Page 1

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 1

USER MANUAL

SM-5300

PC SCALE PRINTER

Edition 2

COPYRIGHT © 2016 TERAOKA WEIGH-SYSTEM PTE. LTD. 21/JAN/2016

Page 2

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 1

Tables of Content

–––––––––––––––––––––––––––––––––––––––––

Model: SM-5300

Table of Content

Table of Content ..................................................................................................... 1

Notice ...................................................................................................................... 3

Safety Information ................................................................................................. 4

Safety Regulation ................................................................................................... 5

Product Information ............................................................................................... 7

1.1 Specification ......................................................................................................... 7

1.2 Overall View of SM-5300 ....................................................................................... 9

1.2.1 SM-5300 Bench Type ........................................................................................9

1.2.2 SM-5300 Pole Type ........................................................................................ 10

1.3 Product Layout .................................................................................................... 11

1.3.1 Overall Layout SM-5300LL............................................................................... 11

1.3.2 Overall Layout of SM-5300P ............................................................................ 12

1.3.3 Overall Layout of SM-5300SSP 19” ................................................................... 13

1.3.4 Interface ....................................................................................................... 14

1.3.5 Indicator Display ............................................................................................ 14

1.3.6 Keys & Key Function ....................................................................................... 16

1.4. Printer Setting ................................................................................................... 17

1.4.1 Receipt, Label and Linerless Specification ......................................................... 17

1.4.2 Character Size & No. of Characters available for Label Printing ........................... 18

1.4.3 Receipt, Label and Linerless Setting ................................................................. 19

Typical Operation.................................................................................................. 23

2.1 Product Setup ..................................................................................................... 23

2.2 Date and Time Setup ........................................................................................... 24

2.3 Registration Mode ............................................................................................... 26

2.3.1 PLU Call Up.................................................................................................... 26

2.3.2 Item Label Printing in Manual Mode ................................................................. 29

2.3.3 Total Label or Receipt Printing ......................................................................... 31

2.3.4 Data Correction .............................................................................................. 37

2.3.5 Item Label Printing in Prepack Mode ................................................................ 43

2.3.6 Tare Operation............................................................................................... 46

2.4 Self Service Mode ................................................................................................ 53

2.4.1 Software Tenkey ............................................................................................ 53

2.4.2 Mechanical Tenkey ......................................................................................... 55

Report Mode ......................................................................................................... 57

3.1 Report Mode Description .................................................................................... 57

Page 3

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 2

Table of Content

––––––––––––––––––––––––––––––––––––––––

Model: SM-5300

3.2.1 PLU Report .................................................................................................... 60

3.2.2 Dept Report ................................................................................................... 62

3.2.3 Clerk Report .................................................................................................. 64

3.2.4 Clerk LOG ...................................................................................................... 66

3.2.5 Terminal Report ............................................................................................. 68

3.2.6 Store Summarized Report ............................................................................... 70

3.2.7 24 Hour Report .............................................................................................. 72

3.2.8 Void Report ................................................................................................... 74

3.2.9 Tax Report .................................................................................................... 76

3.2.10 Queue Report ................................................................................................ 78

3.2.11 Store Report .................................................................................................. 80

3.2.12 MG Report ..................................................................................................... 82

3.2.13 Inventory Report ............................................................................................ 84

3.2.14 Traceability Report ......................................................................................... 86

3.2.15 Prepack Report .............................................................................................. 88

3.2.16 Grand Total Report ......................................................................................... 90

3.2.17 ABC Analysis Report ....................................................................................... 92

3.2.18 Void Label Report ........................................................................................... 94

3.2.19 Batch Report .................................................................................................. 96

Product Maintenance ............................................................................................ 98

4.1 Thermal Head Cleaning ....................................................................................... 98

Appendices......................................................................................................... 100

5.1 Error Messages .................................................................................................. 100

Release Note ...................................................................................................... 103

Page 4

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 3

Notice

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Model: SM-5300

Notice

DIGI®

The material contained in this document is proprietary and for information only and is subject to

change without notice. Teraoka Weigh-System assumes no responsibility for any errors or

damages arising from misinterpretation of any procedure. Screen displays, operating procedures

and supporting features might vary with different software version releases. This document shall

not be reproduced whether in part or whole without the written consent from Teraoka WeighSystem Pte Ltd.

Teraoka Weigh-System Pte Ltd,

4, Leng Kee Road,

#06-01 SIS Building,

Singapore 159088.

Page 5

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 4

Safety Information

––––––––––––––––––––––––––––––––––––––

Model: SM-5300

Safety Information

The operator of the equipment shall comply with the safety and warning indications and procedures

outlined in this document. Teraoka Weigh - System Pte Ltd assumes no responsibility or liability for

failure to comply with these requirements.

- To avoid electric shock, use only the supplied power cords and ensure product is connected

to a properly grounded supply.

- Ensure product is placed on a firm and level surface before operation.

- Avoid overloading the product beyond its rated maximum capacity.

- Ensure commodity to be weighed is loaded centrally on the platter, avoid placing commodity

on corners or edges.

- Care shall be taken during the following operations

~ Receipt paper tearing - to prevent injuries from cutting from paper cutter

~ Changing of labels and receipt paper - to prevent injuries from cutting from paper cutter

and movable printer mechanism.

- Repair and servicing of product shall only be carried out by trained and qualified personnel.

Disclaimer:

Specifications are subject to change without notice. All dimensions shown are approximate. Please

be aware that Teraoka has indicated that its hardware and software used in the product may

require additional updates in the future as our product is continually under development. The need

for such updates most likely applies to the Printer software.

CAUTIONS:

FOR PLUGGABLE EQUIPMENT, THAT THE SOCKET-OUTLET SHALL BE INSTALLED

NEAR THE EQUIPMENT AND SHALL BE EASILY ACCESSIBLE.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE AND RATING OF FUSE.

POUR NE PAS COMPROMETTRE LA PROTECTION CONTRE LES RISQUES D'INCENDIE,

REMPLACER PAR UN FUSIBLE DE MÊME TYPE ET DE MÊME CARACTÉRISTIQUES

NOMINALES.

DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY

WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER.

DISCARD USED BATTERIES ACCORDING TO THE MANUFACTURER'S INSTRUCTIONS

IL Y A DANGER D'EXPLOSION S'IL Y A REMPLACEMENT INCORRECT DE LA BATTERIE.

REMPLACER UNIQUEMENT AVEC UNE BATTERIE DU MÊME TYPE OU D'UN TYPE

RECOMMANDÉ PAR LE CONSTRUCTEUR. METTRE AU RÉBUT LES BATTERIES USAGÉES

CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT.

LASER RADIATION DO NOT STARE INTO BEAM CLASS 2 LASER PRODUCT

RAYONNEMENT LASER NE PAS REGARDER DANS LE FAISCEAU APPAREIL À LASERDE

CLASSE 2

Page 6

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 5

Safety Regulation

––––––––––––––––––––––––––––––––––––––––

Model: SM-5300

Safety Regulation

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment.

IMPORTANT NOTE:

FCC Radiation Exposure Statement: (US)

This equipment complies with FCC RF radiation exposure limits set forth for a portable uncontrolled

environment. To maintain compliance with FCC RF exposure compliance requirements:

1) Please do not attach any decorative components with metal parts to this equipment.

2) The antenna must not be co-located or operating in conjunction with any other antenna or

transmitter.

FCC Radiation Exposure Statement: (Canada)

This equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. To comply with FCC RF exposure compliance requirements:

1) The antenna used for this transmitter must be installed and operated with minimum 20cm

between the antenna and users.

2) The antenna must not be co-located or operating in conjunction with any other antenna or

transmitter.

IDA Compliance Statement: (Singapore)

This equipment registered to comply with IDA (Info-Communications Development Authority of

Singapore) Standard under Dealer's Class License.

Page 7

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 6

Safety Regulation

––––––––––––––––––––––––––––––––––––––––

Model: SM-5300

IDA Label

Page 8

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 7

Product Information

––––––––––––––––––––––––––––––––––––

1.1 Specification

Product Information

1.1 Specification

Variation

:

Description

Model

Dimension (D x W x H in mm)

Bench

SM5300LL

472 (adjustable) x 360 x 136

SM5300B

472 (adjustable) x 360 x 136

Pole

SM5300LL

500 (adjustable) x 360 x 542

SM5300P

500 (adjustable) x 360 x 542

SM5300SSP 19”

500 (adjustable) x 360 x 542

Capacity

:

15kg (Less than 6kg, e= 2g increment, 6kg to 15kg, e= 5g increment)

Display Resolution

:

1/6000

Display

:

SM5300

Operator

:

7” TFT WVGA LCD with Touch Panel (800 RGB x

480)

Customer

:

7” TFT WVGA LCD (RGB 800 x 480)

SM5300-SSP 19”

Operator

:

19” (1280 x 1024) TFT SXGA LCD with LED

Printing

:

Direct Thermal Printer

Base Printer

Media

:

Label with Liner and Linerless and Receipt Paper

Media Size

:

Max Width = 56mm

Speed

:

100mm/s (double strobe for 100% duty)

: 120mm/s (double strobe for 50 – 60% duty)

Print Width

:

56mm, 200dpi

Print Length

:

240mm

Media Roll Size

:

Max Roll = 105mm

Power Source

:

AC Supply 110V / 240V

(Set by Power Unit Jumper Setting)

Power Consumption

:

50W max. (20W nominal)_0.5A max. (0.2A nominal)

Operating Temperature

:

-10 °C to + 40 °C

Operation Humidity

:

15% to 85%RH

Page 9

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 8

Product Information

––––––––––––––––––––––––––––––––––––

1.1 Specification

Operation Humidity

:

15% to 85%RH

CPU

:

ARM Cortex A9 (iMX6 Solo) Single Core 1GHz

System Memory

:

Built-in NAND Flash 1GB

Storage

:

512MB DDR3

OS : LINUX

I/O Interface

:

1 x Ethernet 10/100 Base T

: 4 x USB Ports

Optional Interface

:

USB WLAN

* Specifications are subject to change without notice

Page 10

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 9

Product Information

––––––––––––––––––––––––––––––––––––

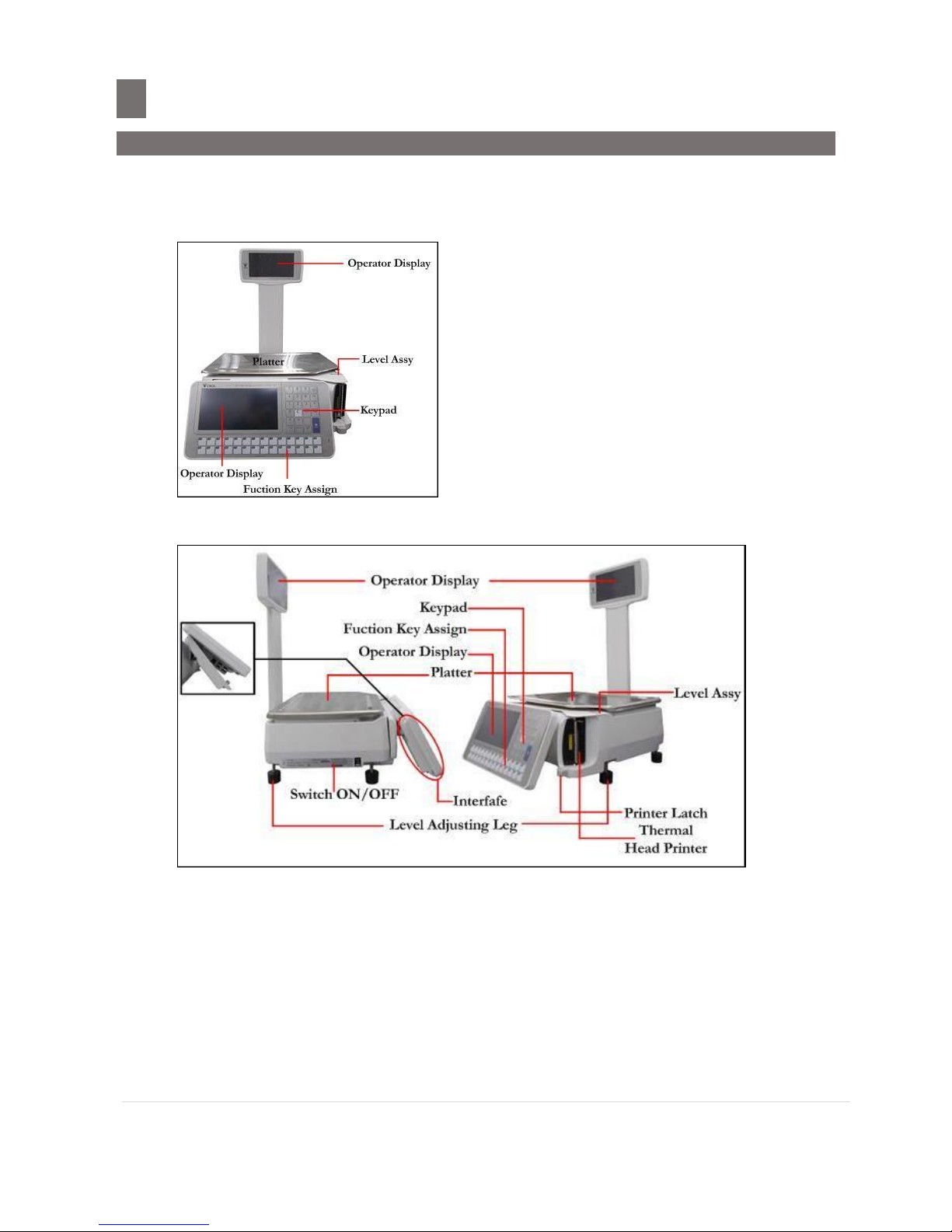

1.2 Overall View of SM-5300

1.2 Overall View of SM-5300

1.2.1 SM-5300 Bench Type

Page 11

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 10

Product Information

––––––––––––––––––––––––––––––––––––

1.2 Overall View of SM-5300

1.2.2 SM-5300 Pole Type

Page 12

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 11

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

1.3 Product Layout

1.3.1 Overall Layout SM-5300LL

1. Front and Back View

2. Left and Right Side View

3. Top View Display

Page 13

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 12

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

1.3.2 Overall Layout of SM-5300P

1. Front View

2. Left and Right Side View Display

Page 14

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 13

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

1.3.3 Overall Layout of SM-5300SSP 19”

1. Front View

2. Left and Right Side View

Page 15

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 14

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

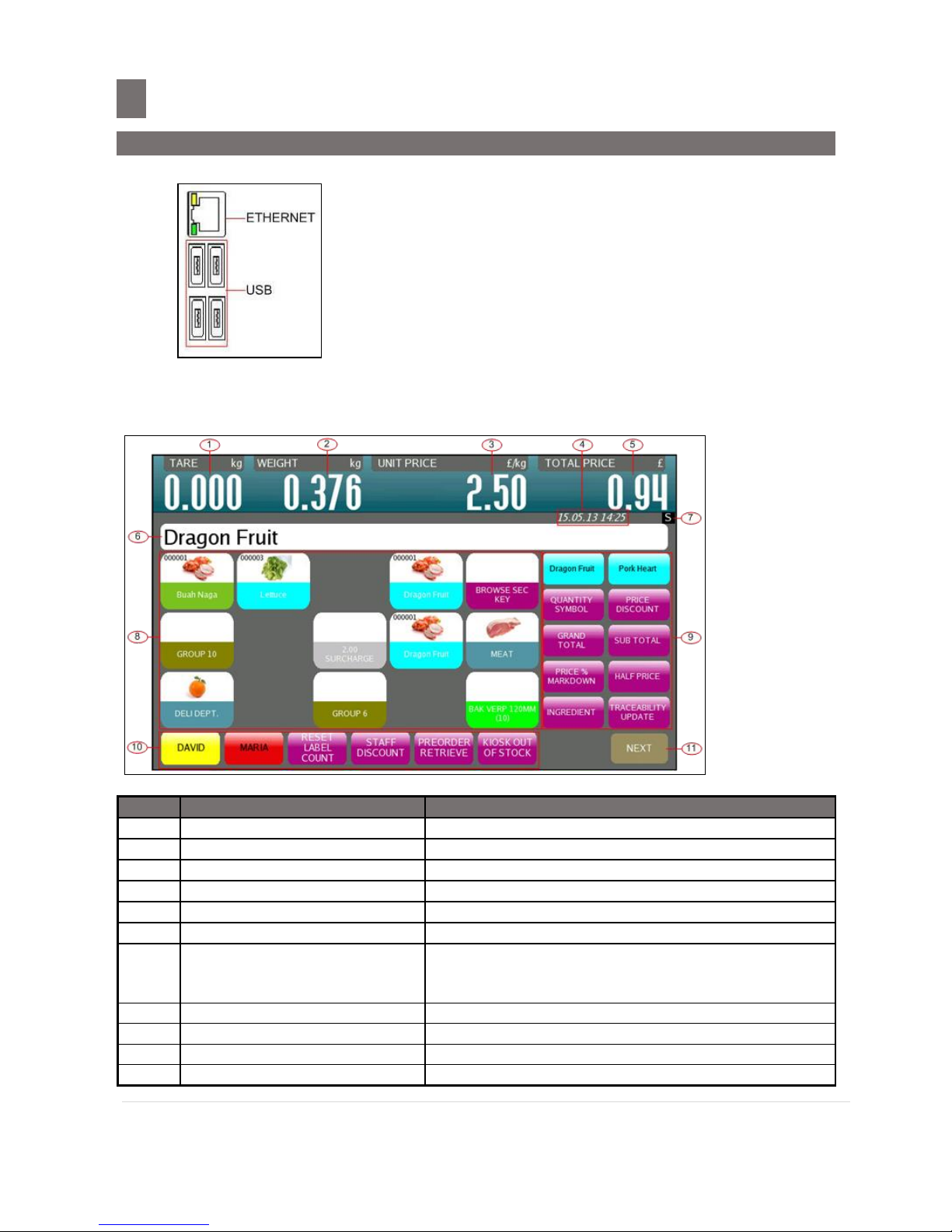

1.3.4 Interface

1.3.5 Indicator Display

1. Registration Mode Screen

No.

Area /Function

USAGE

1

Preset Tare Display

Display Preset Tare

2

Weight Display

Display Weight value

3

Unit Price Display

Display Unit Price amount

4

Date and Time

Display Current Date And Time

5

Total Price Display

Display Total Price amount

6

Commodity Name

Shows the Commodity Name of the called up PLU

7

Scale Indicator

Shows S when Scale is SERVER

Shows C when Scale is CLIENT

Shows L when Client is OFF LINE/LOCAL

8

Reg. Preset keys

Used for calling up PLU / Function keys

9

Reg. Secondary key

Used to call PLU, Function, and etc, except clerk

10

Reg. Clerk/Function keys

Used for calling up Clerk / Function keys

11

Next Page keys

Turn to next page of Preset / Function keys

Page 16

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 15

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

REMARKS:

1. PREV & NEXT keys will appears when there's more than 1 page of Preset/Function keys.

2. When in Prepack Mode, the Clerk/Function keys at the bottom of the screen will not be

shown.

3. When in Manual Mode, the indicator will not be shown.

4. Can display image in Reg. Preset keys, need to select in Programming of Preset Keys.

2. Customer Display

No.

Area /Function

USAGE

1

Commodity Name

Shows the Commodity Name of the called up PLU

2

Image Display

Shows the image of the called up PLU

3

Preset Tare Display

Display Preset Tare

4

Weight Display

Display Weight value

5

Unit Price Display

Display Unit Price amount

6

Total Price Display

Display Total Price amount

Page 17

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 16

Product Information

––––––––––––––––––––––––––––––––––––

1.3 Product Layout

1.3.6 Keys & Key Function

Panel Key

*Actual legends and symbols may differ depending on local regulations and requirements.

Key Function

Turn on/off the display.

to

Enter numeric data.

Reset the weight to "0".

CLEAR key is used for clearing entered data.

Set/Clear the tare value.

Mode key is used for some special operations together with

other keys

Multiply the number of non-weighing product.

Used as escape key in Programming mode.

Not available

PLU key is used for calling up a PLU in Registration mode.

Used as entered key in Programming mode.

Switch mode status, Manual Mode or Pre-pack Mode.

Used for feeding label or receipt.

PRINT key is used for printing label / receipt in Registration

mode.

to

Call up Preset data such as PLU Data.

Call up Preset Function Key.

Page 18

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 17

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

1.4. Printer Setting

1.4.1 Receipt, Label and Linerless Specification

Outer diameter of rolls

Maximum 105mm

Inner diameter of rolls

Minimum 40mm

Wide of receipt roll

Maximum 60mm

Wide of label roll

Maximum 60mm

LABEL TYPE

LABEL SIZE

PCS/ROLL

T1

60 x 28

1400

T2

60 x 31

1300

T3

60 x 34

1200

T4/T10

60 x 40

1000

T5/T11

60 x 43

960

T6

60 x 46

900

T7/T12

60 x 49

840

T8

60 x 55

750

T9

60 x 37

1100

S

40 x 28

1400

A / B

40 x 46

900

C

40 x 62

670

F1- F99 (Free format)

Standard: 60 (max) x 240 (max)

-

REMARKS:

1. LABEL SIZE is in W (width) X L (length) and in unit of millimeter.

2. F1 to F99 is self design free format label to design own label. Please note the maximum

size.

Page 19

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 18

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

1.4.2 Character Size & No. of Characters available for Label Printing

10 kinds of letter sizes are available as follows:

The number of letters per line for Commodity name depends on the label format:

Label Format: A and C

S1 --- the smallest, 45 letters

M1 --- middle size, 27 letters

S2 --- smaller size, 39 letters

M2 --- large size, 19 letters

S3 --- small size, 34 letters

M3 --- large size, 19 letters

S4 --- small size, 34 letters

M4 --- larger size, 15 letters

S5 --- middle size, 27 letters

M5 --- the largest, 12 letters

Label Format: T1 ~ T12

S1 --- the smallest, 70 letters

M1 --- middle size, 42 letters

S2 --- smaller size, 60 letters

M2 --- large size, 30 letters

S3 --- small size, 53 letters

M3 --- large size, 30 letters

S4 --- small size, 53 letters

M4 --- larger size, 23 letters

S5 --- middle size, 42 letters

M5 --- the largest, 19 letters

Note: When selected label format without print area for Commodity Name. Maximum 1 line of 74 letters can

be entered for printing in receipt and not allow to change the character size.

Page 20

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 19

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

1.4.3 Receipt, Label and Linerless Setting

CAUTION

There is a cutter at the printer door near the dispenser. Take care not to touch or cut

your fingers against the cutter during this process.

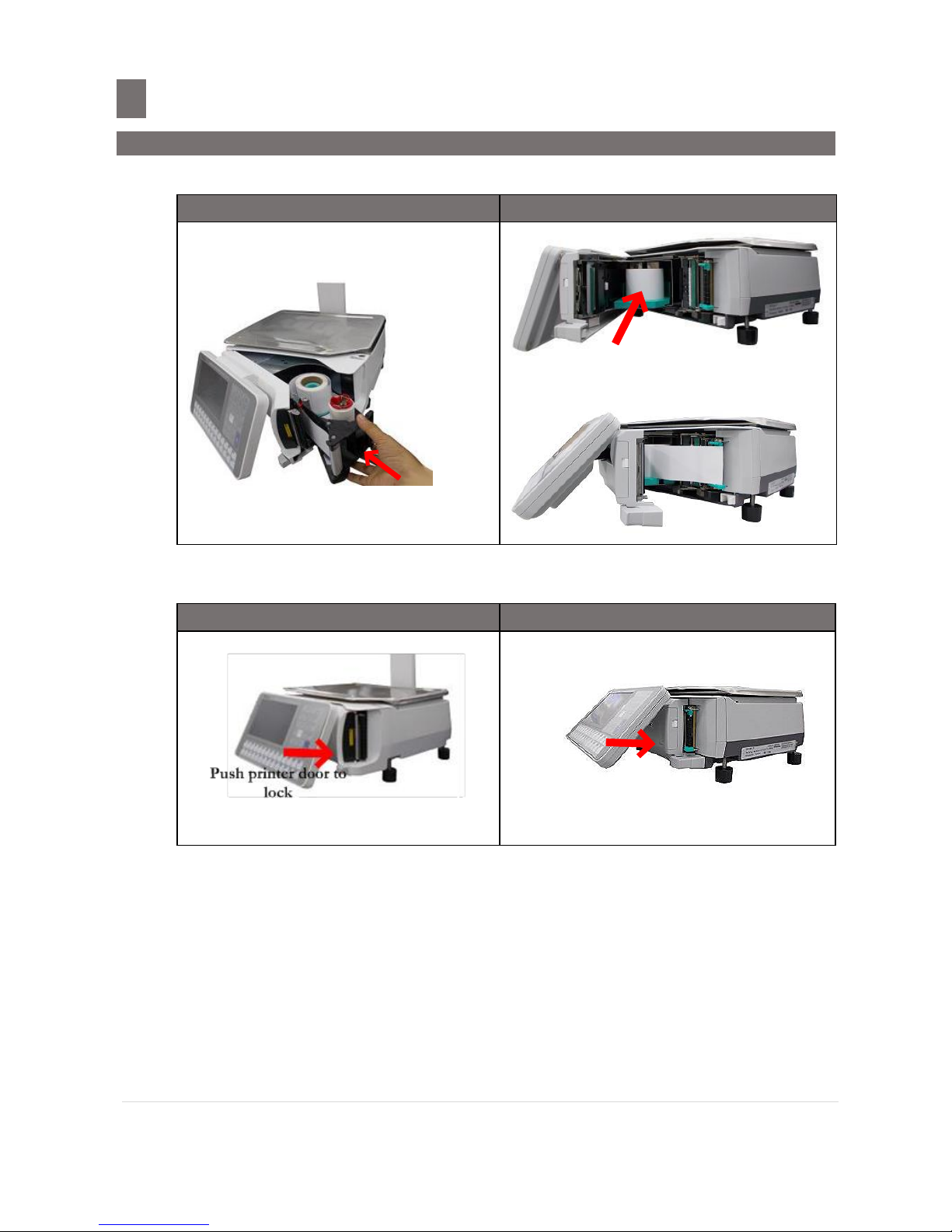

1. Open the printer door by sliding the printer latch to left side.

SM5300P

SM5300LL

Sliding to

left side

Sliding to Left Side

2. Swing open the printer door.

3. Pull out the cassette and remove the empty roll.

SM5300P

SM5300LL

Page 21

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 20

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

4. Insert a new label/receipt roll and then setting cassette For SM5300P

a. Set the cassette a label, receipt or linerless as per diagram below:

Note: Can skip this step if have set the cassette

Label: (∆ ×)

This sticker is paste and set as the default factory setting.

Receipt: (O)

This sticker is given together with the accessory items, for customer to set as an option.

Paste the sticker to the third hole without removing the original label sticker.

Linerless: (∆ O)

This sticker (O) is given together with the accessory items, for customer to set as an

option. Paste the sticker to the ∆ third hole and remove the middle (×, original) label

sticker.

b. For label, take the end of the label and run it across guide [1] and above dispenser [2]

and set back paper in reel [3], and turn the reel clockwise direction to tighten the label

paper tension. Refer to the diagram below:

Page 22

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 21

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

c. For linerless , take the end of the linerless stock and run it through guide [1] and pull

the receipt paper up to the dispenser [2] without rolling it to the reel. Refer to the

diagram below:

d. For receipt, take the end of the receipt stock and run it through guide [1] and pull the

receipt paper up to the dispenser [2] without rolling it to the reel. Refer to the diagram

below:

Page 23

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 22

Product Information

––––––––––––––––––––––––––––––––––––

1.4 Printer Setting

5. Push back the cassette into the main unit until a lock sound is heard, For SM5300LL insert

new linerless roll then pull linerless point to thermal head.

SM5300P

SM5300LL

Push the

Cassette

6. Close the printer door by pushing at the lower area of the printer door until a lock sound is

heard. Refer to diagram below:

SM5300P

SM5300LL

Push printer door to

lock

7. Depress [FEED] key to feed label/receipt, for SM5300LL the printer door will auto feed the

linerless when printer door is lock.

Page 24

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 23

Typical Operation

–––––––––––––––––––––––––––––––––––––––––

2.1 Product Setup

Typical Operation

2.1 Product Setup

1. Place product on a firm and level surface.

2. Set scale leveling by adjusting the stands (Refer to Pictures 1).

3. Connect scale to power supply.

4. Switch on scale and wait for completion of display checking.

5. Upon completion of display checking, confirm scale is at zero (zero lamp/indicator on),

6. Please refer Touch Screens. If zero lamp not on, press the re-zero key.

7. Install label receipt or linerless according to instruction indicated on the label in the scale,

8. Please refer Receipt / Label Setting.

9. Press the feed key several times.

10. Scale is now ready for use.

Page 25

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 24

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.2 Date and Time Setup

2.2 Date and Time Setup

The built-in clock automatically works once they are set:

Date (Month/Day/Year) ------- 2 digits for each part.

Time -------------------------------- 4 digits (24 Hours).

OPERATION

DISPLAY

1. MENU MODE ~> [MAINTENANCE

MENU] ~> [MAINTENANCE]

2. Touch the [DATE AND TIME] key to

enter DATE AND TIME screen.

3. Enter current Date by numeric keypad or

touch date on Calendar box. (e.g. 100814

= 10 August 2014) – this depend on date

format setting

Page 26

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 25

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.2 Date and Time Setup

OPERATION

DISPLAY

4. Touch [TIME] tab

Then enter current Time by numeric

keypad.

(e. g. 1130 = 11:30 AM)

5. Touch [SAVE] key or press [PLU] button

to save the programming data and time

and the screen will return to MAINTENANCE

MODE.

Note: When save date (by pressing [SAVE]

or [PLU] key), it will exit Date and Time

Screen.

Note: Touch [MENU] key to exit without save

the data. A message will appear "SAVE

CHANGES?” select desire choice.

Page 27

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 26

Typical Operation

–––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3 Registration Mode

2.3.1 PLU Call Up

To call up programmed PLU for weighing.

1. Manual PLU Call Up.

2. Automatic PLU Call

3. By Registration Mode Preset Keys.

Note:

The machine will display the following error messages if incorrect operation is performed. "PLEASE

REMOVE WEIGHT" error message, when tried to call Non-Weighed PLU up when something is on

the platter. ~> Remove the item from the platter and try again. "PLU NOT EXIST" error message,

when tried to call a Non Programmed PLU Number. ~> Check the PLU Number and try again.

1. Manual PLU Call Up

This can be programmed at PLU Programming mode, by creating a PLU with PLU code and this PLU

code can be use to call the PLU at Registration Mode. Manual PLU call up can be done by entering

the correct PLU code at Registration (In Self Service Manual PLU call up use only on PLU

Programming)

OPERATION

DISPLAY

1. In REGISTRATION MODE.

Press the PLU Number of the LEMON (e.g. 3)

by numeric keypad and then press [PLU] key

at keypad.

Note: Press [C] key to clear the PLU data.

Page 28

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 27

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. Automatic PLU Call Up

Automatic PLU Call up also can use the scanner to scan the barcode. Wherever the Barcode has

programmed in PLU Program and Barcode programming (Please refer to PLU Program and Barcode

Programming on SM5300 Operation Manual (Part 1 - Main) – Edition 01 [DOC]).

OPERATION

DISPLAY

1. In Registration Mode.

2. Please scan the barcode to automatic PLU

call up.

Page 29

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 28

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

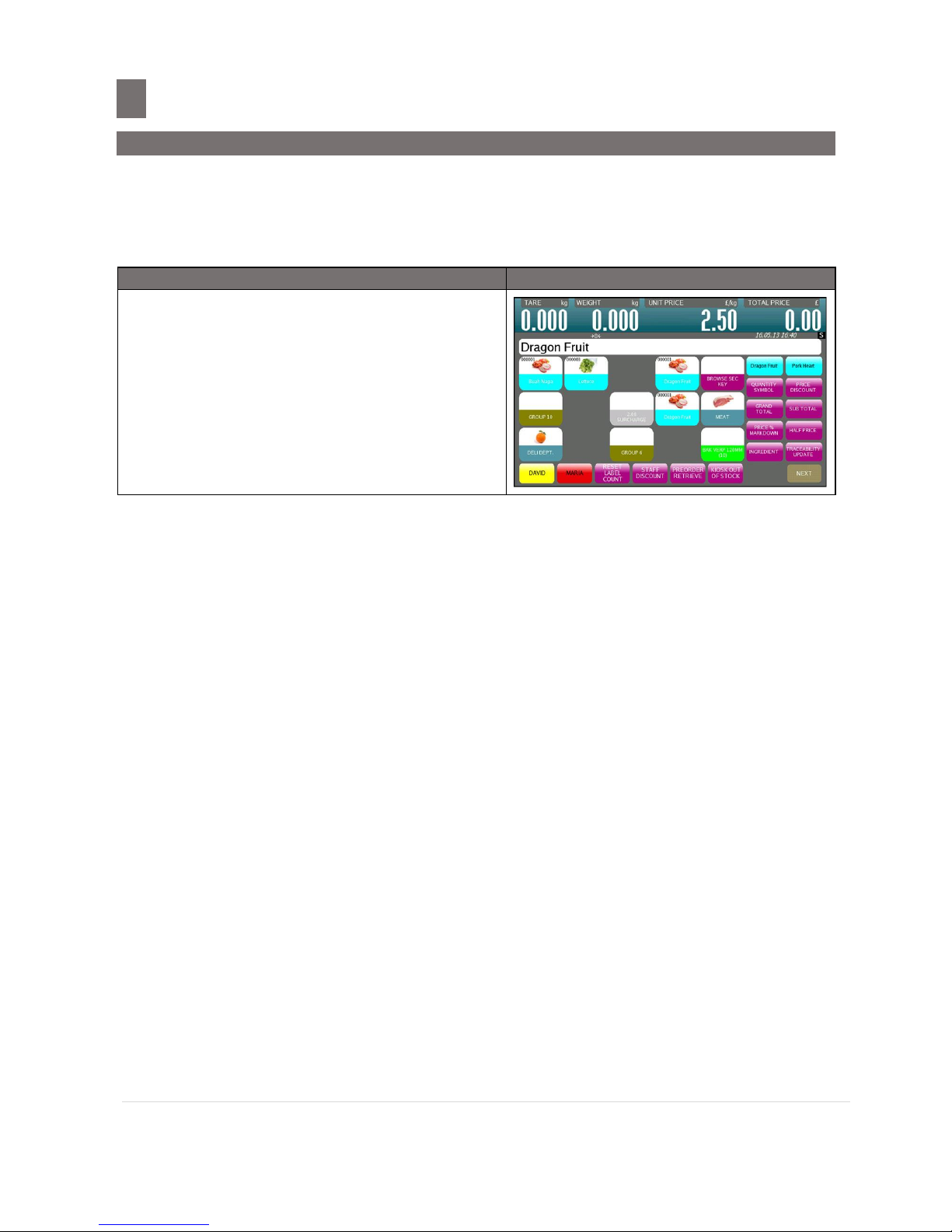

3. PLU Call Up by Preset Key of Registration Mode

To enable this function, the PLU must assign on the Preset Key of Registration Mode in advance

(Please refer to PLU Program and Barcode Programming on SM5300 Operation Manual (Part 1 Main) – Edition 01 [DOC]).

OPERATION

DISPLAY

1. In REGISTRATION MODE, touch the

PRESET KEY with the desired PLU assigned

from Registration Mode Preset Key.

(e.g. The 1st Preset Key – Dragon Fruit)

Note: Press [C] key on keypad to clear the PLU

data.

Page 30

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 29

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3.2 Item Label Printing in Manual Mode

You can use this operation to print out item labels for a PLU or Non-PLU of Weighing Item or Nonweighing Item. Before the operation, check the following point.

- Make sure cassette is set to LABEL or LINERLESS setting (For SM5300P).

- Check whether the Label Size fits the programmed PLU when label is used.

Note:

1) SPEC 142A012 "Actuation Weight for Registration Mode", to set minimum weight for

registration mode.

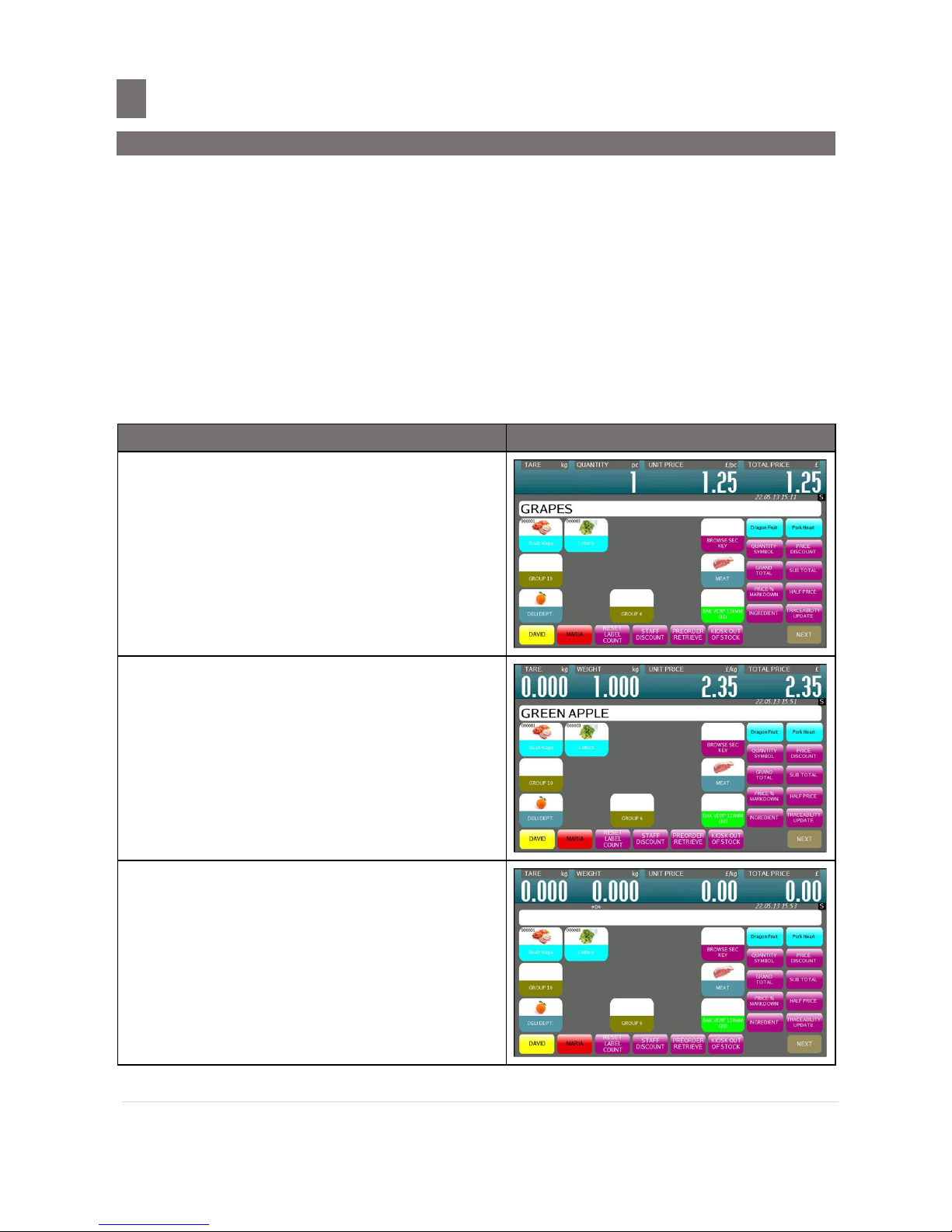

1. Label Printing for PLU Item

Example:

Sell one pack of GRAPES (Non-weighing Item) and Sell 1kg of GREEN APPLE 1

(Weighing Item).

OPERATION

DISPLAY

1. In REGISTRATION MODE, Call up PLU of

GRAPES

2. Touch [PRINT] key to issue out a label.

Then call up item of GREEN APPLE and place

the product on platter (e.g. 1kg).

3. Touch [PRINT] key to issue out a label and

then remove the product from platter.

Page 31

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 30

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. Label Printing for Non-PLU Item

It is possible to print item label for Non-PLU Item at Manual Mode. The Non-PLU Item will be

cleared if a PLU is called up or [CLEAR] key is pressed.

Note:

1) SPEC 141D002 "Manual Price Entry" set to "Allow" - to enable manual price entry.

2) SPEC 142E004 "Manual Weight Entry" set to "Normal and Prepack Mode" - to enable manual

Weight entry.

OPERATION

DISPLAY

1. In REGISTRATION MODE, enter the Price for

Non-PLU item, (e.g. 5.00) by numeric key.

Note: For Non-weight Item, just press [PRINT]

key to issue out a label or press [X] key

to enter multiply mode, then enter sale

quantity and press [PRINT] key to issue

label. For Non-weight of Non-PLU item,

will be registered to PLU # 999999.

2. Place the product on platter (e.g. 1kg) and

then Touch [PRINT] key to issue a label.

Then remove the product from platter.

Note: For Weighing of Non-PLU and PLU Item,

will be registered to PLU # 999998).

Page 32

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 31

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3.3 Total Label or Receipt Printing

This operation is used for printing total label or receipt for counter sales in Manual Mode. For

SM5300P, make sure cassette is set to LABEL for Total Label Printing or set to RECEIPT for Receipt

Printing or set to LINERLESS setting for Total Label and Receipt Printing.

Note:

1) SPEC 141B008 "Total Label Printing" entry the numeric value, to enable total label printing.

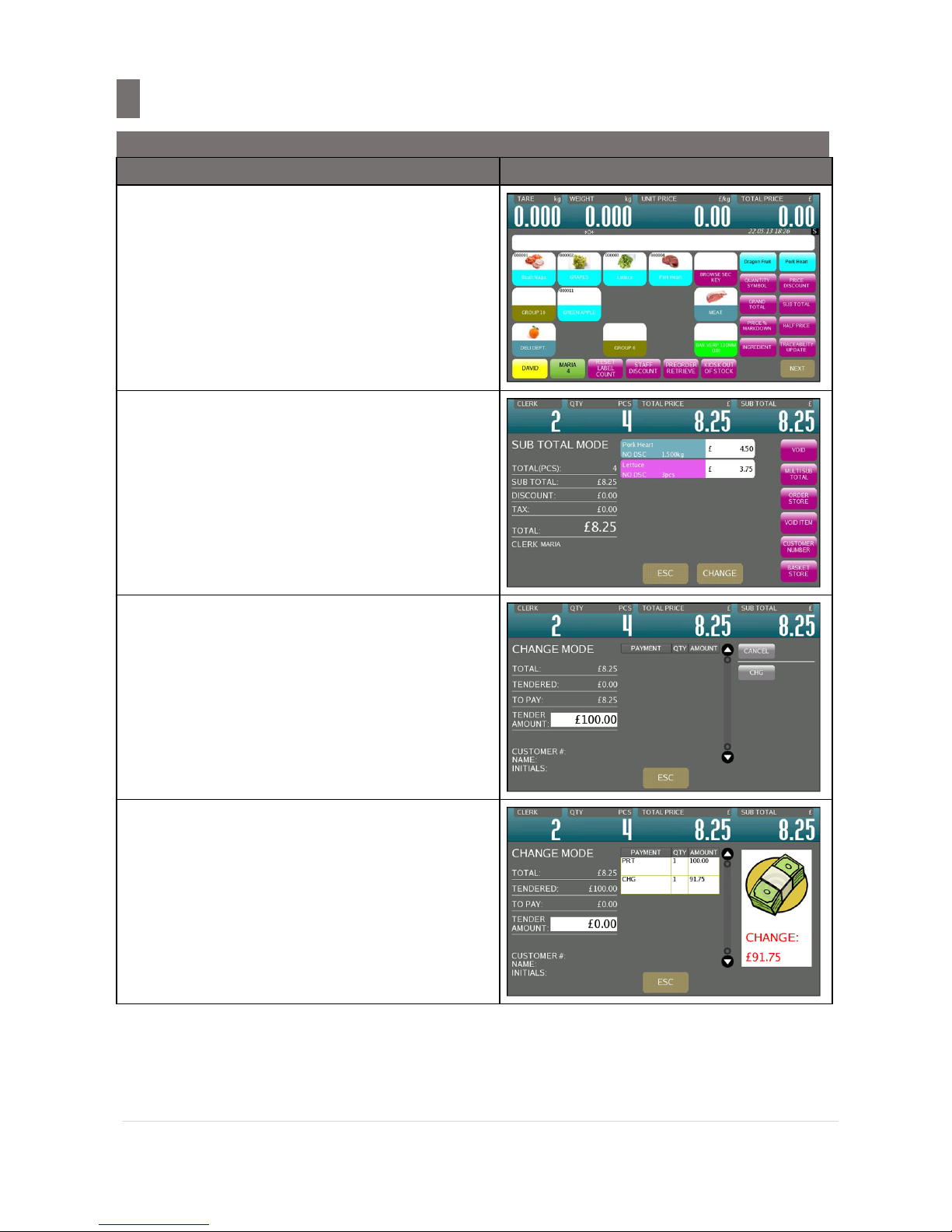

1. Sales Transaction and Change Calculation

This section shows how to operate the transactions with Clerk key. The designated Clerk key

accumulates each transaction data and the Receipt or Total Label will be issued.

Example:

Sells 1.5 kg of PORK HEART and 3 packs of LETTUCE for customer A.

OPERATION

DISPLAY

1. In REGISTRATION MODE, call up a PLU

weight item (e. g. PORK HEART) and place

the product on platter (e.g. 1.500 kg).

2. Touch [MARIA] key to add the sales data.

3. Remove the product from the platter and

call up a PLU non weight item (e. g.

LETTUCE), then Touch [X] key to enter

multiply mode and enter the sell Qty (e.g. 3

packs).

Page 33

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 32

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Touch [MARIA] key to add the sales data.

5. Touch [MARIA] key again to go into the

Accumulation Mode.

Note:

1. After printing of Total Label or Receipt,

display will return to Registration Mode.

2. Press [PRINT] key to Print Total Label.

6. Touch [CHANGE] key to enter to CHANGE

MODE screen.

Enter the amount received by numeric

keypad. (e.g. $100.00)

Note: Touch [ESC] key to escape the CHANGE

MODE.

7. Press [PRINT] key to issue a Receipt.

Note:

1. After printing of Receipt or Total Label,

display will return to Registration Mode.

2. All transaction in Registration mode had

clear.

Page 34

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 33

Typical Operation

–––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. [Price Discount] Function Key in Accumulation Mode

This is used to discount the total price by the following formula.

PRICE TO PAY = ORIGINAL TOTAL PRICE - ENTERED DISCOUNT VALUE

Note: [PRICE DISC] function key must be assigned in advance, please refer to preset key programming in

Operation Manual Advance

Example: Giving Price Discount of $10.00 for buying 2.5kg of CABBAGE.

OPERATION

DISPLAY

1. In REGISTRATION MODE, call up a PLU

weight item (e. g. LEMON) and place the

product on platter (e.g. 2.500kg).

2. Touch [PRICE DISCOUNT] key to enter to

the PRICE DISCOUNT setting screen and

then enter the discount amount (e.g.

$10.00) by numeric keypad.

Note: Touch [ESC] key to cancel PRICE

DISCOUNT function.

3. Touch [ENTER] key.

Note:

1. $10.00 has been deducted from the

Original Total Price.

2. It will show that customer has got

discount $10.00

Page 35

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 34

Typical Operation

–––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Press [PRINT] key to issue a Label and

then remove product from platter.

Page 36

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 35

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

3. [Unit Price % Disc] Function Key in Accumulation Mode

This is used to discount the total price by the following formula.

PRICE TO PAY = ORIGINAL TOTAL PRICE x (100% - ENTERED %)

Note: [%PRICE DISC] function key must be assigned in advance, please refer to preset key programming

in Operation Manual Advance

Example: Giving % Price Discount of 25% for buying 2.5kg of IRISH BACON.

OPERATION

DISPLAY

1. In REGISTRATION MODE, call up a PLU

weight item (e. g. IRISH BACON) and place

the product on platter (e.g. 2.5kg).

2. Touch [UNIT PRICE % DISCOUNT] key

to enter to the Unit Price % Discount setting

screen and then enter the discount %

value (e.g. 25.00%) by numeric keypad.

Note: Touch [ESC] key to cancel UNIT PRICE %

DISCOUNT function.

3. Touch [ENTER] key.

Note: 25.00% have been deducted from the

Original Total Price.

Page 37

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 36

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Press [PRINT] key to issue a Label and then

remove product from platter.

Page 38

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 37

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3.4 Data Correction

The data correction during accumulating operation is to correct sales transaction data when

customer canceled the purchases or operators make a mistake before issuing Total Label or

Receipt. The corrected item data is printed with two lines crossed on the Total Receipt.

Data correction has 2 correcting functions as follows:

1) Void by Item Correction is to void sales data by tracing transaction number.

2) Void by PLU Number Correction is to void sales data by tracing PLU Number.

1. Void by Item Correction

This function is to void the specified transaction during an accumulating operation. Operator

can designate the Number of transaction to be voided even if plural transactions for the same item

are performed.

Note: [VOID ITEM] function key must be assigned in advance, please refer to preset key programming in

operation manual.

Example: Sells 2packs of GRAPES, 1kg of WATER MELON and sell more 1.5kg of MANGO for

customer A. But customer canceled 1kg of WATER MELON accumulated in the operation.

OPERATION

DISPLAY

1. In REGISTRATION MODE, call up PLU of

Grapes then press [X] key to enter multiply

mode and enter the sell Qty (e.g. 2 packs).

2. Touch [SANDRA] key to add the sales data.

Page 39

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 38

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

3. Call Up PLU of MANGO and Place the product

on the platter (e.g. 1.500kg)

4. Touch [SANDRA] key to add the sales data.

5. Remove the product from the platter and Call

up PLU of WATER MELON and place the

product on platter (e.g. 1.000 kg).

6. Touch [SANDRA] key to add the sales data.

Touch [SANDRA] key again to go into the

Accumulation Mode.

Page 40

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 39

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

7. Select transaction item (e.g. Touch the 1st

accumulated item MANGO).

Note: Item No. 1 MANGO will be highlighted.

8. Touch [VOID ITEM] key to cancel the

selected Item.

9. Press [PRINT] key to issue a Receipt or

Total Label and then remove product from

platter.

Note: After printing of Receipt or Total Label,

display will return to Registration Mode.

Page 41

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 40

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. Void by PLU Number Correction

This function is to void the specified item during an accumulating operation, by specifying a PLU

Number in the accumulating operation mode. All transaction data of the PLU number will be

canceled.

Note: [VOID PLU] function key must be assigned in advance, please refer to preset key programming in

Operation Manual Advance

Example: Sells 2packs of GRAPES, 1.500kg of Mango and sell more 2packs of GRAPES for

customer A. But customer canceled all the data of GRAPES.

OPERATION

DISPLAY

1. In REGISTRATION MODE, call up PLU of

Grapes then press [X] key to enter multiply

mode and enter the sell Qty (e.g. 2 packs).

2. Touch [SANDRA] key to add the sales data.

3. Call Up PLU of MANGO and Place the

product on the platter (e.g. 1.500kg)

Page 42

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 41

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Touch [SANDRA] key to add the sales data.

5. Call up PLU of GRAPES again, then press [X]

key to enter multiply mode and enter the sell

Qty (e.g. 2 packs).

6. Touch [SANDRA] key to add the sales data.

7. Touch [SANDRA] key again to go into the

Accumulation Mode.

Page 43

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 42

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

8. Then touch [VOID PLU] key to entry

Transaction Correction Mode

Enter the PLU number of GRAPES by

numeric keypad. (e.g. 2) and Touch

[ENTER] key

Note: [ESC] key used to abort the transaction

9. All the transaction data of PLU2 (GRAPES)

will be canceling.

10. Press [PRINT] key to issue a Receipt or

Total Label and then remove product from

platter.

Note: After printing of Total Label or Receipt,

display will return to Registration Mode.

Page 44

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 43

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3.5 Item Label Printing in Prepack Mode

Pre-pack Mode can be switched from Manual mode by pressing [AUTO] key on keypad. In this

mode, the following functions are available for:

(1) For weighing item, label is automatically issued (without pressing [PRINT] key) after the

weight of the item gets stable. The machine keeps the PLU data until [CLEAR] key is

pressed.

(2) For non-weighing item, the next label is automatically issued (without pressing [PRINT]

key) after a label is taken away. The machine keeps the PLU data until [CLEAR] key is

pressed.

Note:

1) SPEC146A033 "Selection of Prepack Mode" set to "Enable", to enable prepack mode.

2) SPEC141D149 "Continuous print in prepack mode", to enable or disable continuous printing

in prepack mode and set SPEC141B617.

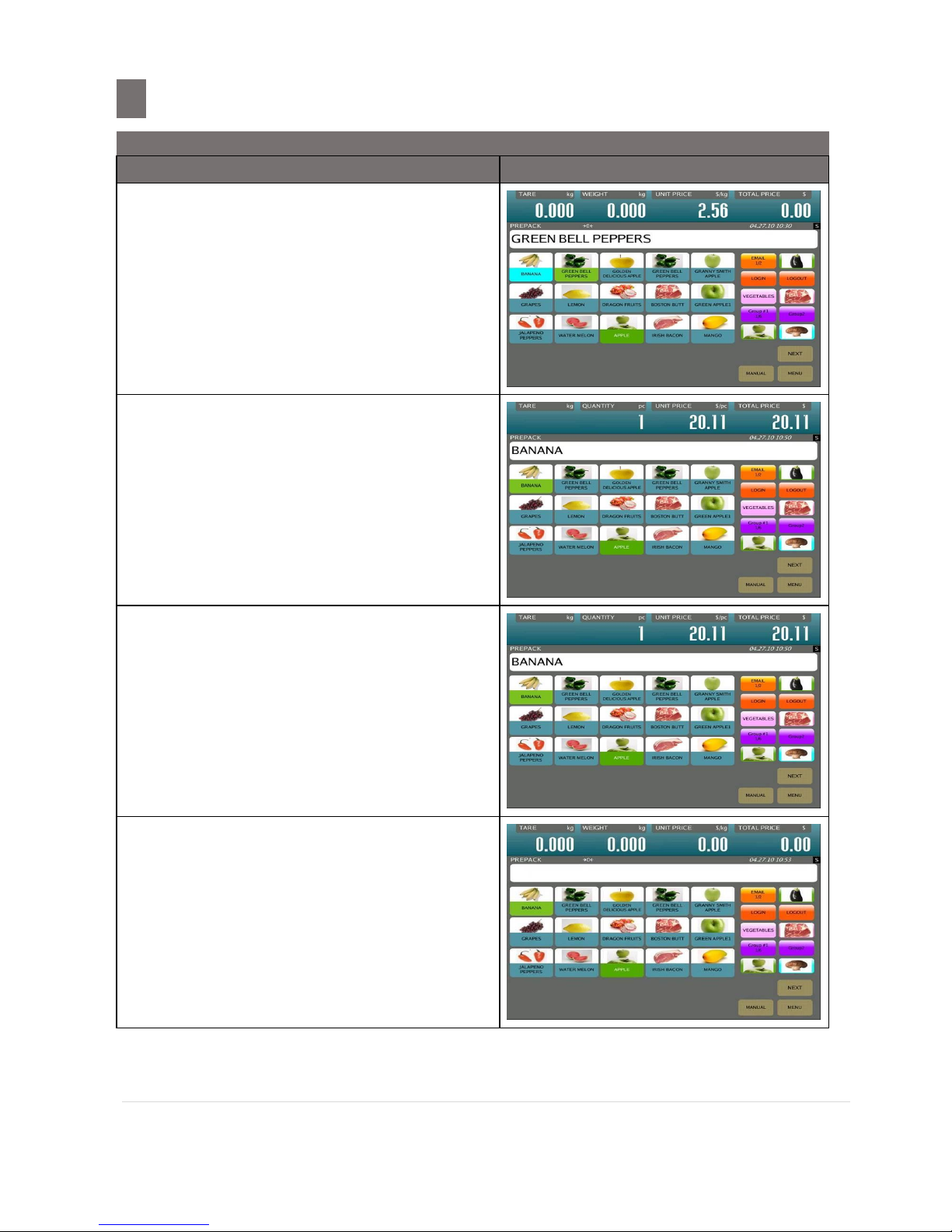

Item Label Issue for PLU Item

Example: To weight (e.g. 1kg) and label 20 packs of GREEN BELL PEPPERS (Weighing Item) and

to issue 20 labels of BANANA (Non-Weighing Item).

OPERATION

DISPLAY

1. In REGISTRATION MODE, press [AUTO]

key until the display change to the PREPACK

MODE screen.

Call up PLU of GREEN BELL PEPPERS

2. Place product on platter. (e.g. 1.500kg of

GREEN BELL PEPPERS)

Note: Label automatically issued after weight

stable.

Page 45

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 44

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

3. Remove the product from the platter and

take the label off.

4. Repeat the above step 2 and 3 to weigh the

next pack, until the last packed is weighed.

Then call up a PLU of BANANA

5. Press [PRINT] key to start issue the first

label.

Take the label away and next label

automatically issued out.

6. After issue last label out, press [CLEAR]

key to stop issuing label.

Then press [CLEAR] key again to clear the

PLU.

Page 46

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 45

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

1. Item Label Issue for Non-PLU Item

It is possible to print item label for Non-PLU Item at Pre-pack Mode. The Non-PLU Item will be

cleared if a PLU is called up or [CLEAR] key is pressed.

OPERATION

DISPLAY

1. In PREPACK MODE, enter the Price for NonPLU item (e.g. $5.00) by numeric key.

Note:

1. For Non-weight Item, just press

[PRINT] key to start issuing out a label.

2. For Non-weight of Non-PLU item, will be

registered to PLU # 999999.

2. Place the product on platter. (e.g. 1.500kg)

Note: The label automatically issued after

weight stable. For Weighing of NonPLU Item, will be registered to PLU #

999998

3. Remove the product from platter.

Note: To change back to MANUAL MODE, press

[AUTO] key, until the display change to

MANUAL MODE screen.

Page 47

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 46

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2.3.6 Tare Operation

There are 2 ways to set Tare Weight at Registration Mode:

(1) One Touch Tare (Weight Tare)

(2) Digital Tare

Tare value subtracted will be displayed on "TARE" window. The following operation examples

show 2 ways of subtracting the Tare weight of a 20g tray.

1. SPEC142B008 "Tare Display" set "Allow" to enable tare display.

1. One Touch Tare

This function is to weight the actual weight of tare then subtract its weight to get the tare value

for all of PLU.

OPERATION

DISPLAY

1. In REGISTRATION MODE, place the weight

on center of the platter (e.g. 20g).

2. Press [TARE] key to subtract the tare

weight.

3. Remove the weight from platter.

Page 48

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 47

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Press [TARE] key to clear the Tare

value.

Page 49

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 48

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. Digital Tare

This function can be used when tare weight is decided in advance. The knowing tare value

(weight of the tray) can be entering by numeric keys.

SPEC: SPEC 142B002 "Digital Tare" set "Yes" to enable this function.

OPERATION

DISPLAY

1. In REGISTRATION MODE, enter Tare Value

by numeric key. (e.g. 200)

2. Press [TARE] key to subtract the tare

weight.

3. Press [TARE] key to clear the Tare value.

Page 50

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 49

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

3. Tare Value Exchange

There are two ways to do tare value exchange, Tare Accumulation and Tare Subtraction. One

Touch Tare and Digital Tare can be used to do Tare Accumulation or Tare Subtraction.

1. Tare Accumulation

SPEC: SPEC 142B003 "Tare Accumulation" must be set to "Yes" in advance to enable Tare

Accumulation function.

OPERATION

DISPLAY

1. In REGISTRATION MODE, put weight on the

e.g. 200g

Note: Also can use digital tare

2. Press [TARE] key to subtract the tare

weight

3. Place another tare weight on the platter

(e.g. 500g)

Note: Also can use digital tare, for digital tare

the next tare accumulation value should

not be lower than the previous tare value.

Page 51

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 50

Typical Operation

––––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

4. Press [TARE] key to subtract the tare

weight

5. Remove all weight from the platter and

press [TARE] key to clear the tare.

Page 52

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 51

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

2. Tare Subtraction

SPEC 142B005 "One Touch Tare subtraction" must be set to "Allow" in advance, to enable

this function.

OPERATION

DISPLAY

1. In REGISTRATION MODE, put weight on the

platter e.g. 200g

Note: Also can use digital tare.

2. Press [TARE] key to subtract the tare

weight

3. Remove e.g. 100g from the platter.

Note: For Digital Tare, subtracted tare value

should not be bigger than the total tare

value.

4. Press [TARE] key to subtract the tare

weight

Page 53

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 52

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.3 Registration Mode

OPERATION

DISPLAY

5. Remove the balance weight and press

[TARE] key to clear the tare weight.

Page 54

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 53

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.4 Self Service Mode

2.4 Self Service Mode

SPEC: Spec 146A017 Self Service “set to YES, to active the Self service mode in Menu mode.

SPEC: Spec 141D072 Tenkey for Self Service Mode, to select the self service mode using

which tenkey.

SPEC: Spec 141D148 Auto Print in Self Service Mode, must set to “YES” because ten key

button will not active.

Note: Self Service available on SM5500 Alpha BS

2.4.1 Software Tenkey

Software Tenkey function only used for weight item in the Self Service mode.

SPEC: SPEC 141D072 TENKEY FOR SELF SERVICE MODE, set to Software Tenkey.

Manual PLU Call up is by enter the PLU Number by numeric Keys. To use the manual PLU call up,

set spec as below:

SPEC: SPEC141D041 Auto PLU Call must set to By Number of Digits.

SPEC: SPEC141D042 Auto PLU Call (By Digits/ By Timeout (0.1 Sec)), this spec depend

on our own setting, for example set to 2.

OPERATION

DISPLAY

1. In SELF SERVICE MODE, touch [01] and it

will prompt PLU Number of the Dragon Fruit

(e.g. 1).

Note: Only used for weight item.

2. The put item on the platter will auto issue

out the label.

Page 55

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 54

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.4 Self Service Mode

OPERATION

DISPLAY

3.

After issue out the label will prompt out

message "PEEL LABEL".

Take out the label,the message will be back

to “PLEASE INPUT PLU CODE” and can

continue next transaction.

4.

Exit from Self Service mode will prompt out

to TENKEY mode.

Press ESC button will back to Self Service

mode.

Note: To exit from this mode must touch the

CLEAR button twice, 0 button twice, and

CLEAR button once touch and 0 buttons

once touch.

5.

Press [MENU] key will go out from ten key

mode to MENU MODE

Page 56

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 55

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.4 Self Service Mode

2.4.2 Mechanical Tenkey

This Mechanical Tenkey function also used for weight item only, this mechanical tenkey self service

mode we can see the image of the item product.

SPEC: SPEC141D143 Self Service Preset Group, this spec depends on our own setting, for

example we set to 1.

Note: The group setting is set in the preset group; this function is used by mechanical tenkey.

Note: The tenkey is working in this mechanical keypad self service mode.

SPEC: SPEC 141D072 TENKEY FOR SELF SERVICE MODE set to Mechanical Keypad.

Manual PLU Call up is by touch the image button and then follow by put item on the platter will

auto issue out label or touch item image first then put item on the platter will auto issue out label.

OPERATION

DISPLAY

1. In Menu Mode Touch [SELF SERVICE] key

2. Select the PLU by Touch the image button

(e. g. LEMON PLU #3)

3. Put the product on the platter and it will

auto issue the label

Page 57

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 56

Typical Operation

–––––––––––––––––––––––––––––––––––––––

2.4 Self Service Mode

OPERATION

DISPLAY

4. After issue out label will direct prompt out

message "PEEL LABEL".

Note: Please take out the label before continue

to do next transaction.

5. Press [MENU] button will back to Original

MENU mode.

Note: We can used auto run self service mode when scale start up by set the SPEC 141D040 AUTO

ENTRY TO OPERATION MODE set to SELF SERVICE, set to YES

Page 58

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 57

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.1 Report Mode Description

Report Mode

3.1 Report Mode Description

Report mode function is to view and print out various kinds of sales transaction reports for analysis.

The following reports are available.

Report Type

Report Type

1.

PLU Report

11.

Store Report

2.

Dept Report

12.

MG Report

3.

Clerk Report

13.

Inventory Report

4.

Clerk Log Report

14.

Traceability Report

5.

Terminal Report

15.

Prepack Report

6.

Store Summarized Report

16.

Grand Total Report

7.

24 Hour Report

17.

ABC Analysis Report

8.

Void report

18.

Void Label

9.

Tax Report

19.

Batch Report

10.

Queue Report

20.

PLU Price Change Report*

*To print PLU Price Change Report, user must use AQT (Advance Query Tool) on PC.

The desirable report can be view and printed out according to the following printing order

selections.

DATE RANGE

For setting the date range, FROM date and TO date have to be entered.

PERIODIC REPORT RANGE

TODAY

:

To select current of day range to day.

LAST 7 DAYS

:

To select from current day to past day of total = 7 day.

TERM 1

:

To select from terminal 1

TERM 2

:

To select from terminal 2

TERM 3

:

To select from terminal 3

REPORT TYPE

STOCK

TAKING

:

To select Report based on Stock Tacking Transaction

WASTE

:

To select Report based on Waste Transaction

ORDER

:

To select Report based on Order Transaction

RECEIVE

:

To select Report based on Receive Transaction

ACCUMULATED

:

To select Report based on Accumulated Transaction

NORMAL

:

To select Report based on Normal Transaction

SALES

:

To select Report based on Sales Transaction

ALL

:

To select Report based on All Transaction

SORT BY

PRICE

:

Actual Total Price order prints (Unit Price Base).

WEIGHT

:

Weight Total order print.

QUANTITY

:

Quantity Total order print.

PROFIT

:

Gross Profit Total order print.

PLU NO

:

PLU number order print

Page 59

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 58

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.1 Report Mode Description

ORDER TYPE

ASCENDING

:

Ascending order print.

DESCENDING

:

Descending order print.

PRINT TYPE

TRUNK

:

Printing Grand Total of Main Group.

BOUGH

:

Printing Grand Total of Main Group and PLU Total.

PRINT LIMIT

For setting the report range, Department Number, Main Group Number, PLU Number,

Clerk number to start and finish is to be entered.

LEVEL TYPE

DEPT

:

Department.

MG

:

Main Group.

Page 60

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 59

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

1. In MENU MODE screen.

2. Touch [REPORT] key to enter to REPORT

GENERATOR screen

Note:

1. Touch [MENU] key o to exit REPORT

GENERATOR screen.

2. [CONFIG] key used to configure which

printer that will use to print a report

3. Touch the desired key to go to the desired

Programming Mode. (e.g. PLU Report)

Note:

1. Touch [EXIT] key to exit REPORT

MODE screen.

2. Touch [VIEW] key to view report.

3. Touch [PRINT] key to print report.

Page 61

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 60

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.1 PLU Report

PLU Report is used to view/print transaction data separated by PLU number. On PLU Report, Sales

transaction report is printed depending on the date range selection.

Example:

Printing report for PLU Report (LAST 7 DAYS).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [PLU REPORT] key to enter to PLU

REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 23-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PRINT TYPE: NORMAL

- SORT BY: PLU NO

- ORDER: DESCENDING

- PLU RANGE: 1 to 20

- MG RANGE : 1 to 999

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 62

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 61

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: PLU Report

Page 63

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 62

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.2 Dept Report

Department Total Report is used to view/print transaction data separated by Department number.

On Department Total Report, Sales transaction report is printed depending on the date range

selection.

Example:

Printing report for Department Total Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [DEPT REPORT] key to enter to

DEPT REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data

For example:

- DATE RANGE: 29-04-10 to 29-04-10

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PRINT TYPE: TRUNK

- SORT BY: PRICE

- ORDER: ASSCENDING

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT]

key to zoom in or zoom out preview

report.

Page 64

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 63

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Department Report

Page 65

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 64

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.3 Clerk Report

Clerk Report is used to view/print transaction data separated by Clerk Number. On Clerk Report,

Sales transaction report is printed depending on the date range selection.

Example:

Printing report for Clerk Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [CLERK REPORT] key to enter to

CLERK REPORT MODE screen.

2. Select the date range and use numeric key

to entry in the number

For example:

- DATE RANGE: 29-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- CLERK RANGE: 1 to 999999

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 66

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 65

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Clerk Report

Page 67

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 66

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.4 Clerk LOG

Clerk Report is used to view/print all transaction that had done by CLERK

Example:

Printing report for Clerk LOG Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [CLERK LOG REPORT] key to enter

to CLERK LOG REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data

For example:

- DATE RANGE: 19-12-15 to 19-12-15

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- Select Printer Type [ALL]

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT]

key to zoom in or zoom out preview

report.

Page 68

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 67

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Clerk Log

Page 69

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 68

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.5 Terminal Report

Terminal Report is used to view/print transaction data separated by Terminal Number. On Terminal

Report, Sales transaction report is printed depending on the date range selection.

Example:

Printing report for Terminal Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [TERMINAL REPORT] key to enter

to TERMINAL REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 29-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PRINT TYPE: TRUNK

- TERM: 1 to 256

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 70

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 69

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample:

TERMINAL REPORT

Page 71

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 70

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.6 Store Summarized Report

Store Summarized Report is used to view/print transaction data separated by Store. On Store

Summarized Report, Sales transaction report is printed depending on the date range selection.

Example:

Printing report for Store Summarized Report (LAST 7 DAYS).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [STORE REPORT] key to enter to

STORE REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data

For example:

- DATE RANGE: 23-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 72

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 71

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Store Summarized Report

Page 73

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 72

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.7 24 Hour Report

24 Hour Report is used to view/print transaction data separated by 24 hour transaction. On 24

Hour Report, Sales transaction report is printed depending on the date range selection.

Example:

Printing report for 24 Hour Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [24 HOUR REPORT] key to enter to

24 HOUR REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data

For example:

- DATE RANGE: 29-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 74

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 73

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: 24 Hour Report

Page 75

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 74

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.8 Void Report

Void Report is used to view/print transaction data separated by Void transaction. On Void Report,

Sales transaction report is printed depending on the date range selection.

Example:

Printing report for Void Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [VOID REPORT] key to enter to

VOID REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 29-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PLU RANGE: 1 to 999999

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 76

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 75

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4.

Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Void Report (Today)

Page 77

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 76

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.9 Tax Report

Tax Report is used to view/print Label data separated by Tax. On Tax Report, Sales transaction

report is printed depending on the date range selection.

Example:

Printing report for Tax Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [TAX] key to go to Tax Report Mode

screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 19-12-15 to 19-12-15

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- TERMINAL: TERM1(--)

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 78

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 77

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Tax Report

Page 79

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 78

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.10 Queue Report

Queue Report is used to view/print Label data separated by Queue. On Queue Report, Sales

transaction report is printed depending on the date range selection.

Example:

Printing report for Queue Report (LAST 7 DAYS)

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [QUEUE] key to go to Queue Report

Mode screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 15-12-15 to 21-12-15

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PRINT TYPE: SUMMARY

- SORT BY: DAY (BRIEF)

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU Total

Report.

3. Touch [ZOOM IN] or [ZOOM OUT] key

to zoom in or zoom out preview report.

Page 80

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 79

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Queue Report (Today)

Page 81

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 80

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.11 Store Report

Store Total Report is used to view/print transaction data separated by store. On Store Total

Report, Sales transaction report is printed depending on the date range selection.

Example:

Printing report for Store Total Report (LAST 7 DAYS).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [STORE TOTAL REPORT] key to

enter to STORE REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data

For example:

- DATE RANGE: 23-05-12 to 29-05-12

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button.

- PRINT TYPE: TRUNK

- INCLUDE CLEARED TRANSACTION: NO

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU

Total Report.

3. Touch [ZOOM IN] or [ZOOM OUT]

key to zoom in or zoom out preview

report.

Page 82

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 81

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: Store Total Report

Page 83

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 82

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.12 MG Report

MG Report is used to view/print transaction data separated by MG number. On MG Report, Sales

transaction report is printed depending on the date range selection.

Example:

Printing report for PLU Total Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.

Touch [MG REPORT] key to enter to MG

REPORT MODE screen.

2. Set the printing order by touching the boxes

and select the desired data or by using the

numeric key to enter in number.

For example:

- DATE RANGE: 21-12-15 to 21-12-15

Note: Also can select by pressing

[TODAY] or [LAST 7 DAYS]

button

- PRINT TYPE: TRUNK

- SORT BY: PRICE

- ORDER: ASCENDING

- DEPT RANGE: 1 to 99

3. Touch [PREVIEW] key to view the report.

Note:

1. Touch [UP] or [DOWN] key, to view

continues of report.

2. Touch [EXIT] key to exit view PLU

Total Report.

3. Touch [ZOOM IN] or [ZOOM OUT]

key to zoom in or zoom out preview

report.

Page 84

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 83

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

OPERATION

DISPLAY

4. Touch [PRINT] key to print out the report.

Note:

1. Touch [MENU] key, to back to Menu

Mode display.

Sample: MAIN GROUP Total Report

Page 85

M o d e l S M - 5 3 0 0 U s e r M a n u a l | 84

Report Mode

–––––––––––––––––––––––––––––––––––––––––––––––––

3.2 Entry to Report Mode

3.2.13 Inventory Report

Inventory Report is used to view/print transaction data separated by Inventory. On Inventory

Report, inventory transaction report is printed depending on the date range selection. In Registration

mode use Inventory function key to select type of mode (Normal Sales, Inventory, Garbage,

Ordering and Reception) and do operation. Other than Normal Sales Mode, all other mode will

record to Inventory report.

Example:

Printing report for Inventory Report (TODAY).

OPERATION

DISPLAY

1. In REPORT GENERATOR screen.