Page 1

Digidesign

888|24 I/O Audio Interface

Installation Guide

Digidesign Inc.

3401-A Hillview Avenue

Palo Alto, CA 94304 USA

tel: 650·842·7900

fax: 650·842·7999

Technical Support (USA)

650·842·6699

650·856·4275

Product Information

650·842·6602

800·333·2137

Fax on Demand

1-888-USE-DIGI (873-3444)

World Wide Web

www.digidesign.com

Digidesign FTP Site

ftp.digidesign.com

Page 2

Copyright

This User’s Guide is copyrighted ©1999 by Digidesign, a

division of Avid Technology, Inc. (hereafter “Digidesign”), with

all rights reserved. Under copyright laws, this manual may not

be duplicated in whole or in part without the written consent of

Digidesign.

DIGIDESIGN, AVID and PRO TOOLS are trademarks or

registered trademarks of Digidesign and/or Avid Technology,

Inc. All other trademarks are the property of their respective

owners.

All features and specifications subject to change without

notice.

PN 932707455-00 REV A 11/99

Communications & Safety Regulation Information

Compliance Statement

The model 888/24 I/O complies with the following standards

regulating interference and EMC:

• FCC Part 15 Class A

• EN55103 – 1, environment E4

• EN55103 – 2, environment E4

• AS/NZS 3548 Class A

• CISPR 22 Class A

Radio and Television Interference

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

Communications Statement

This equipment has been tested to comply with the limits for a

Class A digital device. Changes or modifications to this product

not authorized by Digidesign, Inc., could void the Certification

and negate your authority to operate the product. This product

was tested for CISPR compliance under conditions that

included the use of peripheral devices and shielded cables and

connectors between system components. Digidesign

recommends the use of shielded cables and connectors

between system components to reduce the possibility of

causing interference to radios, television sets, and other

electronic devices.

Safety Statement

This equipment has been tested to comply with USA and

Canadian safety certification in accordance with the

specifications of UL Standards; UL813 and Canadian CSA

standard; CSA C22.2 No.1-M90. Digidesign Inc., has been

authorized to apply the appropriate UL & CUL mark on its

compliant equipment.

Important Safety Instructions

When using electric or electronic equipment, basic precautions

should always be followed, including the following:

• Read all instructions before using this equipment.

• To avoid the risk of shock, keep this equipment away from

rain water, and other moisture. Do not use this equipment

if it is wet.

• The equipment should only be connected to the correct

rating power supply as indicated on the product.

• Do not attempt to service the equipment. There are no

user-serviceable parts inside. Please refer all servicing to

authorized Digidesign personnel.

• Any attempt to service the equipment will expose you to a

risk of electric shock, and will void the manufacturer’s

warranty.

• The product should be connected only to the correct power

supply as indicated on the product.

Page 3

contents

Using the 888/24 I/O

The 888/24 I/O Interface

Changing Operating Levels of Individual 888/24 I/O Channels

Making Signal Connections to the 888/24 I/O

Using the 888/24 I/O Interface as Stand-Alone Audio Converter

Changing the Default Sample Rate of the 888/24 I/O in A/D Stand-Alone Mode

Changing the Default Word Clock Lock Port of the 888/24 I/O in D/A Stand-Alone Mode

Muting the DAC Outputs of the 888/24 I/O in A/D Stand-Alone Mode

Appendix A. Technical Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Appendix B. Calibrating the 888/24 I/O (Pro Tools 5.0)

About Calibration

Calibrating The 888/24 I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix C. Calibrating the 888/24 I/O (Pro Tools 4.x)

About Calibration

Calibrating The 888/24 I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . 9

. . . . 10

. . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . 19

Contents

iii

Page 4

888/24 I/O

iv

Page 5

Using the 888/24 I/O

The 888/24 I/O™ is an 8-channel digital audio interface that features 24-bit analog-todigital, and 24-bit digital-to-analog converters for superior dynamic range, reduced

noise floor, and the capability to work with

the full 24-bit mixing, editing, processing,

and mastering environment of Pro Tools.

The 888/24 I/O can be used in two ways:

As a 24-bit Audio Interface for Pro Tools

◆

As a stand-alone 24-bit audio converter

◆

This User’s Guide explains the indicators

and connectors on the 888/24 I/O. It also

explains how to use it with a Digidesign

Pro Tools

stand-alone 24-bit audio converter in your

studio.

☞

information in this guide is covered in your

Pro Tools TDM Hardware Installation Guide

®

system, or as an independent,

If you own a Pro Tools system, most of the

.

The 888/24 I/O Interface

This section explains each of the connectors and indicators on the front and back

panels of the 888/24 I/O Interface, how

they are used, and offers suggestions for

connecting the 888/24 I/O to your studio.

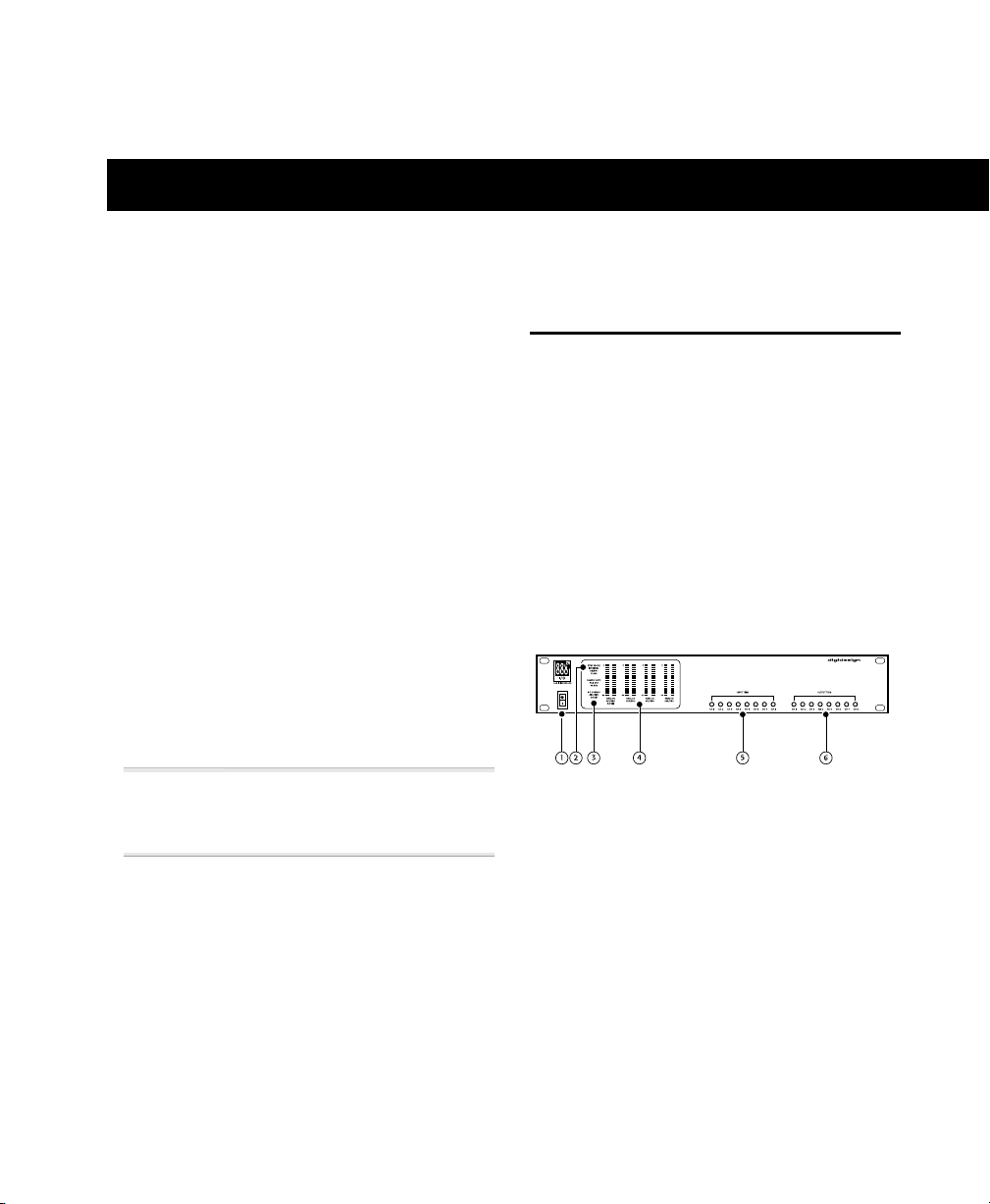

888/24 I/O Front Panel

The 888/24 I/O has the following front

panel indicators, moving from left to right:

Front panel of the 888/24 I/O

1. Power

This switch applies power to the 888/24.

The “I” position is on. The “O” position is

off.

2. Sync Mode

The Sync Mode LEDs indicate which sample rate clock reference is currently used by

the analog-to-digital converters (ADCs)

and the digital-to-analog converters

(DACs).

Using the 888/24 I/O

1

Page 6

Internal

This is the 888/24 I/O standard setting. In this mode, the 888/24 I/O sample

rate is generated by its internal crystal oscillator (whose frequency is determined by

the Sample Rate setting in the Session

Setup window). Internal mode should be

active whenever the 888/24 I/O is not synchronized to an external clock source.

Digital

This setting indicates that an

AES/EBU or S/PDIF word clock signal is currently the source for the 888/24 I/O sample

rate. This is the setting to use for inputting

material from DAT recorders or other digital devices.

To use the 888/24 I/O digital inputs and

outputs as effects sends and returns to digital effects devices, you should set the

888/24 I/O to Internal Sync Mode. You

should then set the digital effects device to

accept an external digital clock (from the

888/24 I/O) so it synchronizes itself to

Pro Tools.

The 888/24 I/O can only synchronize to

and receive word clock lock on channels

1–2 of its digital inputs. To synchronize

your system to an external digital clock

source, it must be connected to digital inputs 1–2 of the 888/24 I/O. In an expanded

Pro Tools system, the system clock is carried by the Audio Interface connected to

the first Pro Tools card in your system. This

Audio Interface will act as the master interface in your system. All other Audio Interfaces will be slaved to it.

▲

Because some digital audio devices do not

output proper clock when they are not playing

back, leaving the 888/24 I/O in Digital Sync

Mode may cause Pro Tools audio playback

quality to suffer, or play back at the wrong

pitch. If you are using digital I/O, reset the

Sync Mode from Digital to Internal after inputting material.

Slave

This LED is lit when the 888/24 I/O

sample rate is synchronized to another

Digidesign Audio Interface or synchronization peripheral. In this mode, the sample

rate of the slave interface is derived from

the frequency of the incoming master

clock signal present at the Slave Clock

(256x) port.

The 888/24 I/O automatically switches to

this mode when a Slave Clock Out signal

from another Digidesign Interface, Universal Slave Driver, Video Slave Driver, or

SMPTE Slave Driver is connected to the

888/24 I/O Slave Clock In port.

In expanded Pro Tools systems, the Super

Clock output of the master Audio Interface

locks all other interfaces together with

sample accuracy, keeping all signals phasesynchronous.

✽

When slaving to a Digidesign Universal

Slave Driver, Video Slave Driver, or SMPTE

Slave Driver, set the clock source to Internal.

The Audio Interface will automatically switch to

Slave mode when it detects the 256x input

clock.

888/24 I/O

2

Page 7

3. Sample Rate and 1–2 Format Indicators

These LEDs indicate the sample rate of the

888/24 I/O internal crystal oscillator and

the digital format (AES/EBU or S/PDIF) of

the audio input signal to channels 1 and 2.

The choice of digital format for these two

channels is made in the Session Setup window or Hardware Setup dialog. Digital input pairs 3–4, 5–6, and 7–8 of the

888/24 I/O are always AES/EBU. Sample

Rate is set in the Session Setup window or

Hardware dialog in Pro Tools.

The 888/24 I/O provides the following

sample rates:

48 kHz

many professional audio devices. It is recommended for use with devices that cannot receive digital transfers at 44.1 kHz.

44.1 kHz

sampling rate and the Pro Tools default

sample rate. To avoid the need for sample

rate conversion, you should use this rate

when you are recording material that will

ultimately be published on a compact disc.

▲

source such as a DAT recorder, the front panel

of the 888/24 I/O indicates only the internal

oscillator sample rate, not that of the external

digital source.

This is a standard sampling rate of

This is the compact disc standard

When you are using an external digital

4. Level Meters

The 888/24 I/O level meters monitor the

channel outputs of Pro Tools. Input levels

are monitored on-screen in the Pro Tools

software.

The 888/24 I/O is factory calibrated so that

a meter reading of –18 dB corresponds to

the 888/24 I/O nominal operating level

(which can be set to either +4 dBu or

–10 dBV). If you sent the output to an analog device with a VU meter, this would correspond to “0 VU” on the VU meter.

The red LED indicators on the Audio Interface indicate both full-code (highest level

before clipping) and clipping of Pro Tools

output signals. The on-screen meters in

Pro Tools software indicate clipping when

at least three consecutive full-code samples

follow each other.

5. Input Level Trims

The 888/24 I/O analog inputs are factory

calibrated at a –18 dB nominal level, referenced to a full code signal. This means at

the nominal reference input level (either

+4 dBu or –10 dBV), you have 18 dB of

headroom before clipping. The input level

trim pots allow adjustment of the

888/24 I/O input levels to match the operating level of your external equipment. Adjustments can be made with a Phillips

screwdriver.

6. Output Level Trims

The 888/24 I/O analog outputs are factory

calibrated at a –18 dB nominal level, referenced to a full code signal. This means at

the nominal reference output level (either

+4 dBu or –10 dBV), you have 18 dB of

headroom before clipping. The output

level trim pots allow adjustment of the

888/24 I/O output levels to match the operating level of your external equipment.

Adjustments can be made with a Phillips

screwdriver.

Using the 888/24 I/O

3

Page 8

To calibrate the input and output levels of

the 888/24 I/O to match your mixing console or other devices in your studio, use

Calibration Tool (for Pro Tools 4.3.1 and

earlier) or use Calibration Mode and the

Signal Generator Plug-In (for Pro Tools 5.0

or later).

pair is disabled when digital input format is

chosen for that channel.

The 888/24 I/O analog audio connectors

are balanced XLRs with pin 2 wired hot,

(or “+”); pin 3 cold, (or “–”); and pin 1

ground.

☞

Instructions for calibrating the 888/24 I/O

appear in Appendix B of this Guide.

888/24 I/O Back Panel

The 888/24 I/O has the following back

panel connectors, moving from left to

right:

Back panel of the 888/24 I/O

1. Analog Audio Outputs

These are balanced male XLR connectors

for analog audio output connections. All

eight output channels are continuously active. The 888/24 I/O analog outputs feature

24-bit digital-to-analog converters.

2. Analog Audio Inputs

These are balanced female XLR connectors

for analog audio input connections. The

888/24 I/O analog inputs feature 24-bit analog-to-digital converters. Because input

channels 1–8 of the 888/24 I/O are software selectable in pairs between analog or

digital format, analog input to a channel

3. AES/EBU Digital Outputs 1–8

The 888/24 I/O AES/EBU output jacks are

balanced, three conductor, XLR connectors

which output a 24-bit digital data stream.

Output is continuously active on both the

AES/EBU and S/PDIF jacks even when the

888/24 I/O input selector is set to analog.

4. AES/EBU Digital Inputs 1–8

The AES/EBU digital format is used in

many professional digital audio devices, including some DAT recorders. The Interface’s AES/EBU input jacks are balanced,

three conductor, XLR connectors which accept a full 24-bit digital data stream.

For AES/EBU connections, 110-ohm cables

are highly recommended for use in professional installations. For best results, cable

lengths should not exceed 30 meters.

Input channels 1–8 of the 888/24 I/O are

software-selectable in pairs between analog

or digital format. Digital input to a channel

pair is disabled when analog input format

is chosen for that channel in the Hardware

Setup dialog. Input to AES/EBU input channels 1–2 is disabled when S/PDIF digital format is chosen for these inputs in the

Pro Tools Session Setup window.

888/24 I/O

4

Page 9

5. 50-pin Interface Connector

7/9. Slave Clock In/Out

This 50-pin Computer connector is used to

connect the 888/24 I/O to a MIX card, d24

audio card, Disk I/O card, or a DSP Farm

card. The necessary cable is supplied with

your Audio Interface. If you plan to connect two 888/24 I/O Interfaces to a MIX

card or d24 card, a 16-channel peripheral

cable adapter is necessary. (This cable is

available from your Digidesign dealer.)

6. S/PDIF Digital Input/Output

The Sony Phillips Digital Interface Format

(S/PDIF) is used in many professional and

consumer CD players and DAT recorders.

The 888/24 I/O S/PDIF in/out jacks are unbalanced 2-conductor phono (RCA) jacks

which utilize a full 24-bit digital data

stream. To avoid RF interference, use 75ohm coaxial cable for S/PDIF transfers and

keep the cable length to a maximum of 10

meters.

Because input channels 1–2 of the

888/24 I/O are software selectable between

analog or digital format, input to these two

digital channels is disabled when analog

input is chosen or when AES/EBU digital

format is chosen in the Pro Tools Session

Setup window. Output is continuously active on both the AES/EBU and S/PDIF output jacks, regardless of which digital input

format is selected for channels 1–2. To

avoid RF interference, use 75-ohm coaxial

cable for S/PDIF transfers and do not exceed a cable length of 10 meters.

The Slave Clock Out jack is a standard BNC

type connector that outputs a 256 times

sample rate Super Clock signal for slaving

and synchronizing multiple Digidesign Interfaces and synchronization peripherals

together.

When the 888/24 I/O Sync Mode is set to

Internal, connecting a valid Slave Clock

Out signal to this port will cause the

888/24 I/O to automatically switch to Slave

mode. When the 888/24 I/O is the master

interface or the first interface in a chain,

Digital sync mode overrides the Slave

Clock input, and an incoming Slave Clock

Out signal will not switch the 888/24 I/O

to Slave mode.

Because crucial timing data is passed over

these ports, you should use high-quality,

75-ohm RG-59 cables for making connections, and keep total cable length to less

than 3 meters between interfaces.

8. Power Input

This connector accepts a standard AC

power cable. The Interface is auto powerselecting (100V to 240V) and will automatically work with a standard modular cable

to connect to AC power receptacles in any

country.

Using the 888/24 I/O

5

Page 10

Changing Operating Levels

of Individual 888/24 I/O

Channels

The 888/24 I/O is factory set to +4 dBu operating levels for input and output. However, the 888/24 I/O allows you to individually switch any of its analog inputs or

outputs to either a +4 dBu or –10 dBV operating level by moving internal jumpers on

its circuit board.

output level

adjustment switches

+4 dBu or -10 dBV

input level

adjustment switches

+4 dBu or -10 dBV

The location of input and output level switches inside

the 888/24 I/O

To change the operating level of an input

channel:

1

Turn off your computer and the

888/24 I/O.

2

With a Phillips screwdriver, remove the

screws from the top of the 888/24 I/O.

3

Using the 1/16-inch hex wrench included with the 888/24 I/O, carefully remove the front four panel screws as noted

on the bag containing the hex wrench.

4

Lift the top off of the 888/24 I/O.

5

Inside the 888/24 I/O chassis, next to

each of the channel input trims, there is a

jumper switch with a removable cap. Lo-

cate the jumper switch for the channel you

wish to modify. Gently lift the cap off the

3-pronged connector. Place it in the position corresponding to the operating level

that you desire. For +4 dBu levels, it should

be placed over the rear two prongs. For

–10 dBV levels, it should be placed over the

front two prongs.

6

After you have made the desired changes,

replace the top of the 888/24 I/O.

7

Replace the four front panel screws using

the hex wrench.

8

Replace the top screws with a Phillips

screwdriver.

pull off jumper

-10

+4

-10

+4

-10

+4

Setting the input level jumper switches

place jumper

in this position

to set input

to +4 dBu level

place jumper

in this position

to set input

to -10 dBV level

To change the operating level of an output

channel:

1

Turn off your computer and the

888/24 I/O.

2

Using the 1/16-inch hex wrench included with the 888/24 I/O, carefully remove the front four panel screws as noted

on the bag containing the hex wrench.

3

With a Phillips screwdriver, remove the

screws from the top of the 888/24 I/O and

lift the top off of the 888/24 I/O.

4

To find the channel output switches, detach the front part of the ribbon cable at

the right side of the chassis. To do this, grip

both sides of the black connector and gently pull up.

888/24 I/O

6

Page 11

5

With the ribbon cable out of the way

you’ll see eight 3-pronged jumper switches,

each with a removable cap. Locate the

switch for the channel you wish to modify.

Making Signal Connections

to the 888/24 I/O

Depending on how you plan to use the

888/24 I/O, the way you connect it to your

studio will vary.

remove jumper

0

-1

4

+

place jumper

in this position

to set output

to +4 dBu level

place jumper

in this position

to set output

to -10 dBV level

detach

ribbon cable

Setting the output level jumper switches

6

Gently lift the cap off of the jumper

switch. Place it in the position corresponding to the operating level that you desire.

For +4 dBu levels, it should be placed over

the left two prongs. For –10 dBV levels, it

should be placed over the right two prongs.

7

After you have made the desired changes,

reconnect the ribbon cable and put the top

back on the 888/24 I/O.

8

Replace the four front panel screws using

the hex wrench.

9

Replace the top screws with a Phillips

screwdriver.

Choosing between +4 dBu and

–10 dBV operation modes

The 888/24 I/O can be set to operate at

+4 dBu or –10 dBV input and output levels.

It is important that you determine which

line level mode is appropriate for your studio. In +4 dBu operating mode, the

888/24 I/O is a 24-bit digital audio device

capable of producing audio signals at or

near +26 dBu.

Check the owner’s manual for your mixer,

power amplifier or effects processor to see if

it can handle this load. If it cannot, consider setting the 888/24 I/O to operate at

–10 dBV line levels.

Consider the following when connecting a

mixer:

◆

If your mixer cannot handle more than

1.5V (RMS) inputs at +4 dBu, then you

should set the 888/24 I/O to run at –10 dBV

line level.

◆

If your mixer can handle up to 8.5V

(RMS) inputs, or has pads or attenuators on

its inputs, then you can use the +4 dBu setting on the 888/24 I/O.

Most manuals contain device input specifications, including whether or not there are

pads or attenuators. Consult the manufacturer of your mixer or power amplifier for

further information.

Using the 888/24 I/O

7

Page 12

Setting Up Your Studio

The following diagram illustrates a typical

studio setup, with the 888/24 I/O connected to a mixing console, effects and

other equipment.

Digital Inputs/Outputs

Channel 3-4

To Digital Effects Devices

1

uter

mp

Co

Analog

Audio

Outputs 5-8

Tape Returns

or Inputs 1-4

2

1/

T

6

5/

U INPU

AES/EB

3/4

1/2

/8

7

D

6

P

/

5/

S

OUTPUT

F

I

D

P

/

S

U

ES/EBU

O

A

3/4

N

I

1

7/8

3

T

2

5

G INPU

ANALO

4

7

6

1

8

3

UT

2

5

G OUTP

ANALO

4

7

6

8

Analog

Audio

Inputs 5-8

Channel

Outputs 1-4

Digital Inputs/Outputs

To DAT Recorder

K

C

O

L

C

E

V

A

L

S

K

T

C

U

O

O

L

C

E

V

A

L

S

N

I

F

I

T

Channel 1-2

Effects Devices

Digital Effects Devices

(set to external sync)

DAT Recorder

Using the 888/24 I/O

Interface as Stand-Alone

Audio Converter

The 888/24 I/O can be used apart from

Pro Tools as a stand-alone 8-channel, 24bit, analog-to-digital or digital-to-analog

converter.

Before you use the 888/24 I/O in standalone mode:

1

Turn off the 888/24 I/O.

2

Do not turn on your computer while the

888/24 I/O is in stand-alone mode. If you

do, the 888/24 I/O will stop functioning in

stand-alone mode.

Instruments

Connected to Console

Power Amp

and Speakers

A typical studio configuration

The 888/24 I/O analog audio connectors

are balanced XLRs with pin 2 wired hot

(or “+”), pin 3 cold (or “–”), and pin 1

ground.

If you are connecting a balanced system,

pin 1 and shield should be connected at

the input only (not at the output). This will

prevent ground loops between the shield

and pin 1 conductor.

If you are connecting an unbalanced signal

to the 888/24 I/O inputs or outputs, connect only pin 2 to the “+” signal, and pins

1 and 3 to ground at all inputs only.

To use the 888/24 I/O as a stand alone A/D

converter:

1

Turn off any digital devices that may

send a word clock signal to the 888/24 I/O

channel 1–2 digital input ports.

2

Turn on the 888/24 I/O. The 888/24 I/O

searches briefly for a word clock signal on

channels 1–2 of its digital input ports.

3

If the 888/24 I/O does not detect word

clock, it functions as a stand-alone A/D

converter using its internal clock. In this

mode you will use analog inputs 1–8 and

AES/EBU outputs 1–8.

✽

The default sample rate of the 888/24 I/O

in stand alone A/D mode is 44.1 kHz.To

change this default setting to 48 kHz, you

must open the 888/24 I/O and manually reset it by moving an internal jumper switch. See

“Changing the Default Sample Rate of the

888/24 I/O in A/D Stand-Alone Mode” on

page 9.

888/24 I/O

8

Page 13

To use the 888/24 I/O as a stand alone D/A

converter:

1

Make sure that a digital device providing

a word clock signal is connected to

AES/EBU inputs 1–2 of the 888/24 I/O and

turned on.

2

Turn on the 888/24 I/O. The 888/24 I/O

will search for a valid word clock or a word

clock signal on channels 1–2 of its digital

input ports.

3

When a valid word clock lock is recognized, the 888/24 I/O will enter digital

sync mode and function as a stand-alone

D/A converter using AES/EBU inputs 1–8

and analog outputs 1–8.

The 888/24 I/O D/A sample rate is determined by the sample rate it detects on

channels 1–2 of its AES/EBU inputs.

✽

The 888/24 I/O defaults to listening to a

digital word clock signal on channels 1–2 of its

AES/EBU digital input ports. To use a S/PDIF

device as your source of word clock, you must

reset this default by opening the 888/24 I/O

and moving an internal jumper switch. See

“Changing the Default Word Clock Lock Port of

the 888/24 I/O in D/A Stand-Alone Mode” on

page 10.

To return the 888/24 I/O to Pro Tools-based

operation:

◆

Turn on your computer.

– or –

◆

If your computer is on, launch Pro Tools.

Changing the Default

Sample Rate of the

888/24 I/O in A/D StandAlone Mode

The default sample rate of the 888/24 I/O

in stand alone A/D mode is 44.1kHz. If you

wish to change this default setting to

48 kHz, you must open the 888/24 I/O and

manually reset it by moving an internal

jumper switch.

To change the default sample rate of the

888/24 I/O in stand alone A/D mode:

1

Make sure that your computer and

888/24 I/O are turned off.

2

With a Phillips screwdriver, remove the

screws from the top of the 888/24 I/O.

3

Using the 1/16 inch hex wrench included with the 888/24 I/O, carefully remove the front four panel screws as noted

on the bag containing the hex wrench.

4

Lift the top off of the 888/24 I/O.

5

Inside the left-front of 888/24 I/O’s chassis, near the large FPGA chip, is a set of

three jumper switches, each with a removable cap. Each of these switches controls a

different default function which is shown

in Figure 1 and 2.

6

Locate the jumper switch for the default

that you wish to modify and gently lift the

cap off the 3-pronged connector.

7

Place it in the position corresponding to

the value that you desire. For a 44.1 kHz default sample rate, it should be placed over

the right two prongs. For a 48 kHz default

sample rate, it should be placed over the

left two prongs. Refer to Figure 1 and 2 for

details.

Using the 888/24 I/O

9

Page 14

8

After you have made the desired changes,

replace the top of the 888/24 I/O.

9

Replace the four front panel screws using

the hex wrench.

10

Replace the top screws with a Phillips

screwdriver.

stand alone mode

default word clock lock switches

AES/EBU or S/PDIF

stand alone mode

DAC muting switches

stand alone mode

default sample rate switches

44.1 kHz or 48 kHz

Figure 1. jumper switch location in the 888/24 I/O

Changing the Default Word

Clock Lock Port of the

888/24 I/O in D/A StandAlone Mode

The 888/24 I/O defaults to “listening” to a

digital word clock signal on channels 1-2 of

its AES/EBU digital input ports. If you wish

to use a S/PDIF device as your source of

word clock, you must reset this default by

opening the 888/24 I/O and moving an internal jumper switch so that channels 1-2

of its S/PDIF digital input ports are used instead.

remove jumper and

place it in desired position

U

B

E

/

S

E

A

IF

D

P

/

S

in this position

DACs are muted

s

C

A

D

te

u

m

z

H

k

8

4

s

C

A

D

te

u

m

n

u

in this position

44.1 kHz is selected

z

H

k

.1

4

4

Figure 2. Changing jumper switch settings

☞

Refer to Figure 1 and 2 for details on jumper

switches and their default positions.

To change the default word clock lock port of

the 888/24 I/O in stand alone D/A mode:

1

Make sure that your computer and

888/24 I/O are turned off.

2

With a Phillips screwdriver, remove the

screws from the top of the 888/24 I/O.

3

Using the 1/16 inch hex wrench included with the 888/24 I/O, carefully remove the front four panel screws as noted

on the bag containing the hex wrench.

4

Lift the top off of the 888/24 I/O.

5

Inside the left-front of 888/24 I/O’s chassis, near the large FPGA chip, is a set of

three jumper switches, each with a removable cap. Each of these switches controls a

different default function which is shown

in Figure 1 and 2.

6

Locate the jumper switch for the word

clock lock default (the back-most jumper)

and gently lift the cap off the 3-pronged

connector.

888/24 I/O

10

Page 15

7 Place it in the position corresponding to

the value that you desire. For an AES/EBU

word clock lock port, it should be placed

over the right two prongs. For a S/PDIF

word clock lock port, it should be placed

over the left two prongs. Refer to Figure 1

and 2 for details.

8 After you have made the desired changes,

replace the top of the 888/24 I/O.

9 Replace the four front panel screws using

the hex wrench.

10 Replace the top screws with a Phillips

screwdriver.

Muting the DAC Outputs of

the 888/24 I/O in A/D

Stand-Alone Mode

In certain cases, you may wish to mute the

888/24 I/O’s D/A converters when in A/D

stand-alone mode. This is useful if, for example, you need to eliminate potential external analog feedback through a console.

To do this, you must open the 888/24 I/O

and move an internal jumper switch so

that the DACs are muted during standalone operation.

3 Using the 1/16 inch hex wrench in-

cluded with the 888/24 I/O, carefully remove the front four panel screws as noted

on the bag containing the hex wrench.

4 Lift the top off of the 888/24 I/O.

5 Inside the left-front of 888/24 I/O’s chas-

sis, near the large FPGA chip, is a set of

three jumper switches, each with a removable cap. Each of these switches controls a

different default function as shown in Figure 1 and 2.

6 Locate the jumper switch for the DAC

muting default (the middle jumper) and

gently lift the cap off the 3-pronged connector.

7 Place it in the position corresponding to

the value that you desire. To mute the

DACs, it should be placed over the left two

prongs. To unmute the DACs (as in normal

operation), it should be placed over the

right two prongs. Refer to Figure 1 and 2 for

details.

8 After you have made the desired changes,

replace the top of the 888/24 I/O.

9 Replace the four front panel screws using

the hex wrench.

10 Replace the top screws with a Phillips

screwdriver.

☞ Refer to Figure 1 and 2 for details on jumper

switches and their default positions.

To change the DAC output mute setting of the

888/24 I/O in stand-alone D/A mode:

1 Make sure that your computer and

888/24 I/O are turned off.

2 With a Phillips screwdriver, remove the

screws from the top of the 888/24 I/O.

Using the 888/24 I/O

11

Page 16

888/24 I/O12

Page 17

appendix a

Technical Specifications

General

Analog Inputs/Outputs:

■ Actively balanced XLR connectors,

outputs internally switchable between

+4 dBu and –10 dBV line levels

Analog Level Trimming:

■ Accessible from front panel

Digital I/O AES/EBU:

■ 8 channel; balanced XLR connectors

Digital I/O S/PDIF:

■ 2 channel; coaxial RCA connectors

Sample Rate:

44.1 kHz or 48 kHz, ±10ppm

Clock Reference:

■ Super Clock (256x) sample clock In/Out;

BNC connectors; additional clock references supported via Digidesign's Universal

Slave Driver, SMPTE Slave Driver, Video

Slave Driver and other optional synchronizers

A/D Specifications

SNR (signal-to-noise ratio):

■ ≥ 113 dB (balanced, A-weighted)

■ ≥ 110 dB (unweighted)

THD:

■ 0.003% –0.01 dB @ 1kHz; 20 Hz-20 kHz

(band-limited)

Maximum Input Level:

■ +26dB

Frequency Response:

■ ±1 dB, 20 Hz–20 kHz

Clock jitter:

■ < 40pS RMS 22Hz-22kHz BW

Nominal Operating Level:

■ +4dBu; factory calibrated at –18dB

headroom

Appendix A: Technical Specifications 13

Page 18

D/A Specifications

SNR (signal-to-noise ratio):

■ ≥ 110 dB (balanced, A-weighted)

■ ≥ 107 dB (unweighted)

THD:

■ 0.003% –0.01dB @ 1kHz; 20 Hz- 20 kHz

(band-limited)

Maximum Output Level:

■ +26 dB/channel (bridging loads)

Frequency Response:

■ ±1dB, 20 Hz–20 kHz

Physical Specifications

Power requirements:

■ 90–260 VAC, 47 63 Hz; 30 VA;

auto-switching

Weight:

■ 7.6 lbs (4.1 kg)

Dimensions:

■ 2U external rackmount device

19" x 3.5" x 9.75"

(48.26 cm x 8.89 cm x 24.77 cm)

888/24 I/O14

Page 19

appendix b

Calibrating the 888/24 I/O (Pro Tools 5.0)

Before you use the 888/24/I/O Audio Interface, you may want to calibrate its input

and output levels to the level of your mixing console.

The 888/24 I/O is factory-calibrated so that

its input operating level is set to +4 dB

nominal with 18 dB headroom nominal at

full code, unity gain, making calibration

unnecessary for most professional applications.

If you do need to recalibrate your interface

or other components of your studio, you

can use the alignment procedure described

here.

About Calibration

Calibrating levels on a digital recording device is different from calibrating levels on

an analog recording device. Unlike analog

devices, most digital devices do not have a

standard “0 VU” level setting that corresponds to nominal input and output levels.

Instead, with an interface such as the

888/24 I/O, the meters are calibrated in

decibels below peak (digital clipping) level.

Headroom

The concept of headroom is slightly different for analog and digital devices.

Analog Most analog devices allow for a cer-

tain amount of headroom above 0 VU. If

you send a signal above the 0 VU level to

an analog recorder, you still have a margin

of headroom, and if tape saturation occurs,

it does so fairly gracefully, giving the audio

a compressed sound that some find desirable.

Digital Digital devices, on the other hand,

do not allow for signals that exceed the dynamic range of the input. When a signal

exceeds the maximum input level for a digital device, clipping occurs, causing digital

distortion, which is harsh and usually undesirable.

The 888/24 I/O provides an industry standard headroom of 18 dB. The exact value

you use will be determined by the amount

of headroom available in the rest of your

system. For example, if your mixing console has 15 dB of headroom above nominal

level, then you may want to calibrate the

888/24 I/O to have 15 dB of headroom.

Appendix B: Calibrating the 888/24 I/O (Pro Tools 5.0) 15

Page 20

The Calibration Process

Analog To calibrate the input level of an an-

alog device to a mixing console’s output

level, you would typically send a 1 kHz

tone at 0 VU from the console to the analog deck and align the recording deck’s

meters to read 0 VU.

ups. You can use these in addition to the

calibration procedure given below.

▲ Turn down your monitoring system before

beginning calibration. The Signal Generator

Plug-In emits a continuous signal when inserted on a track.

Digital With a digital recording device such

as the 888/24 I/O, however, in order to allow for headroom, you must align a 0 VU

tone from the console to a value less than

zero on the 888/24 I/O, by exactly the

amount of headroom that you want.

For example, to have 12 dB of headroom

above 0 VU with the 888/24 I/O, you must

align the incoming 0 VU 1kHz tone to a

level of –12 dB. For 18 dB of headroom,

you would align it to –18 dB. (Since it is assumed that you are using the 888/24 I/O

with a +4 dBu console, a 0 VU signal level

coming out of the console is actually equivalent to a nominal +4 dBu level signal.)

Calibrating The 888/24 I/O

If you are using Pro Tools 5.0 or later, you

can put Pro Tools software in a special operating mode called calibration mode, then

use the Signal Generator Plug-In to generate a test tone for calibration of the

888/24 I/O.

If you are using Pro Tools 4.3.1 or earlier,

refer to Appendix C: Calibrating the

888/24 I/O (Pro Tools 4.x) for calibration instructions.

The Pro Tools Installer includes several preconfigured calibration session templates

that cover most common calibration set-

✽ During calibration, set all Pro Tools track

faders to their default of 0 dB by Option-Shiftclicking (Macintosh) or Alt-Shift-clicking (Windows) on any fader in the session.

To calibrate the 888/24 I/0:

1 In Pro Tools, choose Setups > Preferences

and click Operation.

2 Under Output Options, select Direct Out-

puts.

3 At the bottom of the Operation Prefer-

ences dialog, enter a Calibration Reference

Level value (a level of –18 dB is typical).

4 Click Done.

5 Create a new audio track and insert the

Signal Generator Plug-In on the track.

6 Set Signal Generator’s output level. This

should be the same value you entered as

the Calibration Reference Level in step 3.

7 Set Signal Generator’s frequency to

1000 Hz.

8 Set Signal Generator’s signal waveform to

Sine.

9 Route the track’s output to Bus 1.

10 Create a mono auxiliary input track for

each 888/24 I/O output you want to calibrate. Set the output assignment for each of

these auxiliary inputs to its respective

888/24 I/O output.

11 Set the input of each auxiliary input

track to Bus 1.

888/24 I/O16

Page 21

12 Create an additional mono auxiliary in-

put track for each 888/24 I/O input you

want to calibrate. Set the input assignment

for each of these auxiliary inputs to its respective 888/24 I/O input. Then set the

output of each of these auxiliary inputs to

an unused bus pair (for example bus 31–32)

so that feedback doesn’t occur when monitoring main outputs 1–2.

13 Connect an external VU meter to each

of the 888/24 I/O outputs in turn. (One at a

time as you calibrate.)

14 Adjust the 888/24 I/O output level trim

pots with a Phillips screwdriver to align the

outputs to read “0 VU” on the external VU

meter.

15 Connect each output of the 888/24 I/O

directly to its input: Connect channel 1

output to channel 1 input, and so on for

each channel.

16 In Pro Tools, choose Operations > Cali-

bration Mode.

The names of all uncalibrated tracks begin

to flash. In addition, the track volume indicator of each auxiliary input track receiving

an external input signal now displays the

reference level coming from the calibrated

output.

17 Adjust the 888/24 I/O input level trim

pots with a Phillips screwdriver to align the

inputs to match the reference level. When

the level is properly matched, the track

name will stop flashing.

The Automatch indicator arrows on each

track show the direction of adjustment required for alignment:

◆ When the incoming level is higher than

the reference level, the down arrow will appear lit (blue). In this case, trim the

888/24 I/O input level down.

◆ When the incoming level is lower than

the reference level the up arrow will appear

lit (red). In this case, trim the 888/24 I/O

input level up.

When you have properly aligned the incoming peak signal levels to match the calibration reference level, both Automatch

indicator arrows will light: the up arrow red

and the down arrow blue.

18 When you have finished, choose Oper-

ations > Calibration Mode again to deselect

Calibration Mode.

Calibrating a System With Both

888/24 I/O and 882/20 I/O

Audio Interfaces

The 888/24 I/O is factory preset with 18 dB

of headroom in its +4 dB line level operating mode. The 882/20 I/O, however, is

fixed at 14 dB of headroom and its inputs

are not adjustable.

When setting up an 882/20 I/O (particularly in systems using a combination of the

882/20 I/O and 888/24 I/O), make sure

that you use a headroom setting of –14 dB

for your system. This helps ensure that recorded audio files have the same relative

levels regardless of which interface they are

recorded with.

Appendix B: Calibrating the 888/24 I/O (Pro Tools 5.0) 17

Page 22

888/24 I/O18

Page 23

appendix c

Calibrating the 888/24 I/O (Pro Tools 4.x)

Before you use the 888/24/I/O Audio Interface, you may want to calibrate its input

and output levels to the level of your mixing console.

The 888/24 I/O is factory-calibrated so that

its input operating level is set to +4 dB

nominal with 18 dB headroom nominal at

full code, unity gain, making calibration

unnecessary for most professional applications.

If you do need to recalibrate your interface

or other components of your studio, you

can use the alignment procedure described

here.

About Calibration

Calibrating levels on a digital recording device is different from calibrating levels on

an analog recording device. Unlike analog

devices, most digital devices do not have a

standard “0 VU” level setting that corresponds to nominal input and output levels.

Instead, with an interface such as the

888/24 I/O, the meters are calibrated in

decibels below peak (digital clipping) level.

Headroom

The concept of headroom is slightly different for analog and digital devices.

Analog Most analog devices allow for a cer-

tain amount of headroom above 0 VU. If

you send a signal above the 0 VU level to

an analog recorder, you still have a margin

of headroom, and if tape saturation occurs,

it does so fairly gracefully, giving the audio

a compressed sound that some find desirable.

Digital Digital devices, on the other hand,

do not allow for signals that exceed the dynamic range of the input. When a signal

exceeds the maximum input level for a digital device, clipping occurs, causing digital

distortion, which is harsh and usually undesirable.

The 888/24 I/O provides an industry standard headroom of 18 dB. The exact value

you use will be determined by the amount

of headroom available in the rest of your

system. For example, if your mixing console has 15 dB of headroom above nominal

level, then you may want to calibrate the

888/24 I/O to have 15 dB of headroom.

Appendix C: Calibrating the 888/24 I/O (Pro Tools 4.x) 19

Page 24

The Calibration Process

Analog To calibrate the input level of an an-

alog device to a mixing console’s output

level, you would typically send a 1 kHz

tone at 0 VU from the console to the analog deck and align the recording deck’s

meters to read 0 VU.

Digital With a digital recording device such

as the 888/24 I/O, however, in order to allow for headroom, you must align a 0 VU

tone from the console to a value less than

zero on the 888/24 I/O, by exactly the

amount of headroom that you want.

For example, to have 12 dB of headroom

above 0 VU with the 888/24 I/O, you must

align the incoming 0 VU 1kHz tone to a

level of –12 dB. For 18 dB of headroom,

you would align it to –18 dB. (Since it is assumed that you are using the 888/24 I/O

with a +4 dBu console, a 0 VU signal level

coming out of the console is actually equivalent to a nominal +4 dBu level signal.)

The Calibration Tool software

The Calibration Tool has the following

controls:

Channel Use this pop-up to select the input

channel for the input level readings.

Input Level Use this as a graphic and nu-

merical display of the dB level relative to

the headroom you have specified on that

particular interface. (In other words, the

amount of dB below digital clipping, or the

amount of analog headroom you wish to

use in your system.)

Calibrating The 888/24 I/O

If you are using Pro Tools 4.3.1 or earlier,

you can use the Calibration Tool application (available on your Pro Tools Installer

CD-ROM) to calibrate the outputs and inputs of the 888/24 I//O.

If you are using Pro Tools 5.0 or later, refer

to Appendix B: Calibrating the 888/24 I/O

(Pro Tools 5.0) for calibration instructions.

888/24 I/O20

Signal Present This indicates when a

–60 dB signal relative to the headroom is

present at the input.

Headroom Use this field to enter an amount

of headroom between your 0 dB level and

the 888/24 I/O full scale digital value. Any

values above the full scale digital value will

cause digital clipping.

Oscillator Use this to turn the audio wave-

form generator on or off.

Frequency Click on this pop-up to select

the output frequency of the audio waveform generator. You can choose a 100 Hz,

1 kHz, or 10 kHz signal.

Page 25

Use this to select the output level rel-

Level

ative to the Headroom for the audio waveform generator.

Wave Type Use this to select the type of au-

dio waveform generated the waveform

generator.

Output Every Channel If this option is se-

lected and the Oscillator is on, every output will generate an audio waveform signal

at the selected frequency. If this option is

not selected and the Oscillator is on, only

the selected output Channel will generate

the audio waveform signal. If the Oscillator

is off, this option has no effect.

Hardware Setup Use this to choose which

Digidesign audio interface and card you

wish to adjust using Calibration Tool.

In order to align your system with this software, you must have one of the following:

◆ A device (such as sine wave or test tone

generator) that can send a 1 kHz audio

waveform wave into the 888/24 I/O at

0 VU.

– or –

◆ A device (such as a mixing console with

accurate VU meters) that can measure the

level of a 1kHz audio waveform produced

by the 888/24 I/O.

Using an External Tone Generator

If you have a sine wave generator that can

produce a 0 VU 1 kHz tone, use the following calibration procedure:

2 In the Headroom field, enter the amount

of headroom you desire. The default setting

for the 888/24 I/O is –18 dB.

3 Send a 1kHz tone into the 888/24 I/O

from your external source.

4 In the software, select 888/24 I/O 1

Channel 1 from the Channel pop-up

menu. You should get some level in the onscreen level meter.

5 Adjust the 888/24 I/O Channel 1 Input

Level trim pot by inserting a screwdriver

into the Input Level trim pot and turning it

until the Calibration Tool’s on-screen

meter reaches 0 VU and the numeric readout says 0.0 dB. The input is now aligned.

6 Repeat this procedure for each

888/24 I/O input by selecting them from

the Channel pop-up menu and adjusting

the appropriate front panel Input Level

trim pot on the 888/24 I/O.

7 When you have finished aligning the in-

puts, connect each output of the

888/24 I/O directly to its input: Connect

Channel 1 output to Channel 1 input, and

so on.

8 Select 1kHz from the oscillator Fre-

quency pop-up menu, and turn the oscillator on by clicking On.

9 Choose 888/24 I/O 1 Channel 1 from

the Channel pop-up. Adjust the Output

Level trim pots by inserting the Phillips

screwdriver into the pot and turning it until the on-screen meter reaches 0 VU and

the numeric readout says 0.0 dB.

10 Repeat this procedure for each Audio In-

terface output.

To calibrate the 888/24 I/O with Calibration

Tool using an external source:

1 Start the Calibration Tool application.

Appendix C: Calibrating the 888/24 I/O (Pro Tools 4.x) 21

Page 26

Using a VU meter

If you don't have a sine wave generator or

another way to send a 1 kHz tone into the

888/24 I/O at 0 VU, a second alternative is

to measure the output level of the

888/24 I/O with a VU meter, such as the

kind found on a professional-quality mixing console. To do this, be sure that the

outputs of the 888/24 I/O are connected to

the VU meters of the console or other device. (On most consoles these inputs are

usually the tape returns, or possibly the

line inputs.)

To calibrate the 888/24 I/O with Calibration

Tool using an external VU meter:

1 In the Calibration Tool software, select 1

kHz from the Frequency pop-up menu and

click the oscillator setting to On.

2 Adjust the 888/24 I/O Output Level trim

pots with a Phillips screwdriver to align the

outputs to read “0 VU” on your console's

meters.

3 After you have done this, connect each

output of the 888/24 I/O directly to its input: Connect Channel 1 Output to

Channel 1 Input, and so on for each channel.

4 To align the inputs, select 888/24 I/O 1

Channel 1 from the Channel pop-up

menu. Adjust the 888/24 I/O Input Level

trim pot with the screwdriver until the onscreen meter reaches “0 VU”. This input is

now aligned.

5 Repeat this procedure for each input.

888/24 I/O22

Loading...

Loading...