Page 1

Page 1 of 3

5

Genesys 2 Reference Manual

The Digilent Genesys 2 board is an advanced, high-performance, ready-to-use digital circuit development platform based on

the latest Kintex-7™ Field Programmable Gate Array (FPGA) from Xilinx. With its high-capacity, high-speed FPGA (Xilinx

part number XC7K325T-2FFG900C), fast external memories, high-speed digital video ports, and wide expansions options

make the Genesys 2 well suited for data and video processing applications. Several built-in peripherals, including Ethernet,

audio and USB 2.0, allow a wide range of other applications. The fully-bonded high-speed FMC HPC connector opens the

door to great expansion possibilities.

1)

Page 2

Page 2 of 3

5

Page 3

Page 3 of 3

5

Page 4

Page 4 of 3

5

Page 5

Page 5 of 3

5

Features

• 50,950 logic slices (from Genesys up 7x), each with four 6-input LUTs and 8 flip-flops

• Close to 16 Mbits of fast block

• Ten clock management tiles, each with phase-locked loop (PLL)

• 840 DSP slices (up 17x)

• Internal clock speeds exceeding 450MHz

• On-chip analog-to-digital converter (XADC)

• Up to 10.3125Gbps gigabit transceivers

• 1800Mbps DDR3 data rate with 32-bit data width

• Commercial -2 speed grade

• Fully bonded 400-pin FMC HPC connector

• USB-UART Bridge

• 8 user switches, 6 buttons

•

OLED ()

• VGA connector

• Pmod for XADC signals

•Two four-lane DisplayPort connectors

• HDMI Sink and HDMI Source

• 10/100/1000 Ethernet PHY

• 1GiB 1800Mt/s on-board DDR3

• USB 2.0 Host/Device/OTG PHY

• Digilent Adept USB port for programming and data

• Ten GTX lanes available in the FMC connector

RAM () (up 7x)

Page 6

Page 6 of 3

5

• Micro SD card connector

• Audio codec w/ four 3.5mm jacks

• Serial Flash

•Five Pmod ports

• USB HID Host for mice, keyboards and USB MSD Host for storage

The Genesys 2 can be programmed from various sources, like USB thumb drive, microSD, the on-board non-volatile Flash or

the on-board USB-JTAG programmer circuit.

The Genesys 2 is compatible with Xilinx’s new high-performance Vivado® Design Suite as well as the ISE toolset. Included in

the box is a voucher that unlocks the Design Edition of Vivado that is device-locked to the Genesys 2. This allows designs to

be implemented straight out of the box at no additional cost. The Design Edition of Vivado also unlocks the Logic Analyzer

tool and still includes the ability to create Microblaze soft-core processor projects.

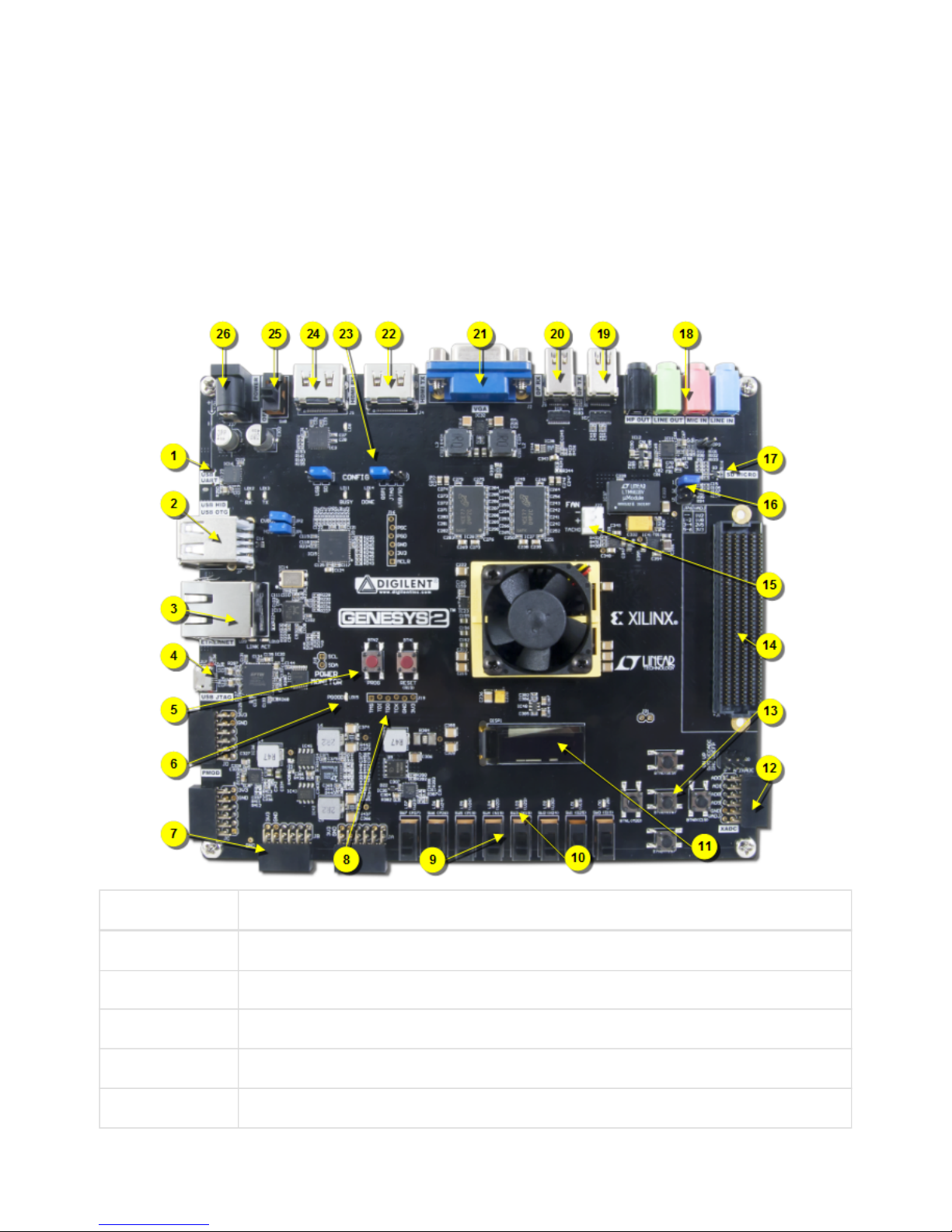

Callout Component Description

1 USB-UART bridge

2 User-USB (bottom) & USB MSD/HID (top)

3 Ethernet RJ-45 10/100/1000

4 USB-JTAG bridge

5 PROG and user reset buttons

Page 7

Callout Component Description

5

6 Power LED ()

7 Digital Pmods

8 JTAG header

9 User slide switches

10 User LEDs

Page 7 of 3

11

12 Dual analog/digital Pmod

13 User pushbuttons

14 FMC HPC

15 Fan header

16 VADJ jumper

17 micro SD slot

18 3.5mm audio jacks

19 DisplayPort source connector

20 DisplayPort sink connector

21 VGA connector

22 HDMI source connector

OLED () display

23 FPGA configuration source jumper

24 HDMI sink connector

25 Power switch

26 Power jack 12VDC

Table 1. Genesys 2 features and connectors.

1. Quick-start

The Genesys 2 comes with an out-of-box demo design that gets loaded from the on-board QSPI flash. It exercises most of the

on-board peripherals. Just power the board with the included 12V wall supply, flick the power switch, wait for the design to

fully load and explore the following features:

Page 8

Page 8 of 3

5

• Connecting an HDMI/DVI, VGA, or DisplayPort monitor shows a demo image with a mouse pointer.

• Connecting a USB mouse controls the mouse pointer on the display.

OLED () shows the Digilent logo and various information on several pages. Advance between pages with the

•The

BTNC button.

• The internal FPGA temperature, voltage and current readings of various power rails are shown on the

• Connecting the board to an Ethernet network will acquire link, IP address and become “pingable” at the IPv4 address

displayed on the

• Connecting the USB-UART port to a PC and opening a terminal (115200, 8, N, 1) shows status messages.

• Pushing BTNU records audio off the microphone input for five seconds and plays it back on the headphone output if

BTND is pushed, or line-out if BTNL. Similarly, BTNR starts a recording off the line-in jack.

• The LEDs are showing a scanning light bar.

• The fan starts when FPGA internal temperature reaches 60°C and stops when it drops back to 40°C.

OLED ().

OLED ().

To develop new FPGA designs for the Genesys 2, download and install the

(http://www.xilinx.com/products/design-tools/vivado.html). The tools include all the USB drivers for the board. Once installed, the USB

JTAG and USB UART ports can be connected to the PC and making the FPGA visible in Vivado Hardware Manager.

Additional resources can be found on the Genesys 2 Resource Center.

Xilinx Vivado® Design Suite

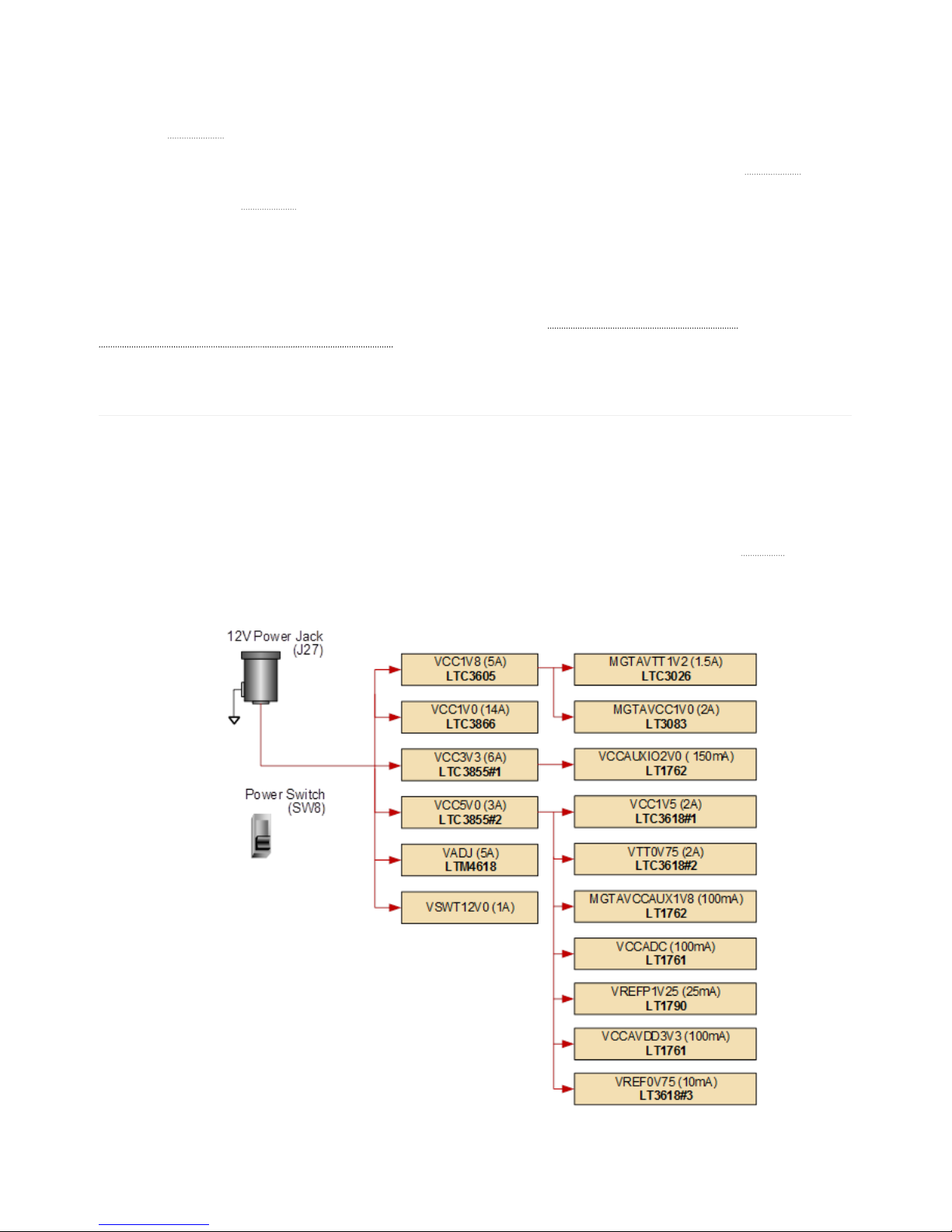

2. Power Supplies

The Genesys 2 board can receive power from an external power supply through the center-positive barrel jack (J27). The

external supply voltage must be 12 V ±5 %. The Genesys 2 cannot be powered from the USB bus.

All Genesys 2 power supplies can be turned on and off together by a single logic-level power switch (SW8). Power supplies are

either enabled/disabled directly by the power switch or indirectly by other supplies upstream. A power-good

driven by the “power good” output of the on-board regulators, indicates that the supplies are turned on and operating

normally. An overview of the Genesys 2 power circuit is shown in Figure 1.

LED () (LD15),

Page 9

Page 9 of 3

5

An external power supply can be used by plugging it into the power jack (J27). The supply must use a coax, center-positive

2.1mm internal-diameter plug, and deliver 12VDC ±5 %. The minimum current rating of the supply depends on the actual

design implemented in the FPGA, but at least 3A (i.e., at least 36W) is recommended. For high-power FMC applications a 60W

supply is recommended.

Voltage regulator circuits from Linear Technology create the different voltages required by the FPGA and on-board peripherals

from the main power input. Some regulators use the outputs of another regulator as input, depending on design considerations.

In some cases this chaining helps in creating the proper power-on sequence for circuits. In other cases the chaining of power

supply enables achieves the same purpose.

Table 2 provides information on maximum and typical currents for each power rail. The typical currents strongly depend on

FPGA configuration and the values provided are the current consumption of the OOB demo.

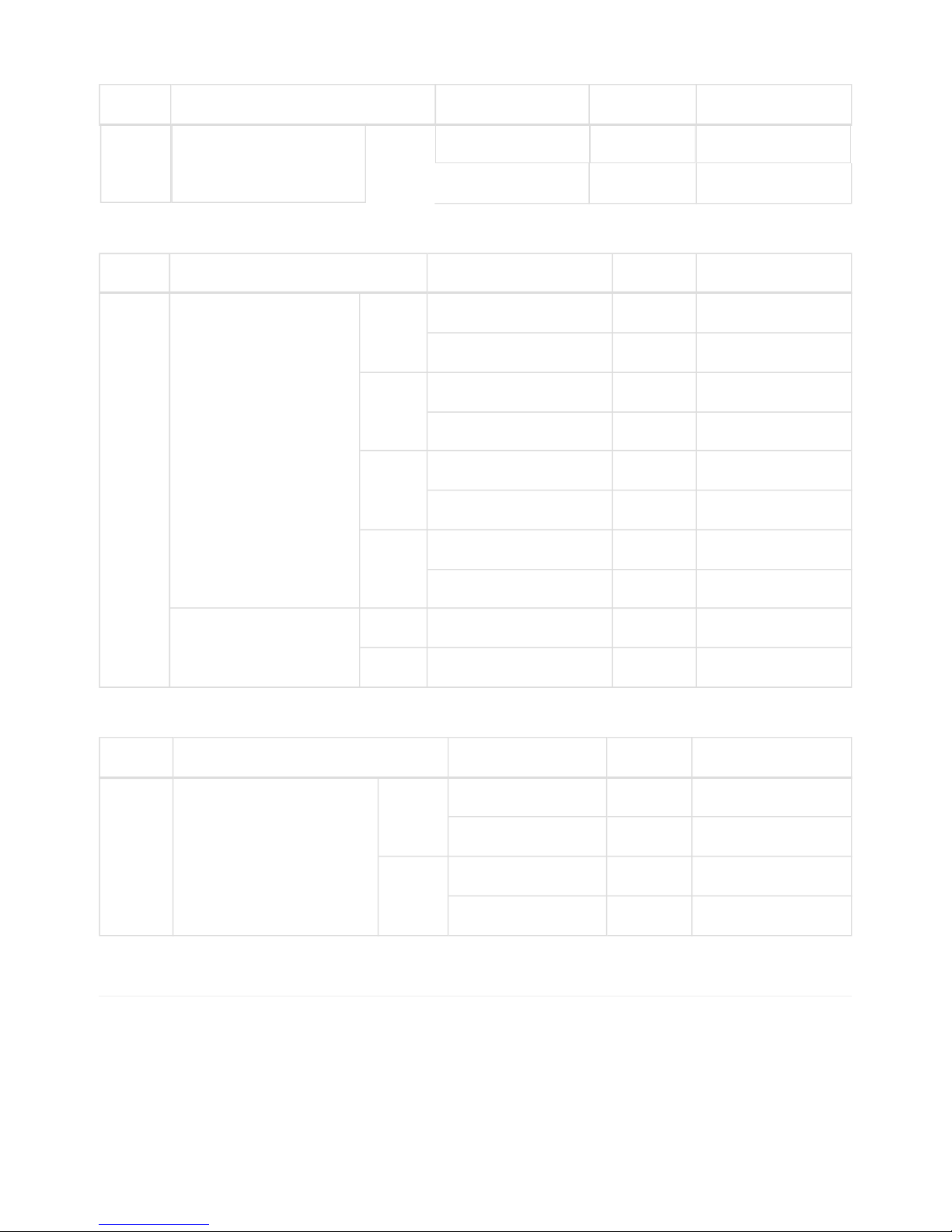

Current

Supply Circuits Device

(max/typical)

3.3 V FPGA I/O, USB, FMC, Clocks, Pmod, Ethernet, SD slot,

Flash, DisplayPort, HDMI

IC42:

LTC3855#1

6 A / 0.8 A

1.0 V FPGA Core IC30: LTC3866 14 A / 1.2 A

1.8 V FPGA Auxiliary IC36: LTC3605 5 A / 1.6 A

1.5 V DDR3 and FPGA I/O IC32: LTC3618 2 A / 0.7 A

0.75V DDR3 termination, reference IC32: LTC3618 2 A

2.0 V FPGA Auxiliary I/O for memory high data rates IC38: LT1762 150 mA

VADJ

User I/O, FMC and FPGA I/O IC37: LTM4618 5A

2)

(1.2-3.3 V)

3.3 V Audio analog supply IC12: LT1761 100 mA

5.0 V USB Host, HDMI IC42:

3 A / 0.3 A

LTC3855#2

MGT 1.0 V Gigabit Transceivers

VCC () IC41: LT3083 2 A

MGT 1.2 V Gigabit Transceivers VTT IC39: LTC3026 1.5 A

MGT 1.8 V Gigabit Transceivers AUX IC40: LT1762 150 mA

XADC 1.8 V XADC supply IC47: LT1761 100 mA

XADC 1.25 V XADC reference IC48: LT1790 5 mA

Table 2. Voltage rail power settings.

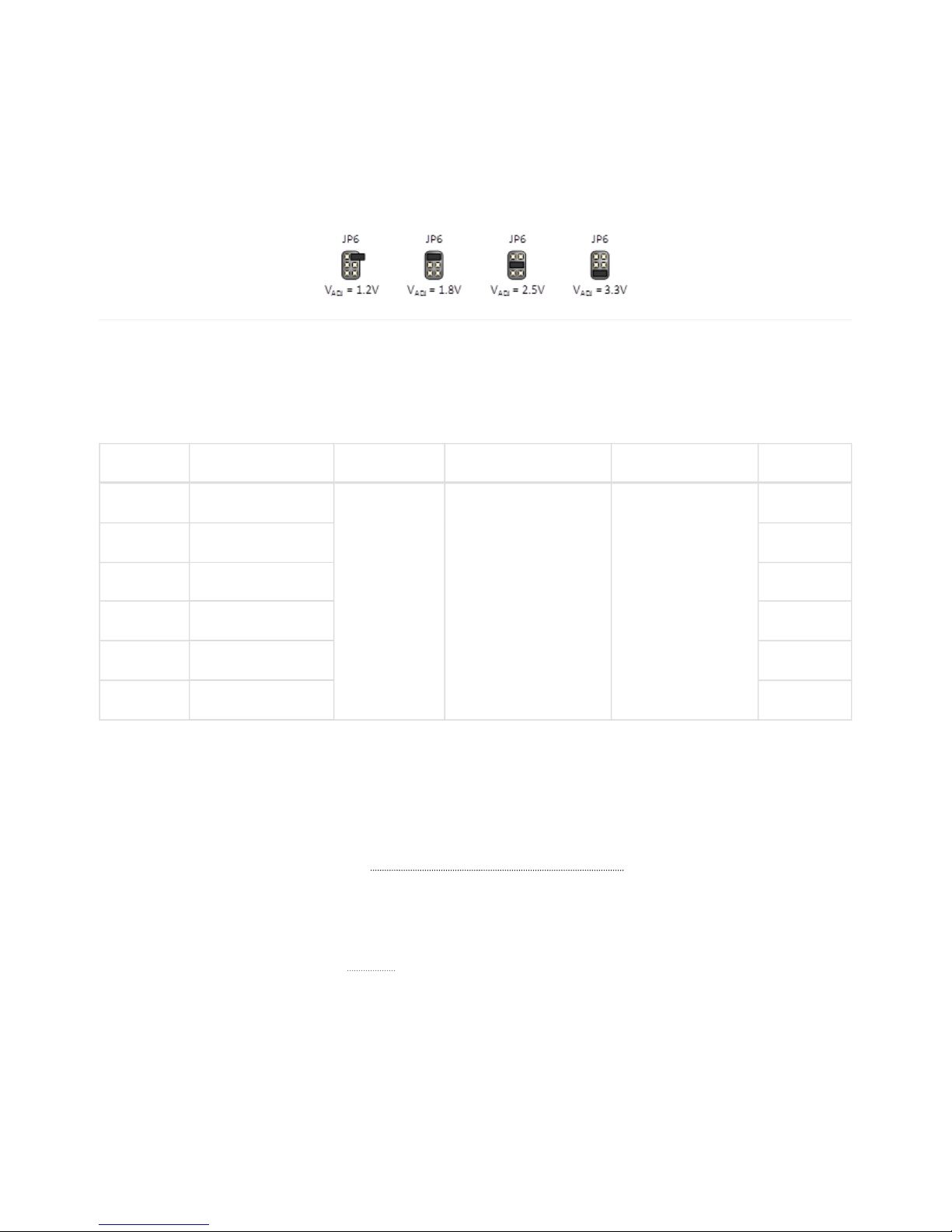

The VADJ power rail requires special attention. It is an adjustable rail that powers the FMC mezzanine connector, user pushbuttons, switches, XADC Pmod connector and the FPGA banks connected to these peripherals (banks 15, 16, 17). The

feedback pin of the VADJ regulator is connected to a resistor network modifiable by jumper JP6. Changing its position

changes the resistor divider in the feedback loop, thereby changing the voltage on the regulator’s output. The possible voltages

Page 10

Page 10 of 3

5

are listed in Figure 2. If JP6 is not set, the VADJ voltage defaults to 1.2 V. This feature enables setting the VADJ voltage to suit

a certain FMC mezzanine card or application. It is recommended to only change the JP6 position with the power switch in the

OFF position.

Please note that for proper voltage levels in digital signals connected to VADJ-powered FPGA banks (ex. user push-buttons),

the correct I/O standard still needs to be set in the design user constraints (XDC or UCF file). See the schematic and/or the

constraints file to determine which signals are in VADJ-powered banks. The provided master UCF and XDC files assume the

default VADJ voltage of 1.2V, declaring LVCMOS12 as the I/O standard for these signals.

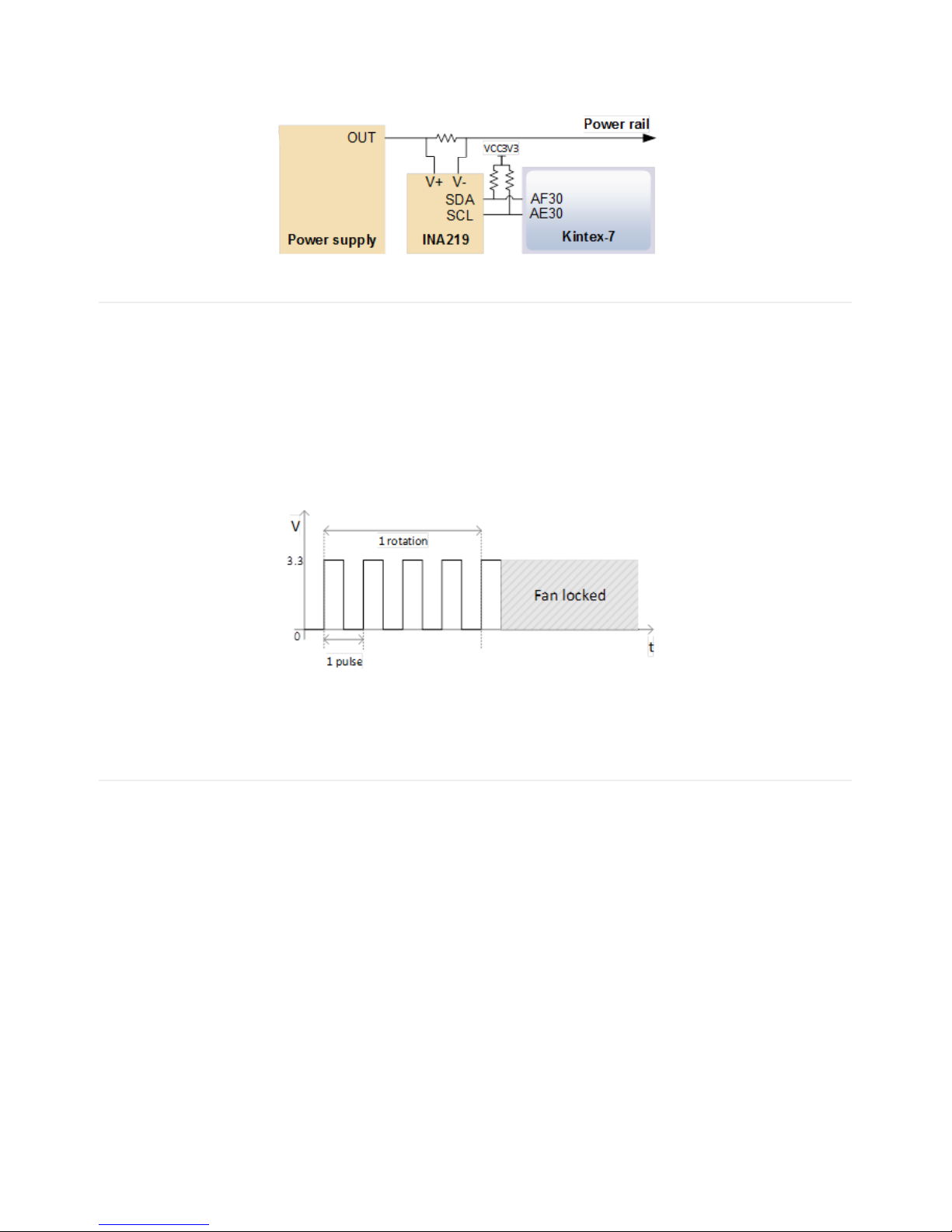

3. Power Monitoring

2

I C-interfaced monitoring circuits, INA219 from Texas Instruments, are available on the main power rails. These allow realtime voltage, current, and power readings in the FPGA. Six such circuits share the same I C bus with different slave addresses.

These are summarized in Table 3, along with recommended configuration values.

Supply rail I2C device address Shunt resistor Configuration register Calibration register Designator

2

VCC1V0 b1000101 5 mΩ 0x0867 0x4000 IC29

VCC1V5 b1001100 IC33

VCC1V8 b1001000 IC35

VADJ b1000001 IC34

VCC3V3 b1000100 IC44

VCC5V0 b1000000 IC46

Table 3. Power monitoring circuit parameters.

The configuration and calibration registers are volatile, so they need to be initialized after power-up. After initialization is done

voltage, current, and power values can be read from dedicated registers. It is recommended to add glitch filters to the I2C

master controller to avoid spurious start or stop conditions occurring on the bus. This is especially important when using an

external I2C master connected to the J18 header (not mounted by default).

For more information on the INA219, see its

datasheet (http://www.ti.com/lit/gpn/ina219).

The principle of operation is measuring bus and shunt voltages using a programmable-gain differential amplifier and an analogto-digital converter. The schematic for one such circuit is shown in Figure 3. The two analog inputs are connected across a

shunt resistor placed in series between the power supply and the load. Current consumed by the load produce a voltage drop

across the shunt resistor. This voltage is measured by the INA219 and is used to calculate the current. In addition, the bus

voltage is measured on V- with respect to

GND () and is the voltage on the respective power rail. The voltage and current

measurements are used to calculate power consumption. If the INA219 is configured, it will correctly calculate all three

parameters. In its default, power-up configuration it provides bus and shunt voltage only, which can be used to calculate

current and power in the FPGA.

Page 11

Page 11 of 3

5

4. Fan

The Genesys 2 comes with a fan and a secondary heat sink pre-installed on the FPGA package heat sink. The fan is powered

from the external 12V DC supply rail and controlled by the FPGA. Control is done by the “FAN_EN” signal. Pulling the

signal high from the FPGA opens the transistor driving the fan. This pin is pulled high by default. Feedback is obtained on the

“FAN_TACH” signal. This generates a pulse with a frequency proportional to the rotation speed of the fan. Each rotation

generates four pulses on “FAN_TACH”. The period of these pulses shortens with higher rotation speed and lengthens at

slower speeds.

The fan uses a 3-pin header for power, ground and feedback. It is recommended leaving the fan connected at all times.

Depending on FPGA design complexity and actual usage the fan might not be needed at all. In this case the enable signal can

be used to stop the fan, and start it when the FPGA internal temperature (as read by the XADC) gets above a certain limit.

5. FPGA Configuration

After power-on, the Kintex-7 FPGA must be configured (or programmed) before it can perform any functions. You can

configure the FPGA in one of four ways:

1. A PC can use the Digilent USB-JTAG circuitry (port J17, labeled “USB JTAG”) to program the FPGA any time the

power is on.

2. A file stored in the nonvolatile serial (SPI) flash device can be transferred to the FPGA.

3. A programming file can be transferred to the FPGA from a micro SD card.

4. A programming file can be transferred from a USB mass-storage device (ex. pen drive) attached to the USB HOST port.

Figure 5 shows the different options available for configuring the FPGA. An on-board “mode” jumper (JP5) and a media

selection jumper (JP4) select between the programming modes.

Page 12

Page 12of 3

5

The FPGA configuration data is stored in files called bitstreams that have the .bit file extension. The ISE or Vivado software

from Xilinx can create bitstreams from VHDL, Verilog, or schematic-based source files (in the ISE toolset, EDK is used for

MicroBlaze™ embedded processor-based designs).

Bitstreams are stored in volatile SRAM-based memory cells within the FPGA. This data defines the FPGA’s logic functions

and circuit connections, and it remains valid until it is erased by removing board power, by pressing the reset button attached to

the PROG input, or by writing a new configuration file using the JTAG port.

A Kintex-7 325T bitstream is typically 91,548,896 bits long and can take a long time to transfer depending on the programming

mode. The time it takes to program the Genesys 2 can be decreased by compressing the bitstream before programming, and

then allowing the FPGA to decompress the bitstream itself during configuration. Depending on design complexity,

compression ratios of 10x can be achieved. Bitstream compression can be enabled within the Xilinx tools (ISE or Vivado) to

occur during generation. For instructions on how to do this, consult the Xilinx documentation for the toolset being used. This

option is available for all programming modes.

Mode-specific speed-ups are also available. JTAG clock frequency can be set to the maximum supported by the programming

cable in iMPACT/Vivado Hardware Manager. Similarly, the clock frequency for the SPI Flash can be increased in device

properties (Vivado) or bitstream generation options (ISE). The micro-SD and USB mass-storage device configuration modes

already operate at their maximum possible speed.

After being successfully programmed, the FPGA will cause the “DONE”

button (BTN2) at any time will reset the configuration memory in the FPGA. After being reset, the FPGA will immediately

attempt to reprogram itself from whatever method has been selected by the programming mode jumpers.

The following sections provide greater detail about programming the Genesys 2 using the different methods available.

LED () (LD14) to illuminate. Pressing the “PROG”

5.1. JTAG Programming

The Xilinx tools typically communicate with FPGAs using the Test Access Port and Boundary-Scan Architecture, commonly

referred to as JTAG. During JTAG programming, a .bit file is transferred from the PC to the FPGA using the onboard

Digilent USB-JTAG circuitry (port J17) or an external JTAG programmer, such as the Digilent JTAG HS2, attached to port

J19. You can perform JTAG programming at any time after the Genesys 2 has been powered on, regardless of what the mode

jumper (JP5) is set to. If the FPGA is already configured, then the existing configuration is overwritten with the bitstream being

transmitted over JTAG. Setting the mode jumper to the JTAG setting is useful to prevent the FPGA from being configured

from any other bitstream source until a JTAG programming occurs.

Programming the Genesys 2 with an uncompressed bitstream using the on-board USB_JTAG circuitry usually takes around

four seconds with a 30MHz JTAG clock.

JTAG programming can be done using the hardware server in Vivado or the iMPACT tool included with ISE and the Labtools

version of Vivado.

The demonstration project available at digilentinc.com gives an in depth tutorial on how to program your board.

5.2. Quad-SPI Programming

Page 13

Page 13of 3

5

For the FPGA to be able to configure itself from the SPI Flash, it first needs to be programmed with the bitstream. This is

called indirect programming and is a two-step process controlled by Hardware Manager (Vivado) or iMPACT (ISE). First, the

FPGA is programmed with a design that can program flash devices, and then data is transferred to the flash device via the

FPGA circuit (this complexity is hidden from the user by the Xilinx tools). After the flash device has been programmed, it can

automatically configure the FPGA at a subsequent power-on or reset event as determined by the mode jumper setting.

Programming files stored in the flash device will remain until they are overwritten, regardless of power-cycle events.

Programming the flash can take as long as four to five minutes, which is mostly due to the lengthy erase process inherent to the

memory technology. Once written however, FPGA configuration can be very fast, less than a second. Bitstream compression,

SPI bus width, and configuration rate are factors controlled by the Xilinx tools that can affect configuration speed. The onboard flash has a Quad-SPI interface, which supports single (x1), dual (x2) and quad (x4) modes. The quad mode results in the

fastest possible data transfer rate. For it to work, the bitstream needs to be generated with the x4 bus width option (Vivado

device property) and the non-volatile quad configuration bit in the flash to be enabled. The Genesys 2 is shipped with this bit

enabled.

Indirect programming of the flash can be done using the iMPACT tool included with ISE or Hardware Manager of Vivado.

The correct part to be set in the tools is s25fl256xxxxxx0 from the manufacturer Spansion.

5.3. USB Host and Micro SD Programming

You can program the FPGA from a pen drive attached to the USB-Host port (J7-top row) or a microSD card inserted into J3

by doing the following:

1. Format the storage device (pen drive or microSD card) with a FAT32 file system.

2. Place a single .bit configuration file in the root directory of the storage device.

3. Attach the storage device to the Genesys 2.

4. Set the JP5 Programming Mode jumper on the Genesys 2 to “USB/SD”.

5. Select the desired storage device using JP4.

6. Push the PROG button or power-cycle the Genesys 2.

The FPGA will automatically configure with the .bit file on the selected storage device. Any .bit files that are not built for the

proper Kintex-7 device will be rejected by the FPGA. The Auxiliary Function Status or “BUSY”

feedback on the state of the configuration process when the FPGA is not yet programmed:

• When steadily lit the auxiliary microcontroller is either booting up or currently reading the configuration medium

(microSD or pen drive) and downloading a bitstream to the FPGA.

• A slow pulse means the microcontroller is waiting for a configuration medium to be plugged in.

• In case of an error during configuration the

getting recognized, it is not properly formatted or the bitstream is not compatible with the FPGA.

When the FPGA is has been successfully configured, the behavior of the

keyboard or mouse is plugged in, a rapid short blink will signal the receipt of an HID input report from peripheral.

LED () will blink rapidly. It could be that the device plugged in is not

LED () is application-specific. For example, if a USB

LED () (LD11) gives visual

6. Memory

The Genesys 2 board contains two external memories: a 1GiByte volatile DDR3 memory and a 32MiByte non-volatile serial

Flash device. The DDR3 uses two 16-bit wide memory component with industry-standard interface soldered on the board

resulting in a 32-bit data bus. The serial Flash is on a dedicated quad-mode (x4) SPI bus.

6.1. DDR3

The Genesys 2 includes two Micron MT41J256M16HA-107 DDR3 memory component creating a single rank, 32-bit wide

interface. It is routed to a 1.5V-powered HP (High Performance) FPGA bank with 40 ohm controlled single-ended trace

impedance. For data signals 40 ohm DCI terminations in the FPGA are used to match the trace characteristics. Similarly, on

the memory side on-die terminations (ODT) are used for impedance matching. Address/Control signals are terminated using

discrete resistors.

The highest data rate supported is 1800Mbps.

Page 14

Page 14of 3

5

For proper operation of the memory a memory controller and physical layer (PHY) interface needs to be included in the FPGA

design. The Xilinx 7-series memory interface solutions core generated by the MIG (Memory Interface Generator) Wizard hides

away the complexities of a DDR3 interface. Depending on the tool used (ISE, EDK or Vivado) the MIG Wizard can generate

a native FIFO-style or an AXI4 interface to connect to user logic. This workflow allows the customization of several DDR3

parameters optimized for the particular application. Table 4 below lists the MIG Wizard settings optimized for the Genesys 2.

Setting Value

Memory type DDR3 SDRAM

Max. clock period 1112ps (~900MHz)

Max. data rate ~1800Mbps

Clock ratio 4:1

VCCAUX_IO 2.0V

Memory type Components

Memory part MT41J256M16XX-107

Memory voltage 1.5V

Data width 32

Data mask Enabled

Input clock period 5004ps (~200MHz)

Output driver impedance RZQ/7

Chip Select pin Enabled

Rtt (nominal) – On-die termination RZQ/6

Internal Vref Disabled

Reference clock Use system clock

Internal termination impedance N/A

DCI cascade Disabled

Table 4. DDR3 settings for the Genesys 2.

The MIG Wizard will require the fixed pin-out of the memory signals to be entered and validated before generating the IP

core. For your convenience an importable UCF/XDC file is provided on the Digilent website to speed up the process.

For more details on the Xilinx memory interface solutions refer to the 7 Series FPGAs Memory Interface Solutions

Guide (ug586) (http://www.xilinx.com/support/documentation/ip_documentation/mig_7series/v2_1/ug586_7Series_MIS.pdf).

6.2. Quad-SPI Flash

User

Page 15

Page 15of 3

5

Non-volatile storage is provided by a Spansion S25FL256S flash memory. FPGA configuration files can be written to it, and

mode settings are available to cause the FPGA to automatically read a configuration from this device at power on. A Kintex-7

325T configuration file requires just over 10 MiB (mebibyte) of memory, leaving about 70% of the flash device available for

user data. Or, if the FPGA is getting configured from another source, the whole memory can be used for custom data.

The contents of the memory can be manipulated by issuing certain commands on the SPI bus. The implementation of this

protocol is outside the scope of this document. All signals in the SPI bus except SCK are general-purpose user I/O pins after

FPGA configuration. SCK is an exception because it remains a dedicated pin even after configuration. Access to this pin is

provided through a special FPGA primitive called STARTUPE2. The AXI Quad SPI IP core is recommended for easy access

to the Flash memory.

NOTE: Refer to the manufacturer’s

Xilinx

information.

user guides (http://www.xilinx.com/support/documentation/user_guides/ug470_7Series_Config.pdf) for more

datasheets (http://www.spansion.com/Support/Datasheets/S25FL128S_256S_00.pdf) and

7. Ethernet PHY

The Genesys 2 board includes a Realtek RTL8211E-VL PHY paired with an RJ-45 Ethernet jack with integrated magnetics to

implement a 10/100/1000 Ethernet port for network connection. The PHY interfaces with the FPGA via RGMII for data and

MDIO for management. Bank 33 powered at 1.5V is populated with these signals. The auxiliary interrupt (INTB), power

management (PMEB) signals are wired to bank 32 and powered at 1.8V. Both of these signals are open-drain outputs from the

PHY and need internal pull-ups enabled in the FPGA, if they are used. The reset signal (PHYRSTB) is wired to bank 12,

powered at 3.3V. The connection diagram can be seen on Figure 7.

At power-on reset, the PHY is set to the following defaults using the configuration pins in parenthesis:

• Auto-negotiation enabled, advertising all 10/100/1000 modes (AN[1:0])

• PHY address=00001 (PHY_AD[2:0])

• No delay for TXD and RXD relative to TXC and RXC for data latching (RXDLY, TXDLY)

If an Ethernet cable is plugged in, establishing link is attempted straight after power-up, even if the FPGA is not programmed.

Two status indicator LEDs are on-board near the RJ-45 connector that indicate traffic (LD10) and valid link state (LD9). The

table below shows the default behavior.

Function Designator State Description

ACT LD10 Blinking Transmitting or receiving

LINK LD9 On Link up

Blinking 0.4s ON, 2s OFF Link up, Energy Efficient Ethernet (EEE) mode

Table 5. Ethernet status LEDs.

Page 16

Page 16of 3

5

The on-board PHY implements Layer 1 in the Ethernet stack, interfacing between the physical copper medium and the media

access control (MAC). The MAC must be implemented in the FPGA and mapped to the PHY’s RGMII interface. Vivadobased design can use the Xilinx AXI Ethernet Subsystem IP core to implement the MAC and wire it to the processor and the

memory subsystem. At the time of writing the IP core needed to be licensed separately.

On an Ethernet network each node needs a unique MAC address. To this end the Genesys 2 comes with a MAC address preprogrammed in a special one-time programmable region (OTP Region 1) of the Quad-SPI Flash6. This unique identifier can be

read with the OTP Read command (0x4B). The out-of-box Ethernet demo uses the unique MAC to allow connecting several

Genesys 2 boards to the same network.

A downloadable demonstration project can be found on the

(https://reference.digilentinc.com/genesys2:genesys2).

Genesys 2 wiki page

8. Oscillators/Clocks

The Genesys 2 board includes several oscillators and crystals, of which two are connected to the FPGA. One differential LVDS

200MHz oscillator is connected to MRCC

to generate clocks of various frequencies and with known phase relationships that may be needed throughout a design. Some

rules restrict which MMCMs and PLLs may be driven by the 200MHz input clock. For a full description of these rules and of

the capabilities of the Kintex-7 clocking resources, refer to the “7 Series FPGAs Clocking Resources User Guide” (

(http://www.xilinx.com/support/documentation/user_guides/ug472_7Series_Clocking.pdf)) available from Xilinx.

Xilinx offers the Clocking Wizard IP core to help users generate the different clocks required for a specific design. This wizard

will properly instantiate the needed MMCMs and PLLs based on the desired frequencies and phase relationships specified by

the user. The wizard will then output an easy to use wrapper component around these clocking resources that can be inserted

into the user’s design. The clocking wizard can be accessed from within the Vivado Block Design or Core Generator tools.

The second oscillator outputs a differential LVDS 135MHz clock which enters the FPGA on MGTREFCLK pins. This

connects to clock primitives dedicated to the gigabit transceivers and is used for DisplayPort designs.

GPIO () pins AD12/AD11 in bank 33. This input clock can drive MMCMs or PLLs

ug472

Page 17

Page 17of 3

5

9. USB UART Bridge (Serial Port)

The Genesys 2 includes an FTDI FT232R USB-UART bridge (attached to connector J15) that lets you use PC applications to

communicate with the board using standard Windows COM port commands. Free USB-COM port drivers, available from

Windows Update or

packets to UART/serial port data. Serial port data is exchanged with the FPGA using a two-wire serial port (TXD/RXD) with

no handshake signals. After the drivers are installed, I/O commands can be used from the PC directed to the COM port to

produce serial data traffic on the Y20 and Y23 FPGA pins.

www.ftdichip.com (http://www.ftdichip.com) under the “Virtual Com Port” or VCP heading, convert USB

Two on-board status LEDs provide visual feedback on traffic flowing through the port: the transmit

receive

LED () (LD12). Signal names that imply direction are from the point-of-view of the DTE (Data Terminal

Equipment), in this case the PC.

The connections between the FT232R and the FPGA are shown in Figure 8.

LED () (LD13) and the

10. PC - FPGA Data Transfer (DPTI/DSPI)

The Genesys 2 provides two interface types that can be used to transfer user data between a PC and an FPGA design. Both of

the interfaces have a software component, a Digilent Adept

controller. Calling

protocol. The functionality is implemented using the on-board dual-port FT2232 USB controller. One port is used exclusively

for JTAG, while the other either DPTI or DSPI. Since the interfaces share pins, DPTI and DSPI cannot be used

simultaneously.

API () functions on the PC will either present or request data on the FPGA pins according to the chosen

API () and a physical interface between the FPGA and the USB

10.1. Parallel Transfer Interface (DPTI)

DPTI is an 8-bit wide parallel FIFO-style data interface. It offers higher bandwidth than DSPI. In FTDI-terminology, DPTI is

equivalent to “FT245-style Asynchronous or Synchronous FIFO Interface”. It is available in both synchronous and

asynchronous modes, configurable from the DPTI

API (). In synchronous mode, data transfer is timed by the clock provided

Page 18

Page 18 of 3

5

by the USB controller that is input to the FPGA. In asynchronous mode data transfer is happening on transitions of read and

write control signals. The USB controller emulates a FIFO memory, providing status signals about the availability of data to be

read or free space for data to be written. The FPGA controls data transfer by read, write and output enable signals.

Direction

Signal

D[7:0] I/O Data bus.

RXF# Input When low, data is available for reading from the FIFO.

TXE# Input When low, data can be written to the FIFO.

RD# Output A low-pulse triggers data to be read out from the FIFO.

WR# Output A low-pulse triggers data to be written to the FIFO.

SIWU# Input Send immediate or Wake-up function. In normal mode a low pulse triggers sending a data

(FPGA) Description

packet with the data currently in the FIFO, even if below the normal packet size. In suspend

mode a low pulse can wake up the Host PC.

OE# Output When low, the data bus is driven by the USB controller (read transfer). When high, the bus is

driven by the FPGA (write transfer).

CLKO Input 60

Table 6. DPTI signal description.

For more information, see the

MHz () clock used in synchronous mode. Data is launched and can be captured on the rising

edge.

FT2232H datasheet (http://www.ftdichip.com/Support/Documents/DataSheets/ICs/DS_FT2232H.pdf).

10.2. Serial Peripheral Interface (DSPI)

An industry-standard SPI interface can also be used for transferring data. It uses only four signals for serial full-duplex

communication. The USB controller acts as a SPI master, with the FPGA taking the slave role. The USB controller initiates a

transaction after

Signal Direction (FPGA) Description

SCK Input Data bus.

MOSI () Output When low, data is available for reading from the FIFO.

MISO () Input When low, data can be written to the FIFO.

API () function calls and transfers data in both directions simultaneously.

SS Input A low-pulse triggers data to be read out from the FIFO.

Table 7. DSPI signal description.

For more information, see the

FT2232H datasheet (http://www.ftdichip.com/Support/Documents/DataSheets/ICs/DS_FT2232H.pdf).

11. USB HID Host

Page 19

Page 19of 3

5

The Auxiliary Function microcontroller (Microchip PIC24FJ128) provides the Genesys 2 with USB HID host capability. After

power-up, the microcontroller is in configuration mode, either downloading a bitstream to the FPGA, or waiting on it to be

programmed from other sources. Once the FPGA is programmed, the microcontroller switches to application mode, which is

USB HID Host in this case. Firmware in the microcontroller can drive a mouse or a keyboard attached to the type A USB

connector at J7 labeled “USB HID”. J7 is a dual-row USB A receptacle, with the top row connected to the Auxiliary Function

microcontroller. Hub support is not currently available, so only a single mouse or a single keyboard can be used. The PIC24

drives several signals into the FPGA – two are used to implement a standard PS/2 interface for communication with a mouse

or keyboard, and the others are connected to the FPGA’s two-wire serial programming port, so the FPGA can be programmed

from a file stored on a USB pen drive or microSD card.

11.1. HID Controller

The Auxiliary Function microcontroller hides the USB HID protocol from the FPGA and emulates an old-style PS/2 bus. The

microcontroller behaves just like a PS/2 keyboard or mouse would. This means new designs can re-use existing PS/2 IP cores.

Mice and keyboards that use the PS/2 protocol use a two-wire serial bus (clock and data) to communicate with a host. On the

Genesys 2, the microcontroller emulates a PS/2 device, while the FPGA plays the role of the host. Both the mouse and the

keyboard use 11-bit words that include a start bit, data byte (LSB first), odd parity, and stop bit, but the data packets are

organized differently, and the keyboard interface allows bi-directional data transfers (so the host device can illuminate state

LEDs on the keyboard). Bus timings are shown in Figure 11.

The clock and data signals are only driven when data transfers occur; otherwise they are held in the idle state at logic ‘1.’ This

requires that when the PS/2 signals are used in a design, internal pull-ups must be enabled in the FPGA on the data and clock

pins. The clock signal is normally driven by the device, but may be held low by the host in special cases. The timings define

signal requirements for mouse-to-host communications and bi-directional keyboard communications. A PS/2 interface circuit

can be implemented in the FPGA to create a keyboard or mouse interface.

When a keyboard or mouse is connected to the Genesys 2, a “self-test passed” command (0xAA) is sent to the host. After this,

commands may be issued to the device. Since both the keyboard and the mouse use the same PS/2 port, one can tell the type

of device connected using the device ID. This ID can be read by issuing a Read ID command (0xF2). Also, a mouse sends its

ID (0x00) right after the “self-test passed” command, which distinguishes it from a keyboard.

11.2. Keyboard

PS/2 uses open-collector drivers so the keyboard or an attached host can drive the two-wire bus (if the host will not send data

to the keyboard, then the host can use input-only ports).

PS/2-style keyboards use scan codes to communicate key press data. Each key is assigned a code that is sent whenever the key

is pressed. If the key is held down, the scan code will be sent repeatedly about once every 100ms. When a key is released, an F0

key-up code is sent, followed by the scan code of the released key. If a key can be shifted to produce a new character (like a

Page 20

Page 20 of 3

5

capital letter), then a shift character is sent in addition to the scan code, and the host must determine which ASCII () character

to use. Some keys, called extended keys, send an E0 ahead of the scan code (and they may send more than one scan code).

When an extended key is released, an E0 F0 key-up code is sent, followed by the scan code. Scan codes for most keys are

shown in Figure 12.

A host device can also send data to the keyboard. Table 8 shows a list of some common commands a host might send.

Command Action

ED Set Num Lock, Caps Lock, and Scroll Lock LEDs. Keyboard returns FA after receiving ED, then host sends

a byte to set

are ignored.

EE Echo (test). Keyboard returns EE after receiving EE

F3 Set scan code repeat rate. Keyboard returns F3 on receiving FA, then host sends second byte to set the repeat

rate.

FE Resend. FE directs keyboard to re-send most recent scan code.

FF Reset. Resets the keyboard.

Table 8. Keyboard commands.

The keyboard can send data to the host only when both the data and clock lines are high (or idle). Because the host is the bus

master, the keyboard must check to see whether the host is sending data before driving the bus. To facilitate this, the clock line

is used as a “clear to send” signal. If the host drives the clock line low, the keyboard must not send any data until the clock is

released. The keyboard sends data to the host in 11-bit words that contain a ‘0’ start bit, followed by 8-bits of scan code (LSB

first), followed by an odd parity bit and terminated with a ‘1’ stop bit. The keyboard generates 11 clock transitions (at 20 to 30

kHz ()) when the data is sent, and data is valid on the falling edge of the clock.

LED () status: bit 0 sets Scroll Lock, bit 1 sets Num Lock, and bit 2 sets Caps lock. Bits 3 to 7

11.3. Mouse

Once entered in stream mode and data reporting enabled the mouse outputs a clock and data signal when it is moved:

otherwise, these signals remain at logic ‘1.’ Each time the mouse is moved, three 11-bit words are sent from the mouse to the

host device, as shown in Figure 10. Each of the 11-bit words contains a ‘0’ start bit, followed by 8 bits of data (LSB first),

followed by an odd parity bit, and terminated with a ‘1’ stop bit. Thus, each data transmission contains 33 bits, where bits 0, 11,

and 22 are ‘0’ start bits, and bits 11, 21, and 33 are ‘1’ stop bits. The three 8-bit data fields contain movement data as shown in

the figure above. Data is valid at the falling edge of the clock, and the clock period is 20 to 30

The mouse assumes a relative coordinate system wherein moving the mouse to the right generates a positive number in the X

field, and moving to the left generates a negative number. Likewise, moving the mouse up generates a positive number in the Y

field, and moving down represents a negative number (the XS and YS bits in the status byte are the sign bits – a ‘1’ indicates a

negative number). The magnitude of the X and Y numbers represent the rate of mouse movement – the larger the number, the

kHz ().

Page 21

Page 21 of 3

5

faster the mouse is moving (the XV and YV bits in the status byte are movement overflow indicators – a ‘1’ means overflow

has occurred). If the mouse moves continuously, the 33-bit transmissions are repeated every 50ms or so. The L and R fields in

the status byte indicate Left and Right button presses (a ‘1’ indicates the button is being pressed).

The microcontroller also supports Microsoft Intellimouse-type extensions for reporting back a third axis representing the

mouse wheel, as shown in Table 9.

Command Action

EA Set stream mode. The mouse responds with “acknowledge” (0xFA) then resets its movement counters and

enters stream mode.

F4 Enable data reporting. The mouse responds with “acknowledge” (0xFA) then enables data reporting and

resets its movement counters. This command only affects behavior in stream mode. Once issued, mouse

movement will automatically generate a data packet.

F5 Disable data reporting. The mouse responds with “acknowledge” (0xFA) then disables data reporting and

resets its movement counters.

F3 Set mouse sample rate. The mouse responds with “acknowledge” (0xFA) then reads one more byte from the

host. This byte is then saved as the new sample rate, and a new “acknowledge” packet is issued.

FE Resend. FE directs mouse to re-send last packet.

FF Reset. The mouse responds with “acknowledge” (0xFA) then enters reset mode.

Table 9. Microsoft Intellimouse type extensions, commands, and actions.

12. User USB 2.0

When the fixed USB roles of the Genesys2 are not enough, an on-board USB 2.0 transceiver (PHY) provides physical layer

implementation for any USB 2.0 user-application. It connect to a USB A (J7-bottom row) and a USB AB micro (J6) receptacle

in parallel, enabling device, host, and OTG USB roles without the need for cable adaptors. Use only one of the connectors at a

time, the one fitting the desired USB role.

The transceiver is a TUSB1210 with a UTMI+ low pin interface (ULPI) towards the FPGA. ULPI is a 12-pin SDR interface

clocked at 60

clock, which is wired to a clock-capable input pin of the FPGA. Figure 14 shows the connection diagram of the PHY.

MHz (), resulting in the maximum data rate of 480 Mbps. On the Genesys 2 the transceiver provides the ULPI

The part of the USB 2.0 stack above the physical layer has to be implemented in the FPGA. Xilinx offers an AXI USB 2.0

Device Controller IP that needed separate licensing at the time of writing.

Auxiliary circuitry, like an electronic power switch and jumpers are used to implement different USB roles. In Host

applications, the switch can be commanded through the PHY to power VBUS. The switch has built-in current limit and short

circuit protection. VBUS error conditions are signaled to the FPGA by means of a status pin. In Device role, this switch should

be disabled. A jumper (JP1) in series with the power switch can be used to make sure VBUS is not inadvertently powered.

Another jumper (JP2) (dis)connects a 150 µF capacitor to/from the VBUS. Use it to implement the different bus capacitance

requirements of the USB roles.

Page 22

Page 22of 3

5

For more information, refer to the TUSB1210 datasheet (http://www.ti.com/lit/gpn/tusb1210) and the USB 2.0 specifications

(http://www.usb.org/developers/docs/usb20_docs).

13. Basic I/O

The Genesys 2 board includes eight slide switches, six push buttons, and eight individual LEDs. The pushbuttons and slide

switches are connected to the FPGA via series resistors to prevent damage from inadvertent short circuits (a short circuit could

occur if an FPGA pin assigned to a pushbutton or slide switch was inadvertently defined as an output). The five pushbuttons

arranged in a plus-sign configuration are “momentary” switches that normally generate a low output when they are at rest, and

a high output only when they are pressed. The red pushbutton labeled “CPU RESET,” on the other hand, generates a high

output when at rest and a low output when pressed. The CPU RESET button is intended to be used in processor designs to

reset the processor, but you can also use it as a general purpose pushbutton. Slide switches generate constant high or low inputs

depending on their position.

Page 23

Page 23of 3

5

The eight individual high-efficiency LEDs are anode-connected to the FPGA via 330-ohm resistors, so they will turn on when

a logic high voltage is applied to their respective I/O pin. Additional LEDs that are not user-accessible indicate power-on,

FPGA programming status, and USB and Ethernet port status.

14. Pmod Connectors

The Pmod connectors are arranged in a 2×6 right-angle, 100-mil female connectors that mate with standard 2×6 pin headers.

Each 12-pin Pmod connector provides two power pins (6 and 12), two ground pins (5 and 11), and eight logic signals, as

shown in Figure 20. The

I/O connected to the FPGA are shown in Figure 16.

The Genesys 2 features four Pmod connectors of different “styles” with subtle differences between them. Table 10 summarizes

these differences.

Pmod

conector Power Analog/Digital Routing

JXADC VADJ Dual Differential; Pairs:

VCC () and Ground pins of can deliver up to 1A of current per pin. Pin assignments for the Pmod

Series

protection Recommended usage

100 ohm Analog inputs; LVDS_25

1-7,2-8,3-9,4-10

input/output (VADJ=2.5V)

Page 24

Page 24of 3

5

Pmod

conector Power Analog/Digital Routing

JA, JB 3.3 V Digital-only Differential; Pairs:

1-2,3-4,7-8,9-10

JC, JD 3.3 V Digital-only Single-ended 200 ohm <10

Table 10. Pmod differences.

JXADC is a dual digital/analog Pmod wired to auxiliary analog FPGA input pins (see description below). JA, JB, JC and JD are

digital-only but routed in a different manner. JC and JD signal traces are routed as single-ended signals with no length matching

or characteristic impedance guarantees. JA and JB connector signals, on the other hand, are routed differentially in pairs at 100

ohm characteristic impedance. Inter-pair matching is +- 20mm. The series resistor on these two Pmods are replaced by 0 ohm

shunts, so care must be exercised not to use voltages higher than 3.3V, or short FPGA-driven pins.

For slow digital signals, below 10

section). For higher frequencies, the routing and series protection need to be taken into account as well.

Pmod Pinouts

JA1: B13 JB1: G14 JC1: K2 JD1: JXADC1: A13

JA2: F14 JB2: P15 JC2: E7 JD2: JXADC2: A15

MHz (), all Pmod connectors are equivalent, if VADJ is set to 3.3 V (see the Power Supplies

Series

protection Recommended usage

0 ohm >=10MHz; LVDS_25 input

MHz (), LVCMOS33

JA3: D17 JB3: V11 JC3: J3 JD3: JXADC3: B16

JA4: E17 JB4: V15 JC4: J4 JD4: JXADC4: B18

JA7: G13 JB7: K16 JC7: K1 JD7: JXADC7: A14

JA8: C17 JB8: R16 JC8: E6 JD8: JXADC8: A16

JA9: D18 JB9: T9 JC9: J2 JD9: JXADC9: B17

JA10: E18 JB10: U11 JC10: G6 JD10: JXADC10: A18

Table 11. Genesys 2 Pmod pin assignments.

Digilent produces a large collection of Pmod accessory boards that can attach to the Pmod expansion connectors to add readymade functions like A/D’s, D/A’s, motor drivers, sensors, and other functions. See

(http://store.digilentinc.com/pmod-peripheral-modules/) for more information.

Digilent's Pmod category

14.1 Dual Analog/Digital Pmod

The on-board Pmod expansion connector labeled “JXADC” is wired to the auxiliary analog input pins of the FPGA.

Depending on the configuration, this connector can be used to input differential analog signals to the analog-to-digital

converter inside the Kintex-7 (XADC). Any or all pairs in the connector can be configured either as analog input or digital

input-output.

The Dual Analog/Digital Pmod on the Genesys 2 differs from the rest in the routing of its traces. The eight data signals are

grouped into four pairs, with the pairs routed closely coupled for better analog noise immunity. Furthermore, each pair has a

partially loaded anti-alias filter (100 ohm, 1 nF) laid out on the PCB. The filter does not have capacitors C151, C152, C153, and

C154. In designs where such filters are desired, the capacitors can be manually loaded by the user.

NOTE: The coupled routing and the anti-alias filters might limit the data speeds when used for digital signals.

Page 25

Page 25of 3

5

The XADC core within the Kintex-7 is a dual channel 12-bit analog-to-digital converter capable of operating at 1 MSPS. Either

channel can be driven by any of the auxiliary analog input pairs connected to the JXADC header. The XADC core is controlled

and accessed from a user design via the Dynamic Reconfiguration Port (DRP). This includes access to the temperature sensor

and voltage monitors inside the FPGA. For more information on using the XADC core, refer to the Xilinx document titled “7

Series FPGAs and Zynq-7000 All Programmable SoC XADC Dual 12-Bit 1 MSPS Analog-to-Digital Converter User Guide” (

ug480 (http://www.xilinx.com/support/documentation/user_guides/ug480_7Series_XADC.pdf)).

15. High Pin Count FMC Connector

The Genesys 2 includes a FPGA Mezzanine Card (FMC) Standard-conforming carrier card connector that enables connecting

mezzanine modules compliant with the same standard. Genesys 2-based designs can now be easily extended with custom or

off-the-shelf high-performance modules.

The actual connector used is a 400-pin Samtec ASP-134486-01, the high-pin count, 10mm stacking height variant of the

standard. It is fully bonded to the FPGA, with the exception of CLK3_BIDIR. The 80 differential pairs wired to regular FPGA

user I/O pins are grouped into FMC banks: 34 pairs in LA, 24 pairs in HA and 22 pairs in HB. LA and HA pairs are powered

by the Genesys 2 VADJ rail adjustable in the 1.2V-3.3V range. On the other hand, HB signals are referenced to a voltage rail

provided by the FMC mezzanine card (VIO_B_M2C). For this reason a whole FPGA bank is dedicated to HB signals

exclusively. This bank remains unpowered, and HB signals cannot be used, if no FMC mezzanine card, or one that does not

provide VIO_B_M2C is connected to the Genesys 2.

Thanks to the flexible voltage range supported by the Genesys 2 it allows high compatibility with existing and future FMC

modules. The Genesys 2 opens the door to the full range of I/O standards supported by the Kintex-7 HR (High Range) I/O

architecture over the FMC connector.

The pin-out of the FMC connector can be found in the UCF/XDC constraints file available on reference.digilentinc.com. The

schematic also shows the mapping between FMC connector pins and FPGA pins. Keep in mind that pin designators for the

connector are not the same as pin designators for the FPGA specified in the UCF/XDC constraints file. For example, the

connector pin with designator K25 and named HB00_P_CC is wired via net FMC_HB00_P to the FPGA pin with designator

G13 and named IO_L12P_T1_MRCC_18. In the constraints file HB00_P_CC will need to be location constrained to G13.

For above-gigabit speed rates, all ten gigabit transceiver lanes and two accompanying clock pairs are wired to GTX transceiver

banks. Kintex-7 transceiver banks group four lanes and two reference clock input together, and are also called quads.

Each transceiver lane includes a receive pair and a transmit pair. Lanes DP0-DP3 are wired to quad 115. Lanes DP4-DP7 go to

quad 116, along with the two reference clocks GBTCLK0 and GBTCLK1. The last two lanes DP8 and DP9 are connected to

quad 117, while the rest of the pins in these three quads are left unused.

Since an MGTREFCLK can be routed to both the quad above and below its own, both reference clocks can be used to clock

any channel in the three quads. Table 12, Table 13, and Table 14 show how the FMC gigabit signals are mapped to pins and

GTX primitives. Refer to the 7 Series FPGAs GTX/GTH Transceivers User Guide (

(http://www.xilinx.com/support/documentation/user_guides/ug476_7Series_Transceivers.pdf)) for more information.

Quad Primitive Pin type Pin FMC signal

115 GTXE2_CHANNEL X0Y0 MGTXTXP/N0 Y2/Y1 DP0_C2M_P/N

MGTXRXP/N0 AA4/AA3 DP0_M2C_P/N

ug476

X0Y1 MGTXTXP/N1 V2/V1 DP1_C2M_P/N

MGTXRXP/N1 Y6/Y5 DP1_M2C_P/N

X0Y2 MGTXTXP/N2 U4/U3 DP2_C2M_P/N

MGTXRXP/N2 W4/W3 DP2_M2C_P/N

Page 26

Page 26of 3

5

Quad Primitive Pin type Pin FMC signal

MGTXTXP/N3 T2/T1 DP3_C2M_P/N

MGTXRXP/N3 V6/V5 DP3_M2C_P/N

Table 12. Quad 115 pinout.

Quad Primitive Pin type Pin FMC signal

116 GTXE2_CHANNEL X0Y4 MGTXTXP/N0 P2/P1 DP4_C2M_P/N

MGTXRXP/N0 T6/T5 DP4_M2C_P/N

X0Y5 MGTXTXP/N1 N4/N3 DP5_C2M_P/N

MGTXRXP/N1 R4/R3 DP5_M2C_P/N

X0Y6 MGTXTXP/N2 M2/M1 DP6_C2M_P/N

MGTXRXP/N2 P6/P5 DP6_M2C_P/N

X0Y7 MGTXTXP/N3 L4/L3 DP7_C2M_P/N

MGTXRXP/N3 M6/M5 DP7_M2C_P/N

IBUFDS_GTE2 X0Y2 MGTREFCLKP/N0 L8/L7 GBTCLK0_P/N

X0Y3 MGTREFCLKP/N1 N8/N7 GBTCLK1_P/N

Table 13. Quad 116 pinout.

Quad Primitive Pin type Pin FMC signal

117 GTXE2_ CHANNEL X0Y8 MGTXTXP/N0 K2/K1 DP8_C2M_P/N

MGTXRXP/N0 K6/K5 DP8_M2C_P/N

X0Y9 MGTXTXP/N1 J4/J3 DP9_C2M_P/N

MGTXRXP/N1 H6/H5 DP9_M2C_P/N

Table 14. Quad 117 pinout.

16. MicroSD Slot

The Genesys 2 provides a microSD slot for both FPGA configuration and user access. The on-board Auxiliary Function

microcontroller shares the SD card bus with the FPGA. Before the FPGA is configured the microcontroller must have access

to the SD card via an SPI interface. Once a bit file is downloaded to the FPGA (from any source), the microcontroller powers

off the SD slot and relinquishes control of the bus. The FPGA design will find the SD card in an unpowered state.

Page 27

Page 27of 3

5

All of the SD pins on the FPGA are wired to support full SD speeds in native interface mode, as shown in Figure 17. The SPI

interface is also available, if needed. Once control over the SD bus is passed from the microcontroller to the FPGA, the

SD_RESET signal needs to be actively driven low by the FPGA to power the microSD card slot.

To talk to an SD card, several communication layers need to be implemented in the FPGA. The physical layer (de)serializes

command and data packets over either the SD native or SPI interface. The data link layer should implement the SD state

machine, issuing initialization and read/write commands specific to the SD standard. The data link layer provides access to raw

blocks/sectors on the SD card. To access a formatted card, a file system layer should abstract sectors into files and directories.

On top of the file system layer comes the actual application.

For more information on implementing an SD card controller, refer to the SD card specification available at

www.sdcard.org (http://www.sdcard.org).

17. HDMI

The Genesys 2 board contains two buffered HDMI ports: one source port J4 (output), and one sink port J5 (input). Both ports

use HDMI type-A receptacles and include HDMI buffer TMDS141. The buffers work by terminating, equalizing, conditioning

and forwarding the HDMI stream between the connector and FPGA pins.

Both HDMI and DVI systems use the same TMDS signaling standard, directly supported by Kintex-7 user I/O infrastructure.

Also, HDMI sources are backward compatible with DVI sinks and vice versa. Thus, simple passive adaptors (available at most

electronics stores) can be used to drive a DVI monitor or accept a DVI input. The HDMI receptacle only includes digital

signals, so only DVI-D mode is possible.

The 19-pin HDMI connectors include three differential data channels, one differential clock channel five

a one-wire Consumer Electronics Control (CEC) bus, a two-wire Display Data Channel (DDC) bus, a Hot Plug Detect (HPD)

signal, a 5V power pin capable of delivering up to 50mA, and one reserved (RES) pin. All are wired to the FPGA with the

exception of RES.

Pin/Signal J4 (Source) J5 (Sink)

FPGA

Description

D[2:0]+/- Data output Data input

CLK+/- Clock output Clock input

CEC Consumer Electronics Control

bidirectional

SCL, SDA DDC bidirectional DDC bidirectional

HPD Hot-plug detect input (inverted, active-

low)

Pin Description

Consumer Electronics Control

bidirectional

Hot-plug assert output (active-high)

GND () connections,

FPGA

Pin

Page 28

Pin/Signal J4 (Source) J5 (Sink)

5

Page 28 of 3

FPGA

Description

5V0 Powered from 5V rail Powers auxiliary signals

Table 15. HDMI pin description and assignment.

Pin Description

FPGA

Pin

13.1. TMDS Signals

HDMI/DVI is a high-speed digital video stream interface using transition-minimized differential signaling (TMDS). To make

proper use of either of the HDMI ports a standard-compliant transmitter or receiver needs to be implemented in the FPGA.

The implementation details are outside the scope of this manual.

13.2. Auxiliary Signals

Presence of a sink on the cable is announced on the hot-plug detect (HPD) pin. Whenever a sink is ready and wishes to

announce its presence, it connects the HPD pin to the 5V0 supply pin. On the Genesys 2 this is achieved by pulling

HDMI_RX_HPA high. This signal defaults low. The source reads the HPD pin through an inverting level-translator, so

HDMI_TX_HPD reads low when a sink is present.

The Display Data Channel, or DDC, is a collection of protocols that enable communication between the display (sink) and

graphics adapter (source). The DDC2B variant is based on I2C, the bus master being the source and the bus slave the sink.

When a source detects high level on the HPD pin, it queries the sink over the DDC bus for video capabilities. It determines

whether the sink is DVI or HDMI-capable and what resolutions are supported. Only afterwards will video transmission begin.

Refer to VESA E-DDC specifications for more information.

The Consumer Electronics Control, or CEC, is an optional protocol that allows control messages to be passed around an

HDMI chain between different products. A common use case is a TV passing control messages originating from a universal

remote to a DVR or satellite receiver. It is a one-wire protocol at 3.3V level connected to an FPGA user I/O pin. The wire can

be controlled in an open-drain fashion allowing for multiple devices sharing a common CEC wire. Refer to the

addendum of HDMI 1.3 (http://www.hdmi.org) or later specifications for more information.

CEC

14. DisplayPort

DisplayPort is a relatively new industry standard for digital display technology. Its advantages over existing technologies are:

higher bandwidth for greater resolutions and color depths, bi-directional auxiliary channel, variable interface width, and flexible

power topologies among others.

DisplayPort defines a high-speed main link carrying audio and video data, an auxiliary channel, and a hot-plug detect signal.

The main link is a unidirectional, high-bandwidth and low-latency channel. It consists of one, two, or four AC-coupled

differential pairs called lanes. Version 1.1 of the

lanes carry both data and an embedded clock at the link rate negotiated between Source and Sink, independent of the resolution

and color depth of the video stream. The link rate is de-coupled from the pixel rate, resulting in a packetized stream. This

differentiates DisplayPort from other digital video standards like DVI/HDMI. Due to the high link rate, the main link can only

be implemented on dedicated gigabit transceiver pins of the Kintex-7 architecture.

The auxiliary channel is a bidirectional channel for link management and device control. It is AC-coupled, just like the main link

lanes, but uses a different encoding and the lower data rate of 1Mbps. Upon hot-plug detection a Source will attempt to

configure the link through link training. Handshaking link parameters happens via the auxiliary channel.

Genesys 2 includes two Mini DisplayPort (mDP) connectors: one wired as Source, the other as Sink. Both support a maximum

lane count of four on the main link. MGT quad 118 is dedicated to DisplayPort. On-board there is a 135

oscillator mapped to MGTREFCLK0 which should be used to generate the desired link rate. See Table 15 for pin mapping.

Refer to the Xilinx 7 Series FPGAs GTX/GTH Transceivers User Guide (ug47613) for more information on how to

implement high-speed interfaces.

standard defines (http://www.vesa.org) two link rates: 1.62 and 2.7 Gbps. The

MHz () reference

Page 29

Page 29of 3

5

Quad Primitive Pin type Pin DisplayPort signal

118 GTXE2_CHANNEL X0Y12 MGTXTXP/N0 D2/D1 Source Lane 0

MGTXRXP/N0 E4/E3 Sink Lane 0

X0Y13 MGTXTXP/N1 C4/C3 Source Lane 1

MGTXRXP/N1 D6/D5 Sink Lane 1

X0Y14 MGTXTXP/N2 B2/B1 Source Lane 2

MGTXRXP/N2 B6/B5 Sink Lane 2

X0Y15 MGTXTXP/N3 A4/A3 Source Lane 3

MGTXRXP/N3 A8/A7 Sink Lane 3

IBUFDS_ X0Y6 MGTREFCLKP/N0 C8/C7 135

Table 17. DisplayPort quad pinout.

The auxiliary channel is a bidirectional LVDS bus. Depending on the Xilinx tool/IP version, instantiating a differential I/O

buffer with LVDS signaling standard might not be possible. The work-around is to have two pairs of pins wired and shorted

together as seen in Figure 19. One pair should be implemented as input-only and the other as output-only.

If the tool/IP allows bidirectional LVDS buffers, only one of the pairs needs to be used (it does not matter which), while the

other declared as input and not used.

The hot-plug detect (HPD) signal connects to a general user I/O pin and should be configured as an input.

MHz ()

Page 30

Page 30 of 3

5

The full implementation details of the DisplayPort standard is outside the scope of this document. Refer to the full

specifications published by VESA for more details. DisplayPort Source and Sink IPs can be licensed separately from Xilinx.

15. OLED

A Univision Technology Inc. UG-2832HSWEG04 is loaded on the Genesys 2. It is a white monochrome, 128 x 32, 0.91”

organic

the FPGA is a 4-wire serial peripheral interface (SPI). The 4 wires in controller-terminology are

SCLK (), but CS ()# is hard-wired to ground. This adds to the reset and two power control signals for proper start-up

sequencing. The signals are summarized in Table 17.

LED () display matrix bundled with a Solomon Systech SSD1306 display controller. The display data interface towards

CS ()#, D/C#, SDIN, and

Signal Description Polarity FPGA Pin

RES# Reset Active-low

CS ()# Chip select (always active) Active-low N/A

D/C# Data (high)/Command (low) Both

SCLK () Serial Clock Active-high

SDIN Serial Data Active-high

VBAT# Power enable for internal power supply Active-low

VDD# Power enable for digital power Active-low

Table 17.

The serial interface is synchronous to

SCLK () and data sent on the falling edge should work.

OLED () signal description.

SCLK () and must conform the timing specifications below. In most cases, a 10 MHz ()

Page 31

Page 31 of 3

5

Start-up sequence:

1. Power up VDD by pulling

2. Pulse RES# low for at least 3us.

3. Send initialization/configuration commands (see Table 17).

4. Power up VBAT by pulling

5. Clear screen by writing zero to the display buffer.

6. Send “Display On” command (0xAF).

Command function Command bytes

Charge pump enable 0x8D, 0x14

Set pre-charge period 0xD9, 0xF1

Contrast control 0x81, 0x0F

Column inversion disable 0xA0

Scan direction 0xC0

COM pins configuration 0xDA, 0x00

OLED ()_VDD low. Wait 1ms.

OLED ()_VBAT low. Wait 100ms for voltage to stabilize.

Page 32

Command function Command bytes

5

Addressing mode: horizontal 0x20

Page 32of 3

Table 18.

After start-up, writing to the display is done by sending data bytes over the serial interface (D/C# high). Each data bit

corresponds to a pixel, with the addressing mode, inversion and scan direction settings determining exactly which.

OLED () configuration commands.

16. Audio Codec

The Genesys 2 board includes an Analog Devices ADAU1761 SigmaDSP audio codec (IC11) complementing its multimedia

features. Four 1/8” (3.5mm) audio jacks are available for line-out (J11-green), headphone-out (J10-black), line-in (J13-blue), and

microphone-in (J12-pink). Each jack carries two channels of analog audio (stereo), with the exception of the microphone input,

which is mono.

To record or play back audio in an FPGA design, the audio data needs to be converted. The audio codec bridges the gap

between the analog jacks and the digital FPGA pins. Analog-to-digital and digital-to-analog conversion is done at up to 24 bits

and 96

kHz () sampling rate. Digital audio data is carried to/from the FPGA on a serial, full-duplex interface, which supports

several different formats, the default being I2S. This interface is clocked by the FPGA through BCLK by default, but the codec

can be configured to provide the clock itself.

Configuring the audio codec can be done over I2C. It responds to slave address 0b0111011, followed by a 16-bit register

address and one or more data bytes. These registers control every functional aspect of the codec.

The codec is clocked from the FPGA through the Master Clock (MCLK) pin. A clock must be provided for the codec to

function, including the I2C port. The exact frequency depends on the desired sample rate and whether PLL will be used, but 12

MHz () is a good start. The clocking infrastructure of 7 series FPGA is more than capable of synthesizing the right frequency

from the on-board 100

MHz () reference oscillator.

For proper use, the concept of audio paths needs to be understood. Internal to the codec there are two signal paths: Playback

and Record. Both are highly configurable analog paths with mixers and amplifiers that route audio signals through the chip.

The Playback path is the output path that routes audio from different sources like the digital-to-analog converter or input

mixers towards the headphone and line out jacks. On the other hand, the record path routes audio from the line-in and

microphone-in towards the analog-to-digital converters. Having routing elements at every step enables signal mixing between

channels, amplification, muting and bypass. However, it also means that each element has to be properly configured along the

path.

Keep in mind that audio jack designations might differ from codec analog frontend designators. For example, the line-in jack

connects to the AUX port of the codec. The microphone jack is wired to the IN port. Also, notice that although some ports

offer differential amplifiers and signaling, they are not used on the Genesys 2. For example, the OUT port is differential,

comprising 4 pins: LOUTP, LOUTN, ROUTP, and ROUTN. However, the N-side of the differential pairs is left floating,

while the P-side connects to the jack.

At the very least an audio-aware FPGA design should do the following:

1. Provide MCLK for the audio codec.

2. Use an I2C master controller to configure the core clocking, sample rates, serial interface format and audio path.

3. Send or receive audio samples over the serial audio data channel for playback or record.

More advanced users might want to try additional features of the ADAU1761. For example, the on-chip SigmaDSP core can be

programmed to do user-defined digital signal processing.

All relevant information can be found in the

sheets/ADAU1761.pdf).

ADAU1761 datasheet (http://www.analog.com/media/en/technical-documentation/data-

Page 33

Signal Name FPGA Pin Pin Function

5

ADC ()_SDATA AH19 Serialized audio resulting from the analog-to-digital conversion (record).

DAC ()_SDATA AJ19 Serialized audio is converted to analog by the codec (playback).

BCLK AG18 Serial data port clock.

Page 33of 3

LRCLK AJ18 Serial data port frame clock.

MCLK AK19 Master clock.

SDA AF18 I2C configuration interface.

SCL AE19 I2C configuration interface.

Table 19. Audio signal description.

reference (https://reference.digilentinc.com/tag/reference?do=showtag&tag=reference), programmable-logic

(https://reference.digilentinc.com/tag/programmable-logic?do=showtag&tag=programmable-logic), genesys-2

(https://reference.digilentinc.com/tag/genesys-2?do=showtag&tag=genesys-2), reference-manual (https://reference.digilentinc.com/tag/reference-

manual?do=showtag&tag=reference-manual)

1)

With the exception of CLK3_BIDIR

2)

See the 7-Series FPGAs SelectIO Resources User Guide (

(http://www.xilinx.com/support/documentation/user_guides/ug471_7Series_SelectIO.pdf)) for details.

ug471

Subscribe to our Newsletter

First Name

Last Name

Email Address

Page 34

Connect With Us

5

Page 34of 3

• (https://twitter.com/digilentinc)

• (https://www.facebook.com/Digilent)

• (https://www.youtube.com/user/DigilentInc)

• (https://instagram.com/digilentinc)

• (https://github.com/digilent)

Page 35

• (https://www.reddit.com/r/digilent)

5

6

• (https://www.linkedin.com/company/1454013)

Page 35of 3

• (https://www.flickr.com/photos/127815101@N07)

https://reference.digilentinc.com/reference/programmable-logic/genesys-2/reference-manu...

11/9/201

Loading...

Loading...