Digital Combo DC16 User Manual

1

Version 1-09

Digital Combo

Multi-Purpose Press

2

Contents

Introduction ............................................................................................................ 3

Setup & Suggestions ......................................................................................... 4

Normal Operation .................................................................................................. 5

Normal Operating Mode ................................................................................... 5

Setting Temperature .......................................................................................... 5

Setting Time ...................................................................................................... 6

Pre-Press Timer ................................................................................................. 6

Setting Pressure ................................................................................................. 7

Digital Pressure Bar Graph ............................................................................... 7

Guidelines & Standard Settings ........................................................................ 8

ERR Mode ......................................................................................................... 9

Over-Temp Alarm ............................................................................................. 9

Using Attachments ................................................................................................ 10

Removing a Heat Platen ................................................................................... 10

Attaching a heat platen ..................................................................................... 11

Cap Hold-down Device (For Cap Attachment Only) ............................................... 12

Aligning the Pedestal ....................................................................................... 12

Optional Forms / Custom Pedestals ................................................................. 12

How to use the Cap Attachment....................................................................... 13

How to use the Mug Attachment ..................................................................... 13

How to use the Plate Attachment ..................................................................... 14

Pressing Ceramic Tile ...................................................................................... 14

Programmable Presets ........................................................................................... 15

How Presets Work............................................................................................ 15

Loading a Preset ............................................................................................... 15

Editing/Programming a Preset ......................................................................... 16

A Walkthrough Tutorial for using Presets ....................................................... 17

User Menus ........................................................................................................... 18

Entering the user menus & options .................................................................. 18

Fahrenheit / Celsius .......................................................................................... 18

Timer Counter Units ........................................................................................ 18

Recorded Pressings (User Odometer) .............................................................. 19

Pressure Minimum ........................................................................................... 19

Pressure Maximum........................................................................................... 20

Temperature Drop Sense .................................................................................. 20

Keypad Beeper ................................................................................................. 21

Alarms .............................................................................................................. 21

Finished Warning Beep .................................................................................... 22

Prepress Timer ................................................................................................. 22

Prepress Alarms ............................................................................................... 23

Operator Lockout ............................................................................................. 23

Parts / Maintenance / Misc .................................................................................... 24

Interchangeable Tables..................................................................................... 24

Maintenance ..................................................................................................... 24

Replacement Parts ............................................................................................ 25

Wiring Diagram ............................................................................................... 26

Troubleshooting ............................................................................................... 27

Troubleshooting (cont.) .................................................................................... 28

Limited Warranty ............................................................................................. 29

3

Introduction

Congratulations on your purchase of the DC16 Digital Combo press!

This heat press machine has many exciting features, all of which are

meant to help make your heat transfer pressing endeavors as successful

and easy as possible. Please take the time now to thoroughly read through

this manual to become acquainted with them. It will explain some key

features, concepts and methods that will save much time and effort in

using this press and in your heat pressing applications.

Throughout this manual, many areas and components of this machine

will be referred to by specic names. Please refer to the illustrations

below in order to become familiar with some of the terminology used

in this manual.

Handle

Pressure Knob

Top Head

Clamp/Linkage

Pwr Inlet/On-Off

Heat Platen

Stop Collar

Lower Table

Silicone Pad

Pedestal

Gibb Plates

Base

Temperature

°F/°C Indicator

Ready/Heating Indicator

Open/Timing/Done Ind.

Time

Pressure Bar Graph

TEMP key

PRG key

Up/Down Arrow keys

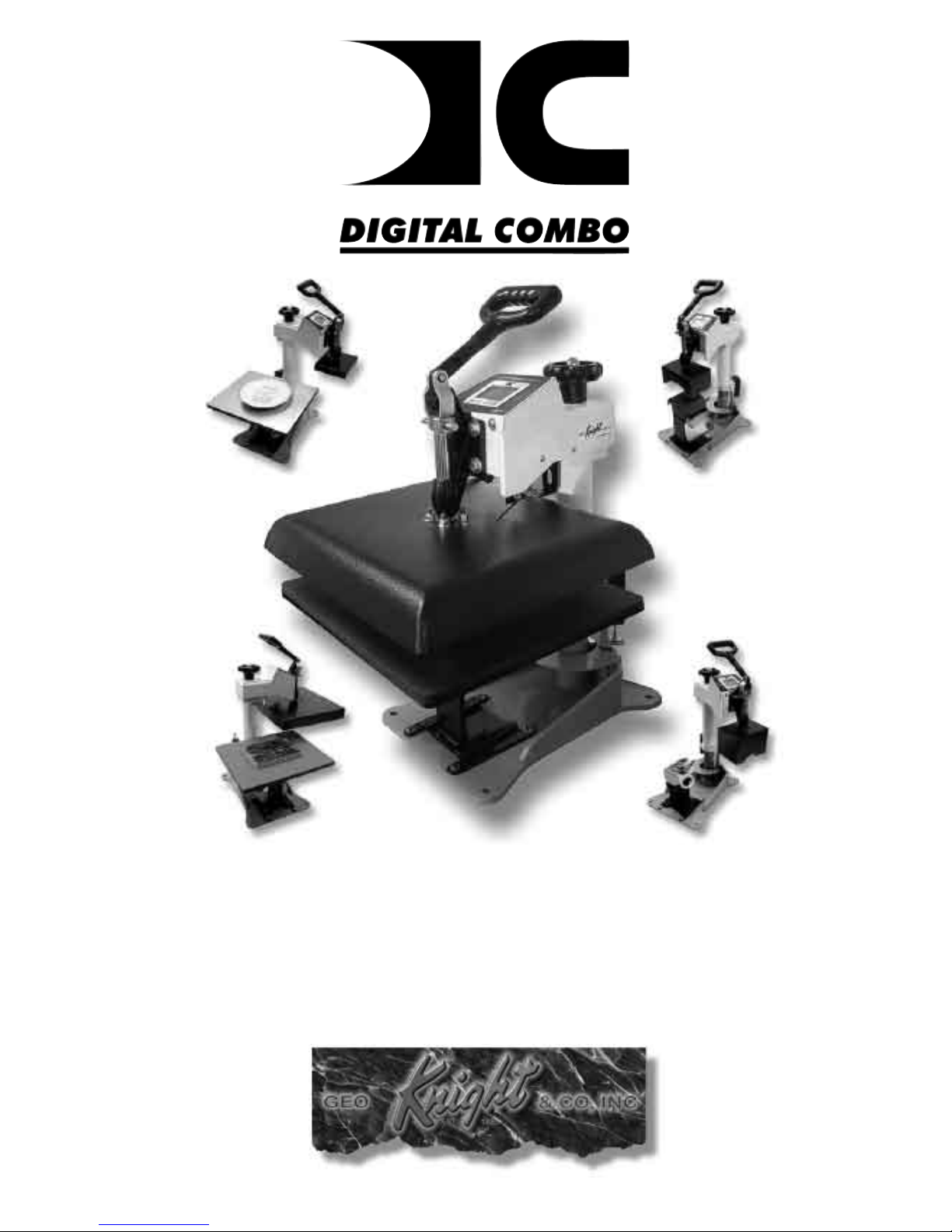

Default Operating Mode of Controller

4

Setup & Suggestions

• Locate the press on a rm, sturdy work surface. It is recommended but

not necessary to bolt the press to a workbench using the rear mounting

holes on the base frame.

• A stand on lockable casters is available from Geo Knight & Co or your

distributor.

• The height of the bench/work space the press is located on would be

ideally 25” to 30” high. The higher the press, the more difcult to

close/lock.

• Attach the power cord from the rear to the underside of the top head.

There is a power inlet under the top head that the modular cord will

plug into.

• It is HIGHLY RECOMMENDED that the cord be strapped or tied to

the back white post of the press, so that the cord is not pulled on and

tugged out of the power inlet where it plugs into the press. TEST and

make sure the cord travels freely when swinging the press, and that

there is no tension or pulling on the inlet socket where the power cord

plugs into the head. Make sure the cord can not be pressed by the

heater.

• The press should remain in the unclamped OPEN position when not in

use. Do not leave the heater block closed on the table when not using,

unless transporting.

• The top head should be swung over the pressing table when not in

use. Do not leave the platen down on the silicone pad when heating.

Always leave the heat platen in the UP position.

5

Normal Operation

Normal Operating Mode

The normal operating mode of

the press will display the current

actual Temperature at the top of

the screen and the time setting

or elapsed time below the

temperature.

The right side the screen will

indicate the heating status by

stating HEATING, READY, both

of those words, or none at all,

depending on if it is cooling down or heating up to the set temperature.

READY is shown only if the current temperature is within 5 degrees of

the set point temperature.

The right side of the screen will also indicate the timing status by stating

OPEN, TIMING or DONE. The DONE indicator may remain on in

some cases until the press is opened back up.

If the pressure feature is enabled, the pressure bar graph will show the

last known pressure exerted when the press was closed.

Setting Temperature

From the normal operating mode,

simply press the TEMP key to set the

temperature.

The ashing 3-digit number is the

temperature setting (not the actual

current temp). Use the Arrow Keys to

set the desired temperature. Hold them

down to increase rapidly, press both

together to set it to 350°F.

Press TEMP again to lock in the setting.

6

Setting Time

From the normal operating mode, simply

use the Arrow Keys ONLY to set the

time. Do not touch the PRG key.

Hold down either the Up or Down arrow

key for more than 2 seconds and the time

will increase rapidly.

Press BOTH Arrow Keys and the time

will reset to 00 seconds.

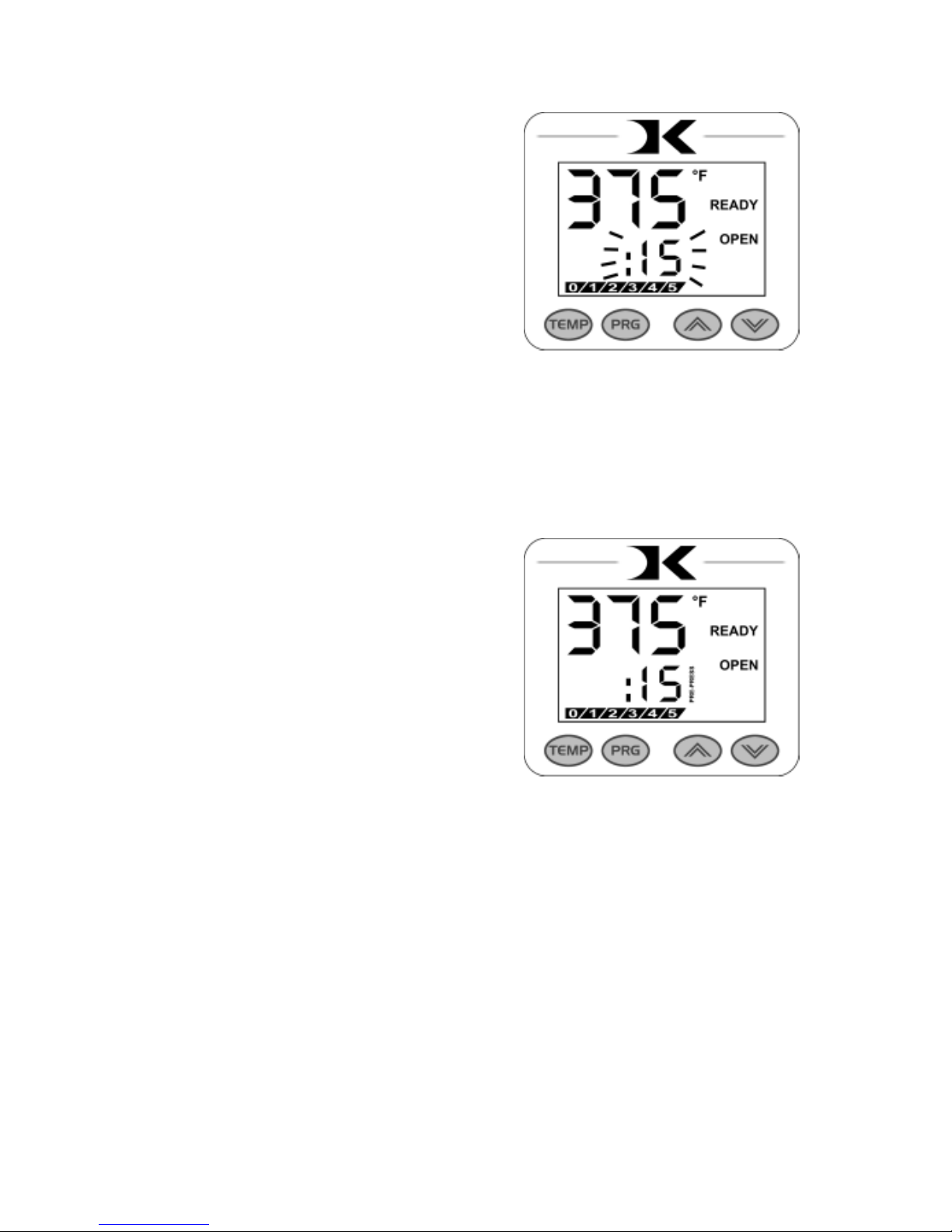

Pre-Press Timer

There is a second timer available for

use, called the “Pre-Press Timer”.

This feature is useful if a multiple-step

process is performed.

For example: If a product must be

pre-pressed for 5 seconds before a

main pressing cycle of 20 seconds, the

Prepress timer can be set for 5 secs, and

the main timer for 20. When the operator closes the press, the 5-sec

time counts down. When the operator opens the press, the time setting

switches to 20 seconds.

The word PREPRESS will be displayed next to the pre-press time setting

when it is active. To set the pre-press time, simply use the Arrow Keys

to set the time. If PREPRESS is not displayed next to the time, quickly

close and then open the press to switch to the prepress time.

To turn ON the prepress timer feature, enter the User Options Menus

(see page 18) and go to the PPR setting and turn it ON. (see page 22)

7

The Digital Pressure Bar

Graph indicates a basic 0-9

scale of pressure exerted.

The pressure bar graph

resets when the press is

closed/locked while timing.

If the pressure adjustment has been changed, or a different thickness

item has been placed in the press, the pressure bar graph will not change

until the press is closed and locked and the timer is counting.

This bar graph is directly related to the amount of pressure, or resistance,

being felt and applied to the bottom table. If a thicker item is placed in

the press, and no adjustments are made to the pressure knob, then the

amount of pressure clamping down will be greater, and the bar graph

will show a higher number. Here are some bar graph guidelines:

A very light pressure slight clamping would be in the 0 to 3 range.

A good medium pressure for most applications would be 4 to 6.

Excessively high pressure for demanding items would be 7-9.

Pressure is set manually using the large black Pressure Adjustment

Knob. There is one important rule of thumb when setting pressure: The

press MUST LOCK IN PLACE when lowering and clamping the press.

Do not simply let the platen rest on the pad. A good solid two-handed

locking force is recommended when rst doing transfers to insure good

results. A “Ka-Thunk” click/clamp sound will result when locking the

press in place.

• To decrease the pressure, turn the

pressure knob to the left, counterclockwise.

The top head will rise away from the lower

table.

• To increase the pressure, turn the

pressure knob to the right, clockwise. The

top head will lower toward the pressing table.

Setting Pressure

Digital Pressure Bar Graph

8

Guidelines & Standard Settings

The following information covers some basic guidelines for pressing,

as well as some generic parameters for basic heat transfer applications.

• When pressing shirts, it is often recommended that the shirts be quickly

pressed for 2 to 4 seconds before transferring to remove wrinkles and water

content.

• When pressing two sides of a garment, pull the garment over the table so

that the printed side drapes underneath the table. This will avoid reheating

previously transferred designs on opposite sides of garments. It will also

avoid any bleed-through of inks on lighter fabrics.

• Avoid laying collars, cuffs, zippers, and other bulky parts of garments

on the lower table, as these can adversely affect pressing conditions, and

reduce the life of the silicone pad.

• When pressing rigid substrates (plastics, metals, woods, etc.), be sure that

any protective lms or laminates are removed before heating.

• Always check that the transfer image is face down against the material, to

avoid sealing the image against the heat platen instead of the substrate.

Always follow the transfer media suppliers instructions when

pressing. The information below is for general reference only, and may

not be as accurate as the instructions provided by the transfer media &

imprintable substrate supplier.

• Hot Split Supplier Transfers 350-375°F, 8-10 secs

• Puff Transfers 350-375°, 5-7 secs (extra heavy pressure)

• Ink-Jet Transfer Papers 360°, 15-18 secs

• ColorCopy/Laser Transfer Papers 375°, 20-25 secs

• Sublimation Inks (Polyester Fabrics) 400°, 35 secs

• Sublimation Inks (Plastics) 400°, 1 min, 15 secs

• Sublimation Inks (Metals) 400°, 1 min

• Sublimation Inks (Woods) 400°, 1 min, 15 secs

• Sublimation Inks (Ceramics) 400°, 4 min

9

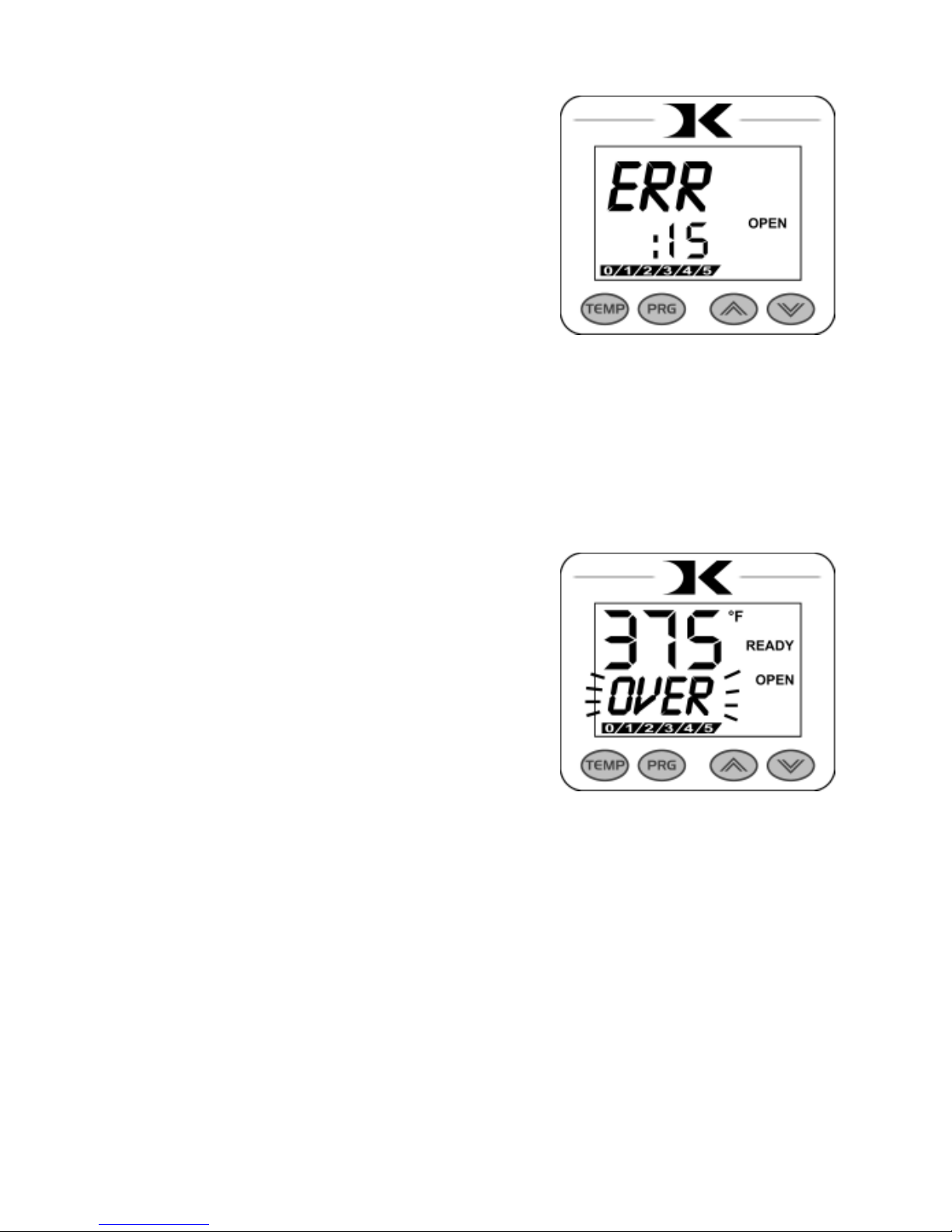

ERR Mode

During operation of the press, if there

is a loss of signal from the temperature

sensor wire, the ERR display will

appear.

This is a safety feature that will shut off

the relay so the press will not overheat

aimlessly without a temperature signal.

Once the temperature signal is restored (no longer broken, or plugged

back into the control) the press will resume the temperature display, and

start heating if necessary. If ERR persists, contact support.

Over-Temp Alarm

If the press heats beyond the set

temperature by 40 degrees or greater,

the OverTemp alarm will sound.

This is a safety feature that warns the

operator of a possible thermal run-away

of the press. This means the press relay

may be locked in a heating position

where it will never stop heating, to a

possibly harmful temperature level.

If the OverTemp alarm sounds, set the temperature to a higher value

than the current actual temp. Wait 30 seconds and then reset the press to

your desired temperature and Watch Carefully. Do not let the press rise

to extremely high temps.

If it continues to rise, turn off the press and let it cool off to room

temperature. Turn the power back on and immediately set the temperature

to a low setting like 200°F. Wait for the press to heat up. When the press

displays “READY”, monitor the temperature and see if it continues to

heat to a level that the OverTemp alarm activates again. If so, contact

the factory.

Loading...

Loading...