Page 1

GP-2401/2501/2601 Series

User Manual

Digital Electronics Corporation

Page 2

Preface

Thank you for purchasing the Pro-face GP-2401/2501/2601 Series programmable

operator interface (hereafter referred to as the "GP unit").

This GP unit, with its expanded functionality and improved overall performance,

is an upgrade of Pro-face's previous GP series panels. GP-2401/2501/2601 Series

units allow you to use the CF Card without attaching separately sold expansion

units.

Please read this manual carefully as it explains, step by step, how to use the GP

correctly and safely .

Also, in this manual's examples, the Mitsubishi MELSEC-AnA Series PLC is

referred, whenever possible, as a point-to-point connection.

<Note>

1) It is forbidden to copy the contents of this manual, in whole or in part, except

for the user’s personal use, without the express permission of Digital Electronics Corporation of Japan.

2) The information provided in this manual is subject to change without notice.

3) This manual has been written with care and attention to detail; however, should

you find any errors or omissions, please contact Digital Electronics Corporation

and inform them of your findings.

4) Please be aware that Digital Electronics Corporation shall not be held liable by

the user for any damages, losses, or third party claims arising from any uses of

this product.

All Company/Manufacturer names used in this manual are the registered trademarks of those companies.

© 2003 Digital Electronics Corporation

1

Page 3

Preface

Table of Contents

Preface........................................................................................................................ 1

Essential Safety Precautions ................................................................................... 6

General Safety Precautions ................................................................................... 10

GP-2401/2501/2601 Series Models....................................................................... 12

Package Contents ................................................................................................... 12

UL/c-UL (CSA) Application Notes ...................................................................... 13

CE Marking Notes................................................................................................ 14

Revision Version ..................................................................................................... 15

Documentation Conventions .................................................................................. 16

CHAPTER 1 INTRODUCTION

1.1 Prior to Operating the GP............................................................................ 1-1

1.2 System Design ............................................................................................... 1-2

1.2.1 GP-2401/2501/2601 Series System Design .......................................1-2

1.3 Accessories.................................................................................................... 1-5

CHAPTER 2 SPECIFICATIONS

2.1 General Specifications .................................................................................2-1

2.1.1 Electrical ..............................................................................................2-1

2.1.2 Environmental ......................................................................................2-2

2.1.3 Structural .............................................................................................2-3

2.2 Functional Specifications .............................................................................2-4

2.2.1 Display.................................................................................................2-4

2.2.2 Memory...............................................................................................2-5

2.2.3 T ouch Panel • Clock............................................................................2-5

2.2.4 Interfaces............................................................................................2-6

2.3 Interface Specifications................................................................................2-7

2.3.1 Serial Interfaces...................................................................................2-7

2.3.2 Printer Interface...................................................................................2-8

2.3.3 AUX Input/Output I/F.........................................................................2-9

2.4 Part Names and Functions ......................................................................... 2-11

2

GP-2401/2501/2601 Series User Manual

Page 4

2.5 Dimensions ..................................................................................................2-13

2.5.1 GP-2401 Series External Dimensions ...............................................2-13

2.5.2 GP-2501 Series External Dimensions ...............................................2-14

2.5.3 GP-2601 Series External Dimensions ...............................................2-15

2.5.4 Panel Cut Dimensions........................................................................2-16

2.5.5 Installation Fasteners .........................................................................2-16

CHAPTER 3 INSTALLATION AND WIRING

3.1 Installation..................................................................................................... 3-1

3.1.1 Installation Procedures ........................................................................3-1

3.2 Wiring Precautions........................................................................................ 3-6

3.2.1 Connecting the Power Cord................................................................3-6

3.2.2 Connecting the Power Supply ............................................................3-8

3.2.3 Grounding ............................................................................................3-9

Preface

3.2.4 I/O Signal Line Placement ...................................................................3-9

3.3 Tool Connector ............................................................................................ 3-10

3.4 CF Card Installation and Removal ........................................................... 3-11

3.4.1 CF card Handling ..............................................................................3-13

3.5 Attaching the Screw Lock Terminal Block .............................................. 3-14

CHAPTER 4 DATA TRANSFER

4.1 Serial Data Transfer.....................................................................................4-1

4.2 Ethernet Data Transfer................................................................................4-4

4.3 CF Memory Loader Tool ............................................................................. 4-5

4.3.1 Data Upload and Download................................................................4-6

CHAPTER 5 OFFLINE MODE

5.1 Entering OFFLINE Mode...........................................................................5-1

5.1.1 After Plugging in the Power Cord........................................................5-1

5.1.2 From the Menu Bar .............................................................................5-2

5.2 OFFLINE Mode Main Menu...................................................................... 5-3

5.3 INITIALIZATION........................................................................................5-4

5.4 SELF-DIAGNOSIS....................................................................................... 5-6

CHAPTER 6 INITIALIZING THE GP

6.1 Initialization Screen ...................................................................................... 6-1

6.2 Initialization Items ........................................................................................ 6-2

GP-2401/2501/2601 Series User Manual 3

Page 5

Preface

6.3 SYSTEM ENVIRONMENT SETUP ..........................................................6-3

6.4 SET UP I/O .................................................................................................. 6-10

6.3.1 SYSTEM SETUP ...............................................................................6-3

6.3.2 SYSTEM AREA SETUP....................................................................6-4

6.3.3 GLOBAL WINDOW SETUP............................................................6-6

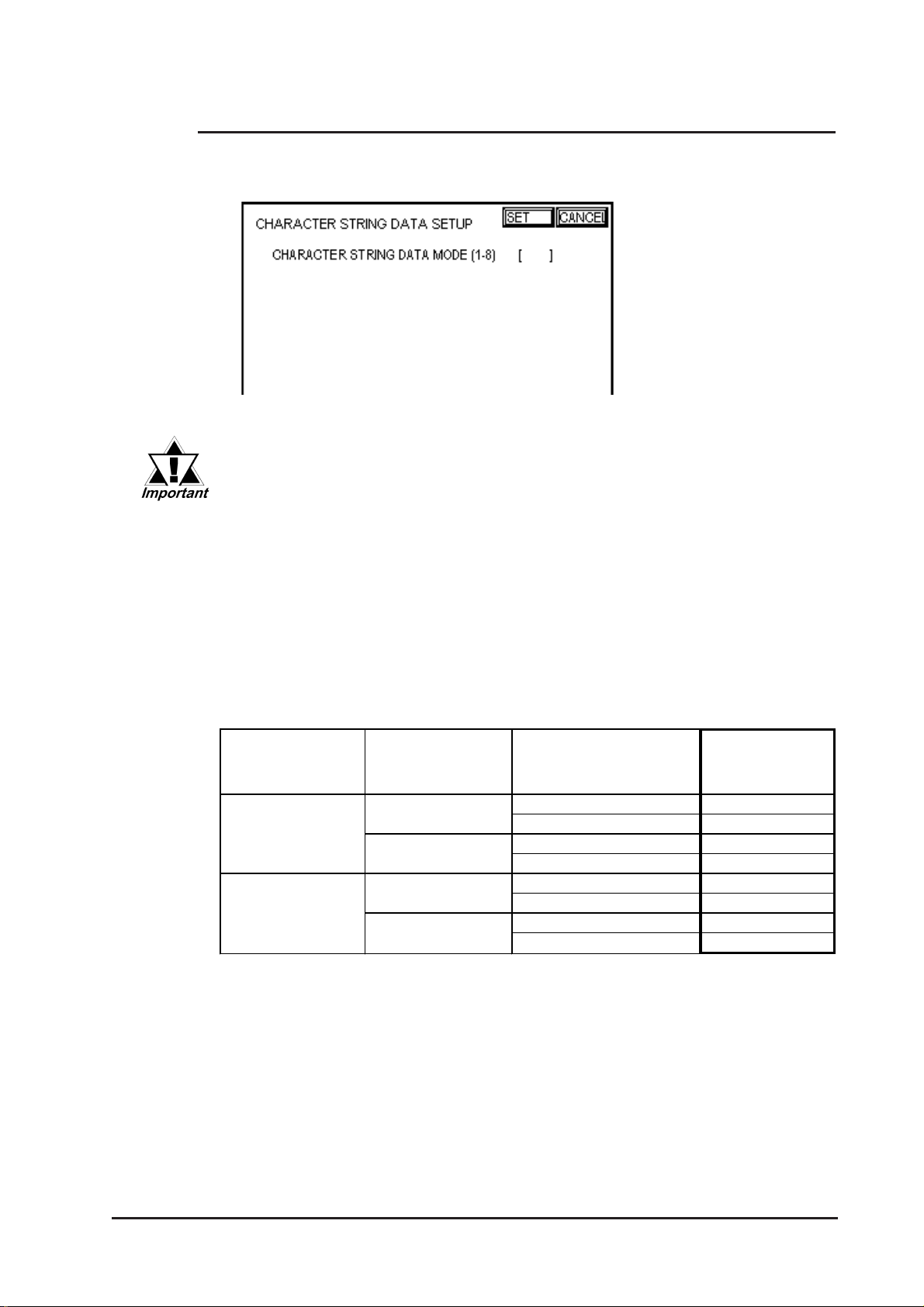

6.3.4 CHARACTER STRING DA T A SETUP.............................................6-7

6.4.1 SET UP SIO .....................................................................................6-10

6.4.2 SET UP PRINTER............................................................................6-12

6.4.3 SET UP TOUCH PANEL.................................................................6-15

6.4.4 COMMUNICATION SETUP..........................................................6-18

6.4.5 Sound Settings...................................................................................6-19

6.4.6 EXPANSION SERIAL COMMUNICA TION SETUP...................6-20

6.4.7 EXPANSION SERIAL ENVIRONMENT SETUP.........................6-21

6.4.8 SETUP CAPTURE OPERATION....................................................6-21

6.4.9 DISPLAY DEVICE SETTINGS ......................................................6-22

6.4.10 FUNCTION SETUP ........................................................................6-22

6.4.11 COMMUNICATION PORT SETUP...............................................6-23

6.5 PLC SETUP ................................................................................................ 6-24

6.5.1 SET UP OPERATION SURROUNDINGS(1:1/n:1) .......................6-24

6.5.2 ST A TION SETUP(n:1) .....................................................................6-25

6.5.3 CUSTOMIZE SETUP (n:1)..............................................................6-27

6.6 INITIALIZE INTERNAL MEMORY ...................................................6-29

6.6.1 INITIALIZE GP MEMOR Y.............................................................6-29

6.6.2 INITIALIZE CF CARD....................................................................6-29

6.6.3 CSV DATA INDEX..........................................................................6-30

6.7 SET UP TIME .............................................................................................6-31

6.8 SET UP SCREEN ....................................................................................... 6-32

CHAPTER 7 RUN MODE AND ERRORS

7.1 RUN Mode................................................................................................... 7-1

7.1.1 After Connecting the Power Cord.......................................................7-1

7.1.2 Via OFFLINE Mode...........................................................................7-2

7.2 SELF-DIAGNOSIS....................................................................................... 7-3

7.2.1 SELF-DIAGNOSIS ITEM LIST........................................................7-3

7.2.2 SELF-DIAGNOSIS - Details..........................................................7-4

4

GP-2401/2501/2601 Series User Manual

Page 6

Preface

7.3 Troubleshooting.............................................................................................7-8

7.3.1 Possible T ypes of T rouble ...................................................................7-8

7.3.2 No Display ..........................................................................................7-9

7.3.3 No GP/Host Communication.............................................................7-12

7.3.4 T ouch Panel Does Not Respond.......................................................7-14

7.3.5 Buzzer Sounds when GP power is turned ON ..................................7-15

7.3.6 Clock Settings Cannot be Entered ....................................................7-16

7.3.7 Error Screens ....................................................................................7-16

7.4 Error Messages ..........................................................................................7-17

7.4.1 Error Message List ............................................................................7-17

7.5 Error Message Details .............................................................................7-19

7.5.1 SYSTEM ERRORS ..........................................................................7-19

7.5.2 ILLEGAL ADDRESS IN SCREEN DA TA......................................7-21

7.5.3 PLC COM. ERROR.........................................................................7-22

7.5.4 CLOCK SET UP ERROR................................................................7-23

7.5.5 SCREEN T AG LIMIT EXCEEDED (max. of 384)..........................7-23

7.5.6 OBJ. PLC HAS NOT BEEN SETUP ..............................................7-23

7.5.7 D-Script and Global D-Script Errors ................................................7-24

7.5.8 Extended SIO Script Error................................................................7-25

7.5.9 Serial I/F Change Error.....................................................................7-25

CHAPTER 8 MAINTENANCE

8.1 Regular Cleaning ..........................................................................................8-1

8.1.1 Cleaning the Display ............................................................................8-1

8.1.2 Installation Gasket Check/Replacement ..............................................8-1

8.2 Periodic Check Points................................................................................... 8-3

8.3 Replacing the Backlight...............................................................................8-4

8.3.1 Replacing CA3-BLU12-01.................................................................8-6

INDEX

GP-2401/2501/2601 Series User Manual 5

Page 7

Preface

Essential Safety Precautions

This manual includes procedures that must be followed to operate the GP correctly and safely. Be sure to read this manual and any related materials thoroughly

to understand the correct operation and functions of this unit.

Safety Icons

Throughout this manual the following icons are provided next to GP operation

procedures requiring special attention, and provide essential safety information.

These icons indicate the following levels of danger:

Indicates situations where severe bodily

W arning

injury, death or major equipment damage

can occur.

Caution

Indicates situations where slight bodily

injury or machine damage can occur.

WARNINGS

System Design

• Do not create GP touch panel switches that could possibly

endanger the safety of equipment and personnel. Damage

to the GP, its I/O unit(s), cable(s), and other related equipment can cause an output signal to remain continuously

ON or OFF and possibly cause a major accident. Therefore, design all monitoring circuits using limit switches,

etc. to detect incorrect device movement. To prevent accidents related to incorrect signal output or operation, design all switches used to control vital machine operations

so they are operated via a separate control system.

• Please design your system so that equipment will not

malfunction due to a communication fault between the GP

and its host controller . This is to prevent any possibility of

bodily injury or material damage.

• Do not use the GP unit as a warning device for critical

alarms that can cause serious operator injury, machine

damage or production stoppage. Critical alarm indicators

and their control/activator units must be designed using

stand-alone hardware and/or mechanical interlocks.

• The GP is not appropriate for use with aircraft control

devices, aerospace equipment, central trunk data transmission (communication) devices, nuclear power control

devices, or medical life support equipment, due to these

devices’ inherent requirements of extremely high levels of

safety and reliability.

6

GP-2401/2501/2601 Series User Manual

Page 8

Preface

WARNINGS

• Do not create switches used to control machine safety

operations, such as an emergency stop switch, or a GP

touch screen icon. Be sure to install these switches as

separate hardware switches, otherwise severe bodily

injury or equipment damage can occur.

• When using the GP with : transportation vehicles (trains,

cars and ships), disaster and crime prevention devices,

various types of safety equipment, non-life support related medical devices, etc., redundant and/or failsafe system designs should be used to ensure the proper degree

of reliability and safety.

Touch Panel

• After the GP’s backlight burns out, unlike the GP’s

“Standby Mode”, the touch panel is still active. If the operator fails to notice that the backlight is burned out and

touches the panel, a potentially dangerous machine operation error can occur.

If your GP's backlight suddenly turns OFF, use the follow-

ing steps to determine if the backlight is actually burned out.

1) If your GP is

screen has gone blank, your backlight is burned out.

2) Or, if your GP

the screen does not cause the display to reappear,

your backlight is burned out.

Also, use the GP’s built-in “USE TOUCH PANEL AFTER

BACKLIGHT BURNOUT” feature to prevent an accidental

machine operation error. This feature can automatically

detect a burnout and disable the touch screen.

Wiring

• To prevent an electric shock, be sure to confirm that the

GP's power cord is not connected to the main power

when connecting power lines to the GP.

• Be sure to replace the GP's plastic terminal block cover

after wiring is completed, since operating the GP without

the cover may lead to an electric shock

• Do not use power beyond the GP's specified voltage

not set to "Standby Mode" and the

is set to Standby Mode, but touching

range. Doing so may cause a fire or an electric shock.

GP-2401/2501/2601 Series User Manual 7

Page 9

Preface

WARNINGS

Battery Replacement

• The GP uses a lithium battery for backing up its internal

clock data. If the battery is incorrectly replaced, the battery may explode. To prevent this, please do not replace

the battery yourself. When the battery needs to be re-

placed, please contact your local GP distributor.

Installation/Maintenance

• High voltage runs through the GP. Except for replacing

the backlight, never take apart the GP, otherwise an electrical shock can occur.

• Do not modify the GP unit. Doing so may cause a fire or

an electric shock.

• Do not use the GP in an environment where flammable

gasses are present, since operating the GP may cause an

explosion.

CAUTIONS

Installation/Maintenance

• Be sure to securely connect all cable connectors to the GP.

A loose connection may cause incorrect input or output.

8

GP-2401/2501/2601 Series User Manual

Page 10

Preface

CAUTIONS

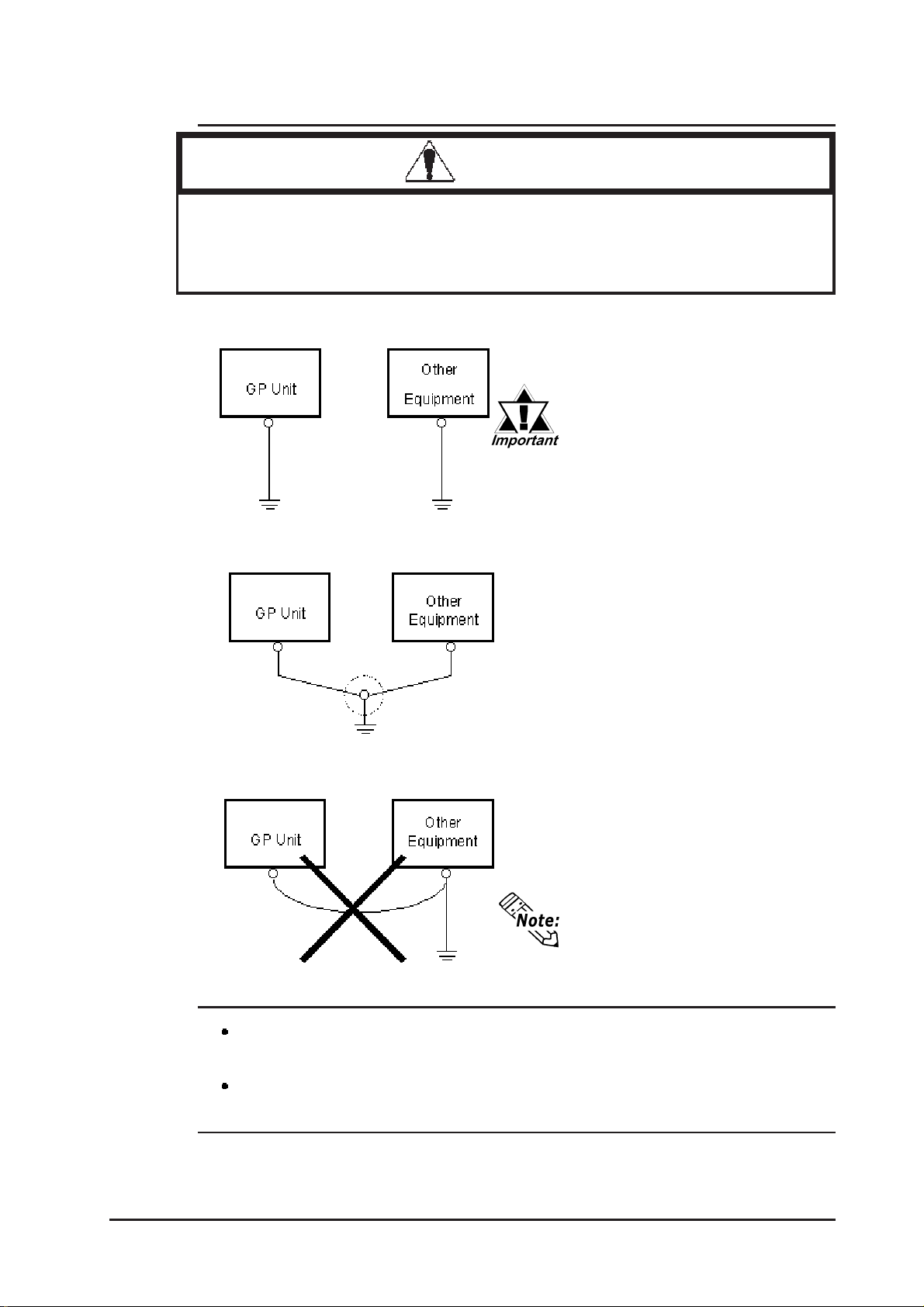

Wiring

• Ground the GP's FG line separately from other units’ FG

lines. Putting these FG lines too close may cause an electric shock or unit malfunction. Be sure to use a grounding

resistance of 100

ΩΩ

Ω or less and a 2mm

ΩΩ

your country’s applicable standard.

• Be sure the GP's rated voltage is within the designated

range, and that the power terminal lines are correctly

attached. If the voltage supplied differs from the rated

voltage, or incorrect wiring or grounding is performed, it

may cause a fire or unit malfunction.

• Use only the designated torque to tighten the GP's termi-

nal block screws. If these screws are not tightened firmly,

it may cause a short-circuit, fire, or GP malfunction.

2

or thicker wire, or

• Be careful that metal filings and wiring debris do not fall

inside the GP, since they can cause a fire, GP malfunction, or incorrect unit operation.

Display Device/CF Card

• The liquid crystal panel contains a powerful irritant and if

for any reason the panel is damaged and this liquid contacts any part of your body, be sure to wash that area with

running water for 15 minutes. If any of this liquid enters

your eye, flush your eye for 15 minutes with running water

and contact a physician.

• Prior to inserting or removing a CF Card, be sure the CF

Card ACCESS lamp is not lit. If you do not, CF Card internal data may be damaged or lost.

• While a CF Card is being accessed, NEVER turn OFF or

reset the GP, or insert or remove the CF Card. Prior to

performing these operations, create and use a special GP

application screen that will prevent access to the CF

Card.

Refer to GP-PRO/PB III for Windows Tag Reference Manual

(included in the screen editor software package)

Unit Disposal

• When this unit is disposed of, it should be done so ac-

cording to your country's regulations for similar types of

industrial waste.

GP-2401/2501/2601 Series User Manual 9

Page 11

Preface

General Safety Precautions

• Do not strike the touch panel with a hard or pointed object, or press

on the touch panel with too much force, since it may damage the

touch panel or the display.

• Do not install the GP where the ambient temperature can exceed the

allowed range. Doing so may cause the GP to malfunction or shorten

its operation life.

• Do not restrict or limit the GP’s naturally occurring rear-face ventila-

tion, or store or use the GP in an environment that is too hot.

• Do not use this unit in areas where large, sudden temperature

changes can occur. These changes can cause condensation to form

inside the unit, possibly causing the unit to malfunction.

• Do not allow water , liquids, metal or charged particles to enter inside

the GP’s case, since they can cause either a GP malfunction or an

electrical shock. The allowable pollution degree is 2.

• Do not use or store the GP in direct sunlight, or in excessively dusty

or dirty environments.

• Do not store or use the unit where strong jolting or excessive vibra-

tion can occur.

• Do not store or use the GP where chemicals (such as organic sol-

vents, etc.) and acids can evaporate, or where chemicals and acids

are present in the air.

Corrosive chemicals: Acids, alkalines, liquids containing salt

Flammable chemicals: Organic Solvents

• Do not use paint thinner or organic solvents to clean the GP.

• Do not store or operate the LCD display in areas receiving direct

sunlight, since the sun's UV rays may cause the LCD display’s quality to deteriorate.

• Storing this unit in areas at a temperature lower than is recommended

in this manual’s specifications may cause the LCD display’s liquid

to congeal, which may damage the panel. Conversely, if the storage

area’s temperature becomes higher than the allowed level, the LCD’s

liquid will become isotropic, causing irreversible damage to the LCD.

Therefore, be sure to store the panel only in areas where temperatures are within those specified in this manual.

10

• Do not connect or disconnect the communication cable between the

GP and the host while power is ON.

• Due to the possibility of unexpected accidents, be sure to back up

the GP’s screen data regularly.

GP-2401/2501/2601 Series User Manual

Page 12

Preface

About the GP's Display Panel

• The GP's currently displayed data, its voltage*1 and brightness setting each affect the intensity of Contouring. (i.e, when some parts of

the screen are brighter than others, creating a wavelike pattern)

• There are minute grid-points (dark and light) on the Display Panel's

surface. This is part of the GP's design and not a defect.

• Extended shadows, or "Crosstalk" may appear on the sides of screen

images. This is normal for an LCD display.

• Sometimes the display area may look as if the display colors have

changed. This is a common attribute of LCD's and is not a defect.

• Displaying a single image for long periods can cause an afterimage

to remain when the display is changed to another screen.

To prevent this effect:

Use the GP's "Stand-by Mode", which automatically turns the

screen OFF when there is no input for a specified period of

time.

5.3.1 System Setup

• Write “FFFFh” to the System Data Area’s “Screen Display Off”

address *2 to turn the screen display OFF when the following actions are not performed for the user's designated period of time.

• Change Screen

• Touch Screen

• Alarm Display

Do not display any single screen for a long period of time. Try

to periodically change the screen display.

*1 If the GP's voltage is at the very low end of its allowable range, it may effect the

intensity of contouring.

*2 The following addresses assume all System Data Area settings are entered. If they are

not all entered, the correct word address may be different from those given here.

With the Direct Access Method — use System Data Area word address +9

With the Memory Link Method — use System Data Area word address +12

GP-PRO/PBIII for Windows Device/PLC Connection Manual

GP-2401/2501/2601 Series User Manual 11

Page 13

Preface

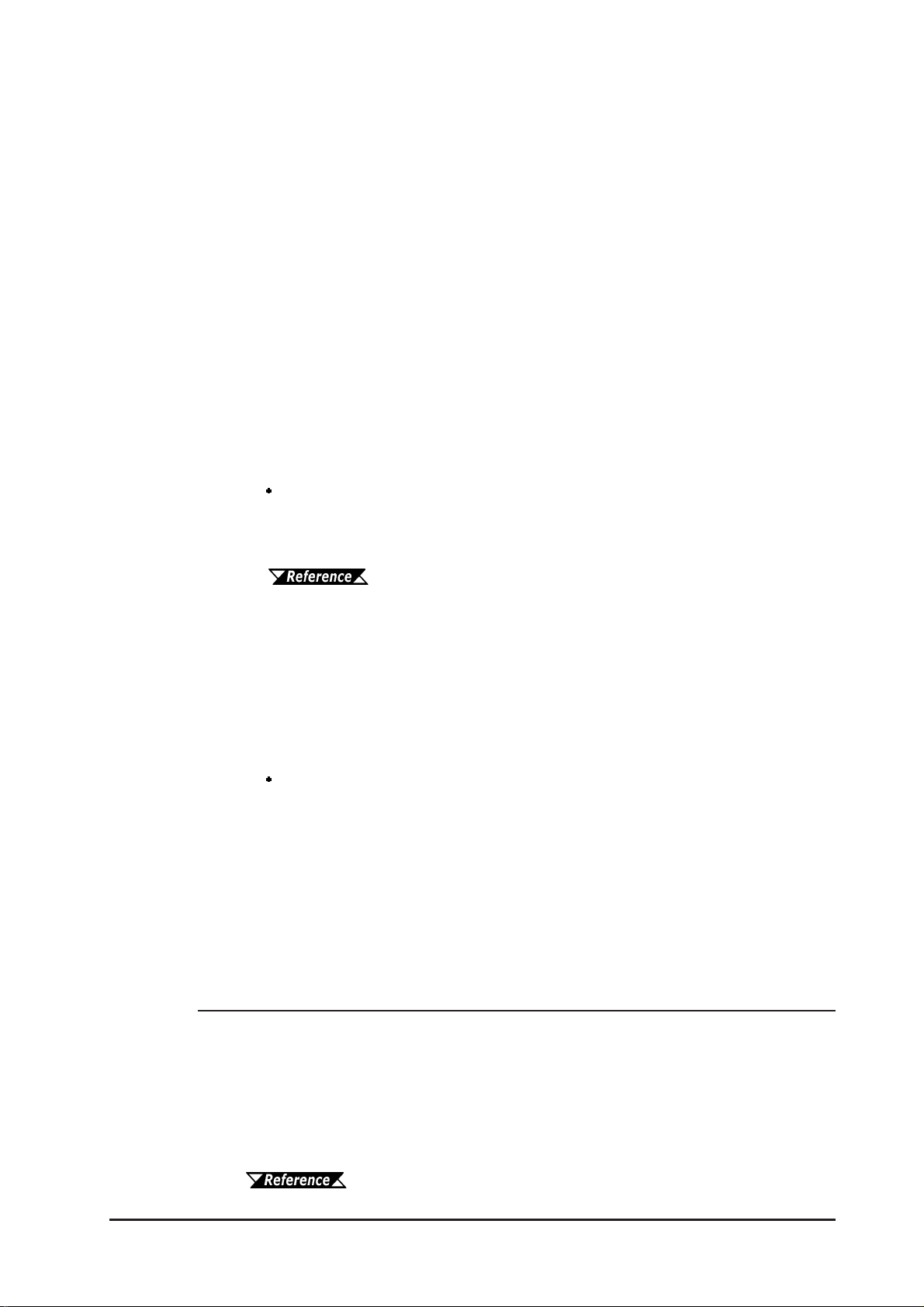

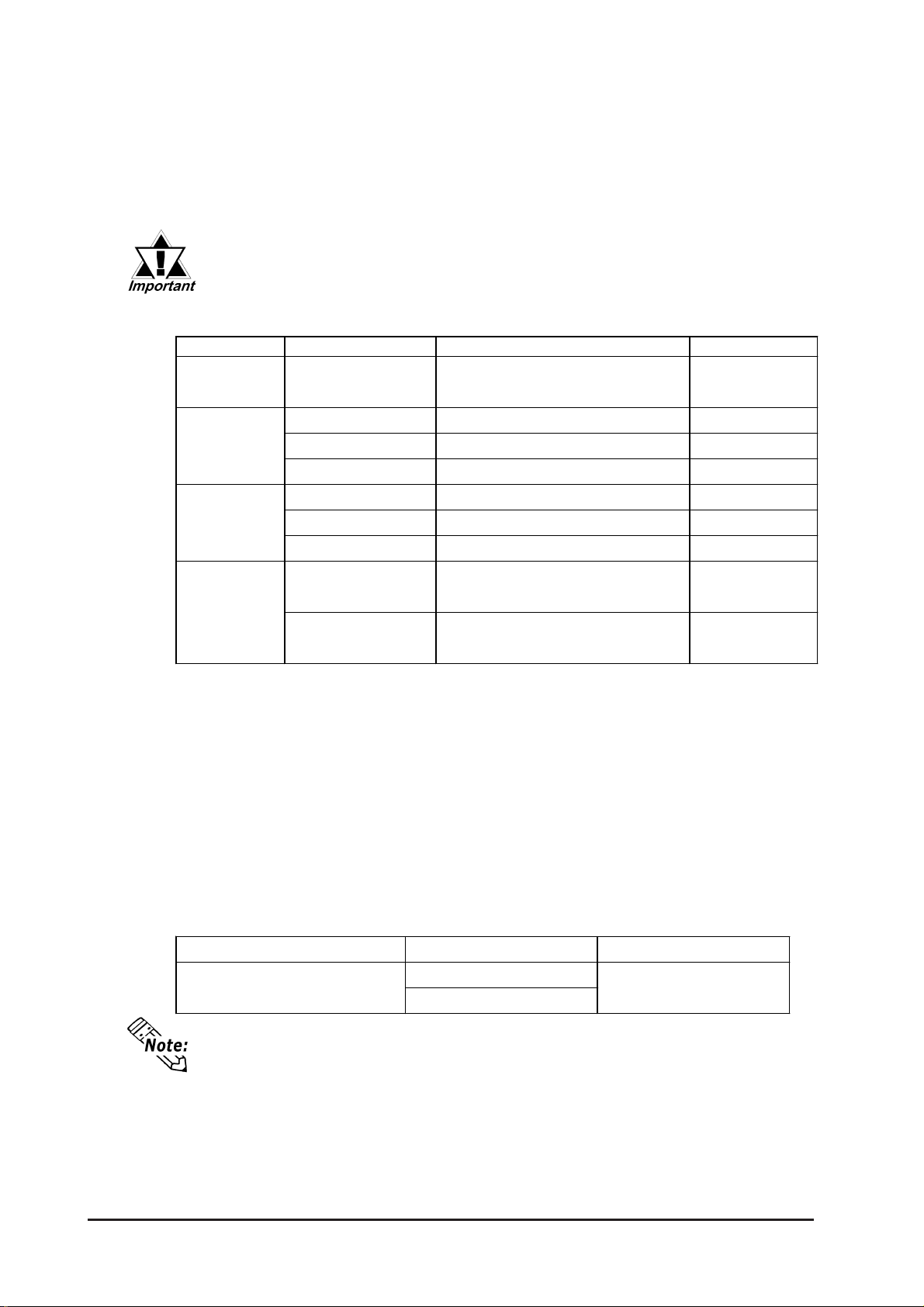

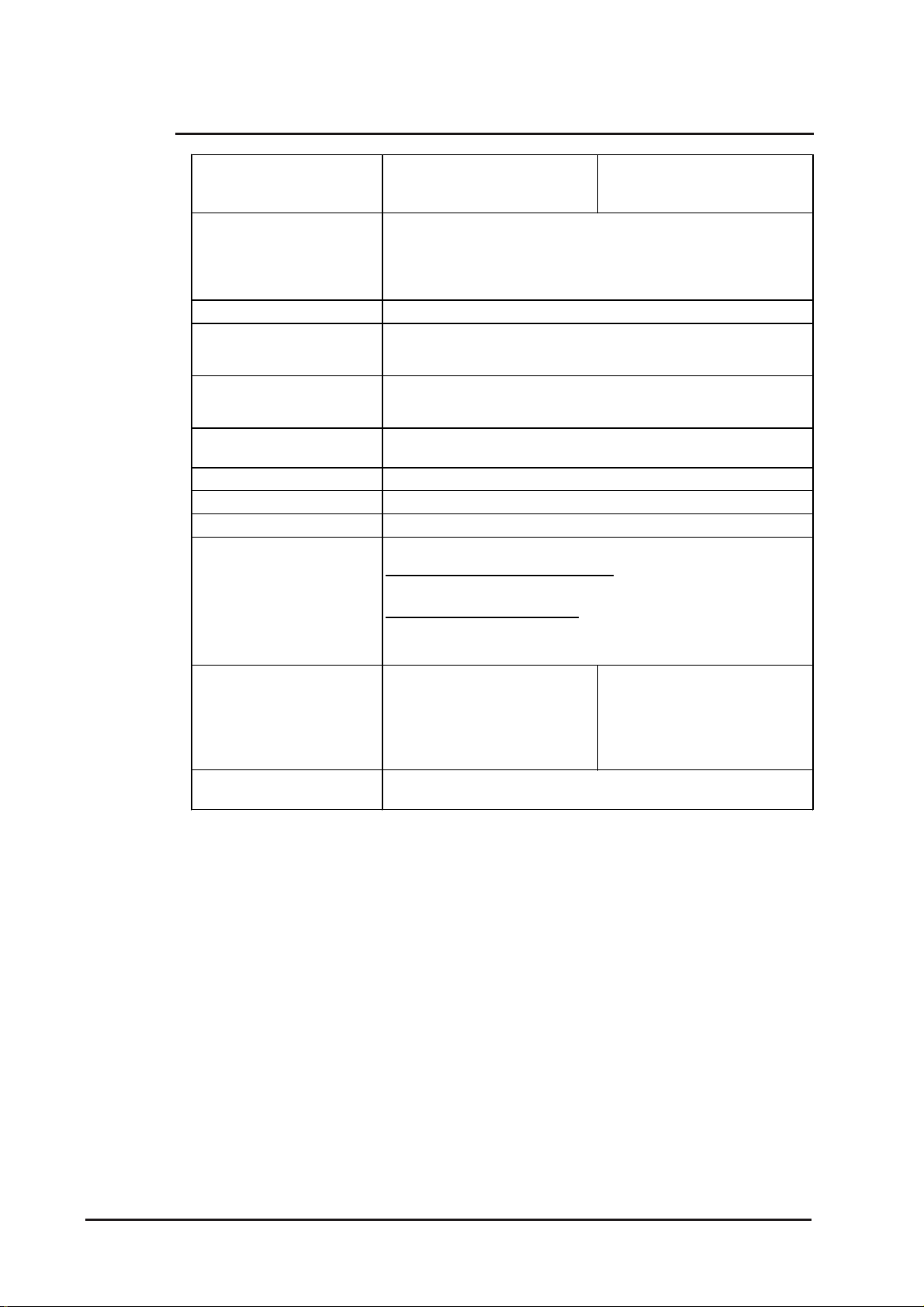

GP-2401/2501/2601 Series Models

The GP-2401/2501/2601 Series refers to the following GP model numbers:

Series

GP-2401

Series

GP2000

Series

GP-2501

Series

GP-2601

Series

*1 Revised models may or may not conform to UL/c-UL (CSA) and CE Markings,

depending on the revision version.

Version" (page 14).

Model Na m e Model Type Comme nts

GP-2401T GP2401-TC41-24V

GP-2501T GP2501-TC11 GP2501

GP-2501S GP2501-SC11 GP2501S

GP-2501L GP2501-LG41-24V

GP-2601T GP2601-TC11

For information on how to determine the revision version, see "Revision

UL/cUL A ppr oved,

CE Marked

*1

UL/cUL A ppr oved,

CE Marked

*1

GP Type in Screen

Creation Software

GP2401

GP2501L

GP2601

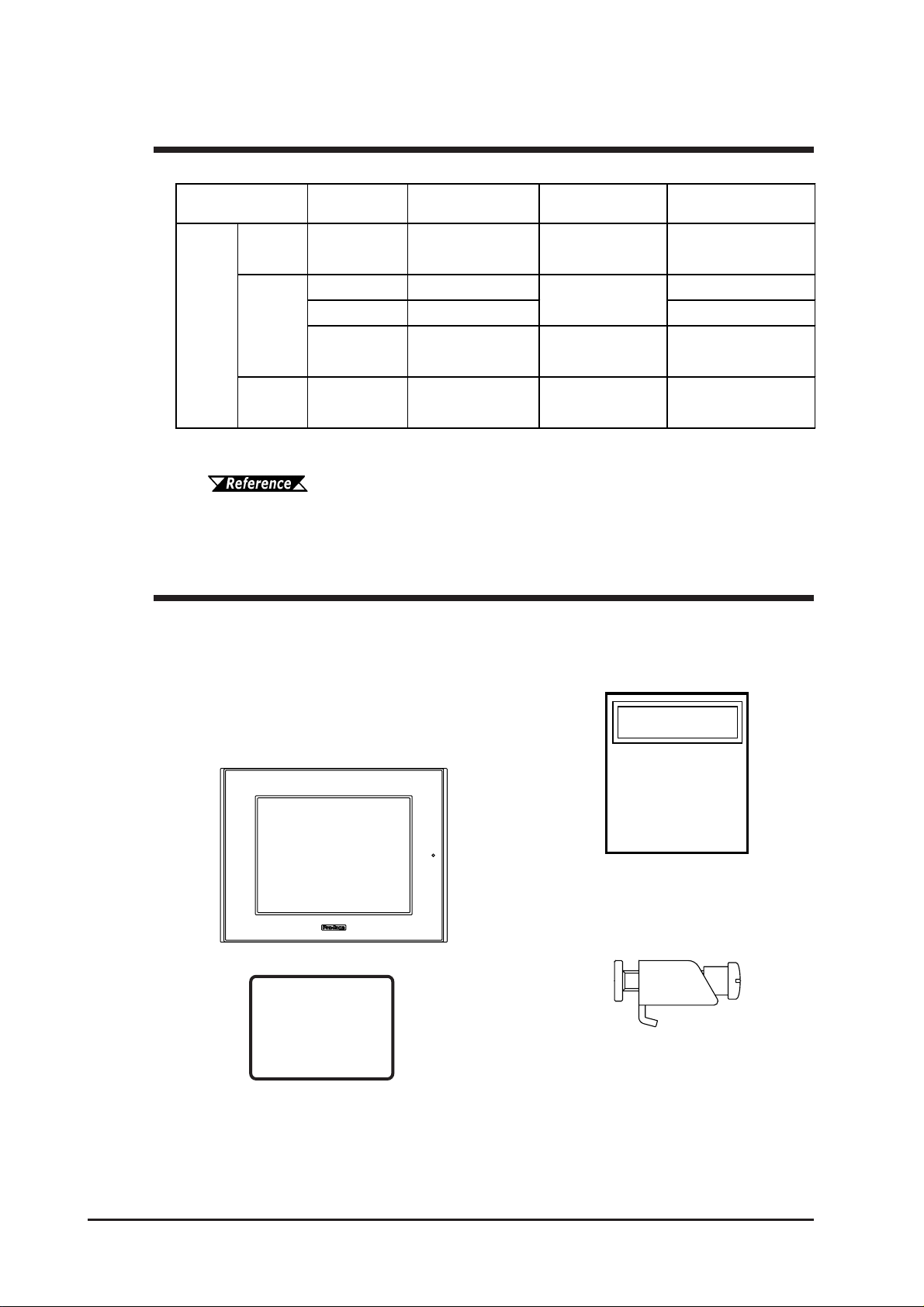

Package Contents

The GP's packing box contains the items listed below. Please check to confirm

that all items shown below have been included.

GP Unit (1)

GP2401-TC41-24V

GP2501-TC11

GP2501-SC11

GP2501-LG41-24V

GP2601-TC11

Installation Gasket (1)

Installation Guide (1)

Installation

Guide

Installation Fasteners

(4/set)

12

This unit has been carefully packed, with special attention to quality. However,

should you find anything damaged or missing, please contact your local GP

distributor immediately for prompt service.

GP-2401/2501/2601 Series User Manual

Page 14

Preface

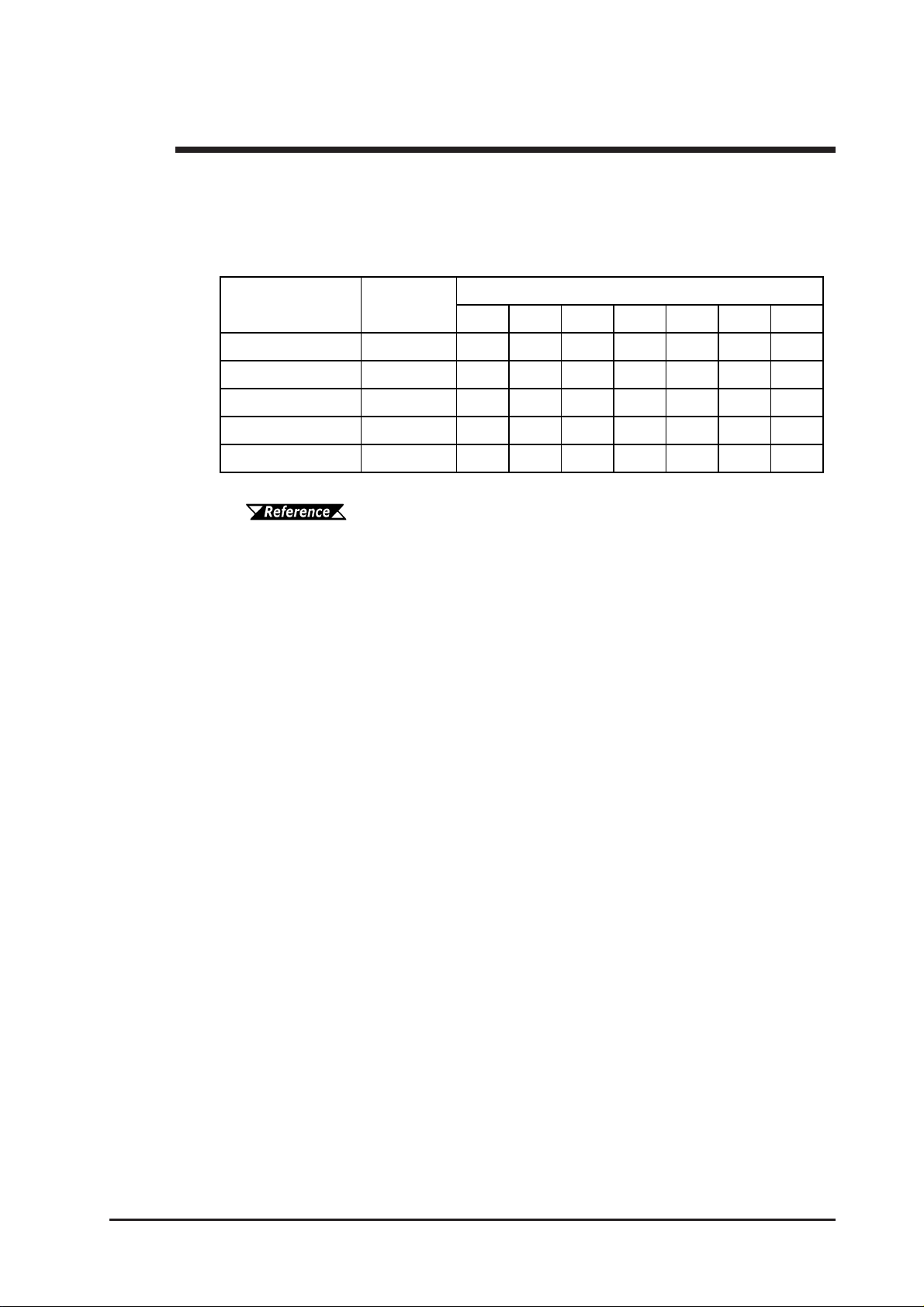

UL/c-UL (CSA) Application Notes

The GP2401-TC41-24V, GP2501-LG41-24V are UL/c-UL (CSA) listed products.

(UL file No.E182139)

The GP2501-TC11*1, GP2501-SC11*1, GP2601-TC11*1 are UL/c-UL (CSA) recognized components. (UL file No.E231702)

These units conform to the following standards:

Model

GP2401-TC41-24V 3180034-01

GP2501-TC11*

GP2501-SC11*

GP2501-LG41-24V 3180045-01

GP2601-TC11*

*1 All GP units marked Revision "3" conform to UL/c-UL standard requirements.

"Revision Version" (page 14).

UL regis tered

format

1

3180021-03

1

3180021-04

1

3180021-05

For more information on how to determine the revision version, see

ABCDEFG

Standards

A) UL508 Industrial Control Equipment

B) UL60950 Safety Standard for Information Technology Equipment (3rd Edition,

issued December 1, 2001)

C) UL1604 Electrical Equipment for use in Class 1 & 2 - Division 2, or Class 3

Hazardous Locations.

D) CAN/CSA-C22.2, Nos. 142, and 213-M1987 Safety Standard for Information

Technology and Electrical Business Equipment

E) CAN/CSA-C22.2 No. 1010-1

Safety Requirement for Electrical Equipment for Measurement, Control and Laboratory Use

F) CAN/CSA-C22.2, No. 60950-00 Safety Standard for Information Technology

Equipment (3rd Edition, issued December 1, 2001)

G) CAN/CSA-C22.2, No. 213-M1987 Safety Standard for Information Technol-

ogy and Electrical Business Equipment

<Cautions>

• GP units must be used as a built-in component of an end-use product.

• GP units must be used indoors only.

• GP units should be installed in the front face of a metal panel.

• If this unit is installed so as to cool itself naturally, be sure to install it in a

vertical panel. Also, be sure that the GP unit is mounted at least 100 mm away

from any adjacent structures or equipment. If these requirements are not met,

the heat generated by the GP unit’s internal components may cause the unit to

fail to meet UL/c-UL standard requirements.

• Be sure to create a power ON/OFF switch for the GP on or in the end-use

product that the GP unit is built-in. Be sure to consider the current and voltage

levels when installing the switch.

• Be sure that the end-use the product uses a UL60950 approved structure.

GP-2401/2501/2601 Series User Manual 13

Page 15

Preface

UL1604 Conditions of Acceptability and Handling Cautions:

1. Power, input and output (I/O) wiring must be in accordance with Class I, Division 2

wiring methods - Article 501- 4(b) of the National Electrical Code, NFP A 70 within

the United States, and in accordance with Section 18-152 of the Canadian Electrical

Code for units installed within Canada.

2. Suitable for use in Class I, Division 2, Groups A, B, C and D Hazardous Locations.

3. W ARNING: Explosion hazard - substitution of components may impair suitability for

Class I, Division 2.

4. W ARNING: Explosion hazard - when in hazardous locations, turn power OFF

before replacing or wiring modules.

5. WARNING: Explosion hazard - do not disconnect equipment unless power has

been switched OFF , or the area is known to be non-hazardous.

6. W ARNING: Explosion hazard - do not connect/ disconnect equipment unless area is

known to be nonhazardous. Port is for system set up and diagnostics.

CE Marking Notes

The GP2401-TC41-24V, GP2501-LG41-24V are CE marked products that conform

to EMC directives EN55011 Class A and EN61000-6-2.

The GP2501-TC11*1, GP2501-SC11

ucts that conform to EMC directives and the Low-voltage directive EN55011

Class A, EN61000-3-2, EN61000-3-3, EN61000-6-2 and EN60950.

For detailed CE marking information, please contact your local GP distributor.

<Cautions>

• GP units must be used as a built-in component of an end-use product.

• GP units must be used indoors only.

• GP units should be installed in the front face of a metal panel.

• If this unit is installed so as to cool itself naturally, be sure to install it in a

vertical panel. Also, be sure that the GP unit is mounted at least 100 mm away

from any adjacent structures or equipment. If these requirements are not met,

the heat generated by the GP unit’s internal components may cause the unit to

fail to meet the standard requirements.

• Be sure to create a power ON/OFF switch for the GP on or in the end-use

product that the GP unit is built-in. Be sure to consider the current and voltage

levels when installing the switch.

• Be sure that the end-use the product uses a EN60950 approved structure.

*1

and GP2601-TC11*1 are CE marked prod-

14

*1 All GP units marked Revision "3" conform to CE Marking standard requirements.

For more information on how to determine the revision version,

see "Revision Version" (page 15).

GP-2401/2501/2601 Series User Manual

Page 16

Preface

Revision Version

The revision version can be determined by the identification label or revision

stickers that are placed on the main unit of the GP. The characters and numerals in

the "REV" area that are replaced with asterisks (*), or marked with a marker

indicate the revision version.

In the example below, the asterisks "*" are placed at positions "D", "1", and "2",

which indicates the revision version as "D, 1, 2".

DIGITAL ELECTRONICS CORP.

REV ABC*EFGHIJKLMNOPQRSTUVWXYZ**345

Identification Label

Revision Sticker

GP-2401/2501/2601 Series User Manual 15

Page 17

Preface

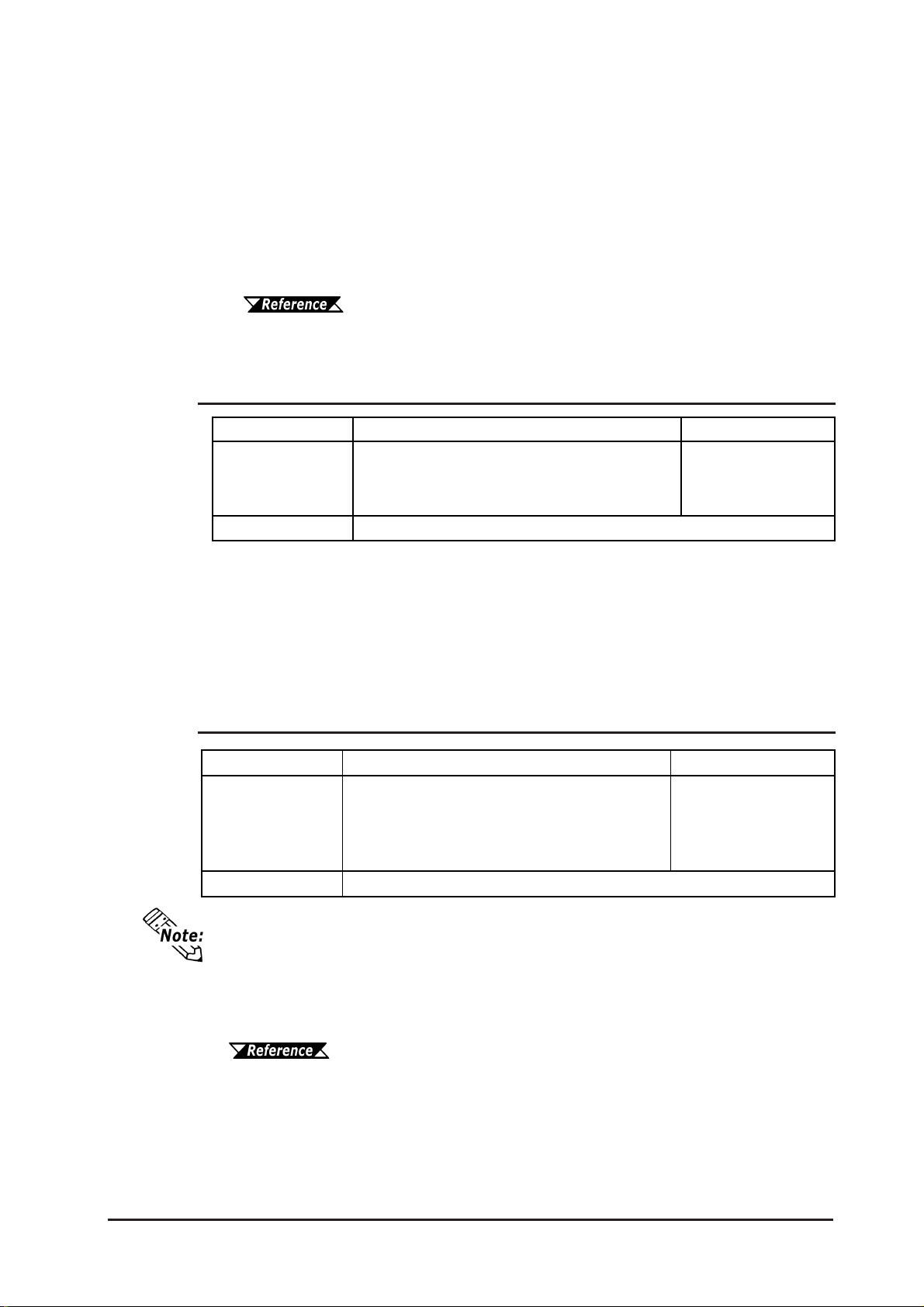

Documentation Conventions

The list below describes the documentation conventions used in this manual.

Symbol Description

Indicates important inf ormation or procedures t hat must be f ollowed for

correct and risk- f r ee s of tware/ device operation.

*1

1) , 2)

GP Screen

Editor

PLC

n:1

Indicates usef ul or important s upplemental information.

Indicates s teps in a procedure. Be sure to perf or m thes e s teps in t he

order given.

Refer s t o use f ul or import ant supplemental inf or mation.

Provides useful or important s upplement al inf or mation.

Indicates t he GP-P RO/ P B I I I for Windows screen editor sof tware

*1

(version 6.10 or higher

For information on how to confirm the version, refer to the “GP-PRO/PB

for Windows Operation Manual”, which is supplied with the GP s creen

editor softwar e.

Abbrev iat ion f or P r ogrammable Logic Controller.

Indicates a multi-link type connection is used.

).

16

*1 GP-PRO/PB III for Windows under Ver.6.22 does not support the following GP units.

Ver.6.10 to Ver.6.1* Ver.6.20 to Ver.6.21

Not suported

GP units

If you install the add-on software, the above GP units will be available.

You can download the add-on software from Pro-face's web site.

(http://www.pro-face.com/)

GP-2401T

GP-2501L

GP-2601T

GP-2501L

GP-2401/2501/2601 Series User Manual

Page 18

1. Prior to Operating the GP

2. System Design

Chapter

3. Accessories

1 Introduction

1.1 Prior to Operating the GP

Be sure to follow these steps when creating projects for the GP unit.

1 Preparation Before using the GP , check that all required hardware is

present and read all specification, wiring, and installation

information.

Chapter 2, "Specifications" and Chapter 3,

"Installation and Wiring"

2 Screen Design Create a sample screen and design a T ag layout, with

the Screen layout sheets and T ag lists provided in the

Editor software.

GP-PRO/PBIII for Windows Operation

Manual

3 Select GP and Using the input areas provided, select the GP and the

PLC types PLC types to be used.

GP-PRO/PBIII for Windows Operation

Manual

GP-PRO/PBIII for Windows Tag

Reference Manual

4 Create Screen/ Run Setup the screen and tags in your screen editing

Screen Setup software according to your Screen Design.

GP-PRO/PBIII for Windows Operation

Manual and Tag Reference Manual

5 Transfer Scr een Data Transfer the data from the Screen editor software on

your PC to the GP unit using the Data Transfer Cable.

GP-PRO/PBIII for Windows Operation

Manual

6 GP/Host Connection Set up the GP so that it can receive data from the Host (PLC).

Chapter 6, "Initialize", and GP-PRO/

PBIII for Windows Device/PLC Connection Manual

7 Connect the GP Link the GP with the host (PLC) using the appropriate con-

nection cable (different cables may be necessary for different

hosts), and then operate the unit.

GP-PRO/PBIII for Windows Device/

PLC Connection Manual

GP-2401/2501/2601 Series User Manual 1-1

Page 19

Chapter 1 - Introduction

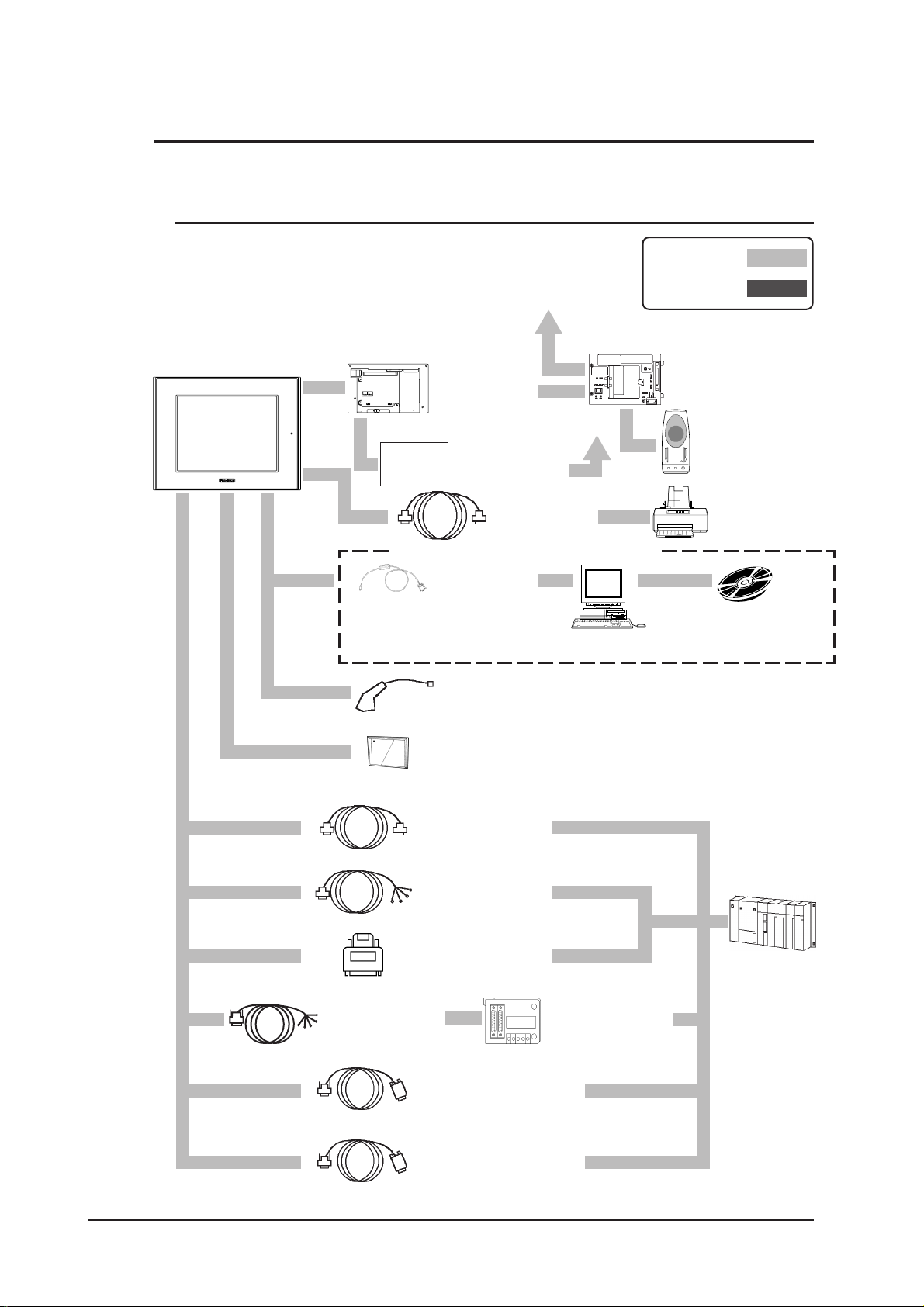

1.2 System Design

The following diagram represents the standard items connected to the GP .

1.2.1 GP-2401/2501/2601 Series System Design

GP RUN Mode Peripherals

To an Ethernet Network

*2

RUN Mode

Edit Mode

GP Unit

(4)

(3)

(1)

(2)

Bus

Conversion

Unit

PSL-CONV00

*1

To each

Expansion

Unit

Network

Communication

Unit

Printer Cable

PSM-PRCB00

When using the Internal 2-Port feature

Data Transfer

Cable

GPW-CB02

Personal

Computer

Bar-Code Reader

(Limited to tested models)

*5

CF Card

CA3-CFCALL/64MB-01, CA3-CFCALL/128MB-01,

CA3-CFCALL/256MB-01, CA3-CFCALL/512MB-01

Speaker

(Commercial

type)

Printer

(Commercial

type)

*5,6

*3

Mitsubishi GPP

Software

*4

1-2

(5) (6)

2 Port Adapter II

Cable

GP070-MDCB11

RS-232C Cable

GP410-IS00-O

RS-422 Cable

GP230-IS11-O

GP230-IS12-O

(for Multi-link cable)

RS-422 Connector

Terminal Adapter

GP070-CN10-O

*7

*7

*7

*7

Mitsubishi PLC A-Series

(7)

Mitsubishi PLC A,

Q, C, FX Series'

2 Port Adapter II

GP070-MD11

(8)

(8)

Program Port I/F Cable

GP430-IP10-O

Mitsubishi PLC FX-Series

Program Port I/F Cable

GP430-IP11-O

(8)

GP-2401/2501/2601 Series User Manual

Host Controller

PLC etc.

Page 20

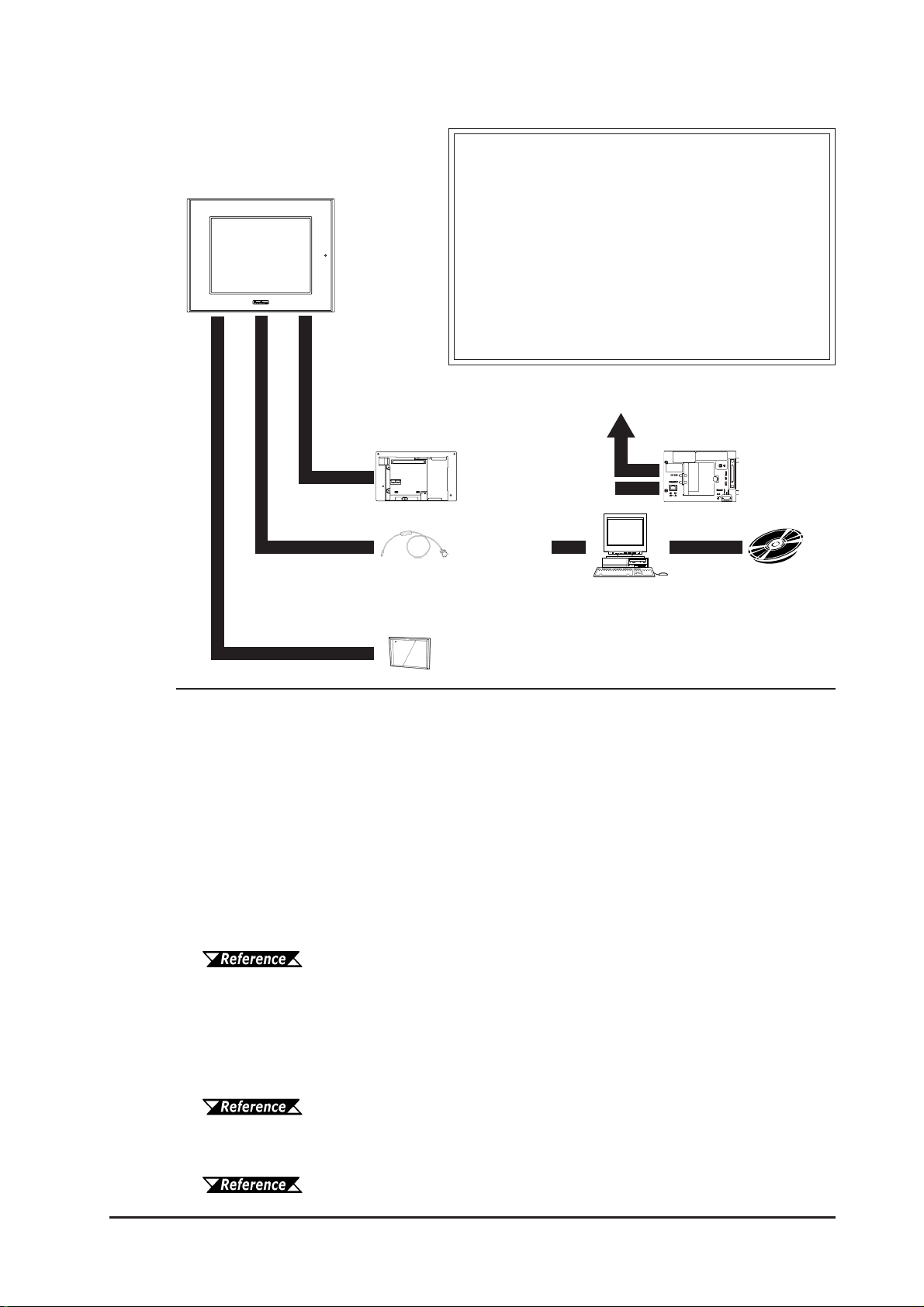

GP Edit Mode Peripherals

Chapter 1 - Introduction

GP Unit

(4)

(3)

(1)

GP Interfaces

(1) Expansion Bus

(2) Printer

(3) T ool Connector

(4) CF Card

(5) SIO

To an Ethernet Network

Bus Conversion Unit

PSL-CONV00

Data Transfer

Cable

GPW-CB02

CF Card

CA3-CFCALL/64MB-01, CA3-CFCALL/128MB-01,

CA3-CFCALL/256MB-01, CA3-CFCALL/512MB-01

*1

Personal

Computer

PLC Interfaces

(6) RS-232C Port

(7) RS-422 Port

(8) Programming Port

*2

GP-PRO/PBIII

*8

for Windows

software

Expansion

Unit

*1 GP-2501T, GP-2501S, GP-2501L and GP-2601T units can use this unit, however the

GP-2401T unit can not.

*2 The optional Bus Conversion Unit and the Ethernet Unit are required to connect a GP-

2501/2601 Series to an Ethernet network.

*3 Compatible with NECPC-PR201/PL , EPSON ESC/P24-J84(C), HP Laser Jet PCL 4

command printers,EPSON PM/Stylus (6-color ink), EPSON Stylus (4-color ink)

printers or their equivalent that are designed for MS-DOS.

Printers designed solely for Windows may not be used. Certain printers containing

both Windows and DOS drivers may be used. For details, please contact your printer's

manufacturer or sales outlet.

*4 About certain types and models of PLC and software, see:

GP-PRO/PBIII for Windows Device/PLC Connection Manual (included

with the screen editor software)

*5 See Page 1-4 for recommended units.

*6 The optional Bus Conversion unit and Sound Output unit (Multi Unit S or Multi Unit

E) are required to connect the GP-2501/2601 Series to speakers.

*7 Certain types and models of PLCs cannot be connected.

GP-PRO/PBIII for Windows Device/PLC Connection Manual (included

with the screen editor software)

*8 Certain types and models of PCs cannot be connected.

GP-PRO/PBIII for Windows Operation Manual (included with the

screen editor software)

GP-2401/2501/2601 Series User Manual 1-3

Page 21

Chapter 1 - Introduction

Recommended Units

The following tables list I/O devices that have been confirmed to be compatible with the

GP . If you connect a device other than those listed below, be sure to confirm that the

connection functions correctly using an actual unit.

Recommended units are subject to change without notice.

Bar code readers (Connected to Tool Connector)

Manufacturer Model Type Description

Aimex

Corporat ion

OPT Electronics

Tohken

NEC Inf rontia

* 1 Be sure to use the Y cable included with the unit and connect it between the GP unit

and a bar code reader. Data cannot be read correctly, if a non-"Y" cable is used, or if

the bar code reader is connected directly to the GP unit.

* 2 The following settings must be entered prior to using the bar code reader with a GP unit.

1) Set the CAPS.

2) Add the Carriage Return (CR) in the Postamble's settings.

For the details about these settings, please refer to the Installation Guide included with the

bar cord reader unit.

BR-331 P C2 Pen

OPT-1105-RSK 98 S et Touch Scanner (Read W idth: 60mm)

OPT-5105-RSK 98 S et Touch Scanner (Read W idth: 80mm)

OPL-6735-RS K 98 Set Touch Scanner (Read W idt h: 100mm)

TCD-5510M Touch Scanner (Read Width: 65mm)

TCD-5510L Touch Scanner (Read W idth: 82mm)

TCD-5510W Touch Scanner (Read Widt h: 105mm)

BCK 5435-STA

BCK 5535-STA

Touch Scanner (Read W idth: 56mm)

Touch Scanner (Read W idth: 85mm)

Includes Y cable for

*1*2

connection cable

Includes Y cable for

*1*2

connection cable

1-4

Speaker

The optional Bus Conversion unit and Sound Output unit (Multi Unit S or Multi Unit E)

are required to connect the GP-2501/2601 Series to speakers.

Manufa cturer Model Connected Vi a

Arrow Electronics Ind. Co. , Ltd. SP OUT, GND

Speakers connected to LINE OUT require an amplifier.

NS-38

NS-105

GP-2401/2501/2601 Series User Manual

Page 22

Chapter 1 - Introduction

1.3 Accessories

All optional equipment listed here is produced by Digital Electronics Corporation.

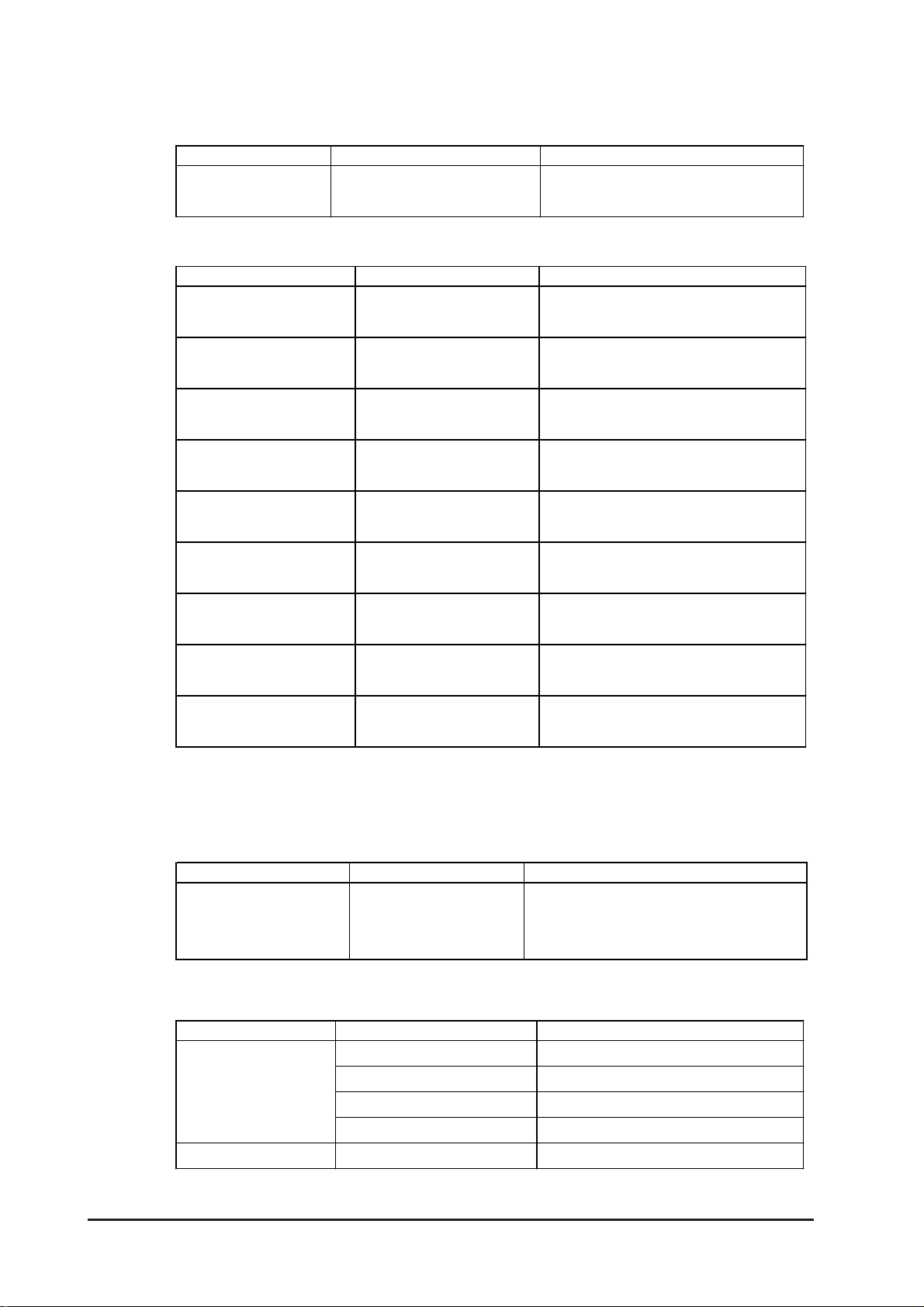

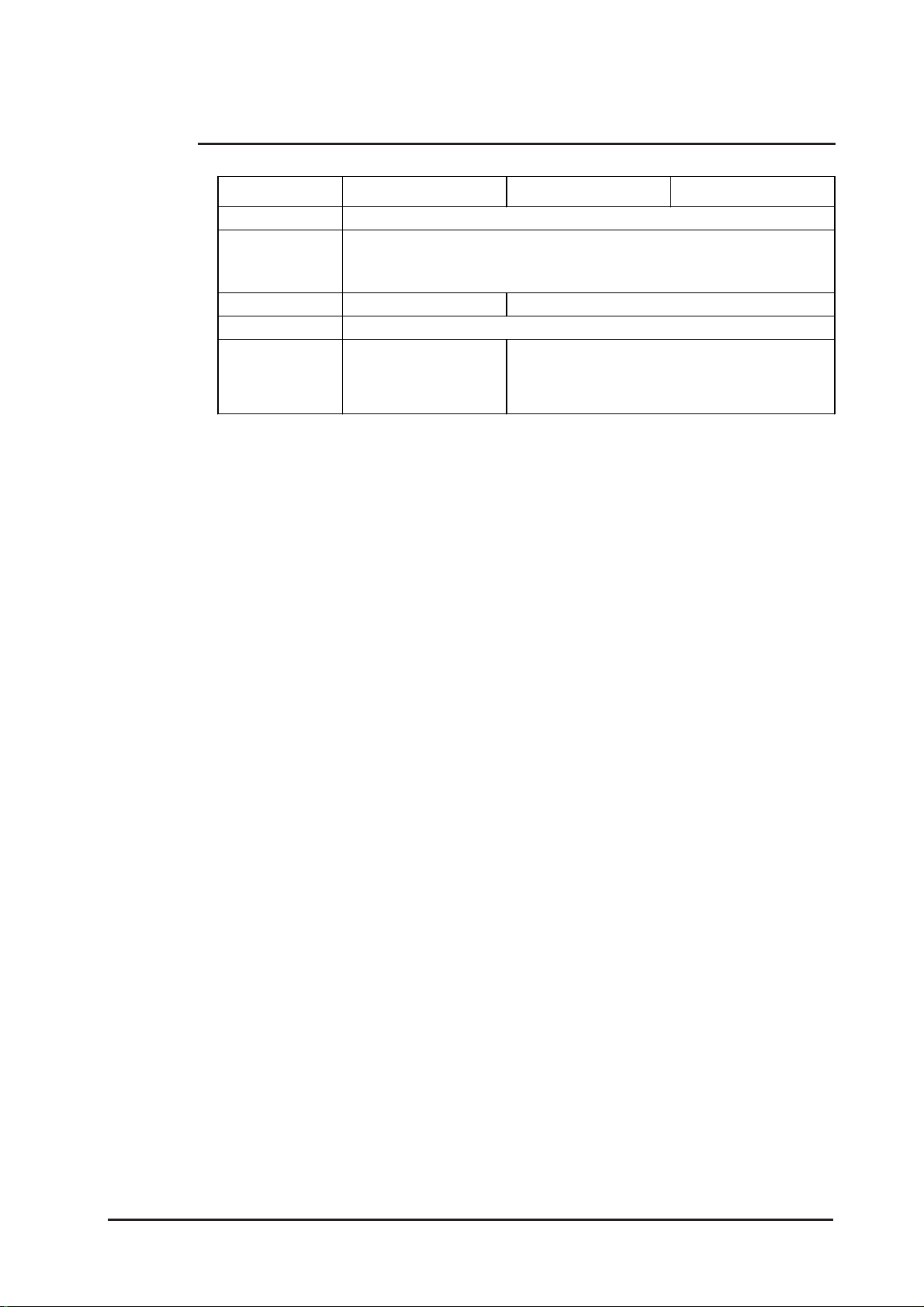

Available Software

Product Na m e Model No. Description

GP-PRO/PB III

C-Package02

(GP-PRO/PB III for

Wi ndows Ver. 6.10 or

later)

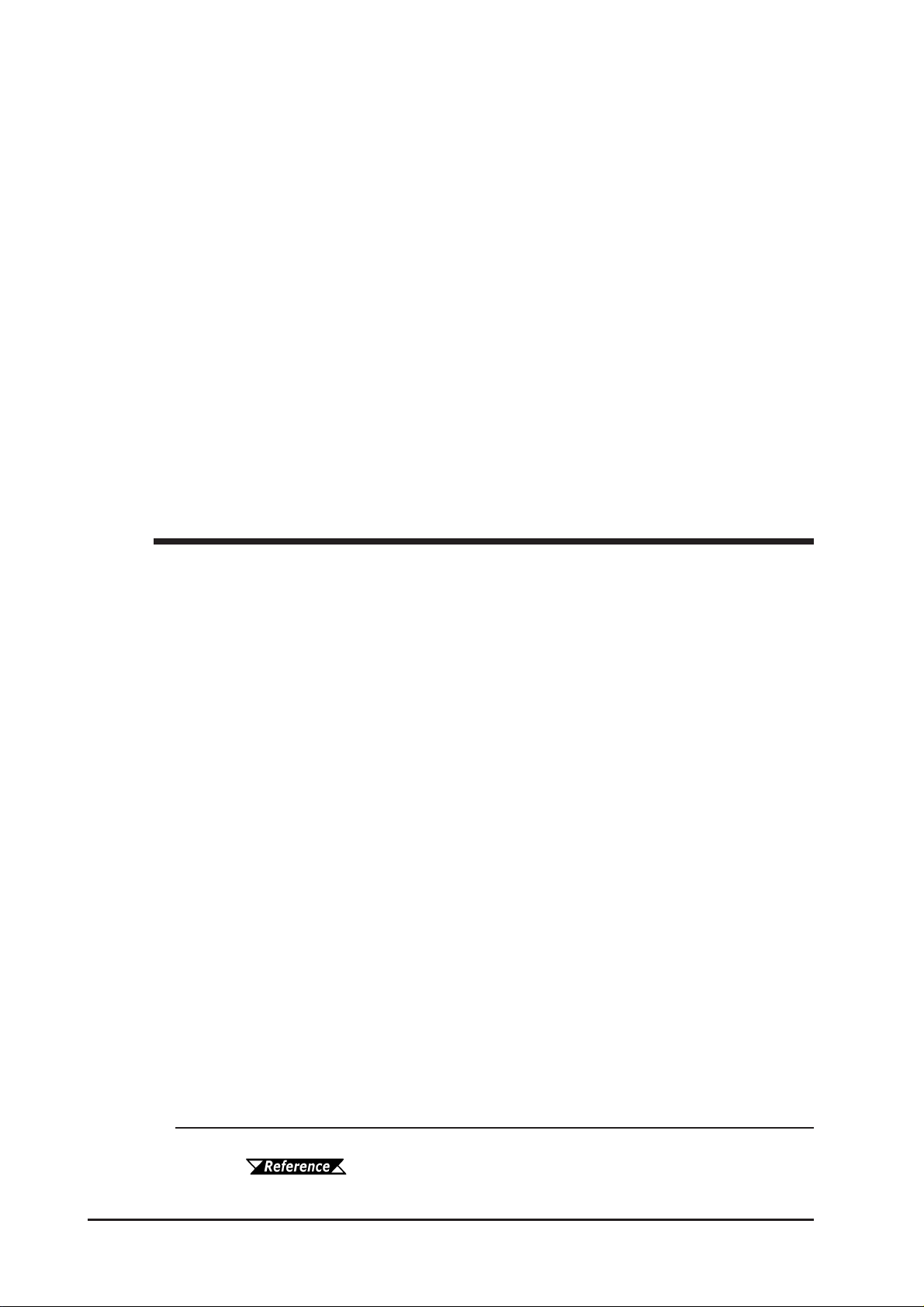

*1 GP-PRO/PB III for Windows under Ver.6.22 does not support the following GP units.

Ver.6.10 to Ver.6.1* Ver.6.20 to Ver.6.21

Not suported

GP units

If you install the add-on software, the above GP units will be available.

You can download the add-on software from Pro-face's web site.

(http://www.pro-face.com/)

GP-2401T

GP-2501L

GP-2601T

GPPRO-CNT01W-P02

*1

GP-2501L

Software to be used to create the GP's

screen data. I ns t alled in a personal

computer.

Tool Connector

Product Na m e Model No. Description

Connects the GP to a personal computer.

Screen Data

Transfer Cable

GPW-CB02

Transfers screen data and us er

program(s).

Serial Interfaces

Product Na m e Model No. Description

RS-232 C cab le

RS-422 C cab les

*1

*1

GP410-IS00-O

GP230-IS11-O

GP230-IS12-O

Int erface cables between t he hos t ( P LC)

and the GP .

(f or Multi- link)

RS-422 Connector

Terminal Adapter

GP070-CN10-O

*1

Conv er sion adapt er t o conv er t s erial dat a

to RS-422 format

Int erf ace unit t hat allows use of both GP

2 Port Adapter II

GP070-MD11

and Mitsubishi A, Q, C and FX ser ies

peripheral equipment.

2 Port Adapter II Ca bl e

Mitsubishi A Serie s

Program m i ng P ort I/F

cable

Mitsubishi FX Seri es

Program m i ng P ort I/F

cable

GP070-MDCB11 Connects t he GP t o 2 P or t Adapter II.

GP430-IP10-O

Connects directly to Mits ubis hi' s P LC

Programming port. S imultaneous use of

programming console, howe ver, is not

GP430-IP11-O

possible.

*1 For detailed information about the range of connectable PLC manufacturers and

models,

GP-PRO/PBIII for Windows Device/PLC Connection Manual

GP-2401/2501/2601 Series User Manual 1-5

Page 23

Chapter 1 - Introduction

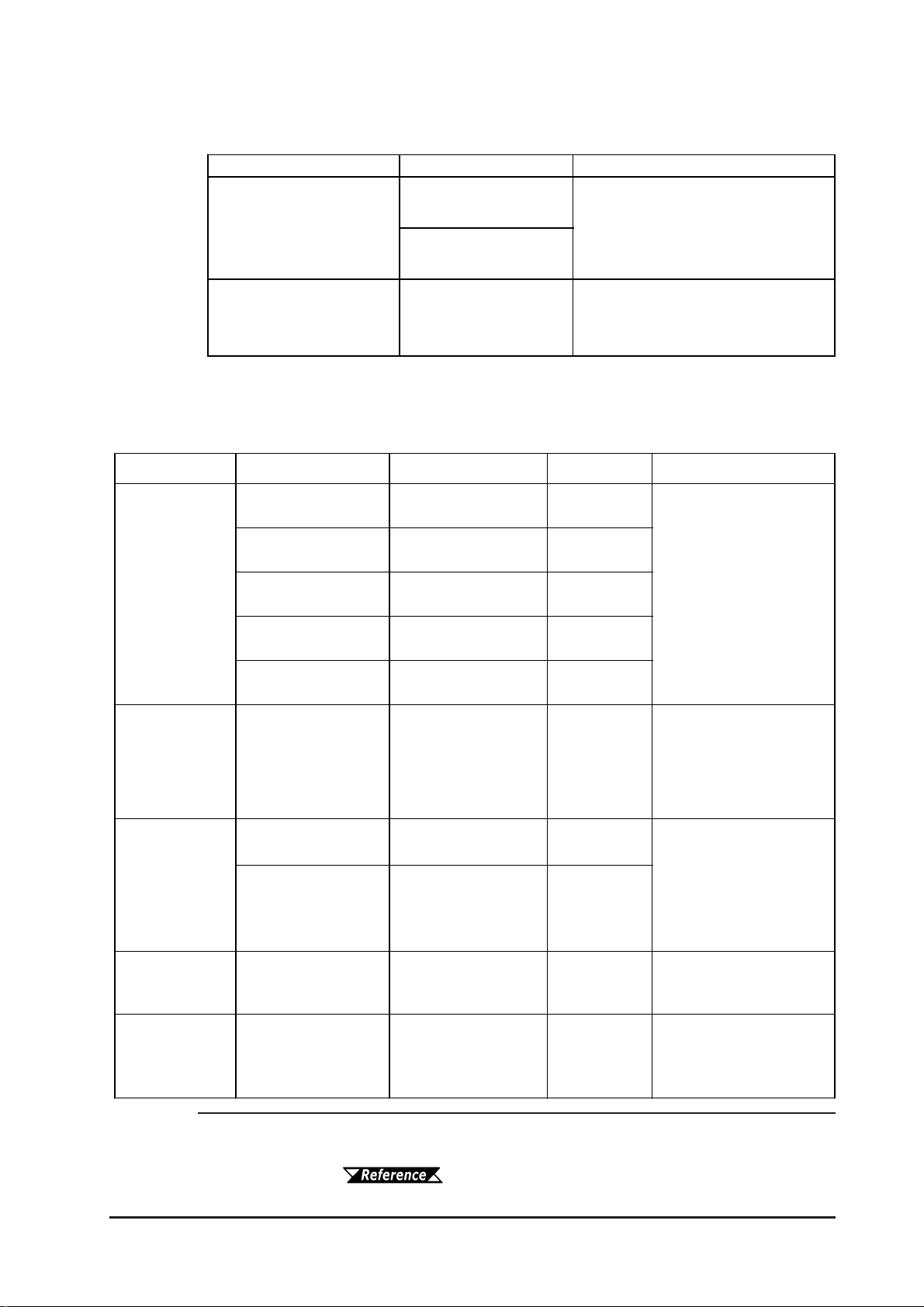

Printer Interface Cable

Product Na m e Mode l No. Description

Printer Ca ble

Expansion Units

Product Na m e Model No. Description

T-Link Unit

De viceNe t Un it

Profibus-DP Unit

IN T ERBUS Unit

CC-Link Unit

MELSECNET/10 Unit

GP Ethernet I/F Unit

Multi Unit S

Multi Unit E

*1

*1

*1

*1

PSM-PRCB00

*1

*1

*1

*1

*1

GP450-ZB21

GP070-DN41

GP070-PF11

GP070-IB41

GP070-CL11

GP070-MNL11

GP070-MNB11

GP070-ET41

GP077-MLTS11

GP077-MLTE41

Cable designed to connect the GP and

a commercial type print er .

Int erface unit t o connect t he GP t o a Fuji

Electric Co. T-Link Networ k .

Int erface unit t o connect t he GP t o a

Dev iceNet Net work . CE / UL

Int erface unit t o connect t he GP t o a

Profibus-DP Net w ork . CE

Int erface unit t o connect t he GP t o an

INTERBUS Network. CE/UL

Int erface unit t o connect t he GP t o a CCLink unit .

Int erface unit t o connect t he GP t o a

MELSECNET/10 unit.

I/ F unit used to connect the GP t o an

Ether net net wor k.

Provides GP-2501/ 2601Ser ies units wit h

a Sound output inter f ace.

Provides GP-2501/ 2601Ser ies units wit h

a Sound ouput and an Ethernet inter f ace.

*1 When using a GP70/77R Series Expansion Unit with a GP-2501/2601 Series unit,

the optional Bus Conversion Unit (PSL-CONV00) is required.

Conversion Unit

Product Na m e Model No. Description

Required when using a GP 70/ 77R S er ies

Bus Conversion Unit PSL-CONV00

Expans ion Unit wit h a GP- 2501/2601 ser ies

unit

CF Card Items

Product Na m e Model No. De scription

CF Card s

CA3-CFCALL/64MB- 01 GP Ser ies CF Car d ( 64MB)

CA 3-CFCALL/128MB-01 GP Series CF Card (128MB)

CA 3-CFCALL/256MB-01 GP Series CF Card (256MB)

CA 3-CFCALL/512MB-01 GP Series CF Card (512MB)

CF Car d Ad ap t o r

GP077-CFAD10 CF Card Adapter f or the PCMCIA S lot .

1-6

GP-2401/2501/2601 Series User Manual

Page 24

Chapter 1 - Introduction

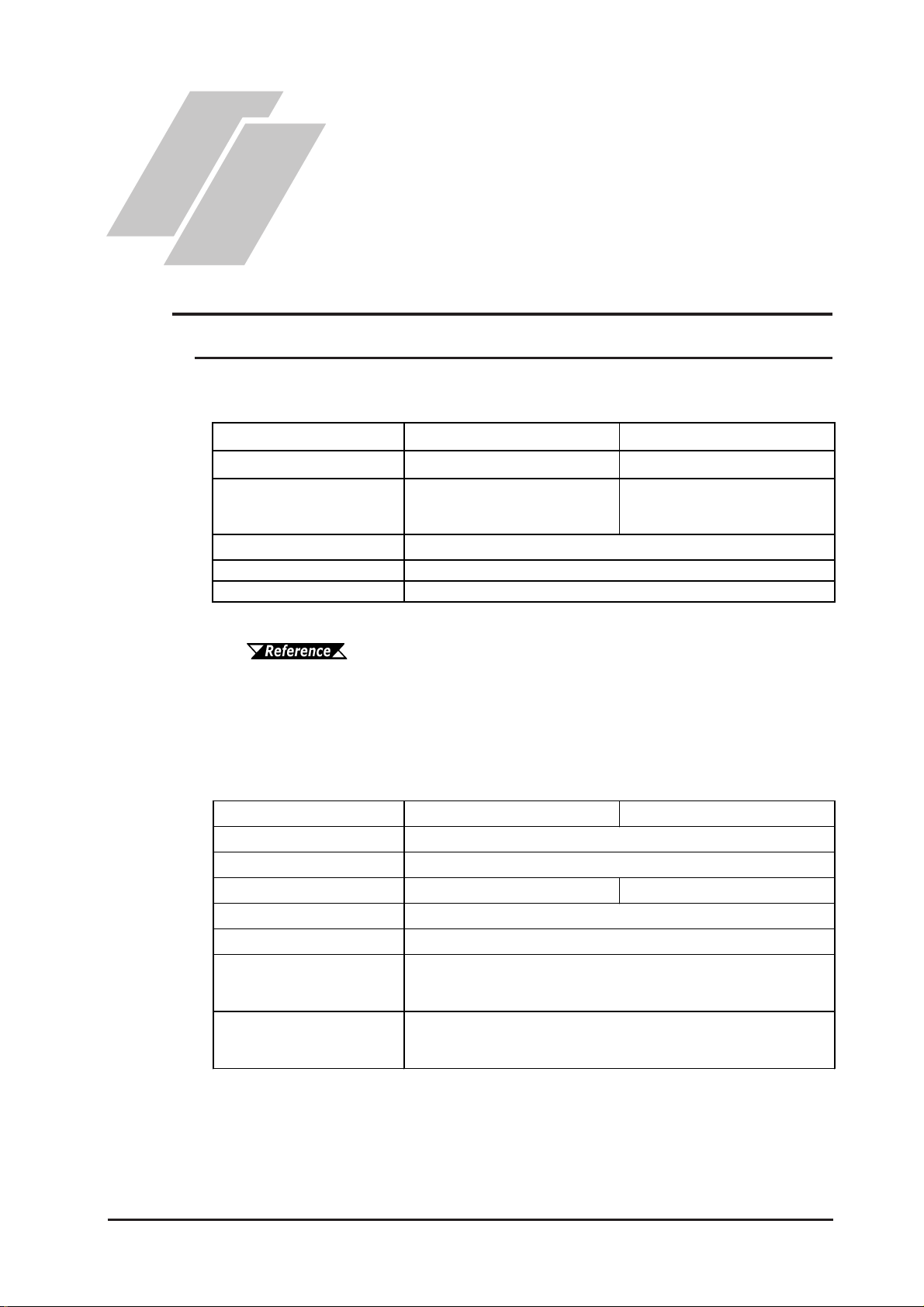

Screen Protection

Product Na m e Mode l No. Description

PSL-DF00

(GP-2501 / 2601 S er ies)

Screen Protection Sheet

PS400-DF00

(GP-2401 S er ies)

Screw Lock Terminal

GPM-AXCN01

Block

Maintenance Items

They are available separately as optional maintenance items.

Product Na m e Mode l No. Corresponding GP Re v. De scription

Disposable, dirt-resistant sheet for the

GP's s creen. The GP's t o uch panel can

be operat ed w it h this cov er s heet

attached. (5 sheets/set)

Connecting to AUX I/O, the terminal can

be used f o r ex ternal res et, alar m outpu t

and buzzer out put .

Backlight

Installation

Fastener

Installation

Gasket

Connector

Cover

Screw Lock

Terminal Block

PS400-BU00-MS GP2401-TC41-24V -

PS501S-BU00 GP2501-SC11 -

GP577RT-BL00-MS GP2501-TC11

CA3-BLU12-01 GP2601-TC11

PS600-BU00 GP2601-TC11

GP-2401 Series

GP070-AT01

PS400-W P00-MS GP-2401 Series -

GP570-WP10-MS

PS-BH01

GPM-AXCN01

GP-2501 Series

GP-2601 Series

GP-2501 Series

GP-2601 Series

GP-2401 Series

GP-2501 Series

GP-2601 Series

GP-2401 Series

GP-2501 Series

GP-2601 Series

Rev.4 is

marked.*1

Rev.4 is not

marked.*1

Replacement Backlight

Facteners to attach the

-

-

-

-

GP to a panel.

(4 fasteners/set)

Provides a moisture

resistant seal when

installing the GP. Same

as the seal include in

the GP's original

equipment package.

Atta c h e s to GP re a r

face connectors.

This Connector is used

for external reset, alarm

output, buzzer output,

or sound output.

*1The corresponding backlight unit differs depending on GP-2601

Series unit's marked Revision.

For more information on how to determine the

revision version, see "Revision Version" (page 15).

GP-2401/2501/2601 Series User Manual 1-7

Page 25

Memo

Page 26

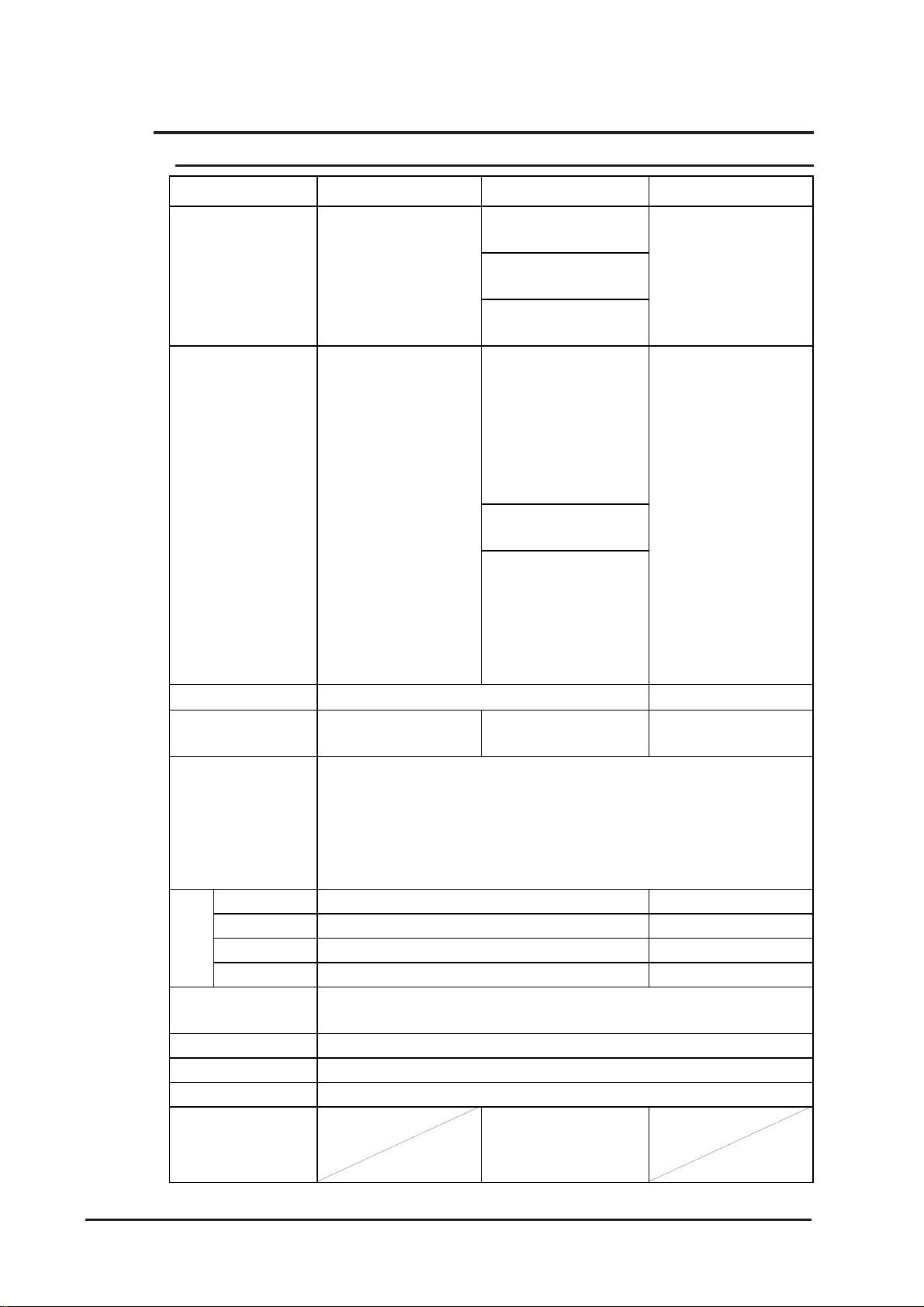

1. General Specifications

Chapter

2. Functional Specifications

3. Interface Specifications

2 Specifications

2.1 General Specifications

2.1.1 Electrical

GP2501-TC11/GP2501-SC11/GP2601-TC11

4. Part Names and Functions

5. Dimensions

Ra ted V o ltag e

Rated Vol ta ge Range

Pow er Consumption

Allowable Voltage Drop

Volta ge Endurance

Insulat ion Re sistance

*1 All GP units marked Revision "3" conform to the specifications.

For more information on how to determine the revision version,

see "Revision Version" (page 14).

GP2401-TC41-24V/GP2501-LG41-24V

Ra ted V o ltag e

Rated Vol ta ge Range

Pow er Consumption

Allowable Voltage Drop

In-rush Current

AC1500V 20mA for 1 minute (b et ween charging and FG ter minals)

10MΩ or higher at DC500V (bet ween charging and FG terminals)

AC100V

AC85V to AC132V

50V A or less (A CI N100V)

50VA or less

85V A or less (A CI N240V)

20ms or less

GP2401-TC41-24V GP2501-LG41-24V

DC24V

DC19.2V to DC28.8V

28W or les s 50W or les s

10ms or less

30A or less

AC100V to AC240V

AC85V to AC265V

*1

*1

*1

*1

Volta ge Endurance

Insulat ion Re sistance

AC1000V 20mA f or 1 minute

(between charging and FG terminals)

10MΩ or higher at DC500V

(between charging and FG terminals)

GP-2401/2501/2601 Series User Manual 2-1

Page 27

Chapter 2 - Specifications

2

2

2.1.2 Environmental

Ambient Operating

Temperature

(Cabinet Interior)

(Panel Face)

Storage Temperature

Opera ting Humi dity

Storage Humidity

Atmosheric Endurance

(G P Oper ation Altitude)

Air P u r ity (Du st)

Pollution De gre e

Corrosive Ga sse s

Vibra tion Re sistance

Noise Immunity

(via noise simulator)

Electr o static Di schar g e

Immunity

GP2401-TC41-24V

GP2501-LG41-24V

0oC to +50oC

-20oC to +60oC

10%RH to 90%RH

(Non condensing, wet bulb t emperat ur e: 39

10%RH to 90%RH

(Non condensing, wet bulb t emperat ur e: 39

800hPa to 1114hPa ( 2000 mete rs o r low er )

0.1mg/m

3

or less (non-conductive levels)

Pollut ion Degre e 2

Free of corrosive gasses

IEC61131-2(JIS B 35 01) c o m pl i ant

W hen vibratio n i s NO T continuo us

10Hz to 57Hz 0. 075mm, 57Hz to 150Hz 9.8m/s

W hen vibratio n i s contin uous

10Hz to 57Hz 0.035mm, 57Hz t o 150Hz 4.9m/s

X, Y, Z directions for 10 times (80min.)

Noise Volt age:

1000Vp-p

Pulse Duration:1µs

Rise Time:1ns

6kV (complies with I E C 61000- 4-2 Level 3)

GP2501-TC11

GP2501-SC11

GP2601-TC11

*1

o

C or less)

o

C or less)

Noise Volt age: 1500Vp-p

Pulse Duration: 1µs

Rise Time: 1ns

2-2

*1 When using GP-2501L/GP-2501S/GP-2601T in an environment where the

temperature becomes or exceeds 40

o

C for an extended period of time, the screen

contrast level may decrease from its original level of brightness.

GP-2401/2501/2601 Series User Manual

Page 28

2.1.3 Structural

Chapter 2 - Specifications

GP-2401 Ser i es GP-2501 Ser i es GP-2601 Ser i es

Grounding

Ratings

(For front panel of

installed unit)

Weight

Cooling Me thod

External

3.

Dimensions

*1

1.7 k g (5.5lb) or les s

W215mm [8.46in]

x H170mm [6.69in]

x D60mm [2.36in]

100Ω or less , or your countr y's applicable standar d

Equivalent t o I P 65f (JE M 1030)

NEMA #250 Type4X/12

3.5k g ( 7.7lb) or les s

Natural air circulation

W317mm [12.48in]

x H243mm [9.57in]

x D58mm [2.28in]

*1 The front face of the GP unit, installed in a solid panel, has been tested using

conditions equivalent to the standards shown in the specification. Even though

the GP unit’s level of resistance is equivalent to these standards, oils that should

have no effect on the GP can possibly harm the unit. This can occur in areas

where either vaporized oils are present, or where low viscosity cutting oils are

allowed to adhere to the unit for long periods of time. If the GP’s front face

protection sheet becomes peeled off, these conditions can lead to the ingress of

oil into the GP and separate protection measures are suggested. Also, if nonapproved oils are present, it may cause deformation or corrosion of the front

panel’s plastic cover. Therefore, prior to installing the GP be sure to confirm the

type of conditions that will be present in the GP’s operating environment. If the

installation gasket is used for a long period of time, or if the unit and its gasket

are removed from the panel, the original level of the protection cannot be guaranteed. To maintain the original protection level, you need to replace the installation gasket regularly.

GP-2401/2501/2601 Series User Manual 2-3

Page 29

Chapter 2 - Specifications

2.2 Functional Specifications

2.2.1 Display

GP-2401 Ser i es GP-2501 Ser i es GP-2601 Series

Type

Colors

TFT type color LCD

256 / No blink *1,

64 colors / 3- sp eed blink

(Color s w it ching is do ne

via software)

GP-2501L

Monochrome LCD

GP-2501S

STN type color LCD

GP-2501T

TFT type color LCD

GP-2501L

Black and Wh it e,

2 lev e ls of gray/

8 lev e ls of gray*

2

(Color s w it ching is do ne

via software)

GP-2501S

64 colors / 3- sp eed blink

GP-2501T

*1

256 / No blink

,

64 colors / 3- sp eed blink

(Color s w it ching is do ne

via software)

TFT type color LCD

256 / No blink *1,

64 colors / 3- sp eed blink

(Color s w it ching is do ne

via software)

Resolution

Effective Display

Area

640 x 480pix els

W149.8mm [5.90in.] x

H112.3mm [4.42in.]

W211.2mm [8.34in.] x

H158.4mm [6.24in.]

800 x 600pix els

W246mm [9.69in.] x

H184.5mm [7.26in.]

ASCI I : (Code page 850) Alphanumeric (incl. Eur. character s)

Chinese: (GB2312-80 codes) simplified Chinese font s

Language Fonts

Japanese: ANK 158, K anji : 6962 (J I S Standards 1 & 2)

Korean: ( K SC5601 - 1992 codes) Hangul fonts

Taiwanese: (Big 5 codes) tradit ional Chinese f ont s

8x8 dot s 100 Char. x 75 ro ws

8x16 dot s 100 Char. x 37 rows

Text

16x16 dots 50 Char. x 37 r ows

32x32 dots 25 Char. x 18 r ows

80 Char. x 60 r ows

80 Char. x 30 r ows

40 Char. x 30 r ows

20 Char. x 15 r ows

Hight can be expanded 1 t o 8 times.

Font Sizes

Character Sizes

Backlight

Brightness Control

Width can be expanded 1/2

*3

8X8 dot font, 8X16 dot font , 16X 16 dot font and 32X32 dot f ont

CCFL (Service life: 50, 000 hrs . at 25

4 lev els of adjustment available v ia t ouch panel.

*4

, 1 to 8 times.

o

C and 24hr. oper at ion)

8 lev e ls of adjust ment

Contrast

Adjustment

available v ia touch panel.

(GP-2501 L/ S Only)

2-4

GP-2401/2501/2601 Series User Manual

Page 30

Chapter 2 - Specifications

*1

*1 Changing the “Colors” setting to “256 colors” will disable the blink feature on

all of your project’s screens. If you wish to use the blink feature, do not change

this setting to “256 colors”.

*2 In order to set the monochrome (eight levels of gray) mode, GP-PRO/PB III for

Windows Ver. 6.2 or later is required. Depending on the color used, selecting

MONOCHROME 8 HUES may cause the GP unit’s screen to flicker and make it

difficult to distinguish colors. Confirm that all colors display as expected prior

to using this mode.

*3 The display font will differ depending on which (language) character set used,

or which size you select.

Chapter 6.8 SET UP SCREEN

*4Only available when using “Half-2 Byte Character” settings via software.

(Only Chinese, Taiwanese, and Korean OS)

2.2.2 Memory

GP-2401/GP-2501 Series

2MB FLASH EPROM

Application

Da ta Backup

[Approx. 640 screens at 3.2K B / s creen]

*1 A Lithium battery's lifetime is:

10 years when the battery's ambient temperature is 40

4.1 years when the battery's ambient temperature is 50

1.5 years when the battery's ambient temperature is 60

When used for backup:

Approximately 60 days, with a fully charged battery

Approximately 6 days, with a half-charged battery

2.2.3 Touch Panel • Clock

GP-2401/ GP -2501 S eri es

Touch P ane l

Resolu ti on

Clock Accuracy

32 x 24 k eys / s creen

1 or 2 point pus h - s electable

+/- 65 s econds/ month (at r oom temperature)

4MB FLASH EPROM

[Approx. 1280 screens

128KB SRAM [uses a lit hium batt er y]

o

C or less.

o

C or less.

o

C or less.

GP-2601 Series

at 3. 2K B/screen]

GP-2601 Ser i es

40 x 30 k eys

/screen

1 or 2 point pus h-

selectable

The GP's internal clock has a slight error. At normal operating temperatures and

conditions, with the GP operating from its lithium battery, the degree of error is 65

seconds per month. Variations in operating conditions and battery life can cause this

error to vary from -380 to +90 seconds per month. For systems where this degree

of error will be a problem, the user should be sure to monitor this error and make

adjustments when required.

Chapter 6.7 SET UP CLOCK

GP-2401/2501/2601 Series User Manual 2-5

Page 31

Chapter 2 - Specifications

2.2.4 Interfaces

Asynchronous Transmission : RS - 232C/ R- S 422, Dat a Lengt h: 7 or 8 bit s ,

Serial Interface

Tool Connector

CF Card Interface

Printer Interface

AUX Input/Output

Stop Bit: 1 or 2 bits, Parity: None, Odd or Even, Data Transmission Speed:

2,400bps t o 115.2kbps

Asynchronous TTL lev el nonprocedural command I/F

<During s creen f ile development>

Used f or transferring data to and f r om t he GP ap plication s oftware and the

GP. U s ed for dat a transf e r w it h the 2-Po rt feature.

<During Oper at ion>

Used f or a variety of devices, including a bar-code reader.

1 slot

Compatible with NECPC-PR201/PL , EPSON ESC/P24-J84(C),

HP Laser Jet PCL 4 command, EPSON PM/Sty lus (6-color ink), EPSON

St ylus ( 4- color ink) compatible print ers

Remote Reset Input : 1 point

Input Voltage : DC24V +/- 10%

Input Current : 4mA (TYP)

Min. Input P uls e Width : 2ms

Operating Voltage : (When ON) Min. DC21.1V

(When OFF) Max. DC3V

*2

Is olation Method : P hotocoupler Isolation

Output - 3 Points (RUN Output - 1 point, System Alarm Output - 1 point,

External Buzz er Output - 1 point)

Rated Voltage : DC24V

Rated Current : 50mA / point

W ire Gauge: AWG28 to AWG16

*1

2-6

*1 Printers with only Windows drivers cannot be used. However, certain types of printers with both

Windows and DOS drivers can be used. For details, contact your local GP distributor.

*2 Using the AUX Input/Output I/F requires the separately sold Screw Lock Terminal Block.

GP-2401/2501/2601 Series User Manual

Page 32

Chapter 2 - Specifications

2.3 Interface Specifications

2.3.1 Serial Interfaces

This interface can be either RS-232C or RS-422. Connects GP to Host (PLC). This

interface uses a socket-type connector .

Pin A ss ignm e nts Pin # Signal N a m e C ondit ion

1 FG Frame ground

(D-Sub 25pin female)

SIO 4 RS Request send (R S -23 2C)

1

14

25

13

2 SD Send data (RS- 232C)

3 R D Receiv e data (RS- 232C)

5 CS Clear s end ( RS - 232C )

6 DR Dat a S et Ready (RS- 232C)

7 SG Sig nal g r oun d

8 CD Carrier detect (RS -232C)

9 TRMX Termination (RS - 422)

10 RDA Receive data A (RS- 422)

11 SDA Send data A (RS-422)

12 NC No connection (Reser ved)

13 NC No connection (Reser ved)

14 V CC 5V± 5% out put 0. 25A

15 SDB Send data B (RS - 422)

16 RDB Receive data B (RS -422)

17 RI Ring Indicate (RS -232C)

18 CSB Clear send B (RS - 422)

19 ERB Enable receiv e B (RS - 422)

20 ER Enable receive (RS-232C)

21 CSA Clear send A (RS - 422)

22 ERA Enable receiv e A (RS-422)

23 NC No connection (Reser ved)

24 NC No connection (Reser ved)

25 NC No connection (Reser ved)

Recommended Connector: Dsub25pin plug XM2A-2501<made by OMRON>

Recommended Cover: Dsub25pin cover XM2S-2511<made by OMRON>

Jack Screws: XM2Z-0071<made by OMRON>

• Use rough metric type M2.6x0.45 threads used to secure the cable's set

screws.

Recommended Cable: CO-MA-VV-SB5PX 28AWG <made by HITACHI Cable

Ltd.>

• To confirm your PLC's connection specifications, refer to

GP-PRO/PBIII for Windows Device/PLC Connection Manual

(included with the screen creation software)

GP-2401/2501/2601 Series User Manual 2-7

Page 33

Chapter 2 - Specifications

When creating your own cable, follow the instructions listed below:

<With RS-422>

• The following pairs of pin numbers must be connected to each other.

#18 (CSB) <—> #19 (ERB)

#21 (CSA) <—> #22 (ERA)

• When connecting the RS-422 cable and the #9 (TRMX) and #10 (RDA) points,

a termination resistance of 100

• When making a cable for a Memory Link system, be sure to use a 4-wire type.

<With RS-232C>

• Do not use the following pins: 9 (TRMX), 10 (RDA), 11 (SDA), 15 (SDB), 16

(RDB), 18 (CSB), 19 (ERB), 21 (CSA), 22 (ERA).

• The #1 (FG) terminal should only be connected if it is required by the device being

connected to.

• This unit’s serial port is not isolated, therefore, it is important that

you connect the SG (Signal Ground) terminals. If this is not done,

the RS422 circuit may be damaged.

ΩΩ

Ω is added between RDA and RDB.

ΩΩ

• Pin 14 (VCC) DC5V output is not protected. To prevent damage or

unit malfunction, be sure to use only the designated level of current.

2.3.2 Printer Interface

When connecting a printer, use Digital’ s printer cable (PSM-PRCB00).

Pin A ss ignm e nts Pin # Signal Na m e Condition

1 GND Ground

2 RESERVE Reserved

3 P DB 5 Dat a S ignal

4 P DB 4 Dat a S ignal

5 P DB 3 Dat a S ignal

6 GND Ground

7 SLCT Select S t at us ( I nput)

1

10

11

20

8 P DB 0 Dat a S ignal

9 PSTB

St r obe S ignal ( Out put)

*1

10 BUSY Busy Signal (Input)

11 PDB7 Data Signal

12 PDB6 Data Signal

13 GND Ground

14

ERROR Printer Error (Input)

*1

15 GND Ground

16 PDB2 Data Signal

17 PDB1 Data Signal

18 PE

Paper Runout

*1

19 INIT Initialization Signal (Output)

2-8

20 GND Ground

*1 Not available with GP software.

GP-2401/2501/2601 Series User Manual

Page 34

Chapter 2 - Specifications

2.3.3 AUX Input/Output I/F

This interface is used for external reset, alarm output and buzzer output.

Pin A ss ingm e nts Pin # S ignal N a m e Condition

1 A UX COM External Reset Common

2 AUXRESET External Reset Input

1

12

3 RUN ONLINE Operation

4 A LARM Syst em A larm Output

5 O UTCP DC24V

6 B UZZ External Buzzer Output

7 RESERVE Reserved

8 O UTCN 0V

9 RESERVE Reserved

10 RESERVE Reserved

11 RESERVE Reserved

12 RESERVE Reserved

Using the AUX Input/Output I/F requires the separately sold Screw Lock

Terminal Block.

T orque: 0.2 to 0.4N•m

Wire Gauge: A WG16 to AWG 28

Removed Wire Length: 7 +/- 0.5mm [0.28 +/- 0.02 in.]

Input Circuit

Input Section

560Ω

Internal Circuit

AUXCOM

DC24V

5.4kΩ

AUXRESET

Input V oltage DC24V +/- 10%

Input Current 4mA/DC24V (TYP)

Min. Input Pulse Width 2ms

Operating V oltage ON V oltage min. DC21.2V

OFF Voltage max. DC 3V

T ermination T ype Photo-Coupler Isolation

GP-2401/2501/2601 Series User Manual 2-9

Page 35

Chapter 2 - Specifications

OutputCircuit

Output Section

OUTCP

Internal Circuit

DOUT*

470PF

OUTCN

22

* DOUT is used for RUN, ALARM, and BUZZ.

Load

Max. Load Current 50mA/point

Rated Load Voltage DC24V (TYP)

The following chart illustrates the relationship between the Load V oltage and the Load

Current:

23

Load Voltage: V

22.8

20.0

DC24V

Load Current: mA

50

403020100

2-10

GP-2401/2501/2601 Series User Manual

Page 36

Chapter 2 - Specifications

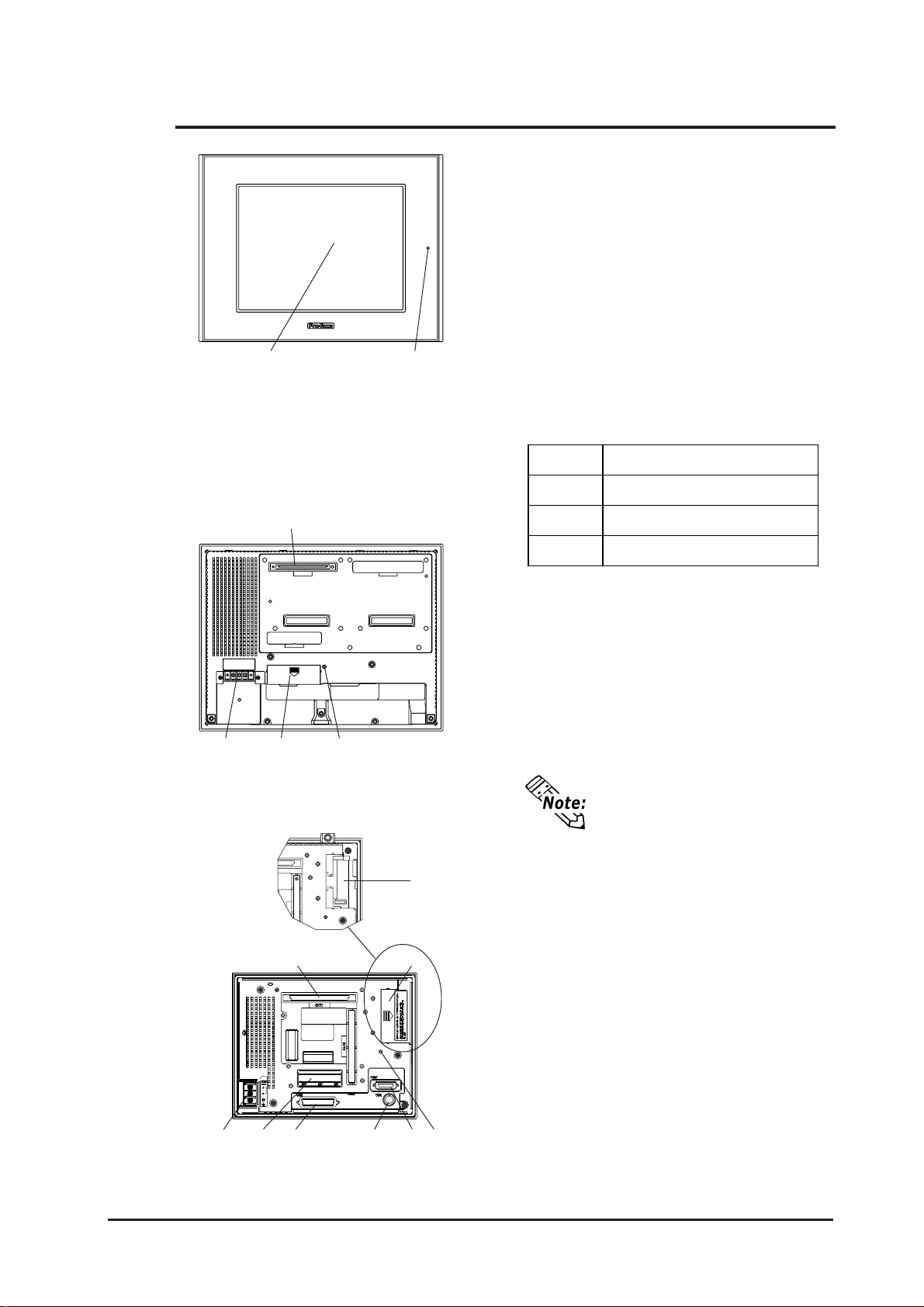

2.4 Part Names and Functions

A:Display Panel

The GP monitor screen displays the screen

setup and corresponding host (PLC) data.

GP-2401T TFT type color LCD

GP-2501T TFT type color LCD

GP-2501S STN type color LCD

GP-2501L Monochrome LCD

GP-2601T TFT type color LCD

B: T ouch Panel

A,B

C

Front

Performs any screen change operations and

sends data to the PLC.

C:Status LED

This LED reflects the GP's condition.

Color Indicates

E

DF G

Rear

(GP-2501/2601 Series)

E

OFF

Green

Orange

No power input

Normal operation

Backligh t is bu r ned ou t

D:Power Input Terminal Block

Connects the power cord.

E: Expansion Unit Interface (EXT1)

Connects expansion units with communication features.

F: CF Card Cover

Open this cover to the CF Card Slot. When

accessing the CF Card, this cover must be

closed.

The GP cannot access the CF

Card if the CF Card cover is already opened.

H

G:CF Card Access Lamp

If the CF Card Cover is closed when the CF

Card is inserted, the LED lamp turns ON.

The LED lamp will remain turned ON even if

the CF Card Cover is opened while the GP

D L J M KFG

Rear

(GP-2401 Series)

GP-2401/2501/2601 Series User Manual 2-11

Page 37

Chapter 2 - Specifications

HJ

I

KML

Bottom

accesses the CF Card.

H:CF Card Slot

Insert a CF Card in this slot.

I : Dip Switches

Dip S witch Functi on ON O FF Note

This Di p switch

setti ng controls

Startup from

CF Card is

Startup from

CF Card is

CF Card with

startup data

1

the startup fr om a

enabled.

disabled.

required.

CF Card.

2 Reserved

3 Reserved

This set ting

controls the forced

Forced close

enabled.

Forced close

disabled.

Keep these

swi tches OFF

Used when CF

Card cover is

4

cl osing of the C F

damaged.

Card cover.

J :Serial Interface (COM1)

Connect the RS-232C and RS-422 cables

here. Connect the other end to the Host

(PLC.)

K :Printer Interface (PRINT)

Connect the printer cable here.

Recommended cable: Digital Electronics Corporation PSM-PRCB00 Cable.

L: Auxiliary Input/Output Interface (AUX

Reset)

Used for external reset, alarm output, buzzer

output. Using this interface requires the separately sold Screw Lock T erminal Block.

M:T ool Connector (TOOL)

The Data Transfer cable or Bar Code Reader

can be connected here.

2-12

GP-2401/2501/2601 Series User Manual

Page 38

Chapter 2 - Specifications

2.5 Dimensions

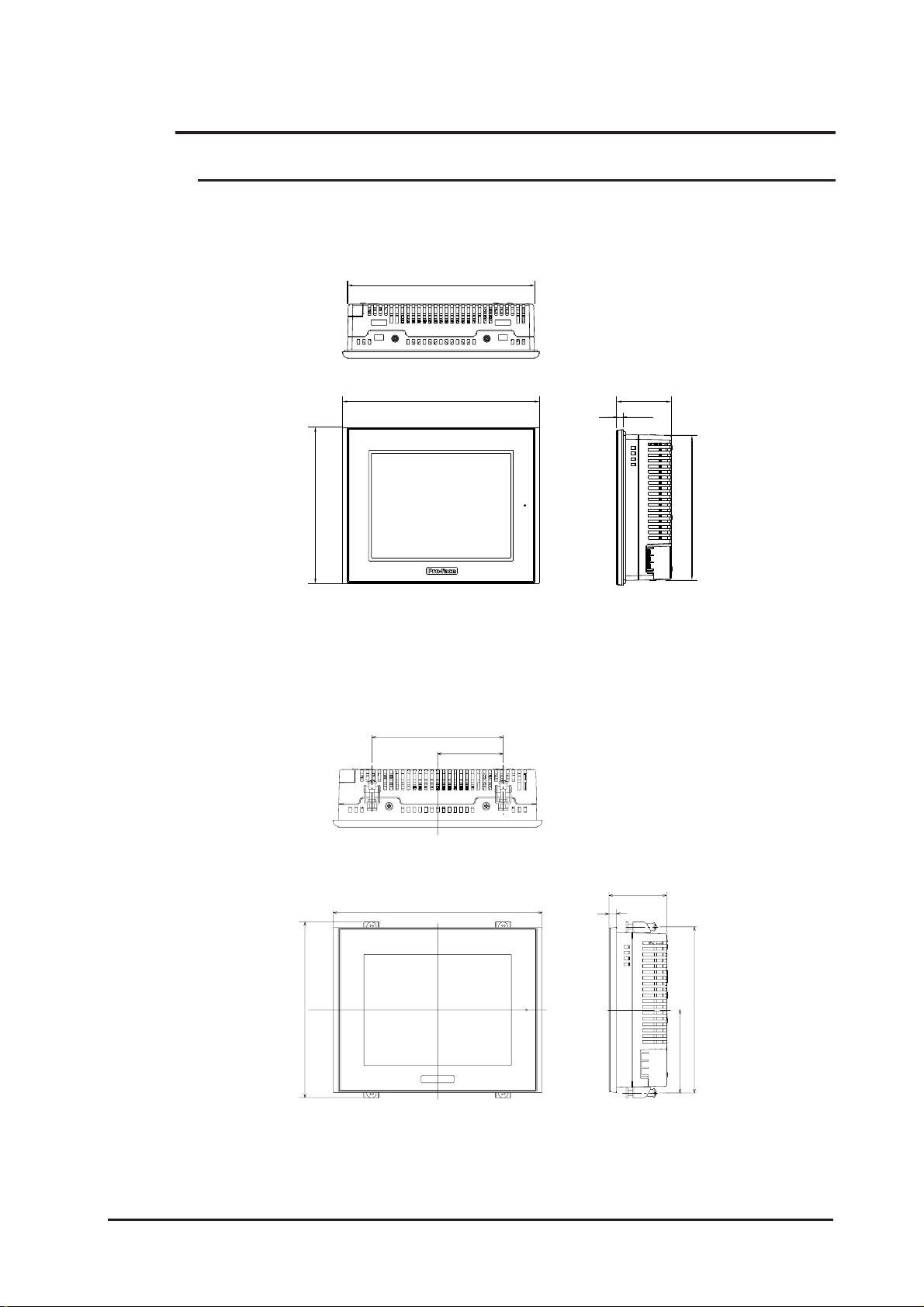

2.5.1 GP-2401 Series External Dimensions

Unit: mm [in.]

204 [8.03]

Top

215 [8.46]

8 [0.31]

170 [6.69]

Front

60 [2.36]

159 [6.26]

Side

The following drawing shows the GP-2401 Series unit with installation fasteners.

135 [5.31]

67.5 [2.66]

Top

60 [2.36]

215 [8.46]

181 [7.13]

Front

8 [0.31]

171 [6.73]

85.5 [3.37]

Side

GP-2401/2501/2601 Series User Manual 2-13

Page 39

Chapter 2 - Specifications

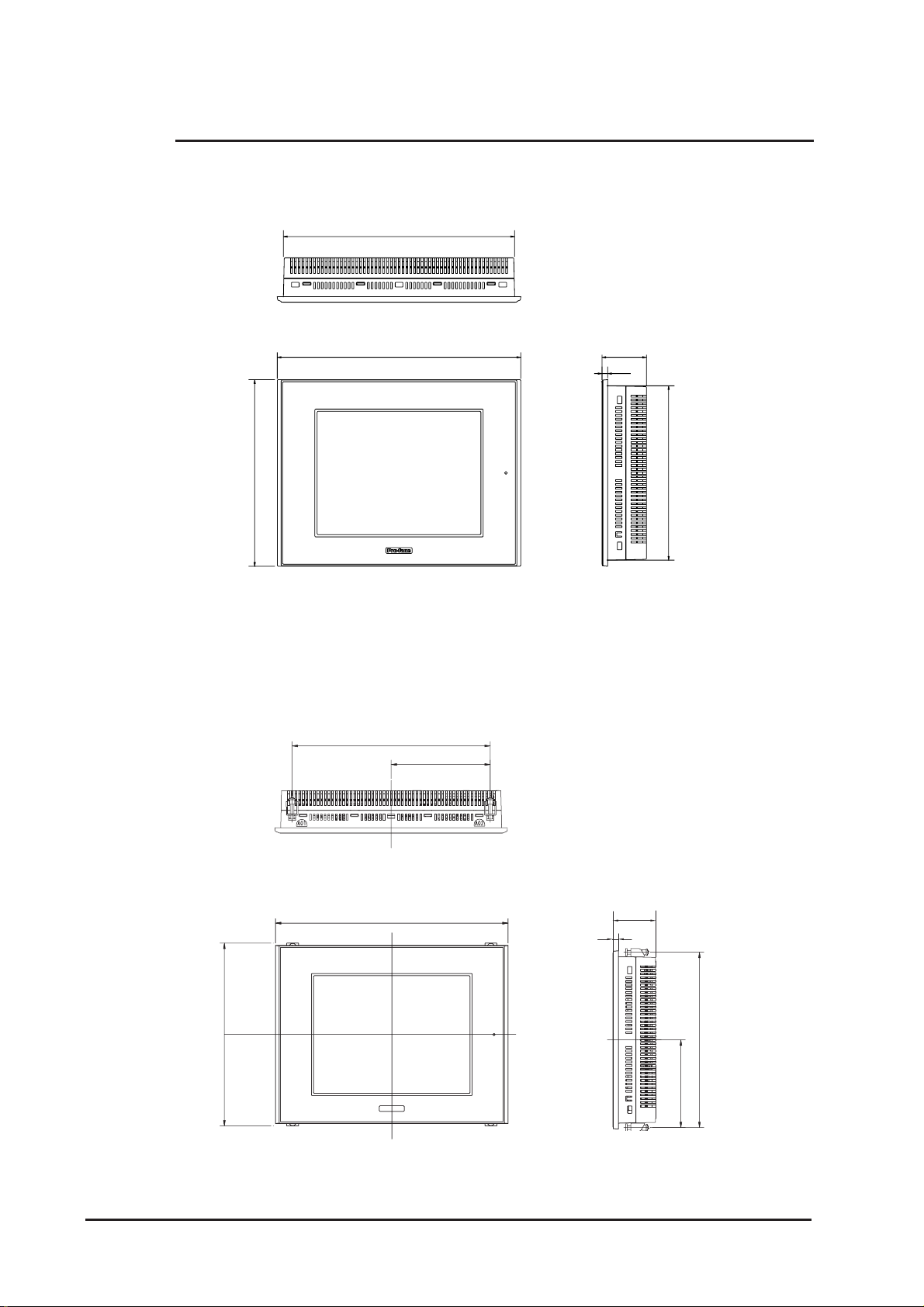

2.5.2 GP-2501 Series External Dimensions

Unit: mm [in.]

301 [11.85]

Top

317 [12.48]

8 [0.31]

243 [9.57]

58 [2.28]

227 [8.94]

Front Side

The following drawing shows the GP-2501 Series unit with installation fasteners.

270 [10.63]

135 [5.31]

2-14

249 [9.80]

Top

58 [2.28]

317 [12.48]

8 [0.31]

239 [9.41]

1 19.5 [4.70]

Front Side

GP-2401/2501/2601 Series User Manual

Page 40

Chapter 2 - Specifications

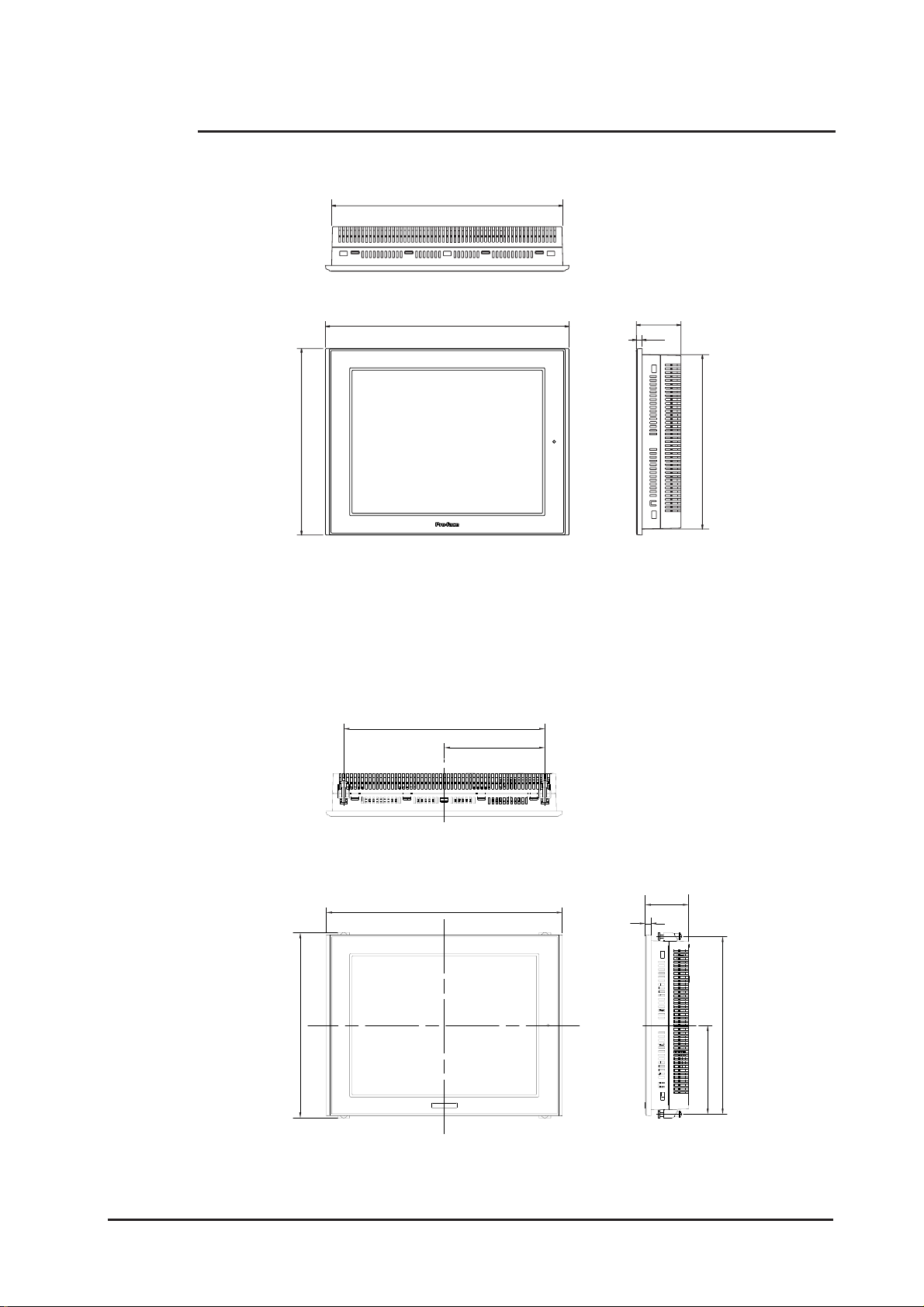

2.5.3 GP-2601 Series External Dimensions

Unit: mm [in.]

243 [9.57]

301 [11.85]

Top

317 [12.48]

8 [0.31]

58 [2.28]

Front Side

227 [8.94]

The following drawing shows the GP-2601 Series unit with installation fasteners.

270 [10.63]

135 [5.31]

Top

317 [12.48]

8 [0.31]

249 [9.80]

58 [2.28]

239 [9.41]

1 19.5 [4.70]

Front

Side

GP-2401/2501/2601 Series User Manual 2-15

Page 41

Chapter 2 - Specifications

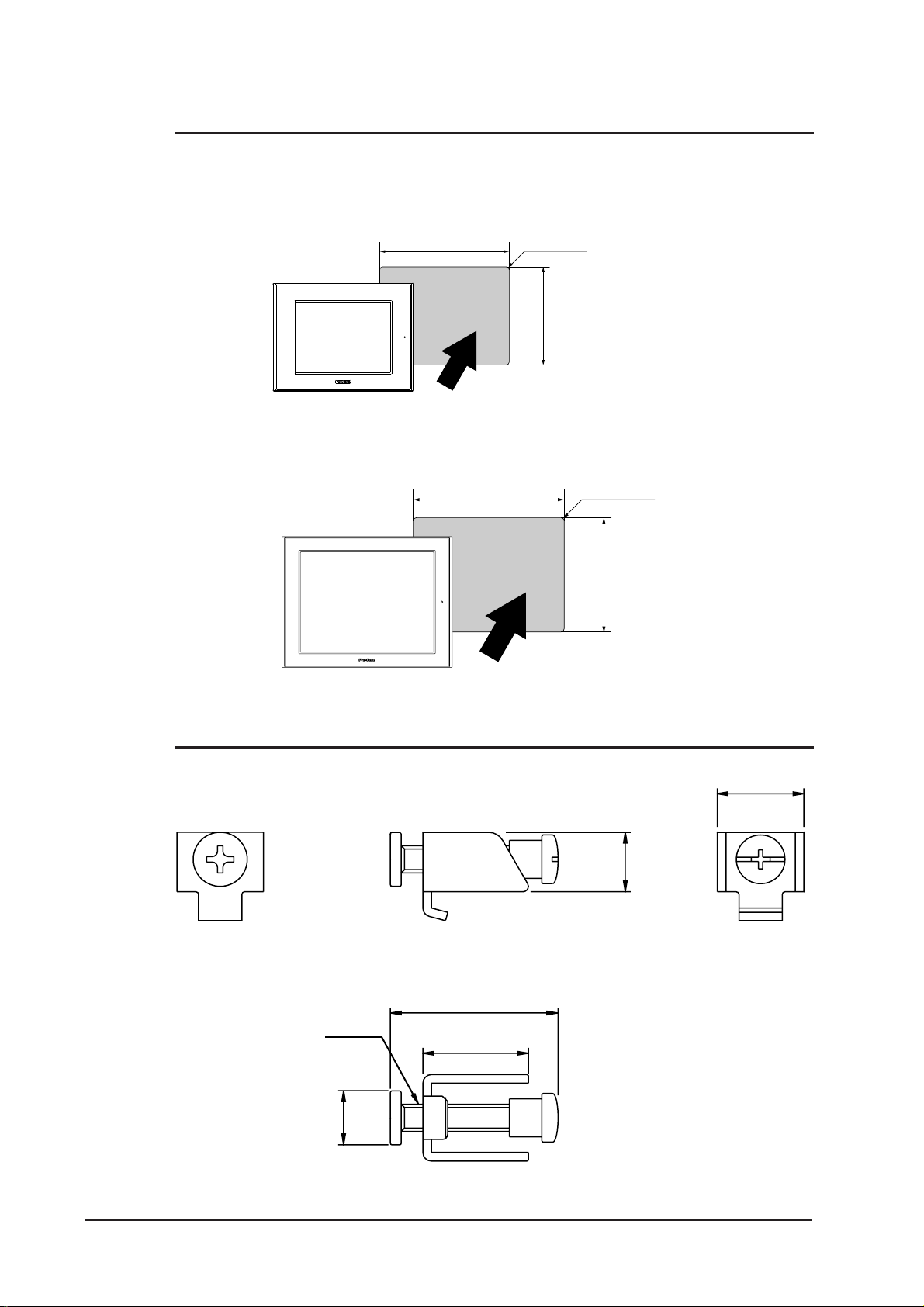

2.5.4 Panel Cut Dimensions

GP-2401 Series

Unit: mm [in.]

+1

204.5

0

GP-2501/2601 Series

Unit: mm [in.]

+0.04

[8.05 ]

0

+1

301.5

[11.87 ]

0

4-R3[0.12] or less

+0.04

0

[6.28 ]

+1

0

159.5

+0.04

0

4-R3[0.12] or less

+0.04

[8.96 ]227.5

+1

0

0

2.5.5 Installation Fasteners

Unit: mm [in.]

M5

19.5[0.77]

10[0.39]

16[0.63]

11[0.43]

31[1.22]

2-16

GP-2401/2501/2601 Series User Manual

Page 42

1. Installation

2. Wiring Precautions

Chapter

3. Tool Connector

3 Installation and W iring

3.1 Installation

3.1.1 Installation Procedures

Follow the steps given below when installing the GP .

Check the Installation Gasket’s Seating

It is strongly recommended that you use the installation gasket, since it absorbs vibration

in addition to repelling water .

Place the GP on a level surface with the display panel facing downward. Check that the

GP’ s installation gasket is seated securely into the gasket’s groove, which runs around

the perimeter of the panel’ s frame.

4. CF Card Insertion and Removal

For details about installing the gasket, refer to

8.1.2 Installation Gasket Check/Replacement

• Before installing the GP into a cabinet or panel, check that the Installation gasket is securely attached to the unit.

• A gasket which has been used for a long period of time may have

scratches or dirt on it, and could have lost much of its dust and drip

resistance. Be sure to change the gasket periodically, or when

scratches or dirt become visible.

• Be sure to use gasket model PS400-WP00-MS (GP-2401 Series)/

GP570-WP10-MS (GP-2501/2601 Series).

• Be sure the gasket's seam is not inserted into any of the unit's corners, only in the straight sections of the groove. Inserting it into a

corner may lead to its eventually tearing.

Rear

face

Installation

Gasket

GP-2401/2501/2601 Series User Manual

3-1

Page 43

Chapter 3 - Installation and Wiring

Creating a Panel Cut

Create the correct sized opening required to install the GP , using the installation dimensions given.

The installation gasket, installation brackets and attachment screws are all required when

installing the GP .

Check that the installation panel or cabinet's surface is flat, in good condition and

has no jagged edges. Also, if desired, metal reinforcing strips can be attached to

the inside of the panel, near the Panel Cut, to increase the panel’s strength.

Panel thickness should be from 1.6mm [0.06in.] to 10mm [0.4in.]. Decide

the panel’s thickness based on the level of panel strength required.

2.5.4 GP Panel Cut Dimensions

Panel

Panel Cut

Area

For easier maintenance, operation, and improved ventilation, be sure to

install the GP at least 100 mm [3.94 in.] away from adjacent structures

and other equipment.

3-2

GP-2401/2501/2601 Series User Manual

Page 44

Chapter 3 - Installation and Wiring

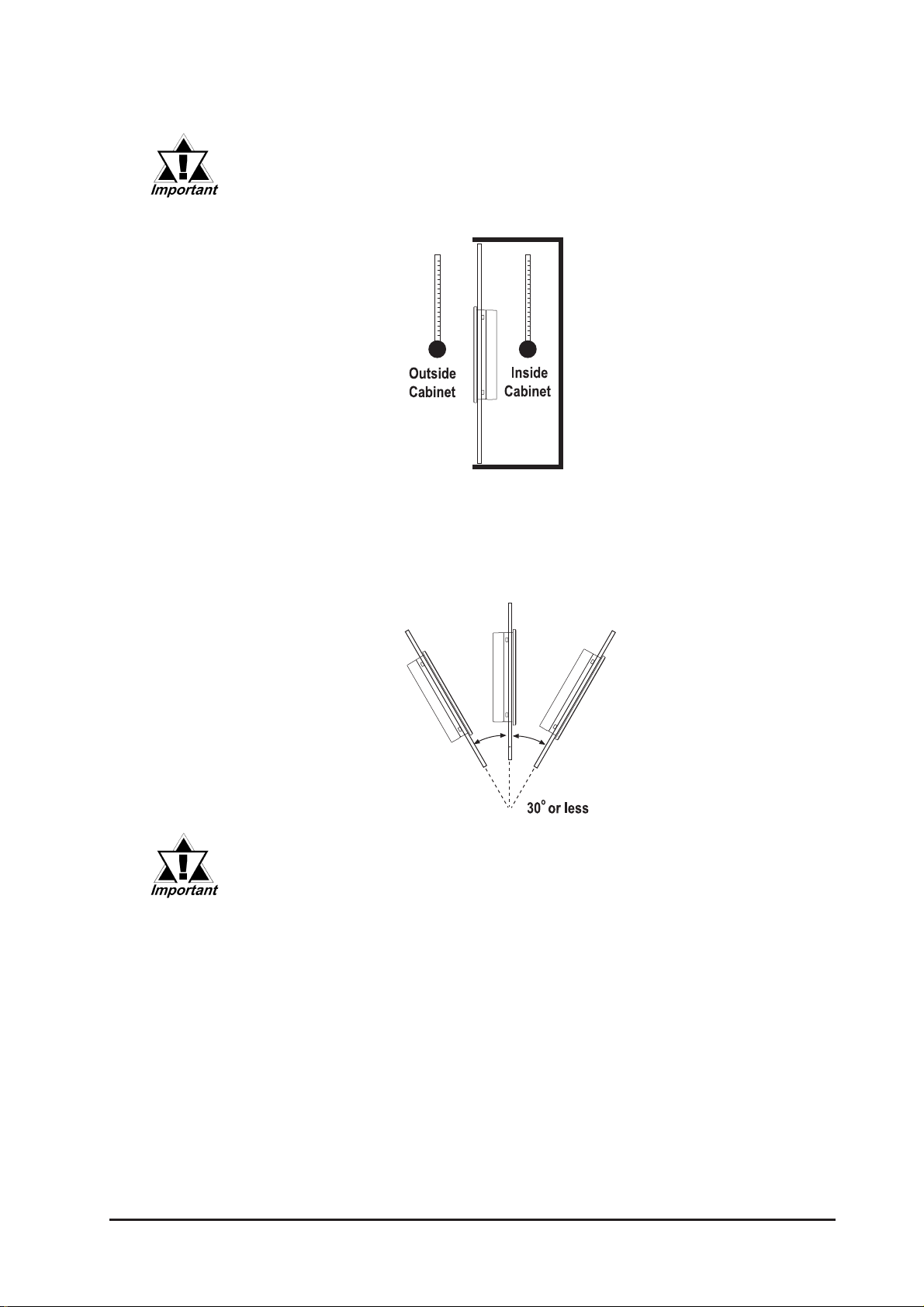

• Be sure that the ambient operation temperature and the ambient humidity are within their designated ranges. (When installing the GP in a

cabinet or enclosure, the term “ambient operation temperature” indicates the cabinet or enclosure’s internal temperature.

• Be sure that heat from surrounding equipment does not cause the GP

to exceed its standard operating temperature.

• When installing the GP in a slanted panel, the panel face should not

incline more than 30o.

• When installing the GP in a slanted panel, and the panel face inclines

more than 30o, the ambient temperature must not exceed 40 oC. You

may need to use forced air cooling (fan, A/C) to ensure the ambient

operating temperature is 40 oC or below.

• When installing the GP vertically, position the unit so that the Power

Input Terminal Block is also vertical.

GP-2401/2501/2601 Series User Manual

3-3

Page 45

Chapter 3 - Installation and Wiring

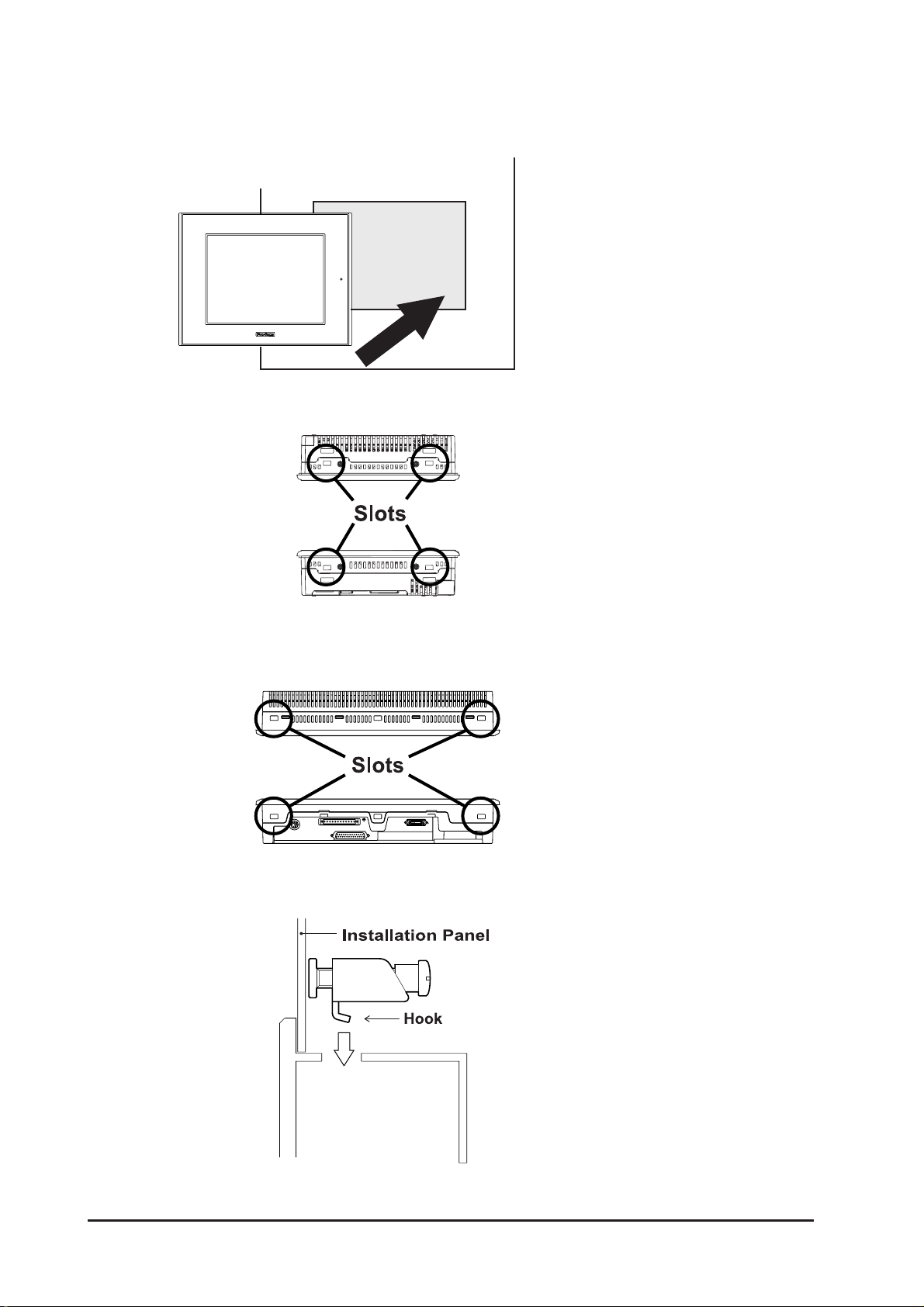

Installing the GP

1) Insert the GP into the panel cut

out, as shown here.

2) Insert the installation fasteners

into the GP’s insertion slots, at

the top and bottom of the unit.

GP-2401 Series

GP-2501/2601 Series

(total: 4 slots)

3-4

GP-2401/2501/2601 Series User Manual

Page 46

Chapter 3 - Installation and Wiring

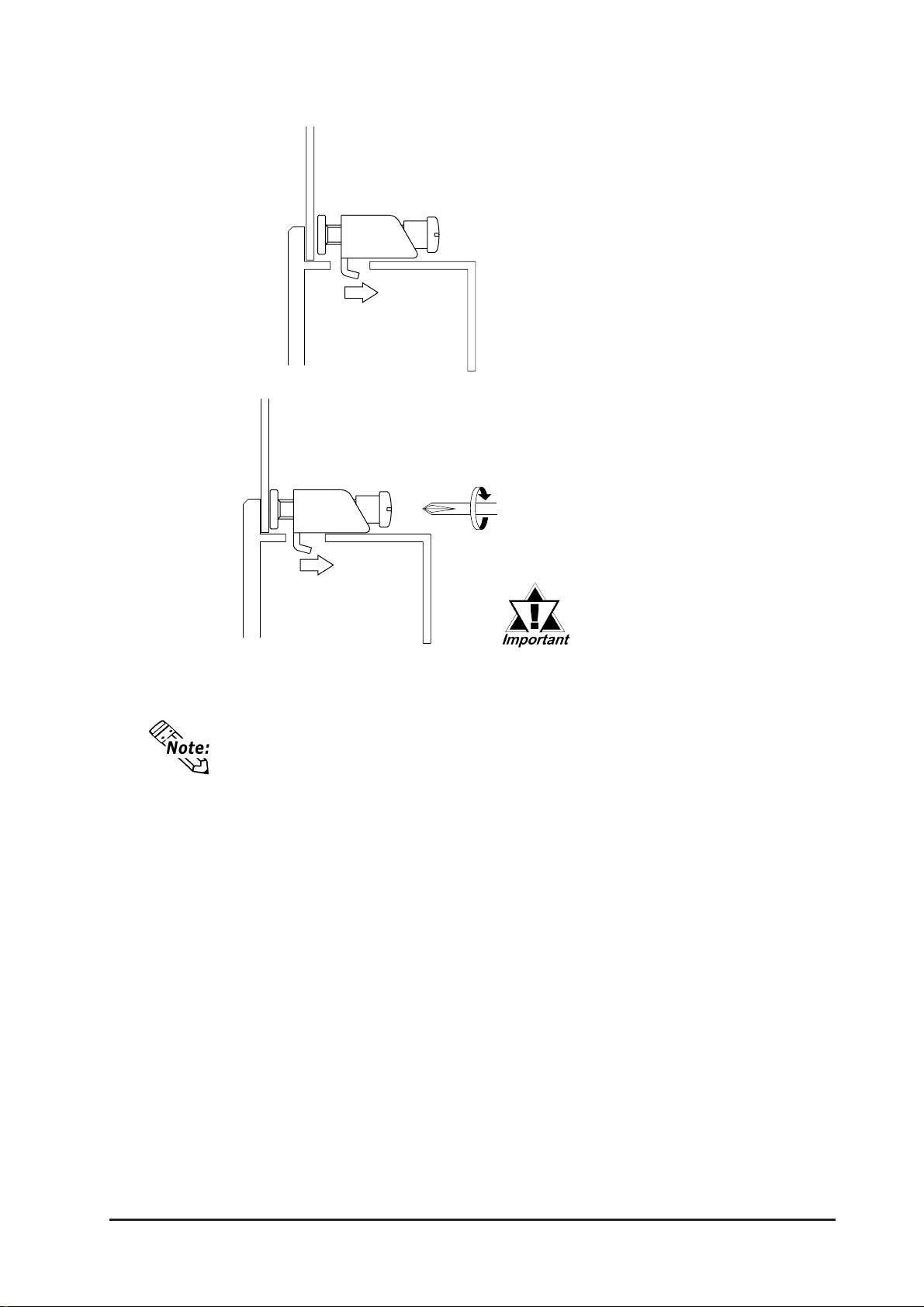

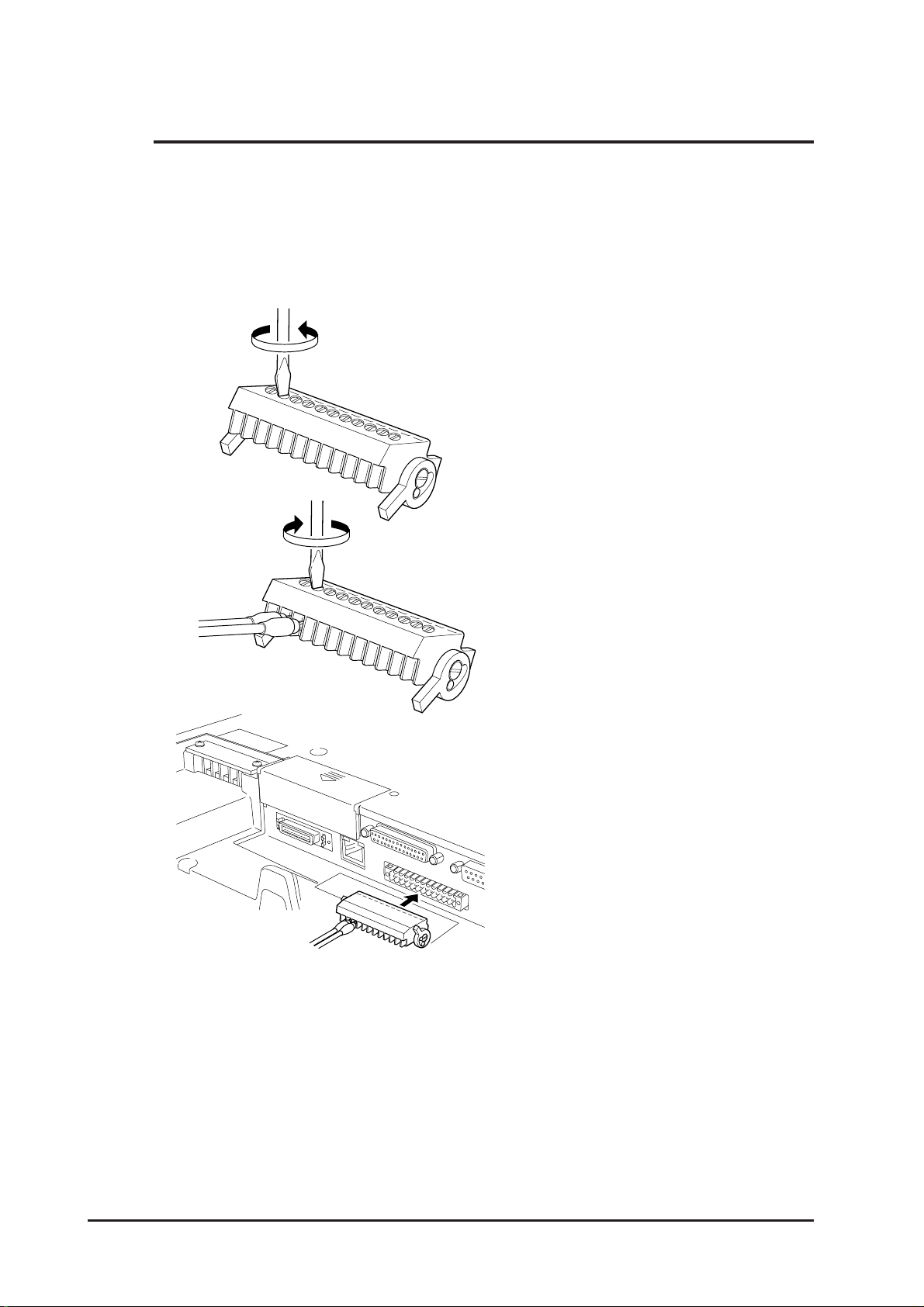

3) Insert each of the fasteners shown

below . Be sure to pull the fastener

back until it is flush with the rear

of the attachment hole.

4) Use a Phillips screwdriver to

tighten each fastener screw and

secure the GP in place.

A torque of only 0.5 N•m is

sufficient to tighten these

screws. Do not use too much

force, since it may damage

the GP unit.

Depending on the installation panel's thickness, etc., the number of installation

fasteners used on a GP-2501 Series or GP-2601 Series can be increased to provide a higher level of moisture resistance. (The GP-2401T is limited to four (4)).

GP-2401/2501/2601 Series User Manual

3-5

Page 47

Chapter 3 - Installation and Wiring

3.2 Wiring Precautions

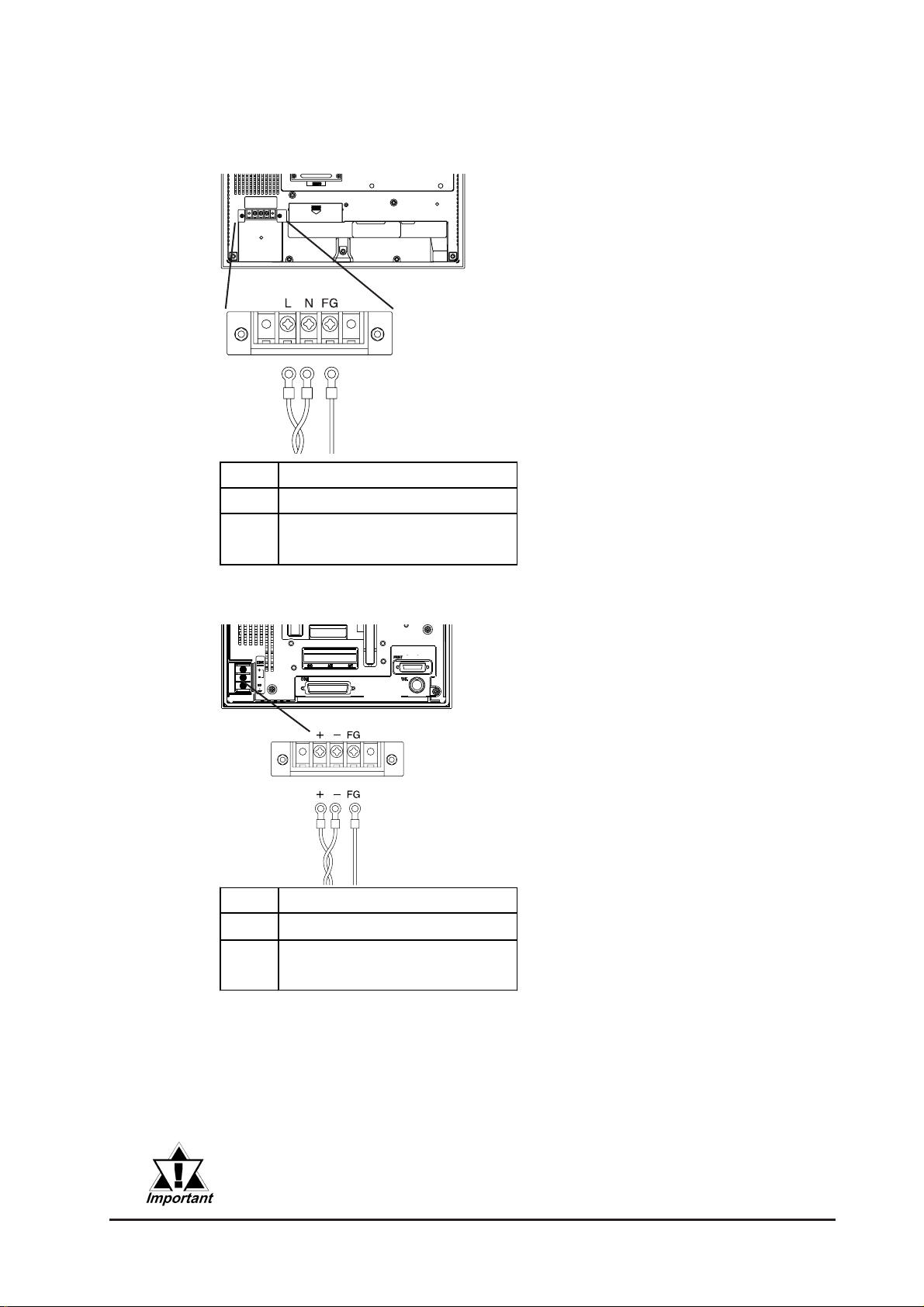

3.2.1 Connecting the Power Cord

WARNINGS

• To avoid an electric shock, be sure the power cord is

unplugged from the power outlet when connecting

the power terminals to the GP unit.

• GP2401-TC41-24V and GP2501-LG41-24V are designed to use only DC24V power. Using any other

level of power can damage both the power supply

and the GP unit.

• For models GP2501-TC11, GP2501-SC11 and GP2600TC11, all products not marked Revision "3" are designed to use only AC100V power. Using any other

level of power can damage both the power supply

and the GP unit.

• Since the GP is not equipped with the power switch,

be sure to connect a breaker type power switch to the

GP’s power cord.

• Be sure to ground the GP’s FG terminal. Failure to do