Page 1

AlphaPC64Motherboard

User’sManual

Order Number: EC–QLJKB–TE

Revision/Update Information: This document supersedes the

AlphaPC64 Motherboard User’s Manual

(EC–QLJKA–TE).

Digital Equipment Corporation

Maynard, Massachusetts

Page 2

July 1995

Possession, use, or copying of the software described in this publication is authorized only

pursuant to a valid written license from Digital or an authorized sublicensor.

While Digital believes the information included in this publication is correct as of the date of

publication, it is subject to change without notice.

Digital Equipment Corporation makes no representations that the use of its products in the

manner described in this publication will not infringe on existing or future patent rights, nor do

the descriptions contained in this publication imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

© Digital Equipment Corporation 1995.

All rights reserved.

Printed in U.S.A.

AlphaGeneration, DEC, DECchip, DECladebug, Digital, OpenVMS, VAX, VAX DOCUMENT,

VMS, the AlphaGeneration design mark, and the DIGITAL logo are trademarks of Digital

Equipment Corporation.

Digital Semiconductor is a Digital Equipment Corporation business.

Digital UNIX Version 3.2 for Alpha is a UNIX 93 branded product.

Centronics is a trademark of Genicom Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

GRAFOIL is a registered trademark of Union Carbide Corporation.

IEEE is a registered trademark of The Institute of Electrical and Electronics Engineers, Inc.

Intel and UPI are trademarks of Intel Corporation.

MACH is a trademark of Advanced Micro Devices, Inc.

Micron is a registered trademark of Micron Corporation.

Motorola is a registered trademark of Motorola, Inc.

National is a registered trademark of National Semiconductor Corporation.

Microsoft is a registered trademark, NT, and Windows NT are trademarks of Microsoft

Corporation.

OSF and OSF/1 are registered trademarks of Open Software Foundation, Inc.

PHOENIX is a registered trademark of Phoenix Technologies, Ltd.

PS/2 is a registered trademark of International Business Machines Corporation.

SPEC is a trademark of Standard Performance Evaluation Corporation.

TriQuint is a registered trademark of TriQuint Semiconductor, Inc.

UNIX is a registered trademark in the United States and other countries, licensed exclusively

through X/Open Company Ltd.

All other trademarks and registered trademarks are the property of their respective owners.

This document was prepared using VAX DOCUMENT Version 2.1.

Page 3

Contents

About This Manual ........................................... vii

1 AlphaPC64 Introduction

1.1 The AlphaPC64 Motherboard . ........................... 1–1

1.2 System Components and Features........................ 1–1

1.2.1 Memory Subsystem ................................ 1–1

1.2.2 DECchip 21072 Support Chipset . . . ................... 1–4

1.2.3 PAL Control Set ................................... 1–4

1.2.4 Level 2 Cache Subsystem Overview . ................... 1–4

1.2.5 Clock Subsystem Overview .......................... 1–5

1.2.6 PCI Interface Overview . . ........................... 1–5

1.2.7 ISA Interface Overview . . ........................... 1–5

1.2.8 Software Support .................................. 1–6

1.2.9 Component Layout ................................. 1–6

1.2.10 System Summary .................................. 1–6

2 System Jumpers and Connectors

2.1 Configuration Jumpers ................................. 2–1

2.1.1 Software Configuration Jumpers . . . ................... 2–1

2.1.2 Hardware Configuration Jumpers . . ................... 2–6

2.2 AlphaPC64 Board Connectors ........................... 2–7

3 Starting and Using the AlphaPC64

3.1 Hardware Requirements ............................... 3–1

3.2 Software Requirements ................................ 3–2

3.3 Hardware Configuration ............................... 3–2

3.4 Software Configuration ................................ 3–9

3.4.1 Starting Windows NT ARC Firmware .................. 3–9

3.4.2 Going to the Debug Monitor from Windows NT ARC

Firmware ........................................ 3–9

iii

Page 4

3.4.3 Returning to Windows NT ARC Firmware from the Debug

Monitor . ........................................ 3–10

4 Functional Elements

4.1 PCI Interrupts and Arbitration . . ........................ 4–1

4.1.1 System Interrupts . ................................ 4–1

4.1.2 PCI/ISA Arbitration ................................ 4–5

4.2 ISA Devices . ........................................ 4–6

4.3 dc Power Distribution . ................................ 4–7

4.4 Flash ROM (System ROM).............................. 4–9

4.4.1 Special Flash ROM Headers . ........................ 4–9

4.4.2 Flash ROM Structure............................... 4–12

4.4.3 Flash ROM Access . ................................ 4–14

5 Board Requirements and Parameters

5.1 Power Requirements . . ................................ 5–1

5.2 Environmental Characteristics . . . ........................ 5–2

5.3 Physical Board Parameters ............................. 5–2

A Supporting Vendor Products

A.1 Products Included .................................... A–1

A.2 Products Not Included . ................................ A–2

B Technical Support and Ordering Information

B.1 Technical Support .................................... B–1

B.2 Ordering Digital Semiconductor Products . . ................ B–1

B.3 Ordering Associated Literature . . ........................ B–2

B.4 Ordering Third-Party Documentation ..................... B–4

C Warranty Registration Information

iv

Page 5

Index

Figures

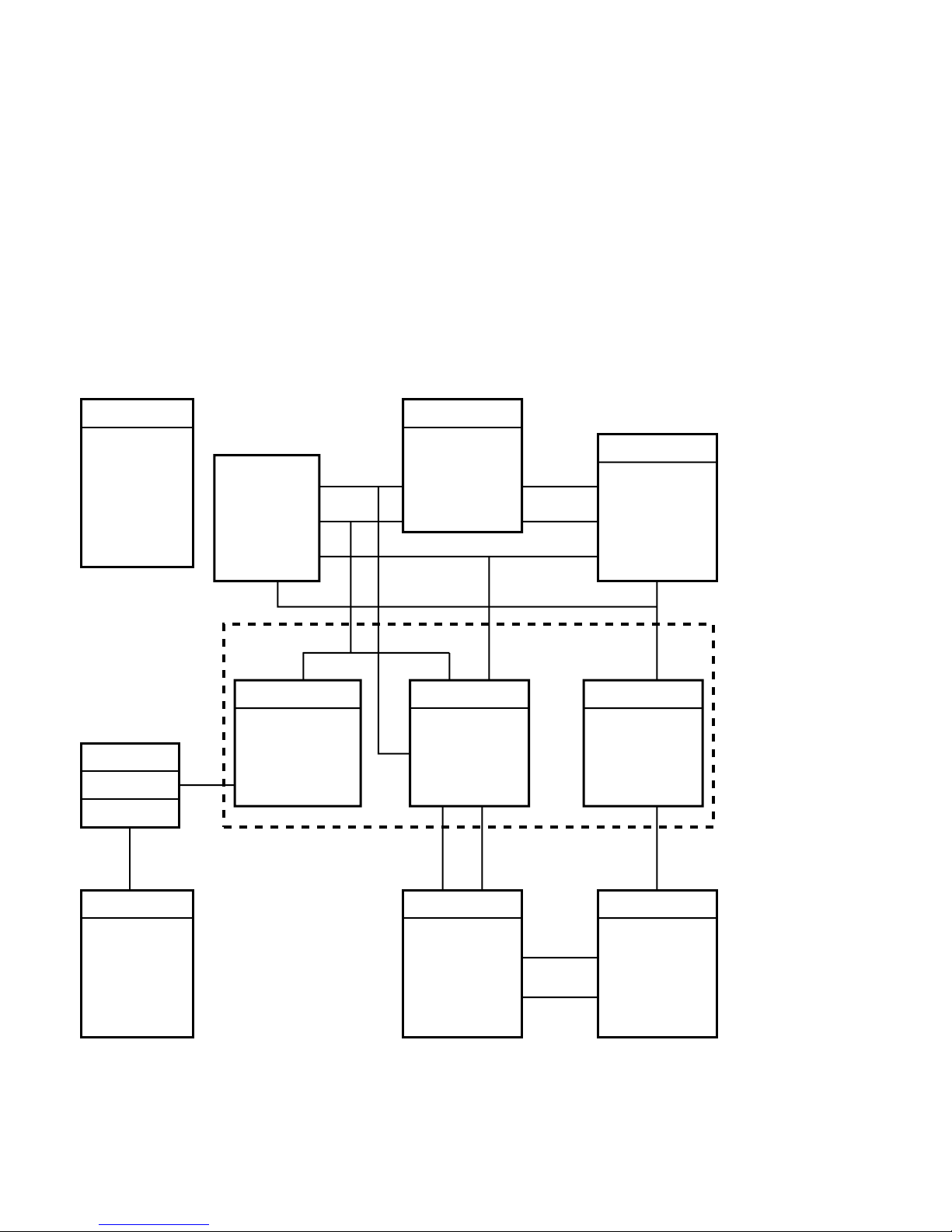

1–1 AlphaPC64 Functional Block Diagram .................. 1–2

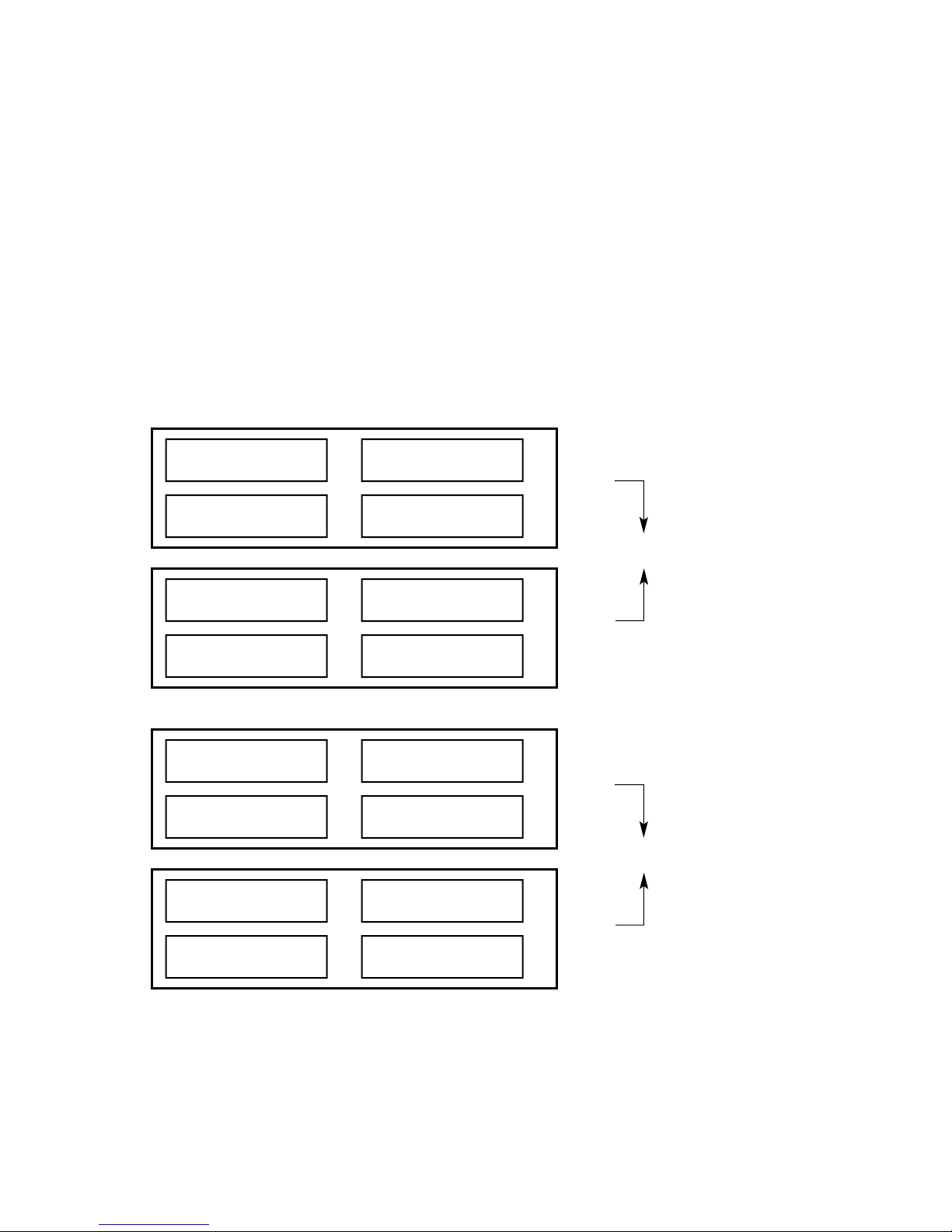

1–2 Maximum and Minimum SIMM Bank Layouts . .......... 1–3

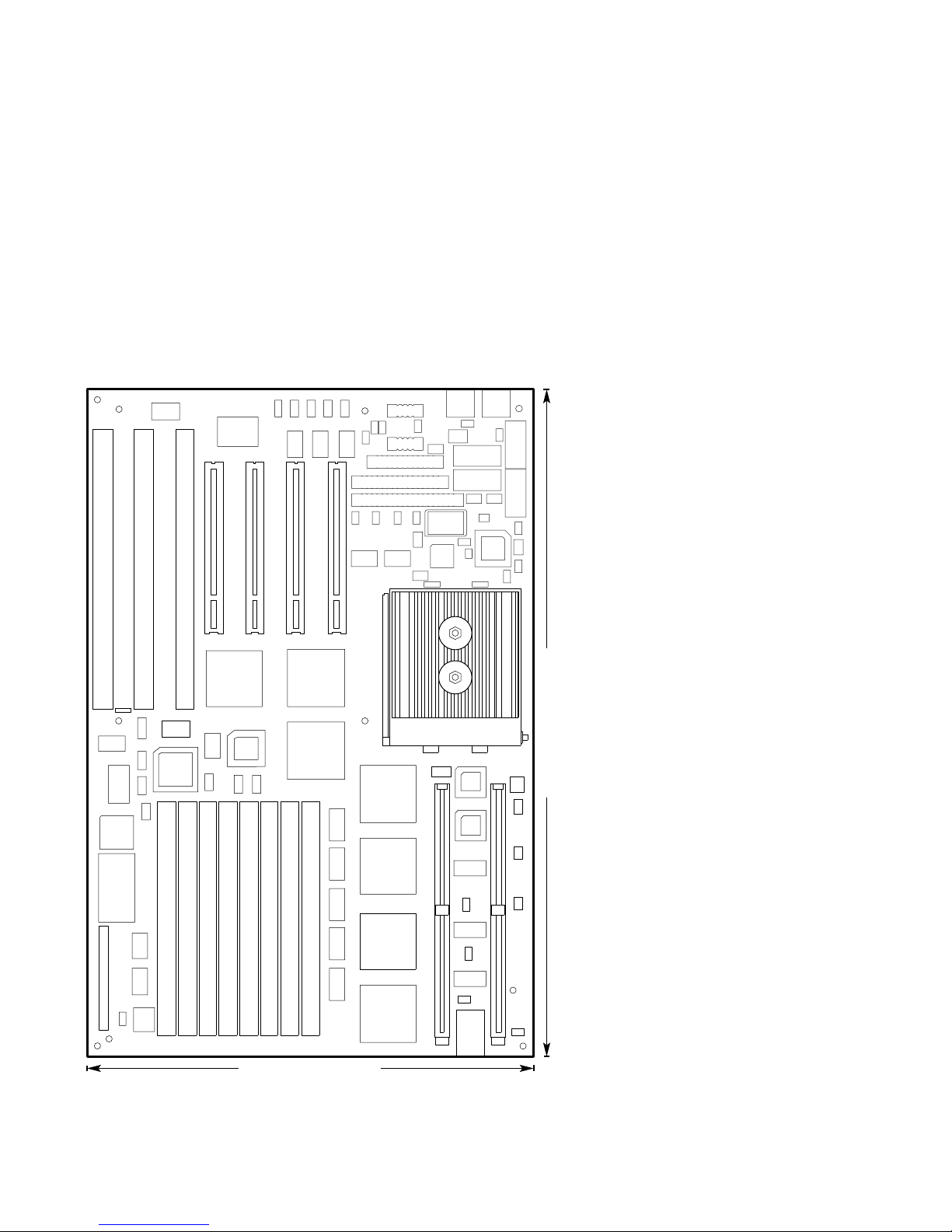

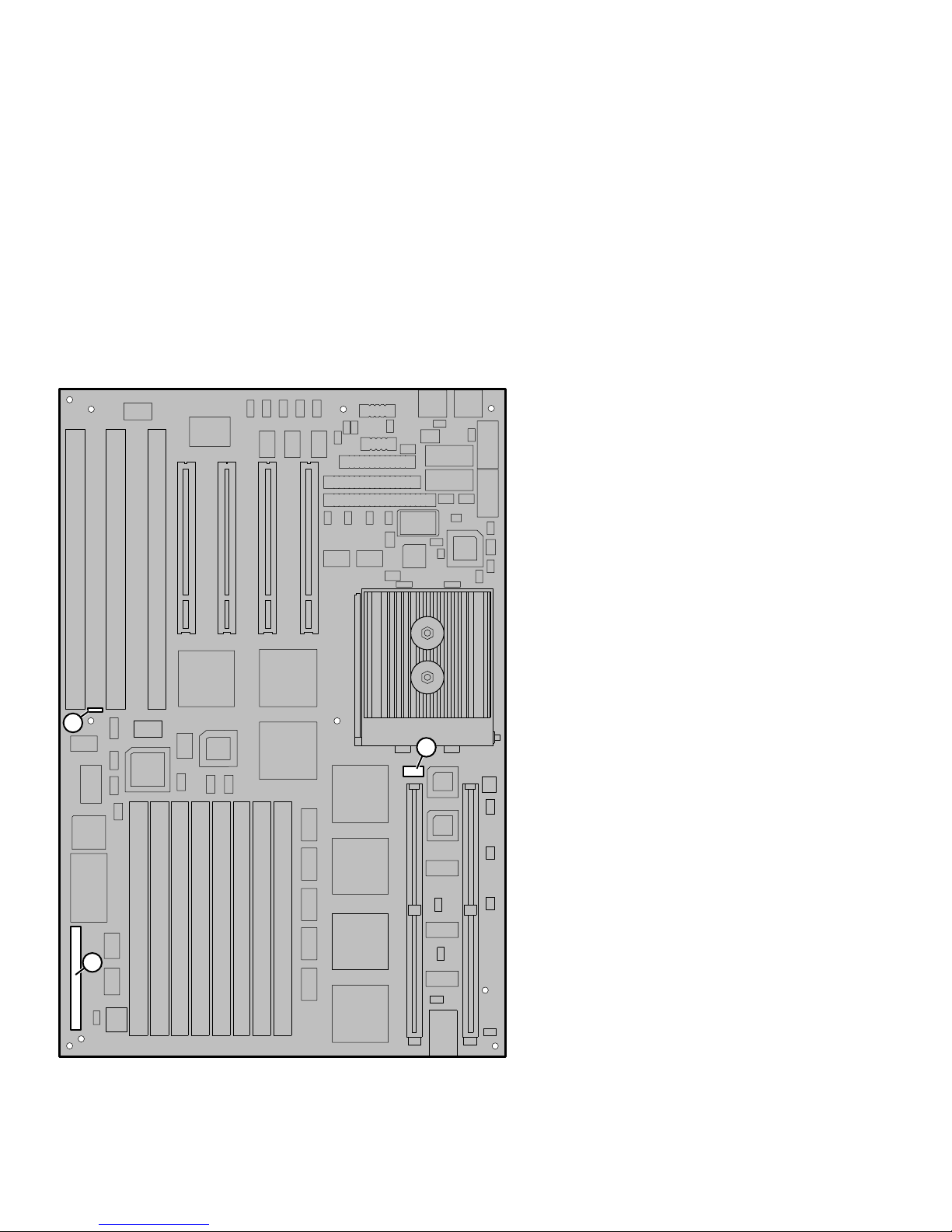

1–3 AlphaPC64 Component Layout and Board Dimensions . . . . . 1–7

2–1 AlphaPC64 Board Jumpers .......................... 2–2

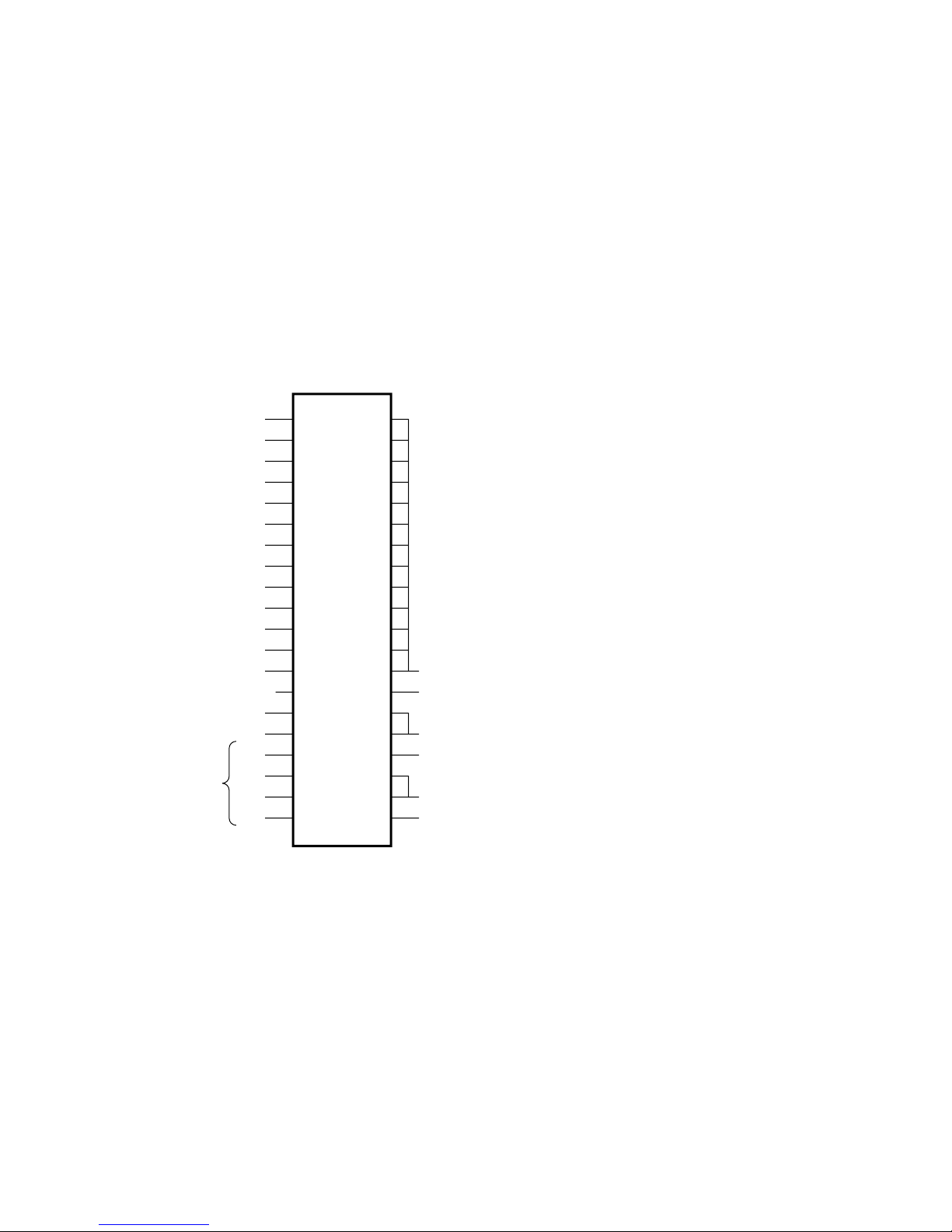

2–2 J3 Jumpers/Connectors . . ........................... 2–3

2–3 AlphaPC64 Board Connectors ........................ 2–8

3–1 Fan/Heat Sink Assembly . ........................... 3–4

3–2 AlphaPC64 Power Connectors ........................ 3–7

4–1 Interrupt Control and PCI Arbitration .................. 4–2

4–2 Interrupt and Interrupt Mask Registers ................ 4–5

4–3 ISA Devices . . . ................................... 4–6

4–4 dc Power Distribution . . . ........................... 4–8

4–5 Special Header Content . . ........................... 4–9

5–1 Board Component Layout ........................... 5–3

Tables

1–1 L2 Cache SIMM Sizes . . . ........................... 1–5

1–2 AlphaPC64 Summary ............................... 1–8

2–1 Jumper Position Descriptions......................... 2–4

2–2 AlphaPC64 Board Jumpers .......................... 2–6

2–3 Module Connector Descriptions ....................... 2–9

4–1 CPU Interrupt Assignment .......................... 4–3

4–2 Special Header Entry Descriptions . ................... 4–10

4–3 Higher 512KB Flash ROM Image Selection .............. 4–12

5–1 Power Supply dc Current Requirements (275 MHz)........ 5–1

5–2 Board Component Descriptions ....................... 5–4

v

Page 6

Page 7

This manual describes Digital’s AlphaPC64 motherboard, a module for

computing systems based on the Alpha 21064A microprocessor and the

DECchip 21072 chipset.

Audience

This guide is intended for users of the AlphaPC64 to assist them in installing

the board and populating it with memory modules and peripheral cards.

Scope

This guide describes the features, configuration, and installation of the

AlphaPC64. This guide does not include specific bus specifications (for

example, PCI or ISA buses). Additional information is available in the

appropriate vendor and IEEE specifications. See Appendix B for information

about how to obtain additional technical support and how to order additional

documentation.

Content

This guide contains the following chapters and appendixes:

About This Manual

• Chapter 1, AlphaPC64 Introduction, is an overview of the AlphaPC64,

including its components, uses, and features.

• Chapter 2, System Jumpers and Connectors, describes the user

environment configuration; board connectors and functions; jumper

functions; and identifies jumper and connector locations.

• Chapter 3, Starting and Using the AlphaPC64, lists additional hardware

and software requirements, provides information on how to configure the

hardware and software, and describes the board startup procedures.

• Chapter 4, Functional Elements, describes some of the functional elements

of the AlphaPC64, such as, interrupt assignments, flash ROM contents,

and power distribution.

vii

Page 8

• Chapter 5, Board Requirements and Parameters, describes the AlphaPC64

power and environmental requirements, and identifies major board

components.

• Appendix A, Supporting Vendor Products, lists suggested vendor sources

for supporting components, such as, power supply, SIMMs, enclosure, and

so forth.

• Appendix B, Technical Support and Ordering Information, describes how to

obtain Digital Semiconductor information and technical support, and how

to order Digital Semiconductor products and associated literature.

• Appendix C, Warranty Registration Information, provides information on

how to register your AlphaPC64 motherboard and be notified of changes

and updates.

Document Conventions

This section provides the conventions used in this document.

Caution: Cautions indicate potential damage to equipment or data.

Note: Notes provide additional information.

Numbering: All numbers are decimal or hexadecimal unless otherwise

indicated. In case of ambiguity, a subscript indicates the radix of nondecimal

numbers. For example, 19 is a decimal number, but 1916and 19A are

hexadecimal numbers.

Extents: Extents are specified by a single number, or a pair of numbers in

angle brackets ( < >) separated by a colon (: ) and are inclusive. For example,

bits <7:3> specify an extent including bits 7, 6, 5, 4, and 3. Multiple bit fields

are shown as extents.

Register Figures: Register figures have bit and field position numbering

starting at the right (low-order) and increasing to the left (high-order).

Signal Names: Signal names in text are printed in boldface lowercase type.

For example, ‘‘ . . . bits data<127:0> are delivered to the Bcache SIMM

connectors . . . ’’

viii

Page 9

AlphaPC64 Introduction

This chapter provides an overview of the AlphaPC64, its components, features,

and uses.

1.1 The AlphaPC64 Motherboard

The AlphaPC64 Motherboard (AlphaPC64) is a module for computing systems,

based on the Alpha 21064A microprocessor and the DECchip 21072 chipset.

The AlphaPC64 runs the Windows NT operating system. For information

on Digital UNIX or OpenVMS operating system support, contact your local

distributor or your Digital sales representative.

1.2 System Components and Features

The AlphaPC64 is implemented in industry-standard parts and uses a 21064A

microprocessor (CPU) running at 200 MHz to 275 MHz. The functional

components are shown in Figure 1–1 and are introduced in the following

subsections.

1.2.1 Memory Subsystem

The AlphaPC64 memory subsystem supports DRAM memory arrays of 16MB

to 512MB with a 128-bit data bus. The memory is contained in two banks of

four commodity single inline memory modules (SIMMs). Each SIMM is 36 bits

wide, with 32 data bits, 1 parity bit, and 3 unused bits with 70-ns or less

access. Figure 1–2 shows the maximum and minimum SIMM bank layouts.

The following SIMM sizes are supported:

1

1M x 36 2M x 36 4M x 36 8M x 36 16M x 36

AlphaPC64 Introduction 1–1

Page 10

1.2 System Components and Features

Figure 1–1 AlphaPC64 Functional Block Diagram

21064A Support

- TriQuint PLL

Clock

- External Clock

Oscillator

- Serial Boot ROM

- Power Supply

- Supervisor

- System Clocking

Alpha 21064A

Microprocessor

Running at

200 MHz to

275 MHz

L2 Cache

Control

Address

21072 Chipset

DECchip 21071-DA

- PCI Bridge

PCI Devices *

PCI Arbitration

ISA Interface

*Three PCI Expansion Slots with

One Shared Expansion Slot

ISA Expansion Memory Buffering

PCI

Bus

- 208-Pin Package

L2 Cache Interface

- L2 Cache PALs

- Address Buffers

tag_adr

data<127:0>

Address

DECchip 21071-CA

- Cache/Memory

Control

- 208-Pin Package

Memory

Control

buff_

address

oe weand

Check Bits<21, 14, 7, 0>

data<15:0>

AddressISA Bus

- 512KB

- 2MB

- 8MB

- Longword Parity

DECchip 21071-BA

- 128-Bit Data Path

- Requires Four

DECchip

21071-BA Chips

Memory

data<127:0>

L2 Cache SIMMs

Memory SIMMs

- 2 or 3 Expansion

Slots

- National 87312

- Intel 8242 Mouse

and Keyboard

- System Support

- IDE

1–2 AlphaPC64 Introduction

ABT162244

Buffers

b_addr

b_mctl

- 128-bit Data Path

- Longword Parity

- 16MB to 512MB

- 2 Banks

LJ04129A.AI5

Page 11

1.2 System Components and Features

Figure 1–2 Maximum and Minimum SIMM Bank Layouts

Maximum 512MB DRAM Layout - Populated with 16M x 36 SIMMs

DRAM 2 - 64MB SIMM

memData64 - 95 + Parity

DRAM 3 - 64MB SIMM

memData96 - 127 + Parity

DRAM 2 - 64MB SIMM

memData64 - 95 + Parity

DRAM 3 - 64MB SIMM

memData96 - 127 + Parity

Minimum 16MB DRAM Layout - Populated with 1M x 36 SIMMs

DRAM 2 - 4MB SIMM

memData64 - 95 + Parity

DRAM 3 - 4MB SIMM

memData96 - 127 + Parity

DRAM 2

Unpopulated

DRAM 3

Unpopulated

DRAM 0 - 64MB SIMM

J9

memData0 - 31 + Parity

DRAM 1 - 64MB SIMM

J8

memData32 - 63 + Parity

DRAM 0 - 64MB SIMM

J5

memData0 - 31 + Parity

DRAM 1 - 64MB SIMM

J4

memData32 - 63 + Parity

J9

J8

J5

J4

DRAM 0 - 4MB SIMM

memData0 - 31 + Parity

DRAM 1 - 4MB SIMM

memData32 - 63 + Parity

DRAM 0

Unpopulated

DRAM 1

Unpopulated

J11

Bank 0

256MB

J10

512MB

J7

Bank 1

256MB

J6

J11

Bank 0

16MB

J10

16MB

J7

Bank 1

0MB

J6

LJ04134A.AI

AlphaPC64 Introduction 1–3

Page 12

1.2 System Components and Features

1.2.2 DECchip 21072 Support Chipset

The 21064A is supported by a DECchip 21072 ASIC chipset (21072), with a

128-bit memory interface. The chipset consists of the following three chips:

• DECchip 21071-CA (21071-CA) provides the interface from the CPU to

cache and main memory, and includes the cache and memory controller.

• DECchip 21071-BA (21071-BA) provides a 32-bit data path from the CPU

to memory and I/O. Four chips provide the 128-bit interface.

• DECchip 21071-DA (21071-DA) provides an interface from the CPU to the

peripheral component interconnect (PCI) bus.

The chipset includes the majority of functions required for a high-performance

PC or workstation, requiring minimum discrete logic on the motherboard. The

chipset provides flexible and generic functions to allow its use in a wide range

of systems.

For more information on the DECchip 21072 chipset, see the DECchip 21071

and DECchip 21072 Core Logic Chipsets Data Sheet.

1.2.3 PAL Control Set

The AlphaPC64 contains a 4-PAL control set and includes the following:

• Two 16V8-5 PALs provide L2 cache output-enable and write-enable

functions.

• One 22V10-25 PAL provides interrupt address decode functions and utility

bus (Ubus) control.

• One MACH210-20 PAL provides the PCI and ISA interrupts.

1.2.4 Level 2 Cache Subsystem Overview

The external level 2 (L2) cache subsystem supports 512KB, 2MB, or 8MB

cache sizes by using a 128-bit data bus. The L2 cache size can be reconfigured

through onboard hardware and software jumpers.

The AlphaPC64 supports the L2 cache SIMM sizes shown in Table 1–1. SIMM

types currently available and supported are 512KB @15 ns and 2MB @12 ns.

Two SIMMs are required per system. See Appendix A for ordering information.

1–4 AlphaPC64 Introduction

Page 13

Table 1–1 L2 Cache SIMM Sizes

L2 Cache Size Static RAM Access Times

512KB 6 ns, 8 ns, 10 ns, 12 ns, 15 ns

2MB 6 ns, 8 ns, 10 ns, 12 ns, 15 ns

8MB 6 ns, 8 ns, 10 ns, 12 ns, 15 ns

1.2.5 Clock Subsystem Overview

The clock subsystem provides clocks to the 21072 chipset and PCI devices. Two

oscillators provide clocks for the ISA and combination chip functions.

1.2.6 PCI Interface Overview

The PCI interface provides a selectable PCI speed between 25 MHz and

33 MHz (based on the 21064A clock divisor). An Intel 82378ZB Saturn IO

(SIO) chip provides a PCI-to-ISA bridge.

The PCI has three dedicated slots and one shared slot with the ISA.

1.2.7 ISA Interface Overview

The ISA provides an expansion bus and the following system support functions:

1.2 System Components and Features

• Mouse and keyboard controller functions provided through an Intel 8242

chip

• A National 87312 chip used as the combination chip providing a diskette

controller; two universal asynchronous receiver–transmitters (UARTs); an

integrated device electronics (IDE) interface; a bidirectional parallel port;

and an interface to the utility bus (Ubus) for ISA interrupts and jumper

status

• A time-of-year (TOY) function provided by a Dallas Semiconductor DS1287

chip

• A 1MB flash ROM memory using the Intel 28F008SA chip

The ISA has two dedicated expansion slots and one shared expansion slot with

the PCI.

AlphaPC64 Introduction 1–5

Page 14

1.2 System Components and Features

1.2.8 Software Support

Software support includes an industry-standard, 1MB flash ROM containing

Windows NT ARC firmware and debug monitor code. The debug monitor

allows you to:

• Download files through serial port, I/O diskette, and optional Ethernet

port.

• Load data from the flash ROM through the debug monitor.

• Examine and deposit the AlphaPC64 system register, 21064A internal

processor registers (IPRs), and I/O mapped registers.

• Examine and modify DRAM and I/O mapped memory.

• Disassemble CPU instructions in memory.

• Transfer control to programs in memory.

• Perform native debugging, including breakpoints and single stepping.

• Perform full source-level debugging, using DECladebug running on a host

communicating through an Ethernet connection.

Development code can be generated on a host system and loaded into the

AlphaPC64 through the serial line, optional Ethernet port, diskette, or flash

ROM. Full design database and user documentation are provided.

A serial ROM (SROM) contains the 21064A initialization code. When reset

is deasserted, the contents of the SROM are read into the Icache and are

executed to perform initialization. During initialization, code is loaded from

the flash ROM to memory. Following initialization, control is transferred to the

code in memory.

1.2.9 Component Layout

Figure 1–3 shows the AlphaPC64 board component layout and dimensions.

1.2.10 System Summary

Table 1–2 lists the physical, performance, and operating characteristics of the

AlphaPC64 motherboard.

1–6 AlphaPC64 Introduction

Page 15

1.2 System Components and Features

Figure 1–3 AlphaPC64 Component Layout and Board Dimensions

22.1 cm (8.7 in ± 0.0005 in)

Scale = 90%

33.0 cm (13.0 in ± 0.0005 in)

LJ-04458.AI5

AlphaPC64 Introduction 1–7

Page 16

1.2 System Components and Features

Table 1–2 AlphaPC64 Summary

Characteristic Description

Operating Systems

Supported operating

systems

Microsoft Windows NT. For information on Digital UNIX

or OpenVMS operating system support, see your local

distributor or your Digital sales representative.

System Characteristics

CPU and clock speed Alpha 21064A at 200 MHz, 233 MHz, or 275 MHz

CPU upgradable ZIF socket for Alpha 21064A upgrade

Instruction issue Up to 2 instructions issued per clock cycle

Word size 64 bits

Address size 34-bit physical address, 43-bit virtual address

Floating-point format VAX (F and G) and IEEE (S and T) data types

Memory (DRAM)

1

Minimum DRAM 16MB plus parity

Maximum DRAM 512MB plus parity

Memory (ROM) 1MB flash ROM

External L2 cache Configurable for 512KB, 2MB, 8MB (128-bit data)

Memory bus width 128 bits plus parity

Performance metrics

Alpha 21064A running

at 275 MHz

Cache SPECint92 SPECfp92

512KB @15 ns 176 217

2MB @12 ns 193 259

2MB @8 ns 205 272

1

Minimum DRAM recommended:

16MB for Windows NT

32MB for Digital UNIX

32MB for OpenVMS

1–8 AlphaPC64 Introduction

(continued on next page)

Page 17

1.2 System Components and Features

Table 1–2 (Cont.) AlphaPC64 Summary

Characteristic Description

Graphics

Graphics options Refer to the Microsoft Hardware Compatibility List for

Input/Output

Input device interfaces PS/2 style keyboard and mouse

Serial Two RS423-compatible (9-position) serial communications

Parallel One parallel (Centronics compatible) communications port

Bus options Total of 6 option slots

PCI bus Supports four 5-V/32-bit PCI option slots at 33 MHz

ISA bus Supports three 16-bit ISA option slots

IDE One IDE interface supporting up to 2 drives

Diskette One 82077-compatible diskette controller supporting up to 2

Physical Characteristics

Form factor Baby-AT-size system board

Width/depth 22.1 cm (8.7 in)

Weight 840 grams (1.85 lb) with high-profile heat sink

Windows NT to determine which graphics cards are

supported. See Section B.4 for information on how to obtain

the listing.

ports

maximum–one long and three short cards

drives with 1.44MB and 2.88MB formats

2

33.0 cm (13.0 in)

(continued on next page)

AlphaPC64 Introduction 1–9

Page 18

1.2 System Components and Features

Table 1–2 (Cont.) AlphaPC64 Summary

Characteristic Description

Environmental Characteristics (Operating)

Temperature 10°C to 40°C (50°F to 104°F)

Temperature change

rate (maximum)

Relative humidity

Maximum wet bulb

Minimum dew point

EMC compliance Compliance certification is the responsibility of the system

Shock and vibration Passing of shock and vibration tests is dependent on the

20°C/hr (36°F/hr)

10%–90% noncondensing

32°C (90°F)

2°C (36°F)

integrator. The AlphaPC64 was tested in industry-

representative enclosures to prove feasibility of emissions

compliance.

method used to mount the system board, the design of the

enclosure, and how the enclosure is supported. Testing is

the responsibility of the system integrator.

1–10 AlphaPC64 Introduction

Page 19

System Jumpers and Connectors

The AlphaPC64 uses jumpers to implement variations in clock frequency and

L2 cache size and speed. These jumpers must be configured for the user’s

environment. Onboard connectors are provided for the I/O, memory SIMMs,

serial and parallel peripherals, integrated device electronics (IDE) devices, and

L2 cache SIMMs.

After the module is configured, you can apply power and run the debug

monitor. The debug monitor and its commands are described in the Alpha

Microprocessors Evaluation Board Debug Monitor User’s Guide. Appendix B

provides information about other software design tools.

2.1 Configuration Jumpers

The software and hardware configuration jumpers are identified in Figures 2–1

and 2–2, and are described in Tables 2–1 and 2–2.

2.1.1 Software Configuration Jumpers

The software configuration jumpers are completely programmable. Each

jumper position is described in Table 2–1.

2

The SROM code defines the software configuration jumpers sp_bit<7:0>,as

shown in Figure 2–2 (see also Chapter 4).

The board ships with the jumpers listed in Tables 2–1 and 2–2 in the default

position.

System Jumpers and Connectors 2–1

Page 20

2.1 Configuration Jumpers

Figure 2–1 AlphaPC64 Board Jumpers

J16

J15

J3

2–2 System Jumpers and Connectors

Scale = 90%

LJ-04459.AI5

Page 21

Figure 2–2 J3 Jumpers/Connectors

2.1 Configuration Jumpers

To Speaker

sysclkdiv

jmp_irq2

jmp_irq1

jmp_irq0

toy_clr

sp_bit0

sp_bit1

sp_bit2

sp_bit3

sp_bit4

sp_bit5

sp_bit6

sp_bit7

hd_act_l

hd_led_l

spkr

Vdd

gnd

Vdd

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

2

4

6

8

gnd

reset_button

gnd

key_lock

gnd

power_led_l

LJ-04132.AI

System Jumpers and Connectors 2–3

Page 22

2.1 Configuration Jumpers

Table 2–1 Jumper Position Descriptions

Select Bit

Register Bit

Name Function

sp_bit7 BOOT_OPTION Jumper out—Boot first image in flash ROM.

Jumper in (default)—Boot one of several alternate

images in flash ROM as specified by NVRAM

location 3F in TOY RAM. See Section 4.4.

sp_bit6 MINI_DEBUG Jumper out (default)—Boot selected image in

flash ROM.

Jumper in—Trap to SROM debug port (J2).

sp_bit<5:3> BC_SPEED<2:0> L2 cache speed selection is shown here.

BC_SPEED

<2> <1> <0>

J3-21 J3-19 J3-17 L2 Cache Period

1

In

In In Out

In In Reserved

2

6ns

In Out In 8 ns

In Out Out 10 ns

Out In In 12 ns (default for

21A02–A3 and 21A02–A4)

Out In Out 15 ns (default for

21A02–A5)

Out Out In Reserved

Out Out Out Reserved

1

Jumper in (logical 0)

2

Jumper out (logical 1)

2–4 System Jumpers and Connectors

(continued on next page)

Page 23

2.1 Configuration Jumpers

Table 2–1 (Cont.) Jumper Position Descriptions

Select Bit

sp_bit<2:0> BC_SIZE<2:0> L2 cache size selection is shown here.

Register Bit

Name Function

<2> <1> <0>

J3-15 J3-13 J3-11 L2 Cache Size

1

In

In In Out

In Out In 1MB

In Out Out 2MB (default for

Out In In 4MB

Out In Out 8MB

Out Out In Reserved

Out Out Out Reserved

BC_SIZE

In In Disables L2 cache

2

512KB (default for

21A02–A5)

21A02–A3 and 21A02–A4)

1

Jumper in (logical 0)

2

Jumper out (logical 1)

System Jumpers and Connectors 2–5

Page 24

2.1 Configuration Jumpers

2.1.2 Hardware Configuration Jumpers

Hardware configuration jumpers are shown in Figure 2–1 and are described in

Table 2–2.

Table 2–2 AlphaPC64 Board Jumpers

Connector Pins Description

L2 Cache Address Lines

J15 4 Adr<22:19> L2 cache

J15-1

Adr19

2

Out

1

In

J15-2

Adr20

J15-3

Adr21

J15-4

Adr22 Size

Out Out Out 512KB (default for

Out Out Out 1MB

In In Out Out 2MB (default for

In In In Out 4MB

In In In In 8MB

Flash ROM

J16 3 Flash ROM update enable/disable connector.

Jumper from pin 1 to pin 2 disables flash ROM update.

Jumper from pin 2 to pin 3 enables flash ROM update

(default).

1

Jumper in (logical 0)

2

Jumper out (logical 1)

(continued on next page)

21A02–A5)

21A02–A3 and

21A02–A4)

2–6 System Jumpers and Connectors

Page 25

2.1 Configuration Jumpers

Table 2–2 (Cont.) AlphaPC64 Board Jumpers

Connector Pins Description

System Clock Functions

J3 4 21064A CPU clock divisor selection.

J3-1

sysclkdiv

In In In In 2

In In In Out 3

In In Out In 4

In In Out Out 5

In Out In In 6

In Out In Out 7

In Out Out In 8

In Out Out Out 9

Divisor 9 is used for 275 MHz (default).

Out In In In 10

Out In In Out 11

Out In Out In 12

Out In Out Out 13

Out Out In In 14

Out Out In Out 15

Out Out Out In 16

Out Out Out Out 17

J3-3

jmp_irq2

Divisor 6 is used for 200 MHz.

Divisor 7 is used for 233 MHz.

J3-5

jmp_irq1

J3-7

jmp_irq0 Divisor

2.2 AlphaPC64 Board Connectors

The module connectors are shown in Figure 2–3 and are described in Table 2–3.

System Jumpers and Connectors 2–7

Page 26

2.2 AlphaPC64 Board Connectors

Figure 2–3 AlphaPC64 Board Connectors

J32

J33

J34

J17 J18 J19

J30

J25

J24

J26

J23J22J21J20

J28

J27

J31

J29

J14

J3

J4 J5 J6 J7 J8 J9 J10 J11

J1

Scale = 90%

2–8 System Jumpers and Connectors

J12

J13

J2

LJ-04457.AI5

Page 27

2.2 AlphaPC64 Board Connectors

Table 2–3 Module Connector Descriptions

Connector Pins Description

PCI Connectors

J23 124 PCI expansion connector 3

J22 124 PCI expansion connector 2

J21 124 PCI expansion connector 1

J20 124 PCI expansion connector 0

ISA Connectors

J19 98 ISA expansion connector 2

J18 98 ISA expansion connector 1

J17 98 ISA expansion connector 0

L2 Cache SIMMs Connectors

J13 160 L2 cache SIMMs connector 1, data<127:64>

J12 160 L2 cache SIMMs connector 0, data<63:00>

Keyboard Connector

J33 6 Keyboard connector

Mouse Connector

J34 6 Mouse connector

(continued on next page)

System Jumpers and Connectors 2–9

Page 28

2.2 AlphaPC64 Board Connectors

Table 2–3 (Cont.) Module Connector Descriptions

Connector Pins Description

J11 72 Bank 0, DRAM 0 SIMM

J10 72 Bank 0, DRAM 1 SIMM

J9 72 Bank 0, DRAM 2 SIMM

J8 72 Bank 0, DRAM 3 SIMM

J7 72 Bank 1, DRAM 0 SIMM

J6 72 Bank 1, DRAM 1 SIMM

J5 72 Bank 1, DRAM 2 SIMM

J4 72 Bank 1, DRAM 3 SIMM

J2 6 SROM test data serial port input connector

Memory SIMMs

SROM Test

Note: This connector can be used as a terminal port for

the Mini-Debugger.

J25 26 Combination chip parallel port connector

J26 40 IDE supports two devices.

J32 10 Combination chip serial communication port 1 (COM1)

J30 10 Combination chip serial communication port 2 (COM2)

J24 34 Combination chip diskette drive connector

2–10 System Jumpers and Connectors

National 87312 Connectors

connector

Note: This connector can be used as a terminal port for

the Debug Monitor.

connector

(continued on next page)

Page 29

2.2 AlphaPC64 Board Connectors

Table 2–3 (Cont.) Module Connector Descriptions

Connector Pins Description

Power Connectors

J27 6 Module power connector (GND, +3.3 V)

Pin Voltage/Signal

1 Ground

2 Ground

3 Ground

4 +3.3 V

5 +3.3 V

6 +3.3 V

J28 6 Module power connector (+3.3 V, GND)

Pin Voltage/Signal

1 +3.3 V

2 +3.3 V

3 +3.3 V

4 Ground

5 Ground

6 Ground

(continued on next page)

System Jumpers and Connectors 2–11

Page 30

2.2 AlphaPC64 Board Connectors

Table 2–3 (Cont.) Module Connector Descriptions

Connector Pins Description

J29 6 Module power connector (GND, –5 V, +5 V [Vdd])

Pin Voltage/Signal

1 Ground

2 Ground

3–5V

4Vdd

5 Vdd

6 Vdd

J31 6 Module power connector (GND, +12 V, –12 V, +5 V

J14 3 CPU fan power and sensor

[Vdd], p_dcok)

Pin Voltage/Signal

1 p_dcok

2 Vdd

3 +12 V

4 –12 V

5 Ground

6 Ground

Note: Power for the AlphaPC64 is provided by a usersupplied, standard PC power supply that includes

3.3 V dc. Digital does not provide this power supply.

Caution: Fan sensor required

The fan must have a built-in sensor that drives a signal

if the airflow stops. The sensor is connected to J14. The

fan supplied with the AlphaPC64 includes an airflow

sensor.

(continued on next page)

2–12 System Jumpers and Connectors

Page 31

2.2 AlphaPC64 Board Connectors

Table 2–3 (Cont.) Module Connector Descriptions

Connector Pins Description

Enclosure Fan

J1 3 Enclosure fan connector (+12 V, GND)

System Reset

J3 (Pins 28, 30) 2 System reset switch connector

Speaker Connector

J3 (Pins 33, 35,

37, 39)

4 Speaker should be connected to pins 33, 35, 37, and 39.

System Jumpers and Connectors 2–13

Page 32

Page 33

Starting and Using the AlphaPC64

This chapter lists hardware, software, and accessories that users must obtain

to completely furnish a functioning computer system. The chapter then

describes how to configure the hardware and software. Finally, the chapter

describes how to start and use the AlphaPC64.

3.1 Hardware Requirements

Before turning on the power to your AlphaPC64, you must provide the

following components in addition to those supplied with your board. The

components listed here round out the complement of parts needed to run the

Windows NT operating system on the AlphaPC64 motherboard.

• An Alpha 21064A microprocessor (200-MHz, 233-MHz, or 275-MHz speed).

• If a 200-MHz or 233-MHz microprocessor is used, the oscillator and PLL

must be changed. Refer to Appendix A for part numbers and sources. The

board ships with parts to complement a 275-MHz microprocessor.

• Four or eight, 72-pin, 36-bit, 5-V, DRAM SIMM memory modules

(connectors J4 through J11). SIMMs must be installed in groups of

four consisting of identical devices. Digital recommends that all SIMMs be

purchased from the same vendor.

3

• Two Alpha L2 cache SRAM SIMMs (connectors J12 and J13). Part

numbers for 512KB or 2MB cache sizes are listed in Appendix A.

• An industry-standard PC power supply that includes a 3.3-V dc output,

rated at a minimum of 275 W (refer to Appendix A).

• A PS/2 compatible 101-key keyboard.

• A PS/2 compatible mouse.

• A supported PCI or ISA bus graphics card, cables, and a compatible

monitor.

• A supported PCI bus SCSI controller card and cables.

Starting and Using the AlphaPC64 3–1

Page 34

3.1 Hardware Requirements

• A SCSI CD–ROM drive.

• An IDE or SCSI hard drive.

• A 3.5-in diskette drive and cable.

• A 9-pin serial line cable.

• A terminal or a serial line connection to a host system with appropriate

cables.

Refer to the Alpha Microprocessors Evaluation Board Windows NT 3.51

Installation Guide provided in the AlphaPC64 Windows NT 3.51 Installation

Kit and the Hardware Compatibility List for Windows NT to determine which

SCSI controllers and graphics cards are supported.

For more information about hardware requirements and for the location of

board connectors and jumpers, see Chapter 2.

3.2 Software Requirements

The following software media is required to install and run the Windows NT

operating system:

• A Windows NT 3.5 or 3.51 CD–ROM

• An AlphaPC64 Windows NT 3.5 or 3.51 installation diskette

3.3 Hardware Configuration

Once you have acquired the necessary hardware, it must be assembled into

a system. This section lists the necessary steps. The system does not have

to be assembled in the order presented. However, if you are installing the

motherboard into an enclosure, Digital recommends that you install the

microprocessor and heat sink first.

Caution: Static-Sensitive Component

Due to the sensitive nature of electronic components to static electricity,

Digital strongly advises that anyone handling the Alpha 21064A wear

a properly grounded antistatic wrist strap. Use of antistatic mats,

ESD approved workstation, or exercising other good ESD practices is

recommended.

3–2 Starting and Using the AlphaPC64

Page 35

3.3 Hardware Configuration

1. Install the Alpha 21064A microprocessor in ZIF socket U36.

a. Observe antistatic precautions.

b. Lift the ZIF socket actuator handle to a full 90° angle.

c. Make sure that all the pins on the Alpha 21064A are straight.

d. The ZIF socket and Alpha 21064A are keyed to allow for proper

installation. Align the Alpha 21064A, with its missing AD01 pin, with

the corresponding plugged AD01 position on the ZIF socket. Gently

lower into position.

e. Close the ZIF socket actuator handle to its locked position.

2. If you are installing a 275-MHz microprocessor, you do not need to change

any other components or associated jumper settings.

If you are installing a 200-MHz or 233-MHz microprocessor, you must

replace oscillator U41 and PLL U40 with the appropriate parts. Refer to

Appendix A for part listings. You must also reconfigure the clock divisor

jumpers on header J3, as described in Table 2–2.

3. Install the heat sink and heat sink fan as directed in the following steps.

Heat sinks and accompanying fans are available from Digital in kit form,

or from recommended vendors as kits or component piece parts.

A TS30 manual nut/torque driver with the following attachments is

required to affix the heat sink and fan to an Alpha 21064A:

• 1/4-in hex bit

• 3/8-in socket with 1/4-in hex drive

• #2 Phillips screwdriver bit

Install the heat sink only after the Alpha 21064A has been assembled

to the board ZIF socket.

Note

Starting and Using the AlphaPC64 3–3

Page 36

3.3 Hardware Configuration

Refer to Figure 3–1 for heat sink and fan assembly details.

Figure 3–1 Fan/Heat Sink Assembly

Screw, 6-32 x 0.875 in

Qty 4

Guard, Fan

Fan

Clip, Heat Sink/Chip/Fan

Nut, Hex, 10-32, 2011-T3

Aluminum, 0.375 in Across

Flats, Qty 2

Torque to 15 +/- 2 in-lb

Heat Sink, with Fan

Mounting Holes

3–4 Starting and Using the AlphaPC64

Thermal Pad

Alpha 21064A

LJ-04412.AI5

Page 37

3.3 Hardware Configuration

a. Put the GRAFOIL thermal pad in place. The GRAFOIL pad is used

to improve the thermal conductivity between the chip package and the

heat sink by replacing micro air pockets with a less insulative material.

Perform the following steps to position the GRAFOIL pad:

1) Perform a visual inspection of the package slug to ensure that it is

free of contamination.

2) Wearing clean gloves, pick up the GRAFOIL pad. Do not do this

with bare hands because skin oils can be transferred to the pad.

3) Place the GRAFOIL pad on the gold-plated slug surface and align

it with the threaded studs.

b. Attach the microprocessor heat sink. The heat sink material is clear

anodized, hot-water-sealed, 6061-T6 aluminum. The nut material is

2011-T3 aluminum (this grade is critical). Perform the following steps

to attach the heat sink:

1) Observe antistatic precautions.

2) Align the heat sink holes with the threaded studs on the ceramic

package.

3) Handle the heat sink by the edges and lower it on to the chip

package, taking care not to damage the stud threads.

4) Set a calibrated torque driver to 15 in-lb,62 in-lb, (1.7 N m,

6

0.2 N m). The torque driver should have a mounted 3/8-in

socket.

5) Insert a nut into the 3/8-in socket, place on one of the studs, and

tighten to the specified torque. Repeat for second nut.

6) If the sink/chip/fan clip is used, install it properly by positioning

it over the assembly and hooking its ends around the ZIF socket

retainers.

Starting and Using the AlphaPC64 3–5

Page 38

3.3 Hardware Configuration

c. Perform the following steps to attach the heat sink fan assembly:

1) Place the fan assembly on top of the heat sink, aligning the fan

mounting holes with the corresponding threaded heat sink holes.

Align the fan so that the fan power/sensor wires exit the fan closest

to connector J14 (see Figure 2–3). Fan airflow must be directed

into the heat sink (fan label facing down toward the heat sink).

2) Place the fan guard on top of the fan. Orient the guard so that the

corner mounting areas lay flush against the heat sink.

3) Secure the fan and fan guard to the heat sink with four

6–3220.875-in screws.

4) Plug the fan power/sensor cable into connector J14 (see

Figure 2–3).

4. Install the two L2 cache SRAM SIMMs into sockets J12 and J13. Refer to

Table 2–3 for socket locations.

5. Install either four or eight system memory DRAM SIMMs. Refer to

Section 1.2.1 for configuration information and Table 2–3 for socket

locations.

a. Observe antistatic precautions. Handle SIMMs at the edges only to

prevent damage.

b. SIMMs must be installed in groups of four consisting of identical

devices.

c. Hold the SIMM at an angle with the notch facing the key in the socket.

d. Firmly push the module into the connector and stand the module

upright.

e. Make sure that the SIMM snaps into the metal locking clips on both

ends.

6. If you intend to mount the motherboard in a system enclosure, do so now.

Install the power supply into the enclosure first, then the motherboard.

Appendix A lists a suggested enclosure and a suggested power supply.

The enclosure you use should be able to accept a standard baby-AT-size

motherboard.

7. Connect the power supply to the motherboard, as shown in Figure 3–2,

with standard power to J29 and J31 and with 3.3-V dc power to J27 and

J28.

3–6 Starting and Using the AlphaPC64

Page 39

Figure 3–2 AlphaPC64 Power Connectors

AlphaPC64 Board

J28

J27

J31

1

1

1

1

3.3 Hardware Configuration

J27

Pin Voltage/Signal

1 Ground

2 Ground

3 Ground

4 +3.3 V

5 +3.3 V

6 +3.3 V

Alpha 21064A

Microprocessor

J29

J28

Pin Voltage/Signal

1 +3.3 V

2 +3.3 V

3 +3.3 V

4 Ground

5 Ground

6 Ground

J29

Pin Voltage/Signal

1 Ground

2 Ground

3 −5 V

4 (+5 V)

Vdd

5 (+5 V)

Vdd

6 (+5 V)

Vdd

J31

Pin Voltage/Signal

p_dcok

1

2 (+5 V)

Vdd

3 +12 V

4 −12 V

5 Ground

6 Ground

MK−2306−33

Starting and Using the AlphaPC64 3–7

Page 40

3.3 Hardware Configuration

8. If you are using an enclosure, mount the 3.5-in diskette drive, hard drive,

and CD–ROM drive. Refer to the manufacturer’s instructions for installing

these devices.

9. Connect the 3.5-in diskette drive. The 34-pin diskette drive cable goes from

connector J24 on your AlphaPC64 to the diskette drive. The drive should

be connected at the very end of the cable closest to the twist in the cable.

Make sure to insert the connector in the proper orientation so that pin 1

on the cable matches pin 1 on the board header (as indicated on the board).

Attach a power connector to the drive.

10. Attach a SCSI cable to the SCSI controller card and install the card in a

free PCI or ISA connector, depending on the card you are using. Attach

the opposite end of the cable to the CD–ROM drive. If you will be using an

IDE hard drive, attach a SCSI bus terminator at the CD–ROM drive.

If you will be using a SCSI hard drive, daisy-chain a SCSI cable from the

CD–ROM drive to the hard drive. Attach a SCSI bus terminator to the

hard drive. Verify that a unique SCSI ID is assigned to each device you

attach to the SCSI bus.

11. If you will be using an IDE hard drive, attach your IDE cable to connector

J26 in the proper orientation and at the opposite end to your hard drive.

The disk should be configured as the primary device on the IDE bus. Refer

to the manufacturer’s instructions for setting up the hard drive.

12. Install the graphics card into either a PCI or ISA connector, depending on

the card you are using. Connect the graphics card to a compatible monitor,

following the graphics card manufacturer’s instructions.

13. Connect the keyboard cable to connector J33.

14. Connect the mouse cable to connector J34.

15. Connect a 9-pin serial port adapter cable to the COM1 connector at J32.

Insert the connector in the proper orientation, so that pin 1 on the cable

matches pin 1 on the board header (as indicated on the board).

16. Connect your host system or terminal to the COM1 port by using an

appropriate cable arrangement. Set the host system communications port

or terminal to 9600 baud, 8 data bits, 1 stop bit, no parity.

17. Connect miscellaneous items such as, enclosure fans, reset button, speaker,

power indicator, hard drive active indicator (if using an IDE drive),

keyboard lock switch, and so forth.

3–8 Starting and Using the AlphaPC64

Page 41

3.4 Software Configuration

Two firmware programs have been loaded into the AlphaPC64 1MB flash

ROM. They are the debug monitor and the Windows NT ARC firmware. The

debug monitor is a serial line monitor program used to perform software and

hardware debug functions. The Windows NT ARC firmware is used to load

and boot Windows NT. The AlphaPC64 system has been configured to start the

Windows NT ARC firmware by default.

The serial ROM firmware uses a value stored in the nonvolatile RAM of the

real-time clock to determine which firmware image to load. Once the Windows

NT ARC firmware is running, you can switch to the debug monitor firmware.

3.4.1 Starting Windows NT ARC Firmware

Start the Windows NT ARC firmware using the following procedure:

1. Verify that the jumper from J16–2 to J16–3 is inserted, allowing the flash

ROM to be written. If the Windows NT ARC firmware is unable to write to

flash ROM, it prints the

2. Verify that the jumper from J3–25/26 is installed (see SP7 on the board).

The presence of the jumper at J3–25/26 forces the serial ROM firmware

to load the alternate image selected by the value in the nonvolatile TOY

RAM. The absence of this jumper overrides the value stored in the TOY

RAM and causes the first image, the debug monitor, to be loaded.

device error

3.4 Software Configuration

message and stops.

3. Turn on the power to the AlphaPC64. After the power-up diagnostics are

run, the ARC console boot menu appears on the graphics display.

If the ARC console boot menu does not appear, check the output of COM1

for error messages and review your hardware configuration.

You are ready for software installation. Refer to the Alpha Microprocessors

Evaluation Board Windows NT 3.51 Installation Guide for instructions.

3.4.2 Going to the Debug Monitor from Windows NT ARC Firmware

You may use either of these two methods to access the debug monitor from the

Windows NT ARC firmware.

A. Use the ARC firmware menus to choose the debug monitor.

1. At the Boot menu, choose Supplementary menu....

2. At the Supplementary menu, choose Setup the system....

3. At the Setup the system menu, choose Machine specific setup....

4. At the Machine specific setup menu, choose Debug Monitor.

Starting and Using the AlphaPC64 3–9

Page 42

3.4 Software Configuration

5. Turn off the power to the AlphaPC64, and then turn the power back

on.

B. Turn off the power to the AlphaPC64, remove the jumper from J3-25/26

(SP7 on the board), and then turn on the power to the AlphaPC64.

3.4.3 Returning to Windows NT ARC Firmware from the Debug Monitor

The following methods may be used to return to the Windows NT ARC

firmware from the debug monitor.

A. If you used item A in Section 3.4.2 to enter the debug monitor, then use

this procedure to return to Windows NT ARC firmware.

The firmware contained in the the serial ROM on your AlphaPC64

determines which firmware image is loaded from the flash ROM at

power-up. The serial ROM firmware uses a value stored in the nonvolatile

RAM of the real-time clock to determine which firmware image to load.

At this point, you want the serial ROM to load the Windows NT ARC

firmware.

1. Use the following debug monitor commands to select Windows NT ARC

firmware, by writing the value 1 to the TOY RAM, and to verify the

selection:

AlphaPC64> bootopt nt

O/S type selected: "The Windows NT Operating System"

....Firmware type: "Windows NT Firmware"

AlphaPC64> bootopt

Predefined bootoptions are...

"0" "Alpha Evaluation Board Debug Monitor" "DBM"

"1" "The Windows NT Operating System" "NT"

"2" "OpenVMS" "VMS"

"3" "Digital UNIX" "UNIX"

O/S type selected: "The Windows NT Operating System"

....Firmware type: "Windows NT Firmware"

AlphaPC64>

2. Turn off the power to the AlphaPC64. Verify the presence of a jumper

at J3-25/26 (see SP7 on the board).

3. Turn on the power to the AlphaPC64. After the power-up diagnostics

are run, the ARC console boot menu appears on the graphics display.

3–10 Starting and Using the AlphaPC64

Page 43

3.4 Software Configuration

B. If you used item B in Section 3.4.2 to enter the debug monitor, then use

this procedure to return to Windows NT ARC firmware:

1. Turn off the power to the AlphaPC64 and install the jumper at J3-25/26

(see SP7 on the board).

2. Turn on the power to the AlphaPC64. After the power-up diagnostics

are run, the ARC console boot menu appears on the graphics display.

If the ARC console boot menu does not appear, check the output of

COM1 for error messages and review your hardware configuration.

Starting and Using the AlphaPC64 3–11

Page 44

Page 45

Functional Elements

This chapter describes some of the functional elements of the AlphaPC64.

Information, such as bus timing and protocol, found in other specifications,

data sheets, and reference documentation is not duplicated. Appendix B

provides a list of supporting documents and order numbers.

Note

For a detailed description of the Alpha 21064A, refer to the

Alpha 21064 and Alpha 21064A Microprocessors Hardware Reference

Manual.

For detailed descriptions of chipset logic, operations, and transactions,

refer to the DECchip 21071 and DECchip 21072 Core Logic Chipsets

Data Sheet.

For details of the PCI interface, refer to the PCI System Design Guide

and the PCI Local Bus Specification.

4

4.1 PCI Interrupts and Arbitration

The following subsections describe the PCI interrupt and arbitration (arbiter)

logic.

4.1.1 System Interrupts

Figure 4–1 shows the AlphaPC64 interrupt logic. Interrupt logic is

implemented in two programmable logic devices (PLDs), MACH210–20 and

22V10–25. The PLDs allow each PCI and PCI-to-ISA bridge chip interrupt to

be individually masked. The PLDs also allow the current state of the interrupt

lines to be read.

Functional Elements 4–1

Page 46

4.1 PCI Interrupts and Arbitration

Figure 4–1 Interrupt Control and PCI Arbitration

CPU

cpu_irq

<5,2:0>

irq_resetd_l

jmp_irq<2:0>

MUX

Clock

Multiplier

Jumpers

sys_irq0

pci_isa_irq (0)

(2)

nmi

PCI-to-ISA

Bridge

(1)

rtc_irq_l

21071-DA

System

Interrupt

PLDs

PCI Bus

sio_int

pci_req_s0_l

pci_gnt_s0_l

pci_req_s1_l

pci_gnt_s1_l

pci_req_s2_l

pci_gnt_s2_l

pci_req_s3_l

pci_gnt_s3_l

pci_inta<3:0>

pci_intb<3:0>

pci_intc<3:0>

pci_intd<3:0>

PCI

Slot 0

PCI

Slot 1

PCI

Slot 2

PCI

Slot 3

drq<7:5,3:0>

ISA

Slots

4–2 Functional Elements

Combination

Control

<7:3> <12, 1>

irq<15:3, 1>

Keyboard/

Mouse

Control

LJ04140A.AI5

Page 47

4.1 PCI Interrupts and Arbitration

The AlphaPC64 interrupt controller has 17 interrupts: four from each of the

four PCI slots (16) and one from the SIO bridge.

All PCI interrupts are combined in the PLD and drive a single output signal,

pci_isa_irq. This signal drives CPU input cpu_irq0 through a multiplexer.

There is also a memory controller error interrupt and an I/O controller error

interrupt within the CPU.

Table 4–1 lists the CPU interrupt assignment during normal operation.

Table 4–1 CPU Interrupt Assignment

Interrupt

Source

pci_isa_irq cpu_irq0 Combined output of the interrupt PLD

rtc_irq_l cpu_irq1 Real-time clock interrupt from DS1287

nmi cpu_irq2 Nonmaskable interrupt from the SIO bridge

— cpu_irq3,

sys_irq0 cpu_irq5 Hardware interrupt from the PCI host bridge

CPU

Interrupt Description

Not used; tied to ground

cpu_irq4

(21071-CA)

Three jumpers (J3-3, J3-5, and J3-7) connect to one side of the multiplexer.

The jumper configuration sets the CPU clock multiplier value through the

cpu_irqn inputs during reset.

Functional Elements 4–3

Page 48

4.1 PCI Interrupts and Arbitration

The ISA bus interrupt signals (irq0 through irq8 and irq12 through irq14)

are all nested through the SIO and then into the CPU. The interrupt

assignment is configurable but is normally used as follows:

Interrupt Level Interrupt Source

IRQ0 Interval timer

IRQ1 Keyboard

IRQ2 Chains interrupt from slave peripheral interrupt controller (PIC)

IRQ3 8-bit ISA from serial port COM2

IRQ4 8-bit ISA from serial port COM1

IRQ5 8-bit ISA from parallel port (or irq7)

IRQ6 8-bit ISA from diskette controller

IRQ7 8-bit ISA from parallel port (or irq5)

IRQ8 Unused (real-time clock internal to the SIO)

IRQ9, IRQ10,

IRQ11

IRQ12 Mouse

IRQ13 16-bit ISA

IRQ14 IDE

IRQ15 16-bit ISA

16-bit ISA

The AlphaPC64 timer interrupt is generated by the real-time clock by means

of cpu_irq1, rather than by the timer within the SIO, which would route the

interrupt through the ISA bus interrupts.

4–4 Functional Elements

Page 49

4.1 PCI Interrupts and Arbitration

Interrupt PLDs Function

The MACH210 PLD acts as an 8-bit I/O slave on the ISA bus at addresses

804h, 805h, and 806h. This is accomplished by a decode of the three ISA

address bits sa<2:0> and the three ecas_addr<2:0> bits.

Each interrupt can be individually masked by setting the appropriate bit in the

mask register. An interrupt is disabled by writing a 1 to the desired position

in the mask register. An interrupt is enabled by writing a 0. For example,

bit <7> set in interrupt mask register 1 indicates that the INTB2 interrupt is

disabled. There are three mask registers located at ISA addresses 804h, 805h,

and 806h.

An I/O read transaction at ISA addresses 804h, 805h, and 806h returns the

state of the 17 PCI interrupts rather than the state of the masked interrupts.

On read transactions, a 1 means that the interrupt source shown in Figure 4–2

has asserted its interrupt. The mask register can be updated by writing

addresses 804h, 805h, or 806h. The mask register is write-only.

Figure 4–2 Interrupt and Interrupt Mask Registers

Interrupt and Interrupt Mask Register 1 (ISA Address 804h)

76543210

inta0inta1inta2inta3intb0intb1intb2 sio

Interrupt and Interrupt Mask Register 2 (ISA Address 805h)

76543210

Interrupt and Interrupt Mask Register 3 (ISA Address 806h)

76543210

RAZ = Read-as-Zero, Read-Only

Notes:

Interrupt Mask Register Is Write-Only

4.1.2 PCI/ISA Arbitration

Arbitration logic is implemented in the Intel 82378ZB Saturn IO (SIO) chip.

The arbitration scheme is flexible and software programmable. Refer to

the Intel 82420/82430 PCIset ISA and EISA Bridges document for more

information about programmable arbitration.

intb3intc0intc1intc2intc3intd0intd1intd2

RAZRAZRAZRAZRAZRAZRAZ intd3

LJ-04211.AI

Functional Elements 4–5

Page 50

4.2 ISA Devices

4.2 ISA Devices

Figure 4–3 shows the AlphaPC64 ISA bus implementation with peripheral

devices and connectors. Also shown is the utility bus (Ubus) with system

support devices.

Figure 4–3 ISA Devices

PCI Bus

la<23:17>

sd<15:0>

PCI-to-ISA

Bridge

82378ZB

Combo

Chip

87312

sa<19:0>

sd<7:0>

Transceiver

Diskette J24

Parallel J25

COM1 J32

COM2 J30

IDE J26

sa<18:0>sa<9:0>

ubus<7:0>

Flash ROM

1M x 8

TOY

1287

flash_adr19

Keyboard/

sa<2>

Mouse

8242

ISA

Slot

0

J17 J18 J19

ISA

Slot

1

86.5%

ISA

Slot

2

LJ04141A.AI5

4–6 Functional Elements

Page 51

4.3 dc Power Distribution

The AlphaPC64 derives its system power from a user-supplied, industrystandard PC power supply. The power supply must provide +12 V dc, –12 V

dc, –5 V dc, Vdd (+5 V dc), and +3.3 V dc. The dc power is supplied through

power connectors J27, J28, J29, and J31 (see Figure 4–4). Power is distributed

to the board logic through dedicated power planes within the 6-layer board

structure.

4.3 dc Power Distribution

Functional Elements 4–7

Page 52

4.3 dc Power Distribution

Figure 4–4 dc Power Distribution

J31

1

p_dcok

3

4

J29

3

4

5

6

J28

1

2

3

4

5

6

J27

1

2

3

4

5

6

+12 V dc

-12 V dc

-5 V dc

Vdd

3 V dc

Ground

3 V dc

ISA

Slots

J31

2

5

6

J29

1

2

PCI

Slots

3 V dc

Logic

IC

Devices

Clocks

Fan

21064A

Vdd

Ground

LJ04143A.AI5

4–8 Functional Elements

Page 53

4.4 Flash ROM (System ROM)

The flash ROM, sometimes called the system ROM, is a 1MB, nonvolatile,

writable ROM. After the SROM code initializes the AlphaPC64 system, flash

ROM code prepares the system for booting. The flash ROM headers, structure,

and access methods are described here.

4.4.1 Special Flash ROM Headers

The MAKEROM tool is used to place a special header on ROM image files. The

SROM allows the flash ROM to contain several different ROM images, each

with its own header. The header informs the SROM where to load the image,

and whether or not it has been compressed with the MAKEROM tool. The

header is optional for flash ROM containing a single image. If the header does

not exist, the 1MB flash ROM is loaded and executed at physical address zero.

Figure 4–5 shows the header content.

Figure 4–5 Special Header Content

31 00

Validation Pattern 5A5AC3C3

Inverse Validation Pattern A5A53C3C

Header Size (Bytes)

Image Checksum

Image Size (Memory Footprint)

Decompression Flag

Destination Address Lower Longword

Destination Address Upper Longword

Flash ROM Image Size

Optional Firmware ID<31:0>

Optional Firmware ID<63:32>

Header Checksum (excluding this field)

4.4 Flash ROM (System ROM)

Firmware ID<15:8>

00

04

08

0C

10

14

18

1C

Header Rev<7:0>Reserved<31:16>

LJ04171A.AI5

20

24

28

2C

30

Table 4–2 describes each entry in the special header.

Functional Elements 4–9

Page 54

4.4 Flash ROM (System ROM)

Table 4–2 Special Header Entry Descriptions

Entry Description

Validation and inverse

validation pattern

Header size (bytes) This longword contains the size of the header block, which

Image checksum This longword is used to verify the integrity of the ROM.

Image size

(memory footprint)

Decompression flag The decompression flag informs the SROM code whether

Destination address This quadword contains the destination address for the

Firmware ID The firmware ID is a byte that specifies the firmware type.

This quadword contains a special signature pattern used to

validate that the special ROM header has been located. The

pattern is 5A5AC3C3A5A53C3C.

varies among versions of the header specification.

When the header is located, SROM code determines where

the image begins based on the header size. Additional data

added to the header will be ignored by older SROM code.

A header size of 32 bytes implies version 0 of the header

specifications.

The image size is used by the SROM code to determine how

much of the flash ROM should be loaded.

the MAKEROM tool was used to compress the ROM image

with a repeating byte algorithm. The SROM code contains

routines that execute the decompression algorithm. Other

compression and decompression schemes, which work

independently from this scheme, may be employed.

image. The SROM code will load the image at this address

and begin execution.

This information facilitates image boot options necessary to

boot different operating systems.

Firmware Name

Debug monitor 0 Alpha evaluation board

Windows NT 1 Windows NT firmware

Alpha SRM 2 Alpha System Reference

4–10 Functional Elements

Firmware

Type Firmware Description

debug monitor

Manual console

(continued on next page)

Page 55

4.4 Flash ROM (System ROM)

Table 4–2 (Cont.) Special Header Entry Descriptions

Entry Description

Header revision The revision of the header specifications used in this header.

Flash ROM image size The flash ROM image size reflects the size of the image as

Optional firmware ID This optional field can be used to provide additional

Header checksum The checksum of the header. This is used to validate the

This is necessary to provide for changes to the header

specification. Version 0 headers are identified by the size of

the header (32 bytes).

it is contained in the flash ROM.

firmware information such as firmware revision or a

character descriptive string up to 8 characters.

presence of a header beyond the validation provided by the

validation pattern.

Functional Elements 4–11

Page 56

4.4 Flash ROM (System ROM)

4.4.2 Flash ROM Structure

During the power-up and initialization sequence, the AlphaPC64 always loads

the first image if the BOOT_OPTION jumper J3-25/26 is not installed. Then

the first image (the debug monitor) will be booted.

If jumper J3-25/26 is installed, the AlphaPC64 reads the value at location 3F

of the TOY NVRAM. The AlphaPC64 uses the value found there to determine

which image will be selected (see Table 4–3). The selected image is loaded and

executed.

Table 4–3 Higher 512KB Flash ROM Image Selection

TOY RAM Value

00 0 Evaluation board debug monitor firmware

01 1 Windows NT ARC firmware

02 2 Alpha SRM firmware (OpenVMS)

03 2 Alpha SRM firmware (Digital UNIX)

8n NA

1

Firmware ID

2

4

Image Description

3

3

SROM code will load the nth image from

flash ROM.

If n=0, the SROM code loads the entire

flash ROM contents.

If n=1, 2, ..., the SROM code loads the first

image, second image, and so on.

1

Operating system type. Found at TOY RAM address 3F.

2

Found in image header.

3

Note: SRM firmware is not included in the AlphaPC64 kit.

The flash ROM contains only one of these images.

4

Not applicable.

If an image is specified and is not found, the AlphaPC64 loads the first image

in the flash ROM with a valid header. If no valid header is found, the entire

1MB flash image is loaded at address 0000 0000.

The following sequence of steps describes how to change the value stored in

TOY RAM location 3F by using either the basic debug monitor commands or

the debug monitor

4–12 Functional Elements

bootopt

command.

Page 57

4.4 Flash ROM (System ROM)

Changing TOY RAM Location 3F—Debug Monitor

Use the debug monitor

In the example shown here, the

bootopt

command to change the value in location 3F.

bootopt

command is used to change the value

bootopt

in location 3F from 0 to 1:

AlphaPC64> bootopt

1

Predefined bootoptions are...

"0" "Alpha Evaluation Board Debug Monitor" "DBM"

"1" "The Windows NT Operating System" "NT"

"2" "OpenVMS" "VMS"

"3" "Digital UNIX" "UNIX"

O/S type selected: "Alpha Evaluation Board Debug Monitor"

....Firmware type: "DBM Firmware"

AlphaPC64> bootopt nt

2

O/S type selected: "The Windows NT Operating System"

....Firmware type: "Windows NT Firmware"

AlphaPC64> bootopt

3

Predefined bootoptions are...

"0" "Alpha Evaluation Board Debug Monitor" "DBM"

"1" "The Windows NT Operating System" "NT"

"2" "OpenVMS" "VMS"

"3" "Digital UNIX" "UNIX"

O/S type selected: "The Windows NT Operating System"

....Firmware type: "Windows NT Firmware"

AlphaPC64>

Command

1

Use the debug monitor

which image is selected.

2

Use the debug monitor

from0to1.

3

Use the debug monitor

has changed from 0 to 1.

bootopt

command to see the image choices and note

bootopt nt

bootopt

command to verify that the selected image

command to change the selected image

Functional Elements 4–13

Page 58

4.4 Flash ROM (System ROM)

4.4.3 Flash ROM Access

The flash ROM can be viewed as two banks of 512KB each. At power-up,

the lower 512KB bank is accessed using the address range 3 FFF8 0000 to

3 FFFF FFFF.

Setting address bit 19 will allow you to access the higher 512KB of flash ROM.

Write a 1 to the register at address 800 to set address bit 19. Manually deposit

a 1 to address 1 C001 0000 or enter the following command from the debug

monitor:

> wb 800 1

The address range for the higher bank is 3 FFF8 0000 to 3 FFFF FFFF, the

same as for the lower bank. Access is now to the higher bank and will continue

until the AlphaPC64 is reset or a 0 is written to the register at address 800.

The update-enable jumper must be installed from pin J16-2 to pin

J16-3 to enable writing to the flash ROM. See connector J16 in

Table 2–3.

Note

4–14 Functional Elements

Page 59

Board Requirements and Parameters

This chapter describes the evaluation board power and environmental

requirements, and physical board parameters.

5.1 Power Requirements

The AlphaPC64 derives its main dc power from a user-supplied, industrystandard PC power supply. The board has a total power dissipation of 96.2 W,

excluding PCI and ISA devices. Table 5–1 lists the power requirements of each

dc supply voltage.

The power supply must supply signal p_dcok to the system reset logic.

Table 5–1 Power Supply dc Current Requirements (275 MHz)

Voltage Current

+5 V dc 10 A (maximum)

+3.3 V dc 10 A (maximum)

–5 V dc 0 A

+12 V dc 1 A (maximum)

–12 V dc 0.1 A (maximum)

5

The 21064A cooling fan must have a built-in sensor that drives a signal

if the airflow stops. The sensor is connected to J14.

When airflow is interrupted, the sensor signal fan_conn_l is asserted

causing the signal cpu_dcok to be deasserted to the 21064A. This

protects the 21064A under fan-failure conditions because the 21064A

dissipates less heat when cpu_dcok is deasserted.

Caution: Fan Sensor Required

Board Requirements and Parameters 5–1

Page 60

5.2 Environmental Characteristics

5.2 Environmental Characteristics

The AlphaPC64 board environmental characteristics are:

• Operating temperature range of 10°C to 40°C (50°F to 104°F)

• Storage temperature range of –55°C to 125°C (–67°F to 257°F)

5.3 Physical Board Parameters

The AlphaPC64 board consists of a 6-layer printed-wiring board. The board

is populated with integrated circuit packages together with supporting active

and passive components. The AlphaPC64 is a baby-AT-size board with the

following dimensions:

• Width: 22.1 cm (8.7 in ± 0.0005 in)

• Length: 33.0 cm (13.0 in ± 0.0005 in)

The board can be used in certain desktop systems that have adequate

clearance for the 21064A heat sink. All ISA and PCI expansion slots are

usable in standard desktop or deskside enclosures.

Figure 5–1 shows the board and component outlines and identifies key

components. The components are described in Table 5–2. Refer to Chapter 2

for jumper and connector locations.

5–2 Board Requirements and Parameters

Page 61

Figure 5–1 Board Component Layout

5.3 Physical Board Parameters

37

38

28

27

24

23

22

30

35

34

29

26

25

3231

41

636

7

33

4339

4240

464544

47 48

2

17

51

49

50

1

8

9

21

20

19

18

Scale = 90%

16

15

14

13

4

3

5

10

11

12

LJ-04460.AI5

Board Requirements and Parameters 5–3

Page 62

5.3 Physical Board Parameters

Table 5–2 Board Component Descriptions

Number Device Component Description

1 U36 Alpha 21064A–275 microprocessor—431 PGA,

2 U24 DECchip 21071–BA0, 208-pin PQFP, ASIC

3 U8 DECchip 21071–BA1, 208-pin PQFP, ASIC

4 U13 DECchip 21071–BA2, 208-pin PQFP, ASIC

5 U2 DECchip 21071–BA3, 208-pin PQFP, ASIC

6 U35 DECchip 21071–DA, 208-pin PQFP, ASIC

7 U31 DECchip 21071–CA, 208-pin PQFP, ASIC

8, 9 U25, 17 PALCE16V8–5, 5-ns, 125-mA, 20-pin PLCC

10, 11, 12 U14, U9, U5 74FCT162244ETPV—48 SSOP

13, 14, 15,

16, 17

18 U1 64K21 CMOS OTP serial ROM (initialization

19, 20 U3, U6 74F244 buffer/line driver

21 U10 Dallas Semiconductor DS1287—24-pin DIP, real-

22 U15 Intel N8242PC/PHOENIX/1991 mouse and

23 U19 E28F008SA–120, 40-pin TSOP, 1MX8 CMOS flash

24 U28 74F245 transceiver

25 U18 74LS05 inverter gate

26 U20 74F14 trigger, SOIC

27 U26 74F02D NOR gate

28 U32 74F257 data selector/multiplexer

29 U27 PLD, MACH210–20, 20-ns, 180-mA, 44-pin PLCC,

30 U33 14.3-MHz crystal oscillator, PCI-to-ISA bridge

31 U21 74F04 hex inverter

U4, U7, U11,

U12, U16

275 MHz

74ABT162244—48-pin SSOP, 16-bit buffer/driver

code)

time clock and 50-byte RAM with crystal

keyboard controller, 44-pin PLCC

ROM, 120 ns

interrupt controller

(SIO) oscillator

(continued on next page)

5–4 Board Requirements and Parameters

Page 63

5.3 Physical Board Parameters

Table 5–2 (Cont.) Board Component Descriptions

Number Device Component Description

32, 33 U22, U23 74F08 AND gate

34 U30 PALCE22V10H–25JC, 28-pin PLCC, 25 ns

35 U29 74ACT244

36 U34 S82378ZB—208-pin PQFP, PCI-to-ISA bridge chip

37 U47 24-MHz crystal oscillator

38 U43 PC87312VF combination diskette controller chip—

39, 41, 43 U48, U50, U52 SN75189 receiver

40, 42 U49, U51 SN75188 driver

44, 45 U44, U45 74F245 transceiver

46 U46 74F244 buffer/line driver

47, 48 U37, U38 IDC FCT805CT—20-pin SOIC

49 U39 AMCC S4402 PLL—28-pin PLCC

50 U40 TriQuint TQ2061—28-pin PLCC, PLL 500-MHz to

51 U41 27.50-MHz crystal oscillator

100-pin PQFP

700-MHz output

Board Requirements and Parameters 5–5

Page 64

Page 65

Supporting Vendor Products

To obtain components and accessories that are not included with your

AlphaPC64 motherboard, Digital Equipment Corporation suggests the

following vendors. In doing so, Digital does not warrant these components or

guarantee that they will function in all configurations.

A.1 Products Included

The following products are included in the AlphaPC64 motherboard kit.

• Alpha microprocessor clock solution. Components available from:

TriQuint Semiconductor

2300 Owen Street

Santa Clara CA 95054

Phone: 408.982.0900 ext 142

FAX: 408.982.0222

NEL Frequency (crystal oscillator source)

A

CPU Frequency

21064A-200 40.0 MHz TQ2060 (optional)

21064A-233 46.66 MHz TQ2060 (optional)

21064A-275 27.5 MHz TQ2061 (included)

• Heat sink and fan solution. Components included: heat sink, GRAFOIL

pad, 2 hex nuts, heat sink clips, 60-mm fan, fan guard, and 4 screws.

Components available from:

United Machine and Tool Design

River Road

Fremont NH 03044

Phone 603.642.5040

FAX 603.642.5819

Oscillator

Frequency TriQuint PLL Part Number

Supporting Vendor Products A–1

Page 66

A.1 Products Included

• L2 cache SIMMs (21A02-A3 does not include cache SIMMs)

Cache Size

512KB, 15 ns

2MB, 12 ns

1

Included in 21A02-A5.

2

Included in 21A02-A4.

2

SIMM

Configuration Qty Vendor/Part Number

1

32K296 2 Digital PN, 21A02-M1

128K292 2 Digital PN, 21A02-M2

A.2 Products Not Included

The following products are not included in the AlphaPC64 motherboard kit.

• DRAM system memory—70 ns DRAM SIMMs (5 V, 72 pin)

1M236, 2M236, 4M236, 8M236, 16M236. DRAM SIMMs must

include provisions for parity.

• Power supply—+3.3 V, +5 V, –5 V, +12 V, –12 V, available from:

Emacs Electronics USA, Inc.

1410 Gail Borden Place C-4

El Paso TX 79935

Phone: 915.599.2688

Part number: AP2-5300F (300 W)

Autec Power System

69 Moreland Road

Simi Valley CA 93065

Phone: 805.522.0888

Part number: PCB-3330-1010-D (275 W)

Motorola PN, MCM96AA32SG15

Motorola PN, MCM92AA128SG12

Micron PN, MBDLS12896G-12

• Enclosure

Axxion Group

7801 Trade Center Avenue

El Paso TX 79912

Phone: 915.877.3990

Part number: DL09-P51

A–2 Supporting Vendor Products

Page 67

Technical Support and Ordering

B.1 Technical Support