Page 1

DDiiggiilleenntt PPmmooddHHBB55™

22AA HH--BBrriiddggee RReeffeerreennccee MMaannuuaall

™

®

Revision: February 28, 2012

Note: This document applies to REV D of the board.

Overview

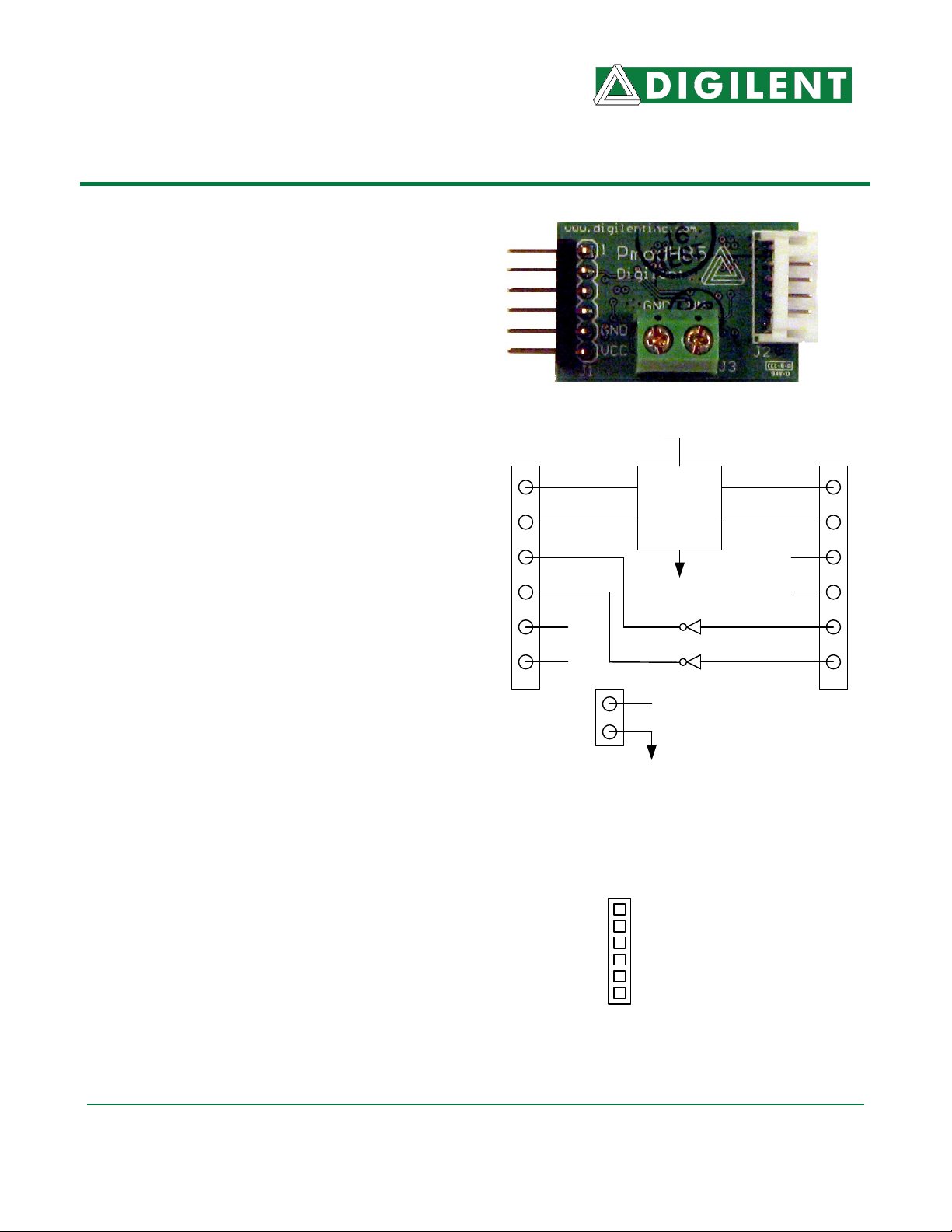

The Digilent PmodHB5TM 2A H-Bridge Module

(the HB5) is an ideal solution for robotics and

other applications where logic signals are used

to drive small to medium-sized DC motors,

such as the Digilent motor-gearbox.

Features include:

• a 2A H-bridge circuit for voltages up to

12V

• a JST 6-pin connector for direct

connection of Digilent motor-gearboxes

• a 2-channel quadrature encoder with

Hall-effect sensors to detect motor

speed

• small form factor (0.8” x 1.30”)

Functional Description

The HB5 works with power supply voltages

from 2.5V to 5V, but is normally operated at

3.3V as this is the supply voltage on most

Digilent system boards.

The HB5 is designed to work with either

Digilent programmable logic system boards or

embedded control system boards. Most

Digilent system boards, such as the Nexys,

Basys, or Cerebot, have 6-pin connectors that

allow the HB5 to plug directly into the system

board or to connect via a Digilent 6-pin cable.

Some older Digilent boards may need a

Digilent Module Interface Board (MIB) and a 6pin cable to connect to the HB5. The MIB plugs

into the system board and the cable connects

the MIB to the HB5.

DIR

EN

SA

SB

GND

VCC

J1 J2

www. d i g i l e n t i n c . c om

215 E Main Suite D | Pullman, WA 99163

(509) 334 6306 Voice and Fax

VM

M+

H-BRIDGE

CIRCUIT

GND

VM

GND

J3

M-

VCC

GND

Motor power is provided via a two-pin terminal

block (J3) that can accommodate up to 18gauge wire. The HB5 circuits can handle motor

voltages up to 12V.

Direction

Enable

Sensor A

Sensor B

GND

Vcc (3.3 - 5v)

HB5 6-Pin Header, J1

Doc: 502-106 page 1 of 3

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 2

PmodHB5 Reference Manual

The HB5 is controlled by a system board

connected to J1. The motor rotation direction is

determined by the logic level on the Direction

pin. Current will flow through the bridge when

the Enable pin is brought high. Motor speed is

controlled by pulse width modulating the

Enable pin. See below for a description of

pulse width modulation. The direction of the

motor should not be reversed while the Enable

pin is active. If the direction is reversed while

the bridge is enabled it is possible to create

brief short circuits across the bridge as one leg

will be turning on while the other leg is turning

off. This could damage the bridge transistors.

Two Schmitt trigger buffered inputs are

provided on connector J2 to facilitate bringing

motor speed feedback signals to the controlling

system board. The Digilent motor/gearboxes

have Hall-effect sensors arranged as a

quadrature encoder. These buffers have 5V

tolerant inputs when operated at 3.3V.

The quadrature encoder signals are a pair of

square waves whose frequency is proportional

to motor rotation speed and which are 90° out

of phase. Motor speed can be determined by

the frequency and motor rotation direction can

be determined by the phase relationship of the

two signals.

Pulse Width Modulation and Motor

Speed Control

In an analog circuit, motor speed is controlled

by varying the input voltage to a circuit. In a

digital circuit, however, only a logic high or

logic low signal can be applied to the motor.

Therefore, there are only two ways to control a

motor digitally: use a variable resistance circuit

to control the motor voltage, or, pulse the

power to the motor. Since variable resistance

circuitry is expensive, complicated, and wastes

much energy in the form of heat, the better

solution is pulse width modulation (PWM).

Digilent, Inc.

www.digilentinc.com

Pulse width modulation is a digital method of

transmitting an analog signal, and while it is

not a clean source of DC output voltage, PWM

suits motors relatively well.

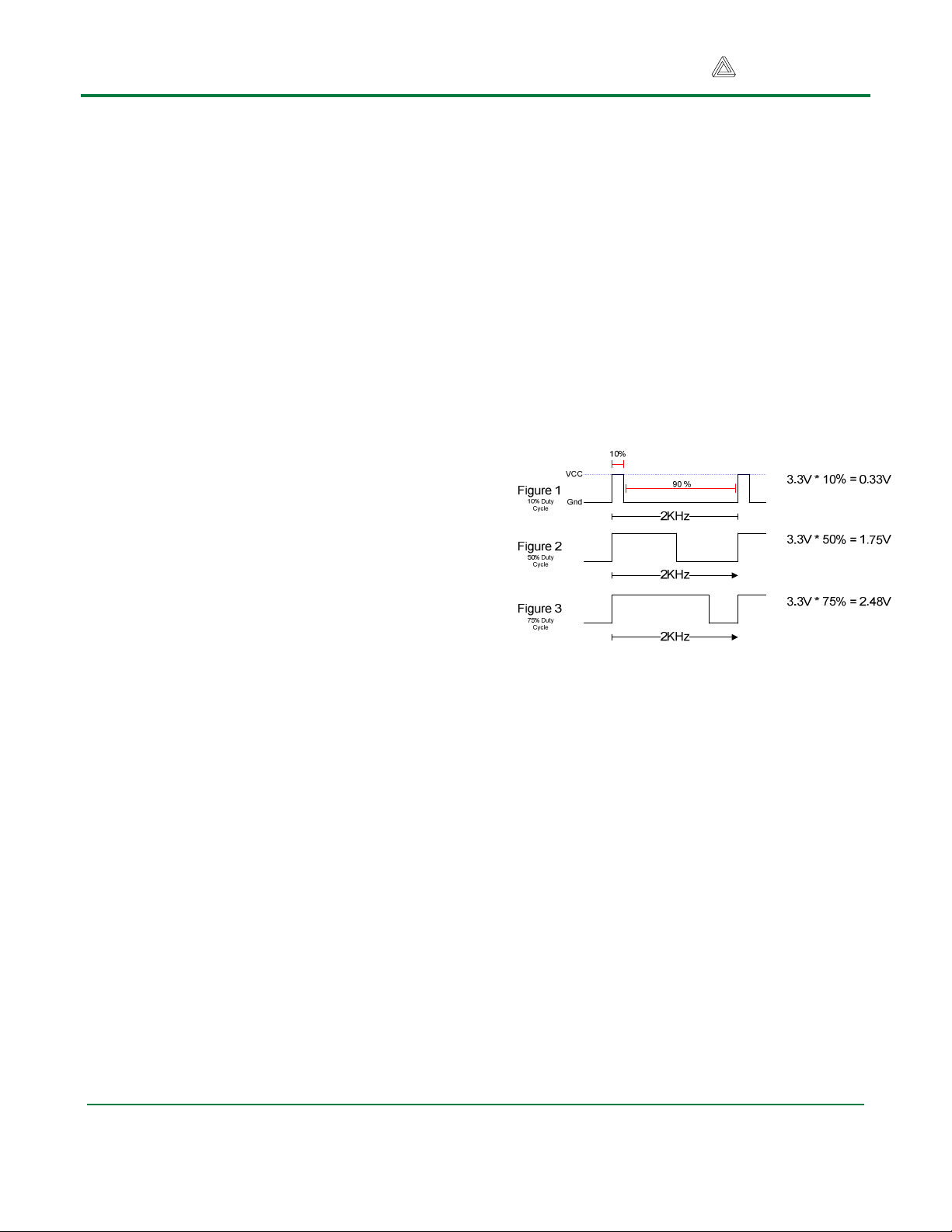

The figures below illustrate a PWM system

with an input frequency of 2KHz. The motor

speed is controlled by adjusting the time each

wave is at peak output power. Figure 1 shows

a 10% “duty cycle” where the signal is logic

high for only 1/10 of a wavelength. This 10%

positive peak is equal to 10% of the total 3.3V

input, or 0.33V (shown in Figure 2). Figures 2

and 3 show duty cycles of 50% and 75%,

respectively.

An H-bridge is a voltage amplification and

direction control circuit that is used to format

the signal to the appropriate motor voltage and

polarity to spin the motor.

While voltage is being applied, the motor is

driven by the changing magnetic forces. When

voltage is stopped, momentum causes the

motor to continue spinning a while. At a high

enough frequency, this process of powering

and coasting enables the motor to achieve a

smooth rotation that can easily be controlled

through digital logic.

PWM has two important effects on DC motors.

Inertial resistance is overcome more easily at

startup because short bursts of maximum

voltage achieve a greater degree of torque

than the equivalent DC voltage. Another effect

is a higher level of heat generation inside the

www.digilentinc.com page 2 of 3

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 3

PmodHB5 Reference Manual

motor. If a pulsed motor is used for an

extended time, heat dissipation systems may

be needed to prevent damage to the motor.

Because of these effects, PWM is best used in

high-torque infrequent-use applications such

as airplane flap servos and robotics.

PWM circuits can also create radio frequency

interference (RFI) that can be minimized by

locating motors near the controller and by

using short wires. Line noise created by

continually powering up the motor may also

need to be filtered to prevent interference with

the rest of the circuits. Placing small ceramic

capacitors directly across the motor terminals

and between the motor terminals and the

motor case can be used to filter RFI emissions

from the motor.

For more information see www.digilentinc.com.

Digilent, Inc.

www.digilentinc.com

www.digilentinc.com page 3 of 3

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Loading...

Loading...