Digital Equipment HA3000 Installation Manual

HA300020-80kVA

UninterruptiblePowerSystem

InstallationManual

Order Number EK-HA32X-IN-002

Digital Equipment Corporation

November 1991

The information in this document is subject to change without notice and should not be construed as a

commitment by Digital Equipment Corporation. Digital Equipment Corporation assumes no responsibility for

any errors that may appear in this document.

Possession, use, duplication, or dissemination of the software described in this documentation is authorized

only pursuant to a valid written license from Digital or the third-party owner of the software copyright.

No responsibility is assumed for the use or reliability of software on equipment that is not supplied by

Digital Equipment Corporation.

Copyright © Digital Equipment Corporation 1991

All Rights Reserved.

Printed in U.S.A.

The postpaid Reader’s Comment Card included in this document requests the user’s critical evaluation to

assist in preparing future documentation.

FCC NOTICE: The equipment described in this manual generates, uses, and may emit radio frequency

energy. The equipment has been type tested and found to comply with the limits for a Class A computing

device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection

against such radio frequency interference when operated in a commercial environment. Operation of this

equipment in a residential area may cause interference, in which case the user at his own expense may be

required to take measures to correct the interference.

The Digital logo is a trademark of Digital Equipment Corporation.

This document was prepared and published by Educational Services Development and Publishing, Digital

Equipment Corporation.

Contents

About This Manual ix

1 INSTALLATION REFERENCE CHECKLISTS

1.1 CUSTOMER RESPONSIBILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1.1 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1.2 Delivery/Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2 TRUCKER/MOVER/RIGGER RESPONSIBILITIES . . . . . . . . . . . . . . . 1–3

1.3 ELECTRICIAN RESPONSIBILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1.3.1 HA32A UPS Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1.3.2 HA32B UPS Battery Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.3.3 HA32C/D/E UPS Auxiliary Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.3.4 HA33D/F UPS CSA Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1.3.5 HA32J/K UPS Distribution Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

1.3.6 HA320-A3 Remote Alarm Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1.4 DIGITAL SERVICES RESPONSIBILITIES . . . . . . . . . . . . . . . . . . . . . 1–9

1.4.1 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1.4.2 Delivery/Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1.4.3 Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

2 SITE PREPARATION

2.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.2 STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.3 HA32A UPS CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.4 HA32B UPS BATTERY CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.4.1 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.4.2 Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.5 HA32C/D/E UPS AUXILIARY CABINET . . . . . . . . . . . . . . . . . . . . . . . 2–8

2.6 HA33D/F UPS CSA CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

2.7 HA32J/K UPS DISTRIBUTION CABINET . . . . . . . . . . . . . . . . . . . . . . 2–12

iii

iv Contents

3 HA3000 UPS RECEIVING AND HANDLING

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.2 RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.3 HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3.3.1 Removing Unit from Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

3.3.2 Removing Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

3.3.3 Removing Unit from Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

3.3.4 Recommended Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.3.5 Moving Unit to Final Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3.3.6 Caster Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

4 INSTALLATION

4.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 HA32A UPS Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2.1 Main AC Input (MAINS1) Connection . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.2.2 Bypass AC Input (MAINS2) Connection . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.3 UPS Output Load Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.4 Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.5 UPS Battery Cabinet Control Wire Connections (TB1) . . . . . . . . . . . 4–5

4.2.5.1 Battery Cabinet Circuit Breaker (QF1) Control Wiring . . . . . . . . . 4–6

4.2.5.2 DC Ground Fault Detector Control Wiring . . . . . . . . . . . . . . . . . . 4–6

4.2.5.3 Smoke Detector Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

4.2.6 Contact Closure Control Wire Connections (TB2) . . . . . . . . . . . . . . . 4–7

4.2.7 Remote Status Panel and Remote Alarm Panel Control Wire

Connections (TB3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

4.2.7.1 Remote Status Panel Control and Power Wire Connections . . . . . 4–7

4.2.7.2 Remote Alarm Panel Control and Power Wire Connections . . . . . 4–8

4.2.8 Checks After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

4.3 HA32B UPS BATTERY CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

4.3.1 General Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

4.3.2 Single UPS Battery Cabinet/HA32A UPS Installation . . . . . . . . . . . 4–10

4.3.3 Two UPS Battery Cabinets/HA32A UPS Installation . . . . . . . . . . . . 4–11

4.3.4 Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–11

4.3.5 Control Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

4.3.6 Interbattery Link Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

4.3.7 Checks After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

4.3.8 Reassembling the UPS Battery Cabinet . . . . . . . . . . . . . . . . . . . . . . 4–13

4.4 HA32C/D/E UPS AUXILIARY CABINET . . . . . . . . . . . . . . . . . . . . . . . 4–14

4.4.1 Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–16

4.4.1.1 AC Input Connection for Input Isolation Transformer Option . . . . 4–16

4.4.1.2 Connecting the Isolation Transformer for Both the UPS Main AC

Input (MAINS1) and Bypass AC Input (MAINS2) . . . . . . . . . . . . 4–19

4.4.1.3 Connecting the Isolation Transformer for the UPS Bypass AC

Input (MAINS2) Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Contents v

4.4.1.4 Connecting the Isolation Transformer for the UPS Main AC Input

(MAINS1) Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

4.4.1.5 Connecting the Input Harmonic Current Filter . . . . . . . . . . . . . . 4–21

4.4.2 Control/Interface Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.4.3 Checks After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.5 HA33D/F UPS CSA CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

4.5.1 Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–26

4.5.1.1 Connecting the HA33D with Input Isolation/Step-Down

Transformer and CSA Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 4–26

4.5.1.2 Connecting the HA33F with CSA Assembly Only . . . . . . . . . . . . . 4–27

4.5.2 Control/Interface Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–29

4.5.3 Checks After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–29

4.6 HA32J/K UPS DISTRIBUTION CABINET . . . . . . . . . . . . . . . . . . . . . . 4–30

4.6.1 Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–31

4.6.1.1 AC Input Connection Without Isolation/Step-Down Transformer . 4–31

4.6.1.2 AC Input Connection With Isolation/Step-Down Transformer . . . . 4–31

4.6.2 Control/Interface Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–32

4.6.3 Installation and Connection of Optional Digital Output Cables . . . . 4–32

4.6.3.1 Output Circuit Breaker Installation . . . . . . . . . . . . . . . . . . . . . . . 4–32

4.6.3.2 Output Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–35

4.6.4 Non-Digital Output Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–35

4.6.5 Checks After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–36

4.7 HA320-AA/AB REMOTE STATUS PANEL . . . . . . . . . . . . . . . . . . . . . . 4–37

4.8 HA320-A3 REMOTE ALARM PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . 4–38

4.9 HA320-C2 DC GROUND FAULT DETECTOR . . . . . . . . . . . . . . . . . . . 4–39

4.10 HA320-B1 SMOKE DETECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–40

A ELECTRICAL CONSIDERATIONS

A.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

A.2 TERMS AND DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

B SPECIFICATIONS

Index

Figures

2–1 Right-Side Cable Access for the UPS Cabinet . . . . . . . . . . . . . . . . . . . . 2–2

2–2 Bottom View, 20 and 40 kVA Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

2–3 Bottom View, 60 and 80 kVA Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

2–4 Floor Tile Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2–5 UPS Auxiliary Cabinet Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

2–6 UPS CSA Cabinet Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

2–7 UPS Cabinet and UPS Distribution Cabinet Placement . . . . . . . . . . . . 2–12

vi Contents

2–8 UPS Cabinet, UPS Auxiliary Cabinet or UPS CSA Cabinet, and UPS

Distribution Cabinet Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

3–1 Handling the HA3000 Series Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–2 HA3000 Series UPS Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

4–1 UPS Cabinet Power Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4–2 Yellow Jumper Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4–3 UPS Cabinet Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . 4–5

4–4 UPS Battery Cabinet Power and Control Wiring Connections . . . . . . . 4–11

4–5 UPS Auxiliary Cabinet Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . 4–14

4–6 Right Side Cable Entry Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

4–7 UPS Auxiliary Cabinet Cable Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–16

4–8 Connecting the Isolation Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . 4–19

4–9 UPS Input and Bypass Input Isolation Transformer Configuration . . . 4–20

4–10 UPS Bypass Input Isolation Transformer Configuration . . . . . . . . . . . . 4–20

4–11 Alternate UPS Bypass Input Isolation Transformer Configuration . . . . 4–21

4–12 UPS Input Isolation Transformer Configuration . . . . . . . . . . . . . . . . . . 4–21

4–13 UPS Cabinet Without Input Harmonic Current Filter Installed . . . . . . 4–22

4–14 UPS Cabinet with Input Harmonic Current Filter Installed . . . . . . . . . 4–23

4–15 UPS CSA Cabinet Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

4–16 Right Side Cable Entry Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–25

4–17 HA33D UPS CSA Cabinet Wiring Diagram . . . . . . . . . . . . . . . . . . . . . 4–27

4–18 HA33F UPS CSA Cabinet Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 4–28

4–19 UPS Distribution Cabinet Mounting Holes . . . . . . . . . . . . . . . . . . . . . . 4–30

4–20 Square-D Distribution Panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–33

4–21 Bryant Distribution Panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–34

Tables

2–1 Standard HA32A UPS Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

2–2 UPS Battery Cabinet Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2–3 UPS Auxiliary Cabinet Weights and Dimensions . . . . . . . . . . . . . . . . . 2–9

2–4 UPS CSA Cabinet Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . 2–11

2–5 UPS Distribution Cabinet Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2–14

4–1 HA32A Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

4–2 Maximum DC Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

4–3 Interbattery Link Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

4–4 HA32C/D/E UPS Auxiliary Cabinet Electrical Specifications . . . . . . . . 4–17

4–9 HA33D/F UPS CSA Cabinet Electrical Specifications . . . . . . . . . . . . . . 4–26

B–1 Standard HA32A UPS Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–4

B–2 HA32A Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–5

B–3 UPS Battery Cabinet Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . B–6

B–4 Maximum DC Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . B–6

B–5 Interbattery Link Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–7

B–6 UPS Auxiliary Cabinet Weights and Dimensions . . . . . . . . . . . . . . . . . B–7

B–7 HA32C/D/E UPS Auxiliary Cabinet Electrical Specifications . . . . . . . . B–8

B–8 UPS CSA Cabinet Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . B–10

B–9 HA33D/F UPS CSA Cabinet Electrical Specifications . . . . . . . . . . . . . . B–10

Contents vii

B–10 UPS Distribution Cabinet Specifications . . . . . . . . . . . . . . . . . . . . . . . . B–11

AboutThisManual

OVERVIEW

This manual is intended for use by the customer for site preparation, by the customer’s

electrician to install the HA3000 20-80 kVA series Uninterruptible Power System (UPS),

and by the Digital Services Engineer to ensure proper installation before performing

the startup procedures. It provides site preparation information and instructions for

receiving, handling, storing, and installing the UPS for the customer and the customer’s

electrician. The installation must be completed before calling Digital Services to

perform the startup procedures. Incomplete installation will result in startup

delays.

WARNING

The HA32B UPS Battery Cabinet contains batteries that are wired together to

produce a high voltage. Even with no external connections, hazardous voltage

exists inside the UPS Battery Cabinet that can cause severe burns or death

upon contact.

The manual covers the following topics:

• Chapter 1 contains a checklist of the responsibilities of the customer, customer’s

electrician, trucker/mover/rigger, and Digital Services during site preparation,

delivery/handling, installation, and startup of the HA3000 series UPS.

• Chapter 2 contains site preparation information for the HA32A UPS cabinet, the

HA32B UPS Battery Cabinet, the HA32C/D/E UPS Auxiliary Cabinet, the HA33D/F

UPS CSA Cabinet, and the HA32J/K UPS Distribution Cabinet.

• Chapter 3 contains information for receiving and handling the HA3000 series

equipment cabinets.

• Chapter 4 contains the installation procedures for the HA32A UPS cabinet, the

HA32B UPS Battery Cabinet, the HA32C/D/E UPS Auxiliary Cabinet, the HA33D/F

UPS CSA Cabinet, the HA32J/K UPS Distribution Cabinet, the HA320-AA/AB

Remote Status Panel, the HA320-A3 Remote Alarm Panel, the HA320-B1 Smoke

Detector, and the HA320-C2 DC Ground Fault Detector.

• Appendix A contains electrical considerations for the HA32A UPS cabinet.

• Appendix B contains specification tables for the HA3000 series components.

ix

x About This Manual

RELATED DOCUMENTS

Title Part Number

HA3000 20-80 kVA Uninterruptible Power System User Guide EK-HA32X-UG

HA3000 20-80 kVA Uninterruptible Power System Installation Drawings EK-HA32X-ID

HA3000 Uninterruptible Power System Handling Instructions EK-HA32X-HI

HA3000 Uninterruptible Power System Technical Manual EK-HA32X-TM

INSTALLATIONREFERENCECHECKLISTS

1.1 CUSTOMER RESPONSIBILITIES

The following sections contain checklists of the responsibilities of the customer during

site preparation and delivery/handling of the HA3000 series UPS.

1.1.1 Site Preparation

The customer’s responsibilities during site preparation are listed below.

Check Off Function Task

1

Electrical

Connections

Site Selection Select the area where the HA3000 series UPS will be

Physical Size and

Weight

Physical Placement Determine the exact physical placement of the

Floor Loading Ensure that the floor can support the total

Obtain an electrician to perform the electrical

connections that are described in Chapter 4.

installed. Where it is located will have a bearing on

the electrical installation cost and installation time.

NOTE: It is highly recommended that the HA3000

series UPS be installed in a computer room

environment with a raised floor.

Obtain the size and weight information on the HA3000

series cabinets that are to be installed. Refer to the

HA3000 20-80 kVA Uninterruptible Power System

Installation Drawings (EK-HA32X-ID) or to Chapter 2

in this manual.

cabinets. The cabinet dimensions and service

clearances must be taken into consideration. The

following is a list of the minimum service clearances

required.

Rear - 60.96 cm (24 in)

Front - 121.92 cm (48 in)

Side - 60.96 cm (24 in) on each end of the cabinet

configuration

Top - 91.44 cm (36 in)

NOTE: Local codes may require more clearance.

configuration weight. If there is any question in this

regard, a structural engineer should be consulted.

1–1

1–2 INSTALLATION REFERENCE CHECKLISTS

Check Off Function Task

Configuration Layout Plan the configuration layout using the following

Floor Marking Mark the outside dimensions of the cabinet

Floor Cutouts On a raised floor, ensure that floor tile cutouts are

Inside Delivery

Route

placement order (left to right): UPS Battery Cabinet(s),

UPS cabinet, UPS Auxiliary Cabinet, UPS CSA

Cabinet, and UPS Distribution Cabinet.

configuration and the floor cutouts on the floor with

tape so that placement and any floor cutouts will be in

the correct place.

provided for cool air supply and cabling. Refer to the

HA3000 20-80 kVA Uninterruptible Power System

Installation Drawings (EK-HA32X-ID) for the cable

entry areas on the UPS cabinet, the UPS Battery

Cabinet, and the UPS Distribution Cabinet.

CAUTION: If perforated tiles are used for cooling,

ensure that air restricting baffles are not installed

beneath them.

Ensure that there is an unobstructed inside delivery

path to the final installation position. Ensure that

elevators, ramps, and flooring along this path can

handle the equipment weights and dimensions.

1.1.2 Delivery/Handling

The customer’s responsibilities during delivery/handling are listed below.

Check Off Function Task

Site Delivery

Coordination

Configuration

Assembly

Final Assembly Assist Digital Services in replacing all exterior skins.

Assist Digital Services in assuring proper delivery and

placement of the HA3000 series cabinets.

Assist Digital Services in removing the appropriate

side skins and cover plates before the cabinets are in

their final position.

Check to ensure that all cabinets are complete.

INSTALLATION REFERENCE CHECKLISTS 1–3

1.2 TRUCKER/MOVER/RIGGER RESPONSIBILITIES

The trucker/mover/rigger’s responsibilities during delivery/handling are listed below.

Check Off Function Task

Inside Delivery and

Handling

Caster Assembly

Removal

Deliver the HA3000 series cabinets from the padded

van to the final resting place at the customer’s site.

Follow the handling instructions in Chapter 3.

Remove the yellow caster assemblies beneath each

cabinet after the cabinets have been moved to their

final resting place.

1.3 ELECTRICIAN RESPONSIBILITIES

The following sections contain the responsibilities of the electrician during the

installation of the HA3000 series UPS. The electrician should refer to the HA3000

20-80 kVA Uninterruptible Power System Installation Drawings (EK-HA32X-ID) and to

the procedures in Chapter 4 when performing the actual installation. All electrical site

wiring must comply with the National Electrical Code (ANSI/NFPA 70) and with local

codes as applicable.

1.3.1 HA32A UPS Cabinet

The electrician’s responsibilities during the installation of the HA32A-xx UPS cabinet are

listed below.

Check Off Function Task

Cable Entry/Exit Perform the cable knockouts and provide the fittings

Input Conductor

Sizing

MAINS1 Input

Conductors (supplied

by the electrician)

MAINS2 Input

Conductors (supplied

by the electrician)

and conduits for this cabinet. Bottom or right-side

cable entry is possible. Refer to Figure 2–1, Figure 2–2,

and Figure 2–3.

Determine the input conductor sizing for the UPS. The

circuit rating needs to be matched to the input circuit

breaker for the unit being installed. Refer to Table 2–1

for the input circuit breaker ratings for the different

UPS models.

Provide four wires for the MAINS1 input; three phase

conductors and a ground. If only one power source

is to be used for the MAINS1 and MAINS2 inputs,

the MAINS1 and MAINS2 busbars must be jumpered

together using the correct gauge wire.

Provide five wires for the MAINS2 input; three phase

conductors, a neutral1(all four of equal ampacity), and

a ground. If only one power source is to be used for

the MAINS1 and MAINS2 inputs, the MAINS1 and

MAINS2 busbars must be jumpered together using the

correct gauge wire. If no neutral1is available from

the building distribution system (for example, DELTA

only service entrance), a UPS Auxiliary Cabinet with

an input isolation transformer may be used to derive a

neutral for the UPS cabinet.

1

If an HA32A-Cx cabinet is being installed, a neutral conductor is not required.

1–4 INSTALLATION REFERENCE CHECKLISTS

1.3.2 HA32B UPS Battery Cabinet

The electrician’s responsibilities during the installation of the HA32B-xx UPS Battery

Cabinet are listed below.

Check Off Function Task

Cable Entry/Exit Perform the cable knockouts and provide the fittings

Power and Ground

Connections

(supplied by the

electrician)

Cable Connections Connect the cables from the dc output busbars in the

Control Wire

Connections

(supplied by the

electrician)

Control Wire

Connections

(supplied by the

electrician)

Option Dependent

Control Wire

Connections

(supplied by the

electrician)

Option Dependent

Control Wire

Connections

(supplied by the

electrician)

and conduits for this cabinet. Refer to the HA3000

20-80 kVA Uninterruptible Power System Installation

Drawings (EK-HA32X-ID) for cable entry/exit location.

Provide three power cables and crimp terminals;

positive, negative, and ground. The battery wiring

should be sized to keep the total cable voltage drop to

less than 0.5 Vdc at the current shown in Table 4–2.

UPS Battery Cabinet (Figure 4–4) to the dc input

busbars in the UPS cabinet (Figure 4–1). Correct

dc polarity must be observed when making these

connections.

Provide two control wires (600 V rated) for the QF1

24 Vdc UV Release, and connect them from TB1-1

and TB1-2 in the UPS Battery Cabinet (Figure 4–4) to

TB1-1 and TB1-2 in the UPS cabinet (Figure 4–3).

Provide two control wires (600 V rated) for the QF1

Auxiliary Contacts, and connect them from TB1-4 and

TB1-5 in the UPS Battery Cabinet (Figure 4–4) to

TB1-4 and TB1-5 in the UPS cabinet (Figure 4–3).

Provide two control wires (600 V rated) if the DC

Ground Fault Detector is installed in the UPS Battery

Cabinet, and connect them from TB1-7 and TB1-8 in

the UPS Battery Cabinet (Figure 4–4) to TB1-7 and

TB1-8 in the UPS cabinet (Figure 4–3).

Provide four control wires (600 V rated) if the Smoke

Detector is installed in the UPS Battery Cabinet,

and connect them from TB1-9, TB1-10, TB1-11, and

TB1-12 in the UPS Battery Cabinet (Figure 4–4) to

TB1-9, TB1-10, TB1-11, and TB1-12 in the UPS cabinet

(Figure 4–3).

INSTALLATION REFERENCE CHECKLISTS 1–5

1.3.3 HA32C/D/E UPS Auxiliary Cabinet

The electrician’s responsibilities during the installation of the HA32C/D/E UPS Auxiliary

Cabinet are listed below.

Check Off Function Task

Cable Entry/Exit Perform the cable knockouts and provide the fittings

Input Conductors

(supplied by the

electrician)

Output Conductors Connect the four output cables that are factory

Harmonic Filter

Connections

Control Wire

Connections

and conduits for this cabinet. Right-side cable entry is

possible (Figure 4–6). Refer to the HA3000 20-80 kVA

Uninterruptible Power System Installation Drawings

(EK-HA32X-ID).

Provide four power cables; three phase conductors

and a ground conductor (all of equal ampacity) if the

UPS Auxiliary Cabinet contains an input isolation

transformer. Refer to Table 4–4 for current ratings.

Refer to the UPS Auxiliary Cabinet installation

instructions in Chapter 4 when making the ac input

cable connections.

If no neutral1is available from the building

distribution system (for example, DELTA only service

entrance), a UPS Auxiliary Cabinet with an input

isolation transformer may be used to derive a neutral

for the UPS cabinet.

installed in the UPS Auxiliary Cabinet, if the

UPS Auxiliary Cabinet contains an input isolation

transformer, to the main ac input (MAINS1) or

bypass ac input (MAINS2) and neutral busbars in

the UPS cabinet. Refer to the UPS Auxiliary Cabinet

installation instructions in Chapter 4 when making the

output cable connections.

Connect the six cables from the UPS Auxiliary Cabinet

to the UPS cabinet if the UPS Auxiliary Cabinet

contains an input harmonic current filter. Refer

to Figure 4–13 and Figure 4–14 when making the

connections.

Connect the two factory installed control wires in the

UPS Auxiliary Cabinet to TB2-11 and TB2-12 in the

UPS cabinet (Figure 4–3).

1

If an HA32A-Cx cabinet is being installed, a neutral conductor is not required.

1–6 INSTALLATION REFERENCE CHECKLISTS

1.3.4 HA33D/F UPS CSA Cabinet

The electrician’s responsibilities during the installation of the HA33D/F UPS CSA

Cabinet are listed below.

Check Off Function Task

Cable Entry/Exit Perform the cable knockouts and provide the fittings

Input Conductors

(supplied by the

electrician)

Output Conductors Connect the output cables that are factory installed in

Control Wire

Connections

and conduits for this cabinet. Right-side cable entry is

possible (Figure 4–16). Refer to the HA3000 20-80 kVA

Uninterruptible Power System Installation Drawings

(EK-HA32X-ID).

Provide five power cables; three phase conductors, a

ground conductor, and neutral (all of equal ampacity)

if the UPS CSA Cabinet contains a CSA assembly

only. Refer to the UPS CSA Cabinet installation

instructions in Chapter 4 when making the ac input

cable connections.

Provide four power cables; three phase conductors and

a ground conductor (all of equal ampacity) if the UPS

CSA Cabinet contains an input isolation/step-down

transformer and a CSA assembly. Refer to Table B–9

for current ratings. Refer to the UPS CSA Cabinet

installation instructions in Chapter 4 when making the

ac input cable connections.

the UPS CSA Cabinet to the main ac input (MAINS1)

and bypass ac input (MAINS2) busbars in the UPS

cabinet. Refer to the UPS CSA Cabinet installation

instructions in Chapter 4 when making the output

cable connections.

Connect the two factory installed control wires in the

UPS CSA Cabinet to TB2-11 and TB2-12 in the UPS

cabinet (Figure 4–3).

INSTALLATION REFERENCE CHECKLISTS 1–7

1.3.5 HA32J/K UPS Distribution Cabinet

The electrician’s responsibilities during the installation of the HA32J/K UPS Distribution

Cabinet are listed below.

Check Off Function Task

Cable Entry/Exit Use the factory installed distribution cable knockout

Input Power

Cables (without

isolation/step-down

transformer)

Input Power Cables

(with isolation/stepdown transformer)

Control Wire

Connections (with

isolation/step-down

transformer)

Output Distribution

Cables

Distribution Circuit

Breakers

Panelboard Labeling Identify on the panelboard labels what each circuit has

panels located behind the dead-front panels. Input

power to this cabinet is routed through the left-side

cable feed area (Figure 4–19).

Route the three phase conductors, the neutral

conductor, and the ground conductor that are factory

attached in cabinets without an isolation/step-down

transformer, from the UPS Distribution Cabinet to the

three phase, neutral, and ground busbars (Figure 4–1)

in the UPS cabinet and attach.

NOTE: If the site has a UPS Auxiliary Cabinet or a

UPS CSA Cabinet, the cables will run through cable

trays in these cabinets on their way to the UPS cabinet

(Figure 4–7).

Route the three phase conductors and the ground

conductor that are factory attached in cabinets with

an isolation/step-down transformer, from the UPS

Distribution Cabinet to the three phase and ground

busbars (Figure 4–1) in the UPS cabinet and attach.

NOTE: If the site has a UPS Auxiliary Cabinet or a

UPS CSA Cabinet, the cables will run through cable

trays in these cabinets on their way to the UPS cabinet

(Figure 4–7).

Connect the two factory installed control wires in the

UPS Distribution Cabinet with an isolation/step-down

transformer to TB2-11 and TB2-12 in the UPS cabinet

(Figure 4–3).

Use the knockout panels located directly below the

panelboards behind the dead-front panel for routing

distribution cables.

Provide any required distribution circuit breakers and

cables.

NOTE: Distribution cables may be purchased from

Digital or made by the electrician. If the distribution

cables are made by the electrician, Digital recommends

that the receptacles be of the isolated ground type (see

Section 4.6.4).

for receptacles.

1–8 INSTALLATION REFERENCE CHECKLISTS

1.3.6 HA320-A3 Remote Alarm Panel

The electrician’s responsibilities during the installation of the HA320-A3 Remote Alarm

Panel are listed below.

Check Off Function Task

Mounting Mount the Remote Alarm Panel in the selected

Control Wiring

Connections

(supplied by the

electrician)

Power Connections

(supplied by the

electrician)

location.

Provide six control wires, 600 V rated, and connect

them from TB3 in the Remote Alarm Panel to TB2 and

TB3 in the UPS cabinet (refer to Section 4.2.7.2).

Provide two power wires and connect them from a 120

Vac source to TB3-14 and TB3-15 in the Remote Alarm

Panel.

INSTALLATION REFERENCE CHECKLISTS 1–9

1.4 DIGITAL SERVICES RESPONSIBILITIES

The following sections contain the responsibilities of Digital Services during site

preparation, delivery/handling, and initial startup of the HA3000 series UPS.

1.4.1 Site Preparation

Digital Services responsibilities during site preparation are listed below.

Check Off Function Task

Physical Size and

Weight

Electrical

Requirements

Physical Placement Aid the customer in determining the exact physical

Configuration Layout Aid the customer in planning the configuration layout

Inside Delivery

Route

Aid the customer in obtaining the size and weight

information on the HA3000 series cabinets that

are to be installed. Refer to the HA3000 20-80 kVA

Uninterruptible Power System Installation Drawings

(EK-HA32X-ID) or to Chapter 2 in this manual.

Aid the customer in ensuring that the customer’s

electrician has the documentation and electrical

requirements necessary for performing the installation.

placement of the cabinets. The cabinet dimensions and

service clearances must be taken into consideration.

The following is a list of the minimum service

clearances required.

Rear - 60.96 cm (24 in)

Front - 121.92 cm (48 in)

Side - 60.96 cm (24 in) on each end of the cabinet

configuration

Top - 91.44 cm (36 in)

NOTE: Local codes may require more clearance.

using the following placement order (left to right):

UPS Battery Cabinet(s), UPS cabinet, UPS Auxiliary

Cabinet, UPS CSA Cabinet, and UPS Distribution

Cabinet.

Aid the customer in ensuring that there is an

unobstructed inside delivery path to the final

installation position. Aid the customer in ensuring

that elevators, ramps, and flooring along this path can

handle the equipment weights and dimensions.

1–10 INSTALLATION REFERENCE CHECKLISTS

1.4.2 Delivery/Handling

Digital Services responsibilities during delivery/handling are listed below.

Check Off Function Task

Site Delivery

Coordination

Configuration

Assembly

Final Assembly Assist the customer in replacing all exterior skins.

Assist the customer in assuring proper delivery and

placement of the HA3000 series cabinets.

Assist the customer in removing the appropriate side

skins and cover plates before the cabinets are in their

final position.

Check to be sure that all cabinets are complete.

1.4.3 Initial Startup

Digital Services responsibilities during initial startup of the HA3000 series cabinets are

listed below.

Check Off Function Task

Prestartup Checks Perform the checks before startup by referring to

Option Checks If the Remote Alarm Panel, the Smoke Detector, or the

Initial Startup Perform the initial startup procedure by referring to

Initial Startup Tests Perform the initial startup tests by referring to

Option Verification If the Remote Alarm Panel, the Smoke Detector, or the

Operator Training Demonstrate the operating modes and controls for the

Customer

Registration

Chapter 3 in the HA3000 20-80 kVA Uninterruptible

Power System Technical Manual (EK-HA32X-TM).

DC Ground Fault Detector options are installed, verify

the wiring connections.

Chapter 3 in the HA3000 20-80 kVA Uninterruptible

Power System Technical Manual (EK-HA32X-TM).

Chapter 3 in the HA3000 20-80 kVA Uninterruptible

Power System Technical Manual (EK-HA32X-TM).

DC Ground Fault Detector options are installed, verify

them for proper operation.

customer’s operator.

Register the customer and give them the 1-800-525-

7104 number to call if a problem occurs.

2

SITEPREPARATION

2.1 GENERAL

This chapter contains site preparation information for the HA32A UPS cabinet, the

HA32B UPS Battery Cabinet, the HA32C/D/E UPS Auxiliary Cabinet, the HA33D/F UPS

CSA Cabinet, and the HA32J/K UPS Distribution Cabinet.

2.2 STORAGE

If the equipment is to be stored prior to installation, it should be stored in a cool, dry,

well-ventilated location that is protected against rain, splashing water, chemical agents,

and so forth. The equipment should be covered with a tarpaulin or plastic wrapper to

protect it against dirt, paint, or other foreign materials.

The UPS Battery Cabinet should be placed into service within 30 days from the date of

shipment, provided that the UPS Battery Cabinet is not stored in a location where it has

been exposed to temperature exceeding 25°C (77°F). Storage at higher temperatures will

reduce storage life, and may reduce battery life.

CAUTION

Never store batteries in a discharged condition. Always recharge batteries for

at least 24 hours before storage.

2–1

2–2 SITE PREPARATION

2.3 HA32A UPS CABINET

The HA3000 series of UPS equipment is intended for use in a computer room

environment (controlled temperature and humidity) and should be installed on a raised

computer room floor. Wiring for power and control cables can be accommodated through

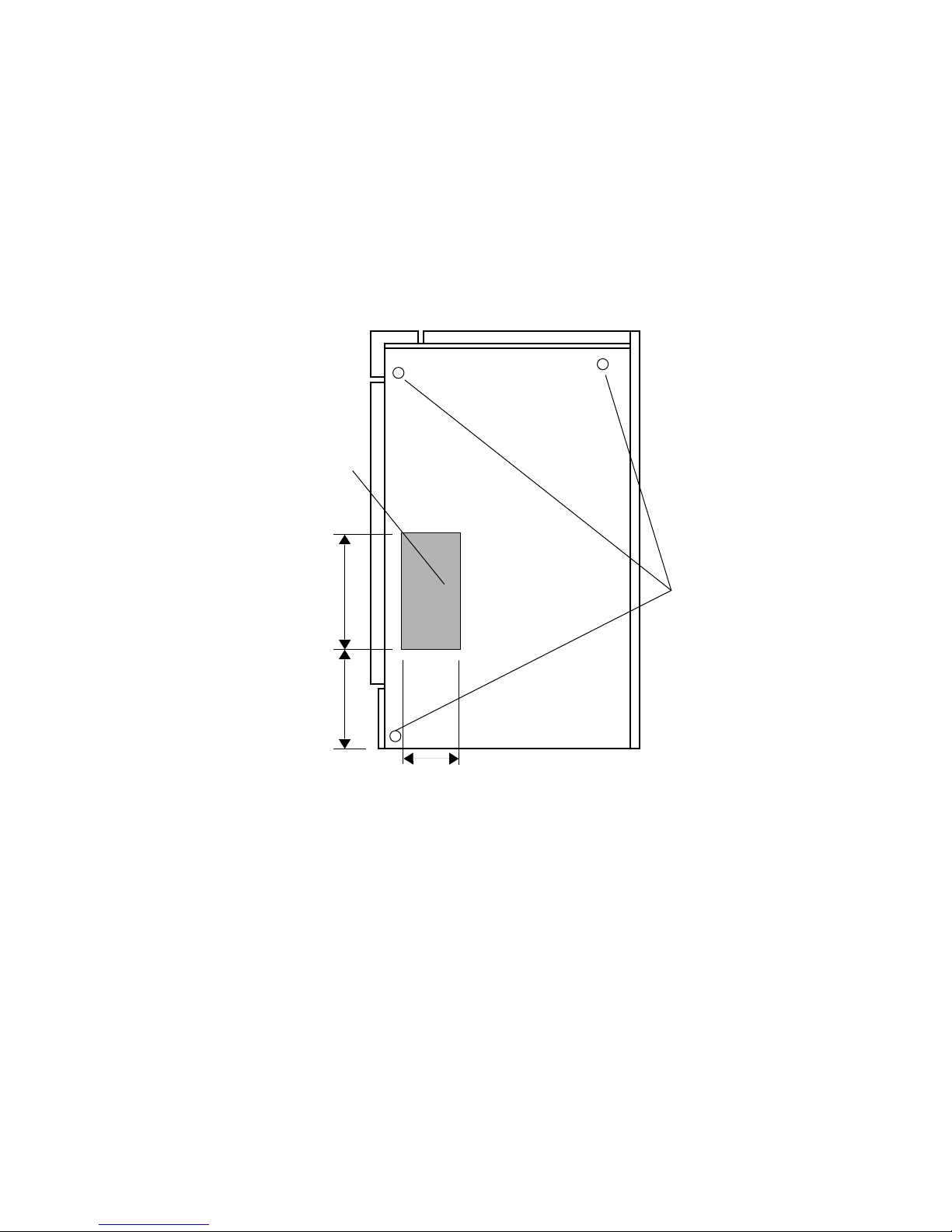

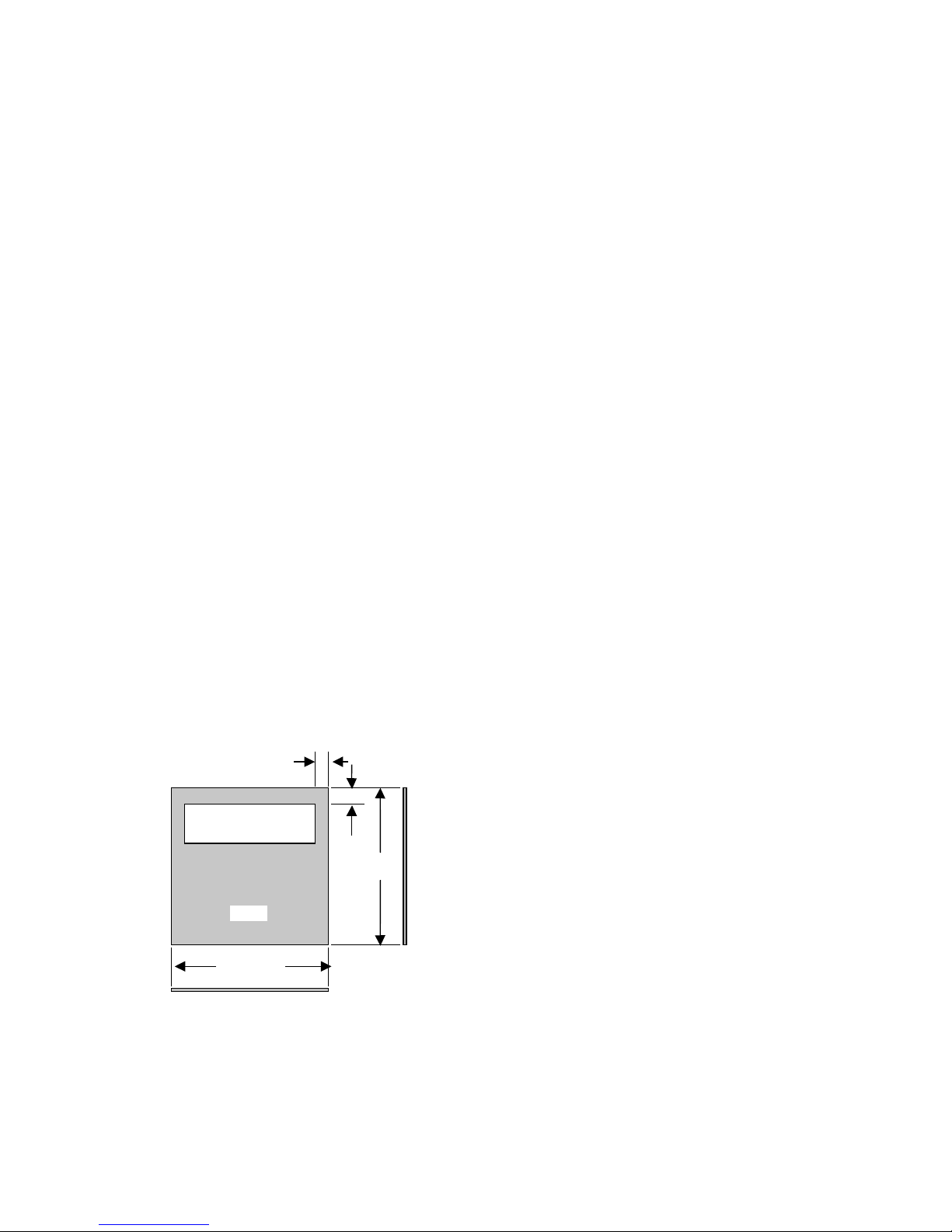

the bottom of the equipment, or through the right side of each enclosure. Right-side wire

entry for the UPS cabinet can be accommodated through the right-side panel (Figure 2–1)

or by use of the UPS Auxiliary Cabinet or the UPS CSA Cabinet.

TOP

FRONT

BACK

REMOVABLE COVER PLATE

SIDE CABLE ENTRY AREA

419 mm

(16.50 in)

191 mm

(7.5 in)

229 mm

(9.00 in)

RIGHT-SIDE VIEW OF UPS

Figure 2–1 Right-Side Cable Access for the UPS Cabinet

MOUNTING HOLES

(3 PLACES)

MKV-A2200-91

SITE PREPARATION 2–3

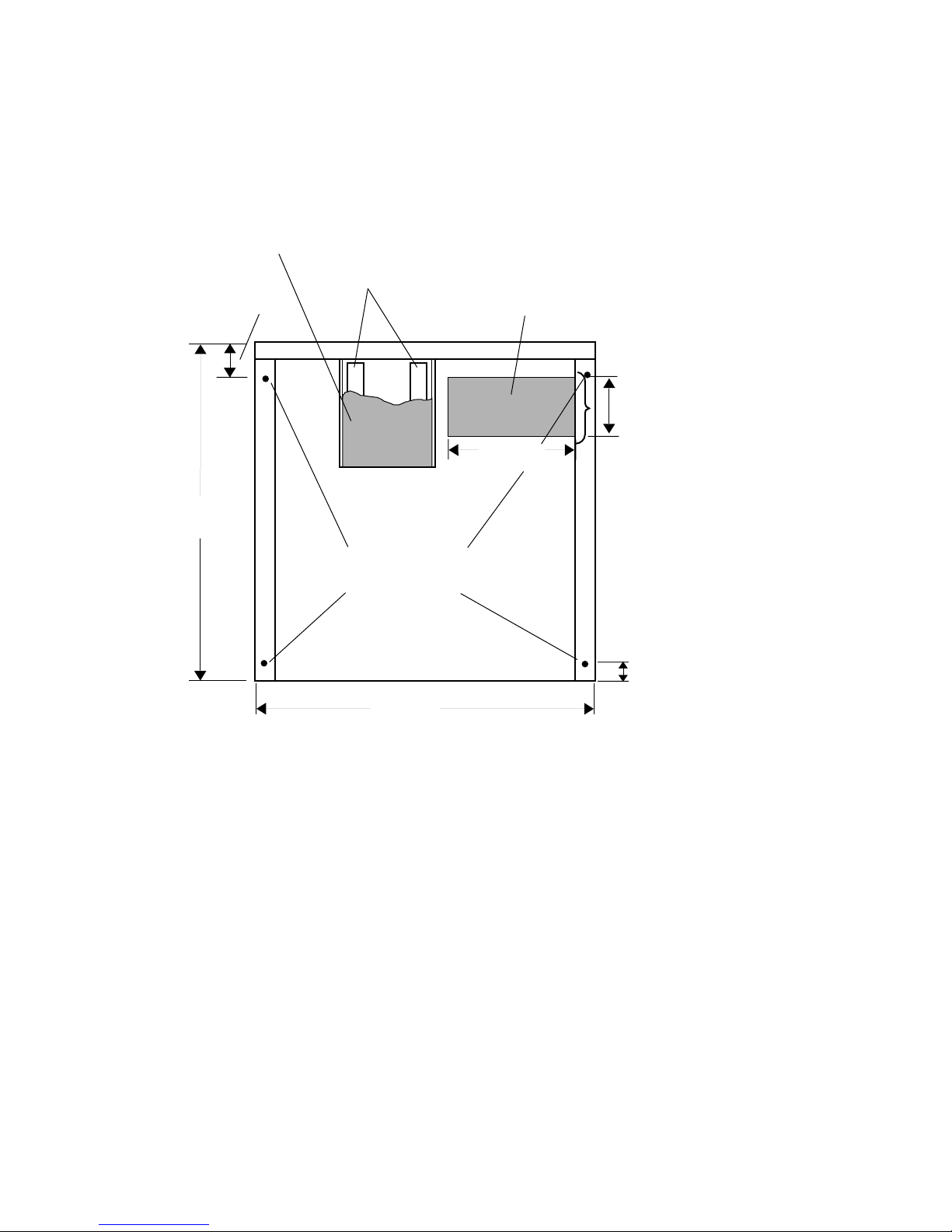

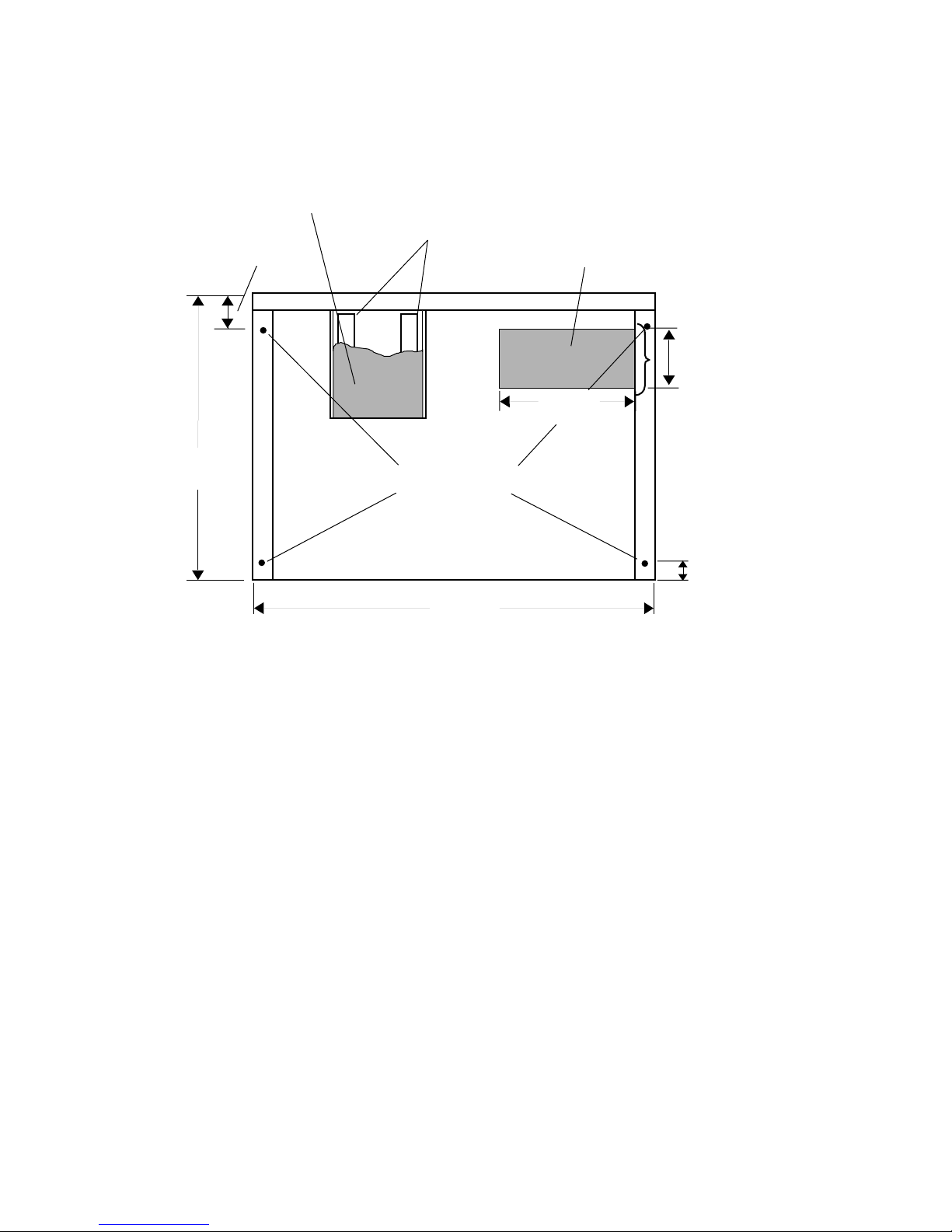

The designated bottom cable entry area for the UPS cabinet is shown in Figure 2–2 for

models rated 20 and 40 kVA, and in Figure 2–3 for models rated 60 and 80 kVA.

FRONT

DRAW-OUT AIR FILTER

(REMOVE DURING SHIPPING)

817 mm

(32.18 in)

86.4 mm

(3.40 in)

AIR INTAKE

REMOVABLE COVER PLATE

BOTTOM CABLE ENTRY AREA

200 mm

(7.88 in)

220 mm

(8.66 in)

MOUNTING HOLES

9 mm DIAMETER (0.375 in)

4 PLACES

50.8 mm

(2.00 in)

800 mm

(31.5 in)

BACK

BOTTOM VIEW LOOKING UP

Figure 2–2 Bottom View, 20 and 40 kVA Models

MKV-A2201-91

2–4 SITE PREPARATION

DRAW-OUT AIR FILTER

(REMOVE DURING SHIPPING)

86.4 mm

(3.40 in)

FRONT

AIR INTAKE

REMOVABLE COVER PLATE

BOTTOM CABLE ENTRY AREA

200 mm

(7.88 in)

356 mm

(14 in)

817 mm

(32.18 in)

MOUNTING HOLES

9 mm DIAMETER (0.375 in)

4 PLACES

50.8 mm

(2.00 in)

800 mm

(31.5 in)

BACK

BOTTOM VIEW LOOKING UP

MKV-A2202-91

Figure 2–3 Bottom View, 60 and 80 kVA Models

For UPS equipment installed on a raised computer room floor, two floor through-holes

should be provided beneath the enclosure. One is for cabling and the other serves as an

air inlet for the cooling air required by the UPS. See Figure 2–2 or Figure 2–3 for the

location of these holes for your UPS.

NOTES

For nonraised floor installations, the area under the draw-out air filter must be

kept clear of obstructions for filter installation and servicing.

The UPS dissipates heat and exhausts warm air through the top portion of the enclosure.

Refer to Table 2–1 for heat dissipated (Btu/Hr). Air exhaust for models rated 20 and 40

kVA is 1200 cubic feet per minute (CFM). Air exhaust for models rated 60 and 80 kVA is

1600 CFM.

SITE PREPARATION 2–5

Table 2–1 also lists the weight and dimensions of the HA32A UPS cabinets.

Table 2–1 Standard HA32A UPS Models

Nominal

Model

Number

HA32A-AH 20/16 208 80 208Y/120 800/31.5 488/1,075 8,189

HA32A-DH 20/16 220 80 220Y/127 800/31.5 488/1,075 8,189

HA32A-BH 20/16 480 40 208Y/120 800/31.5 488/1,075 8,189

HA32A-CH 20/16 480 40 480Y/277 800/31.5 488/1,075 8,189

HA32A-AK 40/32 208 175 208Y/120 800/31.5 628/1,385 15,013

HA32A-DK 40/32 220 175 220Y/127 800/31.5 628/1,385 15,013

HA32A-BK 40/32 480 80 208Y/120 800/31.5 628/1,385 15,013

HA32A-CK 40/32 480 80 480Y/277 800/31.5 628/1,385 15,013

HA32A-AM 60/48 208 250 208Y/120 1,143/45.0 783/1,725 20,130

HA32A-DM 60/48 220 250 220Y/127 1,143/45.0 783/1,725 20,130

HA32A-BM 60/48 480 100 208Y/120 1,143/45.0 783/1,725 20,130

HA32A-CM 60/48 480 100 480Y/277 1,143/45.0 783/1,725 20,130

Rating

kVA/kW

Output

Input

Voltage

(Volts)

3

Input

CB

Rating

(Amps)

Output

Voltage

(Volts)

3

Width

mm/in

Approx.

Weight

kg/lbs

Loss

(Full

Load)

Btu/Hr

Heat

HA32A-AN 80/64 208 350 208Y/120 1,143/45.0 1,023/2,250 26,954

HA32A-DN 80/64 220 350 220Y/127 1,143/45.0 1,023/2,250 26,954

HA32A-BN 80/64 480 150 208Y/120 1,143/45.0 1,023/2,250 26,954

HA32A-CN 80/64 480 150 480Y/277 1,143/45.0 1,023/2,250 26,954

Height of all models: 1,402 mm/55.18 in.

Depth of all models: 817 mm/32.18 in.

The HA32A UPS cabinet is a standalone enclosure. The HA32B UPS Battery Cabinet is

a standalone enclosure. The HA32C/D/E UPS Auxiliary Cabinet, when used, attaches to

the right side of the HA32A UPS cabinet. The HA33D/F UPS CSA Cabinet, when used,

attaches to the right side of the HA32A UPS cabinet or the right side of the HA32C/D/E

UPS Auxiliary Cabinet. The HA32J/K UPS Distribution Cabinet, when used, attaches

to the right side of the HA32A UPS cabinet, the right side of the HA32C/D/E UPS

Auxiliary Cabinet, or the right side of the HA33D/F UPS CSA Cabinet. Refer to the

HA32B, HA32C/D/E, HA33D/F, and HA32J/K installation information before performing

the HA32A UPS cabinet installation.

2–6 SITE PREPARATION

2.4 HA32B UPS BATTERY CABINET

Before installation of the UPS Battery Cabinet, consideration must be given to the

environmental and the structural integrity of its intended location. The electrical wiring

must meet both local and national electrical codes.

2.4.1 Environmental Considerations

• Air Temperature: The recommended operating temperature is 25°C (77°F).

The UPS Battery Cabinet adds an insignificant amount of heat to the environment

when fully charged, and normally is not calculated when sizing the capacity of an air

conditioner.

• Air Quality: The UPS Battery Cabinet should be provided with air free of

contaminants such as excessive moisture, vapor, flammable gases, chemical fumes,

salt, or excessive dirt and dust.

• Ventilation: The UPS Battery Cabinet is designed for operation on a raised

computer room floor or a concrete floor. Cooling air for the UPS Battery Cabinet

is typically provided through a perforated floor tile on a computer room floor. Cutouts

are necessary for bottom access cables only.

• Humidity: 10 to 90%, noncondensing.

• Altitude: Sea level to 2,134 meters (7,000 feet).

2.4.2 Mechanical Considerations

• Floor Tile Cutout: A floor tile cutout is required to provide bottom cable entry to

the UPS Battery Cabinet. When the UPS Battery Cabinet is installed on a raised

computer floor, its weight should be evenly distributed. Locate the corners of the UPS

Battery Cabinet as close as possible to the corners of the tiles. Figure 2–4 gives the

nominal dimensions and location for this cutout.

2 INCH (TYPICAL)

2.5 INCH

6 INCH BY 20 INCH

CUT OUT

24 INCH

(REF)

TILE

TILE FRONT

24 INCH

(REF)

Figure 2–4 Floor Tile Cutout

MKV-A2203-91

SITE PREPARATION 2–7

• Floor Loading: The weight of the UPS Battery Cabinet must be considered when

planning the equipment or computer room layout. The floor must be capable

of supporting the weight of the UPS Battery Cabinet, as well as all associated

equipment (UPS, air conditioning system, furniture, and so forth.) as oriented on

your equipment or computer room layout. Particular attention to weight must be

given when the equipment is installed on a floor raised above ground level. The

approximate weight and dimensions of the UPS Battery Cabinets are listed in

Table 2–2.

• Service Area: The UPS Battery Cabinet requires rear, top, and front access for

servicing. At least 610 mm (24 in.) at the rear of the unit should be allowed for

service. At least 914 mm (36 in.) of clearance above the unit should be allowed for

normal ventilation. At least 1,219 mm (48 in.) in front of the unit should be allowed

for service. This will provide sufficient area to allow the pull-out rack assembly to be

removed from the unit.

Table 2–2 UPS Battery Cabinet Model Numbers

Circuit

Model

Number

kVA

Rating

Nominal

Protection

in Minutes

Breaker

(QF1)

Rating in

Amperes

Width of

Battery

Cabinet

(mm/in)

Approx.

Installed

Weight

(kg/lbs)

HA32B-AH 20 5 90 800/31.5 530/1,169

HA32B-CH 20 15 90 800/31.5 530/1,169

HA32B-FH 20 30 90 1,143/45.0 905/1,995

HA32B-AK 40 5 125 800/31.5 530/1,169

HA32B-CK 40 14 125 1,143/45.0 905/1,995

HA32B-FK

1

40 30 125 2 x 1,143/45.0 2 x 826/1,820

HA32B-AM 60 5 175 1,143/45.0 905/1,995

HA32B-CM

HA32B-FM

1

60 10 175 2 x 1,143/45.0 2 x 826/1,820

1

60 30 175 2 x 1,143/45.0 2 x 826/1,820

HA32B-AN 80 5 225 1,143/45.0 905/1,995

HA32B-CN

HA32B-FN

1

Consists of two battery cabinets with same dimensions and weight.

1

80 14 225 2 x 1,143/45.0 2 x 826/1,820

1

80 22 225 2 x 1,143/45.0 2 x 905/1,995

Height of all models: 1,402 mm/55.18 in.

Depth of all models: 817 mm/32.18 in.

2–8 SITE PREPARATION

2.5 HA32C/D/E UPS AUXILIARY CABINET

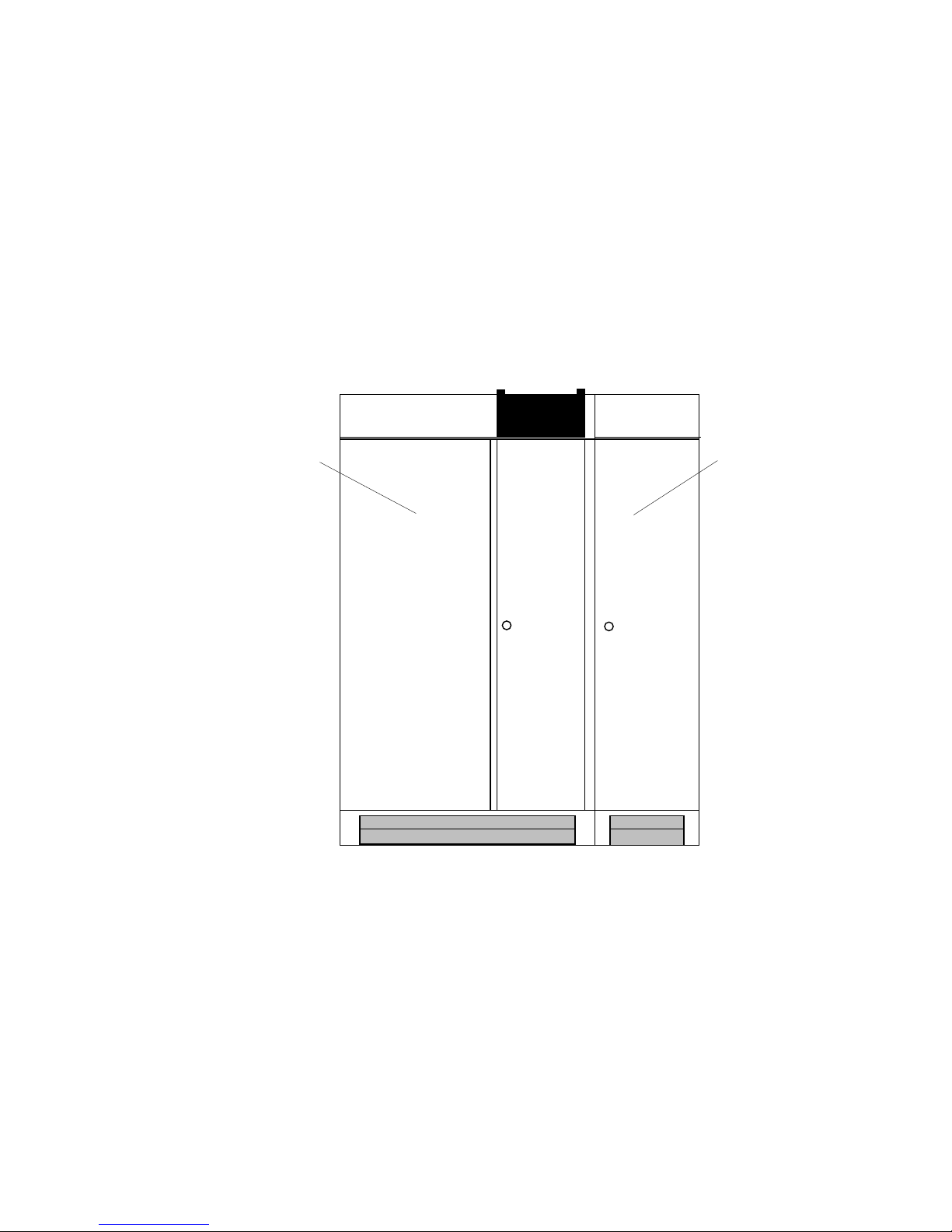

The HA32C/D/E UPS Auxiliary Cabinet is designed to attach to the right side of the

HA32A UPS cabinet (Figure 2–5). The weight and dimensions of the UPS Auxiliary

Cabinets are listed in Table 2–3.

NOTE

The side panels are not provided with the UPS Auxiliary Cabinet. The right

side panel of the UPS cabinet must be removed and attached to the right side of

the UPS Auxiliary Cabinet after installation.

UNINTERRUPTIBLE

HA32A

POWER

SYSTEM

HA32C/D/E

UPS

AUXILIARY

CABINET

MKV-A2204-91

Figure 2–5 UPS Auxiliary Cabinet Placement

Table 2–3 UPS Auxiliary Cabinet Weights and Dimensions

HA32D-XX

Output

Rating

(kVA)

Isolation

Transformer

Only

(kg/lbs)

HA32E-PX

Input Current

Filter Only

(kg/lbs)

20 204/450 154/341 268/591

40 249/550 169/374 328/724

60 327/720 214/473 450/993

80 386/850 260/573 556/1,255

Height of all models: 1,402 mm/55.18 in.

Width of all models: 477 mm/18.78 in.

Depth of all models: 817 mm/32.18 in.

HA32C-XX

Isolation Transformer

and Input Current Filter

(kg/lbs)

SITE PREPARATION 2–9

Loading...

Loading...