Page 1

FP-2500/FP-2600 Series

User Manual

Digital Electronics Corporation

Page 2

1FP-2500/FP-2600 Series User Manual 1

1) It is forbidden to copy the contents of this manual, in whole or in part, except for the

user's personal use, without the express permission of Digital Electronics Corporation of Japan.

2) The information provided in this manual is subject to change without notice.

3) This manual has been written with care and attention to detail; however, should you

find any errors or omissions, please contact Digital Electronics and inform them of

your findings.

4) Regardless of the above clause, Digital Electronics Corporation shall not be held

responsible for any damages or third-party claims for damages or losses resulting

from the use of this product.

All Company/Manufacturer names used in this manual are the registered trademarks of

their respective companies.

© 2004, Digital Electronics Corporation

Thank you for purchasing Digital’s TFT type color display panel, the FP-2500/FP2600 Series unit (hereafter referred to as the FP unit or FP Series).

Please read this manual completely to ensure the correct use and complete understanding of the FP unit's functions.

Preface

<Note>

Page 3

2 FP-2500/FP-2600 Series User Manual

Essential Safety Precautions

This manual describes safety instructions for correct use of the FP unit. Please keep this

manual close at hand and refer to it when necessary .

The following symbols are used throughout this manual to ensure the safe use of the FP

unit. Please be sure to follow all instructions given since they explain important safety

points.

Indicates situations where sever bodily injury , death or

major equipment damage will occur.

Indicates situations where bodily injury or machine

damage can occur .

Warning

Caution

• Prior to connecting the FP-2500/FP-2600 Series (hereafter referred to as the “FP”or FP unit) unit’s power cord

terminals to the Terminal Block, be sure to check that

the FP unit’s power supply is completely turned OFF, via

a breaker, or similar unit.

• Do not use voltage levels that exceed the FP unit’s specified voltage range. Doing so may cause a fire or an electric shock.

• Since the FP unit contains high voltage parts, an electric

shock can occur when opening the unit. Therefore, be

sure to unplug the power cord before opening it.

• Do not modify or remodel the FP unit. Doing so may lead

to a fire or electric shock.

• Do not use FP unit touch panel switches in human-safetyrelated or important disaster prevention situations. For

safety-related switches, such as an emergency stop

switch, be sure to use a separately installed mechanical

switch.

• Do not use the FP unit as a warning device for critical

alarms that can cause serious operator injury, machine

damage or production stoppage. Critical alarm indicators and their control/activator units must be designed

using stand-alone hardware and/or mechanical interlocks.

Essential Safety Precautions

WARNINGS

Page 4

FP-2500/FP-2600 Series User Manual 3

Essential Safety Precautions

• After the FP unit’s backlight burns out, unlike the FP unit’s

“Standby Mode”, the touch panel is still active. If the operator fails to notice that the backlight is burned out and

touches the panel, a potentially dangerous machine operation error can occur. Therefore, do not use FP touch

switches for the control of any equipment safety mechanisms, such as Emergency Stop switches, etc. that protect humans and equipment from injury and damage.

If your FP unit's backlight suddenly turns OFF, use the

following steps to determine if the backlight is actually

burned out.

1) If your current FP application is not set to turn the backlight OFF, and the screen has gone blank, your backlight is burned out.

2) If your current FP application is set to turn the backlight OFF, and if touching the screen does not cause

the display to reappear, your backlight is burned out.

• If substantial amounts of metallic dust, water or liquids

enter the FP unit, turn OFF the power supply immediately, unplug the power cord, and contact your local FP

distributor.

• When installing the FP unit, be sure to follow the instructions given in “Chapter 3 Installation and Wiring".

• Do not use the FP in an environment where flammable

gases are present, since operating the FP may cause an

explosion.

• Do not use the FP with aircraft control devices, aerospace

equipment, central trunk data transmission (communication) devices, nuclear power control devices, or medical

life support equipment, due to these devices’ inherent

requirements of extremely high levels of safety and reliability.

• When using the FP with transportation vehicles (trains,

cars and ships), disaster and crime prevention devices,

various types of safety equipment, non-life support related medical devices and others, be sure to use redundant and/or failsafe system designs to ensure the appropriate degree of system reliability and safety.

• To prevent operator injury or machine damage, be sure

to design your machine operation system so that the

machine will not malfunction due to a communication fault

between the FP unit and its PC host controller.

WARNINGS

Page 5

4 FP-2500/FP-2600 Series User Manual

Essential Safety Precautions

• Do not strike the FP unit’s touch p anel with a hard or heavy

object, or press on the touch panel with too much force,

since it may damage the display.

• When the surface of the display screen becomes dirty or

smudged, clean the display with a cloth soaked in a neutral detergent. Do not use paint thinner or organic solvent.

• Do not press on the touch panel's face with sharp objects, such as a mechanical pencil or screwdriver, since

it might damage the LCD panel.

• Do not use or store the FP in direct sunlight, excessively

dusty or dirty environments, or where chemicals or their

vapors are present in the air.

• Do not restrict the FP unit's natural ventilation, or store or

use the FP in an environment that will increase the FP's

internal temperature.

• Do not use the FP in areas where sudden, large changes

in temperature may occur. These changes can cause condensation to form inside the unit, possibly leading to a

malfunction.

• When the product is disposed of, it should be done so

according to your country's regulations for similar types

of industrial waste.

Notes on the FP unit's Liquid Crystal Display (LCD)

• The FP unit's LCD contains a strong irritant. If the panel

is damaged and the LCD unit's liquid contacts your skin,

be sure to wash it with running water for at least 15 minutes. If any of this liquid should enter your eye, be sure

to flush the eye with running water for more than 15 minutes, and see a doctor immediately.

• The brightness of the LCD screen will depend on the

screen's current display and the LCD unit's contrast adjustment. Any brightness variations that result are normal for LCD displays.

• There are minute grid-points on the LCD surface. These

points are not defects.

CAUTIONS

Page 6

FP-2500/FP-2600 Series User Manual 5

Documentation Conventions

• The displayed color will look different when viewed from

an angle outside the specified view angle. This is also

normal.

• Displaying a single screen image for long periods of time

can cause an afterimage to remain. To correct this, turn

the unit OFF for 5 or 10 minutes, then turn it ON again.

This phenomenon is a common attribute of the LCD unit's

and not a defect. To prevent this effect, you can:

- use the Display OFF feature, if the same image is to be

displayed for a long period of time.

- change the screen display periodically to prevent the displaying of a single image for a long period of time.

Documentation Conventions

Symbol Meaning

Indicates import ant infor mation or pr ocedures that must be followed f or

correct and risk- f ree s of t ware/ device operation.

Refer s t o us eful or import ant s u pplemental inf o rmat ion.

Provides usef ul or import ant s u pplemental inf o rmat ion.

*1

Indicates us ef ul or importan t s upplemental inf or mation .

1) , 2)

Indicates s t eps in a pr ocedure. B e s ur e t o per f or m thes e steps in t he

order given.

The list below describes the documentation conventions used in this

manual.

Page 7

FP-2500/FP-2600 Series Models/ Features

6 FP-2500/FP-2600 Series User Manual

High Quality TFT Color LCD Display

The FP-2500 Series units are equipped with a 10.4 inch TFT type color LCD and the

FP-2600 Series units are equipped with a 12.1 inch TFT type color LCD. Both have

superb brightness and wide viewing angles, not found in ordinary laptop-type TFT

LCDs.

The FP-2500 Series units screen's maximum resolution is 640(H) X 480(W) pixels and

the FP-2600 Series units are 800(H) X 600(W) pixels. Bothe can display 260,000

colors.

Easy Installation In User Cabinets and Panels

The FP unit's slim and compact design makes installation a snap. These panels are

designed specifically for IA (Industrial Automation) or OA (Office Automation) monitor. The flat front panel provides protection equivalent to IP65f. Even without its

optional protective cover the front panel is highly resistant to both water and dust.

Panel can be used as a Display

Since the FP is equipped with an analog RGB interface and a DVI-D Interface, it can

be connected to a PC and other similar devices easily . (The PC's dot clock frequency ,

however, must be within the standard range.)

Easy-to-use Built-In Touch Panel

The FP unit's built-in touch panel is standard equipment, allowing touch panel data to be

output to a host PC via input/output commands and an RS-232C or USB cable. This is

ideal for systems requiring both touch panel operation and data monitoring.

FP-2500/FP-2600 Series Features

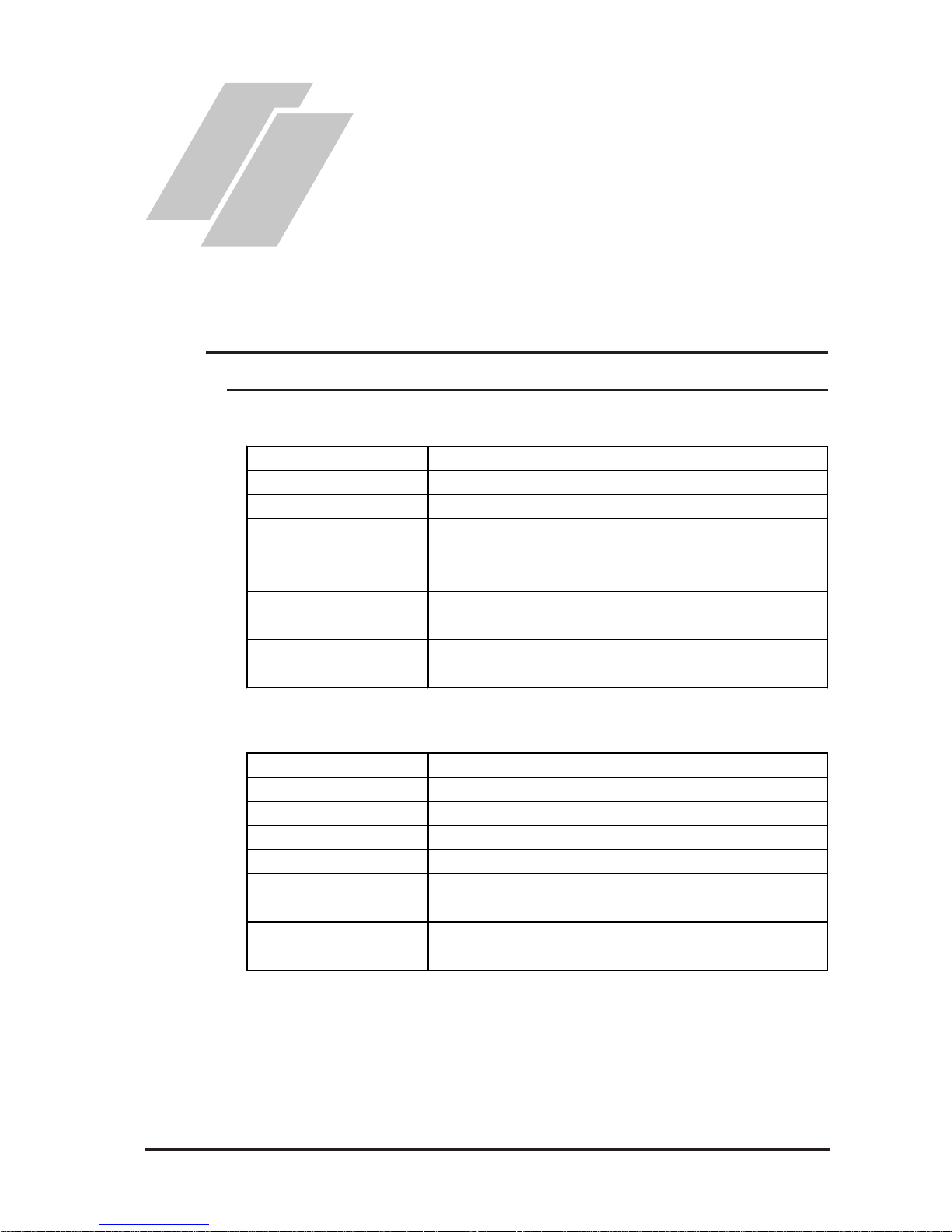

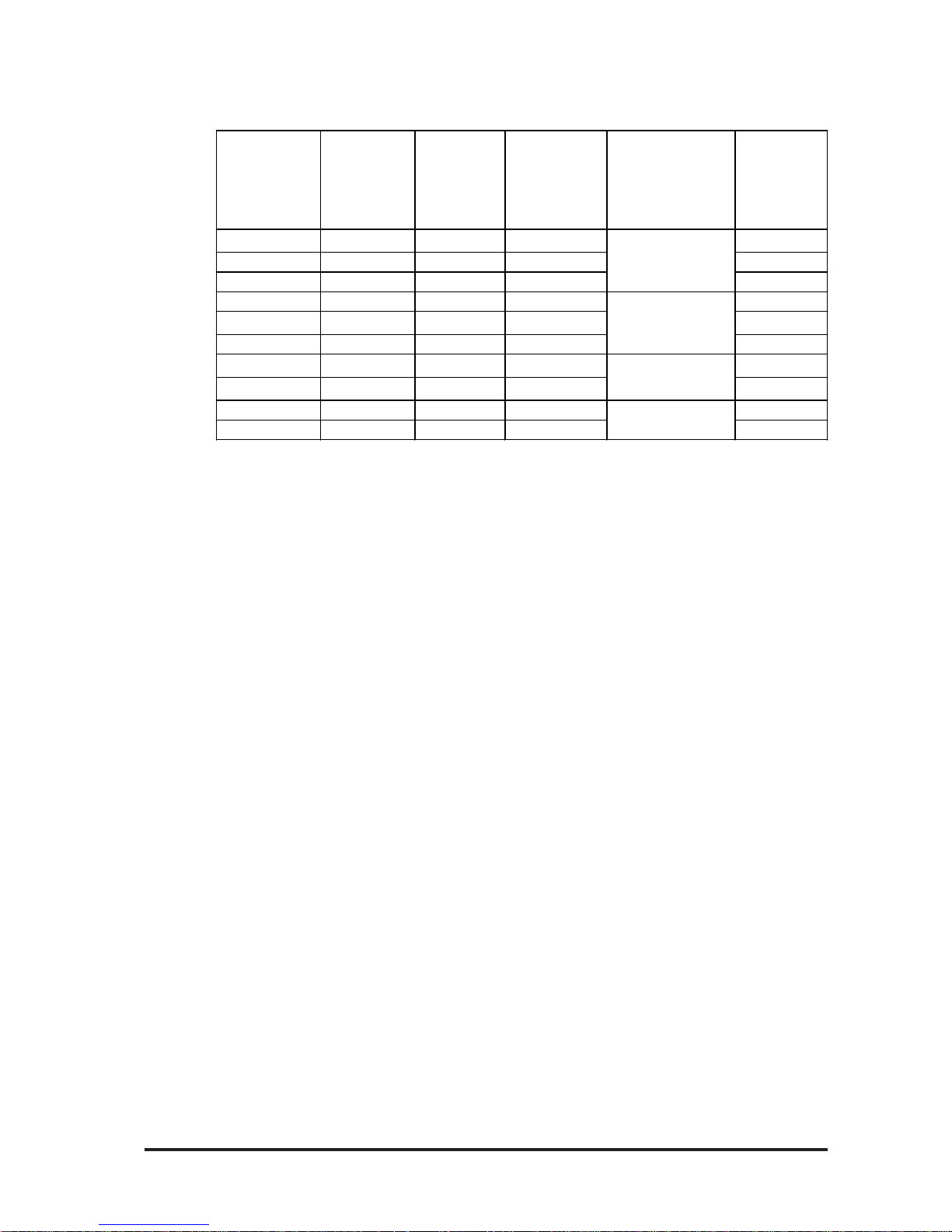

FP-2500/FP-2600 Series Models

The FP-2500/FP-2600 Series refers to the following FP model numbers:

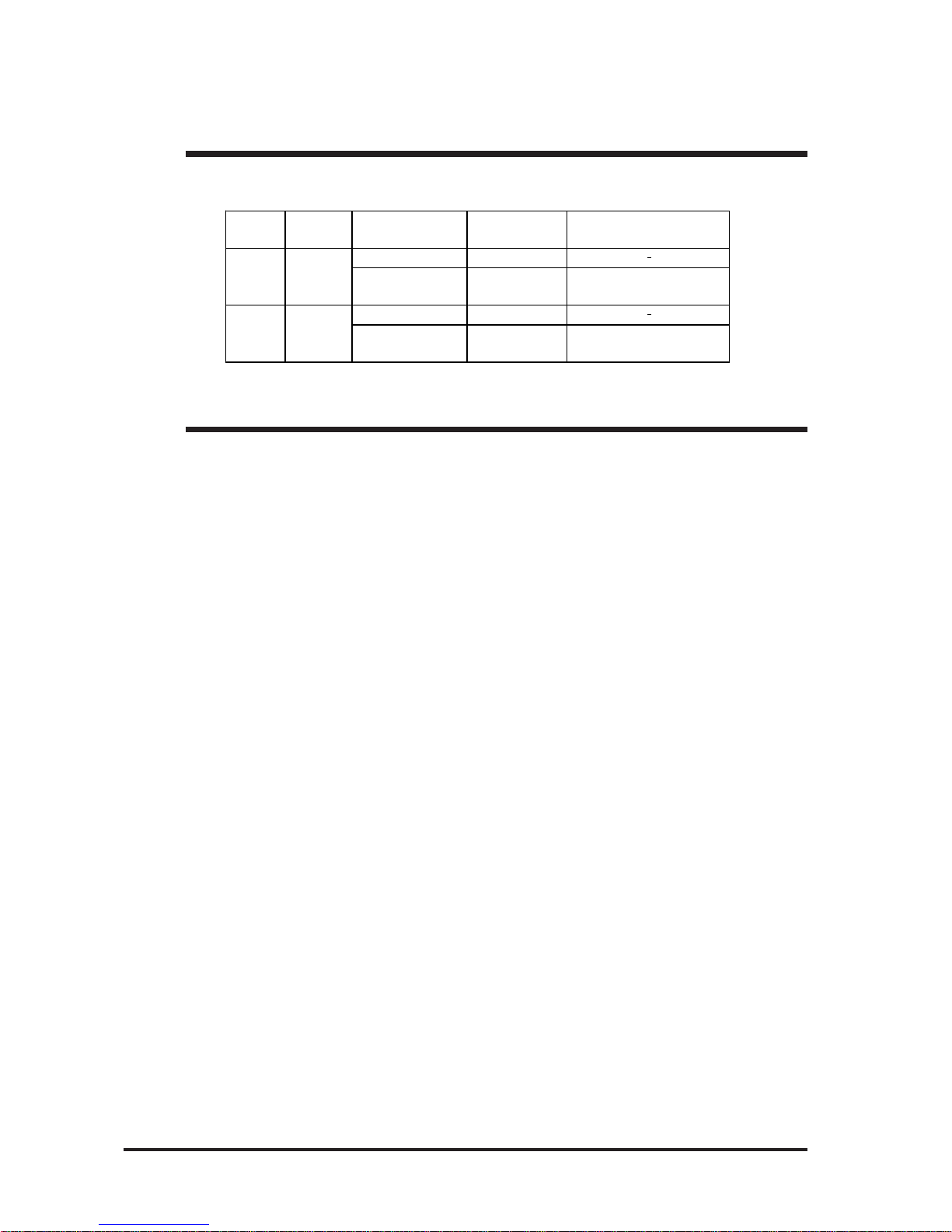

Series

Model

Name

Model Type

Power Input

Type

Standards

FP2500-T12 AC

FP2500-T42-24V DC

UL/c-UL/CSA Approved,

CE Marked

FP2600-T12 AC

FP2600-T42-24V DC

UL/cUL Approved,

CE Marked

FP-2500 F P-2500T

FP-2600 F P-2600T

Page 8

Connecting the FP to a PC/What is IP65f?

FP-2500/FP-2600 Series User Manual 7

• When a signal timing value not compatible with the FP

unit is entered, or if the entered timing value is larger than

can be displayed by the dot clock, an "OUT OF RANGE"

message is displayed. If this occurs, consult your

computer's manual and enter a value that is compatible

with this device.

• If no signal (synchronized signal) is entered, a "NO SIGNAL" message is displayed.

The FP-2500 Series units are designed for standard VGA mode display and the FP2600 Series units are designed as a standard SVGA display .

Be aware that some types of VGA/SVGA equipment may not be within the ranges

specified in this document, and, therefore, cannot be connected to the FP .

Also, if you change your PC's VGA/SVGA board, there is the possiblity that the new

board may not be able to be connected to the FP.

2.3 Interface Specifications

Connecting the FP to a PC

This code indicates the degree of ingress protection provided from the front face of the

FP , and assumes that the FP is securely mounted into a metal panel.

This unit's protection rating of IP65f is actually a composite code, consisting of the

internationally recognized British "Ingress Protection" standard (BS EN 60529:1992) "IP65", and the standard developed by the Japanese Electronics Manufacturer's Association (JEM) - "f". This code is used in this manual to identify this product's degree of

structural resistance to a variety of environmental elements and thus, prevent problems

or accidents related to the inappropriate product use.

The individual meaning of each character of this code is explained below .

(1) Designates the type of protection provided.

(2) Indicates the degree of protection provided to the human body by the unit, and the

degree of protection provided by the unit's front face from particles/dust intrusion

into the interior of the unit.

Here, "6" indicates that the unit is completely protected from dust intrusion.

(3) Indicates the degree of protection provided by the unit's front face from water

intrusion into the interior of the unit.

Here, "5" indicates that the unit is protected from water intrusion from a direct water

jet.

(4) Indicates the degree of protection provided by the unit's front face from oil particle

intrusion into the interior of the unit.

Here, "f" indicates that the unit is completely protected from oil intrusion via either oil

particles or oil splashes from any direction (to the front panel).

IP 6 5 f

(1) (2) (3) (4)

What is IP65f?

Page 9

8 FP-2500/FP-2600 Series User Manual

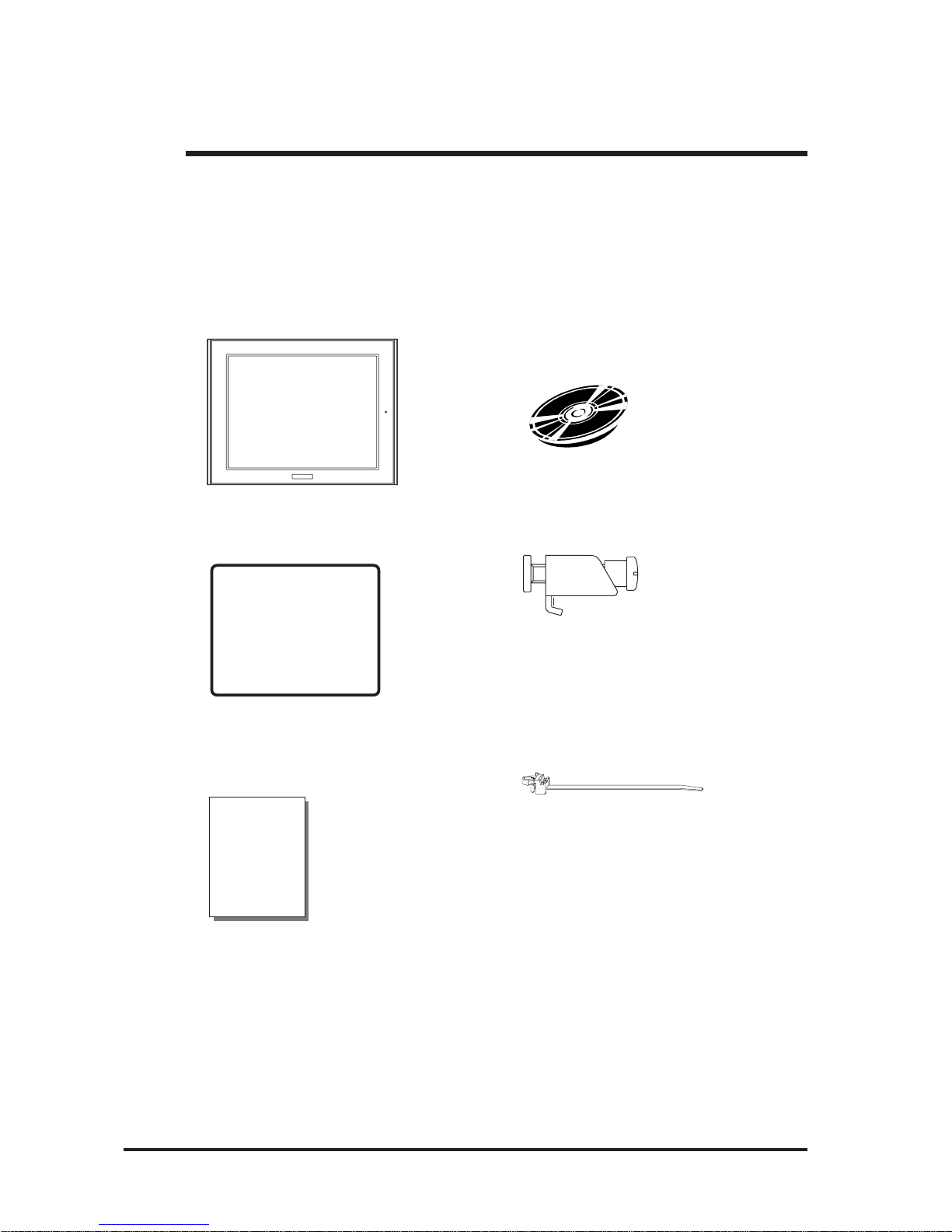

Package Contents

The FP unit's packing box contains the items listed below . Please check to be sure each

item is included and is not damaged.

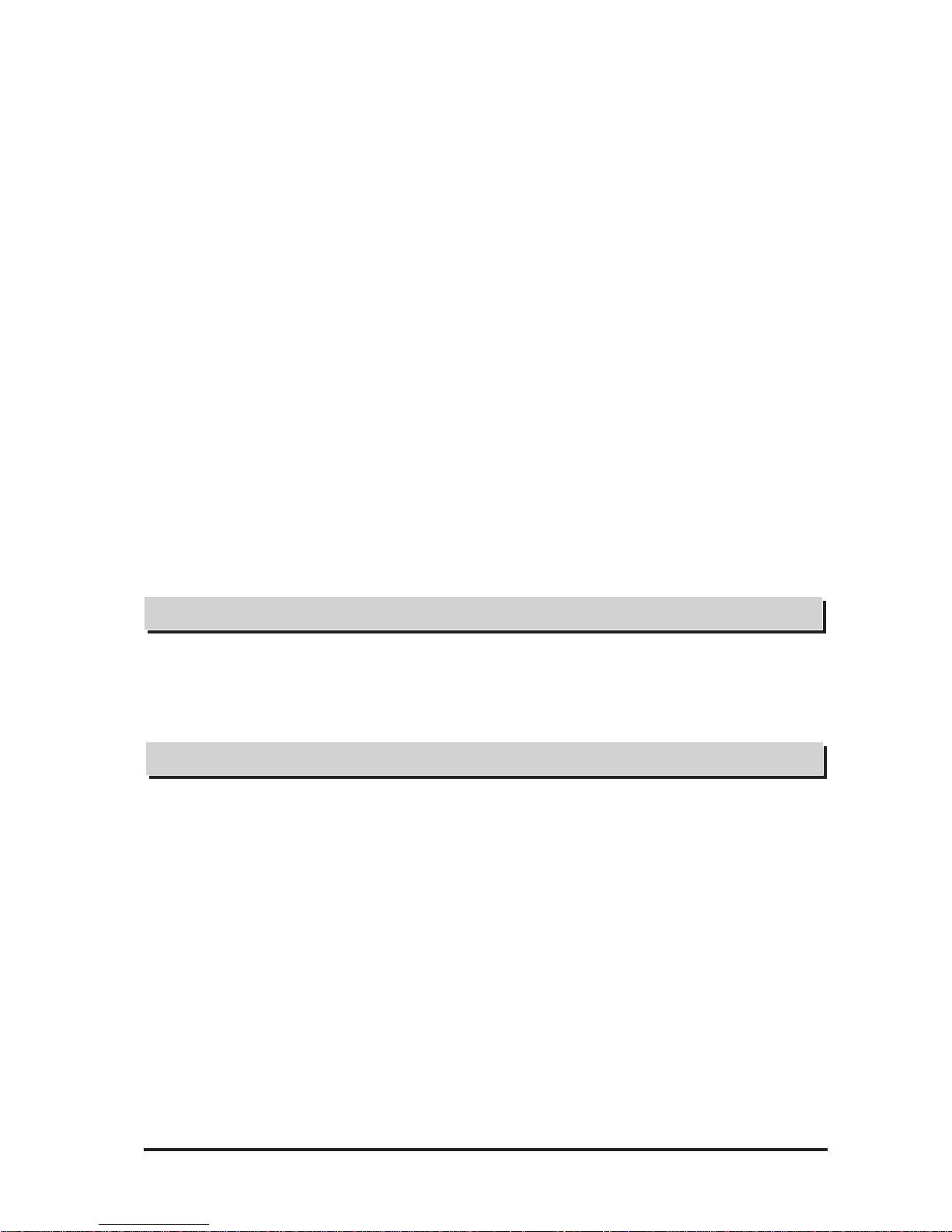

FP unit (1) CD-ROM (1)

(FP2500-T12/FP2600-T12/ (F P-2500/FP-2600 Series User Manual &

FP2500-T42-24V/FP2600-T42-24V) Touch Panel Communication Programs

For MS-DOS®)

Installation Gasket (1) Installation Fasteners (4)

(Attached to the FP unit)

Installation Guide (1) USB Cable Strap (1)

(Japanese/English)

These items have all been carefully packed with special attention to product quality . However,

should you find anything damaged or missing, please contact your local FP distributor immediately for prompt service.

Package Contents

Installation

Guide

Page 10

UL/c-UL/CSA Application Notes/CE Marking Notes

FP-2500/FP-2600 Series User Manual 9

UL/c-UL/CSA Application Notes

The FP2500-T42-24V/FP2600-T42-24V units are UL/c-UL listed products (UL File No.

E182139).

The FP conforms as a component to the following standards:

UL508 Industrial Control Equipment

UL1604 Electrical Equipment for use in Class 1 & 2 - Division 2, and Class III

Hazardous (classified) locations.

CAN/CSA-C22.2, No.1010-1 Measuement and Control Equipment Safety require-

ments for electrical equipment for measurement and

laboratory use.

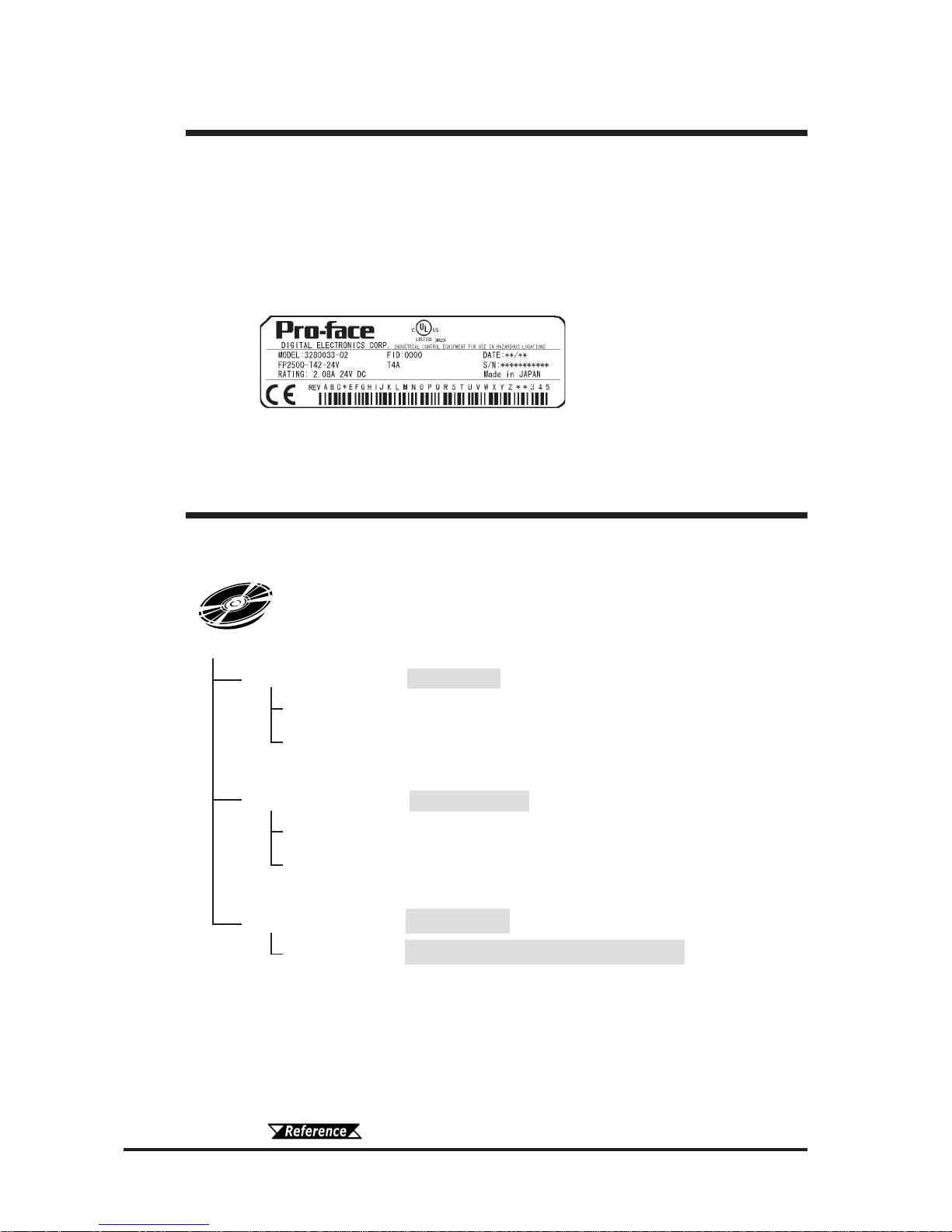

FP2500-T42-24V (UL Registration Model No.:3280033-02)

FP2600-T42-24V (UL Registration Model No.:3280033-04)

<Cautions>

Be aware of the following items when building the FP into an end-use product:

• The FP unit's rear face is not approved as an enclosure. When building the FP unit into an enduse product, be sure to use an enclosure that satisfies standards as the end-use product's overall

enclosure.

• The FP unit must be used indoors only .

• This unit should be installed in the front face of a metal panel.

• If the FP unit is installed so as to cool itself naturally , be sure to mount it in a vertical panel. Also,

be sure that the FP unit is installed at least 100 mm away from any adjacent structures or

machine parts. If these conditions are not met, the heat generated by the FP unit's internal

components may cause the unit to fail to meet UL standards.

UL1604 Conditions of Acceptability and Handling Cautions:

1. Power, input and output (I/O) wiring must be in accordance with Class I, Division 2 wiring

methods - Article 501- 4(b) of the National Electrical Code, NFP A 70 within the United

States, and in accordance with Section 18-152 of the Canadian Electrical Code for units

installed within Canada.

2. Suitable for use in Class I, Division 2, Groups A, B, C and D, Hazardous Locations.

3. W ARNING: Explosion hazard - substitution of components may impair suitability for Class I,

Division 2.

4. W ARNING: Explosion hazard - when in hazardous locations, turn power OFF before replac-

ing or wiring modules.

5. W ARNING: Explosion hazard - do not disconnect equipment unless power has been switched

OFF , or the area is known to be non-hazardous.

6. W ARNING: Explosion hazard - do not connect/disconnect equipment unless area is known to

be nonhazardous.

The FP2500-T42-24V/FP2600-T42-24V are CE marked products that conform to EMC directives EN55011 Class A and EN61000-6-2.

For detailed CE marking information, please contact your local FP distributor.

CE Marking Notes

Page 11

10 FP-2500/FP-2600 Series User Manual

CD-ROM Data

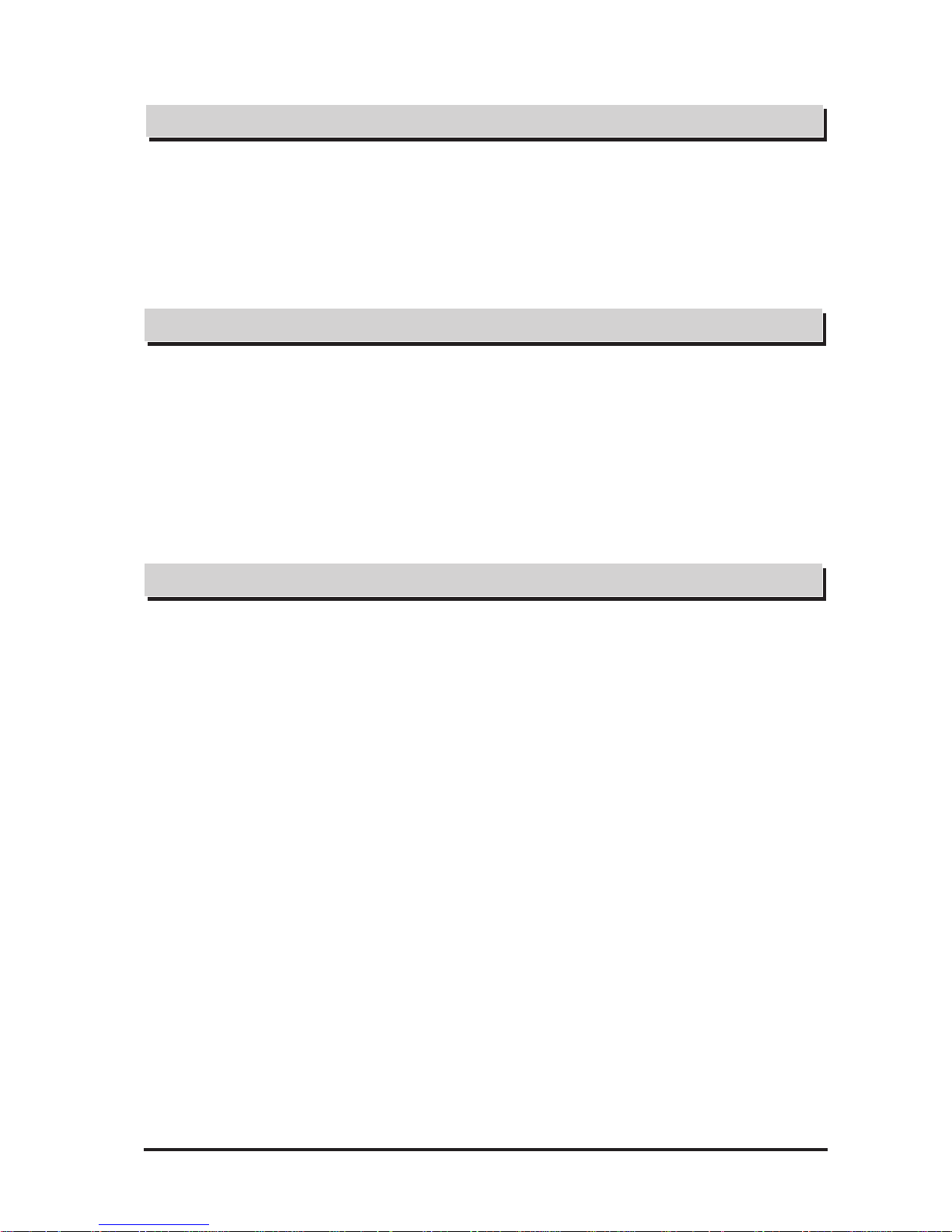

CD-ROM Data

The following data and programs are contained in the FP-2500/FP-2600 Series unit's

CD-ROM.

FP2000-MMCD-02

[Manual] User Manual

[Eng] fp2000e.pdf

[Jpn] fp2000j.pdf

[Reader] Acrobat® Reader

[Eng] ar505enu.exe

[Jpn] ar505jpn.exe

[Utility] Utility Setup <Supported OS>

[Touch] Touch Panel Communication Program *1 MS-DOS

®

FPATPH.CAL

FPATPH.EXE

FPCALIB.EXE

*1 These programs are only for MS-DOS® and FP-2500 series unit. When using

Windows®95, WindowsNT®4.0, Windows®98, Windows®2000 and Windows®XP,

the Mouse Emulator V2 (PL-TD000) is required.

1.2 Optional Equipment

The revision version can be determined by the identification label or revision stickers

that are placed on the main unit of the FP . The characters and numerals in the "REV"

area that are replaced with asterisks (*), or marked with a marker indicate the revision

version.

In the example below , the asterisks "*" are placed at positions "D", "1", and "2", which

indicates the revision version as "D, 1, 2".

Identification Label

Revision V ersion

Page 12

Table of Contents

FP-2500/FP-2600 Series User Manual 11

Table of Contents

Preface..................................................................................................................... 1

Essential Safety Precautions.................................................................................2

Documentation Conventions.................................................................................5

FP-2500/FP-2600 Series Models ............................................................................6

FP-2500/FP-2600 Series Features .........................................................................6

Connecting the FP to a PC..................................................................................... 7

What is IP65f? .........................................................................................................7

Package Contents ..................................................................................................8

UL/c-UL/CSA Application Notes ............................................................................9

CE Marking Notes ...................................................................................................9

Revision Version...................................................................................................10

CD-ROM Data ........................................................................................................10

Chapter 1 Introduction

1. 1 System Design ............................................................................ 1-1

1.2 Optional Equipment................................................................... 1-2

Chapter 2 Specifications

2. 1 General Specifications .............................................................. 2-1

2.1.1 Electrical ........................................................................................2-1

2.1.2 Environmental.................................................................................2-2

2.1.3 Structural .......................................................................................2-2

2. 2 Functional Specifications .......................................................... 2-3

2.2.1 Performance...................................................................................2-3

2.2.2 Display...........................................................................................2-3

2. 3 Interface Specifications............................................................. 2-4

2.3.1 Analog RGB Interface ....................................................................2-4

2.3.2 DVI-D Interface.............................................................................2-7

2.3.3 RS-232C Interface.........................................................................2-9

2.3.4 USB Interface ..............................................................................2-10

Page 13

Table of Contents

12 FP-2500/FP-2600 Series User Manual

2. 4 Cable Diagrams ....................................................................... 2-11

2.4.1 Analog RGB Interface Pin Connections (Optional cable)................ 2-11

2.4.2 DVI-D Interface Pin Connections (Optional cable) ........................2-12

2.4.3 RS-232C Interface Pin Connections (Optional cable) ....................2-13

2.4.4 USB Interface Cable Pin Connections (Option cable) ....................2-13

2. 5 Names and Functions of FP Parts ......................................... 2-14

2. 6 FP Dimensions .......................................................................... 2-15

2.6.1 External Dimensions ....................................................................2-15

2.6.2 External Dimensions (with Installation Fasteners) ...........................2-16

2.6.3 Installation Fasteners ....................................................................2-17

2.6.4 FP Panel Cut Dimensions .............................................................2-17

Chapter 3 Installation and Wiring

3.1 Installation...................................................................... 3-1

3.1.1 Installation Procedures....................................................................3-1

3.2 Wiring Cautions ......................................................................... 3-6

3.2.1 Connecting the Power Cord ...........................................................3-6

3.2.2 Connecting the USB Cable Strap Attachment .................................3-8

3.2.3 Connecting the Power Supply ........................................................3-9

3.2.4 Precautions: Grounding ................................................................3-10

3.2.5 Precautions: Input/Output Signal Lines .........................................3-10

Chapter 4 Setting up and Adjusting the FP unit

4. 1 Operation Mode Setup .............................................................. 4-1

4.1.1 Dip Switch Preset Settings and Adjustments ...................................4-1

4.1.2 Status of Front LED in Operation Modes........................................4-2

4.2 Screen Display Adjustment....................................................... 4-2

4.2.1 Calibration of OSD Display Position ...............................................4-2

4.2.2 OSD Setting Icons .........................................................................4-3

4.2.3 OSD Setting Item Details................................................................4-4

Page 14

Table of Contents

FP-2500/FP-2600 Series User Manual 13

Chapter 5 Touch Panel Data

5. 1 Touch Interface Data................................................................. 5-1

5. 2 Touch Panel Communication Programs For MS-DOS® .... 5-4

5.2.1 FPATPH.EXE (T ouch Panel Handler) ............................................5-4

5.2.2 FPCALIB.EXE (T ouch Panel Data FPCalibration) ........................5-8

Chapter 6 Troubleshooting

6.1 Troubleshooting ......................................................................... 6-1

6.1.1 Possible Device Problems...............................................................6-1

6.1.2 No Display ....................................................................................6-2

6.1.3 T ouch Panel Does Not Respond ...................................................6-4

6.2 Error Message ........................................................................... 6-5

6.2.1 Error Message List .......................................................................6-5

Chapter 7 Maintenance

7.1 Regular Cleaning ...................................................................... 7-1

7.1.1 Cleaning the Display .......................................................................7-1

7.1.2 Installation Gasket Replacement......................................................7-2

7.2 Periodic Check Points ............................................................. 7-3

7.3 Backlight Replacement............................................................ 7-4

7.3.1 Replacing GP577R T-BL00-MS .....................................................7-6

7.3.2 Replacing PS600-BU00 .................................................................7-8

7.3.3 Replacing CA3-BLU12-01 ..........................................................7-10

Page 15

14 FP-2500/FP-2600 Series User Manual14

Memo

Page 16

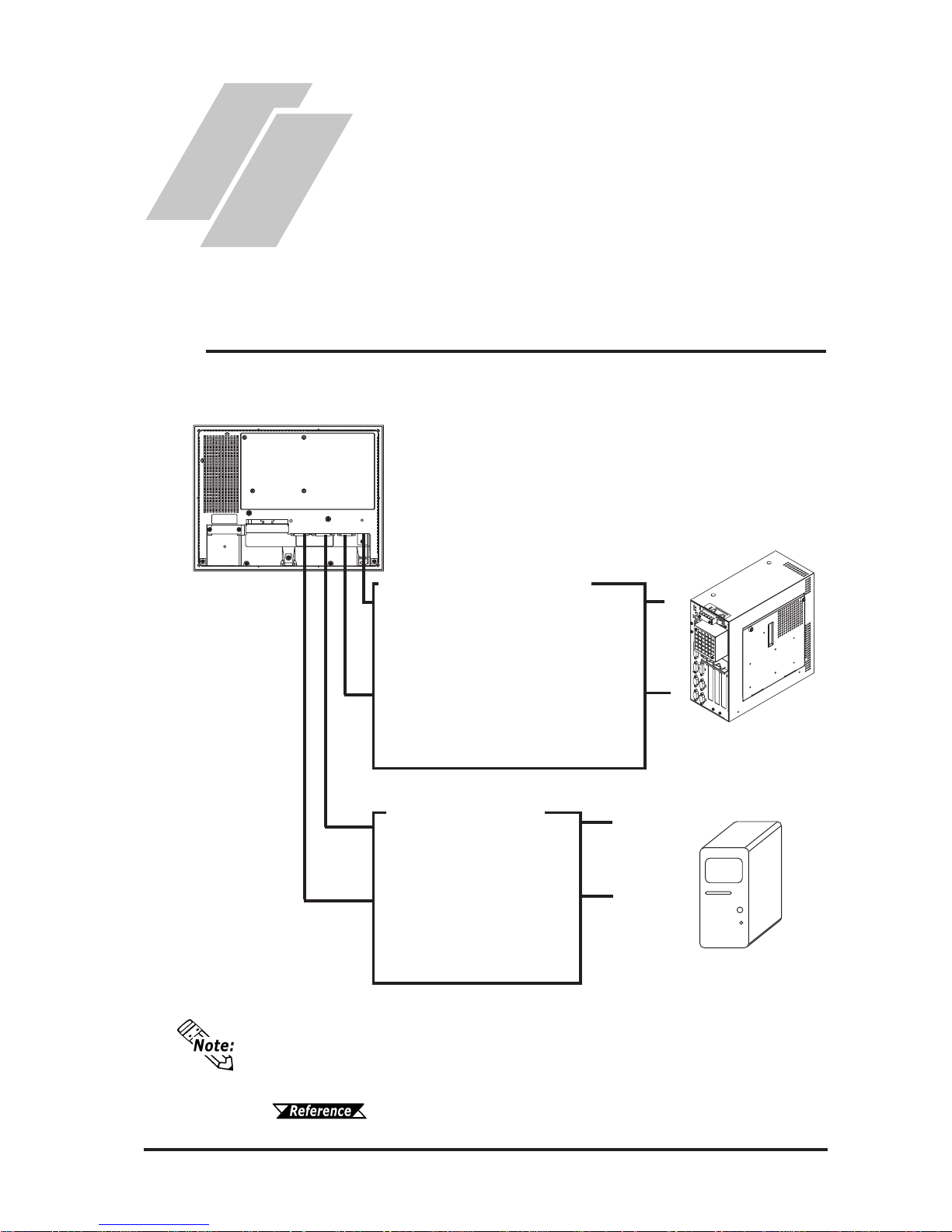

1.1 System Design

1-1FP-2500/FP-2600 Series User Manual

The FP unit’s dip switches set the type of communication method used for sending

touch data and commands (USB or RS-232C), and also for outputing image signals

(DVI-D or Analog RGB).

4.1.1 Dip switch setting

USB Interface Cable

FP-US00 <5m>

A-B type Cable

For Touch data and Command transmission

RS-232C Interface Cable

FP61V-IS00-O <5 m>

Straight Cable : Dsub 9-pin female

For Touch data and Command transmission

DVI-D Cable

FP-DV01-50 <5 m>

For image signal output

Analog RGB Interface Cable

FP-CV00 <2.5m>, FP-CV01 <5m>

FP-CV02-45<4.5m>

For image signal output

Chapter 1

Introduction

1. System Design

2. Optional Equipment

1.1 System Design

PS-2000B

or

Windows

®

compatible PC

FP unit

The FP can be connected to Pro-face's PS-2000B or to a Windows® compatible PC.

Image Signal Output

Touch Panel Communication

Page 17

1.2 Optional Equipment

1-2 FP-2500/FP-2600 Series User Manual

1.2 Optional Equipment

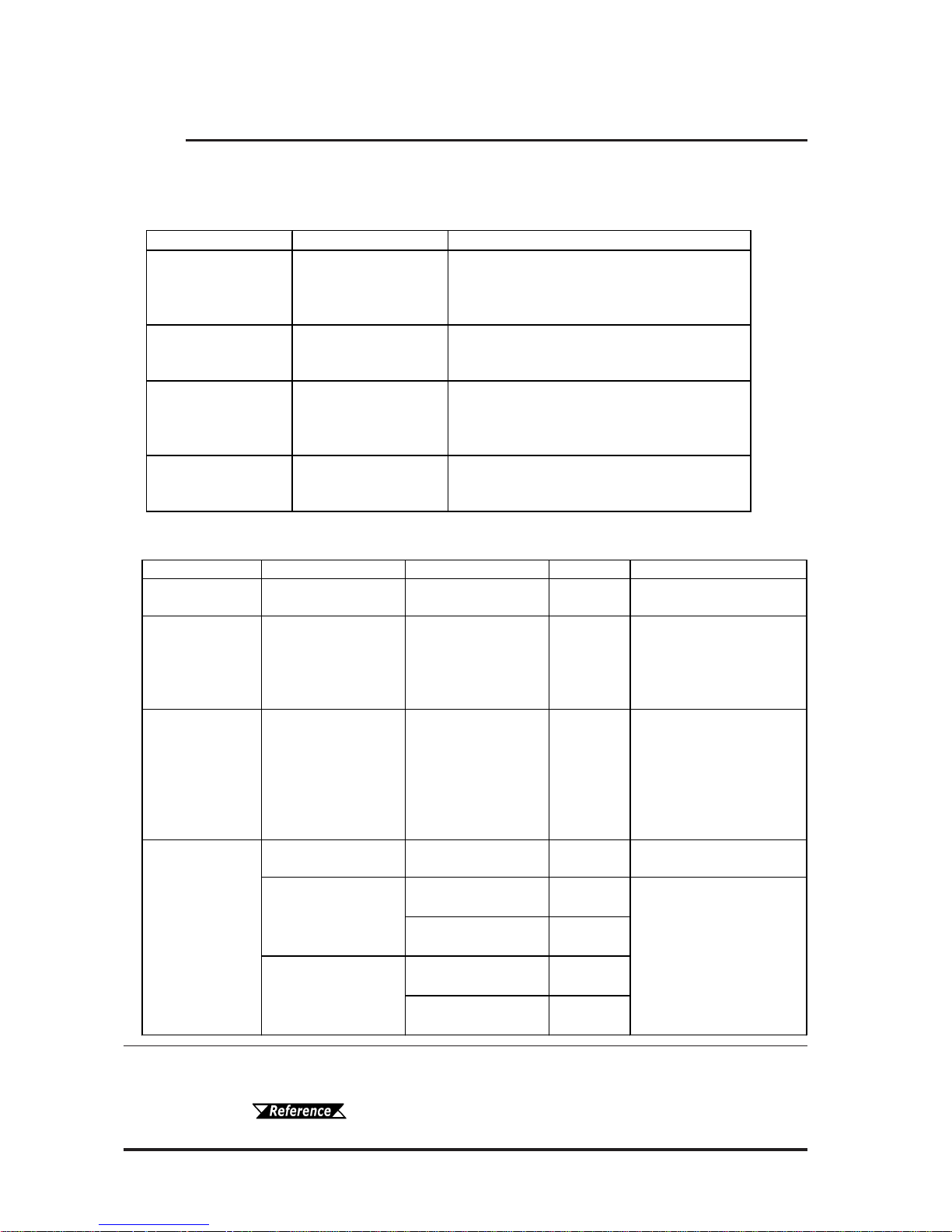

All optional items listed below are Digital Electronics Corporation products.

Item Model Number Description

RS-232 C Cabl e FP 61V-IS00-O (5 m )

Seri al in t erfac e cable used for touc h panel data

transmissi on between the host and t he F P or

command transmission to the FP. This is a

straight Dsub 9-pin femal e cable.

Analog RGB Cable

FP -CV00 (2.5m)

FP -CV01 (5m)

FP -CV02-45 (4. 5m )

Analog RGB i nt erface c abl e used when image

signals are output to the FP from the host.

(Dsub 15-p i n m al e ).

USB Cable FP-US00 (5m)

USB i nterface c abl e used for touc h panel data

trans fer between the hos t and the FP or

command transmission to the FP. A-B type

cable.

DVI-D Cable F P-DV01-50 (5 m )

Digital V i sual Interface cabl e us ed to send the

image signal from the host to the FP. XGA

spec i fic ation DVI-D 24-pin male.

Cables

Maintenance Parts

Item Model Number Corresponding FP Rev. Description

Installation

Fasteners

GP070-AT01

FP-250 0 S eri es

FP-260 0 S eri es

-

Metal installation

fasteners.

Rubber Gasket GP570-WP10-MS

FP-250 0 S eri es

FP-260 0 S eri es

-

Replac em ent rubber

gask et, us ed when

installing the FP. Same as

the FP uni t 's origi nal

gasket.

Sc reen P rot ec tion

Sheet

PSL-DF00

FP-250 0 S eri es

FP-260 0 S eri es

-

Dis posable, di rt resis t an t

sheet for the FP unit's

screen. The FP unit's

touch panel c an be used

with this cover

sheet attached.

(5 sheets/set)

GP577RT-BL00-MS F P -2500 S eries -

Replac em ent backlight for

FP-250 0 S eri es unit s.

FP2600-T12

Rev.1 is not

marked.

*1

FP2600-T42-24V

Rev.1 is not

marked.

*1

FP2600-T12

Rev.1 is

marked.

*1

FP2600-T42-24V

Rev.1 is

marked.

*1

Replac em ent backlight for

FP-260 0 S eri es unit s.

Backlight

PS600-BU00

CA3-BLU12-01

*1 The corresponding backlight unit differs depending on FP-2600 Series unit's

marked Revision.

For more information on how to determine the revision version,

see "Revision Version" (Page 10).

Page 18

1.2 Optional Equipment

1-3FP-2500/FP-2600 Series User Manual

Item Model Number Description

Mous e E m ul at or V 2

*1

PL-TD000 Mouse emulation s o ft ware for t he F P.

Available Software

*1 OS can be Windows®95, WindowsNT®4.0, Windows®98, Windows®2000 or

Windows

®

XP .

Page 19

1.2 Optional Equipment

1-4 FP-2500/FP-2600 Series User Manual

Memo

Page 20

FP-2500/FP-2600 Series User Manual

2-1

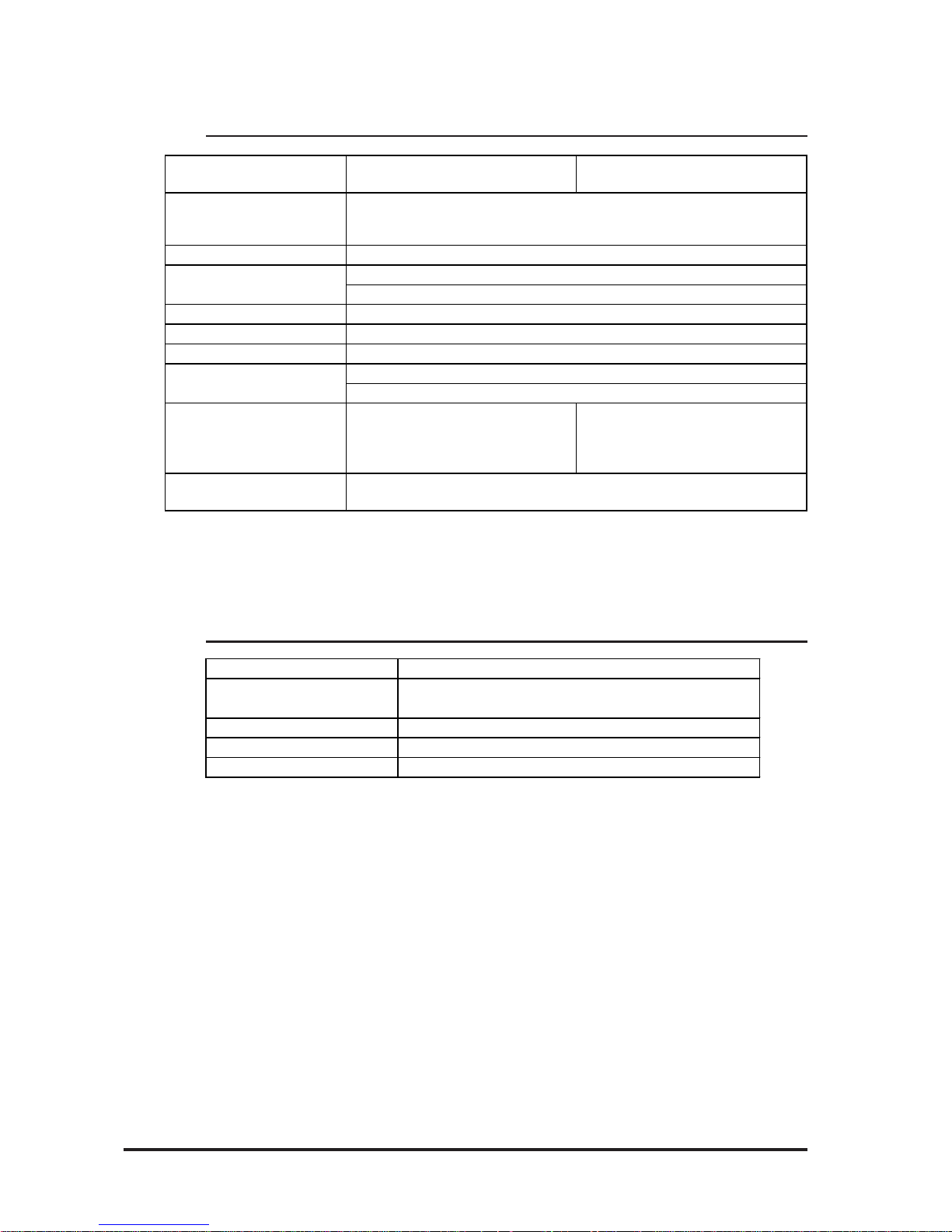

2.1.1 Electrical

1. General Specifications

2. Functional Specifications

3. Interface Specifications

4. Cable Diagrams

5. Names and Functions of FP

Parts

6. FP Dimensions

Chapter 2

Specifications

2.1 General Specifications

Ra ted V o lta g e

A C 100V to AC 240V

Rated Vol ta ge Range

A C 85V to AC 264V

Rated Fre quency

50/60 Hz

Rated Fre quency Range

47 Hz to 63 Hz

Allowable Voltage Drop

20ms or less

Pow er Consumption

50VA (ACIN 100V)/ 85VA ( ACIN 240V)

Voltage Endurance

A C 1500V 20mA for 1 minute

(between charging and FG terminals)

In sula tion Resistanc e

10MΩ or higher at DC500V

(between charging and FG terminals)

FP2500-T12/FP2600-T12

FP2500-T42-24V/FP2600-T42-24V

Ra ted V o lta g e

DC24V

Rated Vol ta ge Range

DC19.2 to DC28.8V

Allowable Voltage Drop

10ms or less

In-rush Current

30A or less

Pow er Consumption

50W or les s

Voltage Endurance

A C 1000V 20mA for 1 minute

(between charging and FG terminals)

In sula tion Resistanc e

10MΩ or higher at DC500V

(between charging and FG terminals)

Page 21

FP-2500/FP-2600 Series User Manual

2.1 General Specifications

2-2

2.1.3 Structural

* 1 The front face of the FP unit, installed in a solid panel, has been tested using condi-

tions equivalent to the standard shown in the specification . Even though the FP unit’s

level of resistance is equivalent to the standard, oils that should have no effect on the

FP can possibly harm the unit. This can occur in areas where either vaporized oils are

present, or where low viscosity cutting oils are allowed to adhere to the unit for long

periods of time. If the FP’s front face protection sheet peels off, these conditions can

lead to the ingress of oil into the FP and separate protection measures are suggested.

Also, if non-approved oils are present, it may cause deformation or corrosion of the

front panel’s plastic cover. Therefore, prior to installing the FP be sure to confirm the

type of conditions that will be present in the FP’s operating environment.

If the installation gasket is used for a long period of time, or if the unit and its gasket

are removed from the panel, the original level of the protection cannot be guaranteed.

To maintain the original protection level, be sure to replace the installation gasket

regularly.

Grounding

External Dim ensions

Weight

Cooling Me thod

Ratings

*1

(

For front panel of installed unit

)

Natural air circulation

100Ω or less , or your country's applicable st an dar d

W317mm [12.48 in] x H243mm [9.57 in] x D58mm [ 2. 28 in]

3.5kg

(

7.7lb) or less

Equivalent to I P 65f ( J E M 1030)

2.1.2 Environmental

FP2500-T12

FP2600-T12

FP2500-T42-24V

FP2600-T42-24V

Ambient Operating

Temperature

Storage Temperature

Air P u r ity (Dust)

Pollution De gre e

Corro sive Gasses

Noise Immunity

(via noise em ul ator)

Noise Voltage: 1,500Vp-p

Pulse Durat ion: 1ms, 500ns, 50ns

Rise Time: 1ns

Noise Voltage: 1,000Vp-p

Pulse Durat ion: 1ms, 500ns, 50ns

Rise Time: 1ns

Electrostatic Discharge

Immunity

10Hz to 25Hz 19.6m/s

2

X, Y, Z directions (30min.)

4kV (complies wit h E N 6100 0- 4- 2)

Vibra tion Re sista nce

0oC to +50oC

*1

(the panel f ace should not incline more than 30oC)

-10

o

C to +60oC

30%RH to 90%RH

(Non condensing, wet bulb temperature: 39

o

C or less)

Free of dus t

Pollution Degree 2

Free of corrosiv e gasses

Ambie nt Humidity

* 1 When using a FP-2600 Series unit in an environment where the temperature reaches or

exceeds 40

o

C for an extended period of time, the screen contrast level may decrease

from its original level.

Page 22

FP-2500/FP-2600 Series User Manual

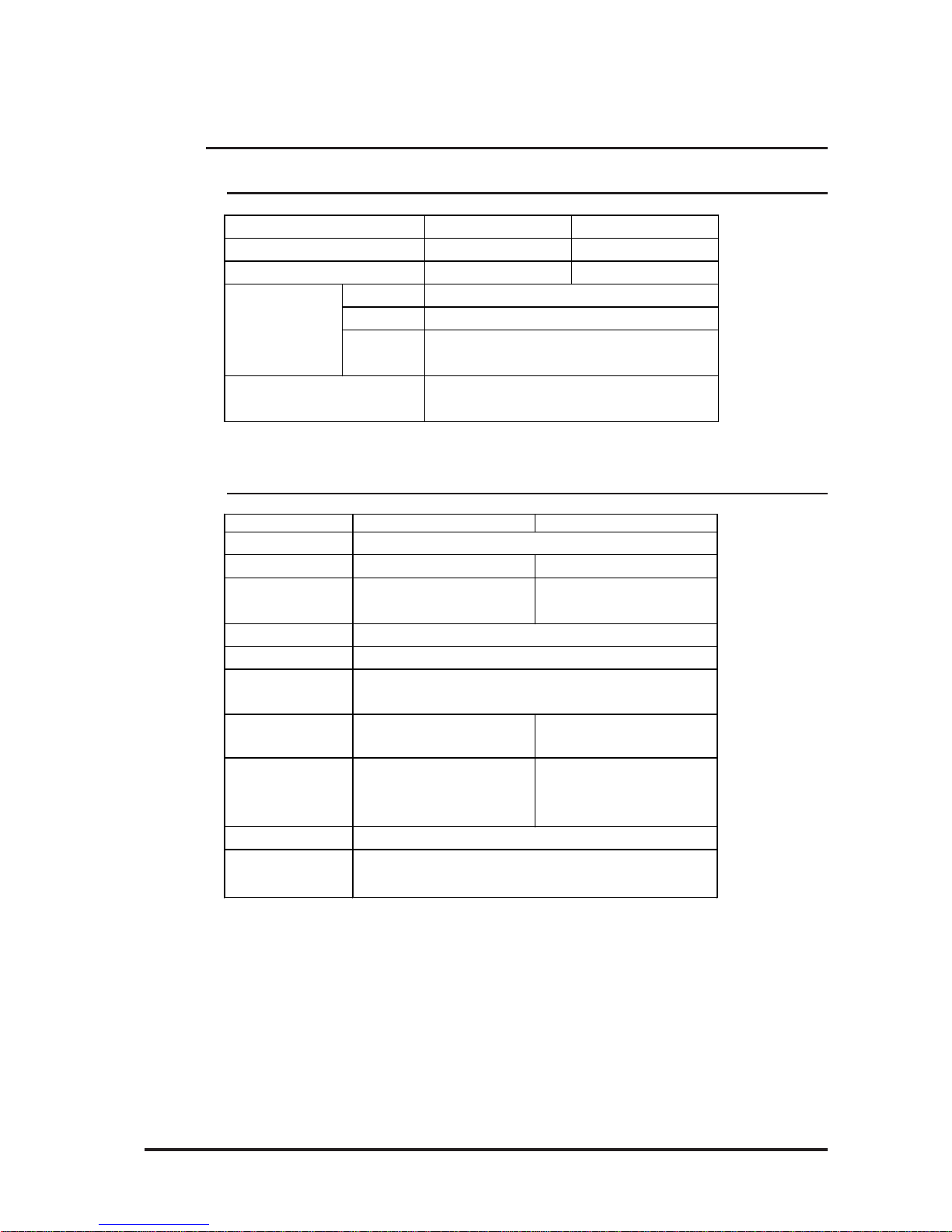

2.2 Functional Specifications

2-3

*1 Setting up OSD. For details, refer to 4.2 Screen Display Ajustment

*2 For details, refer to 2.3 Interface Specifications

*3 50% decreased brightness indicates the backlight needs to be replaced. This value

is only for reference and not a guaranteed value.

2.2.1 Performance

2.2.2 Display

FP-2500 Series FP-2600 Series

V GA (640 X 480) SVGA (800 X 600)

10.4 inch TFT VGA 12.1 inch TFT SVGA

Type

Resolution

Interface

A nalog RGB Interface

DV I-D I nt erface

Resist ive Film (Analog)

1024 X 1024

Serial Interface (RS- 232C)

USB Interface

Vide o I / F

Touch Pane l I / F

Graphics

Displ ay Uni t

FP-2500 Series FP -2600 S eri es

Type

Resolution

640 (H) X 480 ( V) pixels 800 (H) X 600 ( V) pixels

Dot P i t ch

0.330mm [ 0.01in.] (H) X

0.330mm [0.01in. ] ( V)

0.3075mm [0.01in.] (H) X

0.3075mm [0.01in.] (V)

Displa y co l o r s

Brightness Control

Contrast Control

Display area

*1

211.2mm [8.31in. ] ( W) X

158.4mm [6.24 in.] (H)

246.0mm [9.69in. ] ( W) X

184.5mm [7.26in. ] ( H)

Display Modes

*2

640X350, 640X 400,

640X480, 720X 350,

720X400

640X350, 640X 400,

640X480, 720X 350,

720X400, 800X 600

Backlight

Backlight Lifetime

CCFL (Replaceable)

Backlight can be replaced by t he user .

50,000 hours at an ambient temperature of 25

oC*3

TFT Activ e Matrix Color LCD

260,000 colors (R/G/ B six bits each)

Available

A vailable (Analog RGB only)

(when using analog RGB connect ion)

2.2 Functional Specifications

Page 23

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-4

2.3.1 Analog RGB Interface

2.3 Interface Specifications

Input s ignal t ype A n alog RGB

Input signal charact eris t ic Image signal: analog RGB

Synchronous signal: TTL level, negative tr ue or po sitive tr ue

Scanning type: non-int erlaced

Setting v ia OSD

(On Screen Display)

CONTRAST

BRIGHTNESS

H-POS

V-POS

H-SIZE

PHASE

BA CKLIGHT

DEFAULT (ALL CLEA R)

The number of dots (pixels) displayed are as follows:

Resolution

H Sync.

(kHz)

V Sync

(Hz)

Dot Clock

(MHz)

Screen

Resolution

Expansion

(H : Horizontal)

(V : Vert ical)

Display

Resolution

640×350

*1

31.469 70.000 25.175 640×420

640×400 31.469 70.000 25.175 640×480

640×400 24.827 56.420 21.053 640×480

640×480 31.469 59.992 25.175 ×1.0 640×480

720×350 *

1,2,3

31.469 70.000 28.320 640×420

720×400

*2,3

31.469 70.000 28.320 640×480

×1.0(H)

×1.2(V)

×1.0(H)

×1.2(V)

FP-2500 Series

* 1 When the 350 pixel (vertical) signal setting is selected, 400 pixels, including 50 pixels

at the top and at the bottom of the screen, will be enlarged and displayed at 480 pixels

(1.2times).

* 2Select "720 x 400 Display Resolution 720 x 400 DSP" in the OSD (On Screen Display)

"System Setting" screen.

* 3 When the 720 pixel (horizontal) signal setting is selected,

- When "720 x 400 DSP" is ON; only 640 pixels are displayed (80 pixels are not

displayed.)

- When "720 x 400 DSP" is OFF; all pixels are displayed but images may be partially

cut off.

Page 24

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-5

FP-2600 Series

Resolution

H Sync.

(kHz)

V Sync

(Hz)

Dot Clock

(MHz)

Screen

Resolution

Expansion

(H : Horizontal)

(V : Vert ical)

Display

Resolution

640×350

*1

31.469 70.000 25.175 800×525

640×400 31.469 70.000 25.175 800×600

640×400 24.827 56.420 21.053 800×600

640×480 31.469 59.992 25.175 800×600

640×480 35.000 66.670 30.240 800×600

640×480 37.861 72.810 31.500 800×600

720×350

*1*2

31.469 70.000 28.320 ×1.0(H) 720×525

720×400

*2

31.469 70.000 28.320 ×1.5(V) 720×600

800×600 35.156 56.250 36.000 800×600

800×600 37.879 60.317 40.000 800×600

×1.25(H)

×1.5(V)

×1.0

×1.25(H)

×1.25(V)

*1 When the 350 pixel (vertical) signal setting is selected, 400 pixels, including 50 pixels at

the top and at the bottom of the screen will be enlarged and displayed at 600 pixels

(1.5times).

*2Select "720 x 400 Display Resolution 720 x 400 DSP" in the OSD (On Scr een Display)

"System Setting" screen.

Page 25

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-6

Analog RGB Interface

Pin Assignments and Signal Names

11

15

1

5

Pin No. Signa l Na m e Condition Pin Loca tion

1 A nalog R R signal input

2 A nalog G G s ignal input

3 A nalog B B signal input

4 Reserv ed NC (spare for input )

5 Digital ground ing Digital s ignal GND

6 Return R R signal GND

7 Return G G signal GND

8 Return B B signal GND

9 Reserv ed NC (spare for input )

10 Digital grounding Digital s ignal GND

11 Reserved NC (spare for input)

12 Reserved NC (spare for input)

13 H. SY NC

Horizontal synchronous

signal input

14 V. SYNC

Vertical synchronous signal

input

15 Reserved NC (spare for input)

Connector: Mini Dsub 15 pin male

Connector set screw: Inch type (4-40)

Analog RGB Cable:

FP-CV00<2.5m>, FP-CV01<5m>, FP-CV02-45 <4.5m>

manufactured by

Digital Electronics Corporation of Japan

If a cable other than the specified RGB cable is used, FP unit operation

cannot be guaranteed due to the possibility of noise interference.

Page 26

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-7

2.3.2 DVI-D Interface

The number of dots (pixels) displayed are as follows:

Input signal type DVI-D

Sett ing by OSD

(On Screen Display)

H-POS

V-POS

BA CKLIGHT

DEFAULT (ALL CLEA R)

Resolution

H Sync.

(kHz)

V Sync

(Hz)

Dot Clock

(MHz)

Screen

Resolution

Expansion

(H : Horizontal)

(V : Vert ical)

Display

Resolution

640×400 31.469 70.000 25.175 640×480

640×400 24.827 56.420 21.053 640×480

640×480 31.469 59.992 25.175 ×1.0 640×480

640×480

×1.0(H)

×1.2(V)

×1.0(H)

×1.2(V)

720×400

*1

31.469 70.000 28.320

FP-2500 Series

* 1 When the horizontal 720 pixel signal is input;

-VGA Graphic & Text mode displays 640 pixels only and 80 pixels are not displayed.

Resolution

H Sync.

(kHz)

V Sync

(Hz)

Dot Clock

(MHz)

Screen

Resolution

Expansion

(H : Horizontal)

(V : Vert ical)

Display

Resolution

640×400 31.469 70.000 25.175 800×600

640×400 24.827 56.420 21.053 800×600

640×480 31.469 59.992 25.175 800×600

640×480 35.000 66.670 30.240 800×600

640×480 37.861 72.810 31.500 800×600

720×400

*1

31.469 70.000 28.320

×1.0(H)

×1.5(V)

720×600

800×600 35.156 56.250 36.000 800×600

800×600 37.879 60.317 40.000 800×600

×1.25(H)

×1.5(V)

×1.25(H)

×1.25(V)

×1.0

FP-2600 Series

* 1When you use this resolution, select "720 x 400 Display Resolution 720 x 400 DSP" in

"System Setting" of the OSD (On Screen Display) .

Page 27

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-8

Pin

No.

Signal Na me

Pin

No.

Signal Name Pin Location

1 TMDS DATA2- 13 NC

2 TMDS DATA2+ 14 NC

3 TMDS DA TA2/4 SHI E LD 15 GND (+5V)

4 NC 16 Hot Plug Detect

5NC17TMDS DATA06 DDC Clock 18 TMDS DA TA0+

7 DDC Data 19 TMDS DATA0/5 SHIE LD

8NC20NC

9 TMDS DATA1- 21 NC

10 TMDS DATA 1+ 22 TMDS C LOCK S HIELD

11 TMDS DATA1/3 S HI ELD 23 TMDS CLOCK+

12 NC 24 TMDS CLOCK-

DVI-D Interface

Pin Assignments and Signal Names

Connector: DVI-D 24-pin male

Connector set screw: Inch type (4-40)

DVI-D Cable: FP-DV01-50 <5 m> manufactured by Digital Electronics

Corporation

24

17

8

1

• If a cable other than the specified DVI-D cable is used, FP unit operation cannot be guaranteed due to the possibility of noise interference.

Page 28

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-9

Signal Names

Signal names used for the RS-232C Interface are designed to match the pin order

used on most PC RS-232C interfaces, which allows a straight cable to be used to

connect the two.

Therefore, connect each pin's signal to the same signal name on

the PC side.

For example, the FP unit connector's pin #2 'RD' should be connected to the PC

connector's 'RD' terminal. For detailed signal direction information,

2.4 Cable Diagrams

2.3.3 RS-232C Interface

RS-232C Interface

Pin Assignments and Signal Names

Connector: Dsub 9 pin female

Connector set screw: Inch type (4-40)

RS-232C Cable: FP61V-IS00-O <5m> manufactured by Digital Electronics

Corporation of Japan

*1 CD, DTR, and DSR are connected together inside the FP.

If a cable other than the specified RS-232C cable is used, FP unit operation cannot be guaranteed due to the possibility of noise interference.

6

9

1

5

Pin No. S i gna l Na m e Condition Pi n Loca tion

1 CD Carrier Detect

*1

2 RD Receive D ata (FP-> Hos t)

3 SD Send Data (FP<-Host)

4 D TR Data Ter minal Ready

*1

5 GND Ground

6 DSR Data Set Ready

*1

7 RS Request t o S end (FP < - Hos t )

8 CS Clear to Send (FP->Host)

9 NC (Used internally)

RS-232C Int erface

Baud rate: 96 00 bps

Data length: 8 bit s

Parity: none

Stop bit: 1

Page 29

FP-2500/FP-2600 Series User Manual

2.3 Interface Specifications

2-10

Pin

NO.

Signal

Name

Condition Pin Loca tion

1 USB1-5V +5V I N

2 USBD1(-) USB data(-)

3 USBD1(+) USB data(+)

4 GND Grou nd

2.3.4 USB Interface

USB Interface

Pin Assignments and Signal Names

Communication : Low speed Device

Connector : B type connector

USB Cable : FP-US00 <5m> manufactured by Digital Electronics Corporation

1

2

43

If a cable other than the specified USB cable is used, FP unit operation

cannot be guaranteed due to the possibility of noise interference.

Page 30

FP-2500/FP-2600 Series User Manual

2.4 Cable Diagrams

2-11

2.4 Cable Diagrams

Signals and signal names used with the FP and the Analog RGB cable (optional cable) are

the same as those used for PCs. Also, the same pin is used on both sides of the optional

cable so that you can connect the cable regardless of the cable direction.

Inch is used for the pitch of the connector screw on the PC. For this reason, inch (4-40) is

also used for the pitch of the connector screw for the cable and the FP .

FP

PC

RGB cable

1 Analog R Input

2 Analog G Input

3 Analog B Input

4 Reserved -5 Digital ground -6 Return R -7 Return G -8 Return B --

9 Reserved -10 Digital ground -11 Reserved --

12 Reserved --

13 H.SYNC Input

14 V.SYNC Input

15 Reserved --

FG FG --

1RED IN

2GRN IN

3BLU IN

4NC

5GND

6RED GND

7GRN GND

8BLU GND

9NC

10 GND

11 NC

12 NC

13 HSYN

14 VSYN

15 NC

FG FG

RED VIDEO 1

GRN VIDEO 2

BLU VIDEO 3

NC 4

GROUN D 5

GROUND RED 6

GROUND GRN 7

GROUND BLU 8

NC 9

GROUN D 10

MONITOR 11

SENSE(COLOR)

MONITOR 12

SENSE(MONO)

HSYN 13

VSYN 14

NC 15

FG FG

Output RED VIDEO 1

Output GRN VIDEO 2

Output BLU VIDEO 3

-- NC 4

-- GROUN D 5

-- GROUN D RED 6

-- GROUND GRN 7

-- GROUN D BLU 8

-- NC 9

-- GROUN D 10

-- MONITOR 11

--

SENSE(COLOR)

-- MONITOR 12

SENSE(MONO)

Output HSYN 13

Output VSYN 14

-- NC 15

2.4.1 Analog RGB Interface Pin Connections (Optional cable)

Page 31

FP-2500/FP-2600 Series User Manual

2.4 Cable Diagrams

2-12

2.4.2 DVI-D Interface Pin Connections (Optional cable)

Signals and signal names used with the FP and the DVI-D cable (optional cable) are the

same as those used for the PC. Also, the same pin is used on both sides of the optional

cable so that you can use the cable without worrying about the cable's direction.

Inch is used for the pitch of the connector screw on the PC. For this reason, inch (4-40) is

also used for the pitch of the connector screw for the cable and the FP .

FP PC

DVI-D cable

1 TMDS DATA2- Input

2 TMDS DATA2+ Input

3 TMDS DATA2/4 SHIELD -4NC -5NC -6DDC Clock -7 DDC Da ta -8NC --

9 TMDS DATA1- Input

10 TMDS DATA1+ Input

11 TMDS DATA1/3 SHIELD -12 NC -13 NC -14 NC -15 GND(+5V) -16 Hot Plug Detect -17 TMDS DATA0- Input

18 TMDS DATA0+ Input

19 TMDS DATA0/5 SHIELD -20 NC -21 NC -22 TMDS CLOCK SHIELD -23 TMDS CLOCK+ Input

24 TMDS CLOCK- Input

FG FG --

1TMDS DATA22TMDS DATA2+

3 TMDS DATA2/4 SHIELD

4NC

5NC

6 DDC Clock

7 DDC Data

8NC

9TMDS DATA110 TMDS DATA1+

11 TMDS DATA1/3 SHIELD

12 NC

13 NC

14 +5V Power

15 GND(+5V)

16 Hot Plug Detect

17 TMDS DATA018 TMDS DATA0+

19 TMDS DATA0/5 SHIELD

20 NC

21 NC

22 TMDS CLOCK SHIELD

23 TMDS CLOCK+

24 TMDS CLOCK-

FG FG

TMDS DATA2- 1

TMDS DATA2+ 2

TMDS DATA2/4 SHIELD 3

NC 4

NC 5

DDC Clock 6

DDC Data 7

NC 8

TMDS DATA1- 9

TMDS DATA1+ 10

TMDS DATA1/3 SHIELD 11

NC 12

NC 13

+5V Power 14

GND(+5V) 15

Hot Plug Detect 16

TMDS DATA0- 17

TMDS DATA0+ 18

TMDS DATA0/5 SHIELD 19

NC 20

NC 21

TMDS CLOCK SHIELD 22

TMDS CLOCK+ 23

TMDS CLOCK- 24

FG FG

Input TMDS DATA2- 1

Input TMDS DATA2+ 2

-- TMDS DATA2/4 SHIELD 3

-- NC 4

-- NC 5

-- DDC Clock 6

-- DDC Data 7

-- NC 8

Input TMDS DATA1- 9

Input TMDS DATA1+ 10

-- TMDS DATA1/3 SHIELD 11

-- NC 12

-- NC 13

-- +5V Power 14

-- GND(+5V) 15

-- Hot Plug Detect 16

Input TMDS DATA0- 17

Input TMDS DATA0+ 18

-- TMDS DATA0/5 SHIELD 19

-- NC 20

-- NC 21

-- TMDS CLOCK SHIELD 22

Input TMDS CLOCK+ 23

Input TMDS CLOCK- 24

Page 32

FP-2500/FP-2600 Series User Manual

2.4 Cable Diagrams

2-13

2.4.3 RS-232C Interface Pin Connections (Optional cable)

Signals and signal names used with the FP and the RS-232C cable (optional cable) are the

same as those used for PCs. Also, the same pin is used on both sides of the optional cable

so that you can connect the cable regardless of the cable direction.

Inch is used for the pitch of the connector screw on the PC. For this reason, inch (4-40) is

also used for the pitch of the connector screw for the cable and the FP .

1 CD Output 1 CD CD 1 Input CD 1

2 RD Output 2 RD RD 2 Input RD 2

3 SD Input 3 SD SD 3 Output SD 3

4 DTR Input 4 DTR DTR 4 Output DTR 4

5 GND 5 GND GND 5 GND 5

6 DSR Output 6 D SR DSR 6 Input DSR 6

7 RS Input 7 RS RS 7 Output RS 7

8 CS Output 8 CS CS 8 Input CS 8

9 NC 9 NC RI 9 Input RI 9

FG FG FG FG FG FG

FP SIO cable PC

2.4.4 USB Interface Cable Pin Connections (Option cable)

1

+5VIN

Input

2

USB-

Input/Output

3

USB+

Input/Output

4

GND

Input/Output

1

+5VIN

Input

2

USB-

Input/Output

3

USB+

Input/Output

4

GND

Input/Output

Output

+5VIN

1

Input/Output

USB-

2

Input/Output

USB+

3

Input/Output

GND

4

Output

+5VIN

1

Input/Output

USB-

2

Input/Output

USB+

3

Input/Output

GND

4

FP

USB cable

PC

Page 33

FP-2500/FP-2600 Series User Manual

2.5 Names and Functions of FP Parts

2-14

A : TFT Color LCD

Displays host data.

B : Touch Panel

Switches screens or writes/sends data to the host.

C : Front LED

Used to indicate status of power supply , backlight

or image signal input.

3.3.2 Status of Front LED in Op-

eration Modes

D : Power Input Terminal Block

Provides power to the FP unit via the input and

ground terminals

E : Dip Switches

Switches for setting up the FP unit's Operation

Mode.

G : Analog RGB Connector

Connector for analog RGB cable.

H : DVI-D Interface Connector

Connector for DVI-D calbe.

I : RS-232C Connector

Connector for RS-232C (serial) interface. Used

sending touch panel data to the host, and receiving

commands from the host.

J : USB Connector

Connector for USB cable. Used for sending touch

panel data to the host, and receiving commands

from the host.

2.5 Names and Functions of FP Parts

A B

C

FP-2500 Series Front

FP-2600 Series Front

Rear

Bottom

D E F G H I

Page 34

FP-2500/FP-2600 Series User Manual

2.6 FP Dimensions

2-15

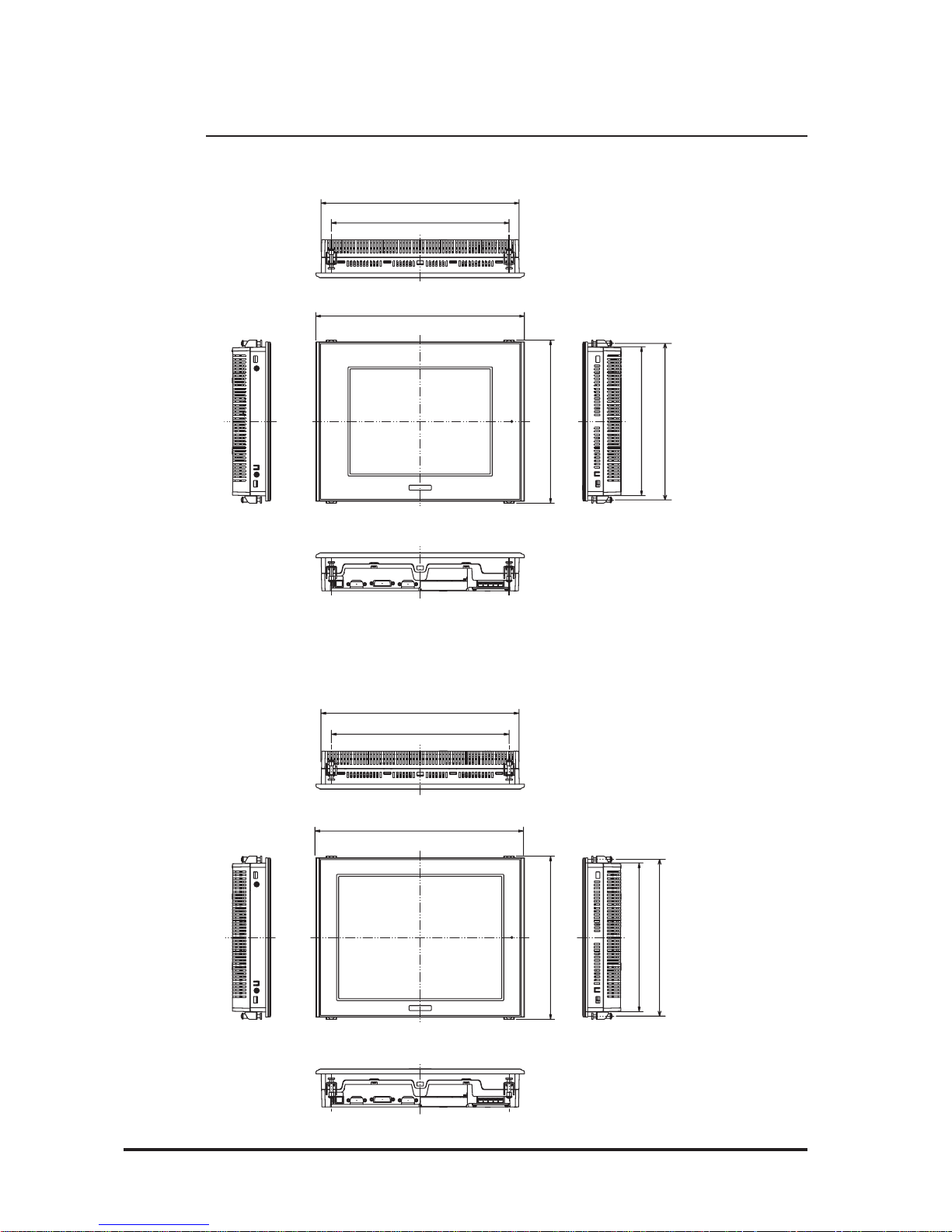

2.6 FP Dimensions

2.6.1 External Dimensions

FP-2600 Series

FP-2500 Series

301 [11.85]

317 [12.48]

243 [9.57]

8 [0.31]

58 [2.28]

227 [8.94]

Unit:mm [in.]

Top

Front Side

301 [11.85]

317 [12.48]

243 [9.57]

8 [0.31]

58 [2.28]

227 [8.94]

Top

Front Side

Unit:mm [in.]

Page 35

FP-2500/FP-2600 Series User Manual

2.6 FP Dimensions

2-16

2.6.2 External Dimensions (with Installation Fasteners)

FP-2600 Series

FP-2500 Series

270 [10.63]

249 [9.80]

239 [9.41]

317 [12.48]

301 [11.85]

227 [8.94]

Top

Front Right

Left

Bottom

Unit : mm [in.]

270 [10.63]

249 [9.80]

239 [9.41]

317 [12.48]

301 [11.85]

227 [8.94]

Top

Front Right

Left

Bottom

Unit:mm [in.]

Page 36

FP-2500/FP-2600 Series User Manual

2.6 FP Dimensions

2-17

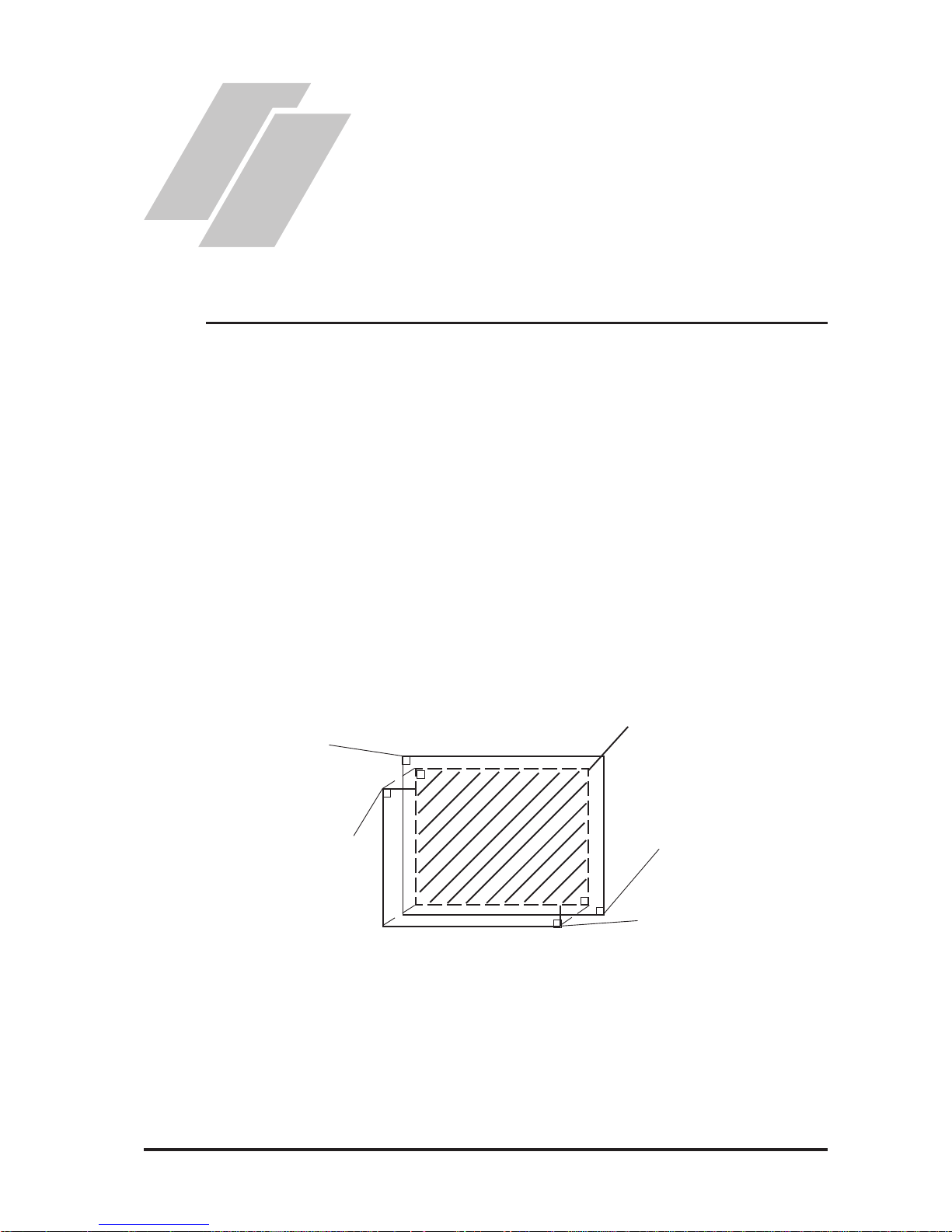

2.6.3 Installation Fasteners

2.6.4 FP Panel Cut Dimensions

Panel

301.5 [11.87 ]

+1

0

+0.04

0

227.5

[8.96 ]

+0.04

0

+1

0

under 4-R3

Unit: mm [in.]

• Panel thickness should be between 1.6mm [0.06in.] and

10.0mm [0.4in.]. Panel’s thickness should be based on

the level of panel strength required.

• Check that the installation panel or cabinet's surface is

flat, in good condition and has no jagged edges.

• If desired, metal reinforcing strips can be attached to

the inside of the panel, near the Panel Cut, to increase

the panel’s strength.

3.1.1 Installation Procedure

• Be sure to create the correct sized panel cut required to

install the FP, using the installation dimensions given.

FP

Panel Cut

11

[0.43]

16 [0.63]

31 [1.22]

19.5 [0.77]

M5

10f

Unit : mm [in.]

Page 37

FP-2500/FP-2600 Series User Manual

2-18

Memo

Page 38

FP-2500/FP-2600 Series User Manual

3-1

3.1 Installation

3.1 Installation

Chapter 3

Installation and Wiring

1. Installation

2. Wiring

3. Operation Mode Setup

and Display Positioning

3.1.1 Installation Procedures

Follow the steps given below when installing the FP .

Check the Installation Gasket’s Seating

It is strongly recommended that you use the installation gasket, since it absorbs vibration

in addition to repelling water.

Place the FP on a level surface with the display panel facing downward. Check that the

FP unit’s installation gasket is seated securely into the gasket’ s groove, which runs

around the perimeter of the panel’s frame.

For details about installing the gasket, refer to

• Before installing the FP into a cabinet or panel, check that the installation gasket is securely attached to the unit.

• A gasket which has been used for a long period of time may have

scratches or dirt on it, and can lose much of its dust and drip resistance. Be sure to change the gasket periodically (or when scratches

or dirt become visible).

• Be sure to use gasket model GP570-WP10-MS.

• Be sure the gasket's seam is not inserted into any of the unit's corners, only in the straight sections of the groove. Inserting it into a

corner may lead to its eventually tearing.

• To ensure the installation gasket’s maximum level of moisture resistance, be sure the gasket’s seam is inserted as shown into the panel’s

bottom face.

6.1.2 Installation Gasket Check/Replacement

Gasket

Rear face

Page 39

FP-2500/FP-2600 Series User Manual

3-2

3.1 Installation

Creating a Panel Cut

Create the correct sized opening required to install the FP , using the installation dimensions given.

• Check that the installation panel or cabinet's surface is flat, in good

condition and has no jagged edges. Also, if desired, metal reinforcing

strips can be attached to the inside of the panel, near the Panel Cut, to

increase the panel’s strength.

• Panel thickness should be from 1.6mm [0.06in.] to 10.0mm [0.4in.].

Decide the panel’s thickness based on the level of panel strength required.

For easier maintenance, operation, and improved ventilation, be sure to

install the FP at least 100 mm [3.94 in.] away from adjacent structures

and other equipment.

2.6.4 FP Installation Dimensions

The installation gasket, installation fasteners and attachment screws are all required

when installing the FP .

Side View

Rear View

100

[3.94]

100

[3.94]

100

[3.94]

100

[3.94]

100

[3.94]

100

[3.94]

100

[3.94]

Panel

Panel Cut

Unit: mm [in.]

1.6mm [0.06in.] to 10.0mm [0.4in.]

> <

Page 40

FP-2500/FP-2600 Series User Manual

3-3

3.1 Installation

• Be sure that the ambient temperature and the ambient humidity are

within their designated ranges. (When installing the FP in a cabinet or

enclosure, the term “ambient temperature” indicates the cabinet or

enclosure’s internal temperature.)

• Be sure that heat from surrounding equipment does not cause the FP

to exceed its standard operating temperature.

• When installing the FP in a slanted panel, the panel face should not

incline more than 30o.

• When installing the FP in a slanted panel, and the panel face inclines

more than 30o, the ambient temperature must not exceed 40 oC. You

may need to use forced air cooling (fan, A/C) to ensure the ambient

operating temperature is 40 oC or below.

Panel

Face

Panel

Interior

NO more than 30 degrees of tilt

Page 41

FP-2500/FP-2600 Series User Manual

3-4

3.1 Installation

Installing the FP

1) Insert the FP into the panel cut,

as shown here.

2) Insert the installation fasteners

into the FP unit’s insertion slots,

at the top and bottom of the

unit. (total:4 slots)

3) Insert each of the fasteners as

shown right. Be sure to pull the

fastener back until it is flush

with the rear of the attachment

hole.

Panel

FP

Panel Cut

Bottom

Insertion Slots

Top

Installation panel

Hook

Page 42

FP-2500/FP-2600 Series User Manual

3-5

3.1 Installation

Do not use too much force, since it may damage the FP

unit. A torque of only 0.5 N•m is sufficient to tighten

these screws.

4) Use a Phillips screw driver to

tighten each fastener screw and

secure the FP in place.

• Depending on the panel condition, you can improve moisture resistant effect by

increasing the number of installation fasteners.

• Installation fasteners are sold by your local FP distributor.

Page 43

FP-2500/FP-2600 Series User Manual

3-6

3.2 Wiring

• Wherever possible, use thick wires (max 2mm2) for power terminals, and twist

the exposed wire ends when connecting the Ring Terminals.

• Please use the following size crimp-on type Ring Terminals.

3.2 Wiring Cautions

3.2.1 Connecting the Power Cord

• To prevent the Ring Terminals from causing a short when the ter-

minal block attachment screws are loosened, be sure to use sleevetype Ring Terminals.

• When the FG terminal is connected, be sure the wire is grounded.

Not grounding the FP unit will result in excessive noise. Use your

country’s applicable standard for grounding.

3.2.3 Grounding

• The SG and FG terminals are connected internally in the FP unit.

• When connecting the SG line to another device, be sure that the

design of the system/connection does not produce a shorting loop.

WARNINGS

• To avoid an electric shock, when connecting the FP

unit's power cord terminals to the power terminal

block, confirm that the power supply is completely

turned OFF, via a breaker, or similar unit.

• FP2500-T12 and FP2600-T12 units are designed to

use only AC100V to AC240V input. FP2500-T42-24V

and FP2600-T42-24V units are designed to use only

DC24V input. Any other power level can damage both

the FP and the power supply.

• Since there is no power switch on the FP unit, be sure

to attatch a breaker-type switch to its power cord.

• Be sure to ground the FP’s FG terminal. Failure to do

so can lead to an electrical shock or FP malfunction.

Page 44

FP-2500/FP-2600 Series User Manual

3-7

3.2 Wiring

1) Confirm that that the FP unit's Power Cord is unplugged from the power supply.

2) Use a screwdriver to remove the Power Input Terminal Block's clear plastic cover .

3) Unscrew the screws from the middle three (3) terminals, align the Ring Terminals and

reattach the screws.

4) Replace the Power Input T erminal Block's clear plastic cover.

• Confirm that the ring terminal wires are connected correctly.

• A torque of only 0.5 to 0.6 N•m is required to tighten an attachment screw.

L

AC Input Live Line

N

AC Input Neutral Line

FG

Grounding Terminal connected to

the FP chassis.

Power

Terminal

Block

Connecting the Power Supply Terminals

FP2500-T12/FP2600-T12

+

Positive electr ode

-

Negative electrode

FG

Grounding Terminal connected to

the FP chassis.

Power

Terminal

Block

FP2500-T42-24V/FP2600-T42-24V

L N FG

L N FG

+ - FG

+ - FG

Page 45

FP-2500/FP-2600 Series User Manual

3-8

3.2 Wiring

3.2.2 Connecting the USB Cable Strap Attachment

USB Cable Strap Attachment Procedure

1) Insert the USB cable into the USB connector.

2) Tighten the strap until the cable is secured in place and insert the cable strap into the

cable strap holder as shown in the following figure.

USB Cable Strap Removal Feature

1) Push in the cable strap's stopper with a standard flat-blade screwdriver until the cable

strap band is unlocked, and remove the strap.

2) Disconnect the USB cable.

Stopper

USB Cable Strap Holder

USB Cable

USB Cable Holder

<A>

• If the stopper will not move, press on <A> (shown in figure) to free the strap

from the strap holder.

Page 46

FP-2500/FP-2600 Series User Manual

3-9

3.2 Wiring

3.2.3 Connecting the Power Supply

• When supplying power to the FP unit, be sure

to separate the input/output and operation unit

lines, as shown.

• T o increase the noise resistance quality of the

power cable, be sure to twist each power wire

before attaching the Ring T erminal.

• The power supply cable must not be bundled or

positioned close to main circuit lines (high

voltage, high current), or input/output signal lines.

• Connect a lightning surge absorber, as shown in

the diagram, to deal with power surges.

• T o avoid excess noise, make the power cable as

short as possible.

• Be sure to ground the

surge absorber (E1)

separately from the FP

unit (E2).

• Select a surge absorber

that has a maximum

circuit voltage greater

than the power supply's

peak voltage.

Input/ Output Power

power

input/output

main circuit

Motor

Operation

Unit

Input/ Output Power

FP unit

Main

Power

FP

power

FP unit

lightning

surge

absorber

input/output unit

Main

Power

FP

power

FP unit

Page 47

FP-2500/FP-2600 Series User Manual

3-10

3.2 Wiring

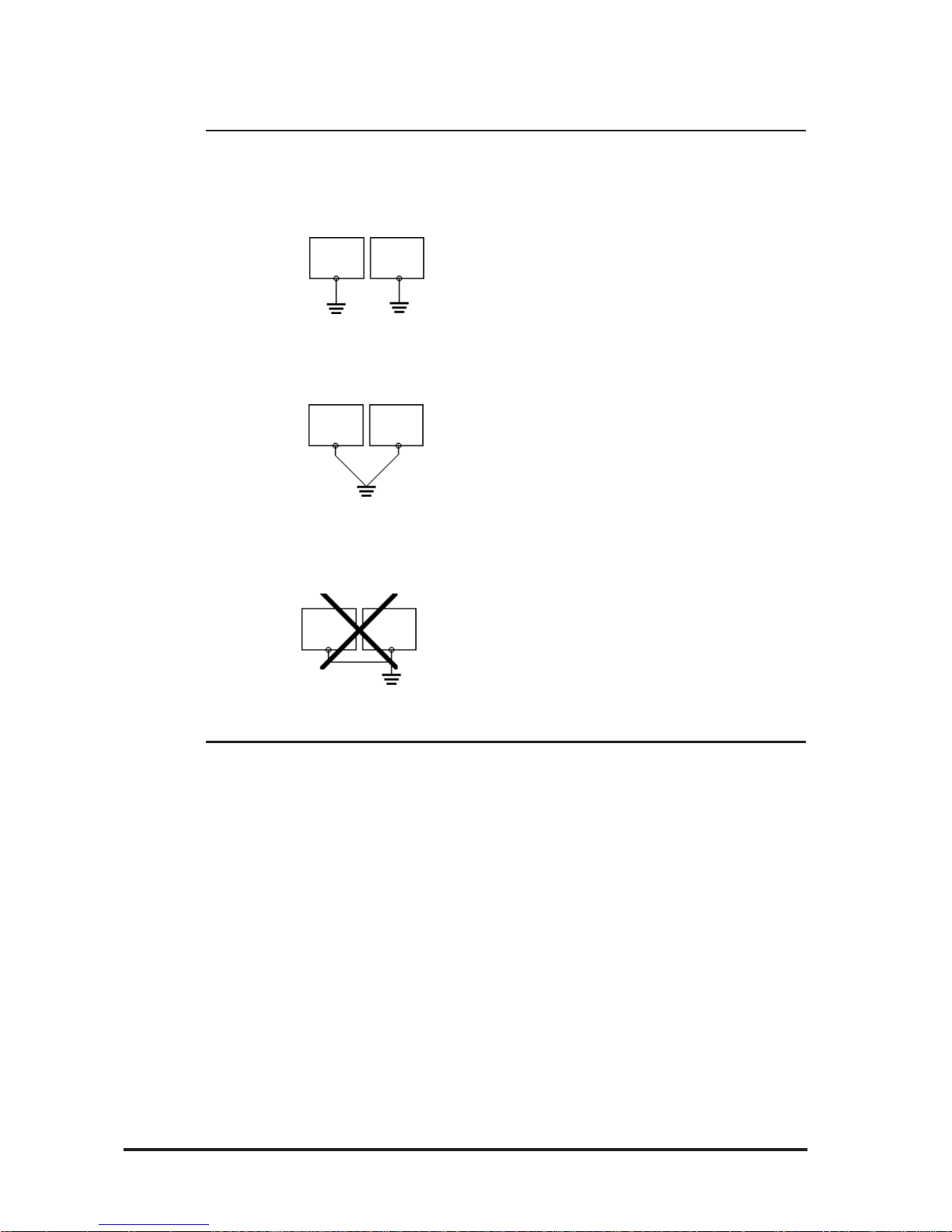

3.2.4 Precautions: Grounding

other

equipment

FP unit

FP unit

other

equipment

FP unit

other

equipment

(a) Exclusive grounding (BEST)

(b) Common grounding (OK)

(c) Common grounding (BAD)

3.2.5 Precautions: Input/Output Signal Lines

• Input and output signal lines must be separated from operating circuit power cables.

If this is not possible, use a shielded cable and connect the shield to the FP chassis.

• Connect the FP unit's FG terminal to

an exclusive ground. [diagram (a) Grounding resistance of under 100Ω.]

• If exclusive grounding is not possible,

use a common connection point.

[diagram (b)]

• The grounding wire should have a

cross sectional area greater than

2mm2. Make the connection point as

close to the FP unit as possible, and

make the wire as short as possible.

When using a long grounding wire,

replace the thin wire with a thicker

wire placed in a duct.

• If this equipment does not function

properly when grounded, disconnect

the ground wire from the FG terminal.

Page 48

FP-2500/FP-2600 Series User Manual

4-1

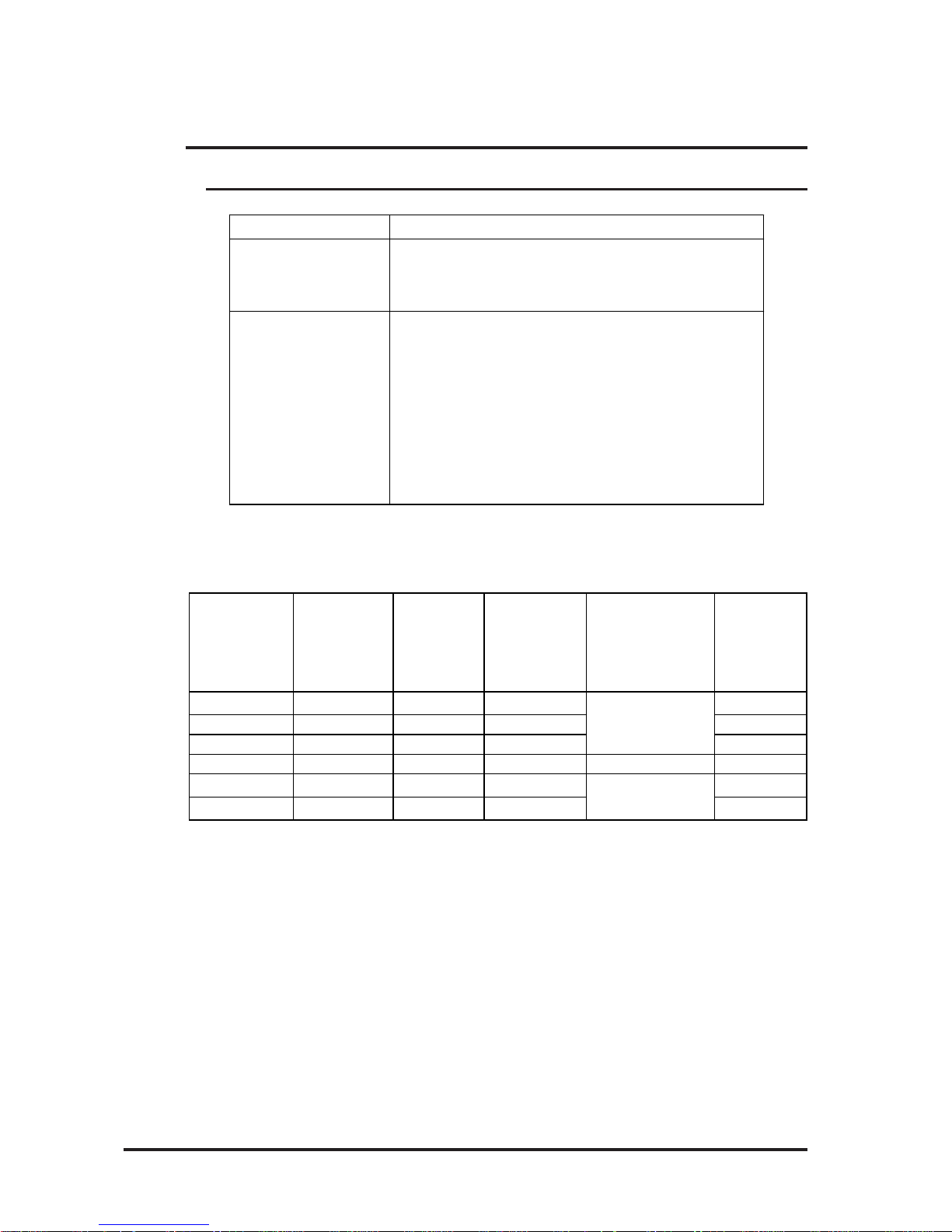

4.1.1 Dip Switch Preset Settings and Adjustments

4.1 Operation Mode Setup

Chapter 4

Setting up and Adjusting the FP unit

1. Operation Mode Setup

2. Screen Display Adjustment

The FP unit's dip switches are located behind the Dip Switch Cover.

ON

SW1

86543271

SW

No.

Function Description

Factory

Settings

1-1

Switch between USB and RS232C for touch panel data

transmission.

Used to set the touch panel data input (command

control) method to either USB or RS-232C.

ON : USB

OFF : RS-232C (Default setting)

1-2 Display/hide the OSD.

Used to display or hide the OSD.

ON : Hide

OFF : Display (Default setting)

1-3

1-4

1-5

Switch between analog RGB

and DVI-D input.

Used to change the image input method.

ON : DVI-D

OFF : analog RGB (Default setting)

1-6

1-7

1-8

All OFF

Reserved Set this switch to OFF

Reserved Be sure these switches are always set to OFF

Dip Switches

Dip switch settings are effective only when starting up the FP unit.

After changing any dip switch settings, be sure to restart your FP unit.

Page 49

FP-2500/FP-2600 Series User Manual

4-2

4.1 IOperation Mode Setup

Starting the OSD

T o start the OSD and enter OSD mode, press the three corners of the touch panel in

the following order ((1)upper left, (2)upper right and (3)lower right) within 5 seconds. In

OSD mode, the setting screen is displayed in the center of the screen and the touch

panel cannot be used to communicate with external devices until the OSD setup is

completed.

4.1.2 Status of Front LED in Operation Modes

OFF

(Not Lit)

Green Orange

Green/

Red Flash

Orange

Flash

Pow e r OFF Power ON Pow er ON Powe r ON P o we r ON

- Normal Normal Burned-out Burned-out

-YesNoYesNo

Panel

Backlight

Image Input

LED

4.2.1 Calibration of OSD Display Position

“V***” indicates the OSD version.

Using the OSD

The setting screen uses icons to (select and) enter settings. When you start up the OSD,

the main menu appears. T ouching an icon displays its submenu or setting change screen.

In the setting screen, and icons are used to change the setting. To apply the setting,

press the button. Press the button to save the defined settings.

Simply touch the touch panel to call up the OSD (On Screen Display) screen.This

screen allows you to perform detailed display adjustment.

4.2 Screen Display Adjustment

OSD is not displayed when DIP SW 1-2 is ON.

OSD Setting screen

1

2

3

Page 50

FP-2500/FP-2600 Series User Manual

4-3

4.2 Screen Display Adjustment

CONTRA ST Adjusts the contrast.

(Analog RGB only)

*1

BLACK LEVEL Adjust s t he color bright nes s .

(Analog RGB only)

*1

H-POS

V-POS

(Analog RGB only)

*1

(Analog RGB only)

*1

BA CKLIGHT

(Analog RGB only)

*1

DISPLAY MODE

OSD CLEAR (RESET)

OSD SAVE

SY STEM

ESCAPE

Cancels the s et ting and returns to the up per level. In the main

menu, this command closes t he OSD.

Save the current value and quit the OSD.

Changes settings s uch as activating t he click sound .

Reset s t he current OS D value to t he default value.

A u t omatically adjus t s t he contr as t and t he bright ne ss .

PHASE

Display s t he r esolut ion of t he input image data.

A UTO GAIN CONTROL

Item Function

Adjust s t h e backlight br ightness. (9 levels)

A d justs t he input s ignal and t he do t clock position. ( 32 levels)

A djusts the vertical position of the screen.

A djust s t he horizontal position of the s creen.

H-SIZE

A d justs t he s creen size in the horizontal direction.

* 1 When using DVI-D, the message "DO NOT NEED SETUP FOR DVI-D" is displayed

and no settings are required.

Quitting the OSD

T o quit the OSD, press the button in the main menu or leave the OSD as it is for at

least 30 seconds. If the OSD is automatically closed after 30 seconds of inactivity , the

values set before the OSD was closed will be applied.

4.2.2 OSD Setting Icons

Page 51

FP-2500/FP-2600 Series User Manual

4-4

4.2 Screen Display Adjustment

Main menu

CONTRAST

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

Sets the contrast setting and then moves to the sub contrast menu.

Sub contrast R

Adjustment buttons

Applies the setting and then returns to the

Sub contrast adjustment screen.

Cancels the setting and then returns to the

Sub contrast adjustment screen.

Sub contrast G

Sub contrast B

H-SIZE

Adjustment buttons

Applies the setting and then returns to the

Sub contrast adjustment screen.

Cancels the setting and then returns to the

Sub contrast adjustment screen.

Adjustment buttons

Applies the setting and then returns to the

Sub contrast adjustment screen.

Cancels the setting and then returns to

the Sub contrast adjustment screen.

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

4.2.3 OSD Setting Item Details

V-POS

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

H-POS

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

BLACK LEVEL

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

Returns to the contrast adjustment screen

Page 52

FP-2500/FP-2600 Series User Manual

4-5

4.2 Screen Display Adjustment

BACKLIGHT

AUTO GAIN CONTROL (Analog RGB only)

Starts the auto gain control and then automatically returns to the

main menu.

DISPLAY MODE

Returns to the main menu.

OSD CLEAR

Clears the setting.

Cancels the setting and then returns to the main menu.

PHASE

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

Adjustment buttons

Applies the setting and then returns to the main menu.

Cancels the setting and then returns to the main menu.

Be sure to perform auto gain control when the screen has both 100%

black and 100% white areas displayed.

SYSTEM

Enables/disables the click sound. With this

parameter, the sound level can also be

adjusted.

(Default value: OFF <Click sound disabled>)

When an input data resolution of 720 x 400 is

used in the VGA text mode, set this parameter

to ON. For other resolutions, set this

parameter to OFF.

(Default: OFF)

2.3.1 Analog RGB Interface

Returns to the main menu.

Page 53

FP-2500/FP-2600 Series User Manual

4-6

4.2 Screen Display Adjustment

Applies the setting and returns to the main menu.

Cancels the setting and returns to the main menu.

Enables/disables the Backlight burnout detect

function.

(Default: ON )

When a burned-out backlight is detected, the

status LED flashes alternately green and red, or a

steady orange.

T ouch-operation will be disabled when the

backlight burns out, which prevents the FP from

sending input signals to the PLC.

Normally , the FP unit detects a backlight

burnout by monitoring the backlight's

current flow , however, the FP may fail to

detect this condition, depending on the

type of backlight problem.

Enables/disables the screen display Auto OFF

function and sets the time when the Auto OFF

function is enabled.

(Default: OFF <Auto OFF function disabled>)

The Auto OFF function automatically turns off the

display to prevent the screen from burning out

when the touch panel is not used for some period

of time. With this parameter, you can set the time

interval to turn off the screen display (how much

time passes before the screen display is turned

off) when the touch panel is not used. If the touch

panel is not touched over the set time, the

backlight will automatically turns off.

Select the time period from 1 min, 3 min, 5 min,

10 min, and OFF (Auto OFF function disabled).

In this screen, touching the value displayed on the panel changes the value of

the time period.

If an analog RGB interface is used and the

horizontal display position exceeds the

normally adjustable range, setting the POLARITY LOCK feature to ON may allow you to

adjust the display position. (Default: OFF

<Disabled>)

This setting is enabled after the OSD is

closed.

Page 54

FP-2500/FP-2600 Series User Manual

4-7

4.2 Screen Display Adjustment

SAVE Saves all the adjusted settings in the EEPROM.

• In the OSD, pressing the button applies the set value and enables

the setting. The set value won't be canceled unless the power is turned

OFF or the value is reset.

If the power is turned OFF without saving the set value, that data will

disappear . The last saved data will be read into the system when the

FP starts. To enable the changed value, be sure to press the SAVE but-

ton.

• When the OSD automatically closes after 30 seconds of inactivity, the

set value that you were modifying at the time will be retained. If you

quit the OSD using the button, the value you were modifying will

be ignored and the previously set value will remain in effect.

Page 55

FP-2500/FP-2600 Series User Manual

4-8

Memo

Page 56

5-1FP-2500/FP-2600 Series User Manual

5.1 Touch Interface Data

Chapter 5

Touch Panel Data

5.1 Touch Interface Data

1. Touch Interface Data

2. Touch Panel Communication

Program for MS-DOS

®

The FP-2500/FP-2600 Series units use an analog type touch panel. This touch panel

needs a calibration program to adjust the actual touch position.

Touch Panel Coordinate Data

The screen display origin point, with 640 x 480 for FP-2500 Series units and 800 x 600

for FP-2600 Series units, is normally at the upper left corner of the screen. Therefore, a

software to convert the touch coordinates to display coordinates is needed.

(1) Resolution

Both the X and Y coordinates have a resolution of 1024.

The origin point (0,0) is located in the upper left corner of the screen.

Display Coordinates

(0,0)

Touch Panel

Coordinates

(1023,1023)

Touch Panel

Coordinates

(0,0)

Display Coordinates

(640,480)

Display Area

Page 57

5.1 Touch Interface Data

5-2 FP-2500/FP-2600 Series User Manual

(2) Data Format

T ouch Panel coordinate data is sent to the host using the following format.

All data is in binary format.

Header: 1 byte (11h= touched; 10h = released)

X coordinate: 2 bytes (0 to 3FFh)