Page 1

1300 Henley Court

Pullman, WA 99163

509.334.6306

www.store. digilent.com

Pmod CAN Reference Manual

Revised August 31, 2017

This manual applies to the Pmod CAN rev. B

SKU: 410-353

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 1 of 8

Overview

The Digilent Pmod CAN (Revision B) is a CAN 2.0B controller with an integrated transceiver. The

embedded Microchip MCP25625 chip connects directly to the physical CAN bus and meets automotive

requirements for high-speed (1 Mb/s), low quiescent current, electromagnetic compatibility, and electrostatic

discharge.

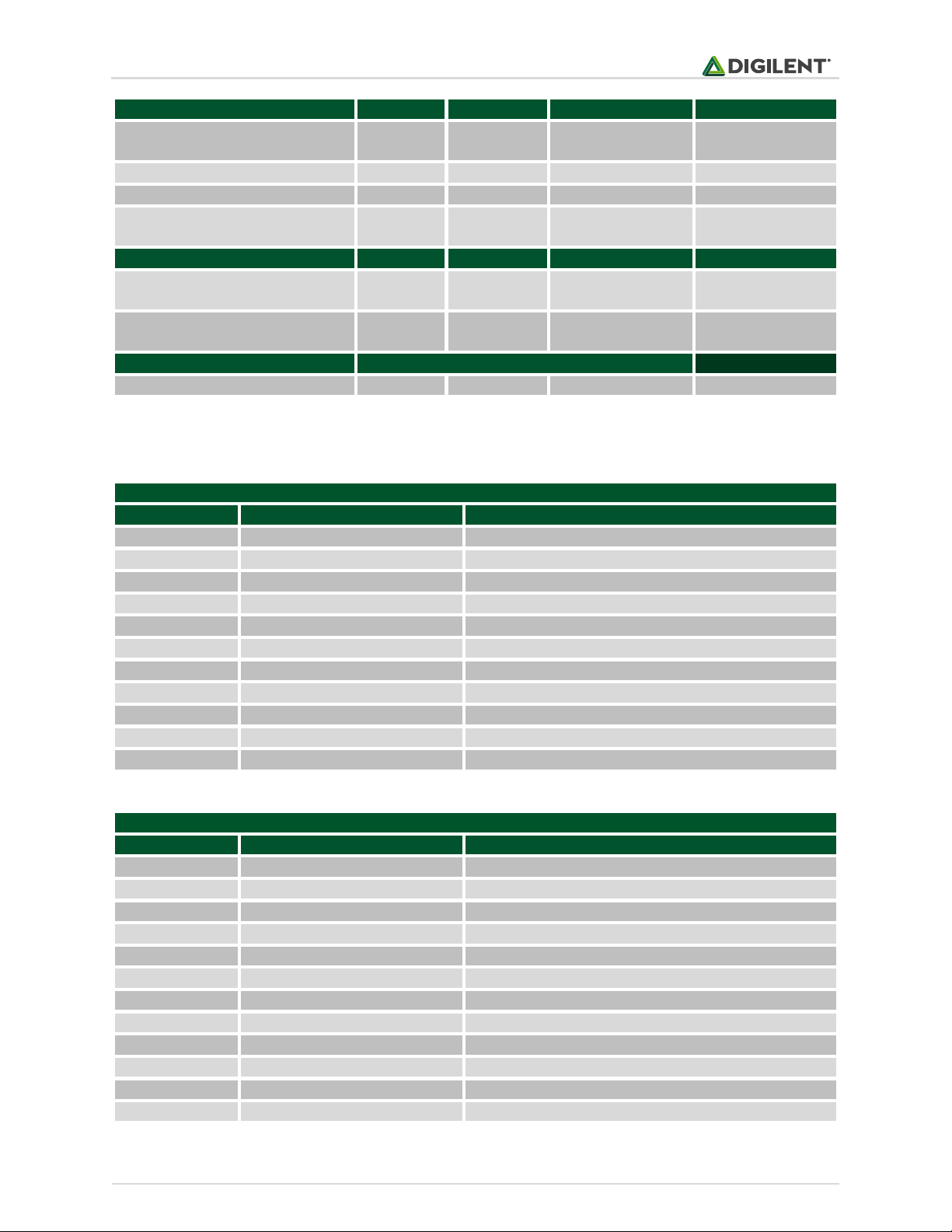

1 Specifications

Parameter

Min

Typical

Max

Units

Power Supply Voltage (Vcc)

2.7 5.5

V

High-Level Input Voltage (RxCAN)

2 - Vcc+1

V

Low-Level Input Voltage (RxCAN)

-0.3 - 0.15*Vcc

V

High-Level Output Voltage (TxCAN)

Vcc-0.7 - -

V

Low-Level Output Voltage (TxCAN)

- - 0.6 V Bit Frequency

14.4 - 1000

kHz

The Pmod CAN.

Standalone CAN 2.0B controller with an

integrated CAN transceiver

Compatible with ISO-11898-1, ISO-11898-2, and

ISO-11898-5

Suitable for automotive applications

Up to 1 Mb/s operation

Up to 10 MHz SPI clock speed

3 Transmit buffers with prioritization and abort

feature

2 Receive buffers

6 Filters and 2 masks with optional filtering on

the first two data bytes

Interrupt output pin

Standard DB9 connector for a secure connection

Suitable for 12 V and 24 V systems

Small PCB size for flexible designs 1.4 in x 1.8 in

(3.6 cm x 4.6 cm)

12-pin Pmod connector with SPI interface

Follows the Digilent Pmod Interface

Specification 1.1.0

Page 2

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 2 of 8

Transmitter

Min

Typical

Max

Units

Recessive Bus Output Voltage

(CANH & CANL)

2.0

0.5 Vcc

3.0

V

Dominant Output Voltage (CANH)

2.75

3.50

4.50

V

Dominant Output Voltage (CANL)

0.50

1.50

2.25

V

Dominant Differential Output

Voltage

1.5

2.0

3.0

V

Receiver

Min

Typical

Max

Units

Recessive Differential Input

Voltage (normal mode)

-1.0 - +0.5

V

Dominant Differential Input

Voltage (normal mode)

0.9 - Vcc

Parameter

Value

Units

Standby Current

10

μA

1.1 Pinout Table Diagram

Header J1

Pin

Signal

Description

1

N/C

Not Connected

2

CANL

CAN Low-Level Voltage I/O

3

GND

Power Supply Ground

4

N/C

Not Connected

5

N/C

Not Connected

6

GND

Power Supply Ground

7

CANH

CAN High-Level Voltage I/O

8

N/C

Not Connected

9

N/C

Not Connected

S1

GND

Power Supply Ground

S2

GND

Power Supply Ground

Header J2

Pin

Signal

Description

1

CS

Chip Select

2

MOSI

Master-Out-Slave-In

3

MISO

Master-In-Slave-Out

4

SCK

Serial Clock

5

GND

Power Supply Ground

6

VCC

Power Supply (3.3V/5V)

7

INT

Interrupt

8

RST

Reset

9

Rx0BF

Receive Buffer 0 Full Interrupt

10

Rx1BF

Receive Buffer 0 Full Interrupt

11

GND

Power Supply Ground

12

VCC

Power Supply (3.3V/5V)

Page 3

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 3 of 8

Header J3

Pin

Signal

Description

1

CANL

CAN Low-Level Voltage I/O

2

CANH

CAN High-Level Voltage I/O

3

GND

Power Supply Ground

Jumpers

Pin

Signal

Description

JP1

Loaded/ Unloaded

End of bus terminated with a combined 120Ω impedance/ Do not

terminate the end of the bus

JP2

Loaded/ Unloaded

Terminate the CAN bus lines with a capacitor to ground/ No termination

1.2 Physical Dimensions

The pins on the pin header are spaced 100 mil apart. The PCB is 1.8 inches long on the sides parallel to the pins on

the pin header and 1.4 inches long on the sides perpendicular to the pin header.

2 Functional Description

The Pmod CAN utilizes the Microchip MCP25625 to enable CAN communication with a variety of external devices.

A complete CAN solution with a controller and transceiver can be implemented on a system board by

communicating with the host board via the SPI protocol in SPI mode 0 or 3. The two differential lines on the

transceiver, CANH and CANL, enable balanced differential signaling to eliminate most of the electromagnetic field

(EMF) and provide high noise immunity within the system.

2.1 Serial Communication

The Pmod CAN communicates with the host board via the SPI protocol. By driving and keeping the Chip Select line

(pin 1) at a logic level low, users may communicate back and forth with the Pmod depending on whether or not

both sets of data lines are enabled. The embedded chip on the Pmod operates in SPI Mode 0 or 3, with data

captured on the rising edge of the clock and data transferred on the falling edge of the clock, and a minimum clock

cycle time of 100 nanoseconds as per Table 7-6 (page 70) of the Microchip MCP25625 datasheet.

Nine SPI instructions are available to read the status of the receiver, load a transmit buffer, modify bits in a register

and more. Most of the instruction commands are single byte instructions followed by an address byte. More

information is available in the Quick Start section as well as Section 5 (page 55) of the MCP25625 datasheet.

2.2 Register Details

2.2.1 CANINTE

The CANINTE register (page 51) enables the generation of interrupts on Pin 7.

Page 4

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 4 of 8

CANINTE 0x2B

Bit Name

Bit Number

Bit Description

Bit Values

Functional Description

MERRE

[7]

Message Error Interrupt Enable Bit

0¹

1-Interrupt on error during

message reception or

transmission/0-Disabled

WAKIE

[6]

Wake-up Interrupt Enable Bit

0¹

1-Interrupt on CAN bus

activity/0-Disabled

ERRIE

[5]

Error Interrupt Enable Bit

0¹

1-Interrupt on EFLG error

condition change/0-Disabled

TX2IE

[4]

Transmit Buffer 2 Empty Interrupt

Enable Bit

0¹

1-Interrupt on TXB2

becoming empty/0-Disabled

TX1IE

[3]

Transmit Buffer 1 Empty Interrupt

Enable Bit

0¹

1-Interrupt on TXB1

becoming empty/0-Disabled

TX0IE

[2]

Transmit Buffer 0 Empty Interrupt

Enable Bit

0¹

1-Interrupt on TXB0

becoming empty/0-Disabled

RX1IE

[1]

Receive Buffer 1 Full Interrupt

Enable Bit

0¹

1-Interrupt when message

received in RXB1/0-Disabled

RX0IE

[0]

Receive Buffer 0 Full Interrupt

Enable Bit

0¹

1-Interrupt when message

received in RXB0/0-Disabled

¹ – This is the default value on power-up or reset

2.2.2 CANINTF

The CANINTF register (page 51) holds the flags of all the interrupts that are enabled through the CANINTE register.

If an interrupt flag is set, it must be cleared by the system board to reset the interrupt condition.

CANINTF 0x2C

Bit Name

Bit Number

Bit Description

Bit

Values

Functional Description

MERRF

[7]

Message Error Interrupt Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

WAKIF

[6]

Wake-up Interrupt Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

ERRIF

[5]

Error Interrupt Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

TX2IF

[4]

Transmit Buffer 2 Empty Interrupt

Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

TX1IF

[3]

Transmit Buffer 1 Empty Interrupt

Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

TX0IF

[2]

Transmit Buffer 0 Empty Interrupt

Flag Bit

0¹

1-Interrupt pending/0-No

interrupt pending

RX1IF

[1]

Receive Buffer 1 Full Interrupt Flag

Bit

0¹

1-Interrupt pending/0-No

interrupt pending

RX0IF

[0]

Receive Buffer 0 Full Interrupt Flag

Bit

0¹

1-Interrupt pending/0-No

interrupt pending

¹ – This is the default value on power-up or reset

2.2.3 CANSTAT

The CANSTAT register (page 54) provides the status of the CAN controller and the source of the interrupt flag.

Page 5

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 5 of 8

CANSTAT 0xXE

Bit Name

Bit Number

Bit Description

Bit

Values

Functional Description

OPMOD2

[7]

Operation Mode Bit 2

1¹

See the Operation Mode Bit

Table

OPMOD1

[6]

Operation Mode Bit 1

0¹

See the Operation Mode Bit

Table

OPMOD0

[5]

Operation Mode Bit 0

0¹

See the Operation Mode Bit

Table

--

[4]

Unimplemented

0¹

Unimplemented - read as '0'

ICOD2

[3]

Interrupt Flag Code Bit 2

0¹

See the Interrupt Flag Code Bit

Table

ICOD1

[2]

Interrupt Flag Code Bit 1

0¹

See the Interrupt Flag Code Bit

Table

ICOD0

[1]

Interrupt Flag Code Bit 0

0¹

See the Interrupt Flag Code Bit

Table

--

[0]

Unimplemented

0¹

Unimplemented - read as '0'

¹ − This is the default value on power-up or reset

2.2.4 Operation Mode Bit Table

Operation Mode Bit Table

Bit values for Operation Mode bits 2,1,0

Mode

0,0,0

Device is in Normal Operation Mode

0,0,1

Device is in Sleep Mode

0,1,0

Device is in Loopback Mode

0,1,1

Device is in Listen-Only Mode

1,0,0

Device is in Configuration Mode

2.2.5 Interrupt Flag Code Bit Table

Interrupt Flag Table

Bit values for Interrupt Flag bits 2,1,0

Interrupt

0,0,0

No Interrupt

0,0,1

Error Interrupt

0,1,0

Wake-up Interrupt

0,1,1

TBX0 Interrupt

1,0,0

TBX1 Interrupt

1,0,1

TBX2 Interrupt

1,1,0

RBX0 Interrupt

1,1,1

RBX1 Interrupt

2.3 Quick Start

Here is the series of SPI commands to set up, transmit, and receive data on the Pmod CAN:

2.3.1 Setup

1. Set CAN control mode to configuration

Page 6

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 6 of 8

1. Send modify register SPI command (0x05)

2. Send the address of the control MCP_CANCTRL (0x0F)

3. Send a mask to get things prepared (0x80)

4. Send the command to place the module in config mode (0x80)

2. Set config rate and clock for CAN

1. Send a write SPI command (0x02)

2. Send the address of the register to modify followed by the value to set

3. Three registers are manipulated in this way with a variety of settings; for more details see

Section 4.4 (page 47) in the MCP25625 datasheet. The following three commands set a CAN

speed of 250 kBPS with a CAN clock of 20 MHz.

1. CNF1 (0x2A) set to 0x41

2. CNF2 (0x29) set to 0xFB

3. CNF3 (0x28) set to 0x86

3. Initiate can buffer filters and registers

1. Set the receive filters to either standard or extended identifiers

1. For all standard inputs and in the demo code, set registers 0x00 through 0x0B, registers

0x10 through 0x1B, and registers 0x20 through 0x27 to a value of 0x00. The transmit

register flags and settings are also all cleared by setting registers 0x30 through 0x3D,

0x40 through 0x4D, and registers 0x50 through 0x5D to a value of 0x00. This can be

done for each register by performing the following steps:

2. Send a write SPI command (0x02)

3. Send the register address of interest

4. Send the value to be written (0x00)

4. Set the CAN mode for any message type

1. Send modify register SPI command (0x05)

2. Send the address of the control RXB0CNTRL (0x60)

3. Send a mask to get things prepared (0x64)

4. Send the actual command to accept any message type (0x60)

5. Set CAN control mode to normal mode

1. Send modify register SPI command (0x05)

2. Send the address of the control MCP_CANCTRL (0x0F)

3. Send a mask to get things prepared (0x80)

4. Send the actual command to put in config mode (0x00)

2.3.2 Receive

1. Send the Read Status SPI command (0xA0) to see if any flags have been set. The Pmod will respond with a

single byte detailing a number of flags status as follows:

Bit 7* (MSB) is TX2IF Transmit Buffer 2 Empty interrupt Flag bit (bit 4 in CANINTF (0x2C)), must be

cleared by system to be reset

Bit 6 is TXREQ Message Transmit request bit (bit 3 in TXB2CTRL register 0x50) auto cleared on

message sent

Bit 5* is TX1IF Transmit Buffer 1 Empty interrupt Flag bit (bit 3 in CANINTF (0x2C)), must be

cleared by system to be reset

Bit 4 is TXREQ Message Transmit request bit (bit 3 in TXB1CTRL register 0x40) auto cleared on

message sent

Bit 3* is TX0IF Transmit Buffer 0 Empty interrupt Flag bit (bit 2 in CANINTF (0x2C)), must be

cleared by system to be reset

Page 7

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 7 of 8

Bit 2 is TXREQ Message Transmit request bit (bit 3 in TXB0CTRL register 0x30) auto cleared on

message sent

Bit 1* is RX1IF Receive Buffer 1 Empty interrupt Flag bit (bit 1 in CANINTF (0x2C)), must be

cleared by system to be reset

Bit 0* (LSB) is RX0IF Receive Buffer 0 Empty interrupt Flag bit (bit 0 in CANINTF (0x2C)), must be

cleared by system to be reset

*-These interrupt flags are disabled by default in the CAN Interrupt Enable register (address

0x2B)

2. If a receive buffer has data in it, determine the length of the message through the four LSBs of the

associated DLC register for the receive buffer (0x65 for RXB0DLC and 0x75 for RXB1DLC)

3. Reset the interrupt flag that was triggered by clearing bit 0 (RX0IF) or bit 1 (RX1IF) as appropriate in the

CANINTF (0x2C) register after reading the data.

2.3.3 Transmit

1. Load data through a Load TX Buffer SPI command. 6 different starting locations are available

Transmit Buffer 0 starting at the standard identifier high register (0x31) – 0x40

Transmit Buffer 0 starting at the data byte register (0x36) – 0x41

Transmit Buffer 1 starting at the standard identifier high register (ox41) – 0x42

Transmit Buffer 1 starting at the data byte register (0x46) – 0x43

Transmit Buffer 2 starting at the standard identifier high register (ox51) – 0x44

Transmit Buffer 2 starting at the data byte register (0x56) – 0x45

2. Send a Request-To-Send SPI command for one or more of the three registers of interest

Transmit buffer 0 (TXB0) uses 0x81

Transmit buffer 1 (TXB1) uses 0x82

Transmit buffer 2 (TXB2) uses 0x84

Multiple transmit buffers can be simultaneously primed by OR'ing the SPI commands

Note that this command does not actually initiate a message transmission. The MCP25625 still

internally goes through arbitration on the bus line and only transmits the message when the bus

is available.

3. Upon completion, the bit set to indicate to the controller that a message is ready to be transmitted will be

cleared and an interrupt will be generated if the TXnIE bit in the CANINTE register is set.

3 Application Information

The CAN protocol uses two communication lines, CANH and CANL, to enable communication between multiple

CAN transceivers called nodes. The two bus lines are actively driven to produce a differential voltage greater than

1.5 V, resulting in the Dominant transmission state. CAN transceivers will interpret a dominant transmission as a

logic low state. A logic high state is created by neither bus driving their lines so that they idle at approximately the

same voltage, typically Vcc/2 as biased by the common mode transceiver. This state is a Recessive transmission

and typically has a differential voltage of less than ±100 mV.

Similar to UART, all nodes on a CAN network must operate at the same nominal bit rate as data is transmitted

without a clock signal in an asynchronous format. The Pmod CAN is compliant with CAN 2.0B (ISO-11898-2 and

ISO-11898-5). In additional to the de-facto RS-232 header, Header J1, screw terminals are provided on Header

J3 for other CAN devices that use twisted pair wiring.

Page 8

Pmod CAN Reference Manual

Copyright Digilent, Inc. All rights reserved.

Other product and company names mentioned may be trademarks of their respective owners.

Page 8 of 8

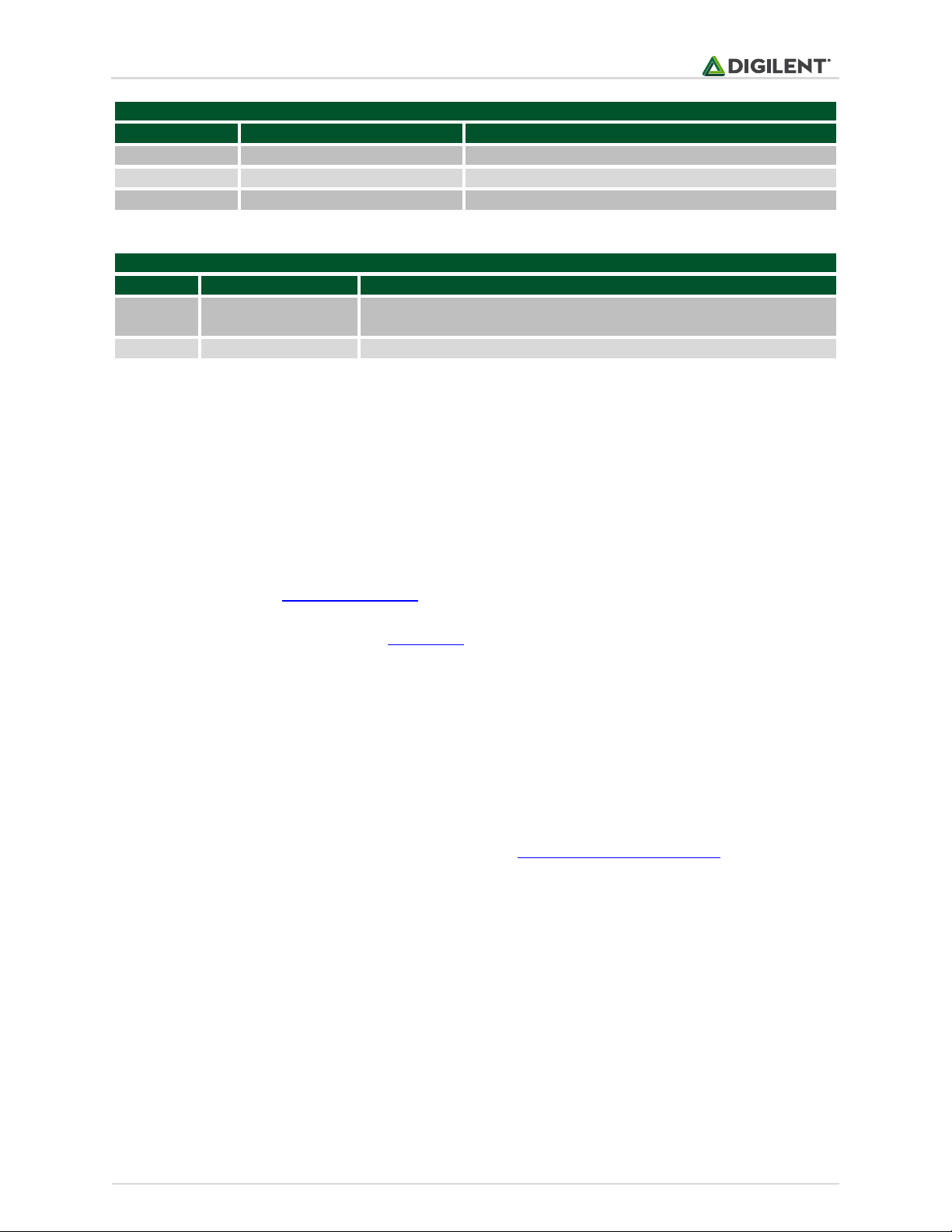

Timing diagrams from page 58 of the MCP25625 datasheet for the Pmod CAN for data coming in and out through

SPI are provided below. The timing values for the parameters shown in the images can be found in Table 7-6 (page

70) of the MCP25625 datasheet.

Figure 1. SPI input timing diagram from MCP25625 datasheet.

Figure 1. SPI output timing diagram from MCP25625 datasheet.

Page 9

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Digilent:

410-353

Loading...

Loading...