Page 1

OPERATING MANUAL

12-Channel Scanning

Thermocouple Thermometer

MENU

EXIT

+ALARM

9

SCAN0CLEAR

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

7

AVG

°F

8

HOLD

Model No.

92000-00 Benchtop 115V

92000-05 Benchtop 230V

Each of the up to 12 thermocouples is scanned once every four seconds to once ever y

hour (settable). The current readings are displa yed on the large liquid crystal display . Readings that exceed a maximum or minimum value can be set to tr igger an alarm.

Thermocouples of types: B, E, J, K, N, R, S or T can be used.

Up to 4,680 data points can be logged (stored) within the unit, including readings from all

12 channels and the date and time of the readings.

The unit can be directly connected to a printer to provide a continuous printout, and/or to

your computer. Software to permit a personal computer using WINDOWS

from the unit, remotely operate the unit, and synchronize the operation of multiple units

is included.

Cole-Parmer Instrument Co.

625 East Bunker Court

(847) 549-7600

(847) 247-2929 (fax)

800-323-4340

www.coleparmer.com

e-mail: techinfo@coleparmer.com

A-1299-0763

Edition 04

Cole

Vernon Hills, Illinois U.S.A. 60061-1844

®

Parmer

®

to store data

Page 2

EU Declaration of Conformity

Name of Apparatus: Scanning Thermocouple Thermometer

Model Number: 92000-05

Description of Apparatus: 12-Channel Benchtop Thermocouple

Scanner

Barnant Company declares that the above model is in conformity

to the following harmonized standards and directives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

73/23/EEC EN61010-1/A2: 1995 TR9866

93/68/EEC

89/336/EEC EN61326-1/A1: 1998 TR9867

92/31/EEC

93/68/EEC

The last two digits of the year in which the current configuration of

the the above model was assessed per the Low Voltage Directive

is: 00.

Manufacturer:

Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

James W . Doll Date

Vice President, Engineering

10 November, 2000

Printed in U.S.A.

040101

Page 3

Introduction

Safety Precautions

Introduction

This Scanning Thermocouple Thermometer continuously monitors

temperatures at up to 12 locations. It is designed for laboratory or

industrial applications for unattended temperature monitoring. An alarm is

set off when any thermometer exceeds its preset minimum or maximum

temperature. Temperature data is stored within the unit and can be

output to a printer or PC.

Safety Precautions

DANGER: If thermocouples are at a high voltage, this voltage may be

present at other points inside the instrument and outside at

all the connectors.

WARNING: Disconnect or turn off power source before making

connections.

WARNING: Turn power off and completely disconnect instrument.

Disconnect power source, thermocouples, computer, links,

and printer.

WARNING: Other than a lithium battery, there are no user serviceable

parts inside. Replacement of the lithium battery must be

performed per the Maintenance section of this Operating

Manual. Refer servicing to your dealer.

CAUTION: Be sure available power matches instrument power require-

ments.

CAUTION: Protection provided by the unit may be impaired if the unit is

installed and/or operated in a manner inconsistent with

these instructions.

WINDOWS, WINDO WS NT - Reg TM Microsoft Corp.

CENTRONICS - Reg TM Genicom Corporation

Trademarks bearing the ® symbol in this publication are

registered in the U.S.A. and in other countries.

1

Page 4

Table of Contents

Page

Introduction ................................................................................. 1

Safety Precautions ...................................................................... 1

Table of Contents ........................................................................ 2

Features ...................................................................................... 4

Package contents........................................................................ 5

Quick reference:

Front panel controls.............................................................. 6

Front panel display ............................................................... 8

Rear panel connections........................................................ 8

Rear panel connections

Thermocouple connections .................................................. 9

Power switch ........................................................................ 9

10-28V DC jack .................................................................... 10

PC/IN jack............................................................................. 10

OUT/LINK jack...................................................................... 11

PARALLEL PRINTER connection......................................... 11

TRIGGER + GND connection............................................... 11

Installation ................................................................................... 12

Front panel displays and controls

1 STORE button ................................................................... 13

2 LOG button ........................................................................ 14

3 RECALL button.................................................................. 15

4 PRINT button ..................................................................... 16

5 MAX button........................................................................ 17

6 MIN button ......................................................................... 18

7 AVG button......................................................................... 19

8 HOLD button...................................................................... 19

9 SCAN button...................................................................... 20

0 CLEAR button.................................................................... 20

MENU button ........................................................................ 21

Up-Down Arrow keys ............................................................ 21

Left-Right Arrow keys ........................................................... 22

EXIT button........................................................................... 23

ALARM button ...................................................................... 23

Temperature alarms .......................................................... 23

Other alarms ..................................................................... 25

MENU

About the MENU................................................................... 26

2

Page 5

Table of Contents continued

Page

MENU - How to:

Set the Scale ........................................................................ 28

Change the resolution .......................................................... 29

Enable/Disable channels ...................................................... 30

Setup thermocouple types.................................................... 31

Adjust the display contrast.................................................... 32

Set trigger type ..................................................................... 33

Set trigger mode ................................................................... 34

Adjust the scan rate.............................................................. 35

Adjust the print rate .............................................................. 36

Adjust the log rate................................................................. 37

Set the alarm mode .............................................................. 39

Set the alarm print ................................................................ 40

Set HI alarm(s) ..................................................................... 41

Set LO alarm(s) .................................................................... 42

Set alarm hysteresis ............................................................. 43

Adjust HI alarm setpoints...................................................... 44

Adjust LO alarm setpoints .................................................... 45

Enable/Disable the alarm beeper ......................................... 46

Set the date format ............................................................... 47

Set the date .......................................................................... 48

Set the time .......................................................................... 49

Do a field calibration ............................................................. 50

Print a calibration report ....................................................... 53

Calibration to water............................................................... 55

Power up modes ......................................................................... 56

Maintenance

Care and cleaning ................................................................ 57

Battery .................................................................................. 58

Warranty...................................................................................... 59

Product Return ............................................................................ 59

Technical Assistance................................................................... 59

Specifications .............................................................................. 60

Appendices

A Error messages .................................................................... 62

B Guidelines to Thermocouple Selection................................. 63

C Temperature conversion ....................................................... 63

D Menu flow chart .................................................................... 64

E Factory default settings......................................................... 66

3

Page 6

Features

Input

• Up to 12 thermocouple probes, each connected to a separate channel.

• Thermocouples can be different types.

• Thermocouples of types B, E, J, K, N, R, S or T can be used.

• Channels can be individually enabled or disabled.

Data storage

• Up to 4,680 data records can be stored in the unit (a record includes

readings of all 12 channels plus time and date).

• Data can be logged (automatically stored).

• Current data can be manually stored by pushing the STORE button.

• Data is maintained even when the instrument is turned off or un-

plugged from power.

Display

• Displays the thermocouple number and temperature as scanned.

• Operator can set the scan interval from a minimum of 4 seconds to a

maximum of 1 hour.

• Readings can be stored and displayed in °C, °F, K, or °R.

• Resolution to 0.1° can be displayed.

• Display can sho w: current, maximum, minimum, or average temperature .

• Average temperature display also displays the number of readings

being averaged.

• Hold function freezes all 12 channels.

Data output

• All 12 channels can be output to a printer simultaneously.

• Current, stored, or logged data can be directly sent to a printer

(CENTRONICS® parallel).

• Time between printing cycles is adjustable.

• Current, stored, or logged data can be sent to a personal computer

(PC)(RS-232 serial).

Calibration

• Channels can be individually calibrated manually.

• F actory calibration remains in memory and can be restored at any time.

Software

• Software (for a PC running WINDOWS 95/98 or WINDOWS NT) is

included.

• Software use is optional.

• Software installation instructions and software manual are on the

provided CD-ROM. See readme.txt for latest information.

• Software permits control of up to 8 units.

• Real time data collection.

• Data can be input to spreadsheet or graphing software.

4

Page 7

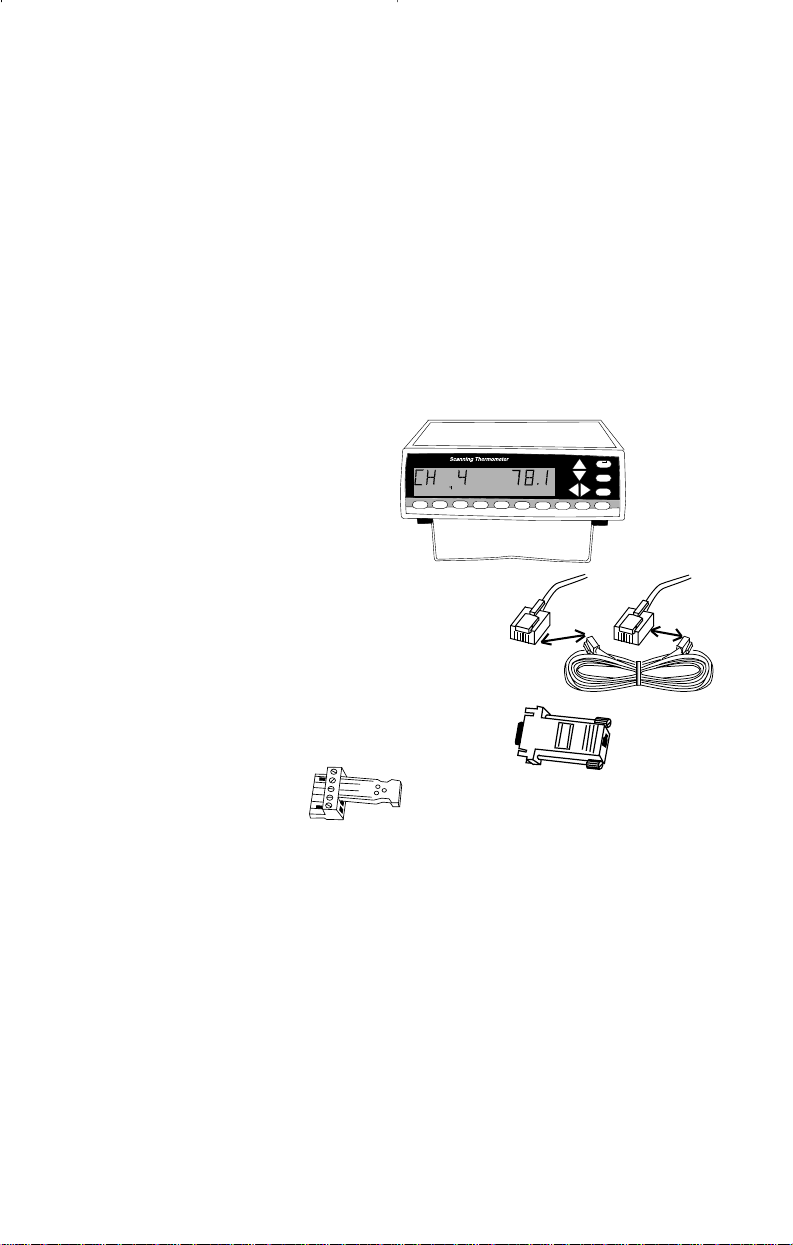

Features continued

Package contents

Alarms

• High and low alarm temperatures can be set for each channel

individually.

• An open thermocouple automatically triggers an alarm.

• An alarm causes the alarm icon to be displayed, and emits an audible

beep.

• The audible beep can be disabled.

Error messages

• Messages indicate channel and fault condition.

Package contents

MENU

°F

Scanning thermometer

Includes wire stand for desktop

1

STORE2 LOG

convenience.

Link cable

RJ-11 to RJ-11 seven feet long. Use to

interconnect scanning thermometer instruments.

3

5

6

4

RECALL

PRINT

7

MAX

MIN

AVG

EXIT

+ALARM

9

8

SCAN0CLEAR

HOLD

PC adapter

RJ-11 to DE-9 female. Used to connect

instrument to your PC, using the link cable.

Trigger Connector

Operating Manual

This book.

Warranty card

AC Adapter - as supplied.

Software

WINDOWS 95/98 and WINDOWS NT on CD-ROM. Serial software specifications on CD-ROM.

Not supplied

Printer cable

DB25 male to the input connection of your parallel printer.

5

Page 8

Quick Reference

Front Panel Controls

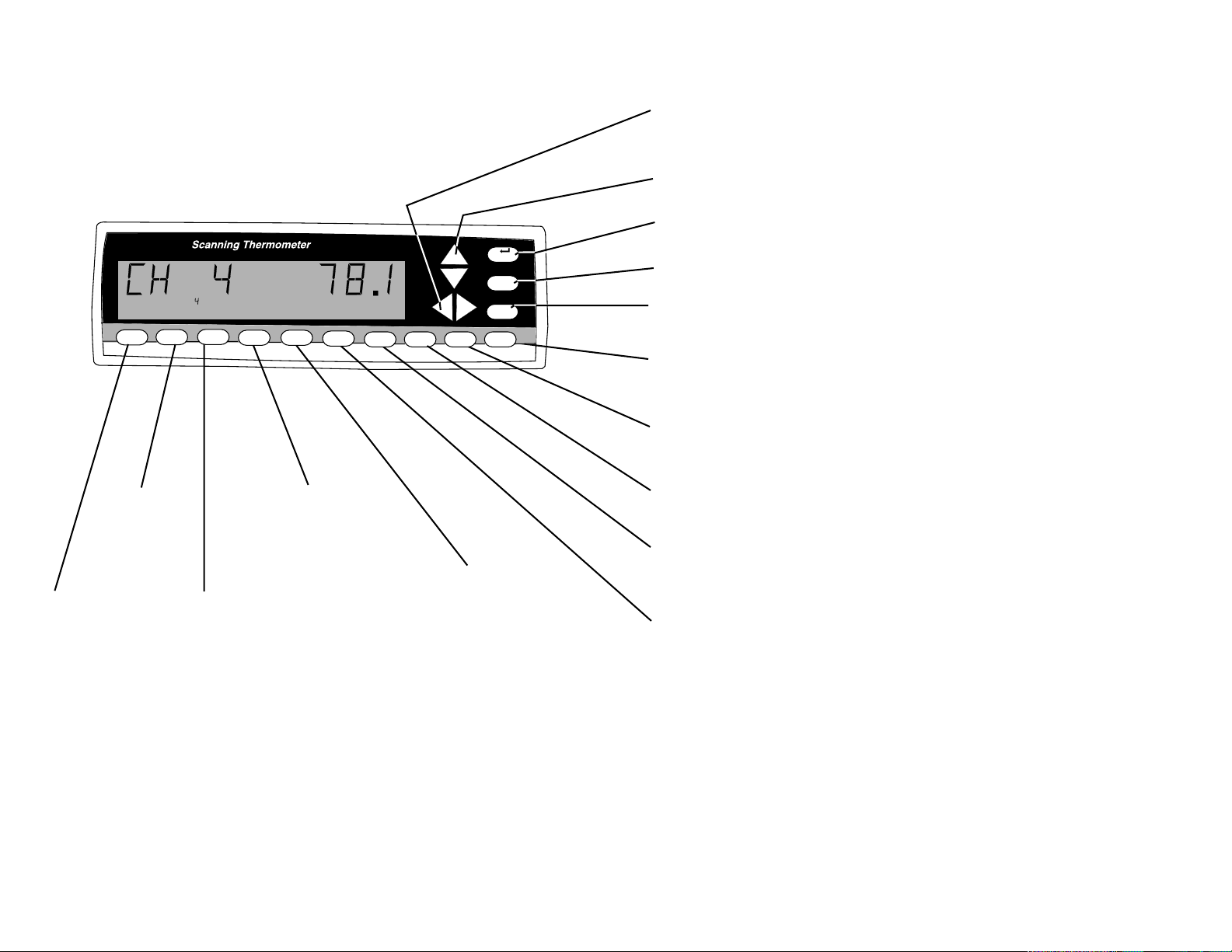

See the page number (in parenthesis) for full information about the item.

Use Left-Right arrow keys to select a channel for display. Scanning

stops. Push SCAN to resume. (22)

Use Up-Down arrow keys to scroll thru the MENU. Otherwise inactive. (21)

MENU Push to sequence through menu choices for instrument setup. (21)

1

STORE2 LOG 3RECALL

LOG Push to

toggle data

logging. (14)

STORE Push to

store the current set

of readings in

memory. “STORE”

appears in the

display. (13)

4

PRINT

5

MAX

6

MIN

PRINT Push to

turn printing on

or off. (16)

RECALL Push to scroll

through logged readings.

Up-Down arrow keys scroll

through reading numbers.

Left-Right arrow keys

select channel displayed.

RECALL cycles through

reading date, reading time,

and reading temperature.

Push and release EXIT to

exit. (15)

°F

7

AVG

8

HOLD9SCAN

0

CLEAR

MAX Push to display the

maximum reading and time

since last power up or last

cleared. Left-Right arrow

keys select channel displayed. To reset push

CLEAR then MAX. To exit

push EXIT. (17)

MENU

EXIT

+ALARM

EXIT Push to exit any menu or display mode. Operation continues. (23)

ALARM Push to silence the audible alarm. Alarm icon remains. (23)

CLEAR Push CLEAR then push STORE, LOG, MAX, MIN, AVG or ALARM.

Clears respective value(s) from memory. (20)

SCAN Push to resume scanning display after pushing Left-Right arrow

keys. Also, this immediately initiates a new scan. (20)

HOLD Push to freeze current display readings. Scanning continues.

Left-Right arrow keys select channel displayed. To exit push HOLD. (19)

AVG Push to display the average reading and number of readings since

last power up or last cleared. Left-Right arrow keys select channel displayed. To reset push CLEAR then AVG. To exit push EXIT. (19)

MIN Push to display the minimum reading and reading time since last

power up or last cleared. Left-Right arrow keys select channel displayed. To

reset push CLEAR then MIN. To exit push EXIT. (18)

6 7

Page 9

Quick Reference Continued

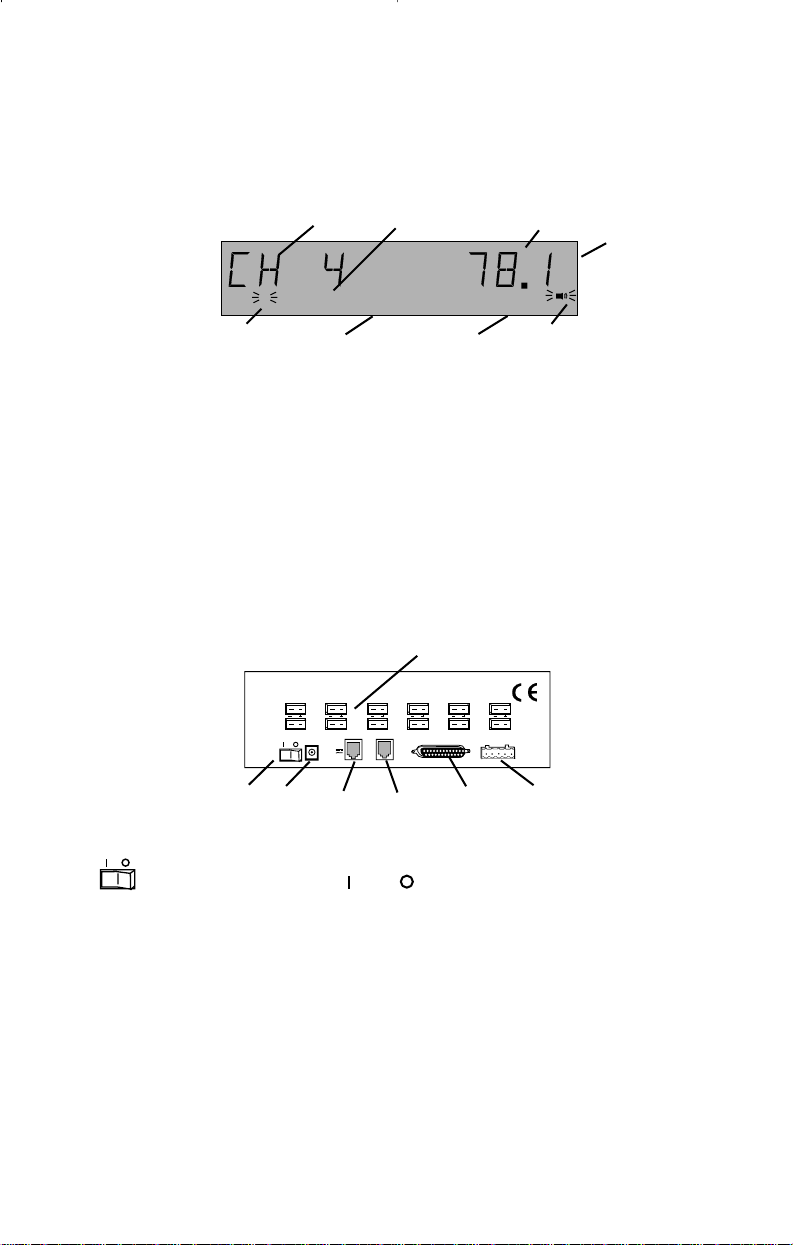

Front Panel Display

Rear Panel Connections

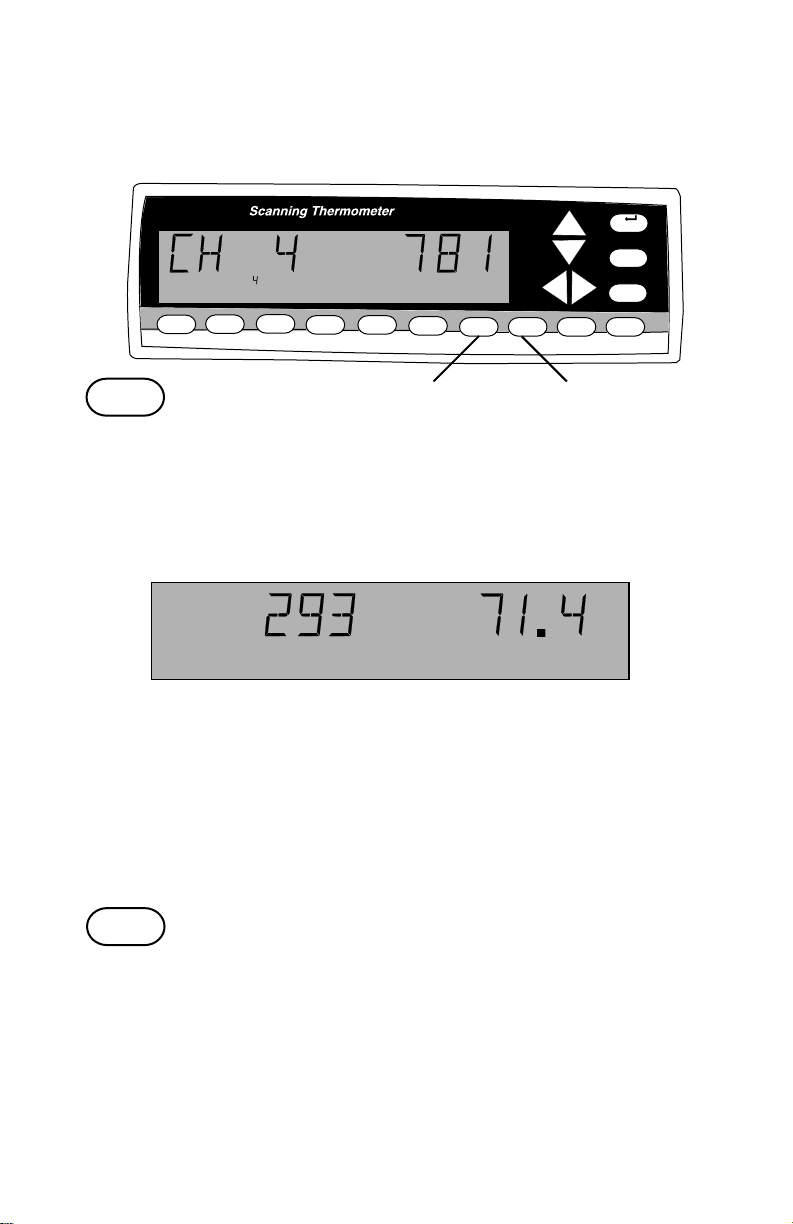

1 2 3

2

4

STORE

56 78

Note: Example display

1. CH and the channel number

display the thermocouple that is

being read.

2. The number of the channel being

displayed is repeated here.

3. The temperature is displayed.

4. The temperature scale is given.

5. A flashing channel number

shows a problem with that probe.

12 CHANNEL TERMOCOUPLE SCANNER

1728394105116

PC/IN

RS-

10-28 VDC

232

7-20 VAC

500 MA

°F

ALARM

6. Words across the bottom of the

display indicate status of the

instrument. (Example: STORE

indicates that temperature

records are logged or stored.)

7. The word ALARM flashes when

an alarm is present.

8. When flashing, indicates an

alarm.

1.

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

USA

PARALLEL PRINTER

12

TRIGGER

+ GND

OUT/LINK

4

2. 3. 4. 5. 6. 7.

1. 1-12 Connect thermocouples here (two blade mini-ANSI

connectors).

2. Power switch: = on, = off.

3. 10-28V DC Power supply input. Connect the input connector of the

supplied AC adapter here.

4. PC/IN Connect (using supplied cable) to a serial port on your PC

computer (RS-232 connection).

5. OUT/LINK For linking additional 12-Channel Scanning Thermocouple

Thermometer instruments. Connect OUT/LINK on one

instrument to PC/IN, using RJ-11 connectors.

6. PARALLEL Use a standard parallel printer cable (25 pin D-sub

PRINTER connector) to directly connect a PC printer.

7. TRIGGER + Connect for external events to trigger printing or

GND data storage.

8

Page 10

A

12 CHANNEL TERMOCOUPLE SCANNER

1

7

2

8

10-28 VDC

7-20 VAC

500 MA

PC/IN

B

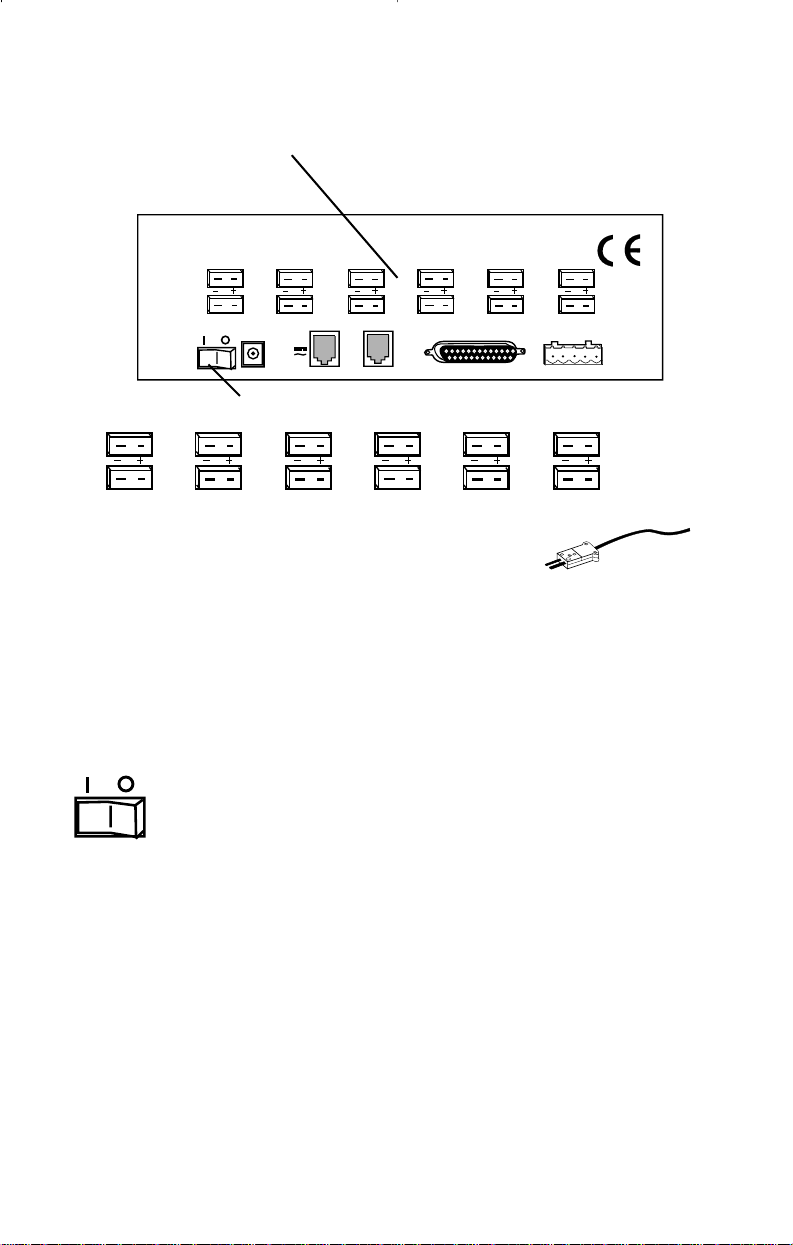

Rear Panel Connections

Thermocouple connections

Power switch

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

USA

3

9

4

10

OUT/LINK

RS232

5

11

PARALLEL PRINTER

12

6

TRIGGER

+ GND

1

7

2

8

3

9

10

4

5

11

6

12

A. Thermocouple connections

• Connect up to twelve thermocouples here.

• Jacks are for two blade mini-ANSI connectors.

• Thermocouples of types B, E, J, K, N, R, S, or T can be used. See

Appendix B for a description of thermocouple types.

• Any combination of thermocouple types can be used at the same time.

• If a thermocouple connection (channel) is not used it may be disabled

using the Menu. See Menu - How to: Enable/Disable channels on

page 30.

B. Power switch

Toggle to l to turn power to the instrument on.

Toggle to 0 to turn power to the instrument off.

When power is turned on the display goes through a display check

sequence: all display elements are turned on momentarily, then

the 1,2,...12 icons (small numbers) turn off in sequence, and then the

display switches to normal operation.

An internal lithium battery maintains the real-time clock for power outages for over a year.

9

Page 11

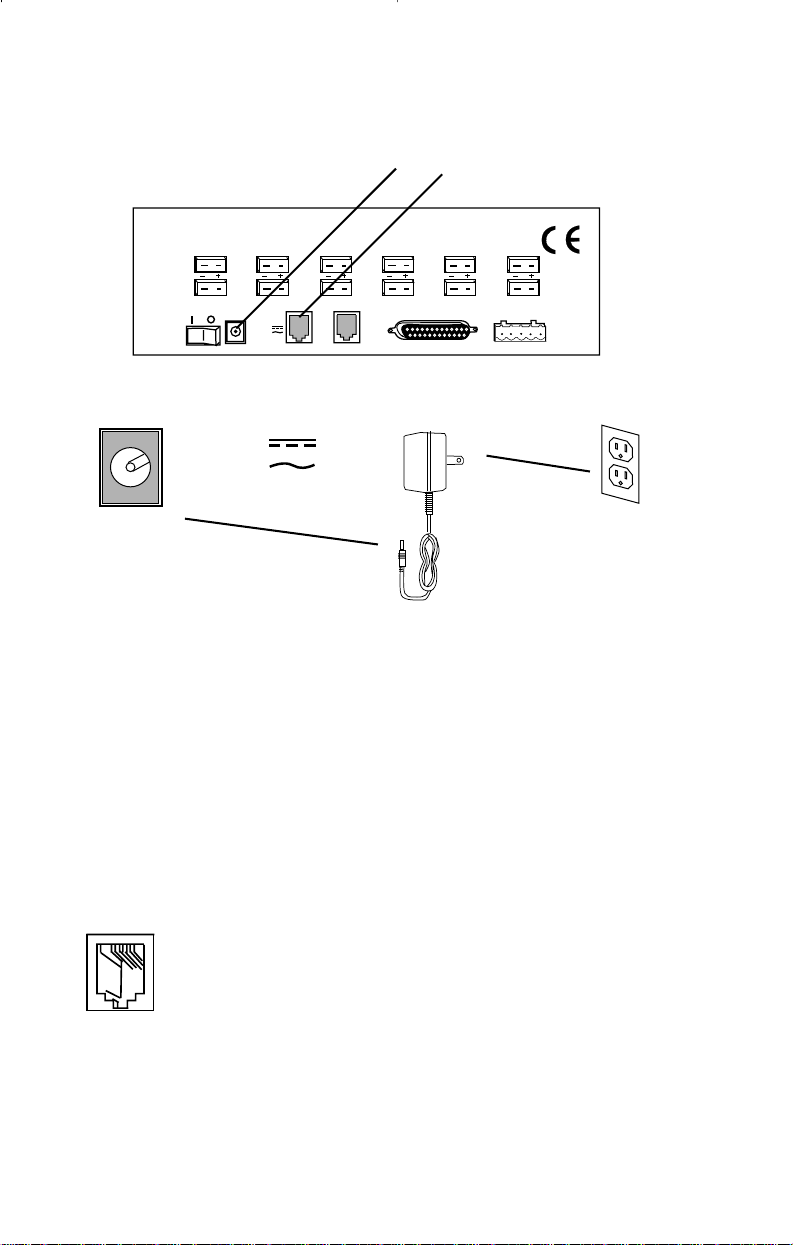

Rear Panel Connections continued

10-28V DC jack

PC/IN jack

1

7

12 CHANNEL TERMOCOUPLE SCANNER

2

8

10-28 VDC

7-20 VAC

500 MA

3

9

PC/IN

RS232

A

4

10

OUT/LINK

10-28 VDC

7-20 VAC

500 MA

A. 10-28V DC jack (Power supply input)

Connect the input connector of the supplied AC adapter here.

5

11

PARALLEL PRINTER

B

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

USA

12

6

TRIGGER

+ GND

Polarity may be either center +, or center –, or AC.

The instrument will accept: 10-28V DC (non-polarized) input @ ~ 300 mA,

or 9-20V AC, 50-400 Hz @~ 500 mA.

The input connector is a 2.5 mm ID, 6.4 mm OD power jack. (Switchcraft

760 or 765 or equivalent.)

PC/IN

B. PC/IN jack (Computer or link connection)

Computer connection Connect (using supplied cable) to a

serial port on your PC computer (RJ-11 connector to DE-9

female using the RS-232 protocol). Software commands

and instructions are available on the supplied CD-ROM. See

package contents page 5.

Link connection Connect PC/IN (using wire with RJ-11 connectors) to

OUT/LINK connection on additional instruments. Uses Linkable Instrument Network connectors and software protocol.

10

Page 12

RS232

OUT/LINK

Rear Panel Connections continued

Out/Link jack

Parallel Printer connection

Trigger + Gnd connection

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

12 CHANNEL TERMOCOUPLE SCANNER

1

2

3

7

8

9

PC/IN

10-28 VDC

7-20 VAC

500 MA

4

10

OUT/LINK

RS232

PARALLEL PRINTER

A B C

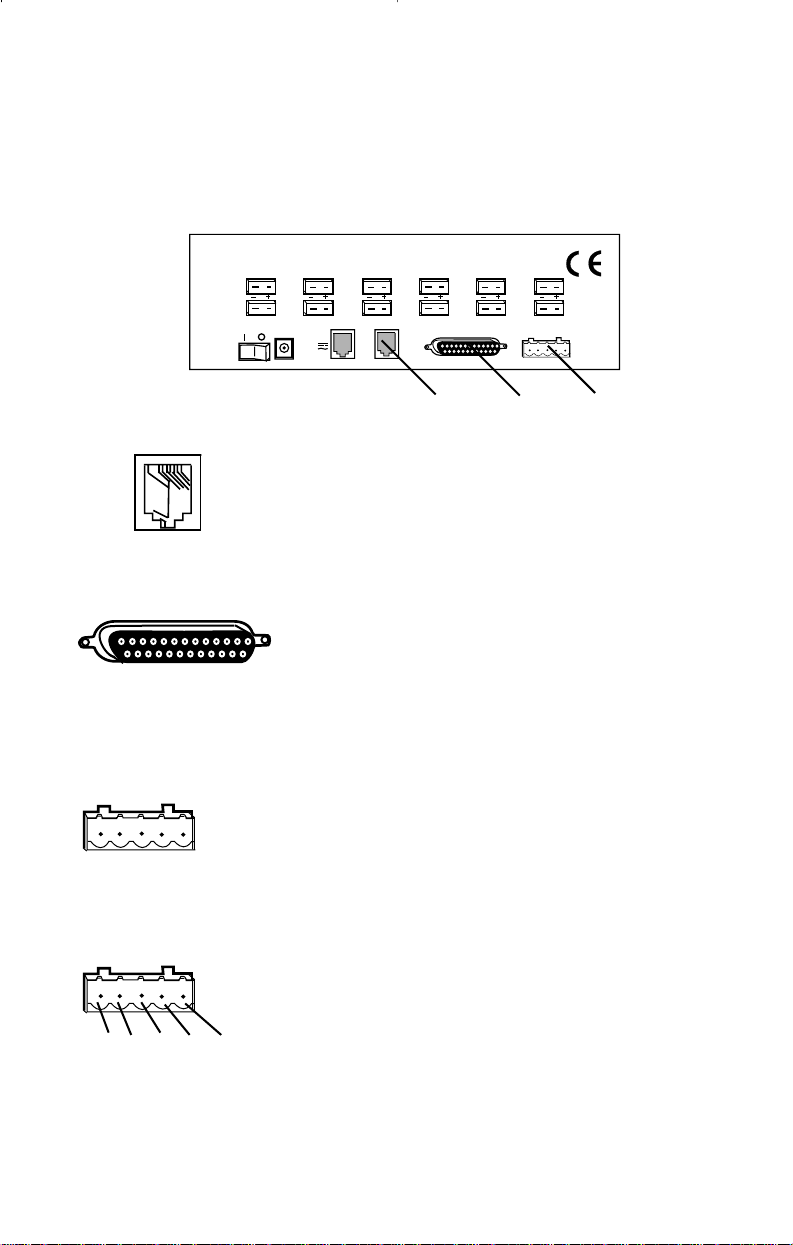

A. OUT/LINK jack

Link connection. Connect OUT/LINK (using wire with

RJ-11 connectors) to PC/IN connection on additional

instruments. Uses Linkable Instrument Network

connectors and software protocol. Either end of the

chain can be used as the computer connection.

USA

5

6

11

12

TRIGGER

+ GND

PARALLEL PRINTER

B. Parallel Printer connection

Use a standard parallel printer cable (DB-25

male to 36 position CENTRONICS male) to

directly connect a PC printer. See PRINT button on page 16. No additional software or hardware is required for printing.

TRIGGER

+ GND

C. TRIGGER + GND connection

Optional. Connect for external events to trigger

printing or data storage. Contact closure or open

collector type logic signal to ground. (Internal 5V

DC pull-up through 5K ohms resistance with

100pf capacitance to ground.) Mating connector

TRIGGER

+ GND

supplied.

Use pins 1 & 2 for contact closure.

12 3 4 5

Pins 3-5 not used.

11

Page 13

Installation

12 CHANNEL TERMOCOUPLE SCANNER

1

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

USA

1

7

2

8

10-28 VDC

7-20 VAC

500 MA

PC/IN

3

9

RS232

OUT/LINK

10

4

5

11

PARALLEL PRINTER

12

TRIGGER

6

+ GND

8256 4 7

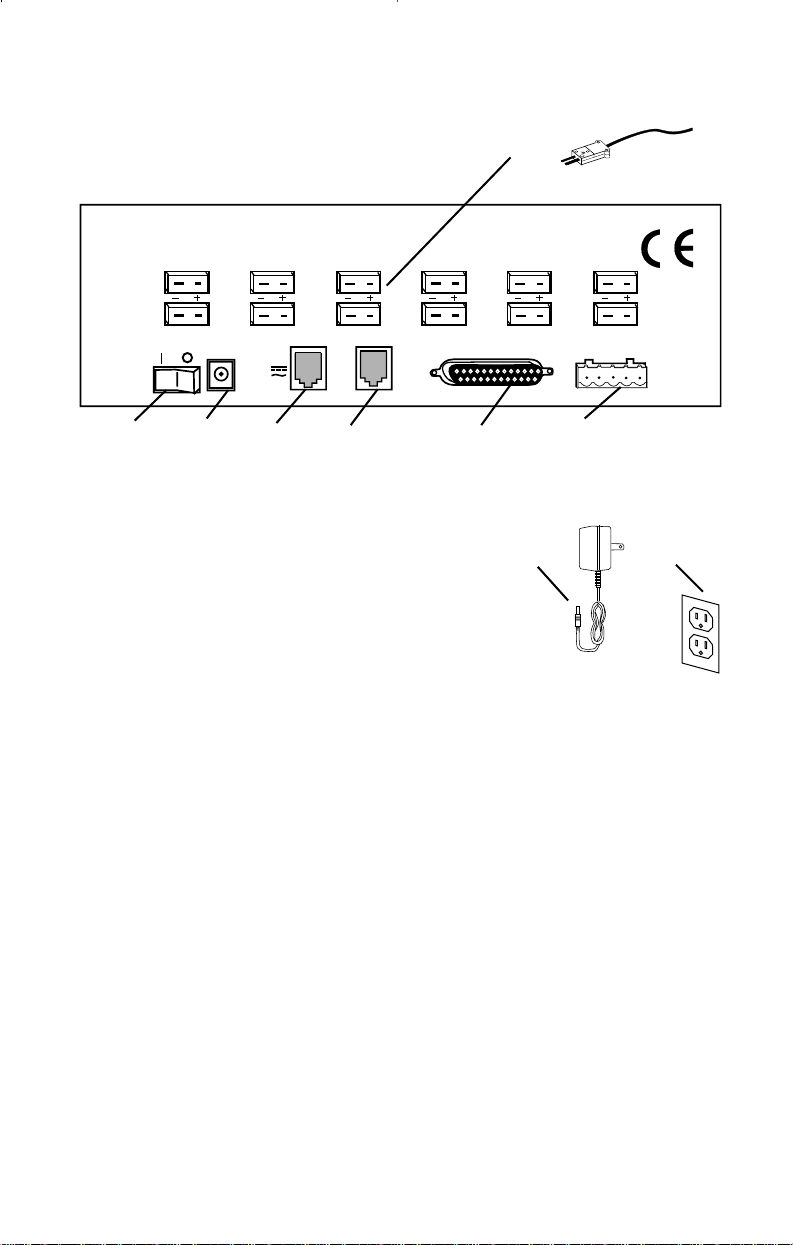

1. Attach up to 12 thermocouples.

2. Connect the AC adapter to the instrument.

3. Plug the AC adapter into an outlet.

4 - 7 are Optional

4. Connect the PARALLEL PRINTER output to a PC printer (standard

parallel port cable - not supplied).

2

3

5. Connect the PC/IN jack to a serial port of your WINDOWS PC (use

the supplied cable).

6. To interconnect instruments connect the OUT/LINK jack of one

Scanning Thermocouple Ther mometer to the PC/IN jack of the next

(cable supplied).

7. To control printing or data storage by external events, connect

momentary contact events to the TRIGGER + GND connector.

8. Switch power switch to on.

12

Page 14

Front panel displays and controls

1 STORE button

MENU

EXIT

+-

ALARM

0

CLEAR

1

STORE

1

STORE2 LOG

1

3

RECALL

4

PRINT

5

MAX

6

MIN

.

7

AVG

°F

8

HOLD9SCAN

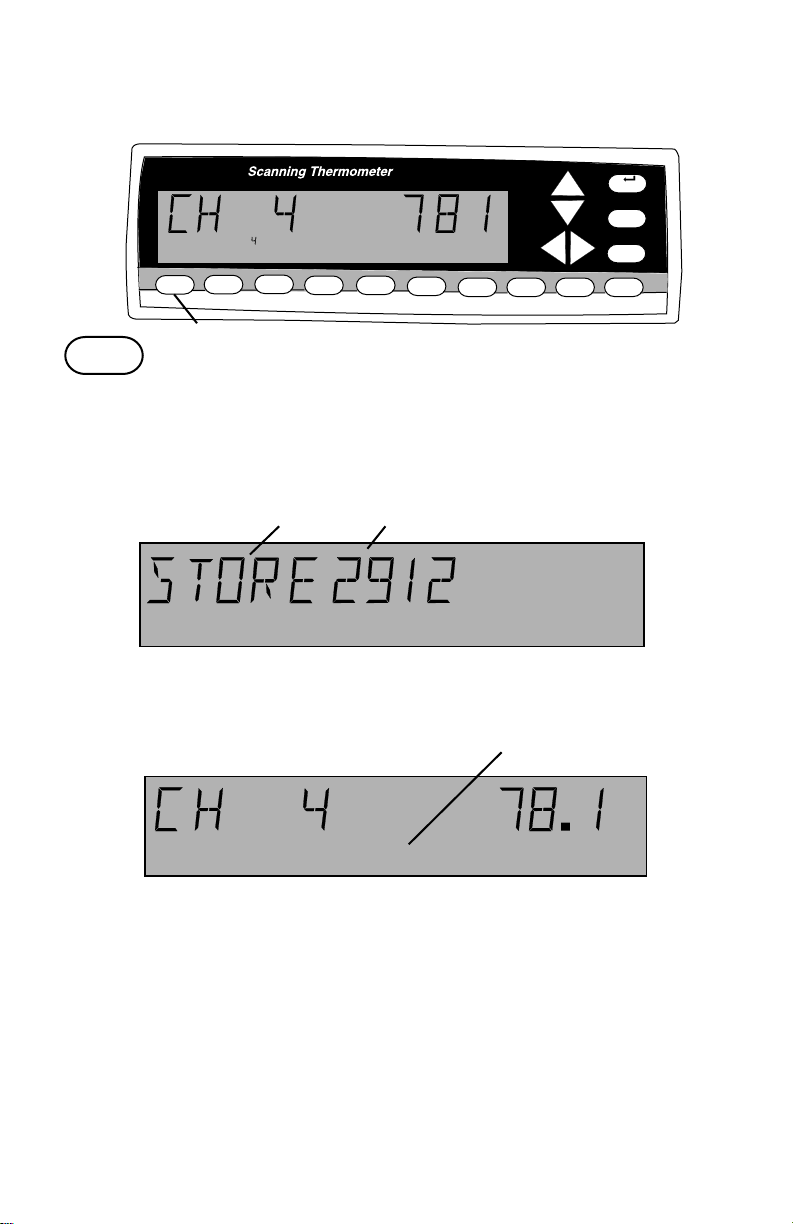

1 STORE button

Push to store one record cycle of the current set of readings in memory.

(Same as LOG, except only one record is stored.)

When a numerical entry is required and the NUM icon is on, push to

enter a ‘1’.

ab

°F

STORE

The word “STORE” a and the record number being stored b appear in

the display for about 3 seconds. Then the display returns to nor mal.

c

°F

4

STORE

“STORE” c appears, and remains in the display when one or more record

cycles are in storage (STORE and/or LOG).

Use to save a particular data record.

• A record includes readings from all 12 channels plus the time and

date.

• Up to 4,680 records may be stored. Memory is shared with LOG.

When no more data can be stored the display reads “STORE

FULL”.

• To clear (erase) stored records, push CLEAR, then push STORE.

“STORE” disappears from the display.

13

Page 15

Front panel displays and controls continued

2 LOG button

MENU

EXIT

+-

ALARM

0

CLEAR

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

.

7

AVG

°F

8

HOLD9SCAN

2

2

LOG

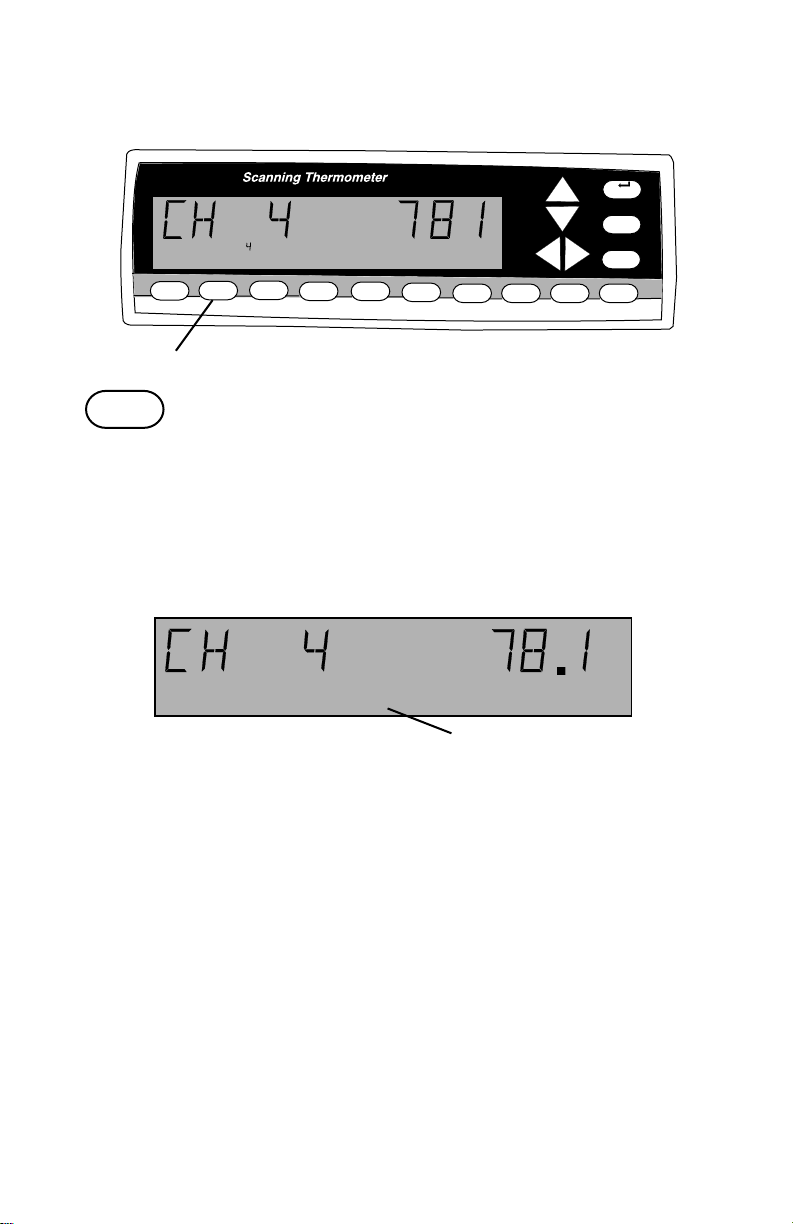

2 LOG button

Push to log record cycles as they are read. (Same as STORE, only

continues automatically.)

When a numerical entry is required and the NUM icon is on, push to

enter a ‘2’.

Push again to turn logging off.

°F

4

LOG

a

The word “LOG” a appears and remains in the display while records are

being logged.

“STORE” appears, and remains, in the display when one or more records

are in storage.

Use to save a particular set of data records.

• Readings from all 12 channels are logged.

• How often records are logged is set using the MENU - LOG

procedure, page 37, which may be different from the scan rate.

• The time and date of the reading is logged.

• Up to 4,680 records may be logged. Memory is shared with the

STORE function. When no more data can be stored the display

reads “LOG FULL”.

• To clear (erase) stored records, push CLEAR, then push LOG.

“STORE” will disappear from the display.

14

Page 16

Front panel displays and controls continued

3 RECALL button

MENU

EXIT

+-

ALARM

0

CLEAR

3

1

STORE2 LOG

°F

.

3

4

PRINT

5

MAX

RECALL

3

6

MIN

7

AVG

8

HOLD9SCAN

RECALL

3 RECALL button

Push to recall stored (STORE or LOG) data.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘3’.

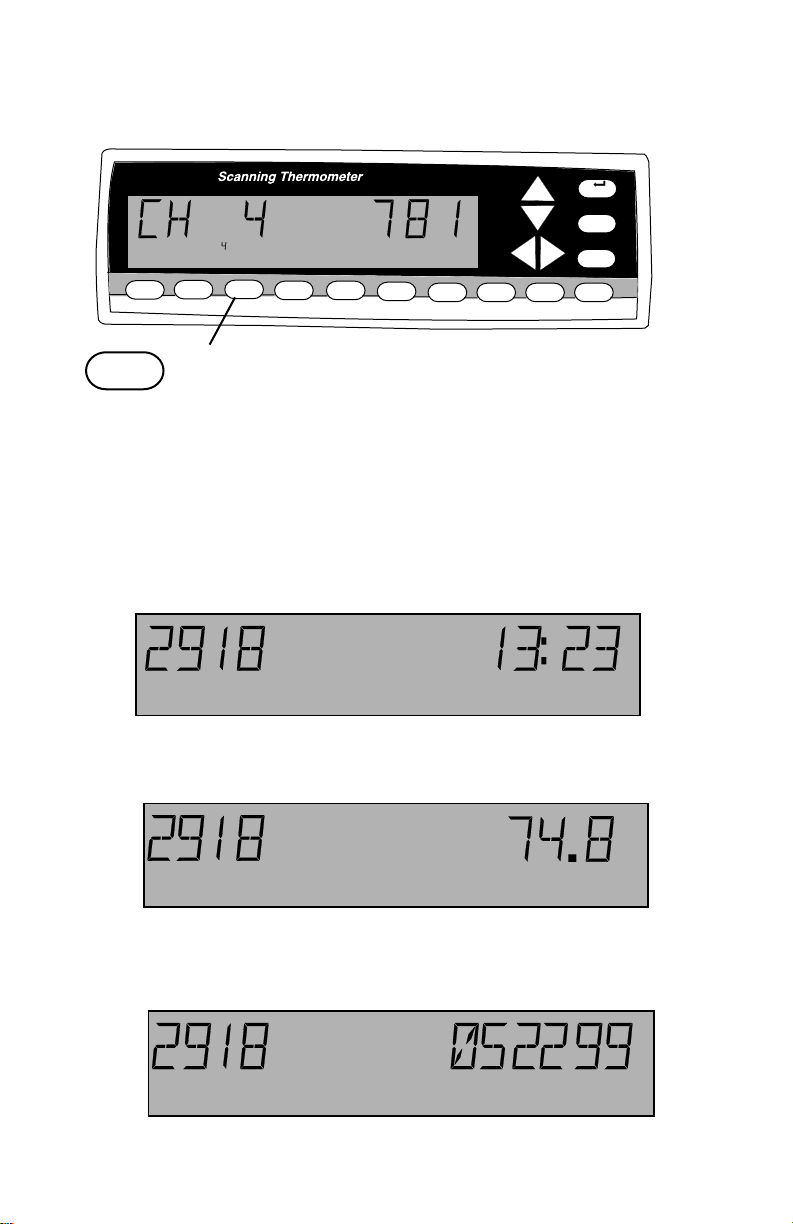

• “RECALL” appears and remains in the display during recall.

• The LOG or STORE record number and time of channel 1 are

displayed first.

1

STORE RECALL

Push RECALL again to display the temperature.

1

STORE RECALL

Push RECALL again to display the date.

1

STORE RECALL

(continued on next page)

°F

15

Page 17

Front panel displays and controls continued

3 RECALL button continued

4 PRINT button

MENU

EXIT

+-

ALARM

0

CLEAR

1

STORE2 LOG

3

3

RECALL

4

PRINT

°F

.

7

6

5

MIN

MAX

4

AVG

8

HOLD9SCAN

3 RECALL button continued

• Any time during RECALL push the Up-Down arrow keys to scroll

through the stored records.

• Any time during RECALL push the Left-Right arrow keys to scroll

through the channels.

• To exit RECALL push EXIT.

4

PRINT

4 PRINT button

Push to print on the printer attached to the PRINTER port. Push again to

stop printing.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘4’.

• “PRINT” appears and remains in the display.

• Records are printed at intervals set in the MENU.

See MENU - How to adjust the print rate, see page 36.

• Push PRINT again to turn off printing.

Example printout:

11:59:48 CH 1: 72.9 CH 2: 75.7 CH 3: UNDER CH 4: 74.6

04/24/99 CH 5: 74.5 CH 6: 74.5 CH 7: 76.0 CH 8: 74.5

CH 9: 74.7 CH 10: 74.1 CH 11: 73.8 CH 12: 73.7

16

Page 18

Front panel displays and controls continued

5 MAX button

MENU

EXIT

+-

ALARM

0

CLEAR

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

.

7

AVG

°F

8

HOLD9SCAN

5

5

MAX

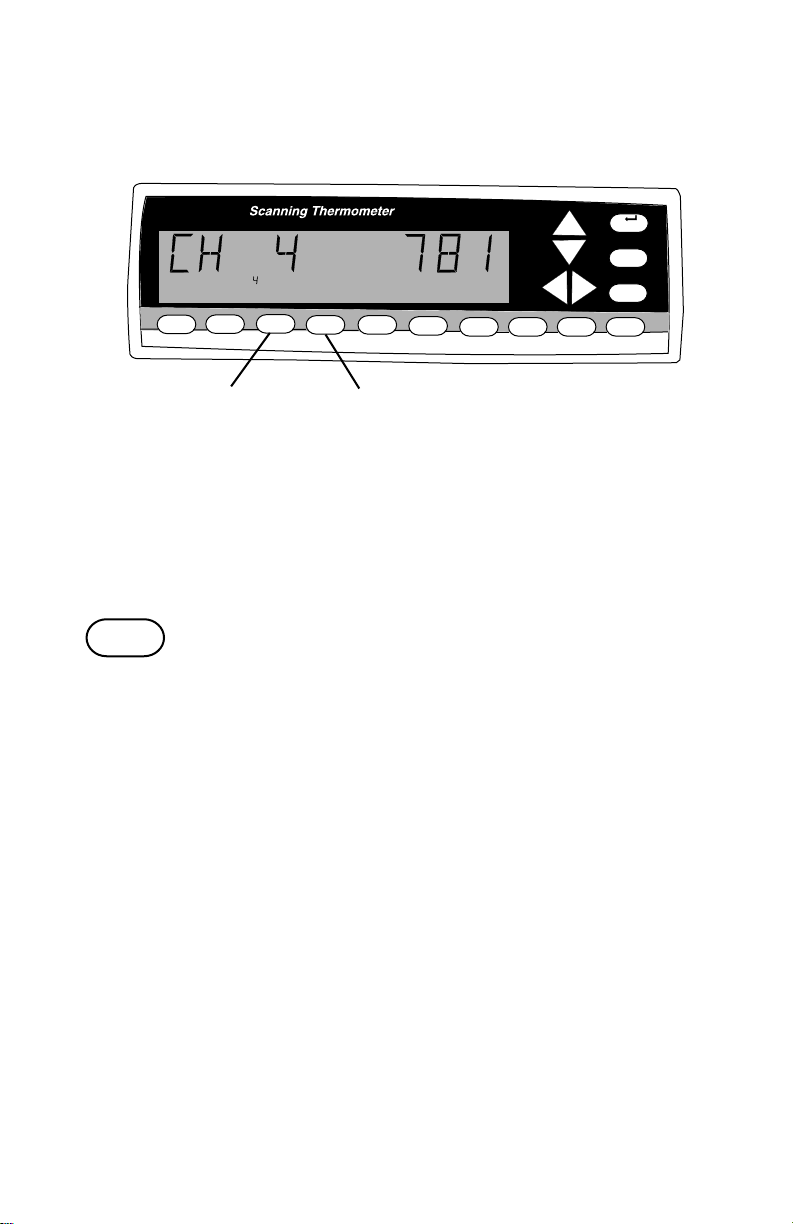

5 MAX button

Push to display the maximum temperature logged for each channel. The

display continues to scan channels.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘5’.

°F

2

MAX

•“MAX” appears and remains in the display.

• The time and maximum reading for a channel are displayed (since

power up or last cleared).

• Push MAX again to switch between the time and the date.

• Use Left-Right arrow keys to stop scanning and to choose the

channel whose maximum value is displayed. Push SCAN to return

to scanning channels while remaining in MAX.

• Push MIN to switch the display to the minimum logged value of the

displayed channel.

• Push EXIT to exit.

17

Page 19

Front panel displays and controls continued

6 MIN button

MENU

EXIT

+-

ALARM

0

CLEAR

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

.

7

AVG

°F

8

HOLD9SCAN

6

6

MIN

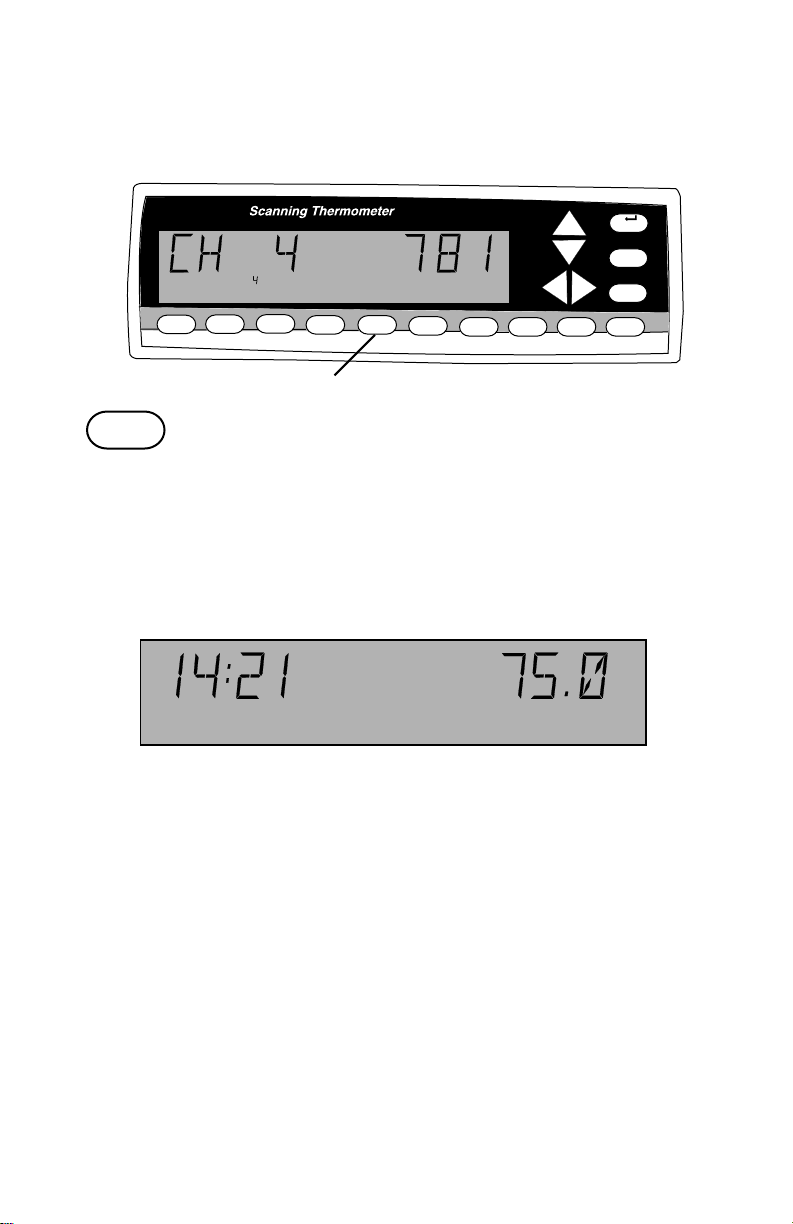

6 MIN button

Push to display the minimum temperature logged for each channel. The

display continues to scan channels.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘6’.

°F

2

MIN

•“MIN” appears and remains in the display.

• The time and minimum reading for a channel are displayed (since

power up or last cleared).

• Push MIN again to switch between the time and the date.

• Use Left-Right arrow keys to stop scanning and to choose the

channel whose minimum value is displayed. Push and release

SCAN to return to scanning channels while remaining in MIN.

• Push MAX to switch the display to the maximum logged value of

the displayed channel.

• Push EXIT to exit.

18

Page 20

Front panel displays and controls continued

7 AVG button

8 HOLD button

MENU

EXIT

+-

ALARM

0

CLEAR

8

7

AVG

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

7

.

7

AVG

°F

8

HOLD9SCAN

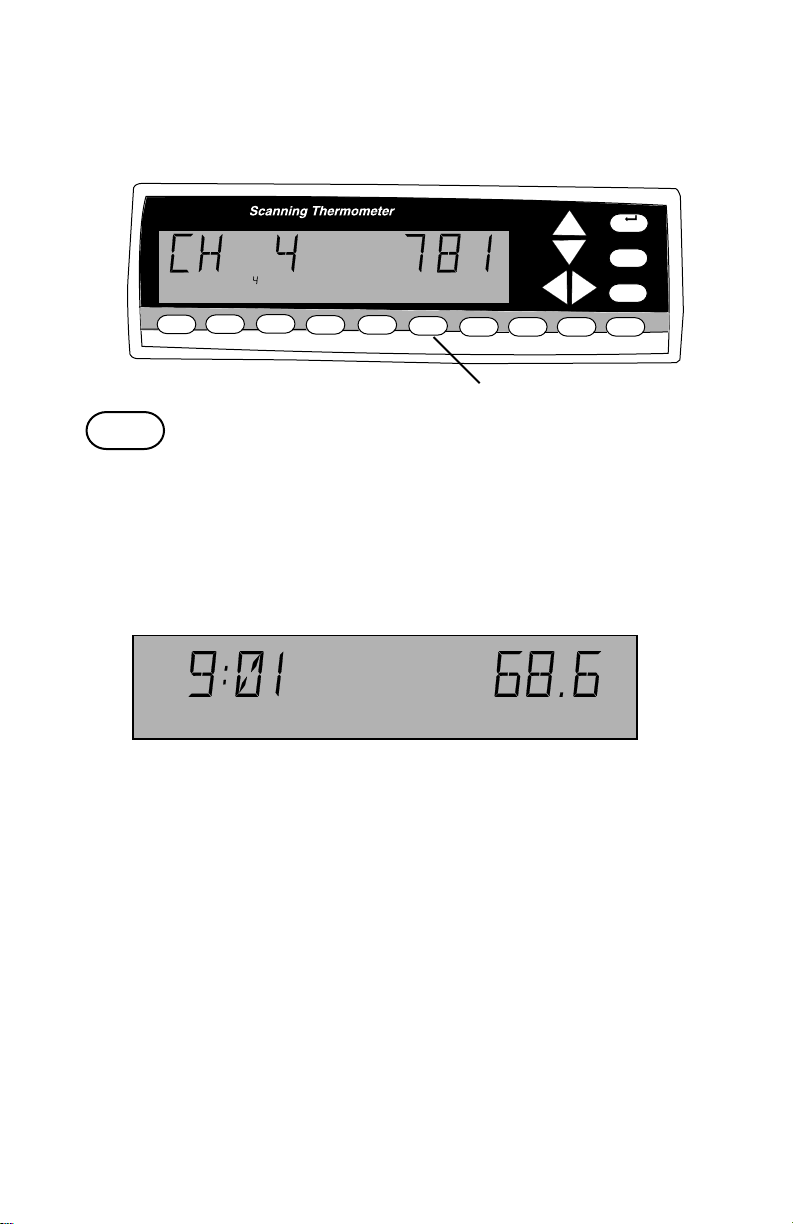

7 AVG button

Push to display the average temperature for each channel and the

number of readings that are being averaged. The display continues to

scan channels.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘7’.

°F

5

AVG

•“AVG” appears and remains in the display.

• Readings from when the instrument was last powered up or

cleared are averaged.

• Opened channel readings are not averaged.

• Use Left-Right arrow keys to stop scanning and to choose the

channel whose average is displayed. Push SCAN to return to

scanning channels while remaining in AVG.

• Push AVG again to exit.

8

HOLD

8 HOLD button

Push to hold the current record in display.

When a numerical entry is required, and the NUM icon is on, push to

enter an ‘8’.

•“HOLD” appears and remains in the display.

• Channel scanning, logging, printing continue normally but the

display remains.

• Push HOLD or EXIT to exit.

19

Page 21

Front panel displays and controls continued

9 SCAN button

0 CLEAR button

MENU

EXIT

+-

ALARM

0

CLEAR

9

SCAN

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

.

7

AVG

°F

8

HOLD9SCAN

9

9 SCAN button

Push to start a channel scan.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘9’.

• Each channel is displayed for three seconds.

• Use to return to scanning after scanning is stopped by using the

Left-Right arrow keys.

• Causes an immediate scan.

0

CLEAR

0 CLEAR button

Push CLEAR, then push A VG, ALARM, MAX, MIN, STORE or LOG to

clear that value.

When a numerical entry is required and the NUM icon is on, push to

enter a ‘0’.

• CLEAR - AVG erases the 12-Channel record containing the

average temperature from memory.

• CLEAR - ALARM turns the alarm buzzer off, all alarm conditions,

error messages, and temperature out of range alarms. Normally

push ALARM when an alarm occurs, that stops the alarm buzzer

and checks the alarm condition.

• CLEAR - MAX erases the 12-Channel record containing the

maximum temperature from memory.

• CLEAR - MIN erases the 12-Channel record containing the minimum temperature from memory.

• CLEAR - STORE erases the 12-Channel records that have been

logged or stored in memory (= CLEAR - LOG).

• CLEAR - LOG erases the 12-Channel records that have been

logged or stored in memory (= CLEAR - STORE).

0

20

Page 22

Front panel displays and controls continued

MENU button

Up-Down Arrow keys

MENU

EXIT

+-

ALARM

0

CLEAR

MENU

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

Up-Down Arrow Keys

.

7

AVG

°F

8

HOLD9SCAN

MENU

MENU button

Push to scroll through the menu to enter or change setup parameters.

The word “SCALE” appears in the display and the current scale setting

(for example °F) flashes.

To scroll backwards through the menu choices push and hold MENU

then press the Left arrow key.

See MENU, starting on page 26, for a complete selection of MENU

choices and how to set up parameters.

Up-Down Arrow keys

Active within the MENU. Used to scroll through menu options.

21

Page 23

Front panel displays and controls continued

Left-Right Arrow keys

°F

.

1

STORE2 LOG

Left-Right Arrow keys

Active within the MENU. Used to scroll through menu options.

• Manually select a channel.

3

4

PRINT

5

MAX

RECALL

Left-Right Arrow Keys

6

MIN

7

AVG

8

HOLD9SCAN

MENU

EXIT

+-

ALARM

0

CLEAR

22

Page 24

Front panel displays and controls continued

EXIT button

ALARM button

MENU

EXIT

+-

ALARM

0

CLEAR

EXIT

1

STORE2 LOG

EXIT

3

RECALL

4

PRINT

5

MAX

6

MIN

°F

.

7

AVG

ALARM

8

HOLD9SCAN

EXIT button

During MENU, push to EXIT the MENU and save any menu choices that

have been made. SAVING SETUP is displayed for two seconds, then the

instrument returns to scanning.

During STORE, RECALL, MAX, MIN, AVG, CLEAR or HOLD displays,

push to EXIT the display and return to scanning.

+ALARM

ALARM button

Push to turn off the alarm beeper. The flashing alarm icon and other

alarm displays remain.

When a numerical function is required and the NUM icon is on, push to

toggle between + and -.

°F

2

1

4

STORE

ALARM

2

Temperature Alarms

When an alarm occurs the alarm beeper will beep (if ALARM BEEPER is

set to ON in the menu) the printer will print the alarm record (if ALARM

PRINT ON is set in the menu), the alarmed channel 1 and the alarm icon

2 will flash.

(continued on next page)

23

Page 25

Front panel displays and controls continued

ALARM button continued

°F

2

4

STORE

ALARM

3

Temperature Alarms continued

• HI temperature alarm: When a thermocouple detects a tempera-

ture above the HI limit setting in the menu, ALARM is displayed,

the alarm icon and the channel number 3 flash. HI will flash when

that channel is displayed.

• LO temperature alarm: When a thermocouple detects a

temperature below the LO limit setting in the menu, ALARM is

displayed, the alarm icon, and the channel number 3 flash. LO will

flash when that channel is displayed.

To turn off the alarm displays: push the Left-Right arrow keys to

display the out of range channel, then push ALARM. Repeat for all

alarmed channels.

To clear all alarm conditions at once: push CLEAR then push ALARM.

24

Page 26

Front panel displays and controls continued

ALARM button continued

Other Alarms

• OPEN thermocouple: A thermocouple channel that is OPEN (no

thermocouple connected) will cause an OPEN alarm.

OPEN will be displayed instead of a temperature when that

channel is displayed.

Check thermocouple connection, wiring to the thermocouple, or

replace the thermocouple.

If the channel is not used, disable the channel (see How to Enable/

Disable channels, page 30).

• UNDER alarm: If the instrument detects a reading indicating a

temperature below the operating range of the thermocouple type

an UNDER alarm occurs.

UNDER will be displayed instead of a temperature when that

channel is displayed.

• OVER alarm: If the instrument detects a reading indicating a

temperature above the operating range of the thermocouple type

an OVER alarm occurs.

OVER will be displayed instead of a temperature when that

channel is displayed.

• LOG FULL alarm: 4,680 12-Channel records can be stored in

memory . A record is stored in memory manually by pushing

STORE, or automatically according to the log rate setting in the

menu.

During a LOG FULL alarm LOG and FULL alternate in the display.

During a LOG FULL alarm you can:

• RECALL - scroll through the logged readings.

• PRINT - print the logged readings.

To clear (erase) the memory: push CLEAR then push LOG.

• Instrument errors: Various hardware errors can also cause an

alarm such as an A/D error, EEPROM verify error, flash write error,

etc. The entire display will flash the alarm message. See Error

Messages, page 62.

Normal display updates stop until the alarm is acknowledged.

Other updates (scanning, printing, other alarms, logging) continue

without interruption.

25

Page 27

Front panel displays and controls continued

About the MENU

1

MENU

EXIT

+-

ALARM

0

CLEAR

MENU

°F

.

1

STORE2 LOG

3

RECALL

4

PRINT

5

MAX

6

MIN

7

AVG

8

HOLD9SCAN

About the Menu

Push the MENU button 1 to scroll through the menu to

enter or change setup parameters.

The word “SCALE” appears in the display and the current scale setting

(for example °F) flashes.

To scroll backwards through the menu choices push and hold MENU

then press the Left arrow key.

MENU lets you adjust the following:

display see page

SCALE temperature scale displayed .................. 28

RESOLUTION the resolution of the displayed

temperature........................................... 29

choose which channels are

scanned ................................................. 30

KKKKKK... thermocouple type ................................. 31

CONTRAST the contrast of the display ...................... 32

TRIGGER OFF trigger off/on........................................... 33

TRIGGER PULSE trigger mode ........................................... 34

SCAN scan time interval ................................... 35

RATE PRINT rate ............................................. 36

RATE LOG rate ................................................ 37

ALARM alarm off, or on....................................... 39

PRINT ON alarm print on or off................................. 40

If alarm is set to ON

choose channel to set HI alarm .............. 41

choose channel to set LO alarm ............. 42

HYST set alarm hysteresis ................................ 43

SETPT set HI alarm setpoints ............................. 44

SETPT set LO alarm setpoints ............................ 45

BEEPER beeper on or off...................................... 46

DATE MM/DD date format ............................................. 47

DATE 042599 set date .................................................. 48

TIME 10:13 set time .................................................. 49

CALPT 1 32.0 field calibration ....................................... 50

REPORT calibration report ..................................... 53

Page 28

Front panel displays and controls continued

About the MENU continued

About the Menu continued

• Quick access - Push MENU then SCAN, PRINT, LOG, or ALARM

to jump to that point in the menu.

• When done with a menu setup either push EXIT to save the setup

and return to scanning or push MENU to continue to the next menu

setup.

• If a numeric entry is required in a menu setup, a flashing NUM icon

is displayed and the number and ± keys are active.

• To erase a single digit while entering a number push the Down

arrow key.

Page 29

Front panel displays and controls continued

How to set the scale

°F

How to set the scale

The instrument can record, display and print at the following scales:

°F Degrees Fahrenheit

°C Degrees Centigrade

°R Degrees Rankin

K Kelvin

The default scale is °F.

5

MAX

6

MIN

1b

7

AVG

°F

8

HOLD9SCAN

1a

1

STORE2 LOG 3RECALL

4

PRINT

To set or change the scale:

1. Push MENU, SCALE 1a is displayed and the current scale

setting 1b flashes.

2. Push the Up or Down arrow keys until the desired scale is

flashing.

3a. Push EXIT to save the setup and return to scanning, or

3b. Push MENU to switch to the next setup topic (adjust

the resolution).

2 1, 3b

MENU

EXIT

+-

ALARM

0

CLEAR

3a

Page 30

Front panel displays and controls continued

How to change the resolution

How to change the resolution

The instrument can display and print temperatures at either 0.1° or 1°

resolution.

The default resolution is 0.1°.

1a

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

1b

6

MIN

7

AVG

8

HOLD9SCAN

2 1, 3b

MENU

EXIT

+-

ALARM

0

CLEAR

To set or change the resolution:

1. Push MENU until RESOLUTION is displayed.

RESOLUTION 1a is displayed and the current resolution setting

1b flashes.

2. Push the Up or Down arrow keys until the desired resolution is

flashing.

3a. Push EXIT to save the setup and return to scanning, or

3b. Push MENU to switch to the next setup topic (Enable/Disable

channels).

3a

Page 31

Front panel displays and controls continued

How to Enable/Disable channels

1 2 3 4 5 6 7 8 9 10 11 12

How to Enable/Disable channels

A thermocouple channel can be turned off if that channel is not used or

not desired. A channel that is turned off will be skipped in a scan and

listed as OFF in a printout.

The default setting is all channels ON.

1a

1 2 3 4 5 6 7 8 9 10 11 12

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

3 2 1, 4b

7

AVG

8

HOLD9SCAN

6

MIN

MENU

EXIT

+ALARM

0

CLEAR

To set or change scan channels:

1. Push MENU until 1’s and 0’s are displayed and the current

channel 1a flashes. (1 is scan channel on, 0 is scan channel off.)

2. Push the Up or Down arrow keys as the channel flashes to

toggle between 1 and 0.

3. Push Left or Right arrow keys to switch channels.

Repeat steps 2 and 3 for all channels you want to change.

4a. Push EXIT to save the setup and return to scanning, or

4b. Push MENU to switch to the next setup topic (setup thermo-

couple types).

4a

Page 32

Front panel displays and controls continued

How to setup thermocouple types

123456789101112

How to setup thermocouple types

Thermocouples of types K, J, B, N, S, R, E or T can be used with this

instrument. Any combination of thermocouple types can be used.

See Appendix B for thermocouple specifications.

The default setting for all channels is type K.

1a

1 2 3 4 5 6 7 8 9 10 11 12

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

2 3 1, 4b

7

6

MIN

AVG

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

To set or change thermocouple type:

1. Push MENU until K’s (or other types) are displayed and the

current channel 1a flashes (disabled channels are blank).

2. Push Left or Right arrow keys to switch channels.

3. Push the Up or Down arrow keys as the channel flashes to scroll

through thermocouple types.

Repeat steps 2 and 3 for all thermocouple type changes.

4a. Push EXIT to save the setup and return to scanning, or

4b. Push MENU to switch to the next setup topic (adjust the display

contrast).

4a

Page 33

Front panel displays and controls continued

How to adjust the display contrast

How to adjust the display contrast

The display contrast can be adjusted from 1 (very dark - the background

interferes with the display) to 50 (very light - display letters and numbers

are dim). This setting adjusts the contrast for varying viewing angles.

The default setting is 25.

1a

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

1b

6

MIN

7

AVG

8

HOLD9SCAN

2 1, 3b

MENU

EXIT

+ALARM

0

CLEAR

To set or adjust the display contrast:

1. Push MENU until CONTRAST 1a is displayed and the current

contrast value 1b flashes.

2. Push and hold the Up or Down arrow keys to adjust the contrast

value quickly. Push an Up or Down arrow key to change contrast

one digit at a time.

The contrast changes as the value is adjusted.

3a. Push EXIT to save the adjustment and return to scanning, or

3b. Push MENU to switch to the next setup topic (set trigger type).

3a

32

Page 34

Front panel displays and controls continued

a

How to set trigger type

How to set trigger type

A trigger (contact between pins 1 and 2 of the trigger) can be set to:

• pulse print (print one record when trigger contact is closed).

• S/S (start/stop) PRINT (equivalent to toggling PRINT on while

trigger contact is closed).

• pulse STORE (equivalent to pushing STORE to log one record).

• S/S (start/stop) STORE (equivalent to pushing LOG to continuously log records while trigger contact is closed).

The default setting is OFF.

2

1a

1b

1, 3b

MENU

EXIT

+ALARM

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

6

MIN

7

AVG

8

HOLD9SCAN

0

CLEAR

To set or adjust the trigger type:

1. Push MENU until TRIGGER 1a is displayed and the current

setting 1b (OFF, STORE or PRINT) flashes.

2. Push the Up or Down arrow keys to scroll between OFF, STORE

and PRINT.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set trigger mode).

3

33

Page 35

Front panel displays and controls continued

How to set trigger mode

How to set trigger mode

If a trigger type is set to PRINT or STORE, the trigger mode can be set.

(See How to set trigger type on preceding page.)

The modes are PULSE (momentary action, as in pushing and releasing a

button), and S/S (start/stop, toggle action as in switching on or off).

The default setting is PULSE.

1a

1

STORE2 LOG 3RECALL

4

PRINT

1b

5

MAX

6

MIN

7

AVG

8

HOLD9SCAN

2

1, 3b

MENU

EXIT

+ALARM

0

CLEAR

To set or adjust the trigger mode:

1. Push MENU until TRIG’R 1a is displayed and the current setting

1b (PULSE or S/S) flashes.

2. Push the Up or Down arrow keys to switch between PULSE and

S/S.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (adjust the scan rate).

3a

34

Page 36

Front panel displays and controls continued

How to adjust the scan rate

NUM

How to adjust the scan rate

The scan rate is the interval between the start of individual scans of all

twelve channels.

The default setting is 00:04 (4 seconds).

It takes 4 seconds to do one 12 channel scan, so a scan rate of 00:04

results in continuous scanning.

With the scan rate at 00:20 there will be 3 scans per minute.

The maximum scan rate that can be set is one hour (60:00).

1a

1b

1, 3b

MENU

EXIT

NUM

1

STORE2 LOG 3RECALL

1c

4

PRINT

5

MAX

7

6

MIN

AVG

8

HOLD9SCAN

2

+ALARM

0

CLEAR

To adjust the scan rate:

1. Push MENU until SCAN is displayed or push MENU at least

once, then push SCAN.

SCAN 1a is displayed and the current setting 1b flashes.

NUM 1c appears and flashes indicating number keys 2 are

active.

2. Push number keys 2 to enter the scan rate. (For example, 36:12

is entered by pushing 3 - 6 - 1 - 2.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (adjust the print

rate).

3a

35

Page 37

Front panel displays and controls continued

How to adjust the print rate

NUM

PRINT

How to adjust the print rate

The print rate is the time the instrument waits between printing

temperature scans on the attached printer.

A printer must be attached and turned on. The instrument only sends the

data, there is no alarm or storage of print information if the printer is

disconnected or turned off.

The PRINT button must be pushed and PRINT displayed.

The default setting is 00:20 (20 seconds).

It takes 4 seconds to do one 12 channel scan so a print rate of 00:04 is the

maximum obtainable.

Note: If the print rate is set more often than the scan rate (lower time

setting) the instrument will scan and print at the print rate.

1a

NUM

1

STORE2 LOG 3RECALL

PRINT

4

PRINT

1b

5

MAX

6

MIN

7

AVG

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1, 3b

3a

1d

1c

2

To adjust the print rate:

1. Push MENU until the PRINT RATE displays or push MENU at

least once, then push PRINT.

RATE 1a is displayed and the current setting 1b flashes.

PRINT 1c is displayed.

NUM 1d appears and flashes indicating number keys are active.

2. Push number k e ys 2 to enter the print rate. (For example, 36:12 is

entered by pushing 3 - 6 - 1 - 2.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (adjust the log rate).

36

Page 38

Front panel displays and controls continued

How to adjust the log rate

NUM

How to adjust the log rate

The log rate is the time the instrument waits between logging temperature

scans in memory .

4,680 12 channel scans can be logged in memory , then LOG FULL is

displayed. When LOG FULL is displayed you can RECALL – scroll through

the logged readings, and you can PRINT – print the entire list of 4,680

logged entries. To clear (erase) memory: push CLEAR, then push LOG.

The default setting is 00:20 (20 seconds).

It takes 4 seconds to do one 12 channel scan so a log rate of 00:04 is the

maximum obtainable. The longest interval that can be set is 1 hour, 60:00.

LOG

Examples: At a setting of (00:20) the log is full in 26 hours . At the minimum setting (00:04) the log is full in 5.2 hours. For 8 hours use a setting of

00:09. At the maxim um setting (60:00) the log is full in 4,680 hours (195

days).

Manually pushing STORE adds one scan to the same memory as LOG.

(continued on next page)

37

Page 39

Front panel displays and controls continued

How to adjust the log rate continued

LOG

4

PRINT

1b

5

MAX

2

6

MIN

7

AVG

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1a

NUM

1

STORE2 LOG 3RECALL

1d

1c

To adjust the log rate continued:

1. Push MENU until the LOG RATE displays or push MENU at least

once, then push LOG. RATE 1a is displayed and the current

setting 1b flashes. LOG 1c is displayed. NUM 1d appears and

flashes indicating number keys 2 are active.

2. Push number keys to enter the log rate. (For example, 36:12 is

entered by pushing 3 - 6 - 1 - 2.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set the alarm

mode).

1, 3b

3a

38

Page 40

Front panel displays and controls continued

How to set the alarm mode

ALARM

How to set the alarm mode

The alarm mode can be ALARMS OFF, or ALARMS ON.

The default setting is ALARMS OFF.

In ALARMS OFF the instrument does not react to temperature extremes

with an alarm.

In ALARMS ON a HI or LO temperature alarm remains until manually

reset.

To set the alarm mode:

1b

2

1, 3b

3a

MENU

EXIT

+ALARM

0

CLEAR

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

6

MIN

ALARM

7

AVG

8

HOLD9SCAN

1a

1. Push MENU until ALARMS is displayed or push MENU at least

once then push ALARM.

ALARM 1a is displayed and the current setting 1b ALARMS OFF,

or ALARMS ON flashes.

2. Push Up/Down arrow keys to switch mode.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set alarm print).

How to set HI alarm(s)

The alarm mode must be ALARMS ON. If the alarm mode is ALARMS

39

Page 41

Front panel displays and controls continued

How to set the alarm print

ALARM

How to set the alarm print

Alarm print can be PRINT ON or PRINT OFF.

The default setting is PRINT ON.

When set to PRINT ON a record is printed on your attached printer when

an alarm event occurs.

1b

2

1, 3b

3a

MENU

EXIT

+ALARM

0

CLEAR

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

6

MIN

ALARM

7

AVG

8

HOLD9SCAN

1a

To set the alarm print:

1. Push MENU until ALARM 1a and PRINT 1b are displayed and the

current setting 1b (ON or OFF) flashes.

2. Push the Up/Down arrow keys to toggle between ON and OFF.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next topic (set HI alarm(s), if the alarm

mode is ALARMS OFF the next setup topic is Enable/Disable the

alarm beeper).

40

Page 42

Front panel displays and controls continued

123456789101112

OFF this setting is skipped in the MENU.

The default settings are all 0’s (HI alarm off).

To set HI alarm(s):

How to set HI alarm(s)

ALARM HI

1c

3

2

1, 4b

4a

MENU

EXIT

1 2 3 4 5 6 7 8 9 10 11 12

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

ALARM HI

6

MIN

7

AVG

8

HOLD9SCAN

+ALARM

0

CLEAR

1a 1b

1. Push MENU until ALARM 1a and HI 1b are displayed and the

current channel settings are indicated by 0’s – HI alarm off, 1’s –

HI alarm on, or blank if that channel is disabled.

The currently selected channel is flashing 1c.

2. Push Left/Right arrow keys to select the channel.

3. Push Up/Down arrow keys to switch between 0 and 1.

Repeat steps 2 and 3 for all HI alarms you wish to change.

4a. Push EXIT to save the settings and return to scanning, or

4b. Push MENU to switch to the next setup topic (set LO alarm(s)).

41

Page 43

Front panel displays and controls continued

How to set LO alarm(s)

123456789101112

ALARM LO

How to set LO alarm(s)

The alarm mode must be ALARMS ON. If the alarm mode is ALARMS

OFF this setting is skipped in the MENU.

The default settings are all 0’s (LO alarm off).

MENU

EXIT

+ALARM

0

CLEAR

1, 4b

1c

1 2 3 4 5 6 7 8 9 10 11 12

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

1a

6

MIN

1b

ALARM LO

2

7

AVG

3

8

HOLD9SCAN

To set LO alarm(s):

1. Push MENU until ALARM 1a and LO 1b are

displayed and the current channel settings are indicated by

0’s – LO alarm off, 1’s – LO alarm on, or blank if that channel is

disabled.

The currently selected channel is flashing 1c.

2. Push Left/Right arrow keys to select the channel.

3. Push Up/Down arrow keys to switch between 0 and 1.

Repeat steps 2 and 3 for all LO alarms you wish to change.

4a. Push EXIT to save the settings and return to scanning, or

4b. Push MENU to switch to the next setup topic (set hysteresis).

4a

42

Page 44

Front panel displays and controls continued

How to set alarm hysteresis

°F

NUM

ALARM

How to set alarm hysteresis

The alarm mode must be ALARMS ON. If the alarm mode is ALARMS

OFF this setting is skipped in the MENU.

Note: Defaults /settings are described in °F, the actual scale used is the

scale that was previously selected.

The default setting is 1.0°F.

Hysteresis can be any value from 0.0°F to 99.9°F.

Hysteresis is the ± temperature range before an alarm is out of range.

For example, if a HI alarm is set at 100° and hysteresis is set at 1°, that

channel’s temperature exceeds 100°, and alarms are set to ON, the

alarm will come on. The alarm will be automatically reset when the

channel’s temperature goes below 99°. If hysteresis was set at 5° the

alarm would be automatically reset when the channel’s temperature goes

below 95°.

5

MAX

1c

1, 3b

3a

+ALARM

0

CLEAR

MENU

EXIT

°F

ALARM

7

6

MIN

AVG

8

HOLD9SCAN

1a

NUM

1

STORE2 LOG 3RECALL

4

PRINT

1d

1b

2

To set alarm hysteresis:

1. Push MENU until HYST 1a, ALARM 1b and current hysteresis

value 1c (flashing) are displayed.

NUM 1d appears and flashes indicating number keys are active.

2. Push number keys to set hysteresis.

(For example, 02.3 is entered by pushing 0 - 2 - 3.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (adjust HI alarm

setpoints).

43

Page 45

Front panel displays and controls continued

How to adjust HI alarm setpoints

NUM

3

ALARM°FHI

How to adjust HI alarm setpoints

The alarm mode must be ALARMS ON. If the alarm mode is ALARMS

OFF this setting is skipped in the MENU.

Only channels whose HI alarms are set to 1 (on) can have their

setpoints changed.

1a

1c

2

1, 4b

4a

MENU

EXIT

NUM

1

STORE2 LOG 3RECALL

1b

1f

3

4

PRINT

To adjust a HI alarm setpoint:

3

5

MAX

1d

6

MIN

1e

ALARM°FHI

7

AVG

8

HOLD9SCAN

+ALARM

0

CLEAR

1. Push MENU until SETPT 1a, the channel number 1b, the

setpoint value 1c, ALARM 1d, and HI 1e are displayed.

NUM 1f appears and flashes indicating number keys 3 are

active.

2. Push Left/Right arrow keys to select channel(s).

3. Push number keys to set the HI alarm temperature.

(For example, 156.8 is entered by pushing 1 - 5 - 6 - 8.)

Repeat steps 2 and 3 for all HI alarm set points you wish to

adjust.

4a. Push EXIT to save the setting and return to scanning, or

4b. Push MENU to switch to the next setup topic (adjust LO alarm

setpoints).

44

Page 46

Front panel displays and controls continued

How to adjust LO alarm setpoints

NUM

5

ALARM°FLO

How to adjust LO alarm setpoints

The alarm mode must be ALARMS ON. If the alarm mode is ALARMS

OFF this setting is skipped in the MENU.

Only channels whose LO alarms are set to 1 (on) can have their

setpoints changed.

1a

NUM

1

STORE2 LOG 3RECALL

1f

1b

5

4

PRINT

1c

6

5

MIN

MAX

1d

3

1e

2

ALARM°FLO

7

AVG

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1, 4b

To adjust a LO alarm setpoint:

1. Push MENU until SETPT 1a, the channel number 1b, the

setpoint value 1c, ALARM 1d, and LO 1e are displayed.

NUM 1f appears and flashes indicating number keys 3 are

active.

2. Push Left/Right arrow keys to select channel(s).

3. Push number keys to set the LO alarm temperature.

(For example, -0.8 is entered by pushing 0 - 8 - 0 ±.)

Repeat steps 2 and 3 for all LO alarm setpoints you wish to

adjust.

4a. Push EXIT to save the setting and return to scanning, or

4b. Push MENU to switch to the next setup topic (Enable/Disable the

alarm beeper).

4a

45

Page 47

Front panel displays and controls continued

How to Enable/Disable the alarm beeper

How to Enable/Disable the alarm beeper

Beeper on allows audible warning of alarm condition. Beeper off prevents

audible warning. In either case, the icon will flash.

This turns the audible beeper on or off. When off and an alarm occurs,

only the flashing alarm icon is displayed.

The following will cause an alarm:

• Channel temperature higher than a HI alarm setpoint.

• Channel temperature lower than a LO alarm setpoint.

• Open thermocouple.

• Disconnected thermocouple (= open thermocouple).

• Log full.

• Hardware errors (error message will appear).

1a

1

STORE2 LOG 3RECALL

1b

4

PRINT

5

MAX

6

MIN

7

AVG

2

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1, 3b

To Enable/Disable the alarm beeper:

1. Push and release MENU until BEEPER 1a, and ON or OFF 1b,

are displayed with ON or OFF flashing.

2. Push the Up/Down arrow keys to switch between ON and OFF.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set date format).

46

3a

Page 48

Front panel displays and controls continued

How to set the date format

How to set the date format

The date can be displayed MM/DD or DD/MM.

1a

1

STORE2 LOG 3RECALL

1b

4

PRINT

5

MAX

6

MIN

7

AVG

2

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1, 3b

To set the date format:

1. Push MENU until the word DATE 1a is displayed and the current

setting 1b flashes.

2. Push the Up or Down arrow keys to toggle between MM/DD and

DD/MM.

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set the date).

3a

47

Page 49

Front panel displays and controls continued

How to set the date

NUM

How to set the date

The date can be displayed MM/DD/YY or DD/MM/YY. Check the date

format (previous page) before setting the date.

The internal calendar is ‘smart’. It automatically adjusts for months with

28, 30 and 31 days, and even compensates for leap year.

1a

NUM

1

STORE2 LOG 3RECALL

1c

1b

4

PRINT

MENU

EXIT

+ALARM

7

6

5

MAX

MIN

AVG

8

HOLD9SCAN

0

CLEAR

2

To set the date:

1. Push MENU until the word DATE 1a is displayed and the

current setting 1b flashes.

NUM 1c is flashing to indicate that number keys 2 are active.

2. Use number keys to enter the correct date.

(To enter 04-28-99 push 0 - 4 - 2 - 8 - 9 - 9.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (set the time).

1, 3b

3a

48

Page 50

Front panel displays and controls continued

How to set the time

NUM

How to set the time

The time must be set as 24-hour time. For times after 12:59 p.m. add 12

to the hours. Thus, 2:22 p.m. is 14:22, and 5:00 p.m. is 17:00.

4

PRINT

2

1b

5

MAX

6

MIN

7

AVG

8

HOLD9SCAN

MENU

EXIT

+ALARM

0

CLEAR

1, 3b

1a

NUM

1

STORE2 LOG 3RECALL

1c

To set the time:

1. Push MENU until TIME 1a is displayed and the current setting 1b

flashes.

NUM 1c is flashing to indicate that number keys 2 are active.

2. Use number keys to enter the correct time.

(To enter 18:21 push 1 - 8 - 2 - 1.)

3a. Push EXIT to save the setting and return to scanning, or

3b. Push MENU to switch to the next setup topic (field calibration).

3a

49

Page 51

Front panel displays and controls continued

How to do a field calibration

°F

NUM

5

CAL

How to do a field calibration

Factory calibration is stored in protected, non-volatile memory. Field

calibration is usually used to reduce probe errors over a specified range.

All field calibration values may be cleared (returning the instrument to

factory calibration) by pushing and holding CLEAR during the power up

display test.

An individual channel's field calibration may be cleared. When CALPT1

is displayed, press and hold CLEAR until CALPT1 CLR is displayed. This

also clears CALPT2 for this same channel. The CAL icon will also go off

for this channel.

There are no restrictions on what values may be entered for field

calibration.

Two calibration points may be entered for each channel. After CALPT1 is

entered the prompt for CALPT2 appears.

If only CALPT1 is entered the offset is affected.

If both CALPT1 and CALPT2 are entered, both slope and offset are

affected.

(See calibrating to the freezing/boiling points of water on page 53, for an

example.)

(continued on next page)

50

Page 52

Front panel displays and controls continued

How to do a field calibration continued

NUM

1

STORE2 LOG 3RECALL

2e

2a

2d

5

4

PRINT

3

5

MAX

2b

CAL

6

MIN

2c

7

AVG

4

MENU

°F

8

HOLD

9

SCAN

EXIT

+ALARM

0

CLEAR

To do a field calibration continued:

1. Place the probe(s) at the desired temperature.

2. Push and release MENU until the display reads CALPT1, 2a.

The entry point 2b flashes.

CAL 2c is displayed. The channel number 2d is displa yed.

NUM 2e appears and flashes indicating number keys 3 are active.

3. Push number keys to enter the temperature of the first calibration

point. (For example, 32.0 is entered by pushing 3 - 2 - 0.)

4. Use Left/Right keys to select ne xt channel. Do all CALPT1's first.

5. Push MENU to switch to CALPT2.

CALPT 2 is skipped if no changes are made in CALPT1.

2, 5

MENU

NUM

1

STORE2 LOG 3RECALL

°F

5

4

PRINT

5

MAX

CAL

6

MIN

7

AVG

8

HOLD9SCAN

EXIT

+ALARM

0

CLEAR

7

6. Place the probe(s) at the desired temperature.

7. Push and release number keys 7 to enter the temperature of the

second calibration point. (For example, 212.0 is entered by

pushing 2 - 1 - 2 - 0.)

(continued on next page)

51

Page 53

Front panel displays and controls continued

How to do a field calibration continued

9b

MENU

EXIT

9

SCAN

+ALARM

0

CLEAR

PRINT CAL

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

6

MIN

7

AVG

8

HOLD

To do a field calibration continued:

8. Push Left or Right arrow keys to switch channels and enter their

CALPT2, or if desired,

9a. Push EXIT to save the setting and return to scanning, or

9b. Push MENU to switch to the next setup topic (cal report).

9a

8

52

Page 54

Front panel displays and controls continued

How to print a calibration report

Note: This is only valid if an optional parallel printer is attached to the

DB-25 (M) input connection. Alternately, this report may be obtained

through “ScanLink”.

1b

2

1a, 3a

1c, 3b

PRINT CAL

1

STORE2 LOG 3RECALL

4

PRINT

5

MAX

6

MIN

7

AVG

8

HOLD

9

SCAN

MENU

EXIT

+ALARM

0

CLEAR

To print a calibration report:

1. If MENU 1a is pushed the display REPORT NO with NO 1b

flashing appears. Push MENU 1a or EXIT 1c to skip printing a

calibration report, or

2. Push either of the Up or Down arrow keys 2 to choose to print a

calibration report.

3. Push MENU 3a or EXIT 3b to save the setup (all setup changes

since MENU was first pushed), print the calibration report (if YES

was chosen) and return to scanning.

Example field calibration report °C:

Note: Service field calibration can only be performed by an authorized

service facility. Contact your authorized dealer for information.

Service calibration performed on 04/09/98 at 13:28:47

Field calibration status as of 04/09/98 14:11:50, scale = C

Ch CalPt.1 Change CalPt.2 Change Date Time

------- ------ ------- ------ -------- -------1 None 0.0 None 0.0 04/09/98 14:01:45

2 -16.7 0.0 482.3 0.0 04/09/98 13:58:51

3 -16.1 0.0 482.4 0.4 04/09/98 13:58:51

4 -15.5 0.1 482.5 0.2 04/09/98 13:58:51

5 -15.0 0.1 482.5 0.2 04/09/98 13:58:51

6 -14.4 0.1 482.6 0.4 04/09/98 13:58:51

7 -13.9 0.1 482.6 0.3 04/09/98 13:58:51

8 -13.3 -0.1 482.7 0.6 04/09/98 13:58:51

9 -12.8 0.0 482.7 0.5 04/09/98 13:58:51

10 -12.2 0.0 482.8 0.5 04/09/98 13:58:51

11 -11.7 0.0 482.8 0.6 04/09/98 13:58:51

12 -11.1 0.0 482.9 0.7 04/09/98 13:58:51

53

Page 55

Front panel displays and controls continued

How to print a calibration report continued

To print a calibration report continued:

Example field calibration report °F:

Service calibration performed on 04/09/98 at 13:28:47

Field calibration status as of 04/09/98 14:12:41, scale = F

Ch CalPt.1 Change CalPt.2 Change Date Time

------- ------ ------- ------ -------- -------1 None 0.0 None 0.0 04/09/98 14:01:45

2 2.0 0.0 900.2 0.1 04/09/98 13:58:51

3 3.0 0.0 900.3 0.7 04/09/98 13:58:51

4 4.0 0.2 900.4 0.4 04/09/98 13:58:51

5 5.0 0.1 900.5 0.4 04/09/98 13:58:51

6 6.0 0.1 900.6 0.6 04/09/98 13:58:51

7 7.0 0.1 900.7 0.6 04/09/98 13:58:51

8 8.0 -0.2 900.8 1.0 04/09/98 13:58:51

9 9.0 0.0 900.9 1.0 04/09/98 13:58:51

10 10.0 0.0 901.0 0.9 04/09/98 13:58:51

11 11.0 0.0 901.1 1.1 04/09/98 13:58:51

12 12.0 0.0 901.2 1.2 04/09/98 13:58:51

54

Page 56

Front panel displays and controls continued

How to calibrate to water

How to calibrate to water

Ice Point

Calibrate CALPT1 to the freezing point of water (0°C or 32°F) by using

crushed ice made of distilled water. Immerse the probe in a flask

(insulated) filled with crushed ice and topped off with distilled water.

Add crushed ice to keep the flask full of crushed ice and water during

calibration.

Boiling Point

Calibrate CALPT2 to the boiling point of water (100°C or 212°F) by using

distilled water and correcting for altitude and barometric pressure. As a

rule of thumb the boiling point of water decreases 1°C or 1.8°F for every

1000 feet above sea level. Correction for barometric pressure is usually

required only in the case of severe high or low pressure weather conditions.

Note: This method is less accurate than using a dry block calibrator or a

thermocouple calibration furnace. Boiling point calibration is only recommended when this equipment is not available and two point calibration is

required.

55

Page 57

Power up modes

Power up modes are special ways to clear memory or defaults during

power up.

To activate a power up mode:

MODEL ####-##

Mfg. By Barnant Company

Barrington, IL 60010-2392

12 CHANNEL TERMOCOUPLE SCANNER

1

7

2

8

10-28 VDC

7-20 VAC

500 MA

PC/IN

3

9

RS232

OUT/LINK

10

4

5

11

PARALLEL PRINTER

USA

12

6

TRIGGER

+ GND

21

1. Turn off the power using the power switch on the back of the

instrument ( ).

2. Turn power back on ( ) and before the instrument completes the

display check,

2a. (before the small 12 turns off).

NUM HOLD MAX PRINT AVG LOG STORE RECALL CAL MIN ALARM LO HI

Push and hold:

CLEAR & MENU to clear a service calibration and revert

to factory calibration, or

56

11

12

°F

°C

°R

K

2a

Page 58

Power up modes continued

Maintenance

Care and cleaning

Push and hold: MIN & MAX to restore factory MENU defaults, or

Push and hold: MENU to display the firmware version.

Push EXIT or CLEAR to switch to the scanning display.

Care and Cleaning

Clean the case by using a mild detergent. Avoid immersion and

excess liquid.

57

Page 59

Maintenance

Battery

Battery

A lithium battery retains the date and time when power is off or the

instrument is disconnected from its power source.