Page 1

XBee® Wi-Fi RF Modules

XBee® Wi-Fi RF Module

This manual describes the operation of the XBee® Wi-Fi RF module, which consists of 802.11 bgn firmware loaded

onto XBee® hardware. The XBee® Wi-Fi RF Modules are designed to operate within the 802.11 protocol and

support the unique needs of low-cost, low-power wireless sensor networks. The modules require minimal power

and provide reliable delivery of data between remote devices and wireless 802.11 b, g or n access points and

routers. The modules operate within the ISM 2.4 GHz frequency band.

Digi International Inc.

11001 Bren Road East

Minnetonka, MN 55343 877 912-3444 or 952 912-3444

http://www.digi.com

© 2011 Digi International, Inc. All rights reserved

No part of the contents of this manual may be transmitted or reproduced in

any form or by any means without the written permission of Digi

International, Inc.

XBee® is a registered trademark of Digi International, Inc.

Technical Support Phone: (866) 765-9885 toll-free U.S.A. & Canada

(801) 765-9885 Worldwide

8:00 am - 5:00 pm [U.S. Mountain Time]

Online Support: http://www.digi.com/support/eservice/login.jsp

Email: rf-experts@digi.com

© 2011 Digi International, Inc. Page 1

Page 2

XBee® Wi-Fi RF Modules

Contents

1. Overview ............................................................................................................................................. 5

Specifications ...................................................................................................................................... 6

General Specifications .................................................................................................................... 6

RF Specifications ............................................................................................................................. 7

Electrical Specifications ................................................................................................................ 11

Environmental Specifications ....................................................................................................... 11

Serial Communications Specifications .......................................................................................... 12

UART ............................................................................................................................................. 12

SPI ................................................................................................................................................. 12

GPIO Specifications ........................................................................................................................... 13

Agency Approvals ............................................................................................................................. 14

Pin Signals ......................................................................................................................................... 14

Design Notes ..................................................................................................................................... 15

Power Supply ................................................................................................................................ 15

Recommended Pin Connections .................................................................................................. 15

Board Layout ................................................................................................................................ 16

Mounting Considerations ............................................................................................................. 18

2. RF Module Operation ....................................................................................................................... 19

Serial Communications ..................................................................................................................... 19

UART Communications ................................................................................................................. 19

SPI Communications ..................................................................................................................... 20

Serial Buffers .................................................................................................................................... 21

Serial Receive Buffer ..................................................................................................................... 21

Serial Transmit Buffer ................................................................................................................... 21

UART Flow Control ....................................................................................................................... 21

Serial Interface Protocols ................................................................................................................. 22

Transparent Operation ................................................................................................................. 22

API Operation ............................................................................................................................... 23

A Comparison of Transparent and API Operation ........................................................................ 23

Modes of Operation ......................................................................................................................... 24

Idle Mode ..................................................................................................................................... 24

Transmit Mode ............................................................................................................................. 24

Receive Mode ............................................................................................................................... 24

Command Mode ........................................................................................................................... 24

© 2011 Digi International, Inc. Page 2

Page 3

XBee® Wi-Fi RF Modules

Sleep Mode ....................................................................................................................................... 26

3. 802.11 bgn Networks ....................................................................................................................... 27

Infrastructure Networks ................................................................................................................... 27

Ad Hoc Networks .............................................................................................................................. 27

Network Basics ................................................................................................................................. 28

XBee® Wi-Fi Standards ..................................................................................................................... 28

Encryption ........................................................................................................................................ 28

CHANNELS ........................................................................................................................................ 29

4. XBee IP Services ................................................................................................................................ 29

XBee Application Service .................................................................................................................. 30

Local Host ..................................................................................................................................... 30

Network Client .............................................................................................................................. 31

Serial Communication Service .......................................................................................................... 34

Transparent mode ........................................................................................................................ 34

API mode ...................................................................................................................................... 34

5. Sleep ................................................................................................................................................. 35

Sleeping with the UART .................................................................................................................... 35

Sleeping with the SPI ........................................................................................................................ 35

Sleep Options ................................................................................................................................... 36

AP Associated sleep ...................................................................................................................... 36

Deep sleep (non-associated sleep) ............................................................................................... 36

Sampling data using sleep modes .................................................................................................... 37

Sample Rate (ATIR) ....................................................................................................................... 37

Wake Host .................................................................................................................................... 37

6. XBee Analog and Digital IO Lines ...................................................................................................... 38

IO Sampling ....................................................................................................................................... 38

Queried Sampling ......................................................................................................................... 40

Periodic IO Sampling ..................................................................................................................... 40

I/O Examples ................................................................................................................................. 41

7. API Operation ................................................................................................................................... 42

API Frame Specifications .................................................................................................................. 42

API UART and SPI Exchanges ............................................................................................................ 45

AT Commands ............................................................................................................................... 45

Transmitting and Receiving RF Data ............................................................................................. 45

Remote AT commands ................................................................................................................. 46

© 2011 Digi International, Inc. Page 3

Page 4

XBee® Wi-Fi RF Modules

Supporting the API ........................................................................................................................ 46

API Frames ........................................................................................................................................ 47

TX (Transmit) request: 64-Bit ....................................................................................................... 47

AT Command ................................................................................................................................ 47

AT Command-Queue Parameter Value ........................................................................................ 48

Remote AT Command Request .................................................................................................... 49

Transmit (TX) request: IPv4 .......................................................................................................... 51

AT Command Response ................................................................................................................ 52

Modem Status .............................................................................................................................. 53

Transmission Status ...................................................................................................................... 54

IO Data Sample RX Indicator ........................................................................................................ 55

Remote Command Response ....................................................................................................... 57

RX (Receive) Packet: IPv4 ............................................................................................................. 58

8. XBee Command Reference Tables.................................................................................................... 59

Addressing ........................................................................................................................................ 59

Networking Commands .................................................................................................................... 60

Security Commands .......................................................................................................................... 60

RF Interfacing Commands ................................................................................................................ 60

Serial Interfacing ............................................................................................................................... 61

I/O Settings ....................................................................................................................................... 62

Diagnostics Interfacing ..................................................................................................................... 65

AT Command Options ...................................................................................................................... 66

Sleep Commands .............................................................................................................................. 66

Execution Commands ....................................................................................................................... 67

9. Module Support ................................................................................................................................ 68

X-CTU Configuration Tool ................................................................................................................ 68

Serial Firmware Updates ............................................................................................................. 68

Regulatory Compliance ................................................................................................................ 68

Agency Certifications ................................................................................................................... 68

United States FCC ............................................................................................................................. 68

OEM Labeling Requirements ....................................................................................................... 69

FCC Notices ................................................................................................................................... 69

FCC-Approved Antennas (2.4 GHz) .............................................................................................. 70

RF Exposure .................................................................................................................................. 73

Europe (ETSI) .................................................................................................................................... 74

© 2011 Digi International, Inc. Page 4

Page 5

XBee® Wi-Fi RF Modules

OEM Labeling Requirements ....................................................................................................... 74

Restrictions .................................................................................................................................. 74

Declarations of Conformity ......................................................................................................... 74

Approved Antennas ..................................................................................................................... 75

XBee RF Module ........................................................................................................................... 75

Canada (IC) ....................................................................................................................................... 76

Transmitters with Detachable Antennas .................................................................................... 76

Detachable Antenna .................................................................................................................... 76

Australia (C-Tick) .............................................................................................................................. 77

10. Warranty Information .................................................................................................................... 78

1-Year Warranty............................................................................................................................... 78

Appendix A: Definitions ...................................................................................................................... 79

1. Overview

The XBee® Wi-Fi RF module provides wireless connectivity to end-point devices in 802.11 bgn

networks. Utilizing the 802.11 feature set, these modules are interoperable with other 802.11

bgn devices, including devices from other vendors. With XBee, users can have their 802.11 bgn

network up-and running in a matter of minutes.

The XBee® Wi-Fi modules are compatible with other devices that use 802.11 bgn technology.

These include Digi external 802.11x devices like the ConnectPort and the Digi Connect Wi-SP, as

well as embedded products like the ConnectCore series and Digi Connect series of products.

More information on these Digi products can be found at:

http://www.digi.com/products/wireless/wifisolutions/

© 2011 Digi International, Inc. Page 5

Page 6

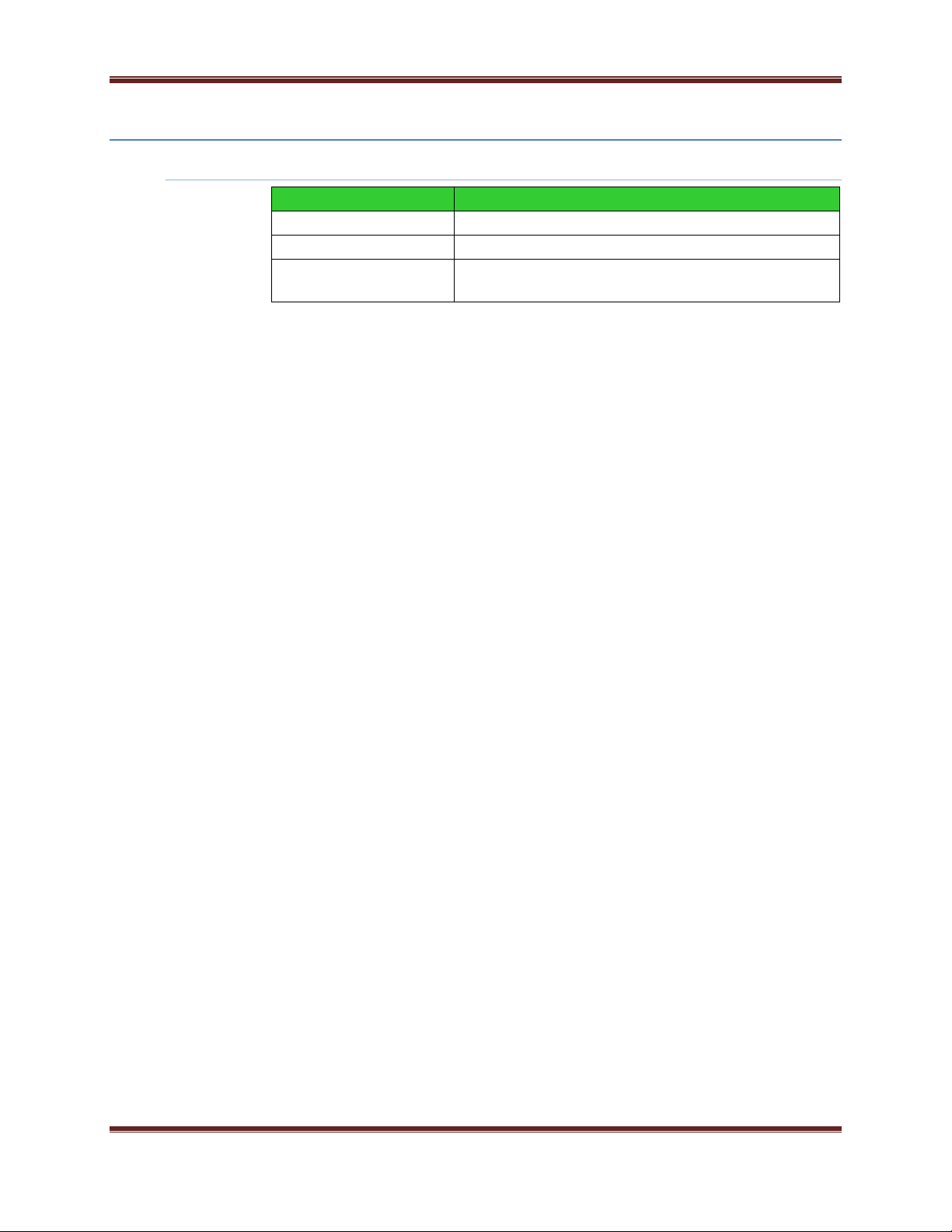

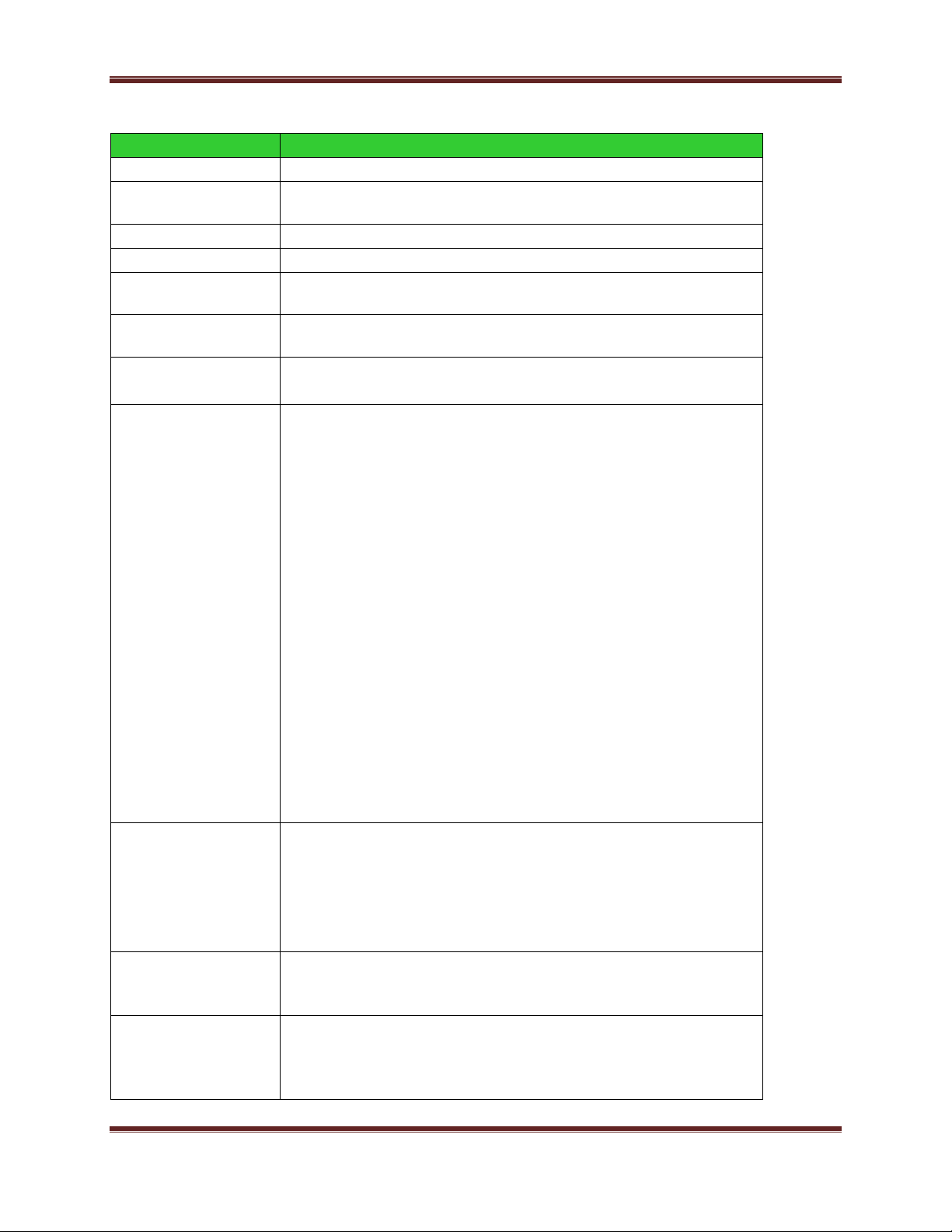

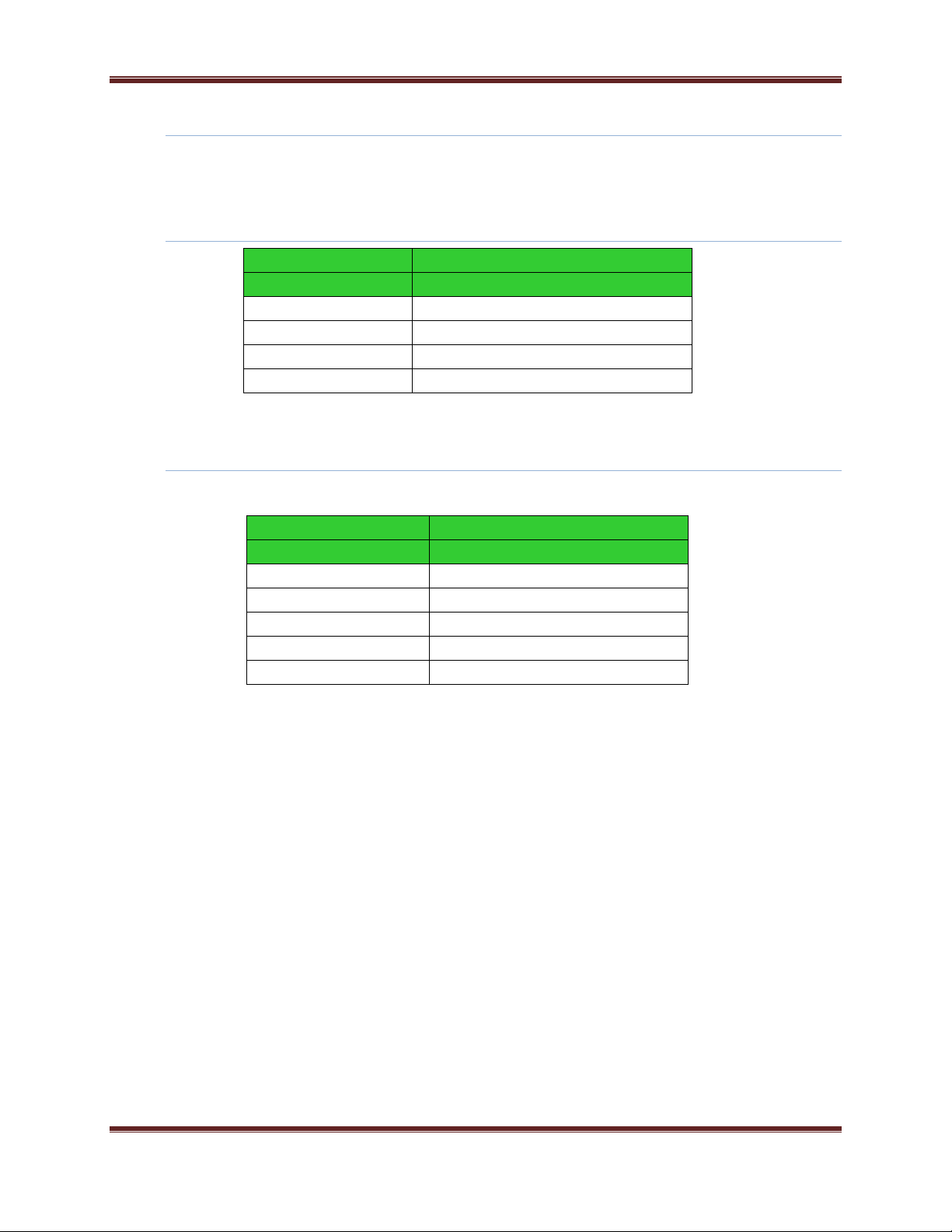

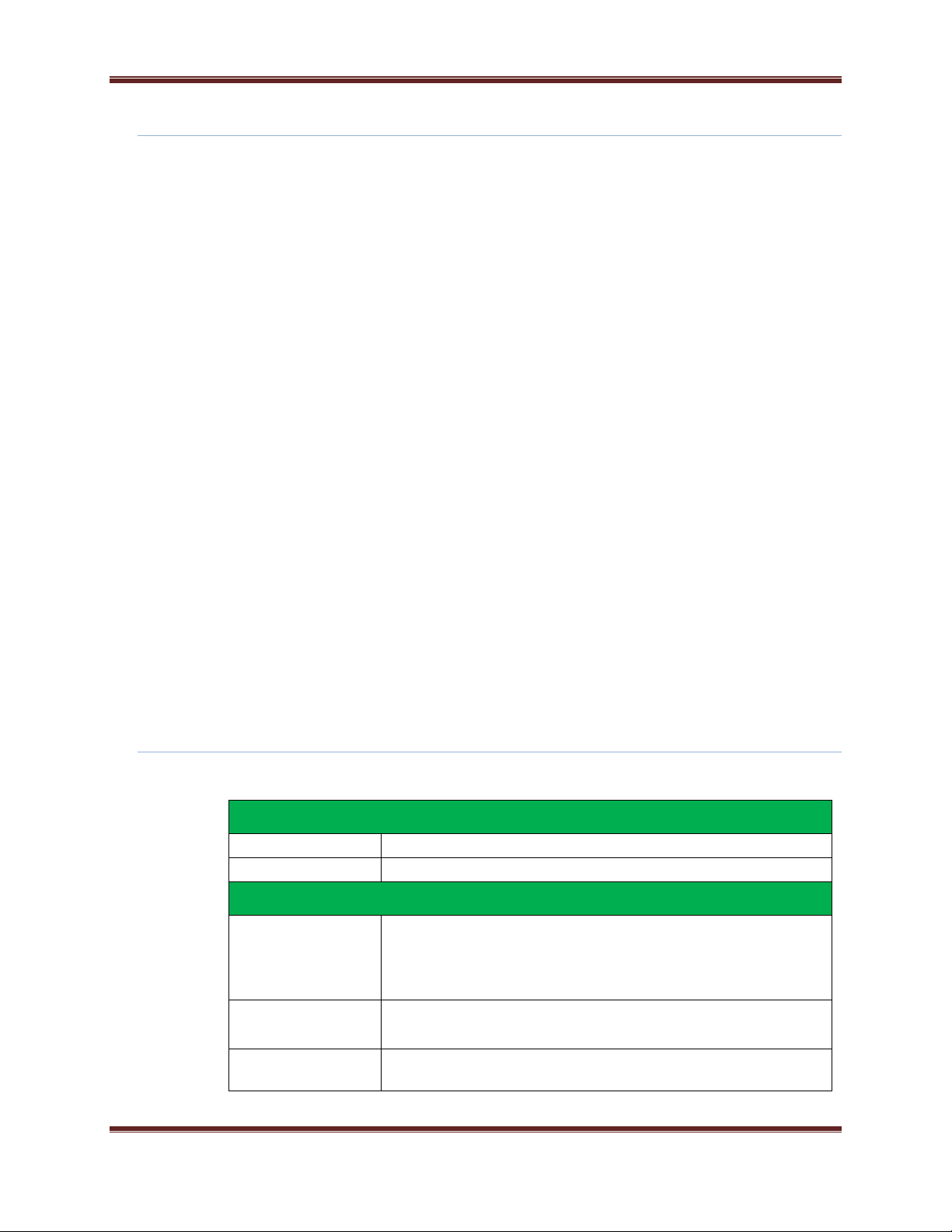

Specification

XBee Wi-Fi

Dimensions

0.960 x 1.297 (2.438cm x 3.294cm)

Operating Temperature

-40 to 85° C (Industrial)

Antenna Options

PCB Antenna, U.FL Connector, RPSMA Connector, or

Integrated Wire

Specifications

General Specifications

XBee® Wi-Fi RF Modules

© 2011 Digi International, Inc. Page 6

Page 7

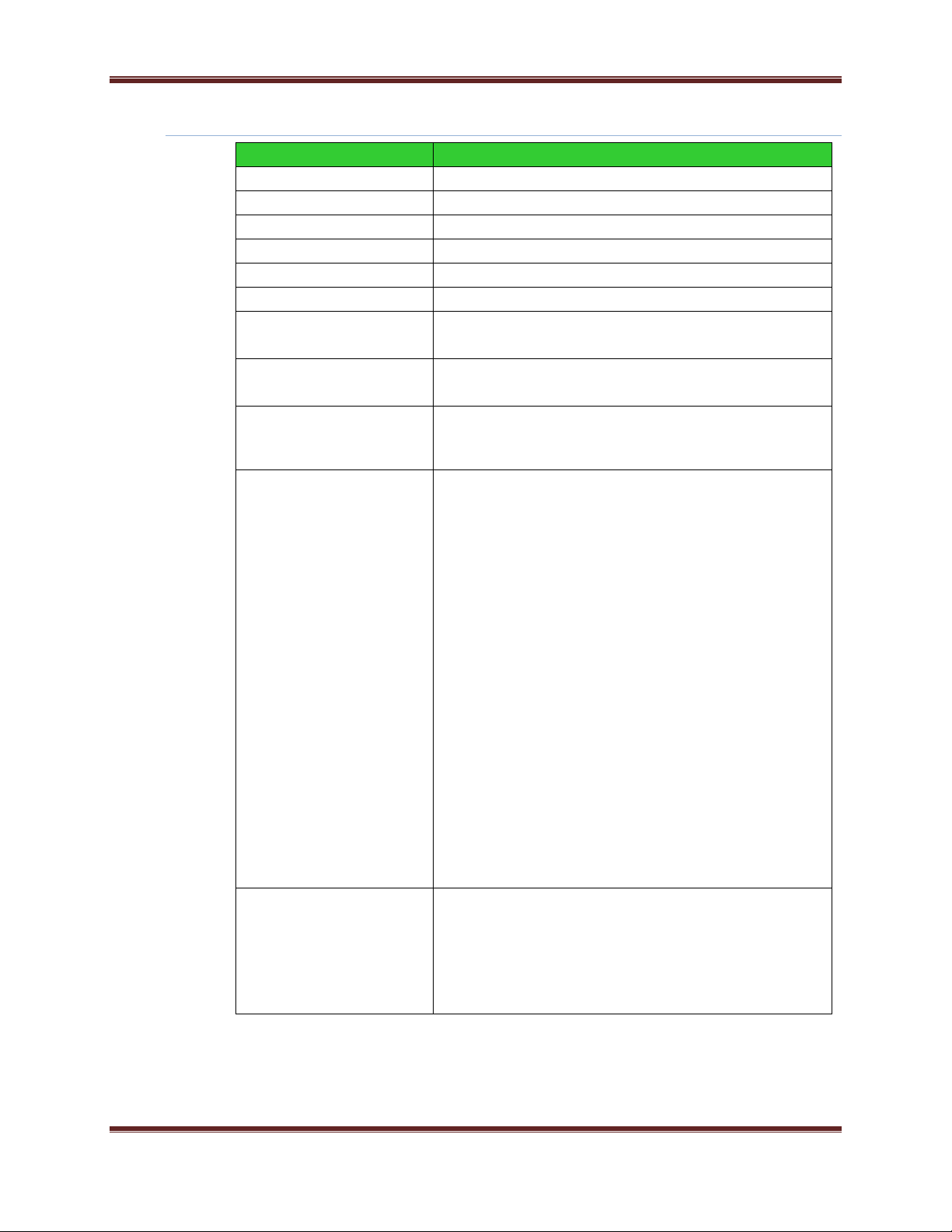

Specification

XBee Wi-Fi

Frequency

ISM 2.4-2.5GHz

Number of Channels

14

Channels

1 to 14

Adjustable Power

Yes

Interface immunity

802.11 b, g, and n

Indoor/Urban Range

TBD

Outdoor RF line-of-sight

Range

TBD

Transmit Power Output

>15dBm

RF Data Rate

802.11 b 1, 2, 5.5, and 11Mbps

802.11 g 6, 9, 12, 18, 24, 36, 48, and 54 Mbps

802.11 n 6.5, 13, 19.5, 26, 39, 52, 58.5, and 65 Mbps

EVM

802.11 b 1Mbps 8%

802.11 b 2Mbps 17%

802.11 b 5.5Mbps 10%

802.11 b 11Mbps 12%

802.11 g 6Mbps -13dB

802.11 g 9Mbps -15dB

802.11 g 12Mbps -16dB

802.11 g 18Mbps -18dB

802.11 g 24Mbps -19dB

802.11 g 36Mbps -21dB

802.11 g 48Mbps -24dB

802.11 g 54 Mbps -25dB

802.11 n MCS0 6.5Mbps -15dB

802.11 n MCS1 13Mbps -16dB

802.11 n MCS2 19.5Mbps -17dB

802.11 n MCS3 26Mbps -19dB

802.11 n MCS4 39Mbps -20dB

802.11 n MCS5 52Mbps -21dB

802.11 n MCS6 58Mbps -23dB

802.11 n MCS7 65Mbps -24dB

Receiver Sensitivity

802.11 b 1Mbps -97dBm (<8% PER)

802.11 b 2Mbps -93dBm (<8% PER)

802.11 b 11Mbps -89dBm (<8% PER)

802.11 g 6Mbps -91dBm (<10% PER)

802.11 g 54 Mbps -75dBm (<10% PER)

802.11 n 65Mbps -72dBm (<10% PER)

RF Specifications

XBee® Wi-Fi RF Modules

© 2011 Digi International, Inc. Page 7

Page 8

XBee® Wi-Fi RF Modules

Specification

XBee Wi-Fi

Frequency

ISM 2.4-2.5GHz

Number of

Channels

14

Channels

1 to 14

Adjustable Power

Yes

Interface

immunity

802.11 b, g, and n

Indoor/Urban

Range

TBD

Outdoor RF line-

of-sight Range

TBD

Transmit Power

(Average)

802.11 b 1Mbps 16dBm

802.11 b 2Mbps 16dBm

802.11 b 5.5Mbps 16dBm

802.11 b 11Mbps 16dBm

802.11 g 6Mbps 16dBm

802.11 g 9Mbps 16dBm

802.11 g 12Mbps 16dBm

802.11 g 18Mbps 16dBm

802.11 g 24Mbps 15dBm

802.11 g 36Mbps 15dBm

802.11 g 48Mbps 14dBm

802.11 g 54 Mbps 14dBm

802.11 n MCS0 6.5Mbps 16dBm

802.11 n MCS1 13Mbps 16dBm

802.11 n MCS2 19.5Mbps 16dBm

802.11 n MCS3 26Mbps 16dBm

802.11 n MCS4 39Mbps 15dBm

802.11 n MCS5 52Mbps 15dBm

802.11 n MCS6 58Mbps 14dBm

802.11 n MCS7 65Mbps 14dBm

Transmit Power

Range (Peak)

802.11b: 11.16 dBm to 19.21 dBm (13.06 mW to 83.37 mW)

802.11g: 13.89 dBm to 20.70 dBm (24.49 mW to 117.49 mW)

802.11n: 14.17dBm to 20.46 dBm (26.12 mW to 111.17 mW)

Overall: 11.16 dBm to 20.70 dBm (13.06 mW to 117.49 mW)

RF Data Rate

802.11 b 1, 2, 5.5, and 11Mbps

802.11 g 6, 9, 12, 18, 24, 36, 48, and 54 Mbps

802.11 n 6.5, 13, 19.5, 26, 39, 52, 58.5, and 65 Mbps

EVM

802.11 b 1Mbps 8%

802.11 b 2Mbps 17%

802.11 b 5.5Mbps 10%

802.11 b 11Mbps 12%

© 2011 Digi International, Inc. Page 8

Page 9

XBee® Wi-Fi RF Modules

802.11 g 6Mbps -13dB

802.11 g 9Mbps -15dB

802.11 g 12Mbps -16dB

802.11 g 18Mbps -18dB

802.11 g 24Mbps -19dB

802.11 g 36Mbps -21dB

802.11 g 48Mbps -24dB

802.11 g 54 Mbps -25dB

802.11 n MCS0 6.5Mbps -15dB

802.11 n MCS1 13Mbps -16dB

802.11 n MCS2 19.5Mbps -17dB

802.11 n MCS3 26Mbps -19dB

802.11 n MCS4 39Mbps -20dB

802.11 n MCS5 52Mbps -21dB

802.11 n MCS6 58Mbps -23dB

802.11 n MCS7 65Mbps -24dB

Receiver

Sensitivity

802.11 b 1Mbps -97dBm (<8% PER)

802.11 b 2Mbps -93dBm (<8% PER)

802.11 b 11Mbps -89dBm (<8% PER)

802.11 g 6Mbps -91dBm (<10% PER)

802.11 g 54 Mbps -75dBm (<10% PER)

802.11 n 65Mbps -72dBm (<10% PER)

© 2011 Digi International, Inc. Page 9

Page 10

XBee® Wi-Fi RF Modules

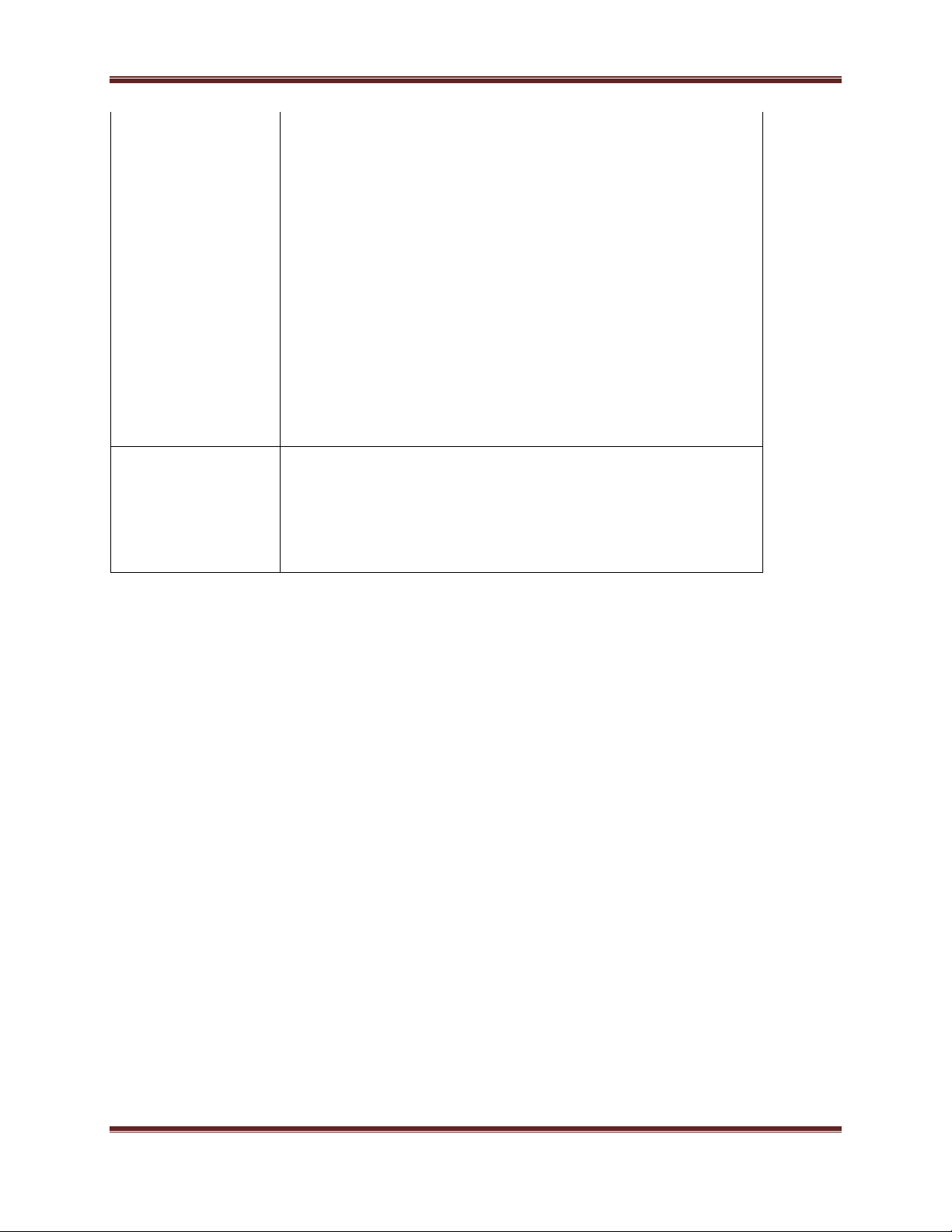

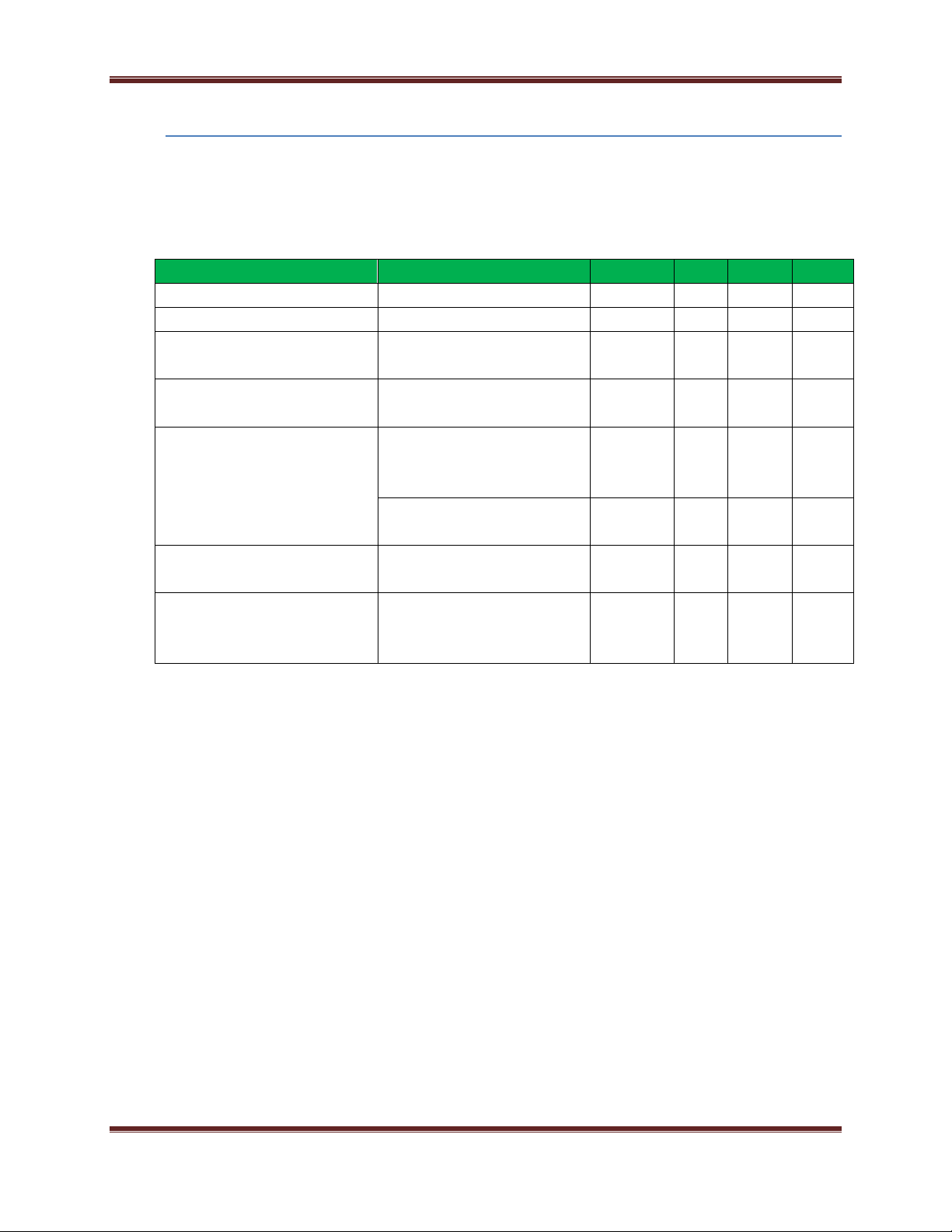

Spectral Mask

XBee Wi-Fi

Data Rate

-50 to 22

MHz

-22 to -11

MHz

11 To 22

Mhz

22 to 50

MHz

Units

802.11 b 1Mbps

-52

-39

-39

-52

dBc

802.11 b 2Mbps

-52

-38

-38

-54

dBc

802.11 b 5.5Mbps

-56

-43

-48

-54

dBc

802.11 b 11Mbps

-54

-39

-37

-55

dBc

Data Rate

-50 to -30

MHz

-30 to -20

MHz

-20 to -11

MHz

-11 to -9

MHz

9 to 11

MHz

11 to 20

MHz

20 to 30

MHz

30 to 50

MHz

Units

802.11 g 6Mbps

-46

-43.5

-28.5

-16.5

-16.5

-27.5

-42.5

-47

dBc

802.11 g 9Mbps

-46

-42.5

-27.5

-17.5

-16.5

-27.5

-42.5

-46

dBc

802.11 g 12Mbps

-46

-42.5

-28.5

-17.5

-17.5

-27.5

-41.5

-47

dBc

802.11 g 18Mbps

-46

-42.5

-27.5

-17.5

-17.5

-27.5

-41.5

-45

dBc

802.11 g 24Mbps

-47

-44.5

-30.5

-19.5

-19.5

-30.5

-43.5

-47

dBc

802.11 g 36Mbps

-47

-44.5

-30.5

-21.5

-21.5

-30.5

-46.5

-49

dBc

802.11 g 48Mbps

-47

-48.5

-36.5

-23.5

-24.5

-36.5

-48.5

-52

dBc

802.11 g 54Mbps

-47

-48.5

-33.5

-24.5

-23.5

-33.5

-49.5

-49

dBc

802.11 n MCS0 6.5Mbps

-45

-39.5

-26.5

-16.5

-16.5

-26.5

-39.5

-45

dBc

802.11 n MCS1 13Mbps

-44

-40.5

-26.5

-16.5

-15.5

-25.5

-39.5

-45

dBc

802.11 n MCS2 19.5Mbps

-44

-41.5

-27.5

-16.5

-16.5

-27.5

-40.5

-45

dBc

802.11 n MCS3 26Mbps

-44

-40.5

-27.5

-16.5

-16.5

-25.5

-38.5

-45

dBc

802.11 n MCS4 39Mbps

-45

-42.5

-30.5

-19.5

-19.5

-29.5

-42.5

-47

dBc

802.11 n MCS5 52Mbps

-46

-43.5

-30.5

-18.5

-18.5

-29.5

-43.5

-46

dBc

802.11 n MCS6 58Mbps

-47

-45.5

-34.5

-22.5

-22.5

-33.5

-46.5

-48

dBc

802.11 n MCS7 65Mbps

-47

-46.5

-34.5

-22.5

-22.5

-33.5

-46.5

-49

dBc

© 2011 Digi International, Inc. Page 10

Page 11

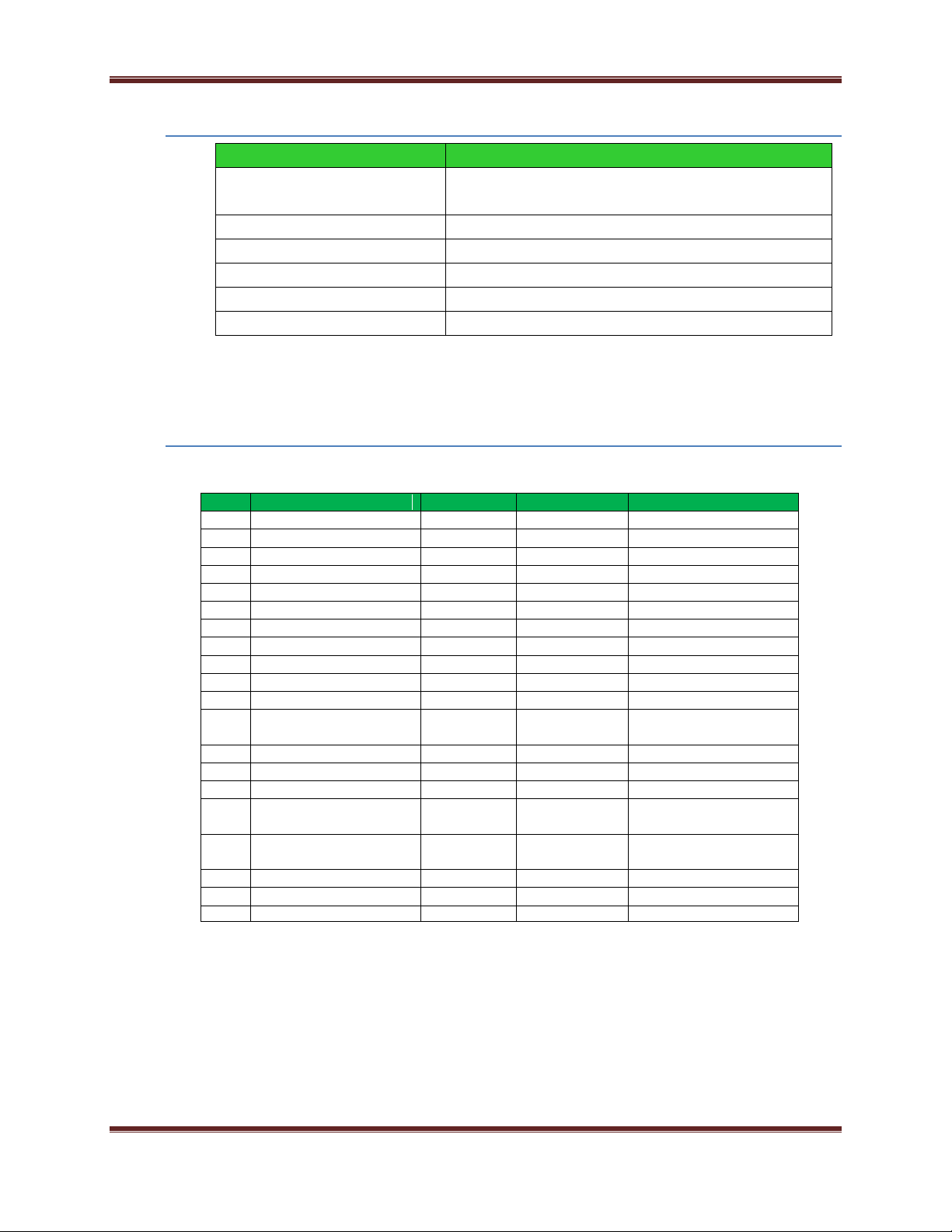

Specification

XBee Wi-Fi

Supply Voltage

3.1 - 3.6 V

Operating Current

(transmit, max output

power)

802.11 b 1Mbps 260mA

802.11 b 2Mbps 260mA

802.11 b 5.5Mbps 260mA

802.11 b 11Mbps 260mA

802.11 g 6Mbps 240mA

802.11 g 9Mbps 220mA

802.11 g 12Mbps 210mA

802.11 g 18Mbps 200mA

802.11 g 24Mbps 190mA

802.11 g 36Mbps 180mA

802.11 g 48Mbps 170mA

802.11 g 54 Mbps 170mA

802.11 n MCS0 6.5Mbps 230mA

802.11 n MCS1 13Mbps 210mA

802.11 n MCS2 19.5Mbps 200mA

802.11 n MCS3 26Mbps 200mA

802.11 n MCS4 39Mbps 190mA

802.11 n MCS5 52Mbps 180mA

802.11 n MCS6 58Mbps 180mA

802.11 n MCS7 65Mbps 180mA

Operating Current

(Receive)

140mA

Deep Sleep

Current

<2uA @25C

Electrical Specifications

XBee® Wi-Fi RF Modules

Environmental Specifications

© 2011 Digi International, Inc. Page 11

Page 12

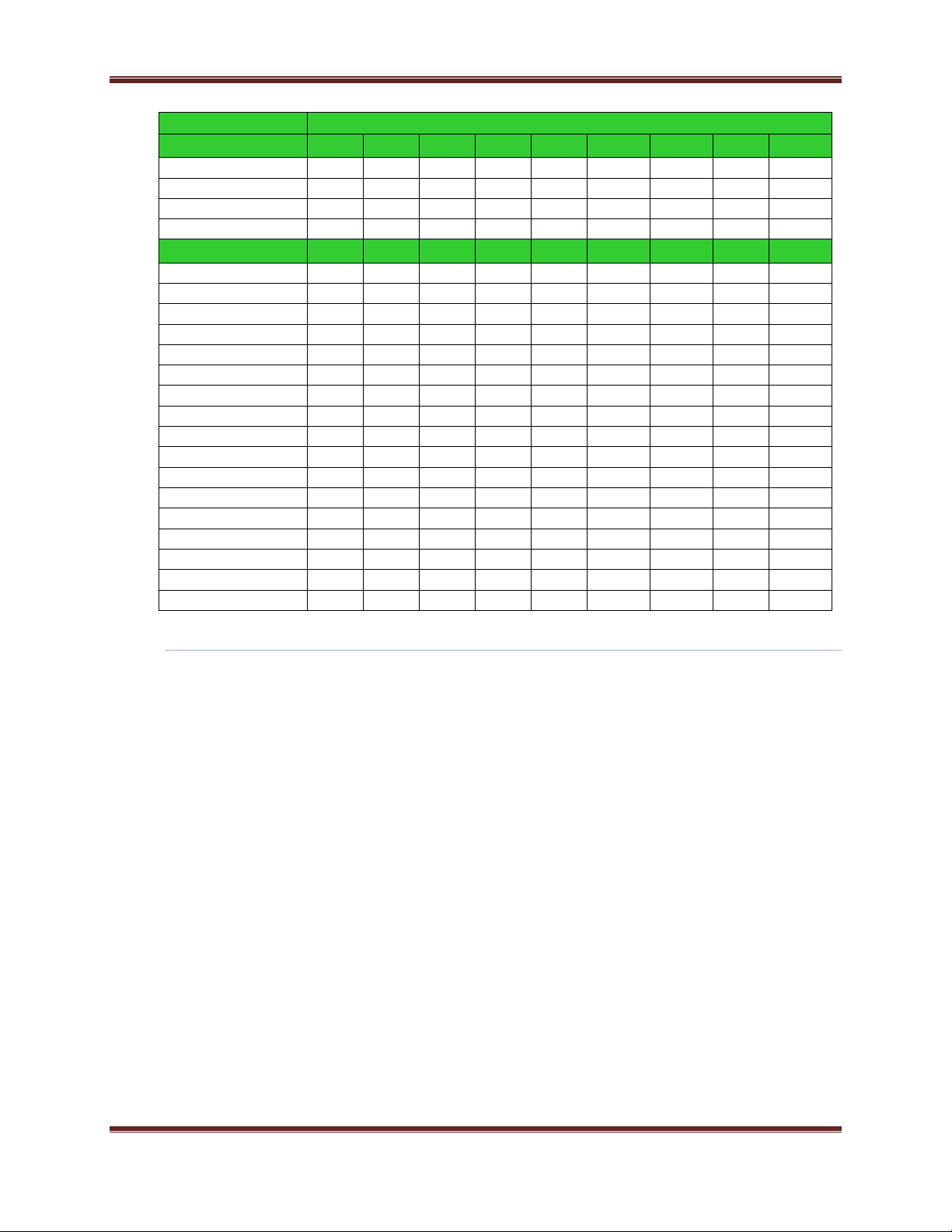

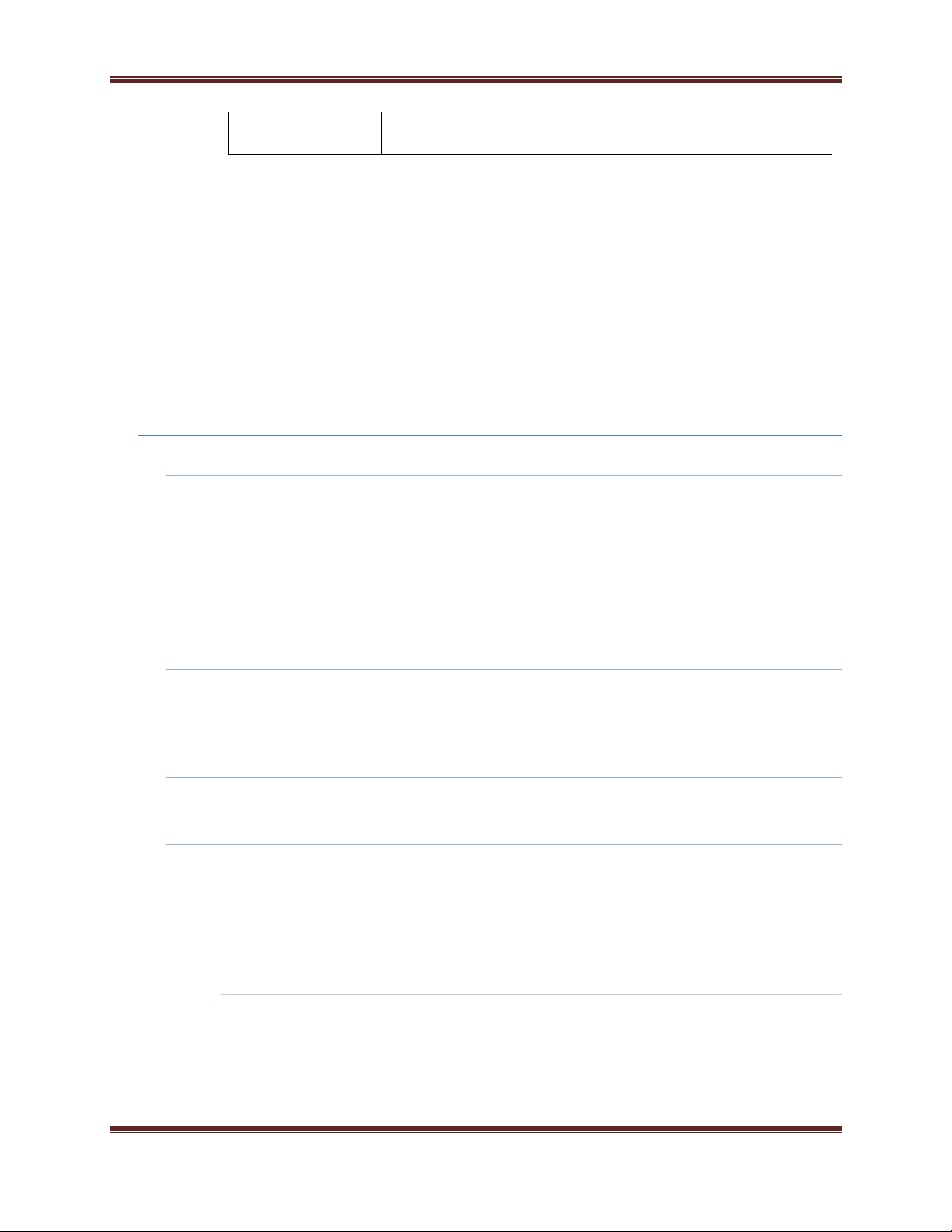

Specification

XBee Wi-Fi

UART Pins

Module Pin Number

DOUT/DIO13

2

DIN/DIO14

3

nCTS/DIO7

12

nRTS/DIO6

16

Specification

XBee Wi-Fi

SPI Pins

Module Pin Number

SPI_SCLK/DIO2

18

SPI_SSEL/DIO3

17

SPI_MOSI/DIO4

11

SPI_MISO/DIO12

4

SPI_ATTN/DIO9

13

Serial Communications Specifications

The XBee Wi-Fi RF modules support both UART (Universal Asynchronous Receiver/Transmitter)

and SPI (Serial Peripheral Interface, in master or slave mode) serial connections.

UART

More information on UART operation is found in the UART section in chapter 2.

SPI

The SC2 (Serial Communication Port 2) of the module is connected to the SPI port.

SPI Pin Assignments

XBee® Wi-Fi RF Modules

For more information on SPI operation see the SPI section in chapter 2.

© 2011 Digi International, Inc. Page 12

Page 13

Parameter

Condition

Min

Typ

Max

Units

Input Low Voltage

0.3VDD

V

Input High Voltage

0.7VDD

V

Output high Voltage relative to

VDD

Sourcing 6mA, VDD=3.0V

95 %

Output low voltage relative to

VDD

Sourcing 6mA, VDD=3.0V

5 %

Output fall time

0.5 mA drive strength and load

capacitance CL=12.5-25pF.

20+0.1CL

250

ns

2 mA drive strength and load

capacitance CL=350-600pF.

20+0.1CL

250

ns

I/O pin hysteresis (VIOTHR+ Viothr-)

VDD=3 to 3.6V

0.1VDD

V

Pulse width of pulses to be

removed by the glitch

suppression filter

10 50

ns

GPIO Specifications

The XBee Wi-Fi modules have 14 GPIO (General Purpose Input Output) ports available. Those

available will depend on the module configuration as some GPIO’s are consumed by serial

communication, etc.

See GPIO section for more information on configuring and using GPIO ports

Electrical Specification for GPIO pads

XBee® Wi-Fi RF Modules

© 2011 Digi International, Inc. Page 13

Page 14

XBee® Wi-Fi RF Modules

Specification

XBee Wi-Fi

United States (FCC Part 15.247)

FCC ID: MCQ-XBS6

Industry Canada (IC)

IC: 1846A-XBS6

Europe (DC)

ETSI

Australia

Pending

Brazil

Pending

Japan

Pending

Pin #

Name

Direction

Default State

Description

1

VCC

- - Power Supply

2

DOUT/DIO13

Both

Output

UART Data out

3

Din/nConfig/DIO14

Both

Input

UART Data In

4

DIO12/SPI_MISO

Both

Output

GPIO/ SPI slave out

5

nRESET

Input

Module Reset

6

DIO10

Both

GPIO

7

DIO11

Both

GPIO

8

reserved

-

Disabled

Do Not Connect

9

nDTR/SLEEP_RQ/DIO8

Both

Input

Pin Sleep Control line /GPIO

10

GND

- - Ground

11

DIO4/AD4/SPI_MOSI

Both

GPIO/SPI slave In

12

nCTS/DIO7

Both

Output

Clear-to-Send Flow

Control/GPIO

13

On_nSLEEP/DIO9/SPI_nATTN

Output

Output

Module Status Indicator/GPIO

14

VREF

Input - NC

15

Associate/DIO5

Both

Output

Associate Indicator/GPIO

16

nRTS/DIO6

Both

Input

Request-to-Send Flow

Control/GPIO

17

AD3/DIO3/SPI_nSSEL

Both

Analog Input/GPIO/SPI Select

18

AD2/DIO2/SPI_CLK

Both

Analog Input/GPIO/SPI Clock

19

AD0/DIO0

Both

Analog Input/GPIO

20

AD1/DIO1

Both

Analog Input/GPIO

Agency Approvals

FCC Approval (USA) Refer to Chapter 12 FCC Requirements. Systems that contain XBee Wi-Fi modules inherit Digi

Certifications.

Pin Signals

Pin Assignment for the XBee Wi-Fi module

(Low‐asserted signals are distinguished with a lower case n before the signal name.)

© 2011 Digi International, Inc. Page 14

Page 15

XBee® Wi-Fi RF Modules

Design Notes

The XBee modules do not specifically require any external circuitry or specific connections for

proper operation. However, there are some general design guidelines that are recommended

for help in troubleshooting and building a robust design.

Power Supply

Poor power supply can lead to poor radio performance especially if the supply voltage is not

kept within tolerance or is excessively noisy. To help reduce noise a 1uF and 8.2pF capacitor

are recommended to be placed as near to pin 1 on the PCB as possible. If using a switching

regulator for your power supply, switching frequencies above 500 kHz are preferred. Power

supply ripple should be limited to a maximum 50mV peak to peak.

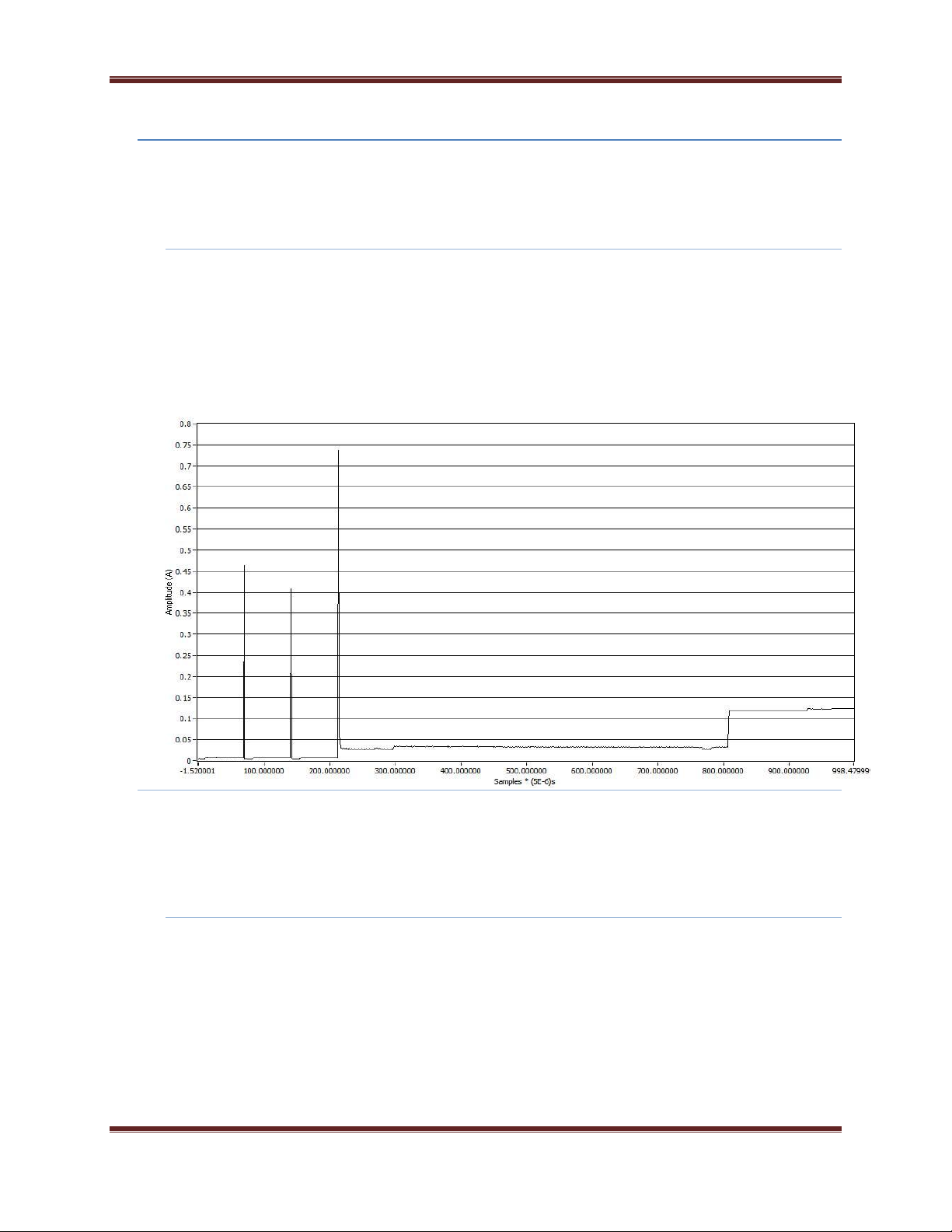

Typical start up current for the module is shown in the graph below:

Due to the fast nature of the current peaks, it is recommended that at least a 500uF capacitor

be placed on the VCC line. This will enable the XBee to start up with an acceptable voltage

slump in the power supply.

Recommended Pin Connections

The only required pin connections are VCC, GND, and either DOUT and DIN or SPI_CLK,

SPI_SSEL, SPI_MOSI, and SPI MISO. To support serial firmware updates, VCC, GND,

DOUT, DIN, RTS, and DTR should be connected.

All unused pins should be left disconnected. All inputs on the radio can be pulled high

with 30k internal pull-up resistors using the PR software command. No specific

treatment is needed for unused outputs.

© 2011 Digi International, Inc. Page 15

Page 16

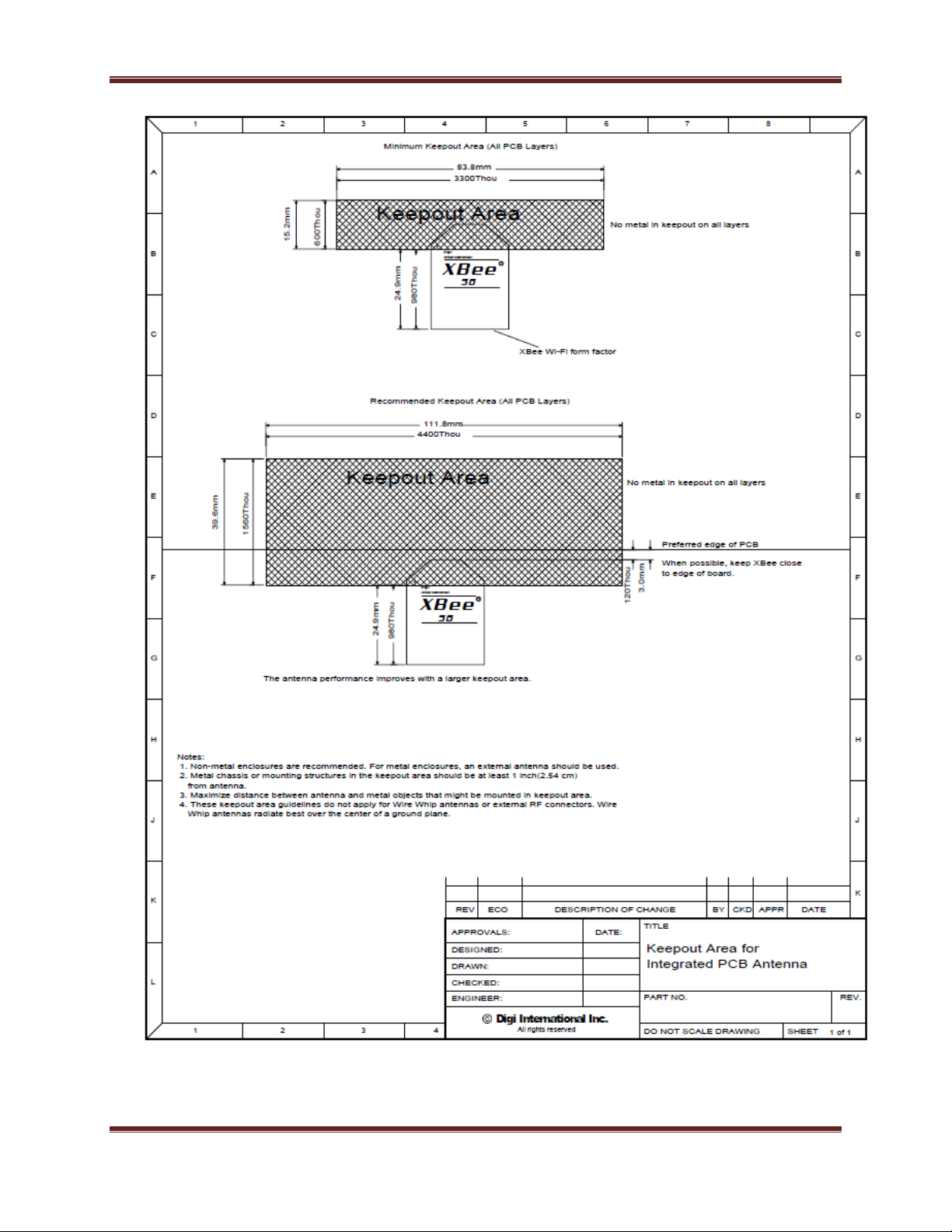

Board Layout

The radios are also designed to be self sufficient and work with the integrated and

XBee® Wi-Fi RF Modules

For applications that need to ensure the lowest sleep current, inputs should never be

left floating. Use internal or external pull-up or pull-down resistors, or set the unused

I/O lines to outputs.

Other pins may be connected to external circuitry for convenience of operation

including the Associate pin (pin 15) and the On_nSLEEP pin (pin 13) will change level or

behavior based on the state of the module.

XBee modules do not have any specific sensitivity to nearby processors, crystals or other

PCB components. Other than mechanical considerations, no special PCB placement is

required for integrating XBee radios except for those with integral antennas. In general,

Power and GND traces should be thicker than signal traces and be able to comfortably

support the maximum currents.

external antennas without the need for additional ground planes on the host PCB.

However, considerations should be taken on the choice of antenna and antenna

location. Metal objects that are near an antenna cause reflections and may reduce the

ability for an antenna to efficiently radiate. Using an integral antenna in an enclosed

metal box will greatly reduce the range of a radio. For this type of application an

external antenna would be a better choice.

External antennas should be positioned away from metal objects as much as possible.

Metal objects next to the antenna or between transmitting and receiving antennas can

often block or reduce the transmission distance. Some objects that are often overlooked

are metal poles, metal studs or beams in structures, concrete (it is usually reinforced

with metal rods), metal enclosures, vehicles, elevators, ventilation ducts, refrigerators

and microwave ovens.

Antennas should reside above or away from any metal objects like batteries, tall

electrolytic capacitors or metal enclosures. Antenna elements radiate perpendicular to

the direction they point. Thus a vertical antenna emits across the horizon.

PCB Antennas should not have any ground planes or metal objects above or below the

module at the antenna location. For best results the module should be in a plastic

enclosure, instead of metal one. It should be placed at the edge of the PCB to which it is

mounted. The ground, power and signal planes should be vacant immediately below the

antenna section (See drawing for recommended keep out area).

© 2011 Digi International, Inc. Page 16

Page 17

XBee® Wi-Fi RF Modules

© 2011 Digi International, Inc. Page 17

Page 18

Mounting Considerations

XBee modules were designed to mount into a receptacle (socket) and therefore do not require

any soldering when mounting to a board. The XBee Wi-Fi Development Kits contain 2 USB

interface boards which use two 10-pin receptacles to receive modules.

The receptacles used on Digi development boards are manufactured by Century Interconnect.

Several other manufacturers provide comparable mounting solutions; however, Digi currently

uses the following receptacles:

Through-hole single-row receptacles - Samtec P/N: MMS-110-01-L-SV (or equivalent)

Through-hole single-row receptacles - Mill-Max P/N: 831-43-0101-10-001000

Surface-mount double-row receptacles - Century Interconnect P/N: CPRMSL20-D-0-1 (or

equivalent)

Surface-mount single-row receptacles - Samtec P/N: SMM-110-02-SM-S

Digi also recommends printing an outline of the module on the board to indicate the

orientation the module should be mounted.

XBee® Wi-Fi RF Modules

© 2011 Digi International, Inc. Page 18

Page 19

XBee® Wi-Fi RF Modules

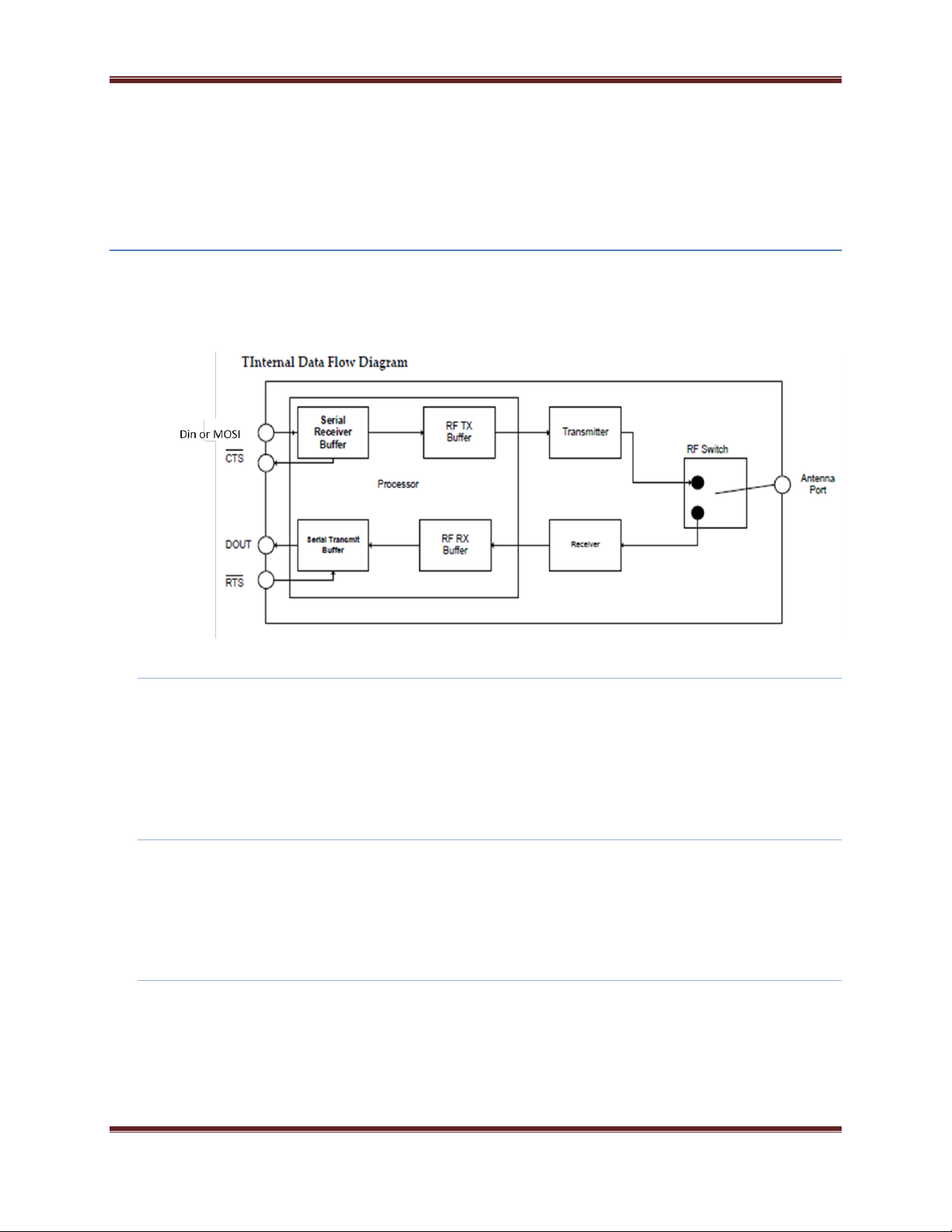

2. RF Module Operation

Serial Communications

The XBee RF Modules interface to a host device through a logic-level asynchronous serial port, or

a Serial Peripheral Interface (SPI) port. Through its serial ports, the module can communicate

with any logic and voltage compatible UART or SPI; or through a level translator to any serial

device (for example: through a RS-232 or USB interface board).

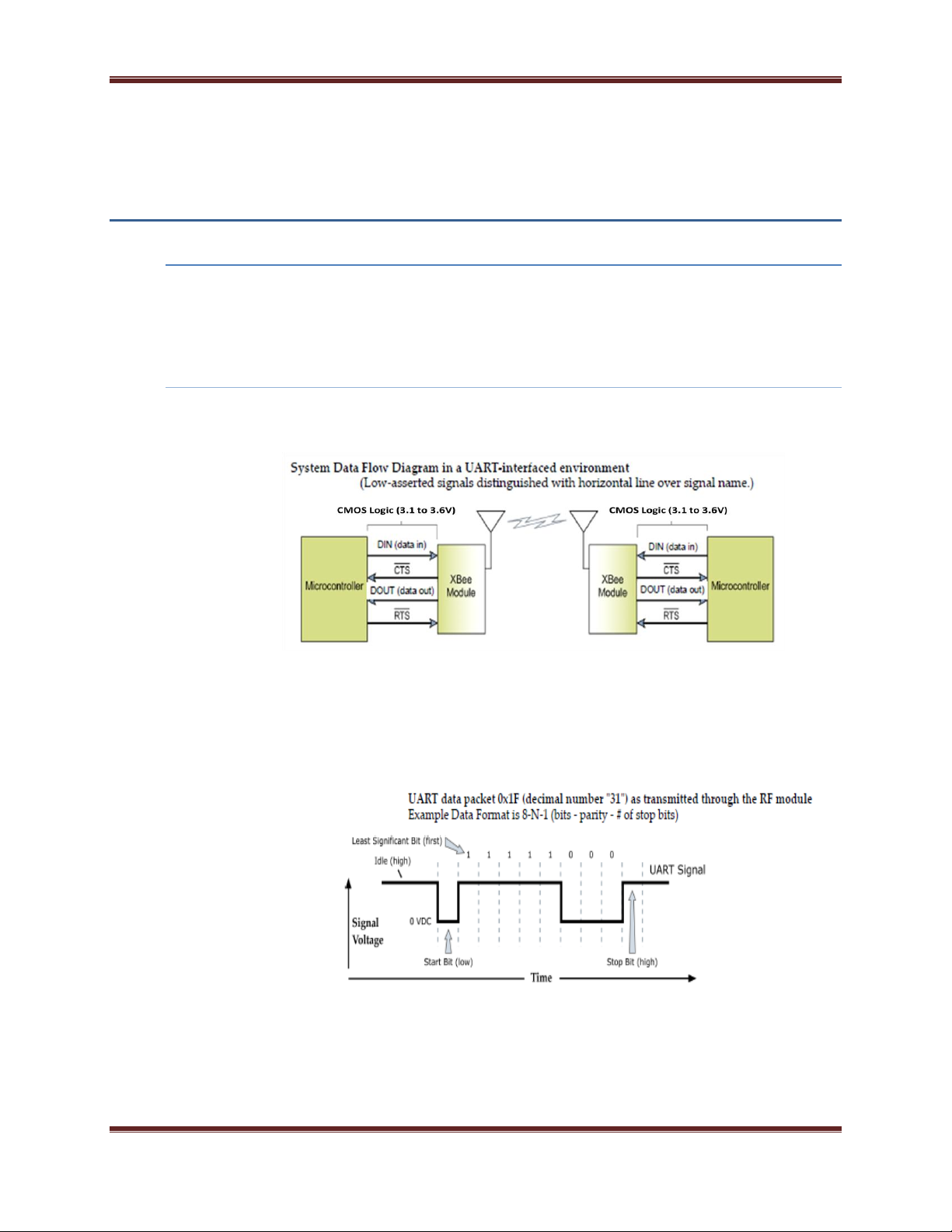

UART Communications

UART Data Flow

Devices that have a UART interface can connect directly to the pins of the RF module as shown in

the figure below.

UART Serial Data

Data enters the module UART through the DIN (pin 3) as an asynchronous serial signal. The signal

should idle high when no data is being transmitted.

Each data byte consists of a start bit (low), 8 data bits (least significant bit first) and a stop bit

(high). The following figure illustrates the serial bit pattern of data passing through the module.

Serial communications depend on the two UARTs (the microcontroller's and the RF module's) to

be configured with compatible settings (baud rate, parity, start bits, stop bits, data bits).

The UART baud rate, parity, and stop bits settings on the XBee module can be configured with

the BD, NB, and SB commands respectively. See the command table in chapter 10 for details.

© 2011 Digi International, Inc. Page 19

Page 20

XBee® Wi-Fi RF Modules

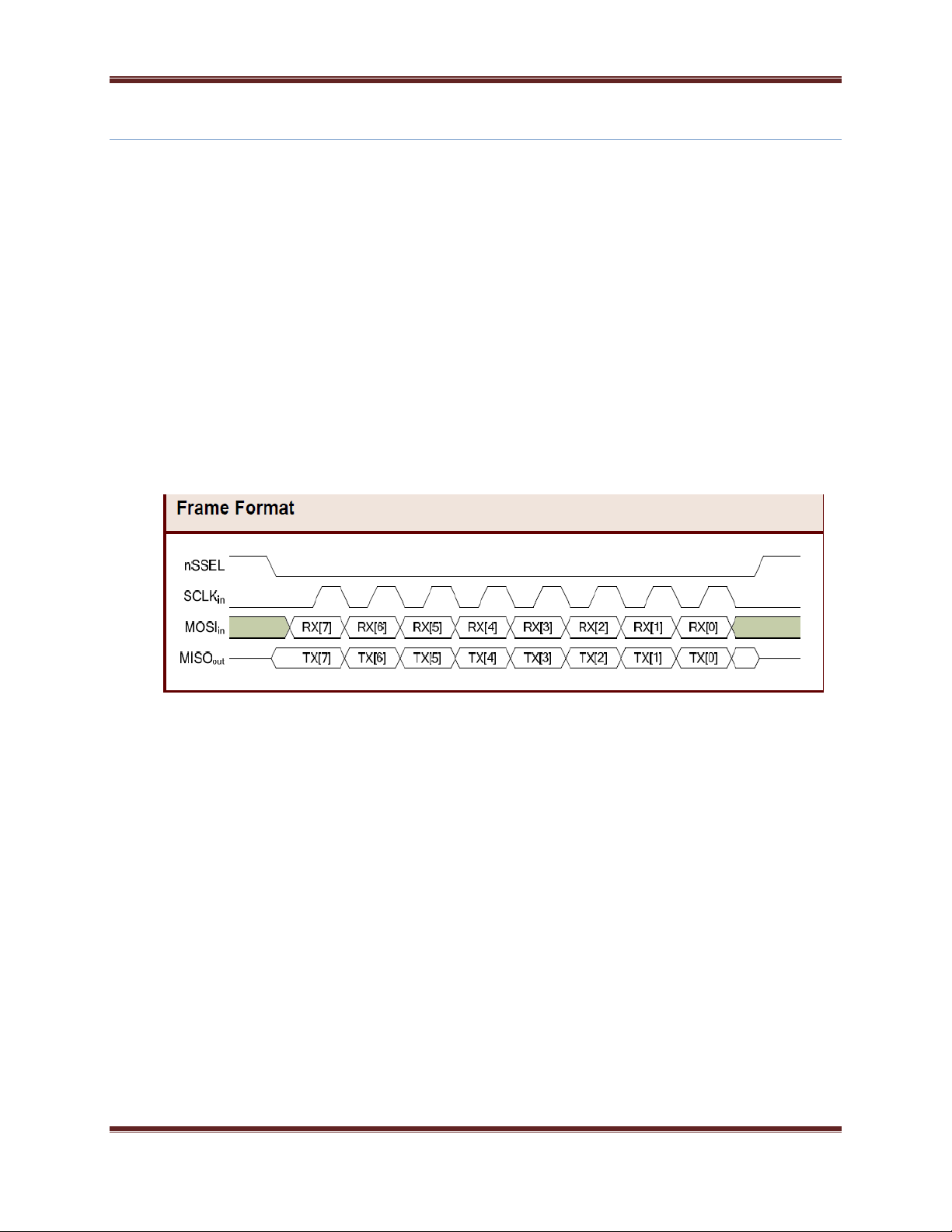

SPI Communications

The XBee Wi-Fi module supports SPI communications in the slave mode. Slave mode receives the clock signal

and data from the master and returns data to the master. The SPI port uses the following signals on the XBee:

SPI_MOSI (Master Out, Slave In) – inputs serial data from the master

SPI_MISO (Master In, Slave Out) – outputs serial data to the master

SPI_SCLK (Serial Clock) – clocks data transfers on MOSI and MISO

SPI_nSSEL (Slave Select) – enables serial communication with the slave

SPI_nATTN(Attention) – Alerts the master that slave has data queued to send. The XBee module will

assert this pin as soon as data is available to send to the SPI master and it will remain asserted until

the SPI master has clocked out all available data.

In this mode the following apply:

SPI Clock rates up to 3.5 MHz are possible.

Data is MSB first

Frame Format mode 0 is used. This means CPOL=0 (idle clock is low) and CPHA=0 (data is sampled on

the clock’s leading edge). Mode 0 is diagramed below.

SPI port is setup for API mode and is equivalent to AP=1.

Frame Format for SPI communications

SPI mode is chip to chip communication. Digi does not supply SPI communication option on the Device

Development Evaluation Boards.

SPI mode is enabled by holding DOUT/DIO13 (pin 2) low while resetting the module until SPI_nATTN

asserts. By this means, the XBee Wi-Fi module will disable the UART and go straight into SPI

communication mode. Once configuration is completed, a modem status frame is queued by the module

to the SPI port which will cause the SPI_nATTN line to assert. The host can use this to determine that the

SPI port has been configured properly. This method internally forces the configuration for the AP, D2, D3,

D4, D9, and P2 commands as needed for SPI operations. As long as a WR command is not issued, these

configuration values will revert back to previous values after a power on reset. If, on the other hand, a

WR command is issued while in SPI mode, these same parameters will be written to flash. It is then the

user’s responsibility to set these parameters as appropriate

When the slave select (SPI_nSSEL) signal is asserted by the master, SPI transmit data is driven to the

output pin SPI_MISO, and SPI data is received from the input pin SPI_MOSI. The SPI_nSSEL pin has to be

asserted to enable the transmit serializer to drive data to the output signal SPI_MISO. A falling edge on

SPI_nSSEL causes the SPI_MISO line to be tri-stated such that another slave device can drive it, if so

desired..

© 2011 Digi International, Inc. Page 20

Page 21

XBee® Wi-Fi RF Modules

If the output buffer is empty, the SPI serializer transmits the last valid bit repeatedly, which may be either

high or low. Otherwise, the module formats all output in API mode 1 format, as described in chapter 7.

The attached host is expected to ignore all data that is not part of a formatted API frame.

Serial Buffers

The XBee modules maintain buffers to collect received serial and RF data, which is illustrated in the figure

below. The serial receive buffer collects incoming serial characters and holds them until they can be

processed. The serial transmit buffer collects data that is received via the RF link that will be transmitted out

the UART or SPI port

Serial Receive Buffer

When serial data enters the RF module through the DIN Pin (or the MOSI pin), the data is stored in the

serial receive buffer until it can be processed. Under certain conditions, the module may not be able to

process data in the serial receive buffer immediately. If large amounts of serial data are sent to the

module such that the serial receive buffer would overflow, then the new data will be discarded. If the

UART is in use, this can be avoided by the host side honoring CTS flow control.

Serial Transmit Buffer

When RF data is received, the data is moved into the serial transmit buffer and sent out the UART or SPI

port. If the serial transmit buffer becomes full and system buffers are also full, then the entire RF data

packet is dropped. Whenever data is received faster than it can be processed and transmitted out the

serial port, there is a potential of dropping data, even in TCP mode.

UART Flow Control

The nRTS and nCTS module pins can be used to provide RTS and/or CTS flow control. CTS flow control

provides an indication to the host to stop sending serial data to the module. RTS flow control allows the

host to signal the module to not send data in the serial transmit buffer out the UAR. RTS and CTS flow

control are enabled using the D6 and D7 commands.

© 2011 Digi International, Inc. Page 21

Page 22

XBee® Wi-Fi RF Modules

nCTS Flow Control

The FT command allows the user to specify how many bytes of data can be queued up in the serial

transmit buffer before the module asserts CTS low. The serial receive buffer can hold up the 2100 bytes,

but FT cannot be set any larger than 2083 bytes, leaving 17 bytes that can be sent by the host before the

data is dropped.

By default, FT is 2035 (0x7F3), which allows the host to send 65 bytes to the module after the module

asserts CTS before the data is dropped.

In either case, CTS will not be re-asserted until the serial receive buffer has FT-17 or less bytes in use.

nRTS Flow Control

If RTS flow control is enabled (D6 command), data in the serial transmit buffer will not be sent out the

DOUT pin as long as nRTS is de-asserted (set high). The host device should not de-assert nRTS for long

periods of time to avoid filling the serial transmit buffer. If an RF data packet is received, and the serial

transmit buffer does not have enough space for all of the data bytes, the entire RF data packet will be

discarded.

Note: If RTS flow control is enabled and the XBee is sending data out the UART when nRTS is de-asserted

(set high), the XBee could send up to 4 characters out the UART to clear its FIFO after nRTS is de-asserted.

This implies that the user needs to de-assert nRTS by the time its receive capacity is within 4 bytes of full.

Serial Interface Protocols

The XBee modules support both transparent and API (Application Programming Interface) serial

interfaces.

Transparent Operation

When operating in transparent mode, the modules act as a serial line replacement. All UART

data received is queued up for RF transmission. When RF data is received, the data is sent out

through the UART. The module configuration parameters are configured using the AT command

mode interface. Please note that transparent operation is not an option when using SPI.

Data is buffered in the serial receive buffer until one of the following causes the data to be

packetized and transmitted:

No serial characters are received for the amount of time determined by the RO

parameter. If RO is zero, data is packetized as soon as it is received, without delay.

If RO is non-zero, the data is packetized after RO character times of no transitions

on the DIN pin. However, if the time required for RO characters is less than 100

microseconds, then DIN must still be idle for at least 100 microseconds, which is the

minimal idle time required for packetizing packets at any baud rate.

The Command Mode Sequence (GT + CC + GT) is received. Any character buffered in

the serial receive buffer before the sequence is packetized and transmitted before

command mode is entered.

The maximum number of characters that will fit in an RF packet is received.

© 2011 Digi International, Inc. Page 22

Page 23

XBee® Wi-Fi RF Modules

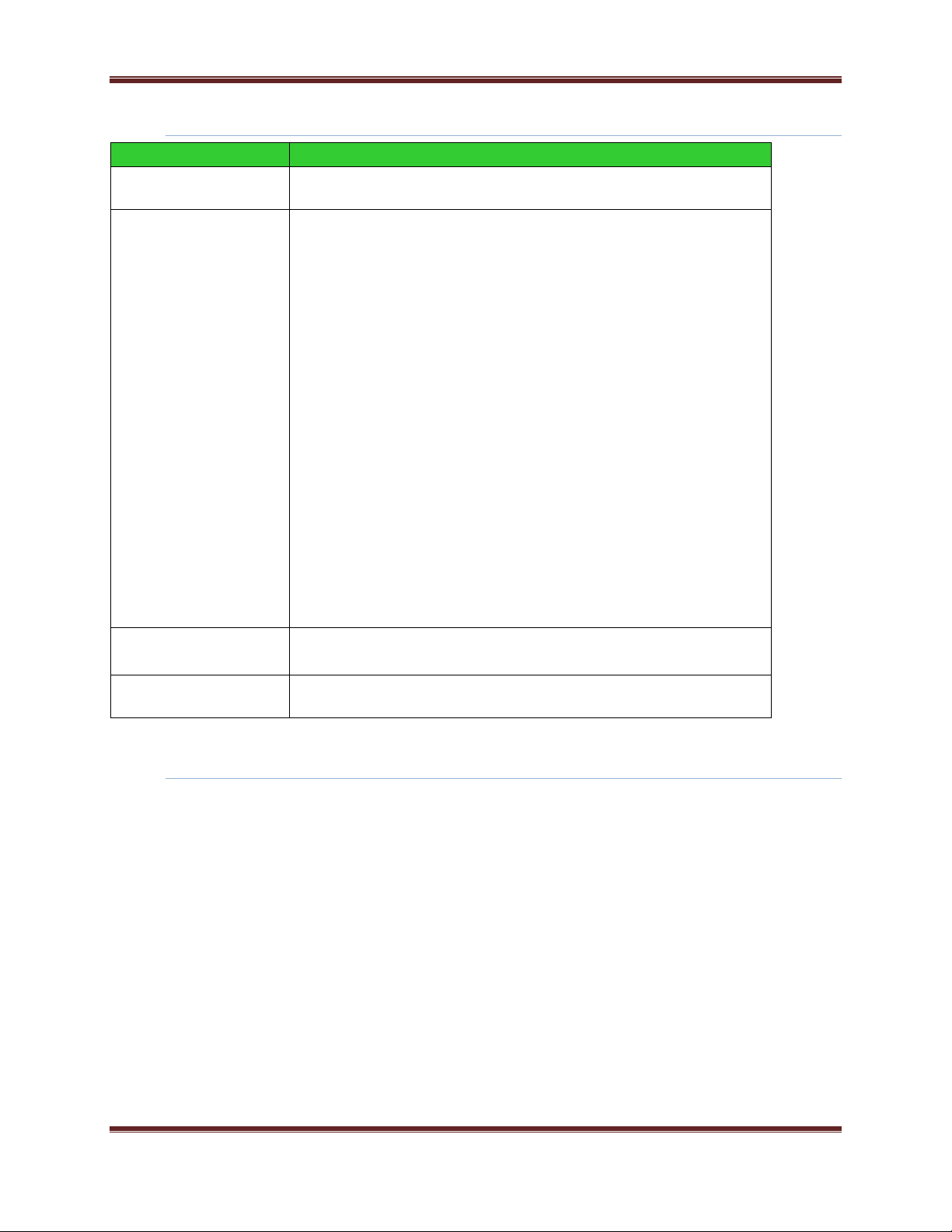

Transparent Operation Features

Simple Interface

All received serial data is transmitted unless the module is in command mode.

Easy to support

It is easier for an application to support transparent operation and command mode.

API Operation Features

Easy to manage data

transmissions to multiple

destinations

Transmitting RF data to multiple remotes only requires changing the address in the

API frame. This Process is much faster than transparent operation where the

application must enter AT command mode, change the address, exit command mode,

and then transmit data. Each API transmission can return a transmit status frame

indicating the success or reason for failure

Received data frames

indicate the sender's

address

All received RF data API frames indicate the source address.

Advanced Networking

diagnostics

API frames can provide indication of IO samples from remote devices, transmission

status messages, and local radio status messages.

API Operation

API operation is an alternative to transparent operation. The frame-based API extends the level

to which a host application can interact with the networking capabilities of the module. When in

API mode, all data entering and leaving the UART or SPI is contained in frames that define

operations or events within the module.

Transmit Data Frames (received through the DIN pin (pin 3) or SPI_MOSI (pin 11 )) include:

RF Transmit Data Frame

Local commands (equivalent to AT commands)

Remote commands to be sent to another radio

Receive Data Frames (sent out the DOUT pin (pin 2) or SPI_MISO (pin 4 )) include:

RF-received data frames

Local command responses

Remote command responses

I/O samples from a remote radio

Event notifications such as transmission status, reset, associate, disassociate, etc.

The API provides an alternative means of configuring modules and of routing data at the local

host application layer. A local host application can send data frames to the module that contain

address and payload information instead of using command mode to modify addresses. The

module will send data frames to the application containing status packets; as well as source, and

payload information from received data packets. The API operation option facilitates many

operations such as the examples cited below:

Transmitting data to multiple destinations without entering Command Mode

Receive success/failure status of each transmitted RF packet

Identify the source address of each received packet

A Comparison of Transparent and API Operation

The following table compares the advantages of transparent and API modes of operation:

© 2011 Digi International, Inc. Page 23

Page 24

Remote Configuration

Set/read configuration commands can be sent to remote devices to configure them

as needed using the API.

As a general rule of thumb, API firmware is recommended when a device:

If the above conditions do not apply, (e.g. in a sensor node, or a simple application) then

transparent operation might be suitable. It is acceptable to use a mixture of devices

running API mode and transparent mode in a network.

Modes of Operation

Idle Mode

When not receiving or transmitting data, the RF module is in Idle Mode. The module

shifts into the other modes of operation under the following conditions:

XBee® Wi-Fi RF Modules

sends RF data to multiple destinations

sends remote configuration commands to manage devices in the network

receives IO samples from remote devices

receives RF data packets from multiple devices, and the application needs to

know which device sent which packet

Transmit Mode (Serial data in the serial receive buffer is ready to be packetized)

Receive Mode (Valid RF data is received through the antenna)

Sleep Mode

Command Mode (Command Mode Sequence is issued)

Transmit Mode

When serial data is received and is ready to be packetized, the RF module will exit Idle

Mode and attempt to transmit the data. The destination address determines which

node(s) will receive the data.

Receive Mode

If a valid RF packet is received, the data is transferred to the serial transmit buffer.

Command Mode

To modify or read RF Module parameters, the module must first enter into Command

Mode - a state in which incoming serial characters are interpreted as commands. Refer

to the API Operation chapter for an alternate means of configuring modules, which is

the only method available for SPI mode. (Command mode is unavailable when using the

SPI interface.)

AT Command Mode

To Enter AT Command Mode:

Send the 3-character command sequence “+++” and observe guard times before and

after the command characters. [Refer to the “Default AT Command Mode Sequence”

below.]

© 2011 Digi International, Inc. Page 24

Page 25

XBee® Wi-Fi RF Modules

Default AT Command Mode Sequence (for transition to Command Mode):

No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

Input three plus characters (“+++”) within one second *CC (Command Sequence

Character) parameter = 0x2B.]

No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

Once the AT command mode sequence has been issued, the module sends an "OK\r"

out the UART. The "OK\r" characters can be delayed if the module has not finished

transmitting received serial data.

When command mode has been entered, the command mode timer is started (CT

command), and the module is able to receive AT commands on the UART or SPI port.

All of the parameter values in the sequence can be modified to reflect user preferences.

NOTE: Failure to enter AT Command Mode is most commonly due to baud rate

mismatch. By default, the BD (Baud Rate) parameter = 3 (9600 bps).

To Send AT Commands, send AT commands and parameters using the syntax shown

below:

To read a parameter value stored in the RF module’s register, omit the parameter field.

The preceding example would change the RF module baud rate to 7, which would allow

operation at 115,200bps. To store the new value to non-volatile (long term) memory,

subsequently send the WR (Write) command.

For modified parameter values to persist in the module’s registry after a reset, changes

must be saved to non-volatile memory using the WR (Write) Command. Otherwise,

parameters are restored to previously saved values after the module is reset.

Command Response

When a command is sent to the module, the module will parse and execute the

command. Upon successful execution of a command, the module returns an “OK”

message. If execution of a command results in an error, the module returns an “ERROR”

message.

Applying Command Changes

Any changes made to the configuration command registers through AT commands will

not take effect until the changes are applied. For example, sending the BD command to

© 2011 Digi International, Inc. Page 25

Page 26

Sleep Mode

Sleep modes allow the RF module to enter states of low power consumption when not in use.

The XBee Wi-Fi modules support both pin sleep (sleep mode entered on pin transition) and

cyclic sleep (module sleeps for a fixed time). XBee sleep modes are discussed in detail in chapter

5.

XBee® Wi-Fi RF Modules

change the baud rate will not change the actual baud rate until changes are applied.

Changes can be applied in one of the following ways:

The AC (Apply Changes) command is issued.

AT command mode is exited.

To Exit AT Command Mode:

1. Send the ATCN (Exit Command Mode) command (followed by a carriage return).

[OR]

2. If no valid AT Commands are received within the time specified by CT (Command

Mode Timeout) Command, the RF module automatically returns to Idle Mode.

For an example of programming the RF module using AT Commands and descriptions

of each configurable parameter, please see the Command Reference Table chapter.

© 2011 Digi International, Inc. Page 26

Page 27

XBee® Wi-Fi RF Modules

3. 802.11 bgn Networks

Infrastructure Networks

The main type of wireless network will involve a number of wireless devices (called

stations) talking through a master wireless device known as an Access Point (AP for

short). This type of setup is called an Infrastructure or BSS (Basic Service Set) network.

Most wireless networks are of this type. An example of an infrastructure wireless

network is shown below:

Infrastructure Wireless Network

Ad Hoc Networks

Wireless devices can get on a wireless network without an access point. This is called an

Ad Hoc or IBSS (Independent Basic Service Set) network. An example of an ad hoc

wireless network is shown below:

© 2011 Digi International, Inc. Page 27

Page 28

XBee® Wi-Fi RF Modules

Network Basics

Clients will need to join the wireless network before they can send data across it. This is

called Association. In order for a device to associate it must know the following items about

the desired wireless network:

SSID: the name of the wireless network.

Encryption: if and how the network encrypts or scrambles its data.

Authentication: how and if the network requires its members to ―prove their identity.

Channel: what channel (frequency range) the wireless network uses.

Once a device is associated it can send and receive data from other associated devices on

the same network. When the client is done or needs to leave, it then can Dis-associate and

be removed from the wireless network.

XBee® Wi-Fi Standards

The XBee Wi-Fi module will operate in three of the available 802.11 standards.

802.11 b

The 802.11b standard was approved in July 1999 and can be considered the second

generation. 802.11b operates in the 2.4 GHz frequency ISM band. The data rate is from

1 to 11 Mbps.

802.11 g

The 802.11g standard was approved in 2003. It provides a maximum data rate of 54

Mbps. In addition, the standard is also fully backwards-compatible with existing 802.11b

wireless networks.

802.11 n

The 802.11n standard was approved in 2009. It provides for data rates up to 300Mbps.

The XBee® Wi-Fi module uses the single stream n mode with 20MHz bandwidth and is

capable of 65 Mbps over the air in n mode.

Encryption

Encryption is a method of scrambling a message that makes it unreadable to unwanted

parties, adding a degree of secure communications. There are different protocols for

providing encryption, and the XBee Wi-Fi module supports WPA, and WPA2.

AUTHENTICATION

Authentication deals with proving the identity of the wireless device attempting to

associate with the network. There are different methods of doing this. The XBee Wi-Fi

module supports Open and Shared Key.

Open

Open Authentication is when the access point simply accepts the wireless devices

identify without verifying or proving it. The benefits to this is simplicity and compatibility

(all devices can do it).

© 2011 Digi International, Inc. Page 28

Page 29

XBee® Wi-Fi RF Modules

Shared Key

Shared Key is when the wireless devices must present the proper key to get on the

network. Although Shared Key has more security than Open Authentication it should

not be considered secure. One of the benefits of Shared Key Authentication is simplicity.

CHANNELS

The XBee® Wi-Fi modules operate in the 2.412-2.484 MHz range. The frequency range is

broken down into 14 channels. Data is transmitted on a channel by radio frequencies

over a certain frequency range. In order to avoid bad performance caused by the

overlapping (“collision”) of channel frequencies in a wireless LAN environment, it is very

important that the channels of neighboring access points are selected accordingly.

The center frequencies of the 14 possible channels range from 2.412 GHz to 2.484 GHz,

with each channel being 22 MHz wide and centered in 5 MHz intervals. This means that

only 3 channels (1, 6, and 11) in North America are not subject to overlapping.

4. XBee IP Services

The XBee provides services using IP (Internet Protocol) for XBee and other clients on the

network. IP services provide functionality to allow XBee configuration and direct serial port

access. There are two XBee services:

© 2011 Digi International, Inc. Page 29

Page 30

XBee® Wi-Fi RF Modules

XBee Application Service

Serial Communication Service

XBee Application Service

This service primarily provides for XBee configuration. It also provides API compatibility

for customers who have designed around other XBee’s. It uses UDP to transfer packets

on port number 0xBEE. Packets are optionally acknowledged by the service but retries

are not available. An extra header is added to the packet data to define commands for

configuration and serial data transfer. The following sections describe how this service

can be accessed from a local host or network client.

Local Host

From a local host this functionality is accessed through XBee API frames. There are

remote AT command frames as well as transmission frames. The API frames are listed

as follows:

TX request: 64-bit (TX64)

RX indicator: 64-bit (RX64)(This frame is generated by the XBee module.)

Remote AT command

TX64 and RX64 API frames

The intent of the XBee transmit and receive 64-bit API frames is to provide a

standardized set of API frames to use for a point to multipoint network—a

closed network of XBee Wi-Fi modules. These frames are compatible with the

XBee 802.15.4 module.

Transmitting data

The local host uses the TX64 frame to send data to another XBee using this

service. When the frame is received through the serial port the XBee converts

the contents of the frame to a serial data transfer command as defined by the

XBee application service.

Receiving data

A received Serial data transfer command will go to the serial port. The mode of

the serial port will determine the format of the data. When in API mode the

data will be sent to the host using the RX 64-bit frame.

Note: It is not recommended to use this service to send data to a network client.

Use the serial communication service.

Remote AT command configuration

The Remote AT command frame is used to change configuration on a remote Xbee. See

Remote AT command frame in the API Operation chapter for more information.

© 2011 Digi International, Inc. Page 30

Page 31

Field

Name

Offset

Description

Command

ID

0

Serial Data:0x0

Remote AT command:0x2 Application acknowledgements are not supported

Serial Data Acknowledgement: 0x80 Sent in response to option bit 1 sent for the Serial Data

command

Serial Data Acknowledgement: 0x80

Remote AT command response:0x82

Command

options

1

Packet Fields

Offset

Example

Description

Client Packet Data

Command

ID

0 0x02

Command

options

1

0

Options are not available for this command

Command

Specific

Data

Frame ID 2 0x01

This is provided for application support and is not used by the

XBee. The value will be sent back as part of the response

packet.

Configuration

options

3

0x02

0 – Queue command parameter. Must send AC command or

use option 2 to apply changes.

2 – Apply changes to all changed commands

AT Command

MSB 4

0x49 (I)

Command Name - Two ASCII characters that identify the AT

command

LSB 5

0x44(D)

Parameter Value

If present, indicates the requested parameter value to set the

given command. If no characters present, command is

queried.

Network Client

This port is accessed by sending a packet from the client using the UDP protocol on port 0xBEE.

Data sent to this port must have an additional header preceding the data. The header

description follows:

Sending configuration commands

AT commands can be sent to the XBee Wi-Fi module from a network client. The following packet

structure must used to send the command.

XBee® Wi-Fi RF Modules

The response will be sent back to the host with the following bytes.

© 2011 Digi International, Inc. Page 31

Page 32

Packet Fields

Offset

Example

Description

Client Packet Data

Command ID

0

0x82

Command

Options

1

0x00

Options not available for this response

Command

Specific Data

Frame ID

3

0x01

Copied from the command

Configuration

command options

3

0x88

Options not available for this response

AT Command

MSB 5

0x49 (I)

Command Name - Two ASCII characters that identify

the AT command

LSB 6

0x44 (D)

Status 0x00

0 = OK

1 = ERROR

2 = Invalid Command

3 = Invalid Parameter

Parameter Value

7

The first

byte of

the ID

value

would

start here

Register data in binary or ASCII format, based on the

command. For the ID command, the data is in ASCII

format. If the command was set, then this field is not

returned.

Packet Fields

Offset

Example

Description

Client Packet data

Command ID

0

0

Command

Options

1

0x2

bit 1 - Request acknowledgment be sent.

Command

Specific Data

Serial Data

3

0x01

Can be up to 1400 bytes. Data will be sent out the

XBee's serial port.

XBee® Wi-Fi RF Modules

Sending serial data command to XBee

Using this service to send data out the serial port is not required. Most users will choose to use

the Serial Communication Service (see below) for sending data from a network client. One

reason to use the XBee Application Service to send the serial data command from a network

client is to receive an acknowledgment when sending a UDP packet.

The client can request an acknowledgement from the XBee but must wait to receive the

acknowledgement before sending the next packet. The client is responsible for retransmissions

due to missed acknowledgments. When resending packets, duplicates can be received at the

destination due to a successful serial data command and a failed acknowledgment packet. The

host in this case must be able to handle duplicate packets.

Serial Data Command:

© 2011 Digi International, Inc. Page 32

Page 33

XBee® Wi-Fi RF Modules

Packet Fields

Offset

Example

Description

Client Packet Data

Command ID

0

0x80

Command

Options

1

0x0

Options not available for this response

Command

Specific Data

No command specific data

X

B

e

e

P

a

c

k

e

t

D

a

t

a

Frame Fields

Offset

Example

Description

Command ID

0

0x04

Command

Options

1

0x00

Options not available for this response

Command

Specific Data

Number Samples

3

0x01

Will be set to one. DIO and ADC considered a sample. At

least one DIO or ADC must be enabled to get this packet

type.

Digital Mask

MSB 4

0x00

Bit Mask. Each bit represents an enabled DIO I/O line

starting with DIO0 at bit 0.

LSB 5

0x01

Analog Mask

6

0x02

Bit Mask. Each bit represents an enabled ADC starting

with ADC0 at bit 0.

Digital Sample

MSB 7

0x00

This field is only present if at least one DIO I/O is

enabled. Use the digital mask to determine if sample is

present. Each bit represents a DIO line start with bit 0 for

DIO0.

LSB 8

0x01

Analog Sample

MSB 9

0x01

Analog Samples start here and will be in order as

indicated in the Analog Mask. Only those lines enabled

will be sent. In the example this sample is for AD1.

LSB 10

0x00

Supply Voltage

11

0xC1C

Indicates that the supply voltage is 0xC1C = 3100

(decimal) mV = 3.1V on the radio that sent the I/O

sample

Serial Data command acknowledgment if requested:

Receiving I/O sampled data

Sample data generated by the module will be sent to the address configured by the DL

commands. This data can be sent to either XBee or a network client. It will be sent using UDP on

the 0xBEE port as with other XBee Application services. Sample data will be received by the

client as follows:

© 2011 Digi International, Inc. Page 33

Page 34

XBee® Wi-Fi RF Modules

Serial Communication Service

A client or XBee can send data directly to the serial port using this service. No additional header

or formatting is required. The port is configured using the C0 command. The behavior of this

service varies based on the mode of the serial port and is discussed in the following sections.

Transparent mode

Only one port is available and can be either UDP or TCP. It is configured through the IP

command. Data received by the service is sent to the serial port without any additional

processing.

UDP

When the IP command is configured for UDP, data received on the serial

port will be packetized and sent to the IP address specified by the DL

command and to the destination port specified by the DE command.

The source port is defined by the C0 command.

TCP

TCP provides for a connection based protocol. When in transparent

mode the module will only allow one connection at a time. A

connection can be initiated by a local host or by a network client.

A local host initiates a connection by sending data to the serial port. A

connection will be created based on the DL (IP address) and DE

(destination port) commands.

A network client establishing a TCP connection to the XBee will use the

port defined by the C0 command. When established any data sent by

the local host will not create a new connection based on DL and DE, but

rather the existing connection will be utilized.

API mode

Because API mode has more capabilities both UDP and TCP are supported at the

same time. The local host will utilize the TX IPv4 transmit frame to send data

from the module and will receive data through the RX IPv4 received frame.

These frames give greater IP control and visibility to the local host. See the API

section for more information.

© 2011 Digi International, Inc. Page 34

Page 35

XBee® Wi-Fi RF Modules

5. Sleep

The XBee Wi-Fi module supports two different sleep modes.

Pin Sleep

Cyclic Sleep

In addition the sleep mode current draw can be modified with the following sleep options.

AP Associated Sleep

Deep Sleep

Pin sleep allows an external microcontroller to determine when the XBee should sleep and when it

should wake by controlling the Sleep_RQ pin when using the UART or SPI_nSSEL when using SPI. In

contrast, cyclic sleep allows the sleep period and wake times to be configured through the use of AT

commands or through the DTIM setting on the access point (associated sleep). The module can stay

associated to the access point or can enter a deeper sleep and associate to the access point for each

sleep/wake occurrence. The sleep mode is configurable with the SM and SO commands.

Besides the four sleep modes mentioned above, each of them operate a little differently based on

the serial interface (UART or SPI).

Sleeping with the UART

When the serial interface is UART, the On/nSleep pin is used to indicate that the module is entering

sleep mode, unless pin 13 is configured for a different usage. (See command reference table) If D9

is configured for On/nSleep, then it is driven low when asleep and high when awake, whether using

pin sleep or cyclic sleep.

If CTS hardware flow control is enabled (D7 command), the CTS pin (pin 12) is de-asserted (high)

when entering sleep to indicate that serial data should not be sent to the module. The module will

not respond to serial or RF data when it is sleeping. Applications that utilize the UART are

encouraged to observe CTS flow control in any of the sleep modes. When the XBee wakes from

sleep with flow control enabled, the CTS pin is asserted (low).

If using pin sleep, D8 (mapped to XBee pin 9) must be configured for SleepRq (See command

reference table) to put the module to sleep. Otherwise, there is no sleep at all, meaning the module

will always stay awake in full power mode. When D8 is configured for SleepRq, the host should

drive pin 9 high to wake the module up and the host should drive pin 9 low to wake the module up.

Sleeping with the SPI

When the serial interface is SPI, pin 13 is used as an attention indicator to tell the SPI master when it

has data to send. Since SPI only operates in API mode, it will assert SPI/nATTN and send out a

modem status indicator after initialization. The host can use this to know when the radio is ready to

operate as a SPI slave. Since the function of pin 13 is to indicate when the XBee has data to send to

the host, it may legitimately be driven high or low while the module is awake. Therefore, there is no

equivalent to the On/nSleep indicator when using the SPI.

© 2011 Digi International, Inc. Page 35

Page 36

XBee® Wi-Fi RF Modules

SPI_SSEL (pin 17) is the equivalent of SleepRq for the SPI interface. The SPI master drives pin 17 low

not only to indicate that the XBee is selected as the active slave, but also to indicate that the XBee

should wake up. When the SPI master drives pin 17 high, that gives the XBee license to go back to

sleep, which it will do after data is clocked out.

Sleep Options

AP Associated sleep

This option allows the module to sync up with beacons sent from the AP which contains

the DTIM (Delivery Traffic Indication Message). The DTIM indicates when broadcast and

multicast data will be sent on the network. This property is configured on the AP and is

typically configured as a number that sets up an interval of beacon sent between

beacons with DTIM.

The sleep modes are described as follows with this option enabled.

Pin sleep mode

The module remains associated to the AP and will wake based on the period of the

DTIM. This wake period will not be seen by the local host unless data has been sent to

the module. In this case the module will ‘wake’ by asserting the appropriate I/O lines.

The local UART host is then required to de-assert SleepRq to awaken the module. Note

that the module will be drawing more current when waiting for the host to de-assert

SleepRq. Once SleepRq is de-asserted the module will then send the data to the host.

SPI operation is similar except that the radio asserts nATTN when data becomes

available and then the local host is expected to assert SPI_SSEL and to provide a clock

until the data available is sent out.

When the local UART host needs to send data it de-asserts SleepRq. Once the

appropriate status I/O lines are asserted (CTS and/or On/nSleep) the module is ready to

accept data. However data will be queued and not sent until the next DTIM.

When the local SPI host needs to send data it asserts nATTN. This wakes up the module,

which will then accept the incoming data. However data will be queued and not sent

until the next DTIM.

Cyclic sleep mode

The module remains associated to the AP and will sleep based on the period of the

DTIM. After DTIM, the module will awaken for 30 milliseconds to check for data from

the AP and to allow the host to send data or commands. This time is factored in as part

of the overall ST time. When data is received or sent then the module will remain

awake for ST time and any further activity will not restart this time. The module will

draw the RX current during the wake period.

Deep sleep (non-associated sleep)

© 2011 Digi International, Inc. Page 36

Page 37

XBee® Wi-Fi RF Modules

This option allows the Wi-Fi circuitry to be power down resulting in the lowest sleep

current but at the expense of longer wake up times. This is due to the module

associating with the access point every time it wakes up. The intent of this option is to

allow for very long sleep times.

Pin sleep mode

In this mode when SleepRq _RQ is asserted the module will power down the Wi-Fi

circuitry. When SleepRq is de-asserted the Wi-Fi circuitry is powered up. This causes

the module to associate to the access point for each wake event. The module could

take many seconds to complete the association and longer if DHCP is used.

Cyclic sleep mode

In this mode the module will enter and exit sleep based on the SP and ST commands.

The module will control power to the Wi-Fi circuitry as it cycles through sleep and wake.

This causes the module to associate to the access point for each wake event. The

module could take many seconds to complete the association and longer if DHCP is

used. However to control battery usage, ST specifies and limits the wake time. If ST

expires before association is successful, sleeping is resumed without ever associating. It

is the user’s responsibility to configure ST as needed. Also, the user should wait for

association after waking up before sending data. When data is sent by the local host

then the module will remain awake for ST time and any further activity will not restart

this time. The module will draw RX current during the wake period.

Sampling data using sleep modes

Data can be sampled when waking from any sleep mode by enabling an ADC or digital input and

setting IR appropriately with respect to ST to obtain the desired number of samples.

Sample Rate (ATIR)

If multiple samples are wanted during the wake period then IR can be used. This will

provide ST/IR+1 samples. Each sample will be sent separately.

Wake Host

Wake host parameter (ATWH) delays UART and sample data from being initiated until

the timer has expired. This allows the host to wake up before receiving data or a sensor

to power up before an I/O sample is taken.