Page 1

Installation Guide

Keypad & RFID

Shared & Assigned Use

Standard, Vertical, & Horizontal Body

Page 2

Before Lock Installation

3

16

16

16

17

18

18

19

20

21

21

22

23

24

25

25

26

27

10

10

13

10

13

11

14

4

4

7

4

7

5

8

Surface Mount Installation

For door thickness measuring between .01” - .480” (0.01mm - 12mm)

Required Components

Installation

For door thickness measuring between .480” - 1.998” (12.2mm -50.7mm)

Required Components

Installation

Recess Mount Installation

For door thickness measuring between .370” - .850” (9.4mm - 21.6mm)

Required Components

Installation

For door thickness measuring between .850” - 2.368” (21.6mm - 60.1mm)

Required Components

Installation

Door Preparation

Strike Plate Installation

Required Components

Installation

Door Mounting Holes Drill Instructions and Templates

Drill Instructions

Template for Standard & Vertical Body

Template for Horizontal Body

Routing Instructions and Template

Routing Instructions

Routing Template for Standard Body

Routing Template for Horizontal Body

Routing Template for Vertical Body

Metal Door Preparation

Compatibility Guide

Removal of 3-hole Lock Plug

Removal of Padlock Hasp

Page 3

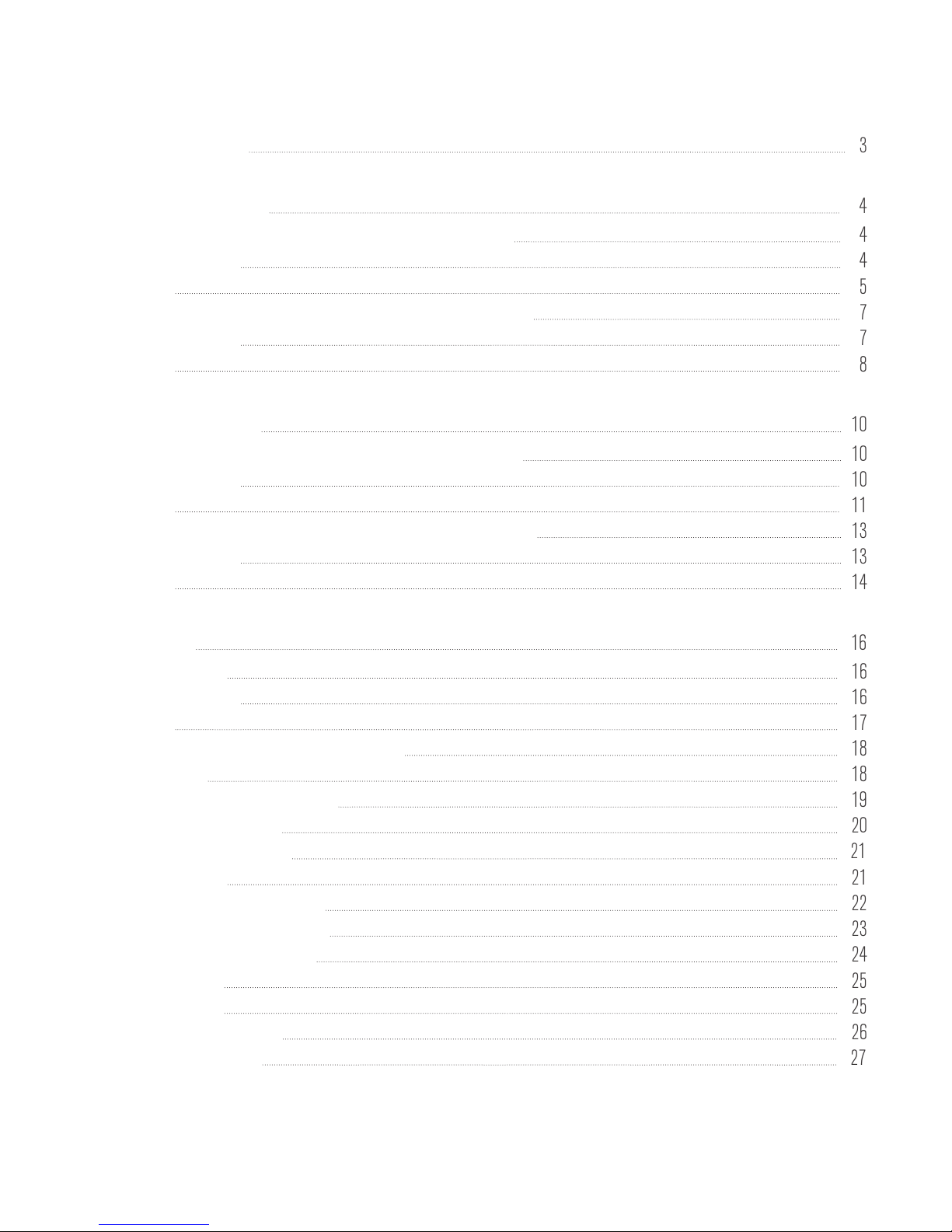

Before Lock Installation

3

The door must be prepared for lock installation.

1.

2a.

Strike Plate

Angled Strike Plate Security Strike Plate Double Door Strike Plate

Door Mounting Holes For surface mount installations, the door must have door mounting holes.

A strike plate must be installed.

2b.

For Standard & Vertical Body For Horizontal Body

Routed Door with Door Mounting Holes

For Standard Body For Vertical Body For Horizontal Body

For recess mount installations, the door must be routed and have door mounting holes.

Page 4

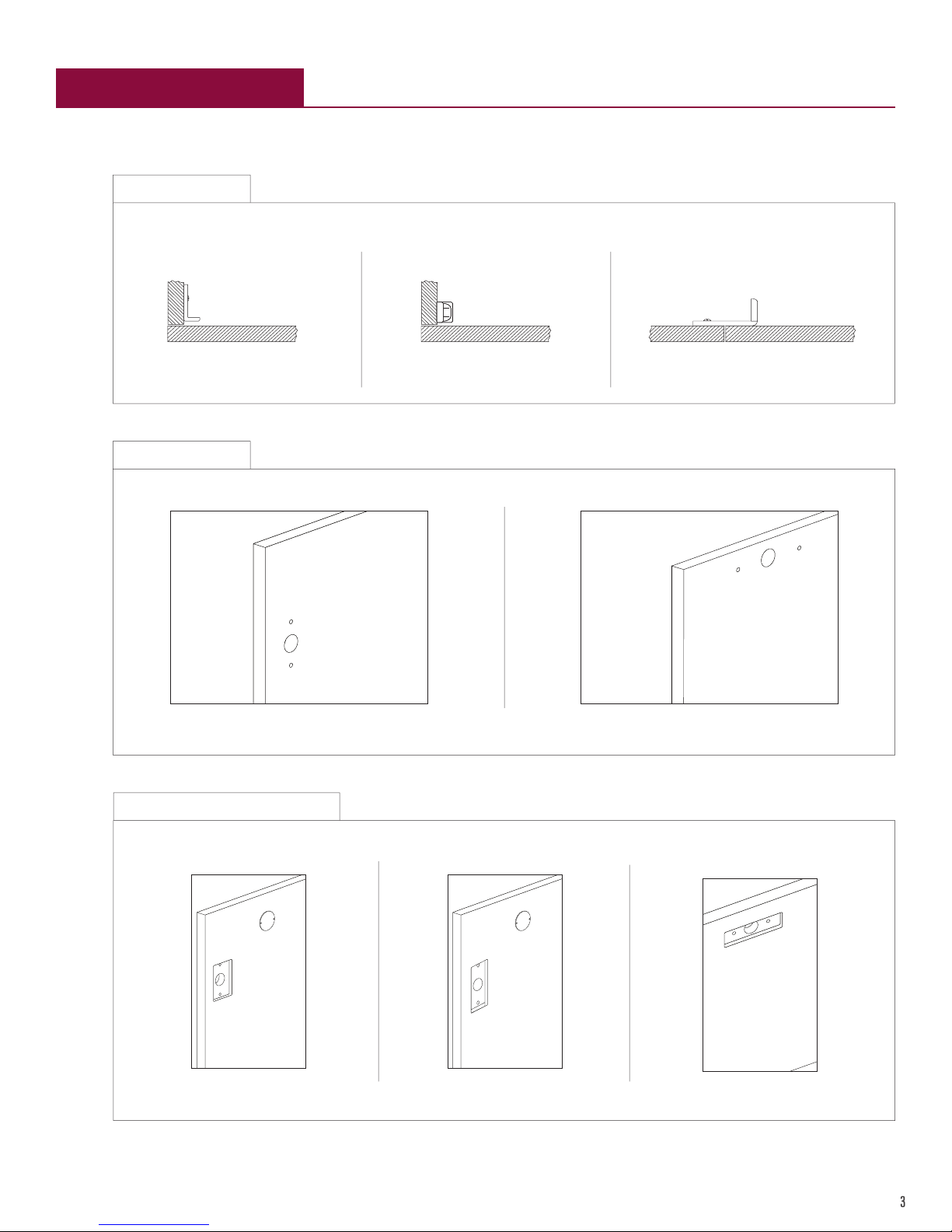

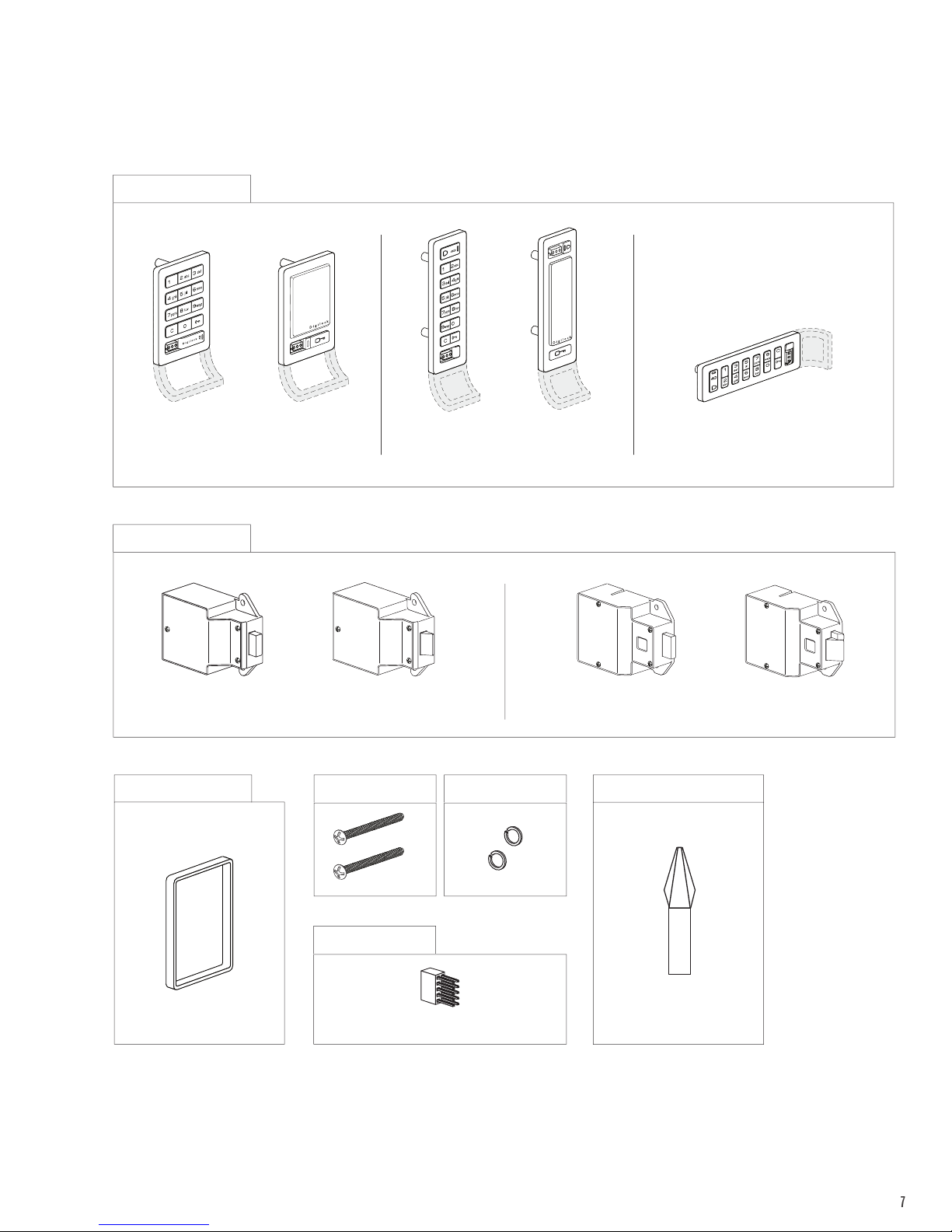

Surface Mount Installation

4

For door thickness measuring between .01” - .480” (0.01mm - 12.0mm)

Required Components

1 - Front Unit

Standard Body Keypad Vertical Body KeypadStandard Body RFID Vertical Body RFID Horizontal Body Keypad

1 - Rear Unit

1 - Plastic Ring

Springbolt Springlatch Deadbolt Deadlatch

1* - Pin Extender

*Required for door thickness measuring between

1* - Ratchet/Screw Gun with a 3/8” Socket

.315”-.480” (8.0-12.2mm)

1 - Locking Nuts

*Not included

u Do not use an electric screw gun unless it is equipped with a torque adjuster and is set to low.

Page 5

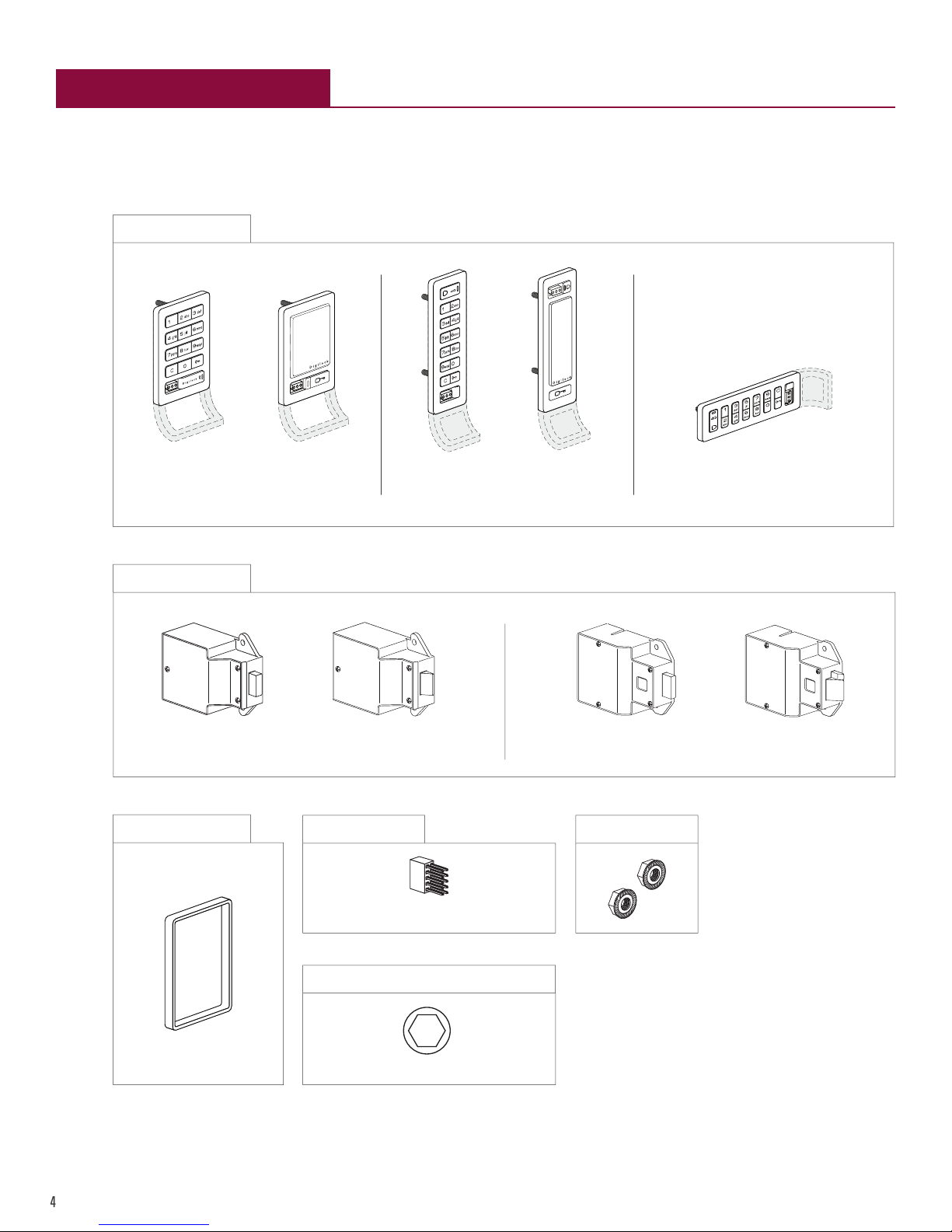

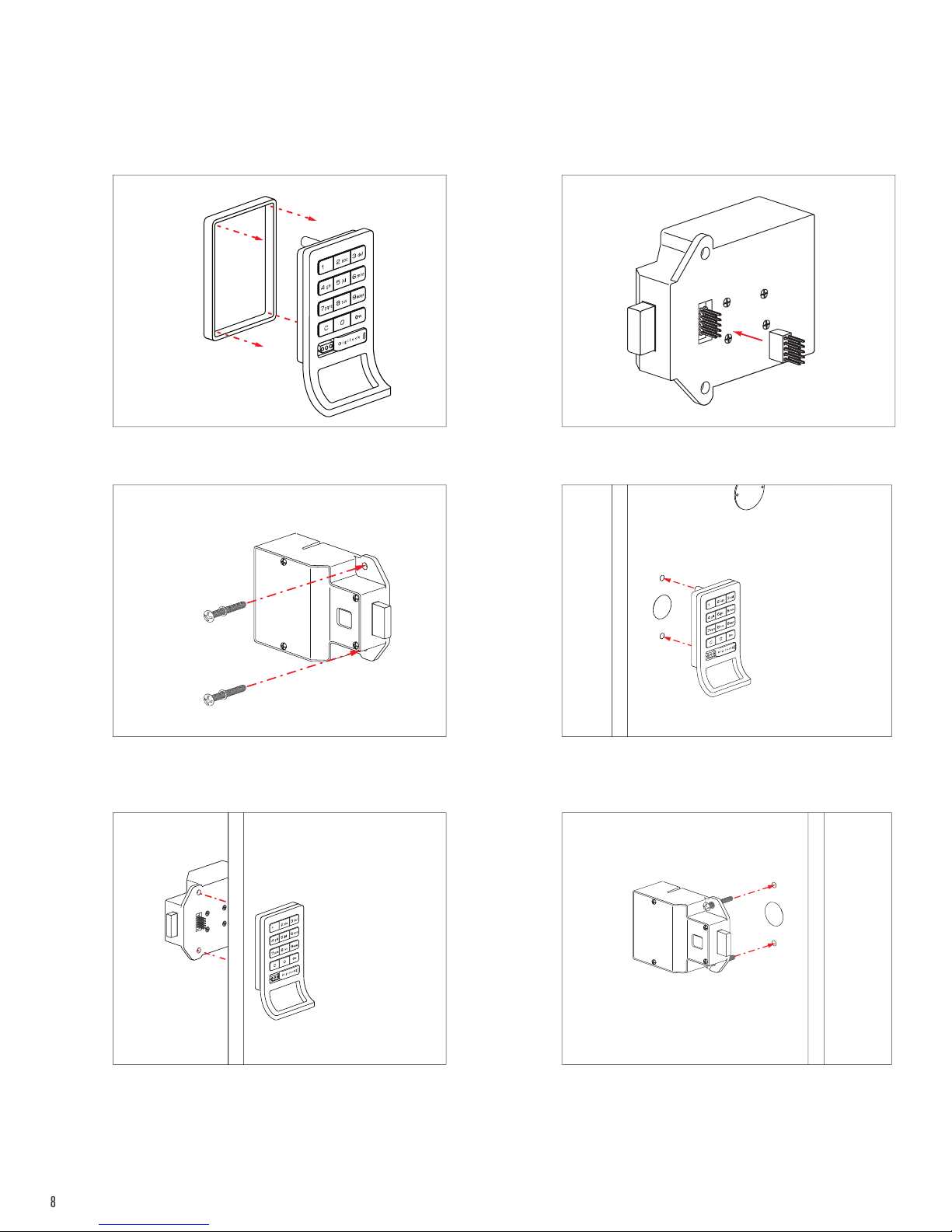

Installation

5

For illustration, a standard body, keypad lock with a bolt rear unit is used.

1 2

Place the plastic ring on the front unit. If required, connect the pin extender to the rear unit.

3

Insert the front unit screw posts through the door

mounting holes.

5

4

Hold the front unit against the front of the door. Use

the rear unit mounting holes as a guide, then slide the

front and rear units together.

6

Make sure the connector pins align properly with the

connector.

If properly connected, a triple beep will be heard and

the LED will flash three times.

Insert the locking nuts on the screw posts and tighten

using the ratchet/screw gun.

u Do not over tighten.

Page 6

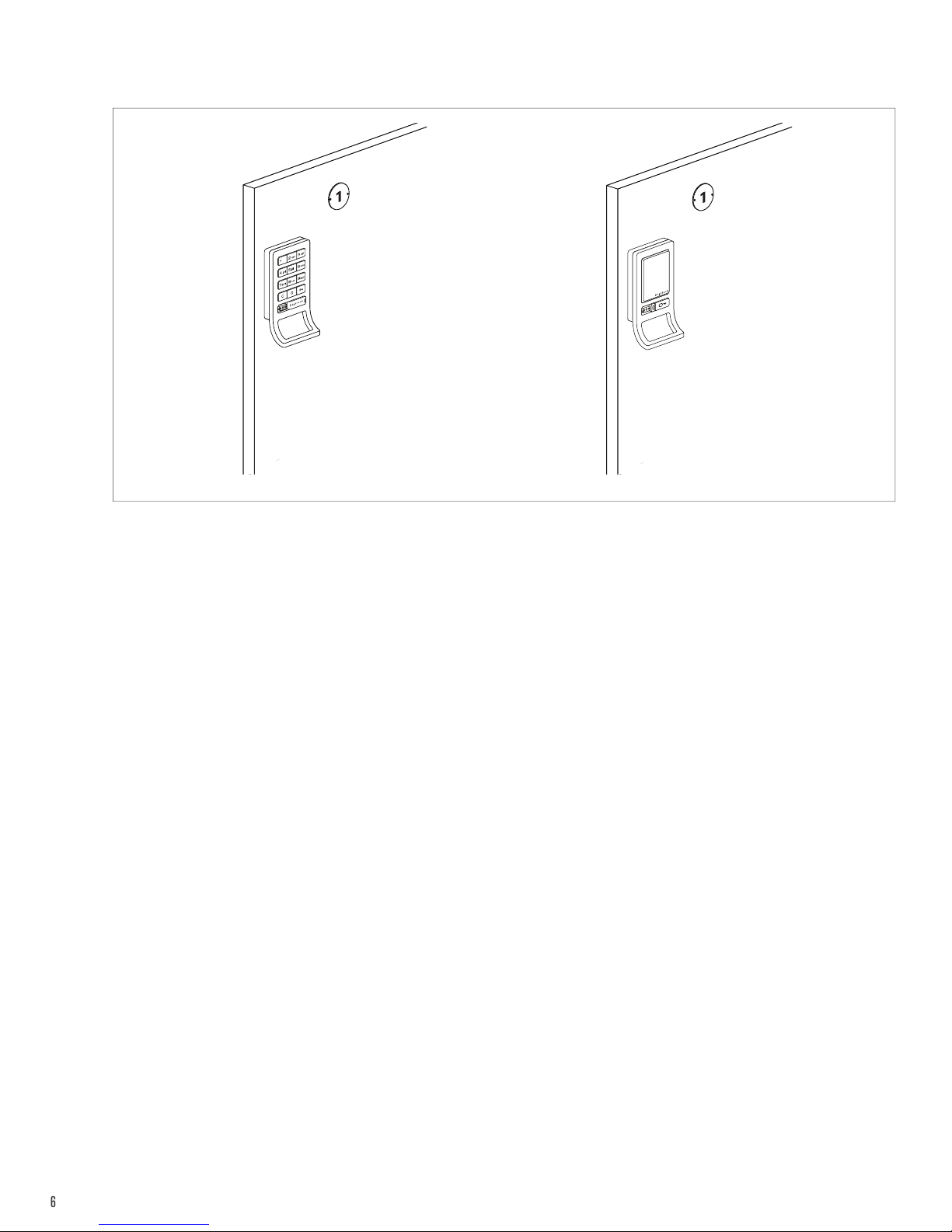

6

7

To test keypad locks: Press = ` To test RFID locks: Press `

Test the locks while the door is open. If locks do not operate, remove and reinstall.

Close the door and test again. If 10 rapid beeps are heard and the LED flashes 10 times, the strike plate and/or the door needs to

be adjusted as it is preventing the lock from operating.

Page 7

For door thickness measuring between .480” - 1.998” (12.2mm - 50.7mm)

7

Required Components

1 - Front Unit

Standard Body Keypad Vertical Body KeypadStandard Body RFID Vertical Body RFID Horizontal Body Keypad

1 - Rear Unit

Springbolt Springlatch Deadbolt Deadlatch

1 - Plastic Ring 2 - Phillips Head Screws

2 - Split Lock Washers 1* - Phillips Head Screwdriver (#2)

1* - Pin Extender

*Two (2) pin extenders are required for door thickness

measuring between 1.20”-1.998” (30.5-50.7mm)

u Do not use an electric screw gun unless it is equipped with a torque adjuster and is set to low.

*Not included

Page 8

Installation

8

For illustration, a standard body, keypad lock with a bolt rear unit is used.

1

Place the plastic ring on the front unit.

3

2

Connect the pin extender to the rear unit.

4

Place the split lock washers on the phillips head screws

and insert them through the rear unit mounting holes.

5

Hold the front unit against the front of the door. Use

the screws of the rear unit as a guide then slide the

front and rear units together.

Insert the front unit nut posts through the door mounting

holes.

6

Make sure the connector pins align properly with the

connector.

If properly connected, a triple beep will be heard and

the LED will flash three times.

Page 9

9

7

Tighten the screws using the phillips head screw driver.

8

To test keypad locks: Press = ` To test RFID locks: Press `

Test the locks while the door is open. If locks do not operate, remove and reinstall.

Close the door and test again. If 10 rapid beeps are heard and the LED flashes 10 times, the strike plate and/or the door needs to

be adjusted as it is preventing the lock from operating.

Page 10

Recess Mount Installation

10

For door thickness measuring between .370” - .850” (9.4mm - 21.6mm)

Required Components

1 - Front Unit

Standard Body Keypad Vertical Body KeypadStandard Body RFID Vertical Body RFID Horizontal Body Keypad

1 - Rear Unit

Solenoid Spring Bolt Solenoid Spring Latch Motorized Dead Bolt Motorized Dead Latch

1* - Pin Extender

*Required for door thickness measuring between

.685”-.850” (17.4-21.6mm)

u Do not use an electric screw gun unless it is equipped with a torque adjuster and is set to low.

*Not included

2 - Locking Nuts1* - Ratchet/Screw Gun with a 3/8” Socket

Page 11

Installation

11

For illustration, a standard body, keypad lock with a bolt rear unit is used.

1

If required, connect the pin extender to the rear unit. Insert the front unit screw posts through the door

3

2

mounting holes.

4

Hold the front unit against the front of the door. Use the

screws of the rear unit as a guide then slide the front

and rear units together.

5

Insert the locking nuts on the screw posts and tighten

using the ratchet/screw gun.

u Do not over tighten.

Make sure the connector pins align properly with the

connector.

If properly connected, a triple beep will be heard and

the LED will flash three times.

Page 12

12

6

To test keypad locks: Press = ` To test RFID locks: Press `

Test the locks while the door is open. If locks do not operate, remove and reinstall.

Close the door and test again. If 10 rapid beeps are heard and the LED flashes 10 times, the strike plate and/or the door needs to

be adjusted as it is preventing the lock from operating.

Page 13

For door thickness measuring between .850” - 2.368” (21.6mm - 60.1mm)

13

Required Components

1 - Front Unit

Standard Body Keypad Vertical Body KeypadStandard Body RFID Vertical Body RFID Horizontal Body Keypad

1 - Rear Unit

Solenoid Spring Bolt Solenoid Spring Latch Motorized Dead Bolt Motorized Dead Latch

1* - Phillips Head Screwdriver (#2) 1* - Pin Extender

*Two (2) pin extenders are required for door thickness

measuring between 1.570”-2.368” (39.9-60.1mm)

2 - Phillips Head Screws 2 - Split Lock Washers

*Not included

u Do not use an electric screw gun unless it is equipped with a torque adjuster and is set to low.

Page 14

Installation

14

For illustration, a standard body, keypad lock with a bolt rear unit is used.

1

Connect the pin extender to the rear unit. Place the split lock washers on the phillips head screws

3

2

and insert them through the rear unit mounting holes.

4

Insert the front unit nut posts through the door mounting

holes.

5

Make sure the connector pins align properly with the

connector.

If properly connected, a triple beep will be heard and

the LED will flash three times.

Hold the front unit against the front of the door. Use

the screws of the rear unit as a guide then slide the

front and rear units together.

6

Tighten the screws using the phillips head screw driver.

Do not over tighten.

Page 15

15

7

To test keypad locks: Press = ` To test RFID locks: Press `

Test the locks while the door is open. If locks do not operate, remove and reinstall.

Close the door and test again. If 10 rapid beeps are heard and the LED flashes 10 times, the strike plate and/or the door needs to

be adjusted as it is preventing the lock from operating.

Page 16

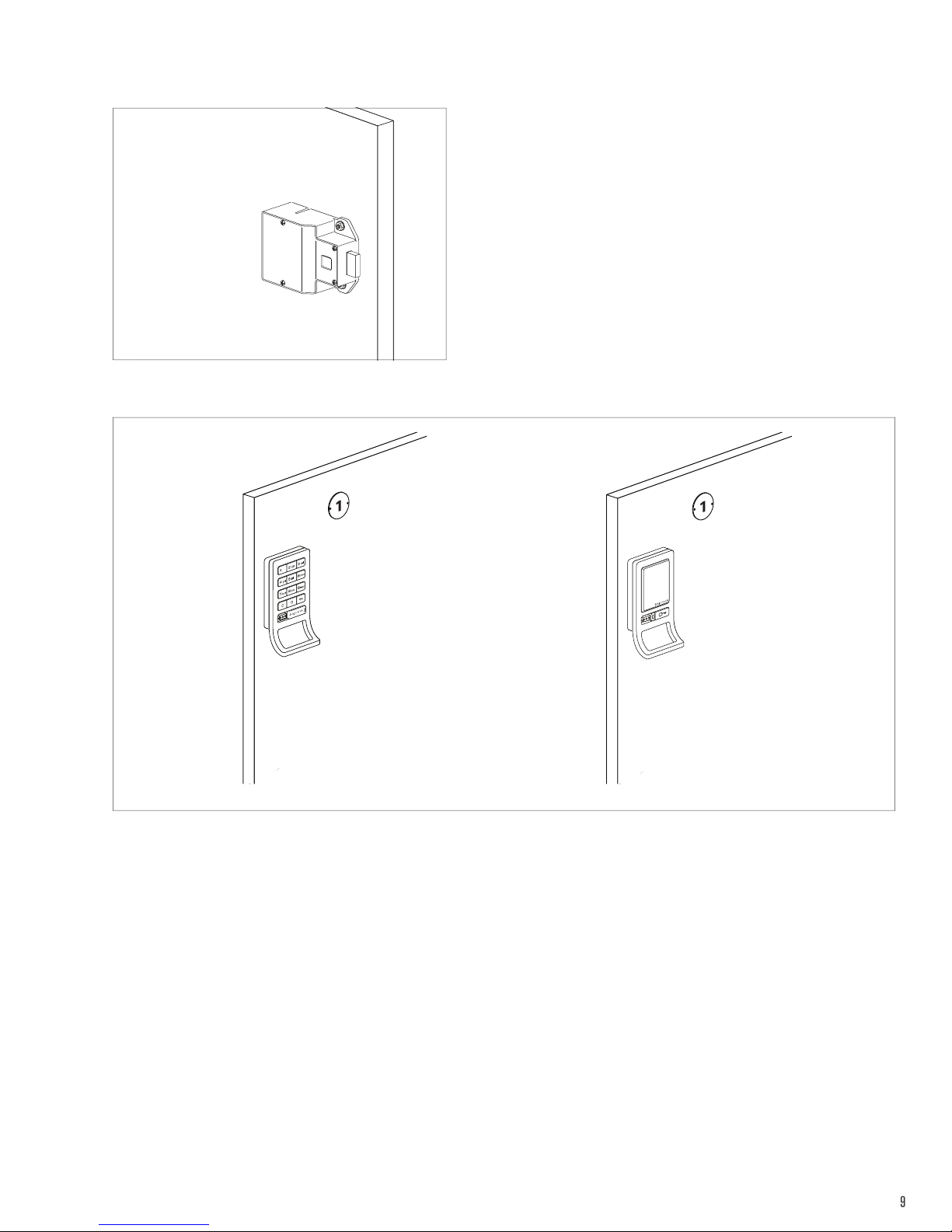

Door Preparation

16

Strike Plate Installation

Required Components

Strike Plate

1. A strike plate must be installed.

Angled Strike Plate Security Strike Plate Double Door Strike Plate

1* - Phillips Head Screwdriver (#1)

*Not included

Do not use an electric screw gun unless it is equipped with a torque adjuster and is set to low.

Page 17

Installation

17

1

Door Frame

Position the strike plate on the door frame centering

it with the center of the desired location of the door

mounting holes.

3

Drill Pilot

Holes Here

2

0.125 in

(3.18 mm)

Mark Here

Door Frame

Allow .125” (3.18mm) from door edge and mark the

position of the adjustment slot holes.

4

Door Frame

Drill 0.25” (6.35mm) pilot holes using a 1/6” drill bit.

5

0.125 in

(3.18 mm)

Door Frame

Door Frame

Position the strike plate and the self tapping screws into

the adjustment slot holes. Do not tighten the screws.

6

Door Frame

Adjust the strike plate to the proper position (.125”

(3.18mm) from the door edge) then tighten the self

tapping screws.

Position and tighten the remaining self tapping screw

into the center hole.

Page 18

Template

Center line

Strike

Plate

Center

Edge of Strike Plate

Strike Edge Marker

Mark

Template

Mark Door Edge

Template

Center line

Strike

Plate

Center

Edge of Strike Plate

Strike Edge Marker

Mark

Template

Mark Door Edge

Door Edge

Drawn

Marker

Template

Center line

Strike

Plate

Center

Edge of Strike Plate

Strike Edge Marker

Template

Center line

Strike

Plate

Center

Edge of Strike Plate

Strike Edge Marker

18

Door Mounting Holes Drill Instructions and Templates

Drill Instructions

For illustration, the mounting holes template for standard & vertical body locks is used.

1

Align both the center line and strike plate edge of the

installed strike plate.

Hold the template in place and close the door.

2

Mark

Template

Mark Door Edge

Mark the edge of the door on the template. Mark the

center line of the template on the edge of the door.

3

Door Edge

Drawn

Marker

Place the template on the front of the door.

Align the edge of the door with the mark on the template,

and then align the center line of the template with the

mark on the door.

Secure the template with removable tape.

4

Drill 3/4” - 0.75 in

(19.1 mm)

Drill x2

5/16” 0.3125 in

(7.94 mm)

Mark the center point of the three door mounting drill

holes on the front of the door.

Use the drill bits specified on the template to drill

appropriately sized door mounting holes.

Page 19

Template for Standard & Vertical Body

19

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn off auto scaling in printer setup and print at 100%.

All measurements in thousandths

ALIGN EDGE OF

STRIKE PLATE HERE

FOR LEFT

CLOSING DOOR

of an inch and millimeters

)mm( 9.72

001.1

.300

7.62 (mm)

use 5/16" bit

ALIGN EDGE OF

STRIKE PLATE HERE

FOR RIGHT

CLOSING DOOR

001.1

)mm( 9.72

CENTER LINE

CENTER LINE

ALIGN EDGE OF

STRIKE PLATE HERE

FOR LEFT

CLOSING DOOR

)mm( 9.72

001.1

.905

23 (mm)

.750

19.05 (mm)

use 3/4" bit

.300

7.62 (mm)

.905

23 (mm)

001.1

)mm(9.72

ALIGN EDGE OF

STRIKE PLATE HERE

FOR RIGHT

CLOSING DOOR

Page 20

Template for Horizontal Body

20

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn off auto scaling in printer setup and print at 100%.

CENTER LINE

ALIGN EDGE OF

STRIKE PLATE HERE

FOR TOP

CLOSING DRAWER

23 (mm)

.905

7.62 (mm)

.300

23 (mm)

.905

ALIGN EDGE OF

STRIKE PLATE HERE

FOR BOTTOM

CLOSING DRAWER

001.1

)mm( 9.72

19.05 (mm)

use 3/4" bit

.750

001.1

)mm( 9.72

ALIGN EDGE OF

STRIKE PLATE HERE

FOR TOP

CLOSING DRAWER

001.1

)mm( 9.72

use 5/16" bit

7.62 (mm)

.300

001.1

)mm(9.72

ALIGN EDGE OF

STRIKE PLATE HERE

FOR BOTTOM

CLOSING DRAWER

All measurements in thousandths

of an inch and millimeters

CENTER LINE

Page 21

Routing Instructions and Template

21

Routing Instructions

1. Choose the appropriate routing template (standard, vertical, or horizontal).

2. Drill the appropriate door mounting holes. Refer to the door mounting holes drill instructions and template.

3. Align the mounting holes drawn on the template with the mounting holes drilled on the door.

4. Route the door according to the measurements shown on the template.

Page 22

Routing Template for Standard Body

(

)

4x

22

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn off auto scaling in printer setup and print at 100%.

2.19 in

56 mm

)

.300 (8

.75 (19

mm

)

)

2.01 in (51 mm

1.98 in (50

)

mm

2x

)

mm

0.400/0.425 in DEEP

(

10/11

mm

)

2.72 in (69 mm

2.68 in (68

mm

R 0.125(3

)

)

mm

Page 23

Routing Template for Horizontal Body

)

)

.400/.425 DEEP

23

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn off auto scaling in printer setup and print at 100%.

(

10/11mm

R 0.125”

(

3mm

4x

0.75”

(

)

)

19mm

)

2.185” (56mm

3.80” (97mm

3.78” (96mm

0.30”

(

8mm

)

)

)

2x

)

1.25” (32mm

1.23” (31mm

Page 24

Routing Template for Vertical Body

)

R 0.125”

)

)

24

Templates may not print to scale. Check all measurements before proceeding.

Before printing, turn off auto scaling in printer setup and print at 100%.

1.25” (32mm

(

3mm

4x

)

1.23” (31mm

)

.400/.425 DEEP

(

10/11mm

0.30”

(

)

8mm

2x

3.80” (97mm

2.185” (56mm

0.75”

(

)

19mm

)

)

3.78” (96mm

Page 25

Metal Door Preparation

25

Compatibility Guide

Digilock is compatible with a majority of 3-hole configuration, latch, and handle door types. Some doors may require modification

to clear obstructions.

Single Point Latch

Handle

Standard Lift

Box Locker Padlock Hasp

Recessed Cup with Multi-point Latch

Recessed Cup with Single Point Latch

Page 26

Removal of 3-hole Lock Plug

26

Remove any obstructions to the door mounting holes.

Example 1Example 2

Rear View of

Locker Door

with Lock Plug

Rear View of

Locker Door

with Lock Plug

Front View of

Locker Door

with Lock Plug

Front View of

Locker Door

with Lock Plug

Page 27

Removal of Padlock Hasp

27

The padlock hasp must be removed

1 - Metal File1 - Handheld Grinder or Hack Saw

Close the door and make sure that

nothing is protruding above the

surface of the door.

Example 1Example 2

Open the door then cut the padlock

hasp on the marked cut-line.

Smooth out rough or sharp edges.

Close the door and mark the area to

cut the padlock hasp.

IG-XXXX-XX-DEN

071114

Phone: 707 766 6000

www.digilock.com | support@digilock.com

Loading...

Loading...