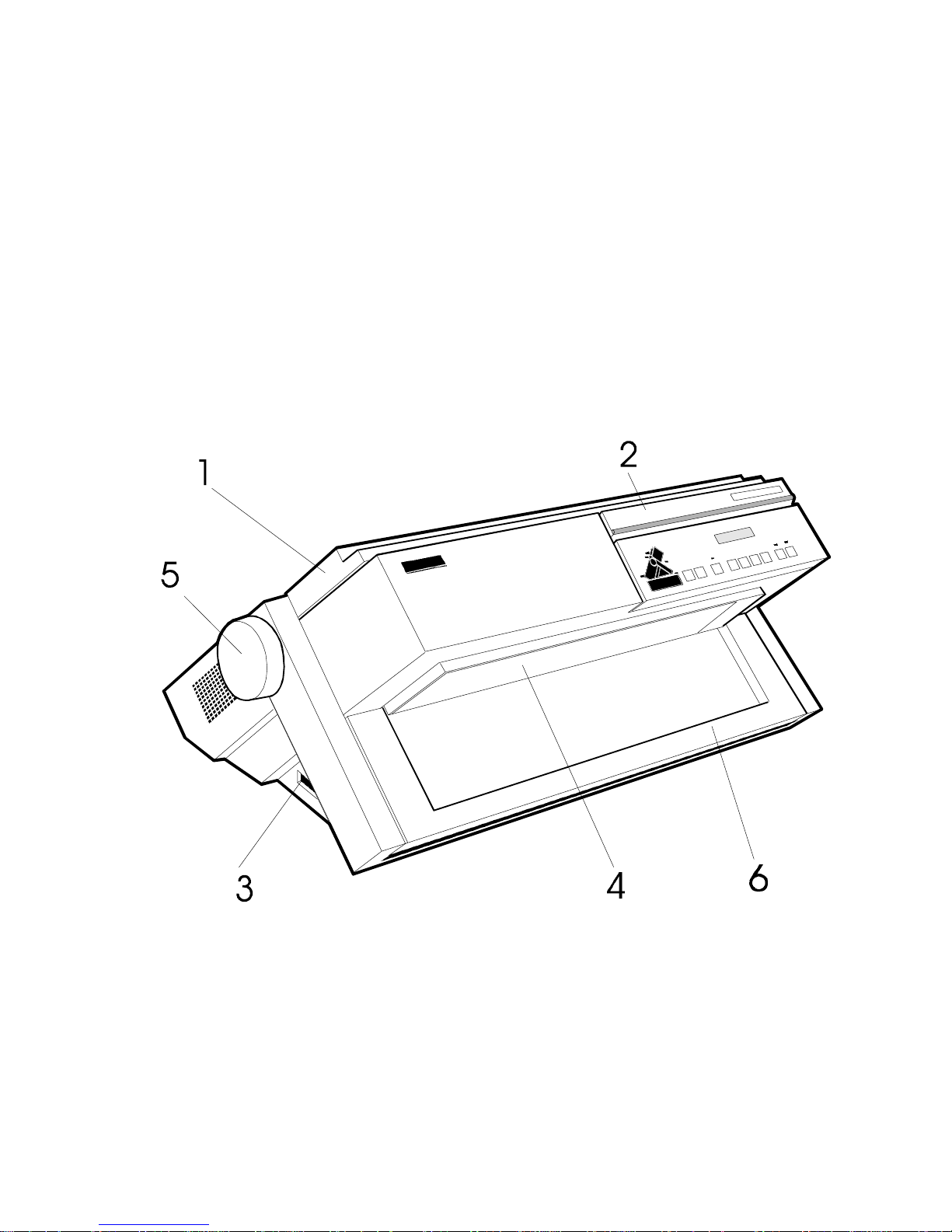

A sketch of the resulting appearance is reported on figures 1.1 and 1.2.

1. Top Cover 4. Single Sheet Support

2. Operator Panel 5. Paper Knob

3. Power Switch 6. Front Tractor Unit Cover

Fig. 1.1 Basic Printer Parts Location (front view)

____________________________________________________________________________________________

LA400 Multiprinter 1. 3 ER-LA400-SV

Page 12

Maintenance Manual General Overview

_______________________________________________________________________________________

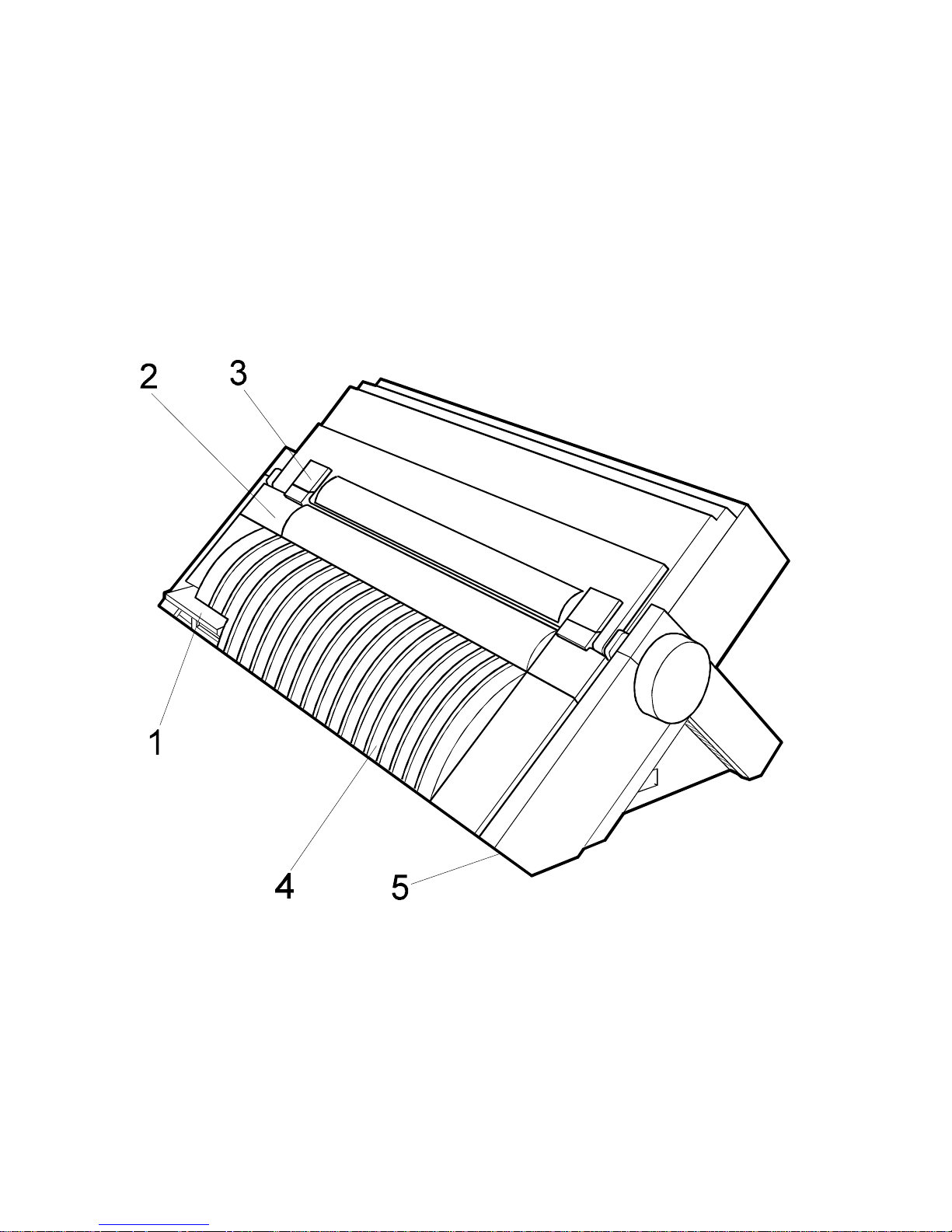

1. Interface Cover 4. ASF Location Cover

2. Rear Tractor Unit Cover 5. AC Power Inlet

3. Paper Stacker Covers

Fig. 1.2 Basic Printer Parts Location (rear view)

____________________________________________________________________________________________

LA400 Multiprinter 1. 4 ER-LA400-SV

Page 13

Maintenance Manual General Overview

_______________________________________________________________________________________

1.2.2 Physical Dimension

Basic printer without options

Dimensions

- HEIGHT 12.1" (310 mm)

- WIDTH 26.2" (665 mm)

- DEPTH 13.3" (390 mm)

- WEIGHT (unpacked) 38 lbs (18 Kg)

1.2.3 Printer Structure

The printer can be described as the complex of the following parts.

In the next figure it is possible to see the internal printer architecture and where the

major blocks described below are located.

•• MECHANICAL ASSY

•• PRINT HEAD

•• CABINET

•• ELECTRONIC HARDWARE

•• INKED RIBBON

Fig. 1.3 Printer Internal Architecture

____________________________________________________________________________________________

LA400 Multiprinter 1. 5 ER-LA400-SV

Page 14

Maintenance Manual General Overview

_______________________________________________________________________________________

1.2.3.1 Mechanical Assy

This block is composed of a rubber platen roller with a carriage carrying a print head with

24 needles in front of the platen.

This movement is obtained via a step-motor (providing 1/120" movement per step) and a

minipitch belt.

The movement of the rubber drum for paper traslation is obtained via a specific step

motor providing a minimum movement of 1/180" and a couple of minipitch belts.

The motion of the ribbon cartridge is obtained through a specific step-motor

indipendently from the actual carriage speed, movement, direction and width.

In this way in front of the print head there is a continuously renewing well inked ribbon.

The ribbon speed is optimized to reduce conflicts with ribbon and graphic printout

appearance when ribbon and print head are moving in the same direction.

The color ribbon and the extended life black cartridges are moved up and down through

a linear actuator (step motor) with a plastic coupler that transmits the axial movement to

the plastic print head mask installed on the color ribbon cartridge.

Another step motors is used for the A.G.A. (automatic gap adjustment) of the print head

movement to have the best perfomance on the paper in use.

1.2.3.1.1 Tractor Unit Assy

A removable push tractor unit is installed on the printer.

Inside of it, a DC motor switches to engage/disengage the gear to allow the fanfold or

the single sheet to be fed.

The tractor unit can be installed in two different positions depending on the type of

fanfold management (front - rear - both).

In the next chapter all the paper handling possibilities of this mechanism are detailed.

1.2.3.2 Print Head

The core of the printer is the print head, which is an electromagnetic non- ballistic type

with a life of 400 MChrs.

See chapter 3.1.3.1 and 7.1.1 for major hardware and mechanical details.

1.2.3.3 Cabinet

The cabinet allows safety-proof lifting of frontal part for ribbon substitution and paper

path check.

It is composed of various parts to allow an easy access to all the printer internal parts.

____________________________________________________________________________________________

LA400 Multiprinter 1. 6 ER-LA400-SV

Page 15

Maintenance Manual General Overview

_______________________________________________________________________________________

1.2.3.4 Electronic Hardware

See chapter 3 for major details.

This section is composed of the following boards:

MAIN BOARD located in the bottom right side of the printer which controls the motors

movement, the various input sensors, the parallel interface and the print head needles.

It also provides the management of the asynchronous host serial interface, external

synchronous serial interface for mechanical options and fonts cartridge.

POWER SUPPLY BOARD located in the bottom left side of the printer which provides

specific voltages for logical area, printhead needles and drive motors.

There are two power supply boards: 120 and 220/240 Vac respectively.

OPERATOR PANEL BOARD placed on the front side of the printer driving 9 push

buttons and 8 leds (3 for printer status and 5 for paper path selection).

This board also drives a 16 Digit LCD Alphanumeric display to easily interact with

parameters setting for menu operation.

SERIAL INTERFACE board located on the rear right side and plugged to the main board

which drives the proper drivers for serial interface.

1.2.3.5 Inked Ribbon Cartridge

The ribbon cartridge is installed in different ways according to the ribbon types.

In case of the black ribbon, the cartridge is fixed on both sides on four points.

Its position is obliquous to the print line to automatically show the complete height of the

ribbon in front of print head while printing on the full print line.

The inked ribbon inside of these cartridges is a continuous loop.

In case a color ribbon is installed, the cartridge is fixed on both sides only on the two rear

points, so that is is free to move its frontal part upward and downward.

Its installation is parallel to the print line to assure the correct color band selection.

A specific step motor is used to move the ribbon band up and down for color selection.

1.2.3.6 Mechanical Options

This printer can provide some mechanical options :

AUTOMATIC SHEET FEEDER (up to 3 bins).

Each bin has a DC motor inside it to automatically load the single sheet paper.

Internally on the bin a series of gears takes the movement of the motor to the rubber

roller shaft.

Together with the first bin a PAPER STACKER is provided to collect the output printed

paper.

Also this part has an internal step motor to select the path where the paper should be

output.

See chapter 9 for more details.

____________________________________________________________________________________________

LA400 Multiprinter 1. 7 ER-LA400-SV

Page 16

Maintenance Manual General Overview

_______________________________________________________________________________________

1.3 Printers Technical Specifications

The following features refer mainly to intrinsic characteristics and can change without notice.

•• PRINT HEAD

N. of Needles 24

Life (MChrs draft) 400

H. Pitch 1/120"

V. Pitch 1/180"

Needle Diameter 0.2 mm (0.0078")

•• PRINT SPEED

CPI= characters per inch

DPI= dots per inch

CPS= characters per second

DPS= dots per second

CPI DPI CPS DPS

Draft mode: 10 60 400

12 60 480

15 60 600

17 120 343

20 120 400

24 120 400

Letter Quality mode: 10 180 133

12 180 160

15 180 200

17 180 229

20 180 267

24 180 320

Dot Graphic Mode: - 60 - 2100

- 80 - 1660

- 90 - 1245

- 120 - 2100

- 180 - 2100

- 240 - 2100

- 360 - 2100

•• THROUGHPUT PPH ECMA 132

PPH= pages per hour

PPH Fanfold ASF

Letter Draft: 402 330

Letter Quality: 208 150

Graphic: 75 95

Spread 17: 226 170

Spead 10: 246 -

____________________________________________________________________________________________

LA400 Multiprinter 1. 8 ER-LA400-SV

Page 17

Maintenance Manual General Overview

_______________________________________________________________________________________

•• CHARACTER PITCH

Basic: 10, 12, 15

Compressed: 16.7, 17.14, 20, 24

Double-Wide: 5, 6, 7.5, 8.33, 8.5

Other: Proportional

Intercharacter spacing n/120

n/180

n/360

n/720

•• CHARACTER FORMATION

DPC= dots per character

H S H Res (V)

Draft (text 10 cpi): 9 3 1/120" (24)

Draft (text 12 cpi): 7 3 1/120" (24)

Draft (text 15 cpi): 7 1 1/120" (16)

Draft (graphic char): 12 0 1/120" (30)

LQ (text 10 cpi): 31 5 1/360" (24)

LQ (text 12 cpi): 27 3 1/360" (24)

LQ (text 15 cpi): 21 3 1/360" (24)

LQ (proportional): 42 0 1/360" (24)

LQ (graphic char): 36 0 1/360" (30)

•• VERTICAL SPACING

LPI= lines per inch

Basic: 2, 3, 4, 6, 8, 12

Incremental n/60

n/72

n/180

n/216

n/360

•• BIT IMAGE (DOT GRAPHICS)

Horizontal: 60, 80, 90, 120,

180, 240, 360

Vertical: 60, 72, 144, 180

____________________________________________________________________________________________

LA400 Multiprinter 1. 9 ER-LA400-SV

Page 18

Maintenance Manual General Overview

_______________________________________________________________________________________

•• MEDIA HANDLING

BACKWARD PAPER MOVEMENT

The reverse paper movement is always allowed except:

- When NO TEAR option is selected in Set-up.

- When PULL TRACTOR option is installed and PULL ONLY mode is selected.

•• MEDIA CHARACTERISTIC

The basic printers can manage a manual single sheet front insertion and up to

3 fanfold modules formats in 4 different paths.

SINGLE SHEET

Front insertion and straight path

The printer can accept these formats:

• A5, A4, A3, portrait and landscape

• A2 portrait

• LETTER, LEGAL and EXECUTIVE

WIDTH minimum 114.3mm 4.5"

maximum 444.5 mm 17.5"

LENGTH minimum 101.6 mm 4"

maximum 558.8 mm 22"

THICKNESS maximum 0.635 mm 0.025"

COPIES 1 + 5 (1 + 7 with High Impact Draft selected)

WEIGHT (original) minimum 50 gr/M² 12.5 lbs

maximum 120 gr/M² 30.0 lbs

WEIGHT (Multicopy)

first sheet minimum 55 gr/M²

maximum 75 gr/M² 18.75 lbs

other minimum 45 gr/M² 11.25 lbs

maximum 75 gr/M² 18.75 lbs

carbon minimum 14 gr/M² 3.5 lbs

maximum 35 gr/M² 8.75 lbs

FRONT PUSH FANFOLD

Frontal push fanfold feeding and straigh path

WIDTH minimum 76.2 mm 3.0"

maximum 431.8 mm 17.0"

LENGTH minimum 76.2 mm 3.0"

maximum 609.6 mm 24"

THICKNESS maximum 0.635mm 0.025"

COPIES 1 + 5

WEIGHT (original) minimum 55 gr/M² 13.75 lbs

maximum 150 gr/M² 37.5 lbs

WEIGHT (Multicopy)

copies minimum 45 gr/M² 11.25 lbs

maximum 75 gr/M² 18.75 lbs

carbon maximum 35 gr/M² 8.75 lbs

____________________________________________________________________________________________

LA400 Multiprinter 1. 10 ER-LA400-SV

Page 19

Maintenance Manual General Overview

_______________________________________________________________________________________

PULL TRACTOR OPTION

Same as Front Push Fanfold

REAR PUSH FANFOLD

Rear push fanfold feeding

WIDTH minimum 76.2 mm 3.0"

maximum 431.8 mm 17.0"

LENGTH minimum 76.2 mm 3.0"

maximum 609.6 mm 24"

THICKNESS maximum 0.35mm 0.0138"

COPIES 1 + 3

WEIGHT (original) minimum 55 gr/M² 13.75 lbs

maximum 80 gr/M² 20 lbs

WEIGHT (Multicopy)

copies minimum 45 gr/M² 11.25 lbs

maximum 75 gr/M² 18.75 lbs

carbon maximum 35 gr/M² 8.75 lbs

The printer can accept also the Automatic Sheet Feeder option with these paper limitations:

ASF ALL BINS

Capacity Bin of 120 sheets

LENGTH maximum 355 mm 14"

THICKNESS maximum 0.35mm 0.0138"

COPIES 1 + 2

WIDTH minimum 88.9 mm 6"

maximum 304.8 mm 12"

WEIGHT (original) minimum 60 gr/M² 15 lbs

maximum 150 gr/M² 37.5 lbs

WEIGHT (Multicopy with carbon)

first/last sheet minimum 70 gr/M² 17.5 lbs

maximum 80 gr/M² 20.0 lbs

other minimum 35 gr/M² 8.75 lbs

maximum 40 gr/M² 10.0 lbs

carbon approx. 25 gr/M² 6.25 lbs

WEIGHT (Multicopy sensitive)

first/last sheet minimum 70 gr/M² 17.5 lbs

maximum 80 gr/M² 20.0 lbs

other minimum 40 gr/M² 10.0 lbs

maximum 60 gr/M² 15.0 lbs

ENVELOPES

Capacity of 30 envelopes max., Size US 6, US 10

ASF 1 BIN

LENGTH minimum 114 mm 4.5"

ASF 2 BIN

LENGTH minimum 216 mm 8.5"

ASF 3 BIN

LENGTH minimum 267 mm 10.5"

____________________________________________________________________________________________

LA400 Multiprinter 1. 11 ER-LA400-SV

Page 20

Maintenance Manual General Overview

_______________________________________________________________________________________

•• INTERFACES

There are two interfaces with automatic protocol and I/F switching on SW commands.

- Parallel interface

Centronics Compatible Bidirectional (IEEE-1284) nibble and byte modes

36 pin Amphenol connector with ESD protection

- Serial interface

Modular 6-pin DECconnect type

Baud Rate:300 to 19200 bps

Character Format: 1 Start bit + 7 or 8 data bits, + optional parity bit + 1 stop bit

•• DEVICE PROTOCOLS

Emulation: Printer Names

EPSON ESC P/2

IBM Proprinter X24E/XL24E

ANSI DEC PPL2

•• ELECTRICAL CHARACTERISTICS

JA/US Specification : 120 V +10% -15%, 50/60Hz ±2Hz

EU/UK Specification : 220/240 V +10% -15%, 50/60Hz ±2Hz

AC Consumption : Idle less than 80 VA

Printing less than 200 VA

•• ENVIRONMENTAL CONDITIONS

The storage and transit environment (1 year) of the device and the related

expansion module and supplies is:

Temperature Range - 20 °C to + 60 °C (-4 °F to 140 °F)

Humidity Range 5% RH to 90% RH (not condensing)

The operating environment is :

Temperature Range + 10 °C to + 40 °C (41 °F to 104 °F)

Humidity Range 20% RH to 80% RH (not condensing)

Additional resctrictions are introduced by the paper.

The ECMA standard suggestions are :

Temperature Range + T16 °C to + 24 °C

Humidity Range 40% RH to 60% RH (not condensing)

•• NOISE

Sound Pressure level bystander position according to ISO 7779:

Printing: less than 56 dBA

Stand-by: less than 45 dBA

____________________________________________________________________________________________

LA400 Multiprinter 1. 12 ER-LA400-SV

Page 21

Maintenance Manual General Overview

_______________________________________________________________________________________

•• STANDARDS, REGULATIONS AND APPROVALS

Printer Safety: - DEC std 119/178

- UL standard 1950

- IEC Publication 950

- European Norm 60950

- CSA Standard C22.2 No 950

AC Power - DEC std 002/122

Electromagnetic - DEC std 103

Compatibility - FCC Rules and Regulations, Part 15 - Subpart J (B Level)

- CISPR 22

- EMC Directive - EN 55022 Class B

EEC/89/336

- EN 55082

Environment - DEC std 102

Approvals - UL Listing to UL 1950

- CSA Certification to CSA C22.2 No 950

- Approval to EN60950 and IEC with a GS Mark

- Nordik deviations to EN60950: EMKO-TSE (74-SEC)

Energy Consumption - EPA compliant with a power consumption of max 30W in stand-by

____________________________________________________________________________________________

LA400 Multiprinter 1. 13 ER-LA400-SV

Page 22

Maintenance Manual General Overview

_______________________________________________________________________________________

•• MAINTAINING PARAMETERS

Next maintaining parameters are valid under the following conditions:

Standard temperature and humidity (23 ± 2 °C, 50 ± 5 RH)

MTTR

The MTTR is the estimated time to repair the printer at Optimum Replaceable

Unit (ORU) level is 15 minutes.

It includes:

- Identifying the faulty ORU

- Changing the ORU

- Cleaning paper paths

- Testing locally

MTBF/RELIABILITY

MTBF depends on duty cycle rate (D.C.).

For these printers it is 10.000 HRS @ 25 % D.C. (excluding print head).

Duty cycle rate estimated for this printer is calculated as follows:

Paper Movement & Print Time

Duty Cycle = ---------------------------------------------------- = 25 %

Power-on Time

Reference usage of 25% duty-cycle is assumed on the basis of the following

parameters : 60% column density, 50% line density, 40% character density, 40

hours/week.

LIFE

- UNIT 5 years

- RIBBON 15 Mcharacters Draft (standard black type)

3 MCharacters Draft each band (color type)

- PRINT HEAD 400 M Characters Draft

•• USER INTERFACE

The Operator Panel of this printer has the overall appearance of a plane surface as

shown in the next figure 1.4 with the following:

- 1 LCD Display with 16 alpha-numeric digit

- 9 Push Buttons

- 8 LED indicators (3 for status and 5 for paper paths)

____________________________________________________________________________________________

LA400 Multiprinter 1. 14 ER-LA400-SV

Page 23

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

Chapter 2

Paper Handling Overview

____________________________________________________________________________________________

LA400 Multiprinter 2. 1 ER-LA400-SV

Page 24

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

2.1 Introduction

As described in chapter 1.1.1, this printer is designed to be extremely flexible in paper

handling.

Moreover, the new mechanism has been designed to be, first of all, ergonomic for a

better and easier end-user operation.

2.1.1 Paper Handling Architecture

All the paper paths described below can co-exist and can be selectable via MENU and

SW commands.

Paper Feed Options (Pull Tractor, Push Tractors) presence and type are detected at

Power-up.

The printer automatically switches from one path to the other except for the rear pull

tractor positions.

Via operator panel menu it is possible to select one macro per each path (up to 6) or a

single format (equal for all paths).

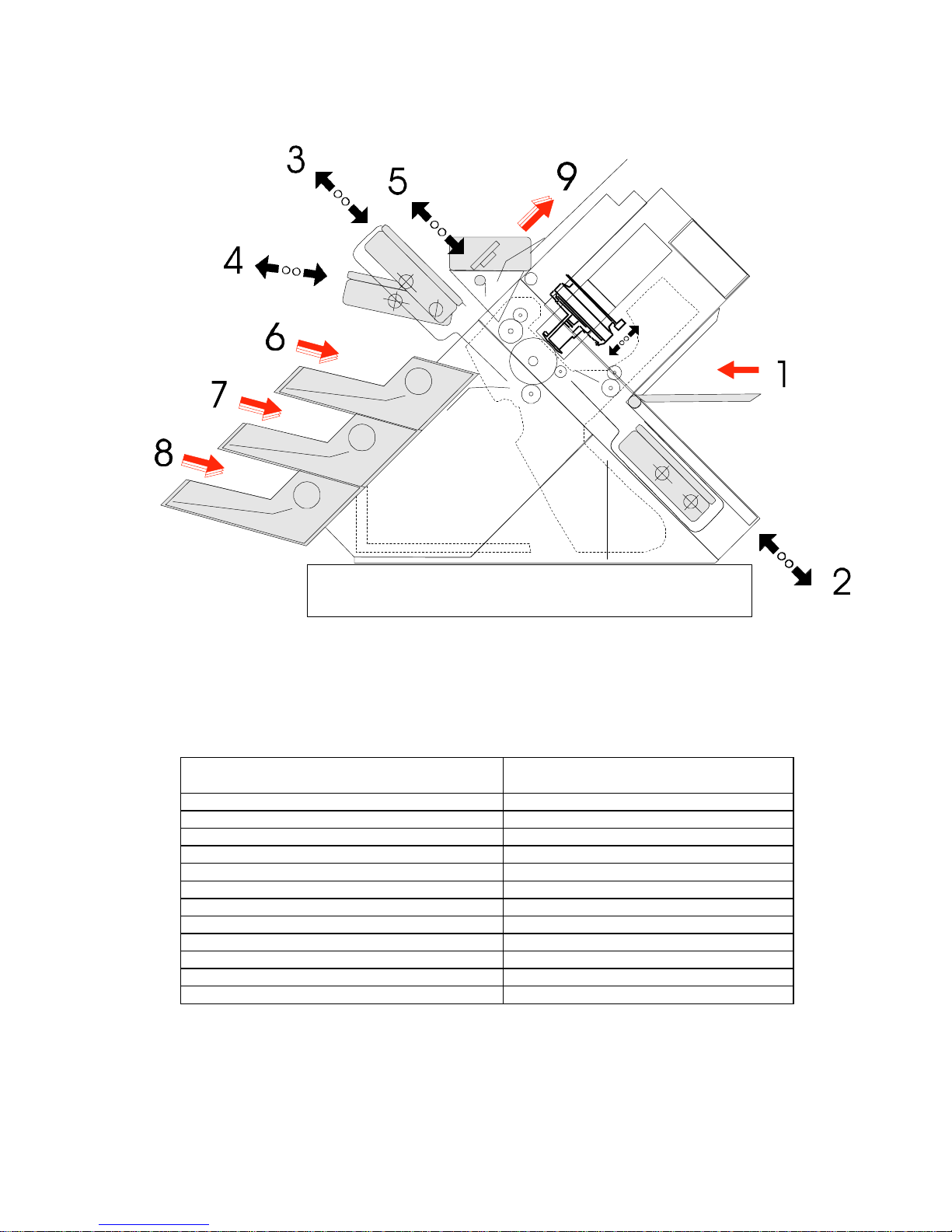

The basic configuration provides these ways to manage the paper formats:

(In the next figure the paths for continuous modules are indicated as <

⋅⋅⋅>, while the

paths for single sheet forms are indicated as --->; each path is identified with a number).

• SINGLE SHEET

A semi-automatic frontal single sheet insertion (PATH 1).

The cut sheets, envelopes or particular paper formats are manually loaded in this

path.

When a sheet is inserted, the sensors detect its presence and the printer

loads the paper automatically through the cut sheet stand without any other action.

• CONTINUOUS MODULE (FANFOLD) WITH PUSH TRACTOR UNIT

Through a user installable/removable push tractor unit the fanfold module can be

fed through the following positions:

PUSH FRONT mode (PATH 2) with push tractor unit installed in the front position.

PUSH REAR mode (PATH 3) with tractor unit installed in the rear position.

The continuous module exits from the rear paper slot (PATH 5).

• DOUBLE MODULE (FANFOLDS) WITH PUSH TRACTOR UNITs

Through a second optional user installable/removable push tractor unit the

following feeding position for continuous module is available for alternate use:

FRONT+REAR PUSH fanfolds mode.

The first fanfold from the front in push mode with basic push tractor unit installed

in the front position (PATH 2), the second from the rear in push mode with the

optional push tractor unit installed in the rear position (PATH 2).

For this path, the fanfolds exit (once at a time) from from the rear paper slot

(PATH 5).

____________________________________________________________________________________________

LA400 Multiprinter 2. 2 ER-LA400-SV

Page 25

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

• CONTINUOUS MODULE (FANFOLD) WITH PULL TRACTOR UNIT

Through the optional user installable/removable pull tractor unit the following

feeding positions for continuous module are available :

PULL mode in which the fanfold can be manually loaded from the front and fed

with the optional pull tractor unit (PATH 4).

PUSH&PULL mode in which the fanfold can be fed from the front in push

mode with the basic tractor unit (PATH 2) and at the same time is pulled from

the optional pull tractor unit in position C (PATH 4).

REAR PULL and PUSH&PULL modes are selectable from Control Panel.

• AUTOMATIC SHEET FEEDER (ASF)

Through the optional Automatic Sheet Feeder the following feeding positions for

single sheets are available :

ASF1 in the first bin (PATH 6).

ASF2 in the second bin (PATH 7).

ASF3 in the third bin (PATH 8).

Inside the paper output stacker, a mechanical switch allows the alternance

between the output single sheets, which are collected to the output stacker

(PATH 9), and the fanfold using this exit (PATH 5).

From control panel it is possibl to set combined asf path configurations (1+2, 2+3

and 1+2+3).

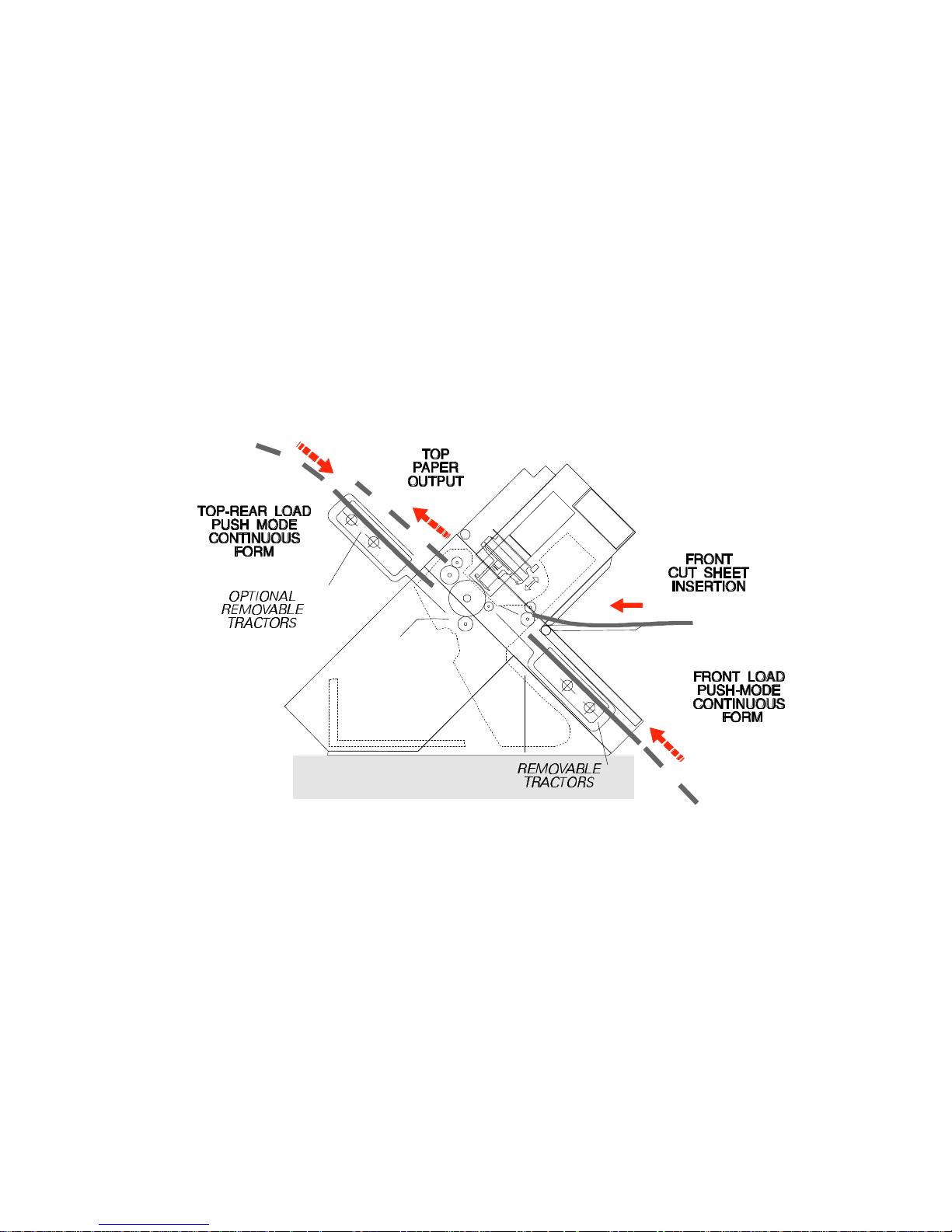

On the next figure 2.1 it is possible to see the internal architecture of this printer in which

the different paper paths handled by the new design of the mechanical assembly are put

in evidence.

On the table 2.1 it is possible to find all the Paper Path Types that can be selected from

the Control Panel in according to the printer Path Configurations.

____________________________________________________________________________________________

LA400 Multiprinter 2. 3 ER-LA400-SV

Page 26

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

Fig. 2.1 Paper Handling Architecture

PAPER PATH TYPES PAPER PATH CONFIGURATIONS

FROM CONTROL PANEL

1------ MANUAL

-2----- PUSH FRONT

--3---- PUSH REAR

-23---- PUSH FRONT+REAR

- - - 4 - - - PULL

- 2 - 4 - - - PUSH+PULL

- - - - 6 - - ASF1

- - - - - 7 - ASF2

------8 ASF3

- - - - 6 7 - ASF1+ASF2

- - - - - 7 8 ASF2+ASF3

- - - - 6 7 8 ASF1+ASF2+ASF3

Table 2.1 Printer Path Configurations

____________________________________________________________________________________________

LA400 Multiprinter 2. 4 ER-LA400-SV

Page 27

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

2.1.2 Paper Path Configurations

2.1.2.1 Basic Configuration

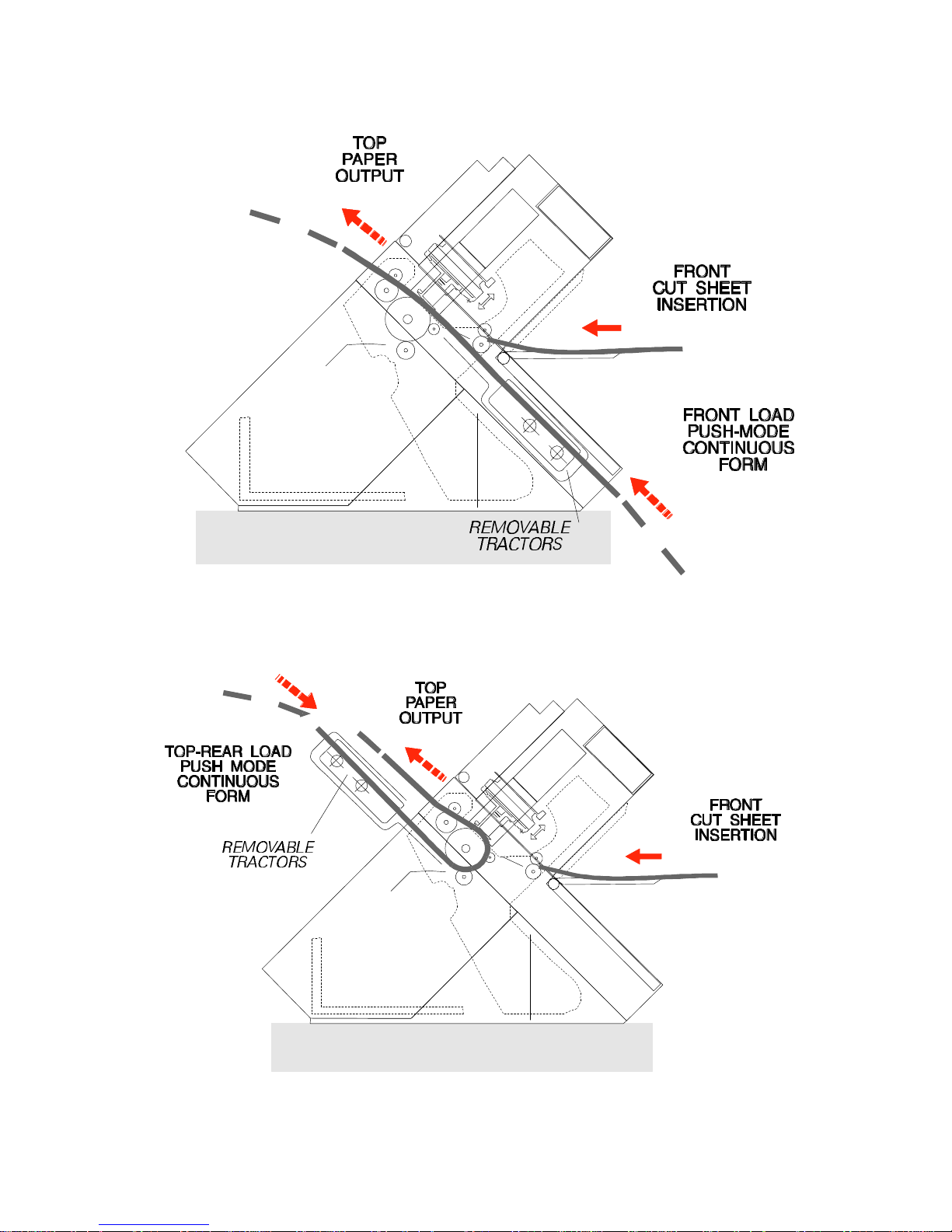

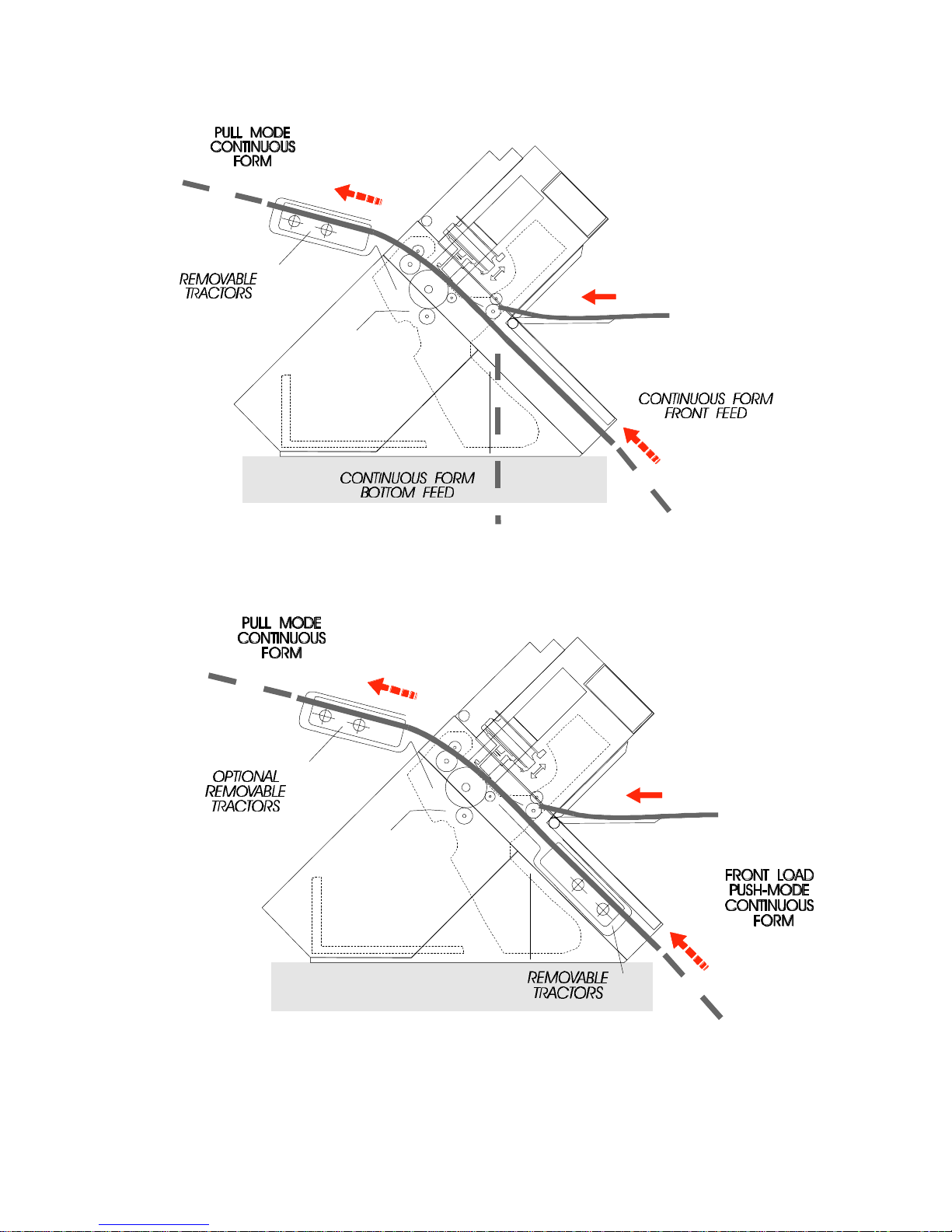

The next figures 2.2, 2.3 show the alternative positions of the standard push tractor unit and

related paper paths, figure 2.4 and 2.5 show the position of the optional pull tractor unit and

related paper path.

The figure 2.2 shows the Front Load Push-Mode of the fanfold.

The figure 2.3 shows the Rear Load Push-Mode of the fanfold.

The figure 2.4 shows the Rear Load Pull-Mode of the fanfold (alternatively the paper

can enter in the bottom feed slot).

The figure 2.5 shows the Front Load Push-Pull Mode of the fanfold.

IMPORTANT REMARK

• There is no the Overlay mode of manual with any fanfold modules.

• For the REAR PUSH mode, the fanfold must have a maximum thickness of

0.35 mm instead of 0.52 mm of the other paths (see chapter 1.4 for major details).

____________________________________________________________________________________________

LA400 Multiprinter 2. 5 ER-LA400-SV

Page 28

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

Figure 2.2 Front Load Push-Mode

Figure 2.3 Rear Load Push-Mode

____________________________________________________________________________________________

LA400 Multiprinter 2. 6 ER-LA400-SV

Page 29

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

Figure 2.4 Rear (Bottom) Load Pull-Mode

Figure 2.5 Front Load Push-Pull Mode with two tractors

____________________________________________________________________________________________

LA400 Multiprinter 2. 7 ER-LA400-SV

Page 30

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

2.1.2.2 Dual Fanfold Configurations

The next figure 2.6 show the dual tractor units configuration allowing the alternance

between two fanfolds, and related paper paths.

IMPORTANT REMARK

• For the REAR PUSH mode, the fanfold must have a maximum thickness of 0.35

mm instead of 0.52 mm of the other paths (see chapter 1.4 for major details).

Figure 2.6 Front Load Push-Mode and Rear Load Push-Mode with two tractors

____________________________________________________________________________________________

LA400 Multiprinter 2. 8 ER-LA400-SV

Page 31

Maintenance Manual Paper Handling Overview

_______________________________________________________________________________________

2.1.2.3 ASF Configuration

The figure 2.7 below shows the positions of the Automatic Sheet Feeder and related paper

paths.

The ASF can co-exists with both the push-pull tractor units (front and rear) installed.

The 1st BIN can accept also envelopes.

See chapter 1.4 for details regarding the paper specifications.

Figure 2.7 Automatic Sheet Feeder

____________________________________________________________________________________________

LA400 Multiprinter 2. 9 ER-LA400-SV

Page 32

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

Chapter 3

Electronic Hardware Overview

____________________________________________________________________________________________

LA400 Multiprinter 3. 1 ER-LA400-SV

Page 33

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1 Hardware General Overview

The electronic structure of this printer is composed of four boards as shown in next figure

3.1:

• Main Controller board

• Power supply board

One for 120 Vac

One for 230 Vac

• Operator panel board

• LCD Display board

plus some optional boards as:

• Serial interface board

• Optionally expansion board

• Font cartridge board

• Paper Stacker board

Figure 3.1 Electronics Structure

____________________________________________________________________________________________

LA400 Multiprinter 3. 2 ER-LA400-SV

Page 34

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.1 Electronic Architecture

The electronic hardware of this printer is based on 1 µprocessors (V55PI NEC).

The electronics architecture of the printer is as illustrated on next figure 3.2.

The controller unit of LA400 printer is implemented on one board.

This board can be splitted in two sections at functional level:

• The first section is a digital one, mainly dedicated to provide the physical and logical

interface between the host and the engine mechanical/electrical feature.

• The second one is an analogic one, mainly dedicated to drives the motors, the print head

needles, the generation of the Reset (power-on phase) and Prefault (power-off phase)

signals.

On this board are also provided the hardware dedicated to the Operator Panel management

and to support mechanical options.

The operator panel hardware, is realized on a specific board connected by flat cable.

Figure 3.2 Electronics Architecture

____________________________________________________________________________________________

LA400 Multiprinter 3. 3 ER-LA400-SV

Page 35

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2 Controller Overview

3.1.2.1 V55PI µµProcessor

The V55PI is microprocessor with a 16 bit CPU, a RAM, a serial interface, a parallel

interface, an A/D converter, a timer, a DMA controller, an interrupt controller and other

relevants units integrated in a single chip.

Therefore, it is best suited for data process systems including mechanical controls, such as

printers.

The V55PI µprocessor has the following functions:

• 16 bit internal architecture: 16/8 bit external data bus width selection enabled.

• Minimum instruction cycle: 160 ns/12.288 MHz (externally operated at 24.576 MHz)

• Address space : 16 Mbytes - 1Mbyte for basic memory space - 15Mbytes for

expansion memory space

• Register file space (on-chip RAM) : 512 bytes / 16 register banks

• I/O space : 64 Kbytes

• Memory space under division control in variable size (6 blocks max.) Automatic wait

control.

• I/O line (input port : 11 bits, input/output port : 42 bits).

• DMA controller (DMAC): configuration possible with a maximum of 4 channels.

4 types of DMA transfer modes (single transfer, demand release, single step, burst).

Intelligent DMA modes 1 and 2.

• Serial interface : 2 channels. Either asynchronous (UART) or clocked mode (CSI) can

be selected.

• Parallel interface : 8 bits. Centronics data input/output and general data input/output.

• A/D converter (8 bit resolution) : 4 channel.

• Realtime output port : 4 bits x 2 channels, or 8 bits x 1 channel.

• PWM (Pulse Width Modulation) signal output function (8 bits).

• Interrupt controller

Multiple interrupt service control by programmable priority (4 lev els).

3 types of interrupt response methods: vectored interrupt function, Register bank

switching function and macro service function.

• bit timer counter : 4 channel.

• Watch-dog timer function.

• Software interval timer (16 bits).

• Address block wait insert function and RAS/CAS switching timing generate function.

• DRAM and pseudo-SRAM refresh function.

• Stanby function (STOP mode and HALT mode).

• Built-in clock generator.

____________________________________________________________________________________________

LA400 Multiprinter 3. 4 ER-LA400-SV

Page 36

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2.1.1 µµP V55PI Internal Block Architecture

The figure 3.3 shows the internal architecture of the µprocessor.

Figure 3.3 Microprocessor Internal Block Diagram

____________________________________________________________________________________________

LA400 Multiprinter 3. 5 ER-LA400-SV

Page 37

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2.1.2 µµP V55PI Block Features

Bus Control Unit (BCU)

This block controls the main bus. In the CPU the necessary internal/external bus cycles are

started in accordance with the physical address obtained with the execution unit (EXU).

Execution Unit (EXU)

This block controls address calculations, arithmetic logic calculations and data transfer with

micro programs (firmware to control the macro sequencer based on the operation code

decoding results).

The EXU incorporates a 512-byte RAM corresponding to the register file space.

Interrupt Controller (INTC)

The interrupt request from the built-in peripheral hardware and external hardware interrupt

requests are processed either by switching between the vectored interrupt and the register

bank or with macro service.

Further, programmable 4-level interrupt prioriry can be controlled and multi ple processing

control can be executed on interrupt sources.

DMA Controller (DMAC)

This block is a general DMA controller and can handle a 16 Mbyte memory space linearly.

The operating modes consist of a memory-to-memory transfer mode, an intelligent DMA

(ring buffer method and counter control method), a next address specify mode and 2channel operating mode.

Serial Interface (UART/CSI)

This block includes the asynchronous serial interface (UART) for data synchronization with

start/stop bit and the clocked serial interface (CSI).

Either interface can be selected for use.

The CSI can employ either the serial bus interface mode (SBI) or the 3-wire serial I/O mode.

Parallel Interface (PIU)

This blocks performs input/output in 8-bit units using strobe signal synchronization and

supports the Centronics interface and general-purpose parallel data communication

functions.

A/D Converter Unit (8-bit A/D)

This is a successive conversion 8-bit A/D converter having 4 analog inputs.

It is equipped with four A/D conversion result registers.

Timer/Counter Unit (TCU)

This units incorporates a 16-bit timer/counter and can be used as the interval timer, the freerunning counter or the event counter.

Pulse Width Modulation Unit (PWM)

This unit is provided with an 8-bit accuracy PWM signal output function.

Watch-Dog Timer (WDT)

An 8-bit watchdog timer is incorporated to detecct an inadvertent overrun and system errors.

The WDT is equipped with the WDTOUT pin to externally notify the generation of a

watchdog timer interrupt.

____________________________________________________________________________________________

LA400 Multiprinter 3. 6 ER-LA400-SV

Page 38

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

Port (PORT)

Up to 53 port pins are available. Port pin and control pin functions can be selected for use.

Port 0 - EEPROM selection,clock and data input lines

- PCMCIA Memory Card line

- Alternance motor front tractor lines

- Alternance motor rear tractor lines

Port 1 - Prefault line

- EEPROM data output line

- Home position and ribbon sensors line

- PCMCIA interface ready/busy line

- Expansion interface line

- Parallel interface input line (INIT)

Port 2 - Memory card address line

- PSRAM resfresh and address lines

- Paper sensors driving lines

- DMA request for fir configuration request line

Port 3 - Serial synchronous I/F lines (CLOCK, TX, RX)

- Enable serial synch. lines for O.P. and options

- Serial asynchronous I/F lines (CTS, TX, RX)

Port 4 - Parallel host data lines

Port 5 - Parallel Host input and output lines (STROBE, ACK, BUSY)

Port 6 - Outputs lines from analog MUX

Head temperature

Single sheet presence

Front fanfold presence

Rear fanfold presence

- Board type line

- Optional voltage reference line

Port 7 - Carriage motor enable and phase lines

- Ribbon motor reference and phase lines

Port 8 - DMA request for "clear bit map" and needles configuration

Realtime Output Port (RTOP)

This block is a reltime output port to be triggered with an interrupt from timer 0. it can

output 8-bit buffer register contents in 4-bit or 8-bit units at a programmable interval.

System Control (SC)

This block generates 1/2, 1/4, 1/8, 1/16 specific frequencies of the crystal or ceramic

resonator connected to the X1 and X2 pins and supplies them as CPU operation clocks.

Also generates the master reset for the correct synchronization of all logic devices.

Software Interval Timer (SIT)

A 16-bit software interval timer is incorporated as one for software timer or clock functions.

It can set interval interrupts by selecting the input clock (count clock) and setting the

software timer counter compare register.

____________________________________________________________________________________________

LA400 Multiprinter 3. 7 ER-LA400-SV

Page 39

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2.2 ASIC

The ASIC (Application Specific Intergrated Circuit) main functions are:

Logic integration such as the memories selection and the I/O registers support.

1) The I/O registers provided to drive output lines or to realize variable memory

mapping and are summarized below.

Reg. 1 - Parallel interface input lines (SLCTIN, AUTOFD).

- Serial asynchronous I/F lines (DCD, DSR).

Reg. 2 - Parallel I/F output lines (SLCT, PE, FAULT).

- Parallel I/F data lines input/output set.

- Serial asynchronous I/F lines (SRTS, RTS, DTR).

Reg. 3 - Operator Panel output control lines

Reg. 4 - Carriage motor reference lines

- Paper motor enable, reference and phase lines

Reg. 5 - Color motor phase lines

- AGA motor reference and phase lines

Reg. 6 - Rear and front fanfolds moving sensor lines

- MUX selection lines

- Fan driving line

Reg. 7 - EPROM/Memory-Card size selection lines

- Power enable line

The ASIC output also provides these control lines:

Carriage motor phase lines

Paper motor phase lines

2) Provides the support for printing management in agree with the head type.

For the printing management the ASIC provide the signal and related timing for the

DMA management usefull to transfer the needles configuration and to clear the bit-map.

It also include some timers necessary to the needles driving.

The count frequency is defined by a prescaler counter set to have a CLK/16 period;

CLK is the V55PI output base clock (12.288 MHz).

The registers are summarized below.

Reg. 8 - Print Head control register

Needles number, print direction, DMA request, needles time reset and

timers enable lines

Reg. 9 - Needles driving Timer 1 value

Reg. 10 - Needles driving Timer 2 value

Reg. 11 - Chopper frequency value Timer 3

Reg. 12 - Negative duty cycle inside choppering (Timer 3 value)

Reg. 13-14-15 Needles configuration registers (up to 24 bit)

____________________________________________________________________________________________

LA400 Multiprinter 3. 8 ER-LA400-SV

Page 40

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2.3 Memories

As memory support must be intended the hardware support for the software, so it includes

registers, memories and logic providing their addressing.

The memories supports can be resident and/or optional and can be located in the 16 MB

addressability provided by the microprocessor with a rescriction for the "code" type that is

located at the first mega address.

Resident Memory : CONTROLLER EPROM i.c. up to 512 KBytes x 8 (4 Mb)

GENERATOR EPROM i.c. up to 512 KBytes x 8 (4 Mb)

Optional Memory : Memory Card, OTP or SRAM types up to 256 KBytes x 8 (2 Mb)

3.1.2.4 Operator Panel

For the operator panel management, a serial port (Port 3) of the µprocessor is used in

synchronous mode to enable lines.

In addition, inside the ASIC, a control register (Reg. 3) is provided for the access to the

register located on the operator panel specific board.

On the operator panel board a specific registers are used to drive the LCD, the LEDs and

the PUSH- BUTTONs.

Port 3 Enable serial synchronous lines

Reg. 3 Operator Panel control register

- Latching strobe for the status selected by the means of the

O.P. selection lines in read mode

- Kind of the data to send to LCD in write mode

- Read/Write type access on O.P. board register

- O.P. status selection in read mode or latch for LEDs register

in write mode

- O.P. status selection in read mode or latch for LCDs register

in write mode

- O.P. status selection in read mode or latch for KEYs register

in write mode

Reg. LED LEDs output data lines.

Reg. LCD LCD input data lines.

Reg. KEY1-2 Push Button input lines.

3.1.2.5 Serial lnterface Board

The logical hardware support are provided on the basic board by the means of specific port

on the µprocessor and register on ASIC.

This board provides only the physical connection with the line receivers and drivers

intergrated circuits.

____________________________________________________________________________________________

LA400 Multiprinter 3. 9 ER-LA400-SV

Page 41

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.2.6 Expansion Bus

The expansion bus is provided to connect additional board to support also complex

functionality such as particolar host interfaces.

This bus provides all the microprocessor signals so the lines managing is implicit in the

microprocessor feature and partially also in the decoding logic with the hardware register

support and the addressing map involved.

3.1.3 Mechanical Drivers

As indicated in previous chapters, analogic part of the board drives the power circuits and

generates the Reset and Prefault signals.

All the driver (excepts for the paper motor) are disable when there are no activities for more

than 20 seconds.

The next figure shows the blocks structure of the DOE (device oriented electronics).

Figure 3.4 DOE Blocks Diagram

____________________________________________________________________________________________

LA400 Multiprinter 3. 10 ER-LA400-SV

Page 42

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.3.1 D.O.E. Block Features

•• RESET and PREFAULT

This block handles some important signals indispensable for the correct intialization of

the microprocessor and power drivers during the power-on and power-off transitions

phases.

There is a Voltage Supervisor TL7705A that monitorizes the voltages during the

transition phases and a Schmitt Trigger that rigenerates the signal edges for the logic

HCMOS compatibility.

This circuit is supplied with the analogic "or" of the two voltages +5 and +38.

In this way it is ready if only one voltage is present.

It generates the CPU Reset when the logic voltage reaches +4.75V.

It also generates the PREFAULT signal to handles the printer status in the NVM.

In the next two figures are shown the schematics and the typical vaweforms of this

circuit.

Typical timing:

with +38 V = +10V and with +5V = +4.4V the signal are as point A.

TD-TB > 30 msec.

TF-TE > 2 msec.

Figure 3.5 Reset and Prefault Circuit

____________________________________________________________________________________________

LA400 Multiprinter 3. 11 ER-LA400-SV

Page 43

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

Figure 3.6 Reset and Prefault Waveform

•• COLOR & PAPER STACKER MOTORS

The color ribbon and the paper stacker movement are obtained via a linear

movement of the rotor of a 15 degrees bipolar step motor.

The driver device is a L293D in which are intergrated four driver with recycle diodes and

logic control circuits.

The figure below shows the schematic of this circuit.

Figure 3.7 Color & Paper Stacker Motors Driving Cicruit

____________________________________________________________________________________________

LA400 Multiprinter 3. 12 ER-LA400-SV

Page 44

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

•• CARRIAGE MOTOR

The carriage movement is obtained via a 1.8 degrees bipolar stepper motor.

This motor operates properly in the range between 6 and 40 IPS (Inch Per

Second) speeds.

•• PAPER MOTOR

The paper movement is obtained via a 1.8 degrees bipolar step motor.

This motors operate at maximum speed of 8 IPS.

For both the motors, the driver device is a dual full bridge driver L298 with a current

controller L6506 as indicated in the figure below.

The current level control is defined as fixed frequency chopper (depending by the

internal oscillator of the controller in a range of 19 to 28 KHhz).

The figure below shows the schematics of this circuit.

Figure 3.8 Carriage and Paper Motors Driving Cicruit

____________________________________________________________________________________________

LA400 Multiprinter 3. 13 ER-LA400-SV

Page 45

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

•• RIBBON MOTOR

The ribbon movement is obtained via a 7.5 degrees bipolar step motor.

•• AGA MOTOR

The ribbon movement is obtained via a 3.6 degrees bipolar step motor.

For both the motors, the driver device is a L6219 in which are intergrated a current

controller, the recycle diodes and the power drivers.

In the figure below is indicated the internal block diagram of this device.

Figure 3.9 Ribbon and AGA Motors Driving Cicruit

•• ALTERNANCE MOTORS

The alternance motor (tractor/friction switching) is a DC motor.

The driver device is a L293D with two resistors in series to the motor coils to prevent

the inrush curent. In the figure below a typical application of this device.

Figure 3.10 Color and Alternance Motors Driving Cicruit

____________________________________________________________________________________________

LA400 Multiprinter 3. 14 ER-LA400-SV

Page 46

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

•• ASF MOTOR

The asf motor is a DC motor.

The driver device is a darlington transistor array with two resistors in series to the

motor coils to prevent the inrush curent. In the figure below a typical application of this

device.

Figure 3.11 ASF Motor Driving Cicruit

•• SENSORS

The DOE is provided with the sensors summarized below.

The following two sensors enters directly in the port 1 of the microprocessor.

- Home Position (interrupting sensor)

- Ribbon Fault (interrupting sensor)

The following sensors enters in a analog MUX (multiplexer) with 8 input and 2 outputs

and then in the A/D section of the microprocessor.

(The number on the diodes represents the pin number of the sensors cable connector,

see chapter 8 for major details).

- Fanfold Front presence

- Fanfold Rear presence

- Single Sheet presence

- Printhead Temperature

Figure 3.12 Sensors Driving Circuit

____________________________________________________________________________________________

LA400 Multiprinter 3. 15 ER-LA400-SV

Page 47

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

•• PRINTING HEAD

Printing head is a electromagnetic non-ballistic type.

With reference to the figure 3.13 below, when the actuator is at rest, the clapper is

ushed to the central O-Ring by the hinge O-Ring and by the leaf spring.

When a dot has to be printed, a proper current pulse is applied to the coil,

magnetic flux is pushed into the core and the clapper is pulled to contact the core,

so that the needle is pushed against the media (fig. 3.13 b).

Figure 3.13 a Figure 3.13 b

Print Head Behaviour

The coil is energized through the TR1 transitor and then is disharged through the

TR2 and D1 drived by the TR3 transistor.

These phases can be repeated more times in the "chopper" mode behaviour.

After that, the phase of coil stored energy discharge is activated and allows the power

to come-back to the power supply through the D2.

Figure 3.14 Print Head Needle Driving Circuit

____________________________________________________________________________________________

LA400 Multiprinter 3. 16 ER-LA400-SV

Page 48

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

The maximum firing frequency is 2400 Hz for alphanumeric printing and 2100 Hz

for graphic printing.

In the next figure are shown the typical waveform of the print head needle current.

The LOW and NORMAL energy can be selected via operator panel in order to

obtain the best performance in term of printout/noise when multiple forms paper is

used.

The timing values (µsec) are programmed by the ASIC timer registers.

Low Normal

T1 = Timer 1 100 115

T2 = Timer 2 typical 100 85

T3 = Timer 3 37.5 37.5

T4 = Negative duty cycle inside T3 12.5 12.5

T1+T2+discharge time 230 230

Energy (mJ) 4 5

Figure 3.15 Print Head Needle Current Waveforms

____________________________________________________________________________________________

LA400 Multiprinter 3. 17 ER-LA400-SV

Page 49

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.4 Power Supply Board

The power supply is an off-line switched mode power supply.

There are two type of boards, one for input voltage of 120 Vac (-18% +10%) and the other

for 230 Vac (-19% +10%).

Stand-by power : 30 W

Continuous power : 100 W

Peak power: 200 W

Output voltages are:

+ 38 VDC ± 4 % (0 to 2.5 A max)

+ 5 VDC ± 4 % (0.3 to 1.2 A max)

Input voltage is:

+ 79 VDC ± 6 % (0 to 0.25 A max)

the tolerance is considered between the difference between +79 V and +38 V.

It is composed of the following main blocks.

The number between brackets ( ), is the one reported on next figure 3.16.

1) RFI Input filter.

2) Main switch with Fuses (1 for 120 V type, 2 for 220 V type).

3) Main Low frequency reftification and filtering.

4) Main Switching Converter (forward type).

5) Main High frequency reftification and filtering.

6) Linear regulator for + 5 output voltage.

7) High precision zener-diode regulator.

8) Optical linear circuit for galvanic insulation.

9) Pulse Width Modulator circuit.

10) Energy recovery Circuit.

The low frequency section includes receptacle, fuses, switch, EMI/RFI filter, rectifier bridge

and smoothing capacitors.

The main converter section is forward type converter, working at a frequency variable of 65

Khz.

The outputs of the transformer are +38 VDC and +9 VDC.

This block includes a safety isolating main transformer, the high frequency rectifier bridge

and smoothing capacitors for the outputs voltages, a voltage regulator, a optodecoupler

which provides safety isolation between the main and the low voltage outputs, a PWM

module which drives the power Mosfet properly.

The linear regulator section delivers + 5 VDC from the +9 VDC.

The Energy Recovery circuit is a block that allows to transfer the not-used energy from the

print head circuits on the +38 VDC.

Internally there is a swicthing DC-DC converter which maintains the +79 VDC on the proper

value.

____________________________________________________________________________________________

LA400 Multiprinter 3. 18 ER-LA400-SV

Page 50

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

4

1

2

3

5

6

7

8

9

10 +78 V

+38 V

+5 V

Fig. 3.16 Power Supply Major Block Diagram

____________________________________________________________________________________________

LA400 Multiprinter 3. 19 ER-LA400-SV

Page 51

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

3.1.5 Controller SW Overview

All software elements are made in a structured way, both for device oriented electronics and

mainly for controller aspects.

The Controller S/W is structured into two separate layers: the APPLICATION layer and the

PLATFORM layer.

The Application layer main task is to provide the emulation function.

It normally contains the Supervisor module, the Interpreter module (s) of the supported

emulation. The Application Interpreter task is the interpretation of the emulated Presentation

protocol commands (typically : Escape Sequences and Control Codes) to convert the string

of received data into printable data, conforming to the interface requirements of the lower

layer involved module.

A separate part, application dependent, is responsible of the emulations and of the font

management.

Due to presence of the Platform layer, the Application layer is significantly independent from

the characteristics of the running H/W.

The PLATFORM layer is structured into several module swhich are personalized on the

H/W characteristics (CPU, Host Interface, Operator Panel H/W, Device, etc.).

The synchronisation of the Platform modules is performed by a Real Time Compuprint

Operating System, which offers a set of primitives to the Application layer in order to

simplify the application programming job and to standardize the S/W interface between the

two layers.

The interfaces among the Platform modules are also standardized to allow independent

programming and (where possible) a stand-alone debugging of the program module with

software simulation of the input and output data.

The Platform layer can be easily improved or updated with new modules to support new

printer features, options and/or hardware characteristics to generate different printer models

or non-standard products.

On the figure below, is reported the Software architecture of these printers.

____________________________________________________________________________________________

LA400 Multiprinter 3. 20 ER-LA400-SV

Page 52

Maintenance Manual Electronic Hardware Overview

____________________________________________________________________________________________

Figure 3.17 Software Architecture

____________________________________________________________________________________________

LA400 Multiprinter 3. 21 ER-LA400-SV

Page 53

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

Chapter 4

Removal and Replacement

____________________________________________________________________________________________

LA400 Multiprinter 4. 1 ER-LA400-SV

Page 54

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.1 Overview

This section describes the removal and replacement procedures for the basic printer.

Before starting any of these procedures, turn the power switch OFF, and take off the plug

from the wall socket.

Before disassembling the printer, remove the paper in the printer and the inked ribbon

cartridge.

After the covers removal, the power supply cover tool must be installed to prevent any

accidental contact of technician hand with the main heat-sink of the power supply itself if

the printer is powered-on without covers.

REMARK

Caution and Warning in this section highlight specific information.

A CAUTION provides information intended to prevent equipment damage.

A WARNING provides information intended to prevent personal injury.

You must observe anti-static precautions when maintaining this printer.

Disassembly procedure must to be executed from the front side of the printer.

4.2 Recommended Hand Tools and Equipment

The following items should be available for the technicians performing corrective

maintenance on printers:

• Assortment of Philips head and common screwdrivers

• Set of spanners for M3 and M5 nut

• Extractor for chip

• Pliers

• Soldering iron (and soldering wire with flux core)

• A Multimeter for resistance and voltage measurements

• Feeler gauge for print head gap adjustment

• Dynamometer for carriage and motor belts adjustment

• Slender spring hook

• Set of fastener loop self-lock

____________________________________________________________________________________________

LA400 Multiprinter 4. 2 ER-LA400-SV

Page 55

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.3 O.R.U. ORDER OF ACCESS

Table 4.1 shows the accessibility of EACH ORU (Optimum Replaceable Unit), and the

procedure necessary to access to each one.

Remove ORU: Requires these procedures in the order shown:

1) Push Tractor Group 1 (section 4.3.1)

2) Operator Panel Boards 2 (section 4.3.2)

3) Print Head 3 (section 4.3.3)

4) Front Cover Parts 1,2,4 (section 4.3.4)

5) Rear Cover Parts 5 (section 4.3.5)

6) Serial Interface Board 5,6 (section 4.3.6)

7) Main Board 5,6,7 (section 4.3.7)

8) Power Supply Board 5,6,8 (section 4.3.8)

9) Ribbon Motor 1,2,4,5,9 (section 4.3.9)

10) AGA Motor 1,2,4,5,10 (section 4.3.10)

11) AGA Support and T/F lever 1,2,4,5,11 (section 4.3.11)

12) Carriage Motor and Fan 1,2,4,5,12 (section 4.3.12) (*)

13) Bail Assy 13 (section 4.3.13)

14) Cut Sheet Assy 1,2,4,14 (section 4.3.14)

15) Upper Feeder Assy 1,2,4,5,15 (section 4.3.15)

16) Platen Assy 1,2,4,5,16 (section 4.3.16) (*)

17) Lower Feeder Assy 1,2,4,5,17 (section 4.3.17) (*)

18) Carriage Assy 1,2,4,5,18 (section 4.3.18) (*)

19) Sensor Cable Assy 1,2,4,5,19 (section 4.3.19) (*)

20) Mechanical Assy 1,2,4,5,20 (section 4.3.20)

21) Paper Motor 1,2,4,5,20,21 (section 4.3.21) (*)

22) Friction Bar Assy 1,2,4,5,20,22 (section 4.3.22)

Table 4-1 ORU ORDER OF ACCESS

NOTE : Procedure with an asterisk require ADJUSTMENT PROCEDURE (see chapter 5)

All the spare parts available on logistic are reported in the specific Illustrated Parts Catalog P.N.:

ER-LA400-IP.

REMARK.

In the following chapters, the steps of removal procedures are labeled in the corresponding

figures.

____________________________________________________________________________________________

LA400 Multiprinter 4. 3 ER-LA400-SV

Page 56

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.3.1 Front Tractor Group

CAUTION

Do not remove and install the push tractor group with the printer at power-on.

1) Open the front antinoise cover.

2) Close the single sheet support cover, if open, by pulling it upward until it is fastened

with the magnetic lock.

3) Disengage the tractor group from the mechanical assy by acting on the two small

levers (located on plastic tractor sides) that block the tractor group on it.

4) Remove the tractor unit by pulling it downward.

Replace the tractor group following the above instructions in reverse order.

Figure 4.1 Push Front Tractor Group removal

____________________________________________________________________________________________

LA400 Multiprinter 4. 4 ER-LA400-SV

Page 57

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.3.2 Operator Panel Boards

CAUTION

Don't attempt this operation without taking all recommended anti-static precautions.

1) Open the operator panel group by acting on its middle top side to disengage it from

the cover.

2) Open the top cover group by acting on the two push-buttons (located on the front side

of the cover).

3) Unscrew the screw securing the operator panel shield to the mechanical assy (in new

printers this action will be not necessary anymore).

4) Unplug the operator panel connector from the operator panel board.

5) Rotate the operator panel group of 90° and at the same time extract it from the front

cover.

6) Unscrew the six screws securing the operator panel boards to the cover and remove

them.

7) Remove the operator panel board from the LCD display board by acting on the two

plastic spacers catches that retain the boards together.

Replace the operator panel boards group following the above instructions in reverse

order.

Figure 4.2 Operator Panel Parts removal

____________________________________________________________________________________________

LA400 Multiprinter 4. 5 ER-LA400-SV

Page 58

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.3.3 Print Head

WARNING

The print head may have hot surface after a certain time of printing.

Wait for it to cool down.

1) Open the top cover group by acting on the two push-buttons (located on the front side

of the cover).

2) Place the print head to the rightmost carriage position and remove the inked ribbon

cartridge and bail assy.

3) Unscrew the screw securing the print head cable to the carriage assy.

4) Unscrew the two screws securing the print head.

5) Open the printhead cable zif-connectors and unplug these connectors and the color

motor connector (if present) by manually acting on their bends.

6) Remove the printhead.

Replace the Print Head following the above instructions in reverse order.

NOTICE : Before securing the screw, push the P.H. to its inside stop position.

No adjustment is required.

Figure 4.3 Printhead Removal

____________________________________________________________________________________________

LA400 Multiprinter 4. 6 ER-LA400-SV

Page 59

Maintenance Manual Removal and Replacement

____________________________________________________________________________________________

4.3.4 Front Cover Parts

1) Remove the front tractor group (refer to chapter 4.3.1)

2) Remove the operator panel group (refer to chapter 4.3.2)

3) Unscrew the four screws securing the main front group (two on left and right printer

side, the other two on the front side).

4) Remove the main front cover by extracting it and, at the same time, rotating it towards

its front side.

5) Open the top cover and extract it from the main front cover by acting on its pins

(located on both sides).

6) Extract the magnet interlock from the front cover by simply pulling it out of the cover.

Replace the Main Front Cover Parts following the above instructions in reverse order.