Page 1

PPmmooddCCLLPP™

RReeffeerreennccee MMaannuuaal

PPaarraalllleell LLCCDD DDiissppllaayy MMoodduullee

Revision: April 28, 2008

™

www. d i g i l e n t i n c . c om

l

215 E Main Suite D | Pullman, WA 99163

(509) 334 6306 Voice and Fax

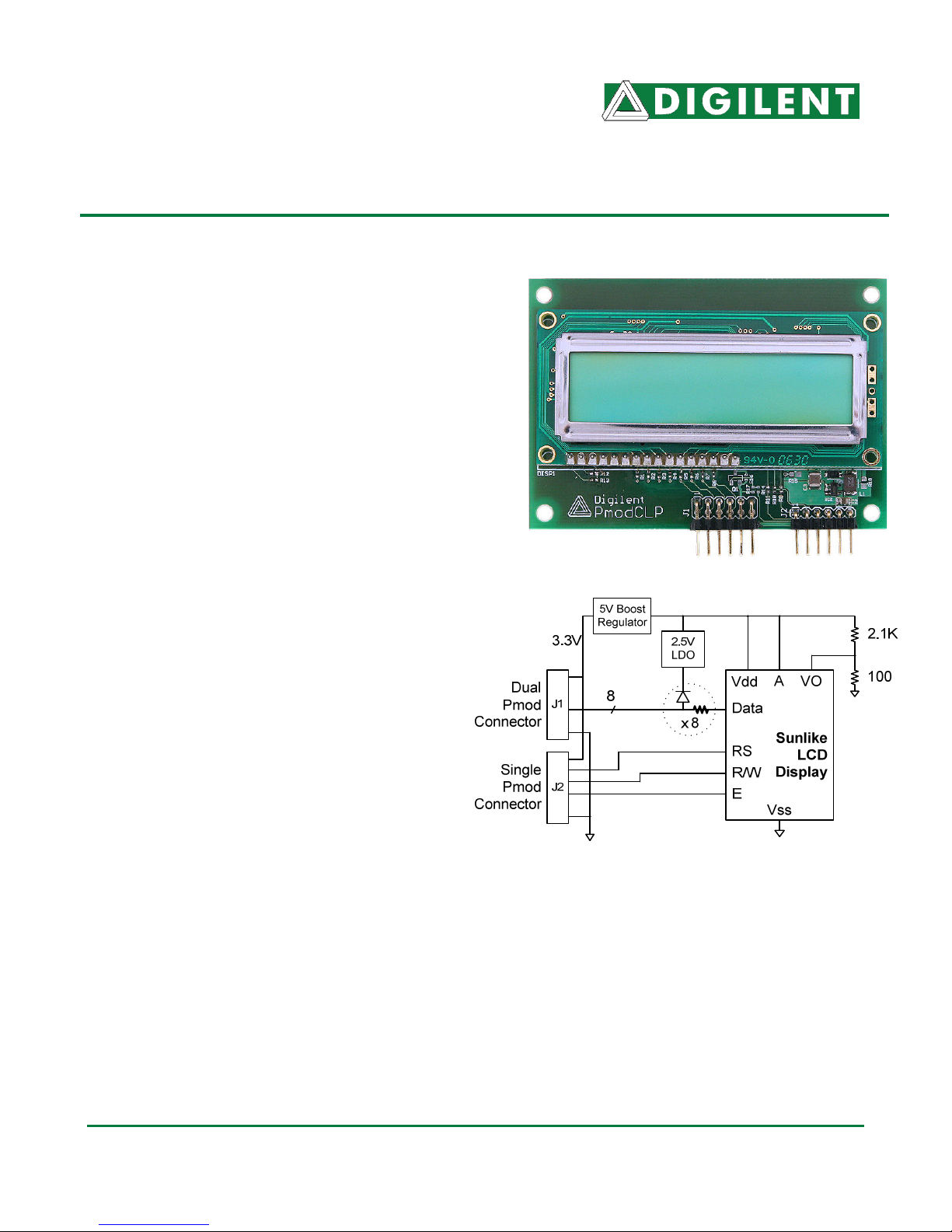

Overview

The PmodCLP is a 16x2 character LCD module that

uses two Pmod connectors to present a 3.3V, 8-bit

parallel data interface to system boards. It is based on

a Sunlike LCD panel that uses a Samsung KS0066 (or

equivalent) LCD controller. The module can be

attached to any number of Digilent system boards to

create a character LCD subsystem.

The PmodCLP can be supplied with 3.3V or 5V.

Because the Sunlike LCD module requires a 5V

supply, the PmodCLP includes a 3.3V-to-5V boost

regulator and a 5V-to-3.3V voltage-translation circuit.

The voltage translation circuit ensures that 3.3V data

signals are returned to the system board whether 3.3V

or 5V is used to supply the module (if 5V signal levels

are desired, the 2.5V regulator can be

removed).

A simple resistor-divider contrast-setting circuit

is used to set the contrast voltage (VO) to

about 200mV, ideal for temperatures around

20C. The divider circuit values can be

changed to define other contrast voltage

settings.

The module is capable of displaying any one

of more than 200 predefined characters in

each of the 32 display locations (organized as

16 characters on two rows). Most characters

use ASCII codes (see the Samsung KS0066

data sheet for a complete list of character

codes). The module can also execute a variety

of instructions, such as erasing specific characters, setting different display modes, scrolling, and

displaying user-defined characters. These instructions are defined in table 3 below. Characters and

instructions are written to the display using the 8-bit data bus as described below. Characters written

to the display appear at the current location of the LCD panel’s cursor.

This document contains much of the information required to drive the PmodCLP, but a good deal of

the information presented in the LCD controller data sheet has not been reproduced here. Please

refer to the Samsung manufacturer’s data sheet for more information.

PmodCLP Block Diagram

®

Doc: 502-142 page 1 of 5

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 2

PmodCLP Reference Manual

Digilent, Inc.

www.digilentinc.com

LCD Controller

The LCD controller contains a character-generator ROM (CGROM) with 192 preset 5x8 character

patterns (see table 4 below), a character-generator RAM (CGRAM) that can hold 8 user-defined 5x8

characters, and a display data RAM (DDRAM) that can hold 80 character codes. Character codes

written into the DDRAM serve as indexes into the CGROM (or CGRAM). Writing a character code into

a particular DDRAM location will cause the associated character to appear at the corresponding

display location. Display positions can be shifted left or right by setting a bit in the instruction register

(IR). The write-only IR directs display operations (such as clear display, shift left or right, set DDRAM

address, etc). Available instructions (and the associated IR codes) are shown in the right-most column

of table 3 below. A busy flag shows whether the display has competed the last requested operation;

prior to initiating a new operation, the flag can be checked to see if the previous operation has been

completed.

The display has more DDRAM locations than can be displayed at any given time. DDRAM locations

00H to 27H map to the first display row, and locations 40H to 67H map to the second row. Normally,

DDRAM location 00H maps to the upper left display corner, and 40H to the lower left. Shifting the

display left or right can change this mapping. The display uses a temporary data register (DR) to hold

data during DDRAM /CGRAM reads or writes, and an internal address register to select the RAM

location. Address register contents, set via the IR, are automatically incremented after each read or

write operation. The LCD display uses ASCII character codes. Codes up through 7F are standard

ASCII (which includes all “normal” alphanumeric characters). Codes above 7F produce various

international characters – please see the manufacturer’s data sheet for more information on

international codes.

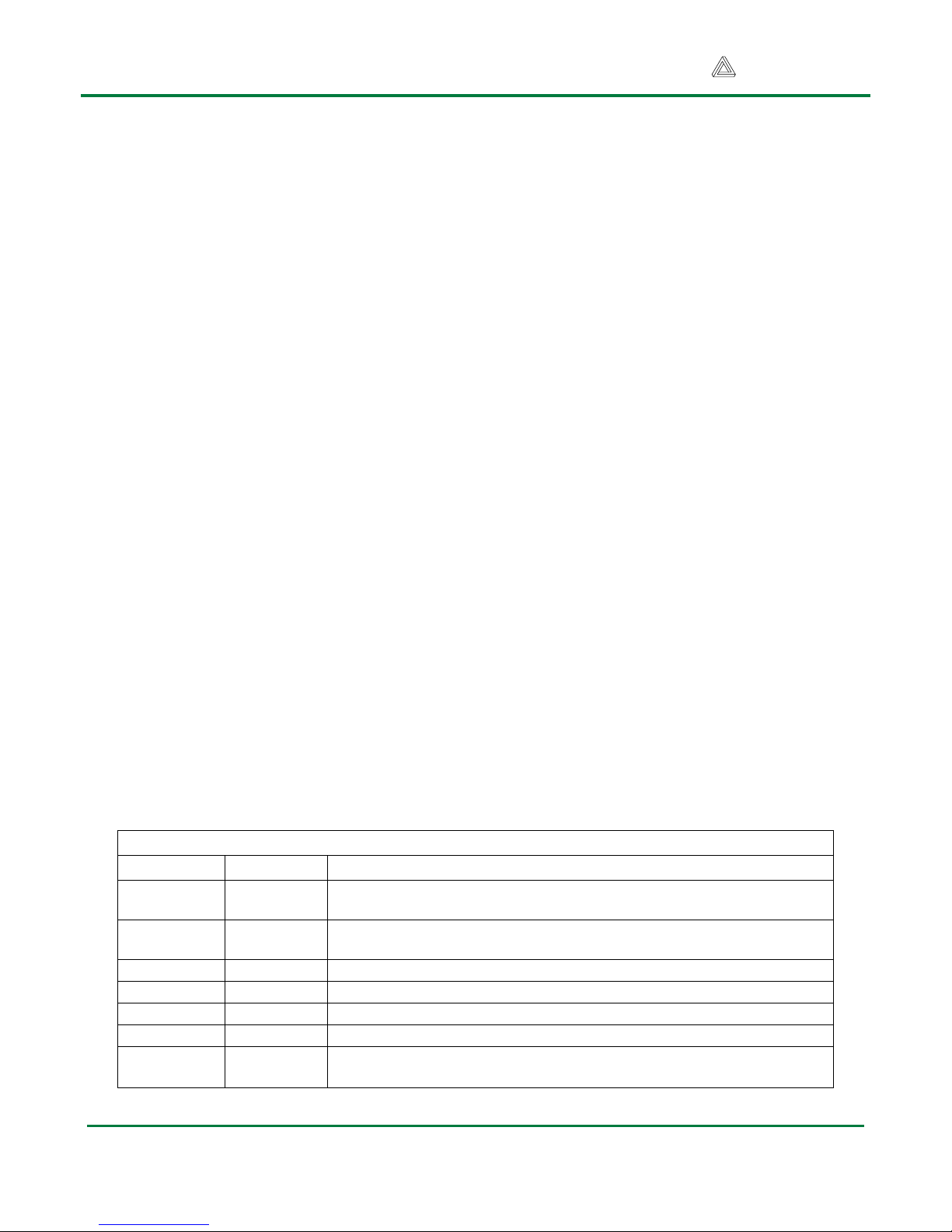

The PmodCLP is connected to the system boards by one dual and one single Pmod connector. The

interface includes eight data and three control signals that are routed from the Pmod connectors to

the LCD controller IC via simple resistor-diode voltage translation circuits. Power (3.3V or 5V) and

GND are routed to the LCD controller, and to a 3.3V-to-5V boost regulator that produces the 5VDC

required by the LCD panel itself. The voltage translation circuit ensures the eight data signals are

returned to the system board at 3.3V (as mentioned, if 5V signals are required, the regulator at IC1

can be removed). The three LCD control signals include RS (Register Strobe) that clocks data into

registers, the R/W signal that determines bus direction, and the E signal that enables the bus for read

or write operations. Pmod connector pin definitions are shown below, and following that is a figure

showing LCD bus signals and timings.

Table 1. PmodCLP Connector Signals

Pin No. Symbol Signal Description

J1.5, J1.11,

J2.5

J1.6, J1.12,

J2.6

J2.1 RS Register select: high for data transfer, low for instruction register

J2.2 R/W Read/write signal: high for read mode, low for write mode

J2.3 E Read/write strobe: high for read OE; falling edge writes data

J2.4 No Connect Optional back-light enable (not connected on PmodCLP)

J1.1,2, 3, 4

J1.7,8,9,10

Vss Signal ground

Vdd Power supply (5V)

Data Bus Bi-directional 8-bit data bus

www.digilentinc.com page 2 of 5

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 3

PmodCLP Reference Manual

www.digilentinc.com

Enable cycle time tc 500 ns E

Enable High pulse width tw 220 ns E

Enable rise/fall time tr, tf 25 ns E

RS, R/W setup time tsu 40 ns RS, R/W

RS, R/W hold time th 10 ns RS, R/W

Read data output delay tD 60 120 ns DB0-DB7

Read data hold time tDH 20 ns DB0-DB7

Write data setup time tsu1 40 ns DB0-DB7

Write data hold time th1 10 ns DB0-DB7

Parameter Symbol Min Max Unit Test Pin

Table 2. LCD Bus Timings

A startup sequence with specific timings is required to ensure proper LCD operation.

This sequence is defined in detail in the Samsung KS0066U data sheet, and

reproduced here for convenience.

After power-on, at least 20ms must elapse before the function-set instruction code

can be written to set the bus width, number of lines, and character patterns (8-bit

interface, 2 lines, and 5x8 dots are appropriate). After the function-set instruction, at

least 37us must elapse before the display-control instruction can be written (to turn

the display on, turn the cursor on or off, and set the cursor to blink or no blink). After

another 37us, the display-clear instruction can be issued. After another 1.52ms, the

entry-mode instruction can set address increment (or address decrement) mode, and

display shift mode (on or off). After this sequence, data can be written into the

DDRAM to cause information to appear on the display.

Note that other compatible LCD controllers use similar start-up sequences which may

not use the same timings as the Samsung controller.

Digilent, Inc.

LCD startup

sequence

www.digilentinc.com page 3 of 5

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 4

PmodCLP Reference Manual

Instruction bit a

ssignments

Description

RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Table 3. LCD Instructions and Codes

Instruction

Clear

Display

Return

Home

Entry mode

set

Display

ON/OFF

control

Cursor or

Display shift

Function Set 0 0 0 0 1 DL N F X X

Set CGRAM

Address

Set DDRAM

address

Read busy

flag/address

Write data to

RAM

Read data

from RAM

0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 1 X

0 0 0 0 0 0 0 1 I/D SH

0 0 0 0 0 0 1 D C B

0 0 0 0 0 1 S/C R/L X X

0 0 0 1 AC5 AC4 AC3 AC2 AC1 AC0

0 0 1 AC6 AC5 AC4 AC3 AC2 AC1 AC0

0 1 BF AC6 AC5 AC4 AC3 AC2 AC1 AC0

1 0 D7 D6 D5 D4 D3 D2 D1 D0

1 1 D7 D6 D5 D4 D3 D2 D1 D0

Clear display by writing a 20H to

all DDRAM locations; set DDRAM

address register to 00H; and

return cursor to home.

Return cursor to home (upper left

corner), and set DDRAM address

to 0H. DDRAM contents not

changed.

I/D = ‘1’ for right-moving cursor

and address increment; SH = ‘1’

for display shift (direction set by

I/D bit).

Set display (D), cursor (C), and

blinking cursor (B) on or off.

S/C = ‘0’ to shift cursor right or

left, ‘1’ to shift entire display right

or left (R/L = ‘1’ for right).

Set interface data length (DL = ‘1’

for 8 bit), number of display lines

(N = ‘1’ for 2 lines), display font (F

= ‘0’ for 5x 8 dots)

Set CGRAM address counter

AC5 – AC0

Set DDRAM address counter

AC6 – AC0

Read busy flag (BF) and address

counter AC6 – AC0

Write data into DDRAM or

CGRAM, depending on which

address was last set

Read data from DDRAM or

CGRAM, depending on which

address was last set

Digilent, Inc.

www.digilentinc.com

www.digilentinc.com page 4 of 5

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 5

PmodCLP Reference Manual

Digilent, Inc.

www.digilentinc.com

Table 4. LCD Character codes

www.digilentinc.com page 5 of 5

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 6

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Digilent:

410-142P

Loading...

Loading...