Page 1

PPmmooddDDHHBB11™

RReeffeerreennccee MMaannuuaal

DIR1

EN1 Result

DIR2 EN2 Result

Revision: February 4, 2013

Note: This document applies to REV A of the board.

™

l

Overview

The PmodDHB1 uses the Texas Instruments

DRV8833 dual H-Bridge motor driver chip to

drive two DC motors or one stepper motor.

Features include:

• Motor voltage can be driven up to

11.8V, with a recommended 10.8V

maximum

• Two H-Bridge interfaces capable of

1.5A RMS (2A Peak)

• 2-channel quadrature encoder

channels for Hall-effect sensors

• Two JST 6-pin connectors for direct

connection to Digilent motor-gearboxes

• Logic input voltage range of 2.5V to 5V

Functional Description

For a detailed description of the Texas

Instruments DRV8833 please refer to the

device data sheet available at TI.com.

The DHB1 is controlled through the Pmod

connector J1. Logical levels on ENx and DIRx

determine the Motor Direction and speed of the

attached motors. The DHB1 uses a

demultiplexer and pull-down resistors on the

inputs to the DRV8833 H-Bridge pins to ensure

that the H-Bridge works in fast decay mode.

The intended operation of the DHB1 uses the

enable pin as the PWM input and the direction

pin as a logic level selector to set the direction

of the motor rotation. Table 1 lists the motor

responses that result from various input

combinations.

The DRV8833 chip provides overcurrent

protection on the motor drive circuits. Each

internal drive FET is independently monitored

for an overcurrent condition and will be shut

down internally to protect the chip. When an

1300 NE Henley Court, Suite 3

Pullman, WA 99163

(509) 334 6306 Voice | (509) 334 6300 Fax

overcurrent condition is sensed the chip will

shut down the FET with the fault and then set

the NFAULT pin low signaling a fault condition

on the chip. The remaining FETs will continue

to operate as normal. When the fault condition

is over, the chip will self-reset and return the

NFAULT logic level to logic high. (See Table 2

for connector descriptions.)

There are two Schmitt trigger buffered inputs

on connectors J2, J3, J7 and J8 that bring

motor speed feedback signals to the controlling

system board. The Digilent motor and gearbox

have hall-effect sensors arranged in a

quadrature encoder format. These buffers

have 5V tolerant inputs, when operated at

3.3V.

0 0 Stop

0 1/PWM Forward

1 0 Stop

1 1/PWM Reverse

0 0 Stop

0 1/PWM Forward

1 0 Stop

1 1/PWM Reverse

Table 1: Motor Control

Doc: 502-259 page 1 of 3

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 2

PmodDHB1™ Reference Manual

Jumper

Setting

Description

Connector J1

– H-Bridge Interf

aces

Pin Signal

Description

Connector J2

- M1 JST 6

-

Pin Motor Connector

Connector J3

- M1 JST 6

-

Pin Motor Connector

Connector J4

- VM

Connector J5

- M1 Power

Connector J6

- M2 Power

Connector J7

- M1 Feedback

Connector J8

- M2 Feedback

Connector J9

- Fault

Connector J10

- Sleep

The quadrature encoder signals are a pair of

square waves whose frequency is proportional

to motor rotation speed and with the pulses 90°

out of phase. You can determine the motor

speed with the frequency and motor rotation

direction by the phase relationship between the

1 EN1 Motor 1 Enable

2 DIR1 Motor 1 Direction

3 S1A Motor 1 Sensor A Feedback

4 S1B Motor 1 Sensor B Feedback

5 GND Power Supply Ground

6 VCC Power Supply (3.3V)

7 EN2 Motor 2 Enable

8 DIR2 Motor 2 Direction

9 S2A Motor 2 Sensor A Feedback

10 S2B Motor 2 Sensor B Feedback

11 GND Power Supply Ground

12 VCC Power Supply (3.3V)

1 VM Motor Power

2 GND Power Supply Ground

1 M1+ Motor 1 Positive Supply

2 M1- Motor 1 Negative Supply

1 M2+ Motor 2 Positive Supply

2 M2- Motor 2 Negative Supply

1 SA1-IN Sensor A From Motor 1

2 SB1-IN Sensor B From Motor 1

3 GND Power Supply Ground

4 VCC Power Supply (3.3V)

1 SA2-IN Sensor A From Motor 2

2 SB2-IN Sensor B From Motor 2

3 GND Power Supply Ground

4 VCC Power Supply (3.3V)

1 NFAULT Overcurrent Condition

2 GND Power Supply Ground

1 NSLEEP Puts device into sleep state

2 GND Power Supply Ground

Table 2: Connector Descriptions

®

two signals.

www.digilentinc.com

Jumper Settings

Jumpers JP1 and JP2 allow both h-bridge

outputs to be run from the same enable and

direction pins. This allows the two bridge

outputs to be operated in parallel to drive a

single motor with twice the current. Refer to

Table 3 for available settings.

JP1

JP2

Pulse Width Modulation and Motor

Speed Control

Operators can control motor speed by varying

the input voltage to a circuit. However, you

can only apply a logic high or logic low signal

to the motor in a digital circuit. There are only

two ways to control a dc motor digitally. Either

use a variable resistance circuit to control the

motor voltage, or pulse the power to the motor.

Since variable resistance circuitry is expensive,

complicated, and energy inefficient because of

heat loss, Digilent recommends controlling

motor speed through pulse width modulation

(PWM).

Pulse width modulation is a digital method of

transmitting an analog signal. Even though

PWM is not a clean source of DC output

voltage, it controls motors well.

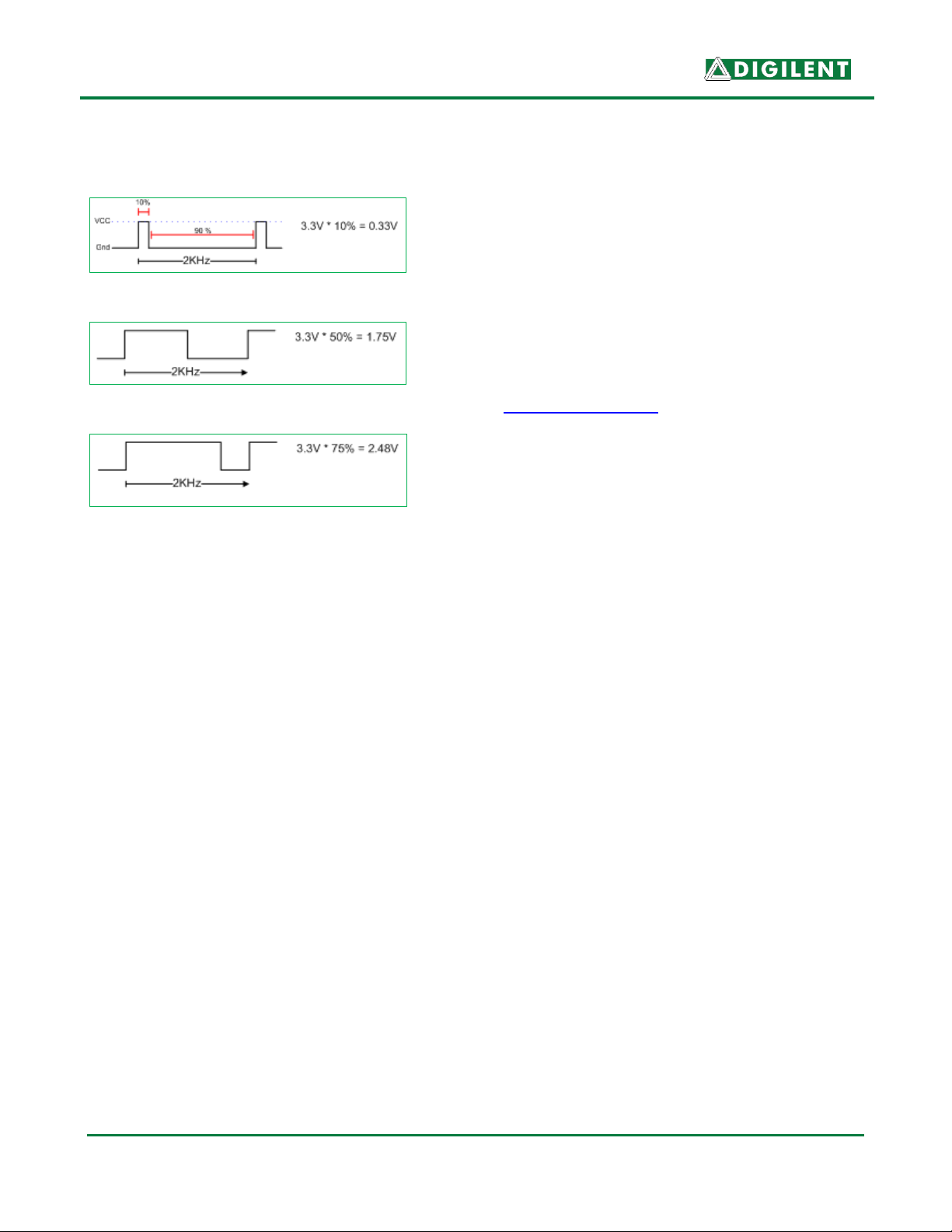

Figures 1 through 3 illustrate a PWM system

with an input frequency of 2KHz. You control

the motor speed by adjusting the time each

wave remains at peak output power. Figure 1

demonstrates a 10% “duty cycle,” where the

signal is logic high for only 1/10 of a

wavelength. This 10% positive peak is equal to

10% of the total 3.3V input, or 0.33V. (See

1 Motor 2 Uses EN1

3 Motor 2 Uses EN2

1 Motor 2 Uses DIR1

3 Motor 2 Uses DIR2

Table 3: Set Jumper Description

www.digilentinc.com Copyright Digilent, Inc. page 2 of 3

Page 3

PmodDHB1™ Reference Manual

Figure 1.) Figures 2 and 3 represent duty

cycles of 50% and 75%.

Figure 1. 10% Duty Cycle

Figure 2. 50% Duty Cycle

Figure 3. 75% Duty Cycle

An H-bridge is a voltage amplification and

direction control circuit. Customers should use

the H-bridge to format the signal to the

appropriate motor voltage and polarity to spin

the motor.

The changing magnetic forces that occur as

you intermittently apply voltage drive the

motor. Even when the voltage stops,

momentum causes the motor to continue

spinning. At a high enough frequency, this

process of powering and coasting enables the

motor to achieve a smooth rotation that can

easily be controlled through digital logic.

PWM has two important effects on DC motors.

PWM overcomes inertial resistance more

easily at startup because short bursts of

maximum voltage achieve a greater degree of

torque than the equivalent DC voltage. PWM

also generates a higher level of heat inside the

motor. If customers use a pulsed motor for an

extended time, they will need heat dissipation

systems to prevent damage to the motor.

Because of these effects, it is best to use PWM

in high-torque infrequent-use applications such

as airplane flap servos and robotics.

www.digilentinc.com

PWM circuits can also create radio frequency

interference (RFI) that operators can minimize

by locating motors near the controller and by

using short wires. You may also need to filter

line noise created by continually powering up

the motor to prevent interference with the rest

of the circuits. You can place small ceramic

capacitors directly across the motor terminals

and between the motor terminals and the

motor case to filter the RFI emissions from the

motor.

Note: For more information on the Pmod

DHB1 see the product page at

www.digilentinc.com.

®

www.digilentinc.com Copyright Digilent, Inc. page 3 of 3

Loading...

Loading...