Page 1

Operation Manual

Instruction Notes for 3622561, 3622562, 3622563, 3622564

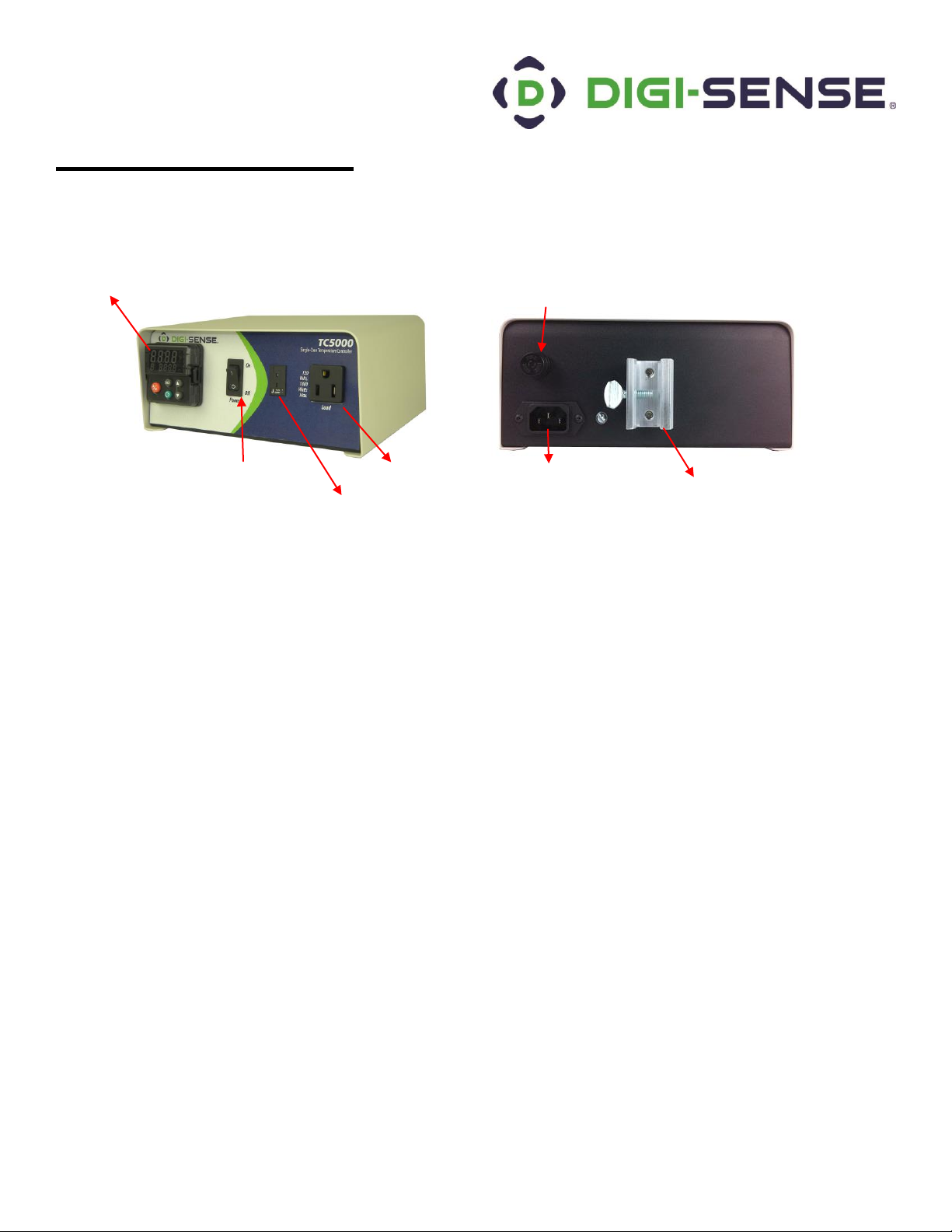

Digital Control Module

Load Fuse

ON / OFF Switch Load Outlet Power Inlet

Grid Support

General Description Sensor Input

This temperature control displays both the setpoint and process temperature and uses the most modern control

technology for the best temperature stability. The Auto-tune feature minimizes setpoint overshoot and learns your

process. Changing your setpoint is easily done with the interface keys. The controller can also perform ramp rate

operations to allow the user to slowly raise the process temperature. There are several input types available. This unit

comes with a 6’ detachable power cord, grid support bracket, which is ideal for fume hood mounting to maximize bench

space. This control is a microprocessor-based, digital indicating, automatic temperature control with a single input and a

single output. It features an auto-tuning function that allows automatic setting of control parameters with a minimum of

user input required. This family of control accepts a type "J", “K”, “T” thermocouple, or RTD (model 3622564) input

depending on the model ordered.

The control automatically sets the PID parameters through a "learning" sequence in the auto-tuning mode. PID

parameters include proportional band, reset/integral and rate/derivative. User-friendly features include automatic LED

indicators to aid in monitoring and setup, as well as dual LED displays for process temperature and set point indication.

This control automatically stores all information in a non-volatile memory.

Control Features

1. On/Off switch.

2. 15-amp output.

3. Control PID with Auto-tune algorithm, solid state relay

4. Circuit protection (fuse)

5. Low profile housing.

6. Safety feature- Output is de-energized if sensing device is unplugged or damaged.

09/14 1 Rev.5

Page 2

How to Setup and Operate

First, connect the heater load and the sensor to the load and sensor receptacles on the front panel. Next, plug the control

line cord into an appropriate 3-wire grounded power receptacle. Push the power switch to the "ON" position. Wait five

seconds for the control unit to energize.

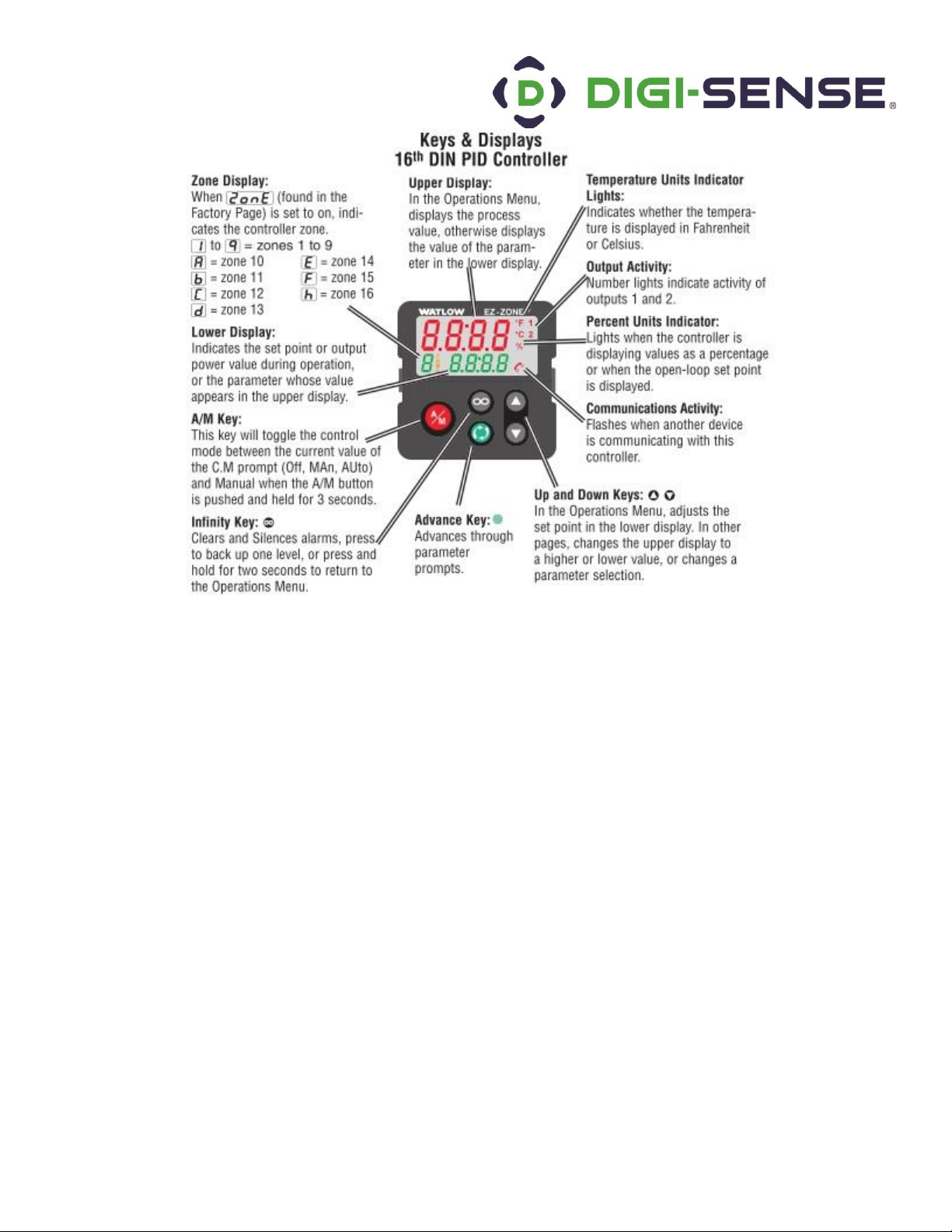

The control is shipped from the factory with the display reading in degrees C. If a display in degrees F is desirable, press

the UP/DOWN arrow keys simultaneously for three seconds to access the Setup Page. Press the Advance key until the

Celsius_Fahrenheit parameter [C-F] is shown in the lower display. Press the UP arrow key to change from C to F.

After changing the display, press the Infinity key to display the set point temperature and the process temperature

(temperature at the sensor).

To begin the heating process, use the Up/Down arrow keys to enter the desired set point temperature. This is shown in

the lower display. Auto-tuning is recommended in all applications. Auto-tuning allows the control to set the PID

parameters without those parameters being manually entered/calculated by the user. It also minimizes the amount of

temperature overshoot of the set point and decreases the time required for the process to stabilize. See page 8 for

instruction on performing the auto-tune function.

It is recommended that the auto-tune feature be used every time the process temperature set point has been changed. If

the process is being repeated, the parameters learned in the initial setup are stored in the memory of the control and the

auto-tune process isn’t required to be repeated in most applications.

09/14 2 Rev.5

Page 3

Control Sensor

Range Type J:

-200°C to 1200°C

Range Type K:

-200°C to 1370°C

Range Type T:

-200°C to 400°C

Range Type RTD:

-200°C to 800°C

Proper placement of the sensor can eliminate many problems associated in the total operation of the system. The probe

should be placed so that it can detect any temperature change with little thermal lag. In a process that requires fairly

constant heat output, the probe should be close to the heating source. In processes where heat demand is variable, the

probe should be placed close to the work area. Experimenting with probe location should be tried to provide optimum

results for your particular process.

Specifications

Control Mode

- Microprocessor-based, single input, single output.

- PID parameters

Proportional band: 1 to 999o F

Reset: 0.00 to 99.99 repeats per minute.

Integral: 0.00 to 99.99 minutes per repeat.

Rate or Derivative: 0.00 to 9.99 minutes.

Operator Interface

- Advance, Infinity, Up and Down keys, and ON/OFF switch.

- (2) 4 character LED display.

- Thermocouple receptacle and 3 wire load receptacle.

Input

- Type J, K , T thermocouple or (RTD): input grounded or ungrounded.

- Automatic cold junction compensation and break protection for sensor.

- Degrees F or degrees C display; user selectable (preset for degrees C)

Primary Output (Heating or Cooling)

- 15A @ 120VAC or 10A @ 240VAC depending on model

Accuracy

- Calibration accuracy: 0.1% of span.

- Temperature stability: 0.2 oF / oF rise in ambient maximum.

- Voltage stability: 0.01% of span / % of rated line voltage.

Power

- 50/60 Hz 5%

- Data retention upon power failure via nonvolatile memory.

Operating Environment

- 32 to 149 oF / 0 to 65 oC; 0 to 90% RH, non-condensing.

09/14 3 Rev.5

Page 4

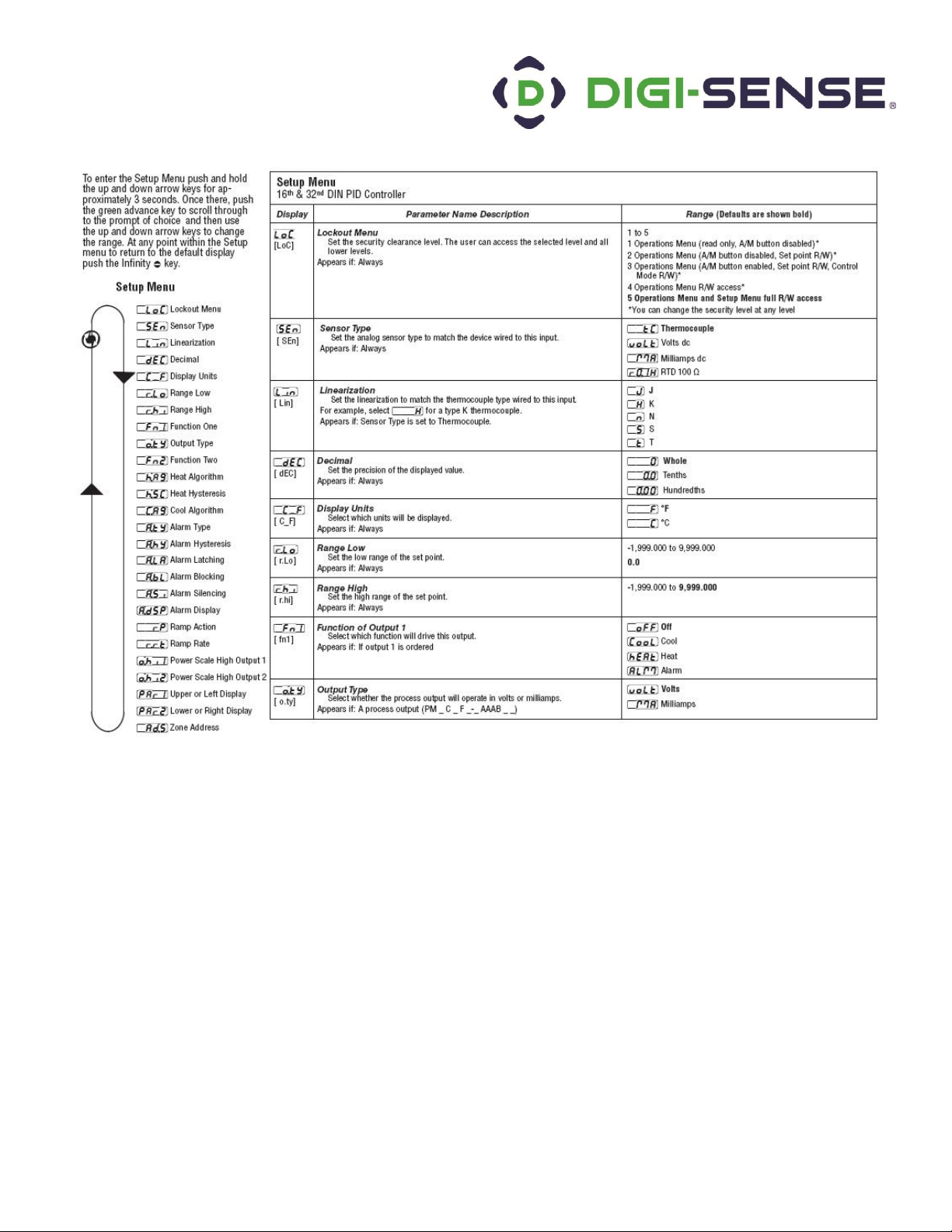

Setup Menu

09/14 4 Rev.5

Page 5

09/14 5 Rev.5

Page 6

Degrees or units per hour

09/14 6 Rev.5

Page 7

Operations Menu

How to Tune and Operate

Manual operation provides direct (time proportioned % time) control from -100% to 100%. A negative value is allowed

only when Ot 1=Cool. Automatic operation provides sensory feedback ON/OFF or PID control. When the operation

transfers from automatic to manual operation, the power level from automatic operation is retained and restored to the

previous set point.

The % LED indicates manual operation. The LED is on when in Manual operation and off when in AUTO operation.

When the LED is flashing, press the Infinity key again within 5 seconds to complete the change in operation. It the

sensor is open and LOC=0, 1 or 2, the control switches to Manual operation if the output was stable before the break

occurred.

09/14 7 Rev.5

Page 8

Tuning-Automatic

It is recommended that auto-tuning be used each time a new process is initiated. If the process is being duplicated, the

parameters learned in the initial auto tune setup are stored in the memory of the control and the auto-tune procedure isn’t

required in most applications.

Auto-tuning: This control can automatically tune the PID parameters to fit the characteristics of your particular thermal

system.

Auto-tune can only be used when Output 1 setting is hEAt and heat algorithm (h.Ag, page 5) is set for PID mode. The

heat algorithm setting is set for PID from the factory. When the auto-tune sequence has started, the lower display will

flash between tun1-attn and the main operation screen.

Changing the set point, while in auto-tune mode, will not change the set point value. The displayed value will change but

the control has locked in the original set point value tell the auto tune in complete or has been turned off by the user. Once

the control has finished "learning" the system, it returns to standard PID control with the values automatically set. Autotuning is complete within 80 minutes. In order for the control to successfully complete auto-tune, the process must cross

the 90% set point value four times within 80 minutes after auto-tune has started. If this does not happen within the 80

minute time limit, Pb1 remains at 0 and the control will operate with the factory default PID values.

To start auto-tuning:

1. Set the set point value with the arrow keys to the desired temperature of operation.

2. Press the Advance key until the Aut prompt appears in the lower display.

3. Change the parameter to YES with the arrow keys.

4. Press the Infinity key to display the set point and sensor temperatures. While the control is in the auto-tuning

mode, the display will alternate between the set point and the "Aut" prompt. When tuning is complete, the lower

display indicates only the set point.

5. When tuning is complete, the lower display indicates setpoint only and Aut reverts to OFF. The control installs

appropriate PID tuning parameters and retains them in the non-volatile memory.

*To abort auto-tuning, the operator must reset Aut to OFF. Auto-tuning may also be aborted by cycling power off and on.

In all cases, aborting auto-tuning restores all original factory default values.

09/14 8 Rev.5

Page 9

Indication

Description

Possible Causes

Corrective Action

Sensor does not provide

a valid signal to controller

Sensor improperely wired or open,

Incorrect setting or sensor type, or

Calibration corrupt

Correct wiring or replace

sensor, Match setting to

sensor , or Check

calibration of controller

Controller is autotuning

the control loop

User started the autotune function

Wait until autotune

complests or disable

autotune feature

Controller is ramping to

new set point

Ramping feature is activiated

Disable ramping feature if

not required

Sensor input above high

alarm set point

Temperature is greater than alarm set

point

Check casue of over

temperature, or Set alarm

source to proper setting

Temperature overshoot

In most cases this is due to a small sample size being heated with a high wattage heater. The control is set at the factory

with the Power Scale High Output 1 with a value of 100. This value can be adjusted in the setup menu, reference page 6

for instructions on how to change value. If excessive temperature overshoot is occurring, adjust the value to 50 and start

the heating process from ambient room temperature. If excessive temperature overshoot is still occurring, decrease to a

lower value and repeat heating process from ambient room temperature. If the process temperature never makes it to the

set point temperature value, increase the power scale high output 1 value. This process can take several value changes

to obtain proper temperature control with your particular application setup. It is recommended to initiate the Auto-Tune

process again after the proper power scale high output 1 value has been determined for your application.

Error Code Definitions and Actions:

09/14 9 Rev.5

Page 10

GLOSSARY

Automatic prompts: Data entry points where a microprocessor-based control "prompts" or asks the operator for

information input.

Auto-tune: Automatically tunes the parameters to fit the characteristics of your particular thermal system.

Cold junction compensation: Electronic means to compensate for the effect temperature at the cold junction.

Cycle time: The time necessary to complete a full On-through-Off period in a time proportioning control system.

Derivative/Rate: Anticipatory action that senses the rate of change of the process, and compensates to minimize

overshoot and undershoot.

Default parameters: The parameters (programmed instructions) permanently stored in microprocessor software to

provide the data base.

Droop: Difference in temperature between set point and stabilized process temperature.

Hysteresis: In On/Off control, the temperature change necessary to change the output from On to full Off.

Input (sensor): Process variable information being supplied to the instrument.

Integral/Reset: Control action that automatically eliminates offset, or "droop", between set point and actual process

temperature.

Offset: Adjustment to actual input temperature and to the temperature valves the control uses for display and control.

ON/OFF control: Control of temperature about a set point by turning the output full On below set point and full Off above

set point.

Output: Action in response to difference between set point and process variable.

Overshoot: Condition where temperature exceeds steeping due to initial power up or process changes.

Parameter: a physical property whose value determines the response of a electronic control to given inputs.

PID: Proportioning control with auto-reset and rate.

Process variable: Thermal system element to be regulated, such as time, temperature, relative humidity, etc.

Proportional band: Span of temperature about the set point where time proportional control action takes place.

Set point: Intended value of the process variable.

Thermal system: A regulated environment consisting of a heat source, heat transfer medium, sensing device and a

process variable control.

Thermocouple: Temperature sensing device that is constructed of two dissimilar metals wherein a measurable,

predicative voltage is generated corresponding to temperature.

Thermocouple break protection: Fail-safe operation that assures output shutdown upon an open thermocouple condition.

Time Proportioning Control: Action which varies the amount of ON and OFF time when "close" to the set point (within the

proportional band). This variance is proportional to the difference between the set point and the actual process

temperature.

09/14 10 Rev.5

Page 11

Digi-Sense

625 East Bunker Court, MS 18

Vernon Hills, Illinois 60061-1844, U.S.A

Phone: 847-549-7600 Fax: 847-549-7676

( 800) 323-4340

Maintenance

Simple preventative maintenance steps include keeping the controller clean. Protect it from overload, excessive dirt, oil

and corrosion.

Warranty

Digi-Sense, for itself does hereby offer a warranty for products from the date of receipt by the user, under normal and

proper usage, against defects in workmanship and materials for 12 months, and will repair or replace any defective

part(s) without charge when same is shipped Prepaid to Digi-Sense from which the product was originally purchased.

Should the nature of any defect require that the product, or any constituent portion thereof, be returned to Digi-Sense,

Vernon Hill, Illinois, prepaid for service, a condition precedent to any return shall be the procurement of authorization from

Digi-Sense assigning a Return Goods Number to the product or part requiring service.

Parts and accessories manufactured by others are warranted only to the extent of the regular warranty of the

manufacturer or supplier of such materials and only insofar as Digi-Sense is able to transfer the benefits of warranty

coverage, if any, to the user. Any adequately warranted defective part or accessory manufactured or supplied by others

may be exchanged through Digi-Sense for a replacement part is shipped prepaid and received at Digi-Sense within 30

days from the date any replacement part is obtained by the user.

This warranty supersedes and is given in lieu of all implied warranties, and is void if the user causes damages from

improper usage of product under normal operating conditions.

12 MONTHS LIMITED WARRANTY ON ALL PARTS AND LABOR IS GIVEN BY DIGI-SENSE.

CATALOG NUMBER 3622561, 3622562, 3622563, or 3622564

SERIAL NUMBER _________

DATE OF PURCHASE _______________

09/14 11 Rev.5

Loading...

Loading...