Page 1

Multifunction Food Safety Thermometer

Scan

Monitor

Probe

Food Safety Thermometer

35625-40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

InfraredProbe

3

IR Channel -35ºC to 275ºC (-30ºF to 525ºF)Temperature Range

Food Safety Thermometer Specifications and Features

Accuracy

Assumes ambient operating

temperature of 23ºC ±2º

(73ºF ±4ºF)

Between 0ºC and 65ºC (32 to 150ºF): ±1ºC (±2ºF)

Below 0ºC (32ºF): ±1ºC (±2ºF) ±0.1

degree/degree

Above 65ºC (150ºF): ±1.5% of reading

<500ms after initial reading

Response Time

8-14 microns

Spectral response

Pre-set at 0.97

Emissivity

2:5:1 @ 90% energy, typical

Distance to Spot Size*

Optical Resolution (D:S)

≈12mm to 300mm (≈0.5” to 12”)

Typical Working Range

(target illumination)

12mm (0.5”)

Minimum Target Size

13mm (0.52”)

Illumination to IR

Channel Offset

-40ºC to 200ºC (-40ºF to 390ºF)

Temperature Range

Accuracy

Assumes ambient operating

temperature of 23ºC ±2º

(73ºF ±4ºF)

Between -5ºC and 65ºC (32ºF to 150ºF):

±0.5ºC (±1ºF)

Below -5ºC (23ºF): ±1ºC (±2ºF)

Above 65ºC (150ºF): ±1% of reading

7-8 seconds (3 time constants)

Response Time

Diameter: 3.0mm (0.118”) Length: 90mm (3.2”)Probe Dimensions

RTD, Class A

Sensor

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

4

Operational

Other

Within accuracy specifications of the unitRepeatability

Food Safety Thermometer Specifications and Features

Ambient Operating Range

0ºC to 50ºC (32ºF to 122ºF)

90% (±5%) RH noncondensing @ 30ºC (86ºF)

Relative Humidity

-20ºC to 60ºC (-4ºF to 140ºF)

Storage Temperature

165mm x 32mm x 50mm (6.5” x 1.25” x 2”)

150g (0.33lbs)

Weight/Dimensions

(with Battery)

9V Alkaline

Power

10 hours minimum @ 23ºC (73ºF)

Battery Life (Alkaline)

High Brightness LED

Tar get Illumination light info

4 digits, 0.2ºC (0.5ºF)

Display Resolution

√Display Hold (7 seconds)

-40ºC to 200ºC (-40ºF to 390ºF)

Temperature Display

Standards

Conforms to EN 61236-1 Electromagnetic

Emissions and Susceptibility, EN6101-1

General Safety, Sealing IP65 (hand washable,

non-submersible)

CE

Certifications

1 yearWarranty

Nylon Carrying Pouch, QuickStart GuideAccessories

√LCD Backlit Display

*At calibration geometry of 279 mm (11”0 with a 140mm (5.5”) diameter, 0/97 emissivity blackbody.

Specifications subject to change without notice

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

5

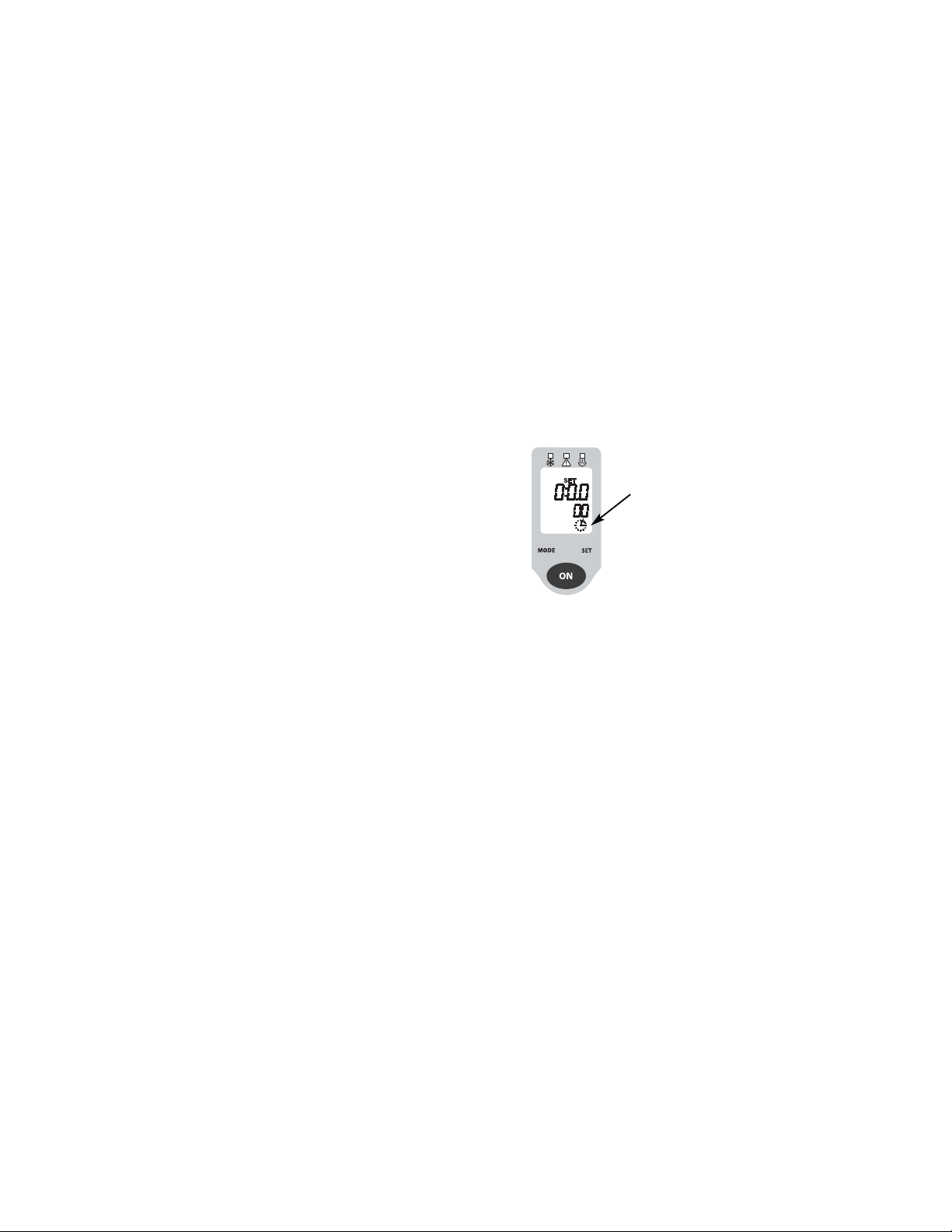

Figure 1/Graphique 1/Figura 1

Probe Icon /

Icône Sonde /

Icono de Sonda

HACCP Zone Indicators / Indicateur zone HACCP / Indicadores de Zona

Cº/Fº Indicator / Affichage Cº/Fº /

Indicador ºC/ºF

Low Battery Icon /

Icône Etat des piles /

Icono de Batería Baja

Timer Icon / Icône Minuterie /

Icono de Temporizador

ON (Measure) / ON (Mesure) /

ON (Medición)

Target Illumination /

Eclairage de la cible Optique /

Iluminación del Objetivo

Window for IR

Optics /

Sonde /

Ventana de

Óptica IR

Probe Thermometer /

Pour rabattre la sonde /

Sonda de Termómetro

ON

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

7

Thank you for purchasing this food safety thermometer. We are confident

that you will be pleased with the quality and performance of this product.

Please take a few moments to familiarize yourself with the operation,

features, and benefits of this fine product. This food safety thermometer

combines two precision thermometers in one unit: a specially calibrated

noncontact infrared thermometer (IRT) and a resistance thermal device (RTD)

penetration probe. The noncontact mode can be used for quick scans of a

surface temperature, while the probe mode is used to accurately measure

internal temperatures.

Product Statement

Table of Contents

Product Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Proper Application and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Noncontact (Infrared) Temperature Measurement Applications . . . . . . . . . . . . 12

Field Verification of Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting/Changing ºC / ºF Temperature Scales . . . . . . . . . . . . . . . . . . . . . . . . 18

Battery Insertion / Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

8

Before You Start

First time users should reference “Battery

Insertion Replacement” before using the unit,

page 19.

Noncontact (Infrared) Mode

Pressing and holding the ON button starts

the food safety thermometer in noncontact

(infrared) measurement mode. The measurement will continue as long as the ON button is

depressed, indicated by the blinking “SCAN”.

When the button is released, “HOLD” appears

on the display and the last measurement

remains visible for 7 seconds before the

display goes blank.

The unit will display the temperature of an

area highlighted by the target illuminator.The

maximum reading is indicated in the lower

portion of the display. (Figure 2).

Note: The infrared temperature measurements

are used for screening and measuring surface

temperatures only. Critical internal temperatures must be verified by using the probe.

Mode Selection

The MODE button has two functions. Pressing

the MODE button after the display has gone

blank will recall the last display. Pressing the

MODE button with an active display cycles

through the three different operating modes:

Noncontact, Probe, and Countdown Timer.

(Figure 3).

Proper Application and Operation

Figure 3

IR Mode Display

IR

Mode

Probe

Mode

Timer

Mode

MODE

Figure 2

Current

Reading

Maximum

Value

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

9

Probe Mode

To measure the internal temperature of an

object, extend the probe (see Figure 4) and

press the MODE button until the Probe Icon is

displayed (see Figure 5). Insert the probe at

least 12mm (1/2") into the target and press

the ON button to measure the core temperature.

The Probe Icon on the display will blink for

approximately 15 seconds as the probe comes

to equilibrium with the object being measured.

Three short beeps will sound to indicate the

reading is complete and the temperature will

be shown on the display. When the highest

accuracy is required, it is advisable to repeat

the measurement cycle to insure the probe

has fully stabilized and reached equilibrium

with the object.

Note: Remember if the display blanks the

mode button will recall the last measurement.

Note: The probe tip must be sterilized before

and between measurements of food samples

to avoid cross contamination.

Countdown (Timer) Mode

The food safety thermometer has a built in

countdown timer to conveniently monitor cooking, cooling, and critical exposure times, as

well as Hazard Analysis Critical Control Points

(HACCP*) inspection intervals. HACCP principles and good food safety practices require

monitoring the length of time perishable foods

1

Figure 4

Extended Contact Probe

Figure 5

Probe Mode Display

Probe

Icon

HACCP Zone Indicators

2

12mm min

(1/2")

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

10

are exposed to temperatures that may support

rapid bacterial growth.

To set the countdown timer, press the MODE

button until the timer icon is displayed (Figure

6). Press the SET button once to enter the set

mode (“SET” on display blinks). Press the SET

button a second time to clear and increment

the timer value. The timer value increase initially by 10 second intervals then by minutes

and hours. The timer can be set for a maximum of 7 hours and 59 minutes.

Once the desired timer value is set, pressing

the ON button will start and stop the countdown. An alarm will sound for approximately

30 seconds when the timer reaches zero.

Note: The timer can be activated and running

in the background (indicated by the flashing

timer icon) during either IR or Probe measurements or when the display is off. Pressing any

button will silence the sounding alarm.

To clear the displayed timer value, press the

SET button once to enter set mode and a

second time to zero the timer value.

HACCP* Check

This thermometer incorporates a “HACCP

Check” feature to graphically display critical

temperature zones. The icons and LED indicators located above the display indicate a food

product is safely held at a sufficient holding

temperature, or if it has fallen within the

unsafe HACCP “Danger Zone” temperatures.

Figure 6

Countdown Timer Display

Timer

Icon

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

11

The HACCP Check indicators operate in both

the Noncontact and Contact modes. The indicator light will flash during an active measurement and will be lit steadily during display

Hold or Recall (Figure 5).

• A Green LED indicator shows a safe chilled or

frozen condition below 4ºC (40ºF) or a safe

holding temperature above 60ºC (140ºF).

• The Red LED indicator light is displayed when

temperatures are within the HACCP “Danger

Zone” of 4ºC to 60ºC (40ºF to 140ºF) where

microbe growth occurs most rapidly

(Figure 7).

Note: When the temperatures within ±1°C

(±2°F) of the HACCP “Danger Zone” boundary,

both the relevant Green and Red LED indicator

lights will be

triggered to alert the user of the bor-

der temperature.

Note: Whenever the Red LED indicator light is

lit it is necessary to evaluate the safe storage

and handling rules dictated by both exposure

time and temperature.

Figure 7

Zone Measurement Map

Green

Red

Green

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

12

Measuring Liquid Temperatures

To accurately measure the temperature of

liquids and semi-liquids, such as soup, chili,

salad dressing, etc., stir the liquid to bring the

internal temperature to the surface, while

taking a measurement with the unit in noncontact mode. Steam, dust, smoke, etc., can prevent accurate measurement by interfering with

the energy emitted from the target. To increase

the reliability of the measurement, do not hold

the unit directly over a steaming or smoking

product. Instead, hold the unit back and at

an angle to ensure the most accurate

measurement (Figure 8).

Measuring Packaged Products

in Cold Storage Cases

Ideally, the temperature of a product should

be measured outside of a refrigerated environment whenever possible. If it is necessary to

measure the product in a refrigerated environment such as a walk-in cooler, either make

rapid measurements (within 1 minute or less)

or allow 30 minutes for the unit to stabilize in

the refrigerated environment (above 0°C /

32°F) before measuring. To measure an item

within a storage case, open the door or curtain, and directly scan the product for uniform

temperatures. The presence of warmer areas

may indicate improper stocking resulting in

blocked airflow in the cabinet.

Figure 8

Noncontact Temperature Measurement Applications

Figure 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

13

Measuring Food at the Receiving Dock

Use the food safety thermometer to accurately

measure perishable products at the receiving

dock. When a delivery of fresh or frozen food

arrives, check that the products, shipping

crates, and internal temperature of the delivery

truck are all at the proper storage temperatures. Check for warm spots in products that

can result from improper stacking and airflow.

Measuring Food in Holding and

Serving Areas

Use the noncontact thermometer to easily

scan and accurately measure surface temperature of products held in hot or cold holding

areas, such as open-top refrigeration units,

steam tables, salad bars, fresh meat or fish

displays and warming ovens.

Use the HACCP Check feature quickly identify

if unsafe temperatures within the HACCP

“Danger Zone” of 4°C to 60°C (40°F to

140°F) by slowly scanning across the surface

of food, storage containers, the contents of

deli cases, chilled salads and desserts, holding

ovens, rotisseries, etc.

Note: If any questionable temperatures are

indicated or if temperature readings are within

±1°C (±2°F) of the HACCP “Danger Zone”

boundary, use the probe to check internal

temperatures.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

14

Infrared (IRT) and Probe channels (RTD)

Follow the steps below to verify the accuracy

of your food safety thermometer.The 0ºC

(32ºF) “stirred ice bath” is the recommended

verification reference point. Since it is more

difficult to measure the surface of hot water,

the hot verification should be used only as a

general accuracy check of the IRT channel.

Cold Temperature Verification Check

1. Fill a large styrofoam cup halfway to the

surface with ice cubes. Add cold water to

just below the rim of the cup.

2. Immerse the tip of a known calibrated probe

thermometer (reference probe) into the

water and stir the mixture with the probe for

one minute, or until the probe temperature

stabilizes.

3. Continue stirring the water with a straw or

swizzle stick while taking simultaneous temperature measurements with the reference

probe and the IR thermometer. The unit

should be held within 3 inches of the surface of the water (Figure 10).To insure

measurement accuracy the probe tip must

be immersed to a minimum depth of 12mm

(1/2").

The noncontact (IRT) measurement should be

within ±1°C (±2°F) of the reference probe

reading (nominally 0°C (32°F)).

Field Verification Of Accuracy

Figure 10

0ºC

(32ºF)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

15

The probe temperature reading should be

within ±0.5°C (±1°F) of the reference probe

reading.

Hot Temperature Verification Check

1. Follow the same procedure as above, substituting hot water (>140°F/60°C). Hot tap

water is adequate for the procedure.

2. Repeat steps two and three from above.

Note: Due to evaporative cooling on the

surface of the hot water, it is particularly

important that the surface of the water be

continually stirred while making the IR

measurement (Figure 11).

Using this method, the noncontact (IRT) channel should be considered accurately calibrated

if the reading is within ±2°C (±3.5°F) of the

reference probe’s reading; the unit’s probe

reading should be within ±0.5°C (±1°F) of the

reference probe reading.

Cautions

• Hold the noncontact thermometer outside

the rim of the cup, approximately 3 inches

from the surface of the water.

• Avoid steam condensation on the unit’s lens.

If condensation forms, carefully wipe the

lens or let it dry at room temperature and

resume measurement.

Figure 11

60ºC

(140ºF)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

16

Field of View

The ideal working range of the noncontact

thermometer (IRT) is between 2cm and 25cm

(1 and 10 inches). The field of view is a circular measurement area approximately equal to

the distance from the target to the unit, divided

by 2. The built in target illumination beam

helps to indicate the measurement area. To

ensure accurate measurements, the measurement target must fill or exceed the field of

view. When conditions permit move in closer

to the subject (Figure 12).

Operating and Ambient

Temperature Range

The food safety thermometer is designed

to operate in environments between

0°C–50°C (32°F–120°F). Avoid subjecting the

unit to extreme or abrupt changes in ambient

temperatures. Allow the unit to stabilize for a

minimum of 30 minutes if exposed to rapid

temperature changes. Failure to precondition

the instrument to the ambient temperature

may result in measurement errors. (Figure 13)

Response Time

The response time of the instrument from

initial start up is approximately 1 second.

The temperature display is updated at

approximately 2 times per second during

sustained operation.

2–25cm

(1–10")

Figure 12

Figure 13

30 Minutes

Hot to Cold and Cold to Hot

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

17

Humidity

Noncontact thermometers (IRTs) are not

intended for use in extremely humid or condensing environments. Condensation on the

lens window will impede the optical performance and prevent accurate temperature measurements. If this occurs, allow the window to

dry by evaporation or wipe with a soft cloth

and resume measurements.

Emissivity

A noncontact thermometer (IRT) determines

temperature by measuring the emitted energy

of an object. Emissivity (E value) is the measure

of an object’s ability to emit infrared energy.

This noncontact thermometer is specially calibrated for high emissivity targets and is preset

to an E value of 0.97. This setting is the most

advantageous for capturing the emitted energy

from water, oils, shortening, fat, vegetables, as

well as frozen, partially frozen and refrigerated

products in boxes and plastic containers.

Note: Shiny metal surfaces (such as polished

or stainless steel) have low emissivities and

reflect the energy of their surrounding, resulting in inaccurate temperature readings. The

emissivity of shiny metal surfaces can be

enhanced to provide more accurate readings

by covering the measurement area with masking tape, flat black paint, or a coating of shorting or oil. Blackened cooking surfaces such as

griddles and cast iron pans make good targets.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

18

Setting/Changing ºC and ºF

Temperature Scales

The food safety thermometer can display

temperature in either the ºC (Celsius) or ºF

(Fahrenheit) scales. The desired scale is

selected at the time the battery is installed:

Selecting the ºC Scale:

When the battery is connected to the battery

leads the ºC scale indicator shows on the

display for approximately 15 seconds. If no

press of the SET button is made, the unit will

time out and default to the ºC or Celsius scale.

Selecting the ºF Scale:

If the SET button is pressed within 15 seconds

of connecting the battery to the battery leads,

the temperature scale display will toggle to the

ºF scale indicator and the unit will now default

to the ºF or Fahrenheit scale (Figure 14).

Note: The ºC/ºF temperature scale initialization

process must be performed whenever battery

power is interrupted or the battery is replaced.

Cleaning Instructions

This food safety thermometer is sealed to IP54

standards. The unit may be wiped down with a

wet sponge or cloth using a mild water based

detergent or anti-bacterial soap and rinsed

under a gentle stream of cold water

(Figure 15).

Note: This unit is not designed for complete

submersion or washing in automated

dishwashers.

9V

Figure 14

Figure 15

NOTE!

For ºF Press SET

within 15 seconds

of connecting

battery

(Disconnect

battery to reset)

Defaults to

ºC after 15

seconds

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

19

Probe Replacement

The modular probe of the food safety thermometer is replaceable. To replace probe,

extend the probe partially to access the rubber

caps. Carefully pry up the rubber caps using a

pin, and remove the cap using a #2 Phillips

screws as shown. Grasp the probe and carefully separate the old probe from the probe

base. Install the new probe in the reverse

order, firmly tightening the screws and replacing the rubber plugs. The calibration accuracy

of the unit is not affected by probe replacement (Figure 16).

Battery Insertion and Replacement

To install a new 9V battery, remove the rubberized battery compartment “plug” at the base of

the unit by grasping the sides of the cover and

pulling straight out, exposing the battery. Gently

shake or tap the base of the unit on your palm

to gain access to the battery. The 9V battery of

the unit is connected to the polarized snap

connector (Figure 17).

Note:

Each time the battery is installed

or replaced, the temperature scale will default

to the ºC or Celsius scale. To select the ºF or

Fahrenheit scale see ‘Setting/Changing ºC

and ºF Temperature Scales’.

Troubleshooting

Code: --- (on display)

Problem: Target temperature is over or

under range

Action: Select target within range specifications

Figure 16

Figure 17

9V

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

20

Code: Battery symbol

Problem: Possible low battery

Action: Check and/or replace battery

Code: Blank display

Problem: Possible dead battery

Action: Check and/or replace battery

Other Operational Considerations

All models should be protected from

the following:

• EMI (Electro Magnetic Interference) from

induction heaters and microwave ovens

• Electrostatic discharge

• Should the unit become damaged, check the

accuracy of the unit by performing the verification process recommended in this manual.

If the unit is out of calibration, do not rely on

it for critical temperature measurements.

• Heat from stovetops, pans, or other hot

surfaces (don’t set it on the stove)

Certifications

CE

This instrument conforms to the following

standards:

• EN 61326-1 Electromagnetic Emissions

and Susceptibility

• EN 61010-1 General Safety

• IP54

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...