Page 1

Digi International Inc.

11001 Bren Road East

Minnetonka, MN 55343

877 912-3444 or 952 912-3444

http://www.digi.com

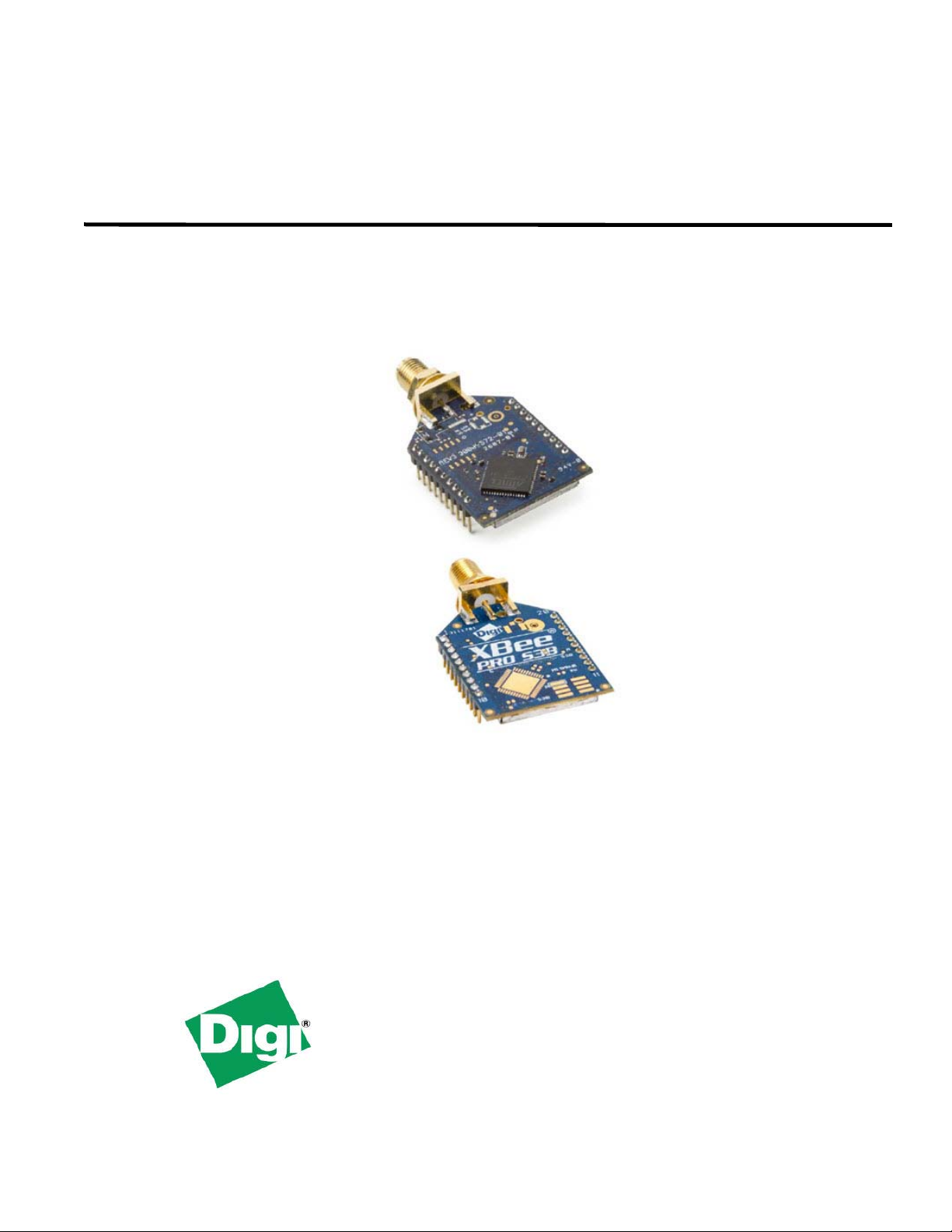

XBee-PRO® 900HP/XBee-PRO® XSC RF Modules

XBee-PRO RF Modules by Digi International

Models: XBEE-PRO S3, XBEE-PRO S3B

Hardware: S3, S3B

90002173_L

2/4/2014

Page 2

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

© 2014 Digi International Inc. All rights reserved

Nopartofthecontentsofthismanualmaybetransmittedorreproducedinany

formorbyanymeanswithoutthewrittenpermissionofDigiInternationalInc.

XBee‐PRO®isaregisteredtrademarkofDigiInternationalInc.

Technical Support: Phone: (866) 765-9885 toll-free U.S.A. & Canada

Online Support: http://www.digi.com/support

Email: rf-experts@digi.com

(801) 765-9885 Worldwide

8:00 am - 5:00 pm [U.S. Mountain Time]

©2014DigiInternationalInc. 2

Page 3

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Contents

1. Preface: How to Use this Manual 6

2. XBee-PRO 900HP RF Module Hardware 7

XBee-PRO S3B Hardware Description 7

Worldwide Acceptance 7

XBee-PRO 900HP Specifications 8

XBee-PRO 900HP Serial Communications

Specifications 9

UART 9

SPI 9

GPIO Specifications 9

Hardware Specifications for Programmable

Variant 10

XBee-PRO 900HP Mechanical Drawings 11

XBee-PRO 900HP Pin Signals 12

XBee-PRO 900HP Design Notes 12

XBee-PRO 900HP Power Supply Design 12

XBee-PRO 900HP Recommended Pin Connections

12

XBee-PRO 900HP Board Layout 13

XBee-PRO 900HP Module Operation for

Programmable Variant 13

XBee-PRO 900HP Programmable Bootloader 15

Overview 15

Bootloader Software Specifics 15

XBee-PRO 900HP Bootloader Menu Commands 19

XBee-PRO 900HP Firmware Updates 20

Output File Configuration 20

3. XBee-PRO 900HP RF Module Operation 22

XBee-PRO 900HP Basic Operational Design 22

XBee-PRO 900HP Serial Communications 22

XBee-PRO 900HP UART Data Flow 22

XBee-PRO 900HP SPI Communications 23

XBee-PRO 900HP SPI Operation 24

XBee-PRO 900HP Configuration 25

XBee-PRO 900HP Data Format 26

XBee-PRO 900HP SPI Parameters 26

XBee-PRO 900HP Serial Buffers 27

XBee-PRO 900HP UART Flow Control 27

XBee-PRO 900HP Serial Interface Protocols 28

XBee-PRO 900HP Modes of Operation 29

XBee-PRO 900HP Description of Modes 29

Transmit Mode 29

Receive Mode 31

Command Mode 31

Sleep Mode 32

4. XBee-PRO 900HP Networking Methods 33

MAC/PHY Basics 33

Related parameters: CM, HP, ID, PL, RR, MT 33

XBee-PRO 900HP Addressing Basics 33

Related parameters: SH, SL, DH, DL, TO 33

Point to Point/Multipoint (P2MP) 34

Throughput 34

Repeater/Directed Broadcast 34

Related parameters: CE, NH, NN, BH 34

DigiMesh Networking 35

Related Command: MR 35

DigiMesh Feature Set 35

Data Transmission and Routing 35

Transmission Timeouts 36

5. XBee-PRO 900HP Sleep Mode 38

Sleep Modes 38

Normal Mode (SM=0) 38

Asynchronous Pin Sleep Mode (SM=1) 38

Asynchronous Cyclic Sleep Mode (SM=4) 38

Asynchronous Cyclic Sleep with Pin Wake Up Mode

(SM=5) 39

Synchronous Sleep Support Mode (SM=7) 39

Synchronous Cyclic Sleep Mode (SM=8) 39

Asynchronous Sleep Operation 39

Wake Timer 39

XBee-PRO 900HP Indirect Messaging and Polling

(P2MP Packets Only) 40

Indirect Messaging 40

Polling 40

Synchronous Sleep Operation (DigiMesh

networks only) 40

Operation 40

Becoming a Sleep Coordinator 43

DigiMesh Configuration 44

DigiMesh Diagnostics 46

6. XBee-PRO 900HP Command Reference Tables 47

7. XBee-PRO 900HP API Operation 58

API Frame Format 58

XBee-PRO 900HP API Serial Exchanges 60

AT Commands 60

Transmitting and Receiving RF Data 60

Remote AT Commands 60

©2014DigiInternationalInc. 3

Page 4

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Contents

Supporting the API 61

XBee-PORO 900HP Frame Descriptions 61

AT Command 61

AT Command - Queue Parameter Value 62

TX Request 62

Explicit TX Request 63

Remote AT Command Request 65

AT Command Response 66

Modem Status 66

Transmit Status 67

Route Information Packet 67

Aggregate Addressing Update 69

RX Indicator 70

Explicit Rx Indicator 71

Data Sample RX Indicator 72

Node Identification Indicator 72

Remote Command Response 74

75

8. XBee-PRO 900HP Advanced Application Features

XBee-PRO 900HP Remote Configuration

Commands 75

Sending a Remote Command 75

Applying Changes on Remote Devices 75

Remote Command Responses 75

XBee-PRO 900HP Network Commissioning and

Diagnostics 75

XBee-PRO 900HP Device Configuration 75

XBee-PRO 900HP Network Link Establishm ent and

Maintenance 76

XBee-PRO 900HP Device Placement 76

XBee-PRO 900HP Device Discovery 77

XBee-PRO 900HP Link Reliability 78

Commissioning Pushbutton and Associate LED 81

XBee-PRO 900HP I/O Line Monitoring 82

I/O Samples 82

Queried Sampling 82

Periodic I/O Sampling 84

Digital I/O Change Detection 85

General Purpose Flash Memory 85

Accessing General Purpose Flash Memory 85

Over-the-Air Firmware Upgrades 91

Distributing the New Application 91

Verifying the New Application 92

Installing the Application 92

Things to Remember 92

Appendix A: XSC Firmware 93

XBee-PRO XSC Key Features 94

Worldwide Acceptance 94

Xbee-PRO XSC Specifications 94

XBee-PRO XSC Pin Signals 96

Xbee-PRO XSC Electrical Characteristics 97

XBee-PRO XSC Timing Specifications 97

XBee-PRO XSC Mechanical Drawings 98

Serial Communications 100

UART-Interfaced Data Flow 100

Serial Data 100

Flow Control 101

XBee-PRO XSC Modes of Operation 102

Idle Mode 102

Transmit Mode 102

Sleep Mode 104

Command Mode 106

XBee Programming Examples 109

AT Commands 109

Binary Commands 109

XBee-PRO XSC Command Reference Table 110

XBee-PRO XSC Command Descriptions 111

XBee-PRO XSC Addressing 129

Address Recognition 129

XBee-PRO XSC Basic Communications 130

Streaming Mode (Default) 130

Repeater Mode 131

XBee-PRO XSC Acknowledged Communications

135

Acknowledged Mode 135

Agency Certifications for S3B Hardware 138

FCC (United States) Certification 138

Labeling Requirements 138

FCC Notices 138

Limited Modular Approval 139

FCC-approved Antennas 139

IC (Industry Canada) Certification 139

IDA (Singapore) Certification 143

Brazil ANATEL 143

Agency Certifications for Legacy S3/S3B Hardware

144

FCC (United States) Certification 144

Labeling Requirements 144

FCC Notices 144

Limited Modular Approval 145

©2014DigiInternationalInc. 4

Page 5

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Contents

FCC-approved Antennas 145

IC (Industry Canada) Certification 145

ANATEL (Brazil) Certification 149

Additional Information 150

©2014DigiInternationalInc. 5

Page 6

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Preface:HowtoUsethisManual

This combined manual contains documentation for two hardware platforms: the S3 and S3B. Existing S3

customers are strongly encouraged to migrate their systems and designs to the newer and sup erior S3B

platform.

This manual also contains documentation for two RF protocols: XStream Compatible (XSC) and 900HP. The

XSC firmware is provided for customers who need compatibility with existing networks that need to be

9XStream compatible. Customers who do not require this compatibility should not use th e XSC firmware, but

rather the newer 900HP firmware.

Documentation for the XSC firmware is contained in Appendix A. All other firmware documentation in the

manual is not applicable to XSC firmware. Likewise documentation in Appendix A is not applicable to the

900HP firmware.

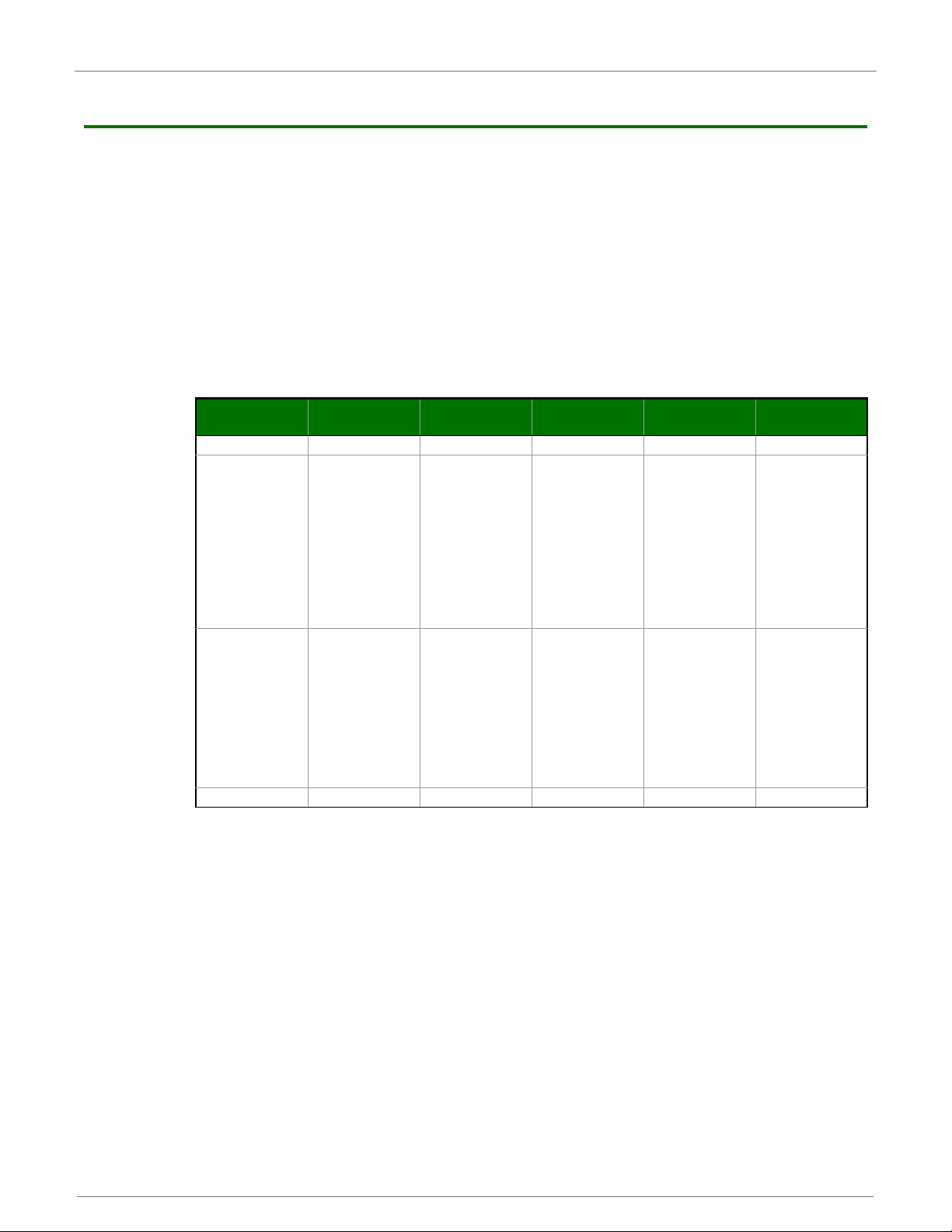

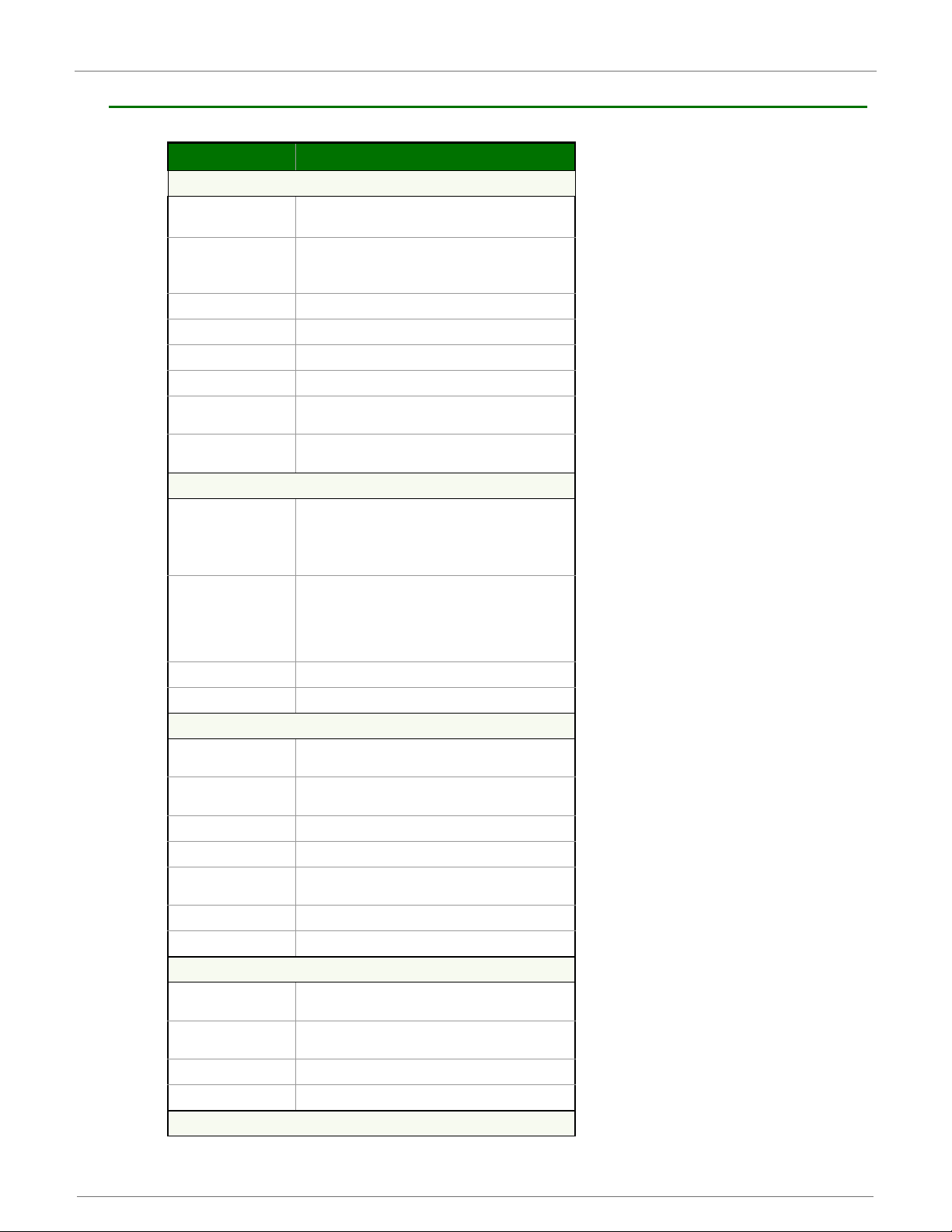

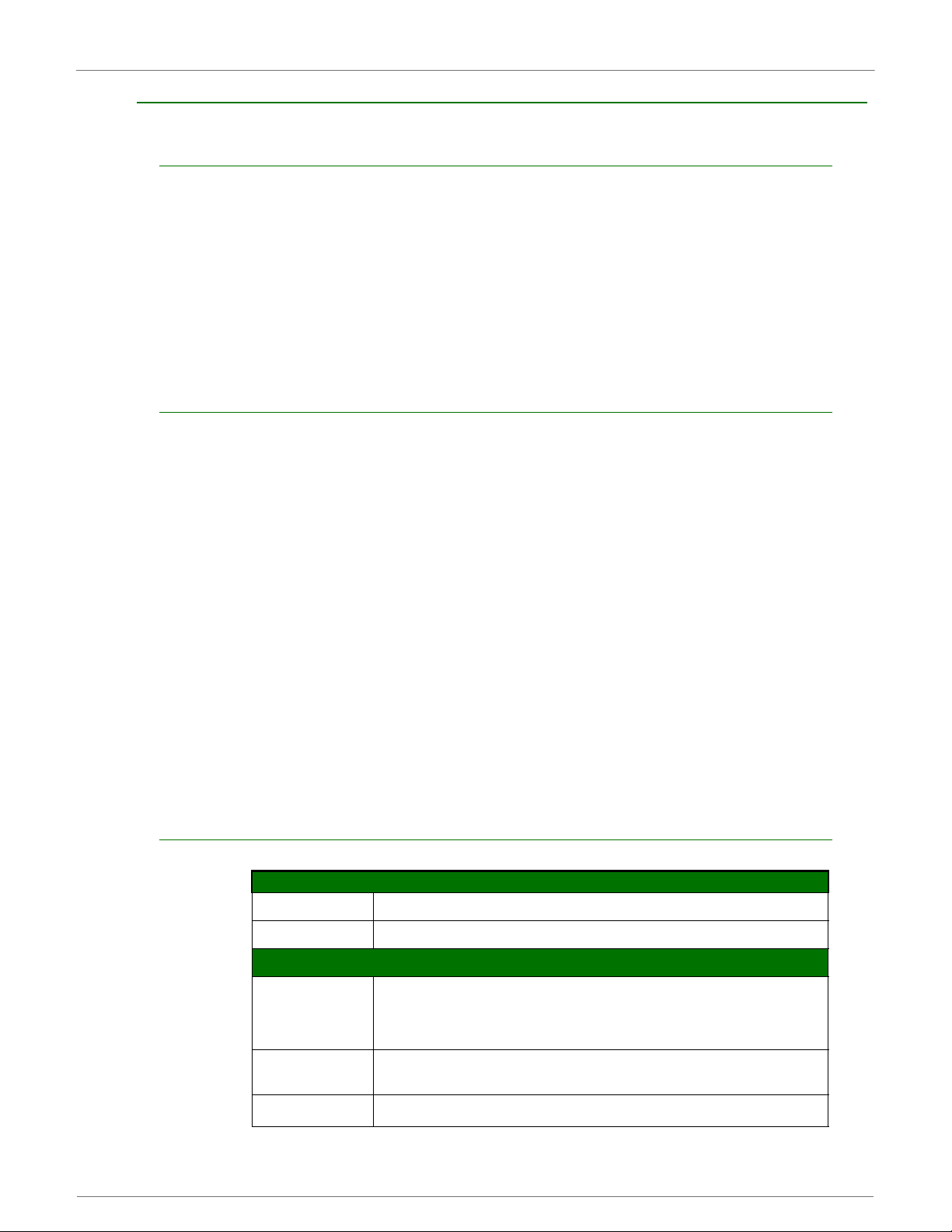

The following table describes how to use this manual based on the Digi part number for the module:

Digi Part

Numbers

XBP09-XC… MCQ-XBEEXSC S3 XSC XSC Appendix C

XBP9B-XC*T-001

(revision G and

earlier)

XBP9B-XC*T-002

(revision G and

earlier)

XBP9B-XC*T-021

(revision F and

earlier)

XBP9B-XC*T-022

(revision F and

earlier)

XBP9B-XC*T-001

(revision H and later)

XBP9B-XC*T-002

(revision H and later)

XBP9B-XC*T-021

(revision G and later)

XBP9B-XC*T-022

(revision G and later)

all other part numbers

beginning XBP9B-

XC...

XBP9B-D… MCQ-XB900HP S3B 900HP XSC / 900HP Appendix B

FCC ID

MCQ-XBPS3B S3B XSC XSC Appendix C

MCQ-XB900HP S3B XSC XSC / 900HP Appendix B

Hardware

Platform

Pre-installed

Firmware

Firmware

Available

Regulatory

Information

©2014DigiInternationalInc. 6

Page 7

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

1.XBee‐PRO900HPRFModuleHardware

This manual describes the operation of the XBee-PRO® 900HP RF module, which consists of firmware loaded onto XBeePRO S3B hardware.

XBee-PRO 900HP embedded RF modules provide wireless connectivity to end-point devices in mesh networks. Utilizing

the XBee-PRO Feature S et, th ese module s are inte roper a ble wi th ot her devi ces. Wi th the XBee , us ers ca n ha v e t hei r network up-and-running in a matter of minutes without configuration or additional development.

XBee-PRO S3B Hardware Description

The XBee-PRO S3B radio module hardware consists of an Energy Micro EFM32G230F128 microcontroller, an

Analog Devices ADF7023 radio transceiver, an RF power amplifier, and in the programmable version, a

Freescale MC9S08QE32 microcontroller.

Worldwide Acceptance

FCC Certified (USA) - Refer to Appendix B for FCC Requirements.

Systems that include XBee-PRO Modules in herit Digi’s FCC Certification

ISM (Industrial, Scientific & Medical) frequency band

Manufactured under ISO 9001:2000 registered standards

XBee-PRO

RoHS compliant

®

(900 MHz) RF Modules are approved for use in U.S. and Canada.

©2014DigiInternationalInc. 7

Page 8

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

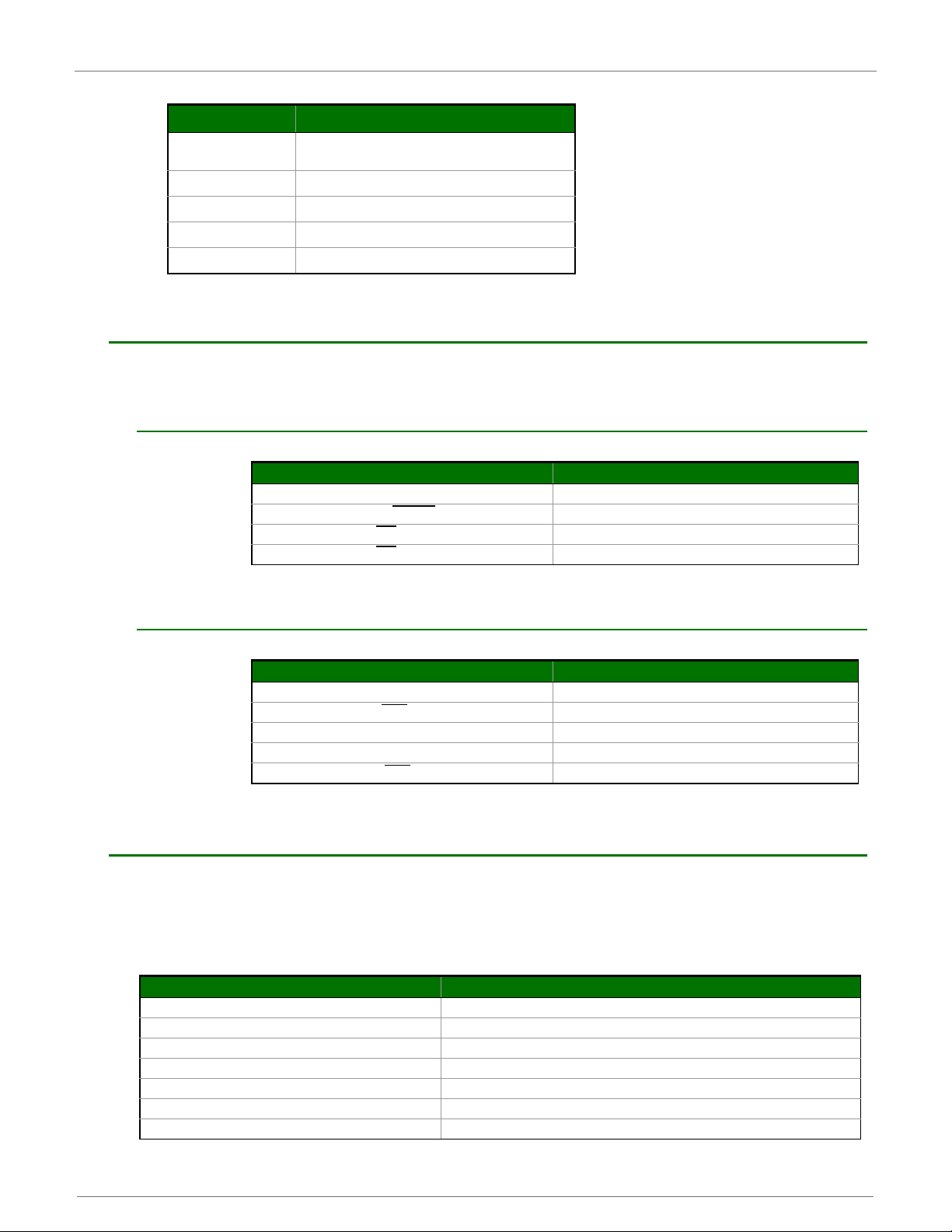

XBee-PRO 900HP Specifications

SpecificationsoftheXBee-PRO® 900HP/XBee-PRO® XSCRFModule

Specification XBee

Performance

* Indoor/Urban Range

* Outdoor RF line-of-sight

Range

Transmit Power Output 24 dBm (250 mW) (software selectable)

RF Data Rate (High) 200 kbps

RF Data Rate (Low) 10 kbps

Serial UART interface CMOS Serial UART, baud rate stability of <1%

Serial Interface Data Rate

(software selectable)

Receiver Sensitivity

(typical)

Power Requirements

Supply Voltage

Transmit Current

Idle / Receive Current 29mA typical at 3.3V, (35mA max)

Sleep Current 2.5 µA (typical)

General

**Operating Frequency

Band

Dimensions

Weight 5 to 8 grams, depending on the antenna option

Operating Temperature -40º to 85º C (industrial)

Antenna Options

Digital I/O 15 I/O lines,

ADC 4 10-bit analog inputs

Networking & Security

Supported Network

Topologies

Number of Channels, user

selectable channels

Addressing Options PAN ID, Preamble ID, and 64-bit addresses

Encryption 128 bit AES

Agency Approvals

-101 dBm, high data rate, -110 dBm, low data rate

**Supply voltages of less than 3.0V may

result in reduced performance. Output

power and receiver sensitivity may be

1.297" x 0.962" x 0.215 (3.29cm x 2.44cm x 0.546cm) Note:

Dimensions do not include connector/antenna or pin lengths

Integrated wire, U. FL RF connector, Rev erse-polarity SMA

Mesh, point-to-point, point-to-multipoint, peer-to-peer

10kbps: up to 2000 ft (610m)

200kbps: up to 1000 ft (305m)

10kbps: up to 9 miles (15.5km)

200kbps: up to 4 miles (6.5km)

(with 2.1dB dipole antennas)

PL=4 : 215mA typical, (290mA max)

902 to 928 MHz (software selectable channels)

9600-230400 baud

2.1 to 3.6 VDC**

degraded.

PL=3 : 160mA typical

PL=2 : 120mA typical

PL=1 : 95mA typical

PL=0 : 60mA typical

connector

64 channels available

©2014DigiInternationalInc. 8

Page 9

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

®

SpecificationsoftheXBee-PRO

Specification XBee

United States (FCC Part

15.247)

Industry Canada (IC) 1846A-XB900HP

Australia C-Tick

Brazil ANATEL 3727-12-1209 (S3B only)

Singapore License No. DA105737 (XB900HP only)

* To determine your range, perform a range test under your operating conditions.

900HP/XBee-PRO® XSCRFModule

MCQ-XB900HP

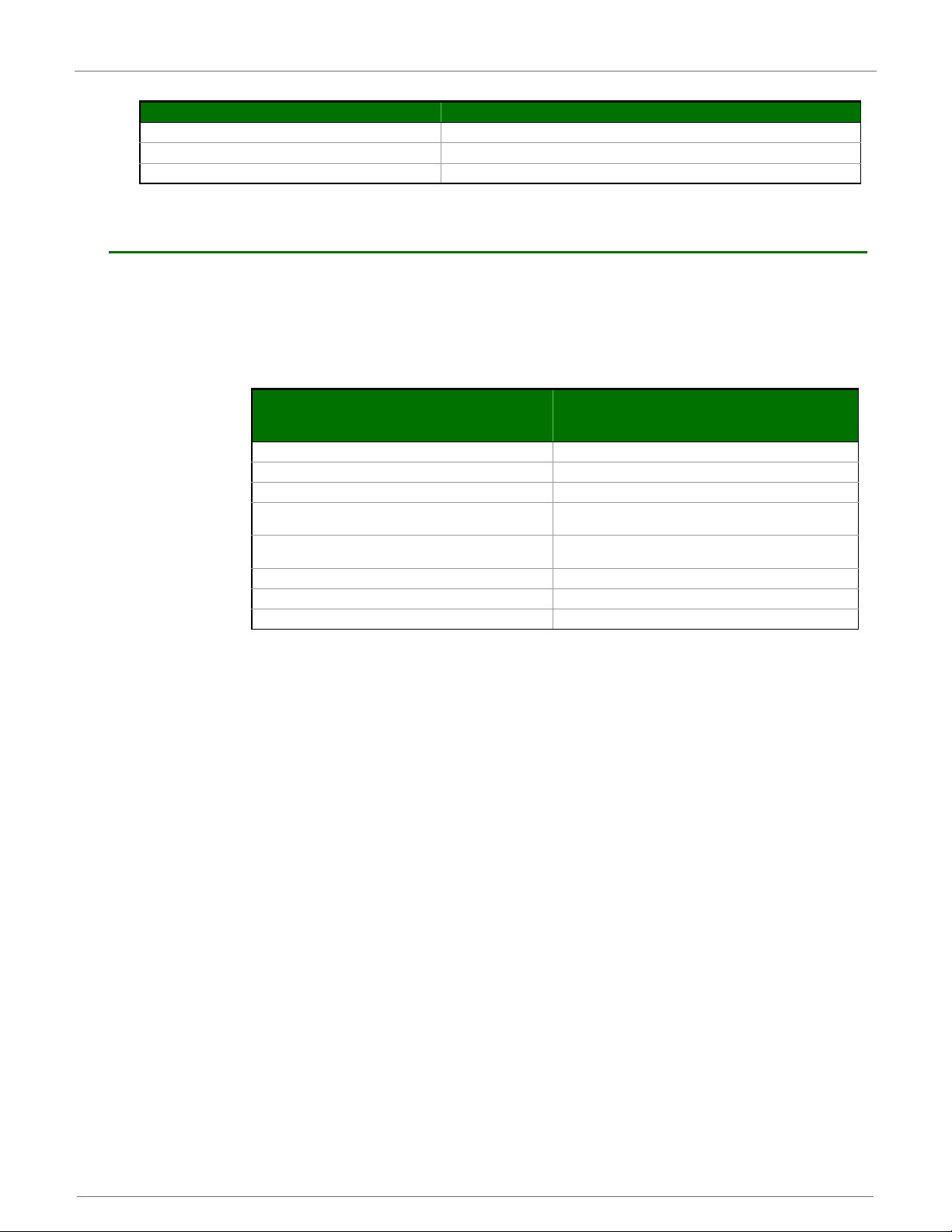

XBee-PRO 900HP Serial Communications Specifications

XBee RF modules support both UART (Universal Asynchronous Receiver / Transmitter) and SPI (Serial

Peripheral Interface) serial connections.

UART

UARTPinAssignments

UART Pins Module Pin Number

DOUT 2

DIN / CONFIG

/ DIO7 12

CTS

/ DIO6 16

RTS

3

More information on UART operation is found in the UART section in Chapter 2.

SPI

SPIPinAssignments

For more information on SPI operation, see the SPI section in Chapter 2.

GPIO Specifications

XBee RF modules have 15 GPIO (General Purpose Input/Output) ports available. The exact list will depend on

the module configuration, as some GPIO pins are used for purposes such as serial communication.

See GPIO section for more information on configuring and using GPIO ports.

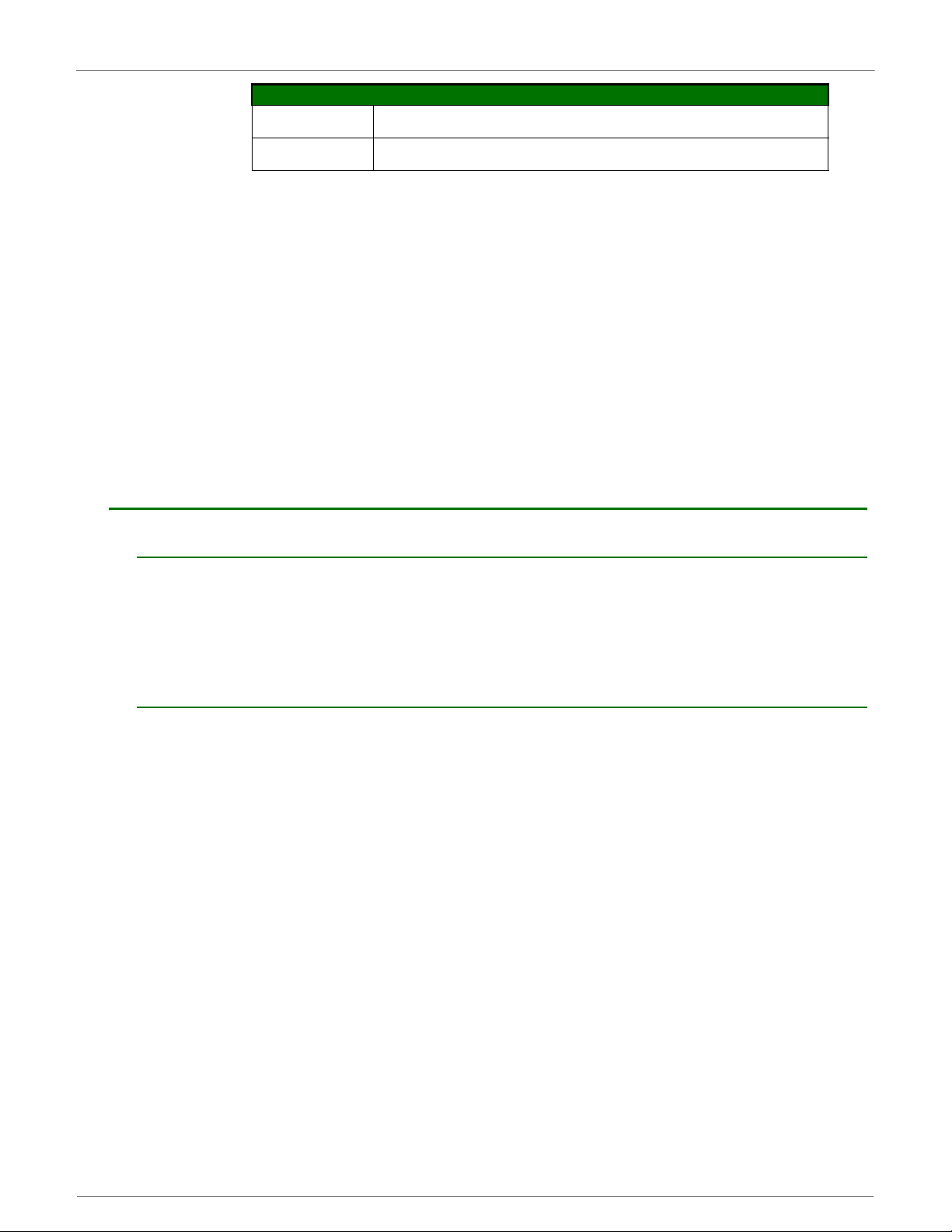

ElectricalSpecificationsforGPIOPins

GPIO Electrical Specification Value

Voltage - Supply 2.1 - 3.6 V, (3.0V or higher required for optimal performance)

Low Schmitt switching threshold 0.3 x Vdd

High Schmitt switching threshold 0.7 x Vdd

Input pull-up resistor value 40 k

Input pull-down resistor value 40 k

Output voltage for logic 0 0.05 x Vdd

Output voltage for logic 1 0.95 x Vdd

SPI Pins Module Pin Number

SPI_SCLK / DIO18 18

SPI_SSEL

SPI_MOSI / DIO16 11

SPI_MISO / DIO15 4

/ DIO17 17

SPI_ATTN

/ DIO1 19

©2014DigiInternationalInc. 9

Page 10

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

ElectricalSpecificationsforGPIOPins

GPIO Electrical Specification Value

Output source current 2 mA

Output sink current 2 mA

Total output current (for GPIO pins) 48 mA

Hardware Specifications for Programmable Variant

If the module has the programmable secondary processor, add the following table values to the specifications

listed on page 7. For example, if the secondary processor is running at 20 MHz and the primary processor is in

receive mode then the new current value will be I

runtime current of the secondary processor and I

Specificationsoftheprogrammablesecondaryprocessor

Optional Secondary Processor Specification

Runtime current for 32k running at 20MHz +14mA

Runtime current for 32k running at 1MHz +1mA

Sleep current +0.5A typical

For additional specifications see Freescale Datasheet and

Manual

Voltage requirement for secondary processor to operate at

maximum clock frequency

Minimum Reset Pulse for Programmable 100nS

Minimum Reset Pulse to Radio 50nS

VREF Range 1.8VDC to VCC

= Ir2 + I

total

is the receive current of the primary.

rx

= 14 mA + 9 mA = 23 mA, where I

rx

(Add to RX, TX, and sleep currents depending on

These numbers add to specifications

mode of operation)

MC9SO8QE32

2.4 to 3.6VDC

r2

is the

©2014DigiInternationalInc. 10

Page 11

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

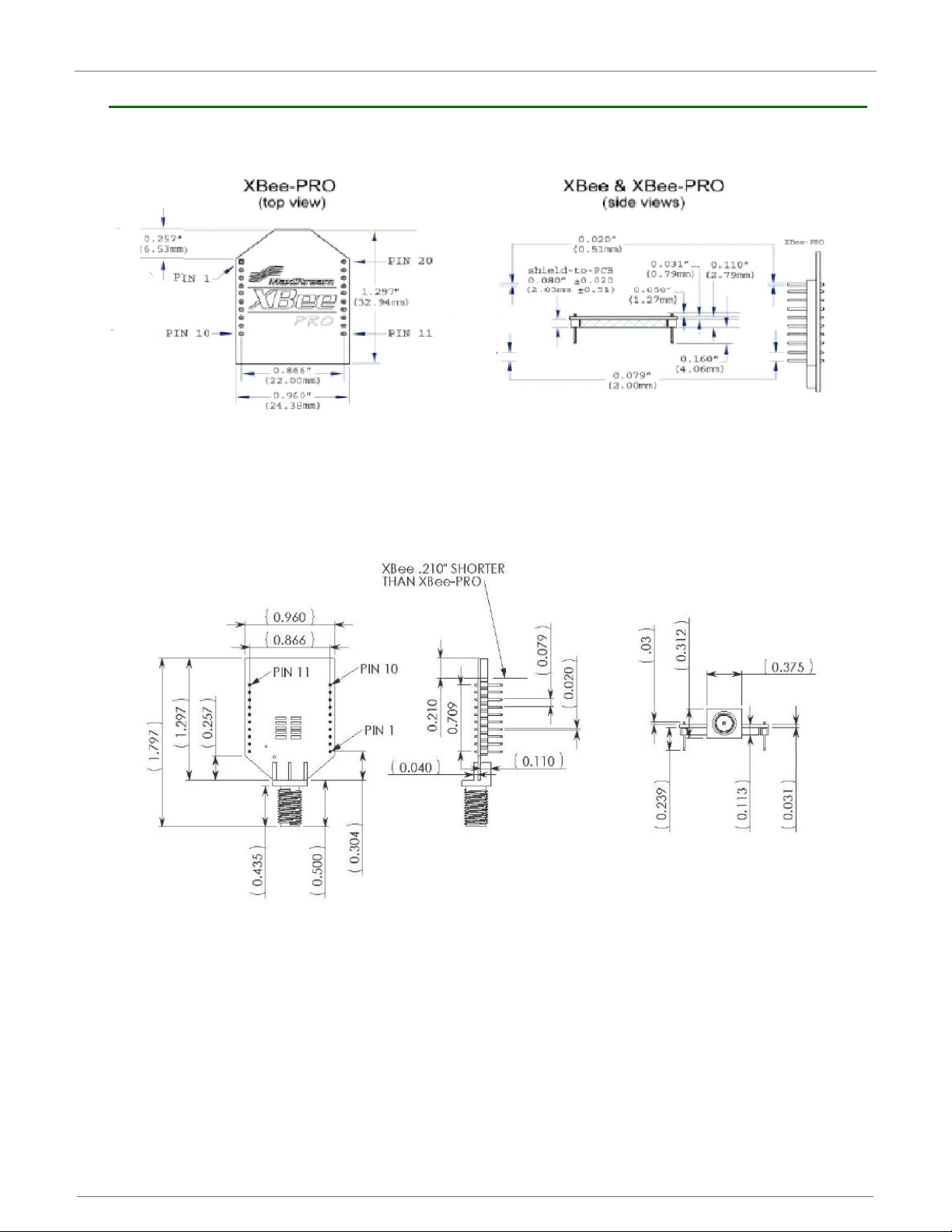

XBee-PRO 900HP Mechanical Drawings

MechanicaldrawingsoftheXBee‐PRO900HPRFModules(antennaoptionsnotshown).Alldimensionsareininches.

.

©2014DigiInternationalInc. 11

Page 12

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

XBee-PRO 900HP Pin Signals

PinAssignmentsforXBeeModules

Pin # Name Direction Default State Description

1 VCC Power Supply

2 DOUT/DIO13 Both Output GPIO / UART Data out

3 DIN/nConfig/DIO14 Both Input GPIO / UART Data In

4 DIO12/SPI_MISO Both Output GPIO / SPI slave out

5 nRESET I nput

6 DIO10/PWM0

7 DIO11/PWM1 Both GPIO / Pulse Width Modulator

8 reserved Disabled Do Not Connect

9 nDTR/SLEEP_RQ/DIO8 Both Input

10 GND Ground

11 DIO4/AD4/SPI_MOSI Both GPIO/SPI slave In

12 nCTS/DIO7 Both Output GPIO / Clear-to-Send Flow Control

13 On_nSLEEP/DIO9 Output Output GPIO / Module Status Indicator

14 VREF Input

15 Associate/DIO5 Both Output GPIO / Associate Indicator

16 nRTS/DIO6 Both Input GPIO / Request-to-Send Flow Control

17 AD3/DIO3/SPI_nSSEL Both GPIO / Analog Input / SPI Slave Select

18 AD2/DIO2/SPI_CLK Both GPIO / Analog Input / SPI Clock

19 AD1/DIO1/SPI_nATTN Both GPIO / Analog Input / SPI Attention

20 AD0/DIO0 Both GPIO / Analog Input

(Low‐assertedsignalsaredistinguishedwithahorizontallineabovesignalname.)

Module Reset. Drive low to reset the modu le. This

is also an output with an open drain configuration

with an internal 20 K ohm pull-up (never drive to

logic high, as the module may be driving it low).

The minimum pulse width is 1 mS.

Both GPIO / RX Signal Strength Indicator

GPIO / Pin Sleep Control Line (DTR on the dev

board)

Internally used for programmable secondary

processor. For compatibility with other XBee

modules, we recommend connecting this pin to the

voltage reference if Analog Sampling is desired.

Otherwise, connect to GND.

• Signal Direction is specified with respect to the module

• See Design Notes section below for details on pin connections.

XBee-PRO 900HP Design Notes

The XBee modules do not specifically require any external circuitry or specific connections for proper

operation. However, t here are some general design guidelines that are recommended for help in

troubleshooting and building a robust design.

XBee-PRO 900HP Power Supply Design

Poor power supply can lead to poor radio performance, especially if the supply voltage is not kept within

tolerance or is excessively noisy. To help reduce noise, we recommend placing both a 1F and 47pF capacitor

as near to pin 1 on the PCB as possible. If using a switching regulator for your power supply, switching

frequencies above 500kHz are preferred. Power supply ripple should be limited to a maximum 50mV peak to

peak.

Note – For designs using the programmable modules, an additional 10F decoupling cap is recommended near

pin 1 of the module. The nearest proximity to pin 1 of the three caps should be in the following order: 47pf,

1F followed by 10F.

XBee-PRO 900HP Recommended Pin Connections

The only required pin connections are VCC, GND, DOUT and DIN. To support serial firmware updates, VCC,

GND, DOUT, DIN, RTS, and DTR should be connected.

©2014DigiInternationalInc. 12

Page 13

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

All unused pins should be left disconnected. All inputs on the radio can be pulled high or low with 40k internal

pull-up or pull-down resistors using the PR and PD software commands. No specific treatment is needed for

unused outputs.

For applications that need to ensure the lowest sleep current, unconnected inputs should never be left

floating. Use internal or external pull-up or pull-down resistors, or set the unused I/O lines to outputs.

Other pins may be connected to external circuitry for convenience of operation, including the Associate LED

pin (pin 15) and the Commissioning pin (pin 20). An LED attached to the the associate LED pin will flash

differently depending on the state of the module to the network, and a pushbutton attached to pin 20 can

enable various join functions without having to send serial p ort commands. Please see the commissioning

pushbutton and associate LED section in chapter 7 for more details. The source and sink capabilities are

limited to 6mA on all I/O pins.

The VRef pin (pin 14) is only used on the programmable versions of these modules. For compatibility with

other XBee modules, we recommend connecting this pin to a voltage reference if analog sampling is desired.

Otherwise, connect to GND.

XBee-PRO 900HP Board Layout

XBee modules are designed to be self sufficient and have minimal sensitivity to nearby processors, cr ystals or

other PCB components. As with all PCB designs, Power and Ground traces should be thicker than signal traces

and able to comfortably support the maximum current specifications. No other special PCB design

considerations are required for integrating XBee radios except in the antenna section.

The choice of antenna and antenna location is very important for correct performance. XBees do not require

additional ground planes on the host PCB. In general , antenna elem ents r adiate perpendicular to the dire ction

they point. Thus a vertical antenna emits across the horizon. Metal objects near the antenna cause reflections

and may reduce the ability for an antenna to radiate efficiently. Metal objects between the transmitter and

receiver can also block the radiation path or reduce the transmission distance, so external antennas should be

positioned away from them as much as possible. Some objects that are often overlooked are metal poles,

metal studs or beams in structures, concrete (it is usually reinforced with metal rods), metal enclosures,

vehicles, elevators, ventilation ducts, refrigerators, microwave ovens, batteries, and t all electrolytic

capacitors.

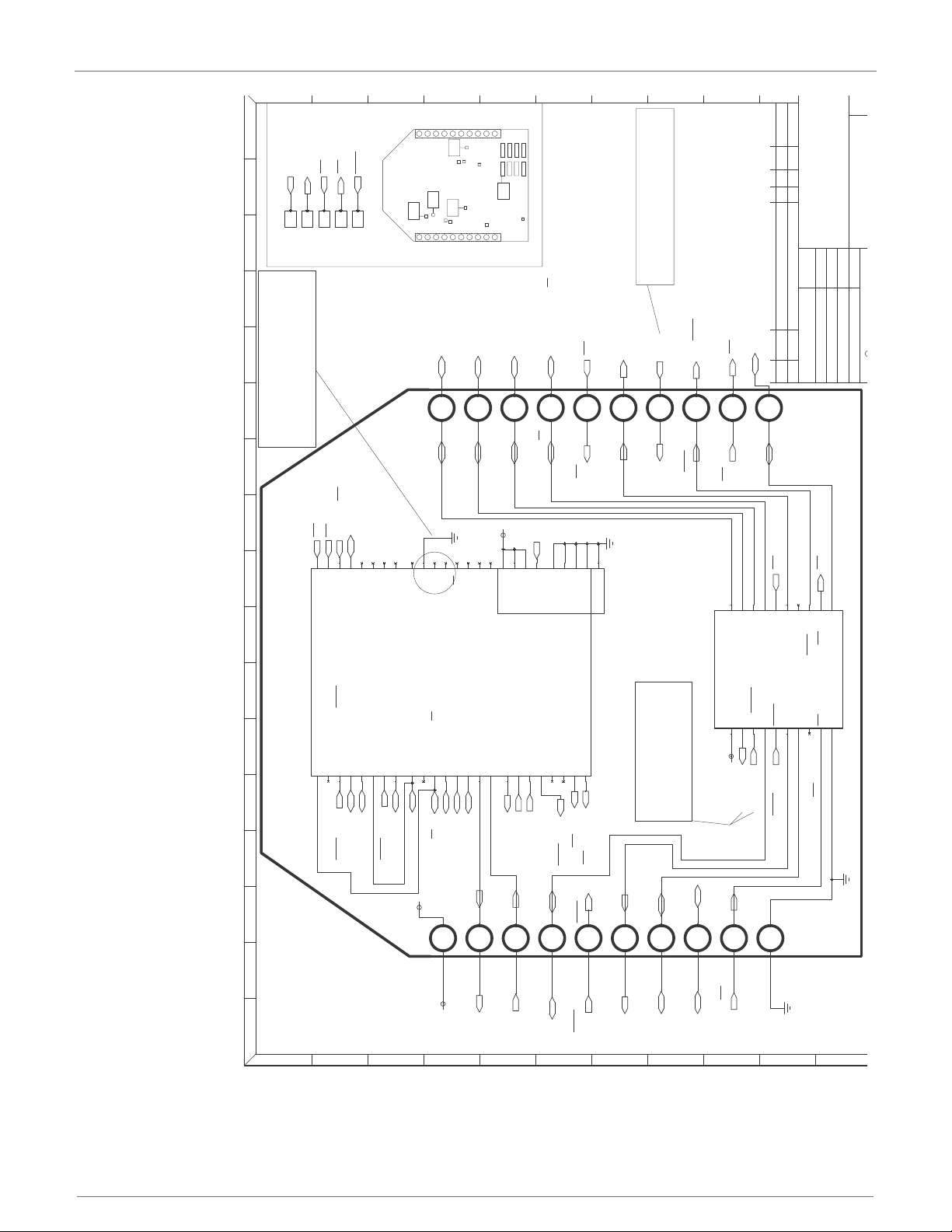

XBee-PRO 900HP Module Operation for Programmable Variant

The modules with the programmable opti on have a s econdary processor with 32k of flash and 2k of RAM. This

allows module integrators to put custom code on the XBee module to fit their own unique needs. The DIN,

DOUT, RTS, CTS, and RESET lines are intercepted by the secondary processor to allow it to be in control of the

data transmitted and received. All other lines are in parallel and can be controlled by either the internal

microcontroller or the MC9SO8QE micro (see Block Diagram for details). The internal microcontroller by

default has control of certain lines. These lines can be released by the internal microcontroller by sending the

proper command(s) to disable the desired DIO line(s) (see XBee Command Reference Tables).

In order for the secondary processor to sample with ADCs, the XBee pin 14 (VREF) must be connected to a

reference voltage.

Digi provides a bootloader that can take care of programming the processor over the air or through the serial

interface. This means that over the air updates can be supported through an XMODEM protocol. The processor

can also be programmed and debugged through a one wire interface BKGD (Pin 8).

©2014DigiInternationalInc. 13

Page 14

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

GND

A

5

4

G

E

12

9

ECO

PART NO.

B

14

2

13

11

REV

TITLE

DATE:

1

ENGINEER:

APPROVALS:

REV

DATE

10

17

16

15

8

3

F

APPR

CKD

BY

C

D

6

DESCRIPTION OF CHANGE

E

G

F

7

DESIGNED:

CHECKED:

DRAWN:

D

C

B

A

L

K

J

H

J

H

Digi Internat ional I nc

C

DOUT/PTB1

DIO3/ADC3/PTB5,A7/SS

BKGD/PTA4

DIO0/ADC0/PTA0

ON/SLEEP/PTA1

CTS/DIO7/PTC0

DIO4/PTB3/MOSI1

BKGD/PTA4

DIO12/PTB4/MISO1

DIN_RADIO

DOUT_RADIO

ASSOC/DIO5/PTD4

RTS/DIO6/PTD7

CTS_RADIO

VREF

CTS_RADIO

SLEEP_RQ/DTR/PTD5

RESET/PTA5

DIO1/ADC1/PTA3/SCL

RESET/PTA5

ASSOC/DIO5/PTD4

DIO2/ADC2/PTB2/SPSCK

DOUT_RADIO

DIN_RADIO

RESET_RADIO

ASSOC/DIO5/PTD4

ON/SLEEP/PTA1

ON/SLEEP/PTA1

RSSI/DIO10/PWM0/PTC 5

DIO1/ADC1/PTA3/SCL

VREF

RTS/DIO6/PTD7

DIO2/ADC2/PTB2/SPSCK

DIO3/ADC3/PTB5,A7/SS

RTS/DIO6/PTD7

DIO2/ADC2/PTB2/SPSC K

DIN/PTB0

VREF

DIO11/PWM1/PTA2/SDA

RTS_RADIO

DIO1/ADC1/PTA3/SCL

DIO12/PTB4/MISO1

DIN/PTB0

SLEEP_RQ/DTR/PTD5

DIO4/PTB3/MOSI1

BKGD/PTA4

DIN_RADIO

DIO12/PTB4/MISO1

DOUT_RADIO

CTS/DIO7/PTC0

DIO11/PWM1/PTA2/SDA

DIO0/ADC0/PTA0

RTS_RADIO

RTS_RADIO

DIO4/PTB3/MOSI1

DOUT/PTB1

CTS/DIO7/PTC0

DIO0/ADC0/PTA0

CTS_RADIO

RESET_RADIO

DIO3/ADC3/PTB5,A7/SS

RSSI/DIO10/PWM0/PTC 5

SLEEP_RQ/DTR/PTD5

RESET/PTA5

RSSI/DIO10/PWM0/PTC5

DIO11/PWM1/PTA2/SDA

RESET_RADIO

VCC

VCC

VCC

VCC

123456789

10

111213141516171819

20

VCC

GND

RESERVED

DIN/CONFIG

DOUT

DTR/SLEEP_RQ/DIO8

PWM0/RSSI/DIO10

PWM1/DIO11

RESET

PWM2/DIO12

CTS/DIO7

RTS/AD6/DIO6

VREF

AD1/DIO1

AD2/DIO2

DIO4

AD3/DIO3

AD0/DIO0

ASSOC/AD5/DIO5

ON/SLEEP/DIO9

S

2728474835363738101114152324252639404546161721

22

44434241291312

321343332201918

PTB6/SDA/XTAL

PTB1/KBI1P15/TxD1/ADP5

PTB2/KBIP6/SPSCK/ADP6

PTB3/KBIP7/MOSI/ADP7

PTB4/TPM2CH1/MISO

PTB5/TPM1CH1/SS

PTE6

PTD6/KBI2P6

PTA3/KBIP3/SCL/ADP3

PTA0/KBI1P0/TPM1CH0/ADP0/ACMP1+

PTA4/ACPM1O/BKGD/MS

PTA7/TPM2CH2/ADP9

PTA1/KBI1P1/TPM2CH0/ADP1/ACMP1-

PTA5/IRQ/TPM1CLK/RESET

PTA6/TPM1CH2/ADP8

PTA2/KBI1P2/SDA/ADP2

PTE4

PTE5

PTE3/SS

PTE2/MISO

PTD7/KBI2P7

PTD1/KBI2P1

PTD2/KBI2P2

PTD3/KBI2P3

PTD5/KBI2P5

PTE0/TPM2CLK/SPSCLK

PTD4/KBI2P4

PTB7/SCL/EXTEL

PTE1/MOSI

PTD0/KBI2P0

PTC4/TPM3CH4

PTB0/KBI1P4/RxD1/ADP4

PTC2/TPM3CH2

PTC7/TxD2/ACPM2-

PTC5/TPM3CH5/ACPM2O

PTC3/TPM3CH3

PTC1/TPM3CH1

PTC0/TPM3CH0

PTE7/TPM3CLK

PTC6/RxD2/ACPM2+

U1-A

MC9S08QE32CFT

304567893149

VSS

VSSAD

VREFL

VSS

VDD

VDD

VDDAD

PAD

VREFH

U1-B

MC9S08QE32CFT

14

8

Commissioning Line

19

10

20

1

9

6

354

2

FREESCALE

A

11

TP5

7

13

TP2

Pin10

Pin11

TP1

VREF must be connected to

external reference for MC9S08

to sample ADC lines

Special Test Points

TP6

XBEE-PRO S3B

PROGRAMMABLE

BLOCK DIAGRAM

TP4

15

Pin1

Pin20

Commissioning Line

MC9S08 controls

DOUT, DIN, RESET, RTS, CTS

for Internal Radio.

These lines are not

connected to the

20 external pins.

TP1

12

Pins PTE4, 5 and 6 are used so

software can determ

ine

fundamental Hardware differences

by turning on internal pull-up

resistors and reading the lines.

011 = Programmable S3B

PROGRAMMABLE XBEE-PRO S3B

16

TP2

18

TP5

TP4

17

TP6

S3B RADIO

©2014DigiInternationalInc. 14

Page 15

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

XBee-PRO 900HP Programmable Bootloader

Overview

The XBee Programmable module is equipped with a Freescale MC9S08QE32 application processor. This

application processor comes with a supplied bootloader. This section describes how to interface the customer's

application code running on this processor to the XBee Programmable module's supplied bootloader.

The first section discusses how to initiate firmware updates using the supplied bootloader for wired and overthe-air updates.

Bootloader Software Specifics

Memory Layout

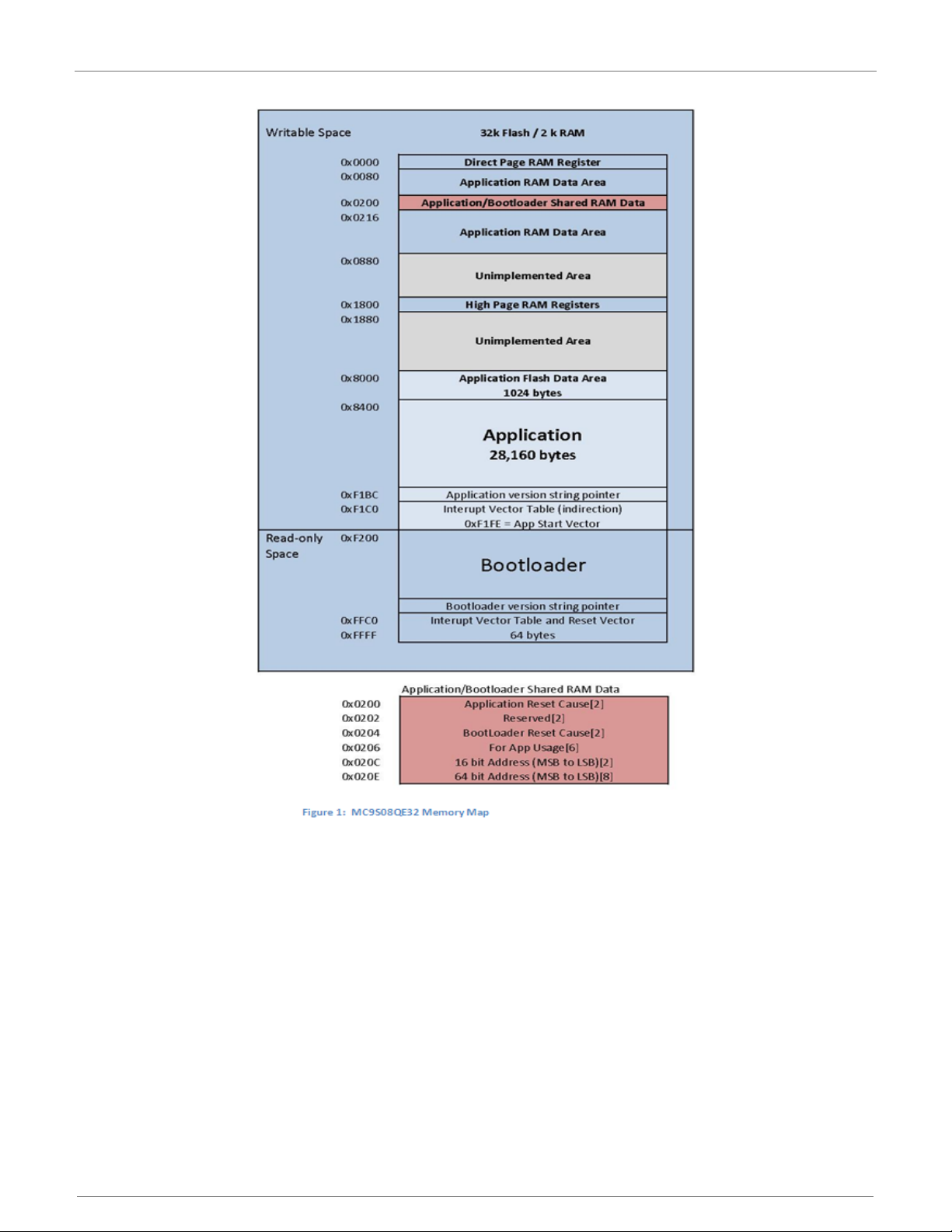

Figure 1 shows the memory map for the MC9S08QE32 application processor.

The supplied bootloader occupies the bottom pages of the flash from 0xF200 to 0xFFFF. Application

code cannot write to this space.

The application code can exist in Flash from address 0x8400 to 0xF1BC. 1k of Flash from 0x8000 to

0x83FF is reserved for Non Volatile Application Data that will not be erased by the bootloader during a

flash update.

A portion of RAM is accessible by both the application and the bootloader. Specifically, there is a shared

data region used by both the application and the bootloader that is located at RAM address 0x200 to

0x215. Application code should not write anything to BLResetCause or AppResetCause unless

informing the bootloader of the impending reset reason. The Application code should not clear

BLResetCause unless it is handling the unexpected reset reason.

T o prevent a malfunctioning application from running forever, the Bootloader increments BLResetCause

after each watchdog or illegal instruction reset. If this register reaches above 0x10 the bootloader will

stop running the application for a few minutes to allow an OTA or Local update to occur. If no update is

initiated within the time period, BLResetCause is cl ear ed and the application is started again. To

prevent unexpected halting of the application, the application shall clear or decrement BLResetCause

just before a pending reset. To disable this feature, the application shall clear BLResetCause at the

start of the application.

©2014DigiInternationalInc. 15

Page 16

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

©2014DigiInternationalInc. 16

Page 17

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Operation

Upon reset of any kind, the execution control begins with the bootloader.

If the reset cause is Power-On reset (POR), Pin reset (PIN), or Low Voltage Detect (LVD) reset (LVD)

the bootloader will not jump to the application code if the override bits are set to RTS(D7)=1,

DTR(D5)=0, and DIN(B0)=0. Otherwise, the bootloader writes the reset cause "NOTHING" to the

shared data region, and jumps to the Application.

Reset causes are defined in the file common. h in an enumeration with the following definitions:

typedef enum {

BL_CAUSE_NOTHING = 0x0000, //PIN, LVD, POR

BL_CAUSE_NOTHING_COUNT = 0x0001,//BL_Reset_Cause counter

// Bootloader increments cause every reset

BL_CAUSE_BAD_APP = 0x0010,//Bootloader considers APP invalid

} BL_RESET_CAUSES;

typedef enum {

APP_CAUSE_NOTHING = 0x0000,

APP_CAUSE_USE001 = 0x0001,

// 0x0000 to 0x00FF are considered valid for APP use.

APP_CAUSE_USE255 = 0x00FF,

APP_CAUSE_FIRMWARE_UPDATE = 0x5981,

APP_CAUSE_BYPASS_MODE = 0x4682,

APP_CAUSE_BOOTLOADER_MENU = 0x6A18,

} APP_RESET_CAUSES;

Otherwise, if the reset cause is a "watchdog" or other reset, the bootloader checks the shared memory

region for the APP_RESET_CAUSE. If the reset cause is:

1."APP_CAUSE_NOTHING" or 0x0000 to 0x00FF, the bootloader increments the

BL_RESET_CAUSES, verifies that it is still less than BL_CAUSE_BAD_APP , and jumps back to

the application. If the Application does not clear the BL_RESET_CAUSE, it can prevent an

infinite loop of running a bad application that continues to perform illegal instructions or

watchdog resets.

2."APP_CAUSE_FIRMWARE_UPDATE", the bootloader has been instructed to update the

application "over-the-air" from a specific 64-bit address. In this case, the bootloader will

attempt to initiate an Xmodem transfer from the 64-bit address located in shared RAM.

3."APP_CAUSE_BYPASS_MODE", the bootloader executes bypass mode. This mode passes the

local UART data direc tly to the internal mi crocontroller allowing for dire ct communicati on with

the internal microcontroller.

The only way to exit bypass mode is to reset or power cycle the module.

If none of the above is true, the bootloader will enter "Command mode". In this mode, users can

initiate firmware downloads both wired and over-the-air, check application/bootloader version strings,

and enter Bypass mode.

Application version string

Figure 1 shows an "Application version string pointer" area in application flash which holds the pointer

to where the application version string resides. The application's linker command file ultimately

determines where this string is placed in application flash.

It is preferable that the application version string be loca ted at address 0x8400 for MC9S08QE32 parts .

The application string can be any characters terminated by the NULL character (0x00). There is not a

strict limit on the number of characters in the string, but for practical purposes should be kept under

100 bytes including the terminating NULL character. During an update the bootloader erases the entire

application from 0x8400 on. The last page has the vector table specifically the redirected reset vec to r.

The version string pointer and reset vector are used to determine if the application is valid.

©2014DigiInternationalInc. 17

Page 18

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Application Interrupt Vector table and Linker Command File

Since the bootloader flash region is read-only, the interrupt vector table is redirected to the region

0xF1C0 to 0xF1FD so that application developers can use hardware interrupts. Note that in order for

Application interrupts to function properly, the Application's linker command file (*.prm extension)

must be modified appropriately to allow the linker to place the developers code in the correct place in

memory. For example, the developer desires to use the serial communications port SCI1 receive

interrupt. The developer would add the following line to the Codewarrior linker command file for the

project:

VECTOR ADDRESS 0x0000F1E0 vSci1Rx

This will inform the linker that the interrupt function "vSci1Rx()" should be placed at address

0x0000F1E0. Next, the developer should add a file to their project "vector_table.c" that creates an

array of function pointers to the ISR routines used by the application.

extern void _Startup(void);/* _Startup located in Start08.c */

extern void vSci1Rx(void);/* sci1 rx isr */

extern short iWriteToSci1(unsigned char *);

void vDummyIsr(void);

#pragma CONST_SEG VECTORS

void (* const vector_table[])(void) = /* Relocated Interrupt vector table */{

vDummyIsr,/* Int.no. 0 Vtpm3ovf (at F1C0)Unassigned */

vDummyIsr, /* Int.no. 1 Vtpm3ch5 (at F1C2) Unassigned */

vDummyIsr, /* Int.no. 2 Vtpm3ch4 (at F1C4) Unassigned */

vDummyIsr, /* Int.no. 3 Vtpm3ch3 (at F1C6) Unassigned */

vDummyIsr, /* Int.no. 4 Vtpm3ch2 (at F1C8) Unassigned */

vDummyIsr, /* Int.no. 5 Vtpm3ch1 (at F1CA) Unassigned */

vDummyIsr, /* Int.no. 6 Vtpm3ch0 (at F1CC) Unassigned */

vDummyIsr, /* Int.no. 7 Vrtc (at F1CE) Unassigned */

vDummyIsr, /* Int.no. 8 Vsci2tx (at F1D0) Unassigned */

vDummyIsr, /* Int.no. 9 Vsci2rx (at F1D2) Unassigned */

vDummyIsr, /* Int.no. 10 Vsci2err (at F1D4) Unassigned */

vDummyIsr, /* Int.no. 11 Vacmpx (at F1D6) Unassigned */

vDummyIsr, /* Int.no. 12 Vadc (at F1D8) Unassigned */

vDummyIsr, /* Int.no. 13 Vkeyboard (at F1DA) Unassigned */

vDummyIsr, /* Int.no. 14 Viic (at F1DC) Unassigned */

vDummyIsr, /* Int.no. 15 Vsci1tx (at F1DE) Unassigned */

vSci1Rx, /* Int.no. 16 Vsci1rx (at F1E0) SCI1RX */

vDummyIsr, /* Int.no. 17 Vsci1err (at F1E2) Unassigned */

vDummyIsr, /* Int.no. 18 Vspi (at F1E4) Unassigned */

vDummyIsr, /* Int.no. 19 VReserved12 (at F1E6) Unassigned */

vDummyIsr, /* Int.no. 20 Vtpm2ovf (at F1E8) Unassigned */

vDummyIsr, /* Int.no. 21 Vtpm2ch2 (at F1EA) Unassigned */

vDummyIsr, /* Int.no. 22 Vtpm2ch1 (at F1EC) Unassigned */

vDummyIsr, /* Int.no. 23 Vtpm2ch0 (at F1EE) Unassigned */

vDummyIsr, /* Int.no. 24 Vtpm1ovf (at F1F0) Unassigned */

vDummyIsr, /* Int.no. 25 Vtpm1ch2 (at F1F2) Unassigned */

vDummyIsr, /* Int.no. 26 Vtpm1ch1 (at F1F4) Unassigned */

vDummyIsr, /* Int.no. 27 Vtpm1ch0 (at F1F6) Unassigned */

©2014DigiInternationalInc. 18

Page 19

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

vDummyIsr, /* Int.no. 28 Vlvd (at F1F8) Unassigned */

vDummyIsr, /* Int.no. 29 Virq (at F1FA) Unassigned */

vDummyIsr, /* Int.no. 30 Vswi (at F1FC) Unassigned */

_Startup /* Int.no. 31 Vreset (at F1FE) Reset vector */

};

void vDummyIsr(void){

for(;;){

if(iWriteToSci1("STUCK IN UNASSIGNED ISR\n\r>"));

}

}

The interrupt routines themselves can be defined in separate files. The "vDummyIsr" function is used

in conjunction with "iWritetoSci1" for debugging purposes.

XBee-PRO 900HP Bootloader Menu Commands

The bootloader accepts commands from both the local UART and OTA. All OTA commands sent must be

Unicast with only 1 byte in the payload for each command. A response will be returned to the sender. All

Broadcast and multiple byte OTA packets are dropped to help prevent general OTA traffic from being

interpreted as a command to the bootloader while in the menu.

Bypass Mode - "B"

The bootloader provides a “bypass” mode of operation that essentially connects the freescale mcu to

the internal microcontroller’s serial UART. This allows direct communication t o the internal

microcontroller’s radio for the purpose of firmware and radio configuration changes. Once in bypass

mode, the X-CTU utility can change modem configuration and/or update module’s firmware. Bypass

mode automatically handles any baud rate up to 115.2kbps. Note that this command is unavailable

when module is accessed remotely.

Update Firmware - "F"

The "F" command initiates a firmware download for both wired and over-the-air configurations.

Depending on the source of the command (received via Over the Air or local UART), the download will

proceed via wired or over-the-air respectively.

Adjust Timeout for Update Firmware - "T"

The "T" command changes the timeout before sending a NAK by Base-Time*2^(T). The Base- Time for

the local UART is different than the Base-Time for Over the Air. During a firmware update, the

bootloader will automatically increase the Timeout if repeat packets are received or multiple NAKs for

the same packet without success occur.

Application Version String - "A"

The "A" command provides the version of the currently loaded application. If no application is present,

"Unkown" will be returned.

Bootloader Version String - "V"

The "V" command provides the version of the currently loaded bootloader. The version will return a

string in the format BLFFF-HHH-XYZ_DDD where FFF repr esents the Flash size in kilo bytes, HHH is the

hardware, XYZ is the version, and DDD is the preferred XMODEM packet size for updates. Double the

preferred packet size is also possible, but not guaranteed. For example "BL032-2 B0-023_064" will ta ke

64 byte CRC XMODEM payloads and may take 128 byte CRC XMODEM payloads also. In this case, both

64 and 128 payloads are handled, but the 64 byte payload is preferred for better Over the Air

reliability.

Bootloader Version BL032-2x0-025_064 only operates at 9600 baud on the local UART as well as

communications to the internal microc ontroller. A newer version of the Bootloader BL032-2x0-033_064

or newer BL032-2B0-XXX_064 has changed the baud rate to 115200 between the Programmable and

©2014DigiInternationalInc. 19

Page 20

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

the internal microcontroller. The internal module is also set to 115200 as the default baud rate. The

default rate of the programmable local UART is also set to 115200, however, the local UART has an

auto baud feature added to detect if the UART is at the wrong baud rate. If a single character is sent, it

will automatically switch to 115200 or 9600 baud.

XBee-PRO 900HP Firmware Updates

Wired Updates

A user can update their application using the bootloader in a wired configuration with the following

steps:

a. Plug XBee programmable module into a suitable serial port on a PC.

b. Open a hyperterminal (or similar dumb terminal application) session with 115200 baud, no par-

ity, and 8 data bits with one stop bit.

c. Hit Enter to display the bootloader menu.

d. Hit the "F" key to initiate a wired firmware update.

e. A series of "C" characters Will be displayed within the hyperterminal window. At this point,

select the "transfer->send file" menu item. Select the desired flat binary output file.

f. Select "Xmodem" as the protocol.

g. Click "Send" on the "Send File" dialog. The file will be downloaded to the XBee Programmable

module. Upon a successful update, the bootloader will jump to the newly loaded application.

Over-The-Air updates

A user can update their application using the bootloader in an “over-the-air” configuration with the

following steps…(This procedure assumes that the bootloader is running and not the application. The

internal microcontroller baud rate of the programmable module must be set to 115200 baud. The

bootloader only operates at 115200 baud between the Radio and programmable bootloader. The

application must be programmed with some way to support returning to the bootloader in order to

support Over the Air (OTA) updates without local intervention.)

a. Open a hyperterminal session to the host module with no parity, no hardwareflow control, 8

data bits and 1 stop bit. (The host module does not have to operate at the same baud rate as the

remote module.) For faster updates and less latency due to the UART, set the host module to a

faster baud rate. (i.e. 115200)

b. Enter 3 pluses "+++" to place the module in command mode. (or XCTU’s “Modem Configuration” tab can be used to set the correct parameters)

c. Set the Host Module destination address to the target module’s 64 bit address that the host

module will update (ATDH aabbccdd, ATDL eeffgghh, ATCN, where aabbccddeeffgghh is the hexadecimal 64 bit address of the target module).

d. Hit Enter and the bootloader command menu will be displayed from the remote module. (Note

that the option "B" doesn't exist for OTA)

e. Hit the "F" key to cause the remote module to request the new firmware file over-the-air.

f. The host module will begin receiving "C" characters indicating that the remote module is

requesting an Xmodem CRC transfer. Using XCTU or another terminal program, Select "XMODEM"

file transfer. Select the Binary file to upload/transfer. Click Send to start the transfer. At the conclusion of a successful transfer, the bootloader will jump to the newly loaded application.

Output File Configuration

BKGD Programming

P&E Micro provides a background debug tool that allows flashing applications on the MC9S08QE parts

through their background debug mode port. By default, the Codewarrior tool produces an "ABS" output

file for use in programming parts through the background debug interface. The programmable XBee

from the factory has the BKGD debugging capability disabled. In order to debug, a bootloader with the

©2014DigiInternationalInc. 20

Page 21

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

debug interface enabled needs to be loaded on the secondary processor or a stand-alone app needs to

be loaded.

Bootloader updates

The supplied bootloader requires files in a "flat binary" format which differs from the default ABS file

produced. The Codewarrior tool also produces a S19 output file. In order to successfully flash new

applications, the S19 file must be converted into the flat binary format. Utilities are available on the

web that will convert S19 output to "BIN" outputs. Often times, the "BIN" file conversion will pad the

addresses from 0x0000 to the code space with the same number. (Often 0x00 or 0xFF) These extra

bytes before the APP code starts will need to be deleted from the bin file before the file can be

transferred to the bootloader.

©2014DigiInternationalInc. 21

Page 22

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Packet Handler

Transparent

Mode

AT Command

Mode

API

Mode

Network Layer (DigiMesh/Repeater)

MAC/PHY Layer (Point-Multipoint)

UART SPI

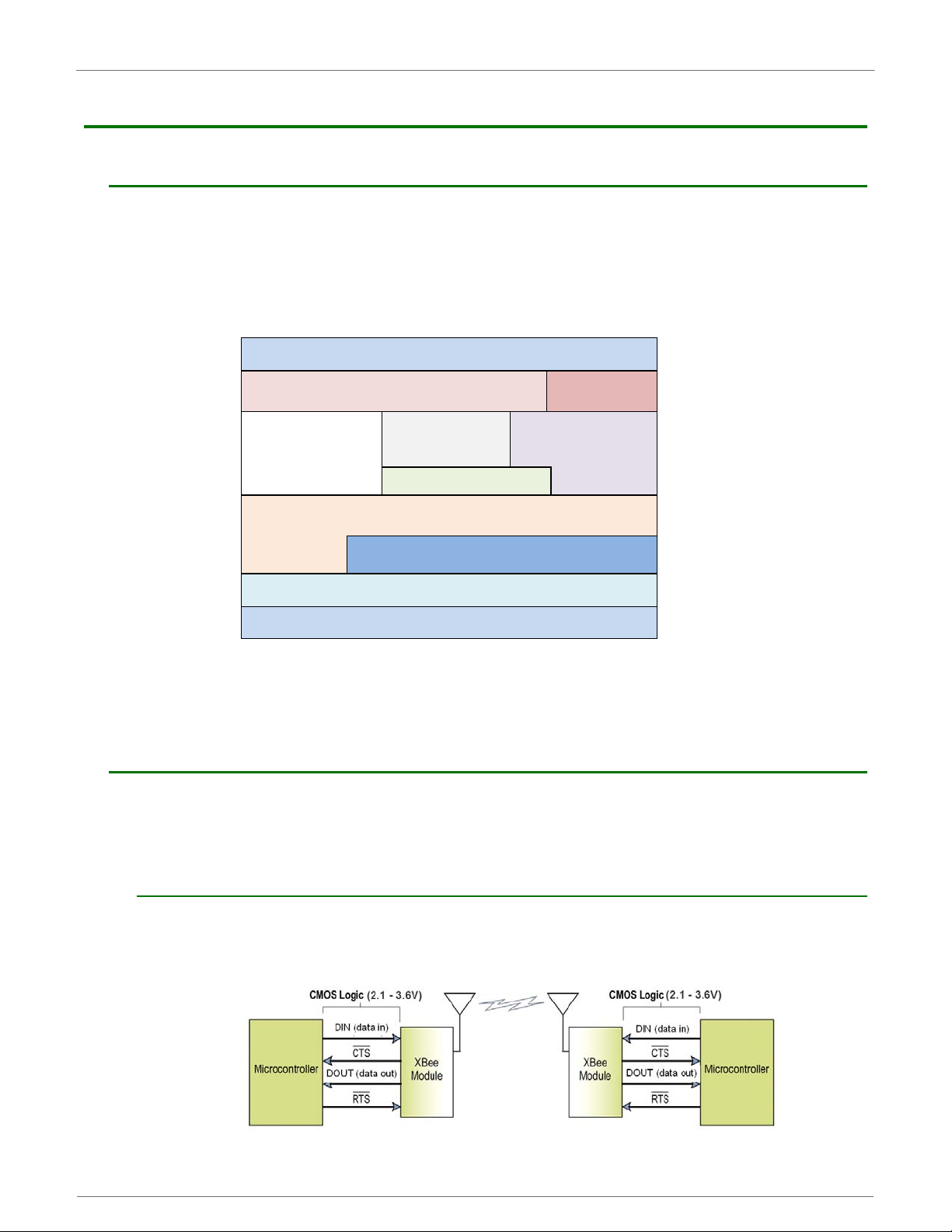

2.XBee‐PRO900HPRFModuleOperation

XBee-PRO 900HP Basic Operational Design

The XBee-PRO® 900HP RF Module uses a multi-layered firmware base to order the flow of data, dependent on the

hardware and software configuration chosen by the user. This configuration block diagram is shown below, with the

host serial interface as the physical starting point, and the antenna as the physical endpoint for the transferred data.

As long as a block is able to touch another block, the two interfaces can interact. For example, if the module is using

SPI mode, Transparent Mode is not available. See below:

Host Serial Interface

Command Handler

Antenna

The command handler is the code that processes commands from AT Command Mode or API Mode (see AT Commands section). The command handler can also proces s commands from re mote r adios ( see Remote AT Command s

section).

XBee-PRO 900HP Serial Communications

XBee RF Modules interface to a host device through a serial port. Through its serial port, the module can

communicate with any logic and voltage compatible UART, through a level translator to any serial device (for

example, through a RS-232 or USB interface board), or through a Serial Peripheral Interface (SPI), which is a

synchronous interface to be described later.

XBee-PRO 900HP UART Data Flow

Devices that have a UART interface can connect directly to the pins of the RF module as shown in the figure

below.

SystemDataFlowDiagraminaUART‐interfacedenvironment

(Low‐assertedsignalsdistinguishedwithhorizontallineoversignalname.)

©2014DigiInternationalInc. 22

Page 23

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

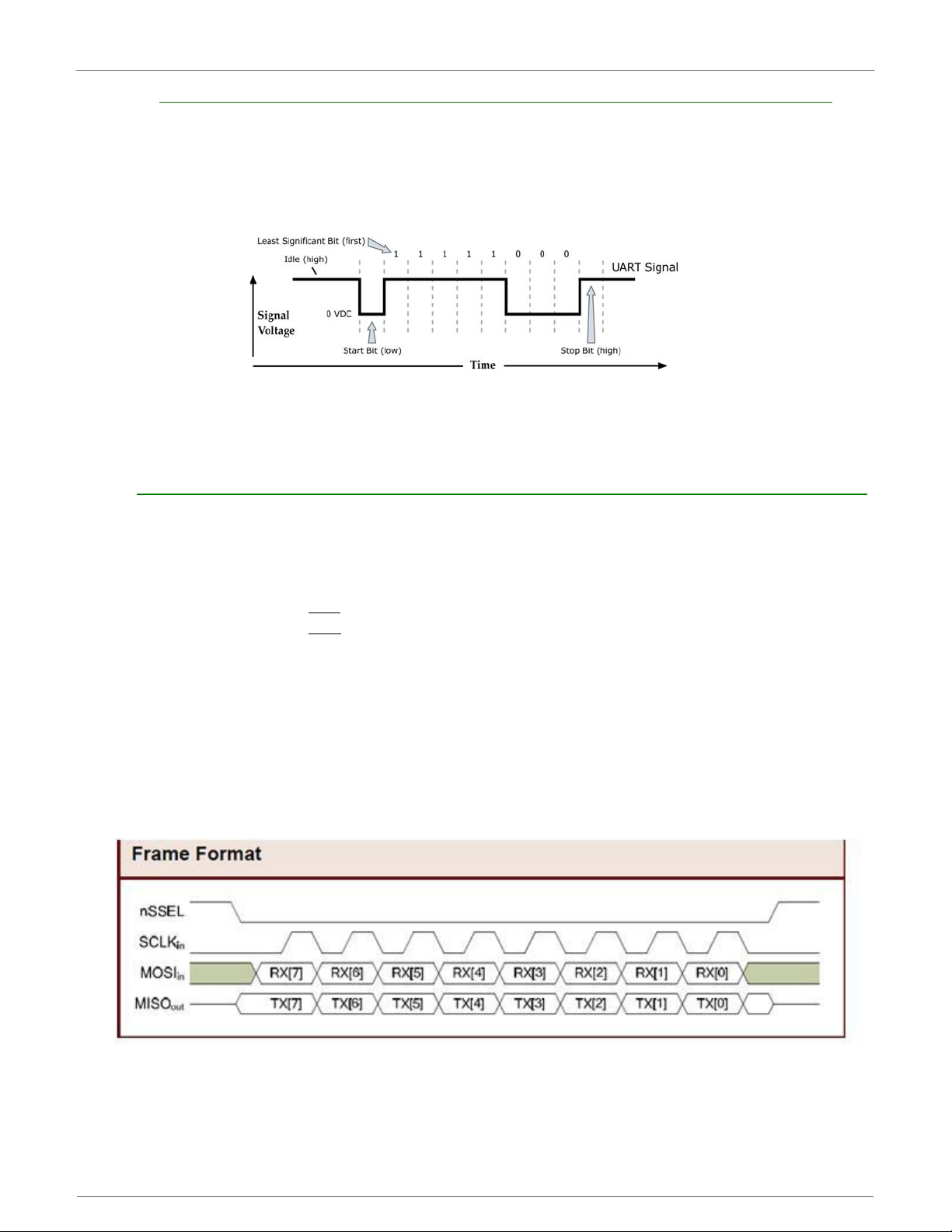

Serial Data

Data enters the module UART through the DIN (pin 3) as an asynchronous serial signal. The signal should

idle high when no data is being transmitted.

Each data byte consists of a start bit (low), 8 data bits (least signif ic ant bit first) and a stop bit (high). The

following figure illustrates the serial bit pattern of data passing through the module.

UARTdatapacket0x1F(decimalnumberʺ31ʺ)astransmittedthroughtheRFmodule

ExampleDataFormatis8‐N‐1(bits‐parity‐#ofstopbits)

Serial communications depend on the two UARTs (the microcontroller's and the RF module's) to be

configured with compatible settings (baud rate, parity, start bits, stop bits, data bits).

The UART baud rate, parity, and stop bits settings on the XBee module can be configured with the BD, NB,

and SB commands respectively. See the command table in chapter 10 for details.

XBee-PRO 900HP SPI Communications

The XBee modules support SPI communications in slave mode. Sla ve mode receiv es the clock signal and data

from the master and returns data to the master. The SPI port uses the following signals on the XBee:

• SPI_MOSI (Master Out, Slave In) - inputs serial data from the master

• SPI_MISO (Master In, Slave Out) - outputs serial data to the master

• SPI_SCLK (Serial Clock) - clocks data transfers on MOSI and MISO

•SPI_SSEL

•SPI_ATTN

ule will assert this pin as soon as data is available to send to the SPI master and it will remain

asserted until the SPI master has clocked out all available data.

In this mode, the following apply:

• SPI Clock rates up to 3.5 MHz are possible.

• Data is MSB first

• Frame Format mode 0 is used. This means CPOL=0 (idle clock is low) and CPHA=0 (data is

sampled on the clock’s leading edge). Mode 0 is diagramed below.

• SPI port is setup for API mode and is equivalent to AP=1.

(Slave Select) - enables serial communication with the slave

(Attention) - alerts the master that slave has data que ued to send. The XBee mod-

FrameFormatforSPICommunications

©2014DigiInternationalInc. 23

Page 24

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

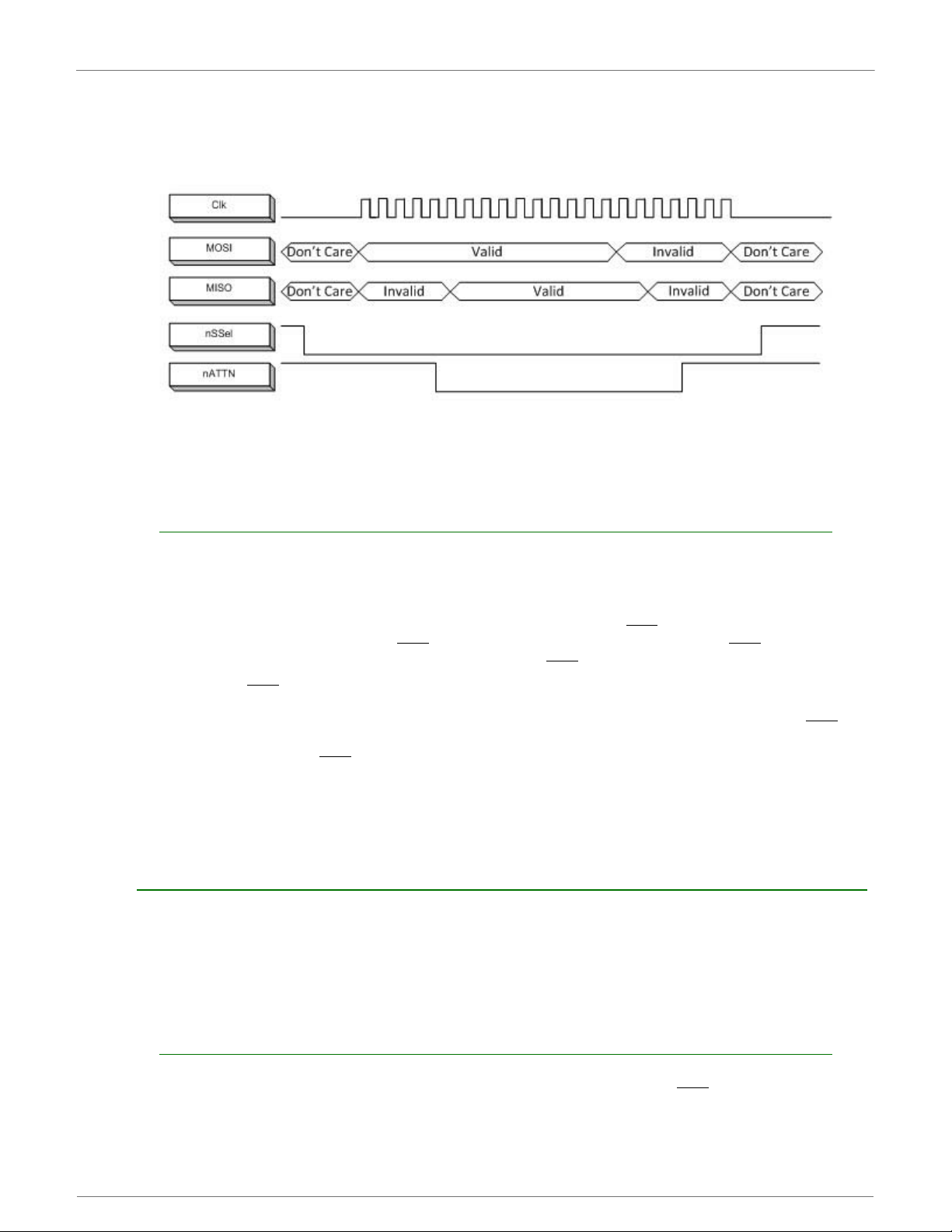

XBee-PRO 900HP SPI Operation

This section specifies how SPI is implemented on the XBee, what the SPI signals are, and how full duplex

operations work.

XBee Implementation of SPI

The module operates as a SPI slave only. This means that an external master will provide the clock and will

decide when to send. The XBee-PRO 900HP supports an external clock rate of up to 3.5 Mbps.

Data is transmitted and received with most significant bit first using SPI mode 0. This means the CPOL and

CPHA are both 0. Mode 0 was chosen because it's the typical default for most microcontrollers and would

simplify configuration of the master. Further information on Mode 0 is not included in this manual, but is welldocumented on the internet.

XBee-PRO 900HP SPI Signals

The official specification for SPI includes the four sign als SPI_MISO, SPI_MOSI, SPI_CLK, and SPI_SSEL.

Using only these four signals, the master cannot know when the sl ave needs to se nd and the SPI slav e cannot

transmit unless enabled by the master. For this reason, the SPI_ATTN

allows the module to alert the SPI master that it has data to send. In turn, the SPI master is expected to

assert SPI_SSEL

in turn, allows the XBee module to send data to the master.

The table below names the SPI signals and specifies their pinouts. It also describes the operation of each pin:

and start SPI_CLK, unless these signals are already asserted and active respectively. This,

signal is available in the design. This

Signal Name Pin Number

SPI_MISO

(Master In, Slave out)

SPI_MOSI

(Master out, Slave in)

SPI_SSEL

(Slave Select)

(Master out, Slave in)

SPI_CLK

(Clock)

(Master out, Slave in)

SPI_ATTN

(Attention)

(Master in, Slave out)

Note: By default, the inputs have pull-up resistors enabled. See the PR command to disable the pull-up

resistors. When the SPI pins are not connected but the pins are configured for SPI operation , then the pull-ups

are needed for proper UART operation.

Full Duplex Operation

SPI on XBee requires usage of API mode (without escaping) to packetize data. However, by design, SPI is a

full duplex protocol, even when data is only available in one direction. This means that whenever data is

received, it will also transmit, and that data will normally be invalid. Likewise, whenever data is transmitted,

invalid data will probably be received. The means of determining whether or not received data is invalid is by

packetizing the data with API packets.

SPI allows for valid data from the slave to begin before, at the same time, or after valid data begins from the

master. When the master is sending data to the slave and the slave has valid data to send in the middle of

receiving data from the master, this allows a true full duplex operation where data is valid in both directions

for a period of time. Not only must the master and the slave both be able to keep up with the full duplex

operation, but both sides must honor the protocol as specified.

An example follows to more fully illustrate the SPI interface while valid data is being sent in both directions.

4ATP2

11 ATD4

17 ATD3

18 ATD2

19 ATD1

Applicable AT

Command

Description

When SPI_SSEL

the module outputs the data on this line at the SPI_CLK

rate. When SPI_SSEL

should be tri-stated such that another slave device can

drive the line.

The SPI master outputs data on this line at the SPI_CLK

rate after it selects the desired slave. When the module is

configured for SPI operations, this pin is an input.

The SPI master outputs a low signal on this line to select

the desired slave. When the module is configured for SPI

operations, this pin is an input.

The SPI master outputs a clock on this pin, and the rate

must not exceed the maximum allowed, 3.5 Mbps. When

the module is configured for SPI operations, this pin is an

input.

The module asserts this pin low when it has data to send to

the SPI master. When this pin is configured for SPI

operations, it is an output (not tri-stated).

is asserted (low) and SPI_CLK is active,

is de-asserted (high), this output

©2014DigiInternationalInc. 24

Page 25

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Low Power Operation

In general, sleep modes work the same on SPI as they do on UART. However, due to the addition of SPI

mode, there is the option of another sleep pin, as described below:

By default, DIO8 (SLEEP_REQUEST) is configured as a peripheral and is used for pin sleep to awaken and to

sleep the radio. This applies regardless of the selected serial interface (UART or SPI).

However, if SLEEP_REQUEST is not configured as a peripheral and SPI_SSEL

then pin sleep is controlled by SPI_SSEL

either awakens the radio or keeps it awake. Negating SPI_SSEL

Using SPI_SSEL

particular slave device) has the advantage of requiring one less physical pin connection to implement pin sleep

on SPI. It has the disadvantage of putting the radio to sleep whenever the SPI master negates SPI_SSEL

(meaning time will be lost waiting for the device to wake), even if that wasn't the intent. Therefore, if the user

has full control of SPI_SSEL

sharing the pin may be a good option in order to make the SLEEP_REQUEST pin av ailable for another purpose.

If the radio is one of multiple slaves on the SPI, then the radio would sleep while the SPI master talks to the

other slave, but this is acceptable in most cases.

If neither pin is configured as a peripheral, then the radio stays awake, being unable to sleep in SM1 mode.

for two purposes (to control sleep and to indicate that the SPI master has selected a

so that it can control pin sleep, whether or not data needs to be transmitted, then

rather than by SLEEP_REQUEST. Asserting SPI_SSEL by driving it low

by driving it high puts the radio to sleep.

is configured as a peripheral,

XBee-PRO 900HP Configuration

The three considerations for configuration are:

•How is the serial port selected? (I.e. Should the UART or the SPI port be used?)

•If the SPI port is used, what should be the format of the data in order to avoid processing invalid

characters while transmitting?

•What SPI options need to be configured?

Serial Port Selection

In the default configuration the UART and SPI ports will both be configured for serial port operation.

If both interfaces are configured, serial data will go out the UART until the SPI_SSEL

Thereafter, all serial communications will operate on the SPI interface.

signal is asserted.

©2014DigiInternationalInc. 25

Page 26

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

If only the UART is enabled, then only the UART will be used, and SPI_SSEL will be ignored. If only the SPI is

enabled, then only the SPI will be used.

If neither serial port is enabled, the module will not support serial operations and all communications must

occur over the air. All data that would normally go to the serial port is discarded.

Forcing UART Operation

In the rare case that a module has been configured with only the SPI enabled and no SPI master is available

to access the SPI slave port, the module may be re covered to UAR T operation by holding DIN / CONFIG

reset time. As always, DIN/CONFIG

up the module in command mode on the UART port. Appropriate commands can then be sent to t he module to

configure it for UART operation. If those parameters are written, then the module will come up with the UART

enabled, as desired on the next reset.

SPI Port Selection

SPI mode can be forced by holding DOUT/DIO13 (pin 2) low while resetting the module until SPI_nATTN

asserts. By this means, the XBee module will disable the UART and go straight into SPI communication mode.

Once configuration is completed, a modem status frame is queued by the module to the SPI port which will

cause the SPI_nATTN line to assert. The host can use thi s to dete rmine th at the SPI port has been co nfigu red

properly. This method internally forces the configuration to provide full SPI support for the following

parameters:

•D1 (note this parameter will only be changed if it is at a default of zero when method is invoked)

•D2

•D3

•D4

•P2.

As long as a WR command is not issued, these configuration values will revert back to previous values after a

power on reset. If a WR command is issued while in SPI mode, these same parameters will be written to flash.

After a reset, parameters that were forced and then written to flash become the mode of operation. If the

UART is disabled and the SPI is enabled in the written configuration, t h en the module will come up in SPI

mode without forcing it by holding DOUT low. If both the UART and the SPI are enabled at the time of reset,

then output will go to the UART until the host sends the first input. If that first input comes on the SPI port,

then all subsequent output will go to the SPI port and the UART will be disabled. If the first input comes on the

UART, then all subsequent output will go to the UART and the SPI will be disabled.

When the slave select (SPI_nSSEL) signal is asserted by the master, SPI transmit data is driven to the output

pin SPI_MISO, and SPI data is received from the input pin SPI_MOSI. The SPI_nSSEL pin has to be asserted

to enable the transmit serializer to drive data to the output signal SPI_MISO. A rising edge on SPI_nSSEL

causes the SPI_MISO line to be tri-stated such that another slave device can drive it, if so desired.

If the output buffer is empty, the SPI serializer transmits the last valid bit repeatedly, which may be either

high or low. Otherwise, the module formats all output in API mode 1 format, as described in chapter 7. The

attached host is expected to ignore all data that is not part of a formatted API frame.

low at

forces a default configuration on the UART at 9600 baud and it will bring

XBee-PRO 900HP Data Format

The SPI will only operate in API mode 1. Neither transparent mode nor API mode 2 (which escapes control

characters) will be supported. This means that the AP configuration only applies to the UART and will be

ignored while using the SPI.

XBee-PRO 900HP SPI Parameters

Most host processors with SPI hardware allow the bit order, clock phase and polarity to be set. For

communication with all XBee radios the host processor must set these options as follows:

•Bit Order - send MSB first

•Clock Phase (CPHA) - sample data on first (leading) edge

•Clock Polarity (CPOL) - first (leading) edge rises

This is SPI Mode 0 and MSB first for all XBee radios. Mode 0 means that data is sampled on the leading edge

and that the leading edge rises. MSB first means that bit 7 is the first bit of a byte sent over the interface.

©2014DigiInternationalInc. 26

Page 27

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

XBee-PRO 900HP Serial Buffers

T o enable the UAR T port, DIN and DOUT must be configured as peripher als. To enable the SPI port, SPI_MISO,

SPI_MOSI, SPI_SSEL

go to the UART until the first input on SPI.

When both the UART and SPI ports are enabled on power-up, all serial data will go out the UART. But, as soon

as input occurs on either port, that port is selected as the active port and no input or output will be allowed on

the other port until the next reset of the module.

If the configuration is changed so that only one port is configured, then that port will be the only one enabled

or used. If the parameters are written with only one port enabled, then the port that is not enabled will not

even be used temporarily after the next reset.

If both ports are disabled on reset, the UART will be used in spite of the wrong configuration so that at least

one serial port will be operational.

Serial Receive Buffer

When serial data enters the RF module through the DIN Pin (or the MOSI pin), the data is stored in the

serial receive buffer until it can be processed. Under certain conditions, the module may not be able to

process data in the serial receive buffer immediately. If large amounts of serial data are sent to the module

such that the serial receive buffer would overflow, then the new data will be discarded. If the UART is in

use, this can be avoided by the host side honoring CTS flow control.

If the SPI is the serial port, no hardware flow control is available. It is the user's responsibility to ensure

that receive buffer is not overflowed. One reliable strategy is to wait for a TX_STATUS response after each

frame sent to ensure that the module has had time to process it.

, and SPI_CLK must be enabled as peripherals. If both ports are enabled then output will

Serial Transmit Buffer

When RF data is received, the data is moved into the serial transmit buffer and sent out the UART or SPI

port. If the serial transmit buffer becomes full and system buffers are also full, then the entire RF data

packet is dropped. Whenever data is received faster than it can be processed and transmitted out the serial

port, there is a potential of dropping data.

XBee-PRO 900HP UART Flow Control

The RTS and CTS module pins can be used to provide RTS and/or CTS flow control. CTS flow control prov ides

an indication to the host to stop sending serial data to the module. RTS flow control allows the host to signal

the module to not send data in the serial transmit buffer out the UART. RTS and CTS flow control are enabled

using the D6 and D7 commands. Please note that serial port flow control is not possible when using the SPI

port.

CTS Flow Control

If CTS flow control is enabled (D7 command), when the serial receive buffer is 17 bytes away from being

full, the module de-asserts CTS

re-asserted after the serial receive buffer has 34 bytes of space. See FT for the buffer size.

RTS Flow Control

If RTS flow control is enabled (D6 command), data in the serial transmit buffer will not be sent out the

DOUT pin as long as RTS

periods of time to avoid filling the serial transmit buffer. If an RF data packet is received, and the serial

transmit buffer does not have enough space for all of the data bytes, the entire RF data packet will be

discarded.

The UART Data Pres e nt In d i ca tor is a useful feature when using RTS flow control. When enabled, the DIO1

line asserts (low asserted) when UART data is queued to be transmitted from the module. See the D1 command in the Command Reference Tables for more information.

Note: If the XBee is sending data out the UART when RTS

up to 5 characters out the UART or SPI port after RTS

(sets it high) to signal to the host device to stop sending serial data. CTS is

is de-asserted (set high). The host device should not de-assert RTS for long

is de-asserted (set high), the XBee could send

is de-asserted.

©2014DigiInternationalInc. 27

Page 28

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

XBee-PRO 900HP Serial Interface Protocols

The XBee modules support both transparent and API (Application Programming Interface) serial interfaces.

Transparent Operation - UART

When operating in transparent mode, the modules act as a serial line replacement. All UART data received

through the DIN pin is queued up for RF transmission. When RF data is received, the data is sent out

through the serial port. The module configuration parameters are configured using the AT command mode

interface. Please note that transparent operation is not provided when using the SPI.

Data is buffered in the serial receive buffer until one of the following causes the data to be packetized and

transmitted:

•No serial characters are received for the amount of time determined by the RO (Packetization Time-

out) parameter. If RO = 0, packetization begins when a character is received.

•The Command Mode Sequence (GT + CC + GT) is received. Any character buffered in the serial

receive buffer before the sequence is transmitted.

•The maximum number of characters that will fit in an RF packet is received. See the NP parameter.

API Operation

API operation is an alternative to transparent operation. The frame-based API extends the level to which a

host application can interact with the networking capabilities of the module. When in API mode, all data

entering and leaving the module is contained in frames that define operations or events within the module.

Transmit Data Frames (received through the serial port) include:

•RF Transmit Data Frame

•Command Frame (equivalent to AT commands)

Receive Data Frames (sent out the serial port) include:

•RF-received data frame

•Command response

•Event notifications such as reset, etc.

The API provides alternative means of configuring modules and routing data at the host applic ation l aye r. A

host application can send data frames to the module that contain address and payload information instead

of using command mode to modify addresses. The module will send data frames to the application

containing status packets; as well as source, and payload information from received data packets.

The API operation option facilitates many operations such as the examples cited below:

-> Transmitting data to multiple destinations without entering Command Mode

-> Receive success/failure status of each transmitted RF packet

-> Identify the source address of each received packet

A Comparison of Transparent and API Operation

The following table compares the advantages of transparent and API modes of operation:

Transparent Operation Features

Simple Interface All received serial data is transmitted unless the module is in command mode.

Easy to support It is easier for an application to support transparent operation and command mode

API Operation Features

Transmitting RF data to mu ltiple remotes only requires changing the address in the API frame. This

Easy to manage data

transmissions to multiple

destinations

Received data frames

indicate the sender's

address

Advanced addressing

support

process is much faster than in transparent operation where the app lication must e nter AT command

mode, change the address, exit command mode, and then transmit data.

Each API transmission can return a transmit status frame indicating the success or reason for

failure.

All received RF data API frames indicate the source address.

API transmit and receive frames can expose addressing fields including source and destination

endpoints, cluster ID and profile ID.

©2014DigiInternationalInc. 28

Page 29

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Advanced networking

diagnostics

Remote Configuration

As a general rule of thumb, API mode is recommended when a device:

• sends RF data to multiple destinations

• sends remote configuration commands to manage devices in the network

• receives RF data packets from multiple devices, and the application needs to know which device sent

which packet

• must support multiple endpoints, cluster IDs, and/or profile IDs

• uses the Device Profile services.

API mode is required when:

• receiving I/O samples from remote devices

• using SPI for the serial port

If the above conditions do not apply (e.g. a sensor node, router, or a simple application), then transparent

operation might be suitable. It is acceptable to use a mixture of devices running API mode and transparent

mode in a network.

API frames can provide indication of IO samples from remote devices, and node identifica tion

messages.

Set / read configuration commands can be sent to remote devices to configure them as needed

using the API.

XBee-PRO 900HP Modes of Operation

Transparent Operation Features

XBee-PRO 900HP Description of Modes

When not transmitting data, the RF module is in Receive Mode. The module shifts into the other modes of

operation under the following conditions:

•Transmit Mode (Serial data in the serial receive buffer is ready to be packetized)

•Sleep Mode

•Command Mode (Command Mode Sequence is issued, not available when using the SPI port)

Transmit Mode

When serial data is received and is ready for packetization, the RF module will attempt to transmit the data.

The destination address determines which node(s) will receive and send the data.

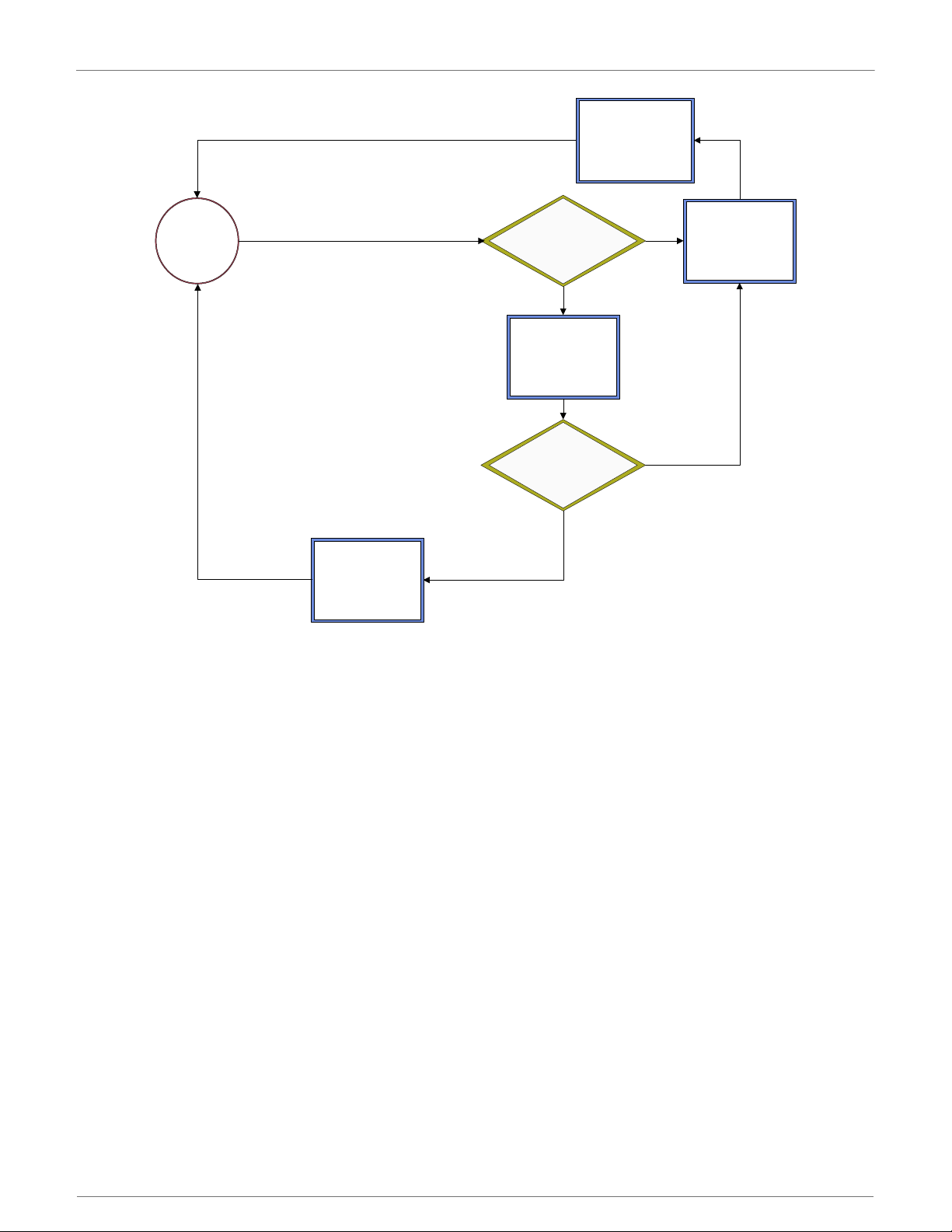

In the diagram below, route discovery applies only to DigiMesh transmissions. The data will be transmitted

once a route is established. If route discovery fails to establish a route, the packet will be discarded.

©2014DigiInternationalInc. 29

Page 30

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Data Discarded

Successful

Transmission

New

Transmission

Route Known?

Route Discovered?

Route Discovery

Transmit Data

Idle Mode

No

Yes

No

Yes

Tra n smitModeSequence

©2014DigiInternationalInc. 30

Page 31

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Example: ATDL 1F<CR>

“AT”

Prex

ASCII

Command

Space

(optional)

Parameter

(optional, HEX)

Carriage

Return

When DigiMesh data is transmitted from one node to another, a network-level acknowledgement is

transmitted back across the established route to the source node. This acknowledgement packet indicates to

the source node that the data packet was received by the destination node. If a network acknowledgement is

not received, the source node will re-transmit the data.

See Data Transmission and Routing in chapter 4 for more information.

Receive Mode

If a valid RF packet is received, the data is transferred to the serial transmit buffer. This is the default mode

for the XBee radio.

Command Mode

To modify or read RF Module parameters, the module must first enter into Command Mode - a state in which

incoming serial characters are interpreted as commands. The API Mode section in Chapter 7 describes an

alternate means for configuring modules which is available with the SPI, as well as over the UART with code.

AT Command Mode

To Enter AT Command Mode:

Send the 3-character command sequence “+++” and observe guard times before and after the command characters. [Refer to the “Default AT Command Mode Sequence” below.]

Default AT Command Mode Sequence (for transition to Command Mode):

•No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

•Input three plus characters (“+++”) within one second [CC (Command Sequence Character) parame-

ter = 0x2B.]

•No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

Once the AT command mode sequence has been issued, the module sends an "OK\r " out the UAR T pin. The

"OK\r" characters can be delayed if the module has not finished transmitting received serial data.

When command mode has been entered, the command mode timer is started (CT command), and the

module is able to receive AT commands on the UART port.

All of the parameter values in the sequence can be modified to reflect user preferences.

NOTE: Failure to enter AT Command Mode is most commonly due to baud rate mismatch. By default,

the BD (Baud Rate) parameter = 3 (9600 bps).

To Send AT Commands:

Send AT commands and parameters using the syntax shown below.

SyntaxforsendingATCommands

To read a parameter value stored in the RF module’s register, omit the parameter field.

The preceding example would change the RF module Destination Address (Low) to “0x1F”. To store the new

value to non-volatile (long term) memory, send the WR (Write) command. This allows modified parameter

values to persist in the module’s registry after a reset. Otherwise, parameters are restored to previously

saved values after the module is reset.

©2014DigiInternationalInc. 31

Page 32

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

Command Response

When a command is sent to the module, the module will parse and execute the command. Upon

successful execution of a command, the module returns an “OK” message. If execution of a command

results in an error, the module returns an “ERROR” message.

Applying Command Changes

Any changes made to the configuration command registers through AT commands will not take effect until

the changes are applied. For example, sending the BD command to change the baud rate will not change

the actual baud rate until changes are applied. Changes can be applied in one of the following ways:

•The AC (Apply Changes) command is issued.

•AT command mode is exited.

To Exit AT Command Mode:

1. Send the ATCN (Exit Command Mode) command (followed by a carriage return).

[OR]

2. If no valid AT Commands are received within the time specified by CT (Command Mode Timeout)

Command, the RF module automatically returns to Idle Mode.

For an example of programming the RF module using AT Commands and descriptions of each configurable parameter, please see the Command Reference Table chapter.

Sleep Mode

Sleep modes allow the RF module to enter sta tes of low power consumption when not in use. XBee RF

modules support both pin sleep (sleep mode entered on pin transition) and cyclic sleep (module sleeps for a

fixed time). XBee sleep modes are discussed in detail in chapter 5.

©2014DigiInternationalInc. 32

Page 33

XBee‐PRO®900HP/XBee‐PRO®XSCRFModules

3.XBee‐PRO900HPNetworkingMethods

This chapter will attempt to explain the basic layers and the three networking methods available on the XBee-PRO®

900HP RF modules, building from the simplest to the most complex.

MAC/PHY Basics

PHY is short for Physical Lay er. It is responsible for managing the hardware that modulates and demodulates the RF bits.

MAC stands for Media Access Layer. The MAC layer is responsible for sending and receiving RF frames. As part of each

packet, there is a MAC layer data header that has addressing information as well as packet options. This layer

implements packet acknowledgements (ACKs), packet tracking to eliminate duplicates, etc.

When a radio is transmitting, it cannot receive packets. When a radio is not sleeping, it is either receiving or

transmitting. There are no beacons or master/slave requirements in the design of the MAC/PHY.

This radio uses a patented method for scanning and finding a transmission. When a radio transmits, it sends out a

repeated preamble pattern, a MAC header, optionally a network header, followed then by packet data. A receiving radio

is able to scan all the channels to find a transmission during the preamble, then once it has locked into that it will

attempt to receive the whole packet.

Related parameters: CM, HP, ID, PL, RR, MT

The Preamble ID (HP) can be changed to make it so a group of radios will not interfere with another group of radios

in the same vicinity. The advantage of changing this parameter is that a receiving radio will not even lock into a

transmission of a transmitting radio that does not have the same ID.

The Network ID (ID) can be changed to further keep radios from interfering with each other. This ID is matched after

the preamble pattern has been matched, and the MAC header has been received. Networks are defined with a

unique network identifier. For modules to communicate they must be configured with the same network identifier.