Page 1

CCeerreebboott MMCC77™

RReeffeerreennccee MMaannuuaal

Cerebot M

C

7 Circuit Diagram

Revision: September 28, 2011

Note: This document applies to REV F of the board.

™ BBooaarrdd

l

Overview

The Cerebot MC7 board is microcontroller

development board based on a Microchip

dsPIC 16-bit Digital Signal Controller.

The Cerebot MC7 is primarily intended to be

used as a controller for electro-mechanical

devices such as DC motors. The microcontroller used, a dsPIC33FJ128MC706A, is a

member of a dsPIC family optimized for motor

control applications.

The Cerebot MC7 provides four Half-Bridge

circuits that are rated for 24V at up to 5A. Each

of these Half Bridge circuits is connected to the

dsPIC A/D converter to measure voltage and

current for closed loop feedback control. These

half bridges can be used to control two

brushed DC motors, two bi-polar stepper

motors, one brushless DC motor, one uni-polar

stepper motor. In addition, the board can be

used to implement controllers for switched DCDC converters.

The Cerebot MC7 works with the Microchip

MPLAB® development environment and

provides built in programming and debugging

support within the MPLAB® IDE.

Features include:

1300 Henley Court | Pullman, WA 99163

(509) 334 6306 Voice and Fax

• 256Kbit I2C EEPROM

• two push buttons and four LEDs

• ESD protection and short circuit

protection for all I/O pins.

• a dsPIC33FJ128MC706A

microcontroller

• four 24V/5A Half Bridge circuits with

current and voltage feedback and

provision for over-current interrupt

• power supply voltage up to 24V

• 5V/4A switching power supply

• integrated programming/debugging

circuit

• one CAN network interface

• three Pmod connectors for Digilent

peripheral module boards

• eight RC servo connectors

• two I2C daisy chain connectors

Doc: 502-185 page 1 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 2

Cerebot MC7 Reference Manual

Features of the dsPIC33FJ128MC706A

include:

• 128KB internal program flash memory

• 16KB internal SRAM memory

• two 40-bit accumulators for DSP MAC

operation

• eight channel hardware DMA

• Advanced 8-channel motor control

PWM unit

• enhanced CAN controller

• eight 16-bit timer/counters

• eight output compare/PWM units

• eight input capture units

• two UART serial interfaces

• two serial peripheral interfaces (SPI)

• two I2C serial interfaces

• sixteen 10-bit analog inputs

• two analog to digital converters capable

of 10-bit at 1.1Msps or 12-bit at

500Ksps

For more information on the

dsPIC33FJ128MC706A microcontroller, refer

to the dsPIC33FJXXXMCX06A/X08A/X10A

Data Sheet and the dsPIC33 Family Reference

Manual available from the Microchip web site:

www.microchip.com.

Functional Description

The Cerebot MC7 is designed for use in

embedded motor control applications as well

as general microprocessor experimentation.

Firmware suitable for many applications can be

downloaded to the Cerebot MC7’s

programmable dsPIC33 microcontroller using

the on-board programmer/debugger circuit.

Refer to the Cerebot MC7 schematic diagram

available from the Digilent web site

(www.digilentinc.com) for detailed information

about the arrangement of the various circuit

features on the board.

The board provides four independent half

bridge circuits capable of up to 5A continuous

current. These half bridges are connected to

the Motor Control PWM Module in the dsPIC

www.digilentinc.com page 2 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

microcontroller and can be used individually or

in various combinations to drive various

external loads, such as brushed DC motors,

brushless DC motors, stepper motors, and so

on.

A switching 5V, 4A regulator with input voltage

up to 24V is provided on the board to simplify

operation of the board from a single power

supply in embedded application, such as

robots.

The board has a variety of input/output

connection options, and is specially designed

to work with the Digilent line of Pmod

peripheral modules with various input and

output functions. For more information, see

www.digilentinc.com. In addition to the Pmod

connectors, the board provides two push

buttons and four LEDs for user i/o, as well as

providing connections for two I2C busses. A

serial EEPROM is provided on one of the I2C

busses.

The Cerebot MC7 can be used with the

Microchip MPLAB development environment.

In-system-programming and debugging of

firmware running on the dsPIC33

microcontroller is supported using an on-board

program/debug circuit licensed from Microchip.

The Cerebot MC7 features a flexible power

supply system with a number of options for

powering the board as well as powering

peripheral devices connected to the board. It

can be USB powered via the debug USB port,

or it can be powered from an external power

supply or batteries.

Programming and In-System

Debugging Using the Microchip

MPLAB® IDE

The Cerebot MC7 board is intended to be used

with the Microchip MPLAB® IDE and the

Microchip C30 C compiler for dsPIC for

firmware development, programming and insystem debugging.

Page 3

Cerebot MC7 Reference Manual

In system programming and debuggin is

accomplished using a programmer/debugger

circuit licensed from Microchip. Either MPLAB

version 8.63 or later or MPLAB-X is required

for its operation. The licensed debugger is

accessed via USB, using connector J13. This

connector is a micro-USB connector on the

upper left corner of the board. The provided

USB cable should be connected from J13 to a

USB port on the development PC for access to

the board.

When creating a new project, use the

Configure.Select Device menu to specify the

dsPIC device in use. Ensure that the device is

set to dsPIC33FJ128MC706A.

To use the on-board programming/debugging

circuit it must be selected as the debugger or

programmer. Use the Debugger.Select Tool

menu, or the Programmer.Select Tool menu,

and select “Licensed Debugger” as the

programmer or debugger.

The dsPIC microcontroller used on the Cerebot

MC7 uses a two wire interface for in-system

programming and debugging. There are three

alternative pairs of pins that can be used for

this purpose. The Cerebot MC7 is designed to

use signal pair 1, PGEC1/PGED1, for the

connection to the licensed debug circuit. This

selection is controlled by configuration bits

programmed when a firmware image is

programmed into the board. This is selected

using configuration macros provided with the

Microchip C30 compiler. A statement similar to

this should appear in the main program module

of the project:

/* Use PGC1/PGD1 for programming and

debugging

*/

_FICD(ICS_PGD1 & JTAGEN_OFF);

Refer to the dsPIC device data sheet, the

appropriate section of the dsPIC33F Family

Reference Manual and the C30 compiler

documentation for more information.

Board Power Supply

Switch SW1, in the lower left corner of the

board is the power switch. Place this switch in

the ON position to turn on board power and in

the OFF position to turn off board power.

The Cerebot MC7 board has three power

supplies.

One power supply is used to regulate power

for the main circuitry on the Cerebot MC7

board. This supply provides power to the 5V

peripherals on the board, such as the CAN

transceiver and provides the regulated 3.3V to

power the microcontroller and most of the

peripherals on the board. This supply requires

a regulated 5V input.

A second power supply is used to provide an

independent supply for the licensed debugger

circuit. This provides power to the debug circuit

as soon as the power switch is turned on. This

power supply uses a Microchip MCP1801 low

dropout regulator.

The USB specification requires that USB

devices not draw more than 100mA of current

until they have enumerated on the USB bus

and requested more current from the host. To

meet this specification, the debug circuit turns

on main board power by driving the PWR_ON

signal high after successfully enumerating on

the USB bus. The bus labeled on the

schematic as BRD5V0 is switched on when

this occurs. The BRD5V0 bus powers the input

to the primary voltage regulator, the power

supply voltage for the CAN transceiver, and

the 5V0 side of the power select jumpers for

the Pmod connectors.

The third power supply is a 5V switching

voltage regulator that can produce 5V at 4A

from an external source between 5V and 24V.

This power supply can be used to supply the

regulated 5V input to the main board power

supply, and also can provide 5V power to

power hobby servos connected to the servo

connectors. This switching regulator allows

single supply operation of the Cerebot MC7

www.digilentinc.com page 3 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 4

Cerebot MC7 Reference Manual

board from an external power supply or battery

at up to 24V DC.

There are two power options for main power to

the board: from an external power source via

the on-board 5V switching regulator or USB

powered from the debug USB connector, J13.

To power the board from an external power

supply, place a shorting block on JP14 (labeled

REG).To select USB power from the USB

debug connector, place a shorting block on

JP15 (labeled USB). Note that the dsPIC and

other circuitry on the board, plus connected

Pmods and I2C devices can be powered from

the USB connector. External loads such as

motors and hobby servos can not be powered

from the USB connector

NOTE: A shorting block should be installed on

either JP14 or JP15, but never both at the

same time. If shorting blocks are installed on

both at the same time, 5V from the on-board

switching regulator could back-feed to the USB

port, potentially damaging the USB port of the

PC or USB hub.

When powering the board from an external

power supply, there are three power supply

connectors that can be used: J21, J22 and

J24.

Connector J21 is a screw terminal connector

providing an alternative power supply

connection for use with battery packs, bench

supplies or other power sources where use of

a hard wired power supply is desirable.

Connector J22 is a two pin header connector

that can be used with some battery packs or

other wired connections. This connector is

rated for a maximum input current of 2A.

The barrel connector, J24, is used to power the

board from a “wall wart” style power supply.

This type of power supply is available from

many sources. Digilent has an optional power

supply available, the 5V Switching Power

Supply, that can be used with connector J17.

Connector J17 is a 2.5mm x 5.5mm coaxial

connector wired with the center terminal as the

positive voltage.

Connectors J21, J22, and J24 are wired in

parallel and connect directly to the input of the

switching 5V regulator.

NOTE: The dropout of the switching 5V

regulator is approximately 100mV when

operated from a 5V input. This allows

operation of the board from an external 5V

supply.

The dsPIC microcontroller and on-board I/O

devices operate at a supply voltage of 3.3V

provided by the BRD3V3 bus. The regulated

voltage on this bus is provided by a Microchip

MCP1725 Low Dropout voltage regulator,

IC22. This regulator is capable of providing a

maximum of 500mA of current. The DSPIC33

microcontroller will use approximately 90mA

when running at 40 MIPS. The other circuitry

on the board will draw 10-20 mA. The

remaining current is available to provide power

to attached Pmods and I2C devices. The

voltage regulator is on the bottom of the board,

below Pmod connector JA, and will get warm

when the amount of current being used is

close to its limit.

The Cerebot MC7 can provide power to any

peripheral modules attached to the Pmod

connectors, JA-JC, and to I2C devices powered

from the I2C daisy chain connectors, J6 and J8.

Each Pmod connector provides power pins

that can be powered from either the switched

main power bus, BRD5V0, or regulated

voltage, BRD3V3, by setting the voltage

jumper block to the desired position. The I2C

power connectors only provide regulated

voltage, BRD3V3.

Half Bridge Circuits

The Cerebot MC7 circuit provides four half

bridges. A half bridge is made up of two

stacked transistors such that the high side

transistor can source current from the motor

power supply and the low side transistor can

sink current to the supply ground.

Each half bridge is made up of an On

Semiconductor NTMD4820N dual N-FET to

www.digilentinc.com page 4 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 5

Cerebot MC7 Reference Manual

provide the transistors and a Microchip

MCP14700MF FET driver. The FET driver

provides a high side transistor drive input and

a low side transistor drive input.

The NTMD4820N FETs are rated for a

maximum V

of 30V, maximum VGS or 20V,

DS

and maximum drain current (ID) of 8A at 25°C,

6.4A at 70°C (t<10s) or 6.4A continuous drain

current at 25°C and 5.1A at 70°C. For more

detailed information on the NTMD4820N, refer

to the device data sheet available at the On

Semiconductor web site.

The steady state temperature of the FETs with

all four half bridges switching at 50% duty

cycle and a load current of 5A each has been

measured to be ~55°C. Operation in some

applications may require heat sinking or fan

cooling of the board to maintain continuous

operation at the full 5A output current.

The high side and low side drive inputs for

each half bridge are connected to PWMH and

PWML outputs from the Motor Control PWM

module in the dsPIC microcontroller. The

Motor Control PWM module is an advanced

pulse width modulation generator optimized for

motor control applications. This PWM unit

provides eight outputs arranged as four high

and low side drive pairs for controlling four half

bridge circuits.

The half bridges can be operated

independently, in pairs to form two h-bridges,

or in other combinations using the Motor

Control PWM module.

Connector J20 is used to provide the power

supply voltage for the high side of the half

bridges, and therefore powers whatever

external load is being controlled by the board.

This is a screw terminal connector on the left

side of the board. A power supply or battery of

5V-24V can be used, with a maximum

continuous current of 10A.

The half bridge connections between the

bridge output signals and the Motor Control

PWM module are configured in the following

way:

VMOT1 PWM1H, PWM1L

VMOT2 PWM2H, PWM2L

VMOT3 PWM3H, PWM3L

VMOT4 PWM4H, PWM4L

These outputs from the bridges are available

on connectors J14 & J15 or J16 & J18.

Connectors J14 & J15 are screw terminal

connectors for wire attachment. Connectors

J16 & J18 are 6-pin JST connectors used by

the gear head motors available from Digilent.

Connectors J14 & J16 provide the outputs

VMOT1 and VMOT2, while J15 & J18 provide

the outputs VMOT3 and VMOT4.

Current and Voltage Feedback

Each of the four half bridges is configured for

monitoring the current flow through the low

side transistor of the bridge. A voltage

proportional to the bridge current is applied to

one of the A/D inputs on the dsPIC

microcontroller for each half bridge.

A 10 milli-ohm (0.01 ohm), 1% current sense

resistor is connected between the source of

each low side FET and ground. A differential

amplifier with a fixed gain of 21 and an offset

voltage of 1.0V is used to buffer and amplify

the voltage across the current sense resistors

before being applied to the inputs to the A/D

converter. The following formula relates the

voltage applied to the A/D converter input to

the sensed bridge current:

V = (0.21 * I) + 1.0

Refer to Appendix C for tables showing data

measured from an example board.

In addition to the bridge current, the output

voltage of each half bridge can be monitored

as well. The output voltage of each half bridge

can be connected via a voltage divider to one

of the inputs to the A/D converter. The voltage

divider ratio is as follows:

Vo = 2.2/17.2 * Vi = 0.128 * Vi

www.digilentinc.com page 5 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 6

Cerebot MC7 Reference Manual

The voltage monitoring can be

enabled/disabled via jumpers JP9-JP12.

The current/voltage monitoring signals are

connected to the A/D converter inputs in the

following way:

IMON1 AN0

IMON2 AN1

IMON3 AN2

IMON4 AN3

VMON1 AN10

VMON2 AN11

VMON3 AN12

VMON4 AN13

Over-current Detection

The Cerebot MC7 provides an over-current

monitoring mechanism for detecting excessive

current flow through any of the half bridge

circuits.

Four comparators are used to monitor the

current measurement from each half bridge

compared to a fixed reference voltage. The

outputs of these comparators are OR’d

together and applied to external interrupt INT1

on the dsPIC microcontroller.

A fixed reference voltage of 2.33V is used to

set the comparator threshold for determining

an over current condition. This sets the

comparator to signal an over-current condition

at 6A. If the current through any half bridge

exceeds ~6A, an interrupt can be triggered on

INT1.

CAN Interface

The Controller Area Network (CAN) standard is

a control networking standard originally

developed for use in automobile systems, but

has since become a standard used in various

industrial control and building automation

networking applications as well.

The dsPIC33 microcontroller used on the

Cerebot MC7 contains a CAN network

controller. This CAN controller in combination

with a Microchip MCP2551 CAN transceiver

allow the Cerebot MC7 board to operate on a

CAN network. Refer to the

dsPIC33FJXXXMCX06A/X08A/X10A Data

Sheet and the dsPIC33F Family Reference

Manual, plus CAN network documentation for

information on operation of the CAN controllers

and CAN networking in general.

There is no standard connector for use with

CAN networks. The Cerebot MC7 board

provides a 2x6 pin header connector, J9, for

access to the CAN signals. Refer to the

schematic for the Cerebot MC7 board for

information on the connectors and signals.

Digilent 6-pin or 2x6 to dual 6-pin cables can

be used to daisy chain Digilent boards together

in a CAN network. A Digilent 6-Pin cable in

combination with a Digilent PmodCON1 Screw

Terminal Connector module can be used to

connect the Cerebot MC7 board to other

network wiring configurations.

The CAN network standard requires that the

network nodes at each end of a network

provide 120 ohm termination. The Cerebot

MC7 provides the termination resistor and

jumpers to enable/disable this resistor

depending on the location of the board in the

network. Jumper JP6 is used to enable/disable

the termination resistor. Install a shorting block

on the jumper pins to enable the termination

resistor, or remove the shorting block to

disable the termination resistor.

RC Servo Connectors

The Cerebot MC7 provides eight 3-pin RC

hobby servo connectors for direct control of

servos in robotics and embedded hardware

actuator applications. These connectors are

on the upper right side of the board.

The servo connectors S1-S8 are connected to

PORTD bits 0-7 in the dsPIC33F

microcontroller. These signals also appear on

Pmod connector JC, and PORTD bits 4-7 are

also used by the on-board LEDs. Devices

connected to Pmod connector JC may interfere

with operation of servos on the servo

www.digilentinc.com page 6 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 7

Cerebot MC7 Reference Manual

connectors, or alternatively, devices connected

to the servo connectors may interfere with

operation of a device connected to JC. Refer

to the dsPIC33F data sheet for information on

how to access the I/O pins.

The three pins on a servo connector provide

the control signal, power and ground. There is

no standard color coding for the wires on

hobby servos. They are wired so that the

center pin of the connector provides power to

the servo. Because of this configuration with

power on the center pin, the servo will not be

damaged if it plugged in backwards. Generally,

the center pin will have a red wire. On many

servos, the ground pin will have a black wire

and the signal wire will be a light color such as

white or yellow. Not all servo manufacturers

adhere to this convention however. The servo

connectors on the Cerebot MC7 board are

configured so that the signal pin (pin 1) is on

the left side (toward the center of the board)

and the ground pin is on the right side (toward

the board edge).

RC Servos use a pulse width modulated

signal, PWM, to control the servo position.

The dsPIC33F microcontroller provides eight

output compare units that can be used to

generate the necessary pulse width modulated

signal. PORTD bits 0-7 correspond to output

compare unit outputs OC1-OC8. The output

compare units can be operated from either

Timer 2 or Timer 3. It is also possible to use

timer interrupts to accomplish the generation of

the PWM outputs to drive the servo

connectors. Using timer interrupts allows a

single timer to be used to control the signal

timing for all eight servo connectors. This can

be useful if some timers need to be used for

other purposes.

The pulse width modulation timing varies

between servo manufacturers. Generally, a

pulse width of 1000us (1 milli-second)

corresponds to the center of rotation, with a

500us (0.5ms) pulse width being full rotation in

one direction and 1500us (1.5ms) being full

rotation in the other direction. Servo

manufacturers also vary on which direction of

rotation is produced by narrower and wider

pulses. Finally, some manufacturers produce

continuous rotation servos. These generally

require wider pulses. For these servos, a

1500us pulse width will result in the servo

stopped and no rotation, 500us will produce

rotation at full speed in one direction and

2500us full speed rotation in the other

direction. This varies widely between

manufacturers, however. Refer to

manufacturer data sheets for the servos, or

experiment to determine how specific servos

operate.

RC hobby servos generally operate at 5V.

Many are specified for operation at up to 6V,

and some specialty servos require higher

voltages. There are two power supply options

for providing power to the servo connectors:

The on-board 5V switching regulator, or an

external power supply

For the first case: Install shorting blocks on

JP5 and JP8 to connect the VS servo power

bus to the REG5V0 power bus. This

connection allows for operation from a single

high voltage power supply and allowing use of

the servos. There are two jumpers, as the

current rating on these jumper blocks is 2A,

and the eight servos can potentially draw up to

4A of current from the REG5V0 power bus.

For operation from an external servo power

supply, remove the shorting blocks from

jumpers JP5 and JP8 and connect the external

power supply to screw terminal connector J4.

An external power supply should not be

connected to J4 without removing the shorting

blocks from JP5 and JP8. Be sure to observe

the proper polarity when connecting the

external power supply.

I2C™ Interfaces

The Inter-Integrated Circuit (I2CTM) Interface

provides a medium speed (100K or 400K bps)

synchronous serial communications bus. The

I2C interface provides master and slave

operation using either 7 bit or 10 bit device

addressing. Each device is given a unique

address, and the protocol provides the ability

to address packets to a specific device or to

www.digilentinc.com page 7 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 8

Cerebot MC7 Reference Manual

broadcast packets to all devices on the bus.

Refer to the data sheet for the dsPIC

microcontroller and the dsPIC33F Family

Reference Manual for detailed information on

configuring and using the I2C interface.

The dsPIC33F microcontroller provides two

independent I2C interfaces. There are two sets

of connectors in the lower left corner of the

board for access to the two I2C ports.

Connector J6 provides access to I2C port #1

while connector J8 provides access to I2C port

#2.

Each I2C connector provides two positions for

connecting to the I2C signals, ground and the

3.3V power supply. By using two-wire or fourwire MTE cables (available separately from

Digilent) a daisy chain of multiple Cerebot MC7

boards or other I2C-capable boards can be

created.

The I2C bus is an open-collector bus. Devices

on the bus actively drive the signals low. The

high state on the I2C signals is achieved by

pull-up resistors when no device is driving the

lines low. One device on the I2C bus must

provide the pull-up resistors. I2C bus #2 has

permanently connected pull-up resistors. I2C

bus #1 has selectable pull-up resistors that can

be enabled or disabled via jumper blocks on J5

and J7. The pull-ups are enabled by installing

shorting blocks and are disabled by removing

the shorting blocks. The shorting blocks are

placed so that they line up with the SCL and

SDA labels on the board. Only one device on

the bus should have the pull-ups enabled.

I2C EEPROM

The Cerebot MC7 provides one on-board I2C

device, a Microchip 24LC256 serial EEPROM.

This device is connected to I2C bus #2. The

24LC256 is a 256Kbit (32Kbyte) serial

EEPROM device to provide non-volatile

memory storage. The device address for the

24LC256 is 1010000 (0x50).

Refer to the Microchip data sheet for detailed

information on the operation of this device.

Pmod Connectors

The Cerebot MC7 has three Pmod connectors

for connecting Digilent Pmod peripheral

modules. Digilent Pmods are a line of small

peripheral modules that provide various kind of

I/O interfaces. The Pmod line includes such

things as button, switch and LED modules,

connector modules, LCD displays, high current

output drivers, and many others.

There are two styles of Pmod connector: sixpin and twelve-pin. Both connectors use

standard pin headers with 100mil spaced pins.

The six-pin connectors have the pins in a 1x6

configuration, while the twelve-pin connectors

use a 2x6 configuration. The six-pin

connectors provide four I/O signals, ground

and a switchable power connection. The

twelve-pin connectors provide eight I/O

signals, two power and two ground pins. The

twelve-pin connectors have the signals

arranged so that one twelve-pin connector is

equivalent to two of the six-pin connectors.

The power connection is switchable between

the regulated 3.3V main board supply and the

unregulated input supply.

On the Cerebot MC7, Pmod connector JA is a

six pin connector that can be used for general

SCL

SDA

Pull-ups

Enabled

3V3

GND

SCL

SDA

Pull-ups

Disabled

3V3

GND

Jumper Settings for I2C Pull-Up Resistors

purpose I/O or for connection to UART1 or

SPI1. Connector JB is a twelve pin connector

that can be used for general I/O and provides

access to SPI2, and two external interrupts

(INT2 and INT3). Connector JC is a twelve pin

connector that can be used for general I/O,

www.digilentinc.com page 8 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 9

Cerebot MC7 Reference Manual

plus access to the output compare units and

two of the input capture units.

Digilent Pmod peripheral modules can either

be plugged directly into the connectors on the

Cerebot MC7 or attached via cables. Digilent

has a variety of Pmod interconnect cables

available.

See the “Connector and Jumper Block Pinout

Tables” section below for more information

about connecting peripheral modules and other

devices to the Cerebot MC7. These tables

indicate the mapping between pins on the

dsPIC microcontroller and the pins on the

various connectors.

SPI Interface

SPI is a four-wire synchronous serial

Pmod connector JB. This SPI controller can be

used as either an SPI master or an SPI slave.

The other SPI controller (SPI1) is available on

Pmod connector JA. The SS signal for SPI1 is

not available at connector JA, and therefore

SPI1 can only be used as an SPI master.

When using SPI1, PORTD bit 9 (RD9) is used

to drive the SS signal of the connected SPI

slave.

Jumpers JP2 and JP3 are used to select

whether SPI2 on connector JB is operating as

an SPI master of as an SPI slave. For

operation as an SPI master, JP2 (SDI2) is

placed in the MISO position (to the left), and

JP3 (SDO2) is placed in the MOSI position (to

the right). For operation as an SPI slave, JP2

is placed in the MOSI position and JP3 is

placed in the MISO position.

communications interface used by many

microcontrollers and peripheral devices.

The SPI interface is made up of the following

four signals generally called: SS (slave select),

MOSI (master out/slave in), MISO (master

in/slave out), and SCK (serial clock). On the

dsPIC microcontroller, the SPI signals are

called SS (slave select), SDO (serial data out),

SDI (serial data in), and SCK (serial clock).

When an SPI master device communicates

with a slave device, it initiates the

communication by bring the SS line low. This

enables the slave device to receive the data.

The master device then sends one or more

bytes to the slave. The data is shifted serially

out the MOSI pin to the slave. The slave

device simultaneously shifts out a byte to the

master on MISO. Each time a byte is sent from

the master to the slave, a byte is sent from the

slave to the master. The master generates the

serial clock on the SCK line, and the slave

uses that as the clock to shift the data in and

out. When the master has finished sending

data to the slave, it ends the transaction by

bringing the SS line high.

The dsPIC microcontroller used on the Cerebot

MC7 provides two SPI controllers. One of

these controllers (SPI2) is available for use on

SDO2

JP3

JP2

SDI2

MISO

SPI Master SPI Slave

JP3

JP2

MOSI

Jumper Settings for SPI

Refer to the data sheet for the dsPIC

microcontroller and the dsPIC33F Family

Reference Manual for detailed information on

configuring and using the SPI interfaces.

User I/O Devices

The Cerebot MC7 board provides two push

button switches for user input and four discrete

LEDs for output. The buttons, BTN1 and

BTN2 are connected to I/O pins RB8 and

RB14 respectively. To read the buttons, bits 8

and/or 14 of PORTB must be set as inputs by

setting the corresponding bits in the TRISB

register and then reading the PORTB register.

When a button is pressed, the corresponding

bit will be high (‘1’).

The four LEDs are connected to bits 4-7 of

PORTD. LED 1 is connected to bit 4, LED 2 is

connected to bit 5, and so on. To use the

SDO2

SDI2

MISO

MOSI

www.digilentinc.com page 9 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 10

Cerebot MC7 Reference Manual

LEDs, set the desired bits as outputs by

clearing the corresponding bits in the TRISD

register and set the bits to the desired value in

the PORTD or LATD register. Setting a bit to 1

will illuminate the LED and setting the bit to 0

will turn it off.

Note that PORTD bits 4-7 are also used by

Pmod connector JC and by four of the RC

servo connectors.

CPU Clock Source

The dsPIC microcontroller on the Cerebot MC7

supports numerous clock source options for

the main processor operating clock. The

Cerebot MC7 board provides an external 8Mhz

crystal for use with the XT oscillator option.

This crystal is on the bottom of the board.

Oscillator options are selected via

configuration macros supplied as part of the

Microchip C30 compiler suite for the dsPIC.

In addition to the crystal oscillator using the

external 8Mhz, the dsPIC microcontroller also

has an internal 8Mhz RC oscillator. It also

provides the capability to switch clock source

and clock speed during operation.

Using the internal system clock phase-locked

loop (PLL), it is possible to select numerous

multiples or divisions of the 8Mhz oscillator to

produce CPU operating frequencies up to

40Mhz. The operating frequency can be

selected using configuration macros. Refer to

section 9.1 CPU Clocking System in the data

sheet for the

dsPIC33FJXXXMCX06A/X08A/X10A family

devices for information on how to set up the

clock source and operating frequency.

The following example code will set the

clocking options for operation at 40 MIPS.

/* The settings below set up the oscillator and PLL for 40 MIPS as

**follows:

** Crystal Frequency * (DIVISOR+2)

** Fcy = -------------------------------- ** PLLPOST * (PRESCLR+2) * 4

** Crystal = Defined in UserParms.h

** Fosc = Crystal * dPLL defined in UserParms.h

** Fcy = DesiredMIPs

*/

PLLFBD = (int)(40 - 2);

CLKDIVbits.PLLPOST = 0; // N1=2

CLKDIVbits.PLLPRE = 0; // N2=2

__builtin_write_OSCCONH(0x03);

__builtin_write_OSCCONL(0x01);

while(OSCCONbits.COSC != 0b011);

// Wait for PLL to lock

while(OSCCONbits.LOCK != 1);

www.digilentinc.com page 10 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 11

Cerebot MC7 Reference Manual

MCU Por

t Bit to Pmod Connector Pin

Appendix A: Microcontroller and Connector Pinout Tables

MCU Port

Bit

RB00 16 N/A PGED3/AN0/VREF+/CN2/RB0 half bridge 1 current sense

RB01 15 N/A PGEC3/AN1/VREF-/CN3/RB1 half bridge 2 current sense

RB02 14 N/A AN2/SS1/CN4/RB2 half bridge 3 current sense

RB03 13 N/A AN3/INDX/CN5/RB3 half bridge 4 current sense

RB04 12 N/A AN4/QEA/IC7/CN6/RB4 motor 1, quadrature encoder input

RB05 11 N/A AN5/QEB/IC8/CN7/RB5 motor 1, quadrature encoder input

RB06 17 N/A PGEC1/AN6/OCFA/RB6 on-board program/debug circuit

RB07 18 N/A PGED1/AN7/RB7 on-board program/debug circuit

RB08 21 U2CTS/AN8/RB8 BTN1

RB09 22 N/C AN9/RB9

RB10 23 N/A TMS/AN10/RB10 half bridge 1, voltage sense

RB11 24 N/A TDO/AN11/RB11 half bridge 2, voltage sense

RB12 27 N/A TCK/AN12/RB12 half bridge 3, voltage sense

RB13 28 N/A TDI/AN13/RB13 half bridge 4, voltage sense

RB14 29 JB-09 U2RTS/AN14/RB14 shared with BTN2

RB15 30 JB-10 AN15/OCFB/CN12/RB15

RC12 39 N/A OSC1/CLKIN/RC12 crystal connection

RC13 47 N/A PGED2/SOSCI/T4CK/CN1/RC13 motor 2, quadrature encoder input

RC14 48 N/A PEGC2/SOSCO/T1CK/CN0/RC14 motor 2, quadrature encoder input

RC15 40 N/A OSC2/CLKO/RC15 crystal connection

RD00 46 JC-01 OC1/RD0 Servo S1

RD01 49 JC-02 OC2/RD1 Servo S2

RD02 50 JC-03 OC3/RD2 Servo S3

RD03 51 JC-04 OC4/RD3 Servo S4

RD04 52 JC-07 OC5/IC5/CN13/RD4 Servo S5, LD1

RD05 53 JC-08 OC6/IC6/CN14/RD5 Servo S6, LD2

RD06 54 JC-09 OC7/CN15/RD6 Servo S7, LD3

RD07 55 JC-10 OC8/UPDN/CN16/RD7 Servo S8, LD4

RD08 42 N/A IC1/FLTA/INT1/RD8 bridge over-current detect

RD09 43 JA-01 IC2/U1CTS/FLTB/INT2/RD9 UART #1

RD10 44 JB-07 IC3/INT3/RD10

RD11 45 JB-08 IC4/INT4/RD11

RE00 60 N/A PWM1L/RE0 PWM1L, half bridge 1 low side

RE01 61 N/A PWM1H/RE1 PWM1H, half bridge 1 high side

RE02 62 N/A PWM2L/RE2 PWM2L, half bridge 2 low side

RE03 63 N/A PWM2H/RE3 PWM2H, half bridge 2 high side

RE04 64 N/A PWM3L/RE4 PWM3L, half bridge 3 low side

RE05 1 N/A PWM3H,RE5 PWM3H, half bridge 3 high side

RE06 2 N/A PWM4L/RE6 PWM4L, half bridge 4 low side

RE07 3 N/A PWM4H/RE7 PWM4H, half bridge 4 high side

RF00 58 N/A C1RX/RF00 CAN RX

RF01 59 N/A C1TX/RF01 CAN TX

RF02 34 JA-03 U1RX/SDI1/RF2 UART #1 RX

RF03 33 JA-02 U1TX/SDO1/RF3 UART #1 TX

MCU

Pin

Connector

Pin

Signal Notes

www.digilentinc.com page 11 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 12

Cerebot MC7 Reference Manual

RF04 31 N/A U2RX/SDA2/CN17/RF4

RF05 32 N/A U2TX/SCL2/CN18/RF5

RF06 35 JA-04 U1RTS/SCK1/INT0/RF6 UART #1

RG02 37 N/A SCL1/RG2

RG03 36 N/A SDA1/RG3

RG06 4 JB-04 SCK2/CN8/RG6 SPI #2

RG07 5 JB-03 SDI2/CN9/RG7 SPI #2, Selectable via JP2

RG08 6 JB-02 SDO2/CN10/RG8 SPI #2, Selectable via JP3

RG09 8 JB-01 SS2/CN11/RG9 SPI #2

7 N/A MCLR on-board program/debug circuit

9 N/A VSS

10 N/A VDD

19 N/A AVDD

20 N/A AVSS

25 N/A VSS

26 N/A VDD

38 N/A VDD

41 N/A VSS

56 N/A Vcap/VDDCORE

57 N/A VDD

I2C Bus #2, not shared with Pmod

connector

I2C Bus #2, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

www.digilentinc.com page 12 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 13

Cerebot MC7 Reference Manual

Pmod Connector Pin To MCU Port Bit

Connector

Pin

JA-01 RD09 43 IC2/U1CTS/FLTB/INT2/RD9 UART #1

JA-02 RF03 33 U1TX/SDO1/RF3 UART #1 TX

JA-03 RF02 34 U1RX/SDI1/RF2 UART #1 RX

JA-04 RF06 35 U1RTS/SCK1/INT0/RF6 UART #1

JB-01 RG09 8 SS2/CN11/RG9 SPI #2

JB-02 RG08 6 SDO2/CN10/RG8 SPI #2, Selectable via JP3

JB-03 RG07 5 SDI2/CN9/RG7 SPI #2, Selectable via JP2

JB-04 RG06 4 SCK2/CN8/RG6 SPI #2

JB-07 RD10 44 IC3/INT3/RD10

JB-08 RD11 45 IC4/INT4/RD11

JB-09 RB14 29 U2RTS/AN14/RB14 shared with BTN2

JB-10 RB15 30 AN15/OCFB/CN12/RB15

JC-01 RD00 46 OC1/RD0 Servo S1

JC-02 RD01 49 OC2/RD1 Servo S2

JC-03 RD02 50 OC3/RD2 Servo S3

JC-04 RD03 51 OC4/RD3 Servo S4

JC-07 RD04 52 OC5/IC5/CN13/RD4 Servo S5, LD1

JC-08 RD05 53 OC6/IC6/CN14/RD5 Servo S6, LD2

JC-09 RD06 54 OC7/CN15/RD6 Servo S7, LD3

JC-10 RD07 55 OC8/UPDN/CN16/RD7 Servo S8, LD4

N/A RB00 16 PGED3/AN0/VREF+/CN2/RB0 half bridge 1 current sense

N/A RB01 15 PGEC3/AN1/VREF-/CN3/RB1 half bridge 2 current sense

N/A RB02 14 AN2/SS1/CN4/RB2 half bridge 3 current sense

N/A RB03 13 AN3/INDX/CN5/RB3 half bridge 4 current sense

N/A RB04 12 AN4/QEA/IC7/CN6/RB4 motor 1, quadrature encoder input

N/A RB05 11 AN5/QEB/IC8/CN7/RB5 motor 1, quadrature encoder input

N/A RB06 17 PGEC1/AN6/OCFA/RB6 on-board program/debug circuit

N/A RB07 18 PGED1/AN7/RB7 on-board program/debug circuit

N/A RB08 21 U2CTS/AN8/RB8 BTN1

N/A RB10 23 TMS/AN10/RB10 half bridge 1, voltage sense

N/A RB11 24 TDO/AN11/RB11 half bridge 2, voltage sense

N/A RB12 27 TCK/AN12/RB12 half bridge 3, voltage sense

N/A RB13 28 TDI/AN13/RB13 half bridge 4, voltage sense

N/A RC12 39 OSC1/CLKIN/RC12 crystal connection

N/A RC13 47 PGED2/SOSCI/T4CK/CN1/RC13 motor 2, quadrature encoder input

N/A RC14 48 PEGC2/SOSCO/T1CK/CN0/RC14 motor 2, quadrature encoder input

N/A RC15 40 OSC2/CLKO/RC15 crystal connection

N/A RD08 42 IC1/FLTA/INT1/RD8 bridge over-current detect

N/A RE00 60 PWM1L/RE0 PWM1L, half bridge 1 low side

N/A RE01 61 PWM1H/RE1 PWM1H, half bridge 1 high side

N/A RE02 62 PWM2L/RE2 PWM2L, half bridge 2 low side

N/A RE03 63 PWM2H/RE3 PWM2H, half bridge 2 high side

N/A RE04 64 PWM3L/RE4 PWM3L, half bridge 3 low side

N/A RE05 1 PWM3H,RE5 PWM3H, half bridge 3 high side

N/A RE06 2 PWM4L/RE6 PWM4L, half bridge 4 low side

N/A RE07 3 PWM4H/RE7 PWM4H, half bridge 4 high side

MCU

Port Bit

MCU

Pin

Signal Notes

www.digilentinc.com page 13 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 14

Cerebot MC7 Reference Manual

N/A RF00 58 C1RX/RF00 CAN RX

N/A RF01 59 C1TX/RF01 CAN TX

N/A RF04 31 U2RX/SDA2/CN17/RF4

N/A RF05 32 U2TX/SCL2/CN18/RF5

N/A RG02 37 SCL1/RG2

N/A RG03 36 SDA1/RG3

N/A 7 MCLR on-board program/debug circuit

N/A 9 VSS

N/A 10 VDD

N/A 19 AVDD

N/A 20 AVSS

N/A 25 VSS

N/A 26 VDD

N/A 38 VDD

N/A 41 VSS

N/A 56 Vcap/VDDCORE

N/A 57 VDD

N/C RB09 22 AN9/RB9

I2C Bus #2, not shared with Pmod

connector

I2C Bus #2, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

www.digilentinc.com page 14 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 15

Cerebot MC7 Reference Manual

MCU Pin to Pmod Connector Pin

MCU Pin MCU

Port Bit

1 RE05 N/A PWM3H,RE5 PWM3H, half bridge 3 high side

2 RE06 N/A PWM4L/RE6 PWM4L, half bridge 4 low side

3 RE07 N/A PWM4H/RE7 PWM4H, half bridge 4 high side

4 RG06 JB-04 SCK2/CN8/RG6 SPI #2

5 RG07 JB-03 SDI2/CN9/RG7 SPI #2, Selectable via JP2

6 RG08 JB-02 SDO2/CN10/RG8 SPI #2, Selectable via JP3

7 N/A MCLR on-board program/debug circuit

8 RG09 JB-01 SS2/CN11/RG9 SPI #2

9 N/A VSS

10 N/A VDD

11 RB05 N/A AN5/QEB/IC8/CN7/RB5 motor 1, quadrature encoder input

12 RB04 N/A AN4/QEA/IC7/CN6/RB4 motor 1, quadrature encoder input

13 RB03 N/A AN3/INDX/CN5/RB3 half bridge 4 current sense

14 RB02 N/A AN2/SS1/CN4/RB2 half bridge 3 current sense

15 RB01 N/A PGEC3/AN1/VREF-/CN3/RB1 half bridge 2 current sense

16 RB00 N/A PGED3/AN0/VREF+/CN2/RB0 half bridge 1 current sense

17 RB06 N/A PGEC1/AN6/OCFA/RB6 on-board program/debug circuit

18 RB07 N/A PGED1/AN7/RB7 on-board program/debug circuit

19 N/A AVDD

20 N/A AVSS

21 RB08 U2CTS/AN8/RB8 BTN1

22 RB09 N/C AN9/RB9

23 RB10 N/A TMS/AN10/RB10 half bridge 1, voltage sense

24 RB11 N/A TDO/AN11/RB11 half bridge 2, voltage sense

25 N/A VSS

26 N/A VDD

27 RB12 N/A TCK/AN12/RB12 half bridge 3, voltage sense

28 RB13 N/A TDI/AN13/RB13 half bridge 4, voltage sense

29 RB14 JB-09 U2RTS/AN14/RB14 shared with BTN2

30 RB15 JB-10 AN15/OCFB/CN12/RB15

31 RF04 N/A U2RX/SDA2/CN17/RF4

32 RF05 N/A U2TX/SCL2/CN18/RF5

33 RF03 JA-02 U1TX/SDO1/RF3 UART #1 TX

34 RF02 JA-03 U1RX/SDI1/RF2 UART #1 RX

35 RF06 JA-04 U1RTS/SCK1/INT0/RF6 UART #1

36 RG03 N/A SDA1/RG3

37 RG02 N/A SCL1/RG2

38 N/A VDD

39 RC12 N/A OSC1/CLKIN/RC12 crystal connection

40 RC15 N/A OSC2/CLKO/RC15 crystal connection

41 N/A VSS

42 RD08 N/A IC1/FLTA/INT1/RD8 bridge over-current detect

43 RD09 JA-01 IC2/U1CTS/FLTB/INT2/RD9 UART #1

44 RD10 JB-07 IC3/INT3/RD10

45 RD11 JB-08 IC4/INT4/RD11

Connector

Pin

Signal Notes

I2C Bus #2, not shared with Pmod

connector

I2C Bus #2, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

I2C Bus #1, not shared with Pmod

connector

www.digilentinc.com page 15 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 16

Cerebot MC7 Reference Manual

46 RD00 JC-01 OC1/RD0 Servo S1

47 RC13 N/A PGED2/SOSCI/T4CK/CN1/RC13 motor 2, quadrature encoder input

48 RC14 N/A PEGC2/SOSCO/T1CK/CN0/RC14 motor 2, quadrature encoder input

49 RD01 JC-02 OC2/RD1 Servo S2

50 RD02 JC-03 OC3/RD2 Servo S3

51 RD03 JC-04 OC4/RD3 Servo S4

52 RD04 JC-07 OC5/IC5/CN13/RD4 Servo S5, LD1

53 RD05 JC-08 OC6/IC6/CN14/RD5 Servo S6, LD2

54 RD06 JC-09 OC7/CN15/RD6 Servo S7, LD3

55 RD07 JC-10 OC8/UPDN/CN16/RD7 Servo S8, LD4

56 N/A Vcap/VDDCORE

57 N/A VDD

58 RF00 N/A C1RX/RF00 CAN RX

59 RF01 N/A C1TX/RF01 CAN TX

60 RE00 N/A PWM1L/RE0 PWM1L, half bridge 1 low side

61 RE01 N/A PWM1H/RE1 PWM1H, half bridge 1 high side

62 RE02 N/A PWM2L/RE2 PWM2L, half bridge 2 low side

63 RE03 N/A PWM2H/RE3 PWM2H, half bridge 2 high side

64 RE04 N/A PWM3L/RE4 PWM3L, half bridge 3 low side

www.digilentinc.com page 16 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 17

Cerebot MC7 Reference Manual

Label

Function

J4 External Servo Power Connector

J5

& J7

Pull

-

up enable for I2C port #1

J6 I2C port #1 daisy chain connector

J8 I2C port #2 daisy chain connector

J9 CAN

Connector

J10-J12 Do Not Use

J13 Debug USB Connector

J14-J15 Motor/Bridge Output Connectors

J16-J17 Motor/Encoder #1 Connector

J18-J19 Motor/Encoder #2 Connector

Appendix B: Connector Descriptions and Jumper Settings

This screw terminal connector is used to power the servo power bus from an external

power supply. JP5 and JP8 must have the shorting blocks removed when using this

option for powering the servo power bus.

These two jumpers are used to enable/disable the pull-up resistors on I2C port #1. Insert

shorting blocks on these two jumpers to enable the pull-up resistors. Remove the shorting

blocks to disable the pull-up resistors. Only a single device on the I2C bus should have

the pull-up resistors enabled.

This connector provides access to the I2C signals, power and ground for I2C port #1.

This connector provides access to the I2C signals, power and ground for I2C port #2.

This connector is used to access the signals for the CAN interface.

.

This connector is used to connect the on-board programming and debug circuit to the PC

for use with the MPLAB® IDE.

These are used to connect external loads to the bridges. J14 provides access to the

VMOT1 and VMOT2 signals. J15 provides access to the VMOT3 and VMOT4 signals.

When the bridge circuits are used to form h-bridges, J14 provides access to one h-bridge

and J15 provides access to the other.

J16 is a six pin JST connector that provides connection to VMOT1 and VMOT2 for use as

an h-bridge to drive a motor. These are the same signals as on J14. Connector J16 also

provides access to the two phase inputs to the quadrature encoder peripheral in the

dsPIC microcontroller. J17 is an alternate connector for access to the quadrature encoder

inputs.

J18 is a six pin JST connector that provides connection to VMOT2 and VMOT3 for use as

an h-bridge to drive a motor. These are the same signals as on J15. Connector J16 also

provides access to two pin-change interrupt capable pins on the dsPIC microcontroller.

These inputs can be used to implement a quadrature in softwarer. J19 is an alternate

connector for access to the quadrature encoder signals.

www.digilentinc.com page 17 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 18

Cerebot MC7 Reference Manual

J20 Motor Power Connector

J21 External Power Connector

J22 External Power Connector

J24 External Power Connector

JP1 CAN 5V0 Enable

JP2 &

SPI Master/Slave

Select

JP4 Do Not Use

JP5 &

Internal Servo Bus Power Select

JP6 CAN

Ter

mination

JP7 Do Not Use

JP9,

V

oltage Monitoring Disconnect

This is used to connect to the external power supply that powers the bridge circuits. This

powers the high side of the bridges and provides the ground connection for the current

return path.

This is a screw terminal connector used to provide external power to the board. Be sure

to observe proper polarity (marked near the connector) when providing power via this

connector, or damage to the board and/or connected devices may result. This provides

the input voltage to the 5V switching regulator on the board. Connectors J21, J22, and

J24 are wired in parallel.

This is a two pin header connector that provides another mean of connecting an external

power supply. Connectors J21, J22, and J24 are wired in parallel.

This is a 2.5mm x 5.5mm, center positive, coax power connector used to provide external

power to the board. The optional Digilent 5V Switching Power Supply is connected here.

Connectors J21, J22, and J24 are wired in parallel.

JP3

JP8

This jumper is used to enable/disable providing 5V to the CAN connector. Insert the

shorting block to connect the board 5V0 supply to pins 9 & 10 of the CAN connector.

Remove the shorting block to disconnect the 5V0 supply.

These jumpers are used to select whether the Cerebot MC7 is configured as an SPI

master device or as an SPI slave device. See the SPI Interface section above for a

discussion of how to set these jumpers.

These jumpers are used to connect the REG5V0 bus (the output of the internal 5V

switching regulator) to the servo power bus to provide power to servos. Install shorting

blocks on these two jumpers to power the servo power bus from the internal power

supply. Remove the shorting blocks from these two jumpers when the servo power bus is

powered from an external supply

This jumper is used to enable/disable the 120 ohm termination resistor for the CAN

interface. Insert the shorting block to enable the termination resistor, remove it to disable

the termination resistor.

JP10,

JP11, &

JP12

www.digilentinc.com page 18 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

These jumpers are used to enable/disable monitoring the voltage at the outputs of the

four half bridge circuits. With shorting blocks installed on these jumpers the voltage at the

output of each bridge is connected to the dsPIC voltage monitoring analog inputs.

Page 19

Cerebot MC7 Reference Manual

JP14 &

Power supply source select

S1-S8 Servo Connectors

JA-JC Pmod Connectors

JPA

–

Pmod header power sele

ct

JP15

JPC

This jumper is used to select the source of main board power.

Place a shorting block on JP15 in the lower, “USB” position to have the board powered

from the USB programmer/debugger connector, J13.

Place a shorting block on JP14 in the upper, “REG” position to have the board powered

from internal 5V switching regulator.

These are used to connect RC servos to the board. The signals on these pins are shared

with Pmod connector JC and the on-board LEDs.

These connectors provide access to the I/O pins on the PIC32MX795 microcontroller.

Digilent Pmod peripheral modules can be attached to these connectors.

Any of the Pmod connectors can provide either regulated or unregulated power. To use

regulated power, place the jumper block over the center pin and the pin marked 3V3. To

use unregulated power, place the jumper block over the center pin and the pin marked

5V0.

www.digilentinc.com page 19 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 20

Cerebot MC7 Reference Manual

Over

Over

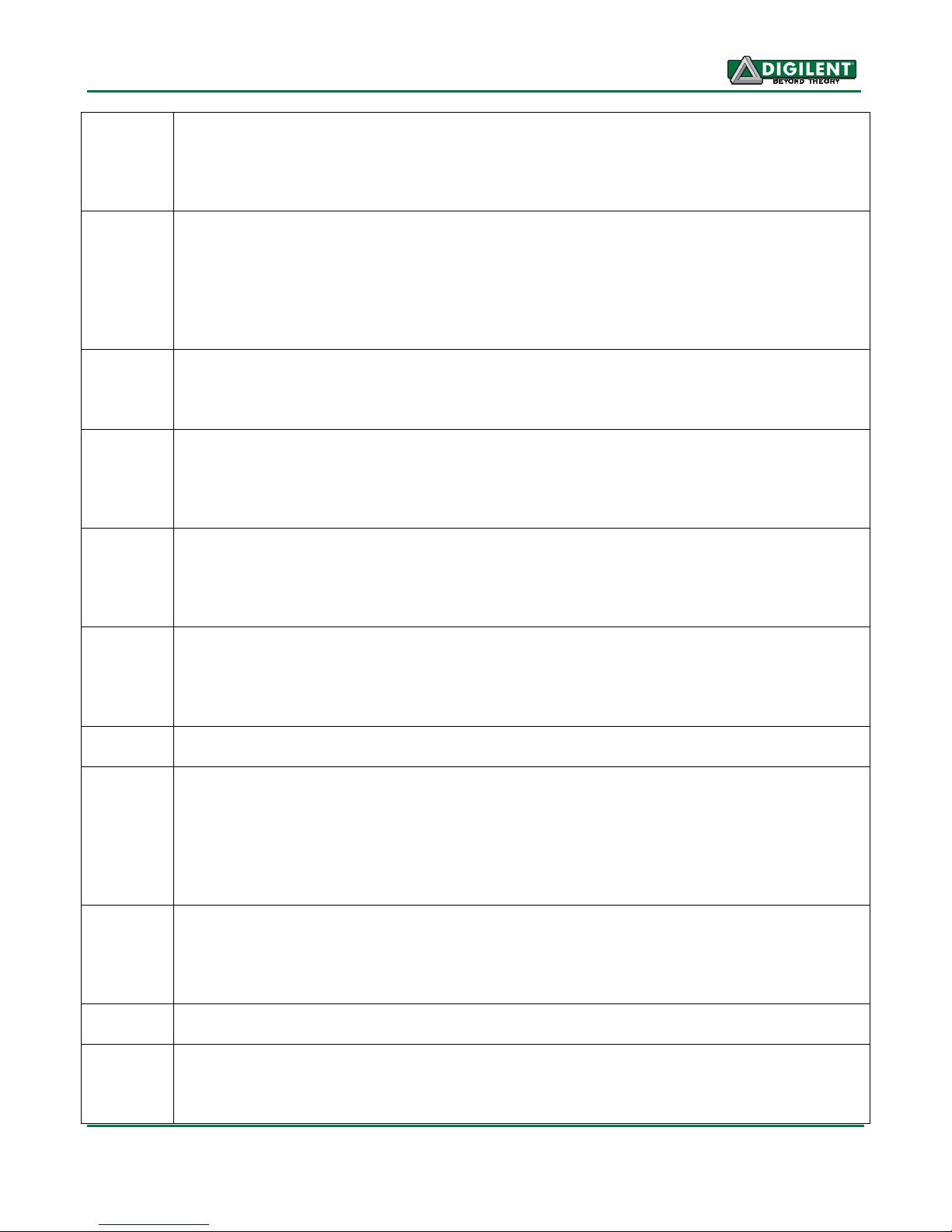

Appendix C: Measured Current Monitoring Data

Half Bridge 1: IMON1

Current

(amps)

0.5

1.5

2.5

3.5

4.5

5.5

0

1

2

3

4

5

6

Voltage

(volts)

0.997

1.11

1.213

1.318

1.424

1.531

1.638

1.747

1.856

1.969

2.084

2.2

2.321

Current

Trip 5.99A

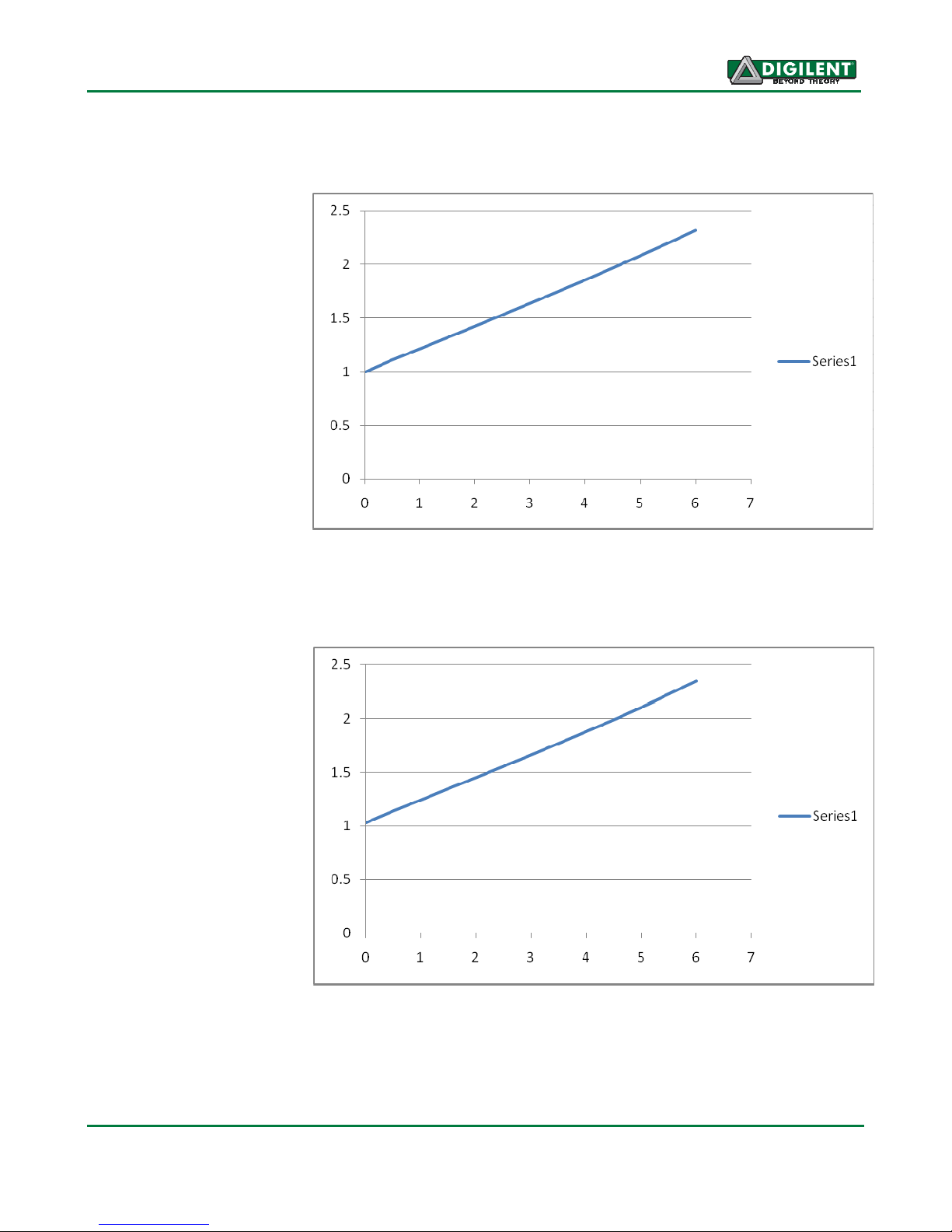

Half Bridge 2: IMON2

Current

(amps)

0.5

1.5

2.5

3.5

4.5

5.5

0

1

2

3

4

5

6

Voltage

(volts)

1.028

1.139

1.242

1.348

1.45

1.556

1.662

1.77

1.88

1.99

2.106

2.223

2.344

Current

Trip 5.87

www.digilentinc.com page 20 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 21

Cerebot MC7 Reference Manual

Over

Over

Half Bridge 3: IMON3

Current

(amps)

0.5

1.5

2.5

3.5

4.5

5.5

0

1

2

3

4

5

6

Voltage

(volts)

1.003

1.113

1.218

1.326

1.43

1.537

1.644

1.752

1.861

1.973

2.092

2.205

2.328

Current

Trip 5.95

Half Bridge 4: IMON4

Current

(amps)

0.5

1.5

2.5

3.5

4.5

5.5

0

1

2

3

4

5

6

Voltage

(volts)

0.967

1.077

1.181

1.282

1.389

1.493

1.6

1.707

1.816

1.926

2.039

2.158

2.278

Current

Trip 6.15

www.digilentinc.com page 21 of 21

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 22

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Digilent:

310-025P

Loading...

Loading...