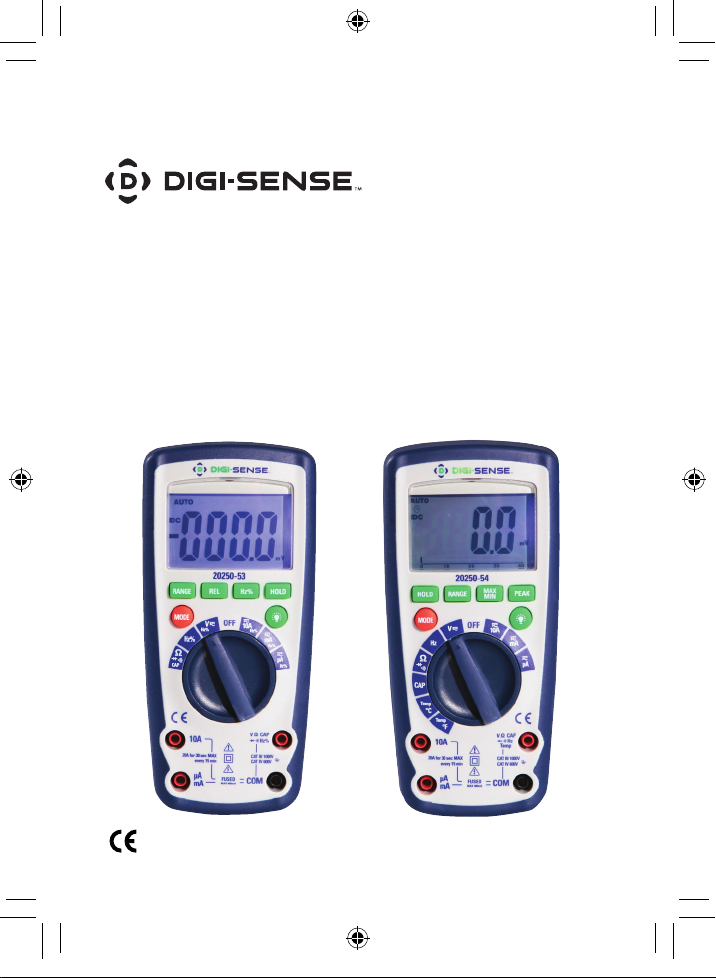

Page 1

THE STANDARD IN PRECISION MEASUREMENT

User Manual

Industrial IP67-Rated Digital Multimeters

with NIST-Traceable Calibration

Model 20250-53

(4000 Count)

Model 20250-54

(4000 Count, True RMS)

1065DGMAN_20250-53-54 Manual.indd 1 8/16/2017 10:42:05 AM

Page 2

Introduction

Digi-Sense Industrial Digital Multimeters (model 20250-53;

TRMS model 20250-54) are a must-have on your electrical

tool belt—especially for those who need a rugged and

reliable meter. These versatile and simple-to-use units safely

measure the full range of common parameters including voltage,

current, resistance, capacitance, frequency, temperature, and

more. All this technology is packaged in a double-insulated

housing that meets IP67 requirements. The instruments are fully

tested and calibrated to NIST-traceable standards. Careful use of

the meter will provide years of reliable service.

Safety

Safety Warnings

The following safety information must be

observed to insure maximum personal safety

during the operation at this meter:

• Measurements beyond the maximum selected range

must not be attempted.

• Extreme care must be taken when measuring above 50 V,

especially on live bus-bars.

• To measure voltage, the instrument must not be switched

to a current or resistance range, or to the diode check or

buzzer position.

• Circuits must be de-energized and isolated before

carrying out resistance tests.

• The rotary function switch must only be turned after

removing test connections.

• All external voltages must be disconnected from the

instrument before removing the battery.

2

1065DGMAN_20250-53-54 Manual.indd 2 8/16/2017 10:42:05 AM

Page 3

• Test leads and prods must be in good order, clean, and

MAX

with no broken or cracked insulation.

• UK Safety Authorities recommend the use of fused test

leads when measuring voltage on high energy systems.

• Replacement fuses must be of the correct type and rating.

• The instrument must not be used if any part of it is damaged.

• Warnings and precautions must be read and understood

before an instrument is used. They must be observed during the operation of this instrument.

Safety used on this instrument are:

Caution: refer to accompanying notes.

This symbol indicates that the operator must refer

to an explanation in the manual to avoid personal

injury or damage to the meter.

Caution: risk of electric shock

This WARNING symbol indicates a potentially

hazardous situation, which if not avoided, could

result in death or serious injury.

This CAUTION symbol indicates a potentially

hazardous situation, which if not avoided, may

result damage to the product.

This symbol advises the user that the terminal(s)

so marked must not be connected to a circuit point

at which the voltage with respect to earth ground

exceeds (in this case) 1000 VAC or VDC.

Equipment protected throughout by Double

Insulation (Class II)

Equipment complies with current EU directives.

1065DGMAN_20250-53-54 Manual.indd 3 8/16/2017 10:42:05 AM

3

Page 4

Unpacking

Check individual parts against the list of items below. If anything is

missing or damaged, please contact your instrument supplier

immediately.

1. Instrument

2. Test leads

3. One type K temperature probe (model 20250-54 only)

4. One 9 V battery

5. Carrying case

6. User manual

7. NIST-traceable calibration report with data

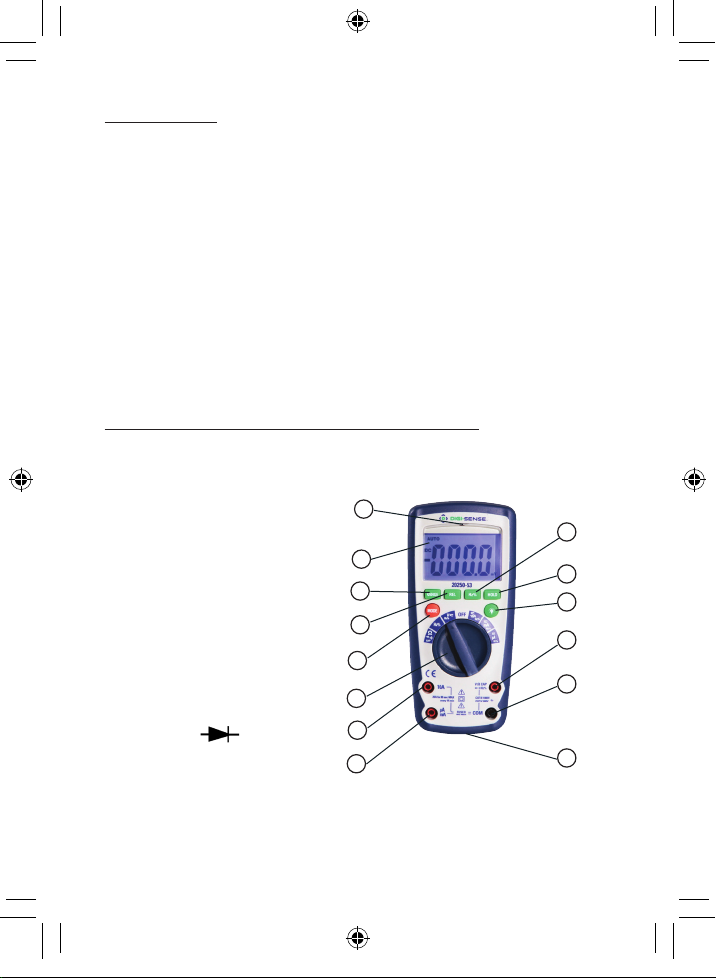

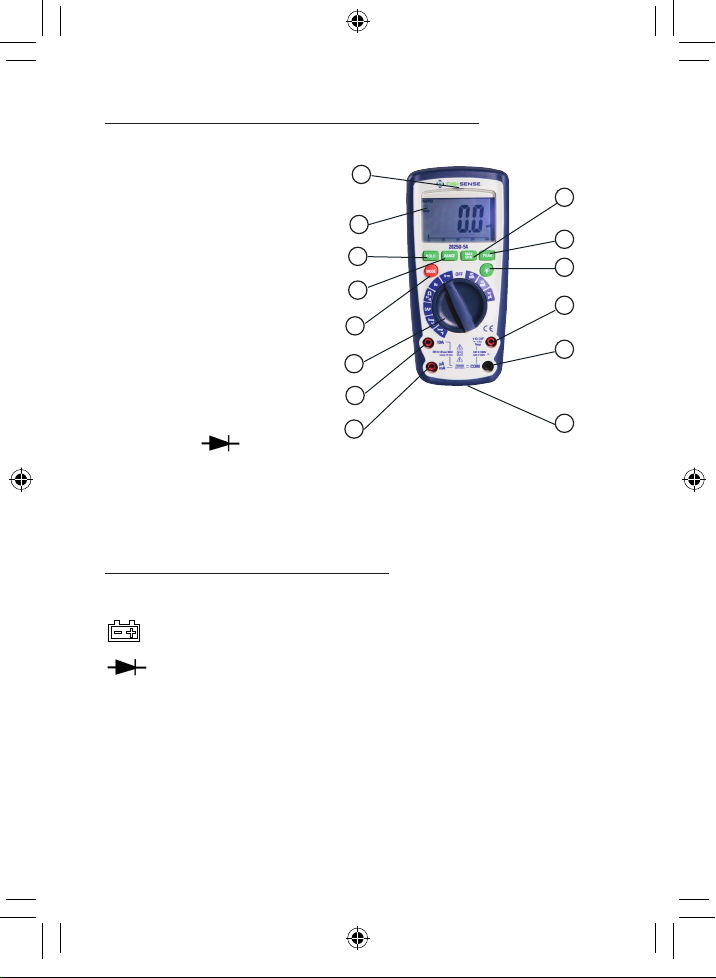

Meter Description (Model 20250-53)

1. NCV detection light

2. LCD with symbols

3. RANGE button

4. REL (Relative) button

5. MODE button

6. Rotary function switch

7. 10A (positive) jack

8. µA/mA jack

9. Hz% button

10. Data HOLD button

11. Backlight button

12. V Ω CAP •))) Hz% jack

13. COM (negative) jack

14. Tilt stand and battery

compartment are on

rear of unit

4

1

9

2

3

4

5

6

7

8

10

11

12

13

14

1065DGMAN_20250-53-54 Manual.indd 4 8/16/2017 10:42:05 AM

Page 5

Meter Description (Model 20250-54)

1. NCV detection light

2. LCD with symbols and

analog bar graph

3. Data HOLD button

4. RANGE button

5. MODE button

6. Rotary function switch

7. 10A (positive) jack

1

2

3

4

5

8. µA/mA jack

9. MAX/MIN button

10. PEAK button

11. Backlight button

12. V Ω CAP •))) Hz

Temp jack

6

7

8

13. COM (negative) jack

14. Tilt stand and battery

compartment are on rear of unit

Symbols and Annunciators

Continuity

•)))

Low battery

Diode test

HOLD Data HOLD

AUTO Autoranging

AC Alternating Current or Voltage

DC Direct Current or Voltage

V Volts

A, mA, µA Current range

9

10

11

12

13

14

5

1065DGMAN_20250-53-54 Manual.indd 5 8/16/2017 10:42:05 AM

Page 6

Setup and Operation

To turn on the instrument turn the rotary function switch

from the OFF position to any measurement range.

NOTE: For best battery life ALWAYS turn the rotary function

switch to the OFF position when the meter is not in use.

Meter has Auto power-off that automatically shuts the

meter off if 30 minutes elapse between uses.

NOTE: On some low AC and DC voltage ranges, with the

test leads not connected to a device, the display may show

a random, changing reading. This is normal and is caused

by the high-input sensitivity. The reading will stabilize and

give a proper measurement when connected to a circuit.

MODE Button

To select AC or DC measurement when Voltages, Amps,

mA , µA, Ω,

HOLD Button

The Data HOLD function allows the meter to "freeze" a

measurement for later reference.

1. Press the HOLD button to “freeze” the reading on the

display. The indicator “HOLD” will be appear in the

display.

2. Press the HOLD button to resume normal operation.

, •))), CAP, or Hz% are selected.

6

1065DGMAN_20250-53-54 Manual.indd 6 8/16/2017 10:42:05 AM

Page 7

RANGE Button

When the meter is rst turned on, it automatically defaults

to Autoranging. This automatically selects the best range

for the measurements being made and is generally the

optimal mode for most measurements. For measurement

situations requiring that a range be manually selected,

perform the following:

1. Press the RANGE button. The “Auto Range” display

indicator will turn off. The “Manual Range” display

indicator will turn on

2. Press the RANGE button to step through the available

ranges until you select the range you want.

3. Press and hold the RANGE button for 2 seconds to exit

the manual ranging mode and return to autoranging.

REL Button (Model 20250-53 only)

The relative (REL) measurement feature allows you to

make measurements relative to a stored reference value.

A reference voltage, current, etc., can be stored and

measurements made in comparison to that value. The

displayed value is the difference between the reference

value and the measured value.

Note: This function works with all functions except Hz%,

Diode, and Continuity.

1. Press the REL button to store the reading in the display

and the "REL" indicator will appear on the display.

2. The display will now indicate the difference between the

stored value and the measured value.

3. Press the REL button again to resume normal operation.

1065DGMAN_20250-53-54 Manual.indd 7 8/16/2017 10:42:05 AM

7

Page 8

MAX/MIN Button (Model 20250-54 only)

The MAX/MIN function allows the meter to capture the

highest or lowest reading for later reference.

1. Press the MAX/MIN button to begin measurement. The

indicator “MAX” or “MIN” will appear in the display.

2. If the “MAX MIN” messages are ashing, the instrument

is in MAX/MIN mode but not recording, press the

MAX/MIN button to select a mode.

3. To resume operation, hold down the MAX/MIN button

for 2 seconds.

PEAK Hold Button (Model 20250-54 only)

The PEAK Hold function captures the peak AC voltage or

current. The meter can capture negative or positive peaks

as fast as 1 millisecond in duration.

1. Set the rotary function switch to the A or V position.

2. Press the MODE button to select “AC”.

3. Allow time for the display to stabilize.

4. Press and hold the PEAK button until “CAL” appears in

the display.

5. This procedure will zero the range selected.

6. Press the PEAK button; the indicator “Pmax” will be

displayed.

7. The display will update each time a higher positive peak

occurs.

8. Press the PEAK button again; the indicator “Pmin” will

be displayed. The display will now update and indicate

the lowest negative peak.

8

1065DGMAN_20250-53-54 Manual.indd 8 8/16/2017 10:42:05 AM

Page 9

9. To return to normal operation, press and hold the PEAK

button until the “Pmax” or “Pmin” indicator switches

off.

10. If the rotary function switch position is changed after a

calibration, the PEAK Hold calibration must be repeated

for the new function selected.

BACKLIGHT Button

1. Press the BACKLIGHT button to switch on the display

light.

2. Press BACKLIGHT button again to exit the light mode.

AC and DC Voltage Measurements

1. Insert the black test lead into the negative COM terminal

and the red test lead into the positive V terminal.

2. Set the rotary function switch to the V AC/DC position.

3. Press the MODE button to select “AC” or “DC” voltage.

4. Connect the test leads in parallel to the circuit under test.

5. Read the voltage measurement on the display.

AC and DC Current Measurements

1. Insert the black test lead banana plug into the negative

COM jack.

2. For current measurements up to 4000 µA, set the rotary

function switch to the µA position and insert the red test

lead banana plug into the (µA, mA) jack.

3. For current measurements up to 400 mA, set the rotary

function switch to the mA range and insert the red test

lead banana plug into the (µA, mA) jack.

1065DGMAN_20250-53-54 Manual.indd 9 8/16/2017 10:42:05 AM

9

Page 10

4. For current measurements up to 10 A, set the rotary

function switch to the 10A position and insert the red

test lead banana plug into the 10A jack.

5. Press the MODE button to select “AC” or “DC” current.

6. Remove power from the circuit under test, then open the

circuit at the point where you wish to measure current.

7. Touch the black test probe tip to the negative side of the

circuit and touch the red test probe tip to the positive

side of the circuit.

8. Apply power to the circuit.

9. Read the current measurement on display. The proper

decimal point, value, and symbol will be indicated.

Resistance Measurement

WARNING: To avoid electric shock, disconnect power

to the unit under test and discharge all capacitors

before taking any resistance measurements. Remove

the batteries and unplug the line cords.

1. Set the rotary function switch to the Ω position.

2. Insert the black test lead plug into the negative COM

socket and the red test lead plug into the positive Ω jack.

3. Press the MODE button until “Ω” appears in the display.

4. Touch the test probe tips across the circuit or part under

test. It is best to disconnect one side of the part under

test so the rest of the circuit will not interfere with the

resistance reading.

5. Read the resistance measurement on the display. The

display will indicate the proper decimal point, value, and

symbol.

10

1065DGMAN_20250-53-54 Manual.indd 10 8/16/2017 10:42:05 AM

Page 11

Continuity Check

WARNING: To avoid electric shock, never measure

continuity on circuits or wires that have voltage on

them.

1. Set the rotary function switch to the •))) position.

2. Insert the black lead plug into the COM socket and the

red test lead plug into the positive •))) socket.

3. Press the MODE button until “•)))” appears in the display.

4. Touch the test probe tips to the circuit or wire you wish

to check.

5. If the resistance is less than 50 Ω (20250-53) or 35 Ω

(20250-54), the audible signal will sound. The display will

also show the actual resistance in ohms.

Diode Test

WARNING: To avoid electric shock, do not test any

diode that has voltage on it.

1. Set the rotary function switch to the

position.

2. Insert the black test lead plug into the COM socket and

the red test lead plug into the

3. Press the MODE button until “

socket.

” appears in the display.

4. Touch the test probe tips to the diode or semiconductor

junction you wish to test. Note the meter reading.

5. Reverse the probe polarity by switching probe position.

Note this reading.

1065DGMAN_20250-53-54 Manual.indd 11 8/16/2017 10:42:05 AM

11

Page 12

6. The diode or junction can be evaluated as follows:

a. If one reading shows a value and the other reading

shows “OL”, the diode is good.

b. If both readings show “OL”, the device is open.

c. If both readings are very small or zero, the device is

shorted.

NOTE: The value indicated in the display during the

diode check is the forward voltage.

Capacitance Measurement

WARNING: To avoid electric shock, discharge the

capacitor under test before measuring.

1. Set the rotary function switch to the CAP position.

2. If needed, press the MODE button until “nF” appears in

the display.

3. Insert the black test lead banana plug into the negative

COM jack and the red test lead banana plug into the

CAP positive jack.

4. Touch the test probe tips across the part under test.

5. Read the capacitance value in the display. The display

will indicate the proper decimal point and value.

Note: For very large values of capacitance, measurement

time can be several minutes before the nal reading stabi-

lizes. The bar graph is disabled in capacitance measurement

mode. The LCD displays “DIS. C”. Discharging through the

chip is quite slow. We recommend that the user discharge the

capacitor with some other apparatus.

12

1065DGMAN_20250-53-54 Manual.indd 12 8/16/2017 10:42:05 AM

Page 13

Frequency or % Duty Cycle Measurements

(Model 20250-53 only)

1. Set the rotary function switch to the Hz% position.

2. Press the Hz% button to indicate “Hz” in the display.

3. Insert the black lead banana plug into the negative COM jack

and the red test lead banana plug into the positive Hz jack.

4. Touch the test probe tips to the circuit under test.

5. Press the Hz% button again to indicate “%” on the

display. Read the % of duty cycle on the display.

Frequency Measurement (Model 20250-54 only)

1. Set the rotary function switch to the Hz position.

2. Insert the black test lead banana plug into the negative

COM jack and the red test lead banana plug into the

positive Hz jack.

3. Touch the test probe tips to the circuit under test.

4. Read the frequency in the display. The digital reading

will indicate the proper decimal point, symbols (Hz, kHz,

MHz), and value.

Temperature Measurement (Model 20250-54 only)

1. Set the rotary function switch to the Temp °C or Temp °F

position.

2. Insert the temperature probe into the input jacks, making

sure to observe the correct polarity.

3. Touch the probe head to the part whose temperature

you wish to measure. Keep the probe touching the part

under test until reading stabilizes (about 30 seconds).

4. Read the temperature measurement on the display.

1065DGMAN_20250-53-54 Manual.indd 13 8/16/2017 10:42:05 AM

13

Page 14

Note: The temperature probe is tted with a type K mini

connector. A mini connector to banana connector adapter

is supplied for connection to the input banana jacks.

Noncontact Voltage Detection

The noncontact voltage (NCV) function works on any rotary

function switch position.

1. Test the detector on a known live circuit before use.

2. Hold the top of the meter very close to the voltage

source as shown.

3. If voltage is present, the NCV indicator light above the

LCD will ash a bright red.

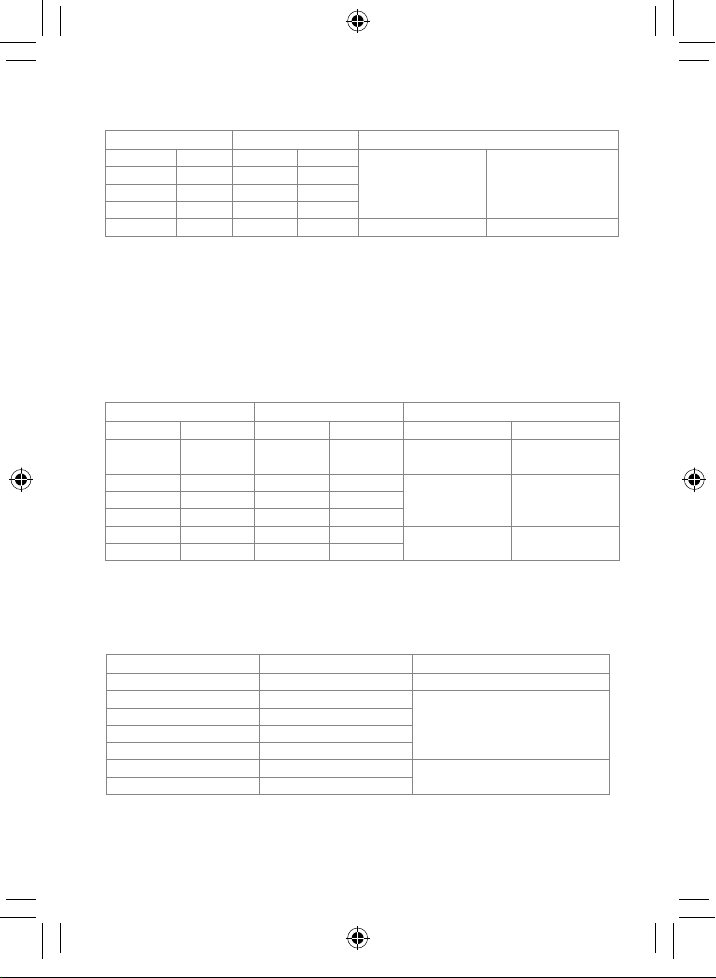

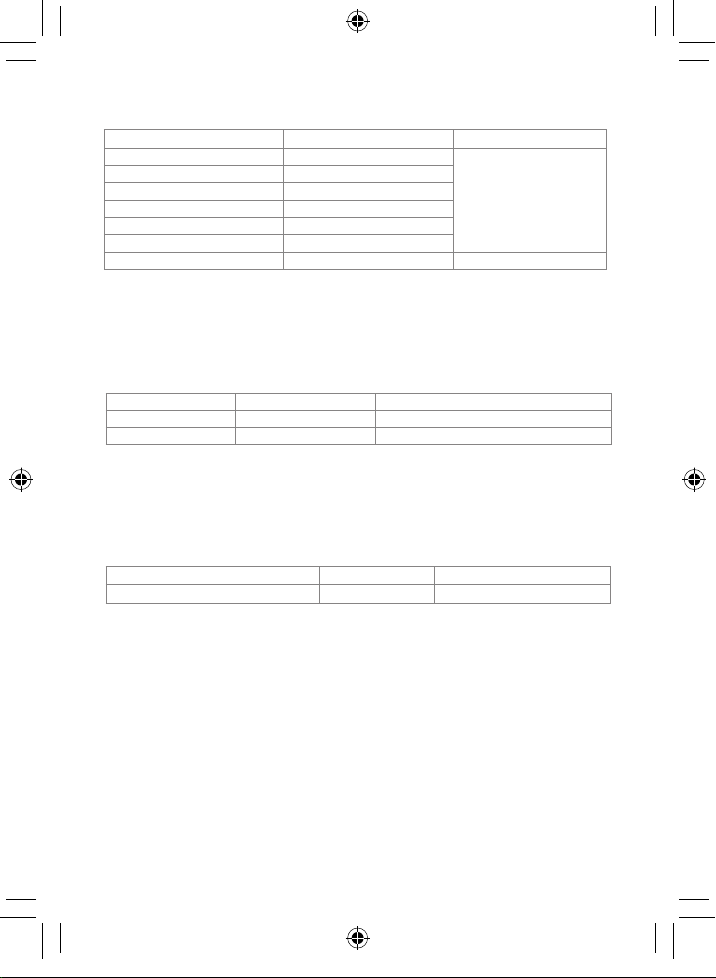

Specifications

Accuracy is given at 65 to 83°F (18 to 28°C), less than 70% RH.

DC Voltage (Autoranging)

Range Resolution Accuracy

20250-53 20250-54 20250-53 20250-54 20250-53 20250-54

400.0 mV 400.0 mV 0.1 mV 0.1 mV

4.000 V 4.000 V 1 mV 1 mV

40.00 V 40.00 V 10 mV 10 mV

400.0 V 400.0 V 100 mV 100 mV

1000 V 1000 V 1 V 1 V

Input impedance: 10 MΩ

Maximum input: 1000 V DC

±1.2% rdg

± 2 dgts

±1.2% rdg

± 4 dgts

±0.8% rdg

± 2 dgts

±1% rdg

± 2 dgts

14

1065DGMAN_20250-53-54 Manual.indd 14 8/16/2017 10:42:05 AM

Page 15

AC Voltage (Autoranging)

Range Resolution Accuracy

20250-53 20250-54 20250-53 20250-54 20250-53 20250-54

400.0 mV 400.0 mV 0.1 mV 0.1 mV

4.000 V 4.000 V 1 mV 1 mV

40.00 V 40.00 V 10 mV 10 mV

400.0 V 400.0 V 100 mV 100 mV

1000 V 1000 V 1 V 1 V

±1.5% rdg

± 3 dgts

±1.5% rdg

± 5 dgts

±1.0% rdg

± 3 dgts

±1.2% rdg

± 5 dgts

Input impedance: 10 MΩ

AC response: 50 to 400 Hz

Maximum input: 1000 V AC RMS

DC Current (Autoranging)

Range Resolution Accuracy

20250-53 20250-54 20250-53 20250-54 20250-53 20250-54

400.0 µA 400.0 µA 0.1 µA 0.1 µA

4000 µA 4000 µA 1 µA 1 µA

40.00 mA 40.00 mA 10 µA 10 µA

400.0 mA 400.0 mA 100 µA 100 µA

10 A 10 A 10 mA 10 mA

Overload protection: FF500mA / 1000V and F10A / 1000V fuse

Maximum input: 400 µA DC on µA range, 400 mA DC on mA range,

10 A DC on 10 A range

±1.2% rdg

± 3 dgts

±2.5% rdg

± 3 dgts

±1.2% rdg

± 5 dgts

±1.5% rdg

± 5 dgts

1065DGMAN_20250-53-54 Manual.indd 15 8/16/2017 10:42:06 AM

15

Page 16

AC Current (Autoranging)

Range Resolution Accuracy

400.0 µA 400.0 µA 0.1 µA 0.1 µA

4000 µA 4000 µA 1 µA 1 µA

40.00 mA 40.00 mA 10 µA 10 µA

400.0 mA 400.0 mA 100 µA 100 µA

10 A 10 A 10 mA 10 mA ±3.0% rdg ± 7 dgts ±1.8% rdg ± 5 dgts

±1.5% rdg ± 5 dgts ±1.2% rdg ± 5 dgts

Overload protection: FF500mA / 1000V and F10A / 1000V fuse

Frequency range: 50 to 400 Hz

Maximum input: 400 µA AC RMS on µA range, 400 mA AC RMS

on mA range, 10 A AC RMS on 10 A range

Resistance (Autoranging)

Range Resolution Accuracy

20250-53 20250-54 20250-53 20250-53 20250-54 20250-53

400.0 Ω 400.0 Ω 0.1 Ω 0.1 Ω

4.000 kΩ 4.000 kΩ 1 Ω 1 Ω

40.00 kΩ 40.00 kΩ 10 Ω 10 Ω

400.0 kΩ 400.0 kΩ 100 Ω 100 Ω

4.000 MΩ 4.000 MΩ 1 kΩ 1 kΩ

40.00 MΩ 40.00 MΩ 10 kΩ 10 kΩ

±1.2% rdg

± 5 dgts

±1.0% rdg

± 2 dgts

±2.5% rdg

± 8 dgts

±0.8% rdg

± 5 dgts

±0.8% rdg

± 2 dgts

±2.5% rdg

± 8 dgts

Input protection: 1000 V DC or 1000 V AC RMS

Capacitance (Autoranging)

Range Resolution Accuracy

40.00 nF 10 pF ±5.0% rdg ± 7 dgts

400.0 nF 0.1 nF

4.000 µF 1 nF

40.00 µF 10 nF

400.0 µF 0.1 µF

4.000 mF 1 µF

40.00 mF 10 µF

Input protection: 1000 V DC or 1000 V AC RMS

±3.0% rdg ± 5 dgts

±5.0% rdg ± 7 dgts

1065DGMAN_20250-53-54 Manual.indd 16 8/16/2017 10:42:06 AM

16

Page 17

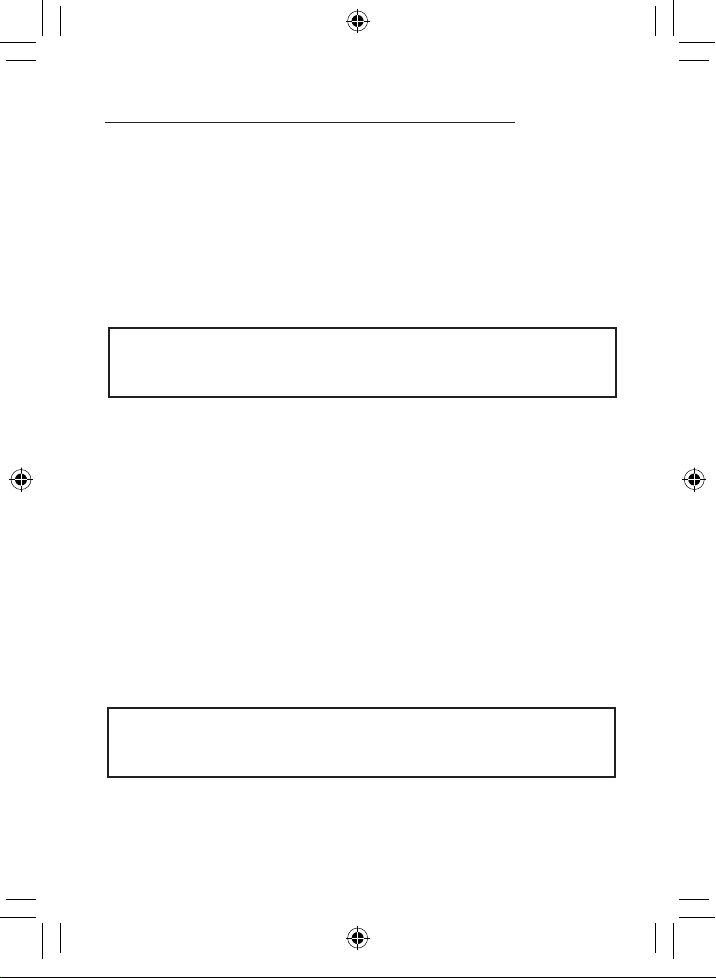

Frequency (Autoranging)

Range Resolution Accuracy

4.000 Hz 0.001 Hz

40.00 Hz 0.01 Hz

400.0 Hz 0.1 Hz

4.000 kHz 1 Hz

40.00 kHz 10 Hz

400.0 kHz 100 Hz

10.00 MHz 1 kHz ±1.2% rdg ± 4 dgts

±1.0% rdg ± 3 dgts

Sensitivity: >0.5 V RMS while ≤1 MHz; >3 V RMS while >1 MHz

Overload protection: 1000 V DC or 1000 V AC RMS

Temperature (Model 20250-54 only)

Range Resolution Accuracy

–4 to 1400°F 1°F ±3% rdg ± 8 dgts

–20 to 760°C 1°C ±3% rdg ± 5 dgts

Sensor: type K thermocouple

Overload protection: 1000 V DC or AC RMS

Diode Test

Test current Resolution Accuracy

1 ma typical, open max 0.3 V 1 mV ±10% rdg ± 5 dgts

Open circuit voltage: max 0.3 V DC

Overload protection: 1000 V DC or AC RMS

Audible Continuity

Audible threshold: Less than 50 Ω (20250-53),

35 Ω (20250-54); Test current max 1.5 mA

Overload protection: 1000 V DC or AC RMS

Compliance: IEC/EN 61010-1:2001 and IEC/EN 61010-031:2002

Insulation: Class 2, Double insulation

1065DGMAN_20250-53-54 Manual.indd 17 8/16/2017 10:42:06 AM

17

Page 18

Overvoltage category: CAT IV 600 V, CAT III 1000 V

NOTE: These meters meet CAT III and CAT IV IEC 61010 standards.

The IEC 61010 safety standard denes four overvoltage categories

(CAT I to IV) based on the magnitude of danger from transient

impulses. CAT III meters are designed to protect against transients in

xed-equipment installations at the distribution level; CAT IV meters

are designed to protect against transients from the primary

supply level (overhead or underground utility service).

Max voltage between any terminal and earth ground:

1000 V DC/AC RMS

Display: 4000 count LCD, 13⁄16" (21 mm) high

Polarity: Automatic, (–) negative polarity indication

Overrange indication: “OL” mark indication is displayed

Low-battery indication: Battery symbol “ ” is displayed

Measurement rate: 2 times per second nominal

Operating environment: 14 to 122°F (–10 to 50°C) at <70% RH

Storage temperature: –4 to 140°F (–20 to 60°C) at <80% RH

Relative humidity: 90% (0 to 30°C); 75% (30 to 40°C);

45% (40 to 50°C)

For inside use, max height: Operating: 9842 ft (3000 m), Storage

32,808 ft (10,000 m)

Pollution degree: 2

Power: One 9 V battery, NEDA 1604, IEC 6F22

Auto power-off: Approximately after 30 minutes

of inactivity

Weight: 13 oz (375 g)

Dimensions: 73⁄16" x 31⁄4" x 23⁄16" (18.2 x 8.2 x 5.5 cm)

1065DGMAN_20250-53-54 Manual.indd 18 8/16/2017 10:42:06 AM

18

Page 19

Maintenance, Recalibration, and Repair

Cleaning and Storage

• Clean meter with a damp cloth and mild detergent when

necessary. Do not use solvents or abrasives.

• Store the meter in an area with moderate temperature

and humidity.

Battery Replacement

WARNING: To avoid electric shock, disconnect the

test leads from any source of voltage before removing the battery door.

1. When the battery becomes exhausted or drops below

operating voltage, the battery warning symbol will

appear in the right-hand side of the LCD. The battery

should be replaced.

2. Disconnect the test leads from the meter.

3. Open the battery door by loosening the screw using a

Phillips head screwdriver.

4. Insert the battery into battery holder, observing the

correct polarity.

5. Put the battery door back in place. Secure with the two

screws.

6. Dispose of the old battery properly.

WARNING: To avoid electric shock, do not operate

your meter until the battery door is in place and

fastened securely.

1065DGMAN_20250-53-54 Manual.indd 19 8/16/2017 10:42:06 AM

19

Page 20

It is recommended that Digi-Sense products are calibrated

annually to ensure proper function and accurate measure-

ments; however, your quality system or regulatory body

may require more frequent calibrations.

To schedule your recalibration, please contact InnoCal,

an ISO 17025 calibration laboratory accredited by A2LA.

Phone: 1-866-INNOCAL (1-866-466-6225)

Fax: 1-847-327-2993

E-mail: sales@innocalsolutions.com

Web: InnoCalSolutions.com

For Product and Ordering Information, Contact:

Toll-Free: 1-800-323-4340

Phone: 1-847-549-7600

Fax: 1-847-247-2929

ColeParmer.com/Digi-Sense

1065DGMAN_20250-53, -54

1065DGMAN_20250-53-54 Manual.indd 20 8/16/2017 10:42:06 AM

Toll-Free: 1-800-358-5525

Phone: 1-847-327-2000

Fax: 1-847-327-2700

Davis.com/Digi-Sense

Manual Part No. 00101-87

20

Loading...

Loading...