digicon catrax automatic plus Product Manual

Product Manual

Copyright– Digicon S.A.

Controle Eletrônico para Mecânica – 2014

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, translated into any language or computer

language in any electronic, magnetic, optical, chemical, manual way, or otherwise,

without the express written permission from Digicon S.A.

Manual code: 069.31.237

English - Revision: 03

This manual was elaborated by: Digicon S.A. Controle Eletrônico para Mecânica

Documentation Sector - EDS

Contents

05

06

06

07

09

10

10

11

11

12

14

14

14

15

16

17

17

18

18

19

19

20

23

24

24

24

25

25

26

26

26

28

29

30

31

31

32

33

35

1. Important instructions ..........................................................................

2.

Orientations ........................................................................................

3. Introduction ........................................................................................

4. Features of Catrax Automatic Plus ..........................................................

4.1. Catrax Automatic Plus operation ..........................................................

5. Installing/Assembling Catrax Automatic Plus ............................................

5.1. Unboxing .........................................................................................

5.2. floor drilling ......................................................................................

5.3. Column fixation .................................................................................

5.4. Assembling the arms .........................................................................

5.5. Access to Catrax Automatic Plus after assembly ......................................

5.5.1. Rear cover .....................................................................................

5.5.2. Front cover ....................................................................................

5.5.3. Column cover .................................................................................

5.6. Connection to power network ..............................................................

6. Installing/assembling optional items .......................................................

6.1. Collecting box kit ...............................................................................

6.1.1. Connection of collecting box kit to control board ...................................

6.2. Pictogram Kit ....................................................................................

6.3. Power supply ....................................................................................

6.4. Electromechanical counter kit ..............................................................

6.5. Control board ....................................................................................

6.5.1. Inputs ...........................................................................................

6.5.2. Outputs .........................................................................................

6.5.2.1 Return signal ................................................................................

6.5.2.2 Electromagnets .............................................................................

6.5.2.3. Sound alarm ................................................................................

6.5.2.4. Connection scheme ......................................................................

6.5.2.5. Pictogram ...................................................................................

6.5.2.6. Pictogram's connections ................................................................

6.5.3. Configuration of control board ..........................................................

6.6. Anti-panic system ..............................................................................

6.6.1. Assembling the arms .......................................................................

6.6.2. Maintenance test ............................................................................

7. Maintenance ........................................................................................

7.1. Preventive and corrective routine maintenance ......................................

7.2. Defects and possible causes ................................................................

8. Technical characteristics ........................................................................

9. Warranty and technical assistance ..........................................................

05

1. mportant nstructionsI i

You can see, below, the symbols that will appear in this manual,

signaling important moments. It is essential to pay attention to them.

TIP: Indicates something Digicon considers important.

CAUTION: Indicates a moment of extreme caution when

handling the equipment/product

ATTENTION: Indicates a moment when your observation

skills should be extremely productive.

INFORMATION: Presents interesting facts about the

purchased product.

QR CODE: Presents additional information or links

with more details about the presented text.

06

2. Orientations

Read the information and instructions of this manual carefully, before using the

product. This ensures the correct use of the equipment and maximum use of its

technical features as well as a prolonged service life.

This product does not present sealing against the rain, that is, it is designed to be

used indoors.

Keep this manual for future consultations.

Digicon reserves its right to alter its products at any moment to adapt them to more

recent technical advancements.

Digicon maintains its right to alter the information contained in this manual without

previous notice.

Digicon does not provide any contractual warranty concerning the information in

this manual, and cannot be held responsible for errors it may contain and problems

due to its use.

The information contained in this manual is exclusive property of Digicon and is

protected by copyright laws.

This manual cannot be reproduced, photocopied or translated, in its entirety or in

part, into any kind of medium, without Digicon's written consent.

3. Introduction

Following a new technological concept focused on solidity and reliability and counting

with

innovative design elements, with variety of colors, lines, and curves, Digicon has

launched the line CATRAX Automatic Plus.

CATRAX Automatic Plus serves most technologies of access control currently available,

becoming the best option in the market for access control.

This manual presents a detailed description of the components and working of CATRAX

Automatic Plus.

To see our complete catalogue, visit www.digicon.com.br.

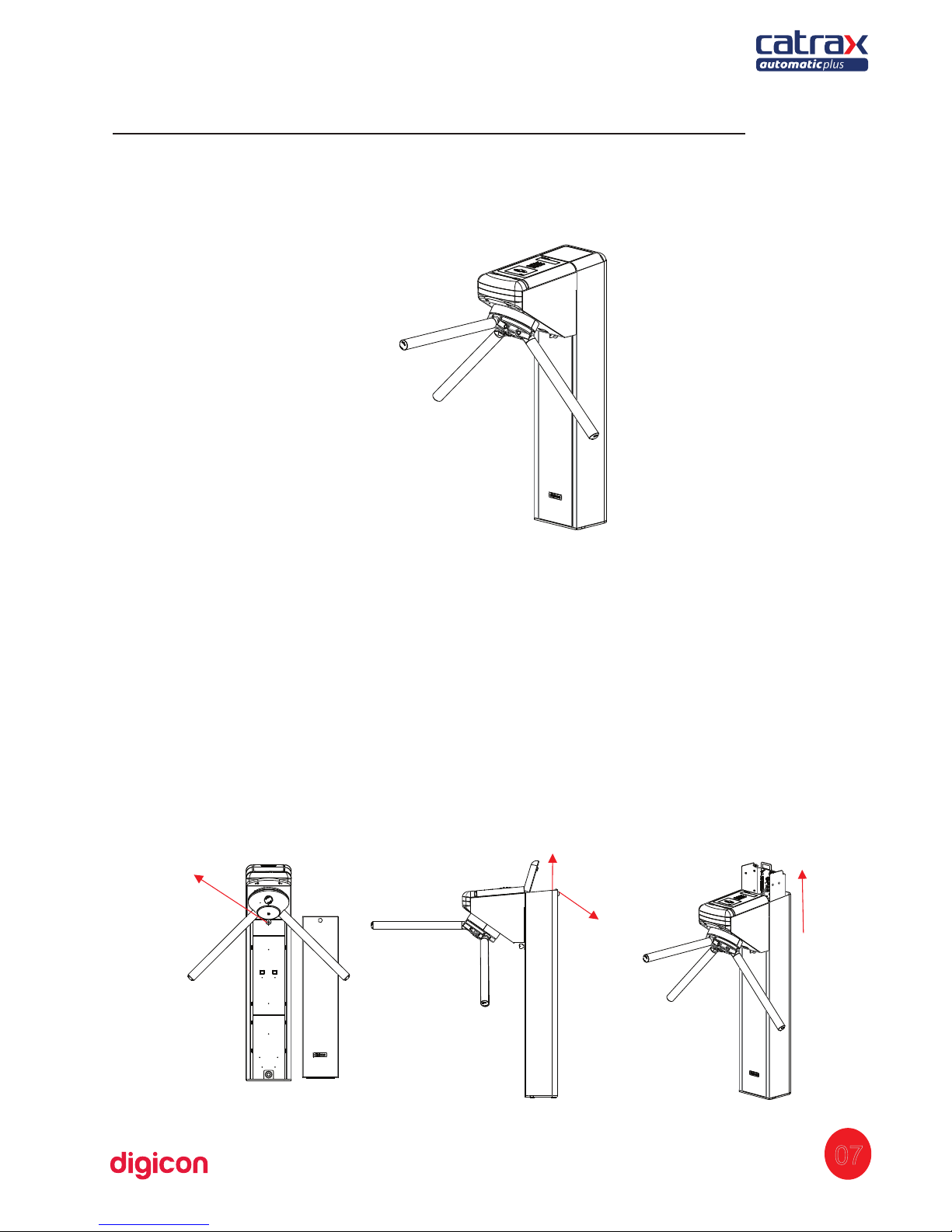

07

Lock

Open (key)

Raise the cover

Pull

4. Features of Automatic Master

CA

TRAX Automatic Plus, an access controller in the model mini turnstile (column

type), presents three bidirectional, equidistant arms at 120 degrees with brushed

stainless steel (AISI 304) finishing.

The column can present external finishing in brushed stainless steel (AISI 304) or

1020 carbon steel with electrostatic painting in black epoxy powder. It has reinforced

structure, fully rounded corners, and non-exposed screws, offering space and comfort

for any access control solution.

Aiming at facilitating assembly and maintenance, the column CATRAX Automatic Plus

presents a U-shaped internal support (mounting rack) with standard holes for the

fixation of additional electronic boards. Moreover, the clients, according to their needs,

can add additional holes. Access to the mounting rack is done through a key with

secret, whose removal and insertion are extremely easy.

08

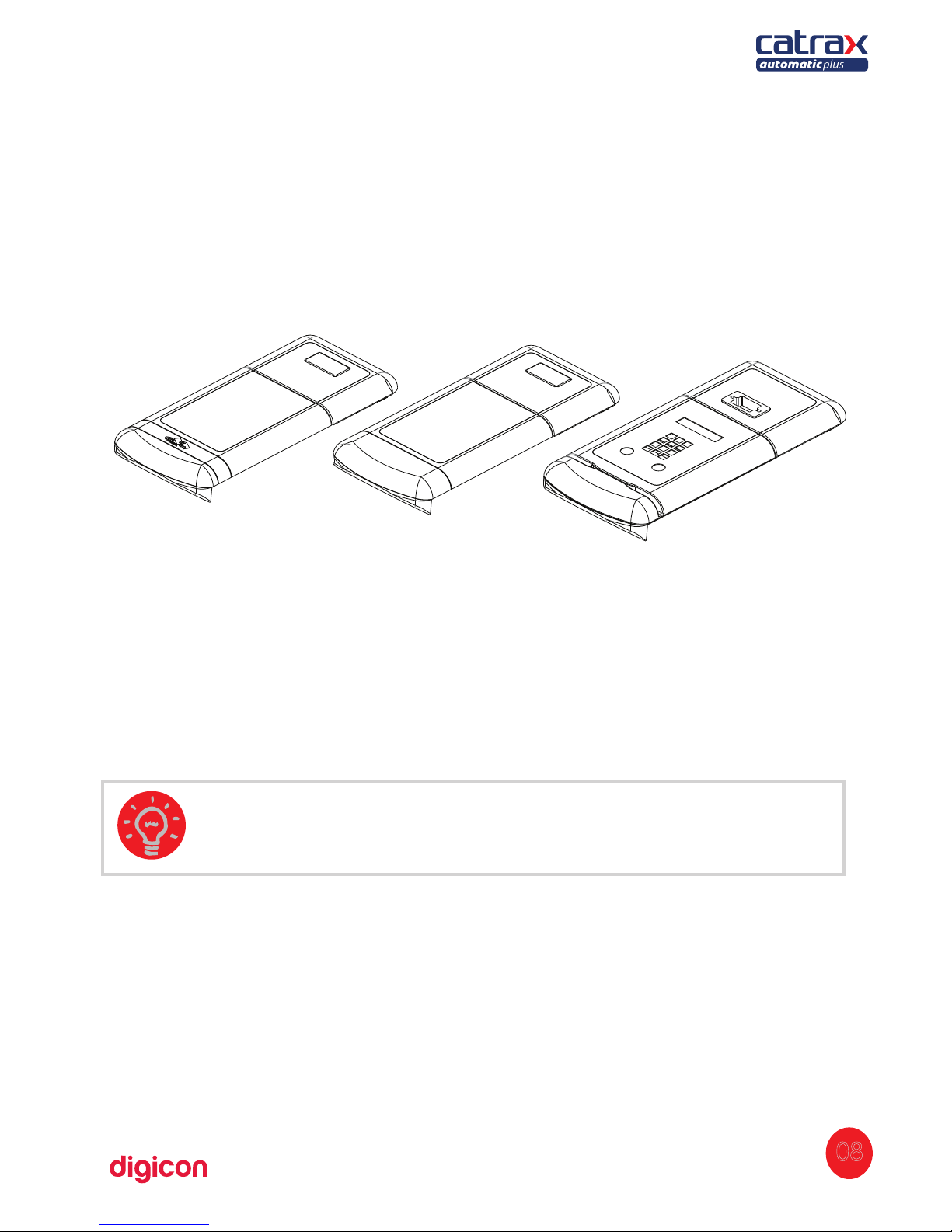

A plastic cover and a stainless steel sheet compose the upper panel. The cover, made

of injected plastic, can be purchased in the colors black, green, or burgundy; or in any

other color desired, on demand.

The upper cover in stainless steel allows easy configuration and low-cost

customization of the product. The sheet can also present slots for optional items, such

as pictogram, collecting box input, display kit (separate manual), or a combination of

these items. The following images show some of the options.

Besides compatibility with most available technologies, Digicon can provide the

following optional items: collecting kit with box, counter kit, power supply, MCA

board, and display kit

Contactless card reader

Flat

Card reader with slot

for barcode

TIP: To see details about the components' dimensions, see 8. Technical

characteristics.

09

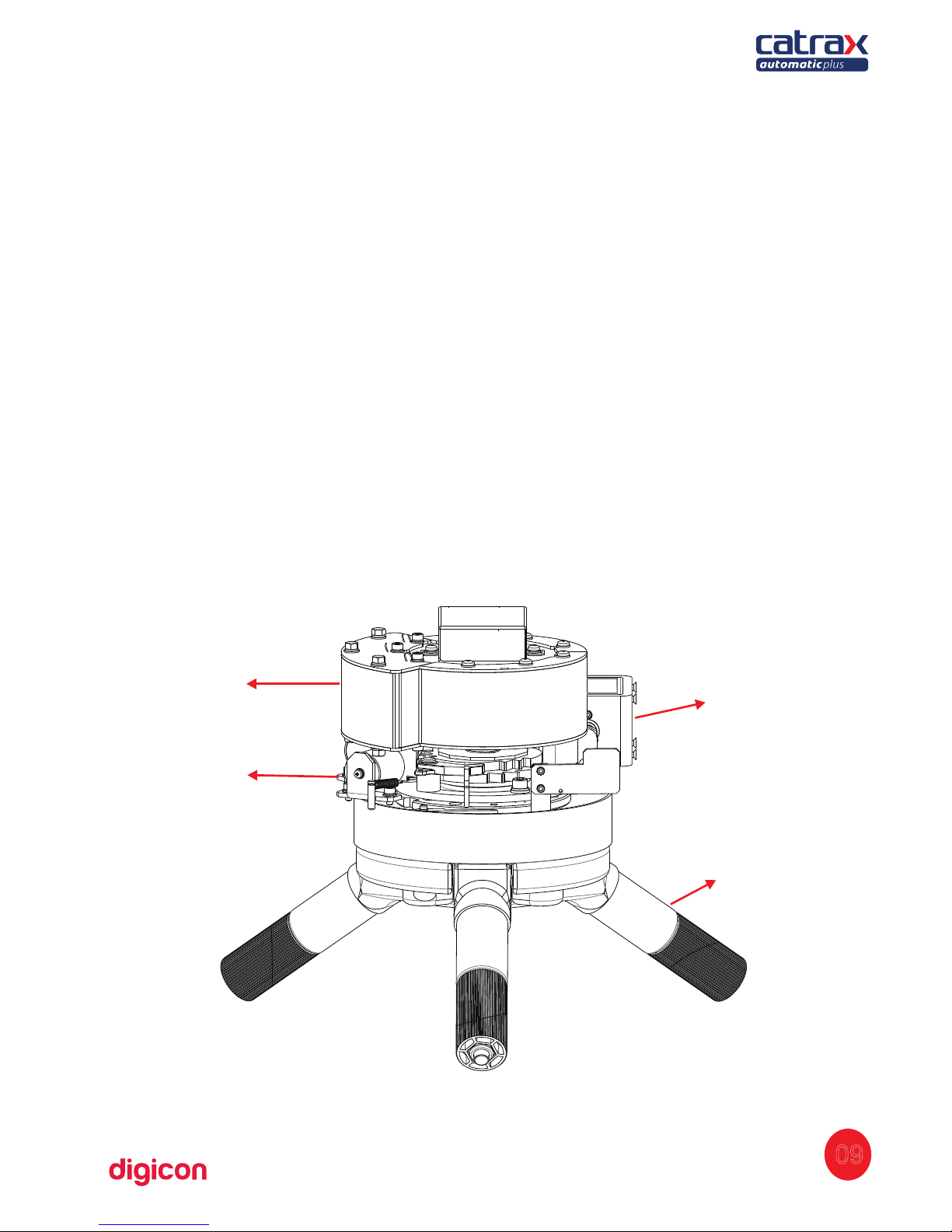

4.1 Catrax Automatic Plus operation:

CATRAX Automatic Plus has bidirectional motorized turning with two 24 Vcc

electromagnets for activating the locks.

It also includes a microprocessor control board, where a signal enabling passage is

sent through one of the inputs, depending on the passage direction. If this signal is

recognized, the equipment will allow the turning of the arm of CATRAX Automatic Plus.

After half of the turning is complete (60 degrees), a 400 milliseconds returning signal

will be sent, informing the passage direction. After the signal, the arm cannot be

returned to the previous position.

Depending on the CATRAX Automatic Plus model and configuration, if the passage is

forced without the enabling signal, an electromagnet will be activated to prevent turn.

In addition, the equipment can emit a signal for a sound alarm and/or the exhibition of

a red X on the upper panel display (models with pictogram). In this case, a return

signal will be sent, indicating that the turnstile was forced, informing the direction of

turn.

The image below shows the operation mechanism of CATRAX Automatic Plus.

Mini arm

Arn-drop

solenoid

(BQC)

Locks

Engine

Bidirectional arms:

- From left right

- From right to left

10

As the items inside the package can vary (depending on the client's requests), it is

important to perform a cautious visual inspection before installing and assembling the

turnstile. A checklist that works as a guide during inspection accompanies all Digicon

packages.

See below the parts that can compose CATRAX Automatic Plus:

ATTENTION: To avoid losses, the screws and the wrenches used for

assembling the CATRAX Automatic Plus are attached to the box containing

the arms. Before discarding the packing materials (cardboard and plastics),

make sure all the items in the checklist are accounted for.

Plastic cover kit

Arm

Lock to access the column

Column door

Upper pictogram

kit (optional)

Collecting box

kit (optional)

Stainless steel

sheet (rear cover)

Stainless steel

sheet (front cover)

Lock to access

the column’s rack

Lock to access the

cover for the pasage

of cables

5.Installing/Assembling Catrax Automatic

Plus

5.1. Unboxing

11

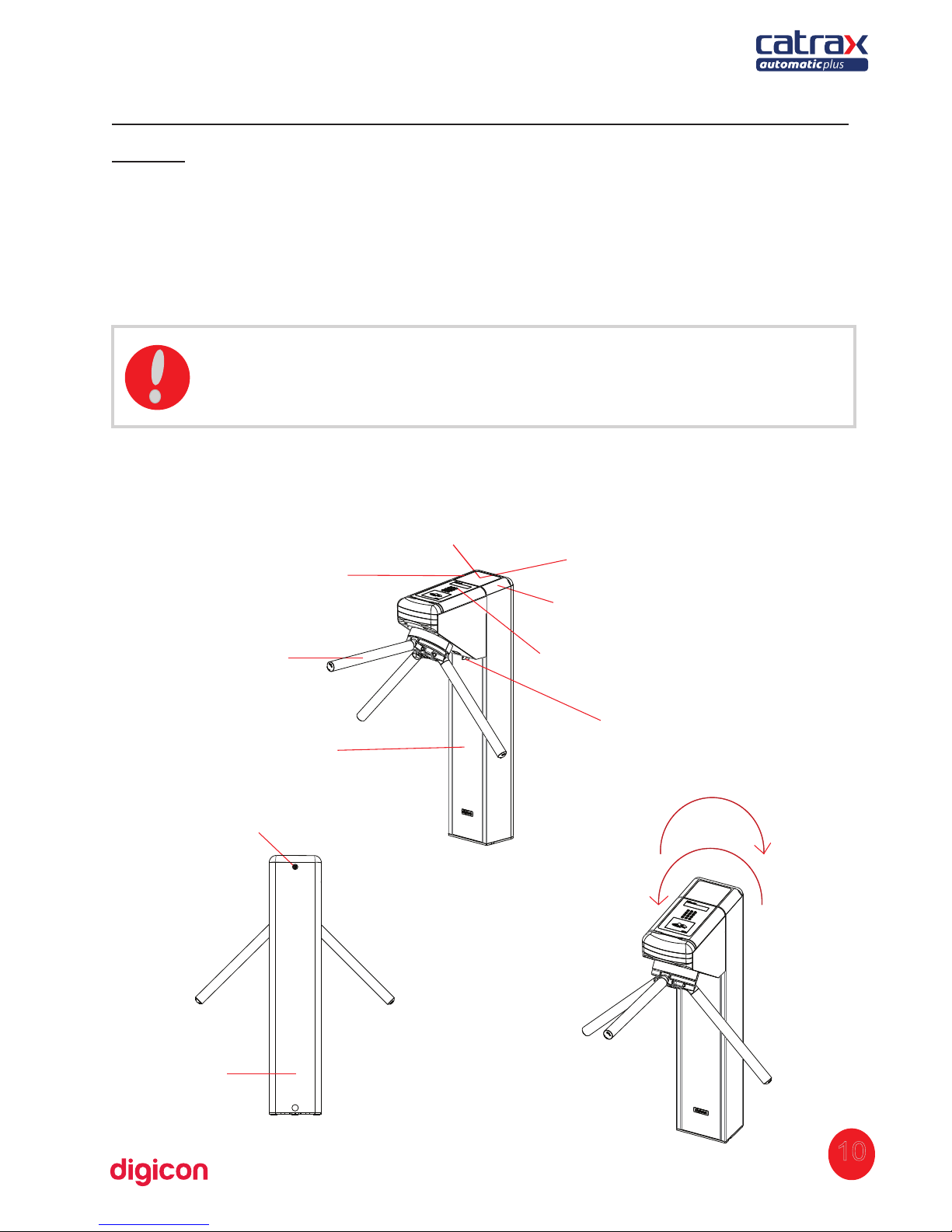

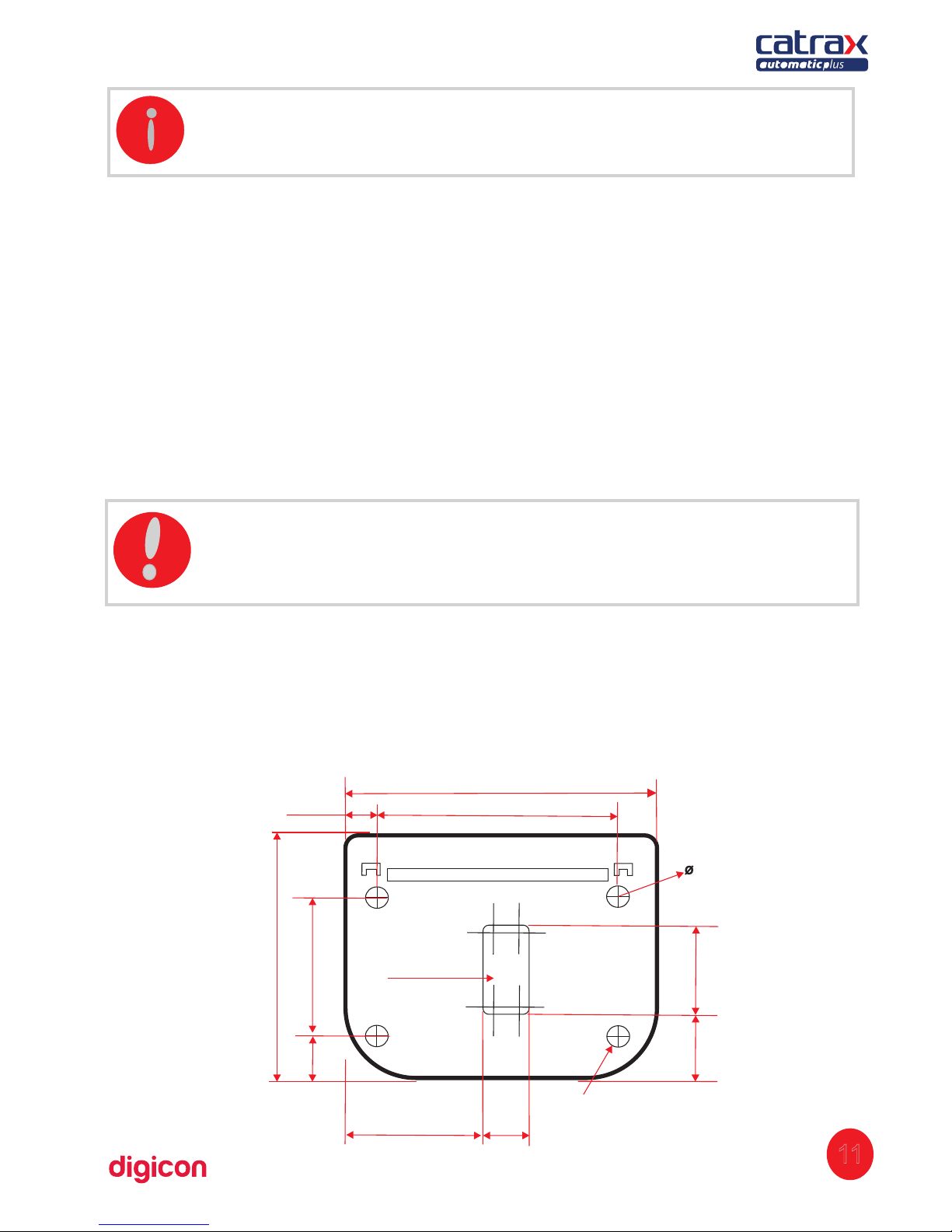

5.2 Floor drilling:

Before installing CATRAX Automatic Plus, check:

1. The place chosen for the installation.

2. If there is a power source or electric socket nearby (ducts for connection).

3. If the place chosen is adequate for the installation of the access controller (indoors).

4. If there will be enough space (minimum 5 cm) between the rear of the CATRAX

Automatic Plus column and the wall. This space is important in order to provide access

to the upper panel and plug's locks for the cables passage.

5. If there will be enough space for the arms after CATRAX Automatic Plus is

assembled.

6. If the floor is in conditions to receive anchor bolts (minimum of 4 cm of FCK15 M.P.A.

concrete or equivalent).

5.3 Column fixation:

To fix the column to the floor, observe the following steps and the indicated images:

1.

rill the floor with 3/8” drills (then use a 12mm or the ½” drill). Make four externalD

holes, according to the measures indicated in the image below:

INFORMATION: Besides the items mentioned above, CATRAX Automatic

Plus can be provided with counter kit and display kit.

12,5 (4x) (0,492")

210 (8,267")

170 (6,692")

78

(3,070")

36

(1,417")

Cables’ output

92,5

(3,641")

32

(1,259")

20

(0,787")

Fixing perforation

51

(2,007)

79,5

(3,129")

160

(6,299")

ATTENTION: Since the CATRAX Automatic Plus's installation requires

floor drilling, it is important that the location be chosen carefully.

12

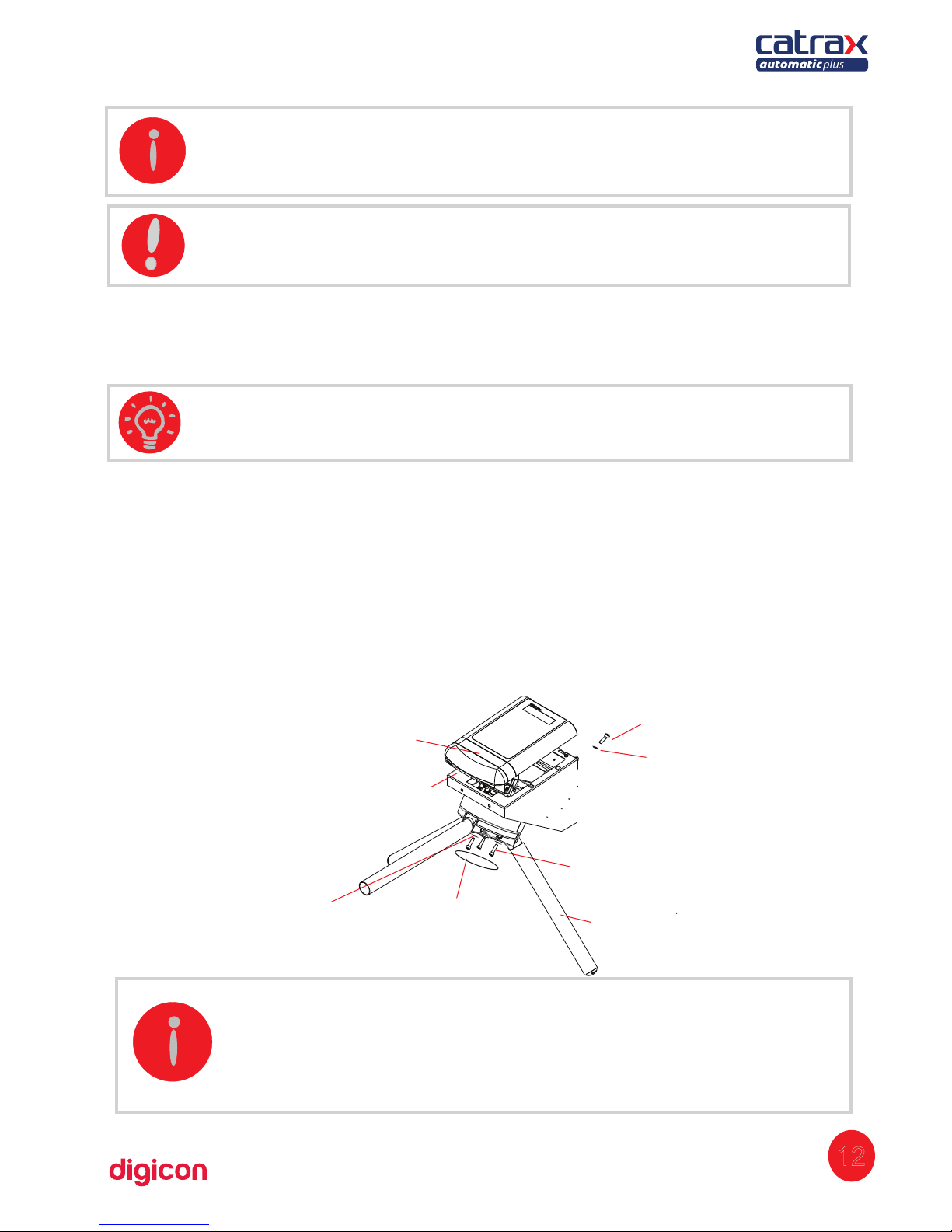

5.4 Montagem dos braços e tampas:

I :NFORMATION

2. Clean the holes, removing any debris from drilling.

3. Place the external part of the bolts in the holes. Leave about 25mm of the bolt out of

the hole.

4. Position the column and fasten it to the floor with the four screws that accompany

the bolts. Use a flex-head socket wrench with ¾'' or an articulated socket wrench.

After drilling the floor and assembling the column, it is possible to assemble the arms

and plastic covers.

The image below shows the specific parts of CATRAX Automatic Plus's arms and upper

frontal cover with assembling instructions.

Arm

Screw M3x8

Flat washer M3

Screwa access cover

Allen M6x20 Screw

Spring washer M6

INFORMATION: n the central slot, destined to the passage of cables, it isI

necessary to measure the cables according to the opening's size.

TIP: As an optional item, Digicon can provide a steel template for fixing

CATRAX Automatic Plus, containing the exact demarcations of the

necessary holes.

TIP: We recommend the bolts by the brand Tecnart, model AF38110,

3/8x4''

Screw M3x16

Upper co

ver plastic

- The cover for accessing the screws is fitted into place, so pressure it to

open or close it.

- To assemble the arms of CATRAX Automatic Plus, use an Allen n. 8

wrench.

Loading...

Loading...