Page 1

Service Manual

Model : SM -5100

July,2009 2nd Version

SHANGHAI TERAOKA ELECTRONIC CO., LTD

SERVICE AND SUPPORT DEPT.

3rd Floor of 2nd Building, Jia Yuan Business Center,

51# Long Wu Road, Shanghai China 200232.

TEL : +86-21-6408-5151 FAX : +86-21-6408-3468

EMAIL ADDRESS :steservice@digi-scale.com

Page 2

SM 5100 GENERAL

1. GENERAL

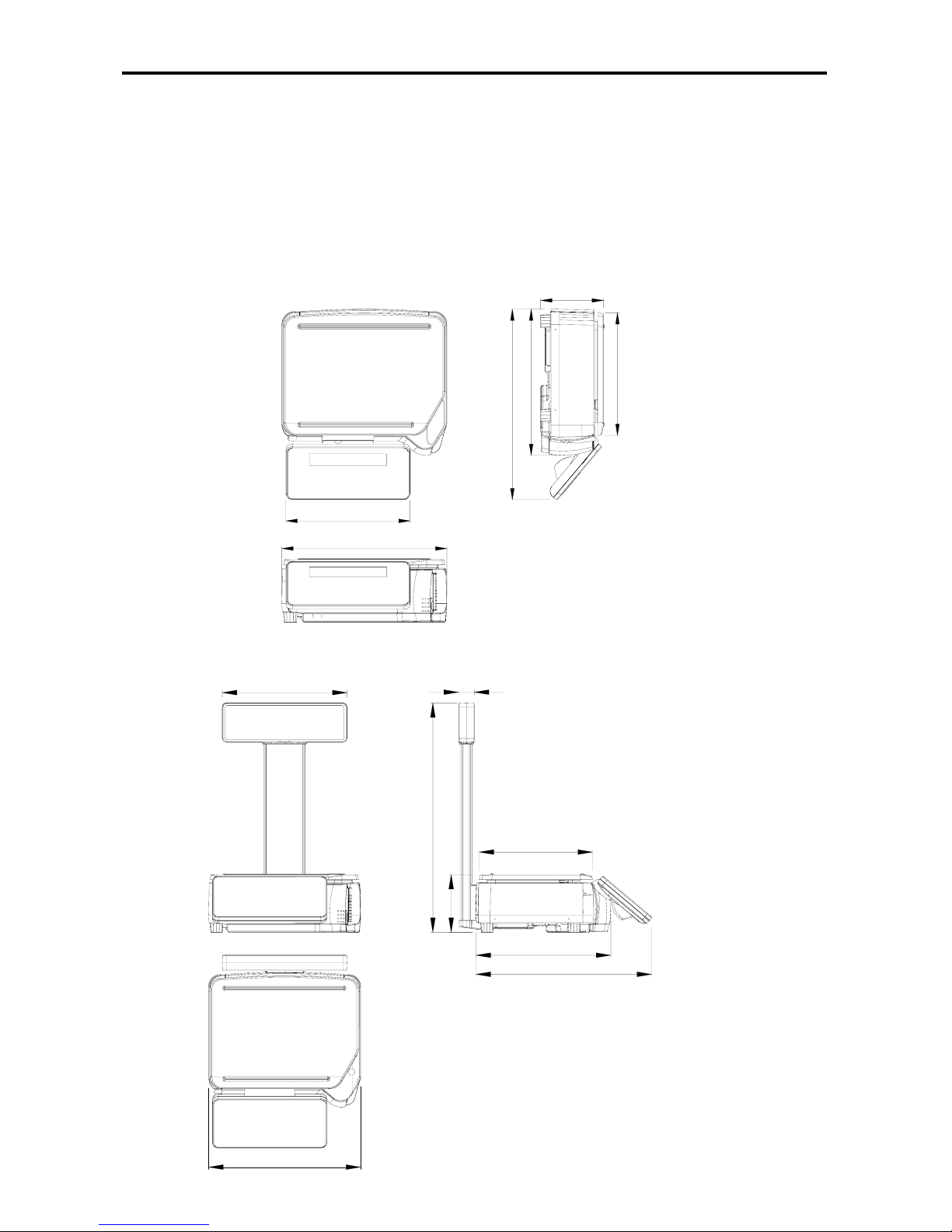

1.1 OVERALL VIEW

Bench

Pole

385

341.5

445

146.6

287

581.7

40

316

287

146.6

445

341.5

385

290

1

Page 3

SM 5100 GENERAL

Elevated

317

146.6

385

492

470

130

1.2 DISPLAY PANEL

2

Page 4

SM 5100 GENERAL

1.3 KEY PANEL

z 32 Preset Key

TOTAL PRICE

$

$/kg

UNIT PRICEWEIGHT

FIX

PLU

7C

LABEL

FIX P

NET

FIX T

ZERO

kgkg

TARE

z 56Preset Key

C

FIX

7

PLU

3

Page 5

SM 5100 GENERAL

1.4 KEY DEFINE

ON/OFF KEY

Turn display "ON" or "OFF".

PRESET KEY

P1~P32(BCS)

P1~P32(BCS+)

P1~P56(PCS)

P1~P56(PCS+)

Set up or call either unit price and tare value.

NUMERIC KEYS

0 ~ 9

Enter numeric data.

TARE KEY

Set or Clear Tare value.

Select "NO" in S and Z Mode.

Item test print in S Mode.

CLEAR KEY

C

For Back space or Clear numeric value.

Select "YES" in S and Z Mode.

RE-ZERO KEY

Reset weight to ZERO.

PREPACK KEY

AUTO

Switch Manual mode and Pre-pack mode alternatively.

(The mode status will be indicated in the P and M indicator.)

▪P - PRE-PACK MODE ▪ M - MANUAL MODE

CHANGE KEY

Calculate the Changed Amount.

Escape the Programming screen without saving data in S Mode.

4

Page 6

SM 110 GENERAL

MULTIPLLE KEY

X

Register the number of Non-Weight products.

Select programming item such as PLU data, Shop Name in S Mode.

Select Report Type in X Mode.

Select Data Transaction Type in Z Mode.

CLERK KEY

V1~V4

Accumulate the Total Price.(PCS/PCS+ version)

VOID KEY

−

Correct the sales data.

PLU KEY

PLU

Call up PLU data in R Mode.

Store the programmed data in S Mode.

FEED KEY

Feed Label or Receipt paper

PRINT KEY

Print out Label or Receipt.

MODE SELECT KEY

Five Modes can be selected using this key.

• Indicator R - REGISTRATION MODE (All the sales transactions are

performed.)

• Indicator X - CHECK MODE (Printing out and sales report.)

• Indicator S - PROGRAM MODE (Programming preset data, such as

products, data, shop name, etc.)

• Indicator Z - TOTAL MODE (Clear sales data stored.)

• Indicator X (Blink) - Password Setting Mode (Set PASS WORD for X,

S, Z mode, set PASSWORD for PASSWORD MODE when all

indicators(R, X, S, Z) blink)

8

Page 7

SM 110 GENERAL

Decrease/Increase Specification Count key

︽,︾

Decrease/Increase Only used when Setting SPEC 141 & 142

<<,>>

Select parameter data such as SPEC data. Move cursor left or right.

1.5 Indicators

z ZERO : On when zero point is adjusted and weight is stable.

z NET : On when tare subtraction is performed.

z FIX T : On when tare weight is fixed.

z FIX P : On when PLU or unit price is fixed.

z P : On when pre-pack mode is chosen; indicate capital letter is use in PLU programming.

z M : On when manual mode is chosen.

z V1 ~ V4 : On when vendor transaction entries (department entry or PLU entry) are performed.

z LABEL : On when label printing mode is chosen.

z R : On when in R (normal operation) mode.

z X : On when in X (read report) mode.

z S : On when in S (programmable item setting) mode.

z Z : On when in Z (reset report and system maintenance) mode.

1.6 FEATURES

z Digital printing scale consists of electronic cash registers function and label printing function.

z High-speed, high reliability thermal head printer.

z Easy paper handing achieved special designed mechanism.

z Built-in clock automatically updates date and time.

z Quick response to weight changes.

z Capacity : 3kg, 6kg, 12kg, 15kg, 30kg, 6lb, 12lb, 15lb and 30lb.

z Resolution : Display Resolution 1/3,000.

z : Internal Resolution 1/90,000.

z Calibrating by software.

z Customer and operator displays (optional customer pole display).

z Character type with back-light for numeric and character display.

z Matrix type with back-light for numeric and character and Chinese character display.

z 55 (bench and pole type) / 83 membrane keys

z a. ON/OFF key.

z b. 10 Numeric keys, to key in numeric data.

9

Page 8

SM 110 GENERAL

z c. 32/56 Preset keys, to preset PLU or function into the key.

z d. 23/27 Operational keys, to perform various functional operations.

z 18 data files for Department, Main Group, PLU, etc.

z Various reports.

z Ethernet function.

z Optional wireless Ethernet card.

z RS232C interface for data communication and barcode scanner connection.

z Optional cash drawer.

z Compact housing.

1.7 SPECIFICATION

1.7.1 Display

z Matrix type with back-light for numeric and character and Chinese character display.

z Tare Weight display : 4 digits.

z Weight display : 5 digits.

z Unit Price display : 6 digits.

z Total Price display : 7 digits.

1.7.2 Operating Conditions

z Power Source : AC 176V ~ 264V, 47~63Hz.

z Operating Temperature : -10 °C ~ +40 °C.

z Operating Humidity : 15% ~ 85% RH.

z Power Consumption : 0.15A.

10

Page 9

SM 5100 INITIAL SETUP

2. INITIAL SETUP

2.1 Paper Handing

Please press the button and take out the cassette to fix the paper when you need to use new

paper.

标签纸

收据纸

Cassette

Button

11

Page 10

SM 5100 INITIAL SETUP

2.2 Bubble Adjustment and SPAN Switch

Place the scale on the flat surface and adjust the

four legs until the bubble on the level is in the

centre as shown above 1

Please remove the screw and use a insulate rod

to enable the Span SW when the scale is power

on and please do not power off it.

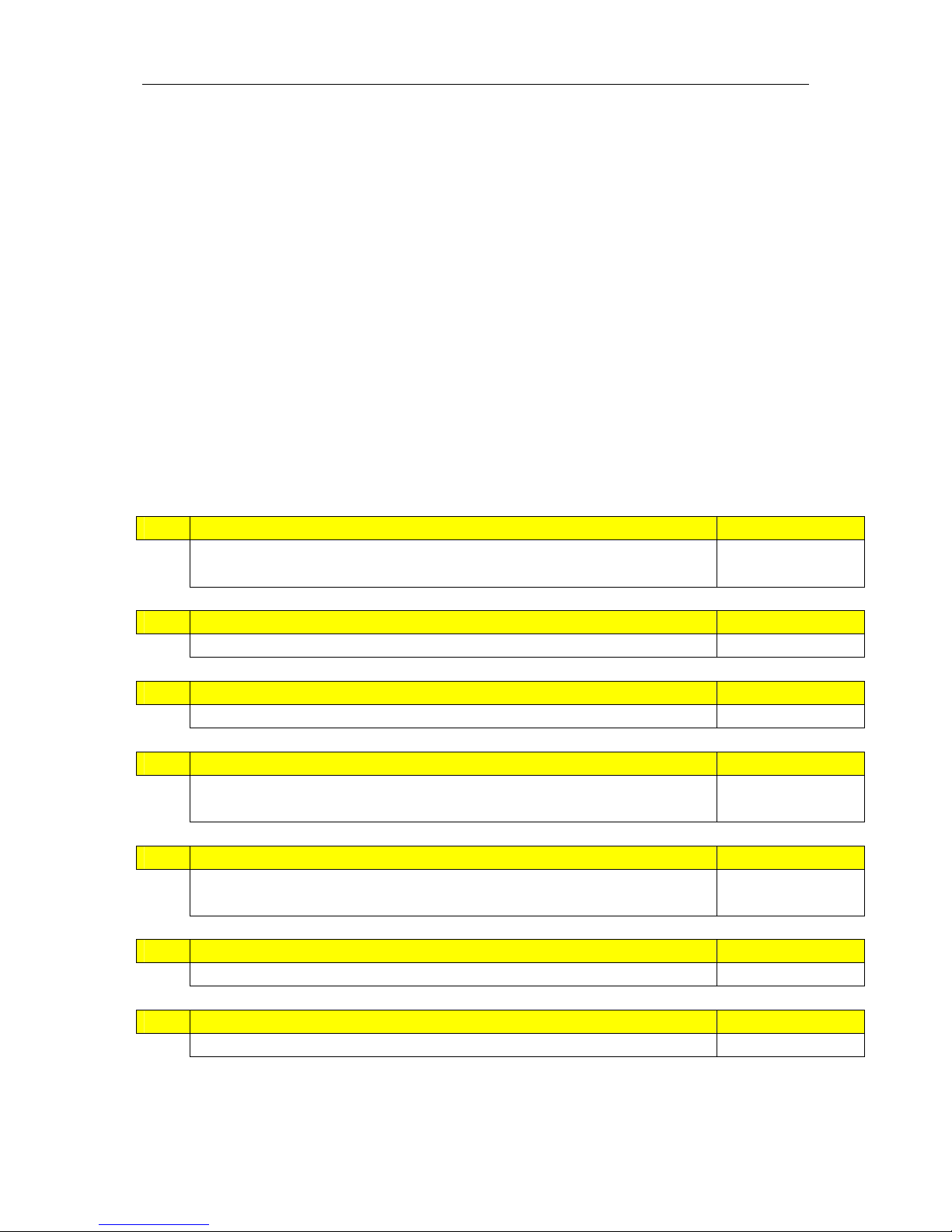

2.3 Memory Initialisation

Clear all of the memory.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Re-zero]+[2][3][0] CLEAR PLU FILE PLU file.

[︾]

CLEAR VENDER DATA

Vender transaction data.

[︾]

CLEAR REPORT FILES

Report files.

[︾]

CLEAR MEMORY DATA

All files in memory.

[*] CLEAR MEMORY Y-C N-T

[C] to clear file data,[T] to

quit.

[C] or [T] Z1.0 RESET SALES DAILY Return to Z mode.

12

Page 11

SM 5100 INITIAL SETUP

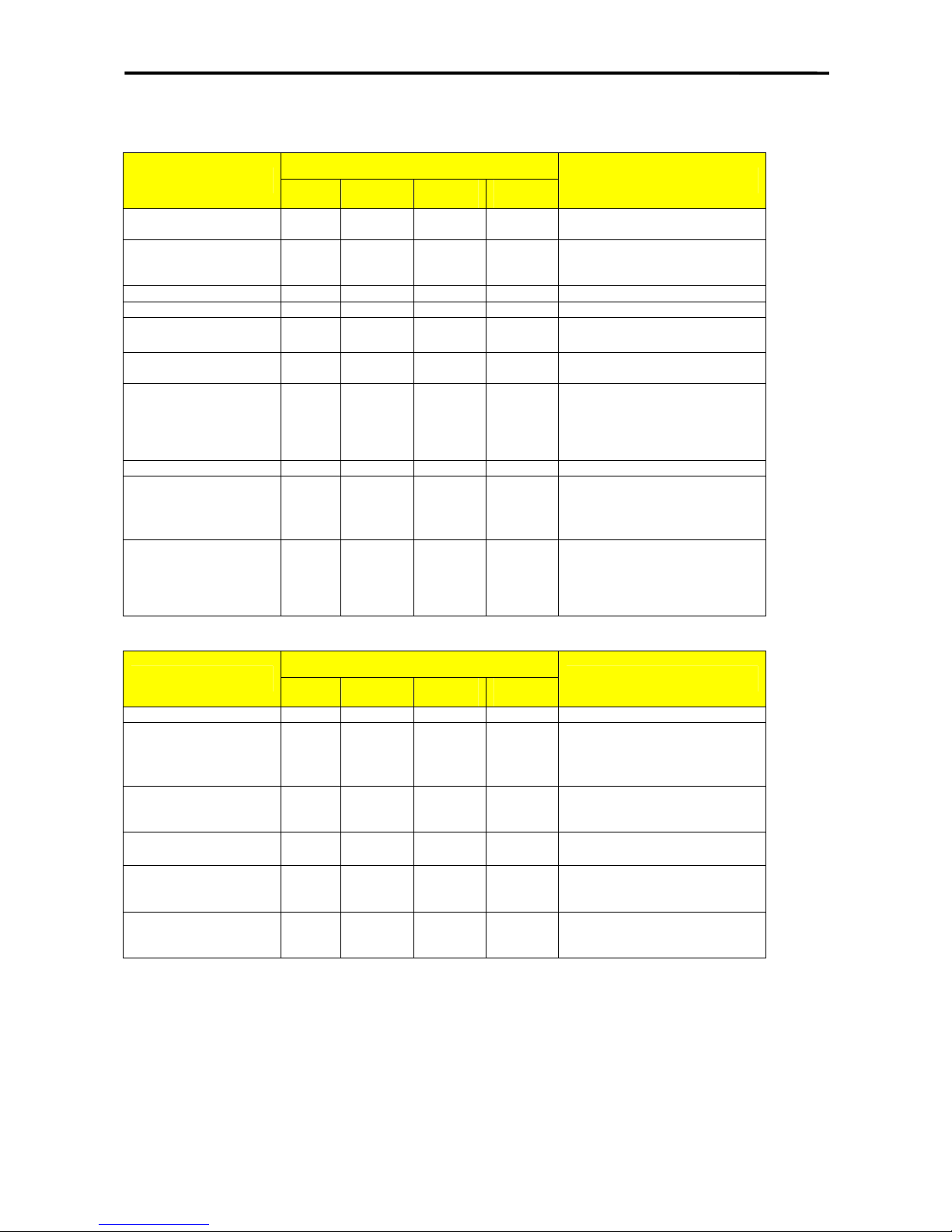

2.4 DEFAULT SPECIFICATION SETTING

Default SPEC setting of individual country.

(Please turn on the span switch before proceed this process.)

¾ Country Set

DISPLAY

OPERATION

TARE lb

$/lb

TARE

REMARK

lb

Z1.0 RESET SALES DAILY Z mode.Lamp Z turns on.

[Rezero]+[8][8][2][2] SPEC 2-STD COUNTRY Set country setting.

[>>] SPEC 1-U1 COUNTRY

[>>],[<<] or [X] to select country.[*]

to update country setting.

[*] LOAD DEFAULT SPEC Y-C N-T

[C] to load default SPEC

setting,[T] to skip.

[C] SCALE TYPE → POLE Set scale type.

[X] … [X] SCALE TYPE → BENCH

[X],[-] to select type [11] or [12]

5100B or 5100P ,[*] to update type

setting.

[*] SCALE CAP. → 3KG Set scale capacity.

[X] SCALE CAP. → 15lb

[X],[ - ] to select capacity,[*] to

update capacity setting.

[*] SCALE RES. → 1/3000S Set resolution.

[X] SCALE RES. → 1/3000M

[X],[- ] to select resolution,[*] to

update resolution setting.

[*] CLEAR MEMORY Y-C N-T [C] to clear memory,[T] to skip.

[C] Z1.0 RESET SALES DAILY Return to Z mode.

Note 1:

For the first using of SM-5100, please take this operation for initialization.

Note 2: Enter a number that represent a country in the country list (refer to the table below)

to initialise and country set.

13

Page 12

SM 5100 INITIAL SETUP

COUNTRY LIST

No. Country Code Country No. Country Code Country

0 AA Japan 41 SA Saudi Arabs

1 U1 U.S.A. 42 IC Iceland

2 STD Standard 43 IE Indonesia

3 CN China 44 CB Cuba

4 HK Hong Kong 45 KY Kenya

5 TW Taiwan 46 IR Israel

6 EX Export 47 VY Slovenia

7 KE Korea 48 MS Malaysia

8 AR Australia And New Zealand 49 SN Spain

9 SF South Africa 50 VZ Venezuela

10 CS Cyprus 51 CO Croatia

11 GC Greece 52 MA Macedonian

12 TU Turkey 53 FR France

13 CV Czech Republic 54 WG Germany

14 HG Hungary 55 BL Bulgaria

15 PL Poland 56 BW Botswans

16 UR Russia 57 CP Comores

17 AS Austria 58 LS Lesotho

18 DM Denmark 59 MU Mauritius

19 FL Finland 60 MW Malawi

20 NW Norway 61 MZ Mozambique

21 SD Sweden 62 NM Namibia

22 PG Portugal 63 RE Reunion

23 UK United Kingdom 64 SH Seychelles

24 IL Ireland (Kg) 65 SW Swaziland

25 IL (LB) Ireland (Lb) 66 WZ Zimbabwe

26 CA Canada (Kg) 67 ZW Zambia

27 CA (LB) Canada (Lb) 68 AE U.A.E

28 AG Argentina 69 TT Trinidad and Tobago

29 MX Mexico 70 UD Uganda

30 BZ Brazil 71 LV Latvia

31 CE Chile 72 CVS Slovakia

32 EA Egypt 73 SK Sri Lanka

33 JD Jordan 74 SV Slovenia

34 LN Lebanon 75 UA Ukraine

35 IRN Iran 76 KZ Kazakhstan

36 CR Canary Islands 77 IT Italy

37 TL Thailand 78 SZ Switzerland

38 EC European Community 79 ID India

39 NL Netherlands 80 CD New Caledonia

40 BG Belgium

14

Page 13

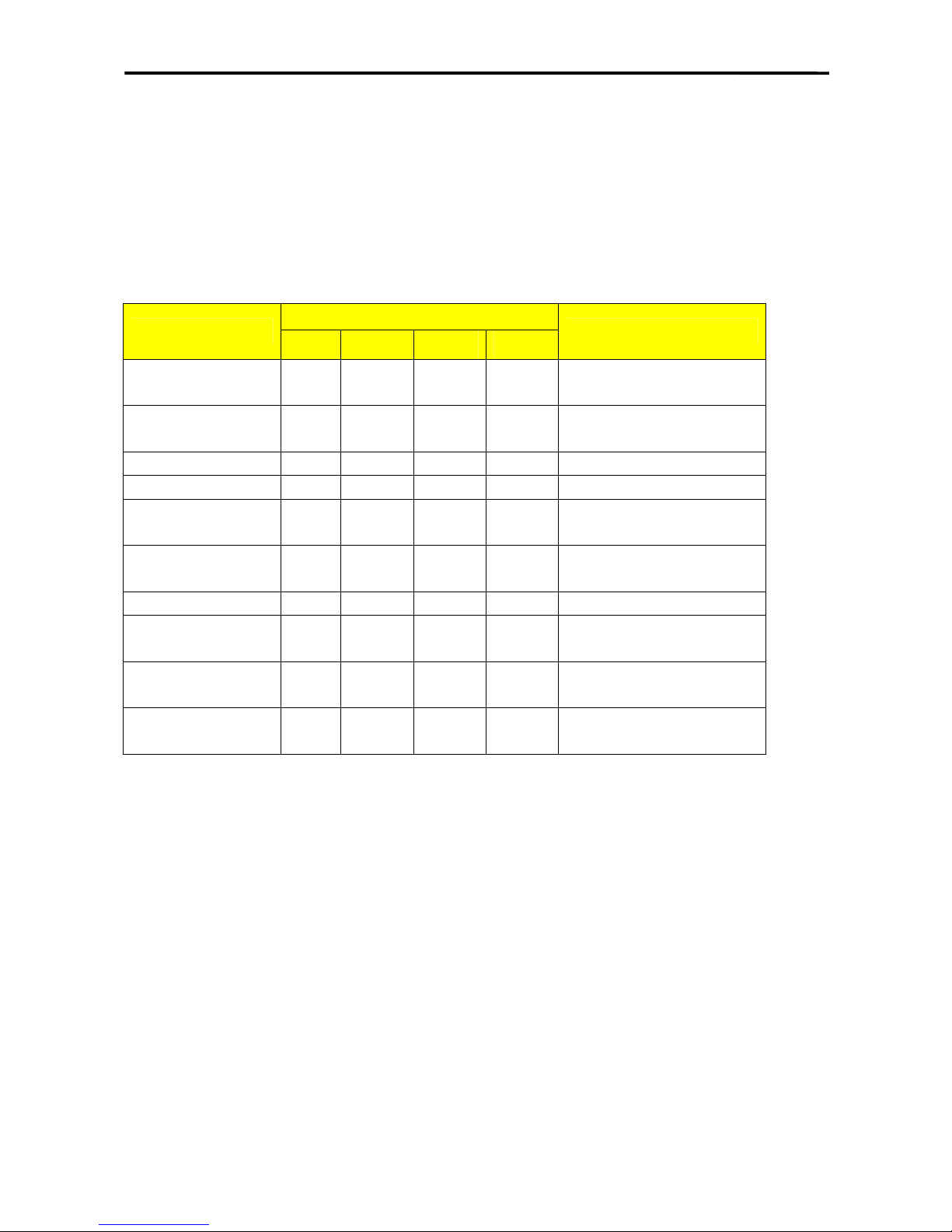

SM 5100 CALIBRATION

3. CALIBRATION

Prior to Calibration, please refer that the specification indicating weight capacity, minimum

graduation, and load cell sensitivity are correctly set.

Caution:

z It can only work when SPAN SWITCH is on (ENABLE).

Before Calibrating, please enter Z mode.

3.1 CALIBRATION OPERATION

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Press SPAN

SWITCH

Z1.0 RESET SALES DAILY

SPAN SWITCH is on

(ENABLE).

[Rezero]+[8][7][1][5] CAL 00

Enter [8][7][1][5] while

depressing [Rezero].

Ensure no weight on

platter,[*]

------

Calibrating zero point.

After storing the zero

Point ‘IR’ count

CAL SP

Put full capacity

weight on platter.[*]

------

Calibrating Span.

After calibration Z1.0 RESET SALES DAILY

Go back to Z mode. Lamp Z

always light.

15

Page 14

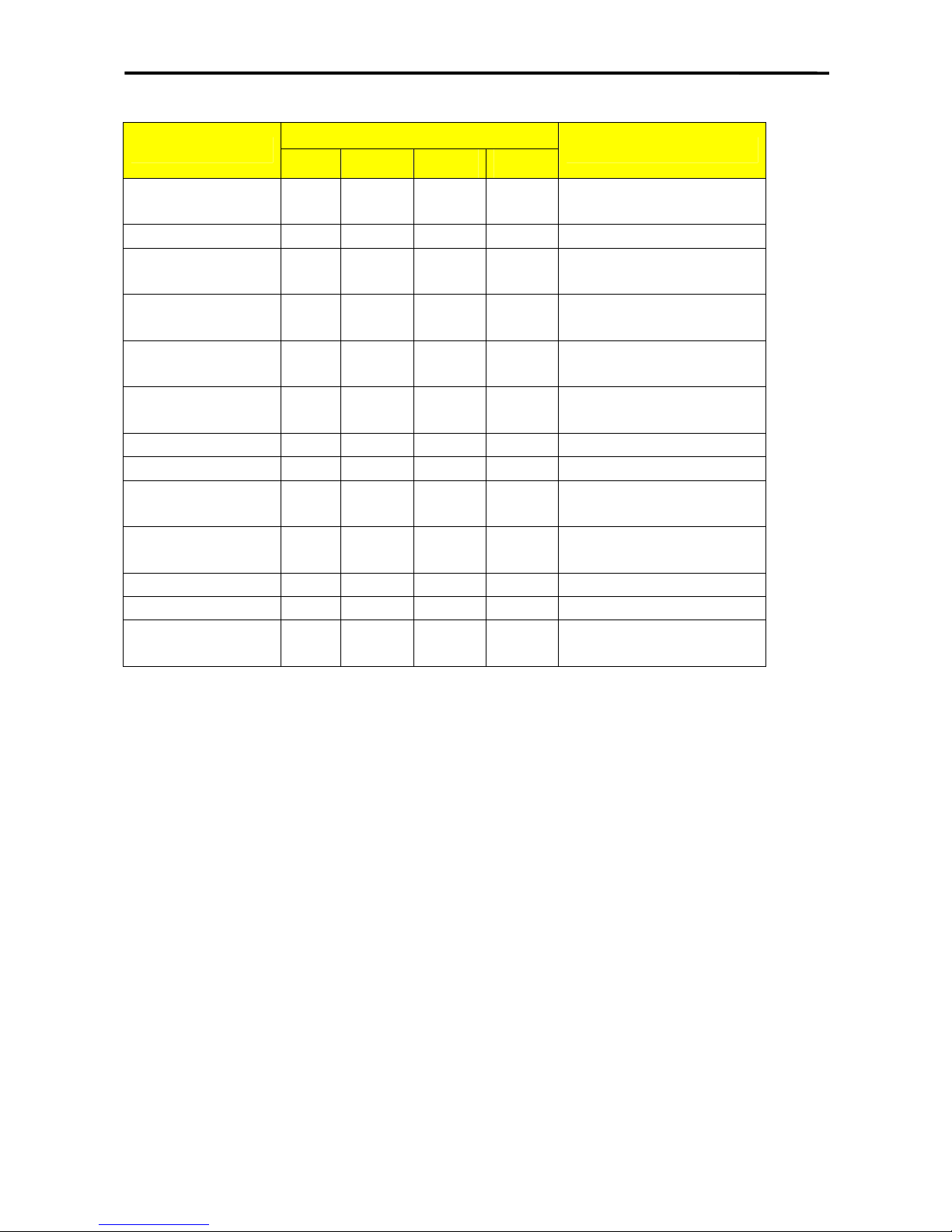

SM 5100 CALIBRATION

3.2 EXIT CALIBRATION

DISPLAY

OPERATION

TARE lb

$/kg

TARE

REMARK

lb

Press SPAN

SWITCH

Z1.0 RESET SALES DAILY

SPAN SWITCH is

on(ENABLE).

[Rezero]+[8][7][1][5] CAL 00

Enter [8][7][1][5] while

depressing [Rezero].

[T] Z1.0 RESET SALES DAILY

Escape to Z mode. Lamp Z

always light

[Rezero]+[8][7][1][5]

[*]

CAL 00

------

The ‘IR’ count will be taken

as the zero point ‘IR’ count.

After storing the zero

Point ‘IR’ count

CAL SP

Calibrating Span.

[T] Z1.0 RESET SALES DAILY

Escape to Z mode. Lamp Z

always light.

16

Page 15

SM 5100 SOFTWARE SETTING

4 SOFTWARE SETTING

4.1 SOFTWARE VERSION UPGRADE

Update Method Introduction

SM-5100 use flash RAM instead of EPROM for the main program storage of the scale.

Our boot program is above Version 2.00, we have two method to update the scale’s

software: update the scale by Ethernet or RS-232 So you can choose either method

between these two ones to update your scale.

Now we will set two parts to introduce the steps of these two updating methods.

Update Steps Introduction

1. Ethernet Update Method

1. Cable & Connection

There are also two ways to connect the PC and the scale in updating the scale by

ethernet.

1) PC to Scale

2) Connect by Hub

17

Page 16

SM 5100 SOFTWARE SETTING

These two twisted cable obey the EIT/TIA 568 standard.

T568B line series

1 Orange & White

2 Orange

3 Green &White

4 Blue

5 Blue & White

6 Green

7 Brown & White

8 Brown

T568A line series

1 Green &White

2 Green

3 Orange & White

4 Blue

5 Blue & White

6 Orange

7 Brown & White

8 Brown

crossing twisted cable: one end with T568A line series, another with T568B line

series

normal twisted cable: two ends both with T568B line series

2 .PC Setting & Programmer Version

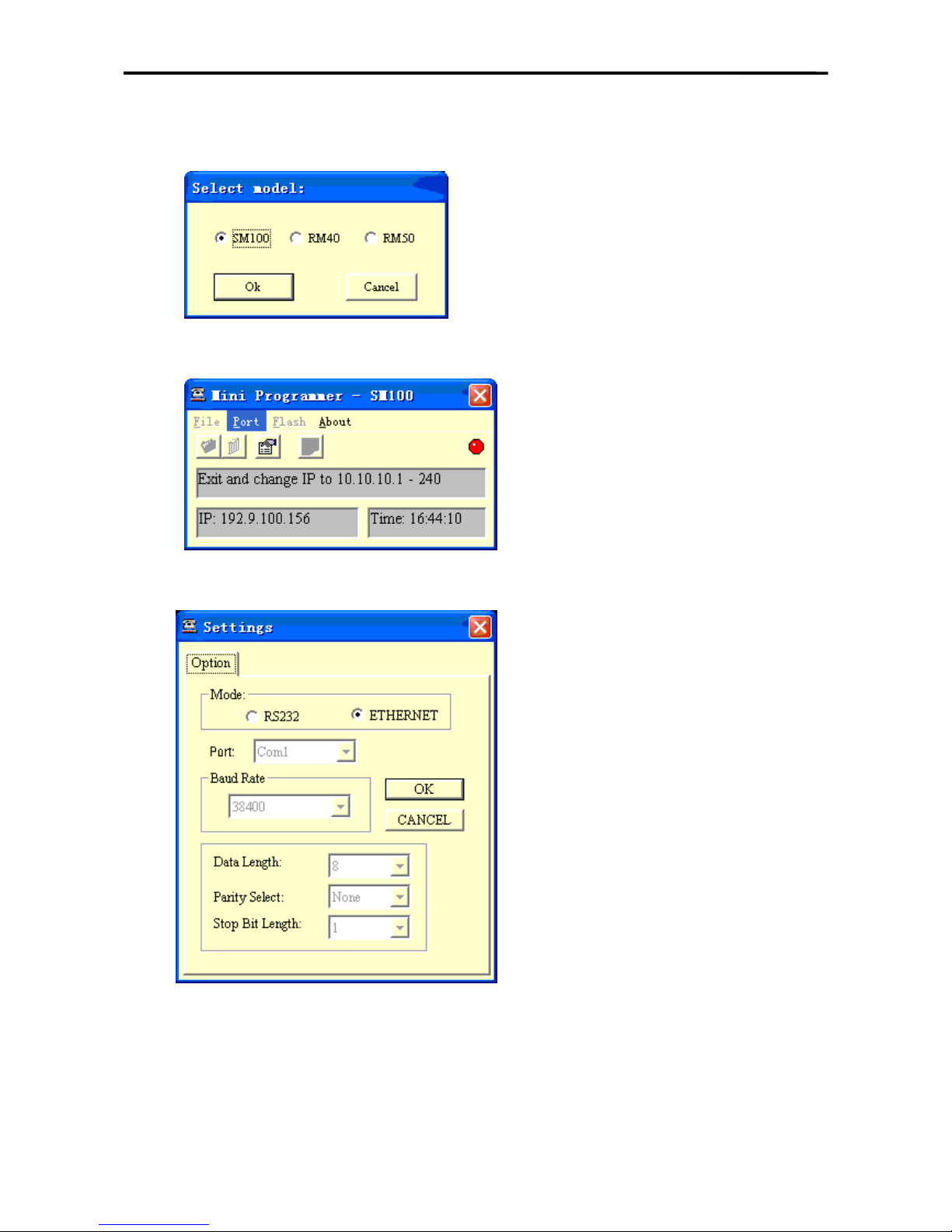

We use “Mini Programmer (Version 2.00)” as the tool to update the scale. As it

needs a default visual IP address for the PC by this kind of update method, You must

set your PC’s IP address within the range of 10.10.10.1-----10.10.10.240, before you

start the software to update the scale.

If you don’t set the IP address like this, you can see an alarm window as Pic. 1 when

you start “Mini Programmer”.

Pic. 1

2. Updating Steps

1) How to start ethernet updating?

A. Turn on the switch on the bottom of the scale.

B. Power off the scale by pressing On/Off Key.

C. After that, press and hold [Re-Zero] and [Preset 22], then start the scale by

pressing the On/Off Key.

D. The screen will display the version of the current boot program for two seconds.

E. Only in new versions(version of the boot program newer than 1.10), you

can choose 2-ethernet.

2) Display on the scale’s screen

A. If you choose 2 and the scale’s connection is correct, it will display “waiting for

connect”.

B. Then the message on the scale’s screen is “getting IP address”.

C. After this, it will display “001 scale ready update”.

D. You can’t stop it unless you press On/Off key. If you want to continue

updating. You also don’t need to press any key on the scale until Mini

Programmer begin to run.

18

Page 17

SM 5100 SOFTWARE SETTING

3) How to upload the scale by Mini Programmer?

A. Select SM-5100 and press “ok”

B. Set the port

Select “ethernet” and press “OK”

19

Page 18

SM 5100 SOFTWARE SETTING

C. Download boot program and update the scale

Select menu “

File->Load File To Programmer Buffer”

Open the source file of boot program (SM100+_Bv200.hex)

You can see a speed mode select window here.

Select menu “Flash->Program”

20

Page 19

SM 5100 SOFTWARE SETTING

Notice: The message “001 scale ready update” must be displayed on the

screen of the scale before pressing the “run” button.

After the transmission has completed, select menu “File->Clear Buffer”.

Notice: 1.If the boot program of this version is already in the scale, you don’t

need to upload it again, skip it and upload the main program.

2.If the scale is updated from 1.xx to 2.xx,firstly you must update the

boot program of the version.

D. Download main program file

You must power off the scale and start the ethernet upload method again when

you have finished a program uploading.

The steps of uploading the main program file is also like uploading the boot

program file. The file you need to open is like Pic. 2

Pic. 2

21

Page 20

SM 5100 SOFTWARE SETTING

E. Download word-stock file

The steps of uploading the word-stock file is also like uploading the boot program

file. The file you need to open is like Pic. 3

Pic. 3

F. Download const text file

The steps of uploading the const text file is also like uploading the boot program.

The file you need to open is like Pic. 4

Pic. 4

G. Exit Mini Programmer

Note: please update the scale according to sequence above.

22

Page 21

SM 5100 SOFTWARE SETTING

4.3 RS232C Method

3. Cable Connection

3 Pins are used for data transmission between PC and SM-5100

9 Pin D-Sub Female Connectors for this cable:

PC Serial Port SM-5100 RS-232C

9 Pin D-Sub (Female) 9 Pin D-Sub (Female)

Pin Signal Signal Pin

1 N.C. N.C. 1

2 RXD RXD 2

3 TXD TXD 3

4 N.C. N.C. 4

5 GND GND 5

6 - 9 GND N.C. 6 - 9

4. Update Steps

1) How to start RS232C updating

A. Turn on the switch on the bottom of the scale.

B. Power off the scale by pressing the On/Off Key.

C. After that press and hold [Re-Zero] & [Preset 22], then start the scale by press

ing the On/Off Key.

D. It will display the version of the current boot program for two seconds.

E.

¾ If the scale boot version is newer than 1.10, it will display a updating method

choice like “1-RS232 2-ETHERNET” on the screen. you can press Numeric 1

to choose 1-RS232C.

¾ If the boot version is older than 1.10, the scale will not display the choice.

F. Then the Scale will display “PROGRAM”. You can’t stop it, unless you press

Tare or On/Off Key.

2) Start Mini Programmer

23

Page 22

SM 5100 SOFTWARE SETTING

1. Select SM-5100 and press “Ok”

2. Set the Port:

Select RS232 and press “OK”

3. Download the boot program and update the scale

Select menu “File->Load File To Programmer Buffer”

24

Page 23

SM 5100 SOFTWARE SETTING

Open the source file of the boot program (e.g. sm100bv100.hex)

Select menu “Flash->Program”

Notice: The message “001 scale ready update” must be displayed on the

scale before pressing the “run” button.

25

Page 24

SM 5100 SOFTWARE SETTING

After the transmission has completed, select menu “File->Clear Buffer”.

Notice: If the boot program of this version is already in the scale, you don’t

need to upload it again, skip it and upload the main program.

26

Page 25

SM 5100 SOFTWARE SETTING

4. Download main program file

You must power off the scale and start the ethernet upload method again when

you have finished a program uploading.

The steps of uploading the main program file is also like uploading the boot

program file. The file you need to open is like Pic. 2

Pic. 2

5. Download word-stock file

The steps of uploading the word-stock file is also like uploading the boot program

file. The file you need to open is like Pic. 3

Pic. 3

6. Download const text file

The steps of uploading the const text file is also like uploading the boot program.

The file you need to open is like Pic. 4

27

Page 26

SM 5100 SOFTWARE SETTING

Pic. 4

7. Exit Mini Programmer

4.2 SPECIFICATION SETTING

Before Specification setting, please press the mode button to enter Z mode.

The detail specification list , please see the appendix.

4.2.1 Customer SPEC Setting

To change setting of the Customer SPEC if there are some SPEC setting in it need to be alter.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[1][4][1]

SPEC

000

XXX

(setting)

XXX

(former)

Enter [1][4][1] while depressing

[Rezero].

XXX:SPEC data

[︾]

SPEC

001

XXX XXX

[︾]key only increase specification

count, it does not update SPEC

data.

[︽]

SPEC

000

XXX XXX

[ ︽ ]key only decrease

specification count, it does not

update SPEC data.

[1][7]

[X]

SPEC

000

017

XXX

XXX

XXX

It goes to a designed specification

count.

28

Page 27

SM 5100 SOFTWARE SETTING

SPEC

017

(000~441 is enabled)

[>>]

SPEC

017

XXX XXX

[>>] key select SPEC data.

Move cursor right.

[<<]

SPEC

017

XXX XXX

[<<] key select SPEC data.

Move cursor left.

[1]

[*]

SPEC

017

SPEC

018

001

XXX

XXX

XXX

[C]

SPEC

018

000 XXX

Clear the enter data.

[PLU]

* Note 1

Z1.0 RESET SALES DAILY

Store the updated specification

and escape to Z mode.

* Remark: The Weight in the display window will display the SPEC number. The Unit

Price window will display the new value setting entered. The Total Price

window will display the old value setting. The selection you have made will

be highlighted in the dot matrix display. Please use [︾] to increase spec

count, [︽] to decrease spec count, [*] to store a new value and [PLU] to save

spec setting.

4.2.2 Weight & Measurement SPEC Setting

To change the setting of the Weight & Measurement SPEC if there are some SPEC need to alter.

(Please turn on the span switch when using this process)

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Press SPAN

SWITCH

Z1.0 RESET SALES DAILY SPAN SWITCH is on(ENABLE).

[Rezero]+[1][4][2]

SPEC

600

XXX

(setting)

XXX

(former)

Enter [1][4][2] while depressing

[Rezero].

XXX:SPEC data

[︾]

SPEC

601

XXX XXX

[︾]key only increase specification

count, it does not update SPEC

data.

[︽]

SPEC

600

XXX XXX

[ ︽ ]key only decrease

specification count, it does not

update SPEC data.

[6][1][5] SPEC 615 XXX It goes to a designed specification

29

Page 28

SM 5100 SOFTWARE SETTING

[X] 600

SPEC

615

XXX XXX count.

(600~709 is enabled)

[>>]

SPEC

615

XXX XXX

[>>] key select SPEC data.

Move cursor right.

[<<]

SPEC

615

XXX XXX

[<<] key select SPEC data.

Move cursor left.

[1]

[*]

SPEC

615

SPEC

616

001

XXX

XXX

XXX

[*] key to update specification,

increase specification count.

[2]

SPEC

616

002 XXX

[C]

SPEC

616

000 XXX

Clear the enter data.

[PLU]

* Note 1

Z1.0 RESET SALES DAILY

Store the updated specification

and escape to Z mode.

Note 1: If press [T] key, it does not store the updated specification and escape to Z mode.

* Remark: The Weight in the display window will display the SPEC number. The Unit

Price window will display the new value setting entered. The Total Price

window will display the old value setting. The selection you have made will

be highlighted in the dot matrix display. Please use [︾] to increase spec

count, [︽] to decrease spec count, [*] to store a new value and [PLU] to save

spec setting.

30

Page 29

SM5100 INTERFACE

5. INTERFACE

5.1 PC INTERFACE

SM 5100 can be connect to PC through Ethernet interface and RS232C. See below for the

connection method.

CONFIGURATION OF PC ETHERNET CARD

Window version client driver

Any Ethernet cards can be used for PC running the Window version client driver

Windows 98

My Computer → Control Panel → Network→TCP/IP of Ethernet card (Select

Properties)

IP address : 192.168.1.XXX ------ XXX - can be any number. But preferable 100 to 255.

Submask : 255.255.255.0

Above IP address is use as a standard address to use for SM 5100 Ethernet

communication.

If whatever reason, the IP address had to be change, it may do so. But the scale IP address

had to be change at the SM 5100 scale also so that they are within the same network. Eg. If

the computer IP address is 192.168.1.XXX, the SM 5100 scale IP address has to be change

to 192.168.1.XXX. The last three digits of the IP address should not be similar within the

computer and scales at all time. As can see the first three set of number of the IP address of

the computer and scale must be the same.

31

Page 30

SM5100 INTERFACE

Before setting the SPEC setting of the scale, please check below.

5.2 SCALE ETHERNET ADDRESS

The main board have a Scale Ethernet Address that is set during production. This address

is a hardware setting for Ethernet communication. But when changing a new main board,

the new main board did not have any this address. If the scale is using Ethernet

communication, a Scale Ethernet Address is needed apart from software IP address.

Please take note that the Scale Ethernet Address can only input once after saving. Please

view and note down the Scale Ethernet Address of the old main board before changing the

new main board. Below procedure is to view and input the Scale Ethernet Address. Please

turn on the span switch before proceed.

KEY TO PRESS DISPLAY OPERATION

TARE lb

$/lb $

Go to Z mode Z1.0 RESET SALES Daily At Z mode

[REZERO] +

[0][6][1][2]

ETHER NET ……. ……. Viewing of Ethernet

address For new main

board, it can act as input

of the address if the

address shown ……..

Else it would not let you to

input

.

[0][0][0][6][C][0]

[0][0][0][0][2]

[4]

ETHER NET 0006C 0000024 For input only. Enter

Ethernet address e.g.

0006C 0000024

[PLU] Z1.0 RESET SALES Daily Save address and escape

to Z mode. After saving it

will not be able to input

again.

[T] Z1.0 RESET SALES Daily Escape to Z mode without

saving.

Power off the

scale

Turn off the power and do

the memory clear

process.

* IMPORTANT : Please take note that this is a one time setting. It cannot be change after

setting it. Please check the old address and input accordingly. As same

internal Ethernet address in a network may conflict during

communication.

32

Page 31

SM5100 INTERFACE

5.3 SCALE IP ADDRESS

This is to set the IP address for PC communication using Ethernet for specific IP address. It

should not be confused with the Scale Ethernet Address as above. The Scale Ethernet

Address is mainly for hardware and Scale IP Address is for software. The software when

communicating to the scale must specify the same IP address on the scale else it will give

error. The default is 192.168.000.000 where the last three digit will change when SPEC 135

change. Please turn on the span switch before proceed.

KEY TO PRESS DISPLAY OPERATION

TARE lb

$/lb $

Go to Z mode Z1.0 RESET SALES Daily At Z mode

[REZERO] +

[0][4][1][6]

SCALE IP ……. ……. Input or viewing of IP

address

[1][9][2][1][6][8]

[0][0][1][0][1][6]

SCALE IP 192168 001016 Enter IP address e.g.

192.168.001.016

( The last 3 digits cannot

be input as it will change

when SPEC 135 change)

[PLU] Z1.0 RESET SALES Daily Save address and escape

to Z mode

[T] Z1.0 RESET SALES Daily Escape to Z mode without

saving.

33

Page 32

SM5100 INTERFACE

5.4 CONNECTION METHOD

5.4.1 RS232C Interface with PC

PC Scale

Com 1 / Com 2 RS232C Port

* Note : Only 1 scale can be connect in this method.

SPEC setting on scale :

SPEC 48 Scale number (For 4 line / RS232C port)

Enter number between 1 to 999,999

SPEC 51 Baud rate for SIO (RS232C port)

0 1200 2 4800 4 19200

1 2400 3 9600 5 38400

6 76800

SPEC 52 Data length for SIO (For RS232C port)

0 7 bit 1 8 bit

SPEC 53 Parity for SIO (For RS232C port)

0 None 1 Odd 2 Even

SPEC 54 Stop bit for SIO (For RS232C port)

0 1 bit 1 2 bits

34

Page 33

SM5100 INTERFACE

5.4.2 Ethernet Connection (Ethernet Interface)

Scale #1 Scale #2 Scale #3 Scale #4

Scale #5

PC

HUB

SPEC setting on scale :

SPEC 49 CLIENT / SERVER INTERFACE

0 No interface 3 Not used

1 Ethernet - Coaxial Cable 4 4 lines, RS485 (For future use)

2 Ethernet - Twisted Cable

SPEC 50 CLIENT / SERVER

0 Client 2 Back-up server

1 Server / Workstation

SPEC 135 PORT NUMBER

* Enter number from 1 to 254

35

Page 34

SM5100 INTERFACE

5.5 WIRE CONFIGURATION

5.5.1 Ethernet Wire - Straight Cable and Crossover Cable

Straight cable is for Client / Server connection. Crossover cable is for Hub to Hub

connection. (Some models of the hub do not need crossover cable for hub to hub

connection. Please refer to the hub operation manual if in doubt)

Telephone Modular Plug (Category 5) -

Preferable type : CviLux CJP3 / CviLux CJP4 (with insert bar)

CABLE TYPE -

Cable type : 4 pair 100MHz Cat.5 AWG 24 or 26 UTP / FTP / STP.

Preferable type : Cat. 5 AWG 24 or 26 FTP / Cat. 5 AWG 24 or 26 STP

(Recommended for CISPR 22B conformance)

PIN CONFIGURATION

1 8

SM 5100 HUB

8 1

Solder to braid wire of the Ethernet

wire if using plug without insert bar

1 8

SM 5100 HUB

8 Solder the braid wire of the Ethernet 1

wire if using plug with insert bar

STRAIGHT CONNECTION CROSSOVER CONNECTION

SCALE HUB HUB HUB

PIN SIGNAL SIGNAL PIN PIN SIGNAL SIGNAL PIN

1 TX+ TX+ 1 1 TX+ TX+ 3

2 TX- TX- 2 2 TX- TX- 6

3 RX+ RX+ 3 3 RX+ RX+ 1

6 RX- RX- 6 6 RX- RX- 2

5,7,8 N.A. N.A. 5,7,8 5,7,8 N.A. N.A. 5,7,8

36

Page 35

SM5100 INTERFACE

5.5.2 RS232C Wire

PC (9 PIN) TO SCALE RS232C PORT

5.5.3 Cash Drawer Connector

SM-5100 uses normal phone mike plug to connect cash drawer and the scale.

Plug in the scale Connector of Cash Drawer

Pin Output

Input Pin

1 Not used.

Not used 1

2 + 8 V

Voltage + 2

3 GDD

GDD 3

4 Not used.

Not used 4

RS-232 PC

Pin

输出 输入

Pin

1

Not used

Not used 1

2 RXD TXD 2

3

TXD

RXD 3

4 DTR Not used 4

5 GND GND 5

6 DSR Not used 6

7 DTR Not used 7

8 DSR Not used 8

9 Not used

Not used 9

PC COM Port(9 Pin) RS232C Port(9 Pin)

4 pin

1 pin

1 pin

4 pin

37

Page 36

SM 5100 MISCELLANEOUS

6. MISCELLANEOUS

6.1 MODE CHANGE

To toggle between R, X, S, Z and Password mode.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

0.000 0.000 0.00 0.00 Weight mode. Lamp R turns on.

[MODE],[MODE]

(within 3 seconds)

XMODE

Enter X mode. Lamp X turns on.

[MODE] S1 → PLU FILE Enter S mode. Lamp S turns on.

[MODE] Z1.0 RESET SALES DAILY Enter Z mode. Lamp Z turns on.

[MODE] PWD X 0 SET

Enter Password Set mode. Lamp

X flicker

[MODE] 0.000 0.000 0.00 0.00

Back to Weight mode. Lamp R

turns on.

* The “X ” mark on the X, S, Z and R mean the indicator light is on. When in Password mode,

the indicator light will be blinking.

** The scale goes back to R mode as normal when the net weight is 0.

***If the scale weight is not equal to 0, error message "E18 PLEASE REMOVE WEIGHT" is

displayed.

1) There is some items on the platter. The scale will go back to R mode if the item is removed.

2) There is nothing on the platter, but the net weight is not equal to 0.

The operator has to press [Rezero] key manually (Tare will auto clear when rezero), then the scale

will go back to R mode if rezero operation is successful.

6.2 SPAN SWITCH STATUS

Check the status of span switch.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Go to Z mode Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[2][8][4] STE16 VX.XX S-OFF

Enter [2][8][4] while depressing

[Rezero].

Z1.0 RESET SALES DAILY Exit after 3 seconds.

38

Page 37

SM 5100 MISCELLANEOUS

6.3 CLEAR ALL PLU DATA

To clear all the PLU data only, the span switch status must be on.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Go to Z mode Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[2][3][0] CLEAR PLU FILE

Enter [2][3][0] while depressing

[Rezero].

* CLEAR PLU Y--C N--T Enter C for Yes, Enter T for No..

C(T) Z1.0 RESET SALES DAILY Back to Z mode

6.4 THERMAL HEAD USAGE

To check how many times the thermal head had been printing.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][8][2][3]

PRINTE

R

USAGE 5

Display thermal printer usage

condition(meter).

[T] Z1.0 RESET SALES DAILY [T] key to exit.

6.5 IP ADDRESS

To check and modify the scale IP address.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1][6] Scale IP

192168

00

000

Display the scale IP address.

[1][9][2][0][0]

[9][1][0] [0]

Scale IP

192009

10

000

Modify the IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

39

Page 38

SM 5100 MISCELLANEOUS

6.6 SERVER IP ADDRESS

To check and modify the server IP address.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1][7] SERVER IP

2552552

5

5000

Display the server IP address.

[1][9][2][0][0]

[9][1][0] [0]

SCALE IP

1920091

0

0000

Modify the server IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

6.7 SUBNET MASK

To check and modify the subnet mask.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0

RESE

T

SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1]8] SERVER IP

2552552

5

5000

Display the server IP address.

[1][9][2][0][0]

[9][1][0] [0]

SCALE IP

1920091

0

0000

Modify the server IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

6.8 MAC ADDRESS

To check the MAC address.

Please turn on the span switch before proceed.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][6][1]2]

ETHERN

ET

0006C07

1

96BE

Display the

MAC address.

[T] Z1.0 RESET SALES DAILY Press [T] key to exit.

40

Page 39

SM 5100 MISCELLANEOUS

* It can only work when SPAN SWITCH is on (ENABLE).

Before Calibrating, please enter Z mode.

6.9 SERIAL NO.

To check the serial NO.

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[1][1][1] SCALE S/N 05386686 Display the serial NO..

[T] Z1.0 RESET SALES DAILY Press [T] key to exit.

6.10 ASCII CHARACTER

Below are the common use of characters of ASCII code in HEX value. Please enter the

hex value when entering commodity name, advertisement, shop name, clerk name,

special message, ingredient, text etc. when using the SM-5100.

A B C D E F G H I J K L M

41 42 43 44 45 46 47 48 49 4A 4B 4C 4D

N O P Q R S T U V W X Y Z

4E 4F 50 51 52 53 54 55 56 57 58 59 5A

a b c d e f g h i j k l m

61 62 63 64 65 66 67 68 69 6A 6B 6C 6D

n o p q r s t u v w x y z

6E 6F 70 71 72 73 74 75 76 77 78 79 7A

0 1 2 3 4 5 6 7 8 9 ! @ #

30 31 32 33 34 35 36 37 38 39 21 40 23

$ % ^ & * ( )

: ; " '

+ <

24 25 5D 26 2A 28 29 3A 3B 22 27 2B 3C

> = / ?

·

,

Spac

3E 3D 2F 3F 2E 2C 20

41

Page 40

SM5100 ERROR MESSAGE

7. SM5100 ERROR MESSAGE

The machine beeps and following error messages appear on display, if

incorrect operation is performed.

No. Error Message Cause

1 PAPER END

Label sensor sense no label. No more labels.

Replace label roll

2 FEED PAPER FIRST Label miss feed, press FEED key to align label.

3 PEEL LABEL Peel sensor activated, remove label away from sensor.

4 CHANGE PAPER Change paper mode between label and receipt.

6 NON PRINT No manual printing.

7 UNIT PRICE OVERFLOW Please check unit price.

9 NON LABEL

No free format is programs. Set a free format or

use standard format.

12 MEMO NOT INITIALIZED Memory problem. Please clear the memory.

14 HEAD IS NOT CLOSED Thermal head no closed. Please close thermal head.

16 FILE MEMORY FULL

Not enough memory. Expand memory or

delete unnecessary data.

18 PLEASE REMOVE WEIGHT Fixed price item, please remove weigh.

19 PLU NOT EXIST No such PLU data or number exists.

20 TOTAL PRICE IS 0

No total price for item. Unit price, weight or quantity is

0.

24 WEIGHT OF Weight over maximum capacity when print.

26 TOTAL PRICE OVERFLOW Total price over the limit to display or print.

29 PLEASE SET TARE VALUE When force tare is enable, a tare weight must be

39 PLEASE PRESS PLU KEY Press PLU(#) key. To save data in some procedure.

44 KEY ALREADY ASSIGNED Preset key already been assigned with function or

48 PLU DATA INVALID U1 only. Quantity setting incorrect when using FOR.

49 QTY OF Quantity data over the limit.

54 BELOW MIN WEIGHT Weight is below min weight set when printing.

57 PRICE ACC OF Accumulated quant ity over the limit.

59 PLEASE SEE LABEL QTY Set print label quantity when the function is use.

61 GRAND TOTAL OF Grand total price over the limit.

71 PRINT INHIBITED Cannot print weigh item at Prepack mode.

74 SELF SERVICE MODE Can only use Self-service procedure only.

95 CAL00 ERROR Zero point calibration error.

96 CALSP ERROR Full scale point Calibration error.

97 FORMAT ERROR No free format is program.

98 NO DATA IN REPORT There is no data in report when printing report.

99 EXCEED WEIGHT QUOTA CN only. Please reset weight quota.

42

Page 41

SM5100 ERROR MESSAGE

SM5100 FATAL MESSAGE

No. Fatal Error Message

F002 External flash memory erase error

F003 External flash memory program error

F004 External flash memory program error

F005 Internal RAM read/write error

F006 External RAM read/write error

F007 External Ethernet IC read/write error

43

Page 42

SM5100 SERVER/CLIENT MANUAL

SM5100 SERVER/CLIENT MANUAL

1. Summary

SM5100 SERVER/CLIENT has three functions:

1) Floating clerk. (SPEC61)

2) Data file synchronization. (SPEC491)

3) Call PLU from server. (SPEC492)

In SERVER/CLIENT system, the maximum count of scales is 5 (1 SERVER and 4 CLIENTs).

Making all functions effective is in recommendation, and these 3 functions also can be used

independently in need.

2. SPEC

50 Setting of Client / Server

0 Client 2 Backup Server

1 Server / Workstation

61 Floating Clerk

0 Inhibit 1 Allow

194 Server IP Address

Enter a value between 1 to 254

For Client scale only.

208 Network Time Out

0 3 sec 2 x4

1 x2 3 x10

254 Auto Update of Client Off-line Report

0 Disable 1 Enable

Effective when SPEC61

= 1.

491 Data File Synchronization

0 Disable 1 Enable

492 Call PLU from Server

0 Disable 1 Enable

44

Page 43

SM5100 SERVER/CLIENT MANUAL

3. Setting

1) Assure network settings of all scale are effective. IP-address of all scales must be set in same

subnet and different from each scale.

2)SPEC141

SPEC number SERVER CLIENT NOTICE

50 1 0

61 1 1

194 Not effective for SERVER

Port Number of SERVER

(SPEC135)

208 Use default value Use default value

254 1 1

491 1 1

492 1 1

1. SPEC61,491,492 can

be set independently, but

the settings on the

SERVER must be same as

the settings on the

CLIENT.

2. SPEC254 is Effective

only when SPEC61 = 1. It

also must be set the same

value on SERVER and

CLIENT.

3. Using SPEC208 default

value is in

recommendation. It may

be set to other value

according to the condition

of network. If wireless

communication is used,

please don’t set SPEC208

as 0. If the setting of

SPEC208 on SERVER is

different from the setting

on CLIENT, the largest

value of SPEC208 will be

used automatically.

4. Effect

When the functions are effective, the operation on SERVER is still same as stand-alone scale.

CLIENT will connect to SERVER automatically after power on. CLIENT becomes into online

status when connection is succeeded. And CLIENT will display “SERVER OFF-LINE” before

finishing connection. CLIENT could turn into offline status via [C] key while it’s displaying

“SERVER OFF-LINE”.

Effect on CLIENT

SPEC61 SPEC491 SPEC492

STATUS online offline online offline online offline

EFFECT

Reports of

CLIENT are only

stored in

SERVER.

When connection

is

succeeded,

machine-setting

and tax file of

CLIENT will be

updated once by

SERVER.

Reports are

stored in

CLIENT.

If SPEC254=1,

CLIENT will

upload the

Off-line reports

to SERVER

after next

successful

connection.

In S mode, only S4, S8

and S20 can be

operated. Rezero+230

and updating file by

PC functions are

forbidden. After

connection is

succeeded, CLIENT

will synchronize data

files from SERVER

automatically. Max

synchronization time is

5 minutes*.

(1000PLUs)

CLIENT

calls up

PLU from

SERVER

instantly.

The PLU

in CLIENT

is invalid.

CLIENT

calls up

PLU from

its own

memory.

*The synchronization time shall be influenced by the counts of PLU.

45

Page 44

SM 5100 FLEXIBLE BARCODE SETTING

SM-100 Flexible Barcode Setting Guide

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Press [mode] third times S1 -- -->

PLU

FILE

Enter programmer.

Press numeric 4 and 6 S46 -- -->

FLEXI

BARCOD

E

Enter Flexible Barcode

programme.

Press [*] S46.0 F BAR 0 NO SET Program Flexible Barcode.

Enter numeric 1 S46.0 F BAR 1 NO SET Program Flexible Barcode 1.

Press [*] S46.1 F BAR 0 FLAG

Program Flag Code.(0 for F2,

1 for F1F2,2 for non.)

Press [*] S46.2 F BAR 0

ITEM

CODE

Enter item code length.

Press [*] S46.3 F BAR 0 DATA1

Enter data format for DATA1.( 0

for weight,1 for quantity,2 for unit

price.3 for weight/quantity,4 for

total price,5 for original price,6

for user programmable.)

Press [*] S46.4 F BAR 0 DIGIT Enter DATA1 length.

Press [*] S46.5 F BAR 0 SHIFT

Shift for DATA1.( 0 for no right

shift,1 for right shift, 2 for right

shift x2, 3 for left shift, 4 for left

shift x2, 5 for left shift x3.)

Press [*] S46.6 F BAR 0 DATA2

Enter data format for DATA2.( 0

for weight,1 for quantity,2 for unit

price.3 for weight/quantity,4 for

total price,5 for original price,6

for user programmable.)

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

Press [*] S46.7 F BAR 0 DIGIT Enter DATA2 length.

Press [*] S46.8 F BAR 0 SHIFT

Shift for DATA2.( 0 for no right

shift,1 for right shift, 2 for right

shift x2, 3 for left shift, 4 for left

shift x2, 5 for left shift x3.)

Press [*] S46.9 F BAR

NO

MIDDLE

CD

Press [ⅹ] to select the middle

check digit.

Press [*] S46.1 F BAR

NO LAST

CD

Press [ⅹ] to select the last

check digit.

Press [*] S46.1 F BAR

ITF

BARCOD

E

Press [ⅹ] to swith ITF and EAN

barcode.

Press [#] S46 -- -->

FLEXI

BARCOD

E

Save the flexible barcode 1.

Note: See the Flexible Barcode Usage Note at 《3.6.1 PLU programming》 in SM-100 Operation manual

46

Page 45

SM 5100 FLEXIBLE BARCODE SETTING

47

Page 46

SM 5100 TRACEABILITY SETTING

SM-5100 Traceability Setting

Prepare

z Set SPEC258 to “1”

Traceability Programming

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

[Mode] [Mode] [Mode] S1

Æ

PLU

FILE

Enter S mode

[3] [4] S34

Æ

COUNTR

Y FILE

Enter country file programming

[*] [1] S34.0 1 NO SET Program country No. 1

[*][C][H][I][N][A] S34.1 COUN CHINA Name 5 Program country name “CHINA”

[#] S34

Æ

COUNTR

Y FILE

Save Country No. 1

[3] [5] S35

Æ

CUTTIN

G HALL

Enter cutting hall programming

[*] [1] S35.0 HALL 1 NO SET Program cutting hall No. 1

[*][1] S35.1 HALL 1

COUNTRY Program cutting hall country No.

1

[*][C][U][T] S35.2 HALL CUT Name 3

Program cutting hall name

“CUT”

[#] S35

Æ

CUTTIN

G HALL

Save cutting hall No. 1

48

Page 47

SM 5100 TRACEABILITY SETTING

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

[3][6] S36

Æ

SLAUGH

TER

HOUSE

Enter slaughter house

programming

[*][1] S36.0 HOUSE 1 NO SET Program slaughter house No. 1

[*][1] S36.1 HOUSE 1

COUNTRY Program slaughter house

country No.1

[*][S][L][A][U][G] S36.2 HOUSE SLAUG NAME 5

Program slaughter house name

“SLAUG”

[#] S36

Æ

SLAUGH

TER

HOUSE Save slaughter house No. 1

[4][7] S47

Æ

KIND

FLIE

Enter kind file programming

[*][1] S47.0 KIND 1 NO SET Program kind file No. 1

[*][M][E][A][T] S47.1 KIND MEAT NAME 4 Program kind name “MEAT”

[#] S47

Æ

KIND

FILE

Save kind file No. 1

[4][8] S48

Æ

CATEGO

RY FILE

Enter category file programming

[*][1] S48.0 CATEG 1 NO SET Program category No. 1

[*][B][E][E][F] S48.1 CATEG BEEF NAME 4 Program category name “BEEF”

[#] S48

Æ

CATEGO

RY FILE

Save category file No. 1

49

Page 48

SM 5100 TRACEABILITY SETTING

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

[4][9] S49

Æ

BREED

FILE

Enter breed file programming

[*][1] S49.0 BREED 1 NO SET Program breed file No. 1

[*][B][U][L][L] S49.1 BREED BULL NAME 4 Program breed name “BULL”

[#] S49

Æ

BREED

FILE

Save breed file No. 1

[3][7] S37

Æ

TRACEA

BILITY

Enter traceability programming

[*][1] S37.0 TRACE 1 NO SET Program traceability No. 1

[*][1] S37.1 TRACE 1 BORN Choose born country No. 1

[*][1] S37.2 TRACE 1 FATTEN Choose fatten country No. 1

[*][1] S 37.3 TRACE 1

S

HOUSE

Choose slaughter house No. 1

[*][1] S37.4 S CNT 1 LNK 1

Choose link country No. 1 for

slaughter house

[*][1] S37.5 TRACE 1 C HALL Choose cutting house No. 1

[*][1] S37.6 C CNT 1 LNK 1

Choose link country No. 1 for

cutting hall

[*][1] S37.7 TRACE 1 ORIGIN Choose original country No. 1

50

Page 49

SM 5100 TRACEABILITY SETTING

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

[*][R][C][D] S37.8 R-CD RCD NAME 3 Program R-CD content “RCD”

[*][G][T][I][N] S37.9 GTIN GTIN NAME 4 Program GTIN content “GTIN”

[*][L][O][T] S37.10 LOT LOT NAME 3 Program LOT content “LOT”

[*][1] S37.11 TRACE 1 KIND Choose kind No. 1

[*][1] S37.12 TRACE 1 CATEG Choose category No. 1

[*][1] S37.13 TRACE 1 BREED Choose breed No. 1

[*][C][O][N][T] S37.14 CONT CONT NAME 4 Program cont content “CONT”

[*][0][6][0][3][1][0] S37.15 TRACE 060310 EAT D Program eat by date “06/03/10”

[*][5][0][0][0] S37.16 TRACE 5.000 WEGHT Program maximum weight “5kg”

[*][S][C][D] S37.17 S CD SCD NAME 3 Program S CD content “SCD”

[*][S][N][M] S37.18 S NM SNM NAME 3 Program S NM content “SNM”

[*][S][A][D][1] S37.19 S AD1 SAD1 NAME 4 Program S AD1 content “SAD1”

[*][S][A][D][2] S37.20 S AD2 SAD2 NAME 4 Program S AD2 content “SAD2”

[#] S37

Æ

TRACEA

BILITY

Save traceability No. 1

Free Format Programming

z Enter “S12 Æ FREE FORMAT”, press [*]

z Edit the correlative items for traceability in free format

PLU ITEM Programming

z Enter “S19 Æ PLU ITEM”, press [*]

z Set “ Item TRACE” to “PROGRAM” and press [#] to save

PLU Programming

z When you edit PLU, set “S1.64 PLU” to “TRACE ALLOW” and press [*]

z Input traceability number and press [#] to save

z In the end, when you call the PLU and print label, you’ll see the traceability information on the label

51

Page 50

SM 5100 Nutrition Fact Setting

SM-5100 Nutrition Fact Setting

Concept

Nutrition uses fix template to print. Totally It has 12 fix templates(No. 70 ~ No. 81).

Setting Method

1. Enter S mode

2. Enter “S19 --- PLU ITEM” and set “IMAGE” and “NUTRI” to “PROGRAM”

3. Enter “S12 --- FREE FORMAT”

4. Enter “S12.5 IMG 1 Å 47 F ITEM” to “S12.5 IMG 10 Å 56 F ITEM” to set the print area of Nutrition. (In

each label format, totally you can print 10 images)

5. Enter “S1 --- PLU FILE” to create PLU.

6. Enter “S1.50 PLU 0 IMAGE 1” to choose the template number for IMAGE 1 (From No. 70~ No. 81).

…

7. Enter “S1.59 PLU 0 IMAGE 10” to choose the template number for IMAGE 10 (From No. 70~ NO. 81).

8. Set “S1.81 PLU PRINT NUTRI” to set nutrition print status to “Print”.

9. Enter from S1.82 to S1.10 to input nutrition contents.

10. For extra details on the Nutrition Fact, Enter S11: TXT form to edit by hands.

11. Enter “S12 --- FREE FORMAT” to set up the TXT position.

12. Press [PLU] key to save.

52

Page 51

SM 5100 PC-FL1 OPERATION

PC-FL1 OPERATION

Note: this guide is available just for SM series expect the SM-5100.

1. The link of the hardware

Link the PC with scale via RS232C.

2. Operation

1. The Spec setting in the scale

3 for SPEC51 (The SIO baud rate is 9600. )

1 for SPEC52 (The SIO data length is 8.)

0 for SPEC53 (No SIO parity digit.)

0 for SPEC54 (1 bit stop bit.)

2 for SPEC60 (SIO work via PCFL-1)

2. The setting in the software

1) open the software

2) the com port setting

53

Page 52

SM 5100 PC-FL1 OPERATION

Please note:

a) The com port should be the same as the one used in your computer.

b) The com port setting must be same as setting in the scale.

3) the folder for save

54

Page 53

SM 5100 PC-FL1 OPERATION

Note: You could set the default folder for save the data received from the scale.

3. Operation

1) receive the data from the scale

55

Page 54

SM 5100 PC-FL1 OPERATION

Note: You could press the key to receive the data from scale.

2) send the data to scale

Note: You could press the key to send the data to scale.

1) the operation in the scale

DISPLAY

OPERATION

TARE lb

$/lb $

REMARK

[M][0][M][M]

DAIL

Y

0 CLR X

Enter the [Z] mode

[zero]+[0][1][0] BAC PLU FILE X

Preset key [8] BAC FOR FILE X

Preset key [8] BAC OTH FILE X

Preset key [8] BAC ALL FILE X

Press preset key [7]or [8] to

select the transmit item:

PLU, Format, Others or All.

[*] BAC

SA

TO

FL-1 X

Preset key [8] BAC

RD

FR

FL-1 X

Preset key [8] BAC

COM

P

FL-1 X

Press preset key [7]or [8] to

select the transmit method:

save data to FL-1,read

data from FL-1,verify data

with FL-1.

[*]

T-

OUT

OPN GOOD X

Transmit successfully.

[Tare]

DAIL

Y

0 CLR X

Back to Z mode.

56

Loading...

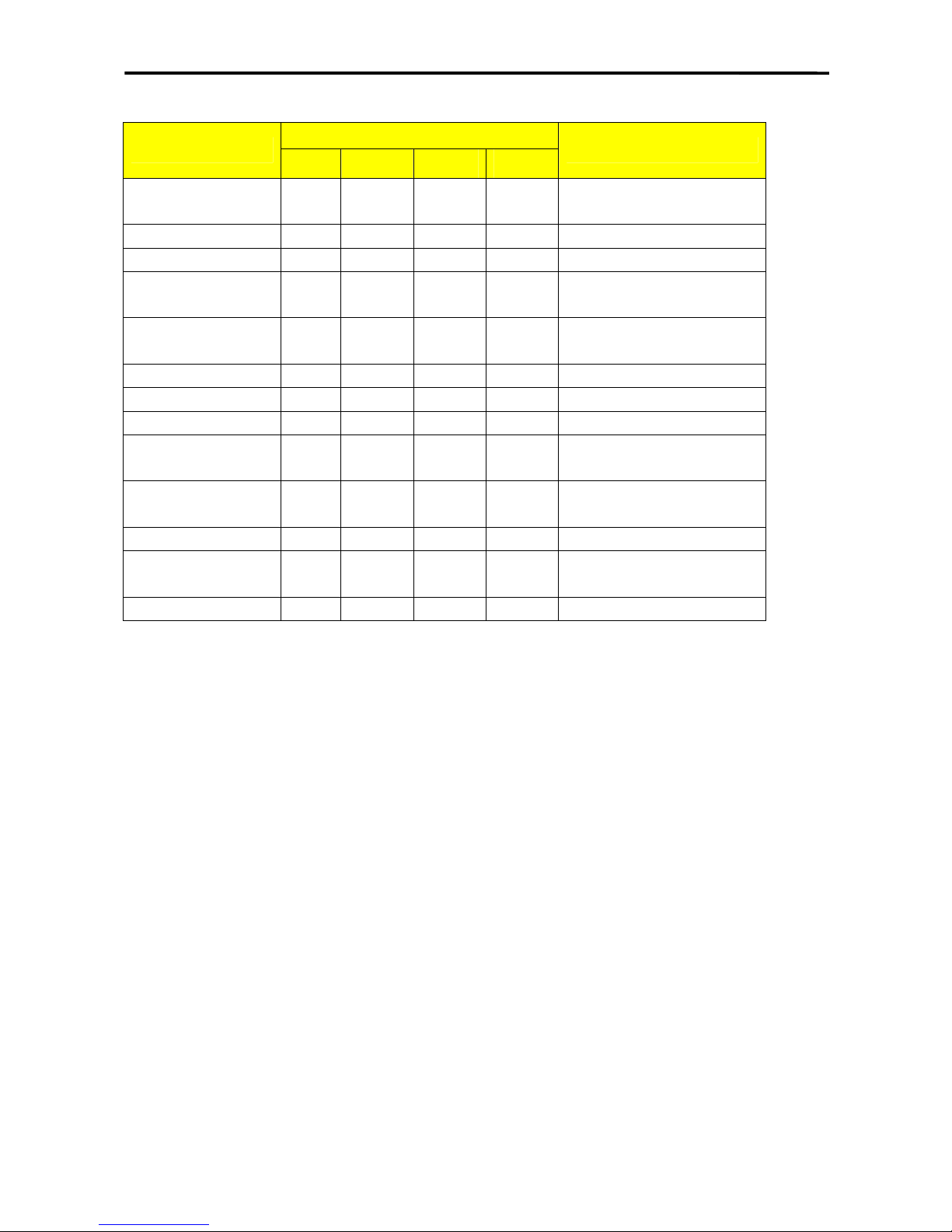

Loading...