Digital Equipment COLORWRITER LSR 2000 Service Manual

COLORWRITER LSR 2000

PRINTER

SERVICE GUIDE

Part Number EK-LSRCW-SV.A01

Digital Equipment Corporation

Maynard, Massachusetts

This document was created with FrameMaker 4.0.4

First Printing, January 1996

Possession, use, or copying of the software described in this publication is authorized only pursuant to a valid written license from

Electronics for Imaging, Inc.

Electronics for Imaging, Inc. 1996. All rights reserved.

Legal Notices

ELECTRONICS FOR IMAGING, INC. MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT

LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

REGARDING THE APPLE SOFTWARE. ELECTRONICS FOR IMAGING DOES NOT WARRANT, GUARANTEE, OR

MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE OF THE APPLE SOFTWARE

IN TERMS OF ITS CORRECTNESS, A CCURACY , RELIABILITY , CURRENTNESS, OR O THER WISE. THE ENTIRE RISK

AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EX CLUSION OF

IMPLIED WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO

YOU.

IN NO EVENT WILL ELECTRONICS FOR IMAGING, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE

LIABLE TO YOU FOR ANY CONSEQUENTIAL, INCIDENTAL OR INDIRECT DAMAGES (INCLUDING DAMAGES

FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, AND THE

LIKE) ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF ELECTRONICS FOR

IMAGING HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES,

THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Electronics for Imaging’s liability to you for actual damages from any

cause whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence], product liability or

otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph

(c)(1)(ii) of the Rights in Technical Data and Computer Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a)

through (d) of the commercial Computer Software Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics for

Imaging’ s standar d commercial agreement for this softwar e. U npublished rights reserved under the copyright laws of the U nited States.

T rademarks

The following are trademarks of Digital Equipment Corporation: OpenVMS, VAX, PATHW ORKS, D igital, and the DIGITAL logo.

The following are trademarks of Electronics for Imaging, Inc.: EFI, the EFI logo, Fiery XJ, Fiery Driven, the Fiery Driven Signature,

EFICOLOR, the EFICOLOR logo, and Fiery Print Calibrator. Fiery, EFICOLOR, and the EFICOLOR logo are registered with the

U.S. Patent and Trademark Office.

All other trademarks and registered trademarks are the property of their respective holders.

The software described in this guide is furnished under a license agreement or nondisclosure agreement. The software may be used or

copied only in accordance with the terms of the agreement.

Printed in U.S.A.

Electronics for Imaging Software License Agreement

Electronics for Imaging, Inc. grants to you a non-exclusive, non-transferable license to use the software and accompanying

documentation (“Software”) included with the Colorwriter LSR 2000 Color printer you have purchased, including without limitation

the PostScript

software provided by Adobe Systems Incorporated.

You may:

a. use the Software solely for your own customary business purposes and solely with Colorwriter LSR 2000;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font Programs”) provided with Colorwriter LSR 2000

in a special encrypted format (“Coded Font Programs”) to reproduce and display designs, styles, weights, and versions of letters,

numerals, characters and symbols (“Typefaces”) solely for your own customary business purposes on the screen of the Colorwriter

LSR 2000 or Macintosh monitor used with Colorwriter LSR 2000;

c. use the trademarks used by Electronics for Imaging to identify the Coded Font Programs and Typefaces reproduced therefrom

(“Trademarks”); and

d. assign your rights under this Agreement to a transferee of all of your right, title and interest in and to Colorwriter LSR 2000 provided

the transferee agrees to be bound by all of the terms and conditions of this Agreement.

You may not:

a. make use of the Software, directly or indirectly, to print bitmap images with print resolutions of 600 dots per inch or greater, or to

generate fonts or typefaces for use other than with Colorwriter LSR 2000;

b. make or have made, or permit to be made, any copies of the Software, Coded Font Programs, accompanying documentation or

portions thereof, except as necessary for use with the Colorwriter LSR 2000 printer purchased by you; provided, however, that under

no circumstances may you make or have made, or permit to be made, any copies of that certain portion of the Software which has been

included on the Colorwriter LSR 2000 hard disk drive. You may not copy the documentation;

c. attempt to alter, disassemble, decrypt or reverse engineer the Software, Coded Font Programs or accompanying documentation.

d. rent or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, Trademarks and accompanying documentation are proprietary

to Electronics for Imaging and its suppliers and that title and other intellectual property rights therein remain with Electronics for

Imaging and its suppliers. Except as stated above, this Agreement does not grant you any right to patents, copyrights, trade secrets,

trademarks (whether registered or unregistered), or any other rights, franchises or licenses in respect of the Software, Coded Font

Programs, Typefaces, Trademarks or accompanying documentation. You may not adapt or use any trademark or trade name which is

likely to be similar to or confusing with that of Electronics for Imaging or any of its suppliers or take any other action which impairs

or reduces the trademark rights of Electronics for Imaging or its suppliers. The trademarks may be used only to identify printed output

produced by the Coded Font Pr ograms. At the reasonable r equest of Electronics for Imaging, y ou must supply samples of any Typeface

identified with a trademark.

The MacApp software is proprietary to Apple Computer, Inc. and is licensed to Electronics for Imaging, Inc. for distribution only for

use in combination with Colorwriter LSR 2000 software utilities.

Confidentiality

You agree to hold the Software and Coded Font Programs in confidence, disclosing the Software and Coded Font Programs only to

authorized users having a need to use the Software and Coded Font P rograms as permitted by this Agreement and to take all r easonable

precautions to prevent disclosure to other parties.

Remedies

Unauthorized use, copying or disclosure of the Software, Coded Font Programs, Typefaces, Trademarks or accompanying

documentation will result in automatic termination of this license and will make available to Electronics for Imaging other legal

remedies.

Export Controls

Y ou agree that you will not export or re-export the Software or Coded F ont P rograms in any form without the appropriate United S tates

and foreign government licenses. Your failure to comply with this provision is a material breach of this Agreement.

Government Use

Use, duplication or disclosure of the Software by the United States Government is subject to restrictions as set forth in subdivision (c)

(1) (ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 or in subparagraphs (c) (1) and (2) of

the Commercial Computer Software—Restricted Right Clause at 48 CFR 52.227-19, as applicable.

Third Party Beneficiary

Y ou ar e hereb y notified that Adobe S ystems Incorporated, a California corporation located at 1585 Charleston R oad, M ountain View,

California 94039-7900 (“Adobe”) is a third-party beneficiary to this Agreement to the extent that this Agreement contains provisions

which relate to your use of the Fonts, the Coded F ont P rograms, the Typefaces and the Trademarks licensed hereby. S uch pro visions are

made expressly for the benefit of Adobe and are enforceable by Adobe in addition to Electronics for Imaging.

General

This Agreement will be governed by the laws of the State of California.

This Agreement is the entire agreement held between us and supersedes any other communications or advertising with respect to the

Software, Coded Font Programs and accompanying documentation. If any provision of this Agreement is held invalid, the remainder

of this Agreement shall continue in full force and effect.

FCC (Federal Communications Commission) Notice

WARNING:

FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved by the

manufacturer could void the user’s authority to operate this equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult a dealer or an experienced radio or television technician for help.

Modifications:

The FCC requires the user to be notified that any changes or modifications made to this device that are not expressly

approved by Digital Equipment Corporation may void the user’s authority to operate the equipment.

Cables:

Connections to this device must be shielded cables with metallic RFI/EMI connector hoods in order to maintain compliance

with FCC Rules and Regulations.

DOC Compliance Notice

This equipment does not exceed the Class B limits for radio noise emissions as described in the Radio Interference Regulations of the

Canadian Department of Communications.

DOC Avis de Conformation

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la

classe B préscrites dans le Règlement sur le brouillage radioélectrique édicté par le Ministère des Communications du Canada.

Acoustics

Declared values per ISO 9296 and ISO 7779:

Sound Power Level Sound Pressure Level

L

,B L

WAd

pAm

, dBA

(bystander positions)

Product Idle Operate Idle Operate

LNC01 (color) 6.2 7.0 44 53

LNC01 (b&w) 6.2 6.9 44 52

(1 B = 10 dBA)

Current values for specific configurations are available from Digital representatives.

Schallemissionswerte

Werteangaben nach ISO 9296 und ISO 7779/DIN EN27779:

Schalleistungspegel Schalldruckpegel

L

,B L

WAd

pAm

, dBA

(bystander positions)

Gerät Leerlaug Betrieb Leerlauf Betrieb

LNC01 (color) 6,2 7,0 44 53

LNC01 (b&w) 6,2 6,9 44 52

(1 B = 10 dBA)

Aktuelle Werte für spezielle Ausrüstungsstufen sind über die Digital Equipment Vertretungen erhältlich.

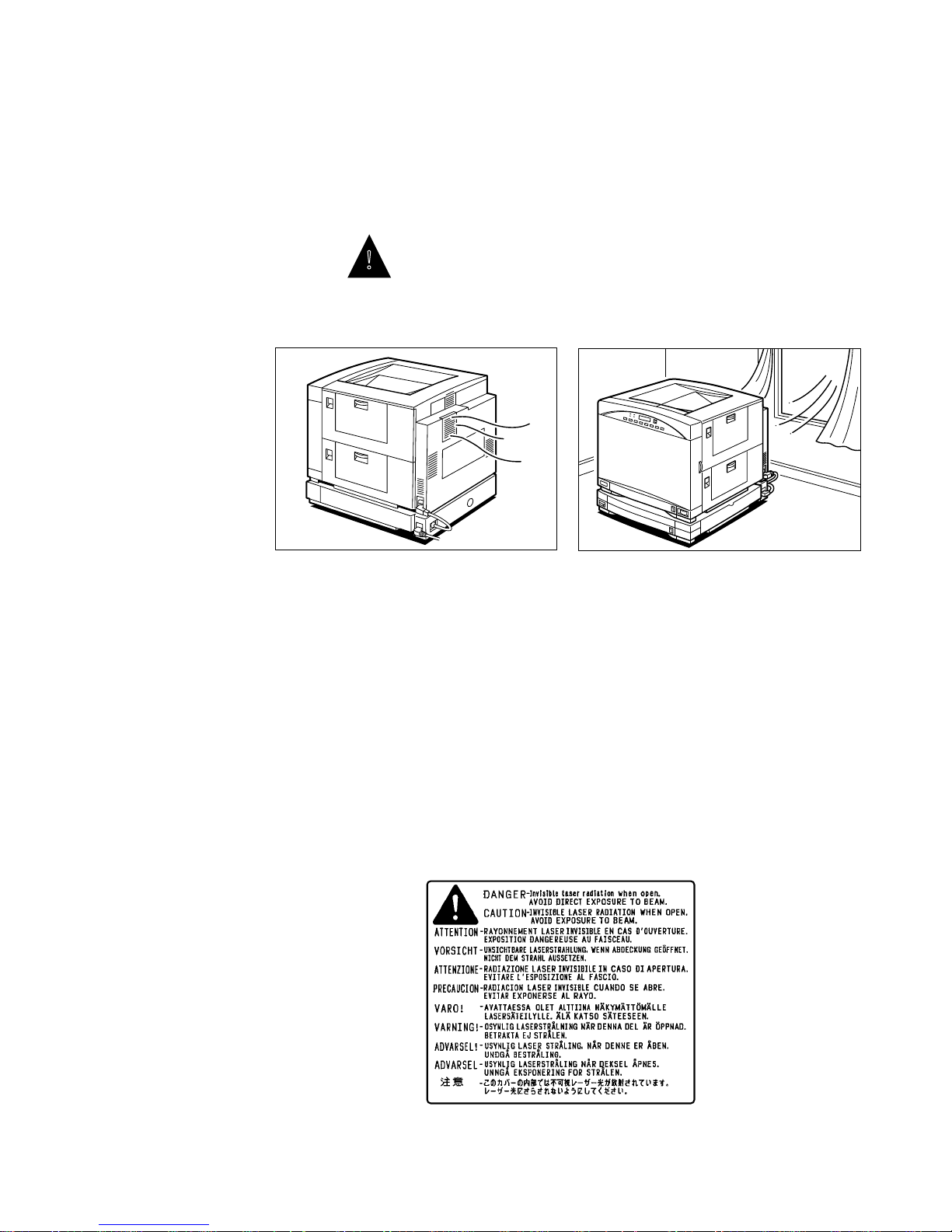

Class 1 Laser Product (100-120V/220-240V models)

Laser radiation could be hazardous to the human body . For this reason, laser radiation emitted inside this printer is hermetically sealed

within the protective housing and external cover. In the normal operation of the product by the user, no radiation can leak from the

machine.

This printer is certified as Class 1 laser product under the U.S. Department of Health and Human Services (DHHS) Radiation

Performance Standard according to the Radiation Control for Health and Safety Act of 1968. (This means that the printer does not

emit hazardous laser radiation.)

The label shown below is attached to this printer.

ATTENTION -

VORSICHT -

ATTENZIONE -

PRECAUTION-

VARO! -

VARNING! -

ADVARSEL! -

ADVARSEL -

WARNING:

DANGER -

CAUTION -

When servicing the machine or laser module, follow the procedures specified in the manual so that there are no hazards

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

INVISIBLE LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO BEAM.

RAYONNEMENT LASER INVISIBLE EN CAS D'OUVERTURE.

EXPOSITION DANGEREUSE AU FAISCEAU.

UNSICHTBARE LASERSTRAHLUNG, WENN ABDECKUNG GEÖFNET.

NICHT DEM STRAHL AUSSETZEN.

RADIAZIONE LASER INVISIBLE IN CASO DI APERTURA.

EVITARE L'ESPOSIZIONE AL FASCIO.

RADICION LASER INVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

AAVATTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD.

BETRAKTA EJ STRÅLEN.

USYNLIG LASER STRÅLING, NÄR DENNE ER ÅBEN.

UNDGÅ BESTRÅLING.

USYNLIG LASERSTRÅLING, NÄR DEKSEL ÅPNES.

UNNGÅ EKSPONERING FOR STRÅLEN.

RS5-8169

from the laser. The use of controls, adjustments, or performance of procedures other than those specified in this manual may result in

hazardous laser radiation exposure.

WARNING:

The label shown above is intended as a warning to persons disassembling the Raster Laser Scanner unit for internal

alignment or repair purposes. It does not apply to any of the maintenance procedures specified in this manual.

CDRH Regulations

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented regulations for

laser products on August 1, 1976. These regulations apply to laser products marketed in the United States. The label on the printer

indicates compliance with the CDRH regulations and must be attached to laser products marketed in the United States.

Contents 1

Preface

About the illustrations in this guide xiii

Terminology and conventions xiv

Important safety information xiv

Handling the printer xv

Choosing a location for the Colorwriter xv

Unpacking and setting up the Colorwriter xvi

Operating the Colorwriter xvii

Network precautions xviii

Protecting the LCD display xviii

Ozone emission xviii

Laser safety xix

Toner safety xx

Chapter 1: Introduction

How the Colorwriter operates 1-2

Parts of the printer 1-5

Print options 1-7

Client utility software 1-7

Chapter 2: Using the Control Panels

Using the density control panel 2-1

Density adjustment 2-2

Test patterns 2-3

Separation voltage control designation 2-5

Edge registration 2-6

Using the printer control panel 2-7

Activity lights 2-8

Display window 2-8

Buttons 2-8

Error messages 2-9

Menu options 2-10

Chapter 3: Operation

Overall control system 3-3

Main PCBs 3-5

Drive system 3-12

Basic sequence of operation 3-14

Laser/scanner system 3-16

Video data processing 3-17

Laser control circuit 3-19

Scanner system 3-23

vii

Table of Contents

Image formation system 3-25

Image formation configuration 3-28

Print process 3-32

High-voltage control 3-45

Photosensitive drum life detection 3-54

Developing unit control 3-58

Image quality stability control 3-69

Pick-up/Feed System 3-74

Paper pick-up 3-76

Transfer drum and peripheral components 3-86

Fixing and delivery unit 3-95

Oil circulation system 3-107

Fixing unit motor drive circuit 3-111

Paper jam detection 3-112

System interface 3-119

Video interface 3-120

Power supply 3-121

Remote switch 3-123

Protection function 3-123

Paper feeder 3-124

Electrical circuit 3-124

Paper feeder driver input/output 3-125

Pick-up/feed system 3-126

Chapter 4: Installation Overview

Removing printer shipping materials 4-1

Installing the photosensitive drum 4-2

Installing the waste toner bottle 4-5

Installing the toner cartridges 4-7

Installing the silicone oil bottle 4-11

Attaching the optional paper feeder unit 4-13

Checking the package contents 4-13

Chapter 5: Service Procedures

Servicing the Colorwriter 5-1

Software service 5-1

Accessing Colorwriter’s internal components 5-2

To shut down the Colorwriter 5-2

Removing covers and panels 5-3

Exhaust Fan 5-19

viii

Table of Contents

Drive System 5-25

Fixing unit motor 5-25

Developing unit motor 5-26

Drum motor 5-27

Drive unit 5-28

Rotary manual unit 5-30

Transfer drum cleaner press drive unit 5-32

Discharge roller press drive unit 5-33

Drum press drive unit 5-34

Attraction roller press drive unit 5-35

Delivery drive unit 5-36

Paper transport system 5-37

Pick-up unit 5-37

Separating the manual feeding tray pick-up unit

from the cassette pick-up unit 5-39

Manual feed solenoid 5-42

Manual feeding pick-up roller 5-43

Separation pad 5-44

Feed roller unit 2 5-46

Pick-up motor 5-48

Registration roller clutch 5-51

Registration upper/lower rollers 5-52

Cassette feed solenoid 5-55

Separation roller 5-56

Feed roller 1 5-57

Transfer Drum Holder Unit 5-58

Exposure system 5-78

Laser/scanner unit 5-78

Charging system 5-79

Drum cartridge 5-79

Density sensor unit 5-82

Developing system 5-84

Toner cartridge 5-84

Developing rotary unit 5-86

Fixing system 5-90

Fixing unit 5-90

Fixing Cleaning Unit 5-106

Fixing delivery unit 5-109

Oil applying unit 5-110

Bottle case unit 5-114

ix

Table of Contents

Electrical components 5-119

Video controller PCB 5-119

DC controller PCB 5-127

Mechanical controller PCB 5-131

Pick-up PCB 5-132

Terminal PCB 5-133

Cassette-size sensing PCB 5-134

Waste Toner Sensor PCB 5-137

Toner-low detect beam PCB 5-139

Toner-low Detect Receive PCB 5-139

Power Supply 5-140

High-voltage Power Supply 5-143

Separation HVT PCB 5-144

Temperature/humidity sensor 5-145

Oil overflow sensor 5-147

Oil sensor PCB 5-149

Ejection PCB 5-150

Paper Feeder 5-152

External paper feeder covers 5-153

Pick-up unit 5-157

Paper feeder PCB 5-164

Power Supply 5-166

Cassette-size sensing PCB 5-167

Installing system software 5-170

Installing system software 5-170

Chapter 6: Troubleshooting Procedures

Preliminary on-site checkout 6-1

Checking the cables 6-1

Checking the installation environment 6-2

Checking the print paper 6-2

Checking consumable materials 6-2

Checking the charging unit 6-2

Other 6-3

Checking for paper jams 6-3

Start-up diagnostics and error messages 6-7

Selecting video controller extended diagnostics 6-9

Basic troubleshooting procedures 6-12

How to read the troubleshooting procedure table 6-13

Printer Driver Tester (PDT) 6-14

Measurement and adjustment 6-16

Electrical system adjustments 6-18

Image Defects 6-22

Troubleshooting image defects 6-25

Troubleshooting malfunctions 6-38

Paper Transport Troubleshooting 6-59

Paper Jams 6-59

Incomplete Paper Feed 6-64

x

Table of Contents

Locations/roles of electrical parts 6-66

Switches 6-66

Sensors 6-68

Clutches/Solenoids 6-71

Motors 6-73

PCBs 6-75

Connectors 6-77

Variable Resistors (VR), LEDs, Test Pins, Jumpers,

and Switches on PCB 6-80

DC controller PCB 6-80

Video controller PCB 6-81

Mechanical controller PCB 6-82

High-voltage power supply PCB 6-83

Separation HVT PCB 6-84

Ejection sensing PCB 6-84

Cassette size-sensing PCB 6-85

Paper feeder driver PCB 6-86

Checking network connections 6-87

Appendix A: Specifications

Hardware features A-1

Networking and connectivity A-1

Style A-2

Options A-2

Supplies A-3

Paper A-3

Feeder A-3

Types A-3

Handling A-4

Fonts A-5

Functions A-5

Additional functions A-5

Product life A-6

Environmental A-6

EMC standards A-8

Immunity A-8

Momentary interruption of power A-8

AC line noise A-9

Surge voltage A-9

Packaging A-9

Vibration A-9

Shock A-10

xi

Table of Contents

Safety approvals A-10

AC input power specifications: LNC01-A2 A-11

AC input power specifications: LNC01-A3 A-12

Remote utility software A-14

Maintenance by serviceperson A-14

Appendix B: Maintenance Requirements

Service maintenance B-1

60K service maintenance B-2

Service checkpoints B-5

Customer maintenance/checks B-6

Metrics B-12

Usage model B-12

Paper feed reliability B-12

Tools you will need B-13

Special tools B-14

List of Lubricants, Cleaners B-15

Appendix C: Moving the printer

Appendix D: Spare Parts

Appendix E: Accessories and Supplies

Optional paper feeder unit E-1

Memory upgrade kits E-2

Ordering consumables E-2

Toner cartridges E-2

Silicone oil E-3

Drum cartridge kit E-4

Transparency film E-5

Paper E-5

Appendix F: Related Documentation

Technical support F-2

Electronic orders F-2

Telephone and direct mail orders F-3

Index

xii

Preface

The Colorwriter LSR 2000 Printer Service Guide is intended for

certified printer technicians installing or servicing a Colorwriter

LSR 2000. If you have not received installation and service

certification, you should not attempt to service the Colorwriter.

This guide is divided into the following sections:

• “Preface ” gives general information about this guide and general

information that you should know before you attempt to install

a Colorwriter.

• Chapter 1, “Introduction”, provides general information about

the Colorwriter.

• Chapter 2, “Using the Control P anels ”, pr ovides o verview of the

Colorwriter Control Panel and the Density Control Panel.

• Chapter 3, “Operation”, provides detailed information on how

the printer functions.

• Chapter 4, “Service Procedures”, describes removal and

replacement procedures for Colorwriter components.

• Chapter 5, “Troubleshooting Procedures”, identifies the source

of common problems that may occur with the printer and

suggests ways of correcting them.

Colorwriter customers should not use the technical service

documentation. Please don’t leave your copy of the

2000 Printer Service Guide

behind after you make a service call.

Colorwriter LSR

About the illustrations in this guide

The illustrations in this guide reflect the version of the Colorwriter

at the time of publication. Components shown in these illustrations

are subject to change. To receive information about any Colorwriter

components that do not match illustrations in this guide, contact

your authorized service/support center.

xiii

Colorwriter LSR 2000 Printer

Service Guide

Preface

Terminology and conventions

The term network administrator refers to the person responsible for

maintaining the network at the customer site.

The term

in the Colorwriter printer control panel.

The term

front of the Colorwriter that includes the activity lights, display

window, and the buttons below the display window.

The

that allows you to change color density, print test patterns, adjust

separation voltage control designation and to adjust edge

registration.

The term

computer capable of running MS-DOS

display window refers to the LCD (liquid crystal display)

printer control panel is used to describe the area on the

density control panel describes the area on the back of the printer

PC-compatible refers to any IBM PC-compatible

version 5.0 or later.

The term PC-based server refers to any device that may be connected

to the Colorwriter for parallel printing.

The arrow highlights important notes and additional information.

!

The caution icon indicates a need for special care and safety when

handling the equipment.

Important safety information

This printer is a high-precision electronic device. Be sure to read

these safety instructions fully before you begin.

Follow all warnings and instructions marked on the printer and

consumables, such as the toner cartridges and silicone oil bottles.

xiv

Service Guide

PrefaceColorwriter LSR 2000 Printer

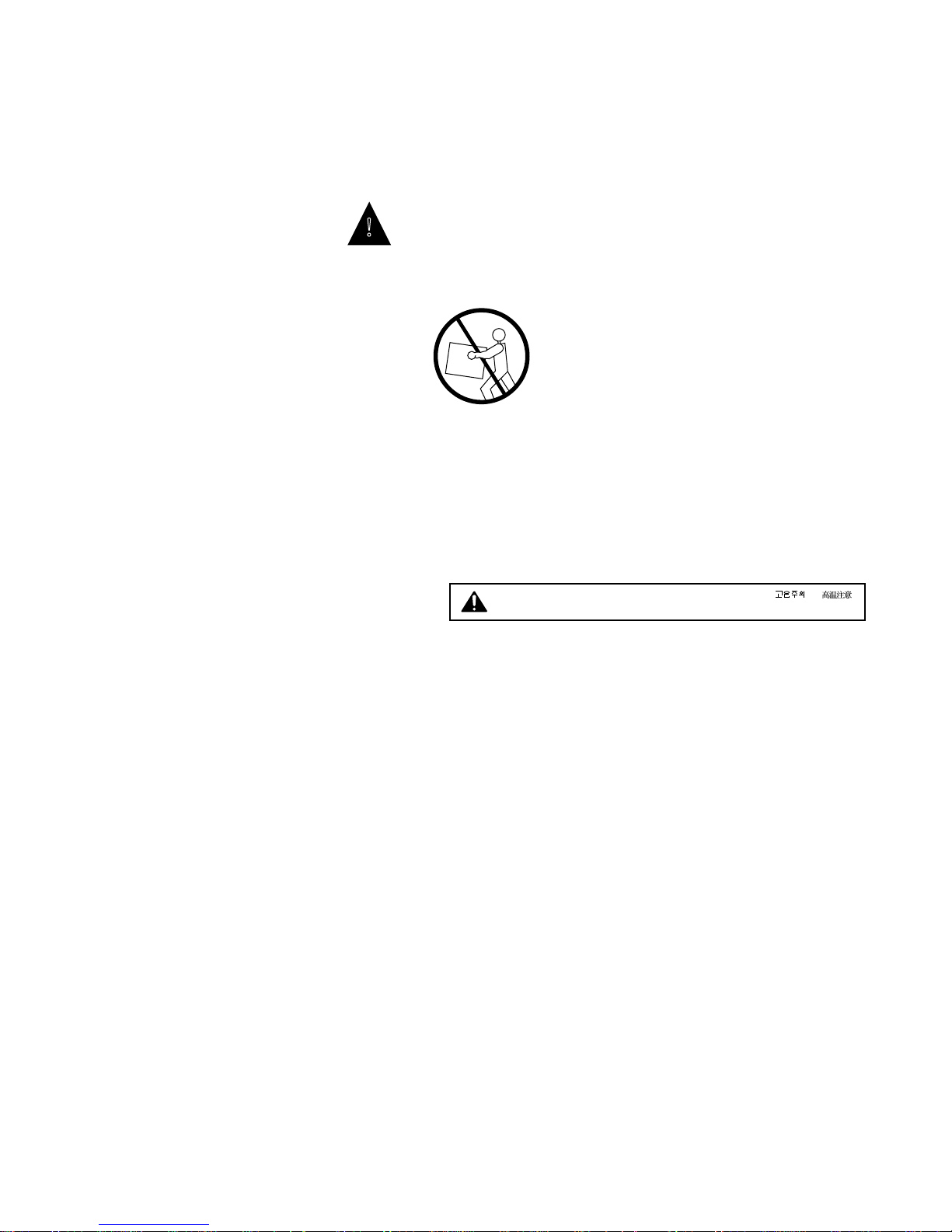

Handling the printer

!

printer alone weighs approximately 110 lb (50 kg). It should always

be moved by two or more people. Do not attempt to move it by

yourself.

• When installing the printer, carefully observe the location

requirement described in this manual.

• Never place the printer near or over a radiator, heat emitter, or

flame.

• When the printer is in use, the fixing assembly and delivery

areas become extremely hot. Be careful not to touch these areas.

Do not place this printer on an unstable cart, stand, or table. The

CAUTION! HOT SURFACE. AVOID CONTACT ACHTUNG HEISS

ATTENTION! TEMPERATURE ELEVEE PRECAUTION! / ATTENZIONE! ALTA TEMPERATURA

• When moving the printer, be sure to turn the power off before

unplugging the power cable.

• Handle all PCBs (printed circuit boards) by their edges only, but

avoid touching the contacts on the edge of the board.

Choosing a location for the Colorwriter

• Do not expose the printer to a wet environment.

• Do not directly expose the printer to a chemical environment,

for example, an experimental laboratory. The exterior of the

printer is made of plastic, and the outside covering may fade,

become deformed, or melt.

• Do not install the printer where it is exposed to smoke or steam

or sun.

• The printer should never be placed near or over a radiator or

heat register. This printer should not be placed in a built-in

installation unless proper ventilation is provided.

xv

Colorwriter LSR 2000 Printer

Service Guide

Preface

Unpacking and setting up the Colorwriter

• Report any shipping damage. If there is any evidence of

shipping or handling damage to the Colorwriter packing boxes

or their contents, save the damaged boxes and parts, call the

shipper immediately to file a claim, and notify your authorized

service/support center.

• Do not operate the printer until all packaging materials

(packing tape, spacers, and styrofoam molds) have been

removed.

• Before connecting the printer to a power source, check the

voltage rating label at the back of the printer to ensure that the

printer voltage matches that of the power source. The voltage

rating label is located on the rear of the printer. If the voltage

label is missing, contact the nearest authorized dealer or your

place of purchase.

• Be sure to unravel the power cord prior to plugging it in. Using

it tied up may lead to damage, overheating, a short-circuit, or

fire.

• Be sure to plug the power cord well into the po wer outlet, as any

flammable material caught between an opening may result in

fire.

• Avoid using an extension cord. If it is unavoidable, be sure to

take the following precautions. Failure to do this may lead to

overheating, fire, or cause flickering due to a drop in voltage.

• Be sure not to exceed the allowed rating current of the

extension cord. Make sure that the total ampere rating of the

products plugged into the extension cord does not exceed

the extension cord ampere rating.

• Use a short extension cord. Do not connect several extension

cords together.

• Be sure to connect the printer to a ground terminal.

• The power cord should be routed so that it is not likely to be

walked on or pinched by items placed on or against it. Pay

particular attention to the plug, the receptacle, and the point

where the cord exits the unit.

xvi

• When connecting cables or disconnecting cables from the

printer, make sure that the power switch is in the off position.

• Keep the power cord and cables away from children.

• Do not handle plugs with wet hands.

Service Guide

PrefaceColorwriter LSR 2000 Printer

• Be sure to turn off the power before unplugging or plugging in

the printer power cord or interface cable.

• Be sure to use a surge suppressor on the Colorwriter.

Operating the Colorwriter

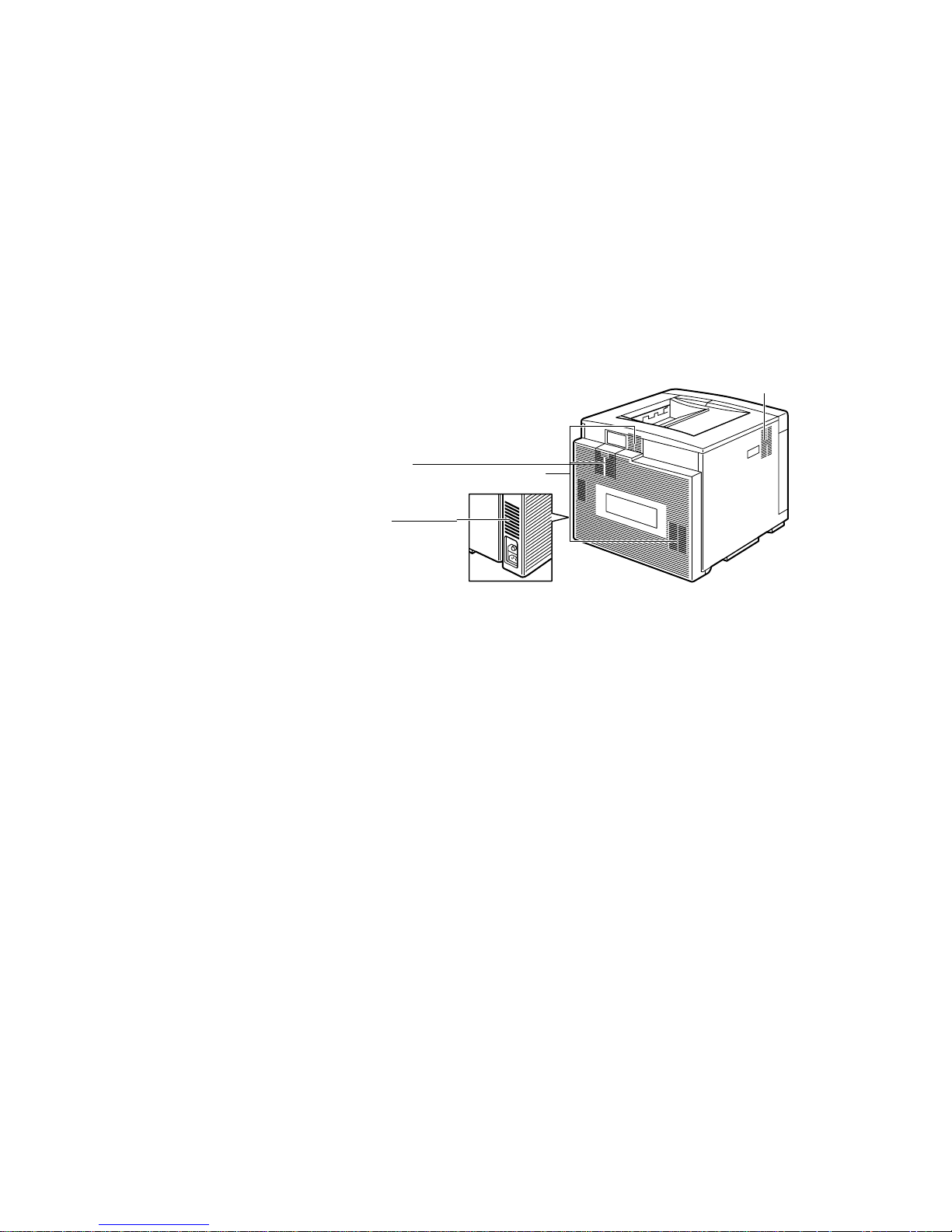

• Slots and openings in the cabinet are provided for ventilation.

To ensure reliable operation of the printer and protect it from

overheating, these openings should never be blocked or covered.

Air ventilation slots

Inhalation slot

• The printer is equipped with a 3-wire grounding type plug,

which has a third (grounding) pin. This plug will fit only into a

grounding-type power outlet. If you are unable to insert the

plug into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the purpose of the groundingtype plug.

• If the printer will not be used for a long period of time, turn the

power off and unplug the power cord.

• Unplug the printer from the wall outlet before cleaning. Use a

damp cloth for cleaning. Do not spray liquid cleaners or aerosol

cleaners directly on the cabinet or the openings, as the spray

could penetrate inside the printer and contaminate internal

parts.

• Never push objects of any kind into the printer through

openings in the enclosure, as the objects may touch dangerous

voltage points or short out parts. This could cause a fire or

electrical shock.

• Never spill any liquids into the printer.

• The outlet should always be free from any obstacles so as to

allow easy access.

• When unplugging the printer, always disconnect the po wer cord

by pulling on the plug, not the cord itself.

xvii

Colorwriter LSR 2000 Printer

Service Guide

Preface

• Any misuse of electrical equipment is hazardous. Do not allow

children to handle power cords or cables.

• Avoid operating the printer when the waste toner bottle and/or

silicone oil bottle is not installed; otherwise the printer may be

damaged.

• Do not attempt to modify the printer.

• Do not remove the warning or instruction labels on the printer.

• Do not dispose of the used waste toner box or the silicone oil

box into a fire.

Network precautions

• Never alter an existing network without permission from the

network administrator. The Colorwriter will probably be

connected to an existing Local Area Network (LAN) based on

Ethernet

customer’s computer other equipment. Never disturb the LAN

by breaking or making a network connection, altering

termination, installing or removing networking hardware or

software, or shutting down networked devices without the

knowledge and express permission of the system or network

administrator or the shop supervisor.

hardware. The network is the link between the

• Never enter an IP address in Colorwriter Network Setup. Only

the network administrator should enter an IP address on a

network device. Assigning a Colorwriter an incorrect IP address

can cause unpredictable errors on any or all devices connected to

the network.

Protecting the LCD display

The Colorwriter has a liquid crystal display (LCD) that is made of

glass and can break. Do not subject the Colorwriter to strong

shocks.

If the display window breaks and the liquid crystal material leaks

out, do not inhale, ingest, or touch it. If the material gets on your

skin or clothing, wash it off with soap and water immediately.

Ozone emission

This printer meets the requirements for ozone emission of the

applicable standard published by Underwriters’ Laboratories, Inc.

(UL). Ozone (O

) is a colorless gas by-product of the

3

xviii

Service Guide

PrefaceColorwriter LSR 2000 Printer

electrophotographic process. Ozone is discharged only while the

printer is printing, and is emitted through the exhaust port on the

rear, left side of the printer.

!

Those who are particularly sensitive to ozone odor may rarely feel

sick if exposed to it excessively. To avoid this, make sure that the

following measures are taken.

• Install the printer in a well ventilated room.

O

3

• Avoid using multiple laser printers simultaneously.

• Avoid facing the exhaust port directly toward users.

• Replace a disposable ozone filter after about 60,000 prints.

• Avoid using the printer without a filter.

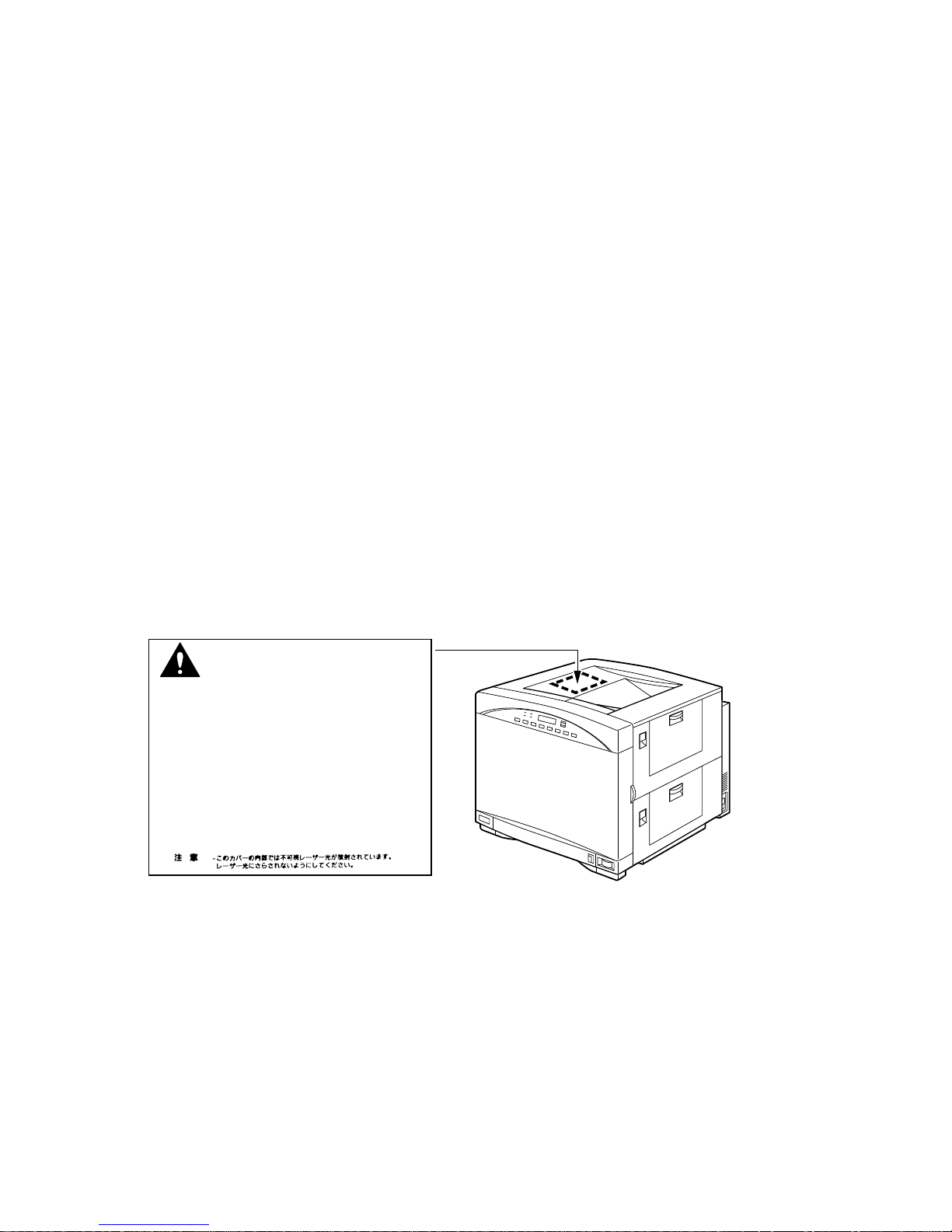

Laser safety

An invisible laser beam is radiated in the laser/scanner unit and

could be hazardous to the human body if exposed to it. For this

reason you should not disassemble the laser/scanner unit and it

should not be adjusted in the field. The following warning is

attached to the cover of the laser/scanner unit.

xix

Colorwriter LSR 2000 Printer

Service Guide

Preface

Toner safety

Toner is a harmless substance. If you get toner on your skin or

clothes, remove as much as possible with a dry tissue and then wash

it with cold water. Do not use hot water; the toner may gel and

become hard to remove. Toner easily decomposes vinyl material;

therefore you should not let it come into contact with this material.

xx

Chapter 1:

Introduction 1

The Colorwriter LSR 2000 printer is a full-color laser beam printer

based on the standard CMYK (cyan, magenta, yellow, and black)

color model. The Colorwriter has the following features:

• Toner cartridges separate from photosensitive drum

The four color toner cartridges (cyan, magenta, yellow, and

black) are installed separately from the photosensitive drum.

When a toner cartridge is used up, just replace the toner

cartridge with a new one of the same color.

• Flexible color range

The four color toner cartridges offer output in full color, a single

color only (monocolor), or the traditional true black (using the

black toner cartridge).

• High resolution

The 600-dpi resolution gives you crisp, clean, and laser sharp

output in full color.

• High print speed

The printer prints at 3 letter-sized pages per minute in full color ,

or 12 letter-sized pages per minute in monocolor (using one of

the toner cartridges). Overhead transparencies are printed at 1

page per minute.

• Flexible paper handling

The supplied paper cassette preset (A4 or letter-size, depending

on the voltage package) can hold about 250 sheets (at 80 g/m2)

of plain paper. The multipurpose tray accepts transparency films

as well as plain paper. You can also purchase a universal paper

cassette which can hold various paper sizes—Letter, A4, B5, or

legal. For higher volume, the optional paper feeder unit can be

used.

1-1

Colorwriter LSR 2000 Printer

Service Guide

1: Introduction

The Colorwriter enables users of Macintosh

computers, PC-

compatibles, and UNIX workstations to:

• Send images over AppleTalk

through a parallel (Centronics

, TCP/IP, Nov ell

) port to print to the

networks, and

Colorwriter.

• Spool print jobs and select a printing priority for each job. U sers

can also control spooled print jobs sent to the Colorwriter with

remote utility software running on networked Macintosh and

PC-compatible computers.

• Print PostScript and EPS files in color and grayscale.

• Use 39 resident fonts. The customer can download additional

PostScript Type 1 or Type 3 fonts as needed.

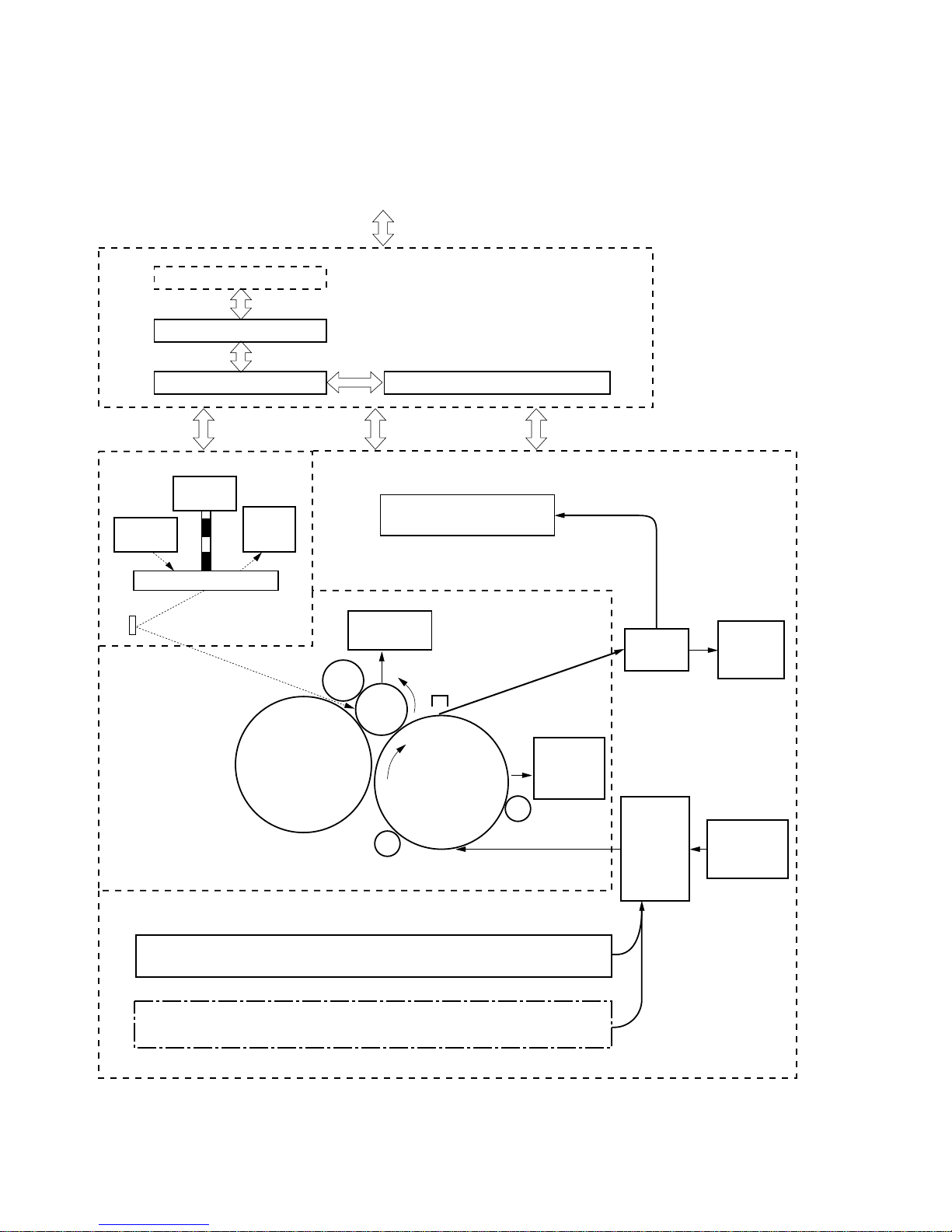

How the Colorwriter operates

The basic operation of the Colorwriter can be divided into four

blocks: the overall control system, the laser/scanner system, the

image formation system, and the pick-up/feed system.

• Overall control system—is controlled by the video controller

PCB, terminal PCB, DC controller PCB and the mechanical

controller PCB. When the video controller board receives a

print command from an external networked device, the

command is sent to the DC controller and the mechanical

controller which begins the printing process. These boards

control the engines that perform the printing process.

• Laser/Scanner system—once printing has begun the DC

controller begins to stabilize the intensity of the laser beam. The

laser beam strikes the scanning mirror which rotates at a

constant speed. The laser beam reflected b y the scanning mirror

focuses on the photosensitive drum after passing through the

focusing lens and being reflected by the reflection mirror. When

the scanning mirror rotates at a constant speed, the laser beam

scans at an even speed across the photosensitive drum. A latent

image is formed on the photosensitive drum as it is also rotating

at a steady speed.

• Image formation system—is made up of the photosensitive

drum, transfer drum, developing unit, primary charging roller,

and other components. The primary charging roller negatively

charges the entire surface of the photosensitive drum while the

laser beam is radiated onto the surface of the photosensitive

drum. The latent image formed across the photosensitive drum

is made visible by the toner, and is transferred to the paper on

1-2

Service Guide

1: IntroductionColorwriter LSR 2000 Printer

the transfer drum. These steps are taken for each color. The

paper is rotated on the transfer drum until the color transfer

process is completed.

The paper is then separated from the transfer drum and

delivered to the fixing unit. The surface of the photosensitive

drum is cleaned with the cleaner blade for removal of remaining

toner, and the drum potential is kept uniform by the primary

charging roller in preparation for forming a new latent image.

The transfer drum surface is cleaned with the cleaning brush for

removal of remaining toner and the discharge roller remo ves the

surface charge.

This printer is also equipped with toner cartridge installation

detection, toner-low detection, toner stirring, and

photosensitive drum life detection functions.

Note:

The cleaning brush is activated after 100 prints.

• Pick-up/Feed system—When a print job is sent to the printer a

sheet of paper is picked up by either the cassette or manual

feeding pick-up roller, fed by the feed rollers. Any skew in the

paper is corrected by the registration roller, and then the paper

stops at the leading edge detection position. The temporarily

stopped paper is fed so that its leading edge will match the

gripper on the transfer drum as well as the leading edge of the

image on the photosensitive drum. Subsequently, the paper

passes through the transfer , separation, fixing, and delivery units

to the face-down or face-up tray.

1-3

Colorwriter LSR 2000 Printer

Service Guide

Video controller PCB

Terminal PCB

LASER/SCANNER SYSTEM

Scanner

motor

Laser

diode

Beam

position

detector

1: Introduction

To external device (computer, etc.)

OVERALL CONTROL SYSTEM

Mechanical controller PCBDC controller PCB

PAPER PICK-UP/FEED SYSTEM

Face-down tray

Scanning mirror

Primary

charging

roller

Developing

unit

IMAGE FORMATION SYSTEM

Cleaning

unit

Separation

charging unit

Photo-

sensitive

drum

Transfer drum

Attraction roller

Cassette

Paper feeder (optional)

Transfer

drum

cleaning

unit

Discharge roller

Fixing

unit

Pick-up

control

unit

Face-up

delivery

tray

Manual

feeding tray

1-4

Figure 1-1 Colorwriter functional diagram

Service Guide

1: IntroductionColorwriter LSR 2000 Printer

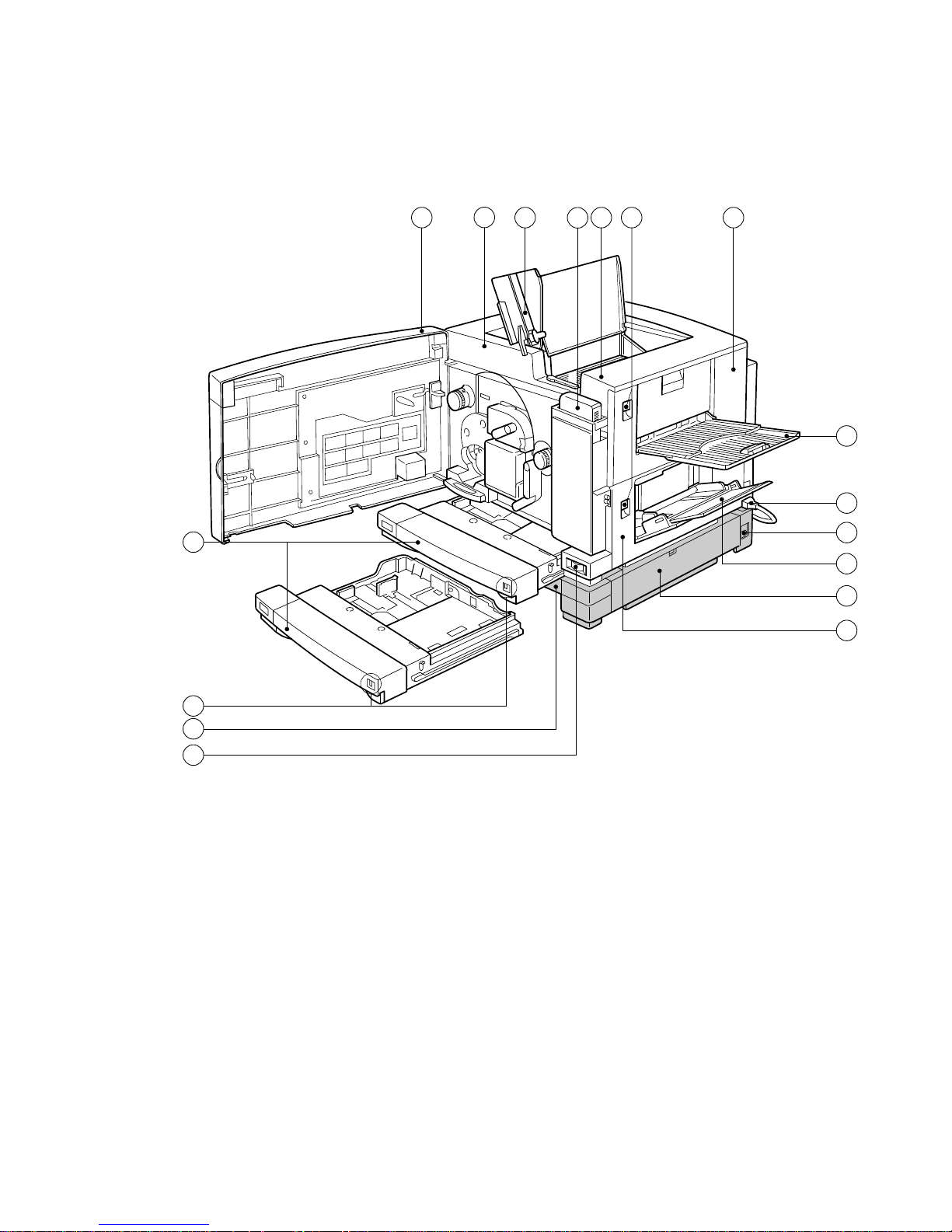

Parts of the printer

14

15

16

17

2 3 4

1

5

6

7

8

9

10

13

12

11

1—Oil bottle

2—Upper cover

3—Release knob

4—Fixing unit cover

5—Face-up tray

6—Power cable

7—Power receptacle

8—Manual feeding tray

Figure 1-2 Printer — external view

9—Paper feeder (right door)

10—Pick-up cover

11—Power switch

12—Paper feeder

13—Paper capacity indicator

14—Cassette

15—Front door

16—Printer Control Panel

17—Face-down tray

1-5

Colorwriter LSR 2000 Printer

Service Guide

1: Introduction

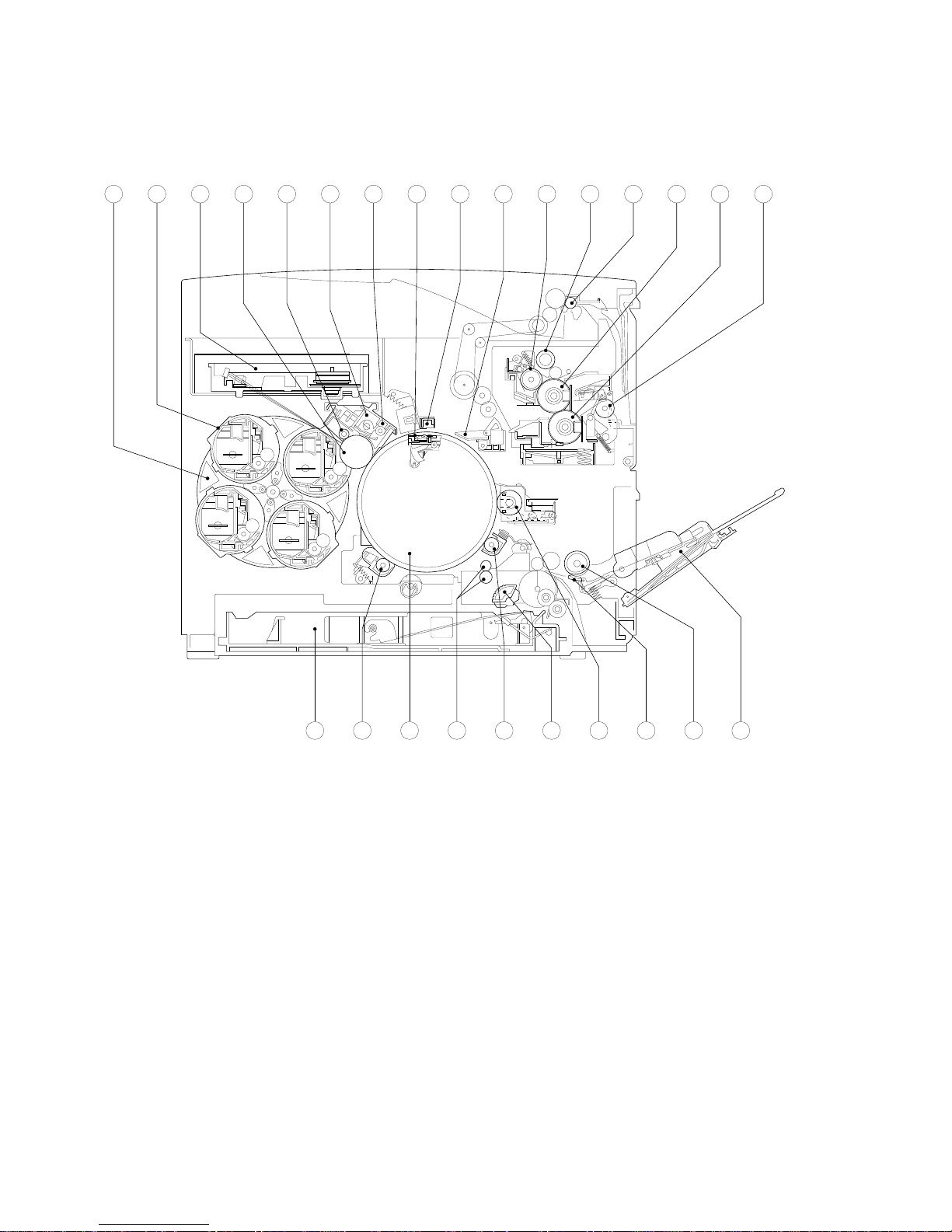

16151413121110987654321

1-6

1—Developing rotary unit

2—Toner cartridge

3—Laser/scanner unit

4—Photosensitive drum

5—Primary charging roller

6—Drum cartridge

7—Cleaning unit

8—Gripper

2223242526

9—Separation charging unit

10—Separation claw

11—Oil applying roller

12—Cleaning belt

13—Face-down delivery roller

14—Fixing upper roller

15—Fixing lower roller

16—Fixing delivery roller

17—Manual feeding tray

21 20 19 18 17

18—Manual feeding pick-up roller

19—Separation pad

20—Cleaning brush

21—Cassette pick-up roller

22—Discharge roller

23—Registration rollers

24—Transfer drum

25—Attraction roller

26—Cassette

Figure 1-3 Printer — cross sectional view

Service Guide

1: IntroductionColorwriter LSR 2000 Printer

Print options

The Colorwriter’ s efficient P ostScript capabilities allow customers to

use a variety of applications to create printed pages with text,

images, or a combination of text and images, and print them in

Contone or Halftone mode. The Colorwriter operates over a

network or by printing directly to the Colorwriter’s parallel port.

RIP-While-Print

processing the next image.

The Colorwriter offers an efficient way to print files that have been

saved in PostScript or EPS (Encapsulated PostScript) format. These

files can be downloaded directly to the Colorwriter using the

Fiery XJ Downloader, one of the remote utilities provided with

Colorwriter.

allows the printer to print an image while

With the parallel port option, customers can print documents

directly from applications running on a PC-compatible computer or

a server that is connected to the Colorwriter’s parallel port.

PostScript files can also be printed to the parallel port from the

DOS prompt or the Windows File Manager.

Client utility software

Colorwriter users who are working with Macintosh and

PC-compatible computers using AppleTalk can download fonts and

flies, scan color images, and control spooled print jobs using client

software delivered with the Colorwriter. The network administrator

at the customer site is responsible for loading software onto

computers that will use the Colorwriter over the network.

The Colorwriter user software floppy disks (for Macintosh or PCcompatible computers) contain the following software:

• The Fiery XJ Downloader

download PostScript or EPS files directly to the Colorwriter

without opening the file or the application that created the file.

The Fiery XJ Downloader also allows the customer to manage

the printer fonts installed on the Colorwriter’s hard disk.

is a utility that allows the user to

• The Fiery XJ Spooler

is a utility that allows a user to control

Colorwriter print jobs from a networked Macintosh or PC

computer. It allows the user to view the order and priority of

jobs, delete jobs, and move jobs between queues.

• A set of Adobe Macintosh screen fonts that correspond to the

PostScript printer fonts resident on the Colorwriter.

1-7

Colorwriter LSR 2000 Printer

Service Guide

1: Introduction

• Printer description files that allow remote users to access

PostScript Level 2 features when printing.

• Printer drivers for Macintosh and Windows that allow

applications to communicate with the Colorwriter and use all

the PostScript Level 2 printing features of the Colorwriter.

• Color reference pages allow users to print CMYK and

PANTONE color swatches to view the range of colors available

on the Colorwriter.

The CD-ROM contains the Fiery Print Calibrator

, printer

calibration software that runs on the Macintosh. The CD includes

an online user guide for the Fiery Print Calibrator, and Adobe

Acrobat Reader software for viewing and printing the user guide.

Instructions for installing the Fiery Print Calibrator and Acrobat

Reader are included in the accompanying booklet.

1-8

Chapter 2:

Using the Control Panels 2

The Colorwriter has two control panels: the density control panel

and the printer control panel. The density control panel on the back

of the printer can be used to change color density settings, change

test pattern pages, adjust separation voltage control designation, and

to adjust edge registration. The printer contr ol panel on the front of

the printer allows you to set options and view information about

print jobs and display status information about the printer.

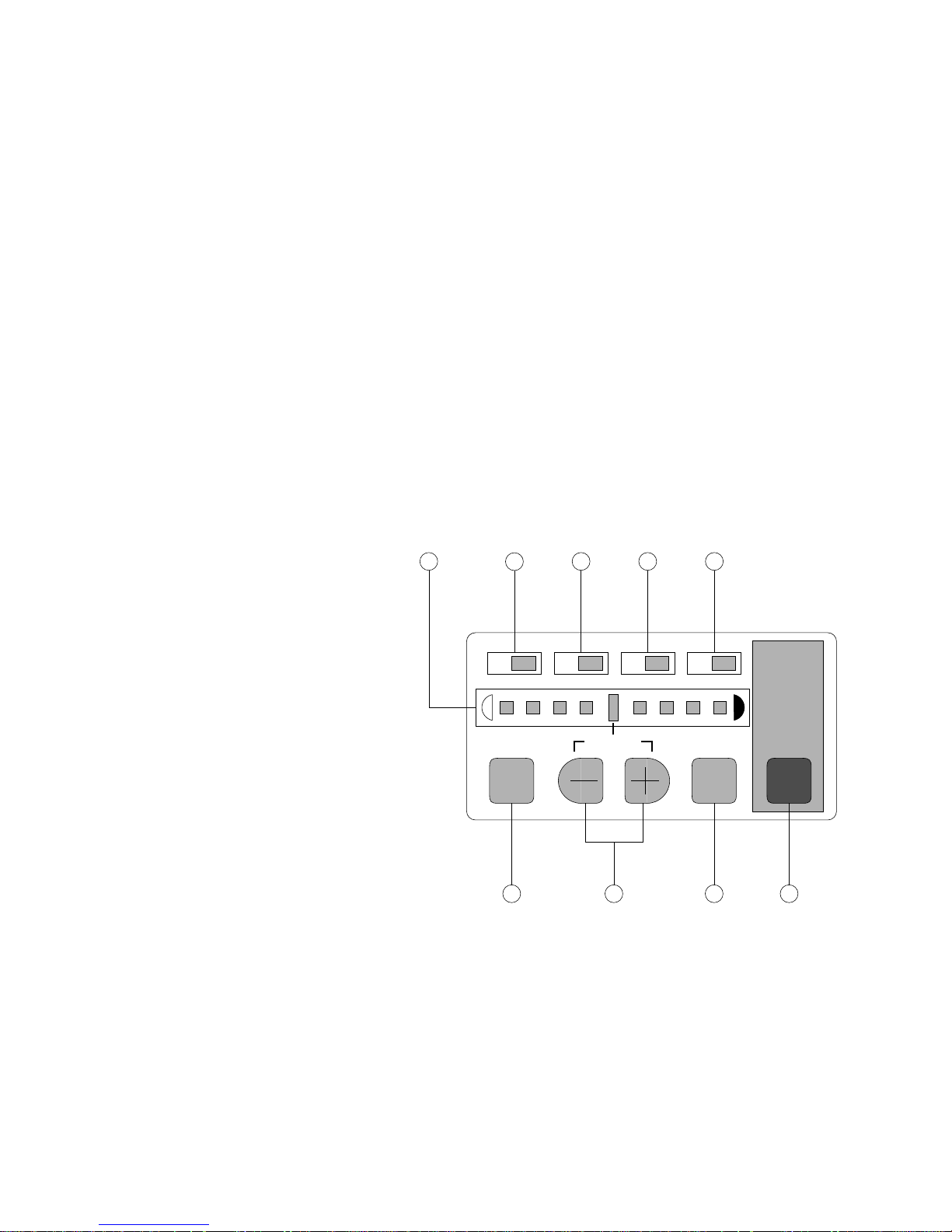

Using the density control panel

This section describes the density control panel on the back of the

printer. Once the printer is installed and powers up correctly, you

can use the density control panel to change color density settings,

test pattern pages, and separation voltage control designation, or to

adjust edge registration.

5

6

M C Y Bk

COLOR

SELECT

4 3 2 1

1—TEST PRINT key

2—ENTER key

3— +/- key

4—COLOR SELECT key

5—Density gauge

DEFAULT ENTER

987

TEST

PRINT

COLOR SELECT indicators:

6—M LED

7—C LED

8—Y LED

9—Bk LED

Figure 2-1 Density control panel

2-1

Colorwriter LSR 2000 Printer

Service Guide

2: Using the Control Panels

•

TEST PRINT

—Prints one of the available test patterns (solid color,

solid white, gradation, horizontal lines, vertical lines, or grid)

and allows you to check the results of a density change.

•

—After you select a new density for one of the color select

ENTER

indicators (M, C, Y, Bk), press this key to save the new density

for the selected color indicator.

—Use these keys to change the density or to select a new test

•

+/-

pattern for the

COLOR SELECT

•

TEST PRINT

—Press this key to select one of the color select

function.

indicators (M, C, Y, Bk) in order to change the density.

•

Density gauge

—Indicates the currently selected color density or

test print pattern.

•

—The color indicator lights when Magenta has been selected.

M

•

—The color indicator lights when Cyan has been selected.

C

•

—The color indicator lights when Yellow has been selected.

Y

•

— The color indicator lights when Black has been selected.

Bk

Density adjustment

Use the following procedure to customize the color density for

printed pages. Note that you can change the color density while

your job is busy printing.

To adjust color density

1. Press the COLOR SELECT key to select a color to change.

The LED lights up indicating the selected color and density (see

Figure 2-2 below).

Selected color Density

M C Y Bk

COLOR

SELECT

DEFAULT ENTER

TEST

PRINT

2-2

Figure 2-2 Color density mode

Loading...

Loading...