Page 1

DDiiggiilleenntt PPeeggaassuuss BBooaarrdd

RReeffeerreennccee MMaannuuaal

Revision: August 11, 2005 215 E Main Suite D | Pullman, WA 99163

l

www.digilentinc.com™

(509) 334 6306 Voice and Fax

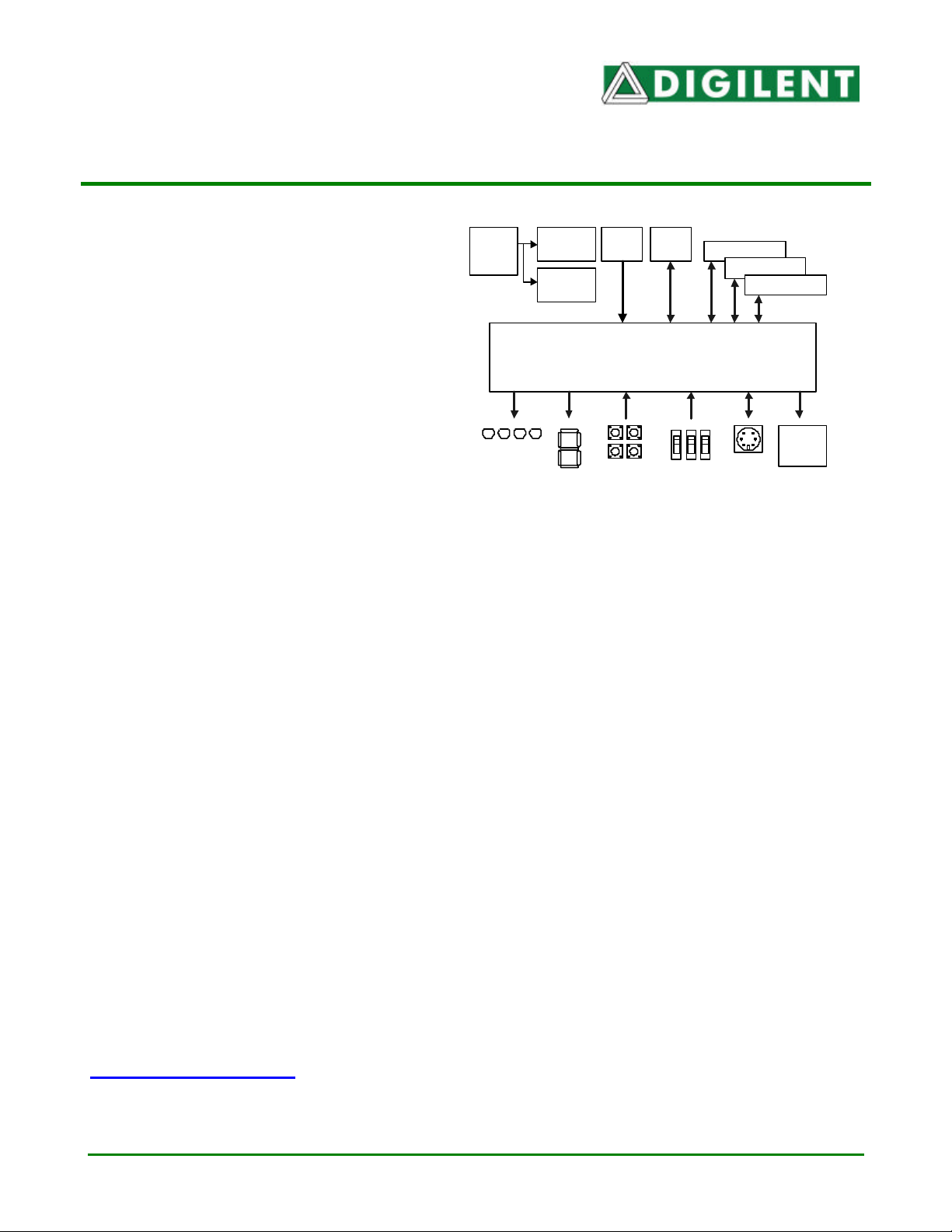

Overview

The Pegasus circuit board provides a complete

circuit development platform centered on a

Xilinx Spartan 2 FPGA. Pegasus features

include:

Power

jack

5-9VDC

2.5VDC

regulator

3.3VDC

regulator

Clock

(50MHz)

Config

ROM

Expansion Connectors

A1

A2

B1

JTAG

• a 50K-gate Xilinx Spartan 2 FPGA with

Xilinx Spartan 2 XC2S50-PQ208

50K gates and 200MHz operation (a

200K-gate version is also availabl e)

• a XCF01S Xilinx Platform Flash ROM

(XCF02S for 200K gate version)

• a collection of I/O devices including eight

LEDs, four-digit seven-segment display,

four pushbuttons, and eight slide

switches

• a 50MHz oscillator and a socket for a

8 LEDs

4 7-seg.

displays

4 buttons

8 switches

Figure 1. Pegasus circuit board block diagram

PS2

Port

VGA

Port

second oscillator

• PS/2 and VGA ports

• 96 I/O signals routed to three standard

40-pin expansion connectors

• all I/O signals have ESD and short-circuit

protection

• a JTAG programming port.

The Pegasus board has been designed to

work seamlessly with all versions of the Xilinx

ISE CA D tools, including the free WebPack

tools available from Xilinx. A growing collection

of low-cost expansion boards can be used with

the Pegasus board to add analog and digital

I/O capabilities, as well as various data ports

like Ethernet and USB. The Pegasus board

ships with a power supply and programming

cable, so designs can be implemented

immediately without the need for any additional

hardware.

Important: This reference manual is

updated for Rev. D Pegasus Boards with a

5V power supply. For a manual for a

previous Pegasus board using a 3.3V

power supply, e-mail

support@digilentinc.com

Functional Description

The Pegasus board provides an inexpensive,

robust, and easy -to-use platform that anyone

can use to gain experience with FPGA devices

and modern design methods. The Pegasus

board is centered on the Spartan 2 FPGA, and

it contains all needed support circuits so

designs can get up and running quickly. The

large collection of on -board I/O devices allows

many designs to be completed without the

need for any other components. Three

standard expansion connectors allow designs

to grow beyond the Pegasus board, either with

user-designed boards or any one of several

analog and digital I/O boards offered by

Digilent. Each expansion connector provides

system voltages and 32 unique I/O signals,

with all I/O signals protected against damage

from ESD and short-circuit connections. JTAG

signals are routed to two expansion

connectors, allowing peripheral boards to drive

the scan chain or to be configured along with

the Spartan FPGA. The collection of on-board

I/O devices and signal protection networks

make the Pegasus board ideally suited to

educational settings.

Copyright Digilent, Inc. All rights reserved 12 pages Doc: 50 0-223

Page 2

Pegasus Reference Manual Digilent, Inc. ™

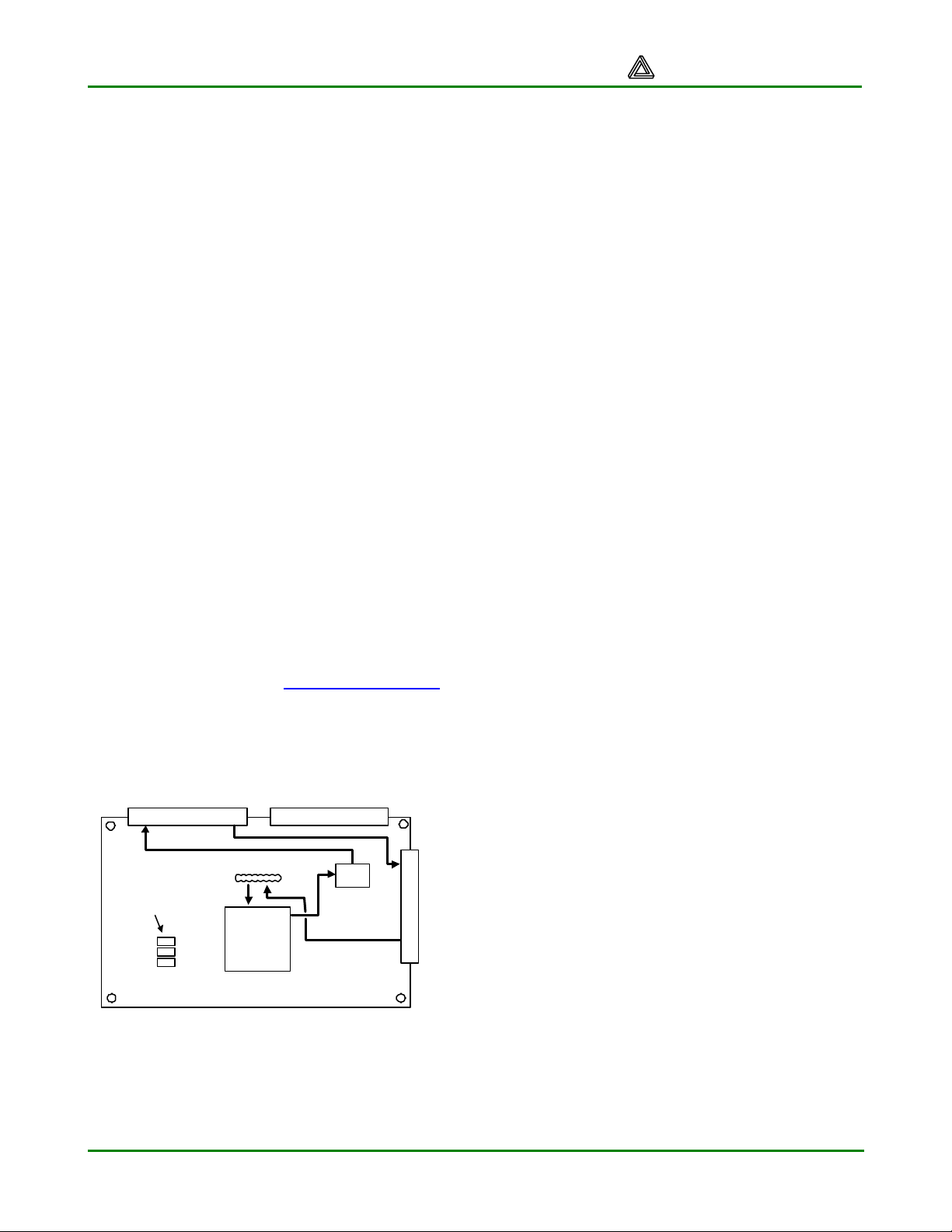

JTAG Ports and Device Configuration

The Spartan 2 FPGA, the XCF01S Platform

Flash ROM, and any programmable devices

on peripheral boards attached to the Pegasus

board can be programmed through JTAG

ports. The JTAG scan chain is routed from the

primary JTAG connector (port 1) to the FPGA,

Platform Flash, and two connection ports as

shown in Figure 2. The primary configuration

port (Port 1) uses a standard 6-pin JTAG

header (J6) that can accommodate Digilent’s

JTAG3 cable (or cables from Xilinx or other

vendors). The other two bi-directional JTAG

ports are available on the A1 and B1

expansion connectors. If no peripheral boards

are present on these connectors, a buffer on

the Pegasus board removes them from the

JTAG chain. If a peripheral board with a JTAGprogrammable device is attached, the scan

chain is driven out the expansion connector so

that the device can be configured. If a Digilent

port module is connected to A1 or B1, then the

port module can drive the JTAG chain to

program all devices in the scan chain. Port

modules include Ethernet, USB, EPP parallel,

and serial modules. (See www.digilentinc.com

for more information). For port modules to

drive the JTAG chain, a jumper must be

installed on the primary JTAG connector

across the TDI and TDO pins.

Port 2

A1 A2

Port 3

JTAG connector

Programming

mode select

jumpers

(Port 1)

Spartan 2E

PQ 208

Platform

Flash

B1

Figure 2. JTAG signal routing on Pegasus

To program the Pegasus board from the

primary port, first power on the Pegasus board,

then connect it to the PC with a JTAG cable,

and then run the “auto-detect” feature of the

configuration software. The configuration

software will identify all devices in the scan

chain, and then each device can be bypassed

or programmed with a suitable configuration

file. Note that both the FPGA and Platform

Flash ROM will always appear in the scan

chain. If the Platform Flash ROM is loaded with

an FPGA configuration file, the FPGA will load

that file at power-on if jumpers are loaded in all

three positions of J4 (M2, M1, and M0).

Power Supplies

The Pegasus board requires a regulated 5V

power supply (it ships with a 5V regulated wallplug supply). If a higher voltage supply is used,

the Pegasus board may be permanently

damaged. The power supply is connected to

the Pegasus board using a 5.5mm OD, 2.5mm

ID center-positive power jack. The 5V supply

from the power jack is connected directly to the

V

supply that drives the FPGA I/O signals,

CCIO

and to a 2.5V regulator that supplies the

Spartan 2 V

CORE

voltage.

Total board current is dependant on FPGA

configuration, clock frequency, and external

connections. In test circuits with roughly 20K

gates routed, a 50MHz clock source, and all

LEDs illuminated, approximately 200mA +/30% of supply current is drawn from the 2.5V

supply, and approximately 100mA is drawn

from the 5V supply. Required current will

increase if peripheral boards are attached.

The Pegasus board uses a four layer PCB,

with the inner layers dedicated to VCC and

GND planes. Most of the VCC plane is at 5V,

with an island under the FPGA at 2.5V. The

FPGA and the other ICs on the board all have

0.047uF bypass capacitors placed as close as

possible to each VCC pin. The power supply

routing and bypass capacitors result in a very

clean, low-noise power supply.

Oscillators

The Pegasus provides a 50MHz SMD primary

oscillator and a socket for a second oscillator.

www.digilentinc.com Page 2

Page 3

Pegasus Reference Manual Digilent, Inc. ™

The primary oscillator is connected to the

GLK1 input of the Spartan 2 (pin 77) and the

secondary oscillator is connected to GCLK2

(pin 182). Both clock inputs can drive a DLL on

the Spartan 2, allowing for a wide range if

internal frequencies are up to four times higher

than the external clock signals. Any 5V

oscillator in a half-size DIP package can be

loaded into the secondary oscillator socket.

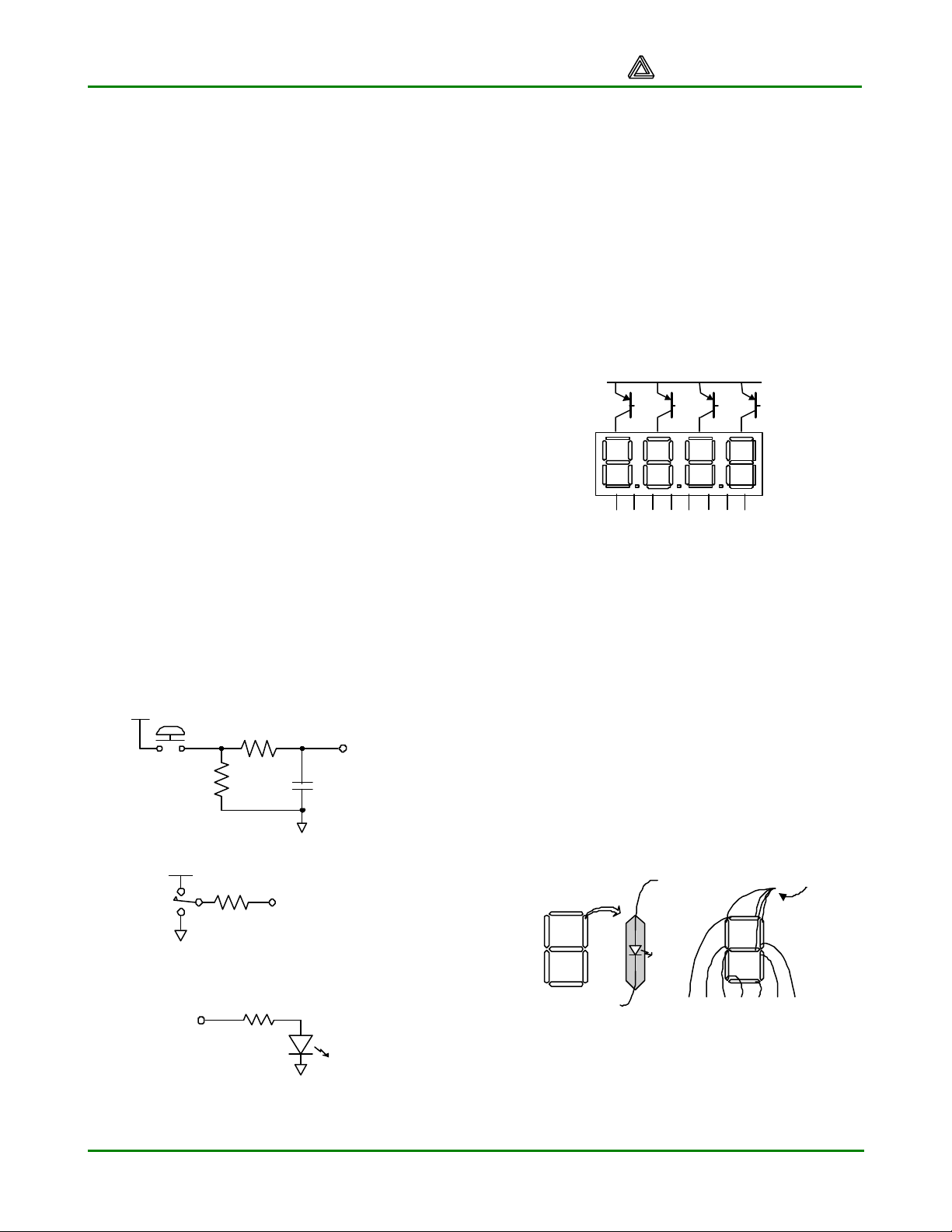

Pushbuttons, Slide Switches, and LEDs

Four pushbuttons and eight slide switches are

provided for circuit inputs. Pushbutton inputs

are normally low, and they are driven high only

when the pushbutton is pressed. Slide

switches generate constant high or low inputs

depending on their position. Pushbutton inputs

use RC networks to provide nominal debounce

and ESD protection. Slide switch inputs use

only a series resistor for protection.

Eight LEDs are provided for circuit outputs.

LED anodes are driven directly from the FPGA

via 470-ohm resistors, and the cathodes are

connected directly to ground. A ninth LED is

provided as a power-on LED, and a tenth LED

indicates JTAG programming status.

3.3V

4.7K ohms

To FPGA

4.7K

ohms

Pushbuttons

3.3V

4.7K

ohms

Slide switches

0.1uF

To FPGA

Seven-Segment Display

The Pegasus board contains a four-digit

common anode seven-segment LED display.

The display is multiplexed, so only seven

cathode signals exist to drive all 28 segments

in the display. Four digit-enable signals drive

the common anodes and these signals

determine which digit the cathode signals

illuminate.

Anodes are connected via

transistors for greater current

Vdd

AN0

AN1AN2AN3

abc d e f g dp

Cathodes are connected to

Xilinx device via 100Ω resistors

Figure 4. Common anode Sseg display

The seven anodes of each digit’s LEDs are

connected together into one “common anode”

circuit node. The display has four such nodes

named AN0 – AN3, and the signals that drive

these nodes serve as digit enablers. Driving an

anode signal low enables the corresponding

digit. The cathodes of similar segments on all

four displays are connected into seven circuit

nodes labeled CA through CG. Driving cathode

signals low illuminates segments on any digit

whose digit enable is low.

Common anode

a

f

e

b

g

c

From

FPGA

LEDs

Figure 3. Pushbutton, slide switch, and LED circuits

www.digilentinc.com Page 3

390 ohms

This connection scheme creates a multiplexed

display, where driving the anode signals and

corresponding cathode patterns of each digit in

d

a f g e d c b

Figure 5. Common anode detail

Page 4

Pegasus Reference Manual Digilent, Inc. ™

PS/2 Power

a repeating, continuous succession can create

the appearance of a four-digit display. Each of

the four digits will appear bright and

continuously illuminated if the digit enable

signals are driven low once every 1 to 16ms

(for a refresh frequency of 1KHz to 60Hz). For

example, in a 60Hz refresh scheme, each digit

would be illuminated for one quarter of the

refresh cycle, or 4ms. The controller must

assure that the correct cathode pattern is

present when the corresponding anode signal

is driven.

Refresh period = 1ms to 16ms

AN0

AN1

AN2

AN3

Digit 0

Digit period = Refresh / 4

Digit 1 Digit 2 Digit 3

Figure 6. Sseg signal timing

To illustrate the process, if AN0 is driven low

while CB and CC are driven low, then a “1” will

be displayed in digit position 0. Then, if AN1 is

driven low while CA, CB and CC are driven

low, then a “7” will be displayed in digit position

1. If AN0 and CB, CC are driven low for 4 ms,

and then AN1 and CA, CB, CC are driven low

for 4 ms in an endless succession, the display

will show “71” in the rightmost two digits.

Digit Cathode Signals

Shown

0

1 1 0 0 1 1 1 1

2

3

4

5

6

7

8

9

a b c d e f g

0 0 0 0 0 0 1

0 0 1 0 0 1 0

0 0 0 0 1 1 0

1 0 0 1 1 0 0

0 1 0 0 1 0 0

0 1 0 0 0 0 0

0 0 0 1 1 1 1

0 0 0 0 0 0 0

0 0 0 1 1 0 0

Figure 7. Cathode patterns for decimal digit s

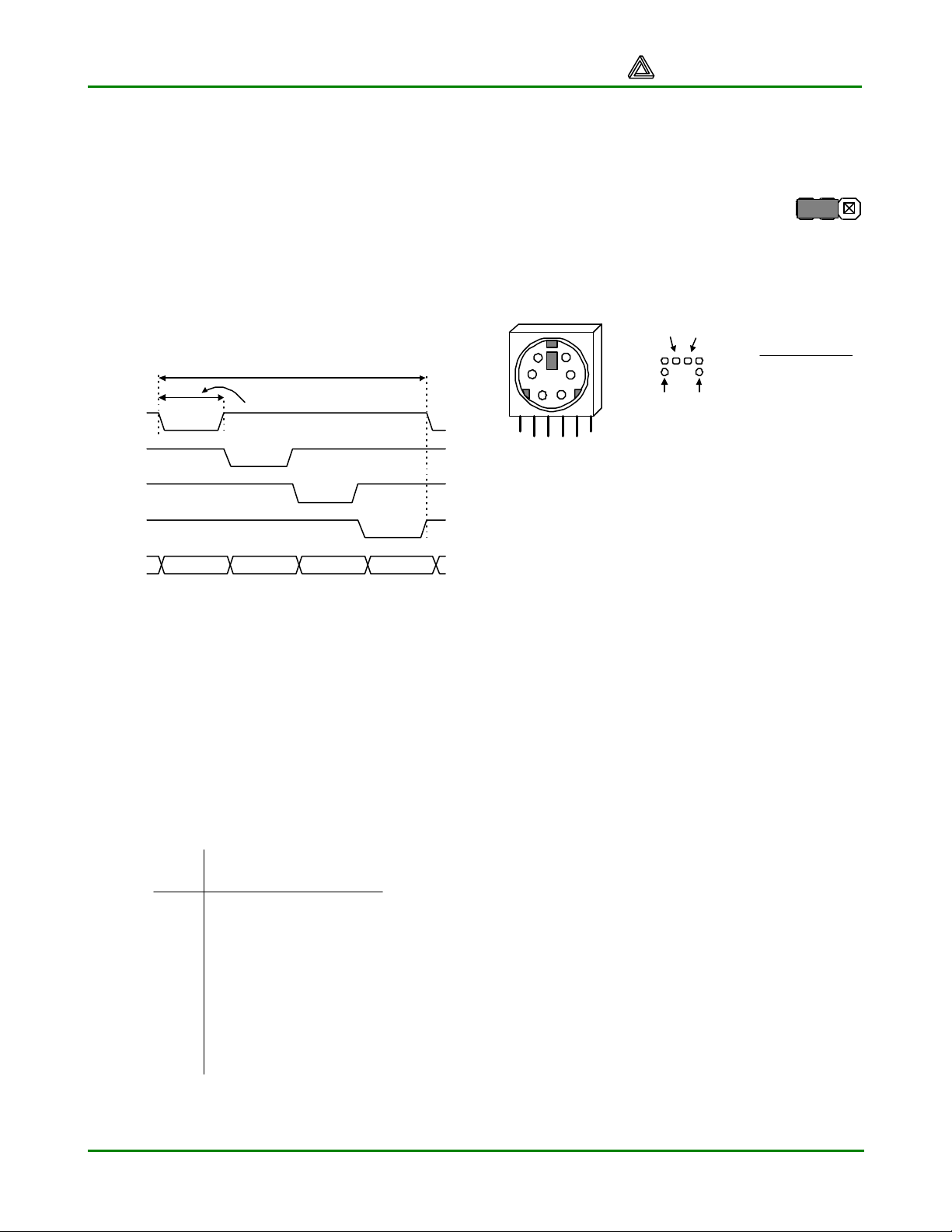

PS/2 Port

The Pegasus board includes a 6-pin mini-DIN

connector that can accommodate a PS/2

mouse or keyboard connection. A jumper on

the Pegasus board (J9) can be

loaded to provide 5V to the PS/2

J9

VCC33

PS2VCC

VU

port, or an external supply can be

connected to the “PS2VCC” pin of

J9 (some PS/2 devices require 5V

to work properly).

Pin Definitions

Pin Function

1 Data

2 Reserved

3 GND

4 Vdd

5 Clock

6 Reserved

1

2

4

PS2 Connector

3

6

5

Pin 1

Pin 2

Pin 5Pin 6

Bottom-up

hole pattern

Figure 8. PS/2 connections

The PS/2 protocol uses a bi-directional two wire interface that includes a serial data and a

clock signal (the host -to-keyboard data

direction is used to send status LED data).

Driver circuits on both ends of the clock and

data signals use open-collector buffers with

10K pull-ups. The signals are only driven when

a key is actively pressed (or when the host is

actively sending LED status data). If the PS/2

device is only used as an input device, then

the host system can just use input buffers

(open-collector buffers are not required).

PS/2 mouse and keyboard devices use11-bit

data words that include a start bit, eight data

bits, and odd parity bit, and a stop bit. Data

timings are shown in the figure below. The

mouse and keyboard use eight-bit data

packets that are organized differently – the

keyboard sends eight-bit key scan codes, and

the mouse sends three eight-bit data elements

to define relative mouse movements.

Keyboard

Each key has a single, unique scan code that

is sent whenever the corresponding key is

pressed. If a key is continuously pressed for

more than 570ms, its scan code is repeated

each 104ms (but the time interval between first

and second transmission of the same code is

www.digilentinc.com Page 4

Page 5

Pegasus Reference Manual Digilent, Inc. ™

570ms). When releasing a key that was

pressed for more than 570ms, an “F0” key-up

code is sent, followed immediately by the key

scan code. If a key can be “shifted” to produce

a new character (like a capital letter), then the

shift character is sent before the key scan

code. Some keys, called extended keys, send

an “E0” ahead of the scan code (and they may

send more than one scan code). When an

extended key is released, an “E0 F0” key-up

code is sent, followed by the scan code.

Signals timings and scan codes for most keys

are shown in the figure below.

A host device can also send data to the

keyboard. Below is a short list of some oftenused commands.

ED Set Num Lock, Caps Lock, and Scroll Lock

LEDs. After receiving an “ED”, the keyboard

returns an “FA”. Then the host sends a byte

to set LED status: bit 0 sets Scroll Lock, bit 1

sets Num Lock, and bit 2 sets Caps Lock.

Bits 3 to 7 are ignored.

EE Echo. Upon receiving an echo command, the

keyboard replies with “EE”.

F3 Set scan code repeat rate. The keyboard

acknowledges receipt of an “F3” by returning

an “FA”, after which the host sends a second

byte to set the repeat rate.

FE Resend. Upon receiving FE, the keyboard re -

sends the last scan code sent.

FF Reset. Resets the keyboard.

The keyboard should send data to the host

only when both the data and clock lines are

high (or idle). Since the host is the “bus

master”, the keyboard should check to see

whether the host is sending data before driving

the bus. To facilitate this, the clock line can be

used as a “clear to send” signal. If the host

pulls the clock line low, the keyboard must not

send any data until the clock is released.

Mouse

The mouse outputs a clock and data signal

when it is moved; otherwise, these signals

CLK

DATA

T

Edge 0

CK

'0 ' start bit '1 ' stop bit

T

CK

T

SU

T

HLD

Edge 10

Symbol Parameter Min Max

T

CK

Clock time

T

SU

Data-to-clock setup time

T

HLD Clock-to-data hold time 5us 25us

30us

5us

50us

25us

~3.1ms

Timing for a two-byte

scan code

Figure 9. PS/2 timings

~570ms

Scan code repeat timing

(key pressed and held)

~104ms

remain at logic ‘1’. Each time the mouse is

www.digilentinc.com Page 5

Page 6

Pegasus Reference Manual Digilent, Inc. ™

moved, three 11-bit words are sent from the

mouse to the host device. Each of the 11-bit

words contains a ‘0’ start bit, followed by eight

bits of data (LSB first), followed by an odd

parity bit, and terminated with a ‘1’ stop bit.

Thus, each data transmission contains 33 bits,

where bits 0, 11, and 22 are ‘0’ start bits, and

bits 10, 21, and 32 are ‘1’ stop bits. The three

8-bit data fields contain movement data as

shown below. Data is valid at the falling edge

of the clock, and the clock period is 20 to

30KHz.

The mouse assumes a relative coordinate

system wherein moving the mouse to the right

generates a positive number in the X field, and

moving to the left generates a negative

Mouse status byte X direction byte Y direction byte

L R 0 1 XSYS XY YY P X0 X1 X2 X3 X4 X5 X6 X7 P Y0 Y1 Y2 Y3 Y4 Y5 Y6 Y7 P1 0 1 00 11

Idle state

Start bit Stop bit

Start bit

Figure 10. PS/2 mouse data

number. Likewise, moving the mouse up

generates a positive number in the Y field, and

moving down represents a negative number

(the XS and YS bits in the status byte are the

sign bits – a ‘1’ indicates a negative number).

The magnitude of the X and Y numbers

represent the rate of mouse movement – the

larger the number, the faster the mouse is

moving (the XV and YV bits in the status byte

are movement overflow indicators – a ‘1’

means overflow has occurred). If the mouse

moves continuously, the 33-bit transmissions

are repeated every 50ms or so. The L and R

fields in the status byte indicate left and right

button presses (a ‘1’ indicates the button is

being pressed).

Stop bit

Start bit

Stop bit

Idle state

VGA Port

The five standard VGA signals red (R), green

(G), blue (B), horizontal sync (HS), and vertical

ync (VS) are routed from FPGA pins to the

VGA connector. The color signals pass

through 270-ohm resistors on the Pegasus

board to create a resistor-divider with the 75ohm VGA cable termination. This limits the

voltage at the VGA connector to the specified

0V (fully-off) to 0.7V (fully-on) range. This

three-bit color system allows for eight different

colors as shown in the table.

Color Red Green Blue

Black 0 0 0

Blue 0 0 1

Green 0 1 0

Cyan 0 1 1

Red 1 0 0

Purple 1 0 1

Yellow 1 1 0

White 1 1 1

Table 1. Three-bit color system

CRT Display Systems Background

Cathode ray tube (CRT)-based VGA displays

use amplitude-modulated, moving electron

beams (or cathode rays) to display information

on a phosphor-coated screen. LCD displays use

an array of switches that can impose a voltage

across a small amount of liquid crystal, thereby

changing light permittivity through the crystal on

a pixel-by-pixel basis. Although the following

description is limited to CRT displays, LCD

displays have evolved to use the same signal

timings as CRT displays (so the “signals”

discussion below pertains to both CRTs and

LCDs).

CRT displays use three electron beams (one for

red, one for blue, and one for green) to energize

the phosphor that coats the inner side of the

display end of a cathode ray tube (see drawing

below). Electron beams emanate from electron

guns, which are finely-pointed heated cathodes

placed in close proximity to a positively charged

annular plate called a “grid”.

www.digilentinc.com Page 6

Page 7

Pegasus Reference Manual Digilent, Inc. ™

The electrostatic force imposed by the grid

pulls away rays of energized electrons as

current flows into the cathodes. These cathode

rays are initially accelerated towards the grid,

but they soon fall under the influence of the

much larger electrostatic force that results from

the entire phosphor-coated display surface of

the CRT being charged to 20kV (or more). The

particle rays are focused to a fine beam as

they pass through the center of the grids, and

then they accelerate to impact on the

phosphor-coated display surface. The

phosphor surface glows brightly at the impact

point, and the phosphor continues to glow for

several hundred microseconds after the beam

is removed. The larger the current fed into the

cathode, the brighter the phosphor will glow.

Between the grid and the display surface, the

beam passes through the neck of the CRT

where two coils of wire produce orthogonal

electromagnetic fields. Because cathode rays

are composed of charged particles (electrons),

they can be deflected by these magnetic fields.

Current waveforms are passed through the

coils to produce magnetic fields that interact

with the cathode rays and cause them to

transverse the display surface in a “raster”

pattern, horizontally from left to right and

vertically from top to bottom.

As the cathode ray moves over the surface of

the display, the current sent to the electron guns

can be increased or decreased to change the

brightness of the display at the cathode ray

impact point. Information is only displayed when

the beam is moving in the “forward” direction (left

to right and top to bottom), and not during the

time the beam is reset back to the top left edge

of the display. Much of the potential display time

is therefore lost in “blanking” periods when the

beam is reset and stabilized to begin a new

horizontal or vertical display pass.

The size of the beams, the frequency at which

the beam can be traced across the display, and

the frequency at which the electron beam can be

modulated determine the display resolution.

Modern VGA displays can accommodate

different resolutions, and a VGA controller circuit

dictates the resolution by producing timing

signals to control the raster patterns. The

controller must produce synchronizing pulses at

5V to set the frequency at which current flows

through the deflection coils, and it must ensure

that video data is applied to the electron guns at

the correct time.

Raster video displays define a number of “rows”

that corresponds to the number of horizontal

passes the cathode makes over the display area,

and a number of “columns” that corresponds to

an area on each row that is assigned to one

“picture element” or pixel. Typical displays use

Anode (entire screen)

Cathode ray tube

Deflection coils

Cathode ray

Cathode ray tube display system

Grid

Electron guns

(Red, Blue, Green)

R,G,B signals (to guns)

gun

deflection

control

High voltage supply (>20kV) Control board

www.digilentinc.com Page 7

grid

control

control

Sync signals

(to deflection control)

VGA cable

Page 8

Pegasus Reference Manual Digilent, Inc. ™

from 240 to 1200 rows, and from 320 to 1600

columns. The overall size of a display, and the

number of rows and columns determines the

size of each pixel.

Video data typically comes from a video

refresh memory, with one or more bytes

assigned to each pixel location (the DIO4

board uses three bits per pixel). The controller

must index into video memory as the beams

move across the display, and retrieve and

apply video data to the display at precisely the

time the electron beam is moving across a

given pixel.

VGA System Timing

VGA signal timings are specified, published,

copyrighted, and sold by the VESA

organization (www.vesa.org). The following

VGA system timing information is provided as

an example of how a VGA monitor might be

driven in 640 by 480 mode. For more precise

information, or for information on higher VGA

frequencies, refer to the VESA website above.

A VGA controller circuit must generate the HS

and VS timing signals and coordinate the

delivery of video data based on the pixel clock.

The pixel clock defines the time available to

display one pixel of information. The VS signal

defines the “refresh” frequency of the display,

i.e., the frequency at which all information on

the display is redrawn. The minimum refresh

frequency is a function of the display’s phosphor

and electron beam intensity, with practical

refresh frequencies falling in the 50Hz to 120Hz

range.

The number of lines to be displayed at a given

refresh frequency defines the horizontal “retrace”

frequency. For a 640-pixel by 480 -row display

using a 25MHz pixel clock and 60 +/-1Hz

refresh, the signal timings shown in the table

below can be derived. Timings for sync pulse

width and front and back porch intervals (porch

intervals are the pre- and post -sync pulse times

during which information cannot be displayed)

are based on observations taken from VGA

displays.

A VGA controller circuit decodes the output of a

horizontal-sync counter driven by the pixel clock

to generate HS signal timings. This counter can

be used to locate any pixel location on a given

row. Likewise, the output of a vertical-sync

counter that increments with each HS pulse can

be used to generate VS signal timings, and this

counter can be used to locate any given row.

These two continually running counters can be

used to form an address into video RAM. No

time relationship between the onset of the HS

pulse and the onset of the VS pulse is specified,

so the designer can arrange the counters to

easily form video RAM addresses, or to minimize

Symbol Parameter

T

Sync pulse time

S

T

Display time

disp

p

T

Pulse width

w

T

Front porch

fp

T

Back porch

bp

Horizontal

Counter

Vertical Sync

Time Clocks Lines

16.7ms

15.36ms

320 us

928 us

Zero

Detect

3.84us

Detect

64 us

416,800

384,000

1,600

8,000

23,200

Set

Horizontal

Synch

Reset

521

480

2

10

29

Horizontal Sync

Time

25.6 us

3.84 us

640 ns

1.92 us

Clocks

32 us

800

640

96

16

48

CE VS

Vertical

Counter

p

T

w

Zero

Detect

64us

Detect

T

S

T

disp

Reset

Set

Vertical

Synch

T

fp

T

bp

HS

www.digilentinc.com Page 8

Page 9

Pegasus Reference Manual Digilent, Inc. ™

decoding logic for sync pulse generation.

Expansion Connectors

40-Pin Connectors

Three expansion connectors labeled A1, A2,

and B1 are available on the Pegasus board.

These female so cket connectors mate with

100-mil spaced, 2x20 right-angle headers

(available at most distributors). All three

connectors have GND on pin 1, VU on pin 2,

and 5V on pin 3. Pins 4-35 route to FPGA I/O

signals, and pins 36-40 are reserved for JTAG

and/or clock signals (see Figure 13).

Each of the expansion connectors provides 32

unique I/0 signals. These signals have been

grouped into three different types of busses for

documentation purposes, and to facilitate

communications with external boards. The

lower 18 pins (pins 4-21) of the A1 and B1

connectors are designated as the “system

bus”. The system bus defines eight data

signals, six address lines, two strobes (WE and

USB or Ethernet boards) use the module bus.

Module bus timings are consistent with EPP bus

timings.

6-Pin Connector

The Pegasus board also contains a 6-pin

accessory port (J1). This port provides Vdd,

GND, and four unique FPGA signals. Several 6pin module boards that can attach to this

connector are available from Digilent, including

speaker boards, H -bridge boards, sensor

boards, etc.

Peripheral Bus

System Bus

The “system bus” is a protocol used by certain

expansion boards that mimics a simple 8-bit

microprocessor bus. It includes eight data lines,

six address lines, a write-enable (WE) strobe

that can be used by the peripheral to latch

written data, an output-enable (OE) strobe that

can be used by the peripheral to enable read

Figure 7. Expansion Connector Pins

OE), a chip select, and a clock. The lower 18

pins of the A2 connector are designated as the

“peripheral bus”, and the individual pins are not

assigned any further definitions. The upper 14

pins of each expansion connector (pins 22-35)

have been designated as “module busses”.

Module bus pin definitions are consistent with

enhanced parallel port (EPP) pin definitions,

and they include eight address/data lines,

three strobes (address write, data write, and

read/write), and three status lines (wait, reset,

and initialize). Figure 13 below shows

expansion connector signal routing. Some

Digilent peripheral boards use the system bus

pins. Bus timings mimic a simple 8-bit

microprocessor bus, with signal timings shown

in figure 14 below. Module boards (like the

Pin 4

Pin 1: GND

Pin 2: VU

Pin 39

Pin 40

Pin 3: 3.3V

data, a chip select, and a clock to enable

synchronous transfers. Figure 14 shows bus

signal timings used by Digilent to create bus

controllers in peripheral devices. However, any

bus and timing model can be used by modifying

circuits in the FPGA and attached peripheral

devices.

Module Bus

The module bus protocol is used by various

module boards (like the Ethernet and U SB

modules) to communicate with the Pegasus

board. The module bus signals and timings are

borrowed from the EPP protocol. Timings and

signals are shown here.

www.digilentinc.com Page 9

Page 10

Pegasus Reference Manual Digilent, Inc. ™

System Bus Timing

Symb

ol

ten Time to enable after CS asserted 10ns

th Hold time 1ns

tdoe Time to disable after OE de-

asserted

teoe Time to enable after OE asserted 15ns

tw Write strobe time 10ns

tsu Data setup time 5ns

twd Write disable time 0ns

Parameter Time

(typ)

10ns

Write Cycle

Ten

CS

Tdoe

OE

Tw

WE

Tsu

DB0-DB7

Th

Teoe

Th

Module Bus Timing

Symb

Parameter Time

ol

tstb Strobe time 10ns

twt Strobe to wait time 10 ns

twr Time to enable write 15 ns

tsu Data setup time 5 ns

th Data hold time 5 ns

Write Cycle*

ASTB

DSTB

WAIT

nWR

T

STB

T

STB

T

WT

T

WR

T

H

T

H

(typ)

Read Cycle

CS

OE

WE

DB0-DB7

Twd

Tsu

Read data latch time

ThTen

TdoeTeoe

Th

Th

DATA

Read Cycle*

ASTB

DSTB

WAIT

nWR

DATA

Figure 14. Peripheral bus signals and timings

* ASTB and DSTB determine whether an address or

data write cycle occurs. Only one should be

asserted for each bus transaction.

T

SU

T

STB

T

STB

T

WT

T

WR

Tsu

T

H

T

H

T

H

Th

www.digilentinc.com Page 10

Page 11

Pegasus Reference Manual Digilent, Inc. ™

Pegasus Expansion Connector Pinout

Connector B1 Connector A1 Connector A2

Pin Signal B1 Pin Signal A1 Pin Signal A2

39 TDO TDO 39 TDO TDO 39 GCK0 GCK0

40 TDI TDI 40 TDI TDI 40 GND GND

37 TMS TMS 37 TMS TMS 37 n/c n/c

38 TCK TCK 38 TCK TCK 38 n/c n/c

35 MB1-INIT 90 35 MA1-INIT 189 35 MA2-INT 138

36 GND GND 36 GND GND 36 Not used n/c

33 MB1-WAIT 95 33 MA1-WAIT 192 33 MA2-WAIT 140

34 M1-RST 94 34 M1-RST 191 34 MA2-RST 139

31 MB1-DSTB 97 31 MA1-DSTB 194 31 MA2-DSTB 142

32 MB1-WRIT 96 32 MA1-WRIT 193 32 MA2-WRIT 141

29 MB1-DB7 99 29 MA1-DB7 199 29 MA2-DB7 147

30 MB1-ASTB 98 30 MA1-ASTB 195 30 MA2-ASTB 146

27 MB1-DB5 101 27 MA1-DB5 201 27 MA2-DB5 149

28 MB1-DB6 100 28 MA1-DB6 200 28 MA2-DB6 148

25 MB1-DB3 108 25 MA1-DB3 203 25 MA2-DB3 151

26 MB1-DB4 102 26 MA1-DB4 202 26 MA2-DB4 150

23 MB1-DB1 110 23 MA1-DB1 205 23 MA2-DB1 160

24 MB1-DB2 109 24 MA1-DB2 204 24 MA2-DB2 152

21 P-LSBCLK 112 21 LSBCLK 3 21 P-IO18 162

22 MB1-DB0 111 22 MA1-DB0 206 22 MA2-DB0 161

19 P1-DB7 114 19 DB7 5 19 P-IO16 164

20 P-CSA 113 20 CSA 4 20 P-IO17 163

17 P-DB6 119 17 DB6 7 17 P-IO14 166

18 P-OE 115 18 OE 6 18 P-IO15 165

15 P-DB5 121 15 DB5 9 15 P-IO12 168

16 P-WE 120 16 WE 8 16 P-IO13 167

13 P-DB4 123 13 DB4 14 13 P-IO10 173

14 P-ADR5 122 14 ADR5 10 14 P-IO11 172

11 P-DB3 126 11 DB3 16 11 P-IO8 175

12 P-ADR4 125 12 ADR4 15 12 P-IO9 174

9 P-DB2 129 9 DB2 18 9 P-IO6 178

10 P-ADR3 127 10 ADR3 17 10 P-IO7 176

7 P-DB1 133 7 DB1 21 7 P-IO4 180

8 P-ADR2 132 8 ADR2 20 8 P-IO5 179

5 P-DB0 135 5 DB0 23 5 P-IO2 187

6 P-ADR1 134 6 ADR1 22 6 P-IO3 181

3 VCCO VCCO 3 VCCO VCCO 3 VCCO VCCO

4 P-ADR0 136 4 ADR0 24 4 P-IO1 188

1 GND GND 1 GND GND 1 GND GND

2 VU VU 2 VU VU 2 VU VU

Pin Name FPGA Pin Pin Name FPGA Pin

1 AC0 P49 4 AC3 P47

2 AC1 P48 5 GND 3 AC2 P81 6 Vdd -

Accessory Port Pinout

www.digilentinc.com Page 11

Page 12

Pegasus Reference Manual Digilent, Inc. ™

LD5

Pegasus FPGA Pin Assignments

Pin Function Pin Function Pin Function Pin Function

1 GND 53 VCCO 105 VCCO 157 TDO

2 TMS 54 MODE2 106 PROGRAM 158 GND

3 LLSBCLK 55 PB-IO14 107 INIT/IO 159 TDI

4 LCSA 56 PB-IO13 108 LMB1-DB3 160 LMA2-DB1

5 LDB7 57 BTN2 109 LMB1-DB2 161 LMA2-DB0

6 LOE 58 BTN1 110 LMB1-DB1 162 LPA-IO18

7 LDB6 59 BTN0 111 LMB1-DB0 163 LPA-IO17

8 LWE 60 AN0 112 LPB-LSBCLK 164 LPA-IO16

9 LDB5 61 CE 113 LPB-CSA 165 LPA-IO15

10 LADR5 62 CD 114 LPB-DB7 166 LPA-IO14

11 GND 63 DP 115 LPB-OE 167 LPA-IO13

12 VCCO 64 GND 116 GND 168 LPA-IO12

13 VCCINIT 65 VCCO 117 VCCO 169 GND

14 LDB4 66 VCCINIT 118 VCCINIT 170 VCCO

15 LADR4 67 CC 119 LPB-DB6 171 VCCINIT

16 LDB3 68 CG 120 LPB-WE 172 LPA-IO11

17 LADR3 69 AN1 121 LPB-DB5 173 LPA-IO10

18 LDB2 70 CB 122 LPB-ADR5 174 LPA-IO9

19 GND 71 AN2 123 LPB-DB4 175 LPA-IO8

20 LADR2 72 GND 124 GND 176 LPA-IO7

21 LDB1 73 CF 125 LPB-ADR4 177 GND

22 LADR1 74 CA 126 LPB-DB3 178 LPA-IO6

23 LDB0 75 AN3 127 LPB-ADR3 179 LPA-IO5

24 LADR0 76 VCCINIT 128 VCCINIT 180 LPA-IO4

25 GND 77 GCK1 129 LPB-DB2 181 LPA-IO3

26 VCCO 78 VCCO 130 VCCO 182 GCK2

27 VS 79 GND 131 GND 183 GND

28 VCCINT 80 GCK0 132 LPB-ADR2 184 VCCO

29 HS 81 SW7/AC2 133 LPB-DB1 185 GCK3

30 BLUE 82 SW6 134 LPB-ADR1 186 VCCINIT

31 GRN 83 SW5 135 LPB-DB0 187 LPA-IO2

32 GND 84 SW4 136 LPB-ADR0 188 LPA-IO1

33 RED 85 GND 137 GND 189 LMA1-INT

34 PS2C 86 SW3 138 LMA2-INT 190 GND

35 PS2D 87 SW2 139 LMA2-RESET 191 LMA1-RESET

36 LD7 88 SW1 140 LMA2-WAIT 192 LMA1-WAIT

37 LD6 89 SW0 141 LMA2-WRITE 193 LMA1-WRITE

38 VCCINIT 90 LMB1-INT 142 LMA2-DSTB 194 LMA1-DSTB

39 VCCO 91 VCCINIT 143 VCCINIT 195 LMA1-ASTB

40 MC1-DB4 92 GND 144 VCCO 196 VCCINIT

41

42 LD4 94 LMB1-RESET 146 LMA2-ASTB 198 GND

43 LD3 95 LMB1-WAIT 147 LMA2-DB7 199 LMA1-DB7

44 LD2 96 LMB1-WRITE 148 LMA2-DB6 200 LMA1-DB6

45 LD1 97 LMB1-DSTB 149 LMA2-DB5 201 LMA1-DB5

46 LD0 98 LMB1-ASTB 150 LMA2-DB4 202 LMA1-DB4

47 AC3 99 LMB1-DB7 151 LMA2-DB3 203 LMA1-DB3

48 AC1 100 LMB1-DB6 152 LMA2-DB2 204 LMA1-DB2

49 AC0 101 LMB1-DB5 153 DIN/D0/IO 205 LMA1-DB1

50 MODE1 102 LMB1-DB4 154 BTN3 206 LMA1-DB0

51 GND 103 GND 155 CCLK 207 TCK

52 MODE0 104 DONE 156 VCCO 208 VCCO

93 GND 145 GND 197 VCCO

www.digilentinc.com Page 12

Loading...

Loading...