Page 1

dt

EF5XX-Series Solid State Disk Drive

User Guide

EK–EF5XX–UG–001

Digital Equipment Corporation

Page 2

November 1992

Copyright © Digital Equipment Corporation 1992

The information in this document is subject to change without notice and should not be construed as a

commitment by Digital Equipment Corporation. Digital Equipment Corporation assumes no responsibility

for any errors that may appear in this document.

The software described in this document is furnished under a license and may be used or copied only in

accordance with the terms of such license.

No responsibility is assumed for the use or reliability of software on equipment that is not supplied by

Digital Equipment Corporation or its affiliated companies.

Restricted Rights: Use, duplication, or disclosure by the U.S. Government is subject to restrictions as set

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS

252.227-7013.

All Rights Reserved.

Printed in U.S.A.

FCC NOTICE: The equipment described in this manual generates, uses, and may emit radio frequency

energy. The equipment has been type tested and found to comply with the limits for a class A computing

device pursuant to Part 15 of FCC Rules, which are designed to provide reasonable protection against

such radio frequency interference when operated in a commercial environment. Operation of this

equipment in a residential area may cause interference, in which case the user at his own expense may

be required to take measures to correct the interference.

Page 3

German Noise Declaration: The following information is provided to meet the German Noise

Declaration Decree (part of the German Equipment Safety Law).

English:

--------------------------------------------------------------------Acoustics - declared values per ISO 9296 and ISO 7779:

Sound Power Level Sound Pressure Level

L , B L , dBA

WAd pAm

Product Idle Operate Idle Operate

EF51/2R-AA/F 4.4 4.5 34 35

BA430/440 +

3xEF51/2R 5.6 5.6 39 39

R400X +

7xEF51/2R 5.6 5.6 40 41

[Current values for specific configurations are available from Digital

representatives. 1 B = 10 dBA.]

---------------------------------------------------------------------

German:

---------------------------------------------------------------------

Schallemissionswerte - Werteangaben nach ISO 9296 und ISO 7779/DIN EN27779:

Schalleistungspegel Schalldruckpegel

L , B L , dBA

WAd pAm

Product Leerlauf Betrieb Leerlauf Betrieb

EF51/2R-AA/F 4.4 4.5 34 35

BA430/440 +

3xEF51/2R 5.6 5.6 39 39

R400X +

7xEF51/2R 5.6 5.6 40 41

[Aktuelle Werte für spezielle Ausrüstungsstufen sind über die Digital

Equipment Vertretungen erhältlich. 1 B = 10 dBA.]

---------------------------------------------------------------------

September 18, 1992

(operator position)

September 18, 1992

(Bediener position)

Page 4

The following are trademarks of Digital Equipment Corporation: DEC, DECmailer, DECservice, DSA,

DSSI, EF, KA640, KFQSA, MicroVAX, MSCP, Q-Bus, RF31, RF72, SERVICenter, TMSCP, ULTRIX, VAX,

VAXsimPLUS, VMS and the Digital logo.

Page 5

Preface

1 General Information

Overview ................................................ 1–1

EF5XX ISE Specifications .................................... 1–7

Shipping Contents/Related Documents .......................... 1–12

2 Installation Overview

Introduction . . ............................................ 2–1

Installing into the BA400-Series Enclosure . . . .................... 2–2

Installing into the SF7X Enclosure . . ............................ 2–8

3 Controls and Indicators

Introduction . . ............................................ 3–1

BA400-Series Controls and Indicators ........................... 3–3

Changing the DSSI Node ID Plugs (BA400-Series OCPs) . ........... 3–5

SF7X Controls and Indicators ................................. 3–6

EF5XX ISE Controls and Indicators . ............................ 3–8

Contents

4 Local Programs

Introduction . . ............................................ 4–1

How to Access Local Programs . . . ............................ 4–4

Descriptions of Local Programs ................................ 4–9

DRVEXR ................................................ 4–10

DRVTST ................................................ 4–14

HISTRY ................................................. 4–17

DRINIT ................................................. 4–18

BATTST ................................................. 4–19

Contents–iii

Page 6

MEMTST ................................................ 4–23

PARAMS ................................................ 4–27

5 Data Retention System

Introduction .............................................. 5–1

EF5XX Data Retention Description ............................. 5–2

Battery Subsystem Parameters ................................ 5–7

6 Troubleshooting Procedures

Performing Troubleshooting Procedures ......................... 6–1

Index

Figures

1–1 EF5XX-Series ISE–Front and Rear Views (Brackets shown are used only

for certain installations.) ...................................... 1–5

2–1 Removing the Plastic Skid Plate (AF or AA version only) ............. 2–4

2–2 Installing the ISE in the Enclosure (RF and RZ front panels shown for

reference.) ............................................... 2–6

2–3 Removing the Top and Bottom Brackets (AF or AA version only)........ 2–10

2–4 Inserting the Wedges on the EF5XX ISE ......................... 2–12

2–5 The SF7X Enclosure ........................................ 2–14

3–1 BA400-Series OCP (front panel) for DSSI ISEs . . . ................. 3–3

3–2 SF7X Controls and Indicators ................................. 3–6

3–3 Drive Module Switch and LED Locations ......................... 3–9

Contents–iv

Page 7

Tables

1–1 EF5XX Series Performance Features ............................ 1–6

5–1 Battery Maintenance Errors ................................... 5–3

5–2 BSS Parameter Definitions ................................... 5–7

Contents–v

Page 8

Page 9

Introduction

Preface

In This Guide

Intended

Audience

Chapter 1

Chapter 2

Chapter 3

This guide introduces the EF5XX-series solid state disk drive

and describes the installation and operating procedures.

This guide is intended for the EF5XX disk drive user.

‘‘General Information’’ describes the different variations of the

EF5XX solid state disk drive including the data retention

system, the Digital Storage System Interconnect (DSSI)

bus function, performance features, specifications, shipping

contents, and related documents.

‘‘Installation Overview’’ describes how to prepare the EF5XX

disk drive for installation and how to install the EF5XX into

the BA400-series system and SF7X storage enclosures.

‘‘Controls and Indicators’’ describes the controls and indicators

used to operate the EF5XX disk drive and how to assign the

DSSI node ID.

Continued on next page

vii

Page 10

Introduction, Continued

Chapter 4

Chapter 5

Chapter 6

Conventions

‘‘Local Programs’’ describes how to access local programs

through the:

VMS system and the console by using the SET HOST/DUP

command

MicroVAX Diagnostic Monitor (MDM)

‘‘Data Retention System’’ discusses integrated data retention

system features including battery testing and monitoring.

‘‘Troubleshooting Procedures’’ describes the internal self-tests

the EF5XX Integrated Storage Element (ISE) conducts and

what to do if the EF5XX disk fails to operate correctly.

The term EF5XX refers to the EF51R, EF52R, or the EF53 solid

state disk drive.

viii

Page 11

Overview

Chapter 1

General Information

In this Chapter

This chapter includes:

EF5XX-series solid state disk drive description

Using the EF5XX disk drive

EF5XX options

Data retention system description

Digital Storage System Interconnect (DSSI) bus function

Integrated Storage Element (ISE)

EF5XX-Series ISE

Drive performance features

Drive specifications

Shipping contents

Related documents

Continued on next page

1–1

Page 12

Overview,Continued

Description

The EF5XX series is Digital Equipment Corporation’s first

generation of solid state disk drives packaged in a full-height,

5¼-inch form factor. These DSSI ISEs supply highly reliable

data storage using semiconductor memory as the storage media.

Like all DSSI ISEs, the EF5XX-series disks communicate with

the host using Digital Storage Architecture (DSA) and Systems

Communications Architecture (SCA) protocols such as the Mass

Storage Control Protocol (MSCP). EF5XX-series disk drives

retain the familiar packaging, control panel, diagnostics, and

utilities of the RF series ISEs.

Continued on next page

1–2

Page 13

Overview,Continued

Using the

EF5XX

EF5XX

Options

Data

Retention

System

Description

You can use the EF5XX-series ISEs with these VAX family

systems:

VAX4000

VAX6000

VAX7000

VAX10000

These are the EF5XX ISEs covered in this guide and their

formatted storage capacities:

EF51R, 107 megabytes

EF52R, 205 megabytes

EF53, 267 megabytes

The EF51R and the EF52R ISEs provide non-volatility of data

by a data retention system including:

Power sensing logic

An internal winchester magnetic disk drive

A battery to power the EF5XX while dumping data to the

winchester disk

For more detailed information on data retention, refer to

Chapter 5.

Continued on next page

1–3

Page 14

Overview,Continued

DSSI Bus

Function

ISE

The DSSI bus is a logical equivalent to the CI bus used on

larger Digital systems. The DSSI bus is used with low-end and

mid-range VAX systems.

The DSSI bus is a 50-conductor cable that allows one or more

hosts to communicate directly with storage devices. The hosts

and devices communicate through the SCA protocols. As many

as eight nodes (integrated storage elements and adapters) can

connect to one DSSI bus.

The DSSI bus located:

Inside an enclosure may be a flat ribbon cable or a round

bundle of twisted pairs

Between enclosures is a shielded, round cable

approximately one-half inch in diameter

An ISE is a DSSI device that contains an:

Embedded, intelligent controller

On-board Mass Storage Control Protocol (MSCP) server

Each ISE executes commands and transfers data independently

of other ISEs attached to the DSSI bus. Commands and data

are transferred over the DSSI bus in small packets, allowing

multiple ISE transfers to simultaneously complete successfully.

1–4

Continued on next page

Page 15

Overview,Continued

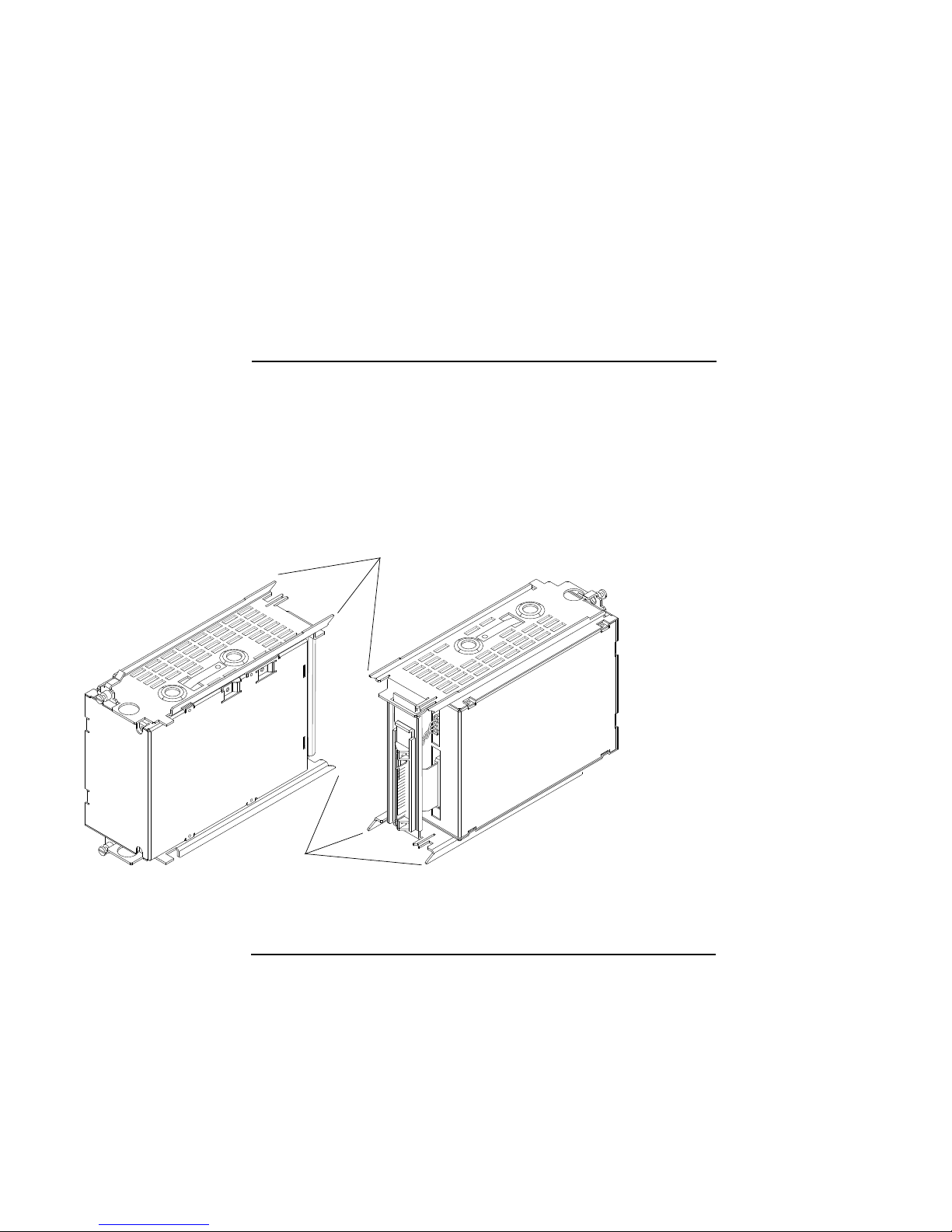

EF5XX-Series

ISE

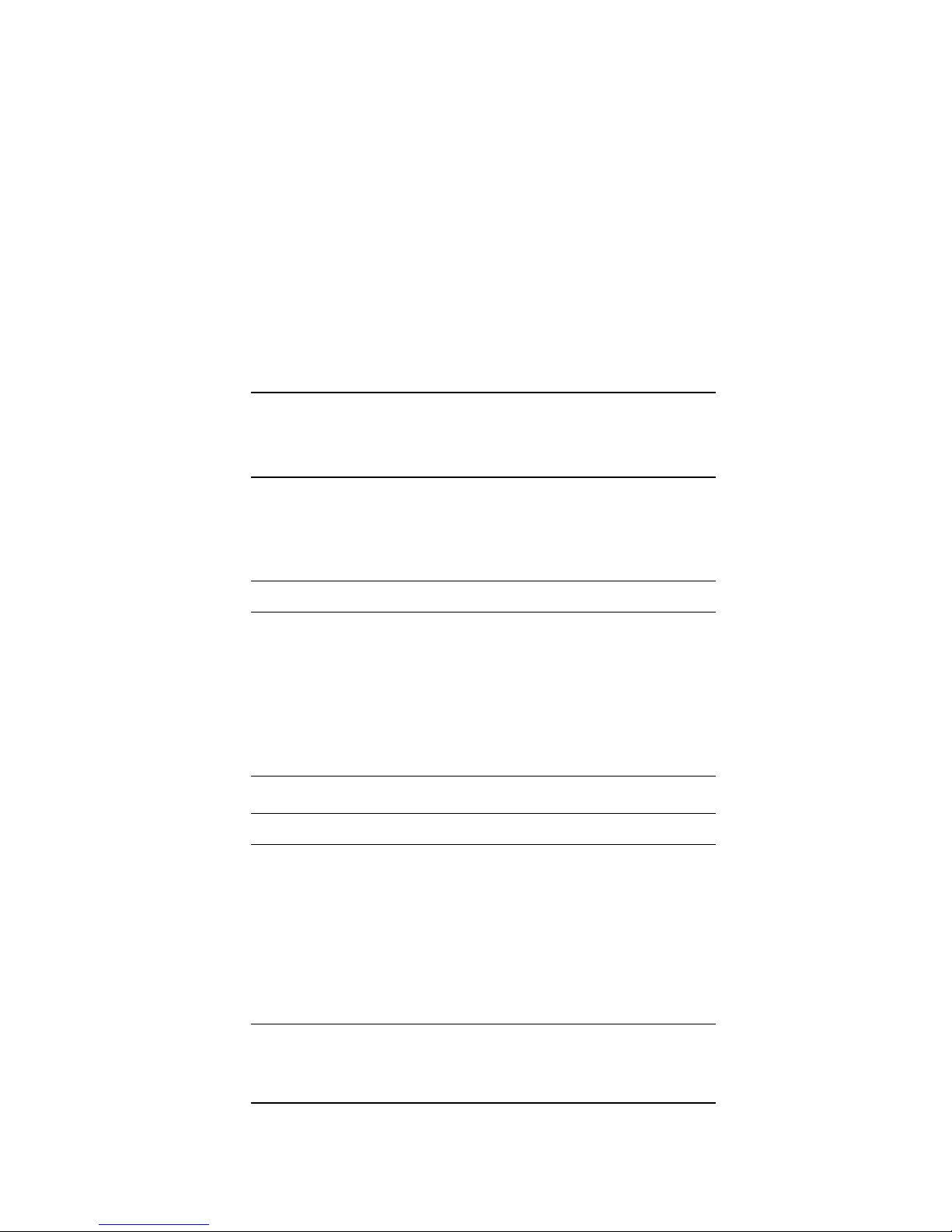

Figure 1–1 shows the EF5XX-series disk, a full-height, 5-¼inch,

fixed-disk storage device. Its dimensions are 8.26 cm (3.25 in)

by 14.60 cm (5.75 in) by 20.32 cm (8.00 in).

Figure 1–1 EF5XX-Series ISE–Front and Rear Views (Brackets shown are used only

for certain installations.)

Bracket Slides

Bracket Slides

Front View Rear View

MLO-009301

Continued on next page

1–5

Page 16

Overview,Continued

Performance

Features

EF5XX-series disks offer powerful performance features that

are not typically available on disk storage devices in this form

factor. Table 1–1 lists some of these features:

Table 1–1 EF5XX Series Performance Features

Feature Function

Multihost support This allows a single ISE to be used by more than one host

670-bit Error

Correction Code

(ECC)

Controllerinitiated Bad

Block Replacement

(BBR)

Replacement

Control Table

(RCT) Cache

at the same time. For example, two VAX4000 systems

can be booted from a single ISE.

EF5XX ISEs store a large, 670-bit ECC in each block,

capable of correcting up to 320 erroneous bits.

With controller-initiated BBR, the ISE presents the

host with a set of logically contiguous blocks, and

disk capacity does not decrease because bad blocks

are detected and automatically moved to spare blocks.

DSSI ISEs cache the RCT allowing replaced blocks to

be located without the time required to access the RCT

stored on the media.

1–6

Page 17

EF5XXISESpecifications

Introduction

Performance

Specifications

This section includes performance, power, media, and

environmental specifications.

The following table lists the physical, functional, and

performance specifications of the EF51R, EF52R, and EF53

ISEs:

Physical EF51R EF52R EF53

Height 8.26 cm (3.25") 8.26 cm (3.25") 8.26 cm (3.25")

Width 14.60 cm (5.75") 14.60 cm (5.75") 14.60 cm (5.75")

Depth 20.32 cm (8.00") 20.32 cm (8.00") 20.32 cm (8.00")

Weight 2.55 kg (5 lbs 10

Functional EF51R EF52R EF53

Formatted Storage

Capacity (Mbytes)

oz)

107 205 267

2.32 kg (5 lbs 2 oz) 2.21 kg (4 lbs 14

oz)

Interface DSSI DSSI DSSI

Number of

Memory Modules

Data Retention Yes Yes No

215

Continued on next page

1–7

Page 18

EF5XX ISE Specifications, Continued

Performance EF51R EF52R EF53

Avg Access Time

(ms)

Peak Transfer

Rate to DSSI Bus

(Mbytes/sec)

Start Time (total

min)

.25 .25 .25

4.00 4.00 4.00

2.00 2.00 2.00

NOTE

The average access time includes commands, array

access, Error Correction Code (ECC), and buffer

delays. It does not include host software or host

adapter latency.

Continued on next page

1–8

Page 19

EF5XXISESpecifications,Continued

Current

and Power

Consumption

The following table lists the maximum current and power

consumption and the typical current and power specifications:

Maximum

Current & Power EF51R EF52R EF53

5.0 V Supply

Current (amps)

Normal 0.0 0.0 2.2

Peak 0.0 0.0 3.7

12.0 V Supply

Current (amps)

1

Normal

2

Peak

Total Power

(watts)

Normal

1

1.5 1.4 0.0

2.3 2.2 0.1

18.0 16.6 11.2

2

Peak

1

"Normal maximum" indicates the maximum power and current under normal

conditions with heavy drive activity occurring.

2

"Peak maximum" indicates the maximum power and current under peak

conditions with heavy drive activity occurring. With the EF51R and EF52R,

peak power occurs during the first half hour of fast charge after full discharge.

With the EF53, peak power occurs during self-test, which happens during the

first two minutes of operation.

27.6 26.2 18.4

Continued on next page

1–9

Page 20

EF5XX ISE Specifications, Continued

Typical Current

& Power EF51R EF52R EF53

5.0 V Supply

Current (amps)

12.0 V Supply

Current (amps)

Total Power

(watts)

0.0 0.0 1.8

1.2 1.0 0.0

14.3 12.4 8.9

Continued on next page

1–10

Page 21

EF5XX ISE Specifications, Continued

Environmental

Specifications

The following table lists environmental specifications:

Environmental

Specifications EF51R, EF52R, EF53

Temperature

Operating 10 to 50°C (50 to 122°F), ambient, with

Non-operating -40 to 66°C (-40 to 151°F), ambient, with a

Relative humidity

Operating 10 to 90% with maximum wet bulb

Non-operating

(storage/shipping)

Altitude

a gradient of 11°C (20°F) per hour (as

introduced to the drive enclosure)

gradient of 20°C (36°F) per hour

temperature of 28°C (82°F) and a

minimum dew point of 2°C (36°F), with

no condensation

8 to 95%, with no condensation

Operating 2,438 meters (8,000 feet)

Non-operating 4,876 meters (16,000 feet)

Noise (closed office

environment)

Air flow 15 ft³/min (minimum)

4.2 Bels operating (ISO 779) EF51R, EF52R

0.0 Bels operating (ISO 779) EF53

1–11

Page 22

Shipping Contents/Related Documents

Check

Shipment

Shipping

Contents

Listing

Ensure your shipment has all the items listed on the contents

listing. If any item is missing or damaged, contact your delivery

agent or your Digital representative.

NOTE

Save the packing materials until you are sure you

will not reship any items.

The EF5XX and its accessories are:

Part Number Description

One of the following:

EF51R–AA, AF Solid state disk, 107 MB, with a 5-1/4-inch drive

and a DSSI controller

EF52R–AA, AF Solid state disk, 205 MB, with a 5-1/4-inch drive

and a DSSI controller

EF53–AA, AF Solid state disk, 267 MB, with a 5-1/4-inch drive

and a DSSI controller

All of the following:

74–45432–01 Wedges (2)

70–27049–04 Disk Drive Bezel Assembly

17–03571–01 DSSI flat cable (50 conductor)

17–03572–01 Front panel cable (10 conductor)

17–03573–01 Power cable (5 conductor)

12–28766–19 DSSI ID plug kit

36–33183–02 Label RF71 drive

36–33183–04 Label RF71 drive

EK–EF5XX–UG User guide

EK–BA44A–IN BA400-series installation guide

1–12

Continued on next page

Page 23

Shipping Contents/Related Documents, Continued

Related

Documents

Along with your system documentation, the following

documents supplement this guide:

Title Order Number

BA400-Series Enclosures Storage

Devices Installation Procedures

DECarray Installation Guide EK–SF2XX–IG

EK–BA44A–IN

1–13

Page 24

Page 25

Introduction

Chapter 2

Installation Overview

In this Chapter

This chapter tells you how to prepare the EF5XX ISE and

install the ISE into the:

BA400-series system enclosure

SF7X storage enclosure

For more detailed information about the:

Installation into the BA400-series enclosure, refer to

BA400-Series Enclosures Storage Devices Installation

Procedures, (EK–BA44A–IN).

SF7X enclosure, refer to DECarray Installation Guide,

(EK–SF2XX–IG).

2–1

Page 26

Installing into the BA400-Series Enclosure

Preparing

for the

Installation

To prepare for the installation:

CAUTION

Static electricity can damage integrated circuits.

Use the antistatic wrist strap and antistatic pad

found in the static-protective field service kit

(29-26246-00) when you work with the internal

parts of a computer system.

Handle the ISE with care. Dropping or bumping the

ISE can damage the disk surface.

1. After the system manager shuts down the operating system,

set the lock of the enclosure to the bottom position to open

both the top and bottom enclosure doors.

2. Set the enclosure power switch to off (0).

3. Always install ISEs working from right to left.

NOTE

The first or rightmost mass storage cavity in

the mass storage area is wider than the rest to

accommodate a larger device such as a tape

drive. A small filler panel (70-27414-01) is used

to fill the gap when an EF5XX ISE is installed in

this first cavity.

4. Loosen the captive Phillips screw at the top of the blank

ISE front panel assembly and remove the panel.

Before installing an EF5XX-series ISE into a BA400-series

enclosure, you must first remove the skid plate, explained in

the next section.

2–2

Continued on next page

Page 27

Installing into the BA400-Series Enclosure, Continued

Removing the

Skid Plate

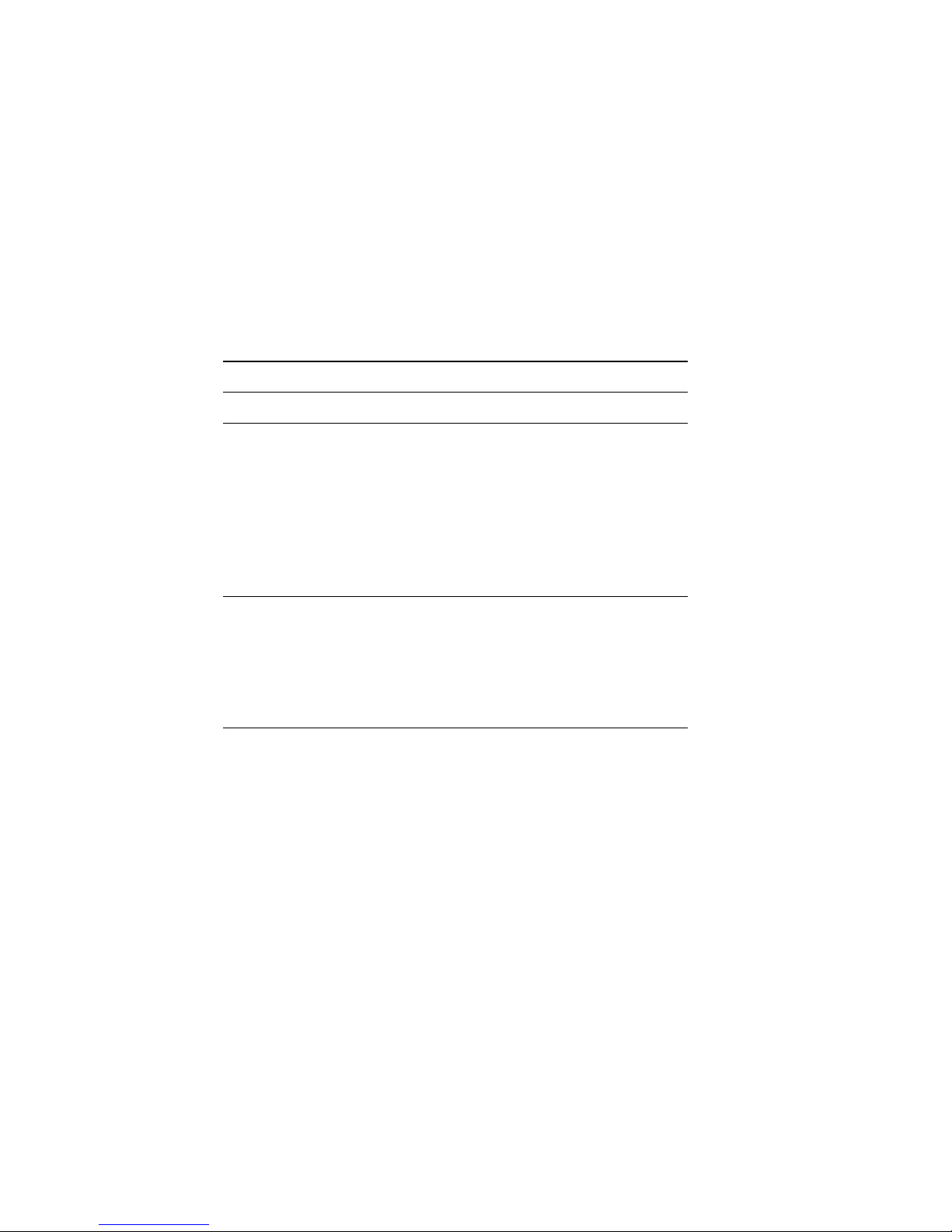

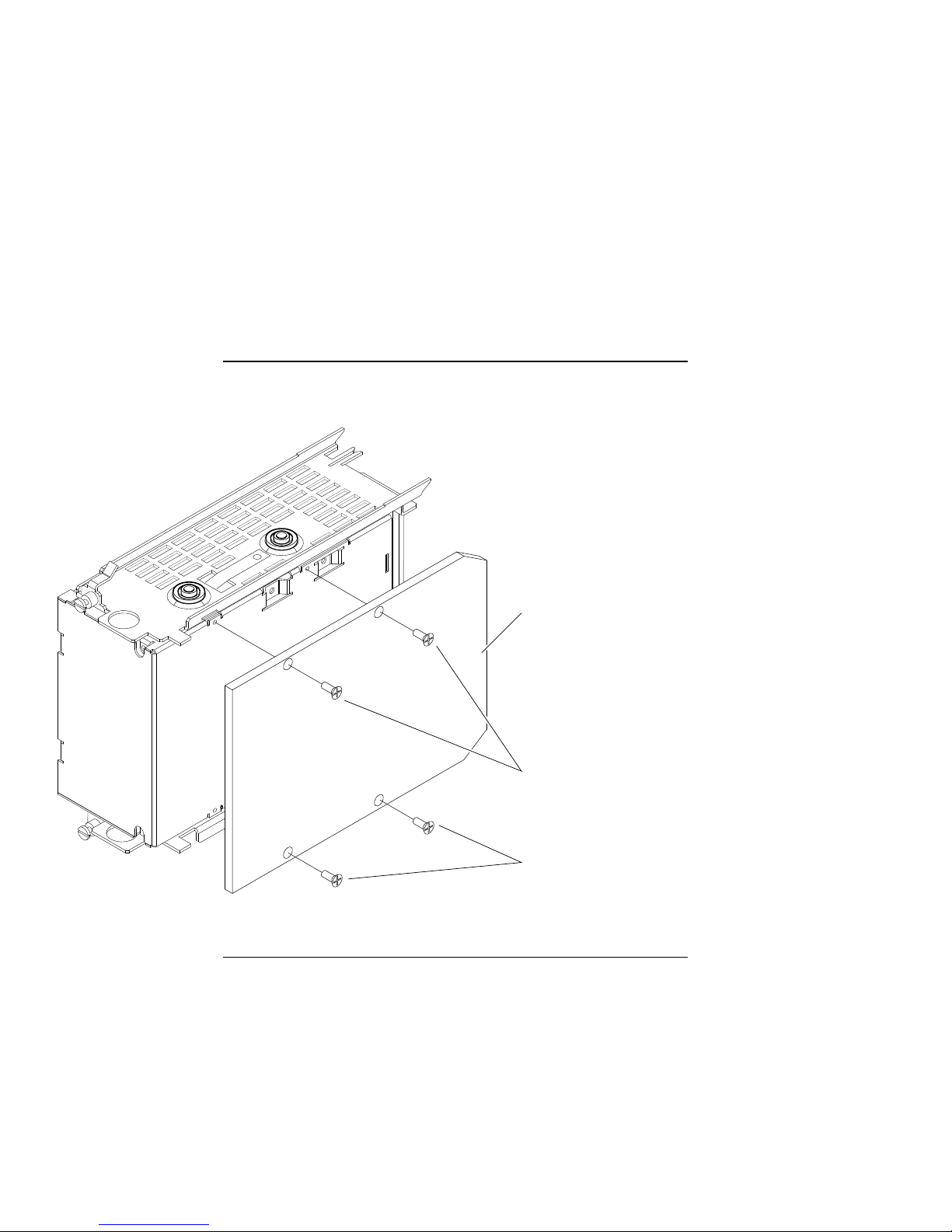

Remove the plastic skid plate from the right side of the ISE by

removing the four screws (Figure 2–1). Discard the skid plate.

Continued on next page

2–3

Page 28

Installing into the BA400-Series Enclosure, Continued

Figure 2–1 Removing the Plastic Skid Plate (AF or AA version only)

Skid Plate

Screws

2–4

Screws

MLO-009302

Continued on next page

Page 29

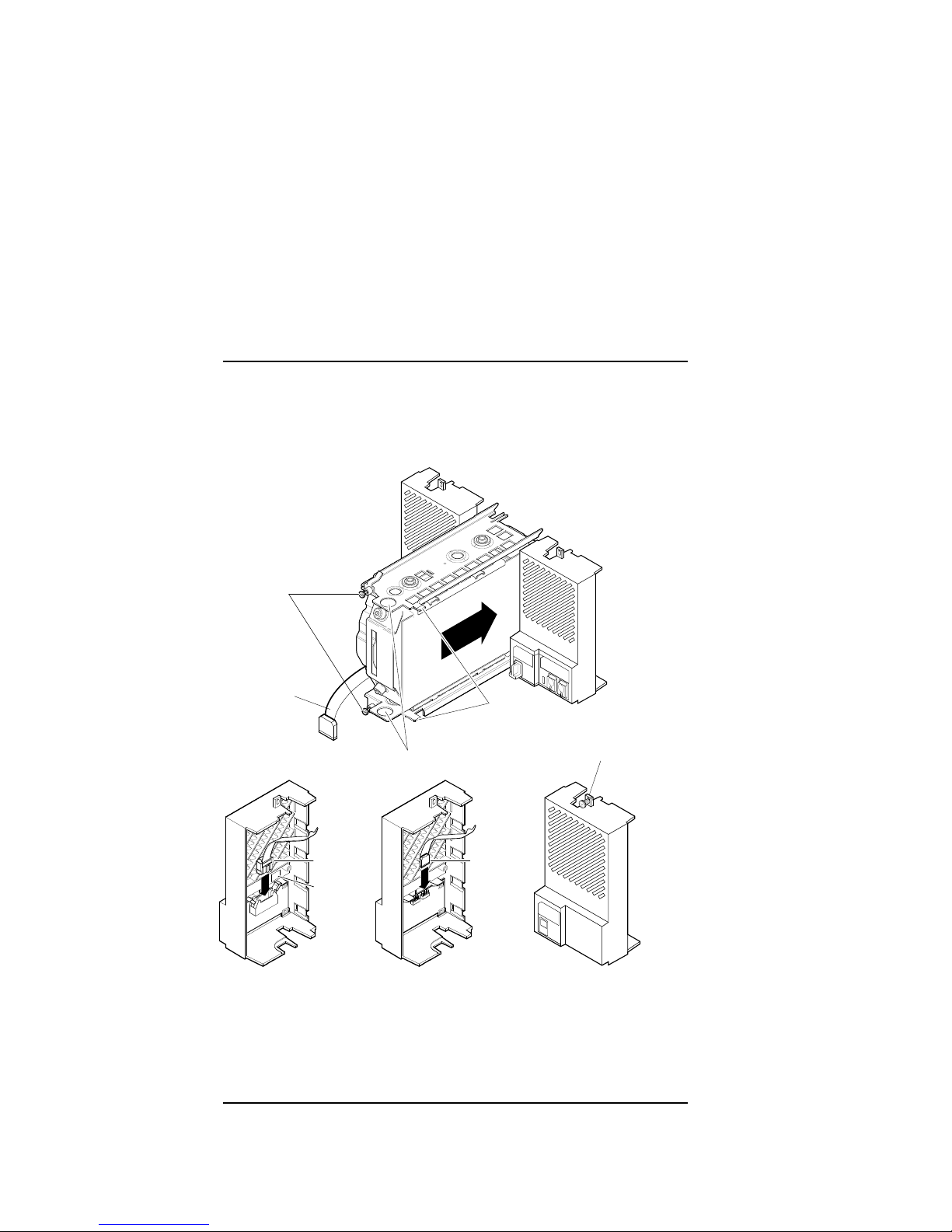

Installing into the BA400-Series Enclosure, Continued

Installation

Steps

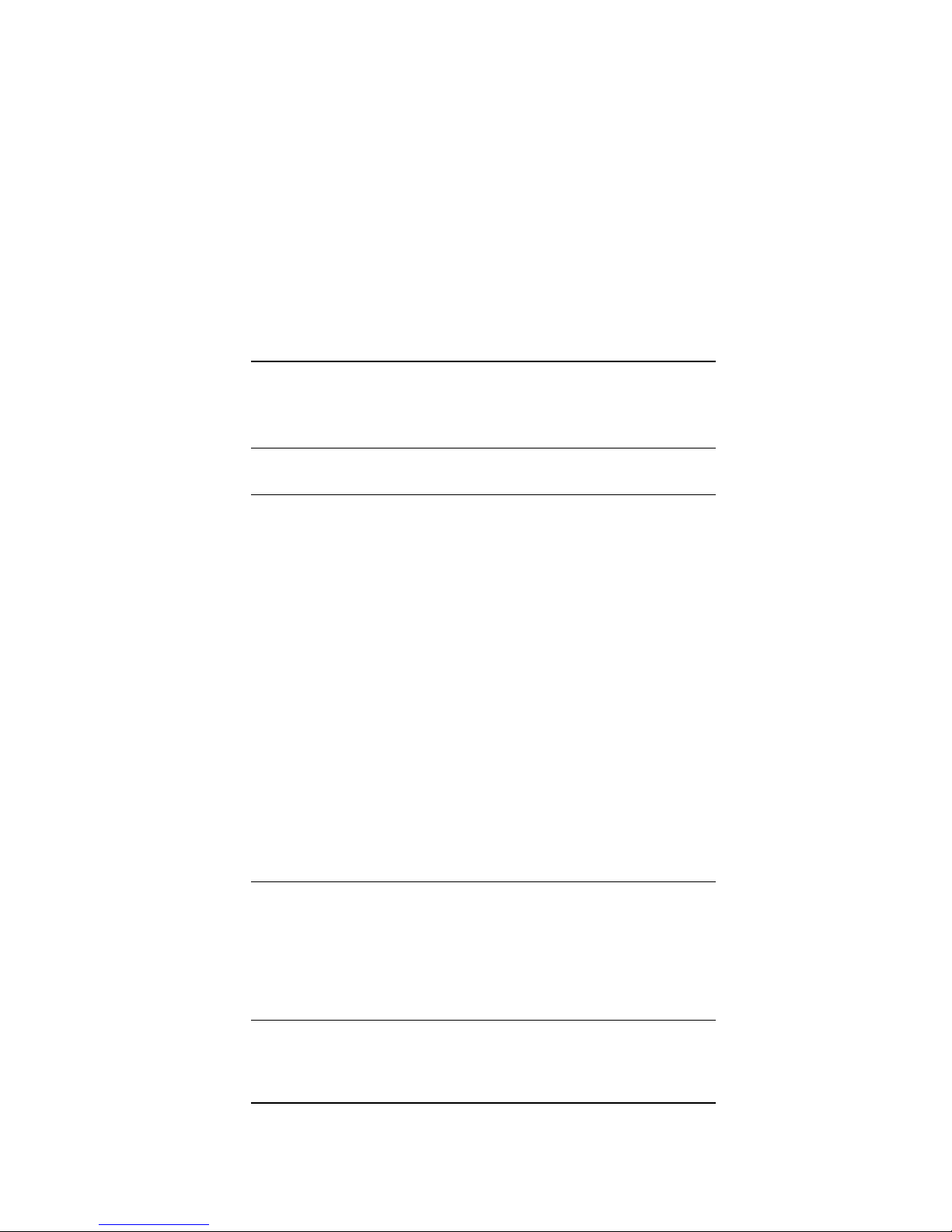

To install the ISE into the BA400-series enclosure:

1. With the side that had the skid plate attached to it facing to

the right, slide the ISE along the guide rails into the mass

storage cavity (Figure 2–2A).

2. Using the upper and lower finger cutouts on the ISE

brackets, firmly push the ISE brackets until the interface

card at the rear of the ISE plugs into its backplane

connector. The guide tabs on the upper and lower brackets

should line up with the cutouts in the chassis. Tighten the

two captive screws (Figure 2–2A).

CAUTION

It is normal to have a small gap between the ISE

mounting bracket tabs and the enclosure frame.

Tighten the captive screws only until they are

securely fastened (9 inch-pounds). Do not try to

force the tabs to fit flush against the frame.

3. Plug the remote front panel cable(s) into the connector(s)

inside the ISE front panel (Figure 2–2B).

Use Velcro on the cable and on the inside of the ISE front

panel to secure the remote front panel cable.

4. Attach the ISE front panel to the enclosure by first fitting

the panel’s lower tabs into position. Fit the panel into

position and secure the panel with its single captive Phillips

screw (Figure 2–2D).

Continued on next page

2–5

Page 30

Installing into the BA400-Series Enclosure, Continued

Figure 2–2 Installing the ISE in the Enclosure (RF and RZ front panels shown for

reference.)

A

Captive Screws

Remote Front

Panel Cable

Guide

Tabs

2–6

Finger Cutouts

Phillips Screw

BCD

Remote Front

Panel Cable

Velcro

EF/RF/RZ 5.25-inch RF 3.5-inch

Remote Front

Panel Cable

RZ 5.25-inch

MLO-007244

Continued on next page

Page 31

Installing into the BA400-Series Enclosure, Continued

For further information, refer to the BA400-Series Enclosures

Storage Devices Installation Procedures, (EK–BA44A–IN).

2–7

Page 32

Installing into the SF7X Enclosure

Preparing

for the

Installation

Removing the

Brackets

Prepare for the installation into an SF7X enclosure as detailed

in the DECarray Installation Guide, (EK–SF2XX–IG).

CAUTION

Static electricity can damage integrated circuits.

Use the antistatic wrist strap and antistatic pad

found in the static-protective field service kit

(29-26246-00) when you work with the internal

parts of a computer system.

Handle the ISE with care. Dropping or bumping the

ISE can damage the disk surface.

Before installing into the SF7X enclosure, you must first:

Remove the ISE’s top and bottom brackets

Insert wedges on the ISE

Removing the brackets and inserting the wedges are explained

in the next sections.

To remove the ISE’s top and bottom brackets:

1. Place the ISE on an antistatic mat.

2. Remove the two Phillips screws at the rubber shock

bushings that secure the top bracket to the side of the

chassis (Figure 2–3). Put the screws aside.

3. Slide the interface card assembly up and lift off the top

bracket (Figure 2–3). Place the bracket aside.

4. Unplug the interface card assembly power cable (5 pin

cable) from the drive.

5. Unplug the interface card assembly 50 pin data cable from

the drive.

6. Unplug the remote front panel cable from the drive.

2–8

Continued on next page

Page 33

Installing into the SF7X Enclosure, Continued

7. Remove the ISE bottom bracket by removing the two

Phillips screws at the rubber shock bushings that secure

the bracket to the chassis (Figure 2–3).

NOTE

Carefully note the orientation and routing of the

remote front panel cable.

Continued on next page

2–9

Page 34

Installing into the SF7X Enclosure, Continued

Figure 2–3 Removing the Top and Bottom Brackets (AF or AA version only)

Screws

Top Bracket

Chassis

Interface Card

Assembly

2–10

Bottom Bracket

Screws

MLO-009303

Continued on next page

Page 35

Installing into the SF7X Enclosure, Continued

Inserting the

Wedges

To insert the wedges:

1. Remove the two wedges from the shipment box.

2. Hold one wedge at the front end (contains the screw) and

insert the two rear prongs into the two elongated holes on

the side of the chassis (Figure 2–4). The two holes are 2-3/4

inches from the rear of the chassis.

3. Lower the front end of the wedge and insert the front

prongs into the two circular holes next to the connectors on

the front of the drive (Figure 2–4).

4. Do the same steps to insert the other wedge on the opposite

side of the chassis.

Continued on next page

2–11

Page 36

Installing into the SF7X Enclosure, Continued

Figure 2–4 Inserting the Wedges on the EF5XX ISE

2–12

Continued on next page

Page 37

Installing into the SF7X Enclosure, Continued

Installation

Steps

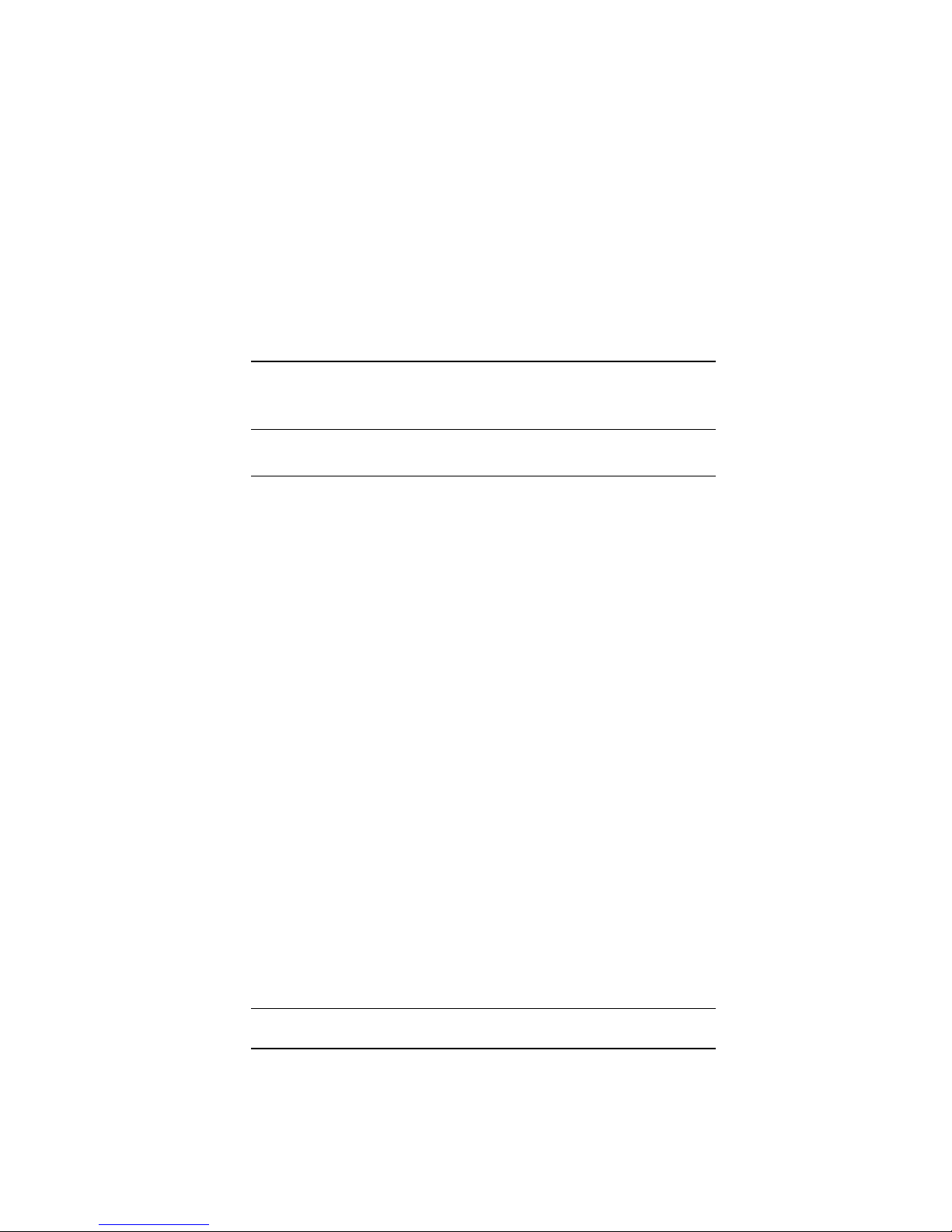

To install the ISE into the SF7X enclosure (Figure 2–5):

1. With the ISE skid plate facing the enclosure guide rails,

slide the ISE along the guide rails until the ISE is locked in

place inside the SF7X enclosure.

2. Use a Phillips head screwdriver to tighten the screws on

the wedges, so the ISE sets securely in the enclosure.

3. Take the three extension cables from the shipping box:

DSSI flat cable (50 conductor)

Front panel (Operator Control Panel (OCP)) cable (10

conductor)

Power cable (5 conductor)

4. Connect one end of each extension cable to the EF5XX ISE

and the other end of each extension cable to the cables

already attached (Figure 2–5) to the SF7X enclosure.

Continued on next page

2–13

Page 38

Installing into the SF7X Enclosure, Continued

Figure 2–5 The SF7X Enclosure

NOTE TO

ILLUSTRATOR:

front panel for this

hardware is SHR_X1127_89

ISOL and reduced

17/64 (.265625)

Write

Protect

Ready

DSSI

ID

Fault

d

Ready

DSSI

ID

l

a

t

Fault

i

g

i

Write

Protect

DSSI CABLE

10-PIN

OCP CABLE

5-PIN DRIVE

POWER CABLE

SHR-X0135A-90

For more information about the SF7X enclosure, refer to the

DECarray Installation Guide, (EK–SF2XX–IG).

2–14

Page 39

Introduction

Chapter 3

Controlsand Indicators

In this Chapter

Operator

Control Panel

(OCP)

This chapter describes the controls and indicators associated

with ISE operation. The controls and indicators are located on

the:

Operator control panel (OCP) on the system enclosure

ISE front panel (Figure 3–1)

The operator control panel (OCP) is a set of controls on the

enclosure that overrides the drive module switches and lets

you set the DSSI node ID and write-protect mode for the ISE.

The OCP also contains a fault LED that indicates if the ISE is

malfunctioning.

Continued on next page

3–1

Page 40

Introduction, Continued

The following table compares the OCPs in the and BA400-series

and SF7X enclosures.

In the ... an OCP ...

BA400-series enclosures, is contained on each

SF7X enclosure, contains four identical

ISE and is mounted to

a panel in front of the

ISE (Figure 3–1).

sets of controls and

indicators.

3–2

Page 41

BA400-Series Controls and Indicators

OCP

Each ISE installed in a BA400-series enclosure has a front

panel with the following controls and indicators:

DSSI bus node ID plug

Fault indicator (LED)

Run/Ready button

Write-Protect button

Figure 3–1 BA400-Series OCP (front panel) for DSSI ISEs

RUN/READY BUTTON

WRITE-PROTECT BUTTON

BUS NODE

ID PLUG

FAULT

INDICATOR

MLO-004044

SHR-X0058-90

Continued on next page

3–3

Page 42

BA400-Series Controls and Indicators, Continued

Control and

Indicator

Functions

The following table describes the functions of the controls and

indicators on the BA400-series DSSI operator control panel:

Control Status Function

Fault LED Lit Indicates an error condition within the ISE.

Run/Ready

Button

WriteProtect

Button

Not lit Indicates an error-free condition within the

Quick flash

(10 Hz)

In (lit) The ISE is on line. When the ISE is available

Out (not lit) The ISE is off line and cannot be accessed. The

Slow flash (1

Hz)

In (lit) The ISE is write-protected. System software

ISE.

OCP failure, or drive select plug is missing.

for use, the green LED is lit. When the ISE is

being used, the green LED flickers.

green LED cannot be lit when the Run/Ready

button is out.

Data retention system is initializing, saving, or

restoring data.

cannot write to the ISE.

Out (not lit) The ISE is not write-protected. This is the

3–4

normal position for software operation. System

software is free to read or write to the ISE.

Page 43

Changing the DSSI Node ID Plugs (BA400-Series OCPs)

Spare Plugs

Removal

Insertion

Renumbering

ISEs

Spare DSSI node ID plugs are supplied with the EF5XX. Use

these spare plugs to reconfigure your DSSI system because of

adding or removing ISEs or creating a multihost configuration.

The DSSI node ID plugs have prongs on the back that indicate

the bus node number (and by default, the unit number) of the

ISE. To remove a DSSI node ID plug, grasp it firmly and pull it

straight out.

To insert a new plug, align the two center prongs with the two

center slots and press the plug into the slots.

Use the following rules to renumber your ISEs:

For each DSSI bus, do not use duplicate DSSI node IDs.

By convention, ISEs are numbered in increasing order from

right to left and top to bottom.

Use a blank DSSI node ID plug where no ISE is present.

NOTE

If you change the bus node ID plugs while the

system is operating, you must turn off the system

and then turn it back on for the new plug positions

to take effect.

3–5

Page 44

SF7X Controls and Indicators

OCP

Each ISE in the SF7X storage enclosure is represented by an

icon on the door located on the OCP. Each set of controls and

indicators is dedicated to one of the four storage compartments

in the enclosure (Figure 3–2).

Figure 3–2 SF7X Controls and Indicators

igital

d

Write

Ready Fault

Protect

DSSI

ID

1

2

DSSI

Ready Fault

ID

Write

Protect

SHR_X1128_89

3–6

Continued on next page

Page 45

SF7X Controls and Indicators, Continued

Control and

Indicator

Functions

The following table describes the functions of the controls and

indicators on the front of the SF7X enclosure.

Control/

Indicator Color Function

Ready Green Illuminates when ISE is on

line and read/write ready.

Fault Red Illuminates when fault is

detected.

DSSI Node ID Green Displays ISE DSSI Node ID.

Write Protect Yellow Commands write protect

mode. Shows write protect

enabled.

Terminator Power Green On while when Terminator

Power is being supplied.

Split Bus Green On when enclosure is in

Split Bus mode.

DSSI Node ID Select N/A 3 bits, selects DSSI node ID

number.

MSCP Enable/Disable N/A 1 bit, enables or disables the

DC power switches (4) Green Applies DC power to ISE.

ISE MSCP server.

Shows power status.

3–7

Page 46

EF5XX ISE Controls and Indicators

Description

Two LEDs and a DIP switchpack containing three switches are

mounted on the edge of the drive module. The switches provide

a means of setting the DSSI node ID if an OCP is not connected

to the drive, or if the OCP fails. The two LEDs indicate drive

status:

READY LED

FAULT LED

Figure 3–3 shows the location of the switches and LEDs on the

drive module.

3–8

Continued on next page

Page 47

EF5XX ISE Controls and Indicators, Continued

Figure 3–3 Drive Module Switch and LED Locations

Continued on next page

3–9

Page 48

EF5XX ISE Controls and Indicators, Continued

Assigning the

DSSI Node ID

To assign the DSSI node ID, set the three switches to the binary

equivalent of the selected ID number, as shown in the following

table. These switches are ignored when an operator control

panel is connected to the ISE.

DSSI Node ID Switch Positions

Address 1 2 3

0

1

2

3

4

5

6

2

7

1

Up is toward the top cover of the EF5XX, down is toward the module.

2

DSSI address 7 is normally assigned to a host adapter.

Up

Up

Up

Up

Down

Down

Down

Down

1

Up

Up

Down

Down

Up

Up

Down

Down

Continued on next page

Up

Down

Up

Down

Up

Down

Up

Down

3–10

Page 49

EF5XX ISE Controls and Indicators, Continued

Drive Module

LEDs

The two LEDs mounted on the drive module monitor ISE status

during operation. The following table describes the state of

these two LEDs during the various phases of ISE operation.

When . . .

The ISE is first powered up On On

POST has run successfully Off Off

The ISE is ready to accept a

command

Drive activity Flickering Off

A read/write or serious physical

error is detected

The ISE is saving or restoring

data to the data retention

system

The green

LED is . . .

On Off

Off On

Blinking once

per second

And the yellow LED

is . . .

Off

3–11

Page 50

Page 51

Introduction

Chapter 4

Local Programs

In this Chapter

Overview

This chapter includes:

How to access local programs through the VMS system, the

console, and the MicroVAX Diagnostic Monitor (MDM)

Descriptions of accessible local programs

Local programs are diagnostics and utilities that are internal to

the ISE. You can access them in one of three ways, depending

on which system you are using.

Continued on next page

4–1

Page 52

Introduction, Continued

The following table refers to each section with instructions on

how to access local programs:

To access local programs ... Refer to ...

Through VMS, using the SET HOST

command,

From the console, using the SET HOST

command,

Through MDM, using the Device Resident

Programs menu,

Once you establish a connection, the local program controls the

operations that are performed. The following is a list of local

programs and the sections in which they are located:

Using VMS

Using Console

Commands

Using MDM

4–2

Continued on next page

Page 53

Introduction, Continued

Programs

DIRECT DIRECT Program Description

DRVEXR DRVEXR Program Description

DRVTST DRVTST Program Description

HISTRY HISTRY Program Description

DRINIT DRINIT Program Description

BATTST BATTST Utility Description

MEMTST MEMTST Utility Description

PARAMS PARAMS Utility Description

1

For users familiar with the RF-series ISEs, notice that the DKUTIL, ERASE,

and VERIFY local programs are not available in the EF5XX-series ISEs.

The DRINIT local program in the EF5XX provides a function similar to the

ERASE utility. The STATUS BB command in PARAMS provides the bad block

information available in DKUTIL and VERIFY.

1

Section

When the program ends, control returns to the system. To abort

the program and return control to the system, press

Ctrl/Y

.

Ctrl/C

or

4–3

Page 54

How to Access Local Programs

Using VMS

To access a local program from a MicroVAX system running

VMS version 5.3-2 or greater, use the command:

$ SET HOST/DUP/SERVER=MSCP$DUP/TASK=taskname nodename

The following table defines taskname and nodename:

Term Meaning How to find

Taskname Name of the local

program

Nodename Node name of the ISE To find the node name of an

Descriptions found in this

chapter

ISE, type SHOW DEVICES

or SHOW CLUSTER at the

DCL ( $ ) prompt and press

Return

To create a file in your directory of what appears on the screen,

add the qualifier:

/log=filename.ext

to:

$ SET HOST/DUP/SERVER=MSCP$DUP/TASK=taskname nodename

(Where "filename.ext" is, insert name of file and extension.)

4–4

Continued on next page

Page 55

How to Access Local Programs, Continued

Using Console

Commands

Q–bus

Adapters

Some systems allow you to access the local programs using

console commands. The command you use depends on whether

your system uses a Q–bus adapter such as the KFQSA module,

or an embedded adapter such as the KA640 module.

To access a local program from a system with a Q–bus adapter,

use the command:

>>> SET HOST/UQSSP/DUP/DISK # taskname

taskname = name of the local program

# = controller number of the ISE

To find the controller number, type SHOW UQSSP at the

console prompt (>>>). An example of the SHOW UQSSP

command is:

>>> show uqssp

UQSSP Disk Controller 0 (772150)

-DUA0 (RF31)

UQSSP Disk Controller 1 (760334)

-DUB1 (RF31)

UQSSP Disk Controller 2 (760340)

-DUC2 (RF31)

UQSSP Tape Controller 0 (774500)

-MUA0 (TK70)

>>>

Continued on next page

4–5

Page 56

How to Access Local Programs, Continued

Q–bus

Adapters

(continued)

To access a local program from a system with an embedded

adapter, use the command:

>>> SET HOST/DUP/DSSI/BUS:n #

n = bus number where the ISE is located

# = DSSI node number of the ISE

The system then prompts you for the name of the local program

you want to run.

To find the DSSI node number and node name, type SHOW

DSSI at the >>> prompt. To see a list of the devices on

the Q–bus, type SHOW QBUS or SHOW UQSSP at the >>>

prompt.

To abort the program and return control to the system, press

Ctrl/C

or

Ctrl/Y

.

Continued on next page

4–6

Page 57

How to Access Local Programs, Continued

Using MDM

If neither VMS nor console commands are available on your

system, you can run local programs using MDM. Use the

following procedure:

1. Boot MDM.

2. Enter the date and time.

3. Select the menus in the following order:

Service menu

Device menu

KFQSAA-KFQSA subsystem menu

Device Utilities menu

Device Resident Programs menu

When you select the Device Resident Programs menu, the

following displays:

RUNNING A UTILITY SERVICE TEST

To stop the test at any time and return to the previous

menu, press

CTRL/C

.

Continued on next page

4–7

Page 58

How to Access Local Programs, Continued

Using MDM

(continued)

4. Enter the name of the local program you want to run and

press

programs, refer to the program descriptions on the following

pages.

5. To exit MDM, press the

Return

. For information about the available local

Break

key.

4–8

Page 59

Descriptions of Local Programs

Overview

)

DIRECT

Program

Description

The rest of this chapter describes local programs you can access.

The DIRECT program provides a directory of local programs

resident in the ISE.

4–9

Page 60

DRVEXR

)

DRVEXR

Program

Description

The DRVEXR program is a diagnostic program that applies

several types of stress to the ISE.

Access DRVEXR the same way you would the other local

programs. Once a connection is established, the system

prompts you to answer a series of questions. Your responses

determine the mode and test duration.

Stopping

DRVEXR

Dialogue

To stop DRVEXR in progress, press

Ctrl/C,Ctrl/Y

,or

Ctrl/Z

When DRVEXR stops, a short report is printed.

To run DRVEXR, first respond to the following dialogue

messages:

Message Explanation

Copyright © 1989 Digital Equipment

Corporation

Write/read anywhere on the medium?

[1=Yes/(0=No)]

User data will be corrupted. Proceed?

[1=Yes/(0=No)]

(This question is omitted if you typed

0 to answer the previous question.)

No response is expected.

Do you want to write to the user data

area?

Do you really want to overwrite

existing data on the user data area?

Continued on next page

.

4–10

Page 61

DRVEXR, Continued

Dialogue

(continued)

Message Explanation

Test time in minutes?

[(10)-100]

Number of sectors to transfer at a

time? [0 - 50]

Compare after each transfer? [1=Yes

/(0=No)]

Test the DBN area?

[2=DBN only/(1=DBN and LBN)

/0=LBN only]:

Your response determines the length

of the test, in minutes.

This question is included for

compatibility with DRVEXR in RFseries ISEs. The response can be any

valid entry, 0 through 50. The entry

is checked for validity, but otherwise

ignored.

Your response determines whether the

processor ‘‘manually’’ compares the

results of the read with the expected

data (if writing is enabled) or the

hardware does the compares after

each read.

Your response determines how to

include the DBN area in the test. If

you enter 2, the test always includes

writes, even if you answered the first

question with 0.

Continued on next page

4–11

Page 62

DRVEXR, Continued

DRVEXR

Modes

You can run the DRVEXR program in one of the following

modes depending on your responses to the dialogue questions:

Mode Function

Read/Write Writes and reads as many blocks as possible in the given

amount of time.

Data Integrity Similar to Read/Write mode, but with a ‘‘manual’’ check

of data buffers done by the ISE processor.

Max Stress Reads the inner DBNs and outer DBNs alternately.

Continued on next page

4–12

Page 63

DRVEXR, Continued

Mode/Dialogue

Relationship

Example

The following table shows the relationship between the four test

modes and the responses to the six questions in the dialogue:

Modes Response to Question

123456

Read/Write 1 1 Any Any 0 Any

Data Integrity 1 1 Any Any 1 Any

Max Stress 0 N/A Any 0 N/A 2

The following is an example of what is displayed when you run

DRVEXR.

Copyright (C) 1990, 1991, 1992 Digital Equipment Corporation

Write/read anywhere on medium? [1=Yes/(0=No)] 1

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

Test time in minutes? [(10)-100]

Number of sectors to transfer at a time? [0 - Device Size] 1

Compare after each transfer? [1=Yes/(0=No)]: 1

Test the DBN area? [2=DBN only/(1=DBN and LBN)/0=LBN only]: 1

10 minutes to complete.

249080 operations completed.

124508 LBN blocks (512 bytes) read.

124508 LBN blocks (512 bytes) written.

32 DBN blocks (512 bytes) read.

32 DBN blocks (512 bytes) written.

0 uncorrectable ECC errors.

0 bytes in error (soft).

Complete.

4–13

Page 64

DRVTST

DRVTST

Program

Description

Dialogue

The DRVTST program provides a comprehensive test of the ISE

hardware. Errors detected by this program can be isolated to

the FRU level.

The following table describes the DRVTST dialogue:

Message Explanation

Copyright © 1989 Digital Equipment

Corporation

Write/read anywhere on the medium?

[1=Yes/(0=No)]

User data will be corrupted. Proceed?

[1=Yes/(0=No)]

5 minutes to complete. No response is expected.

Test passed. The test was successful. Choose

No response is expected.

Do you want to write to the user data

area? If you type 0, this is a read-only

test. DRVTST does, however, write to

a diagnostic area on the disk.

Do you really want to overwrite

existing data on the user data area?

If you type 0, this is a read-only test.

another local program or return

control to the system.

4–14

Continued on next page

Page 65

DRVTST, Continued

Error

Messages

The following table describes DRVTST error messages.

Message Description

Unit is currently in use. This can mean that the ISE unit is

Operation aborted by user. This message appears if the user stops the

xxxx - Unit diagnostics failed. This is a fatal error message where xxxx is

xxxx - Unit read/write test

failed.

inoperative, in use by a host, or is currently

running another local program.

program while it is in progress.

the MSCP error code. Call Digital Services.

This is also a fatal error message where

xxxx is the MSCP error code. Call Digital

Services.

Continued on next page

4–15

Page 66

DRVTST, Continued

DRVTST

Examples

The following is an example of what is displayed when DRVTST

runs successfully:

Copyright (C) 1990, 1991, 1992 Digital Equipment Corporation

Write/read anywhere on medium? [1=Yes/(0=No)] 1

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

5 minutes to complete.

Test passed.

The following is an example of what is displayed when DRVTST

has failed:

Copyright © 1989 Digital Equipment Corporation

Write/read anywhere on medium? [1=Yes/(0=No)]

0106 - Unit read/write test failed.

4–16

Page 67

HISTRY

HISTRY

Program

Description

Example

The HISTRY program displays ISE information that is used by

programs running in the host (such as MDM).

The information is displayed in the following order:

copyright notice

product name

serial number

node name

allocation class

firmware revision level

hardware revision level

power-on hours

power cycles

last bug check codes (up to 11)

The following is an example of what is displayed when you run

the HISTRY program:

Copyright (C) 1990, 1991, 1992 Digital Equipment Corporation

EF53

GA23040879

E1ZDCI

1

RFX T043

EF53 PCB-1/ECO-00

236

1

Complete.

4–17

Page 68

DRINIT

DRINIT

Program

Description

Copyright (C) 1990 Digital Equipment Corporation

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

Test passed.

The DRINIT program initializes the firmware data structures

and on-disk structure of the internal data retention disk. This

prepares the EF5XR ISE for saving data in case of a power

failure.

You should not normally need to run DRINIT. Use

the DRINIT program with caution, since running it

erases the EF5XX.

CAUTION

4–18

Page 69

BATTST

BATTST Utility

Description

Accessing

BATTST

BATTST is a utility that allows testing the batteries in an

EF51R and EF52R. It also allows for conditioning the batteries

to avoid or correct the voltage depression effect that sometimes

occurs in nickel-cadmium batteries after a series of incomplete

discharges.

BATTST operates by continuing to exercise the memory and

data retention disk under battery power after external DC

power is removed. The time that the batteries lasted is stored

in the PARAMS parameter BAT_TEST.

Access the BATTST program the same way you would the other

local programs. Once a connection is established, the system

prompts you to answer a series of questions.

Continued on next page

4–19

Page 70

BATTST, Continued

Stopping

BATTST

To stop a BATTST in progress, re-execute the BATTST local

program. You will be given an opportunity to abort the test.

Aborting BATTST requires the EF5XX to reset itself.

Digital recommends running the BATTST utility at least once

per year, or whenever a "Battery Maintenance Error" is logged

to the error log. This error is logged when EF5XX charging

and battery test firmware detect potential problems with the

charging or discharging of the batteries.

The result of the BATTST utility is checked by examining the

BAT_TEST parameter with the PARAMS utility. BAT_TEST

gives the time, in minutes and seconds, that the batteries ran

under the BATTST utility. A time:

Greater than 30 minutes indicates a good battery

Less than 30 minutes indicates that you should call Digital

Services to replace the battery

Continued on next page

4–20

Page 71

BATTST, Continued

Dialogue

The following table explains the BATTST dialogue.

Message Explanation

Copyright © 1990,1991,1992 Digital

Equipment Corporation

Test requires the unit power to be

removed. Proceed? [1=Yes/(0=No)]

Remove external power, Variable

BAT_TEST will contain the time

Test passed. This message indicates that the

No response is expected.

Do you want to remove power from

the EF5XX? This may affect other

drives in the cabinet or may require a

system shutdown.

Remove power from the EF5XX under

test. Depending on the configuration,

this may require a system shutdown.

After the test is completed, the

results are available in the parameter

BAT_TEST.

BATTST operation has started. The

program stops automatically when the

batteries are exhausted.

Continued on next page

4–21

Page 72

BATTST, Continued

Example

The following is an example of the BATTST utility:

Copyright © 1990, 1991, 1992 Digital Equipment Corporation

Test requires the unit power to be removed.

Proceed? [1=Yes/(0=No)] 1

Remove external power, Variable BAT_TEST will contain the time

Test passed.

After removing the power and allowing the batteries to drain,

the following example shows how to get the test results. In this

case, the batteries lasted for 40 minutes and 12 seconds.

Copyright © 1990, 1991, 1992 Digital Equipment Corporation

PARAMS>SHOW BAT_TEST

Parameter Current Default Type Radix

--------- -------- -------- ----- ------

BAT_TEST 00:40:12 00:00:00 String Ascii

PARAMS>EXIT

Exiting...

4–22

Page 73

MEMTST

MEMTST

Utility

Description

Accessing

MEMTST

MEMTST is a utility that allows testing of the memory modules

in EF5XX drives. Various patterns are written and read to the

memory arrays to detect problems with the memory devices,

address and data buffers, memory control, and ECC logic.

Access the MEMTST program the same way you would the

other local programs. Once a connection is established, the

system prompts you to answer a series of questions.

Continued on next page

4–23

Page 74

MEMTST, Continued

Dialogue

The following table explains the MEMTST dialogue.

Message Explanation

Copyright © 1990,1991,1992 Digital

Equipment Corporation

User data will be corrupted. Proceed?

[1=Yes/(0=No)]

Test time in minutes? [0 (= 1 pass)

<-> 200]

Testing slot n: Memory module n is currently being

Array OK - has 2 bad blocks The memory module has passed the

Test completed. The test has finished without errors.

No response is expected.

Do you want to overwrite the data in

the memory arrays?

Enter the time to run the test. Enter

0 to run the test once on memory

module.

tested.

test with the indicated number of bad

blocks.

4–24

Continued on next page

Page 75

MEMTST, Continued

Example

The following is an example of a successful run of the MEMTST

utility. In this case, each memory module was tested twice and

passed.

DUP Array Bad Block Test

Copyright © 1990, 1991, 1992 Digital Equipment Corporation

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

Test time in minutes? [0 (= 1 pass) <-> 200] 16

Testing slot 0:

Array OK - has 2 bad blocks

Testing slot 1:

Array OK - has 0 bad blocks

Testing slot 2:

No array installed

Testing slot 3:

No array installed

Testing slot 4:

No array installed

Testing slot 0:

Array OK - has 2 bad blocks

Testing slot 1:

Array OK - has 0 bad blocks

Testing slot 2:

No array installed

Testing slot 3:

No array installed

Testing slot 4:

No array installed

Testing slot 0:

Test completed.

Continued on next page

4–25

Page 76

MEMTST, Continued

To test each memory module just once, use a test time of 0 as

shown in the following example. MEMTST will calculate a test

time based on the number of memory arrays installed.

DUP Array Bad Block Test

Copyright © 1990, 1991, 1992 Digital Equipment Corporation

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

Test time in minutes? [0 (= 1 pass) <-> 200] 0

1 pass (= 10 minutes) selected

Testing slot 0:

Array OK - has 2 bad blocks

Testing slot 1:

Array OK - has 0 bad blocks

Testing slot 2:

No array installed

Testing slot 3:

No array installed

Testing slot 4:

No array installed

Testing slot 0:

Test completed.

The following is an example of MEMTST output when a

memory module is found bad.

DUP Array Bad Block Test

Copyright (C) 1990, 1991, 1992 Digital Equipment Corporation

User data will be corrupted. Proceed? [1=Yes/(0=No)] 1

Test time in minutes? [0 (= 1 pass) <-> 200] 10

Testing slot 0:

Array OK - has 2 bad blocks

Testing slot 1:

Array fails - has more than 20 bad blocks

4–26

Page 77

PARAMS

PARAMS

Utility

Description

The PARAMS utility allows you to examine and change internal

ISE parameters such as node name, allocation class, and MSCP

unit number. You can also use PARAMS to display the state of

the ISE and performance statistics maintained by the ISE.

The PARAMS program is an interactive, customer accessible

DUP local program that functions as both a parameter editor

(similar to the VMS SYSGEN utility) and a utility to display

status, history, and counters. PARAMS also performs well as a

manufacturing tool for gauging the goodness of the drive.

PARAMS polls for control characters (note that the DUP server

strips control characters of interest out of the input stream and

sets control flags). PARAMS processes control characters as

follows:

Character Function

CTRL/Y Terminates the program

CTRL/C Terminates the program

CTRL/Z Terminates the program

CTRL/R Ignored

CTRL/W Ignored

CTRL/G Emulates VMS CTRL/T behavior

Continued on next page

4–27

Page 78

PARAMS, Continued

The following is an example response given to CTRL/G:

PARAMS> ^G

E1QSAA::MSCP$DUP 26-APR-1990 15:01:51 PARAMS CPU=00:00:01.09 PI=17

PARAMS>

Accessing

PARAMS

PARAMS

Process

The PARAMS utility is invoked on demand from the user.

Once a connection is established, all interaction occurs through

the use of commands and responses. PARAMS has its own

command line interpreter.

PARAMS prompts you for a command at the PARAMS>

prompt.

Once you enter a command, PARAMS executes it and then

prompts you for another command.

Continued on next page

4–28

Page 79

PARAMS, Continued

PARAMS

Commands

Available PARAMS commands are:

Name Function

ENABLE

MSCP

EXIT Terminates PARAMS

HELP Prints a brief list of commands and their syntax

LOCATE Causes a soft fault in the ISE to help locate it

SET Sets a parameter to a value

SHOW Displays a parameter or a class of parameters

STATUS Displays information about the drive’s history

WRITE Updates the NVR from the cached copy

ZERO Clears a block of counters or all known blocks of

Enables MSCP server

counters

The following sections describe these commands.

ENABLE

MSCP

The ENABLE MSCP command, used with certain types of

hosts/configurations, enable the MSCP server.

Continued on next page

4–29

Page 80

PARAMS, Continued

ENABLE

MSCP Syntax

ENABLE

MSCP

Parameters

EXIT

EXIT Syntax

EXIT

Parameters

HELP

ENABLE MSCP

None

Use the EXIT command to terminate the PARAMS utility. The

message

Exiting...

displays on the terminal.

EXIT

None

HELP displays a brief list of the available commands and their

syntax.

Command

HELP

Syntax

HELP

None

Parameters

4–30

Continued on next page

Page 81

PARAMS, Continued

HELP

Example

PARAMS> help

PARAMS>

ENABLE MSCP

EXIT

HELP

LOCATE

SET {parameter | .} value

SHOW {parameter|.|/class}

/ALL /CONST

/DUP /SCS

/MSCP /BSS

STATUS [type]

CONFIG LOGS DUMP

THREADS MEMORY

MSCP PATHS DATALINK

HOURLY VCLOGS BB

WRITE

ZERO counter

ALL HOURLY

MSCP

LOCATE

The LOCATE command causes a soft fault in the ISE (it has no

effect on its current operation or state) to help find it. The fault

indicator on the drive module (red LED), the OCP (red LED), or

on the canister (magnetic disk with small green stripe) turn on

and stay on until you press

LOCATE

LOCATE parameter-name value

Syntax

Return

at the PARAMS> prompt.

Continued on next page

4–31

Page 82

PARAMS, Continued

LOCATE

Example

SET

SET Syntax

SET

Parameters

The following appears on the screen when this command is

used:

PARAMS> locate

Drive has been soft faulted to help locate it

Press RETURN to continue:

PARAMS>

Use the SET command to change the value of a given parameter

in the cached copy of the NVR image that is maintained

by PARAMS. The type and radix of the new value for the

parameter is determined by the type and radix of the parameter

itself ONLY and not by radix specifiers or quotes in your input.

ASCII parameters are left justified and blanks are padded into

their field width.

SET parameter-name value

parameter-name is the name of the parameter you want

to change. If abbreviated, the first matching parameter

name is used without regard to uniqueness. In addition,

the character "." may be used to reference the previously

referenced parameter. If there is no previously referenced

parameter, an error message is displayed.

value is the value assigned to the parameter. The radix

and type is specified by the parameter and not by radix

specifiers or quotes. For example, the command SET NODE

SUSAN sets parameter NODENAME equal to SUSAN.

4–32

Continued on next page

Page 83

PARAMS, Continued

SHOW

Command

Examples

SHOW

NOTE

Since it is important to view the current value of a

parameter before changing it, examples of the SHOW

command are included.

PARAMS> show add_cr

Parameter Current Default Type Radix

--------- -------- -------- ------- -----ADD_CR 0 0 Boolean 0/1

PARAMS> set . 1

PARAMS> show .

Parameter Current Default Type Radix

--------- -------- -------- -------- ----ADD_CR 1 0 Boolean 0/1

PARAMS> set add_cr 0

PARAMS> show .

Parameter Current Default Type Radix

--------- -------- -------- -------- ----ADD_CR 0 0 Boolean 0/1

PARAMS>

The SHOW command displays the settings of a parameter or

a class of parameters. The full name of the parameter (8

characters or less), the current value, the default value, radix

and type, and any flag associated with each parameter is

displayed.

SHOW Syntax

SHOW param-or-class

Continued on next page

4–33

Page 84

PARAMS, Continued

SHOW

Parameters

SHOW /Class

Examples

param-or-class is either the parameter name, possibly

abbreviated, or a class name. If you use an abbreviation,

the first matching parameter displays regardless of

uniqueness. The parameter name may also be the special

character "." which displays the most recently-shown

parameter. If there is no previously-shown parameter,

an error message is displayed. If you use a class name, be

sure to prefix it with a slash ("/"). Classes available are:

ALL, CONST, SCS, MSCP, DUP, and BSS.

PARAMS> show /dup

Parameter Current Default Type Radix

--------- --------- --------- ----- -----SDI_TMO 20 20 Byte Dec RO

ABT_TMO 20 20 Byte Dec RO

ELP_TMO 20 20 Byte Dec RO

DUPEXT RFX RFX String Ascii RO

ADD_CR 0 0 Boolean 0/1

ADD_LF 0 0 Boolean 0/1

PARAMS> show add_cr

Parameter Current Default Type Radix

--------- --------- --------- -------- ----ADD_CR 0 0 Boolean 0/1

PARAMS> show .

Parameter Current Default Type Radix

--------- --------- --------- -------- ----ADD_CR 0 0 Boolean 0/1

PARAMS>

4–34

Continued on next page

Page 85

PARAMS, Continued

STATUS

STATUS

Syntax

STATUS

Parameters

STATUS displays miscellaneous information such as module

configuration, history, current counters, and so forth, depending

on the type specified.

STATUS type

The type is the optional ASCII string that denotes the

type of data desired. You can also abbreviate type;an

abbreviation selects all types with matching names. If

omitted, all available data are displayed. The following

types are available:

CONFIG displays the module name, node name, power

on hours, power cycles, and other such configuration

information. Any unit failures as well as NVR failures

are displayed if applicable.

BB displays the bad block log for the device. A list of

physical blocks that have been replaced is given.

LOGS displays the last eleven (11) machine and bug

checks on the module. Included in each dump are the

M68000 registers (D0-D7, A0-A7), the time and date of

the failure (if not available, 17 November 1858 is used),

and a few hardware registers.

DATALINK displays the data link counters.

PATHS displays available path information (open VCs)

from the point of view of the controller. Included are

the remote node names, DSSI IDs, software type and

version, and counters for messages/datagrams sent

/received.

SYSTEM displays system statistics and counters.

Continued on next page

4–35

Page 86

PARAMS, Continued

MSCP displays MSCP statistics such as the number and

type of I/O commands and various histograms.

THREADS displays the known programs in the system,

the amount of CPU time consumed, and other

information.

VC displays the last 8 virtual circuit closures.

STAT

Examples

PARAMS> stat conf

Configuration:

Node EQSAA is an EF51R controller using Apache V1.1

Software EFX V100 built on 11-MAR-1990 22:21:45

Electronics module name is EN00500250

Last known unit failure code 300D(X)

In 485 power-on hours, power has cycled 681 times

System up time is 3 22:50:02.68

System time is 23-MAR-1990 15:00:17

PARAMS> stat paths

ID Path Block Remote Node DGS_S DGS_R MSGS_S MSGS_R

-- ------------ --------------- ---------- ---------- ---------- ---------1 PB FF846D66 Internal Path 0 0 0 0

0 PB FF846E9A KFQS A RFX T102 0 0 0 0

7 PB FF847236 KF0Y7B KFX V1.7 0 0 8393 8391

PARAMS> stat datalink

Datalink Counters:

Interval: 341421 seconds

Pkts Rcv’d: 53952:***************************

Pkts Xmt’d: 53954:***************************

Naks Rcv’d: 45717:**********************

Naks Xmt’d: 0:

Resets Rcv’d: 99662:**************************************************

Resets Xmt’d: 3040:*

No response: 42677:*********************

Duplicates: 0:

Unrecogs: 0:

4–36

Continued on next page

Page 87

PARAMS, Continued

PARAMS> stat logs

NOTE: bugcheck code is last word on first line of each log.

Log History:

Log #175-27-50-01/0000 17-NOV-1858 0:00:00

FFFFFFFF 0000FFFF FFFFFFFF FFFE2801 FFFFFFFF EFFF2801 FFF7FFFB 0000A056

FFDFC029 FFDFC74B FFFFB74C BFFEFFFF FFFF80BA FBFFFFFF FFFFBFFF FFFF807C

00000000 00000000 00000000

Log #176-27-50-01/0000 17-NOV-1858 0:00:00

FFFF1441 0000004D FFFFFFFF FFFE2801 FFFFFFFF EFFF2801 FFF7FFFB 0000A050

FFDF80BE FFDFC0EB FFFFB750 BFFEFFFF FFFF80BA FBFFFFFF FFFFBFFF FFFF807C

00000000 00000000 000006EC

...Eight logs omitted...

Log #174-27-50-01/0000 17-NOV-1858 0:00:00

FFFF1441 0000004D FFFFFFFF FFFE2801 FFFFFFFF EFFF2801 FFF7FFFB 0000A050

FFDF80BE FFDFC6AF FFFFB750 BFFEFFFF FFFF80BA FBFFFFFF FFFFBFFF FFFF807C

00000000 00000000 000006EC

PARAMS> stat mscp

MSCP statistics:

Primary revectors: 0

Tertiary revectors: 0

Max Queue Depth: 0

Queue Depth Histogram:

Commands Processed Histogram:

GetUnit: 5691:********************************************

SetCon: 2:*

Blocks Accessed Histogram (cylinder ranges):

Read Lengths Histogram (block count ranges):

Write Lengths Histogram (block count ranges):

PARAMS>

Interval: 341481 seconds

I/O Commands: 0

WRITE

Command

Use the WRITE command to copy the cached copy of

NVR_G_IMAGE back to NVR. This is equivalent to the VMS

SYSGEN WRITE command.

Continued on next page

4–37

Page 88

PARAMS, Continued

A WRITE command may fail for several reasons:

If a parameter is modified that requires the unit and the

unit cannot be acquired. (For example, it is not in the

available state with respect to all hosts. Changing the unit

number is an example of a parameter that requires the

unit.)

If a parameter is modified that requires controller

initialization and the user replies negatively to the request

for reboot. (Changing the nodename or the allocation

class are examples of parameters that require controller

initialization.)

Initial drive calibrations are in progress on the unit. (WRITE

is inhibited during this time.)

WRITE Syntax

WRITE

Parameters

ZERO

ZERO Syntax

WRITE

None

The ZERO command clears a block of counters or all known

blocks of counters.

ZERO counter

Continued on next page

4–38

Page 89

PARAMS, Continued

ZERO

Parameters

Counter is a block of performance counters or all known

counters.

Counter types include the following:

* All - Clears all performance counter blocks.

* MSCP - Clears the MSCP performance counters and

histograms.

* SEEKS - Clears the seek performance counters and

histograms.

4–39

Page 90

Page 91

Introduction

Chapter 5

DataRetention System

In This

Chapter

The EF51R and EF52R ISEs contain advanced hardware and

firmware that protect the data in the memory arrays from loss

in case of power or other system failure.

This chapter discusses the following features of the integrated

data retention system:

Continuously saving data

Restoring data on line

Battery testing and monitoring

Fast charge circuit

Automatic write protect

Comprehensive battery test

5–1

Page 92

EF5XX Data Retention Description

Continuously

Saving Data

Unlike Digital’s earlier ESE20 and ESE50 solid state disks, the

EF5XX ISE continuously moves modified data to the internal

winchester disk drive. This minimizes the amount of data

that must be saved under battery power and ensures that the

data retention disk is still functional. Saving of data is a low

priority, background task that minimizes the effect of saving

data on performance.

Upon a power failure, the EF5XX instantly switches over to

battery power. Within one minute, firmware detects external

power has failed. Firmware then write-protects the EF5XX

ISE, preventing further data changes. Saving data to the

internal winchester (magnetic) disk drive continues under

battery power until all contents of the memory arrays are safely

on the winchester disk.

The EF5XX ISE then shuts itself off to conserve battery power.

Although continuously saving data dramatically decreases the

length of time to completely save final data, the fully charged

battery has sufficient power to completely save the contents of

the EF5XX to the winchester disk. While saving the data under

battery power, the yellow Write-Protect LED will be on and the

green Run/Ready LED will blink once per second.

Restoring

Data

5–2

When power is restored, the EF5XX undergoes approximately

two minutes of power-on self-test (POST), which verifies the

integrity of the electronics and firmware.

After POST, the EF5XX is available for mounting and begins

restoring data to the memory arrays. While restoring data in

the offline state, the green Run/Ready LED blinks once per

second.

Continued on next page

Page 93

EF5XX Data Retention Description, Continued

After mounting, users’ requests from the host receive top

priority and are satisfied before restore requests. If a user

requests data that has not been restored yet, the EF5XX

fetches the data from the internal magnetic disk and returns

the data to the user.

Battery

Testing and

Monitoring

The battery subsystem (BSS) firmware logs a "Battery

Maintenance Error" under certain conditions. Table 5–1 lists

the type of error and why it occurs:

Table 5–1 Battery Maintenance Errors

Error Reason

Battery failed periodic test. The batteries undergo

a periodic trickle test

to check for shorted

cells.

Continued on next page

5–3

Page 94

EF5XX Data Retention Description, Continued

Table 5–1 (Continued) Battery Maintenance Errors

Error Reason

Battery age. The batteries have

Battery charging out-of-specification. Battery charging

had more than 3 years

of power-on time and

need to be replaced.

The number of poweron days until the

battery needs to be

replaced is available

in the parameter

BSS_REPL. A value

of 0 indicates the age

is the cause of the

maintenance error.

time was not within

specification.

Battery deep discharge. If the parameter BSS_

5–4

SHUT is 0 and the

BSS_DISC is 1, the

batteries were deep

discharged on the

last power failure and

should be replaced.

Continued on next page

Page 95

EF5XX Data Retention Description, Continued

Using

PARAMS

Running

BATTST

Overtemperature

Errors

Fast Charge

Circuit

Use the PARAMS local program (Chapter 4) to check the cause

of the battery maintenance error. You can use the PARAMS

command SHOW /BSS to show all BSS parameters. Except in

the case of deep discharge, use the battery test utility BATTST

to verify battery health when a "Battery Maintenance Error"

appears in the error log.

In addition, Digital recommends running the BATTST utility

(Chapter 4) at least once a year to condition and test the

batteries. If deep discharge occurs or the BATTST fails, please

call Digital Services to replace the battery.

Overtemperature conditions are also logged to the error log by

BSS firmware. Frequent overtemperature conditions shorten

battery life. A battery replacement interval of less than three

years is recommended if frequent overtemperature errors are

logged to the error log.

The EF5XX employs a fast-charge battery charge circuit to

reduce exposure to multiple power failures. The battery charger

is capable of replacing 90% of a full discharge in 4 hours. After

the batteries are charged, the battery charger trickle charges

the batteries to maintain the charge level.

Continued on next page

5–5

Page 96

EF5XX Data Retention Description, Continued

Automatic

Write Protect

Comprehensive

Battery Test

The EF5XX can optionally write-protect itself automatically

while the battery capacity is insufficient for saving data

completely. Automatic write protect is controlled by the

parameter BSS_WPLC. The default value of 1 indicates that

data should be protected by write-protecting automatically.

The BATTST local program provides a comprehensive battery

test that measures the life of the battery under full load. More

information on the battery test is available in Chapter 4.

5–6

Page 97

Battery Subsystem Parameters

BSS

Parameter

The following shows the parameters that control the battery

subsystem (BSS).

Example

Parameter Current Default Type Radix

--------- --------- --------- ------- -------BSS_MAXR 1095 1095 Word Dec B

BSS_REPL 1095 1095 Word Dec B

BSS_CHRG 15 15 Word Dec B

BSS_TINT 10020 10020 Word Dec B

BSS_TLEN 60 60 Byte Dec B

BSS_SHUT 1 0 Boolean 0/1 B

BSS_DISC 1 1 Boolean 0/1 B

BSS_WPLC 0 1 Boolean 0/1

BSS_REST 0 0 Boolean 0/1

BSS_UPNV 0 0 Boolean 0/1

BSS

Table 5–2 lists the BSS parameters and their definitions:

Parameter

Definitions

Table 5–2 BSS Parameter Definitions

Parameter Definition

BSS_MAXR Maximum number of days of battery life. This

value is used to initialize BSS_REPL when

replacing a battery.

Continued on next page

5–7

Page 98