Page 1

ESE50SDISolidStateDisk

UserGuide

Order Number: EK–ESE50–UG. B01

Page 2

June 1993

The information in this document is subject to change without notice and should not be construed

as a commitment by Digital Equipment Corporation. Digital Equipment Corporation assumes no

responsibility for any errors that may appear in this document.

The software described in this document is furnished under a license and may be used or copied

only in accordance with the terms of such licence.

© Digital Equipment Corporation 1992, 1993.

All Rights Reserved.

Printed in U.S.A.

The following are trademarks of Digital Equipment Corporation: Digital, HSC40, HSC60, HSC70,

HSC90, KDM, OpenVMS, RA, SA, SDI, VMS, and the DIGITAL logo.

All other trademarks and registered trademarks are the property of their respective holders.

This document was prepared using VAX DOCUMENT, Version 2.1.

Page 3

Contents

Preface ............................................................ v

1 Introduction

1.1 General Information. . ........................................ 1–1

1.1.1 Media Type, Model Byte, and Capacity . ....................... 1–3

1.2 Hardware Maintainability ..................................... 1–4

1.3 Dual-Port Capability . ........................................ 1–4

1.4 Drive-Resident Diagnostics Overview ............................ 1–5

1.5 User Precautions/Recommendations.............................. 1–5

1.5.1 Data Retention. . . ........................................ 1–5

1.5.2 Orderly Shutdown ........................................ 1–6

1.5.3 Recommended Operating Temperature . ....................... 1–7

1.5.4 Electrostatic Discharge Protection ............................ 1–7

1.6 ESE50 SSD Maintenance Strategy .............................. 1–9

1.7 ESE50 SSD Specifications ..................................... 1–9

2 Installation

2.1 Introduction ................................................ 2–1

2.2 Site Preparation and Planning. . ................................ 2–1

2.3 Unpacking ESE50 Add-Ons .................................... 2–2

2.4 Installing SDI Cables and Power Cords ........................... 2–4

2.4.1 Installing Internal SDI Cables ............................... 2–4

2.4.2 Installing Internal Power Cords.............................. 2–4

2.4.3 Installing External SDI Cables .............................. 2–4

2.5 Power and Safety Precautions . . ................................ 2–5

2.6 AC Power Wiring ............................................ 2–7

3 Operating Instructions

3.1 Introduction ................................................ 3–1

3.2 OCP Functions, Switches, and Indicators . . ....................... 3–1

3.3 Powerup Diagnostics . ........................................ 3–2

3.3.1 Problems at Powerup ...................................... 3–2

3.3.2 Operator Control Panel Lamp Testing . . ....................... 3–2

3.3.3 Testing Spin-Up Drive ..................................... 3–3

3.4 Programming the Drive Unit Address ............................ 3–4

3.5 ESE50 Operating Modes ...................................... 3–6

3.5.1 Normal Mode Setup ....................................... 3–6

3.5.2 Fault Display Mode Setup . . ................................ 3–6

3.5.3 Test Mode Setup . ........................................ 3–8

iii

Page 4

4 Diagnostics

4.1 General Information. . ........................................ 4–1

4.2 Drive-Resident Diagnostics .................................... 4–1

4.2.1 Powerup Resident Diagnostics ............................... 4–2

4.3 Test Selection from the OCP . . . ................................ 4–2

A Customer Equipment Maintenance

A.1 Customer Responsibilities ..................................... A–1

A.1.1 Cleaning Supplies ........................................ A–1

A.1.2 Ongoing Equipment Care . . . ................................ A–2

A.1.3 Monthly Equipment Maintenance ............................ A–2

A.1.4 Maintenance Records ...................................... A–2

Index

Figures

1–1 ESE50 Solid State Disk .................................... 1–2

1–2 Typical ESE50 SSD Subsystem Configuration ................... 1–4

1–3 ESE50 Dual-Port Configuration .............................. 1–5

1–4 ESD Wrist Strap . ........................................ 1–8

2–1 ESE50 Disk Drive Packaging ................................ 2–3

2–2 881 Power Controller (Example) ............................. 2–6

2–3 Electrical Plug Configurations ............................... 2–8

3–1 ESE50 OCP ............................................. 3–2

3–2 Unit Address Programming Flowchart. . ....................... 3–5

3–3 Fault Display Example .................................... 3–7

3–4 Fault Mode Flowchart ..................................... 3–7

3–5 ESE50 Test Display ....................................... 3–8

3–6 Running Test OCP Display . ................................ 3–8

4–1 Test Selection Flowchart . . . ................................ 4–3

A–1 Customer Equipment Maintenance Log . ....................... A–3

Tables

1–1 SDI SSD Capacity ........................................ 1–3

1–2 Summary of Data Retention Times ........................... 1–6

1–3 Specifications for the ESE50 SSD ............................ 1–9

1–4 Additional Electrical Specifications by Model for the ESE50 SSD .... 1–10

iv

Page 5

Preface

This manual contains the following information:

• ESE50 solid state disk specifications

• Environmental considerations

• Installation information and references

• Start-up procedures

• Acceptance testing criteria

• Troubleshooting procedures

Although this manual is written primarily for ESE50 solid state disk customers,

installation procedures described or referenced in this manual are intended for

Digital Customer Services engineers performing original installation of the ESE50

solid state disk. Qualified Customer Services engineers must be trained in the

following:

• ESE50 solid state disk

• DSA concepts

• ESD procedures

This manual does not cover cabinet cable routing and connections. Specific

information concerning subsystem cabinet-related procedures can be found in

product-specific manuals. A list of related documentation follows:

Document Title Order Number

SA300/SA350 Storage Array Family Configuration Guide EK–SA300–CG

SA600/SA800 Storage Array Family Configuration Guide EK–SA600–CG

SA650/SA850 Storage Array Family Configuration Guide EK–SA650–CG

SAxxx Storage Array Family Configuration Guide EK–SAxxx–CG

Conventions Used in This Guide

The following conventions are used in this guide:

Note — Notes provide general information on the current topic.

Caution — Cautions provide information to prevent damage to equipment or

software. Read these carefully.

Warning — Warnings contain information to prevent personal injury. Read these

carefully.

v

Page 6

Page 7

1.1 General Information

The ESE50 solid state disk (SSD) is a member of the Digital Storage

Architecture/Standard Disk Interconnect (DSA/SDI) family, and is plugcompatible with all DSA/SDI controllers.

The ESE50 solid state disk is a random access low latency mass storage device

that uses DRAM semiconductor technology for fast response time. The ESE50 is

Digital’s fastest disk drive and is used when I/O response time is a key metric.

The ESE50 is contained in a half rack (RA92 style) enclosure with its own power

and data retention capabilities. It connects and operates on the standard disk

interface (SDI) and may be used with controllers implementing this bus. The

operator control panel (OCP) from the RA9x disk drive is also used on the ESE50

SSD. The ESE50 can also be packaged in any SA3xx, SA6xx, SA8xx, or SA9xx

storage array cabinet.

The following controllers support the ESE50:

• HSC (40/60/65/70/90/95)

• KDM70

1

Introduction

The ESE50 has been tested under OpenVMS Versions 5.4 and 5.5. Under these

versions, the ESE50 is identified as a DU device (rather than by the ESE50

name). Identification as a DU device does not impact any standard Digital disk

functionality. Shadowing, failover, dual porting, bound volumes, and so forth are

supported.

However, when running the ESE50 under OpenVMS Versions 5.4-n, 5.5, or 5.5-1,

key things to be aware of are:

• All shadow sets must be comprised of the same capacity ESE50 units.

• Controller-based volume shadow sets require manual verification that all

members of the shadow set are on the same controller.

The ESE50 is fully supported under OpenVMS Version 5.5-2 and OpenVMS AXP

Version 1.5 (and all subsequent releases).

Figure 1–1 shows an ESE50 solid state disk.

Introduction 1–1

Page 8

Introduction

1.1 General Information

Figure 1–1 ESE50 Solid State Disk

1–2 Introduction

Page 9

1.1.1 Media Type, Model Byte, and Capacity

The ESE50 has a unique media type and model byte depending on the capacity.

This is done for operating system compatibility.

Option Media Type Model Byte Capacity (LBNs)

ESE50–AA,AB ESE52 31 238080

ESE50–BA,BB ESE56 48 1196544

ESE50–DA,DB ESE58 49 1915392

The storage medium for the ESE50 SSD are 4M bit DRAMs and the data is

accessed in 512-byte blocks. The formatted capacity of the ESE50 option is shown

in Table 1–1.

Table 1–1 SDI SSD Capacity

1

Option

ESE50–Ax 2 128.0 MB 121.9 MB 465 238080

ESE50–Bx 10 640.0 MB 612.6 MB 2337 1196544

ESE50–Dx 16 1024.0 MB 980.6 MB 3741 1915392

No. of

Arrays

Unformatted

Capacity

Formatted

Capacity

Introduction

1.1 General Information

No. of

LBN Cyl’s

No. of

Logical

Blocks

1

"x" equals "A" for 120 Vac or "B" for 240 Vac.

The ESE50 has the following common characteristics:

• 20.0 megabits/second transfer rate

• Full data retention

• Extensive resident microcode diagnostics

• Internal error log capabilities

• Multifunction OCP

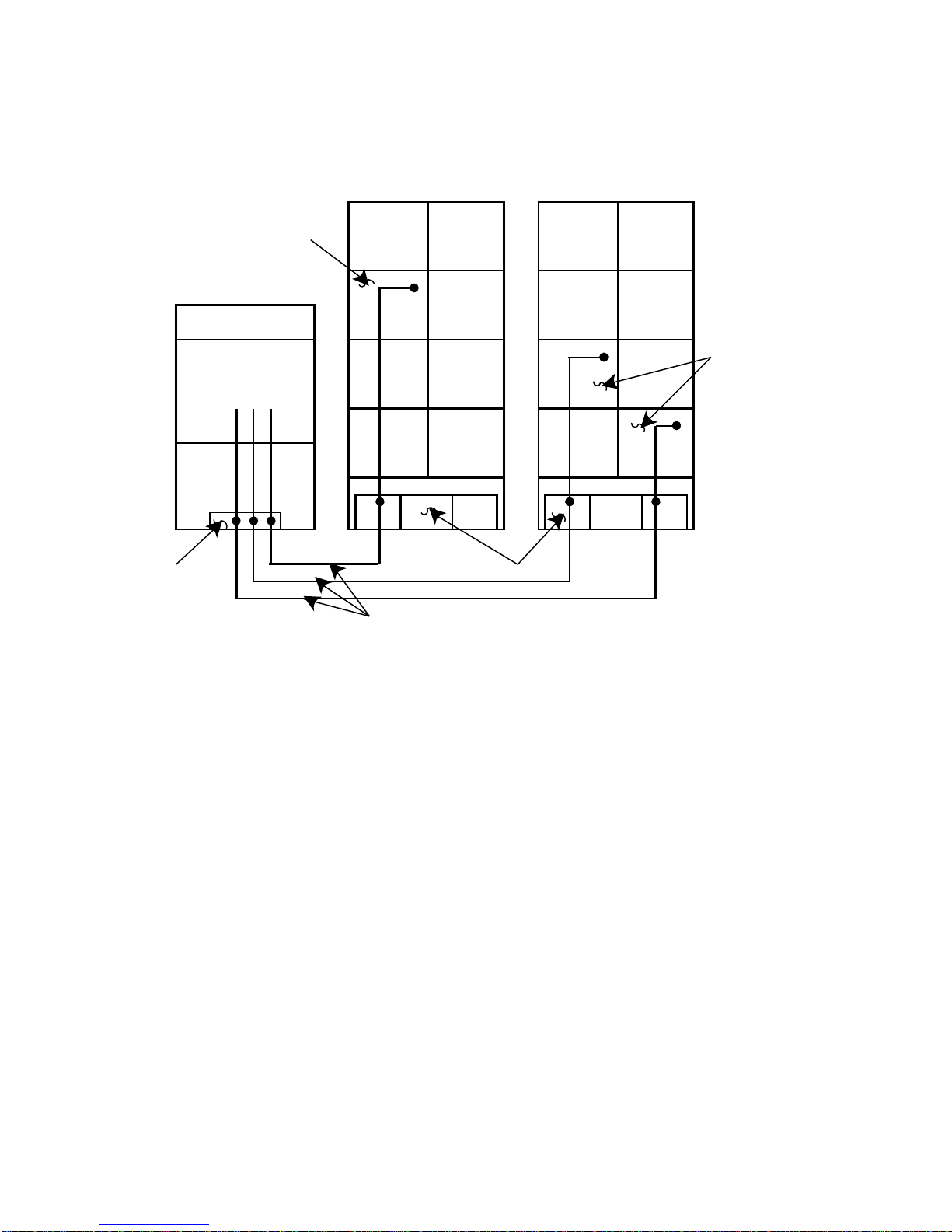

Figure 1–2 represents a typical ESE50 SSD subsystem configuration including an

SDI controller.

Introduction 1–3

Page 10

Introduction

1.1 General Information

Figure 1–2 Typical ESE50 SSD Subsystem Configuration

DRIVE CABINET DRIVE CABINET

ESE50

CONTROLLER A

SDI CONTROLLER A

ESE50

I/O BULKHEAD

SDI CABLES

1.2 Hardware Maintainability

The ESE50 SSD uses modular field replaceable units (FRUs) for easy access

and servicing. An extensive set of drive-resident microcode diagnostics and a

drive-resident error log help simplify problem isolation.

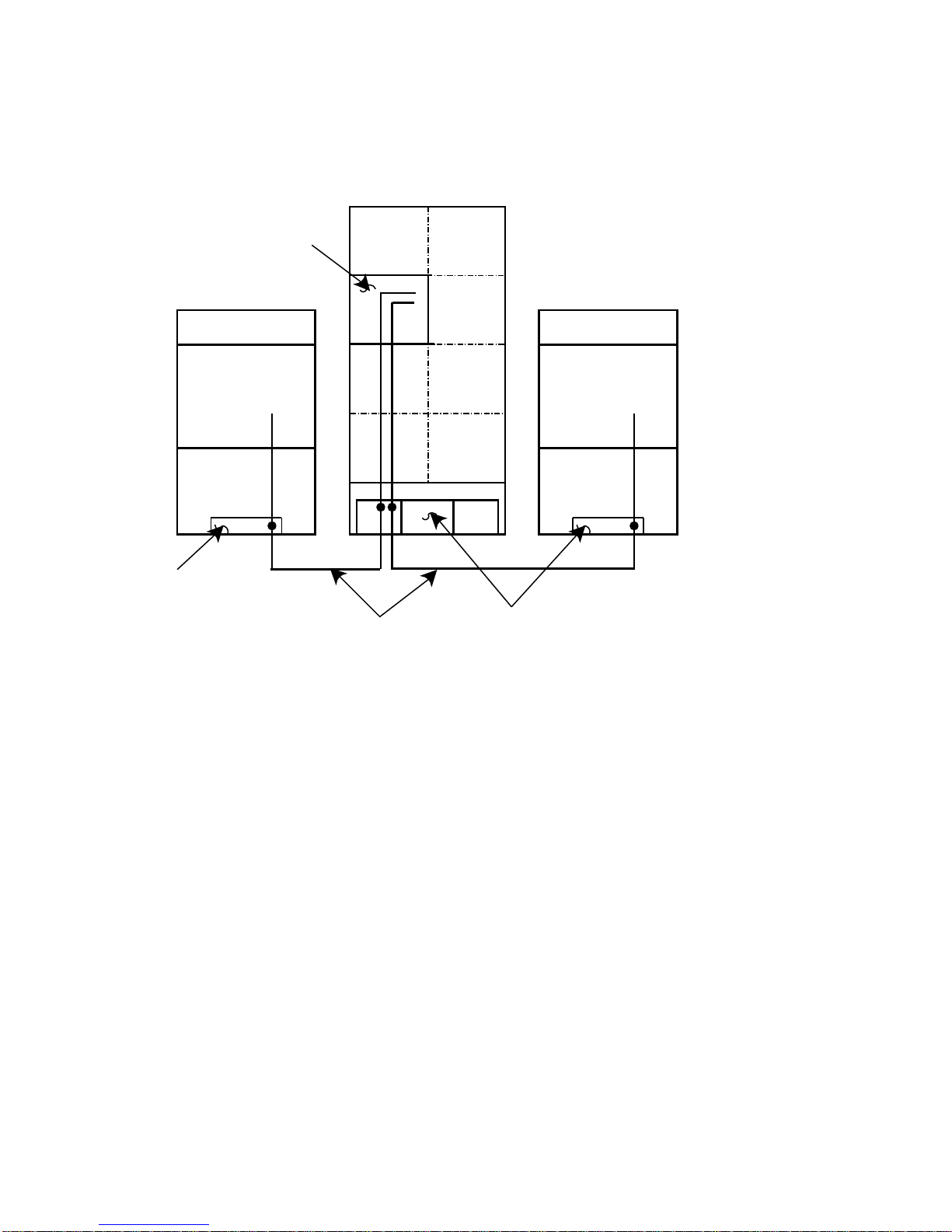

1.3 Dual-Port Capability

Ports are enabled by the port select switches (A or B) on the front of the OCP.

With both port switches selected, the ESE50 operates in a static dual-port mode.

Static dual porting means that an SSD is shared between two controllers but is

on line to only one controller at a time for data transfers. The second controller

must wait until the drive is available before placing the drive on line.

An additional SDI cable is required for dual porting. Figure 1–3 shows an ESE50

dual-port configuration.

I/O BULKHEAD

1–4 Introduction

Page 11

Figure 1–3 ESE50 Dual-Port Configuration

DRIVE CABINET

ESE50

PORT

CONTROLLER A

A

B

Introduction

1.3 Dual-Port Capability

CONTROLLER B

SDI CONTROLLER A

I/O BULKHEAD

SDI CABLES

I/O BULKHEAD

SDI CONTROLLER B

1.4 Drive-Resident Diagnostics Overview

Drive-resident diagnostics run during powerup and spin-up cycles to test basic

drive functions.

Patrol diagnostics run periodically during normal operations.

Drive-resident diagnostics can be run from the OCP while the drive is off line.

See Chapter 4 for a list of drive-resident diagnostics.

1.5 User Precautions/Recommendations

Digital recommends that certain precautions be taken to protect equipment

and user data. These precautions involve data backup methods, recommended

operating temperatures, and electrostatic discharge protection, and are described

in this section.

1.5.1 Data Retention

The ESE50 provides data nonvolatility through the use of an integrated data

retention system. This data retention system is comprised of a controller, an

SCSI magnetic Winchester disk drive, and batteries. Data retention is invoked

only when ac power is lost to the ESE50 unit during normal operation. In this

situation, the batteries will power the unit while all data in the memory arrays

is transferred to the Winchester disk drive. If ac power is restored any time

during the transfer process, then the ESE50 unit is instantly available. On Rev.

A and B ESE50 units, the ESE50–AA/AB (120 MB) and ESE50–BA/BB (600 MB)

options contain the complete data retention system. On Rev. C ESE50 units, the

Introduction 1–5

Page 12

Introduction

1.5 User Precautions/Recommendations

ESE50–AA/AB (120 MB), ESE50–BA/BB (600 MB), and ESE50–DA/DB (1 GB)

options options contain the complete data retention system.

Table 1–2 lists the data retention times.

Table 1–2 Summary of Data Retention Times

Data

ESE50 Option Revision

ESE50_AA/AB A or B 120 MB 90 seconds 120 seconds 8

ESE50_BA/BB A or B 600 MB 360 seconds 390 seconds 2

ESE50_AA/AB C 120 MB 60 seconds 90 seconds 16

ESE50_BA/BB C 600 MB 300 seconds 360 seconds 4

ESE50_DA/DB C 1 GB 480 seconds 540 seconds 3

†A two-hour battery recharge period is required afterward. Power failure exceeding this duty cycle

may result in data loss.

Although the ESE50 provides nonvolatile features, it is the user’s responsibility

to protect data by using proper backup procedures similar to backup of magnetic

disks. The following backup methods are recommended for an ESE50:

Retention

Time

Backup

Time Start Time

Maximum Number of

Complete Backups

(Within Two-Hour

Period)†

• File duplication

This method normally involves copying the data onto removable media, such

as magnetic tape.

• Journaling

This method is recommened for files up to the last checkpoint or backup.

A data retention operation does not occur when the ESE50 main ac power

switch, located on the rear panel, is turned off. A data retention operation

is invoked automatically only when ac power is lost to the input power

cord. Refer to Section 1.5.2 for the orderly shutdown procedures.

1.5.2 Orderly Shutdown

To shut down an ESE50–AA/AB, –BA/BB (Rev. A, B, or C) , or –DA/DB (Rev. C)

system and to preserve data within the data retention system, the following

procedures are recommended:

1. Dismount the ESE50 unit from the OpenVMS operating system without

using the /NOUNLOAD qualifier. Wait for the RUN indicator to extinguish

(approximately six minutes) while data is transferred to the ESE50 internal

Winchester disk.

Caution

2. Press the RUN/STOP button out, and wait for the RUN indicator to

extinguish (approximately six minutes) while data is transferred to the

ESE50 internal Winchester disk.

1–6 Introduction

Page 13

1.5 User Precautions/Recommendations

Caution

The ESE50 data retention system should never be considered a substitute

for a site-specific data backup policy. The ESE50 should be treated as any

other master media in this regard.

1.5.3 Recommended Operating Temperature

The ESE50 SSD is designed to operate in a Class A environment.

1.5.4 Electrostatic Discharge Protection

Electrostatic discharge (ESD) is caused by the buildup and release of static

electricity. An electrical charge from a person or object can damage hardware

components and result in premature device or option failure.

Caution

To avoid product damage, always use ESD grounding straps when

handling static-sensitive modules and components.

Introduction

Use the following guidelines when handling static-sensitive components and

modules:

• Read all instructions and installation procedures included with the static

control materials and kits.

• Wear a properly grounded ESD wrist strap when handling modules,

components, or static-sensitive devices. Figure 1–4 shows an ESD wrist

strap in use.

When using an ESD wrist strap:

Ensure that the wrist strap fits snugly for proper conductivity.

Attach the alligator clip securely to a clean, unpainted, grounded metal

surface, such as the drive or cabinet chassis.

Do not overextend the grounding cord.

• Use static-protective containers to transfer modules and components

(including bags and tote boxes).

Introduction 1–7

Page 14

Introduction

1.5 User Precautions/Recommendations

Figure 1–4 ESD Wrist Strap

1–8 Introduction

Page 15

1.6 ESE50 SSD Maintenance Strategy

1.6 ESE50 SSD Maintenance Strategy

It is recommended that only trained Digital Customer Services engineers attempt

to service an ESE50 SSD.

To repair an ESE50, replace the FRU. An extensive set of drive-resident

microcode diagnostics and a drive-resident error log help simplify problem

isolation. A listing to all ESE50 FRUs is contained in the ESE50 Electronic

Storage Element Service Guide.

Appendix A describes the customer’s equipment maintenance responsibilities.

1.7 ESE50 SSD Specifications

Table 1–3 lists the data organization, performance, physical, electrical, and

environmental specifications of the ESE50 electronic storage element.

Table 1–3 Specifications for the ESE50 SSD

Data Organization ESE50–Ax ESE50–Bx ESE50–Dx

Storage capacity, formatted 120.0 MB 612.6 MB 980.6 MB

Storage capacity, unformatted 128.0 MB 640.0 MB 1024 MB

User logical cylinders 465.0 2337 3741

Cylinder/group 1 1 1

Tracks/group 128 128 128

Sector/track 4 4 4

Number of logical blocks 238,080 1,196,544 1,915,392

Introduction

Performance

Access time 0.25 milliseconds

Transfer rate 20.0 Mbits/sec

Single Start/Stop Time

Start† 90 to 540 seconds (capacity dependent)

Stop 60 to 480 seconds (capacity dependent)

Physical Dimensions

Height 26.56 cm (10.42 inches)

Width 22.19 cm (8.74 inches)

Depth 46.99 cm (18.50 inches)

Weight (maximum) 24.95 kg (55 pounds)

†Starting time is slightly longer due to powerup diagnostics.

(continued on next page)

Introduction 1–9

Page 16

Introduction

1.7 ESE50 SSD Specifications

Table 1–3 (Cont.) Specifications for the ESE50 SSD

Power Requirements

Standards UL listed; CSA certified; FCC Class A verified

Voltage 120/208 Vac at 60 Hz; Single-phase WYE

Inrush Current:

Running current:

Power factor:

Operating Environment

220/240 Vac at 50 Hz

5.08 amperes peak @ 132 Vac

2.31 amperes peak @ 264 Vac

1.87 amps @ 120 Vac

1.105 amps @ 220–240 Vac

0.65 @ 120 Vac

0.57 @ 220–240 Vac

Temperature 15 to 32°C (59 to 90°F)

Maximum allowable operating temperature is reduced by a factor

of 1.8°C/1000 m (1°F/1000 ft) for operation at high altitude sites

Relative humidity 20 to 80%

Maximum wet bulb 25°C (77°F)

Minimum dew point 2°C (36°F)

Table 1–4 contains additional electrical specifications by model for the ESE50

SSD.

Note

The ESE50 is not line-frequency dependent.

Table 1–4 Additional Electrical Specifications by Model for the ESE50 SSD

Nominal

Model Voltage Startup Current Power Dissipation

ESE50 120v 2.4A 300w (max)

ESE50 240v 1.5A 300w (max)

1

Currents are for nominal voltages of 120 Vac phase to neutral or for 240 Vac phase to neutral. For

101 Vac and 220 Vac nominal voltages, the drives will have proportionately higher phase currents by

a ratio of 120/101 or 240/220 to the currents specified in this table.

Input Current (Amps)

1

1–10 Introduction

Page 17

2.1 Introduction

This chapter describes site preparation and planning considerations and

procedures for unpacking the ESE50. Cabling, safety precautions, and voltage

selection are also discussed.

2.2 Site Preparation and Planning

Site preparation and planning are necessary before installing an ESE50 or

subsystem. Consider the following:

• Power Requirements: The ESE50 SSD use a single-phase power supply;

however, operating voltages are supplied through an 881, 874, H405, or other

applicable (system-specific) power controller.

• Thermal Stabilization: Thermal stabilization prevents temperature

differences between the equipment and its environment from damaging drive

components. Equipment must be placed in its operating environment at least

24 hours before operation.

2

Installation

Caution

The thermal stabilization procedure is mandatory. Failure to do this may

cause premature equipment failure.

• Environment: The ESE50 SSD must be operated in an environment where

the ambient air particle count does not exceed 500,000 particles (larger

than 0.5 micron) per cubic foot of air. Refer to Chapter 1 for additional

environmental specifications.

• Floor Loading: Consider placement and calculate the total weight of your

subsystem. An ESE50 weighs approximately 24.95 kg (55 pounds).

• Operating Temperature and Humidity: The required relative humidity

range is between 10 percent and 90 percent, with a minimum wet bulb

temperature of 28°C (82°F) and a minimum dew point of 2°C (36°F)

(noncondensing) with a step change of 10 percent or less.

The ESE50 can be operated in temperatures ranging from 10°C to 40°C (50°F

to 104°F). However, it is recommended that the ESE50 be operated in a

temperature below 25°C (77°F) to increase reliability and extend product life.

Installation 2–1

Page 18

Installation

2.3 Unpacking ESE50 Add-Ons

2.3 Unpacking ESE50 Add-Ons

Check packaging for external damage. Read and save any packing information.

Unpack the ESE50 SSD using the following procedure (Figure 2–1):

1. Cut and remove the shipping straps.

2. Open the shipping container.

3. Remove and save all packing material surrounding the disk drive.

4. Lift the disk drive from the shipping container.

ESE50s weigh approximately 24.95 kg (55 pounds) each and must be

handled with care.

Do not use the cardboard handles to lift the disk drive from the shipping

container. Injury to personnel or damage to equipment could result if the

cardboard handles are used for this purpose.

5. Once the mandatory thermal stabilization period has elapsed, remove the

barrier bag surrounding the disk drive.

Warning

Caution

The thermal stabilization procedure is mandatory. Failure to do this may

cause premature equipment failure.

2–2 Installation

Page 19

Figure 2–1 ESE50 Disk Drive Packaging

Installation

2.3 Unpacking ESE50 Add-Ons

Installation 2–3

Page 20

Installation

2.4 Installing SDI Cables and Power Cords

2.4 Installing SDI Cables and Power Cords

Use this section as a reference only. For detailed procedures and illustrations,

refer to subsystem-specific documentation.

Most fully configured cabinets have internal SDI cables and power cords in place.

However, when installing an ESE50 unit in an SA900 cabinet, the CK-SA900-L2

installation kit is required. Internal SDI cables are connected to the rear I/O

bulkhead located at the base of the cabinet.

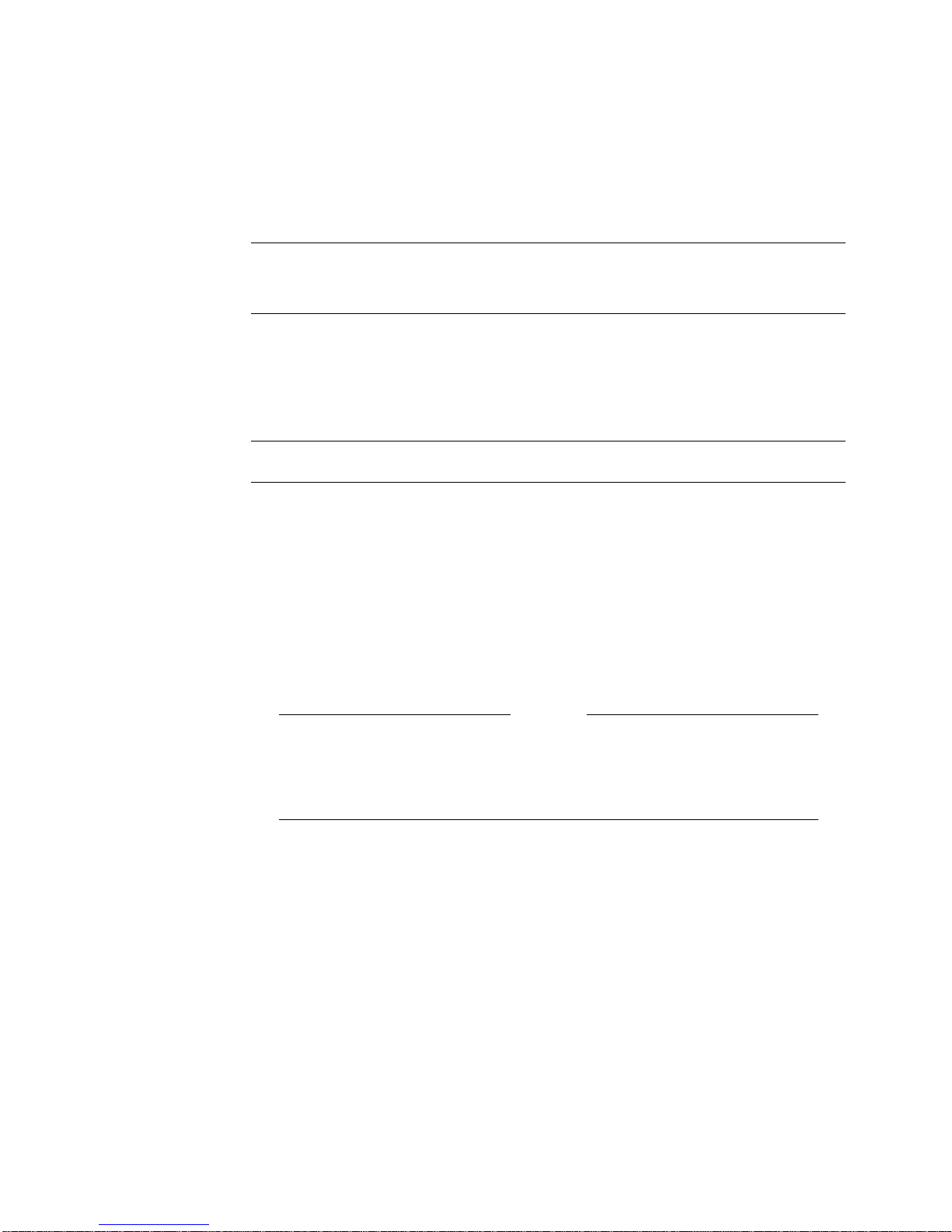

Drive power cords are connected to the 881 (or system-specific model) power

controller located behind the rear I/O bulkhead at the bottom of the cabinet.

Figure 2–2 shows the 881 power controller, used with some ESE50 storage array

products, as viewed from the rear of the cabinet. Drive power cords are routed

through the grommeted cord opening in the front of the power controller, then

plugged into the rear power receptacles of the power controller.

Note

For a list of related documentation, refer to the preface in the front of this

manual. The list supplies titles and Digital part numbers of subsystem

manuals that contain specific ESE50 SSD system cabling and power cord

information.

2.4.1 Installing Internal SDI Cables

Internal SDI cables are installed at the factory for all drive positions in most

subsystem configurations (with exception of the SA900). Refer to subsystemspecific documentation for details about internal SDI cable routing, connections,

and availability.

2.4.2 Installing Internal Power Cords

Internal power cords are installed at the factory and connected to existing drives

and the power controller for your system. Connect add-on drive power cords using

the illustrations and procedures found in your system-specific documentation.

2.4.3 Installing External SDI Cables

When installing external SDI cables from the I/O bulkhead to the host, refer

to system-specific documentation for procedures and illustrations of bulkhead

port configurations. Many systems have an I/O port label adhered to the rear

door/panel of the system.

2–4 Installation

Page 21

2.5 Power and Safety Precautions

The ESE50 does not present any unusual fire or safety hazards. However, it

is recommended that you check ac power wiring for the computer system to

determine adequate capacity for expansion. To protect personnel and equipment,

ensure that power sources meet the specifications required for this equipment.

Hazardous voltages are present inside the ESE50. Installation and

service must be performed by trained Digital Customer Services

personnel. Bodily injury or equipment damage may result from incorrect

servicing.

Installation

2.5 Power and Safety Precautions

Warning

Installation 2–5

Page 22

Installation

2.5 Power and Safety Precautions

Figure 2–2 881 Power Controller (Example)

BUS/OFF/ON SWITCH

(CLOCKWISE FROM TOP)

POWER CONTROL

BUS CONNECTORS

POWER

CONTROLLER

FUSE

LABEL

CIRCUIT

BREAKER

POWER CORD

STRAIN RELIEF

GROMMETED

CORD

OPENING

J10

J11

J12

J13

UNDELAYED

DELAYED

(0.5 SEC)

I

CB

O

POWER

FUSE

CORD

SERIAL/LOGO

LABEL

CXO-2136A

2–6 Installation

Page 23

2.6 AC Power Wiring

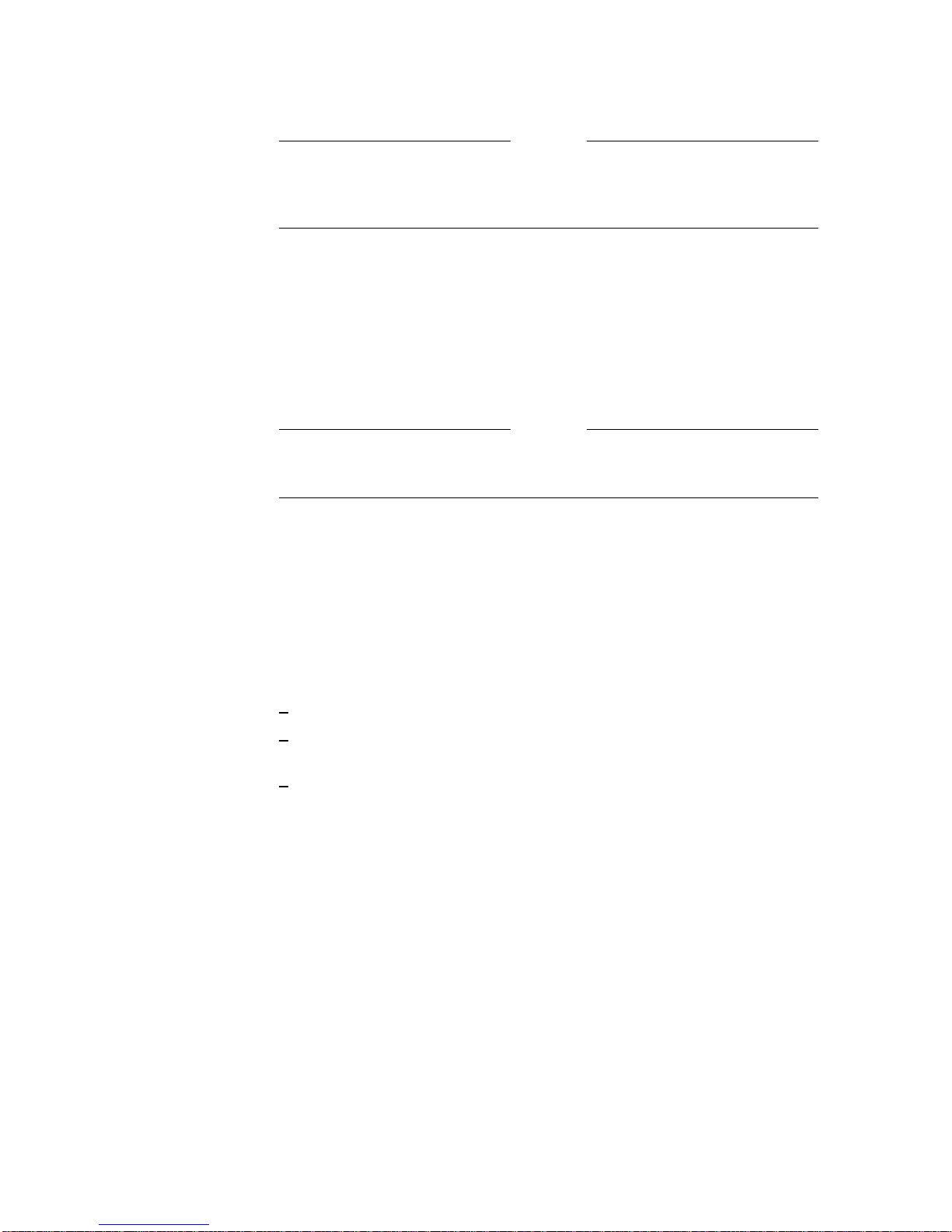

Three-phase power must be present to support the installation of the 60-inch

cabinet. The 40-inch cabinet requires single-phase power. Check system-specific

documentation for the power requirements for your system.

The wiring used by Digital Equipment Corporation conforms to UL, CSA, and

ISE standards. Figure 2–3 shows the ac plug configurations for the ESE50s and

the 881 and 874 power controllers.

Do not apply power to the power controller until proper voltage has been

selected.

Installation

2.6 AC Power Wiring

Note

Installation 2–7

Page 24

Installation

2.6 AC Power Wiring

Figure 2–3 Electrical Plug Configurations

POWER CORDS GOING TO POWER CONTROLLER

120V 60HZ

POWER CORD

DEC NO. A-PS-1700083-23

PLUG - POWER CONTROLLER END

240V 50HZ

POWER CORD

DEC NO. A-PS-1700083-24

PLUG - POWER CONTROLLER END

120/240V 47-63HZ

10A/6A

POWER CORD

DEC NO. A-PS-1700442-18 OR

A-PS-1700442-19

PLUG - DRIVE END

PLUGS GOING TO WALL OUTLET (FROM CONTROLLER)

120V 60HZ

24A

1-PHASE

40-INCH

CABINET

60-INCH

CABINET

220/240V 50-60HZ

16A

1-PHASE

120/208V AC 60HZ

30A

3-PHASE

WYE

USED WITH 881-A AND 881-C

POWER CONTROLLERS

220-240/380-415V AC 50HZ

20A OR 16A

3-PHASE

WYE

USED WITH 881-B

POWER CONTROLLER

NEMA NO. L5-30P

DEC NO. 12-11193

(874-D)

IEC 309 320-P6W

DEC NO. 12-14379-03

(874-F)

5-WIRE

NEMA NO. L21-30P

5-WIRE, 4-POLE,

IEC 309

2–8 Installation

CXO-1872D

Page 25

Operating Instructions

3.1 Introduction

This chapter describes the operator control panel (OCP), drive-resident powerup

diagnostics, acceptance tests, and ESE50 operating modes. Functional flowcharts

are included to aid the user when operating the ESE50.

3.2 OCP Functions, Switches, and Indicators

The OCP interfaces with the ESE50 SSD and performs the following functions:

• Selects Run, Write Protect, Port A, and Port B

• Displays faults and error codes

• Selects tests in the test mode

• Communicates with the ESE50 master processor

Use the following OCP switches and indicators to execute these functions

(Figure 3–1):

• Six input switches (Run, Fault, Write Protect, Port A, Port B, and Test)

3

• Seven LED indicators (Ready, Run, Fault, Write Protect, Port A, Port B, and

Test)

• A four-character alphanumeric display

There are no physical in or out states for the OCP switches. Instead, the logical

state of the switch is changed each time a switch is selected, similar to the way a

calculator works.

The switch states are shown in the OCP display. The LED indicators show the

state of the drive relative to the controller.

Operating Instructions 3–1

Page 26

Operating Instructions

3.2 OCP Functions, Switches, and Indicators

Figure 3–1 ESE50 OCP

ESE50

Status

LED

Indicator

3.3 Powerup Diagnostics

Do not select any OCP switches.

A sequence of drive-resident diagnostics run when power is applied to the drive.

This sequence consists of hardcore tests and basic processor tests. Successful

completion of these tests is indicated by a series of OCP displays, as follows:

1. Blank (30 seconds)

2. [WAIT] (1 minute for 120 MB, 8 minutes for 600 MB, and 1 GB units)

Four−Character Alphanumeric Display

WRITE

RUN

Switch

FAULT

Switch

WRITE

PROTECT

Switch

Unit Number

PORT A

Switch

PORT B

Switch

ESE50_OCP

TESTBAFAULTRUNREADY PROTECT

TEST

Switch

3. [0000] (If previously programmed, the drive unit number is displayed;

otherwise, zeros are displayed)

3.3.1 Problems at Powerup

If a problem occurs during powerup, the Fault LED indicator should light.

However, if any of the basic processor functions fail and no front panel activity

occurs, perform the following steps:

1. Ensure that the OCP is seated properly.

2. Check ac power at the outlet.

3.3.2 Operator Control Panel Lamp Testing

Next, perform an OCP lamp test to ensure that the LED indicators and the

alphanumeric display are functioning properly. Use the following procedure:

1. Select the Test switch. (The Test LED indicator lights.)

2. Select the Fault switch. (All lamps light momentarily.)

3. Deselect the Test switch.

3–2 Operating Instructions

Page 27

3.3.3 Testing Spin-Up Drive

To spin up the drive:

1. Deselect the Test switch. The Test LED indicator goes out and the unit

address (if programmed) is displayed.

2. Select the Run switch. (An R appears in the OCP display, and the Run LED

indicator lights.)

Allow the drive to reach the ready state, as indicated by the front panel Ready

LED indicator.

The steps that follow invoke a sequence of resident diagnostic tests. These tests

check drive functions in the following areas:

• Processor

• IMB bus

• Internal SCSI bus

• Power monitor logic

• Controller logic

• Fault detection circuitry

Operating Instructions

3.3 Powerup Diagnostics

Operating Instructions 3–3

Page 28

Operating Instructions

3.4 Programming the Drive Unit Address

3.4 Programming the Drive Unit Address

Once power has been applied to the drive, set the unit address. You must set the

drive unit address before placing the ESE50.

The ESE50 unit address is programmable from 0 to 4094. (Remember that the

operating system or subsystem type can limit the unit address range.)

Use the following procedure to set the drive unit address. Refer to Figure 3–2 for

a flowchart of this procedure.

1. Select the Test switch. (The Test LED indicator lights and a unit address (if

previously programmed) is displayed; otherwise, zeros are displayed.)

2. Select the Port A switch for the 1’s position. (Position 0 blinks.)

3. Select the Port B switch. (Position 0 increments 1 through 9 every time Port

B is selected.)

4. Select the Port A switch for the 10’s position. (Position 1 blinks.)

5. Select the Port B switch. (Position 1 increments 1 through 9 every time Port

B is selected.)

6. Select the Port A switch for the 100’s position. (Position 2 blinks.)

7. Select the Port B switch. (Position 2 increments 1 through 9 every time Port

B is selected.)

8. Select the Port A switch for the 1000’s position. (Position 3 blinks.)

9. Select the Port B switch. (Position 3 increments 1 through 4 every time Port

B is selected.)

10. Select the Test switch to exit.

3–4 Operating Instructions

Page 29

3.4 Programming the Drive Unit Address

Figure 3–2 Unit Address Programming Flowchart

NORMAL MODE

Operating Instructions

RABDISPLAY =

DESELECT

PORT A AND

B TO SET UNIT

ADDRESS

RDISPLAY =

SELECT TEST

SWITCH (TEST

LED LIGHTS)

SELECT

PORT A

SWITCH

000DISPLAY =

0

INCREMENT

NUMBERS 0−9

BY SELECTING

PORT B

SWITCH

SELECT

PORT A

SWITCH

*

0DISPLAY =

0

00

INCREMENT

NUMBERS 0−9

BY SELECTING

PORT B

SWITCH

SELECT

*

PORT A

SWITCH

INCREMENT

NUMBERS 0−9

BY SELECTING

PORT B

SWITCH

SELECT

PORT A

SWITCH

0DISPLAY =

*

Indicates Flashing Readout

0

*

00

0

DISPLAY =

*

INCREMENT

NUMBERS 0−4

BY SELECTING

PORT B

SWITCH

SELECT

TEST

SWITCH

0000

DONE

Operating Instructions 3–5

Page 30

Operating Instructions

3.5 ESE50 Operating Modes

3.5 ESE50 Operating Modes

The ESE50 operates in three setup modes: normal, fault display, and test.

The following sections describe the functions of each mode.

3.5.1 Normal Mode Setup

The normal mode setup is the usual operating mode of the ESE50 SSD. Switch

selection during normal operation usually consists of the Run switch, Write

Protect switch (for normal write protection), and Port A or B switches. No Fault

or Test LED indicators are lit.

During normal operations:

• Selecting the Run switch causes an R to appear in the OCP display and

causes the drive to spin up. Additionally, the Run LED indicator lights. The

Ready LED indicator lights once the drive is up to speed.

• Selecting the Port A or Port B switch causes an A or B to appear in the OCP

display and logically makes the drive available to the controller.

• Selecting the Write Protect switch logically write-protects the drive and lights

the Write Protect LED indicator.

• Selecting the Fault switch:

– (Without a fault indication) causes a two-second OCP lamp test.

– (With a fault indication) causes an error code to display. Selecting the

Fault switch a second time (with a fault indication) clears the fault.

• Selecting the Test switch:

– (With the Port A or Port B switch selected) causes a two-second display of

the unit address.

– (Without the Port A or Port B switch selected) causes the drive to enter

the test mode.

3.5.2 Fault Display Mode Setup

To enter the fault display mode, select the Fault switch. The fault display mode

can only be entered if the Fault LED indicator is lit; otherwise, selecting the

Fault switch causes a two-second OCP lamp test.

An error code is displayed in the format shown in Figure 3–3. To exit the fault

display mode and clear the fault, select the Fault switch a second time.

Hard faults will not clear. If a hard fault occurs, note the error code and

contact Digital Services.

Note

3–6 Operating Instructions

Page 31

Figure 3–3 Fault Display Example

NORMAL MODE

W

RABDISPLAY =

Operating Instructions

3.5 ESE50 Operating Modes

FAULT

INDICATION

ON DRIVE

?

SELECT

FAULT

SWITCH

*

EDISPLAY =

SELECT

FAULT

SWITCH

FAULT

CLEARS

F0

SELECT

FAULT

SWITCH

OCP LAMP

TEST

(2 SEC)

*

Any combination of legal alphanumericNOTE:

error codes (HEX).

Refer to Figure 3–4 for a fault display mode flowchart.

Figure 3–4 Fault Mode Flowchart

NORMAL MODE

F0EDISPLAY =

Operating Instructions 3–7

Page 32

Operating Instructions

3.5 ESE50 Operating Modes

3.5.3 Test Mode Setup

You must enter the test mode to set the ESE50 unit address or to run resident

diagnostic tests. In this mode, Port A and Port B switches have the function of

selecting both the unit address numbers and test numbers. In addition, the port

switches are used to abort running diagnostics. The Write Protect switch starts

the tests and the Port A or Port B switches stop selected tests. The tests that run

are a subset of the power-on diagnostics.

The test mode is characterized by three displays. Figure 3–5 shows an OCP after

test selection is made. Figure 3–6 shows a display while the test is running.

Figure 3–5 ESE50 Test Display

*

Indicates Flashing Readout

Figure 3–6 Running Test OCP Display

*

0TDISPLAY =

1

0

TDISPLAY =

0

SDISPLAY =

CDISPLAY =

0

0TDISPLAY =

*

Indicates Flashing Readout

*

1

(START)

1

(COMPLETE)

1

*

1

3–8 Operating Instructions

Page 33

4.1 General Information

This chapter contains general information concerning drive-resident diagnostics

and acceptance testing procedures.

4.2 Drive-Resident Diagnostics

Drive-resident diagnostics are invoked under four conditions:

• Powerup or master processor reset

• External init (SDI command)

• Operator control panel (OCP) test mode selection

• Functional firmware sequences (idle loop)

Drive-resident diagnostics test three hardware areas. These areas are:

• Hardcore (CPU, ROM, RAM, SCSI, and timer)

• Logic

4

Diagnostics

• Functional

Diagnostics 4–1

Page 34

Diagnostics

4.2 Drive-Resident Diagnostics

4.2.1 Powerup Resident Diagnostics

The drive-resident diagnostics that run at powerup or master processor reset run

without manual intervention in the following order:

• Master CPU test

• Master ROM test

• Master RAM test

• Master timer test

• Servo data bus loopback test

• Head select test

4.3 Test Selection from the OCP

Use the following procedure to select and run resident diagnostics from the OCP

(Figure 4–1):

1. Select the Test switch. (Test defaults to zero.)

2. Select the Write Protect switch to initiate resident diagnostics.

3. Select the diagnostic using Port A and Port B switches (Figure 4–1).

4. Start the test by selecting the Write Protect switch.

5. Stop the test by selecting the Port A or Port B switch.

6. Restart the test by selecting the Write Protect switch again.

7. Select the Test switch to exit the test mode.

Run the resident diagnostics from the OCP in the following order:

1. Test T 00: Drive spin down.

2. Test T 00: Drive spin up.

4–2 Diagnostics

Page 35

Figure 4–1 Test Selection Flowchart

NORMAL MODE

Diagnostics

4.3 Test Selection from the OCP

RABDISPLAY =

SELECT PORT

SWITCHES TO

DESELECT

PORT(S)

RDISPLAY =

SELECT TEST

SWITCH (TEST

LED LIGHTS)

SELECT WRITE

PROTECT

SWITCH

0TDISPLAY =

0

SELECT PORT

A SWITCH

(LSD BEGINS

FLASHING)

SELECT PORT

A SWITCH

(MSD BEGINS

FLASHING)

*

DISPLAY =

BY SELECTING

PORT B

SWITCH

SELECT WRITE

PROT. SWITCH

(TEST STARTS)

DIAG CAN BE STOPPED BY

SELECTING PORT A OR PORT

B, RESTARTING BY SELECTING

WRITE PROTECT, OR EXITED

BY SELECTING TEST SWITCH

0

T

INCREMENT

NUMBERS 0−9

*

1

0TDISPLAY =

1

*

TDISPLAY =

INCREMENT

NUMBERS 0−9

BY SELECTING

PORT B

SWITCH

Indicates Flashing Readout

*

0

0

Diagnostics 4–3

Page 36

Page 37

Customer Equipment Maintenance

This appendix will assist customers in maintaining their equipment to ensure the

highest level of equipment performance and reliability. Specifically, this appendix

addresses the maintenance of SA6xx/SA8xx storage array cabinet systems.

A.1 Customer Responsibilities

The customer is directly responsible for:

• Supplying accessories, including storage racks, cabinetry, tables and chairs,

as required.

• Making the appropriate documentation available in a location convenient to

the system.

• Obtaining cleaning supplies specified in this appendix.

• Performing the specific equipment maintenance described in this appendix.

A.1.1 Cleaning Supplies

To properly maintain the equipment, the customer must acquire the following

items and supplies:

A

• Vacuum cleaner with flexible hose and nonmetallic, soft-bristle brush

attachment

• Isopropyl alcohol (at least 91%) (PN 29-19665)

• Lint-free tissues or cloths

• All-purpose spray cleaner

Caution

When using spray cleaner, do not spray the cleaner directly into computer

equipment. This could adversely affect equipment reliability or damage

electrical components.

Customer Equipment Maintenance A–1

Page 38

Customer Equipment Maintenance

A.1 Customer Responsibilities

A.1.2 Ongoing Equipment Care

Routine care of the equipment should be done on a regular basis:

• Keep the immediate area in front of the storage array cabinets free of

obstructions.

• Keep the exterior of the cabinets and the surrounding area clean. Use a

lint-free cloth and isopropyl alcohol to remove sticky residue left on painted

surfaces by customer cabinet number labels, and so forth.

• Maintain the site temperature/humidity to comply with Digital’s

recommended environmental range (reference product-specific

documentation). This will ensure that the highest product reliability and

product life goals are achieved.

A.1.3 Monthly Equipment Maintenance

The following tasks should be performed on a monthly basis, or more often if

environment warrants:

Avoid touching the operator control panel switches during cleaning

operations. The state of the drives could change and affect the operation

of the subsystem.

Caution

• Vacuum and/or wipe top of storage array cabinet with a lint-free cloth.

• With a soft-bristle brush attachment, vacuum the air vent grill on the front

door of the storage array cabinet. Leave the front door assembly attached to

the storage array cabinet while vacuuming.

A.1.4 Maintenance Records

Digital suggests that the customer keep an accurate log of all equipment

maintenance. A maintenance log form for SA6xx/SA8xx storage array cabinets

is included in this appendix for customer use. This form may be reproduced and

inserted in the customer’s site management guide for record-keeping purposes.

A–2 Customer Equipment Maintenance

Page 39

Figure A–1 Customer Equipment Maintenance Log

CUSTOMER EQUIPMENT MAINTENANCE LOG

FOR STORAGE ARRAY CABINETS

DATE OF

SERVICE CABINET S/NCABINET S/NCABINET S/NCABINET S/NTYPE OF SERVICE PERFORMED

Customer Equipment Maintenance

A.1 Customer Responsibilities

CXO-2964A

Customer Equipment Maintenance A–3

Page 40

Page 41

A

AC power wiring, 2–7

Index

idle loop, 1–5

input current (amps), 1–10

inrush current, 1–9

C

configurations

ESE50 SSD subsystem, 1–3

controllers

881 power, 2–5

customer equipment maintenance, A–1

customer equipment maintenance log, A–3

D

data rates, 1–9

descriptions

ESE50 SSD, 1–1

diagnostics

drive-resident, 1–4, 1–5, 4–1

sequence, 4–2

documentation

related, v

DSA/SDI compatibility, 1–1

dual-port configuration, 1–4

E

electrical specifications, 1–10

electrostatic discharge, 1–7

ESD wrist strap, 1–8

G

grounding

static protection, 1–7

M

maintenance strategy, 1–9

O

OCP

functions, 3–1

lamp testing, 3–2

switches and indicators, 3–1

operating modes

RA90/RA92, 3–6

operating modes, ESE50

fault display mode setup, 3–6

normal mode setup, 3–6

test mode setup, 3–8

operator control panel

See OCP, 1–4

P

performance, 1–9

physical dimensions, 1–9

power cord installation

internal, 2–4

power dissipation, 1–10

power precautions, 2–5

powerup

problems, 3–2

resident diagnostics, 1–5, 3–2, 4–2

preventive maintenance, 1–4

programming drive unit address, 3–4

H

hardware maintainability, 1–4

I

I/O port label

location, 2–4

R

related documentation, v

S

safety precautions, 2–5

SDI cable installation

external, 2–4

internal, 2–4

Index–1

Page 42

site preparation and planning

environment, 2–1

floor loading, 2–1

operating temperature and humidity, 2–1

power requirements, 2–1

specifications

ESE50 SSD, 1–9

start/stop time, 1–9

T

temperature

operating recommendations, 1–7

test selection from the OCP, 4–2

testing

spin-up drive, 3–3

thermal stabilization, 2–1

U

unit address

programming from the OCP, 3–4

unpacking add-on disk drives, 2–2

user precautions/recommendations, 1–5

Index–2

Loading...

Loading...