TellerScan 215 & 230 User Manual Rev 050609

TellerScan

® 215 & 230

Countertop Check Scanners

User Manual

May, 2009

Rev 050609

1

TellerScan 215 & 230 User Manual Rev 050609

TABLE OF CONTENTS

TellerScan® 215 & 230 Equipment….......................................................... 3

Inside the TellerScan® 215 & 230 Scanner…………………………………...5

TellerScan® Installation................................................................................6

Installing the Ink Jet Cartridge…………………………………………………...7

Installing the USB Driver…………………………………………………………8

Getting Started…………………………………………………………………….9

TellerScan® 215 & 230 Troubleshooting......................................................10

TellerScan® Operator Maintenance.............................................................11

Cleaning The Scanner…………………………………………………………....12

Common Error Codes....................................................................................15

Frequently Asked Questions..........................................................................17

TellerScan® 215 & 230 Specifications......................................................... 18

2

TellerScan 215 & 230 User Manual Rev 050609

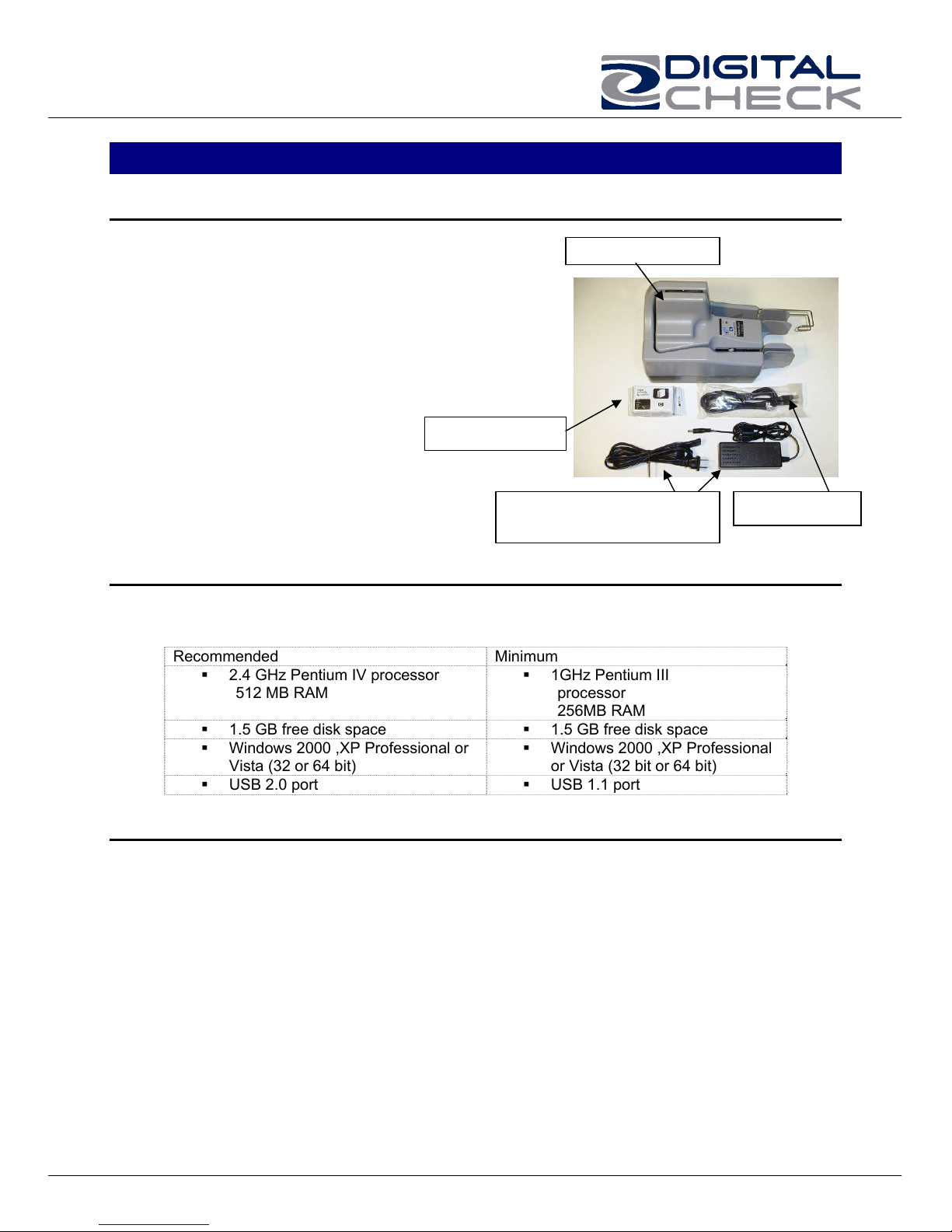

TellerScan® 230 Equipment

TellerScan® 215 & 230 Equipment Checklist

The TellerScan® 215 & 230 package

includes the following pieces:

TellerScan® 215 or 230 scanner unit

USB 2.0 cable

100v-240v -50/60 hz Voltage Sensing,

external power supply

HP inkjet cartridge (Optional feature)

inkjet cartridge

Power supply & standard

TellerScan® 215 & 230 System Requirements

The following PC specifications are required to operate the TellerScan® 215 or 230 with

your scanning application software:

Recommended Minimum

2.4 GHz Pentium IV processor

512 MB RAM

1.5 GB free disk space 1.5 GB free disk space

Windows 2000 ,XP Professional or

Vista (32 or 64 bit)

USB 2.0 port USB 1.1 port

1GHz Pentium III

processor

256MB RAM

Windows 2000 ,XP Professional

Radio Frequency Interference

The TellerScan® 215 & 230 generates, uses, and can radiate radio frequency energy. If

the unit is not installed and used properly that is, in strict accordance with the

instructions in this manual it may cause harmful interference to radio communications. It

has been tested and found to comply with the limits for Class digital devices pursuant to

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection

against harmful interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause interference, in which

case, the user (at their own expense) will be required to take whatever measures may

be required to correct the interference. The use of shielded cables is required when

connecting this device to any/all peripheral or host devices. Failure to do so may violate

FCC rules.

TS215 or 230

USB cable

US wall plug

or Vista (32 bit or 64 bit)

3

TellerScan 215 & 230 User Manual Rev 050609

r

About the TellerScan® 215 & 230

The TellerScan® 215 & 230 Countertop Check Scanners are an easy-to-use, compact,

scanner that connects to a personal computer (PC). The TellerScan® 215 & 230

automatically scans the front and/or back of checks and also reads the MICR (Magnetic

Ink Character Recognition) code line. The images and data are then transmitted through

a Universal Serial Bus (USB) interface to the PC. The TS215 is a single check at a time

feeder (drop and slide). The TS230 models have an auto feeder that handles up to 50

items.

Features of the TellerScan® 215 & 230

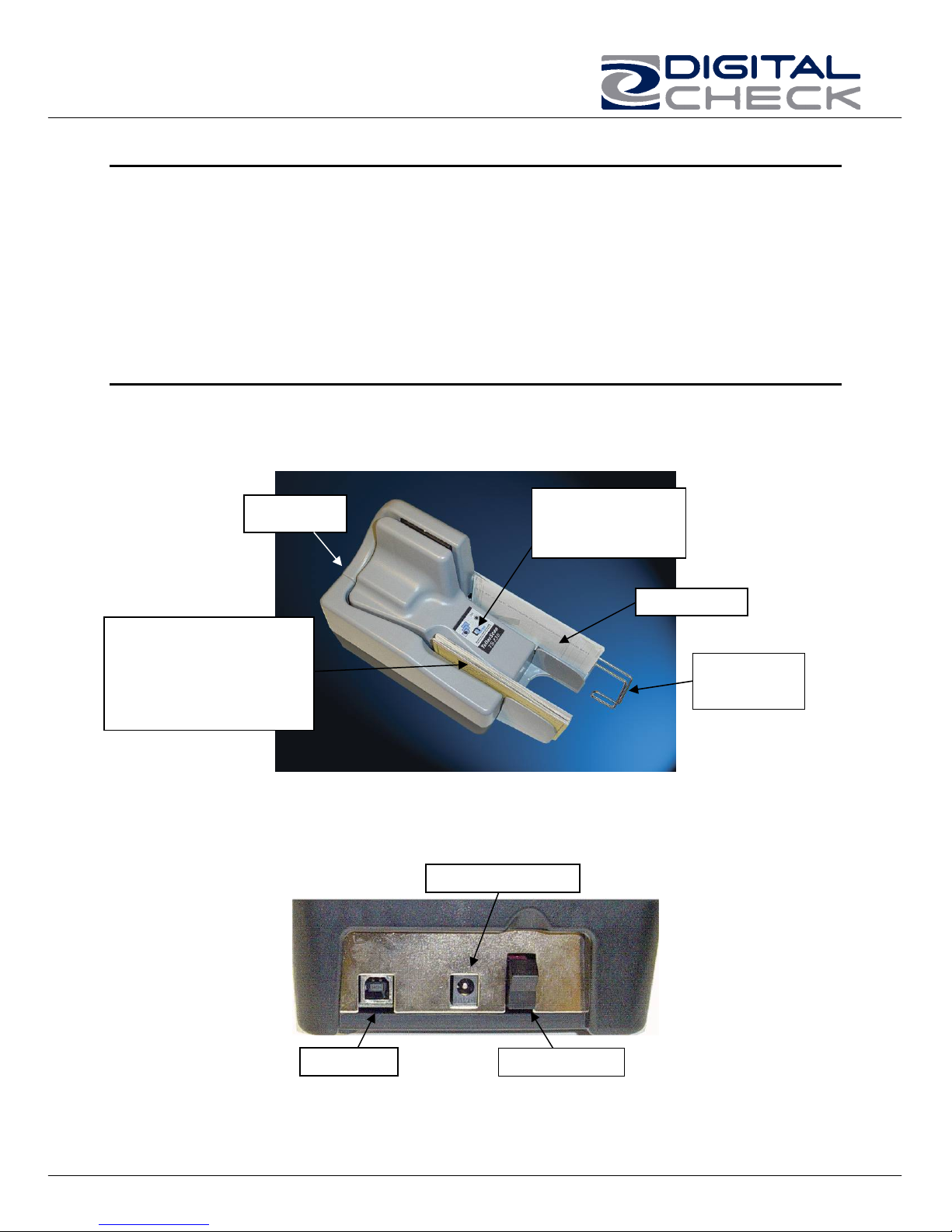

Outside the TellerScan® 215 & 230

Fig. 1.

Rear Deck

A single item at a time

feeder (TS 215)

or

Automatic Feeder

(TS 230)

Rear Deck of TellerScan® 215 / 230

Fig. 2

Control Panel

w/ LED Status

Indicators

Exit Pocket

Adjustable

Wire Stop

Power Connecto

USB Port

ON/OFF Switch

4

TellerScan 215 & 230 User Manual Rev 050609

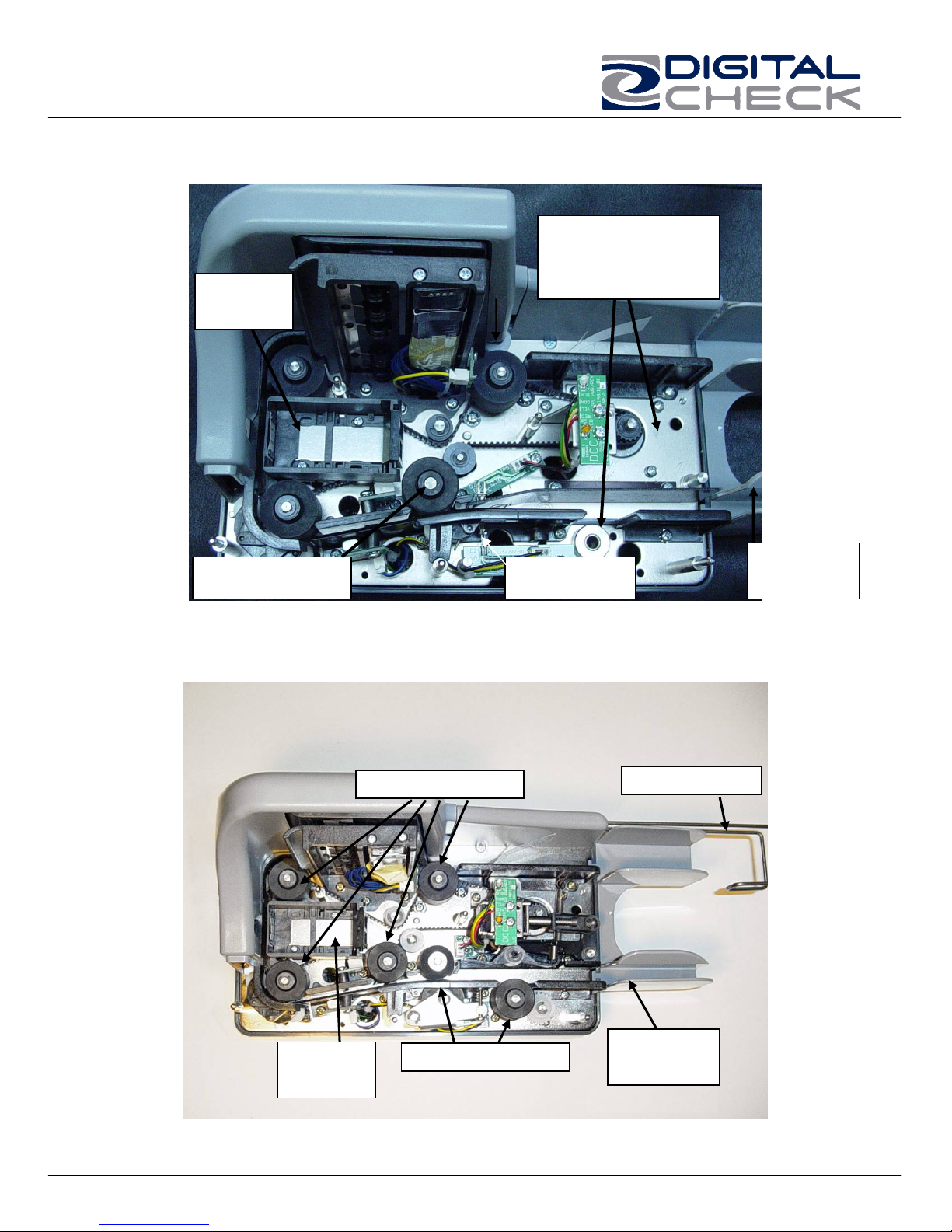

Inside the TellerScan® 215

Fig. 3A

Inkjet

Printer

Fewer Parts.

No Solenoid or

Second Drive Motor

Entry Drive Roller

Inside the TellerScan® 230

Fig. 3B

Main Drive Rollers

Entry Sensor

Entry / Exit

Tray

Exit Stop Wire

Inkjet

Printer

Entry Drive Rollers

5

Entry / Exit

Tray

TellerScan 215 & 230 User Manual Rev 050609

y

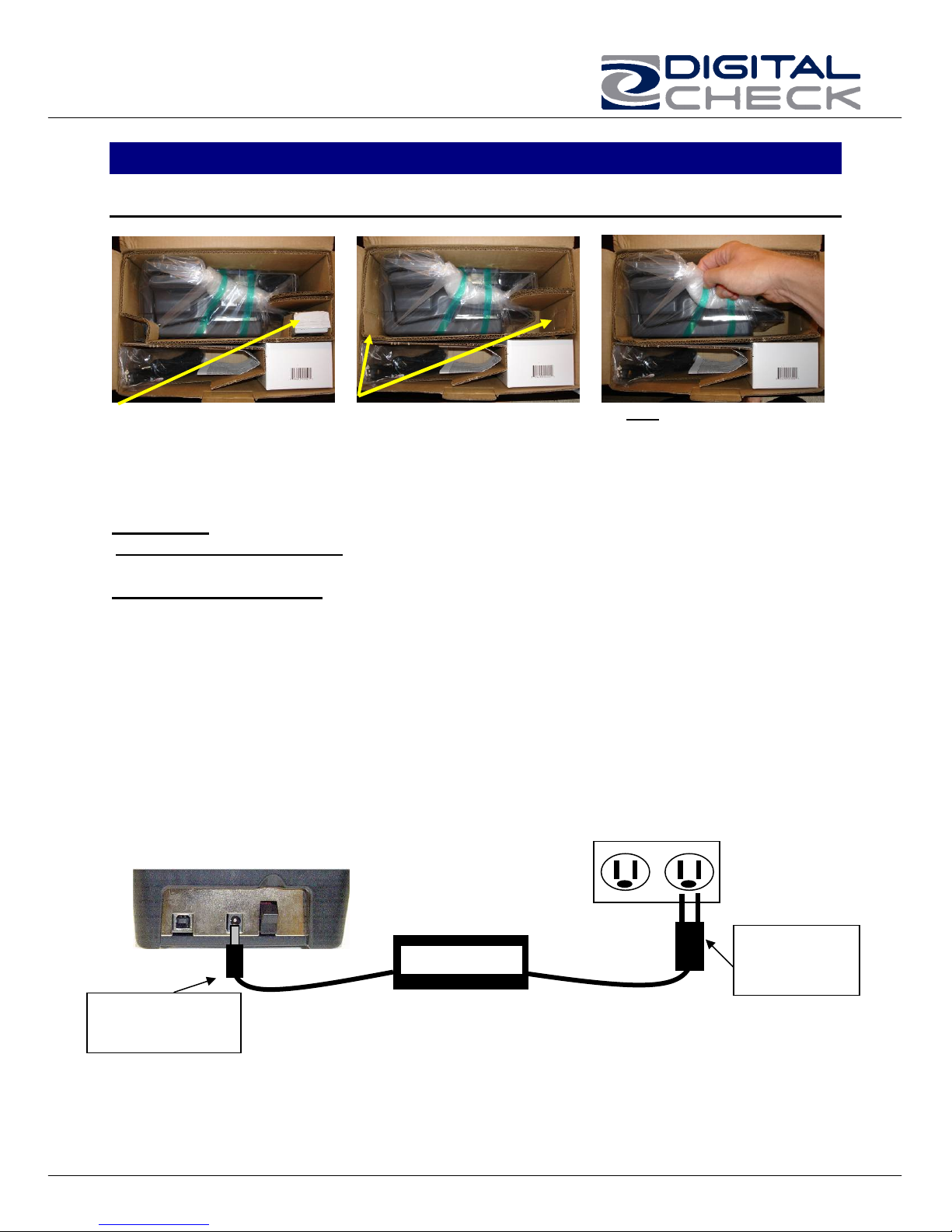

TellerScan® 215 & 230 Installation

Un-Boxing the TellerScan® 215 & 230

Step 1: Step 2: Step 3:

Remove inkjet cartridge

from package slot

Pop-out package corners. Do NOT open the protective

bag. First remove the scanner

from the box by lifting up on

the bag.

WARNING: Before powering on the scanner, you will want to install the USB driver. See

‘Installing the Driver Files’ section on page 8 for instructions.

Setting Up The Scanner

1. Place the unit on a flat surface near the PC and away from direct light.

2. Connect the power cord from the external power supply to the power connector on

the scanner rear deck. (See fig. 2 and fig. 4)

3. Place the external power supply in a ventilated area several feet away from the

scanner and connect to an appropriate source of power.

4. Make sure the TellerScan® 215 or 230 is turned off. Verify that the red power

indicator on the Control Panel is not lit. The power switch is on the rear deck. (See

Fig. 2)

5. Connect the USB cable by plugging it into the port on the rear deck. Do not turn on

the scanner until the driver has been loaded.

Fig. 4

First, plug the power

connector into the

back of the scanner.

Power Suppl

6

Then, plug the

power adaptor

into the wall

receptacle.

TellerScan 215 & 230 User Manual Rev 050609

Installing the Rear Endorser Inkjet Cartridge

Follow these instructions when installing the inkjet cartridge for the first time, or when

replacing an empty cartridge:

1. Remove the center cover and locate the

inkjet printer. (Fig. 5)

2. If replacing an existing cartridge, remove the

inkjet cartridge by grasping the small tab at

the rear end and gently pulling upward.

Discard the used cartridge.

3. Obtain a new inkjet cartridge (HP part

number C6602A). For new installations, one

new cartridge is included with each inkjet

model scanner. Be certain to read the

instructions included with the cartridge.

Fig. 5

4. Remove the protective tape covering the ink

nozzles. Be careful not to touch the ink with

your fingers or allow it to come in contact

with any clothing.

5. Carefully, insert the nose (inkjet end) of the

cartridge into the cradle (Fig. 6) in the

scanner and slide forward while keeping the

reservoir end of the cartridge tilted slightly

upward.

6. Push the cartridge downward until it snaps

into position, and then replace the top-center

Fig. 6

scanner cover.

Note: If the scanner has to be transported by common carrier from one place to another

or extended periods of inactivity, it’s advisable to remove the inkjet cartridge from the

scanner and seal in an airtight bag. If the cartridge has not been used for an extended

period of time, it may be necessary to clean the inkjet nozzles with a wet towel, and

then blot dry.

7

TellerScan 215 & 230 User Manual Rev 050609

Installing the Driver Files ( Use this process if not included as part of the application

installation or instructions from the reseller)

Windows 2000, XP & Vista - Drivers

1) Download the TellerScan_USB_Vxx_Driver.zip driver file from the web site.

http://www.digitalcheck.com/integration_support/drivers_and_demo_programs

2) Unzip the file and run the driver utility program to automatically install the firmware

and create a folder for the driver files (C:\Program Files\Tellerscan\Drivers).

3) Turn ON the unit. The right LED on the scanner control panel should now be

showing ‘red’.

4) Windows detects a new hardware device. For first time installations, you should not

have to do anything. If the wizard will not finish, go to Device Manager and select to

Update Driver for the USB device and point to the new folder and the TSUSB2.inf

file. When running the utility a second time, select the ‘Repair’ option.

5) The USB controller will install as a TSDevice. The TS215 & 230 device will install as

a Tellerscan, once acquired by the application.

6) The right LED will turn ‘green’ when the application launches and acquires the

scanner.

NOTE: While the scanner will run on a USB 1.1 port, it is recommended that a USB 2.0

port be used to provide better overall performance. An INI file parameter may need to

be increased to allow running on a USB 1.1 port due to the slower throughput. Check

with your application provider.

Install the Demo Software Program (Download from the Digital Check web site. Use

the ScanLite program for testing the scanner and during the cleaning process)

To download ScanLite Go to:

http://www.digitalcheck.com/

integration_support/drivers_and_demo_programs/

The demo software is a basic scan program that allows you to operate the scanner,

change different scanner settings, view images, and store them on your PC’s hard disk.

The demo program is not the software to run the system. Additional application software

is required. Scanlite is an easier demo program to use and is recommended that it be

used when cleaning the scanner.

NOTE: In most cases, your scanner will operate under the application provided by the

solution provider that installed it. If you need to manually copy down the demo code:

1. Create a sub directory, i.e. “TS230” or “ScanLite” on the PC.

2. Copy the scanlite files into the directory.

3. Launch the scanlite.exe to open the demo application.

8

TellerScan 215 & 230 User Manual Rev 050609

Getting Started with the TellerScan® 215 & 230

How to Load Checks

TS215 – Checks are placed into the scanner one item at a time.

1. Place the item into the entry tray with the

face of the document toward the outside.

2. Then slide the document into the path

until the leading edge contacts the 1st roller.

3. If the application is set to scan, it will start

the motor and grab the document.

TS230 – The automatic-feeder can hold up to 50 items. Use the following directions:

1. Remove all rubber bands, staples,

paper clips, pins, etc.

2. Load the items into the automaticfeeder with the front of the items

facing away from the scanner (Fig 8).

NOTE: Checks must be jogged properly

in order to feed correctly. The bottom and

left leading edges of the check stack

must align with one another (See Fig. 7).

Fig. 7: bottom & left

edges aligned

3. Slide the items into the automaticfeeder until the left LED light

illuminates (Fig. 10).

4. This indicates the scanner is ready to

begin feeding the items. DO NOT

force the items into the automaticfeeder after the light illuminates, as

this may increase jam rates.

Fig. 8: Front of

checks are facing out

LED Status Indicators

Fig. 9: The right LED

comes on ‘Red’ to

indicate power to the

unit.

Fig. 10: When the

scanner is acquired by

the application, the right

LED turns green.

9

The left LED is the

document in pocket

indicator after

acquisition.

TellerScan 215 & 230 User Manual Rev 050609

The standard sequence for the two top cover LEDs is:

1. When the scanner is powered on, the right LED will light up ‘red’. This indicates

initial power to the scanner.

2. If the firmware and drivers have been properly loaded, once the application

launches and acquires the scanner, the right LED will now turn ‘green’.

3. Once the TellerScan® 230 is synchronized with the application, the left LED is

now used to detect the presence of documents in the entry pocket.

4. Note: Both the power cable and both ends of the USB cable must be plugged in

for the red LED light to come on. If the red LED does not come on, check the

power and reseat both the power and the end of the USB cable going into the PC

and into the scanner.

TellerScan® 230 Troubleshooting

Clearing Jams

If a jam occurs, the paper path must be cleared. To do this, try to advance the jammed

document by pressing the “EJECT” button within your application (if applicable). In case

the document does not exit the document track, you can grab the document with both

hands and carefully wiggle the document back and forth while lifting up. Otherwise,

follow these steps:

1. Remove the central cover, if needed, to remove the document.

2. Clear the path of any jammed document and make sure that the rollers are free of

paper and debris.

3. Replace the cover.

Document Feeding Problems

The TellerScan® 215 is a drop and slide style of feeder. If the documents are not being

grabbed by the first drive roller, try cleaning the entry rollers using a TellerScan®

cleaning card and the procedures described within this users guide.

The TellerScan® 230 is designed with a self adjusting auto-feeder and should not

require user adjustments. If you notice feeding problems, check the documents for bent

of folded edges and for debris in the scanner document track. If feeding problems are

still experienced, try cleaning the entry rollers using a TellerScan® cleaning card and

the procedures described within this users guide.

Check Images are streaking or fading

If you notice either streaking or fading on the images, the scanheads may require

cleaning. Refer to the section on page 14 regarding cleaning the scanhead area.

10

TellerScan 215 & 230 User Manual Rev 050609

TellerScan® 230 Operator Maintenenace

Cleaning the TellerScan® 215 & 230

Over time, ink, dirt and dust particles will collect on the scanner rollers and document

track. Therefore, it is necessary to clean these areas on a regular basis to assure

reliable performance. Tips for performing preventative maintenance by the user on the

TellerScan® 215 or TS230 include:

• A Periodic inspection of the entire document track area. The use of flashlight will

enhance the visual inspection between the scanheads and throughout the

document track.

• Remove any staples, paper clips, and rubber bands that may have accumulated

during use.

• Have a can of compressed air available to blow out the document track on a

regular basis.

• Purchase the TellerScan® cleaning cards to have on hand for regular cleaning

maintenance. Run several scan cycles, flipping the card between cycles, while

holding the card to ‘scrub’ the first drive or entry rollers. Once the entry rollers no

longer deposit dirt onto the card, allow the card to scan through the entire path.

Run this through several times while flipping the card end to end and top to

bottom.

• Use the special cleaning swabs, which come with the TellerScan® cleaning kit, to

‘scrub’ the four drive rollers under the center cover.

• Inspect the quality of the captured images on a regular basis. If the image quality

drops off, inspect and clean the scanheads following the procedure described on

page 13 & 14. If the quality does not appear to be related to dirt or debris,

contact your service provider to determine if the scanheads can be recalibrated.

11

TellerScan 215 & 230 User Manual Rev 050609

Cleaning your scanner’s Rollers, Magnetic Head and Camera Faceplates

Scanner Cleaning Supplies (to order call 847.446.2285)

In severe environments where ink and dirt build up rapidly, it may be necessary to clean the scanner rollers,

magnetic read head, scanhead faceplates, and document track every 3,000 to 5,000 documents. This simple

maintenance will dramatically improve the reliability of your scanner over its useful life.

1. Compressed Air - (acquired for a local office supply provider)

2. Cleaning Kit

– Consisting of one box of 25 cleaning cards & 6 Cleaning Swabs – (#130007-03)

Cleaning The TellerScan® 215 & 230 using Scanlite Software

The Scanlite program, which is available from the

Digital Check web site, is an excellent utility to run

while performing the cleaning procedures

recommended below. Scanlite provides an easy way

to initiate the scan cycles in order to feed the cleaning

cards properly through the scanner. Scanlite also

includes an ‘Eject’ button which operates the scanner

at half its normal speed, making it easy to scrub off the

four main drive rollers when using the cleaning swabs.

Visit the following site to download Scanlite:

http://www.digitalcheck.com/integration_support/drivers

_and_demo_programs

Cleaning Steps

Step Action

Use compressed air to clean the document

track as illustrated below:

You may need to remove the center or outer

covers to check for other debris that may have

entered the scanner. Using two hands pull

straight up on the center and left side covers

to remove. See the section below for

removing the rear right cover.

Helpful Hints

1. Do not use stickers to cover up previously

sprayed numbers on documents. The

backing from the stickers can rub off onto

the rollers and cause documents to jam.

2. Do not use White Out on scanned

documents, the White Out can rub off the

documents onto the scanner camera

faceplate and distort the images.

3. Watch for loose debris falling into the

scanner such as staples and rubber

bands.

4. Carefully, turn the scanner upside down

and shake it to remove any loose debris.

12

Step Action

Insert a new TellerScan® cleaning card in the

entry pocket (single feed or auto-feeder)

Open the imaging application and initiate

feeding while holding the card firmly to prevent

the card from actually feeding through the

scanner. You will want to cancel the

transaction after running several scan cycles.

You may use the remote deposit

Note:

application to run the scanner during the

cleaning cycle, or the Scanlite demo program

available from the Digital Check web site.

Important:

Run a scan cycle and hold onto the card, but

allow it to move into the path so that the

second set of rollers is scrubbing on the

cleaning card.

Flip the card over and run the same procedure

again. This ensures that the main entry drive

roller and the double feed rollers are being

properly cleaned.

Tip:

Getting the rollers to scrub on the cleaning

cards is the most important part of the cleaning

procedure. Rollers with a severe build up of ink

and dirt will require use of the swabs to be

used to manually scrub all four of the main

drive rollers.

TellerScan 215 & 230 User Manual Rev 050609

Cleaning Steps (continued)

Step Action

Flip the card top to bottom and scan the card

again, this time letting it move through the

scanner into the exit pocket.

Turn the card around and repeat the same

process of scanning the card several times on

the reverse side.

Result: The TellerScan cleaning card should

have been run through the scanner three to

four times, periodically flipping the card or

swapping it end for end.

After completing the cleaning process, cancel

the transaction and discard the used

TellerScan card.

13

TellerScan 215 & 230 User Manual Rev 050609

Note: This is only performed when document images are unclear, distorted or have a dark line laterally through

every image.

Step Action

Pull out the wire document guide.

Remove the left & right side covers.

The covers lift off vertically.

Note: The swabs are typically used to clean

off the four main drive rollers, but can also

be used on the scanheads if you have a

tough buildup on the glass.

Cleaning Scan-Head Steps

Step Action

Unscrew the nylon screw and gently open the

scanner camera faceplates.

Use the cleaning swab or a clean cloth to wipe

the camera faceplate (the two white strips and

both sides of the camera faceplate section of

the scanner).

Reassemble the scanner components by

replacing the nylon screw, right and left cover

and the wire document guide.

14

TellerScan 215 & 230 User Manual Rev 050609

g

Common Error Codes From The Scanner

There are three common error codes that can

typically show up depending upon the type of

documents being scanned. There are no user

available adjustments in the TS215 or TS230

scanners.

Periodic and scheduled cleanings should be

performed before determining if any further

problem determination is needed. See the

scanner cleanin

document.

Helpful Hints

1. Always hand-jog the documents to align

the leading and bottom edges for the auto

feed models. Visually check the leading

edges for bent or curled or curled corners

and straighten them as needed.

2. Place the stack of documents half way into

the entry slot, then slide the stack forward

until the Document In Pocket LED light

comes on.

3. Be sure that the entry tray is fully seated

and that the exit wire stop is extended

enough to allow for approximately ½” more

than the longest document..

216

217

220

Mis-Feed

entry pocket on time).

Double Document Feed (More than one

document is detected & passed into the exit

pocket) Check the exit pocket for a double

document feed. (TS 230 only)

Document Stopped in the path (A document

stopped in the path or was slow in exiting).

(The documents failed to leave the

• Remove the documents and re-align

the leading edges.

• Check for bent or excessively curled

leading edges and straighten as

needed.

• Verify that documents are not stuck

together

• Insert and rescan the documents. If

they continue to get -216 errors, this

might indicate that;

o The entry drive rollers may

be dirty

o Something may also be

lodged in the path

• If the document is still in the path,

grab the upper edges with both

hands and wiggle the document back

and forth, vertically to remove it.

• If they continue to get -217 errors,

this might indicate:

o The entry drive rollers may

need to be cleaned

o Check the condition of the

documents for bent edges

o Remove left side cover, turn

adjustment screw ½ turn

counter-clockwise and

retest.

• Eject the documents. To clear the

error condition.

• If the document will not eject, grab

the upper edges with both hands and

wiggle the document back and forth,

vertically to remove it from the path.

• Check the leading edges and corners

of the document and straighten as

needed.

• A -220 error code where the

document is stopping in the path

repeatedly could indicate debris,

paper or a staple in the path. Check

if the document’s leading edge looks

OK or is catching on something.

• All of the main drive rollers may need

to be cleaned.

15

TellerScan 215 & 230 User Manual Rev 050609

Additional Error Codes

Error Action

212

No Checks

entry pocket)

553

No Print Head

sensed by the scanner)

125

No Scanner

the application to scanner initialization)

(There are no checks indicated in the

• A scan cycle has been initiated, but the

Document In Pocket LED (the left LED)

is not on indicating that no documents

are present.

• Restack the batch of documents and

insert them back into the entry pocket.

Slide them forward until the LED comes

on.

• This typically can happen when a scan

cycle is initiated and the LED is not on.

(The ink jet cartridge is not being

• When endorsing characters using the

ink jet option, the print string is the first

function sent down to the scanner at the

start of a scan cycle. This error will

come up immediately if no cartridge is

present.

• Open the center cover by lifting

vertically. Remove and reseat the ink jet

cartridge, being sure it snaps into place.

• If that fails, try using a new cartridge.

(The scanner was not found during

• The right LED must be on and ‘Red’ for

the application to acquire the unit.

• Check the USB cable connections or try

a different cable.

• Try a different USB port.

• Verify that the PC has the proper drivers

and the scanner firmware file is

installed.

Additional Scanner Information

There are other helpful documents available

in PDF format on the Digital Check web site.

Go to http://www.digitalcheck.com

The ink jet cartridge used in the TS215 &

230 is the standard HP C6602A cartridge

which is available at most office supply

stores. Typical yield is from 5 to 7 million

characters.

The TS215 & 230 scanner can run on a USB

1.1 port, but it is recommended to use a

USB 2.0 port for optimum performance and

application timing.

For support, contact your dealer or Digital

Check Corporation at 847-446-2285. The

Service request form to send scanners into

the plant for repair can be filled out on-line

by going to the web site at:

HTTPs:www.digitalcheck.com/clientarea

following instructions on the screen.

Periodic and scheduled cleanings should be

performed before determining if any further

problem determination is needed. See the

scanner cleaning section.

and

16

TellerScan 215 & 230 User Manual Rev 050609

Frequently Asked Questions

How many checks per minute should my TS215 & TS230 scan?

T

he TS215 can scan up to 30 DPM. Application delay may slow this down.

The TS230 has a rated throughput speed of up to 35, 65 or 100 documents per minute DPM

depending on the specific model (TS230-35, TS230-65, TS230-100). Actual throughput will

vary depending on the PC configuration, physical size of the items scanned, simple or complex

endorsement and the speed of the application. Under a USB 2.0 interface, the expected speed

range is 30 to 90 DPM. If speeds in the 15 to 20 DPM range are experienced, please check to

be sure the scanner is not connected to a slower USB 1.1 port.

What is the proper sequence of the LED lights when the scanner is powered on?

The proper LED sequence is for the right LED to come on ‘Red’, followed by the right LED

turning ‘green’ once the application has been launched. If the right LED does not come on ‘Red’,

check the power and USB cable connections. If the LED is ‘Red’, but will not turn ‘Green’,

contact customer support for assistance with checking firmware and reloading the drivers.

What is a safe distance to keep the power supply from the TS215 or TS230 check

scanner to prevent electromagnetic interference with the MICR read head in the

scanner?

Keep power supplies and other electromagnetic devices 12-18 inches away from the scanner to

keep them from interfering with the Magnetic read head.

How often should the TS215 or TS230 check scanner be cleaned?

The recommended cleaning cycle is every 3,000 to 5,000 items in severe environments where

ink and dirt may build up quickly. Please reference the cleaning instructions section for specific

instructions on how to properly clean the TS215 and TS230.

How many characters does the HP C6602A inkjet cartridge yield?

Once opened, the practical life of the inkjet cartridge is six months. However, the rated

character yield on the inkjet cartridge is between 5-7 million characters. Do not shake or drop to

cartridge which can cause the printing to fail. Keep a spare cartridge on hand in case the current

cartridge cannot be used.

What are the minimum and maximum document dimensions for the TS230?

Minimum Maximum

Document Height: 2.12"(54 mm) 4.17" (106mm)

Document Length: 3.19" (80mm) 8.97" (228mm)

Document Weight: 16 lb (60gr/sqm) 32 lb (120gr/sqm)

17

TellerScan 215 & 230 User Manual Rev 050609

TellerScan® 230 Specifications

Paper Size

Scanning Method

Transport Speed

Image resolution

Image Format

MICR Recognition

Diagnostics

Power-On Self Test

Software Tools

Options

H. min. 2.12” – max. 4.17” (54-106 mm.)

L. min. 3.19” – max 8.97” (80-228 mm.)

Concurrent two-sided Duplex

Image Creation: 2 x 850 cell, 108mm CIS

Light Source: Tricolor LED

B/W, 16 or 256 gray levels, 24 bit color

MICR recognition firmware for E13B or CMC7

On-Board Diagnostics: Tests the functionality of the

Automatic self-testing when switching on the unit

Ink jet printer (Rear endorse),

Uses HP C6602A cartridge

50 cm/sec

Up to 200 dpi

standards

scanner

API Toolkit 32 bit

Part #130007-03

TellerScan® Cleaning Kit

(25 cards + 6 Swabs)

Electrical

Consumption: 1.5A

Voltage: 100 to 240 VAC, 50/60 Hz,

auto sensing power supply

Product life

Designed for useful life of 1,000,000 items (TS215) &

2,000,000 items (TS230)

MTTR:

Temperature Ratings:

15 minutes

Operating: 60°- 90° F

Storage: 0° - 40° C

Humidity:

Dimensions

H 17 cm – L 21.7 cm (27.9cm incl. I/O trays) – D 13 cm

Operating: 35-85% (non condensing)

(6.6” x 8.6” x 5.1”)

Weight

Certifications

4.4 lbs (2 kg)

UL – FCC – CE

Specifications subject to change

Trademarks and registered trademarks are property of their respective owners

18

TellerScan 215 & 230 User Manual Rev 050609

Corporate Headquarters:

Digital Check Corp.

466 Central Ave, Suite 31

Northfield, IL 60093

Tel: 847/446-2285 ⋅

Fax: 847/441-5507

Website: www.digitalcheck.com

Email: support@digitalcheck.com

19

Loading...

Loading...