Page 1

SPECIFICATIONS

Range: -58.0 to 1832.0 °F

-50.0 to 1000.0 °C

Resolution: 0.1°

OPERATION

Press and continue to hold down the trigger to

take temperature readings. The unit will take

temperature readings while the trigger is pressed

and held (SCAN ashing on the display indicates

measurements are being taken).

After the trigger is released, the last temperature

measured will be displayed for approximately 8

seconds, the display will then turn off automatically.

HOLD will appear on the display when the trigger

has been released to indicate that the unit is no

longer taking temperature measurements.

SWITCH LOCATIONS

The following switches are located in the handle:

°C/°F

LOCK ON/OFF

SET ALARM ON/OFF

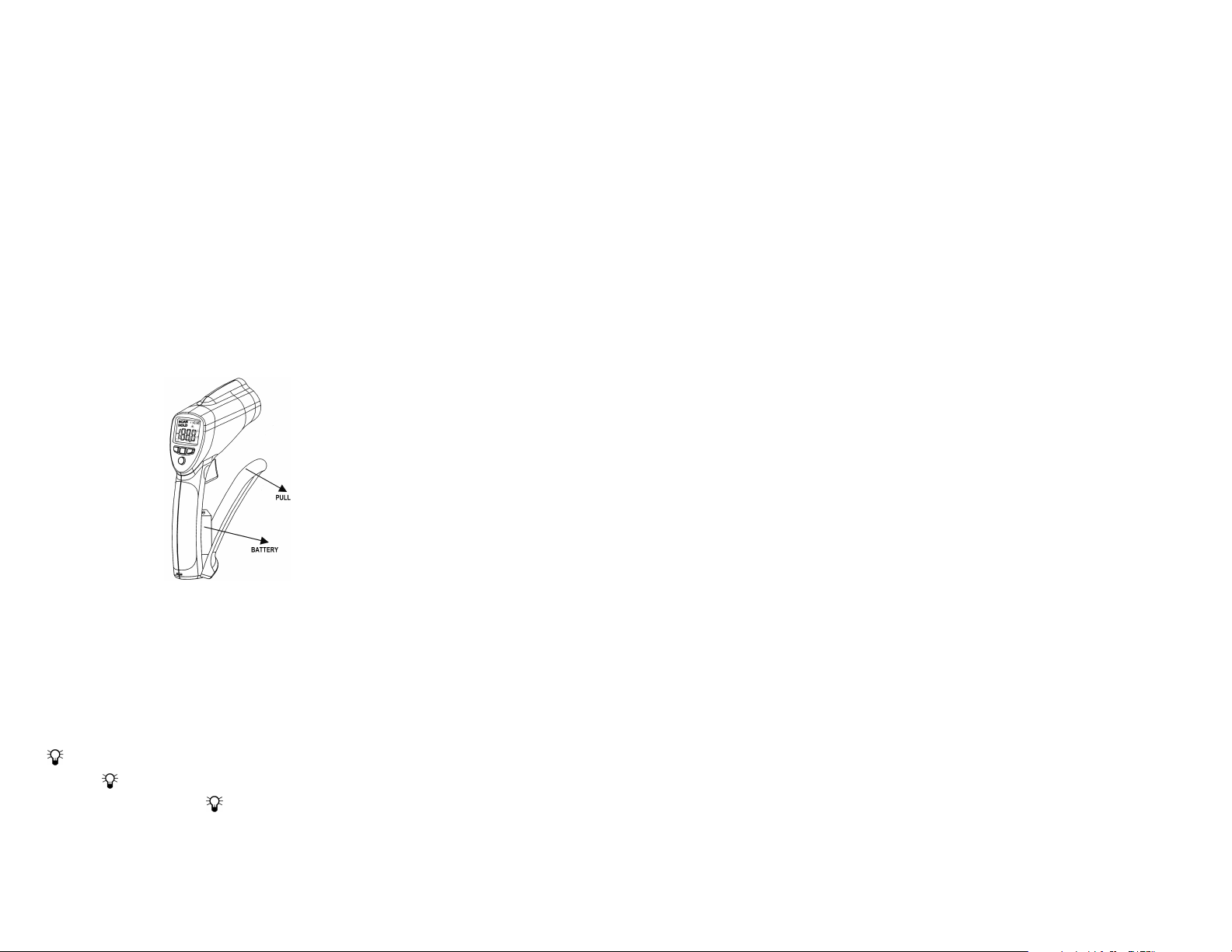

To access these switches,

locate the indentions on

either side of the plastic

case near the trigger.

Open the handle by pulling

the rubber portion of the

handle out and away from

the trigger. Pull hard, it

requires a good amount of

force to open the handle.

Close the handle by snapping it shut.

SELECTING UNITS OF MEASURE

Locate the °C/°F switch inside the handle. Slide the

switch to °C to display the temperature in °C. Slide

the switch to °F to display the temperature in °F.

LASER TARGETING/BACKLIGHT

While pressing and holding the trigger, each press

ð

the /

button toggles through the following:

r

Backlight ON ( appears on the display)

Backlight and Laser Targeting ON ( and

ð

r

appear on the display)

Laser Targeting ON, Backlight OFF (

ð

r

appears

on the display)

Backlight and Laser Targeting OFF (no display

indicators)

With the backlight on, each time the trigger

is pressed and held, the LCD display will be

illuminated by the backlight.

With laser targeting on, each time the trigger is

pressed and held, the laser beam will be emitted.

CAUTION: Eye damage may result from direct

exposure to laser light.

DISTANCE SPOT/RATIO

There are other factors that may affect measurement

accuracy. The target must completely ll the spot

diameter seen by the infrared sensor; otherwise

readings will be inuenced by the surface

surrounding the target. The ratio of the distance to

the size of the spot being measured is 50:1. For

example, an object’s diameter of 100mm can be

measured from 5000mm.

VALUES RECORDED

With each press of the trigger, ve values are

recorded:

1. MAX - Highest temperature measured

2. MIN - Lowest temperature measured.

3. dIF - Difference between MAX and MIN

4. AVG - Time-weighted average temperature.

5. Value last displayed before releasing the trigger.

DISPLAY MODES

Each press of the MODE button will select one of

the 7 display modes. You can cycle through the

modes in this order:

“MAX” (Maximum temperature) - press the MODE

button until MAX appears on the display. In the

MAX mode the highest temperature measurement

taken is displayed to the right of MAX. This value

will update each time a higher temperature is

measured.

“MIN” (Minimum temperature) - Press the MODE

button until MIN appears on the display. In MIN

mode, the lowest temperature measurement taken

is displayed to the right of MIN. This value will

update each time a new lower temperature is

measured.

“dIF“ (Temperature differential between MAX and

MIN) - Press the MODE button until dIF appears

on the display. The difference between the MAX

and MIN reading is displayed to the right of dIF.

This value is updated as new MAX and MIN

temperatures are measured.

“AVG” (Calculated {time weighted} average

temperature)- Press the MODE button until AVG

appears on the display. The time weighted average

temperature reading is displayed to the right of

AVG. This value is updated continuously while

the trigger is being pressed.

The term “time”, in reference to the averaging

mode, means all temperature measurements

are averaged together from the rst press of

the trigger. Example: If the temperature was

72° for one minute, then 20° for 1/2 second, no

signicant change in average temperature would

be displayed.

“HAL” (High Temperature Alarm) - Press the

MODE button until HAL appears on the display.

The high temperature alarm value that has been

set is displayed to the left of HAL. (See High/

Low Alarms section)

“LAL” (Low Temperature Alarm) - Press the

MODE button until LAL appears on the display.

The low temperature alarm value that has been set

is displayed to the left of LAL. (See High/Low

Alarms section)

“EMS” - Emissivity adjustment mode (See the

Emissivity section).

NOTE: The last mode selected will remain selected

the next time the trigger is pressed.

MEMORY RECALL

With each press of the trigger, ve values are

recorded:

1. MAX - Highest temperature measured

2. MIN - Lowest temperature measured.

3. dIF - Difference between MAX and MIN

4. AVG - Time-weighted average temperature.

5. The value last displayed before releasing the

trigger.

To cycle through each of the values recorded

during the last measurement, press the MODE

button. (See the “Display Modes” section for an

explanation of the values displayed)

HI/LOW ALARMS

An audible alarm will sound at both an upper and a

lower temperature limit.

To adjust the alarm temperature set points:

1. Press the MODE button until “HAL” (High

Temperature Alarm) or “LAL” (Low Temperature

Alarm) is displayed.

2. To adjust the temperature alarm set point, press

the p or q button. (Do not press the trigger while

adjusting the alarm set points). Press and hold to

advance the display rapidly.

To turn the Hi/Low Alarm function On/Off:

1. Locate the SET ALARM ON/OFF switch in the

handle.

2. Slide the switch to the desired position.

With the Alarm function set to ON, (indicated by

(

(

(

and

HI

)

)

) appearing on the display), while

LOW

taking temperature measurements, an alarm will

sound when the temperature measured is above or

below the High and Low alarm set points that have

been entered. If the temperature is above the High

(

Alarm set point, (

(

will ash on the display. If

HI

the temperature is below the Low Alarm set point,

)

)

) will ash on the display.

LOW

The alarm will sound regardless of the Display

Mode if the temperature measured is above or

below the High and Low alarm set points that have

been entered.

LOCK FUNCTION

The lock function allows the thermometer to take

long term measurements without having to hold the

trigger. When the lock function is activated, the unit

will take continuous temperature measurements

until the LOCK function is set to OFF.

To use the lock function:

1. Locate the LOCK ON/OFF switch in the

handle.

2. Slide the switch to the ON position.

3. Close the handle.

4. Press and release the trigger to begin taking

measurements.

The unit will continue to take measurements

without holding the trigger until the LOCK ON/

OFF switch is set to OFF.

5. When nished taking measurements, locate

the LOCK ON/OFF switch in the handle.

6. Slide the switch to the OFF position.

7. Close the handle.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

EMISSIVITY

Emissivity adjustment is optional. Emissivity

adjustments are used to provide a truer

temperature reading. The emissivity value appears

at the top of the display (ε=#.##).

Different materials radiate infrared energy at

slightly different temperatures. The emissivity

adjustment is used to compensate for different

types of materials. The default emissivity of 0.95

will cover 90% of typical applications.

The emissivity table provides a guide of different

emissivity values for different materials.

When the emissivity of an object is unknown use

a non-infrared thermometer, such as a thermom-

eter with a surface probe to measure the object’s

surface temperature. Adjust the emissivity until

the temperature of the Infrared Thermometer

SURFACE ...........................................................EMISSIVITY

Iron and Steel

Cast iron (polished) ............................................................0.2

Cast iron (tumed at 100oC) ...............................................0.45

Cast iron (tumed at 1000oC) .....................................0.6 to 0.7

Steel (ground sheet) ...........................................................0.6

Mild steel ..................................................................0.3 to 0.5

Steel plate (oxidized) ..........................................................0.9

Iron plate (rusted) ...................................................0.7 to 0.85

Cast iron (rough) rusted ....................................................0.95

Rough ingot iron .................................................................0.9

Molten cast iron ..................................................................0.3

Molten mild steel .......................................................0.3 to 0.4

Stainless steel (polished) ....................................................0.1

Stainless steel (various) ...........................................0.2 to 0.6

Aluminum

Polished aluminum ........................................................... 0.1*

Aluminum (heavily oxidized) .............................................0.25

Aluminum oxide at 260oC ...................................................0.6

Aluminum oxide at 800oC ...................................................0.3

Aluminum Alloys, various ........................................0.1 to 0.25

Brass

Brass (polished) ................................................................ 0.1*

Brass (roughened surface) .................................................0.2

Brass (oxide) ......................................................................0.6

Copper

Copper (polished) ........................................................... 0.05*

Copper (oxide) ....................................................................0.8

Molten copper ...................................................................0.15

Lead

Lead (polished) ................................................................. 0.1*

Lead (oxide at 25oC) ...........................................................0.3

Lead (oxide) ........................................................................0.6

Nickel and Its Alloys

Nickel (pure) ..................................................................... 0.1*

Nickel plate (oxide) ...................................................0.4 to 0.5

Nichrome ............................................................................0.7

Nichrome (oxide) ..............................................................0.95

Zinc (oxidized) .................................................................. 0.1*

Galvanized iron ...................................................................0.3

Tin-plated steel ................................................................. 0.1*

Gold (polished) ................................................................. 0.1*

Silver (polished) ................................................................ 0.1*

Chromium (polished) ........................................................ 0.1*

METALS (Typical Emissivity Values)

Find Quality Products Online at: sales@GlobalTestSupply.com

matches the temperature of the surface probe.

The emissivity value arrived at by this method

may be used to measure similar materials.

To adjust the emissivity (optional):

1. Press the MODE button until EMS appears on

the display.

2. To adjust the emissivity value, press the p or

q button. (Do not press the trigger while adjusting

the emissivity value). Press and hold to advance

the display rapidly.

The emissivity can be set from 0.10 to 1.00.

This emissivity value will be used for all temperature measurements until the value is re-set.

NON-METALS (Typical Emissivity Values)

SURFACE EMISSIVITY

Refractory & Building Materials

Red brick (rough) ....................................................0.75 to 0.9

Fire clay ............................................................................0.75

Asbestos ...........................................................................0.95

Concrete .............................................................................0.7

Marble .................................................................................0.9

Carborundum ....................................................................0.85

Plaster ................................................................................0.9

Alumina (ne grain) ..........................................................0.25

Alumina (coarse grain) .....................................................0.45

Silica (ne grain) .................................................................0.4

Silica (coarse grain) ..........................................................0.55

Zirconium silicate up to 500oC ..........................................0.85

Zirconium silicate at 850oC .................................................0.6

Quartz (rough) ....................................................................0.9

Carbon (graphite) .............................................................0.75

Carbon (soot) ....................................................................0.95

Timber (various) .......................................................0.8 to 0.9

Miscellaneous

Enamel (any color) .............................................................0.9

Oil paint (any color) ..........................................................0.95

Lacquer ...............................................................................0.9

Matte black paint ..................................................0.95 to 0.98

Aluminum lacquer ...............................................................0.5

Water ................................................................................0.98

Rubber (smooth) .................................................................0.9

Rubber (rough) .................................................................0.98

Plastics (various, solid) ...........................................0.8 to 0.95

Plastic lms (0.05 mm thick) ...................................0.5 to 0.95

Polythene lm (0.03 mm thick) .................................0.2 to 0.3

Rubber (smooth) .................................................................0.9

Rubber (rough) .................................................................0.98

Plastics (various, solid) ...........................................0.8 to 0.95

Plastic lms (0.05 mm thick) ...................................0.5 to 0.95

Polythene lm (0.03 mm thick) .................................0.2 to 0.3

Paper and cardboard ..........................................................0.9

Silicone polish .....................................................................0.7

*Emissivity varies with purity

www.GlobalTestSupply.com

DISPLAY MESSAGES

“1” will appear on the display when the temperature

being measured is outside the range of the unit.

ALL OPERATIONAL DIFFICULTIES

If this thermometer does not function properly for

any reason, replace the battery with a new high

quality battery (see Battery Replacement section). Low battery power can occasionally cause

any number of “apparent” operational difculties.

Replacing the battery with a new fresh battery will

solve most difculties.

BATTERY REPLACEMENT

Erratic readings, faint readings, no display, or a

battery symbol appearing on the display are all

indications that the battery

must be replaced.

Locate the indentions

on either side of the

plastic case near the

trigger. Open the battery

compartment by pulling

the rubber portion of the

handle out and away from

the trigger. Pull hard, it

requires a good amount of

force to open the battery

compartment. Remove

the exhausted battery and replace it with a new

9-volt alkaline battery. Close the battery cover by

snapping it shut.

TRACEABLE

INFRARED

THERMOMETER

INSTRUCTIONS

© 2014 92-4484-40 Rev. 0 111914

®

GUN

Loading...

Loading...