Page 1

Stick-Style Water-Resistant

Infrared Thermometer

for Foodservice Applications

with 4:1 Distance-to-Sight Ratio

Model 35625-15

THE STANDARD IN PRECISION MEASUREMENT

1

Page 2

Introduction

The Digi-Sense Stick-Style Infrared Thermometer (Model

35625-15) with 4 to 1 distance-to-sight ratio offers fast

response and high accuracy at the touch of a button. The

built-in laser pointer increases target accuracy while the

convenient push button and backlight LCD combine for

ergonomic handheld operation. Unit features a dust- and

water-resistant IP54 rating. Infrared thermometers can be

used to safely measure the temperature of objects that are

hard or improper to be measured by traditional contact

thermometers. Careful use of this meter will provide years

of reliable service.

Unpacking

Check individual parts against the list of items below. If

anything is missing or damaged, please contact your

instrument supplier immediately.

1. Meter

2. One 9 V battery

3. User manual

2

Page 3

Key Features

• 4:1 Distance-to-sight ratio

• 2% basic accuracy

• Precise noncontact IR measurements

• Laser sighting

• Fixed emissivity (0.97)

• User-selectable °F or °C temperature units

• Automatic data Hold

• Backlight LCD

• Automatic power-off to conserve battery life

3

Page 4

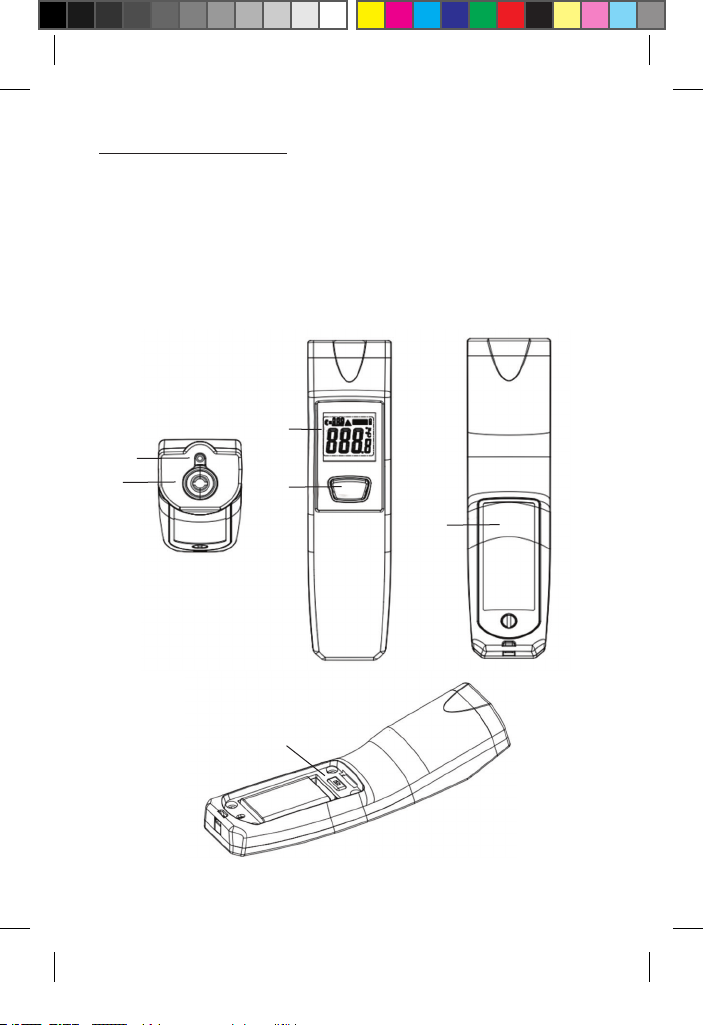

Meter Description

1. Laser pointer beam

2. IR sensor

3. LCD

4. MEASURE button

5. Battery cover

6. °F/°C switch

1

2

3

4

5

6

4

Page 5

Display Layout

1. Emissivity value

2. Laser pointer indicator

3. Data HOLD icon

4. Low-battery indicator

5. °F and °C temperature icons

6. Temperature readout

1 2 3

6

4

5

5

Page 6

How it Works

Infrared thermometers measure the surface temperature of an object. The unit’s optics sense emitted,

reflected, and transmitted energy, which is collected

and focused onto a detector. The unit’s electronics

translate the information into a temperature reading

which is displayed on the unit. The laser is used for

aiming purposes only.

Field of View

Make sure that the target is larger than the unit’s

spot size. The smaller the target, the closer you

should be to it. When accuracy is critical, make sure

the target is at least twice as large as the spot size.

Distance and Spot Size

As the distance (D) from the object increases, the

spot size (S) of the area measured by the unit

becomes larger.

Locating a Hot Spot

To find a hot spot, aim the thermometer outside

the area of interest, then scan across with an

up-and-down motion until you the locate the hot

spot.

6

Page 7

Emissivity

Emissivity is a term used to describe the energy-

emitting characteristics of materials. Most (90% of

typical applications) organic materials and painted

or oxidized surfaces have an emissivity of 0.95.

Inaccurate readings will result from measuring shiny

or polished metal surfaces. To compensate, cover

the surface to be measured with black tape or flat

black paint. Allow time for the tape to reach the

same temperature as the material underneath it.

Measure the temperature of the tape or painted

surface. (Refer to table below.)

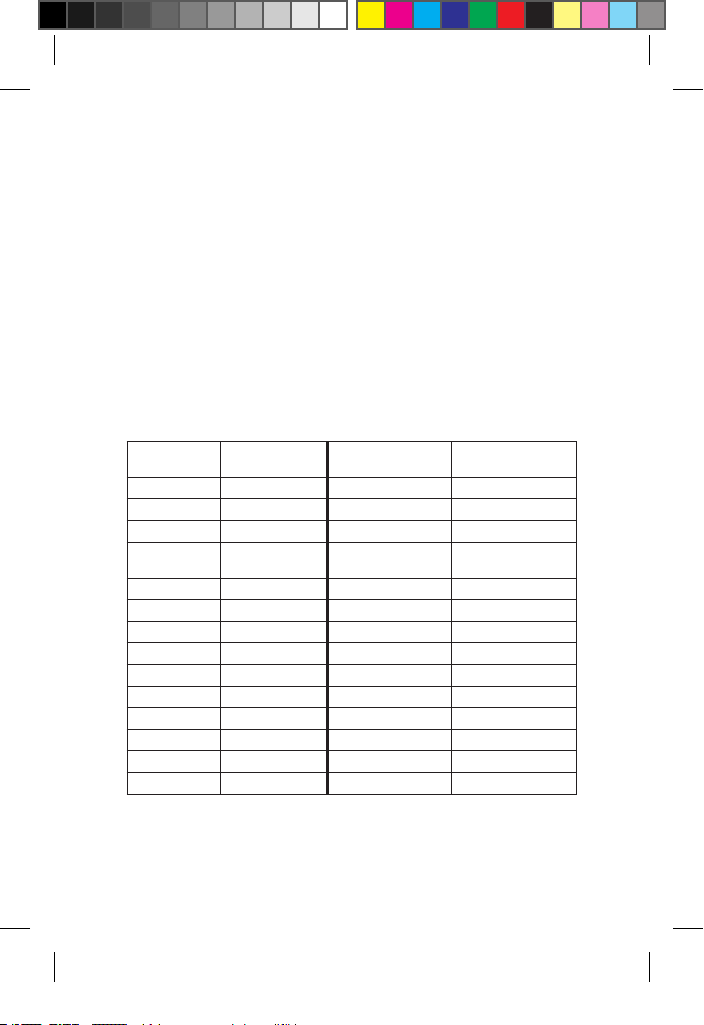

Substance

Asphalt 0.90 to 0.98 Cloth (black) 0.98

Concrete 0.94 Human skin 0.98

Cement 0.96 Lather 0.75 to 0.80

Sand 0.90

Earth 0.92 to 0.96 Lacquer 0.80 to 0.95

Water 0.92 to 0.96 Lacquer (matte) 0.97

Ice 0.96 to 0.98 Rubber (black) 0.94

Snow 0.83 Plastic 0.85 to 0.95

Glass 0.90 to 0.95 Timber 0.90

Ceramic 0.90 to 0.94 Paper 0.70 to 0.94

Marble 0.94 Chromium oxides 0.81

Plaster 0.80 to 0.90 Copper oxides 0.78

Mortar 0.89 to 0.91 Iron oxides 0.78 to 0.82

Brick 0.93 to 0.96 Textiles 0.90

Thermal

emissivity

Substance

Charcoal

(powder)

Thermal

emissivity

0.96

7

Page 8

How it Works (continued)

Good Measuring Practices

Holding the meter by its handle, point the IR sensor

toward the object whose temperature is to be

measured. The meter automatically compensates for

temperature deviations from ambient temperature.

Keep in mind that it will take up to 30 minutes for

the IR sensor to stabilize if going from ambient

temperatures to a much higher (or lower)

temperature measurement.

Reminders

• The unit is not recommended for measuring

shiny or polished metal surfaces (stainless steel,

aluminum, etc.). See Emissivity on page 7.

• The unit cannot measure through transparent

surfaces such as glass. It will measure the

surface temperature of the glass instead.

• Steam, dust, smoke, etc. can prevent accurate

measurement by obstructing the unit’s optics.

8

Page 9

Setup and Operation

1. To select the desired temperature units, open the

battery cover and select °F or °C.

2. Hold the meter by its handle grip and point it

toward the surface to be measured.

3. Push and hold the MEASURE button to turn the

meter on and begin testing. The display will light

if the battery is good. Replace the battery if the

display does not light.

4. While measuring, the current temperature will

appear on the LCD.

5. Release the MEASURE button to hold the reading.

6. Note: To conserve battery life, meter automatically

powers down in 7 seconds once button is released.

Specifications

Temperature range –31 to 525°F (–35 to 302°C)

Resolution 0.1°F/C

Accuracy

Response time Less than 150 ms

Emissivity Fixed at 0.97

Distance-to-sight

ratio (field of view)

Laser Single Class 2 (II) laser

Spectral range 8 to 14 µm

Oper. temperature 32 to 122°F (0 to 50°C)

Storage temp. 14 to 140°F (–10 to 60°C)

Dimensions 7" x 1

Power One 9 V battery

39 to 150°F (4 to 65°C) ±2°F (1°C)

Below 39°F (4°C) ±3.6°F (2°C)

Above 150°F (65°C) ±1% of reading + 2°F (1°C)

D/S = Approximately 4:1 ratio

(D = distance, S = spot)

3

⁄4" x 11⁄2" (17.8 x 4.4 x 3.8 cm)

9

Page 10

Field of View

The meter’s field

of view is 4:1,

meaning that if

the meter is

4 inches from

the target, the

diameter of the

object under test

must be at least

1 inch. Other distances are shown in the diagram

above. Make sure that the target is larger than the

meter’s spot size. The smaller the target, the closer

you should be to it. When accuracy is critical, make

sure the target is at least twice as large as the spot

size.

Safety

• Use extreme caution when laser beam is turned on.

• Do not let the laser beam enter your eye, another

person’s eye or the eye of an animal.

• Be careful not to let the laser beam on a reective

surface strike your eye.

• Do not allow the laser

light beam to impinge on

any gas which can explode.

10

Page 11

Maintenance, Calibration, and Repair

Cleaning and Storage

• The meter should be cleaned with a damp cloth

and mild detergent when necessary. Do not use

solvents or abrasives.

• Store the meter in an area with moderate

temperature and humidity

Battery Replacement

If the battery power is insufficient, the Low-battery

icon will appear on the LCD. Unscrew the battery

cover and replace the 9 V battery. Rescrew the cover

until it is securely closed.

11

Page 12

Maintenance, Calibration, and Repair

(continued)

It is recommended that Digi-Sense products are

calibrated annually to ensure proper function and

accurate measurements; however, your quality system

or regulatory body may require more frequent

calibrations. To schedule your calibration, please

contact InnoCal, an ISO 17025 calibration laboratory

accredited by A2LA.

Phone: 1-866-INNOCAL (1-866-466-6225)

Fax: 1-847-327-2993

E-mail: sales@innocalsolutions.com

Web: InnoCalSolutions.com

For Product and Ordering Information, Contact:

Toll-Free: 1-800-323-4340,

Phone: 1-847-549-7600

Fax: 1-847-247-2929

ColeParmer.com/Digi-Sense

In Canada

Toll-Free: 1-800-363-5900

Phone: 1-514-355-6100

Fax : 1-514-355-7119

ColeParmer.ca/Digi-Sense

1065DGMAN_20250-00 Rev.1

12

Toll-Free: 1-800-358-5525

Phone: 1-847-327-2000

Fax: 1-847-327-2700

Davis.com/Digi-Sense

Manual Part No. 00100-48

Page 13

Manuel d'utilisation

Thermomètre infrarouge

hydrorésistant avec sonde

pour service alimentaire avec ratio

distance-cible de 4:1

Modèle 35625-15

LA NORME EN MATIÈRE DE PRÉCISION DES MESURES

Page 14

Introduction

Grâce au thermomètre infrarouge avec sonde Digi-Sense

(modèle 35625-15) avec ratio distance-cible de 4:1, rapidité

de réponse et grande précision sont obtenus par simple

pression d'un bouton. Le pointeur laser intégré de l'appareil rehausse la précision du ciblage, tandis que le bouton-pression et le rétroéclairage ACL s'allient pour

permettre une utilisation manuelle ergonomique. L'unité

répond à l'exigence IP54 relativement à la résistance à l'eau

et aux poussières. Les thermomètres à infrarouge peuvent

être utilisés pour mesurer en toute sécurité la température

d'objets qui sont difciles à mesurer au moyen des

thermomètres compacts traditionnels ou inadaptés à

ceux-ci. Une utilisation consciencieuse de ce thermomètre

vous permettra de l’utiliser pendant de nombreuses

années, en toute abilité.

Déballage

Comparez les pièces incluses avec la liste des pièces figu-

rant ci-dessous. Si un article est manquant ou endommagé,

veuillez communiquer avec votre fournisseur sans délai.

1. Appareil de mesure

2. Batterie 9 V

3. Manuel d'utilisation

FR-2

Page 15

Caractéristiques clés

• Ratio distance-cible 4:1

• Précision de base de 2 %

• Mesures IR sans contact précises

• Visée au laser

• Émissivité xe (0,97)

• Unité de température (°F ou °C) au choix de l'utilisateur

• Mode de mémorisation automatique des mesures

• Rétroéclairage ACL

• Mode arrêt automatique pour préserver la batterie

FR-3

Page 16

Description de l'appareil de mesure

1. Faisceau du pointeur laser

2. Capteur IR

3. ACL

4. Bouton MEASURE (mesure)

5. Couvercle de compartiment à batterie

6. Commutateur °F/°C

3

1

2

4

5

FR-4

6

Page 17

Format d'affichage

1. Valeur d'émissivité

2. Indicateur de pointeur laser

3. Icône de mémorisation des données (HOLD)

4. Indicateur de batterie faible

5. Icônes d'unité de température °F et °C

6. Lecture de température

1 2 3

6

4

5

FR-5

Page 18

Mode de fonctionnement

Les thermomètres à infrarouge mesurent la température

de surface d’un objet. Les capteurs optiques de l'appareil

mesurent l'énergie émise, rééchie et transmise, qui est

recueillie et focalisée sur un détecteur. Le système

électronique de l'appareil convertit l'information en

mesure de température, qui s'afche à l'écran de l'unité.

Le laser est utilisé à des ns de visée seulement.

Champ de visée

Assurez-vous que la cible est plus grande que le point

laser émis par l'appareil. Plus la cible est petite, plus

vous devrez vous en rapprocher. Lorsque la précision est

cruciale, assurez-vous que la cible est au moins deux fois

plus grande que le point.

Distance et taille du point

Plus la distance (D) entre l'instrument et l'objet est grande,

plus la taille (T) du point laser sur la zone mesurée de

l'objet augmente.

Repérer un point chaud

Pour repérer un point chaud, viser le thermomètre vers

une zone à l'extérieur du champ d’intérêt et balayer la zone

vers le haut et vers le bas jusqu'à l'obtention du point

chaud.

FR-6

Page 19

Émissivité

L'émissivité est un terme utilisé pour décrire les

caractéristiques émettrices d'énergie des matières. La

plupart (90 % des applications typiques) des matières

organiques et des surfaces peintes ou oxydées afchent

une émissivité de 0,95. La mesure de surfaces métalliques

polies ou brillantes engendre des lectures erronées. Pour

compenser, couvrez la surface à mesurer avec du ruban

adhésif noir ou de la peinture noir mat. Laissez le temps à

la peinture ou au ruban de s'harmoniser avec la

température de la surface couverte. Mesurez la

température du ruban masque ou de la surface peinte.

(Reportez-vous au tableau ci-dessous.)

Substance

Asphalte 0,90 à 0,98 Tissu (noir) 0,98

Béton 0,94 Peau humaine 0,98

Ciment 0,96 Cuir 0,75 à 0,80

Sable 0,90

Terre 0,92 à 0,96 Laque 0,80 à 0,95

Eau 0,92 à 0,96 Laque (mat) 0,97

Glace 0,96 à 0,98 Caoutchouc (noir) 0,94

Neige 0,83 Plastique 0,85 à 0,95

Verre 0,90 à 0,95 Bois d'œuvre 0,90

Céramique 0,90 à 0,94 Papier 0,70 à 0,94

Marbre 0,94 Oxydes de chrome 0,81

Plâtre 0,80 à 0,90 Oxydes de cuivre 0,78

Mortier 0,89 à 0,91 Oxydes de fer 0,78 à 0,82

Brique 0,93 à 0,96 Textiles 0,90

Émissivité

thermique

Substance

Poussière de

charbon de bois

Émissivité

thermique

0,96

FR-7

Page 20

Mode de fonctionnement (suite)

Plage de température -35 à 302°C (-31 à 525°F)

Résolution 0,1°C/F

Précision

Temps de réponse Moins de 150 ms

Émissivité Fixe à 0,97

Ratio distance-cible

(champ de visée)

Laser Laser simple de classe 2 (II)

Domaine spectral 8 à 14 µm

Temp. de fonctionnement 0 à 50°C (32 à 122°F)

Temp. d'entreposage -10 à 60°C (14 à 140°F)

Dimensions 17,8 x 4,4 x 3,8 cm (7" x 1

Alimentation Batterie 9 V

Bonnes pratiques de mesure

Le thermomètre se tient par la poignée, en pointant le

capteur IR vers l'objet à analyser. Le thermomètre

compense automatiquement les écarts de température

par rapport à la température ambiante. Rappelez-vous

qu'il faudra environ 30 minutes au capteur IR pour se

stabiliser si vous passez de la température ambiante à

une température nettement plus élevée ou basse.

Rappels

• Il est déconseillé d'utiliser le thermomètre pour

analyser des surfaces brillantes ou polies (acier

inoxydable, aluminium, etc.) Reportez-vous au

chapitre Émissivité de la page 7.

• Le thermomètre peut ne pas prendre des mesures

exactes à travers des surfaces transparentes telles

que le verre. Il mesurera plutôt la température de

surface du verre.

• La vapeur, la poussière, la fumée, etc. sont autant de

facteurs qui peuvent fausser les mesures car elles

obstruent les capteurs optiques de l'instrument.

FR-8

Page 21

Configuration et utilisation

1. Pour choisir l'unité de température voulue, ouvrez le couvercle du compartiment à batterie et sélectionnez °F ou °C.

2. Tenez le thermomètre par la poignée et pointez-le vers

la surface à mesurer.

3. Appuyez sur le bouton MEASURE (mesure) et maintenez-le enfoncé pour allumer le thermomètre et commencer la mesure. L'écran s'allumera si la batterie est chargée.

Remettez la batterie en place si l'écran ne s'allume pas.

4. Pendant la prise de mesure, la température actuelle

s'afche à l'écran ACL.

5. Relâchez le bouton MEASURE pour enregistrer la mesure.

6. Remarque : Pour préserver la durée de vie de la batterie,

le thermomètre s'éteint automatiquement 7 secondes

après avoir relâché le bouton.

Caractéristiques

Plage de température -35 à 302°C (-31 à 525°F)

Résolution 0,1°C/F

Précision

Temps de réponse Moins de 150 ms

Émissivité Fixe à 0,97

Ratio distance-cible

(champ de visée)

Laser Laser simple de classe 2 (II)

Domaine spectral 8 à 14 µm

Temp. de fonctionnement 0 à 50°C (32 à 122°F)

Temp. d'entreposage -10 à 60°C (14 à 140°F)

Dimensions 17,8 x 4,4 x 3,8 cm (7" x 1

Alimentation Batterie 9 V

4 à 65°C (39 à 150°F) ±1°C (2°F) En deçà de

4°C (39°F) ±2°C (3,6°F) Au delà de 65°C (150°F)

±1% de la lecture + 1°C (2°F)

D/S = ratio d'env. 4:1

(D = distance, S = Point ou cible)

3

⁄8" x 11⁄8")

FR-9

Page 22

Champ de visée

Le thermomètre

propose un champ

de visée de 4:1.

En d'autres mots,

lorsque le thermo-

mètre est à 4

pouces (10 cm) de

la cible, le diamètre

de l'objet analysé

doit être d'au moins 1 pouce (2,5 cm). Les autres distances sont indiquées dans le schéma ci-dessus. Assurez-vous que la cible est plus grande que le point laser

émis par l'appareil. Plus la cible est petite, plus vous

devrez vous en rapprocher. Lorsque la précision est cruciale, assurez-vous que la cible est au moins deux fois

plus grande que le point.

Sécurité

Redoublez de prudence lorsque le laser est en marche.

• Ne pointez pas le laser vers vos yeux, les yeux d'autrui

ou les yeux d'un animal.

• Prenez soin de ne pas laisser un laser rééchi par une

surface atteindre vos yeux.

• Veillez à ce que le faisceau

laser n'entre pas en contact

avec des gaz pouvant

exploser.

FR-10

Page 23

Entretien, étalonnage et réparation

Nettoyage et rangement

• Le thermomètre doit être nettoyé avec un linge

humecté d'une solution détergente douce lorsque cela

est nécessaire. N'utilisez ni solvants, ni substances

abrasives.

• Rangez le thermomètre dans un endroit à température

et humidité modérées.

Remplacement de la pile

Si la batterie n'est plus sufsamment chargée, l'icône

de batterie faible apparaît à l'écran ACL. Dévissez le

couvercle du compartiment à batterie et remplacez la

batterie 9 V. Revissez le couvercle en vous assurant

qu'il est correctement fermé.

FR-11

Page 24

No de pièce du manuel : 00100-48

1065DGMAN_20250-15_FR Rév.1

Entretien, étalonnage et réparation (suite)

Il est recommandé d'étalonner les produits Digi-Sense

annuellement pour assurer leur fonctionnement adéquat

et la précision des mesures. Toutefois, votre système de

qualité ou vos organismes de réglementation pourraient

exiger des étalonnages plus fréquents. Pour xer un

rendez-vous d'étalonnage, veuillez communiquer avec

InnoCal, un laboratoire d'étalonnage certié ISO 17025,

agréé par A2LA.

Tél : 1-866-INNOCAL (1-866-466-6225)

Fax : 1-847-327-2993

E-mail: sales@innocalsolutions.com

Web: InnoCalSolutions.com

Pour de l'information ou commander des produits:

Sans frais (aux EUA) :

1-800-323-4340

Tél. : 1-847-549-7600

Fax : 1-847-247-2929

ColeParmer.com/Digi-Sense

Au Canada

Sans frais : 1-800-363-5900

Tél. : 1-514-355-6100

Fax : 1-514-355-7119

ColeParmer.ca/Digi-Sense

Sans frais (aux EUA) :

1-800-358-5525

Tél. : 1-847-327-2000

Fax : 1-847-327-2700

Davis.com/Digi-Sense

Loading...

Loading...