Page 1

XBee/XBee-PRO S1 802.15.4 (Legacy)

RF Modules

User Guide

Page 2

Revision history—90000982

Revision Date Description

T December

2015

U May 2016

V October

2016

W June 2017 Modified regulatory and certification information as required by RED (Radio

X May 2018 Added note on range estimation. Changed ICto ISED.

Corrected RESET pin information.

Noted that bit 13 of the SC parameter is not available for XBee-PRO devices.

Corrected an error in the I/O line passing parameters table. Added S1 and

Legacy to the product name. Updated the certifications.

Updated and rebranded the documentation.

Equipment Directive).

Trademarks and copyright

Digi, Digi International, and the Digi logo are trademarks or registered trademarks in the United

States and other countries worldwide. All other trademarks mentioned in this document are the

property of their respective owners.

© 2018 Digi International Inc. All rights reserved.

Disclaimers

Information in this document is subject to change without notice and does not represent a

commitment on the part of Digi International. Digi provides this document “as is,” without warranty of

any kind, expressed or implied, including, but not limited to, the implied warranties of fitness or

merchantability for a particular purpose. Digi may make improvements and/or changes in this manual

or in the product(s) and/or the program(s) described in this manual at any time.

Warranty

To view product warranty information, go to the following website:

www.digi.com/howtobuy/terms

Customer support

Gather support information: Before contacting Digi technical support for help, gather the following

information:

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

2

Page 3

Product name and model

Product serial number (s)

Firmware version

Operating system/browser (if applicable)

Logs (from time of reported issue)

Trace (if possible)

Description of issue

Steps to reproduce

Contact Digi technical support: Digi offers multiple technical support plans and service packages.

Contact us at +1 952.912.3444 or visit us at www.digi.com/support.

Feedback

To provide feedback on this document, email your comments to

Include the document title and part number (XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide,

90000982 X) in the subject line of your email.

techcomm@digi.com

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

3

Page 4

Contents

About the XBee/XBee-PRO S1 802.15.4 (Legacy) RF Modules

Technical specifications

Electrical characteristics 10

DC Characteristics (VCC = 2.8 - 3.4 VDC) 10

ADC timing/performance characteristics1 11

Performance specifications 12

Power requirements 12

General specifications 13

Networking and security specifications 13

Regulatory conformity summary 13

Hardware

Antenna options 16

XBee/XBee-PRO S1 802.15.4 (Legacy) Mechanical drawings 16

Mounting considerations 16

Pin signals 17

Design notes 19

Power supply design 19

Board layout 19

Antenna performance 19

Pin connection recommendations 20

Keepout area 20

Operation

Serial communications 23

UART data flow 23

Transparent operating mode 24

API operating mode 24

Flow control 25

ADC and Digital I/O line support 26

I/O data format 27

API support 27

Sleep support 27

DIO pin change detect 28

Sample rate (interval) 28

I/O line passing 28

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

4

Page 5

Configuration example 30

Networks 30

Peer-to-peer networks 31

NonBeacon (with coordinator) 31

Association 31

Addressing 34

Unicast mode 34

Broadcast mode 35

Modes of operation 35

Idle mode 36

Transmit/Receive modes 36

Sleep modes 38

Multiple AT commands 41

Parameter format 41

Configuration

Configure the device using XCTU 44

Programming the RF module 44

Setup 44

Remote configuration commands 45

Send a remote command 45

Apply changes on remote devices 46

Remote command responses 46

Software libraries 46

XBee Network Assistant 46

AT commands

Special commands 49

WR (Write) 49

RE (Restore Defaults) 49

FR (Software Reset) 49

Networking and security commands 50

CH (Channel) 50

ID (PAN ID) 50

DH (Destination Address High) 50

DL (Destination Address Low) 51

MY (16-bit Source Address) 51

SH (Serial Number High) 51

SL (Serial Number Low) 51

RR (XBee Retries) 52

RN (Random Delay Slots) 52

MM (MAC Mode) 53

NI (Node Identifier) 53

ND (Node Discover) 54

NT (Node Discover Time) 55

NO (Node Discovery Options) 55

DN (Destination Node) 55

CE (Coordinator Enable) 56

SC (Scan Channels) 56

SD (Scan Duration) 57

A1 (End Device Association) 58

A2 (Coordinator Association) 59

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

5

Page 6

AI (Association Indication) 60

DA (Force Disassociation) 61

FP (Force Poll) 61

AS (Active Scan) 61

ED (Energy Scan) 62

EE (AES Encryption Enable) 63

KY (AES Encryption Key) 63

RF interfacing commands 64

PL (Power Level) 64

CA (CCA Threshold) 64

Sleep commands (low power) 65

SM (Sleep Mode) 65

SO (Sleep Options) 66

ST (Time before Sleep) 66

SP (Cyclic Sleep Period) 66

DP (Disassociated Cyclic Sleep Period) 67

Serial interfacing commands 67

BD (Interface Data Rate) 67

RO (Packetization Timeout) 69

AP (API Enable) 69

NB (Parity) 70

PR (Pull-up/Down Resistor Enable) 70

I/O settings commands 71

D0 (DIO0 Configuration) 71

D1 (DIO1 Configuration) 71

D2 (AD2/DIO2 Configuration) 72

D3 (DIO3 Configuration) 72

D4 (DIO4 Configuration) 73

D5 (DIO5 Configuration) 73

D6 (DIO6 Configuration) 74

D7 (DIO7 Configuration) 74

D8 (DIO8 Configuration) 75

IU (I/O Output Enable) 75

IT (Samples before TX) 76

IS (Force Sample) 76

IO (Digital Output Level) 77

IC (DIO Change Detect) 77

IR (Sample Rate) 77

IA (I/O Input Address) 78

T0 (D0 Output Timeout) 78

T1 (D1 Output Timeout) 79

T2 (D2 Output Timeout) 79

T3 (D3 Output Timeout) 79

T4 (D4 Output Timeout) 80

T5 (D5 Output Timeout) 80

T6 (D6 Output Timeout) 80

T7 (D7 Output Timeout) 81

P0 (PWM0 Configuration) 81

P1 (PWM1 Configuration) 81

M0 (PWM0 Output Level) 82

M1 (PWM1 Output Level) 82

PT (PWM Output Timeout) 83

RP (RSSI PWM Timer) 83

Diagnostic commands 83

VR (Firmware Version) 84

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

6

Page 7

VL (Version Long) 84

HV (Hardware Version) 84

DB (Last Packet RSSI) 84

EC (CCA Failures) 85

EA (ACK Failures) 85

ED (Energy Scan) 85

Command mode options 86

CT (Command Mode Timeout) 86

CN (Exit Command mode) 86

AC (Apply Changes) 86

GT (Guard Times) 87

CC (Command Sequence Character) 87

API operation

API frame specifications 89

API operation (AP parameter = 1) 89

API operation-with escaped characters (AP parameter = 2) 89

Calculate and verify checksums 90

Example 90

API types 91

Modem Status - 0x8A 91

Modem status codes 93

Local AT Command Request - 0x08 93

Queue Local AT Command Request - 0x09 95

Local AT Command Response - 0x88 96

Remote AT Command Request - 0x17 98

Remote AT Command Response- 0x97 100

64-bit Transmit Request - 0x00 102

16-bit Transmit Request- 0x01 104

Transmit Status - 0x89 106

64-bit Receive Packet - 0x80 108

16-bit Receive Packet - 0x81 109

64-bit I/O Sample Indicator - 0x82 111

16-bit I/O Sample Indicator - 0x83 113

Regulatory information

United States (FCC) 116

OEM labeling requirements 116

FCC notices 116

FCC-approved antennas (2.4 GHz) 117

RF exposure 123

Europe (CE) 123

Maximum power and frequency specifications 123

OEM labeling requirements 123

Declarations of conformity 124

Antennas 124

ISED (Innovation, Science and Economic Development Canada) 125

Labeling requirements 125

Japan 125

Labeling requirements 125

Brazil ANATEL 125

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

7

Page 8

About the XBee/XBee-PRO S1 802.15.4 (Legacy) RF Modules

The XBee and XBee-PRO RF Modules were engineered to meet IEEE 802.15.4 standards and support

the unique needs of low-cost, low-power wireless sensor networks. The devices require minimal

power and provide reliable delivery of data between devices.

The devices operate within the ISM 2.4 GHz frequency band and are pin-for-pin compatible with each

other.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

8

Page 9

Technical specifications

Electrical characteristics 10

Performance specifications 12

Power requirements 12

General specifications 13

Networking and security specifications 13

Regulatory conformity summary 13

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

9

Page 10

Technical specifications Electrical characteristics

Electrical characteristics

The following tables list the electrical characteristics of the XBee/XBee-PRO XBee/XBee-PRO S1

802.15.4 (Legacy) RF Modules.

DC Characteristics (VCC = 2.8 - 3.4 VDC)

Symbol Characteristic Condition Min Typical Max Unit

V

IL

V

IH

V

OL

V

OH

Input low voltage All Digital Inputs - - 0.35 *

Input high voltage All Digital Inputs 0.7 *

Output low voltage IOL= 2 mA, VCC >= 2.7 V - - 0.5 V

Output high

IOH= -2 mA, VCC >= 2.7VVCC

voltage

II

IN

II

OZ

Input leakage

Current

High impedance

leakage current

VIN = VCC or GND, all

inputs, per pin

VIN = VCC or GND, all

I/O High-Z, per pin

TX Transmit current VCC = 3.3 V -

RX Receive current VCC = 3.3 V -

PWRDWN

Power-down

current

SM parameter = 1 - <10 - µA

V

VCC

- - V

VCC

- - V

- 0.5

- 0.025 1 µA

- 0.025 1 µA

45 (XBee)

- mA

215, 140 (XBee-PRO,

International)

50 (XBee)

- mA

55 (XBee-PRO)

ADC characteristics (operating)

Symbol Characteristic Condition Min Typical Max Unit

V

REFH

I

REF

V

INDC

1. V

2. Maximum electrical operating range, not valid conversion range.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

VREF - analog-to-digital converter

reference range

VREF - reference supply current Enabled - 200 - µA

Analog input voltage

is connected to VCC.

DDAD

2

Disabled or

Sleep Mode

2.08 - V

DDAD

1

V

- <0.01 0.02 µA

V

SSAD

0.3

-

V

DDAD

0.3

+

V

10

Page 11

Technical specifications Electrical characteristics

ADC timing/performance characteristics

1

Symbol Characteristic Condition Min Typical Max Unit

R

AS

V

AIN

Source impedance at input

Analog input voltage

RES Ideal resolution (1 LSB)

DNL Differential non-linearity

INL Integral non-linearity

E

ZS

F

FS

E

IL

E

TU

Zero-scale error

Full-scale error

Input leakage error

Total unadjusted error

7

8

9

2

- - - kW

3

4

5

6

- V

REFL

- V

REFL

V

2.08V < VDDAD < 3.6V 2.031 - 3.516 mV

- - ±0.5 ±1.0 LSB

- - ±0.5 ±1.0 LSB

- - ±0.4 ±1.0 LSB

- - ±0.4 ±1.0 LSB

- - ±0.05 ±5.0 LSB

10

- - ±1.1 ±2.5 LSB

1. All accuracy numbers are based on the processor and system being in WAIT state (very little

activity and no I/O switching) and that adequate low-pass filtering is present on analog input

pins (filter with 0.01 µF to 0.1 µF capacitor between analog input and VREFL). Failure to

observe these guidelines may result in system or microcontroller noise causing accuracy errors

which will vary based on board layout and the type and magnitude of the activity. Data

transmission and reception during data conversion may cause some degradation of these

specifications, depending on the number and timing of packets. We advise testing the ADCs in

your installation if best accuracy is required.

2. RASis the real portion of the impedance of the network driving the analog input pin. Values

greater than this amount may not fully charge the input circuitry of the ATD resulting in

accuracy error.

3. Analog input must be between V

REFL

and V

for valid conversion. Values greater than V

REFH

REFH

will convert to $3FF.

4. The resolution is the ideal step size or 1LSB = (V

REFH–VREFL

)/1024.

5. Differential non-linearity is the difference between the current code width and the ideal code

width (1LSB). The current code width is the difference in the transition voltages to and from

the current code.

6. Integral non-linearity is the difference between the transition voltage to the current code and

the adjusted ideal transition voltage for the current code. The adjusted ideal transition voltage

is (Current Code–1/2)*(1/((VREFH+EFS)–(VREFL+EZS))).

7. Zero-scale error is the difference between the transition to the first valid code and the ideal

transition to that code. The Ideal transition voltage to a given code is (Code–1/2)*(1/(VREFH–

VREFL)).

8. Full-scale error is the difference between the transition to the last valid code and the ideal

transition to that code. The ideal transition voltage to a given code is (Code–1/2)*(1/(VREFH–

VREFL)).

9. Input leakage error is error due to input leakage across the real portion of the impedance of

the network driving the analog pin. Reducing the impedance of the network reduces this error.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

11

Page 12

Technical specifications Performance specifications

10. Total unadjusted error is the difference between the transition voltage to the current code and

the ideal straight-line transfer function. This measure of error includes inherent quantization

error (1/2LSB) and circuit error (differential, integral, zero-scale, and full-scale) error. The

specified value of ETU assumes zero EIL (no leakage or zero real source impedance).

Performance specifications

The following table describes the performance specifications for the devices.

Note Range figure estimates are based on free-air terrain with limited sources of interference. Actual

range will vary based on transmitting power, orientation of transmitter and receiver, height of

transmitting antenna, height of receiving antenna, weather conditions, interference sources in the

area, and terrain between receiver and transmitter, including indoor and outdoor structures such as

walls, trees, buildings, hills, and mountains.

Specification

Indoor/urban range

Outdoor RF line-of-sight range

Transmit power output (software

selectable)

RF data rate

Serial interface data rate

(software selectable)

Receiver sensitivity (typical)

Power requirements

The following table describes the power requirements for the XBee/XBee-PRO S1 802.15.4 (Legacy).

XBee

Up to 100 ft (30 m)

Up to 300 ft (90 m)

1 mW (0 dBm)

250,000 b/s 250,000 b/s

1200 b/s - 250 kb/s

(non-standard baud rates also

supported)

-92 dBm

(1% packet error rate)

XBee-PRO

Up to 300 ft. (90 m)

Up to 200 ft (60 m)

International variant

Up to 1 mile (1600 m)

Up to 2500 ft (750 m)

international variant

63 mW (18 dBm)*

10 mW (10 dBm) for

international variant

1200 bps - 250 kb/s

(non-standard baud rates also

supported)

100 dBm

(1% packet error rate)

Specification

Supply voltage 2.8 - 3.4 V 2.8 - 3.4 V

Transmit current

(typical)

Idle/receive current

(typical)

Power-down current < 10 uA < 10 uA

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

XBee XBee-PRO

45 mA

(@3.3 V)

50 mA

(@3.3 V)

n 250 mA (@3.3 V) (150 mA for international variant)

RPSMA module only.

n 340 mA (@3.3 V) (180 mA for international variant)

55 mA (@ 3.3 V)

12

Page 13

Technical specifications General specifications

General specifications

The following table describes the general specifications for the devices.

Specification XBee XBee-PRO

Operating

frequency

band

Dimensions 0.960 in x 1.087 in (2.438 cm x 2.761 cm) 0.960 in x 1.297 in (2.438 cm x 3.294 cm)

Operating

temperature

Antenna

options

ISM 2.4 GHz ISM 2.4 GHz

-40 to 85ºC (industrial) -40 to 85ºC (industrial)

Integrated whip antenna, embedded

PCB antenna, U.FL connector, RPSMA

connector

Networking and security specifications

The following table describes the networking and security specifications for the devices.

Specification

Supported network topologies Point-to-point, point-to-multipoint and

Number of channels (software

selectable)

Addressing options PAN ID, channel and addresses PAN ID, channel and

XBee

peer-to-peer

16 direct sequence channels 12 direct sequence

Integrated whip antenna, embedded

PCB antenna, U.FL connector, RPSMA

connector

XBee-PRO

channels

addresses

Regulatory conformity summary

This table describes the agency approvals for the devices.

Specification XBee XBee-PRO

United States (FCC Part 15.247) OUR-XBEE OUR-XBEEPRO

Innovation, Science and

Economic Development Canada

(ISED)

Europe (CE) Yes Yes (Maximum 10 dBm transmit power

1

See Regulatory information or region-specific certification requirements.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

4214A-XBEE 4214A-XBEEPRO

output)

1

13

Page 14

Technical specifications Regulatory conformity summary

Specification XBee XBee-PRO

Japan R201WW07215214

Australia/New Zealand RCM/R-NZ RCM/R-NZ

Brazil ANATEL 0369-15-

1209

R201WW08215111

(Maximum 10 dBm transmit power output)*

Wire, chip, RPMSA, and U.FL versions are

certified for Japan. PCB antenna version is

not.

ANATEL 0378-15-1209

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

14

Page 15

Hardware

Antenna options 16

XBee/XBee-PRO S1 802.15.4 (Legacy) Mechanical drawings 16

Mounting considerations 16

Pin signals 17

Design notes 19

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

15

Page 16

Hardware Antenna options

Antenna options

The ranges specified are typical for the integrated whip (1.5 dBi) and dipole (2.1 dBi) antennas. The

printed circuit board (PCB) antenna option provides advantages in its form factor; however, it typically

yields shorter range than the whip and dipole antenna options when transmitting outdoors. For more

information, see XBee and XBee-PRO OEM RF Module Antenna Considerations Application Note.

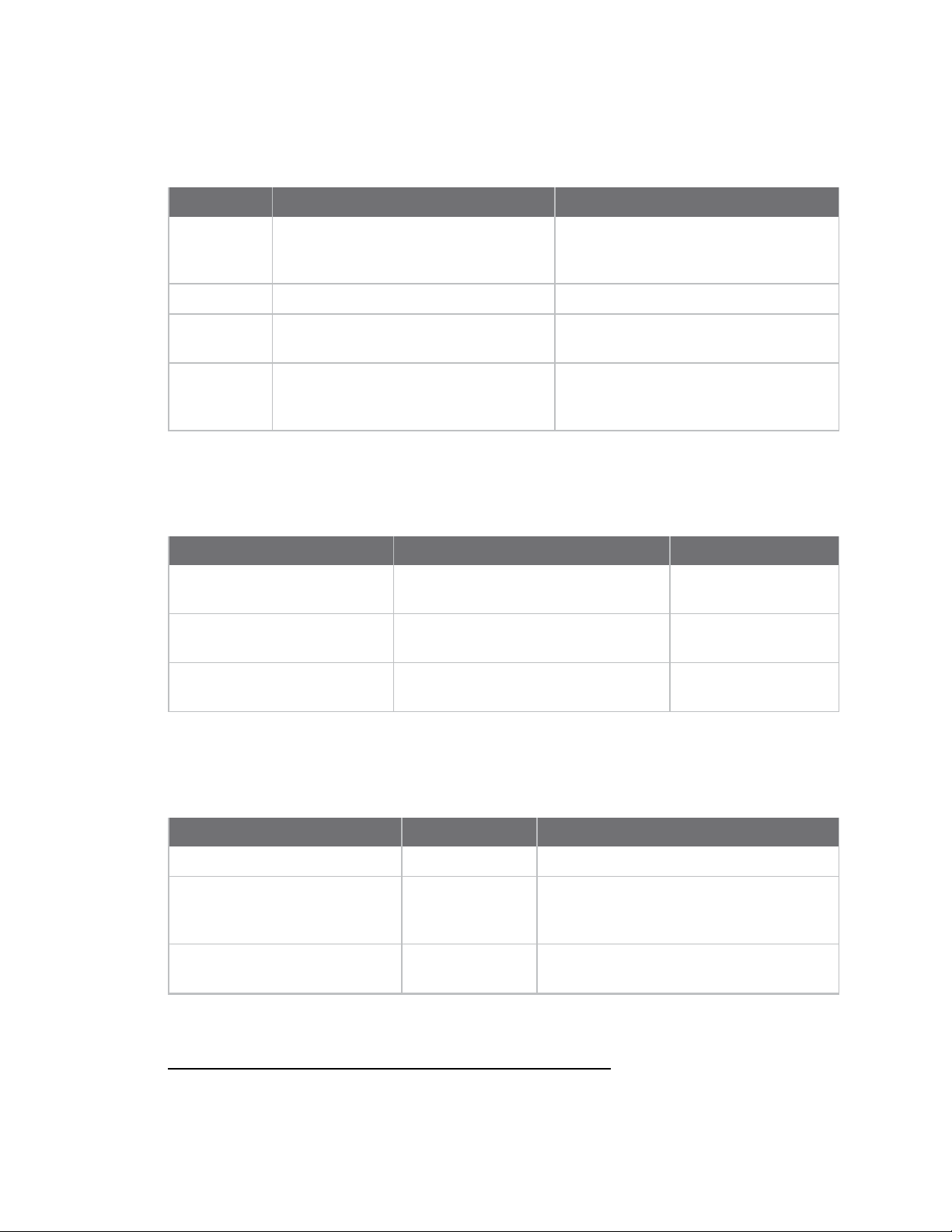

XBee/XBee-PRO S1 802.15.4 (Legacy) Mechanical drawings

The following graphics show the mechanical drawings of the XBee / XBee-PRO OEM RF Modules. The

XBee and XBee-PRO RF Modules are pin-for-pin compatible.

Note The antenna options not shown.

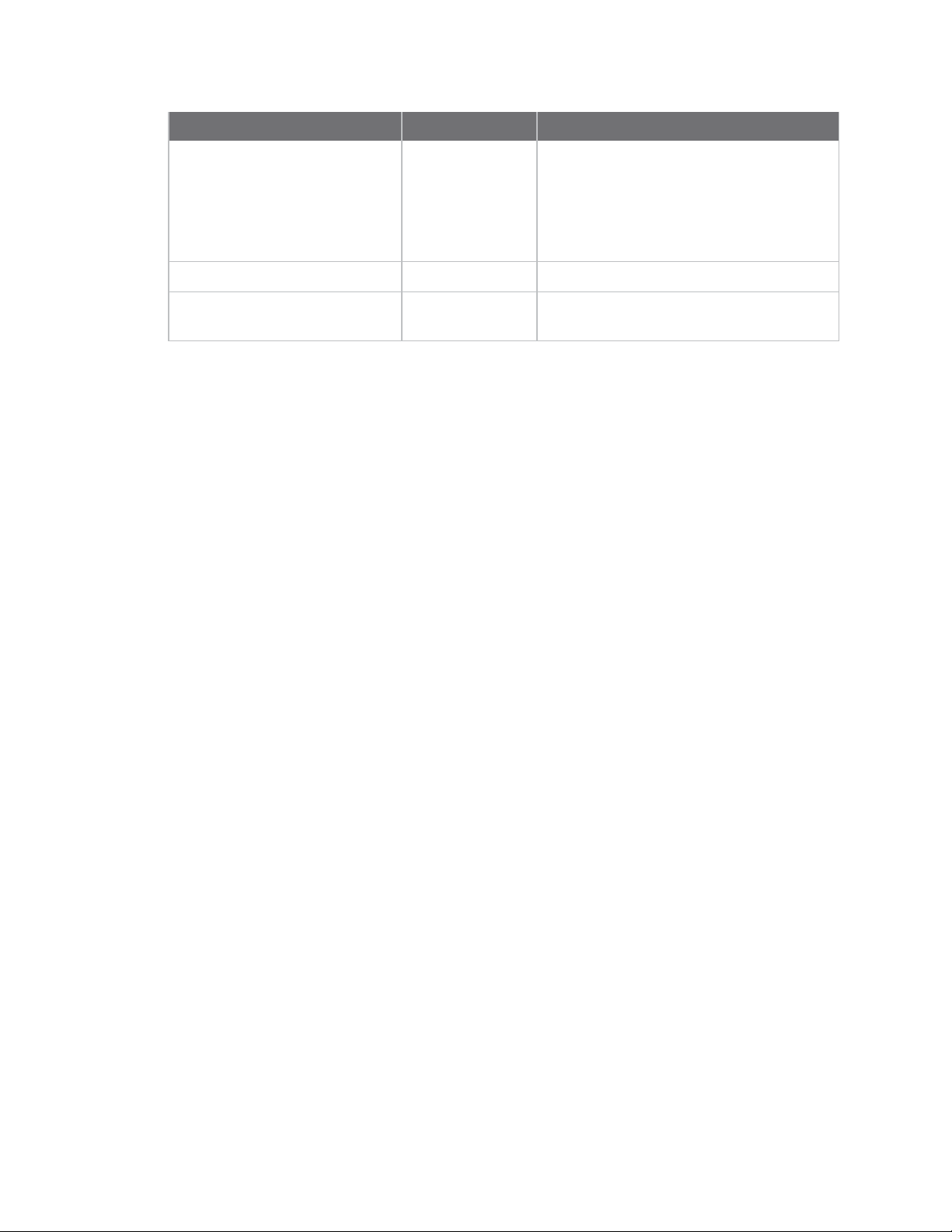

Mounting considerations

We design the through-hole module to mount into a receptacle so that you do not have to solder the

module when you mount it to a board. The development kits may contain RS-232 and USB interface

boards that use two 20-pin receptacles to receive modules.

The following illustration shows the module mounting into the receptacle on the RS-232 interface

board.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

16

Page 17

Hardware Pin signals

Century Interconnect manufactures the receptacles used on Digi development boards. Several other

manufacturers provide comparable mounting solutions; however, Digi currently uses the following

receptacles:

n Through-hole single-row receptacles: Samtec part number: MMS-110-01-L-SV (or equivalent)

n Surface-mount double-row receptacles: Century Interconnect part number: CPRMSL20-D-0-1

(or equivalent)

n Surface-mount single-row receptacles: Samtec part number: SMM-110-02-SM-S

Note We recommend that you print an outline of the module on the board to indicate the

correct orientation for mounting the module.

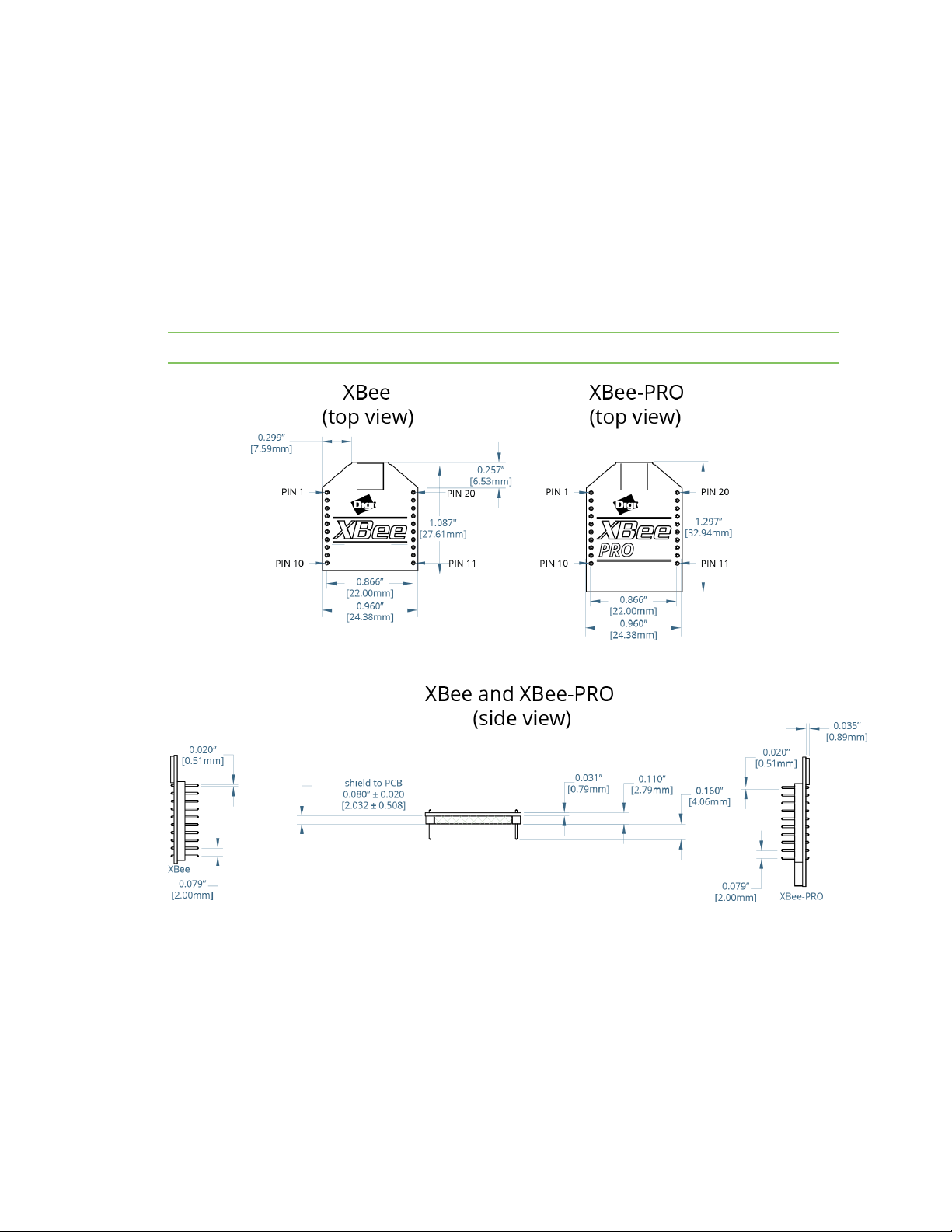

Pin signals

The following image shows the pin numbers; it shows the device's top sides, the shields are on the

bottom.

The following table describes the pin assignments for the devices. A horizontal line above the signal

name indicates low-asserted signals.

Pin Name Direction Description

1

VCC - Power supply

2

DOUT Output UART data out

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

17

Page 18

Hardware Pin signals

Pin Name Direction Description

3 DIN/CONFIG

DO8

1

4

5 RESET

Input UART data In

Either Digital output 8

Input/Open

drain output

Device reset (reset pulse must be at least 200 ns). This

must be driven as an open drain/collector. The device

drives this line low when a reset occurs. Never drive this

line high.

6

PWM0/RSSI Either PWM output 0 / RX signal strength indicator

7

PWM1 Either PWM output 1

8

[reserved] - Do not connect

9 DTR/SLEEP_RQ/DI8

10

GND - Ground

11

AD4/DIO4 Either Analog input 4 or digital I/O 4

12 CTS /DIO7

13 ON/SLEEP

14

VREF Input Voltage reference for A/D inputs

15

Associate/AD5/DIO5 Either Associated indicator, analog input 5 or digital I/O 5

Either Pin sleep control line or digital input 8

Either Clear-to-send flow control or digital I/O 7

Output Device status indicator

16 RTS/DIO6

17

AD3/DIO3 Either Analog input 3 or digital I/O 3

18

AD2/DIO2 Either Analog input 2 or digital I/O 2

19

AD1/DIO1 Either Analog input 1 or digital I/O 1

20

AD0/DIO0 Either Analog input 0, digital I/O 0

Either Request-to-send flow control, or digital I/O 6

Notes:

n Minimum connections: VCC, GND, DOUT and DIN

n Minimum connections for updating firmware: VCC, GND, DIN, DOUT, RTS and DTR

n Signal direction is specified with respect to the module

n The module includes a 50 kΩ pull-up resistor attached to RESET

n You can configure several of the input pull-ups using the PR command

n Leave any unused pins disconnected

1

Function is not supported at the time of this release.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

18

Page 19

Hardware Design notes

Design notes

The XBee modules do not specifically require any external circuitry specific connections for proper

operation. However, there are some general design guidelines that we recommend for help in

troubleshooting and building a robust design.

Power supply design

A poor power supply can lead to poor device performance, especially if you do not keep the supply

voltage within tolerance or if it is excessively noisy. To help reduce noise, place a 1.0 μF and 8.2 pF

capacitor as near as possible to pin 1 on the PCB. If you are using a switching regulator for the power

supply, switch the frequencies above 500 kHz. Limit the power supply ripple to a maximum 100 mV

peak to peak.

Board layout

We design XBee devices to be self sufficient and have minimal sensitivity to nearby processors,

crystals or other printed circuit board (PCB) components. Keep power and ground traces thicker than

signal traces and make sure that they are able to comfortably support the maximum current

specifications. There are no other special PCB design considerations to integrate XBee devices, with

the exception of antennas.

Antenna performance

Antenna location is important for optimal performance. The following suggestions help you achieve

optimal antenna performance. Point the antenna up vertically (upright). Antennas radiate and receive

the best signal perpendicular to the direction they point, so a vertical antenna's omnidirectional

radiation pattern is strongest across the horizon.

Position the antennas away from metal objects whenever possible. Metal objects between the

transmitter and receiver can block the radiation path or reduce the transmission distance. Objects

that are often overlooked include:

n metal poles

n metal studs

n structure beams

n concrete, which is usually reinforced with metal rods

If you place the device inside a metal enclosure, use an external antenna. Common objects that have

metal enclosures include:

n vehicles

n elevators

n ventilation ducts

n refrigerators

n microwave ovens

n batteries

n tall electrolytic capacitors

Do not place XBee devices with the chip or integrated PCB antenna inside a metal enclosure.

Do not place any ground planes or metal objects above or below the antenna.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

19

Page 20

Hardware Design notes

For the best results, mount the device at the edge of the host PCB. Ensure that the ground, power,

and signal planes are vacant immediately below the antenna section.

Pin connection recommendations

The only required pin connections are VCC, GND, DOUT and DIN. To support serial firmware updates,

you should connect VCC, GND, DOUT, DIN, RTS, and SLEEP (DTR).

Leave all unused pins disconnected. Pull all inputs on the device high with internal pull-up resistors

using the PR command. You do not need a specific treatment for unused outputs.

Other pins may be connected to external circuitry for convenience of operation including the Associate

LED pin (pin 15). The Associate LED flashes differently depending on the state of the device.

If analog sampling is desired, attach the VRef (pin 14) to a voltage reference.

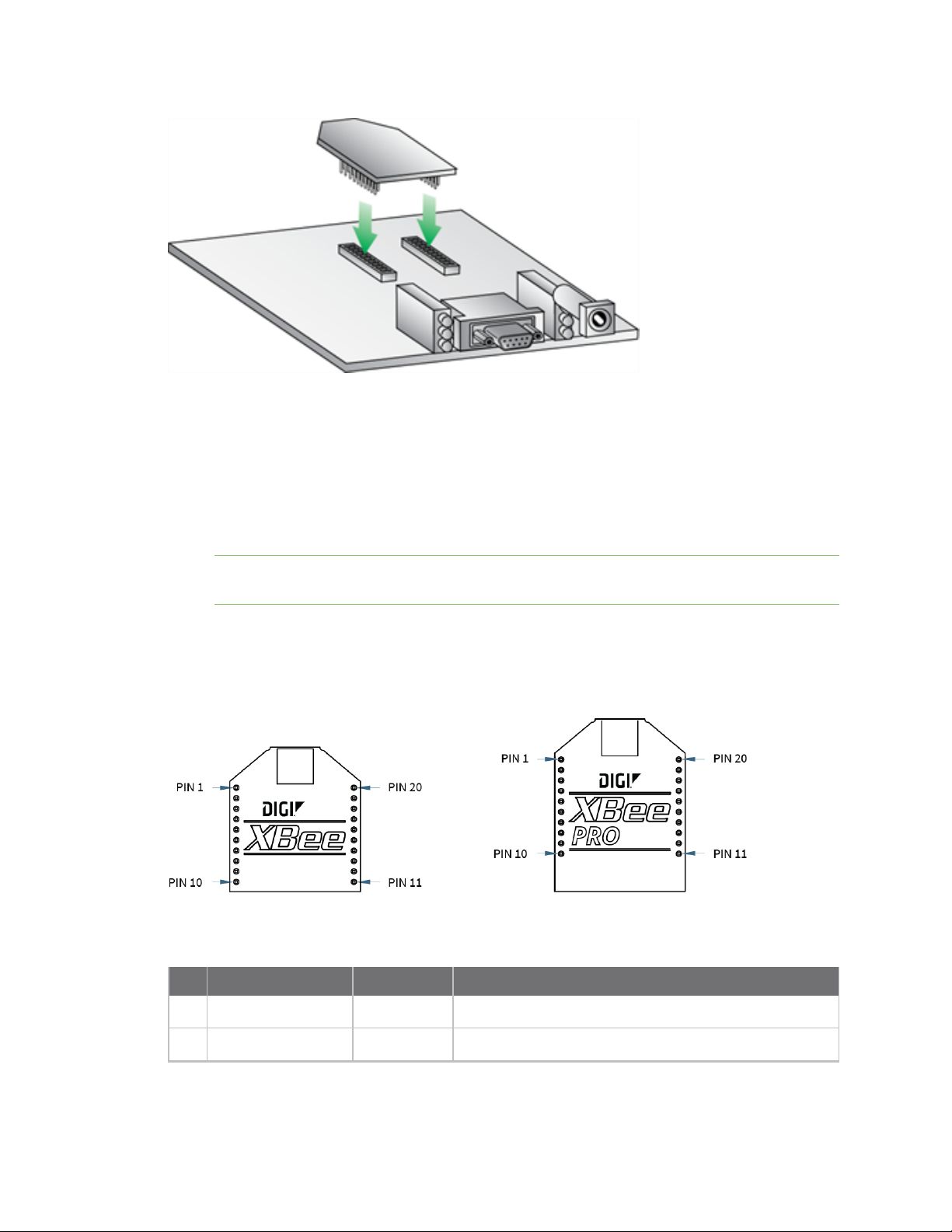

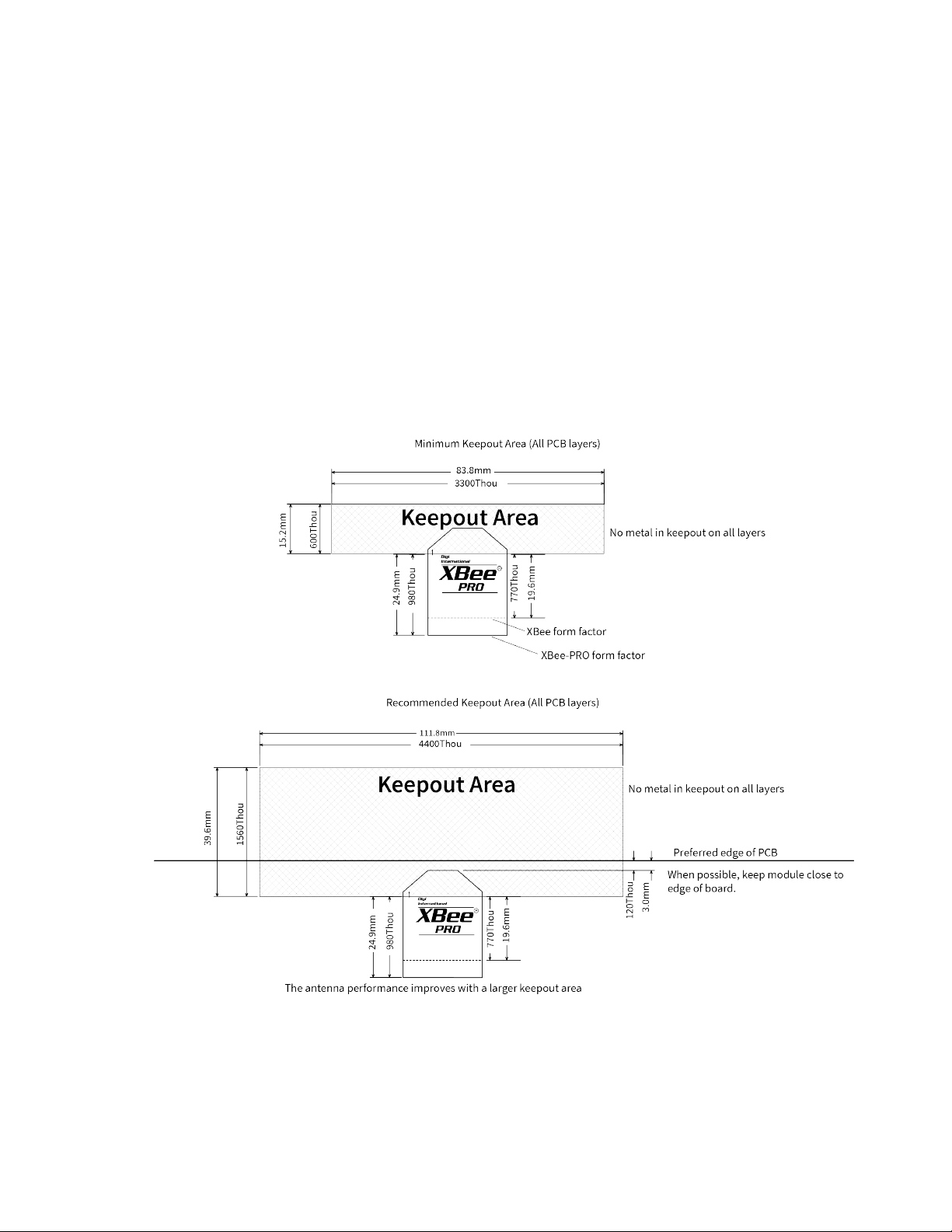

Keepout area

We recommend that you allow a “keepout” area, as shown in the following drawing.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

20

Page 21

Hardware Design notes

Notes

1. We recommend non-metal enclosures. For metal enclosures, use an external antenna.

2. Keep metal chassis or mounting structures in the keepout area at least 2.54 cm (1 in) from the

antenna.

3. Maximize the distance between the antenna and metal objects that might be mounted in the

keepout area.

4. These keepout area guidelines do not apply for wire whip antennas or external RFconnectors.

Wire whip antennas radiate best over the center of a ground plane.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

21

Page 22

Operation

Serial communications 23

ADC and Digital I/O line support 26

Networks 30

Addressing 34

Modes of operation 35

Multiple AT commands 41

Parameter format 41

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

22

Page 23

Operation Serial communications

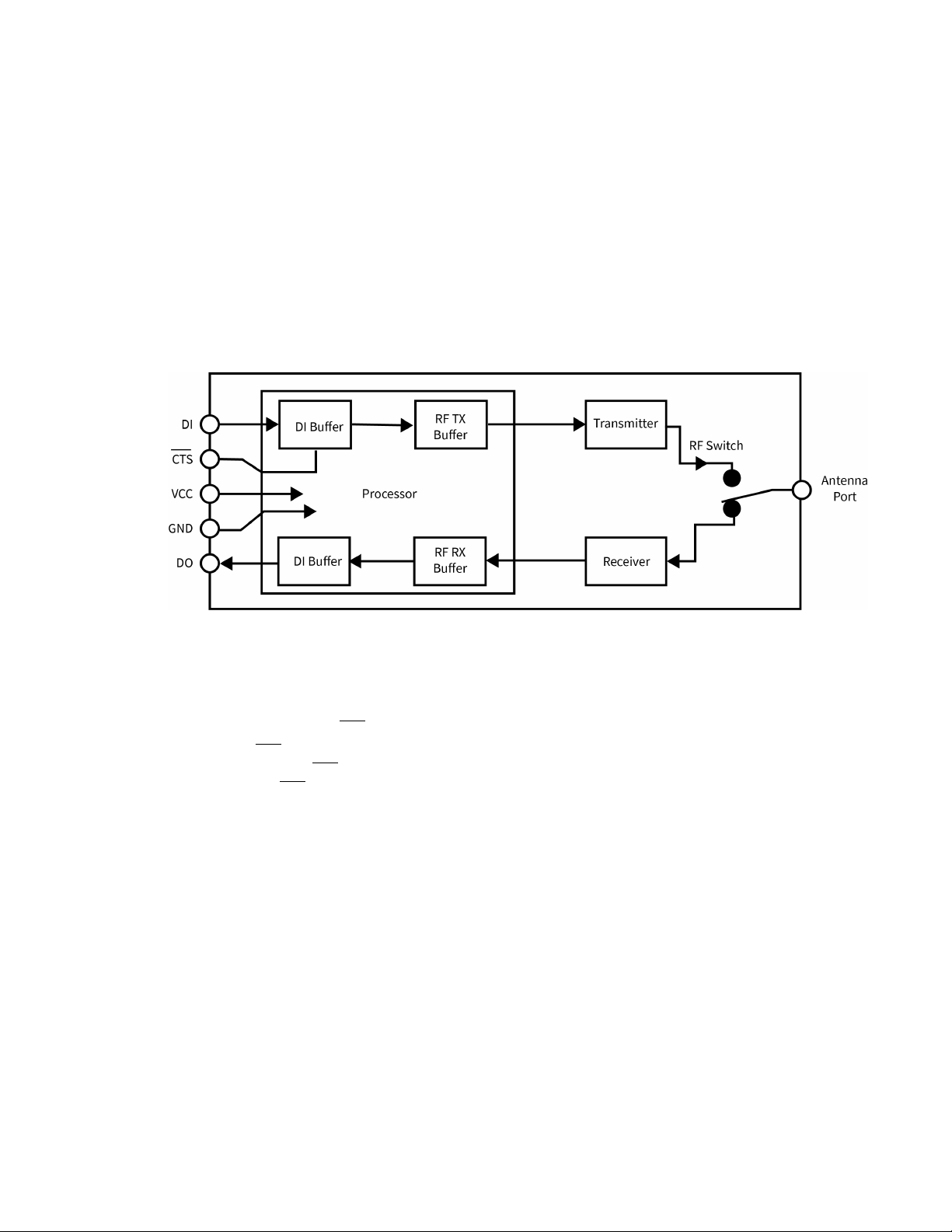

Serial communications

RF Modules interface to a host device through a serial port. Using its serial port, the device

communicates with any of the following:

n Logic and voltage compatible UART

n Level translator to any serial device (for example, through an RS-232 or USB interface board)

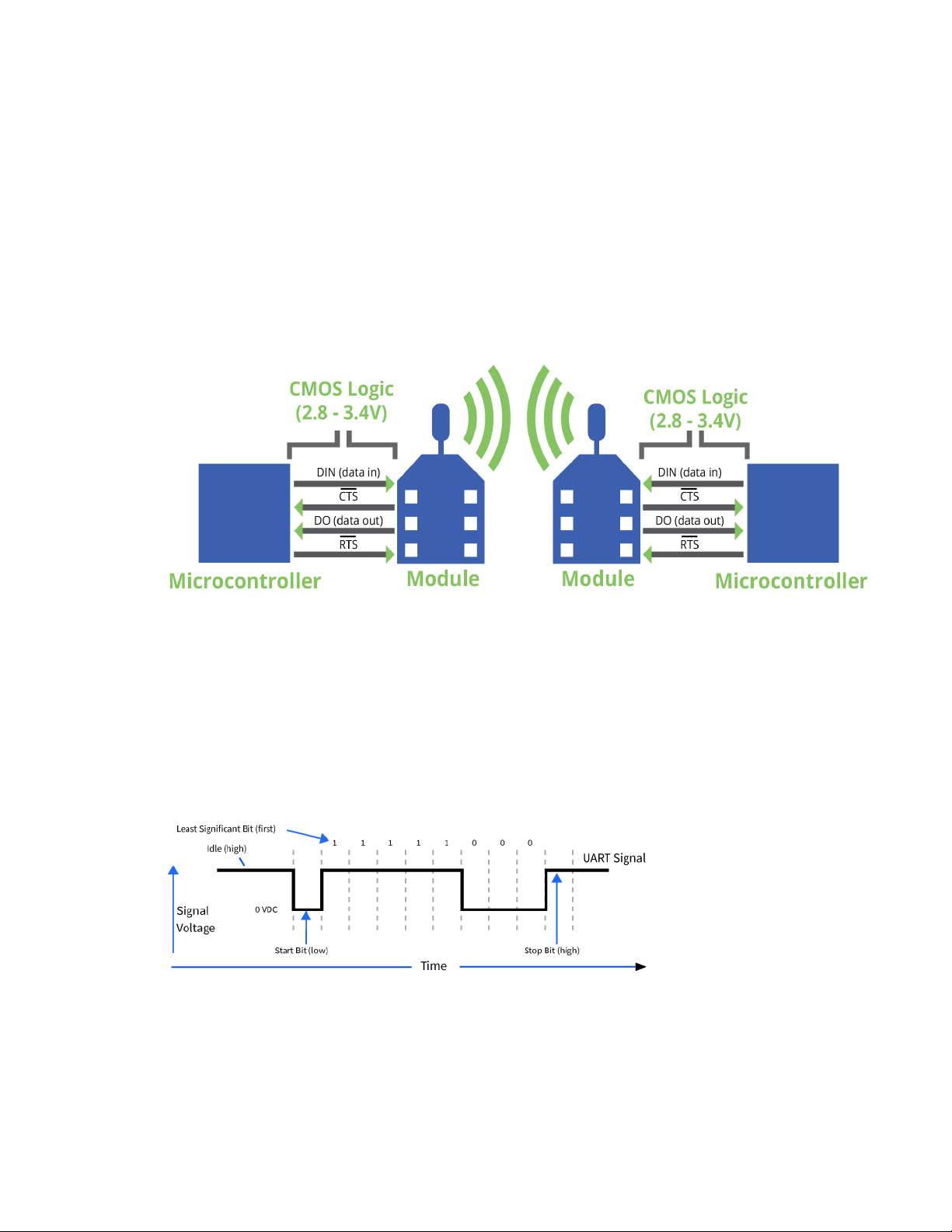

UART data flow

Devices that have a UART interface connect directly to the pins of the XBee/XBee-PRO S1 802.15.4

(Legacy) as shown in the following figure. The figure shows system data flow in a UART-interfaced

environment. Low-asserted signals have a horizontal line over the signal name.

Serial data

A device sends data to the XBee/XBee-PRO S1 802.15.4 (Legacy)'s UART through pin 3 DIN as an

asynchronous serial signal. When the device is not transmitting data, the signals should idle high.

For serial communication to occur, you must configure the UART of both devices (the microcontroller

and the XBee/XBee-PRO S1 802.15.4 (Legacy)) with compatible settings for the baud rate, parity, start

bits, stop bits, and data bits.

Each data byte consists of a start bit (low), 8 data bits (least significant bit first) and a stop bit (high).

The following diagram illustrates the serial bit pattern of data passing through the device. The

diagram shows UART data packet 0x1F (decimal number 31) as transmitted through the device.

Serial communications depend on the two UARTs (the microcontroller and the RF device) to be

configured with compatible settings, including baud rate, parity, start bits, stop bits, and data bits.

The UART baud rate and parity settings on the XBee module can be configured with the BD and NB

commands, respectively. For more information, see AT commands.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

23

Page 24

Operation Serial communications

Transparent operating mode

Devices operate in this mode by default. The device acts as a serial line replacement when it is in

Transparent operating mode. The device queues all UART data it receives through the DIN pin for RF

transmission. When a device receives RF data, it sends the data out through the DOUT pin. You can set

the configuration parameters using Command mode.

Serial-to-RF packetization

The device buffers data in the serial receive buffer until one of the following causes the data to be

packetized and transmitted:

n The device receives no serial characters for the amount of time determined by the RO

(Packetization Timeout) parameter. If RO = 0, packetization begins when a character is

received.

n The device receives the Command Mode Sequence (GT + CC + GT). Any character buffered in

the serial receive buffer before the sequence is transmitted.

n The device receives the maximum number of characters that fits in an RF packet (100 bytes).

If the device cannot immediately transmit (for example, if it is already receiving RF data), it stores the

serial data in the DI buffer. The device packetizes the data and sends the data at any RO timeout or

when it receives the maximum packet size (100 bytes).

If the DI buffer becomes full, hardware or software flow control must be implemented in order to

prevent overflow (that is, loss of data between the host and module).

API operating mode

API (Application Programming Interface) operating mode is an alternative to the default Transparent

operating mode. The frame-based API extends the level to which a host application can interact with

the networking capabilities of the module.

When in API mode, all data entering and leaving the device is contained in frames that define

operations or events within the module.

Transmit data frames (received through the DI pin (pin 3)) include:

n RF Transmit data frame

n Command frame (equivalent to AT commands)

Receive Data frames (sent out the DO pin (pin 2)) include:

n RF-received data frame

n Command response

n Event notifications such as reset, associate, disassociate, and so on

The API provides alternative means of configuring modules and routing data at the host application

layer. A host application sends data frames to the device that contains address and payload

information instead of using command mode to modify addresses. The device sends data frames to

the application containing status packets, as well as source, RSSI, and payload information from

received data packets.

The API operation option facilitates many operations such as the following examples:

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

24

Page 25

Operation Serial communications

n Transmitting data to multiple destinations without entering Command Mode

n Receiving success/failure status of each transmitted RF packet

n Identifying the source address of each received packet

To implement API operation, see API operation.

Flow control

The XBee/XBee-PRO S1 802.15.4 (Legacy) maintains buffers to collect serial and RF data that it

receives. The serial receive buffer collects incoming serial characters and holds them until the device

can process them. The serial transmit buffer collects the data it receives via the RF link until it

transmits that data out the serial port. The following figure shows the process of device buffers

collecting received serial data.

DI (Data in) buffer

When serial data enters the RF module through the DI pin (pin 3), the device stores data in the DI

buffer until it can be processed.

Hardware Flow Control (CTS)

If you enable CTS flow control (by setting D7 to 1), when the DI buffer is 17 bytes away from being full,

the device de-asserts CTS (sets it high) to signal to the host device to stop sending serial data. The

device reasserts CTS after the serial receive buffer has 34 bytes of space.

To eliminate the need for flow control:

1. Send messages that are smaller than the DI buffer size (202 bytes).

2. Interface at a lower baud rate [BD (Interface Data Rate) parameter] than the throughput data

rate.

Example where the DI buffer may become full and possibly overflow:

If the device is receiving a continuous stream of RF data, it places any serial data that arrives on the

DI pin in the DI buffer. The device transmits data in the DI buffer over-the-air when it is no longer

receiving RF data in the network.

For more information, see the following command descriptions:

n RO (Packetization Timeout)

n BD (Interface Data Rate)

n D7 (DIO7 Configuration)

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

25

Page 26

Operation ADC and Digital I/O line support

DO (Data out) buffer

When RF data is received, the data enters the DO buffer and is sent out the serial port to a host

device. Once the DO Buffer reaches capacity, any additional incoming RF data is lost.

Hardware Flow Control (RTS)

If you enable RTS flow control (D6 (DIO6 Configuration) Parameter = 1), the device does not send data

out the DO buffer as long as RTS (pin 16) is de-asserted.

Examples where the DO buffer may become full, resulting in dropped RF packets:

1. If the RF data rate is set higher than the interface data rate of the device, the device may

receive data faster than it can send the data to the host. Even occasional transmissions from a

large number of devices can quickly accumulate and overflow the transmit buffer.

2. If the host does not allow the device to transmit data out from the serial transmit buffer due to

being held off by hardware flow control.

See the D6 (DIO6 Configuration) command description for more information.

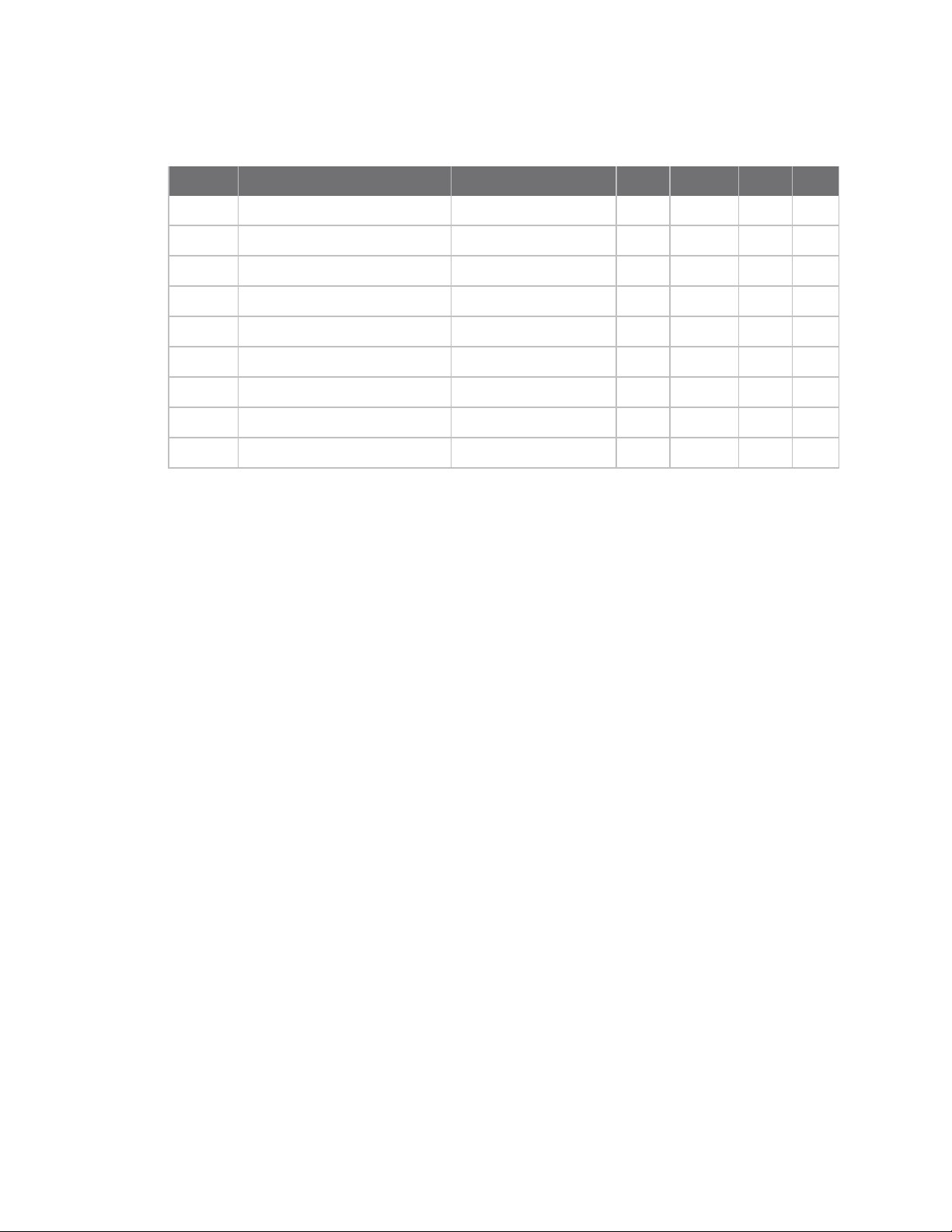

ADC and Digital I/O line support

The XBee/XBee-PRO RF Modules support ADC (analog-to-digital conversion) and digital I/O line

passing. The following pins support multiple functions:

n Pin functions and their associated pin numbers and commands

n AD = Analog-to-Digital Converter, DIO = Digital Input/Output

Note Pin functions in parentheses are not applicable to this section.

Pin function Pin# AT Command

AD0/DIO0 20

AD1/DIO1 19

AD2/DIO2 18

AD3/DIO3 / (COORD_SEL) 1

AD4/DIO4 11

AD5/DIO5 / (ASSOCIATE) 15

DIO6/(RTS) 16

DIO7/(CTS) 12

DI8/(DTR) / (Sleep_RQ) 9

Use the following setting to enable ADC and DIO pin functions:

D0

D1

D2

D3

D4

D5

D6

D7

D8

Support type Setting

ADC support ATDn = 2

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

26

Page 27

Operation ADC and Digital I/O line support

Support type Setting

Digital input support ATDn = 3

Digital output low support ATDn = 4

Digital output high support ATDn = 5

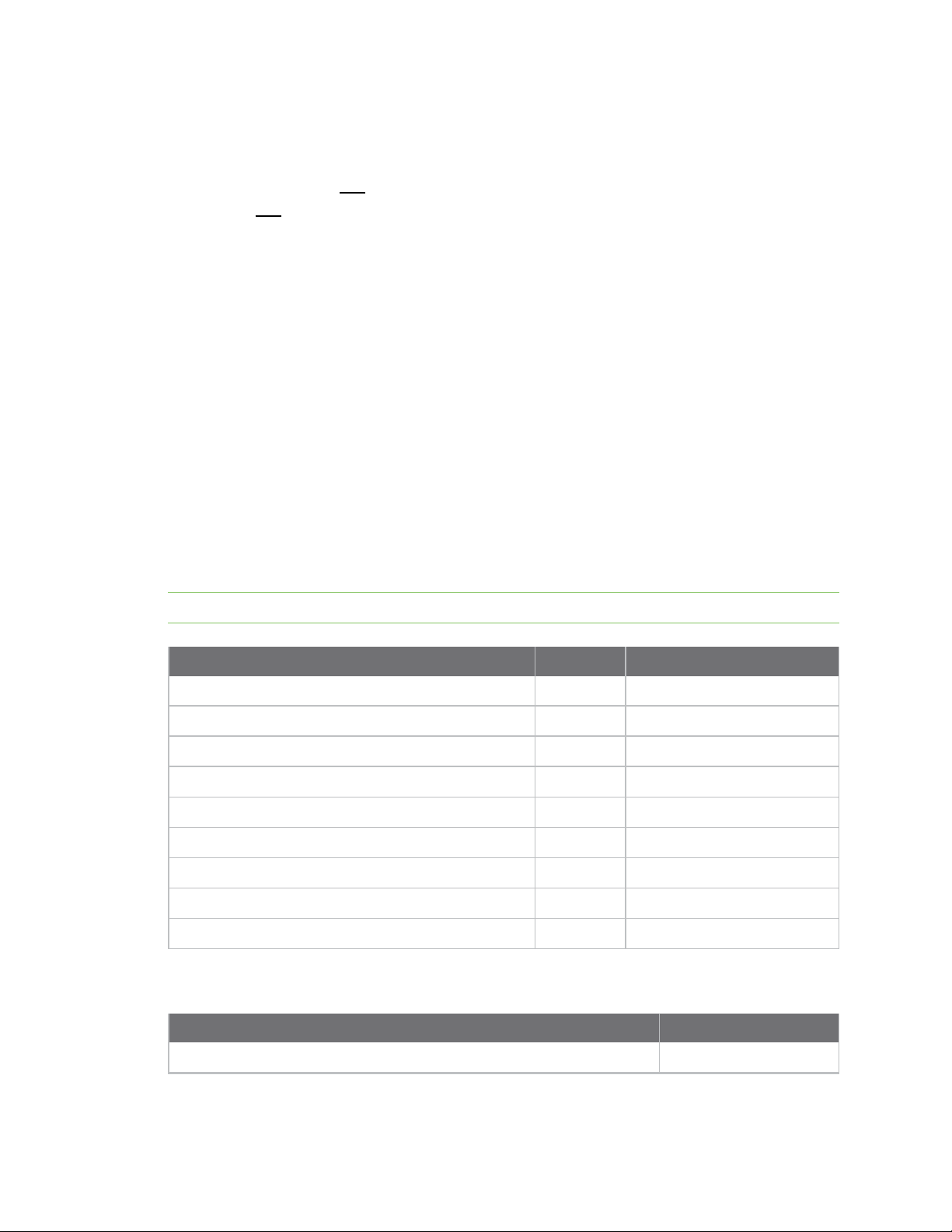

I/O data format

I/O data begins with a header. The first byte of the header defines the number of samples

forthcoming. The last two bytes of the header (Channel Indicator) define which inputs are active. Each

bit represents either a DIO line or ADC channel. The following figure illustrates the bits in the header.

Sample data follows the header and the channel indicator frame determines how to read the sample

data. If any of the DIO lines are enabled, the first two bytes are the DIO sample. The ADC data follows.

ADC channel data is represented as an unsigned 10-bit value right-justified on a 16- bit boundary. The

following figure illustrates the sample data bits.

API support

I/O data is sent out the UART using an API frame. All other data can be sent and received using

Transparent Operation or API frames if API mode is enabled (AP > 0).

API Operations support two RX (Receive) frame identifiers for I/O data (set 16-bit address to 0xFFFE

and the device does 64-bit addressing):

n 0x82 for RX Packet: 64-bit Address I/O

n 0x83 for RX Packet: 16-bit Address I/O

The API command header is the same as shown in 64-bit Receive Packet - 0x80 and 16-bit I/O Sample

Indicator - 0x83. RX data follows the format described in I/O data format.

Sleep support

Set SO (Sleep Options) bit 1 to suppress automatic wake-up sampling.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

27

Page 28

Operation ADC and Digital I/O line support

When a device wakes, it always performs a sample based on any active ADC or DIO lines. This allows

sampling based on the sleep cycle whether it be Cyclic Sleep (SM = 4 or 5) or Pin Sleep (SM = 1). Set

the IR (Sample Rate) parameter to gather more samples when awake.

For Cyclic Sleep modes: If the IR parameter is set, the device stays awake until the IT (Samples before

TX) parameter is met. The device stays awake for ST (Time before Sleep).

DIO pin change detect

When you use the IC (DIOChange Detect) command to enable DIO Change Detect, DIO lines 0 - 7 are

monitored. When a change is detected on a DIO line, the following occurs:

1. An RF packet is sent with the updated DIO pin levels. This packet does not contain any ADC

samples.

2. Any queued samples are transmitted before the change detect data. This may result in

receiving a packet with less than IT (Samples before TX) samples.

Note Change detect does not affect Pin Sleep wake-up. The D8 pin (DTR/Sleep_RQ/DI8) is the only line

that wakes a device from Pin Sleep. If not all samples are collected, the device still enters Sleep Mode

after a change detect packet is sent. Change detect is only supported when the Dx (DIOx

Configuration) parameter equals 3, 4 or 5.

Applicable Commands: IC (DIO Change Detect), IT (Samples before TX)

Note Change detect is only supported when the Dx (DIOx Configuration) parameter equals 3, 4 or 5.

Sample rate (interval)

The Sample Rate (Interval) feature allows enabled ADC and DIO pins to be read periodically on devices

that are not configured to operate in Sleep Mode. When one of the Sleep Modes is enabled and the IR

(Sample Rate) parameter is set, the device stays awake until IT (Samples before TX) samples have

been collected.

Once a particular pin is enabled, the appropriate sample rate must be chosen. The maximum sample

rate that can be achieved while using one A/D line is 1 sample/ms or 1 kHz. The device cannot keep up

with transmission when IR and IT are equal to 1 and we do not recommend configuring the device to

sample at rates greater than once every 20 ms.

I/O line passing

You can set up virtual wires between XBee/XBee-PRO Modules. When a device receives an RF data

packet that contains I/O data, it can be setup to update any enabled outputs (PWM and DIO) based on

the data it receives.

I/O lines are mapped in pairs. For example, AD0 can only update PWM0 and DI5 can only update DO5.

The default setup is for outputs not to be updated, which results in the I/O data being sent out the

UART (See the IU (I/O Output Enable) command). To enable the outputs for updating, set the IA (I/O

Input Address) parameter with the address of the device that has the appropriate inputs enabled. This

binds the outputs to a particular device's input. This does not affect the ability of the device to receive

I/O line data from other modules; if affects only its ability to update enabled outputs. The IA

parameter can also be set up to accept I/O data for output changes from any module by setting the IA

parameter to 0xFFFF.

When outputs are changed from their non-active state, the device can be setup to return the output

level to its non-active state. Set the timers using the Tn (Dn Output Timer) and PT (PWM Output

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

28

Page 29

Operation ADC and Digital I/O line support

Timeout) commands. The timers are reset every time the device receives a valid I/O sample packet

with a matching IA address.

You can adjust the IC (Change Detect) and IR (Sample Rate) parameters to keep the outputs set to

their active output if the system needs more time than the timers can handle.

Note DI8 cannot be used for I/O line passing.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

29

Page 30

Operation Networks

Applicable commands:

n IA (I/O Input Address)

n TN (Dn Output Timeout)

n P0 (PWM0 Configuration)

n P1 (PWM1 Configuration)

n M0 (PWM0 Output Level)

n M1 (PWM1 Output Level)

n PT (PWM Output Timeout)

n RP (RSSSI PWM Timer)

Configuration example

The following table provides an example of a pair of RF devices for a simple A/D link:

Remote Configuration Base Configuration

DL = 0x1234 DL = 0x5678

MY = 0x5678 MY = 0x1234

D0 = 2 P0 = 2

D1 = 2 P1 = 2

IR = 0x14 IU = 1

IT = 5 IA = 0x5678 (or 0xFFFF)

These settings configure the remote device to sample AD0 and AD1 once each every 20 ms. It then

buffers 5 samples each before sending them back to the base device. The base then receives a 32byte transmission (20 bytes data and 12 bytes framing) every 100 ms.

Networks

The following table describes some common terms we use when discussing networks.

Term Definition

Association Establishing membership between end devices and a coordinator.

Coordinator A full-function device (FFD) that provides network synchronization by polling nodes.

End device When in the same network as a coordinator. Devices that rely on a coordinator for

synchronization and can be put into states of sleep for low-power applications.

PAN Personal Area Network. A data communication network that includes one or more

end devices and optionally a coordinator.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

30

Page 31

Operation Networks

Peer-to-peer networks

By default, XBee/XBee-PRO S1 802.15.4 (Legacy) modules are configured to operate within a peer-topeer network topology and therefore are not dependent upon master/slave relationships. This means

that devices remain synchronized without the use of master/server configurations and each device in

the network shares both roles of master and slave. Our peer-to-peer architecture features fast

synchronization times and fast cold start times. This default configuration accommodates a wide

range of RF data applications.

You can establish a peer-to-peer network by configuring each module to operate as an End Device (CE

= 0), disabling End Device Association on all modules (A1 = 0) and setting ID and CH parameters to be

identical across the network.

NonBeacon (with coordinator)

You can configure a device as a Coordinator by setting the CE (Coordinator Enable) parameter to 1.

Use the A2 (Coordinator Association) parameter to power up the Coordinator .

In a Coordinator system, you configure the Coordinator to use direct or indirect transmissions. If the

SP (Cyclic Sleep Period) parameter is set to 0, the Coordinator sends data immediately. Otherwise,

the SP parameter determines the length of time the Coordinator retains the data before discarding it.

In general, SP (Cyclic Sleep Period) and ST (Time before Sleep) parameters should be set to match the

SP and ST settings of the End Devices.

Association

Association is the establishment of membership between End Devices and a Coordinator. Establishing

membership is useful in scenarios that require a central unit (Coordinator) to relay messages to or

gather data from several remote units (End Devices), assign channels, or assign PAN IDs.

An RF data network that consists of one Coordinator and one or more End Devices forms a PAN

(Personal Area Network). Each device in a PAN has a PAN Identifier (ID (PAN ID) parameter), which

must be unique to prevent miscommunication between PANs. Set the Coordinator PAN ID using the ID

(PAN ID) and A2 (Coordinator Association) commands.

An End Device can associate to a Coordinator without knowing the address, PAN ID, or channel of the

Coordinator. The A1 (End Device Association) parameter bit fields determine the flexibility of an End

Device during association. Use the A1 parameter for an End Device to dynamically set its destination

address, PAN ID, and/or channel.

For example, if the PAN ID of a Coordinator is known, but the operating channel is not, set the A1

command on the End Device to enable the ‘Auto_Associate’ and ‘Reassign_Channel’ bits. Additionally,

set the ID parameter to match the PAN ID of the associated Coordinator.

Coordinator / End Device setup and operation

To configure a module to operate as a Coordinator, set the CE (Coordinator Enable) parameter to ‘1’.

Set the CE parameter of End Devices to ‘0’ (default). Coordinator and End Devices should contain

matching firmware versions.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

31

Page 32

Operation Networks

NonBeacon (with Coordinator) systems

You can configure the Coordinator to use direct or indirect transmissions. If the SP (Cyclic Sleep

Period) parameter is set to ‘0’, the Coordinator sends data immediately. Otherwise, the SP parameter

determines the length of time the Coordinator retains the data before discarding it. In general, SP

(Cyclic Sleep Period) and ST (Time before Sleep) parameters should be set to match the SP and ST

settings of the End Devices.

Coordinator start-up

The A2 (Coordinator Association) command governs coordinator power-up. On power-up, the

Coordinator undergoes the following sequence of events:

1. Check A2 parameter- Reassign_PANID flag

Set (bit 0 = 1)

The Coordinator issues an Active Scan. The Active Scan selects one channel and transmits a request to

the broadcast address (0xFFFF) and broadcast PAN ID (0xFFFF). The Coordinator then listens on that

channel for beacons from any Coordinator operating on that channel. The SD (Scan Duration)

parameter value determines the listen time on each channel.

Once the time expires on that channel, the Active Scan selects another channel and again transmits

the BeaconRequest as before. This process continues until all channels have been scanned, or until 5

PANs have been discovered. When the Active Scan is complete, the results include a list of PAN IDs and

Channels being used by other PANs. This list is used to assign an unique PAN ID to the new

Coordinator. The ID parameter will be retained if it is not found in the Active Scan results. Otherwise,

the ID (PAN ID) parameter setting will be updated to a PAN ID that was not detected.

Not set (bit 0 = 0)

The Coordinator retains its ID setting. No Active Scan is performed.

2. Check A2 parameter - Reassign_Channel flag (bit 1)

Set (bit 1 = 1)

The Coordinator issues an Energy Scan. The Energy Scan selects one channel and scans for energy on

that channel. The SD (Scan Duration) parameter specifies the duration of the scan. Once the scan is

completed on a channel, the Energy Scan selects the next channel and begins a new scan on that

channel. This process continues until all channels have been scanned.

When the Energy Scan is complete, the results include the maximal energy values detected on each

channel. This list is used to determine a channel where the least energy was detected. If an Active

Scan was performed (Reassign_PANID Flag set), the channels used by the detected PANs are

eliminated as possible channels. The device uses the results of the Energy Scan and the Active Scan (if

performed) to find the best channel (that is, the channel with the least energy that is not used by any

detected PAN). Once the device selects the best channel, the CH (Channel) parameter value is

updated to that channel.

Not set (bit 1 = 0)

The Coordinator retains its CH setting, and an Energy Scan is not performed.

3. Start Coordinator

The Coordinator starts on the specified channel (CH parameter) and PAN ID (ID parameter).

Note These may be selected in steps 1 or 2.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

32

Page 33

Operation Networks

The Coordinator only allows End Devices to associate to it if the A2 parameter “AllowAssociation” flag

is set. Once the Coordinator has successfully started, the Associate LED blinks 1 time per second. If

the Coordinator has not started, the LED is solid.

4. Modify coordinator

Once a Coordinator has started, modifying the A2 (Reassign_Channel or Reassign_PANID bits), ID, CH

or MY parameters causes the Coordinator’s MAC to reset. The Coordinator RF module (including

volatile RAM) is not reset.

Changing the A2 AllowAssociation bit does not reset the Coordinator’s MAC. In a non-beaconing

system, End Devices that associated to the Coordinator prior to a MAC reset have knowledge of the

new settings on the Coordinator. If the Coordinator were to change its ID, CH or MY settings, the End

Devices would no longer be able to communicate with the non-beacon Coordinator. Do not change the

ID, CH, MY, or A2 (Reassign_Channel or Reassign_PANID bits) once a Coordinator has started.

End device start-up

The A1 (End Device Association) command governs End Device power-up. On power-up, the End Device

undergoes the following sequence of events:

1. Check A1 parameter - AutoAssociate Bit

Set (bit 2 = 1)

The End Device attempts to associate to a Coordinator. See 2. Discover Coordinator (if Auto-Associate

Bit Set) and 3. Associate to a valid coordinator.

Not set (bit 2 = 0)

The End Device does not attempt to associate to a Coordinator. The End Device operates as specified

by its ID, CH and MY parameters. Association is considered complete and the Associate LED blinks

quickly (5 times per second).

2. Discover Coordinator (if Auto-Associate Bit Set)

The end device issues an Active Scan. The Active Scan selects one channel and transmits a

BeaconRequest command to the broadcast address (0xFFFF) and broadcast PAN ID (0xFFFF). The

Active Scan then listens on that channel for beacons from any Coordinator operating on that channel.

The SD parameter determines the listen time on each channel.

Once the time expires on that channel, the Active Scan selects another channel and again transmits

the BeaconRequest command as before. This process continues until all channels have been scanned,

or until 5 PANs have been discovered. When the Active Scan is complete, the results include a list of

PAN IDs and Channels that are being used by detected PANs.

The end device selects a coordinator to associate with according to the A1 parameter “Reassign_

PANID” and “Reassign_Channel” flags:

n Reassign_PANID bit set (bit 0 = 1) - End device can associate with a PAN with any ID value.

n Reassign_PANID bit not set (bit 0 = 0) - End device only associates with a PAN whose ID

setting matches the ID setting of the End Device.

n Reassign_Channel bit set (bit 1 = 1) - End device can associate with a PAN with any CH

value.

n Reassign_Channel bit not set (bit 1 = 0) - End device will only associate with a PAN whose

CH setting matches the CH setting of the end device.

After applying these filters to the discovered coordinators, if multiple candidate PANs exist, the end

device selects the PAN whose transmission link quality is the strongest. If no valid coordinator is

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

33

Page 34

Operation Addressing

found, the end device either goes to sleep (as dictated by its SM (Sleep Mode) parameter) or retry

Association.

Note An end device also disqualifies coordinators if they are not allowing association (A2 -

AllowAssociation bit), or, if the coordinator is not using the same NonBeacon scheme as the end

device. They must both be programmed with NonBeacon code.

3. Associate to a valid coordinator

Once the device finds a valid coordinator (2. Discover Coordinator (if Auto-Associate Bit Set)), the end

device sends an AssociationRequest message to the coordinator. The end device then waits for an

AssociationConfirmation from the coordinator. Once it receives the Confirmation, the end device is

Associated and the Associate LED blinks rapidly (two times per second). If the end device has not

associated, the LED is solid.

4. End Device changes once an End Device has associated

Changing A1, ID or CH parameters causes the End Device to disassociate and restart the Association

procedure.

If the End Device fails to associate, the AI command indicates the failure.

Addressing

Every RF data packet sent over-the-air contains a Source Address and Destination Address field in its

header. The XBee/XBee-PRO S1 802.15.4 (Legacy) conforms to the 802.15.4 specification and supports

both short 16-bit addresses and long 64-bit addresses. A unique 64-bit IEEE source address is assigned

at the factory and can be read with the SL (Serial Number Low) and SH (Serial Number High)

commands. You must manually configure short addressing. A device uses its unique 64-bit address as

its Source Address if its MY (16-bit Source Address) value is 0xFFFF or 0xFFFE.

n To send a packet to a specific device using 64-bit addressing, set the Destination Address (DL +

DH) of the sender to match the Source Address (SL + SH) of the intended destination device.

n To send a packet to a specific module using 16-bit addressing, set DL (Destination Address

Low) parameter to equal the MY parameter of the intended destination module and set the DH

(Destination Address High) parameter to '0.'

Unicast mode

By default, the XBee/XBee-PRO S1 802.15.4 (Legacy) operates in Unicast mode. Unicast Mode is the

only mode that supports retries. While in this mode, receiving devices send an ACK (acknowledgment)

of RF packet reception to the transmitter. If the transmitting device does not receive the ACK, it resends the packet up to three times or until it receives the ACK.

Short 16-bit addresses

You can configure the device to use short 16-bit addresses as the Source Address by setting (MY <

0xFFFE). Setting the DH parameter (DH = 0) configures the Destination Address to be a short 16-bit

address (if DL < 0xFFFE). For two devices to communicate using short addressing, the Destination

Address of the transmitter device must match the MY parameter of the receiver.

The following table shows a sample network configuration that enables Unicast mode

communications using short 16-bit addresses.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

34

Page 35

Operation Modes of operation

Parameter RF device 1 RF device 2

MY (Source Address)

DH (Destination Address High)

DL (Destination Address Low)

0x01 0x02

0 0

0x02 0x01

Long 64-bit addresses

You can use The RF device’s serial number (SL parameter concatenated to the SH parameter) as a 64bit source address when the MY (16-bit Source Address) parameter is disabled. When you disable the

MY parameter (MY = 0xFFFF or 0xFFFE), the device’s source address is set to the 64-bit IEEE address

stored in the SH and SL parameters.

When an End Device associates to a Coordinator, its MY parameter is set to 0xFFFE to enable 64-bit

addressing. The 64-bit address of the device is stored as SH and SL parameters. To send a packet to a

specific device, the Destination Address (DL + DH) on the sender must match the Source Address (SL +

SH) of the receiver.

Broadcast mode

Any RF device within range accepts a packet that contains a broadcast address. When configured to

operate in Broadcast Mode, receiving devices do not send ACKs (acknowledgments) and transmitting

devices do not automatically re-send packets as is the case in Unicast Mode.

To send a broadcast packet to all devices regardless of 16-bit or 64-bit addressing, set the destination

addresses of all the devices as shown below.

Sample Network Configuration (All modules in the network):

n DL (Destination Low Address) = 0x0000FFFF

If RR is set to 0, only one packet is broadcast. If RR > 0, (RR + 2) packets are sent in each broadcast.

No acknowledgments are returned. For more information, see RR (XBee Retries).

n DH (Destination High Address) = 0x00000000 (default value)

When you are programming the device, enter the parameters in hexadecimal notation (without the

“0x” prefix). Leading zeros may be omitted.

Modes of operation

This section describes the different operating modes for the device.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

35

Page 36

Operation Modes of operation

Idle mode

When not receiving or transmitting data, the device is in Idle mode.

The device shifts into the other modes of operation under the following conditions:

n Transmit mode (serial data is received in the DI buffer).

n Receive mode (valid RF data received through the antenna).

n Sleep mode (Sleep mode condition is met).

n Command mode (Command mode sequence issued).

Transmit/Receive modes

This section provides information about the different types of transmit and receive modes.

RF data packets

Each transmitted data packet contains a Source Address and Destination Address field. The Source

Address matches the address of the transmitting device as specified by the MY (Source Address)

parameter (if MY ≥ 0xFFFE), the SH (Serial Number High) parameter or the SL (Serial Number Low)

parameter. The <Destination Address> field is created from the DH (Destination Address High) and DL

(Destination Address Low) parameter values. The Source Address and/or Destination Address fields

either contain a 16-bit short or long 64-bit long address.

The RF data packet structure follows the 802.15.4 specification. For more information, see

Addressing.

Direct and indirect transmission

There are two methods to transmit data:

n Direct transmission: data is transmitted immediately to the Destination Address

n Indirect transmission: a packet is retained for a period of time and is only transmitted after the

destination device (source address = destination address) requests the data.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

36

Page 37

Operation Modes of operation

Indirect transmissions can only occur on a Coordinator. Thus, if all nodes in a network are End Devices,

only direct transmissions occurs. Indirect transmissions are useful to ensure packet delivery to a

sleeping node. The Coordinator currently is able to retain up to two indirect messages.

Direct transmission

A Coordinator can be configured to use only direct transmission by setting the SP (Cyclic Sleep Period)

parameter to 0. Also, a Coordinator using indirect transmissions reverts to direct transmission if it

knows the destination device is awake.

To enable this behavior, the ST (Time before Sleep) value of the Coordinator must be set to match the

ST value of the End Device. Once the End Device either transmits data to the Coordinator or polls the

Coordinator for data, the Coordinator uses direct transmission for all subsequent data transmissions

to that device address until ST time occurs with no activity (at which point it reverts to using indirect

transmissions for that device address). "No activity" means no transmission or reception of messages

with a specific address. Broadcast messages do not reset the ST timer.

Indirect transmission

To configure Indirect Transmissions in a Personal Area Network (PAN), the SP (Cyclic Sleep Period)

parameter value on the Coordinator must be set to match the longest sleep value of any End Device.

The sleep period value on the Coordinator determines how long (time or number of beacons) the

Coordinator retains an indirect message before discarding it.

An End Device must poll the Coordinator once it wakes from Sleep to determine if the Coordinator has

an indirect message for it. For Cyclic Sleep Modes, this is done automatically every time the device

wakes (after SP time). For Pin Sleep Modes, the A1 (End Device Association) parameter value must be

set to enable Coordinator polling on pin wake-up . Alternatively, an End Device can use the FP (Force

Poll) command to poll the Coordinator as needed.

Clear Channel Assessment (CCA)

Prior to transmitting a packet, the device performs a CCA (Clear Channel Assessment) on the channel

to determine if the channel is available for transmission. The detected energy on the channel is

compared with the CA (Clear Channel Assessment) parameter value. If the detected energy exceeds

the CA parameter value, the device does not transmit the packet.

Also, the device inserts a delay before a transmission takes place. You can set this delay using the RN

(Backoff Exponent) parameter. If you set RN to 0, then there is no delay before the first CCA is

performed. The RN parameter value is the equivalent of the “minBE” parameter in the 802.15.4

specification. The transmit sequence follows the 802.15.4 specification.

By default, the MM (MAC Mode) parameter = 0. On a CCA failure, the device attempts to re-send the

packet up to two additional times.

When in Unicast packets with RR (Retries) = 0, the device executes two CCA retries. Broadcast

packets always get two CCA retries.

Note Customers in Europe who have the XBee 802.15.4 module must manage their CCA settings. See

CA (CCA Threshold) for CA values.

Acknowledgment

If the transmission is not a broadcast message, the device expects to receive an acknowledgment

from the destination node. If an acknowledgment is not received, the packet is resent up to three

more times. If the acknowledgment is not received after all transmissions, an ACK failure is recorded.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

37

Page 38

Operation Modes of operation

Sleep modes

Sleep modes enable the device to enter states of low-power consumption when not in use. In order to

enter Sleep mode, one of the following conditions must be met (in addition to the device having a nonzero SM parameter value):

n SLEEP_RQ is asserted and the device is in a pin sleep mode (SM = 1, 2, or 5)

n The device is idle (no data transmission or reception) for the amount of time defined by the ST

(Time before Sleep) parameter.

Note ST is only active when SM = 4 or 5.

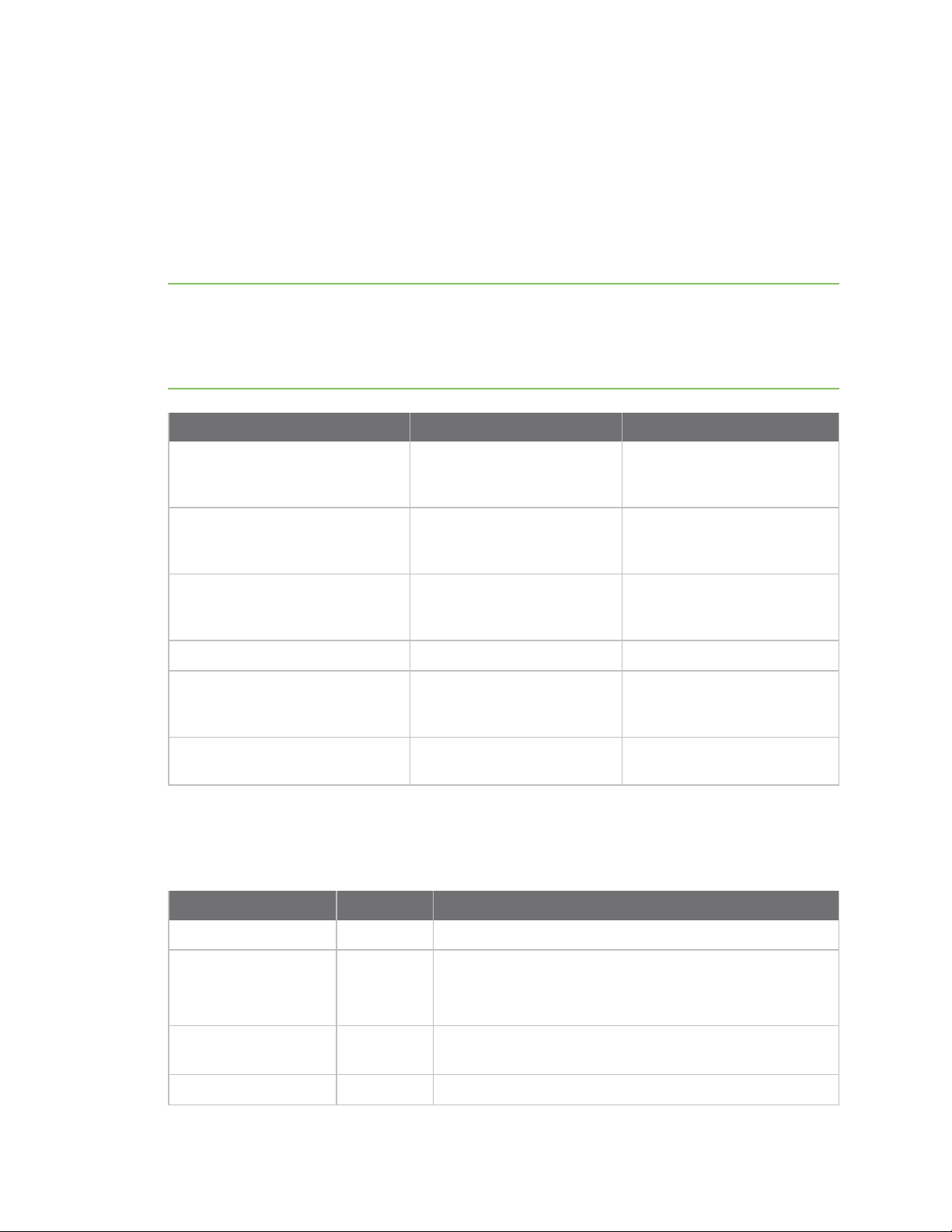

The following table shows the sleep mode configurations.

Transition

Sleep mode

setting

Transition

into sleep

mode

out of sleep

mode

(wake) Characteristics

Related

commands

Power

consumption

Pin hibernate

SM 1

Pin doze SM 2 Assert (high)

Cyclic Sleep

SM 4

Assert (high)

Sleep_RQ (pin

9)

Sleep_RQ (pin

9)

Automatic

transition to

Sleep Mode as

defined by the

SM (Sleep

Mode) and ST

(Time before

Sleep)

parameters

De-assert

(low) Sleep_

RQ

De-assert

(low) Sleep_

RQ

Transition

occurs after

the cyclic

sleep time

interval

elapses. The

time interval

is defined by

SP

the

(Cyclic Sleep

Period)

parameter.

Pin/Hostcontrolled/NonBeacon

systems only/Lowest

Power

Pin/Hostcontrolled/NonBeacon

systems only/Fastest

wake-up

RF module wakes in

pre-determined time

intervals to detect if

RF data is

present/When SM = 5

(SM

) < 10 µA (@3.0

VCC)

(SM) < 50 µA

(SM),SP,ST< 50 µA when

sleeping

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

38

Page 39

Operation Modes of operation

Transition

Sleep mode

setting

Transition

into sleep

mode

out of sleep

mode

(wake) Characteristics

Related

commands

Power

consumption

Cyclic Sleep

SM 5

Automatic

transition to

Sleep Mode as

defined by the

SM (Sleep

Mode) and ST

(Time before

Sleep)

parameters or

on a falling

edge

transition of

Transition

occurs after

the cyclic

sleep time

interval

elapses. The

time interval

is defined by

SP

the

(Cyclic Sleep

Period)

parameter.

RF module wakes in

pre-determined time

intervals to detect if

RF data is present.

Module also wakes on

a falling edge of

SLEEP_RQ.

(SM),SP,ST< 50 µA when

sleeping

the SLEEP_RQ

pin

The SM command is central to setting Sleep mode configurations. By default, Sleep modes are

disabled (SM = 0) and the device remains in Idle/Receive Mode. When in this state, the device is

constantly ready to respond to serial or RF activity.

Pin/Host-controlled sleep modes

The transient current when waking from pin sleep (SM = 1 or 2) does not exceed the idle current of the

module. The current ramps up exponentially to its idle current.

Pin hibernate (SM=1)

n Pin/Host-controlled

n Typical power-down current: < 10 µA (@3.0 VCC)

n Typical wake-up time: 10.2 ms

Pin Hibernate Mode minimizes quiescent power (power consumed when in a state of rest or

inactivity). This mode is voltage level-activated. When the device assterts Sleep_RQ (pin 9), it finishes

any transmit, receive or association activities, enters Idle Mode, and then enters a state of sleep. The

device does not respond to either serial or RF activity while in pin sleep.

To wake a sleeping device operating in Pin Hibernate Mode, de-assert Sleep_RQ (pin 9). The device

wakes when Sleep_RQ is de-asserted and is ready to transmit or receive when the CTS line is low.

When waking the device, the pin must be de-asserted at least two 'byte times' after CTS goes low.

This assures that there is time for the data to enter the DI buffer.

Pin doze (SM = 2)

n Pin/Host-controlled

n Typical power-down current: < 50 µA

n Typical wake-up time: 2.6 ms

Pin doze mode functions the same as Pin hibernate mode. However, Pin doze features faster wake-up

time and higher power consumption.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

39

Page 40

Operation Modes of operation

To wake a sleeping device operating in Pin Doze Mode, de-assert Sleep_RQ (pin 9). The device wakes

when Sleep_RQ is de-asserted and is ready to transmit or receive when the CTS line is low. When

waking the device, the pin must be de-asserted at least two 'byte times' after CTS goes low. This

assures that there is time for the data to enter the DI buffer.

Cyclic sleep modes

This section provides information on the different types of cyclic sleep modes.

Cyclic Sleep Remote (SM = 4)

n Typical Power-down Current: < 50 µA (when asleep)

n Typical wake-up time: 2.6 ms

The Cyclic Sleep modes allow devices to periodically check for RF data. When the SM parameter is set

to 4, the XBee/XBee-PRO S1 802.15.4 (Legacy) is configured to sleep, then wakes once per cycle to

check for data from a from a device configured as a Cyclic Sleep Coordinator (SM = 0, CE = 1). The

Cyclic Sleep Remote sends a poll request to the coordinator at a specific interval set by the SP (Cyclic

Sleep Period) parameter. The coordinator transmits any queued data addressed to that specific

remote upon receiving the poll request.

If no data is queued for the remote, the coordinator does not transmit and the remote returns to

sleep for another cycle. If the device transmits queued data back to the remote, it stays awake to

allow for back and forth communication until the ST (Time before Sleep) timer expires.

If configured, CTS goes low each time the remote wakes, allowing for communication initiated by the

remote host if desired.

Cyclic Sleep Remote with Pin Wake-up (SM = 5)

Use this mode to wake a sleeping remote device through either the RF interface or by de-asserting

SLEEP_RQ for event-driven communications. The cyclic sleep mode works as described previously with

the addition of a pin-controlled wake-up at the remote device. The Sleep_RQ pin is edge-triggered, not

level-triggered. The device wakes when a low is detected then set CTS low as soon as it is ready to

transmit or receive.

Any activity resets the ST (Time before Sleep) timer, so the device goes back to sleep only after there

is no activity for the duration of the timer. Once the device wakes (pin-controlled), it ignores further

pin activity. The device transitions back into sleep according to the ST time regardless of the state of

the pin.

Cyclic Sleep Coordinator (SM = 6)

n Typical current = Receive current

n Always awake

Note The SM=6 parameter value exists solely for backwards compatibility with firmware version

1.x60. If backwards compatibility with the older firmware version is not required, always use the CE

(Coordinator Enable) command to configure a device as a Coordinator.

This mode configures a device to wake cyclic sleeping remotes through RF interfacing. The

Coordinator accepts a message addressed to a specific remote 16 or 64-bit address and holds it in a

buffer until the remote wakes and sends a poll request. Messages not sent directly (buffered and

requested) are called "Indirect messages". The Coordinator only queues one indirect message at a

time. The Coordinator holds the indirect message for a period 2.5 times the sleeping period indicated

by the SP (Cyclic Sleep Period) parameter. Set the Coordinator's SP parameter to match the value

used by the remotes.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

40

Page 41

Operation Multiple AT commands

Command mode

Command mode is a state in which the firmware interprets incoming characters as commands. The

XBee/XBee-PRO S1 802.15.4 (Legacy) supports two Command mode options:AT commands and API

operation.

AT Command Mode

This section provides information about entering, sending, and exiting Command Mode.

Enter Command mode

Send the three-character command sequence +++ and observe guard times before and after the

command characters.

Default AT Command Mode Sequence (for transition to Command mode):

n No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

n Input three plus characters (“+++”) within one second [CC (Command Sequence Character)

parameter = 0x2B]

n No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

You can modify all parameter values in the sequence to reflect user preferences.

Failure to enter AT Command Mode is most commonly due to a baud rate mismatch. Ensure the Baud

setting on the PC Settings tab matches the interface data rate of the RF module. By default, the BD

(Baud Rate) parameter = 3 (9600 b/s).

Send AT commands

Once the device enters Command mode, use the syntax in the following figure to send AT commands.

Every AT command starts with the lettersAT, which stands for "attention." TheATis followed by two

characters that indicate which command is being issued, then by some optional configuration values.

To read a parameter value stored in the device’s register, omit the parameter field.

The preceding example changes NI (Node Identifier) to My XBee.

Multiple AT commands

You can send multiple AT commands at a time when they are separated by a comma in Command

mode; for example,ATNIMy XBee,AC<cr>.

The preceding example changes theNI (Node Identifier) to My XBeeand makes the setting active

through AC (Apply Changes).

Parameter format

Refer to the list of AT commands for the format of individual AT command parameters. Valid formats

for hexidecimal values include with or without a leading0xfor exampleFFFFor0xFFFF.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

41

Page 42

Operation Parameter format

Exit Command mode

1. Send CN (Exit Command mode) followed by a carriage return.

or:

2. If the device does not receive any valid AT commands within the time specified byCT

(Command Mode Timeout), it returns to Transparent or API mode. The default Command mode

timeout is10seconds.

For an example of programming the device using AT Commands and descriptions of each configurable

parameter, see AT commands.

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

42

Page 43

Configuration

Configure the device using XCTU 44

Programming the RF module 44

Remote configuration commands 45

Software libraries 46

XBee Network Assistant 46

XBee/XBee-PRO S1 802.15.4 (Legacy) User Guide

43

Page 44

Configuration Configure the device using XCTU

Configure the device using XCTU

XBee Configuration and Test Utility (XCTU) is a multi-platform program that enables users to interact

with Digi radio frequency (RF) devices through a graphical interface. The application includes built-in

tools that make it easy to set up, configure, and test Digi RF devices.

For instructions on downloading and using XCTU, see the XCTU User Guide.

Click Discover devices and follow the instructions. XCTU should discover the connected XBee/XBeePRO S1 802.15.4 (Legacy)s using the provided settings.

Click Add selected devices.The devices appear in the Radio Modules list. You can click a module to

view and configure its individual settings. For more information on these items, see AT commands.

Programming the RF module

This section provides examples on how to program an RF module using AT Command Mode.

For more information about using AT Command Mode, see AT commands.

For information regarding module programming using API Mode, see API operation.

Setup

The programming examples in this section require the installation of XCTU and a serial connection to

a PC. We stock RS-232 and USB boards to facilitate interfacing with a PC. For more information about

XCTU installation and setup, see the XCTU User Guide.

1. Download XCTU from the Digi website.

2. After you have downloaded the .exe file to your PC, double-click the file to launch the XCTU

Setup Wizard. Follow the steps in the wizard to completely install XCTU.

3. Mount the RF module to an interface board, and then connect the module assembly to a PC.