Page 1

VVmmooddCCAAMM™™ RReeffeerreennccee MMaannuuaal

Revision: July 19, 2011

Note: This document applies to REV C of the board.

Overview

The VmodCAM board provides digital imaging

capabilities for any Digilent FPGA system

board with a VHDCI connector. It features two

Aptina MT9D112 2-megapixel CMOS digital

image sensors. The sensors can provide frame

rates from 15 FPS upwards, depending on the

resolution.

Its system-on-a-chip design integrates an

image flow processor and enables selectable

output formats, scaling, and special effects.

The integrated PLL (phase-locked loop) and

microprocessor offer a flexible serial control

interface. The output data is sent on a parallel

bus in processed YCrCb, RGB, or raw Bayer

formats.

Features include:

• two independent Aptina MT9D112 2megapixel CMOS digital image sensors

• 1600x1200 maximum resolution at 15

FPS

• 63mm inter-camera spacing (stereo

baseline)

• 10-bit raw color depth

• I2C control bus

• Bayer, RGB, YCrCb output formats

• automatic exposure, gain, and white

balance

• powerful image correction algorithms

• image scaling

• output FIFO

• 68-pin female VHDCI connector

Functional Description

The two MT9D112 cameras can be controlled

independently and can acquire two separate,

simultaneous image feeds. They are controlled

by a two-wire interface.

l

1300 NE Henley Court, Suite 3

Pullman, WA 99163

(509) 334 6306 Voice | (509) 334 6300 Fax

Each camera has a 2 megapixel color sensor

array in Bayer color filter arrangement. The

sensor readout is 10-bit and supports skipping

or binning rows/columns.

The integrated PLL can generate an internal

clock from the master clock and supports a

wide range of resolutions and frame rates.

The integrated image flow processor applies

correction algorithms to improve image quality.

It can process raw sensor data into RGB or

YCrCb output formats, and crop or scale the

image.

Since some of the processing algorithms

output data in bursts, the parallel output

interface can use a FIFO buffer to provide

constant data rate.

The camera also features a sequencer to

coordinate events triggered by the user.

Operation

The camera systems first need to be properly

configured. This includes not only setting

imaging parameters like resolution or output

format, but PLL configuration and

microprocessor sequencing too. The order in

which these steps are performed is very

important.

Doc: 502-179 page 1 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 2

VmodCAM Reference Manual

First, you must set up the power-up and reset

sequence. Then you need to understand the

control interface in order to configure the

cameras. The following sections describe this

in detail.

Power-Up and Reset Sequence

The VmodCAM should only be attached to the

system board once the signals driven by the

system board are defined.

The camera uses the analog and digital supply

voltage rails provided on-board. The power

supplies are on by default, but can be turned

off, by driving the VDD-EN signal low (see

Table 3.)

The power supplies are used by both cameras.

While the cameras do power-on reset

themselves, it’s always a good idea to do a full

reset as part of the controller routine.

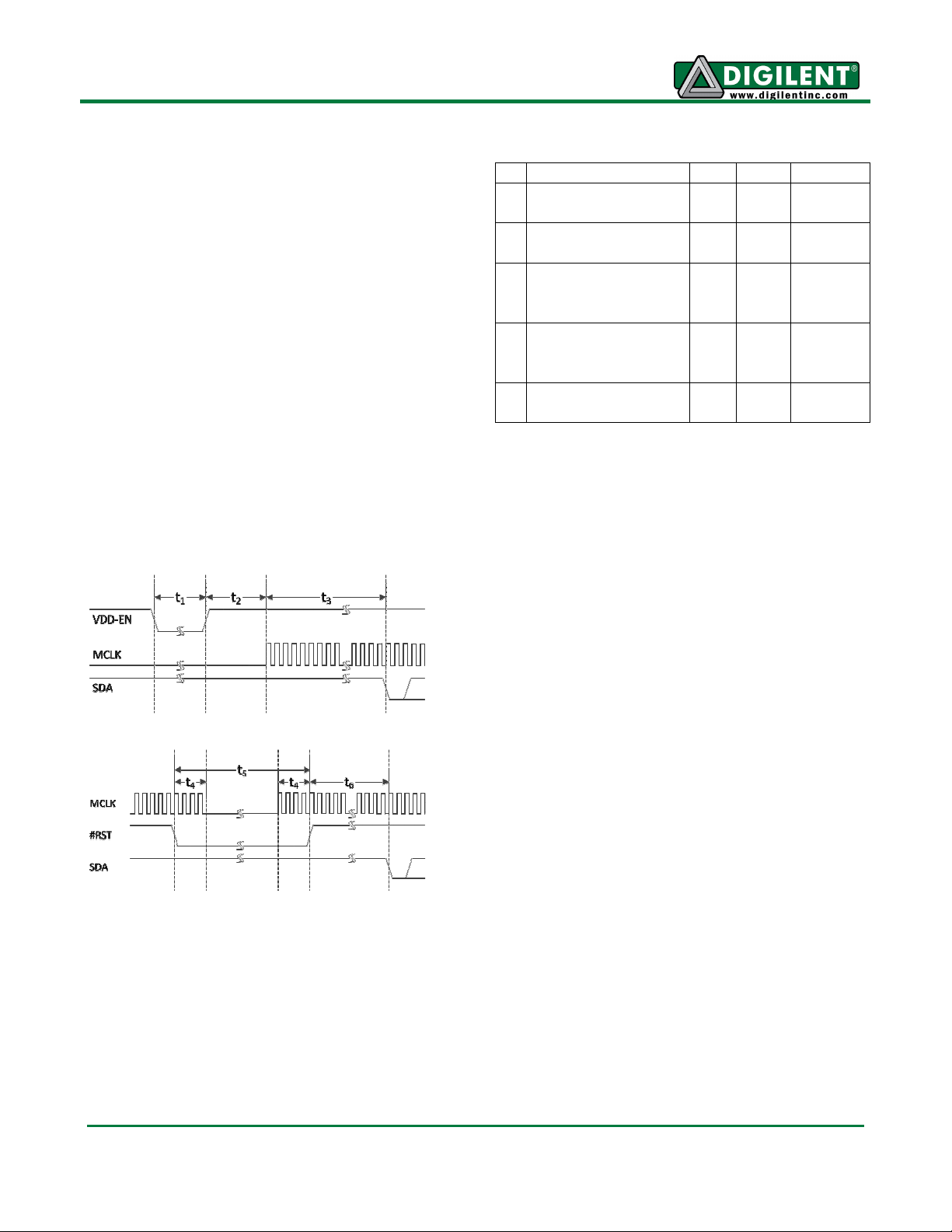

Figure 1 Power-Up Sequence

Figure 2 Reset Sequence

The MCLK is important. If the PLL in the

camera is enabled, MCLK should be stable.

Stopping MCLK without respecting the reset

sequence might leave the camera in an

undefined state. This could be the case when

the FPGA is re-configured. Performing a

power-cycle in the first stages of the controller

is recommended.

Description Min Max Unit

t1 VDD-EN negative

100

ms

pulse width

t2 VDD-EN high to

75 us

first MCLK pulse

t3

ROM read time

t6

until first control

6000 MCLK

cycles

byte

t4 Active MCLK

before/after #RST

10 MCLK

cycles

edge

t5 #RST negative

pulse width

Table 1 Power-Up/Reset Timing

30 MCLK

cycles

Control Interface

The two-wire serial interface (SDA, SCL) can

be used to control various parts of the camera.

The camera acts as a slave device.

A typical register write consists of:

• start condition

• 8-bit device address (0x78 for the

MT9D112) + acknowledge bit

• upper byte of 16-bit register address +

acknowledge bit

• lower byte of register address +

acknowledge bit

• upper byte of the 16-bit data +

acknowledge bit

• lower data byte + acknowledge bit

• stop condition.

www.digilentinc.com page 2 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 3

VmodCAM Reference Manual

A register read consists of:

• start condition

• 8-bit device address (0x78 for the

MT9D112) + acknowledge bit

• upper byte of 16-bit register address +

acknowledge bit

• lower byte of register address +

acknowledge bit

• start condition

• 8-bit device address (0x79 for the

MT9D112) + acknowledge bit

• upper byte of the 16-bit data +

acknowledge bit

• lower data byte + no-acknowledge bit

• stop condition.

There are two types of configuration controls,

hardware registers and driver variables. The

hardware registers usually control the sensor

and some other sub-systems, while the driver

variables sequence the on-chip

microprocessor. These two types of controls

are accessed differently.

Hardware registers are two-wire accessible,

meaning their address can be used directly in

the register address phase of the two-wire

transfer. Hardware registers are referred to by

their address. For example, R[0x3000] refers

to the register located at address 0x3000.

Driver variables can be accessed via two

hardware registers, R[0x338C] and R[0x3390].

To access a variable, its address first needs to

be written to R[0x338C], which is a standard

two-wire register write. Then, reading register

R[0x3390] reads the variable and writes a

value to it, thus setting the variable to that

value. Driver variables are referred to by their

address. For example, V[0x2797] refers to the

driver variable located at address 0x2797.

Configuration

The cameras start up with their registers set to

default values. This also means they are in

standby. To acquire images from the cameras,

both have to be initialized properly. As the

power-on and reset sequences show, the

camera needs certain signals set and a

running MCLK before the two-wire interface is

enabled.

Once the necessary number of MCLK cycles

are provided, the following registers/variables

need to be read/written.

Identify the camera:

To verify that the camera is working, read

R[0x3000] to return 0x1580, which is the

device ID of the camera.

Reset the MCU:

1. R[0x3386] = 0x0501

2. R[0x3386] = 0x0500; release from reset

Set the PLL:

1. R[0x3214] = 0x0D85; this sets the slew

rate of the output pins

2. R[0x341E] = 0x8F0B; power-down and

bypass PLL; if you want to use MCLK

as the pixel clock, skip steps 3-5.

3. R[0x341C][13:8] = N

R[0x341C][7:0] = M;

Where PCLK = MCLK * M / (N+1) / 8.

For example, to obtain a pixel clock of

80MHz (maximum) from an MCLK of

24MHz, set M=80, N=2.

4. R[0x341E] = 0x8F09; power up PLL,

wait 1ms for the PLL to stabilize

5. R[0x341E] = 0x8F08; use PLL clock

instead of MCLK

Wake up from standby:

1. R[0x3202] = 0x0008

Insert image parameters:

You can change the image parameters to suit

your project. See the Image Configuration

Example below to insert an image parameter

configuration sequence.

www.digilentinc.com page 3 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 4

VmodCAM Reference Manual

Enable output:

1. R[0x301A] = 0x02CC; parallel enable,

drive pins, start streaming.

Image Processing

Raw sensor data coming from the pixel array is

fed to a color processing pipeline called an

image flow processor (IFP). This is where all

the image processing, correction, scaling,

interpolation, and output formatting algorithms

are applied.

The IFP can also be bypassed, causing the

camera to output the uncompressed raw 10-bit

Bayer data in this mode.

The IFP is controlled indirectly, through

microprocessor variables and the sequencer.

The IFP can be controlled directly by

accessing its hardware registers, but normally

the on-chip microprocessor regularly adjusts

these parameters.

Output Formats

Mode Byte D7:D0

RGB565 Odd R7R6R5R4R3G7G6G

Even G4G3G2B7B6B5B4B3

RGB555 Odd 0R7R6R5R4R3G7G6

Even G5G4G3B7B6B5B4B3

RGB444x Odd R7R6R5R4G7G6G5G

Even B7B6B5B40000

RGBx444 Odd 0000R7R6R5R4

Even G7G6G5G4B7B6B5B4

YUV 4*i Cb

4*i+1 Y

4*i+2 Cr

4*i+3 Y

Contexts

The microprocessor uses two contexts, each

with their own set of parameters. Context A is

preconfigured for preview mode. Context B is

for snapshot and video capture.

You can set the parameters using the two-wire

interface to command the sequencer to switch

contexts. If the parameters being modified

belong to the active mode, the changes only

take effect after the Refresh and Refresh Mode

commands are executed.

Sequencer

The sequencer is a state machine responsible

for coordinating events triggered by the user.

You can query the current state and instruct

the sequencer to change state.

The sequencer command variable V[0xA103]

accepts the following values:

• 0-Run

• 1-Go to Preview

• 2-Go to Capture

• 3-Go to Standby

• 4-Do lock

• 5-Refresh

• 6-Refresh mode

For the video capture, the Video bit (bit 1)

5

needs to set in variable V[0xA120]. Otherwise,

the capture state will only take a single

snapshot.

4

The sequencer state variable V[0xA104] reads:

• 0-Initialize

• 1-Mode Change to Preview

• 2-Enter Preview

• 3-Preview

• 4-Leave Preview

• 5-Mode Change to Capture

• 6-Enter Capture

• 7-Capture

• 8-Leave Capture

• 9-Standby

www.digilentinc.com page 4 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 5

VmodCAM Reference Manual

0 4

0 4

11

10

0 0

0 0

8

4

3

2

0

Variable Address

Description Context A

Context B Bits

Current Context (0 = A, 1 = B) 0xA702 7:0

Output Width 0x2703

Output Height 0x2705

Sensor Row Start 0x270D

Sensor Row End 0x2711

Sensor Column Start 0x270F

Sensor Column End 0x2713

Read Mode 0x2719

0x2707 15:0

0x2709 15:0

0x272F 15:0

0x2733 15:0

0x2731 15:0

0x2735 15:0

0x273B 15:0

x-bin enable

xy-bin enable

x odd increment 7:5

y odd increment 4:2

vertical flip

(0=normal)

horizontal flip

(0=normal)

Crop X0 0x2751

Crop X1 0x2753

Crop Y0 0x2755

Crop Y1 0x2757

Output format 0x2795

0x275F 15:0

0x2761 15:0

0x2763 15:0

0x2765 15:0

0x2797 15:0

processed Bayer mode

RGB output format

0x0=RGB565

0x1=RGB555

7:6

0x2=RGB444x

0x3=RGBx444

RGB/YUV

0x1=RGB

0x0 = YUV

Use CCIR656 codes when bypassing FIFO

Monochrome output

Progressive Bayer

Swap chrominance/luminance bytes in YUV, swap odd/even bytes in

RGB

Swap Cr/Cb in YUV, swap R/B in RGB

Default

Context A Context

800

600

1213

1613

0x046C

0x0

0x1

0x3

0x3

1

0

0x0

0x0

800

600

0x0000

0x0

0x0

5

0x0

0x0

0x0

0x0

1

0x0

0x0

B

0x0000

1600

1200

1211

1611

0x0024

0x0

0x0

0x1

0x1

0x0

0x0

1600

1200

0x0000

0x0

0x0

0x0

0x0

0x0

0x0

0x0

0x0

Table 2 Image Parameters

www.digilentinc.com page 5 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Page 6

VmodCAM Reference Manual

Image Configuration Example

The following commands can be inserted into

the initialization sequence to configure the

camera for 16-bit RGB565 output and

1600x1200 resolution in video capture mode.

Note that most of these parameters are driver

variables and can be accessed as described in

the

Control Interface section above.

1. V[0x2797] = 0x0030; Context B output

format RGB565

2. V[0x2707] = 0x0640; Output width 1600

3. V[0x2709] = 0x04B0; Output height

1200

4. V[0x275F] = 0x0000; Crop X0 0

5. V[0x2763] = 0x0000; Crop Y0 0

6. V[0x2761] = 0x0640; Crop X1 1600

7. V[0x2765] = 0x04B0; Crop X1 1200

8. V[0x2741] = 0x0169; Auto

exposure/gain fix

9. V[0xA120] = 0x00F2; Auto White

Balance, Auto Exposure, Auto

Histogram, Video On in Capture mode

10. V[0xA103] = 0x0002; Sequencer

Refresh Mode

11. Read V[0xA103] until == 0x0000,

meaning the command got executed.

CAM1 refers to IC2, the camera on the lower

part of the PCB.

CAM2 refers to IC6, the camera on the upper

part of the PCB.

Camera Output Camera Input

VHDCI CAM VHDCI CAM

IO1-P CAM1_D3 IO1-N VDD-EN

IO2-P CAM1_D4 IO2-N CAM1_D2

IO3-P CAM1_D5 IO3-N CAM1_RESET

IO4-P CAM1_D6 IO4-N CAM1_MCLK

IO5-P CAM1_D7 IO5-N CAM1_PWDN

IO6-P CAM1_FV IO6-N CAM1_SCL

IO7-P CAM1_LV IO7-N CAM1_SDA

IO8-P CAM1_D0 IO8-N NC

IO9-P CAM1_D1 IO9-N NC

IO10-P CAM1_PCLK IO10-N NC

IO11-P CAM2_PCLK IO11-N NC

IO12-P CAM2_D2 IO12-N CAM2_PWDN

IO13-P CAM2_D3 IO13-N CAM2_RESET

VHDCI Connector

The VmodCAM should only be attached to the

system board once the signals driven by the

IO14-P CAM2_D4 IO14-N CAM2_MCLK

IO15-P CAM2_D5 IO15-N NC

IO16-P CAM2_D6 IO16-N CAM2_SCL

system board are defined.

IO17-P CAM2_D7 IO17-N CAM2_SDA

IO18-P CAM2_FV IO18-N NC

IO19-P CAM2_LV IO19-N NC

IO20-P CAM2_D0 IO20-N CAM2_D1

Table 3 VHDCI Connector Pin-Out

www.digilentinc.com page 6 of 6

Copyright Digilent, Inc. All rights reserved. Other product and company names mentioned may be trademarks of their respective owners.

Loading...

Loading...