Page 1

Instruction Manual

Single-Input

RTD Thermometer

(Model 91428-07)

68X001350 Rev0 0717 065DGMAN_91428-07

Page 2

Page 3

TABLE OF CONTENTS

QUICK-START GUIDE ............................. 1

1. INTRODUCTION ................................ 2

2. SAFETY PRECAUTIONS ................... 3

3. SPECIFICATIONS .............................. 4

4. BATTERY INSTALLATION AND

REPLACEMENT ................................. 6

5. INSERTING AND REMOVING

OPTIONAL RUBBER ARMOR ............ 7

6. ASSEMBLING OPTIONAL HANDS-

FREE ACCESORIES .......................... 8

7. CONNECTING AN RTD PROBE ........ 9

8. KEY FUNCTIONS ..............................10

9. DISPLAY OVERVIEW .......................11

10. MEASUREMENT MODE ...................12

11. SELECTING TEMPERATURE

SCALE ..............................................13

12. MIN AND MAX FUNCTION ................14

13. AUTO OFF FUNCTION .....................14

14. CALIBRATION ...................................15

15. CLEAR FIELD CALIBRATION ...........16

16. FIELD CALIBRATION UNLOCK ........16

17. FIELD CALIBRATION LOCKOUT ......17

18. MAINTENANCE .................................18

19. CLEANING ........................................18

20. TROUBLESHOOTING .......................19

21. SERVICE ...........................................20

22. REPLACEMENT METER &

ACCESSORIES .................................20

23. WARRANTY ......................................21

24. PRODUCT RETURN .........................21

25. INNOCAL® CALIBRATION AND

REPAIR SERVICES ..........................22

Page 4

- 1 -

QUICK-

START

GUIDE

To ensure best results please read the

complete manual.

1. Connect probe.

2. Press the on/off key.

Press again to turn on backlight.

3. Select °C or °F display using °C/°F key.

4. Insert probe in sample.

Allow adequate time for reading to

stabilize.

Response time will vary depending on

probe.

5. Take reading.

Press hold key to freeze display.

Press min/max to display minimum or

maximum temperature.

6. Press and hold the on/off key for three

seconds to turn meter off.

Page 5

- 2 -

1. INTRODUCTION

This versatile handheld

instrument provides highly

accurate temperature

measurements and is

designed for easy operation,

which includes the following

features:

• Operator selection of Celsius or

Fahrenheit scale

• Resolution of 0.1° (auto ranging)

• Four-digit backlit LCD

• Hold feature to retain a reading

temporarily

• Field calibration capability

• Low-battery warning

• Auto power off with Enable/Disable

function

• Min and Max readings display

• 3-pin circular connector input

• Operates with a wide selection of

probes

Page 6

- 3 -

2. SAFETY PRECAUTIONS

Voltages present at the RTD may also be

present at the battery terminals. Always

disconnect the RTD when changing

batteries.

This instrument is designed to accept low

level signals supplied by standard 100 Ω

RTDs. Under no circumstances should the

input voltage exceed the specified 10V rms.

1. Do not use or store this instrument in

microwave ovens or any abnormally

hot or cold areas.

2. Weak batteries should not be left in the

instrument. Dead batteries can leak and

cause damage to unit.

WWARNING

Page 7

- 4 -

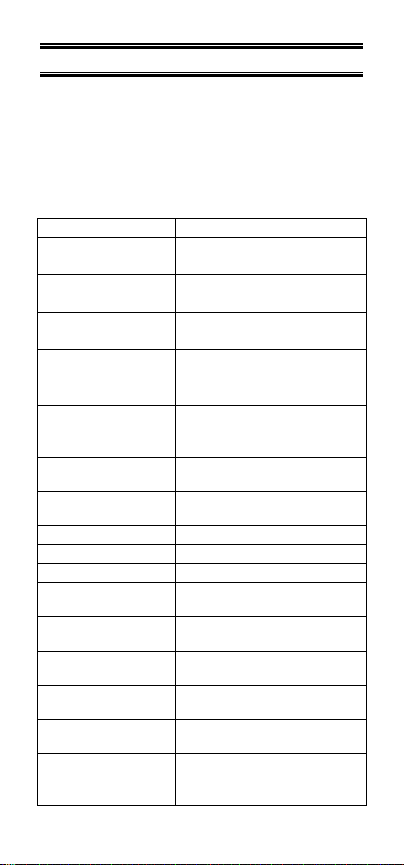

3. SPECIFICATIONS

Platinum RTD Probes

100 ohm platinum: alpha = 0.003850

–200 to 850°C (–392 to 1562°F)

Out-of-range display: “Ur”, “Or”, “OPEN”

Range

Accuracy

–200.0 to –100.0°C

(–392 to –148°F)

±2.0°C

(±4.0°F)

–99.9 to 199.9°C

(–148 to 392°F)

±0.2°C

(±0.4°F)

200.0 to 850.0°C

(392 to 1562°F)

±2.0°C

(±4.0°F)

Resolution

0.1° (–200.0 to 850.0°C);

0.1° (–392.0 to 999.9°F);

1° (1000 to 1562°F)

Display

4-digit LCD (¼ x ½" digits);

2 1/3 x 1 ½" backlit viewing

area

Display update

rate

0.5 sec per update

Input

One probe with 3 pin circular

connector (Switchcraft TA3F)

Input protection

10V rms

Battery

Three AA, 1.5V alkaline

Battery life

700 hours continuous

Auto shutoff

17 minutes after last

keypress

Stated accuracy

18 to 28°C

(64 to 82°F)

Useful range

0 to 40°C

(32 to 104°F)

Storage

–40 to 65°C

(–40 to 149°F)

Humidity

10% to 90% RH

(noncondensing)

Dimensions

Without armor

With armor

(L x W x H )

175 mm x 97 mm x 42 mm

180 mm x 102 mm x 52 mm

Page 8

- 5 -

Weight

Without armor

With armor

267 g

362 g

Ingress protection

(with probe

attached)

Meets IEC-529 IP54 for

dust and water-resistant

enclosures

CE compliance

EN61326-1/A1:

1998 (EU EMC Directive)

Page 9

- 6 -

4. BATTERY INSTALLATION AND

REPLACEMENT

Voltages present at the RTD may also be

present at the battery terminals. Always

disconnect the RTD when changing

batteries.

Weak batteries should not be left in the

instrument. Dead batteries can leak and

cause damage to unit.

The typical battery life is about 700 hours.

Selected settings are stored in memory and

will remain in memory even after power is

turned off, or while batteries are being

replaced.

1. Before

changing

battery, tur

n

instrume

nt off

and disconnect probe

.

2.

Loosen screw and

lift battery

cover

off

the

back

of case.

3.

Remove

the t

hree

AA batteries.

4. Insert three

new

batteries

observing

pol

arity.

5.

Install

cover and

tighten

screw

.

Page 10

- 7 -

5. INSERTING AND REMOVING

OPTIONAL RUBBER ARMOR

Figure 1: Removing Optional Rubber Armor

1. To insert thermometer into the optional

rubber armor, slide in from the top of

meter before pushing the bottom edges

of meter down to set it into position. Lift

up the stand at the back of meter for

bench top applications if necessary.

2. To remove thermometer from armor,

push out from the bottom edges of meter

until it is completely out of boot.

Page 11

- 8 -

6. ASSEMBLING OPTIONAL

HANDS-FREE

ACCESORIES

You can use the optional magnets and

strap in the Hands-Free Kit accessories for

hands-free operations.

Figure 2: Hands-Free Kit

Page 12

- 9 -

7.

CONNECTING

AN RTD PROBE

Use the correct 100 Ω RTD (alpha =

0.003850) for your instrument. Using an

incorrect probe type will result in erroneous

readings. Insert the 3-pin plug into the

mating connector on the top of the

instrument.

Figure 3: Top view of RTD thermometer

RTD Input

Page 13

- 10 -

8. KEY FUNCTIONS

Figure 4: Keypad

Toggles between Celsius or

Fahrenheit in measurement mode

and user calibration mode.

Press and hold this key for 3 seconds

to enter Calibration mode if field

calibration is unprotected.

Activates/deactivates freezing of the

measured reading while in

measurement mode.

Toggles between minimum and

maximum readings (MIN and MAX

readings are calculated from the last

min/max keypress).

Press and hold this key for 3

seconds to clear the MIN/MAX

reading stored.

Powers on and shuts off the

thermometer by holding it for

3 seconds.

Press this key to activate/ deactivate

the backlight display. (Backlight will

automatically turn off within 30

seconds of activation).

°C/°F

cal

hold

min

max

on/off

light

Page 14

- 11 -

9. DISPLAY OVERVIEW

Figure 5: Meter Display

°C/°F

Celsius or Fahrenheit indicator.

MIN

Minimum reading annunciator.

MAX

Maximum reading annunciator.

3 Bars: 700 – 550 hours

2 Bars: 350 – 550 hours

1 Bar: 150 – 350 hours

Blinking: < 150 hours

CAL

Blinks during calibration mode.

Remains in display indicating

field calibration is active.

HOLD

Remain in display during hold

mode.

STABLE

Displayed upon recognizing

final value.

Page 15

- 12 -

10. MEASUREMENT MODE

Press the on/off key. The thermometer

performs a self-test and all display digits

and indicators should remain on for

approximately two seconds before the

meter enters measurement mode.

If a probe is not connected or if the probe is

defective, the display will indicate “OPEN”.

Figure 6: Display when no probe is detected

For optimum instrument accuracy, allow one

minute for ambient temperature stabilization.

If the unit has been stored at an extreme

ambient condition, more time will be needed.

A STABLE indicator appears at the top right

corner of the display when reading is

continuously stable for 5 seconds.

To freeze reading, press hold. Press hold

key again to release the reading and resume

normal operation.

Figure 7: HOLD and STABLE function

The display will show “Ur” (under range) or

“Or” (over range) if the temperature reading

is out of range of the instrument.

°c

°c

HOLD STABLE

Page 16

- 13 -

11. SELECTING TEMPERATURE

SCALE

Figure 8: Press °C/°F key to toggle

between °C and °F

Select °C or °F by pressing the °C/°F key.

Each time the key is pressed, the

temperature scale will switch. Switching

between °C and °F can be done at any time

during operation.

Each time you turn the instrument on, it will

power up with the same settings that were

set when the unit was last turned off.

°c

°F

°C/°F

Page 17

- 14 -

12. MIN AND MAX FUNCTION

Press the min/max key to toggle between

the minimum and maximum readings. The

minimum and maximum reading function is

ideal for monitoring unattended operations

while continually displaying every

temperature change that occurs. The

minimum and maximum values are sensed

and automatically stored. To exit and clear

the MIN/MAX reading stored, press and hold

the min/max key for 3 seconds.

13. AUTO OFF FUNCTION

The thermometer has a default auto off

function of 17 minutes.

To deactivate this function, press the

min/max key while turning the thermometer

on with the on/off key. “A.OFF no” flashes

to show indicate that the auto off function

has been disabled for that session.

Figure 9: Disabling the auto off function

Page 18

- 15 -

14. CALIBRATION

The CAL function allows single point

calibration of the thermometer at 0°C (32°F)

to compensate for probe offset error. Use

the field calibration feature to improve

thermometer/probe accuracy.

The thermometer comes with a calibration

lock function to prevent accidental changes

to calibration settings. A field calibration can

only be performed when the function has

been unlocked. To unlock field calibration,

follow steps 1 through 4 in FIELD

CALIBRATION UNLOCK section.

To calibrate:

1. Pack sensing end of probe in a

container tightly packed with crushed ice

and filled with distilled water. Allow

temperature to stabilize.

2. Press and release the cal key for

3 seconds to enter the calibration

mode. The CAL indicator starts blinking.

Release the cal key.

3. If the measured temperature is from

–5°C to 5°C (23 to 41°F) when the

temperature reading is stable, press

the cal key.

The CAL indicator will stop blinking, and the

reading will be set to 0°C (32°F). The CAL

indicator will remain in display, indicating

that field calibration is now active.

If “Err” is displayed, the displayed reading

is outside the above limits.

NOTE: Press any key (except the cal key)

while in calibration mode to abort calibration.

Page 19

- 16 -

15. CLEAR FIELD CALIBRATION

To clear user calibration:

1. Turn the thermometer off.

2. Hold the cal key down while pressing

the on/off key.

3. The measurement mode window

appears without the CAL indicator to

indicate that the user calibration has

been successfully cleared.

16. FIELD CALIBRATION UNLOCK

The calibration unlock feature enables field

calibration operation. To unlock field

calibration:

1. Turn the thermometer off.

2. Hold the cal key and hold key down

simultaneously, then press the on/off

key.

3. The “CAL” indicator appears

momentarily with the version-model

window to indicate that the usercalibration function has been unlocked

successfully (Figure 10).

Figure 10: Successful field calibration unlock

CAL

Page 20

- 17 -

4. When the cal and hold keys are

released, the unit will go to

measurement mode (Figure 11).

Figure 11: Unit goes to measurement mode

17.

FIELD CALIBRATION LOCKOUT

The calibration lockout feature prevents any

field calibration changes. The lockout

remains in effect until an unlock has been

performed. To lock the field calibration

operation:

1. Turn the thermometer off.

2. Hold the cal key and °C/°F key down

simultaneously, then press the on/off

key. Do not release cal and °C/°F keys

until the measurement mode is on

display.

3. If field calibration lockout is successful,

the version-model window appears

without the CAL indicator (Figure 12).

Figure 12: Successful field calibration lockout

°c

STABLE

Page 21

- 18 -

4. When the cal and °C/°F keys are

released, the unit will return to

measurement mode (Figure 13).

Figure 13: Unit returns to measurement mode

18. MAINTENANCE

Properly used, the thermometer should

maintain calibration indefinitely and not

require service other than occasional

cleaning of the housing and changing of the

batteries. Do not clean with abrasives or

solvents. Use mild detergents; never

immerse nor use excessive fluid.

19. CLEANING

WARNING:

TO PREVENT IGNITION OF A

HAZARDOUS ATMOSPHERE BY

ELECTROSTATIC DISCHARGE, CLEAN

WITH DAMP CLOTH.

Do not clean with abrasives or solvents.

Use mild detergents, never immerse nor

use excessive fluid.

°c

STABLE

Page 22

- 19 -

20. TROUBLESHOOTING

Problem

Cause

Solution

Power on

but no

display

Batteries not in

place or wrong

polarity.

Insert batteries.

or re-insert

batteries in

correct polarity.

“OPEN”

display

on LCD

Probe not

connected

Make sure

probe is firmly

connected.

“Ur” or

“Or”

display

on LCD

Measurement

over (Or) or

Under (Ur)

range

Ensure

temperature

taken is within

meter’s

specification.

Unstable

reading

1. Probe not

deep enough

in sample

2. Broken probe

1. Place probe

deeper in

sample.

2. Replace

probe.

Slow

response

Dirty probe

Clean probe

Page 23

- 20 -

21. SERVICE

There are no internal adjustments or user

replaceable parts.

Note: Serial number label is located behind

the meter.

22. REPLACEMENT METER &

ACCESSORIES

Item

Catalog

number

Single-input RTD thermometer

91428-07

Rubber armor with stand

35427-80

Hands-free kit (two magnets

and a strap)

35427-85

General-purpose probe,

10 in. long x 0.188 in. dia,

10-second time constant.

08117-70

PTFE-coated generalpurpose probe,

10 in. long x 0.145 in. dia,

15-second time constant.

08117-87

Penetration probe,

4 in. long x 0.188 in. dia,

sharp tip,

10-second time constant.

08117-85

Surface probe,

8 in. long with 0.25 in. dia,

aluminum and ceramic tip,

24-second time constant.

08117-75

Air/gas probe,

10 in. long sheath with 0.25

in. dia radiant heat shield.

4-second time constant.

08117-90

Page 24

- 21 -

23. WARRANTY

The Manufacturer warrants this product to

be free from significant deviations from

published specifications for a period of

three years. If repair or adjustment is

necessary within the warranty period, the

problem will be corrected at no charge if it is

not due to misuse or abuse on your part as

determined by the Manufacturer. Repair

costs outside the warranty period, or those

resulting from product misuse or abuse,

may be invoiced to you.

24.

PRODUCT RETURN

To limit charges and delays, contact the

seller or Manufacturer for authorization and

shipping instructions before returning the

product, either within or outside of the

warranty period. When returning the

product, please state the reason for the

return. For your protection, pack the

carefully and insure it against possible

damage or loss. The Manufacturer will not

be responsible for damage resulting from

careless or insufficient packing.

Page 25

- 22 -

25. INNOCAL® CALIBRATION AND

REPAIR SERVICES

Optimum performance of your temperaturemeasuring instrument is not a timeless

condition. To ensure quality measurements,

have your instrument calibrated regularly.

Trust InnoCal to satisfy your calibration and

equipment repair needs. With over a decade

of service, we've helped thousands of

customers meet ISO, FDA, EPA,

GLPs/cGMPs and other quality standards.

Conformity*

ISO/IEC 17025:2005 accredited

NIST Handbook 150, 2000 Edition

ANSI/NCSL Z540-2-1997

NIST Technical Note 1297

ISO 9000:2000

Fast Service

Our substantial inventory of replacement

parts ensures a fast turnaround and

prevents costly downtime. Most instruments

serviced in five business days!

Excellent Value

Get quality at a fair price. Our InnoCal

NIST-traceable certificates offer extensive

test data on a broad range of measurement

parameters without breaking the bank!

Reliable Support

Trust in our free diagnostic support and

troubleshooting advice. Our factory-trained

metrologists and technicians are armed

with years of experience and extensive

technical data.

Page 26

- 23 -

Convenient Reminders

It’s so easy to keep your instruments

functioning properly. Based on your

requirements, InnoCal will send you a

reminder when it’s time to re-certify or

service your instrument.

We provide you with the documentation you

need to meet your most stringent quality

requirements for the control of inspection,

measuring, and test equipment.

Certification includes certificate of

calibration with test data, including:

• Description and identification of the

item certified

• Condition of the item

• Issue date

• Identification of calibration procedure

• Calibration date

• As found/as left test data (where

applicable)

• Signature of technician

• Statement of estimated uncertainty

• List of equipment used to perform

calibration (including their calibration

dates)

With today's high quality standards such

as ISO 9000, certification is becoming

increasingly important. Traceability is not a

timeless condition. It must be verified and

maintained over the life of the calibration to

ensure the highest accuracy possible. When

you have your calibration done by InnoCal,

we will send you an automatic reminder

when it is time to recalibrate your

instrument.

Page 27

- 24 -

Are your calibration certificates

good enough?

InnoCal surpasses the competition by

providing the most complete certificates as

required by NIST. All of our certificates

include measured data and point-by-point

measurement uncertainty, and by request,

we will provide test accuracy and test

uncertainty ratios at no extra cost.

Call us today and see why InnoCal is

The Choice of Quality.

*See our Scope of Accreditation for any

limitations.

Calibration

test points

against NIST-

traceable

standards

Meter

only

Probe

only

System

(meter +

probe)*

Four test

points across

range of

instrument.

17000-04

17001-04

17002-04

InnoCal—The Choice of Quality

866-INNOCAL (866-466-6225)

InnoCalSolutions.com

For calibration services outside of North

America, please contact your Local

Distributors or Local Certification Body.

Page 28

- 25 -

TECHNICAL ASSISTANCE

If you have any questions about the

use of this product, please contact

the Manufacturer or authorized

seller.

For more information, contact:

Cole-Parmer

Toll-Free: 1-800-323-4340

Phone: 1-847-549-7600

Fax: 1-847-247-2929

ColeParmer.com/Digi-Sense

1065DGMAN_91428-07

Loading...

Loading...