Page 1

4G Rear Units (Latch and Bolt)

Installation Guide

Range Oval Front Unit (Keypad and RFID)

Range Narrow Front Unit (Keypad and RFID)

Range Standard Front Unit (Keypad and RFID)

Range Rear Unit (Latch and Bolt 5G)

Page 2

Table of Contents

Before Lock Installation..................................................................................................................................................................................................................................3

Surface Mount Installation

For door thickness measuring between .16” - .91” (4 mm - 23 mm)

Required Components ...............................................................................................................................................................................................................4

Installation

For door thickness measuring between .01" - .16" (0.2mm - 4 mm)

Required Components ...............................................................................................................................................................................................................7

Installation

Door Preparation

.........................................................................................................................................................................................................................................5

.........................................................................................................................................................................................................................................8

Strike Plate Installation

Required Components ............................................................................................................................................................................................................10

Installation

......................................................................................................................................................................................................................................11

Door Mounting Holes Drill Instructions and Template

Drill Instructions .........................................................................................................................................................................................................................12

Template for Standard & Vertical Body

Metal Door Preparation

Compatibility Guide

Removal of 3-hole Lock Plug

Removal of Padlock Hasp

.............................................................................................................................................................14

............................................................................................................................................14

..................................................................................................................................................15

......................................................................................................................................................................13

Page 3

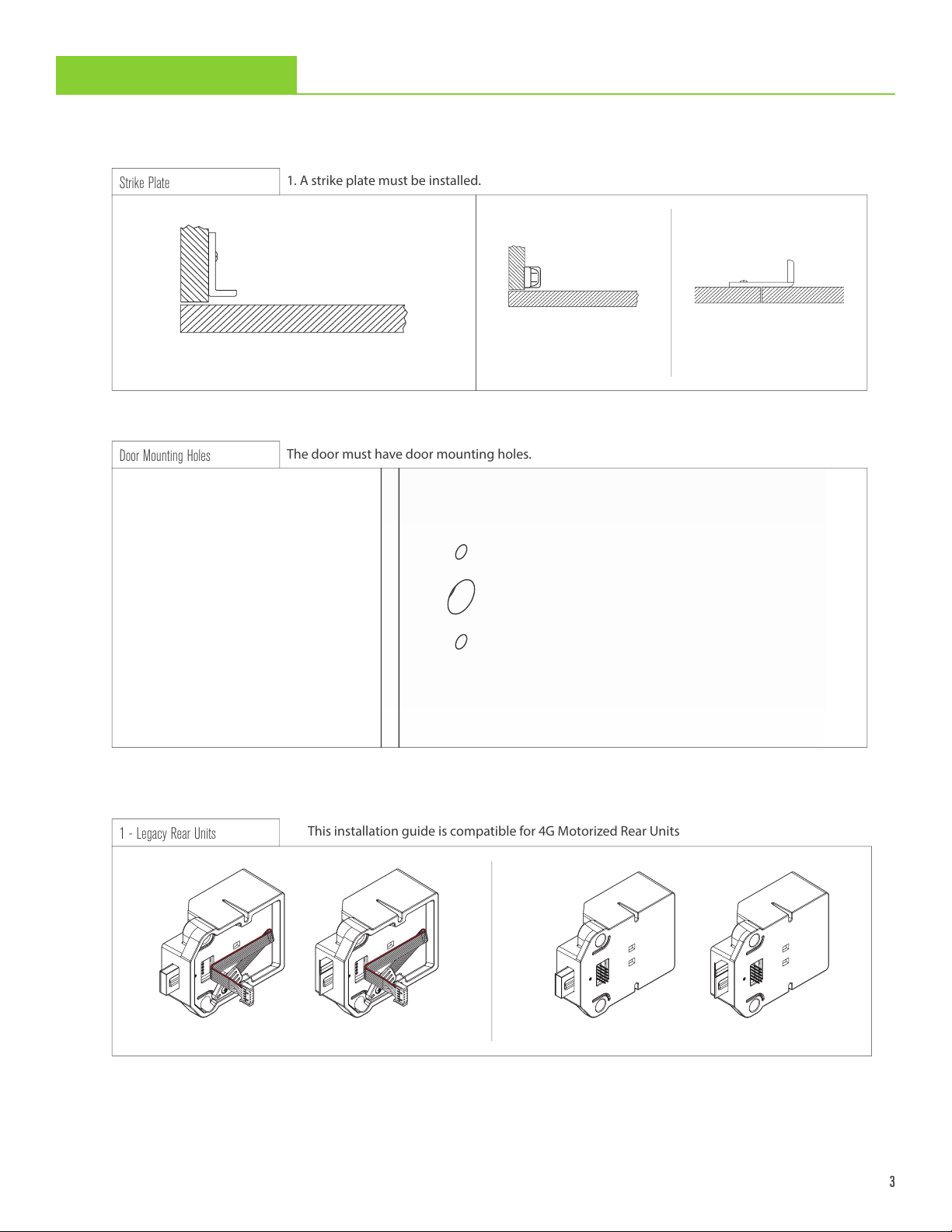

3

The door must have door mounting holes.

Door Mounting Holes

Before Lock Installation

1. A strike plate must be installed.

Strike Plate

1 - Legacy Rear Units

This installation guide is compatible for 4G Motorized Rear Units

The door must be prepared for lock installation.

1

Double Door Strike Plate

Angled Strike Plate

Security Strike Plate

Recommended for latch products

2

Deadbolt - Cable Deadlatch - Cable

Deadbolt - Cable Deadlatch - Cable

Page 4

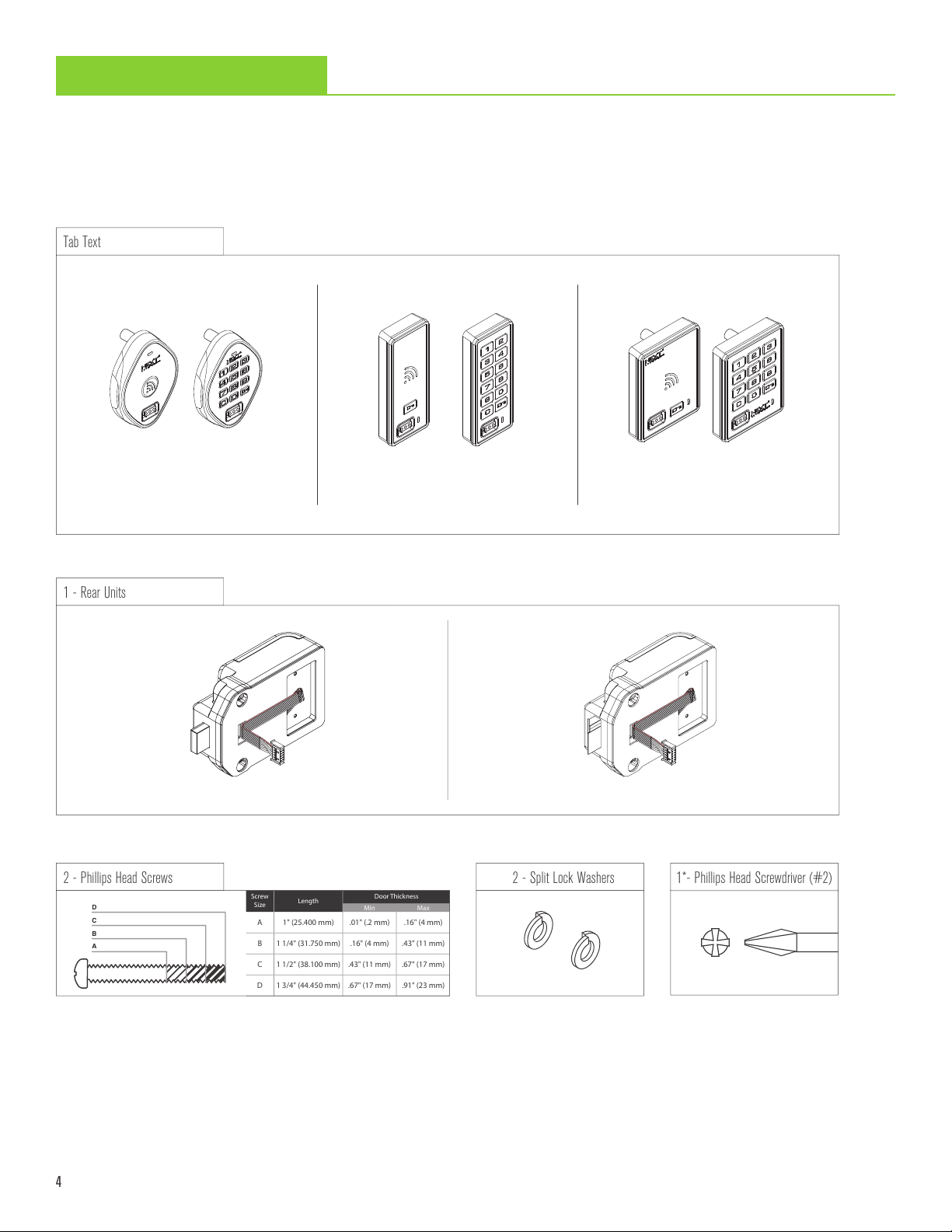

4

1*- Phillips Head Screwdriver (#2)

2 - Phillips Head Screws

D

C

B

A

Screw

Size

Length

Door Thickness

Min Max

A 1" (25.400 mm) .01" (.2 mm) .16" (4 mm)

B 1 1/4" (31.750 mm) .16" (4 mm) .43" (11 mm)

C 1 1/2" (38.100 mm) .43" (11 mm) .67" (17 mm)

D 1 3/4" (44.450 mm) .67" (17 mm) .91" (23 mm)

2 - Split Lock Washers

Surface Mount Installation

1 - Rear Units

Tab Text

For door thickness measuring between .16" - .91" (4 mm - 23 mm)

Required Components

Oval Body

RFID and Keypad

Narrow Body

RFID and Keypad

Standard Body

RFID and Keypad

Deadbolt - Cable Deadlatch - Cable

*Not included

Page 5

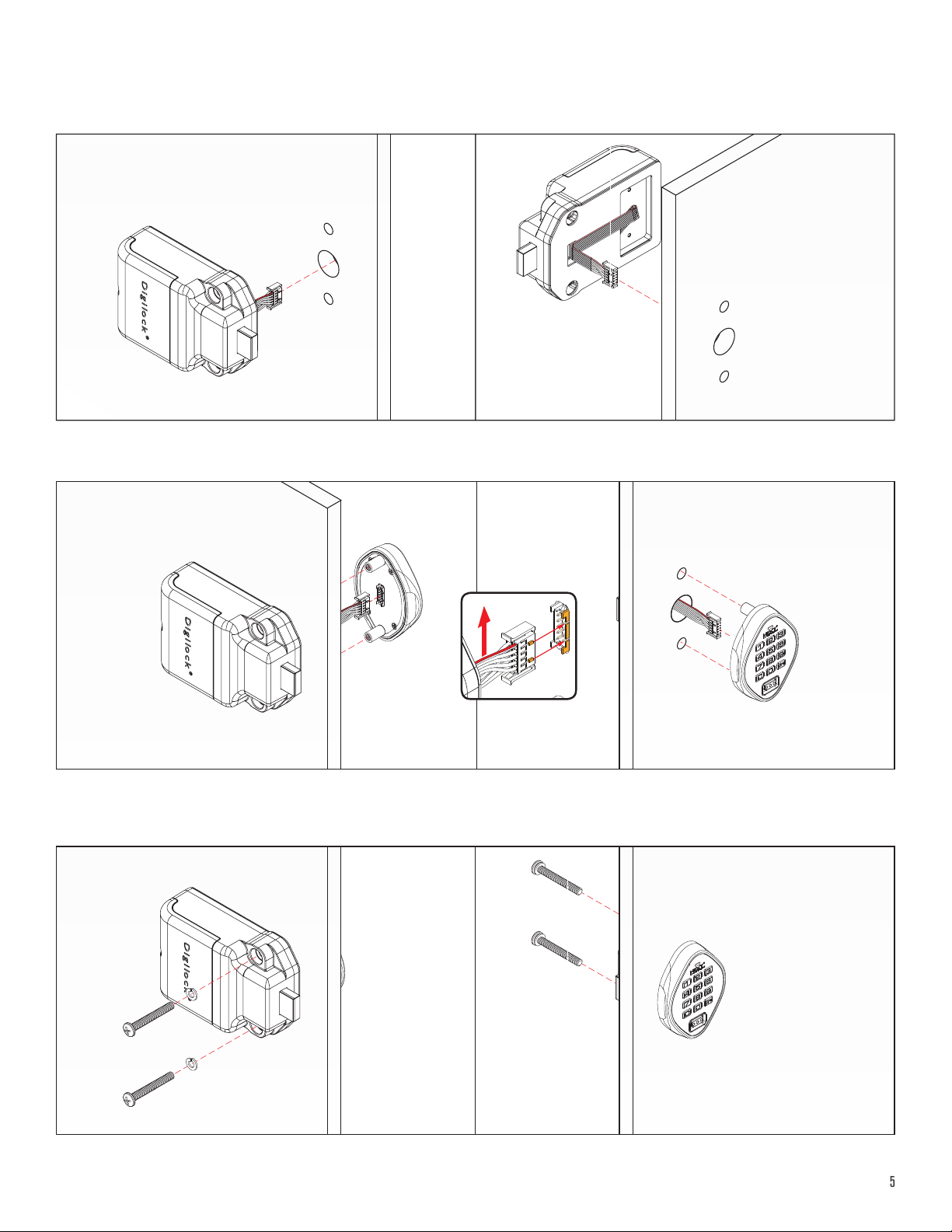

5

Installation

For illustration, a oval body keypad front unit with a bolt rear unit is used.

1

REAR VIEW FRONT VIEW

With the rear unit behind the door, extend the cable through the door’s mounting hole.

2

g.-1

REAR VIEW FRONT VIEW

Orient the cable with the red wire position on the top of the ribbon (see g-1). Attach the cable to the front unit using the corresponding

channel guides to ensure the snap connector is properly secured. Once connected a triple beep indicates successful connection.

3

REAR VIEW FRONT VIEW

Hold the front and rear units against the door and secure with the mounting screws. Ensure the remaining cable is not pinched.

Page 6

6

4

REAR VIEW FRONT VIEW

Test the lock while the door is open to ensure that the bolt or latch is operating properly.

For keypad locks with deadbolt rear units:

Press = ` to extend the bolt.

Press = ` again to retract the bolt.

For keypad locks with deadlatch rear units:

Press = ` to retract the latch.

The latch will extend automatically.

Repeat test with the door closed.

If ten rapid beeps are heard, the strike plate or door alignment may need adjustment to allow the lock to operate properly.

If the door does not lock when the bolt/latch is extended, the strike plate or lock position may need adjustment.

For touch RFID locks with deadbolt rear units:

Press RFID to extend the bolt.

Press RFID again to retract the bolt.

For touch RFID locks with deadlatch rear units:

Press RFID to retract the latch.

The latch will extend automatically.

Page 7

7

Surface Mount Installation

1* - 3/8” Nut Driver

2 - Locking Nuts

1 - Rear Units

Tab Text

For door thickness measuring between .01” - .16” (0.2 mm - 4 mm)

Required Components

Oval Body

RFID and Keypad

Narrow Body

RFID and Keypad

Deadbolt - Cable Deadlatch - Cable

Standard Body

RFID and Keypad

*Not included

Page 8

8

Installation

For illustration, a oval body keypad front unit with a bolt rear unit is used.

1

REAR VIEW FRONT VIEW

Insert the front unit screw posts through the door mounting holes.

2

REAR VIEW FRONT VIEW

Hold the front unit against the front of the door. Use the rear unit mounting holes as a guide, then slide the front and rear units together.

Make sure the connector pins align properly with the connector.

If properly connected, a triple beep will be heard and the LED will ash three times.

3

REAR VIEW FRONT VIEW

Insert the locking nuts on the screw posts and tighten using the ratchet/screw gun. Do not over tighten.

Page 9

9

4

REAR VIEW FRONT VIEW

Test the lock while the door is open to ensure that the bolt/latch is operating properly.

For keypad locks with deadbolt rear units:

Press = ` to extend the bolt.

Press = ` again to retract the bolt.

For keypad locks with deadlatch rear units:

Press = ` to retract the latch.

The latch will extend automatically.

Repeat test with the door closed.

If ten rapid beeps are heard, the strike plate or door alignment may need adjustment to allow the lock to operate properly.

If the door does not lock when the bolt/latch is extended, the strike plate or lock position may need adjustment.

For touch RFID locks with deadbolt rear units:

Press RFID to extend the bolt.

Press RFID again to retract the bolt.

For touch RFID locks with deadlatch rear units:

Press RFID to retract the latch.

The latch will extend automatically.

Page 10

10

1. A strike plate must be installed.

Strike Plate*

1*- Phillips Head Screwdriver (#1)

1*- Drill

1*- Pencil

1*- 1/6” Drill bit

Removable tape*

1*- 5/16” Drill bit

1*- Ruler

1*- 3/4” Drill bit

Door Preparation

Strike Plate Installation

Required Components

Angled Strike Plate

Security Strike Plate

Recommended for latch products

Double Door Strike Plate

*Not included

Page 11

11

Installation

Door Frame

0.32 in

(8 mm)

Mark Here

Door Frame

Drill Pilot

Holes Here

Door Frame

0.32 in

(8 mm)

Door Frame

0.32 in

(8 mm)

Mark Here

Door Frame

Door Frame

1

Position the strike plate on the door frame aligning it with

the center of the lock’s mounting holes.

3

2

Allow .32" (8 mm) from door edge and mark the position

of the adjustment slot holes.

4

Drill 0.25" (6.35 mm) pilot holes using a 1/6" drill bit.

5

Adjust the strike plate to the proper position (.32" (8 mm)

from the door edge) then tighten the self tapping screws.

Position the strike plate and the self tapping screws into the

adjustment slot holes. Do not tighten the screws.

6

Position and tighten the remaining self tapping screw

into the center hole.

Page 12

12

Door Mounting Holes Drill Instruction and Template

(a)

(b)

Strike Center

(b)

(a)

(a)

(b)

Drill x2

5/16” 0.3125 in

(7.94 mm)

Drill 3/4”

0.75 in (19.1 mm)

Drill Instructions

1

With the door open place the Template over the locker frame.

(a) Align the Edge of Strike Plate with the Strike Plate Marker.

(b) Center the Template to the center of the Strike Plate.

You may secure the Template with removable tape.

3

2

Close the door over the Template.

(a) Mark the door edge at the Template Center Line.

(b) Mark the Template with the edge of the door.

4

Place the Template on the front of the door.

(a) Align the drawn mark on the Template with the door edge.

(b) Center the Template with the mark on the door.

Secure the Template with removable tape.

Mark the center points of the door mounting holes on the front of

the door. Drill the holes according the specied dimensions.

Page 13

13

Template for Door Mounting Holes

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn o auto scaling in printer setup and print at 100%

All measurements in thousandths

ALIGN EDGE OF

STRIKE PLATE HERE

FOR LEFT

CLOSING DOOR

of an inch and millimeters

)mm( 9.72

001.1

.300

7.62 (mm)

use 5/16" bit

ALIGN EDGE OF

STRIKE PLATE HERE

FOR RIGHT

CLOSING DOOR

001.1

)mm( 9.72

CENTER LINE

CENTER LINE

ALIGN EDGE OF

STRIKE PLATE HERE

FOR LEFT

CLOSING DOOR

)mm( 9.72

001.1

.905

23 (mm)

.750

19.05 (mm)

use 3/4" bit

.300

7.62 (mm)

.905

23 (mm)

001.1

)mm(9.72

ALIGN EDGE OF

STRIKE PLATE HERE

FOR RIGHT

CLOSING DOOR

Page 14

14

Metal Door Preparation

Single Point Latch

Handle

Standard Lift

Box Locker Padlock Hasp

Compatibility Guide

Digilock is compatible with a majority of 3-hole conguration, latch, and handle door types. Some doors may require modication to clear

obstructions.

Removal of 3-hole Lock Plug

Remove any obstructions to the door mounting holes.

1 2

Rear View of Locker Door with Lock Plug

Page 15

15

Removal of Padlock Hasp

1* - Handheld Grinder or Hack Saw

1* - Metal File

The padlock hasp must be removed

*Not included

1

Close the door and make sure that nothing is

protruding above the surface of the door.

3

2

Close the door and mark the area to cut the

padlock hasp.

4

Open the door then cut the padlock hasp on

the marked cut-line.

Smooth out rough or sharp edges.

Page 16

IG-NL-R-DEN

010919 707 766 6000 | sales@digilock.com | www.digilock.com

Loading...

Loading...