FP790-T21

Installation Guide

WARNINGS

•T o prevent an electric shock, be sure to turn FP-790 unit’s (hereafter referred to as the “FP”) main

power supply OFF before attaching the power cord terminals to the FP unit’s power terminal strip.

•A fire or electrical shock may occur if voltages used with the FP are beyond the specified

range. Be sure to use only the specified voltage.

•Before opening the FP unit’s protective cover, be sure to turn the unit’s power OFF. This is

because the FP unit’s internal parts carry high voltages.

•To avoid fires or electrical hazards, do not modify the FP in any way.

•If metal particles, water or other types of liquids contact any of the FP unit’s internal parts,

immediately turn the unit’s power OFF, unplug the power cord, and contact your FP distributor.

• Prior to changing the FP unit’s backlight, be sure to diconnect the FP unit’s power supply.

•To prevent a possible explosion, do not install the FP in areas containing flammable gases.

•The FP is not appropriate for use with aircraft control devices, aerospace equipment, central

trunk data transmission (communication) devices, nuclear power control devices, or medical

life support equipment, due to these devices’ inherent requirements of extremely high levels of

safety and reliability .

•When using the FP with transportation vehicles (trains, cars and ships), disaster and crime

prevention devices, various types of safety equipment, non-life support related medical devices, etc. redundant and/or fail-safe system designs should be used to ensure the proper

degree of reliability and safety.

• Do not use the FP as a warning device for critical alarms that can cause serious operator

injury, machine damage or production stoppage. Critical alarm indicators and their control/

activator units must be designed using stand-alone hardware and/or mechanical interlocks.

CAUTIONS

•Do not push on the FPs screen too strongly, with either your finger or with a hard object.

Excessive pressure can scratch, crack or damage the screen. Do not use a pointed object,

such as a mechanical pencil or screwdriver, to press any of the touch panel’s switches, since

it can damage the display.

•If the screen becomes dirty or smudged, moisten a soft cloth with diluted neutral detergent,

wring the cloth well, and wipe the display. Do not use thinner or organic solvents.

•Avoid storing and operating the FP in direct sunlight, high temperatures and humidity, and in

areas where excessive dust and vibration will occur.

•Avoid using the FP in areas where sudden, extreme changes in temperature can occur. This

may cause condensation to form inside the unit, possibly leading to an accident.

•To prevent the FP from overheating, be sure its air circulation vents are clear and clean, and

keep the unit’s operation area well-ventilated.

•Avoid operating or storing the FP near chemicals, or where chemicals can come into contact with the

unit.

- 1 -

CE Marking Notes

The FP79*-2* units are CE marked, EMC compliant products.

<Complies with the following Standards>

• Safety

EN60950

• EMI (EN50081-2)

EN55011 group1 (Class A)

• EMS (EN61000-6-2)

EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6,

EN61000-4-8, ENV50204

If the following requirements are not met, the FP may fail to meet EN60950

standard requirements.

• The FP must be used as a built-in component of an end-use product.

• Use the FP indoors only.

• When connecting the FP’s power cable, be sure to use a cable that is appropriate

for the current and voltage used and that has conductive wires that are 0.75 mm

larger.

• When using the FP in an end-use product, be sure to install the FP unit's power cut-

off switch where the operator can easily reach it.

• There is a danger of explosion if the backup battery is incorrectly replaced. This

battery should be replaced only with same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

• Be sure the FP unit's enclosure is an EN60950 approved sheet steel structure.

2

or

Package Contents

The FP package should include the following items:

FP Unit

(FP790-T21)

Installation Gasket

Installation Guide

(This document)

FP790-T21

Installation

Guide

Installation Brackets (12)

CD-ROM (1)

(Contains the FP User

Manual’s PDF file.)

These items have all been carefully packed with special attention to product quality. However,

should you find any item(s) damaged or missing, please contact your FP distributor immediately

for prompt service.

*1

*1 For a description and usage of the application programs stored in the CD-ROM, see the

“READM_E.DOC” file.

- 2 -

About The PDF Manual

The FP unit’s CD-ROM contains the following PDF manual file:

FP-790 Series User Manual (English/Japanese)

Reading a PDF file requires installation of the Adobe Corporation’s Acrobat

®

Reader.

Acrobat

To install the Acrobat

®

Reader Installation:

®

Reader software, follow the steps given below.

1) This software, in the form of a self-extracting file, is located in this CD-ROM

in the folder titled [reader]. Use the Explorer software to find the file

[reader\ENG\ar405eng.exe], and double-click on the file icon to begin the

Reader installation.

2) After Installation begins, follow the instructions given on the Installation

screens.

Viewing the PDF manual:

To view the PDF manual contained in this CD-ROM, follow the steps given below.

1) Use the Explorer software to locate the file [manual\ENG\fp790e.pdf] in the

folder titled [manual].

2) Double-click on the PDF file's icon. Acrobat

®

Reader will automatically start

and the first page of the PDF manual will appear.

- 3 -

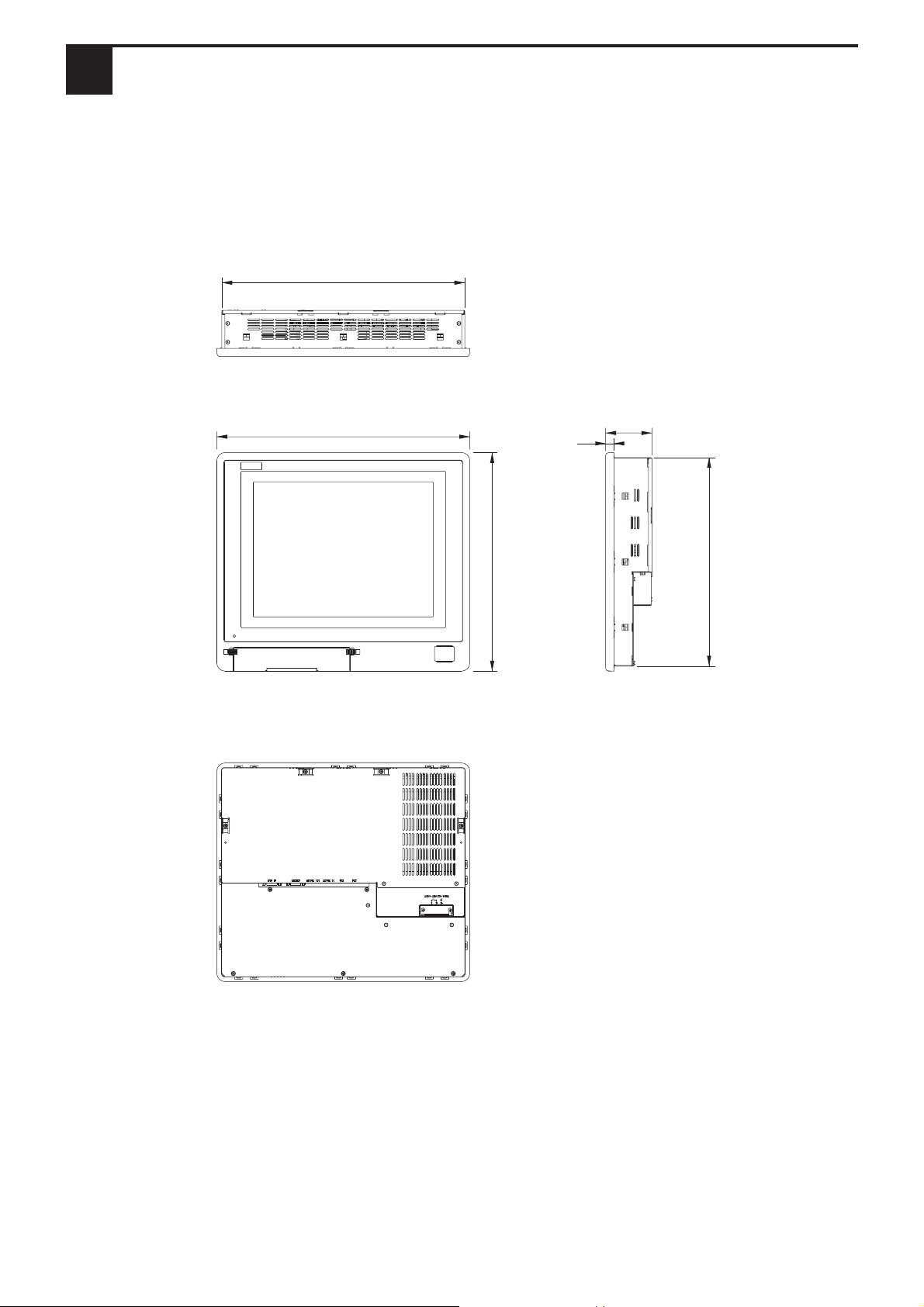

1 FP External Features

A, B

J

Front

View

A: TFT type color LCD

The FP units’ output display. Data

from the host are displayed.

B: Touch panel

Used to switch screens and write data

to the host.

C: Power input terminal block

Used to connect the power supply

cable.

D: Status LED (Under development)

E: Setup switches (DIP switches)

Used to set the FP's operation mode.

F: MOUSE Connector (MOUSE IN)

Used to connect a mouse.

G: MOUSE Host connector (MOUSE

OUT)

Sends mouse output data from the FP.

Rear

C

View

Connects to the Host’ s PS\2 equivalent

Mouse input connector.

H: Serial I/F Connector (RS-232C)

Serial RS-232C interface. This

connects a serial cable to the FP, and

sends FP touch panel data to the Host,

HGF DE

Bottom

View

CI

and Host commands to the FP.

I: Analog RGB I/F connector

Analog RGB interface connector

J: Front Maintenance Cover (unused)

• Prior to attaching peripheral units to the FP, be sure the FP unit’s

power cord is disconnected from the main power supply.

• To prevent an electrical shock, be sure to disconnect the FP unit’s

power cord from the power supply before connecting the cord’s power

terminals or any peripheral devices to the FP.

- 4 -

2 FP Dimensions

If detailed dimension information is needed, please contact your local FP distributor.

(Unit: mm [in.] - excluding projections)

389 [15.31]

Top View

405 [15.94]

Front View

14 [0.55]

74 [2.91]

334 [13.15]

350 [13.78]

Side View

Rear View

- 5 -

3 General Specifications

Electrical

Input Voltage

Rated Voltage

Frequency

Allowable Voltage Drop

Power Consumption

In-Rus h Current

Voltage Endurance

Insulation Resistance

Environmental

Ambient Operating

Temperature

(Cabinet interior and exterior)

Storage Temperature

Ambient Humidity 30% RH to 85% RH (no condensation)

AC 100V to AC 240V

AC 85V to AC 265V

50/60Hz

1 cycle or less

65VA or less

30A (normal), 45A (40

o

C)

AC 1500V at 20m A for 1 minute

(between charging and FG terminals)

Greater than 10MΩ at DC 500V

(between charging and FG terminals)

o

C to 40oC

0

o

C to 60 oC

-10

Air Purity Level

Atmosphere

Vibration Resistance

Noise Endurance

(via n oise simulator )

0.1mg/m3 or less ( f r ee o f conductive particles and dust )

800 to 1114 hP a ( 2000 meter s o r lower )

19.6m/s2 at 10Hz to 25Hz in X, Y, Z directions for 30 minu t es

Noise Voltage: 1500Vp-p

Pulse Width: 50ns , 500ns, 1µs

Rise Time: 1ns

Structural

Grounding

Less than 100Ω, or your countr y’s applicable standard.

Rating

*1

Cooling Method Via natural cooling

Weight

W 405mm [15.94in.] x H 350mm [13.78in.] x D 74mm [2.91in.]

External Dimensions

*1 The front face of the PL unit, installed in a solid panel, has been tested using conditions equivalent to

the standard shown in the specification . Even though the PL unit’s level of resistance is equivalent to

the standard, oils that should have no effect on the PL can possibly harm the unit. This can occur in

areas where either vaporized oils are present, or where low viscosity cutting oils are allowed to

adhere to the unit for long periods of time. If the PL’s front face protection sheet becomes peeled off,

these conditions can lead to the ingress of oil into the PL and separate protection measures are

suggested. Also, if non-approved oils are present, it may cause deformation or corrosion of the front

panel’s plastic cover. Therefore, prior to installing the PL be sure to confirm the type of conditions

that will be present in the PL’s operating environment.

If the installation gasket is used for a long period of time, or if the unit and its gasket are removed from

the panel, the original level of the protection cannot be guaranteed. To maintain the original protection level, you need to replace the installation gasket regularly.

Exclusive grounding only:

Equivalent to IP65f (JEM1030)

Less than 6.5kg (14.3lb)

(with HDD and FDD installed)

(excluding projections)

- 6 -

Display

Contrast Control Possible via adjustment menu

Effective Display Area (mm) W 279[10.98] X H 209[8.23]

Type TFT color LCD

Colo rs 260,000

Dot Pitch (mm) W 0.279 X H 0.279

640 X 480 (VGA)

Display Mo des

(set via selector switch)

Backlight

Touch Panel

Resolution (dots) 1024 X 1024

Type Resistive film (Analog)

External Interfaces

720 X 400 (US Text)

800 X 600 (SVGA)

1024 X 768 (XGA)

CFL

(under continuous 24 hour operation, lifespan = 10,000 hours)

Input Signal Analog RGB

Image Signal Analog RGB

Sync hronous Signal TTL Level, negative true or positive true

Scanning Type Non-interlaced

Analog RGB I/F

Serial I/F

(RS-232C )

Mouse I/F

Display Adjustment

Clock adjustment: -128 to 128

Phase adjus tment: 64 levels

Contrast Control via touch panel

Brightness Control via touch panel

Color Control via red, green, blue set tings

Horizontal Display

Positioning control

Vertical Display

Asyn chronous Transmis sion, RS 232C , Dat a Lengt h: 8 b its , S t op B it : 1, P arity:

None, Transfer S peed: 960 0bps

(MOUSE IN)

(MOUSE OUT)

PS /2 Int er face mini DIN 6-pin female

PS /2 Int er face mini DIN 4-pin female

- 7 -

4 Interface Specifications

Analog RGB Interface

Dsub15-pin (female)

5 4 3 2 1

10 9 8 7 6

15 14 13 12 11

Screw Size: (4-40): Inch Type

Pin No. Signal Name Condition

1 Analog R R signal input

2 Analog G G signal input

3 Analog B B signal input

4 NC Not Connected

5 NC Not Connected

6 Retu rn R R signal GND

7 Retu rn G G signal GND

8 Retu rn B B signal GND

9 NC Not Connected

Digital

10

Digital signal GND

Ground

11 NC Not Connected

12 NC Not Connected

Horizontal synchronous

13 H. SYNC

signal input

Vertical synchronous

14 V. SYN C

signal input

15 NC Not Connected

Recommended Connector: Mini Dsub 15 pin (JST Co.) KEY-15S-2A3F eqivalent

Connector set screw: Inch type (4-40UNC)

Cable: Digital Electronics Corporation RGB cable (FP-CV00, FP-CV01)

VESA Standard

Horizontal

Vertical

Dot Clock

Synch. Processing

Size

Display Mo de

Frequency

Frequency

Frequency

V, H

VGA 640×480 31.469 kHz 59.992 Hz 25.175 M Hz -,-

37.500 kHz 75.000 Hz 31.500 M Hz -,-

SVGA 800×600 37.879 kHz 60.317 Hz 40.000 M Hz +,+

46.875 kHz 75.000 Hz 49.500 M Hz +,+

XGA 1024×768 48.363 kHz 60.004 Hz 65.000 MHz -,-

56.476 kHz 70.069 Hz 75.000 M Hz +,+

60.023 kHz 75.029 Hz 78.750 M Hz +,+

US Text 720×400 31.469 kHz 70.087 Hz 28.322 MHz +,-

37.927 kHz 85.039 Hz 35.500 M Hz +,-

The allowable frequency fluctuation range in both the horizontal and

vertical frequencies is +/- 1%. If fluctuations exceed these ranges, the

FP will enter power save mode and the display will go blank.

- 8 -

RS-232C Interface (COM1/COM2/COM3)

This is an FP-790 Windows®-type Mouse Emulator RS-232C connector.

Signal

Name

Meaning

Dsub 9 pin (Male)

1 2 3 4 5

6 7 8 9

Screw Size: (4-40): Inch Type

Pin No.

1 CD Carrier Detect (FP->Hos t)

2 RXD Receive Data (FP->Host)

3 TXD Send Data (FP<-Host)

4 DTR Terminal Ready (FP<-Host)

5 GND Ground

6 DSR Data Set Ready (FP->Host)

7 RTS Ready to Send (FP<-H os t )

8 CTS Clear t o S end ( FP- > Ho st)

9 RI Not us ed

Recommended Connector: Mini Dsub 9-pin (JST Co.) JEY-9P-1A3F eqivalent

Connector set screw: Inch type (4-40UNC)

Cable: Digital Electronics Corporation SIO cable (FP-61V-IS00-0)

• Since all serial interface signals are the same on the PC side, use a

straight cable to connect the FP to the PC.

• The GND terminal is the signal ground. Be sure to connect the GND

terminal to other unit’s SG (signal ground).

- 9 -

Mouse Connector (MOUSE IN)

Mini - DIN 6 pin (Female)

6

4

2

Recommended Connector: Hoshi Electronics,Inc.: TCS7568-43-201 or equivalent

Recommended Mouse: Microsoft Corporation Microsoft mouse (PS/2 type)

5

3

1

• The mouse connection can be used for all equipment conforming to

the PS/2 mouse standards. However, Pro-face cannot guarantee the

FP will operate normally for all types of host and mouse combinations.

This unit was developed using the Microsoft Mouse

mouse products, the "IntelliMouse" and the "3 Button" mouse cannot

be used with this unit.

Pin N o. S igna l N ame

1Mouse DATA

2NC

3GND

4+5V

5Mouse CLK

6NC

SHIELD GND

®

. Microsoft's other

• When connecting the Mouse, be sure to use the Mouse Type Host

connector (MOUSE OUT) and the Host PC Mouse/Keyboard cable

(FP-CK01)

• Do not connect this cable when the power to the FP and the host (PC)

are both ON.

• After connecting the mouse, please re-start the Host unit's OS.

• When Windows 95 or Windows NT is used, set the “Control panel - Mouse Motion” feature to the standard pointer speed and hide the pointer trace.

Mouse Type Host Connector (MOUSE OUT)

Mini - DIN 4 pin (Female)

4

21

3

Pin N o. Signal N a m e

1GND

2 +V5

3 MOUSE CLK

4DATA

Recommended Connector: JST Corporation Mini DIN 4-pin (female) MD-S6100 or equivalent

• If the Host PC Mouse/Keyboard cable (FP-CK01) is not used with the

Mouse Type Host connector (MOUSE OUT), the mouse cannot be

used.

• Do not connect this cable when the power to the FP and the host (PC)

are both ON.

- 10 -

5 Installing the FP

Installation Procedures

Follow the steps given below when installing the FP.

Attaching the Installation Gasket

Even if the your FP unit’s Installation Gasket is not needed to prevent water from

entering the unit, the gasket also acts as a vibration absorber and should always be

attached. To install the gasket, place the FP face down on a soft surface and attach the

gasket to the rear side of the display face, in the plastic bezel’s groove (see picture

below).

Be sure the grooved face of the gasket is vertical.

• Before mounting the FP into a cabinet or panel, check that the Installation Gasket is attached to the unit.

• A gasket which has been used for a long period of time may have

scratches or dirt on it, and could have lost much of its dust and drip

resistance. Be sure to change the gasket periodically, or when

scratches or dirt become visible.

• The gasket must be inserted correctly into the groove for the GP’s

moisture resistance to be equivalent to IP65f.

• The upper surface of the gasket should protrude approximately 2mm

out from the groove. Be sure to check that the gasket is correctly inserted before installing the GP into a panel.

FP Rear Face

Installation

Gasket

• The gasket is flexible, but not elastic, and may tear if stretched too far.

Do not stretch the gasket around the ribs, only push.

• Be sure the gasket’s seam is not inserted into any of the unit’s corners, only in the straight sections of the groove. Inserting it into a corner may lead to its eventually tearing.

- 11 -

Create a Panel Cut

Create a panel cut for the FP, according to the dimensions given here. Two additional items, the installation gasket and installation fasteners are also required when

installing the FP.

+0.5

390.0

0

Attaching the Installation Fasteners

+0.02

[15.35 ]

0

4-R3 or less

+0.02

0

[13.19 ]

+0.5

0

335.0

The FP-790 is equipped with 12 installation fastener holes (3 on each side). Use the

drawings below to locate the top and bottom face holes and use a Phillips screwdriver

to tighen each fastener.

Installation Fasteners Installation Fasteners

Panel

FP

Top View

Installation

Fastener

Bottom View

• A torque of only 0.5 to 0.6 N•m is sufficient to tighten these

screws. Do not use too much force, since it may damage the

FP unit.

• If the dimensions of the Panel Cut are larger than those given

here, the panel can warp and distort the FP unit’s display.

- 12 -

6 Wiring the FP

WARNINGS

•To prevent an electric shock, be sure to turn FP unit’s main power supply OFF before attaching the power cord terminals to the FP unit’s power terminal strip.

• Be sure to use only the FP unit’s rated power level. Using any other level of power can

damage both the power supply and the FP unit.

• Since the FP is not equipped with the power switch, be sure to connect a breaker-type

power switch to the FP unit’s power cord.

• Use thick wire (2 mm2 max.) for the FP's power cable. Be sure that the cable is

twisted near the ring terminals.

• Use ring terminals with the following dimensions:

• To prevent the power terminals from being short-circuited due to a loose

screw, use ring terminals with insulating sleeves.

Rear of FP

LNFGLN FG

Power input

terminal block

Ring terminal *1

*1 L = Live line for AC input

N = Neutral line for AC input

FG = Ground terminal to be connected to the FP housing

Recommended ring terminal: V2-MS3 or equivalent (Manufactured by JST Co.)

- 13 -

7 Power Supply Cautions

When connecting the FP unit’s AC power terminals, please be aware of the following:

Constant

voltage

transformer

Insulating

transformer

AC100V to

AC200V

Main

power

source

Main power

source

AC 100V

to AC200V

source

I/O power

FP

power

source

I/O power

source

Twisted-pair

cable

Twisted-pair

cable

FP

power

source

T1

T2

FP

FG

FP

FG

FP

I/O device

FP

I/O

device

• If voltage fluctuations are expected to vary

beyond the specified range, connect a constant

voltage transformer.

• Use a low-noise power supply both between

the lines and between the FP and its ground. If

there is still excess noise, connect an insulating

transformer (noise-prevention type) .

Be sure any constant or insulating

transformer used has a capacity of

100VA or more.

• Wire the power cords of the FP, I/O devices,

and power supply devices separately.

• To improve noise immunity, it is recommended to attach a ferrite core to the power

cord.

• Isolate the main circuit (high voltage, large

current) line, I/O signal lines, and power cord,

and do not bind or group them together.

AC

Twisted-pair

cable

Main circuit

power source

E1

Lightning surge

absorber

FP

FG

E2

I/O

device

Power

device

• To prevent damage from lightning, connect a

lightning surge absorber.

• To prevent excessive noise, be sure to make

the power cord as short as possible.

• Ground the lightning surge absorber (E1) and the FP (E2) separately.

• Select a lightning surge absorber

which will not exceed the allowable circuit voltage, even when

the voltage rises to the maximum.

- 14 -

8 Grounding Cautions

(a) Dedicated Ground

FP

Other

device

(b) Shared Ground - allowed

FP

Other

device

(c) Shared ground - not allowed

FP

Other

device

• Set up a dedicated ground

*1

when using

the rear panel’s FG terminal.

• If a dedicated ground is not possible,

use a shared ground, as shown in figure

(b).

• The grounding wire should have a cross

sectional area greater than 2mm

2

. Create the connection point as close to the

FP unit as possible, and make the wire

as short, as possible. When using a

long grounding wire, replace the thin

wire with a thicker wire, and place it in

a duct.

*1Use a grounding resistance of less than 100Ω and a 2mm2 or greater thickness wire, or your

country’s applicable standard. For details, contact your local FP distributor.

- 15 -

9 Changing the Backlight

The FP-790 unit’s backlight is user replaceable.

For detailed information about changing the backlight, refer to the FP-790 User

Manual (sold separately) or the Replacement Backlight (sold separately) explanation.

The FP-790 uses the following backlight.

FP Mode l Backlight Model

FP790-T21 FP790-BL00

Be sure to use only Pro-face’s recommended backlight. Use of any other

backlight can lead to an accident or FP unit malfunction.

Note

Be aware that the Digital Electronics Corporation shall not be held liable for any real or estimated

damages or losses, or third party claims resulting from the use of this product.

© 2001 Digital Electronics Corporation. All rights reserved.

055524K .FP790-MT01-PROE

- 16 -

Loading...

Loading...