EVOLUTION SC

INK JET PRINTERS

INSTALLATION AND OPERATION MANUAL

digital design inc.

67 Sand Park Road

Cedar Grove, NJ 07009

(973) 857-9500

www.evolutioninkjet.com

This manual is for use in operating and maintaining the EVOLUTION SC Ink Jet

Printer. For basic start-up instructions, please refer to PART 1 Installation

Procedures.

All rights reserved. No part of this document may be reproduced, stored on a

retrieval system, or transmitted in any form, or by any means electronic,

mechanical, photocopying, recording or otherwise, without the prior permission of

Digital Design Inc.

Digital Design Inc. has a policy of continual product improvement. The Company

therefore reserves the right to modify the information contained in this manual

without prior notice.

ALL PRINT CARTRIDGES SUPPLIED BY DIGITAL DESIGN INC.

ARE FACTORY TESTED AND USE INKS SPECIALLY

FORMULATED TO PRODUCE AN OPTIMUM AND CONSISTANT

CODE. USING OTHER THAN AUTHORIZED CARTRIDGES MAY

CAUSE UNDESIRABLE RESULTS.

EVOLUTION SC IS A FULL FEATURED MODEL WITH VARIABLE

FIELD PROGRAMMING CAPABILITIES.

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

TABLE OF CONTENTS

PART 1: INSTALLATION AND OPERATIONS................................. 1

INSTALLING THE EVOLUTION SC PRINTING System .................................................................. 1

MOUNTING ON PRODUCTION LINE ..................................................................................... 1

GROUNDING STRAP INSTALLATION ................................................................................... 2

INPUT POWER CONNECTION AND MODIFICATION........................................................... 2

INSTALLING THE PRINT CARTRIDGE .................................................................................. 3

CONNECTING THE CONTROLLER TO THE PRINT HEAD...................................................... 4

CONFIGURING THE PRINTER .................................................................................................. 5

SYSTEM RESET...................................................................................................................... 5

SOFT RESET: ...................................................................................................................... 5

HARD RESET:...................................................................................................................... 6

MULTIPLE PRINT HEADS .......................................................................................................... 7

EVOLUTION SC QUICK START....................................................................................................... 8

CHANGING LANGUAGE PROMPTS ...................................................................................... 8

ENABLING PRINT MODE........................................................................................................ 8

HEAD SELECT MODE............................................................................................................. 8

ENTERING A MESSAGE......................................................................................................... 9

STORING A MESSAGE......................................................................................................... 10

LOADING A MESSAGE......................................................................................................... 11

EVOLUTION SC QUICK SETUP .................................................................................................... 12

PART 2: OPERATION PROCEDURES............................................. 1

OVERVIEW.................................................................................................................................. 1

CONTROLLER AND LCD........................................................................................................ 1

KEYPAD KEY DESCRIPTIONS........................................................................................... 2

TURNING ON THE PRINT STATION FOR THE FIRST TIME ............................................ 3

CHECKING SYSTEM INFORMATION................................................................................. 3

CHECKING LOADED FONTS.............................................................................................. 3

CHANGING SYSTEM DATE AND DAY OF WEEK CODES ............................................... 4

CHANGING SYSTEM TIME AND DATE ROLL OVER TIME .............................................. 5

PROGRAMMING ......................................................................................................................... 7

DEFINITIONS........................................................................................................................... 7

PRINTING MODE AND STOPPED “COMMAND” MODE ....................................................... 7

MENU STRUCTURE ................................................................................................................... 8

F1 MENU.................................................................................................................................. 8

F1 MENU.................................................................................................................................. 9

1 = CHARACTER SPACING:............................................................................................... 9

2 = EXT. ENCODER:............................................................................................................ 9

3 = DATE OFFSET:............................................................................................................ 10

F2 MENU................................................................................................................................ 11

1 - DIRECTION:..................................................................................................................11

2 - PRINT INVERSE:.......................................................................................................... 11

3 – NOT AVAILABLE:......................................................................................................... 11

4 - AUTO REPEAT: ............................................................................................................ 11

F3 MENU................................................................................................................................ 12

1 – product count: ............................................................................................................... 12

2 – SHIFT CODE: ............................................................................................................... 13

3 – DATE FORMAT:........................................................................................................... 14

4 – TIME FORMAT:............................................................................................................ 16

F4 MENU................................................................................................................................ 17

1 - LANGUAGE:.................................................................................................................. 17

2 - INK SUPPLY: ................................................................................................................ 17

3 – SET UNIT I.D.:..............................................................................................................18

4 – NOT AVAILABLE:......................................................................................................... 18

SETTING PRINT DELAY AND LINE SPEED............................................................................ 19

2 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

SETTING LINE SPEED.......................................................................................................... 19

SETTING PRINT DELAY ....................................................................................................... 20

SETTING HEAD ALIGNMENT............................................................................................... 20

INPUT, EDIT OR DELETE MESSAGES ................................................................................... 21

MESSAGE STORAGE............................................................................................................... 28

STORING A MESSAGE......................................................................................................... 28

RECALLING A STORED MESSAGE..................................................................................... 28

PART 3: MAINTENANCE PROCEDURES....................................... 1

SHORT PERIODS OF SHUTDOWN........................................................................................... 1

LONG PERIODS OF SHUTDOWN ............................................................................................. 2

PRINT CARTRIDGE MAINTENANCE......................................................................................... 3

PRINT CARRIAGE MAINTENANCE ........................................................................................... 5

EXPLODED VIEW OF THE C20991 PRINT CARRIAGE ........................................................... 5

PART 4: TROUBLESHOOTING AND REPAIRS ............................. 1

FAULTS ....................................................................................................................................... 1

PART 5: PARTS LIST AND OPTIONS............................................. 1

PART 6: COMMUNICATIONS PROTOCOL .................................... 1

DESCRIPTION............................................................................................................................. 2

DATA WORD DEFINITION...................................................................................................... 2

BAUD RATE............................................................................................................................. 2

DEFINITIONS........................................................................................................................... 2

CABLING FOR EVLINK ENVIRONMENT ............................................................................... 2

HARDWARE INTERFACE....................................................................................................... 3

PHYSICAL CONNECTIONS RS485 print carriage.................................................................. 3

PROTOCOL FORMAT:............................................................................................................ 3

EVOLUTION PRINTABLE CHARACTER SET........................................................................ 3

SOFTWARE PROTOCOL ........................................................................................................... 4

ERROR CODES .......................................................................................................................... 4

COMMANDS:............................................................................................................................... 6

PART 7: OPTION JUMPER DESCRIPTIONS................................. 23

VSEL J4 ..................................................................................................................................... 23

ENSEL J5................................................................................................................................... 23

PRSEL J6................................................................................................................................... 23

JUMPER LOCATION.................................................................................................................24

OPTION CABLING DESCRIPTIONS ........................................................................................ 25

PART 8: PRINTER SPECIFICATIONS.............................................. 1

PRINT CHARACTERISTICS ....................................................................................................... 1

CONTROLLER............................................................................................................................. 1

PRINT CARRIAGE ...................................................................................................................... 1

ENVIRONMENTAL CONDITIONS .............................................................................................. 1

GENERAL.................................................................................................................................... 1

DEFAULT SETTINGS.................................................................................................................. 2

3 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

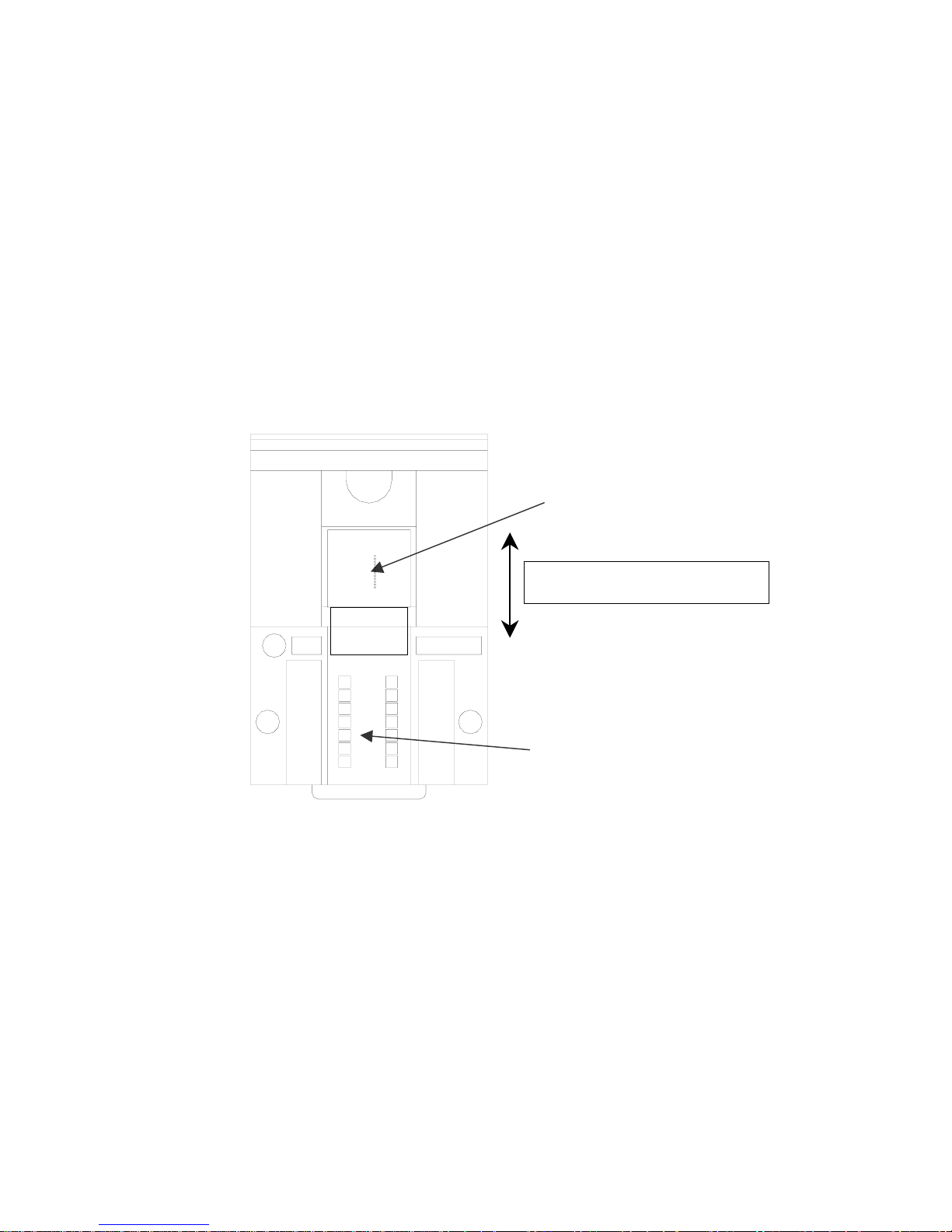

EVOLUTION CONTROLLER

PRINT HEAD

CABLE PLUG

EVSC STOPPED

HD 1<- - SPEED= 120

EVOLUTION SC

EVOLUTION CODERS

GRAPHIC

(WSYWIG)

LCD DISPLAY

EVOLUTION

CONTROLLER

KEYBOARD

NOTE:

THE EVOLUTION

GRAPHIC CONTROLLER

WILL CONTROL THE

EVOLUTION 1 (EV1)

EVOLUTION 2 (EV2)

EVOLUTION SC (EVSC)

THE UPPER LEFT

CORNER OF THE DISPLAY

INDICATES THE SPECIFIC

PRINTER CONNECTED TO

THE HAND HELD

CONTROLLER

4 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PART 1: INSTALLATION AND OPERATIONS

INSTALLING THE EVOLUTION SC PRINTING SYSTEM

Caution should be taken while installing the EVOLUTION SC printing system on your

equipment. Digital Design Inc. has taken every precaution to ensure a safe and

accurate instruction set to guide the installer through the installation process.

Follow the operational guidelines in the installation procedures.

VERIFY THAT YOUR EQUIPMENT IS IN PROPER OPERATING

CONDITION.

LOCATE A CONVENIENT POSITION ON YOUR EQUIPMENT.

EVOLUTION SC REQUIRES 4-1/2" OF SPACE ON THE

PRODUCTION LINE.

FOLLOW THE INSTALLATION PROCEDURES.

READ CAREFULLY ALL INSTALLATION PROCEDURES BEFORE

PROCEEDING.

INSTALL THE PRINTING SYSTEM ON YOUR EQUIPMENT.

THERE IS NO EXTRA HARDWARE REQUIRED OTHER THEN

THAT SUPPLIED IN THE INSTALLATION KIT.

MOUNTING ON PRODUCTION LINE

Locate the supplied mounting template

and affix in a convenient location on the

production line. Spot and drill both

mounting holes for a 5/16” bolt. NOTE:

the user may also thread the side of the

conveyer using a 5/16” tap.

Fasten the mounting bracket to the

conveyer using the supplied mounting

hardware and ensuring that the supplied

ground strap is located securely beneath

either of the two mounting bolts, and that

conductivity to earth ground is less than 1 ohm. This ensures a proper path for

static discharge, should the need arise.

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

GROUNDING STRAP INSTALLATION

INSTALL STRAP

UNDER 5/16”

SCREW. E

CONDUCTIVITY TO

EARTH GROUND IS

LESS THAN 1 OHM

NSURE

INPUT POWER CONNECTION AND MODIFICATION

Insert the power plug to the available power source. The supplied power supply

will is universal and will auto detect 100/240 VAC 50-60hZ.

No other adjustments are necessary.

2 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

INSTALLING THE PRINT CARTRIDGE

Remove the protective film from the face of the print head and retain the film.

This protective film may be re-applied to store partially used cartridges. If it is

necessary to remove the print head and store for a long period of time, it is best

to re-apply the plastic film, and place the cartridge in a closeable plastic bag.

The print cartridge is installed into the print head by inserting at a slight angle and

depressing the rear of the cartridge until it snaps into place. To remove the

cartridge gently lift the rear tab on the

NOTE: EACH PRINT CARTRIDGE HAS BEEN TESTED

AT THE FACTORY AND CONTAINS SPECIALLY

FORMULATED INKS. USING ANY OTHER PRINT

CARTRIDGE WILL HAVE UNDESIRABLE RESULTS.

INSERT PRINTHEAD INTO

HOLDER FROM THIS ANGLE

AND PRESS DOWNWARD UNTIL

SEATED

PRINTHEAD SEATED CORRECTLY

3 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

CONNECTING THE CONTROLLER TO THE PRINT HEAD

Connect the Controller to the print carriage using the supplied 3 FT (.9 mm)

interconnect cable C21008-3 supplied with the Printing System. The cable is a

standard RJ50 (10 conductor). Longer cables are available as required.

Connect either end of the cable to the Carriage Assembly and securely lock in

place. NOTE: THE CONNECTOR MUST BE PLUGGED INTO THE INPUT RJ50

CONNECTOR LOCATED BELOW THE POWER CONNECTOR AND MARKED

WITH AN ARROW POINTING TO THE CONNECTOR. A click will be heard

when the connector is in the appropriate position. Connect the free end to the

Controller Assembly and ensure connector is securely seated.

GREEN

CYCLE LED

RED PRINT

ENABLE LED

POWER INPUT

+12VDC @1.5A

PRINT CARRIAGE RJ50

INPUT CONNECTOR

PRINT CARRIAGE RJ50

OUTPUT CONNECTOR

CONTROLLER RJ50

CONNECTOR

CAUTION:

NOTE ORIENTATION OF THE CONNECTORS. DO NOT FORCE

CONNECTORS INTO POSITION SECURELY LATCH (CLICK) INTO

POSITION.

CONTROLLER MUST PLUG INTO THE PRINT CARRIAGE RJ50 INPUT

CONNECTOR FOR PROPER OPERATION. THE PRINT CARRIAGE RJ50

OUTPUT CONNECTOR IS USED EITHER FOR CONNECTION TO THE NEXT

PRINTER ON A NETWORK OR FOR EXTERNAL PRODUCT OR EXTERNAL

ENCODER INPUT.

THE POWER INPUT CONNECTOR MUST BE SECURELY INSERTED INTO

THE PRINT CARRIAGE. UPON PROPER INSERTION BOTH THE RED AND

GREEN LED’S WILL FLASH INDICATING PROPER CONNECTION.

4 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

CONFIGURING THE PRINTER

To verify the current operating software press the STOP PRINT

key.

Press the V key

CONTROLLER 1.06

EVSC 1.03_++++

PRINTER SN XXXXXX

ANY KEY TO EXIT

The fist line indicates the version of the controller software

The second line is the software of the printer

The third line indicates the serial number of the printer

SYSTEM RESET

SOFT RESET:

A Soft Reset may be performed by first removing the power from the system and

while holding the R key depressed re-apply the power. Refer to the section on

Soft Reset.

ERASE STORED

MESSAGES

YES OR NO Y/N

RESET PRINT HEAD

YES OR NO Y/N

ALL HEADS

WILL BE RESET

CONTINUE = X KEY

ANY OTHER EXITS

Pressing the R key while applying power to the

unit will display the reset command mode

CAUTION: A response of Y will delete all stored

messages.

The next screen to appear prompts the user to

determine if a print head is to be restored to its

default value.

CAUTION: ALL PRINT HEADS CONNECTED

TO THE CONTROLLER WILL BE RESET TO

FACTORY DEFAULT CONDITIONS. THIS

INCLUDES RESETING EACH UNIT ADDRESS

TO 1. TO PREVENT THIS REMOVE ALL

INTERCONNECTED PRINT HEADS EXCEPT

FOR THE UNIT TO BE RESET FROM THE

DATA LINK.

5 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

HARD RESET:

In the event it is necessary to perform a hard reset, disconnect the power cable,

insert a standard paperclip into the hole located on the top of the cabinet, and

while holding the paper clip in place (a light click will be felt) re-apply the power

connector.

This operation will reset the print carriage assembly to the factory default settings

and clear any current message.

Note: upgrading the system to a newer version of software will automatically

perform this operation.

6 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

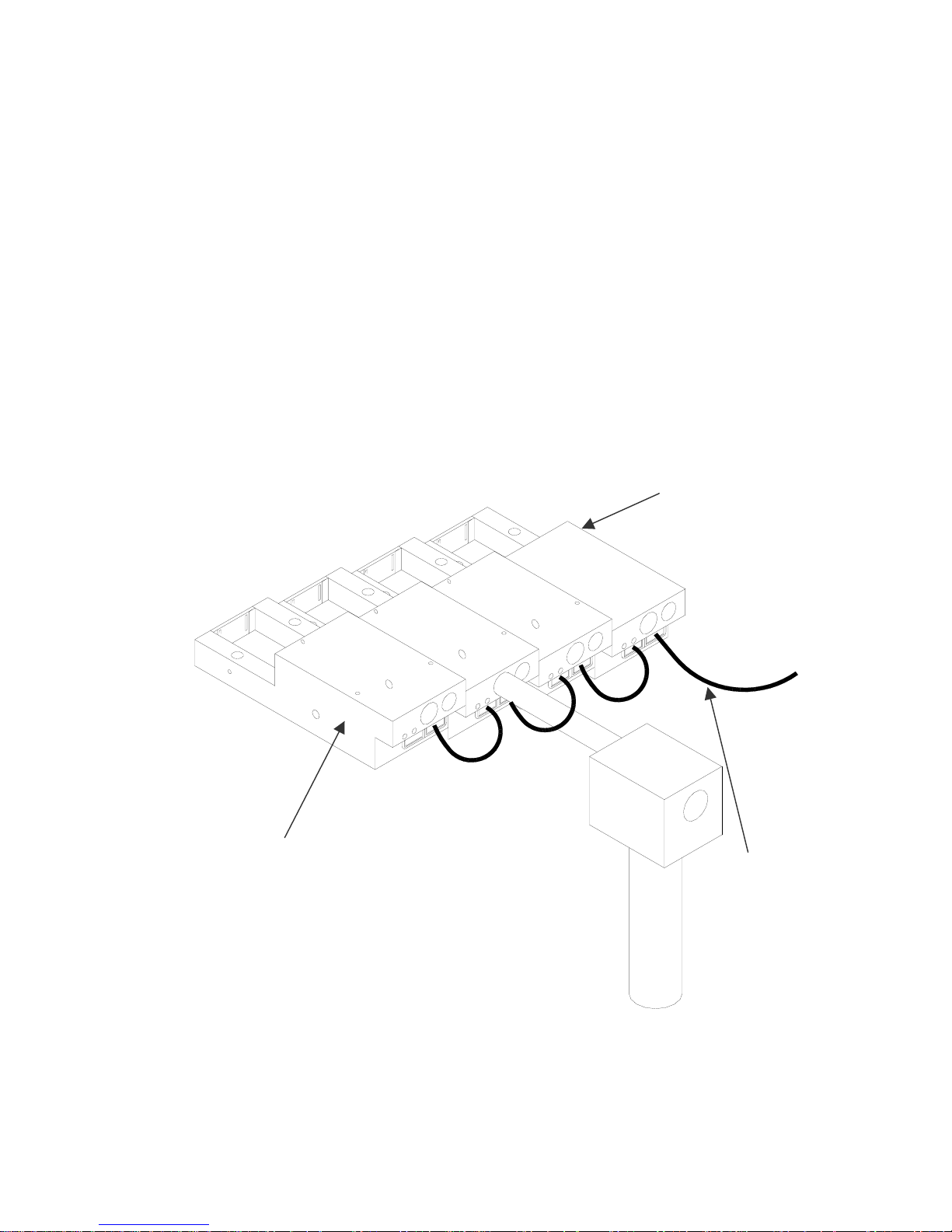

MULTIPLE PRINT HEADS

EVOLUTION printing systems have the ability to reside on a network. The network

may contain from 1 to 32 print carriages connected via RJ50 cables. These

cables are available in varying lengths depending on the application.

Each mounting bracket can support up to 4 print carriages and would typically

interconnect with a 6” RJ50 data cable.

NOTE: Special care must be taken to connect the output of the first print carriage

to the input of the next print carriage.

When connecting multiple print carriages place no more than 2 stations on a side

of the mounting bracket as shown.

PRINT CARRIAGE

ADDRESS 1

PRINT CARRIAGE

ADDRESS 4

7 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

TO

CONTROLLER

OR COMPUTER

DATA LINK

EVOLUTION SC QUICK START

Connect the printer carriage to the appropriate

EVSC STOPPED

HD 1< - - SPEED=120

EVOLUTION SC

power source.

Connect the controller to the carriage assembly.

The controller derives power from the carriage.

On startup the LCD will display as pictured.

CHANGING LANGUAGE PROMPTS

< - - SELECT - - >

ENGLISH

Press the F4 key

LANGUAGE. Use the keys to select the

desired language and press the to select the

language.

ENABLING PRINT MODE

EVSC PRINTING

HD 1< - - SPEED=120

EVOLUTION SC

Press the GREEN PRINT key to start printing

HEAD SELECT MODE

EVSC STOPPED

HD 1< - - SPEED=120

The hand held controller can program up to 32 print

carriages on an RS485 data link. The factory default

sets each print carriage to ADDRESS 1. Selection

of another print head other than ADDRESS 1, press

EVOLUTION SC

and select for

< - - SELECT - - >

WHICH HEAD = 1

EVOLUTION SC

NO RESPONSE

ANY KEY TO EXIT

8 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

the

alternate print carriage number and press the

key. The print carriage whose address was selected

will respond with the current message and

appropriate parameters.

As an added convenience using the

scan to find the next available head connected to

the environment

Accessing an address not associated with any print

carriage will result in a no response message.

key. Use the keys to select the

will auto

ENTERING A MESSAGE

EVSC STOPPED

HD 1< - - - SPEED=120

EVOLUTION SC

MESSAGE ENTRY

- - - - FONT – 1 S12

EVOLUTION SC

MESSAGE ENTRY

- - - - FONT - 1 S12

MESSAGE ENTRY

- - - - FONT – 1 S 12

EXP 12/10/04

EVSC PRINTING

HD 1< - - - SPEED=120

EXP 12/10/04

Press the GREEN PRINT key

The LCD display will change from PRINTING to

STOPPED.

Press the GREEN EDIT key

Press the BLUE F3 key

message

Press the BLUE FONT key to select the

desired font size and enter the text EXP 12/10/04

Press the ENTER key

EDIT mode

Press the GREEN print enable key to enter

the print mode

to end the MESSAGE

to delete the entire

9 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

STORING A MESSAGE

EVSC STOPPED

HD 1< - - - SPEED=120

EXP 12/10/04

MESSAGE # 1 EVSC

MESSAGE # 1 EVSC

MESSAGE STORED

EXP 12/10/04

EVSC STOPPED

HD 1< - - - SPEED=120

EXP 12/10/04

Press the GREEN STOP PRINT KEY

Note: There are a maximum of 100

messages stored.

Press the RED MESSAGE STORE key

The LCD display will display the message storage

screen

Use the

location

Press the RED MESSAGE STORE KEY

second time and the current message appears in

the selected location and is stored.

Press the ENTER key

command prompt.

or to select the desired storage

a

to return to the

10 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

LOADING A MESSAGE

EVSC STOPPED

HD 1< - - - SPEED=120

EVOLUTION SC

MESSAGE # 1 EVSC

PLEASE WAIT

MESSAGE # 1 EVSC

EXP 12/10/04

EVSC STOPPED

HD 1< - - - SPEED=120

EXP 12/10/04

EVSC PRINTING

HD 1< - - - SPEED=120

EXP 12/10/04

Press the GREEN STOP PRINT KEY

Note: There are a maximum of 100

messages stored.

Press the RED MESSAGE STORE key

NOTE: The top line indicates that this message

is for an EVSC – Evolution Small Character

printer.

Use the

message

Press the ENTER

Press the GREEN print enable key

the print mode

or keys to select the desired

key

to enter

11 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

EVOLUTION SC QUICK SETUP

Install a new cartridge. Press the following keys in order:

REMAINING INK

100 %

C NEW CARTRIDGE

OTHER KEY EXIT

To reset the ink level detector press

Each time a new print cartridge is installed the system automatically profiles the

correct operating parameters for the new cartridge. These parameters set the

required voltage and on time to produce consistent results without user

intervention..

NOTE: USING OTHER THAN AUTHORIZED CARTRIDGES MAY CAUSE

UNDESIRABLE RESULTS.

Press the GREEN print enable key

to enter the print mode

To set the LINE SPEED, press to put the system in the Printing mode.

Set character width by

To set the PRINT DELAY press: to put the system in the Printing mode.

Set print delay by

. NOTE: Each increment or decrement changes the delay by the pre-defined

amount.

You may continue to experiment with line speed and print delay until the desired

code registration on the product is achieved.

12 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PART 2: OPERATION PROCEDURES

OVERVIEW

CONTROLLER AND LCD

The keypad on the print

station, pictured here,

contains 64 keys. The LCD

will display various messages

STOPPED

HD 1 - ->SPEED= 120

EVOLUTION SC

EVOLUTION CODERS

to assist in programming on

the upper half of the display.

The lower half of the display

will show up to two lines of

the entered print message.

The system operates is 3

basic modes. They are: Print

Mode, Command Mode, and

Message Entry Mode. In

Print Mode the majority of the

keys on the keypad are

disabled to avoid inadvertent

changes. When in Print Mode

the Top line of the LCD will

display PRINTING.

The Command Mode is used

to change the functions of the

printer. When in the

Command Mode the display

will show STOPPED on the

top line. The Message Entry

Mode is used to create or

modify printable codes, when

in this mode the top line of the

display will show MESSAGE

ENTRY.

The 4 keys on the top row are

the function keys F1 through

F4. They each consist of

submenus for modifying

various printer functions.

Their specific menus are

detailed later in this section.

The next two rows of keys

with icon legends directly

control specific parameters of

the printer as follows.

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

KEYPAD KEY DESCRIPTIONS

This is the manual cycle key. When in the Stopped mode, pressing this

key causes the printer to print one code

.

This is the Print key. Use it to place the unit in the Print mode

This is the Purge key. Use it to purge ink for maintenance purposes. The

unit must be in the Command mode to use this key.

This is the Head Select key. Use it to select the address of the head to be

S1

communicated with. In edit mode it enters the DAY of WEEK

Use this arrow to decrease values, and use it to move the cursor in the

message line while editing the message.

Use this arrow to increase values and use it to move the cursor in the

message line while editing the message.

Use this arrow to move the cursor between the message lines while in

Edit mode and building a message.

Use this arrow to move the cursor between the message lines while in

Edit mode and building a message.

This key is the Message Storage key. Use it to store and to recall

individual codes.

This is the Delete key. Use it to backspace to delete a character when

mistyped as well as to exit from certain menus.

This is the Message Entry key. Use this key to enter the Message Entry

mode, to input a code or to edit a code.

This is the Date key. Use this key to enter the Date in Message Entry

Mode. Change Date in STOPPED mode.

This is the Time key. Use this key to enter the Time in Message Entry

Mode. Change Time in STOPPED mode.

This is the Sequence Number key. Use this key to enter the Sequence

Number in Message Entry Mode. Command mode sets count parameters

This is the Enter or Return key. When pressed, the unit will accept input

and exit certain menus.

This is the Print Delay key.

In Message Entry Mode this is the DATE OFFSET FUNCTION

This is the Line Speed key.

In Message Entry Mode this is the SHIFT CODE FUNCTION

This key selects the Font size in the EDIT mode.

In the COMMAND mode pressing this key displays the current fonts

loaded in the print head.

Pressing this key while in the Message Entry mode accesses special

characters

S2

2 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

This key is reserved for special customer Logos

TURNING ON THE PRINT STATION FOR THE FIRST TIME

To turn the print station on insert the power jack

EVSC STOPPED

HD1- - >SPEED=120

EVOLUTION SC

important information regarding the system:

The Top line indicates the PRINT SYSTEM TYPE and the operating mode of the

unit: “STOPPED” when in Command mode, “ PRINTING” when in Print mode,

and “MESSAGE ENTRY when in message entry.

The 2

product and the programmed SPEED.

The lower half two lines of the display shows the message entered for printing.

This may represent one or two lines of code.

nd

line shows the print head currently selected, the direction of travel for the

into the DC power connector.

There is no on/off switch.

The first time the print station is turned on, as

received from the factory, the LCD will look like

the illustration on the left. Each line gives

CHECKING SYSTEM INFORMATION

CONTROLLER 1.06

EVSC 1.03_++++

PRINTER SN284955

ANY KEY TO EXIT

pack 1, the second + indicates option pack 1.5 and the last + indicates option

pack 2.

Verify system information by pressing the V key

on the hand held controller keyboard. The LCD

screen will display the software, firmware, serial

number and options enabled. Enabled options

are indicated on the second line as a series of +

characters where the first + indicates option

CHECKING LOADED FONTS

EVSC ACTIVE FONTS

2 LINE DDI S_5

1 LINE DDI S_7

1 LINE DDI B_7

1 LINE DDI S_12

1 LINE DDI B_12

ANY KEY TO EXIT

12x9 1 line of text

12x9 bold 1 line of text

7x5 1 line of text

7x5 bold 1 line of text

5x5 2 lines of text

Press the FONT key in the COMMAND

mode to check what fonts are currently loaded

in the print head.

NOTE: The Evolution small character has 5

font styles:

3 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

CHANGING SYSTEM DATE AND DAY OF WEEK CODES

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

ENTER MONTH-

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

ENTER DAY-

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

ENTER YEAR-

< - - SELECT - - >

DAY OF WEEK- 1

DAY FORMAT

1= NUMERIC

2= LETTERS

PRESENT SETTING

ANY CHANGES Y/N

04/23/05

When the unit is in the STOPPED mode

pressing the DATE key allows the user to

change the system date. If there are no

changes press the N key to return to the

STOPPED mode.

Press the Y key to change the date.

The system will prompt the user first for the

Month (enter 2 digits), then the Day (2 digits)

and finally the year (2 digits).

After the date is entered the system requests

the actual date day of week. This parameter is

usually set to 1 for Sunday, 2 for Monday etc.

The day of the week can be entered into a

message as either a number 1-7 or as a letter

A-G. The day of the week is entered into a

message by pressing the

After the data is entered the system displays

the currently entered date and pressing the N

key returns the user to the STOPPED mode,

or press Y to the correct the date.

key.

4 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

CHANGING SYSTEM TIME AND DATE ROLL OVER TIME

TIME SETTINGS

1= SET TIME

2= DATE CHANGE TIME

PRESENT SETTING

ANY CHANGES Y/N

23:05

PRESENT SETTING

ANY CHANGES Y/N

23:05

ENTER HOURS -

PRESENT SETTING

ANY CHANGES Y/N

23:05

ENTER MINUTES -

PRESENT SETTING

ANY CHANGES Y/N

13:50

TIME SETTINGS

1= SET TIME

2= DATE CHANGE TIME

DATE TIME CHANGE

ANY CHANGES Y/N

00:00

Changing the system time is accomplished by

selection option 1.

Select the N key if the time is correct and

return to the STOPPED mode.

Press the Y key to change to the correct time.

Enter the correct hours (2 digits) followed by

the correct minutes (2 digits). The screen

displays the corrected time. Press the Y key to

make further changes or N key to return to the

STOPPED mode.

Notice the time is in 24-hour format.

The Date Change option is enabled by

selecting option 2. This feature allows the date

to roll over at a specified time other than

12:00AM (midnight). For example if the start of

a new shift day occurs at 6:00AM the date will

be changed each day at 6:00AM.

Selecting Y allows changing of the roll over

time. Setting this parameter to 00:00 disables

the function.

5 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

DATE TIME CHANGE

ANY CHANGES Y/N

00:00

ENTER HOURS -

DATE TIME CHANGE

ANY CHANGES Y/N

00:00

ENTER MINUTES -

RESET CLOCK

ENTER HOURS -

RESET CLOCK

ENTER MINUTES -

Similar to entering the time enter first the hours

then at the next prompt enter the minutes.

Remember the time is entered in military time.

Entering 06:00 sets the date change time at

6:00AM.

Enabling this function requires resetting the

current correct time.

Enter both the current time in hours and

minutes.

This resets the correct time and establishes a

new Date Rollover Time.

6 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PROGRAMMING

DEFINITIONS

There are two parts to programming the EVOLUTION SC ink jet printer,

• setting the operations parameters, (character width, delay, etc.) and

• building the message.

MODES OF OPERATION

The system operates is 3 basic modes. They are: Print Mode, Command Mode,

and Message Entry Mode.

In Print Mode the majority of the keys on the keypad are disabled to avoid

inadvertent changes. When in Print Mode the Top line of the LCD will display

PRINTING.

The Command Mode is used to change the functions of the printer. When in the

Command Mode the display will show STOPPED on the top line.

The Message Entry Mode is used to create or modify printable codes, when in

this mode the top line of the display will show MESSAGE ENTRY.

PRINTING MODE AND STOPPED “COMMAND” MODE

EVSC PRINTING

HD1< - - - SPEED=120

EVOLUTION SC

EVSC STOPPED

HD1< - - - SPEED=120

EVOLUTION SC

Mode. To enter Command mode, press

When in the Print mode the screen will look like

the screen on the left. When PRINTING is seen

on the LCD, the unit will print as product passes

in front of the carriage assembly. To enter Print

mode, press

When in the Command Mode the screen looks

like the illustration at left. When STOPPED the

printer will not print when product is moved past

the carriage assembly.

In Command mode, access can be made to the

menus under the function keys, F1 through F4

icon control keys plus access to Message Entry

.

.

7 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

MENU STRUCTURE

In the Command mode, access is allowed to the menu structure for basic

parameters. The menus reside within the function keys, F1 through F4. In order

to select one of the parameters, press the number key that corresponds to the

desired parameter.

The F1 key, when pressed, brings up the menu as shown below.

1=CHAR. SPACING

2=EXT. ENCODER

3=DATE OFFSET

4=NOT AVAILABLE

The F2 key, when pressed, brings up the menu as shown below.

1=DIRECTION

2=PRINT INVERSE

3=NOT AVAILABLE

4=AUTO REPEAT

The F3 key, when pressed, brings up the menu as shown below.

1= PRODUCT COUNT

2= SHIFT CODE

3=DATE FORMAT

4=TIME FORMAT

The F4 key, when pressed, brings up the menu as shown below.

1=LANGUAGE

2=INK SUPPLY

3=SET UNIT I.D.

4=NOT AVAILABLE

8 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

F1 MENU

1=CHAR. SPACING

2=EXT. ENCODER

3=DATE OFFSET

4=NOT AVAILABLE

reserved for future system expansion.

Place the unit in the Command mode and press

. The screen shown to the left is produced.

Press the correct number to make changes to that

parameter. Those selections designated as NOT

AVAILABLE will not respond to selection. They are

1 = CHARACTER SPACING:

< - - SELECT - - >

# OF SPACES- 1

This parameter controls the amount of space

between characters in the code. Spacing can be

varied from 1 to 25 columns. Use this control to

make printed codes more legible when code is

change the value. Press

compressed. Press the

once the desired value is displayed.

then press or to

2 = EXT. ENCODER:

ENCODER

1=INTERNAL

2=EXTERNAL

aspect ratio character (96 dpi vertical and horizontal) or compressed by setting

the print head line speed faster than the actual line speed, or expanded by

changing the internal speed slower than the actual line speed.

In the event there is an acceleration or deceleration to the production line, or

there is a requirement to guarantee accurate aspect ratio, an external encoder is

necessary. Press

selected the LINE SPEED key will adjust the expansion and compression of

the printed message. Selecting the correct encoder is important to allow for both

compression and expansion of printer text. The correct aspect ratio can be

calculated as follows:

Swath height is 0.125 (1/8”) / 12 vertical dots = 0.0104” between vertical dots

Therefore to print a perfect aspect ratio character requires an encoder pulse

every 0.0104”. The encoder range adjustment is from 0 to 7 and assuming the

mean is a count of 4 then by connecting an encoder that produces a pulse for

each 0.0026” the correct character aspect ratio can be achieved. This allows to

either compression or expansion of the printed text.

to select external encoder. While external encoder is

Press to select internal time base. This

parameter controls the source of the time base used

for printing. Each vertical column printed requires a

signal necessary to produce a character

representative of the line speed of the production

line. The printer can be set to produce a perfect

9 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

3 = DATE OFFSET:

DATE OFFSET

USE KEYS 0->9

# OF DAYS = 100

To enter a date offset (expiration date) change the

value equal to the number of days until expiration.

Legal entries are 0 to 999 days. The format of the

date offset can be different than a normal date and

may be set with the F3 #3 option DATE FORMAT.

10 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

F2 MENU

Place the unit in the Command mode and press

1=DIRECTION

2=PRINT INVERSE

3=NOT AVAILABLE

4=AUTO REPEAT

produced. Press the correct number to make

changes to that parameter

. The screen shown to the left is

1 - DIRECTION:

The arrow shown on the LCD’s third line screen

< - - SELECT - - >

should agree with the direction of product travel.

LINE DIRECTION

< - - - -

Press

for the unit to accept the change.

or to change direction. Press

2 - PRINT INVERSE:

CODE ORIENTATION

1 = NORMAL PRINT

2 = UPSIDE DOWN

This parameter allows the code to print right side

up or upside down. Pressing

will produce

the following screen. Press for normal print

or

for upside down codes. Save the choice

by pressing . Look for the change of direction

on the imprint.

3 – NOT AVAILABLE:

4 - AUTO REPEAT:

< - - SELECT - - >

REPEAT TIME= 0

time delay adds or subtracts a distance equivalent to the pre-defined setting.

Save your choice by pressing

where each count is equal to 2 character columns or 0.020”. This allows for a

total displacement of 5.31”. Setting a print delay that uses the same

mathematical equation can increase this number. Thus a total displacement of

10.62” can be realized.

This option enables the unit to continuously print

repeated codes at specified time intervals along

the entire length of the product. A time of 0

disables the Auto Repeat option. Use

or

to change the repeat time. Each number in the

. The maximum repeat spacing is 255 counts

11 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

F3 MENU

1= PRODUCT COUNT

2= SHIFT CODE

3= DATE FORMAT

4= TIME FORMAT

1 – PRODUCT COUNT:

PRODUCT COUNTER

CHANGES Y/N OR C

08:00 - - > 17:00

COUNT = 000000

PRODUCT COUNTER

START TIME

08:00 - - > 17:00

ENTER HOURS -

PRODUCT COUNTER

START TIME

08:00 - - > 17:00

ENTER MINUTES -

PRODUCT COUNTER

STOP TIME

08:00 - - > 17:00

ENTER HOURS -

PRODUCT COUNTER

STOP TIME

08:00 - - > 17:00

ENTER MINUTES -

PRODUCT COUNTER

CHANGES Y/N OR C

08:00 - - > 17:00

COUNT = 000000

The product counter is a non-printable entity,

and must be read after the end of the set time

period. The counter indicates each print cycle

sensed by the external photo eye. Depressing

the C key may clear the counter.

If there are no changes press the N key.

To change the settings depress the Y key.

All times are in Military Time 00:00 to 23:59

hours.

Enter the start time HOURS.

At the next screen prompt enter the start time

MINUTES

The system then prompts the user for the STOP

TIME.

Enter both the stop time HOURS and then the

MINUTES.

The newly entered data is re-displayed for

verification or correction if necessary Press the

Y key to change the data or the N key to finish

and return to the STOPPED MODE

12 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

2 – SHIFT CODE:

1= PRODUCT COUNT

2= SHIFT CODE

3= DATE FORMAT

4= TIME FORMAT

Shift codes may be encoded directly in the

printable message. The printer can print 6

individual shift codes. Each shift code contains a

unique start time and alpha/numeric code to be

printed.

ADJUST SHIFTS

< - - SELECT - - >

SHIFT 1 07:00 A

ANY CHANGES Y/N

ADJUST SHIFTS

SHIFT 1

START TIME

ENTER HOURS -

ADJUST SHIFTS

SHIFT 1

START TIME

ENTER HOURS -

ADJUST SHIFTS

SHIFT 1

START TIME

ENTER MINUTES -

ADJUST SHIFTS

SHIFT 1

PRINT CODE =

ADJUST SHIFTS

< - - SELECT - - >

SHIFT 1 07:00 A

ANY CHANGES Y/N

Press

view or change.

The shift code option allows the user to enter 6

different shift times per day. Use the arrow keys

to select a shift and enter a Y to change a shifts

start time.

All times are in Military Time 00:00 to 23:59

hours.

Enter the correct start time HOURS the shift

selected.

Enter the correct start time MINUTES for the

shift selected.

Finally, enter the desired code to be printed in

the message. Legal characters are the letters A

to Z and the numbers 0 to 9.

The printer re-displays the data for the selected

shift for verification.

NOTE: THIS PROCEDURE MAY BE

REPEATED FOR ALL DESIRED SHIFTS.

or to change the desired shift to

NOTE: TO DISABLE A SHIFT ENTER A

SPACE CHARACTER IN THE PRINT CODE FIELD. THE SHIFT

TIMES WILL BE DISPLAYED AS --:-- FOR ALL DISABLED SHIFT

TIMES.

13 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

3 – DATE FORMAT:

1= PRODUCT COUNT

2= SHIFT CODE

3= DATE FORMAT

4= TIME FORMAT

CHANGE FORMAT

1=CALANDER DATE

2=OFFSET DATE

3=WEEKLY DATE

MONTH FORMAT

1=NUMERIC

2=LETTERS

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

dm/dd/dy

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

jjj

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

jjjyy

have been entered by selecting the appropriate key on the keyboard. Legal

delimiters are the colon (:), the forward slash (/) or the period (.).

Press F3 to change the date formatting. Each of

the following screens prompts the user to enter

the desired format for printing.

NOTE: THE USER MAY INDIVIDUALLY

CHANGE THE FORMAT OF BOTH THE

CALANDER FORMAT AND THE DATE

OFFSET FORMAT

NOTE: THE FOLOWING PROCEDURE

APPLYS TO BOTH CALANDER AND OFFSET

DATE FORMATS.

Selecting the standard numeric format will

prompt the user to enter the format of the date in

standard number format.

The default as shipped from the factory is

dm/dd/dy, and may be modified as required.

If the offset format was selected the word DATE

is replaced with the word OFFSET.

To change the format press the delete key and

the last line on the display will be erased. The

entire format will be erased and must be reentered.

Press either of the designator keys (i.e. M for

month) and the display will display the correct

code for the item selected. As an example enter

the Julian date and year. Press the J key

followed by the Y key. The code entered will

print the Julian date followed by the 2-digit year.

Notice no delimiters were selected, but may

14 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

MONTH FORMAT

1=NUMERIC

2=LETTERS

Alpha month characters are selected by pressing

option 2.

DATE FORMAT

D=DAY M=MONTH

Y=YEAR

jjjyy

DATE FORMAT

D=DAY M=MONTH

Y=YEAR

ddmmmyy

WEEKLY DATE

1=ENABLE

2=DISABLE

Delete the current formatting by pressing the

Delete key.

Enter the desired Date Format and notice when

the M (month) is selected the display shows

mmm. Select the appropriate key on the keyboard

by entering in the desired code. Press the Enter

key to return to the STOPPED mode.

The software performs a special function allowing

the user to set the current date to change only at a

certain day of the week. This function is typically

used in batch processing, where a batch may be

prepared on Sunday and packaged from Monday

through Friday of the following week.

Entering either the current date or offset date in a message will result in the initial

date being printer for either function throughout the following week. Selecting

option 2 returns the user to the STOPPED mode.

15 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

4 – TIME FORMAT:

1= PRODUCT COUNT

2= SHIFT CODE

3=DATE FORMAT

4=TIME FORMAT

TIME FORMAT

H=HOURS

M=MINUTES

hh:mm

H=HOURS

M=MINUTES

hh

TIME FORMAT

Change the Time Format by selecting option 4.

NOTE: Delimiter characters like a :

code may be entered to separate fields

The factory default for time formatting is hh:mm

and may be changed as required. Press the

Delete key and the last line on the display is

erased.

Enter the desired format by pressing the H and or

M keys, and select delimiters as required. Select

H if only hours are required.

Press the Enter key to return to the STOPPED

mode.

16 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

F4 MENU

1 = LANGUAGE

2 = INK SUPPLY

3 = SET UNIT I.D.

4 = LOAD CARD

Place the unit in the Command mode and press

. The screen shown at left is produced.

Press the number that corresponds to the

parameter you wish to change.

1 - LANGUAGE:

< - - SELECT - - >

ENGLISH

mode. Whenever language is chosen, all prompts and commands shown on the

screen will be in that language.

Press and the screen will change like the

one on the left. The default language is English;

the other choice is Spanish. Scroll through the

choices using either or . Once the

desired language is shown on the screen, press

. This will return the unit to the Command

2 - INK SUPPLY:

The second line of the display shows the

REMAINING INK

100

C NEW CARTRIDGE

OTHER KEY EXIT

When a C is entered the system automatically profiles the operating conditions

for the new cartridge.

Each cartridge is tested at the factory and uses specially formulated and

proprietary inks. The correct drive voltage, pulse width timing and pre-fire pulse

warming may be adjusted for optimum operation.

percentage of ink remaining in the print

cartridge.

Each time a new cartridge is installed the user

must reset the system ink gauge by pressing the

C key.

NOTE: USING NON-AUTHORIZED CARTRIDGES WILL

PRODUCE UNDESIRABLE RESULTS

17 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

3 – SET UNIT I.D.:

< - - SELECT - - >

SET HEAD # = 1

when adding multiple print carriages to affix a label indicating the unique

ADDRESS number of the individual carriage.

Each print carriage can contain a unique address

to distinguish multiple carriages when controlled

by a single hand held controller or computer data

link using an RS485 protocol. The default for each

new print carriage module is ADDRESS 1.

Addresses can range from 1 to 32. It is advisable

NOTE: To program a carriage it must be connected directly to

the hand held controller, with no other PRINTHEADS connected.

4 – NOT AVAILABLE:

18 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

SETTING PRINT DELAY AND LINE SPEED

LINE SPEED – This setting adjusts the width of the printer message on the

product. This setting should be adjusted to produce the desired print on the

product. Line speed can be increased or decreased to stretch or compress the

message to fit the desired print area.

PRINT DELAY – This setting adjusts the location of the printed message on the

product.

EVSC STOPPED

HD1< - - SPEED=120

EVOLUTION SC

EVSC PRINTING

HD1< - - SPEED=120

EVOLUTION SC

Access to these parameters is possible when the

unit is in either the STOPPED or PRINTING mode

as shown to the left.

Pressing the delay key allows the user to

determine the amount of print delay. Each count at

a normal aspect ratio is approximately 0.0208”.

This will vary according the amount of

compression or expansion used.

SETTING LINE SPEED

Normally, the system will be set to use the internal

< - - SELECT - - >

LINE SPEED = 100

time base for line speed control. The default value is

100, which creates a normal width character on a

line moving at 100 ft per min. The print can be

narrowed by increasing the number and widened by

parameter. Once pressed, a new screen appears, as shown to the left.

Changes can now be made by using

character width is 1 to 200. Once the desired number is chosen, press

save your entry.

< - - SELECT - - >

ENCODER DIV = 4

19 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

decreasing the number. Pressing

or . The range of values for

If external encoder is enabled and the unit is in the

PRINTING mode the user has the option of

adjusting the compression ratio of the printer

message. Changes may be made by using

. Once the desired number is chosen, press

to save your entry.

accesses this

to

or

SETTING PRINT DELAY

EVSC STOPPED

HD1- - >SPEED=120

EVOLUTION SC

NOTE: This parameter may be set when the unit is either in the PRINTING

or STOPPED mode

PRINTING

HD1- - >SPEED=120

EVOLUTION SC

< - - SELECT - - >

PRINT DELAY= 100

NOTE: THE DIMENSION INDICATED IS WHILE PRINTING A PERFECT

ASPECT RATIO CHARACTER. WHEN PRINTING A COMPRESSED OR

EXPANDED CHARACTER THE ACTUAL DIMENSIONAL NUMBER WILL BE

DIFFERENT BUT CAN BE ESTIMATED BASED ON THE 18 COLUMNS PER

COUNT.

NOTE: Setting the line speed first, then adjusting the print delay may prove

to be the best starting point

Print delay is used to position a message on the

product at a location other than at the leading

edge. Access this parameter by pressing

the keypad.

To change the value use either

range of values for this parameter is 1 to 255.

Each increment represents 2 columns,

approximately .0208” (.5mm). Therefore, a delay

of 255 would approximate 5.3” (135mm). Once a

number is chosen, press

to save the entry.

or . The

on

SETTING HEAD ALIGNMENT

Aligning the vertical print for messages in multiple

< - - SELECT - - >

HEAD ALIGN = 0

head alignment. Valid selections are from 0-16.

print heads is fine-tuned with an additional feature

found in either the PRINTING or STOPPED mode.

Pressing the letter O on the keyboard accesses

this feature.

A count of 0 disables this feature while using the

arrow keys allows the user to fine-tune the print

20 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

y

INPUT, EDIT OR DELETE MESSAGES

EVSC STOPPED

HD1- - >SPEED=120

EVOLUTION SC

MESSAGE ENTRY

- - - - FONT- 1 S12

EVOLUTION SC

MESSAGE ENTRY

- - - - FONT- 1 S12

MESSAGE ENTRY

- - - - FONT- 1 S12

EXP dm/dd/dy

To input, delete or edit a message, the unit must

be in the STOPPED Mode. If the LCD reads

PRINTING, press

similar to the one shown at the left.

Enter the Message Entry mode by pressing

The top portion of the screen will change as

shown on the left.

The user has two options to edit or change a

message. If a new message is to be entered press

the

message.

For example, to produce a single line of text.

Press the font key until the S12 font size

is shown, and enter EXP followed by the

key to delete the entire existing

. The screen should be

.

MESSAGE ENTRY

- - - FONT- 2 S5

BEST BY

EXP dm/dd/dy

EVSC STOPPED

HD1- - >SPEED=120

BEST BY

EXP dm/dd/d

LINE character size. To enter and print only 1 line of 2 LINE select the line and

enter data to that line only.

Once the message line(s) is complete, save the change by pressing

NOTE: USE THE DATE OFFSET KEY TO ENTER AN EXPIRATION DATE.

key. This enters the date offset as defined in

the F1menu. This enters the date offset as defined

in the F1 menu.

To place two lines use the to select 2

LINE size. Press the

entire message. Press the

which line the data will be entered on. Enter BEST

BY. The pictorial at the left shows two lines of 2

to delete the

to select

.

21 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

MESSAGE ENTRY

- - - - FONT- 1 S12

PRICE $ 1.29/10

MESSAGE ENTRY

- - - - FONT- 1 S12

PRICE $

MESSAGE ENTRY

- - - - FONT- 1 S12

PRICE $ 1.75/12

MESSAGE ENTRY

- - - - FONT- 1 S12

PRICE $ 1.75/09

< - - SELECT - - >

!#

$&( )*+=¢ŇẾỖ

EVSC STOPPED

HD1- - >SPEED=120

PRICE $ 1.75/12

return to the Command mode.

The second option is to replace characters by

using the key or moving the cursor over a

character to be replaced. When the MESSAGE

ENTRY mode is entered the cursor is placed at

the end of the line. Pressing the key will delete

the last character on the line. Successive

continue to delete the last character on a line.

At the left the characters 1.29/10 were deleted.

Enter the correct data, in this case 1.75/12.

The alternative approach if just a few characters

are to change is to use the

cursor over the characters to be changed and

retype the correct characters. In this example the

1.29/12 WAS CHANGED TO 1.75/09.

Symbols are inserted by pressing

Message Entry mode, position the cursor where a

symbol is needed and press . The screen will

show a line of symbols as presented on the left.

Position the cursor by pressing

special character to be inserted and press

Continue to build the message or press

or to place the

. When in

or on the

’s will

.

to

22 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

MESSAGE ENTRY

- - - - FONT- 1 S12

MESSAGE ENTRY

- - - - FONT- 1 S12

DM/DD/DY

MESSAGE ENTRY

- - - - FONT- 1 S12

HH:MM

MESSAGE ENTRY

#### FONT- 1 S12

0000

MESSAGE ENTRY

- - - - FONT- 1 S12

0000

Enabling variable field programming requires the

use of the special function keys.

To enter a date that automatically changes use

the key. The current date format as set in

the F3 menu is entered into the message.

To enter a time that automatically changes use

the

the F3 menu is entered into the message.

Sequence numbers may be added to a message

with the

depressed the four ---- are changed to ####

indicating a sequence number field. After

entering the correct sequence number press the

maximum number of digits allowable is 9

numeric characters.

key. The current date format as set in

key. Note when the key is

key to terminate the sequence field. The

MESSAGE ENTRY

< < < < FONT- 1 S12

DM.DD.DY

MESSAGE ENTRY

- - - - FONT- 1 S12

S

23 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

Date offset codes are entered by using the

key.

The correct date offset format as defined in the

F3 menu is entered into the message

Finally use the

Shift codes are defined in the F3 menu and will

automatically change at the appropriate shift

times. The shift designator S is displayed to

indicate the data entry.

key to enter a shift code.

MESSAGE ENTRY

- - - - FONT- 1 S5

MFG DM/DD/DY HH:MM

EXP DM.DD.DY S 0009

For purposes of clarity the font sized is changed to

S5 allowing a number of parameters to be

displayed. The first line contains the alpha

characters MFG followed by the

key then a

space and the

alpha characters EXP followed by the the

entered, followed by a 4-digit sequence number using the key.

Sequence number format is programmable in the

SEQ. NUMBER

1= COUNT UP

2= COUNT DOWN

CLEAR SEQ# FIELD

YES OR NO Y/N

COUNTER LIMIT

ANY CHANGES Y/N

ENTER #000000000

COUNTER LIMIT

ANY CHANGES Y/N

ENTER #000005000

STOPPED mode. The counter may be set to

count either up or down by selecting number 1 or

2. Pressing enter advances the user to the next

menu prompt.

Clearing the sequence field resets the counter to

their initial settings.

The next prompt allows for changes in the

sequence limit field. Selecting Y allows the user to

enter the desired maximum (minimum for down

count) count. Digits are enter via the keyboard

right justified. As an example to set a maximum

count of 5000 enter 5000. Pressing the DEL key

allows for re-entry while pressing the ENTER key

returns the user to the STOPPED mode.

key. The second line has the

key. Then a shift code is

24 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

Moving the cursor back over the various characters contained in the message

may be used to validate the message. Note that the field designator will normally

appear as - - - - indicating an alpha/numeric code as would be seen by moving

the cursor under the M F G or the E X P on the second line. The same

designator will be seen when the cursor is placed under any non-changeable

field including the space character.

Moving the cursor under a variable programmable field will display the correct

field designator in place of the - - - - alpha/numeric designator.

MESSAGE ENTRY

- - - - FONT- 1 S5

MFG DM/DD/DY HH:MM

EXP DM.DD.DY S 0009

The various field designators displayed are:

- - - - Alpha/Numeric non-changeable data

# # # # Sequence number field

< < < < Shift code field

OM Offset date month field

OD Offset date day field

OY Offset date year field

DM Current date month field

DD Current date day field

DY Current date year field

TH Current time hour field

TM Current time minute field

For example, moving the cursor under the S (shift

code) on the second line would display the field

designator as < < < <

NOTE: ONLY 15 FIELD DESIGNATORS ARE PERMITTED ON A

PARTICULAR LINE. IN THE ABOVE EXAMPLE THE FIRST LINE

OF DATA MFG DM/DD/DY HH:MM CONTAINS 10 OBJECT

FIELDS. FOR PURPOSES OF CLARITY THE SPACE

CHARACTER IS SHOWN AS THE UNDERLINE _ CHARACTER

WHERE:

MFG_ = ALPHA/NUMERIC FIELD

DM = DATE MONTH FIELD

/ = ALPHA/NUMERIC FIELD

DD = DATE DAY FIELD

/ = ALPHA/NUMERIC FIELD

DY = DATE YEAR FIELD

_ = ALPHA/NUMERIC FIELD

HH = TIME HOURS FIELD

: = ALPHA/NUMERIC FIELD

MM = TIME MINUTES FIELD

25 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

The above constitutes 10 object fields. Even though there are 48

characters permitted per line data entry will be inhibited when

the 15

th

object is entered, although the last field, if it is an

alphanumeric object, may contain enough characters to meet

the 48-character limit.

26 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PASSWORD PROTECTION

The EVOLUTION SC contains a password

PASSWORD XXXXX

ENABLE PASSWORD

YES OR NO Y/N

PASSWORD XXXXX

If the new password is misplaced or forgotten, reset the unit.

function designed to limit access to the edit

menu and prevent unauthorized changing of

message lines. To activate this function, switch

the unit off, then press and hold

switching the unit on. The display changes and

requests the default password (which is

12345). Enter the 12345.

The screen to the left appears and prompts the

operator or ENABLE PASSWORD

A response of N maintains the current

password and disables password protection.

If the response Y is selected the screen at the

left appears to prompt the user to enter a new

password. Enter the new 5 character password

any combination of letters and numbers may

be used. Once this has been completed, the

unit will not allow message editing without the

entry of the password.

while

27 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

MESSAGE STORAGE

STORING A MESSAGE

MESSAGE # 1 EVSC

MESSAGE # 1 EVSC

PLEASE WAIT

MESSAGE # 1 EVSC

MESSAGE STORED

All EVOLUTION SC printers are able to store up to

100 system wide programmed messages and their

associated parameters. Follow these steps to

store a message. Create the message and press

. Press . Using or , scroll to the

desired message location number.

Press a second time. This places the

message into that numeric location for recall at a

later time. Use the same procedure to overwrite

an existing stored message as well.

The LCD display will indicate that the message is

stored.

EVOLUTION SC

Press

to exit.

NOTE: Message storage should be used after the product has

been coded satisfactorily. When a message is stored all

operating parameters of the printed code are saved. Once

recalled, codes will be printed the same as they had been before.

NOTE: EACH STORED MESSAGE WILL SHOW THE SPECIFIC

UNIT THAT THE MESSAGE WAS CREATED FOR.

RECALLING A STORED MESSAGE

MESSAGE # 1 EVSC

EVOLUTION SC

EVSC STOPPED

HD1< - - SPEED=120

Place the unit in “Stopped” mode and press .

Use the or to scroll through the stored

messages. Find the desired message and press

. That message is now displayed on the screen

ready for printing.

EVOLUTION SC

28 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PART 3: MAINTENANCE PROCEDURES

SHORT PERIODS OF SHUTDOWN

When the printer has been shut down overnight, the system might require a

purge to clear out dust particles that have settled on the nozzle area during nonuse. This is only necessary if there are missing dots in the printed code on

product.

EVSC STOPPED

HD1< - - SPEED=120

EVOLUTION SC

PURGING

EVSC STOPPED

HD1< - - SPEED=120

EVOLUTION SC

EVSC PRINTING

HD1< - - SPEED=120

EVOLUTION SC

To purge be sure that the unit is in the STOPPED

Mode by pressing green

changes to STOPPED as shown to left.

Place a piece of lint free wipe (or absorbant paper)

in front of the print head and press the red

Allow the unit to purge for several seconds. There

is an automatic shut down after a preset time

period to ensure that the print head will not be

damaged. If ink residue has solidified on the

nozzle area a small drop of water may be applied

to the lint free wipe.

When purging is complete the LCD will be

returned to the STOPPED mode.

Press the green

PRINTING, as shown at the left. The unit is ready

to begin coding.

and the screen changes to

key. The screen

.

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

LONG PERIODS OF SHUTDOWN

When the printer is to be shut down for extended periods, or the ink cartridge

needs to be changed to insert a different color cartridge, the ink cartridge should

be removed.

Clean the print head nozzle area with a soft, lint free wipes and insure there is no

ink residue remaining on the nozzle area. Re-apply the sealing tape. The print

cartridge may be stored in a closeable plastic bag.

CAUTION: USE THE ORIGINAL SEALING TAPE SUPPLIED WITH

THE EVOLUTION SC INK CARTRIDGE. DO NOT USE ANY OTHER

MATERIAL OR ANY ADHESIVE BACKED PRODUCT, AS THIS

WILL DAMAGE THE NOZZLE AREA.

2 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PRINT CARTRIDGE MAINTENANCE

It is necessary to maintain the EVOLUTION SC print cartridge free from

accumulated dust and debris. Periodically the cartridge should be removed and

cleaned. This is totally dependent on the operating environment and the average

printable life of the ink cartridge. In extremely dusty environments, this

maintenance procedure may be required regularly.

To clean the cartridge, carefully clean the face of the cartridge with a soft, lint

free wipe. Use caution in wiping the NOZZLE area so as not to scratch the face.

Always wipe in the ARRAY PLATE vertically as indicated.

Clean the CONTACT area in a similar fashion.

NOZZLES

DIRECTION OF WIPING

CONTACT AREA

3 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

NOTE:

Ingested air or severe nozzle clogs may be eliminated with the

use of the cleaning syringe supplied with each EVOLUTION SC unit.

The photo below shows the correct procedure in using the syringe. Place the tip

of the syringe on the print head nozzle area. While holding the syringe securely

in place gently draw back on the syringe plunger until ink flows into the syringe.

Normally, it is not necessary to evacuate more than 0.05 cc’s of ink at a time as

indicated below. Following ink withdrawal remove the syringe by sliding the

syringe vertically toward the top of the print head as indicated below. Never pull

the syringe away from the print head, as this will withdraw an excessive amount

of ink. Moving the syringe in this upward direction also wipes the print head

clean. Remove any remaining ink from the nozzle face with a lint free wipe. Place

a piece of clean white paper directly in front of the print head and perform a

purge function by pressing and releasing the purge key

on the release of the key. Swipe the paper quickly past the print head to expand

the purge pattern so the individual droplets may be viewed.

Perform a test print and verify that all nozzles are firing correctly.

. The key is activated

Remove the syringe in this

direction only

Scale gradation is in 0.10

major increments

0.05 cc’s of ink

drawn at any one

time

4 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

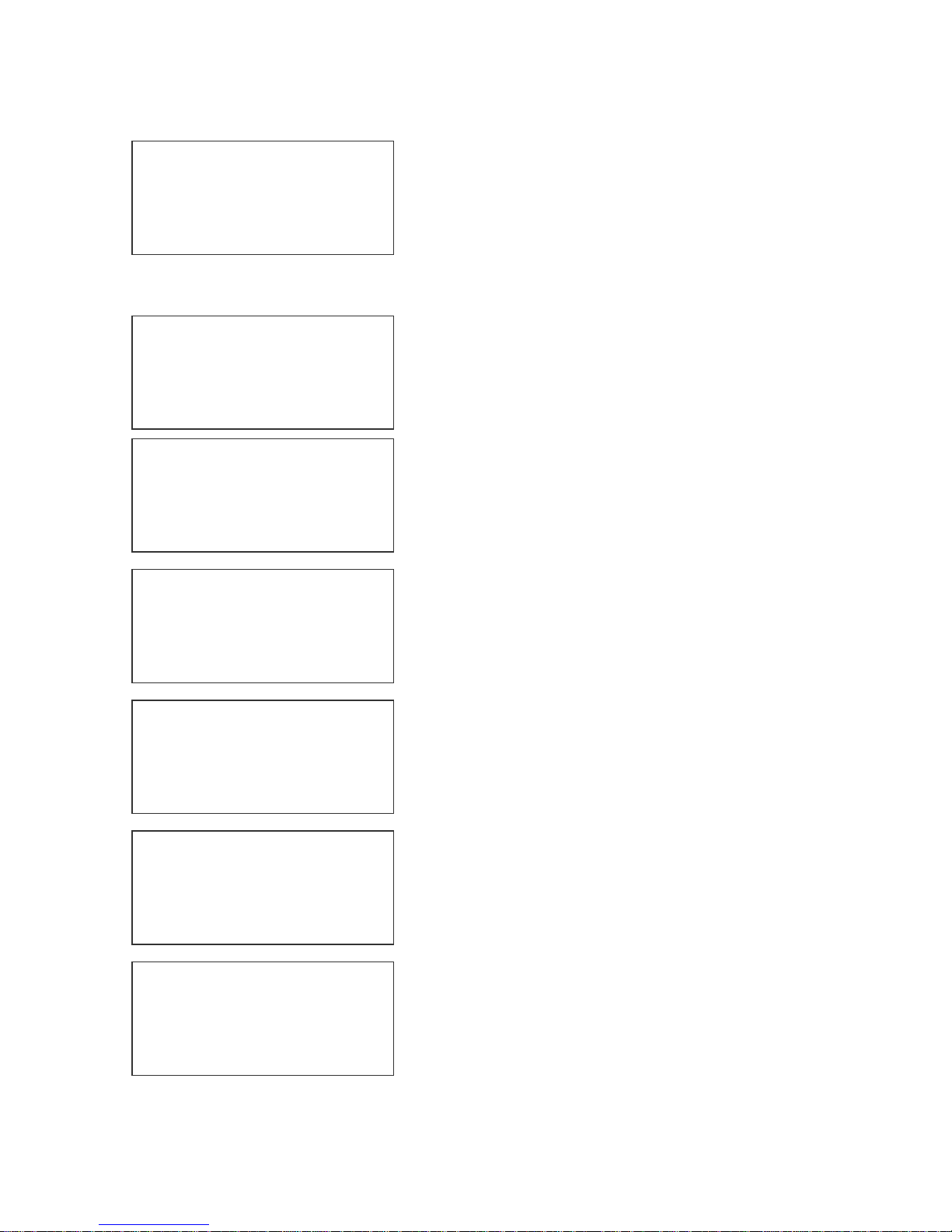

PRINT CARRIAGE MAINTENANCE

It is necessary to maintain the print head carriage free from accumulated dust

and debris. Periodically the print head carriage should be inspected and cleaned.

This is totally dependent on the operating environment. In extremely dusty

environments, this maintenance procedure may be required occasionally but on

average every week should be sufficient.

Remove the print cartridge and carefully inspect the print carriage C0991 for dust

and debris.

Re-insert the print cartridge and place the unit into the PRINTING mode by

pressing

.

EXPLODED VIEW OF THE C20991 PRINT CARRIAGE

5 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PART 4: TROUBLESHOOTING AND REPAIRS

FAULTS

This chart was created to assist the user in troubleshooting the unit. Find the

problem in the first column; apply the remedy(s) suggested in the third column.

Condition Probable Cause Remedy

LCD remains blank. No power.

Ensure the controller is securely

connected to the correct port on

the print carriage assembly

Unit does not print, although

LCD shows information.

Unit in “COMMAND”

No ink. Replace ink cartridge; reset ink

Low ink indicator on with full

ink cartridge.

Unit does not purge. Out of ink. Replace with full ink cartridge.

Unit in “PRINTING” mode

Ink cartridge clogged Clean Ink Cartridge Nozzle area

Missing one or more dots

from code.

Long downtime. Follow daily start-up procedure if

Unit loses data while printing Static electricity Eliminate source of static.

High levels of radio

Spikes in electrical line. Use AC line filter

No message in unit Input your message (see pages

2-18).

Press

mode.

volume parameter (press

and follow the sequence.

Did not reset ink volume

parameter.

No ink. Clean or Replace cartridge and

frequency.

Press . Continue key

entry following menu prompts.

Reset ink volume parameter

(press

Press Stop Print.

with lint free wipe

purge system (press ).

your line experienced a long

down time.

Attach ground strap between

print head and low impedance

earth ground.

Move unit to an alternate

location or attach ground strap

as above.

.

).

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

PART 5: PARTS LIST AND OPTIONS

Part No. Description

C21030 Controller

C21001-1 Controller Cabinet

C21030-2 Controller LCD Assembly

C21030-1 Controller PCB Assembly

C30238 Controller Keypad

C20991

C20991-3

C20991-4

C20991-5 Mounting Bracket Assembly

70335-01 Power supply

96280-01 Floor stand

C21003 Top Coding Mounting Bracket

C21006-6 External Product Detect

C21007 External Encoder

SPARE PARTS

EVOLUTION SC Print Head Cabinet Assembly

EVOLUTION SC Print Head CPU PCB Assembly

EVOLUTION SC Print Head Power Supply PCB Assembly

OPTIONS

C21012 Optional Junction Box

C21008-1 RJ50 Cable 6 INCH

C21008-3 RJ50 Cable 3 Feet

C21008-10 RJ50 Cable 10 Feet

C21008-25 RJ50 Cable 25 Feet

C21008-50 RJ50 Cable 50 Feet

C21008-100 RJ50 Cable 100 Feet

CABLES

INKS

4052BK 4 Pack of Black Ink Cartridges (porous)

4052RD 4 Pack of Red Ink Cartridges (porous)

4052GR 4 Pack of Green Ink Cartridges (porous)

4052BL 4 Pack of Blue Ink Cartridges (porous)

4053BK 4 Pack of Black Ink Cartridges (semi/non porous)

EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006 1

PART 6: COMMUNICATIONS PROTOCOL

This communication protocol covers all EVOLUTION

products. Some commands are not applicable to

certain units, and care must be taken in determining

what valid commands are for a specific unit.

Commands that reference specific units are so noted.

ASCII CHARACTER CHART

0 1 2 3 4 5 6 7 8 9 A B C D E F

0 NUL SOH STX ETX EOT ENQ ACK BEL BS HT LF VT FF CR SO SI

1 DLE DC1 DC2 DC3 DC4 NAK SYN ETB CAN EM SUB ESC FS GS RS US

2 SP ! " # $ % & ' ( ) * + , - . /

3 0 1 2 3 4 5 6 7 8 9 : ; < = > ?

4 @ A B C D E F G H I J K L M N O

5 P Q R S T U V W X Y Z [ \ ] ^ _

6 ` a b c d e f g h i j k l m n o

7 p q r s t u v w x y z { | } ~ DEL

1 EVOLUTION SC SYSTEM MANUAL Issue 1.1 15 November 2006

DESCRIPTION

This communication protocol is based on Version 1.4, which was released NOV

2005 and is used with all EVOLUTION products. The communications option

converses with a host computer via an RS485 data link.

NOTE: EACH REQUEST OR COMMAND SENT TO A PRINT STATION

RECEIVES A RESPONSE FROM THAT PRINT STATION. COMMUNICATIONS

SOFTWARE MUST WAIT FOR A RESPONSE TO DETERMINE IF THE PRINT

STATION WAS READY TO ACCEPT THE COMMAND, AND THE DATA WAS

VALID AND PROCESSED. NO RESPONSE COULD INDICATE THE DATA

WAS LOST. IF AN ERROR WAS DETECTED IN PROCESSING A NAK WITH

AN ERROR CODE IS RETURNED.

DATA WORD DEFINITION

Full Duplex

7 Data Bits

1 Even Parity Bit

1 Start Bit

1 Stop Bit

BAUD RATE

115,200 Bits per second

DEFINITIONS

Q= QUERY TO HEAD

R= RESPONSE FROM HEAD

D= DATA UPDATE TO HEAD

X= ACK FROM HEAD

{ }= ASCII CHARACTER OR CHARACTER STRING

| FIELD SEPARATOR

0x21 HEX DATA EQUIVELENT

ADDRESS= TWO ASCII REPRESENTATIONS OF HEX CHARACTERS