Page 1

SERVICE MANUAL

MODEL : SM-100

Æ

EDITION

Month Year

1

st

December 2004

2nd March 2006

3rd February 2007

4th February 2009

SHANGHAI TERAOKA ELECTRONIC CO., LTD

TECHNICAL SUPPORT DEPARTMENT

1rd Floor of 2nd Building, Jia Yuan Business Center,

51# Long Wu Road, Shanghai China 200232.

TEL : +86-21-6408-5151 FAX : +86-21-6408-3468

EMAIL ADDRESS :steservice@digi-scale.com

Page 2

Table of Content

1. GENERAL INFORMATION ........................................................................ 1

1.1 Overall View ................................................................................................................................................... 1

1.2 Display Panel .................................................................................................................................................. 3

1.3 Key Panel ........................................................................................................................................................... 3

1.4 Thermal Printer Head ............................................................................................................................ 9

1.5 Features ............................................................................................................................................................. 10

1.6 Specification .................................................................................................................................................. 11

1.7 Label Type ...................................................................................................................................................... 12

2. Initial Setup .................................................................................................................. 13

2.1 Setup .................................................................................................................................................................... 13

2.2 Location of Switches and Connectors .................................................................................. 15

2.3 Memory Initialisation ............................................................................................................................ 15

2.4 Default Specification Setting ......................................................................................................... 16

3. Calibration ..................................................................................................................... 18

3.1 Calibration Operation .......................................................................................................................... 18

3.2 Exit Calibration .......................................................................................................................................... 19

Page 3

4. Software Setting ....................................................................................................... 20

4.1 Software Version Upgrade .............................................................................................................. 20

4.2 Specification Setting .............................................................................................................................. 32

5. Adjustment ................................................................................................................... 34

5.1. Peer Sensor Voltage and Label Sensor Sensitivity Adjustment.................... 34

5.2. Adjustment of Printing Position ............................................................................................... 37

5.3. Voltage Checkpoint .............................................................................................................................. 38

6. Interface ......................................................................................................................... 39

6.1. PC Interface ................................................................................................................................................. 39

6.2. Scale Ethernet Address ..................................................................................................................... 40

6.3. Scale IP Address ...................................................................................................................................... 41

6.4. Connection Method ............................................................................................................................. 42

6.5. Wire Configuration ............................................................................................................................... 44

7. Miscellaneous ............................................................................................................ 46

7.1. Mode Change ............................................................................................................................................. 46

7.2. Span Switch Status ................................................................................................................................. 46

7.3. Clear All PLU Data ............................................................................................................................... 46

7.4. Thermal Head Usage ........................................................................................................................... 47

7.5. IP ADDRESS ............................................................................................................................................ 47

Page 4

7.6. SERVER IP ADDRESS .................................................................................................................. 47

7.7. SUBNET MASK .................................................................................................................................... 47

7.8. MAC ADDRESS .................................................................................................................................... 48

7.9. SERIAL NO ............................................................................................................................................... 48

8.0. ASCII CHARACTER ........................................................................................................................ 49

8. Appendix ...........................................................................................................................

A. SpecificationList_V200

B. FlexibleL Barcode Setting Guide

C. Traceability Setting Guide

D. Nutrition Setting Guide

E. PC-FL1 Operation Guide

F. Circuit

9. Error Message ..........................................................................

Page 5

SM 100 GENERAL

1

1. GENERAL

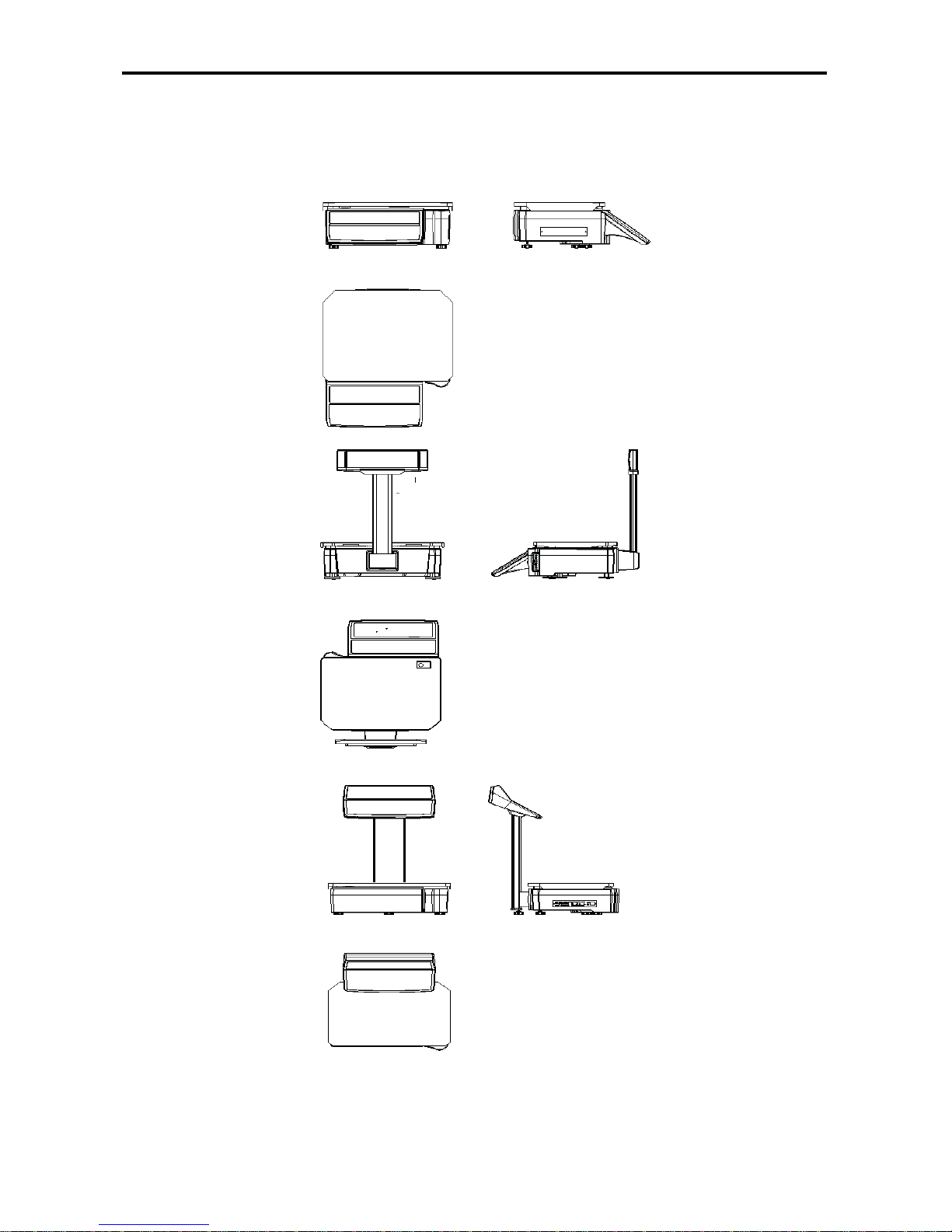

1.1 OVERALL VIEW

” Bench Type

” Pole Type

” Elevated Type

Page 6

SM 100 GENERAL

2

” Bench-CS Type

” Pole-CS Type

” Hand Type

Page 7

SM 100 GENERAL

3

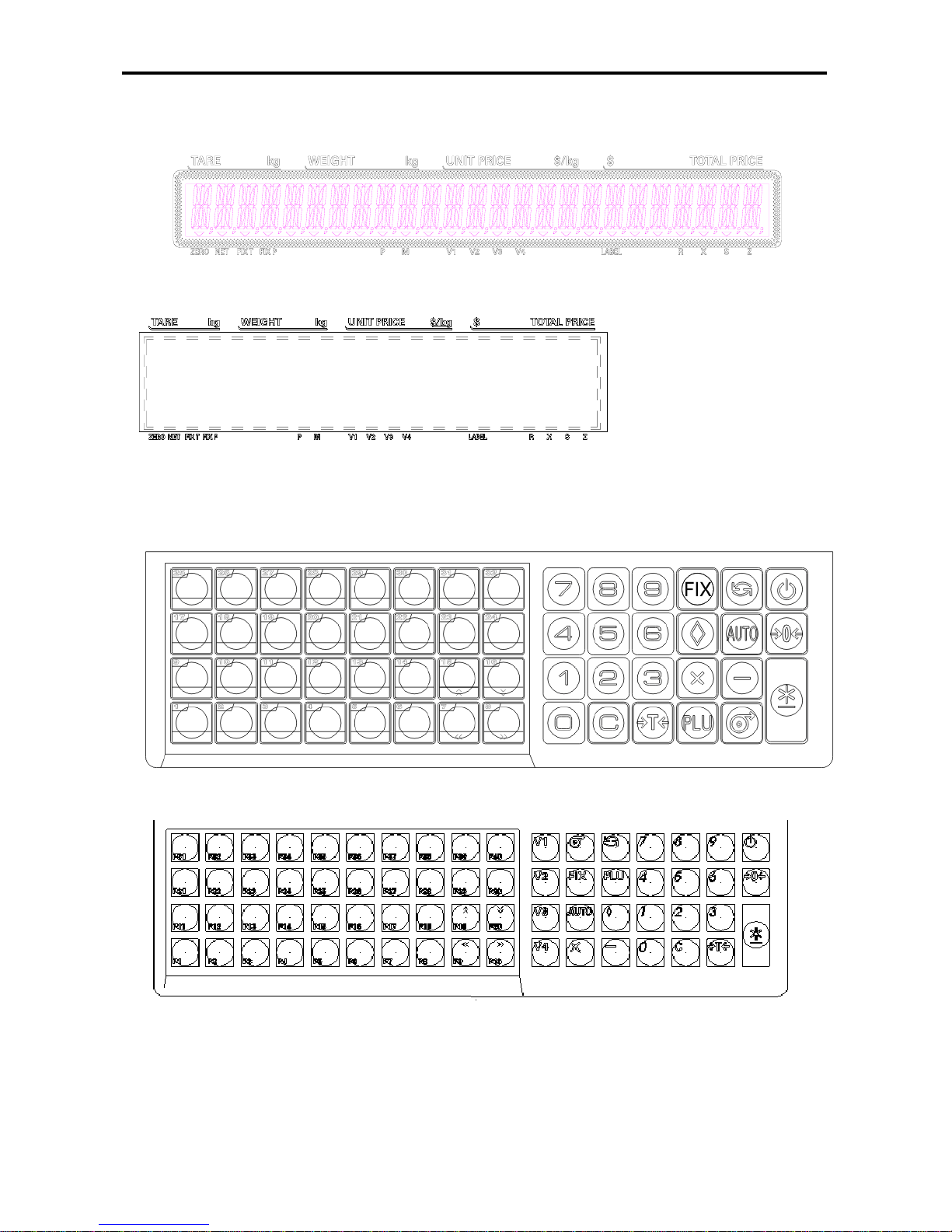

1.2 DISPLAY PANEL

” 25 digits × 19 segments TN type LCD

” 32 × 202 full dot Matrix Green LCD

1.3 KEY PANEL

” Preset Keys Type ------ B/P

32 Preset keys:

40Preset Keys:

Page 8

SM 100 GENERAL

4

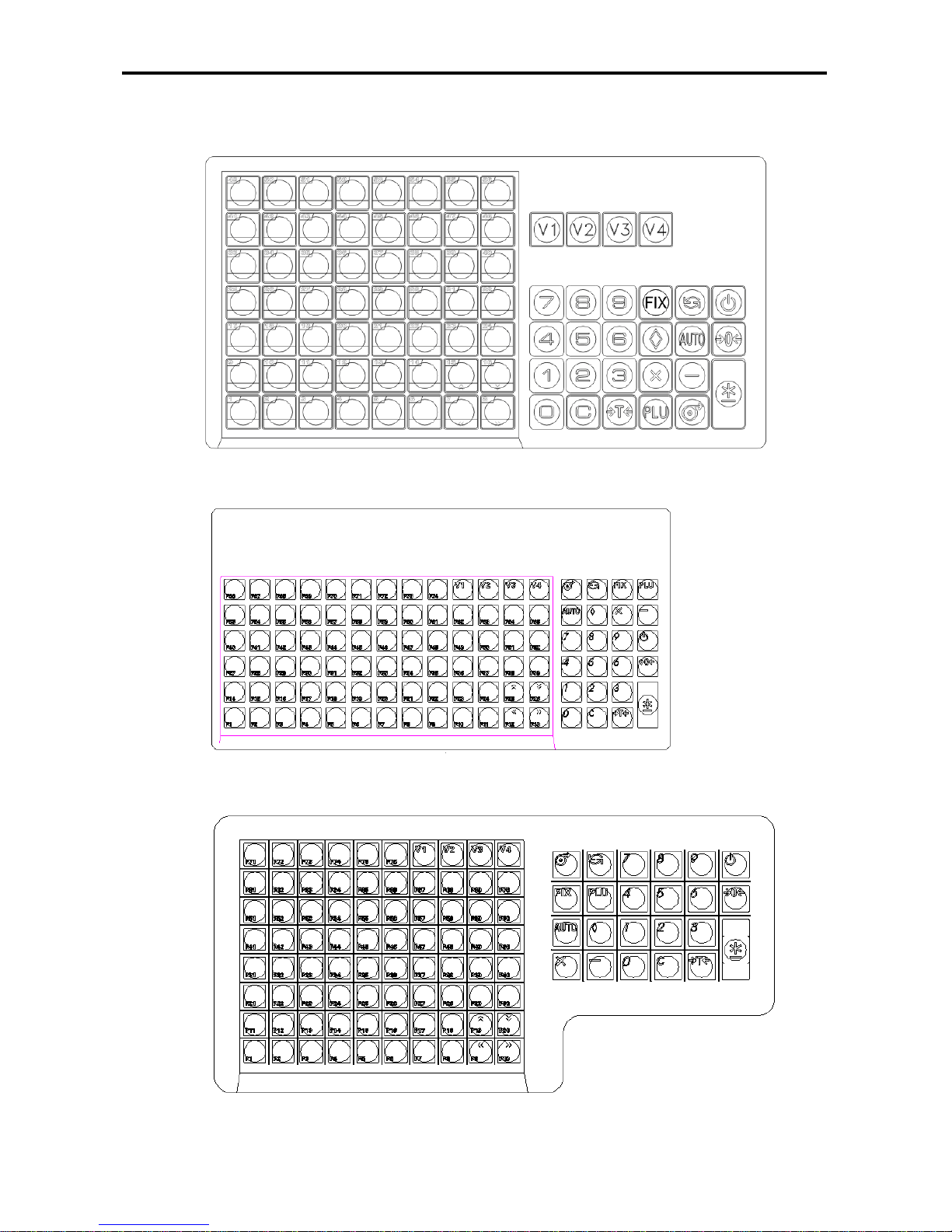

” 56 Preset Keys Type ------ PCS(New), PCS+ (New)

” 74 Preset Keys Type ------ EV, PCS(Old)

” 76 Preset Keys Type (Hanging)

Page 9

SM 100 GENERAL

5

ON/OFF KEY

¬ Turn display "ON" or "OFF".

PRESET KEY

P1 ~ P40 (B/P)

P1 ~ P74 (EV)

P1~P32(BCS)

P1~P56(PCS)

P1~P76(H)

¬ Set up or call either unit price and tare value.

NUMERIC KEYS

0 ~ 9

¬ Enter numeric data.

TARE KEY

¬ Set or Clear Tare value.

¬ Select "NO" in S and Z Mode.

¬ Item test print in S Mode.

CLEAR KEY

C

¬ For Back space or Clear numeric value.

¬ Select "YES" in S and Z Mode.

RE-ZERO KEY

¬ Reset weight to ZERO.

PREPACK KEY

AUTO

¬ Switch Manual mode and Pre-pack mode alternatively.

(The mode status will be indicated in the P and M indicator.)

P - PRE-PACK MODE M - MANUAL MODE

CHANGE KEY

¬ Calculate the Changed Amount.

¬ Escape the Programming screen without saving data in S Mode.

Page 10

SM 100 GENERAL

7

MULTIPLLE KEY

X

¬ Register the number of Non-Weight products.

¬ Select programming item such as PLU data, Shop Name in S Mode.

¬ Select Report Type in X Mode.

¬ Select Data Transaction Type in Z Mode.

CLERK KEY

V1~V4

¬ Accumulate the Total Price.

VOID KEY

−

¬ Correct the sales data.

PLU KEY

PLU

¬ Call up PLU data in R Mode.

¬ Store the programmed data in S Mode.

FEED KEY

¬ Feed Label or Receipt paper

PRINT KEY

¬ Print out Label or Receipt.

Note: BCS or PCS stands for the scale with cassette.

Page 11

SM 100 GENERAL

8

MODE SELECT KEY

¬ Five Modes can be selected using this key.

• Indicator R - REGISTRATION MODE (All the sales transactions are

performed.)

• Indicator X - CHECK MODE (Printing out and sales report.)

• Indicator S - PROGRAM MODE (Programming preset data, such as

products, data, shop name, etc.)

• Indicator Z - TOTAL MODE (Clear sales data stored.)

• Indicator X (Blink) - Password Setting Mode (Set PASS WORD for X, S, Z

mode, set PASSWORD for PASSWORD MODE when all indicators(R, X, S,

Z) blink)

Decrease/Increase Specification Count key

,

¬ Decrease/Increase Only used when Setting SPEC 141 & 142

<<,>>

¬ Select parameter data such as SPEC data. Move cursor left or right.

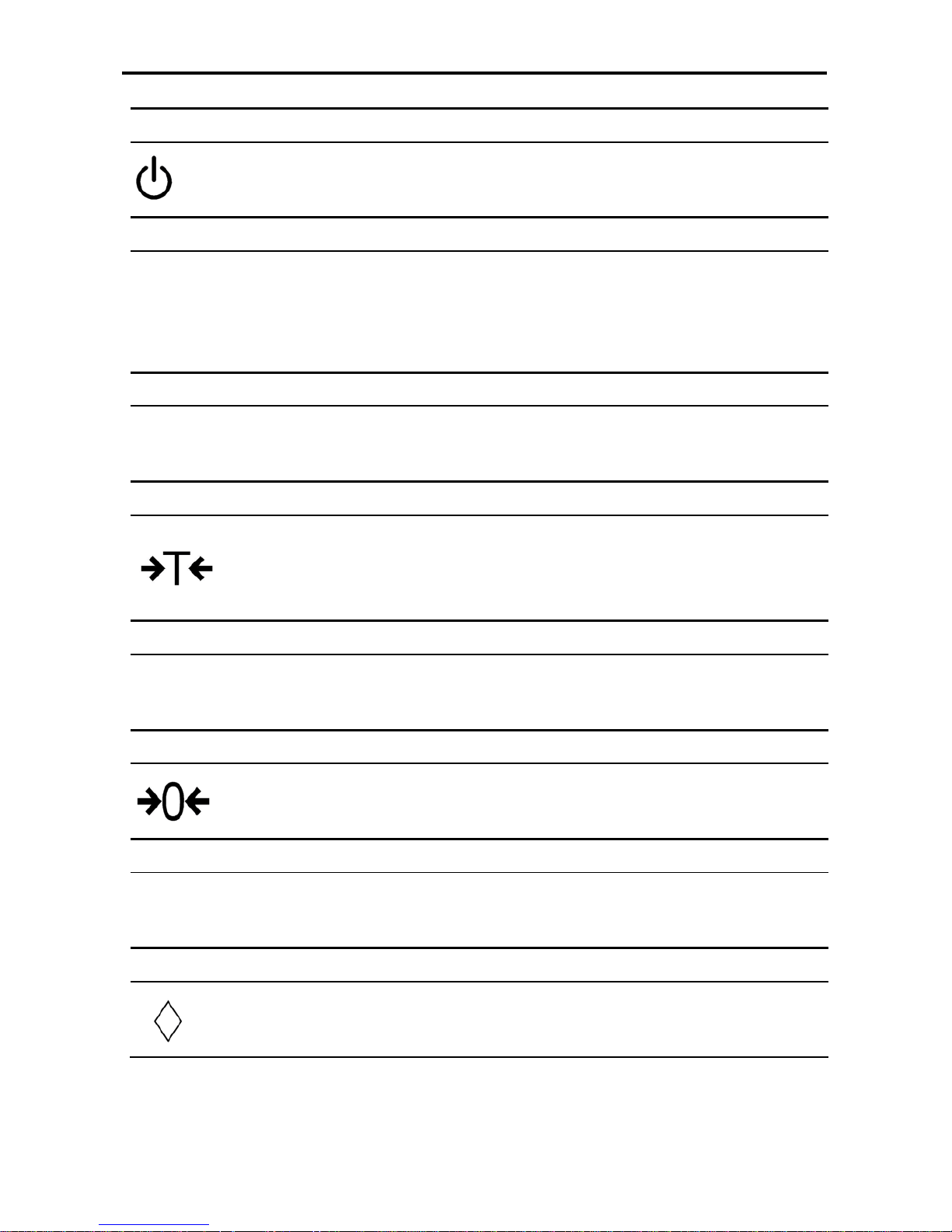

1.4 Thermal Printer Head

” Max Printing With: 56mm

Page 12

SM 100 GENERAL

9

1.5 FEATURES

„ Digital printing scale consists of electronic cash registers function and label printing function.

„ High-speed, high reliability thermal head printer.

„ Easy paper handing achieved special designed mechanism.

„ Built-in clock automatically updates data and time.

„ Quick response to weight changes.

„ Capacity and Resoultion

Capacity 3kg 6kg 12kg 15kg 30kg 60kg

Resolution 1/3000

1/3000S,

1/3000M,

1/6000S

1/3000

1/3000S,

1/3000M,

1/7500S

1/3000S,

1/3000M,

1/6000S

1/3000

Capacity 3lb 6lb 12lb 15lb 30lb 60lb

Resolution

1/3000S,

1/3000M

1/6000S

1/3000

1/3000S,

1/3000M,

1/7500S

1/3000S,

1/3000M,

1/6000S

1/3000S,

1/3000M,

1/6000S

1/3000S,

1/3000M,

1/6000S

Internal count: 1/90000.

„ Calibrating by software.

„ Customer and operator display (optional customer pole display).

SM-100:

25 digits x 19 segments TN type LCD with back-light for numeric digit and character display.

SM-100+:

32 x 202 full dot Martix Green LCD display.

„ membrane keys

a. ON/OFF key

b. 10 Numeric keys, to key in numeric data.

c. Preset keys, to preset PLU or function into the key.

d. 16 Operational keys, to perform various functional operations.

„ 18 data files, Department, Main Group, PLU, etc.

„ Various reports, PLU daily report, Sales daily report,24 hours daily report, etc.

„ Ethernet function.

„ Optional wireless Ethernet bridge.

„ RS232C interface for data communicate and barcode scanner connection.

„ Optional cash drawer.

„ Compact housing.

Page 13

SM 100 GENERAL

10

1.6 SPECIFICATION

1.6.1 Display

SM-100

25 digits × 19 segment TN type LCD with back-light for numeric digit and character display.

„ Tare weight display : 4 digits.

„ Weight display : 5 digits.

„ Unit price display : 6 digits.

„ Total price display : 7 digits.

SM-100+

32 x 202 full dot Martix Green LCD display.

„ Tare weight display : 4 digits.

„ Weight display : 5 digits.

„ Unit price display : 6 digits.

„ Total price display : 7 digits.

1.6.2 Operating Conditions

” Power Source : AC 110V,220V(+10%,-15%), 50~60Hz.

” Operating Temperature : -10 °C ~ +40 °C.

” Operating Humidity : 15% ~ 85% RH.

” Power Consumption : 70 W.

1.6.3 Dimensions

” Platter size

Bench, Pole and Elevated : 386(W) x 270(D) mm.

Bench-CS and Pole-CS : 359(W) x 277(D) mm.

Hanging : 274(d) x 35(h) mm.

” Overall size

a) Bench : 386(W) x 415(D) x 127(H) mm.

b) Pole : 386(W) x 478(D) x 480(H) mm.

c) Elevated : 386(W) x 416(D) x 550(H) mm.

d) Bench-CS : 380(W) x 360(D) x 162(H) mm.

e) Pole-CS : 380(W) x 380(D) x 509(H) mm.

f) Hand : 340(W) x 310(D) x 544(H) mm.

Page 14

SM 100 GENERAL

11

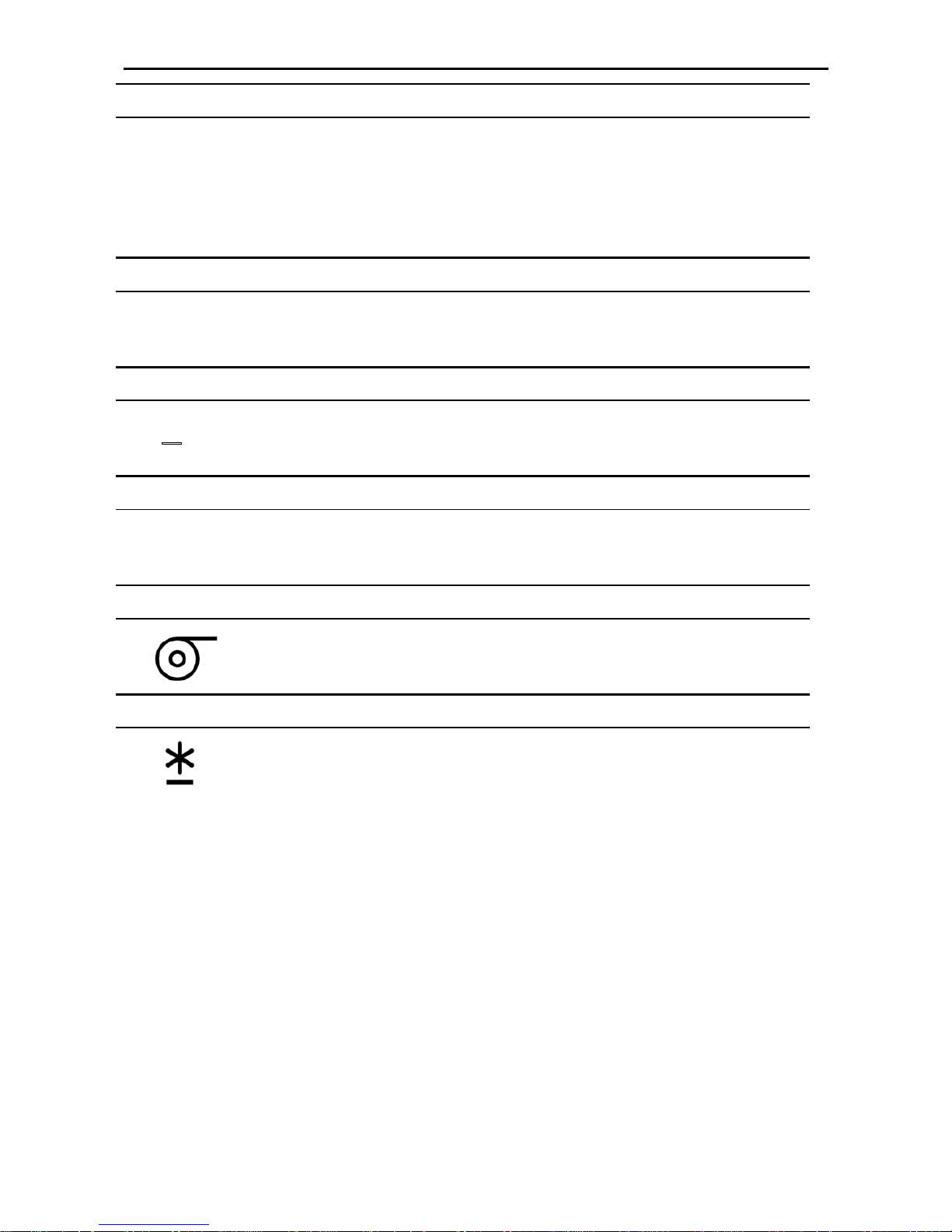

1.7 LABEL TYPE

The label diameter range is from 40 to 105 mm.

Note

: Labels must be winding outwards (on top backing paper) and not inwards (under backing paper) within the

core (see diagram above). If labels are wound wrongly, printing problem may result. We do not recommend the

use of varnish labels.

Label Type Dimension (mm)

T1 28 X 56

T2 31 X 56

T3 34 X 56

T4 40 X 56

T5 43 X 56

T6 46 X 56

T7 49 X 56

T8 55 X 56

T9 37 X 56

T10 40 X 56

T11 43 X 56

T12 49 X 56

S 28 X 37

A 46 X 37

B 46 X 37

C 62 X 37

F1 – F99 Free Format

Page 15

SM 100 INITIAL SETUP

13

2. INITIAL SETUP

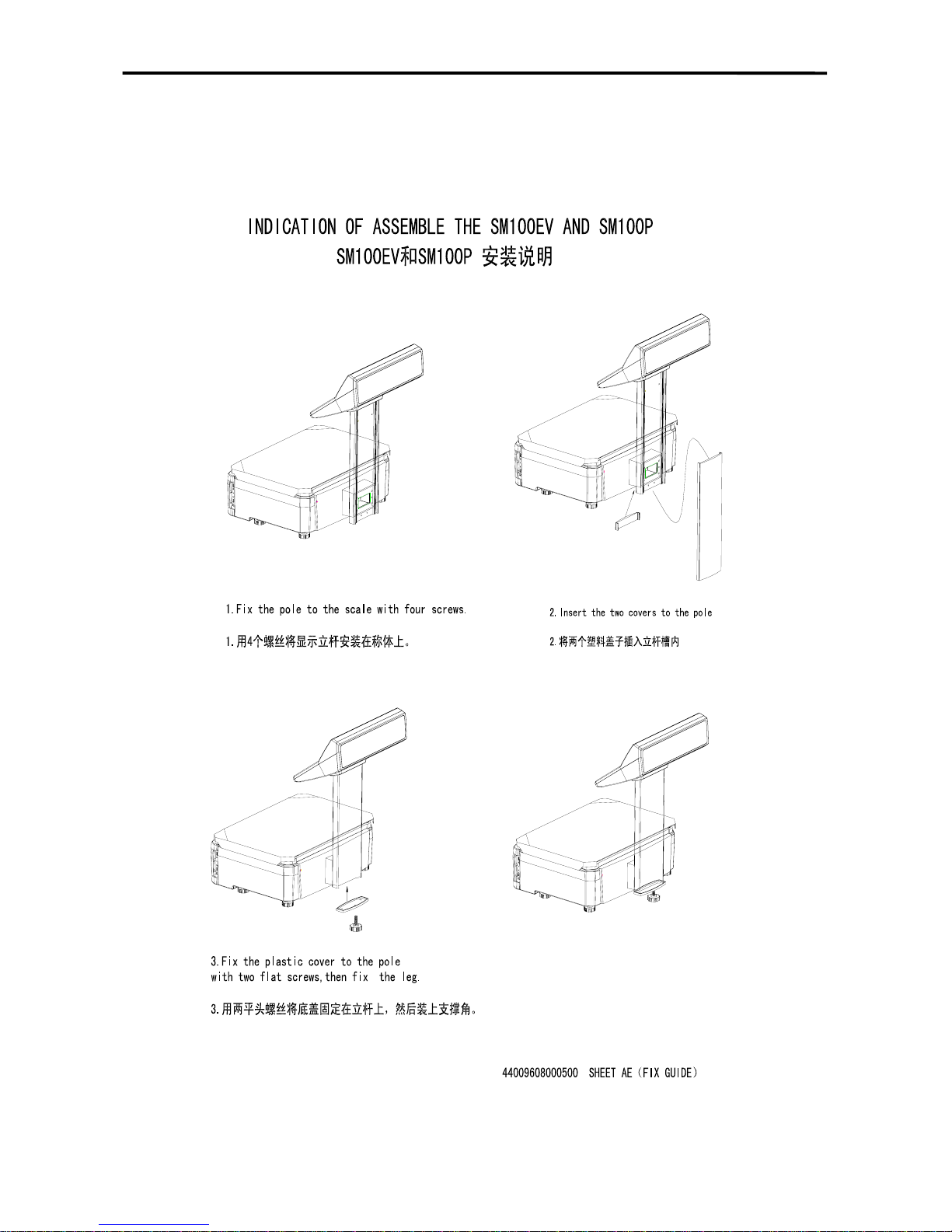

2.1 SETUP

Ü Indication of Assemble

Page 16

SM 100 INITIAL SETUP

14

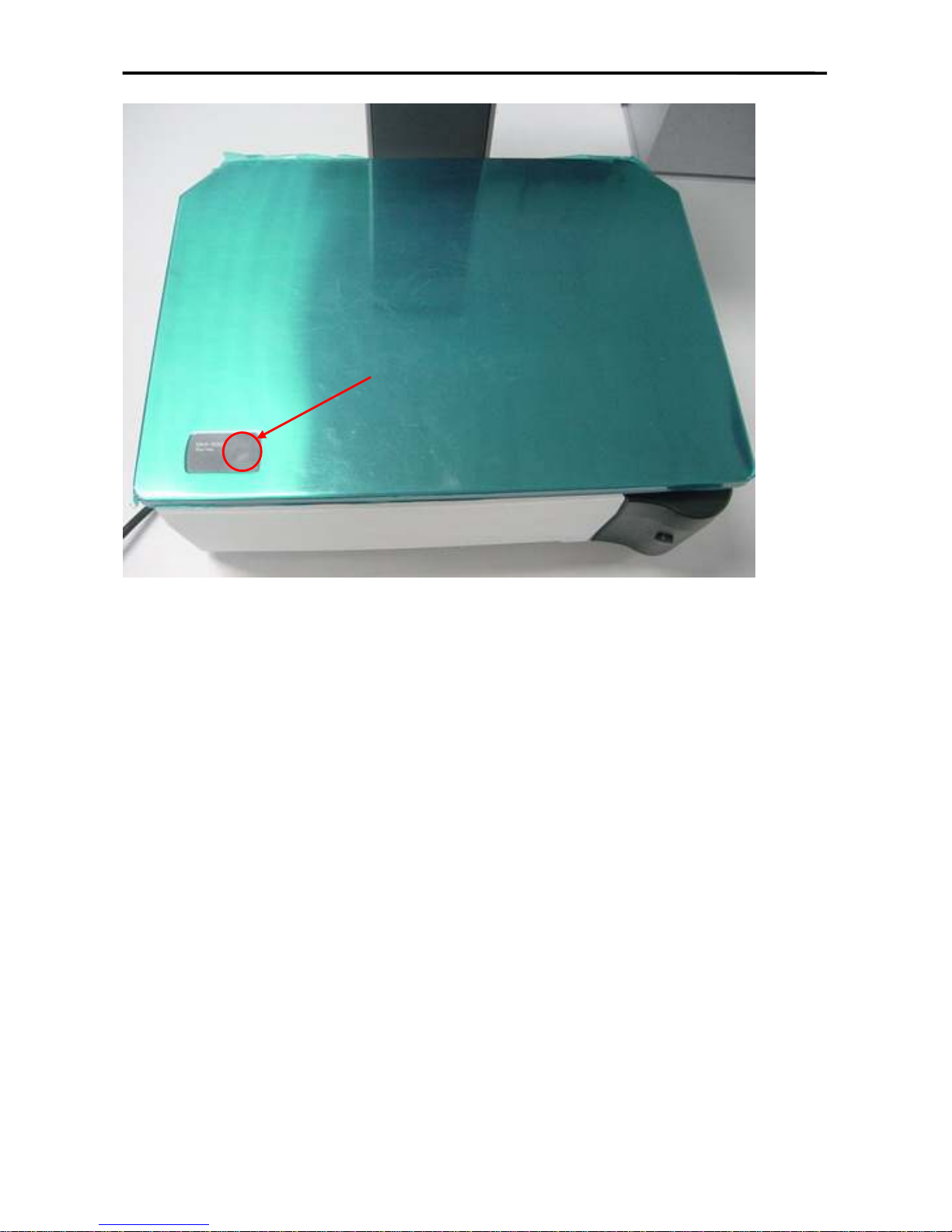

Ü Bubble Adjustment

Place the scale on the flat surface and adjust the four legs until the bubble on the level is in the

centre as shown above.

Bubble

Page 17

SM 100 INITIAL SETUP

15

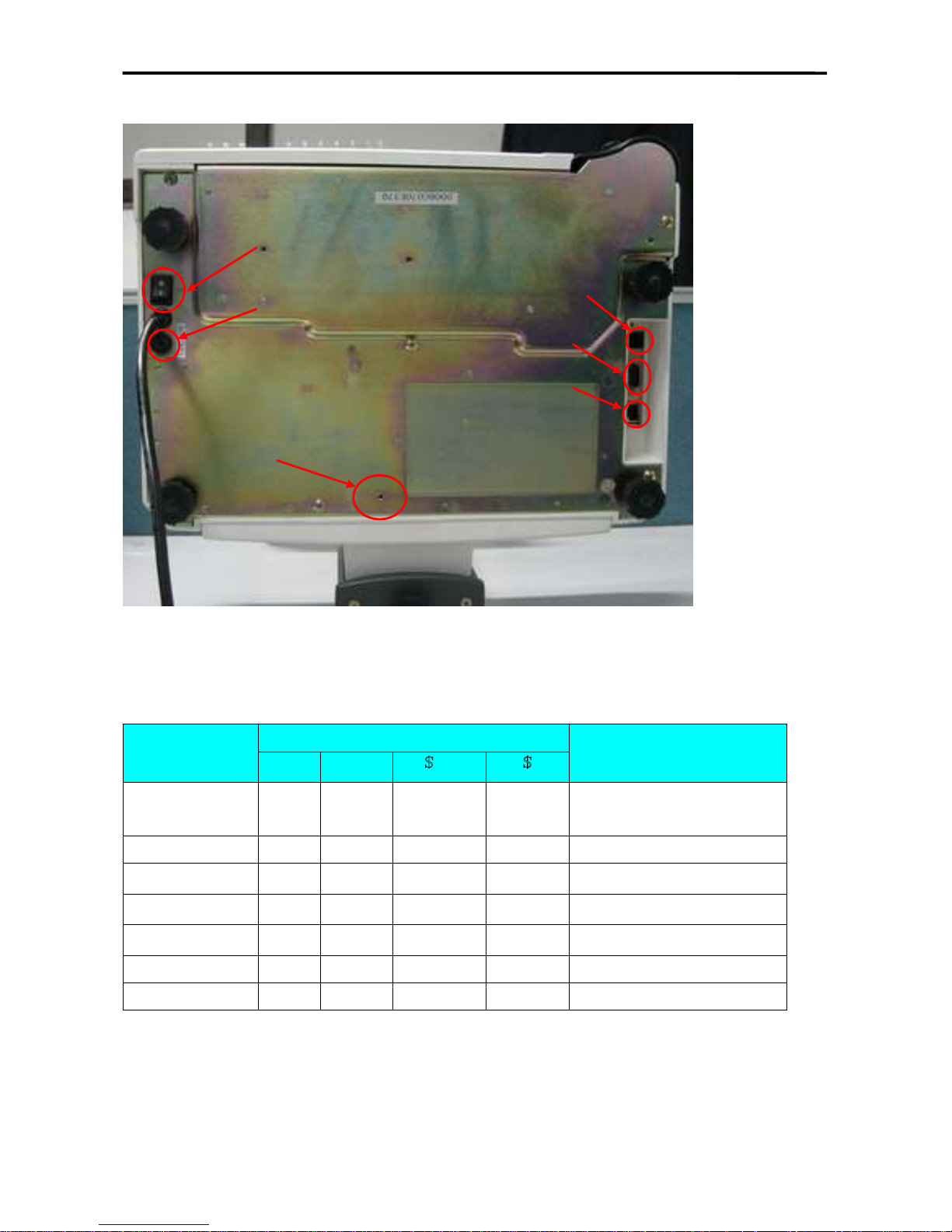

2.2 LOCATION OF SWITCHES AND CONNECTORS

2.3 MEMORY INITIALISATION

To clear all memory.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[2][3][0] CLEAR PLU FILE PLU file.

[]

CLEAR VENDER DATA

Vender transaction data.

[]

CLEAR REPORT FILES

Report files.

[]

CLEAR MEMORY DATA

All files in memory.

[*] CLEAR MEMORY Y-C N-T [C] to clear file data,[T] to quit.

[C] or [T] Z1.0 RESET SALES DAILY Return to Z mode.

Span Switch

Power

Switch

Cash Drawer Port

RS232 Port

Ethernet Port

Fuse

Holder

Page 18

SM 100 INITIAL SETUP

16

2.4 DEFAULT SPECIFICATION SETTING

Default SPEC setting of individual country.

(Please turn on the span switch before proceed this process.)

Ü Country Set

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY Z mode.Lamp Z turns on.

[Rezero]+[8][8][2][2] SPEC 2-STD COUNTRY Set country setting.

[>>] SPEC 3-CN COUNTRY

[>>],[<<] or [X] to select country.[*]

to update country setting.

[*] LOAD DEFAULT SPEC Y-C N-T

[C] to load default SPEC setting,[T]

to skip.

[C] SCALE

TYPE

POLE

Set scale type.

[X] SCALE

TYPE

BENCH

[X],[] to select type,[*] to update

type setting.

[*] SCALE

CAP.

3KG

Set scale capacity.

[X] SCALE

CAP.

6KG

[X],[ ] to select capacity,[*] to

update capacity setting.

[*] SCALE

RES.

1/3000S

Set resolution.

[X] SCALE

RES.

1/3000M

[X],[ ] to select resolution,[*] to

update resolution setting.

[*] CLEAR MEMORY Y-C N-T [C] to clear memory,[T] to skip.

[C] Z1.0 RESET SALES DAILY Return to Z mode.

Note 1: For the first using of SM-100,Please take this operation for initialization.

Note 2: Enter a number that represent a country in the country list (refer to the table below) to

initialise and country set.

Page 19

SM 100 INITIAL SETUP

17

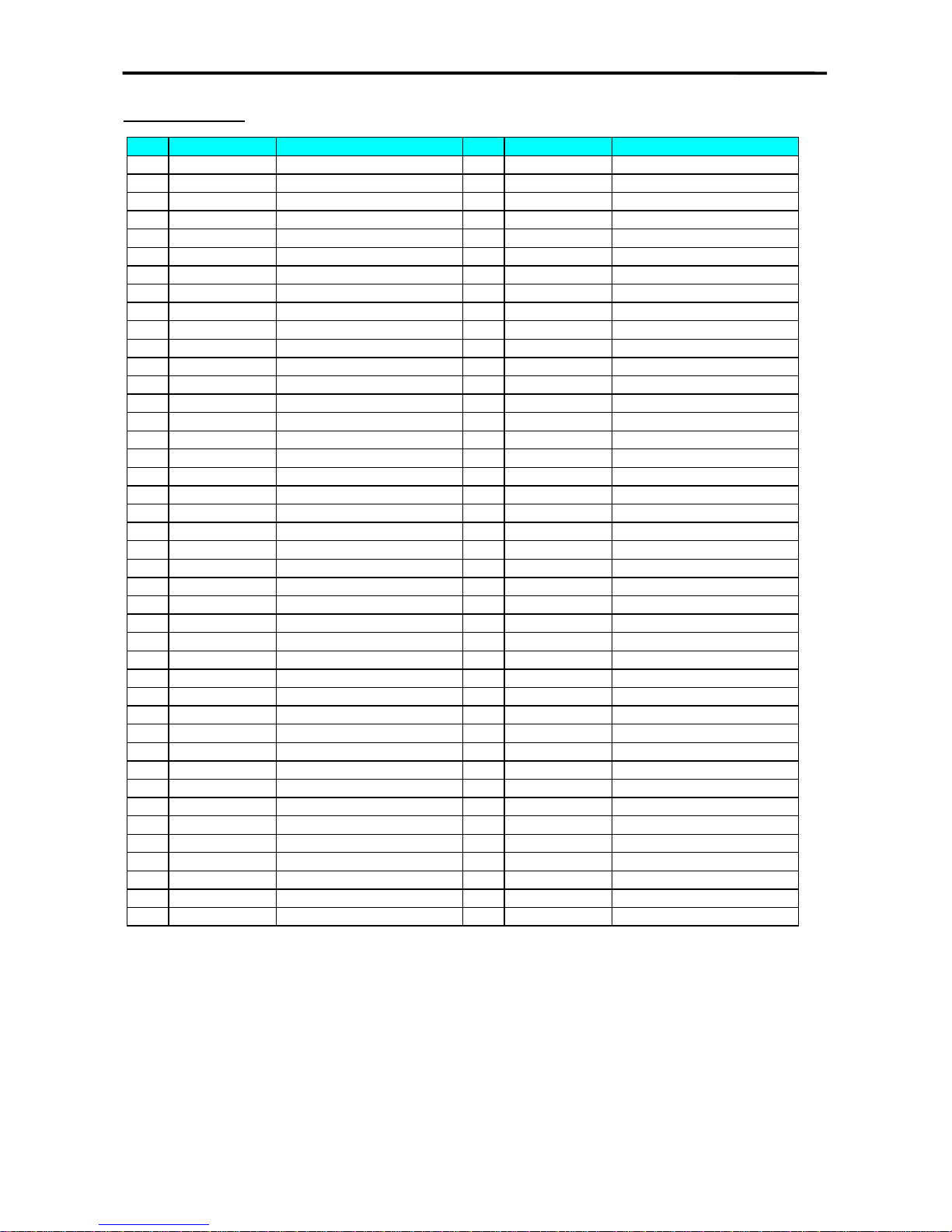

COUNTRY LIST

No. Country Code Country No. Country Code Country

0 AA Japan 41 SA Saudi Arabs

1 U1 U.S.A. 42 IC Iceland

2 STD Standard 43 IE Indonesia

3 CN China 44 CB Cuba

4 HK Hong Kong 45 KY Kenya

5 TW Taiwan 46 IR Israel

6 EX Export 47 VY Slovenia

7 KE Korea 48 MS Malaysia

8 AR Australia And New Zealand 49 SN Spain

9 SF South Africa 50 VZ Venezuela

10 CS Cyprus 51 CO Croatia

11 GC Greece 52 MA Macedonian

12 TU Turkey 53 FR France

13 CV Czech Republic 54 WG Germany

14 HG Hungary 55 BL Bulgaria

15 PL Poland 56 BW Botswans

16 UR Russia 57 CP Comores

17 AS Austria 58 LS Lesotho

18 DM Denmark 59 MU Mauritius

19 FL Finland 60 MW Malawi

20 NW Norway 61 MZ Mozambique

21 SD Sweden 62 NM Namibia

22 PG Portugal 63 RE Reunion

23 UK United Kingdom 64 SH Seychelles

24 IL Ireland (Kg) 65 SW Swaziland

25 IL (LB) Ireland (Lb) 66 WZ Zimbabwe

26 CA Canada (Kg) 67 ZW Zambia

27 CA (LB) Canada (Lb) 68 AE U.A.E

28 AG Argentina 69 TT Trinidad and Tobago

29 MX Mexico 70 UD Uganda

30 BZ Brazil 71 LV Latvia

31 CE Chile 72 CVS Slovakia

32 EA Egypt 73 SK Sri Lanka

33 JD Jordan 74 SV Slovenia

34 LN Lebanon 75 UA Ukraine

35 IRN Iran 76 KZ Kazakhstan

36 CR Canary Islands 77 IT Italy

37 TL Thailand 78 SZ Switzerland

38 EC European Community 79 ID India

39 NL Netherlands 80 CD New Caledonia

40 BG Belgium

Page 20

SM100 CALIBRATION

18

3. CALIBRATION

Prior to Calibration, please refer that the specification indicating weight capacity, minimum

graduation, and load cell sensitivity are correctly set.

Caution:

” It can only work when SPAN SWITCH is on (ENABLE).

Before Calibrating, please enter Z mode.

3.1 CALIBRATION OPERATION

OPERATION

DISPLAY

REMARK

PT kg

/kg

Press SPAN SWITCH Z1.0 RESET SALES DAILY

SPAN SWITCH is on

(ENABLE).

[Rezero]+[8][7][1][5] CAL 00

Enter [8][7][1][5] while

depressing [Rezero].

Ensure no weight on

platter,[*]

------

Calibrating zero point.

After storing the zero

Point ‘IR’ count

CAL SP

Put full capacity weight

on platter.[*]

------

Calibrating Span.

After calibration Z1.0 RESET SALES DAILY

Go back to Z mode. Lamp Z

always light.

Page 21

SM100 CALIBRATION

19

3.2 EXIT CALIBRATION

OPERATION

DISPLAY

REMARK

PT kg

/kg

Press SPAN SWITCH Z1.0 RESET SALES DAILY

SPAN SWITCH is

on(ENABLE).

[Rezero]+[8][7][1][5] CAL 00

Enter [8][7][1][5] while

depressing [Rezero].

[T] Z1.0 RESET SALES DAILY

Escape to Z mode. Lamp Z

always light

[Rezero]+[8][7][1][5]

[*]

CAL 00

------

The ‘IR’ count will be taken as

the zero point ‘IR’ count.

After storing the zero

Point ‘IR’ count

CAL SP

Calibrating Span.

[T] Z1.0 RESET SALES DAILY

Escape to Z mode. Lamp Z

always light.

Page 22

SM 100 SOFTWARE SETTING

20

4 SOFTWARE SETTING

4.1 SOFTWARE VERSION UPGRADE

Æ Update Method Introduction

SM-100 use flash RAM instead of EPROM for the main program storage of the scale.

Before the boot program Version 1.10, we just have one method to update the scale’s

software: PC to scale via RS232 interface.

After the boot program Version 1.10 (including V1.10), we add a new method to update

the scale’s software: update the scale by ethernet. So you can choose either method

between these two ones to update your scale.

Now we will set two parts to introduce the steps of these two updating methods.

Æ Update Steps Introduction

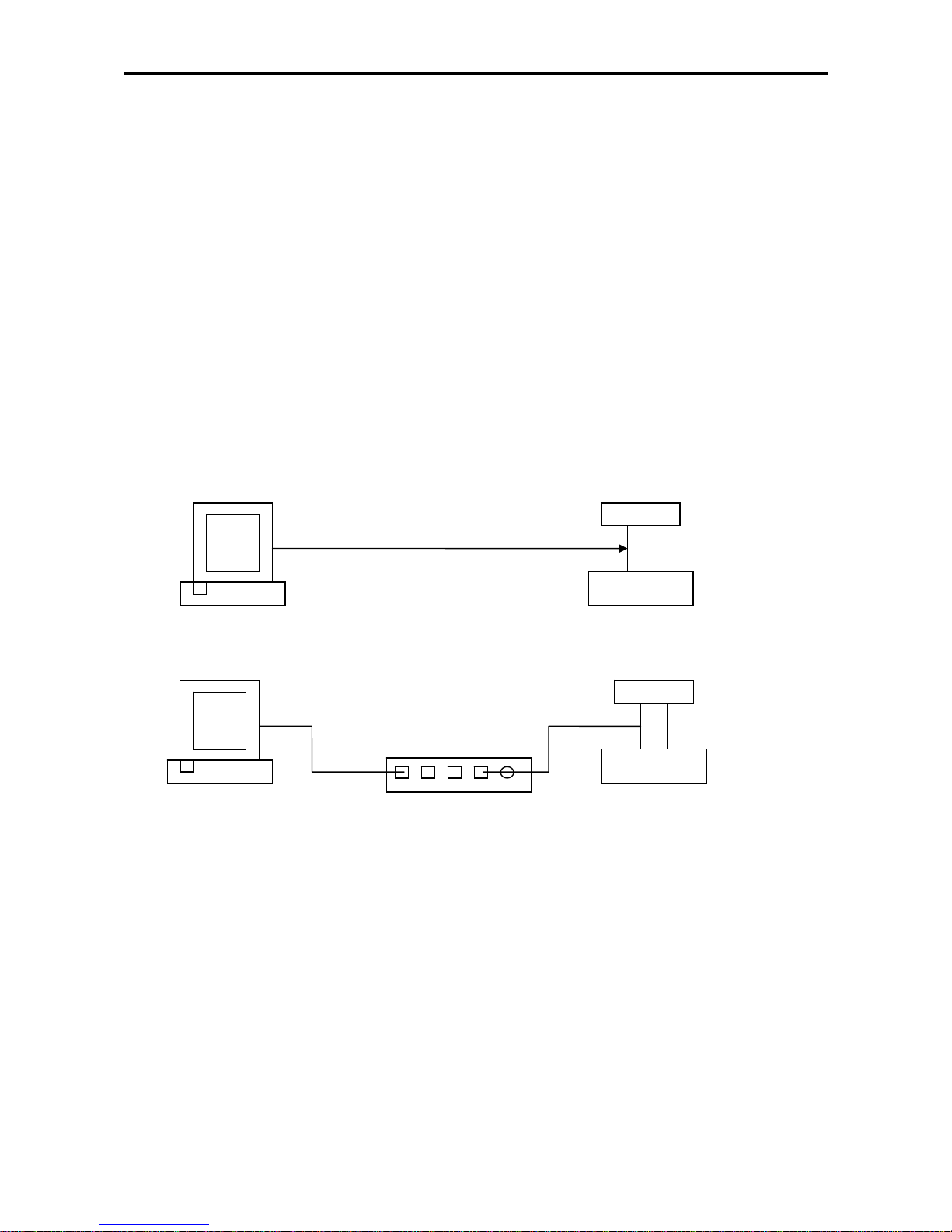

I. Ethernet Update Method

1. Cable & Connection

There are also two ways to connect the PC and the scale in updating the scale by

ethernet.

1) PC to Scale

2) Connect by Hub

PC

Sm-100

Crossing Twisted Cable

PC

Sm-100

Normal Normal

Twisted Cable Twisted Cable

HUB

Page 23

SM 100 SOFTWARE SETTING

21

These two twisted cable obey the EIT/TIA 568 standard.

T568A line series

1 Green &White

2 Green

3 Orange & White

4 Blue

5 Blue & White

6 Orange

7 Brown & White

8 Brown

crossing twisted cable: one end with T568A line series, another with T568B line

series

normal twisted cable: two ends both with T568B line series

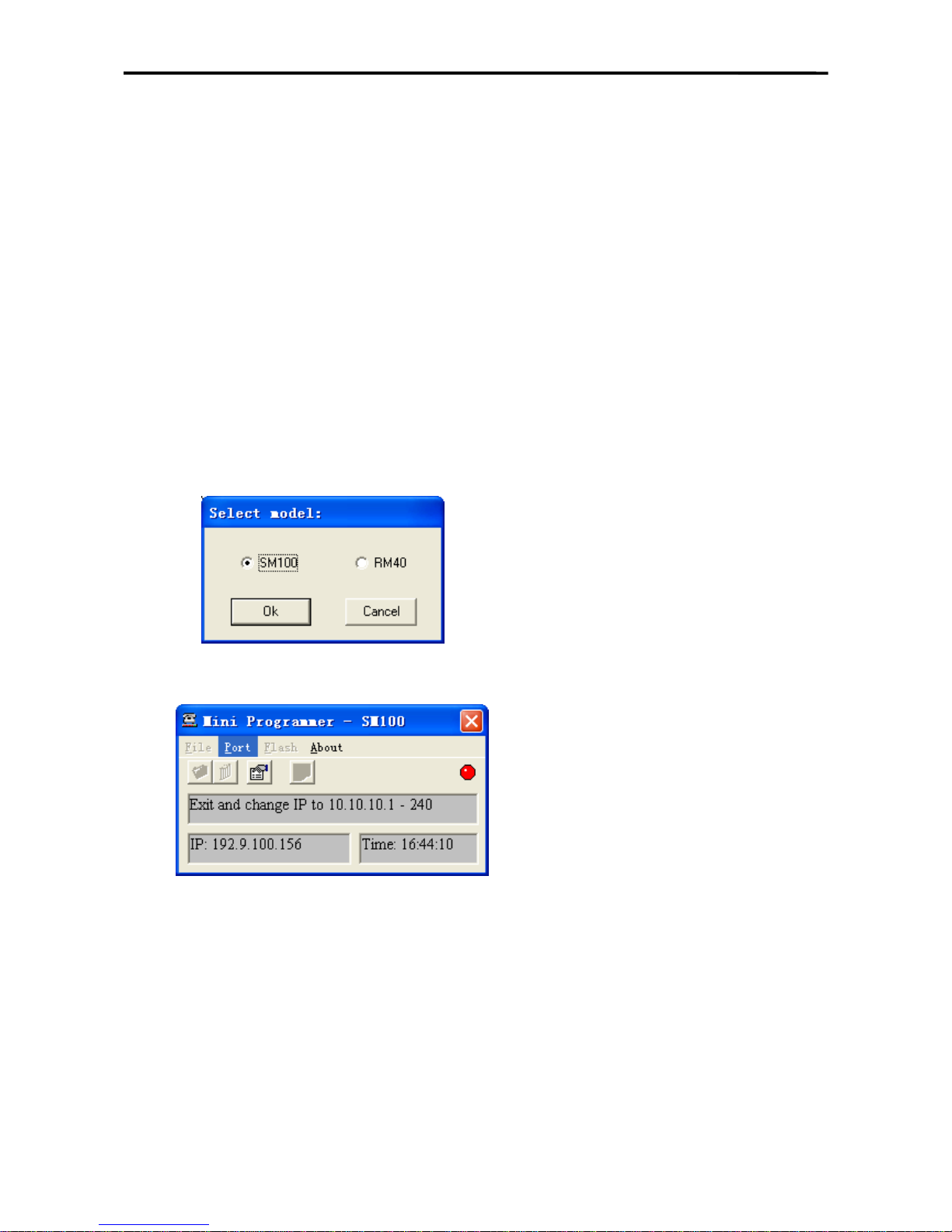

2. PC Setting & Programmer Version

We use “Mini Programmer (Version 2.00)” as the tool to update the scale. As it

needs a default visual IP address for the PC by this kind of update method, You must

set your PC’s IP address within the range of 10.10.10.1-----10.10.10.240

, before you

start the software to update the scale.

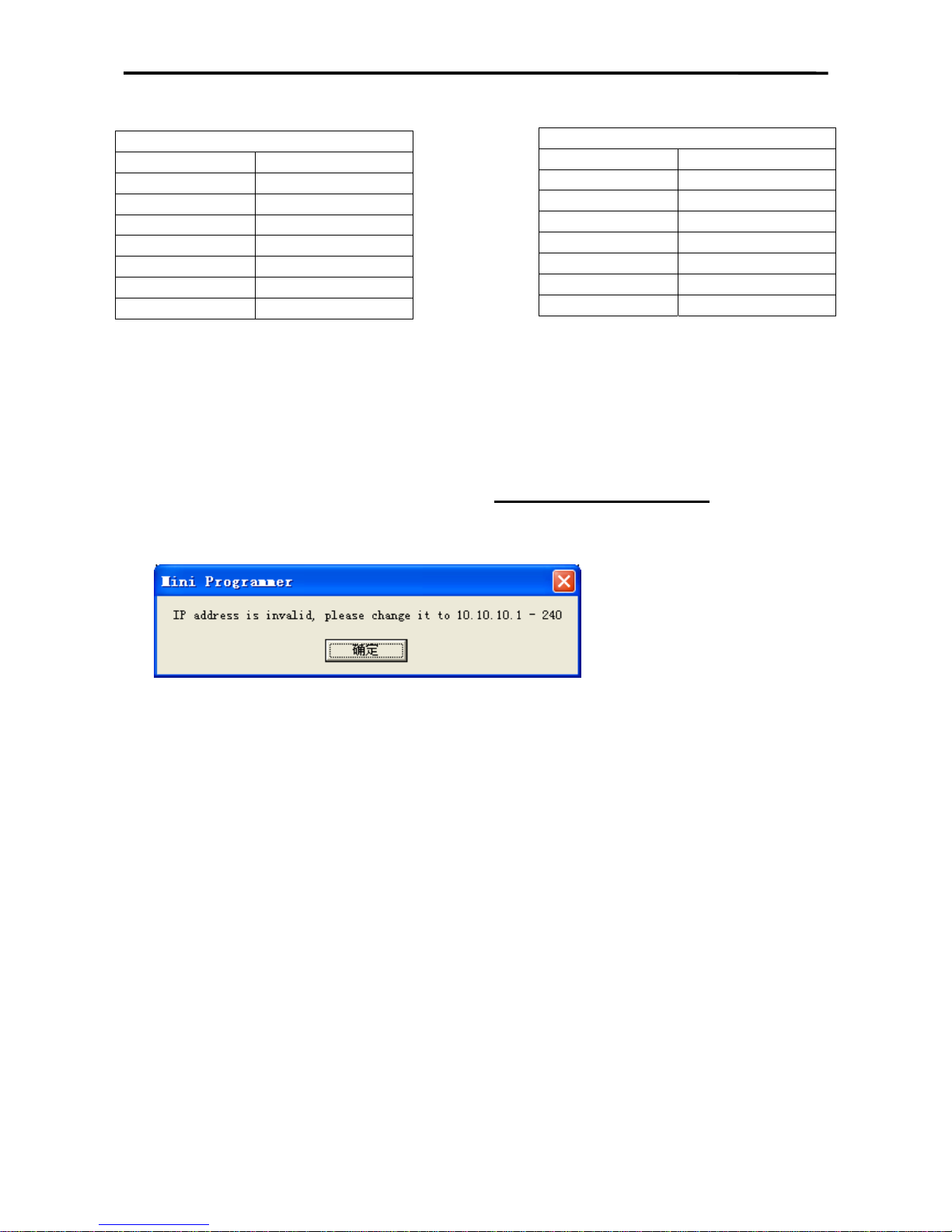

If you don’t set the IP address like this, you can see an alarm window as Pic. 1 when

you start “Mini Programmer”.

Pic. 1

3. Updating Steps

1) How to start ethernet updating?

A. Turn on the switch on the bottom of the scale.

B. Power off the scale by pressing On/Off Key.

C. After that, press and hold [Re-Zero] and [Preset 22], then start the scale by

pressing the On/Off Key.

D. The screen will display the version of the current boot program for two seconds.

E. Only in new versions(version of the boot program newer than 1.10),

you

can choose 2-ethernet.

2) Display on the scale’s screen

A. If you choose 2 and the scale’s connection is correct, it will display “waiting for

connect”.

B. Then the message on the scale’s screen is “getting IP address”.

C. After this, it will display “001 scale ready update”.

D. You can’t stop it unless you press On/Off key. If you want to continue

updating. You also don’t need to press any key on the scale until Mini

Programmer begin to run.

T568B line series

1 Orange & White

2 Orange

3 Green &White

4 Blue

5 Blue & White

6 Green

7 Brown & White

8 Brown

Page 24

SM 100 SOFTWARE SETTING

22

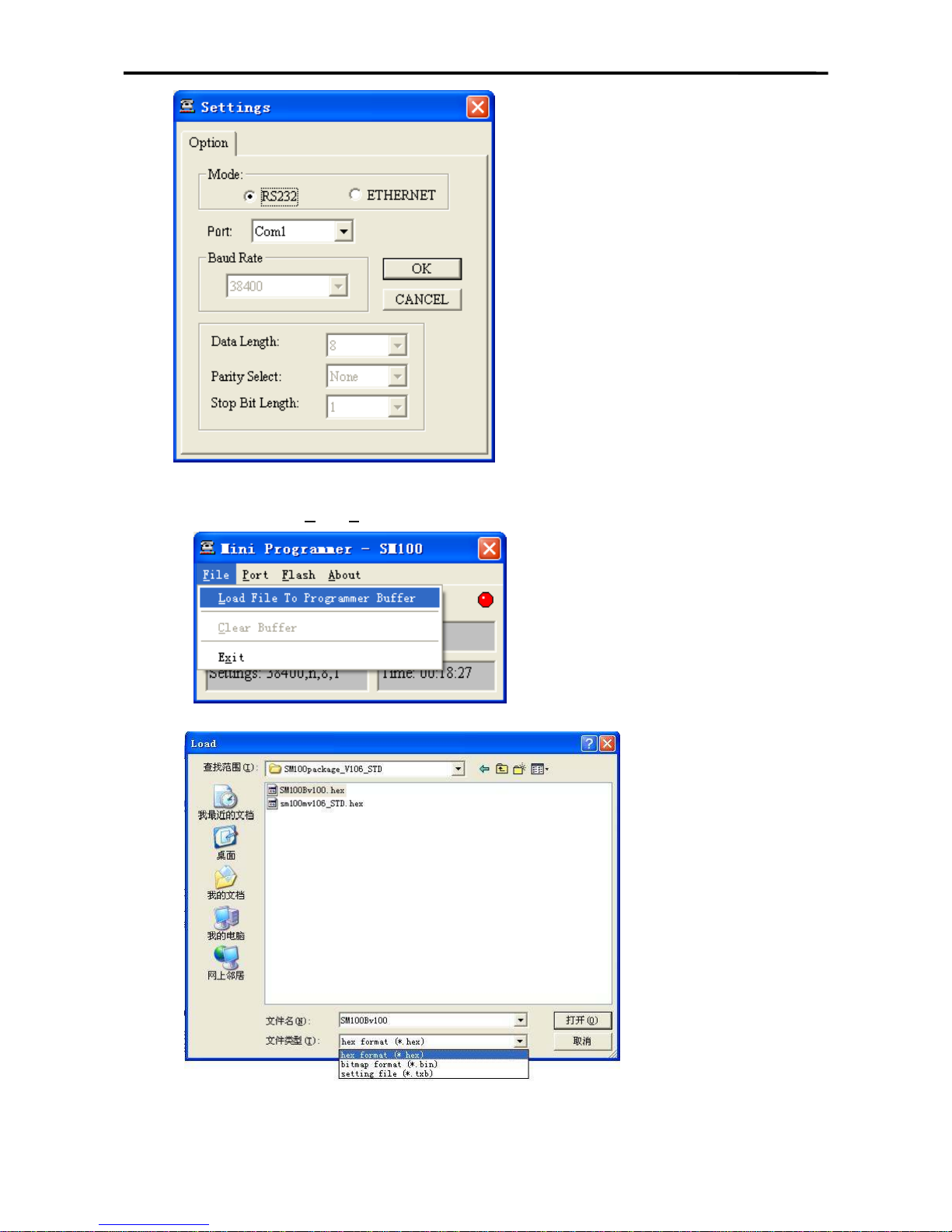

3) How to upload the scale by Mini Programmer?

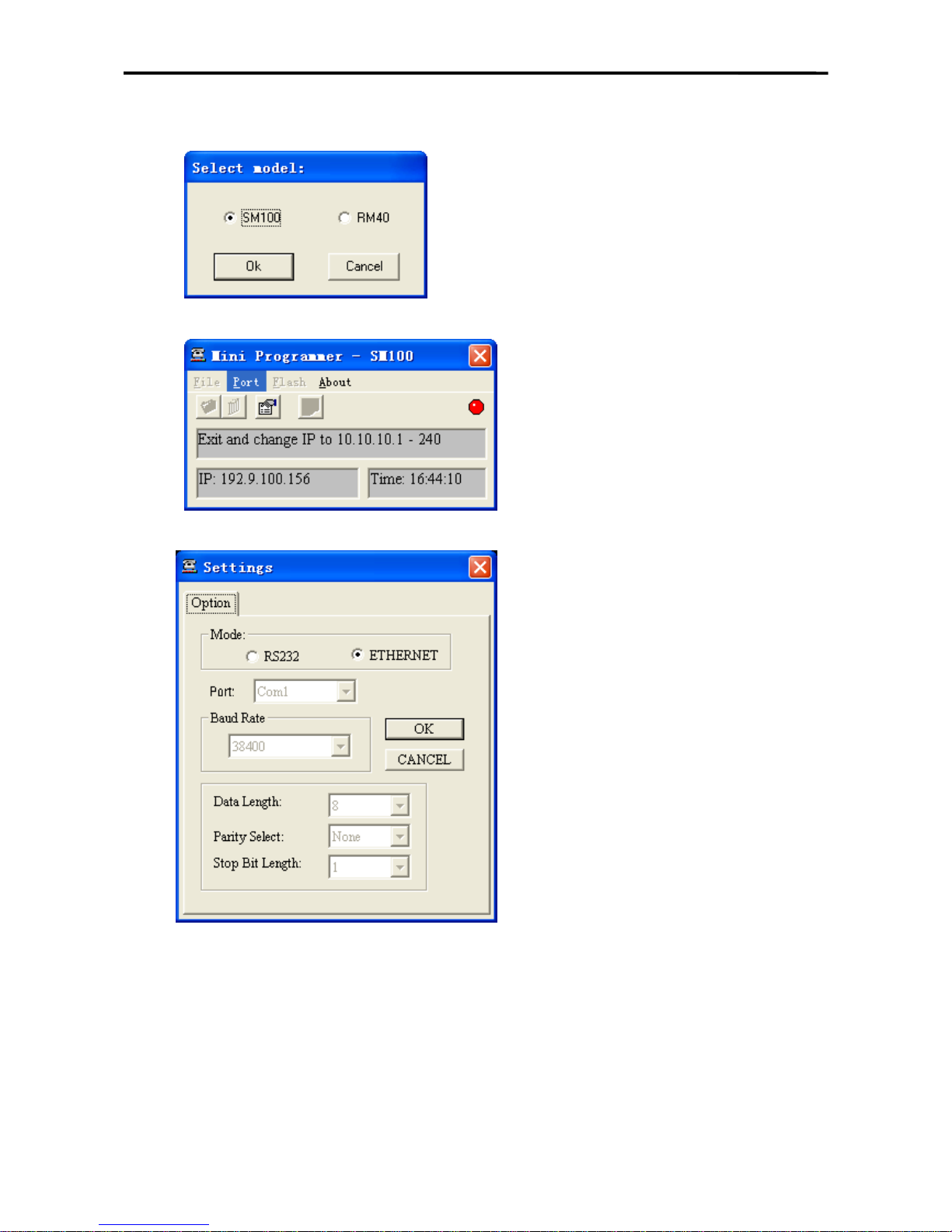

A. Select SM-100 and press “ok”

B. Set the port

Select “ethernet” and press “OK”

Page 25

SM 100 SOFTWARE SETTING

23

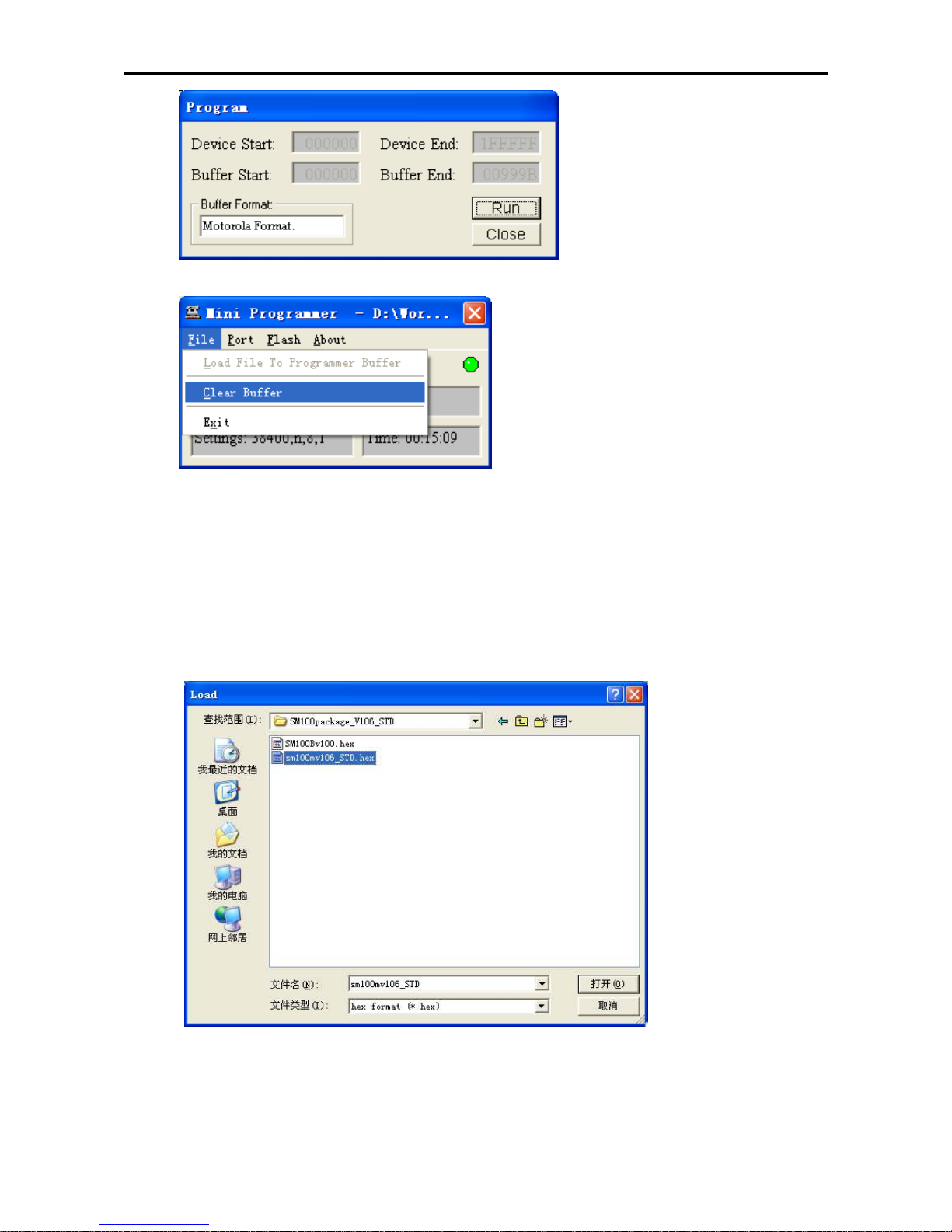

C. Download boot program and update the scale

Select menu “F

ile->Load File To Programmer Buffer”

Open the source file of boot program (e.g. sm100bv100.hex)

You can see a speed mode select window here.

Select menu “F

lash->Program”

Notice: The message “001 scale ready update” must be displayed on the

screen of the scale before pressing the “run” button.

Page 26

SM 100 SOFTWARE SETTING

24

After the transmission has completed, select menu “File->Clear Buffer”.

Notice: 1.If the boot program of this version is already in the scale, you don’t

need to upload it again, skip it and upload the main program.

2.If the scale is updated from 1.xx to 2.xx,firstly you must update the

boot program of the version.

D. Download main program file

You must power off the scale and start the ethernet upload method again when

you have finished a program uploading.

The steps of uploading the main program file is also like uploading the boot

program file. The file you need to open is like Pic. 2

Pic. 2

Page 27

SM 100 SOFTWARE SETTING

25

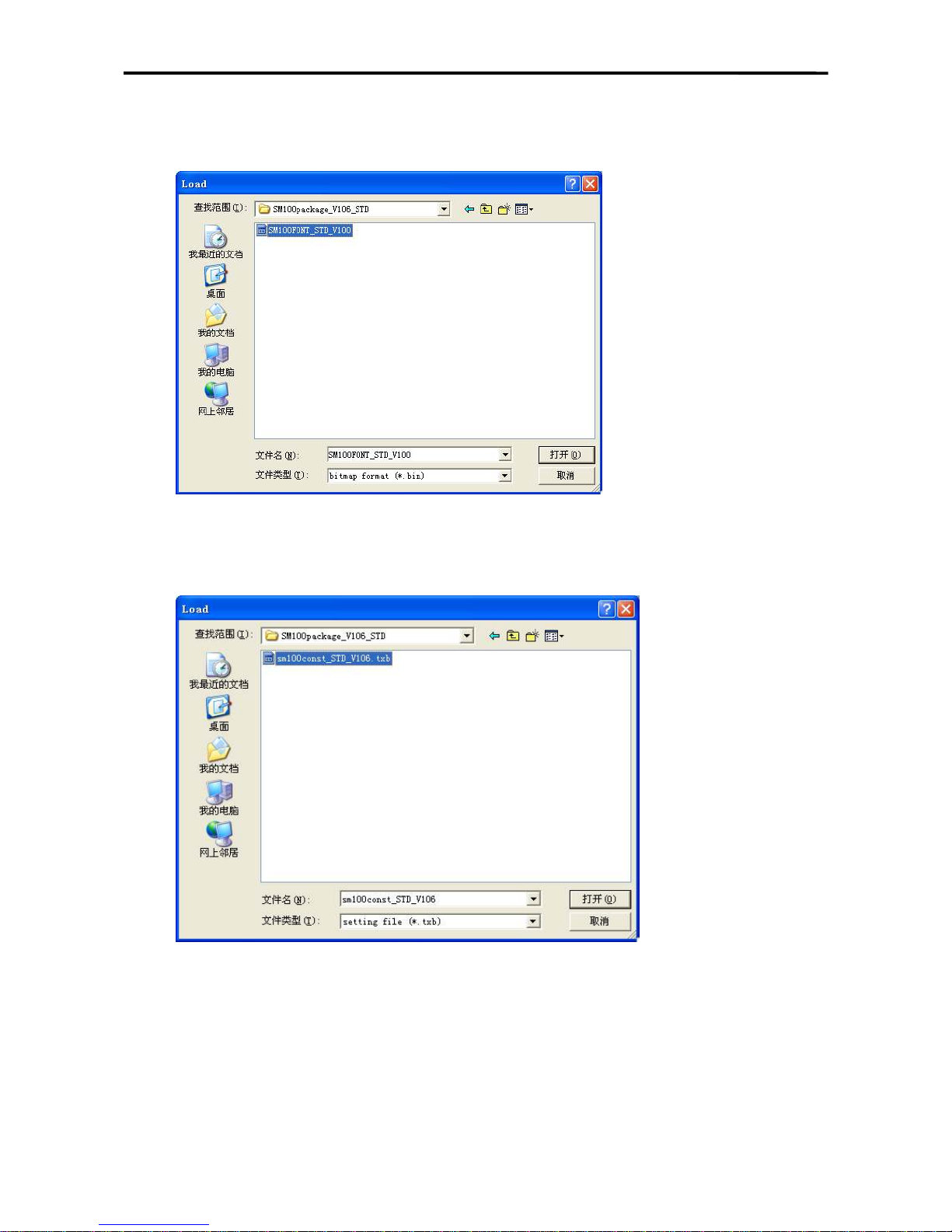

E. Download word-stock file

The steps of uploading the word-stock file is also like uploading the boot program

file. The file you need to open is like Pic. 3

Pic. 3

F. Download const text file

The steps of uploading the const text file is also like uploading the boot program.

The file you need to open is like Pic. 4

Pic. 4

G. Exit Mini Programmer

Note: please update the scale according to sequence above.

Page 28

SM 100 SOFTWARE SETTING

26

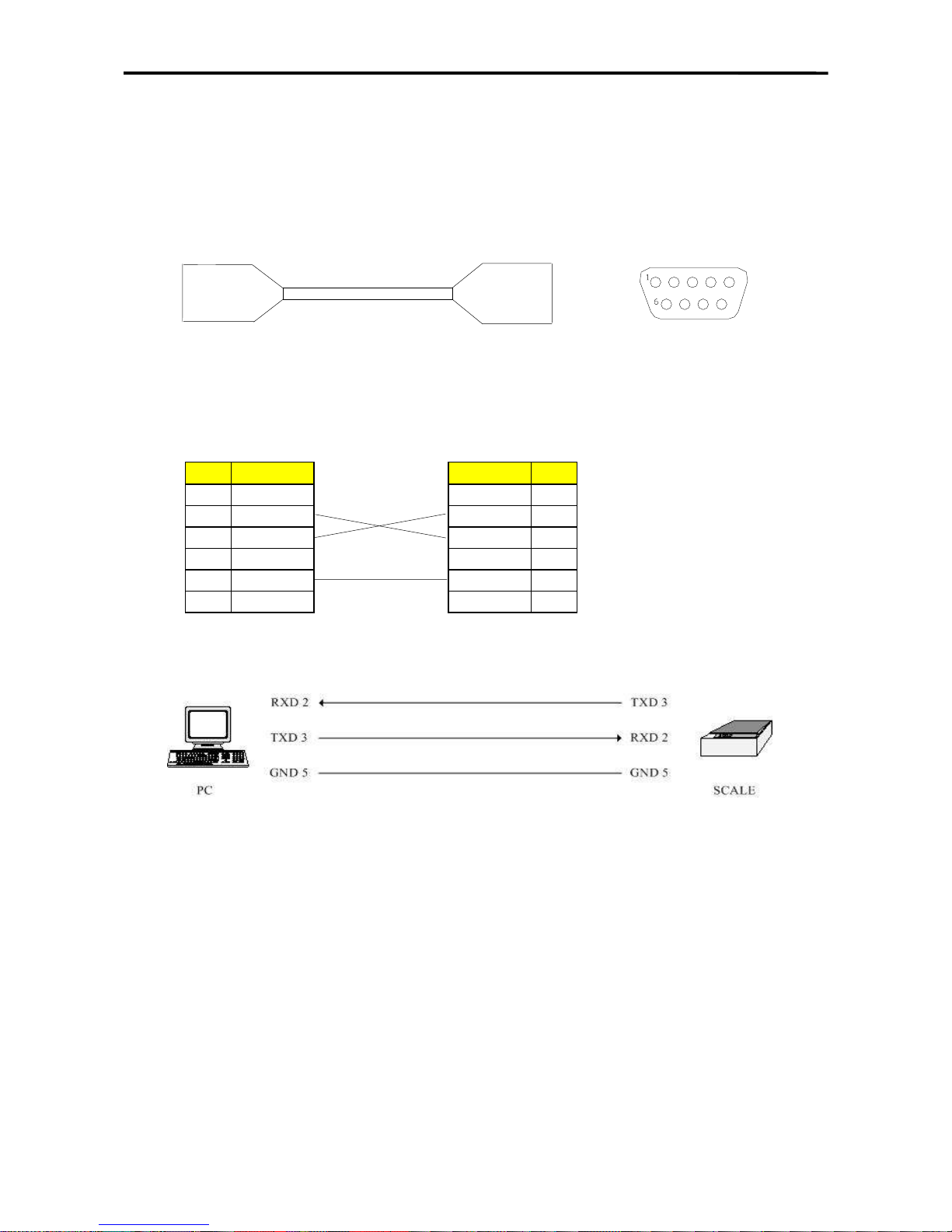

RS232C Method

4. Cable Connection

3 Pins are used for data transmission between PC and SM-100

9 Pin D-Sub Female Connectors for this cable:

PC Serial Port SM-100 RS-232C

9 Pin D-Sub (Female) 9 Pin D-Sub (Female)

Pin Signal Signal Pin

1 N.C. N.C. 1

2 RXD RXD 2

3 TXD TXD 3

4 N.C. N.C. 4

5 GND GND 5

6 - 9 GND N.C. 6 - 9

Page 29

SM 100 SOFTWARE SETTING

27

5. Update Steps

1) How to start RS232C updating

A. Turn on the switch on the bottom of the scale.

B. Power off the scale by pressing the On/Off Key.

C. After that press and hold [Re-Zero] & [Preset 22], then start the scale by press

ing the On/Off Key.

D. It will display the version of the current boot program for two seconds.

E.

Ü If the scale boot version is newer than 1.10, it will display a updating method

choice like “1-RS232 2-ETHERNET” on the screen. you can press Numeric 1

to choose 1-RS232C.

Ü If the boot version is older than 1.10, the scale will not display the choice.

F. Then the Scale will display “PROGRAM”. You can’t stop it, unless you press

Tare or On/Off Key.

2) Start Mini Programmer

1. Select SM-100 and press “Ok”

2. Set the Port:

Select RS232 and press “OK”

Page 30

SM 100 SOFTWARE SETTING

28

3. Download the boot program and update the scale

Select menu “F

ile->Load File To Programmer Buffer”

Open the source file of the boot program (e.g. sm100bv100.hex)

Page 31

SM 100 SOFTWARE SETTING

29

Select menu “Flash->Program”

Notice: The message “001 scale ready update” must be displayed on the

scale before pressing the “run” button.

After the transmission has completed, select menu “File->Clear Buffer”.

Notice: If the boot program of this version is already in the scale, you don’t

need to upload it again, skip it and upload the main program.

Page 32

SM 100 SOFTWARE SETTING

30

4. Download main program file

You must power off the scale and start the ethernet upload method again when

you have finished a program uploading.

The steps of uploading the main program file is also like uploading the boot

program file. The file you need to open is like Pic. 2

Pic. 2

5. Download word-stock file

The steps of uploading the word-stock file is also like uploading the boot program

file. The file you need to open is like Pic. 3

Pic. 3

6. Download const text file

The steps of uploading the const text file is also like uploading the boot program.

The file you need to open is like Pic. 4

Page 33

SM 100 SOFTWARE SETTING

31

Pic. 4

7. Exit Mini Programmer

Page 34

SM 100 SOFTWARE SETTING

32

4.2 SPECIFICATION SETTING

Before Specification setting, please press the mode button to enter Z mode.

The detail specification list , please see the appendix.

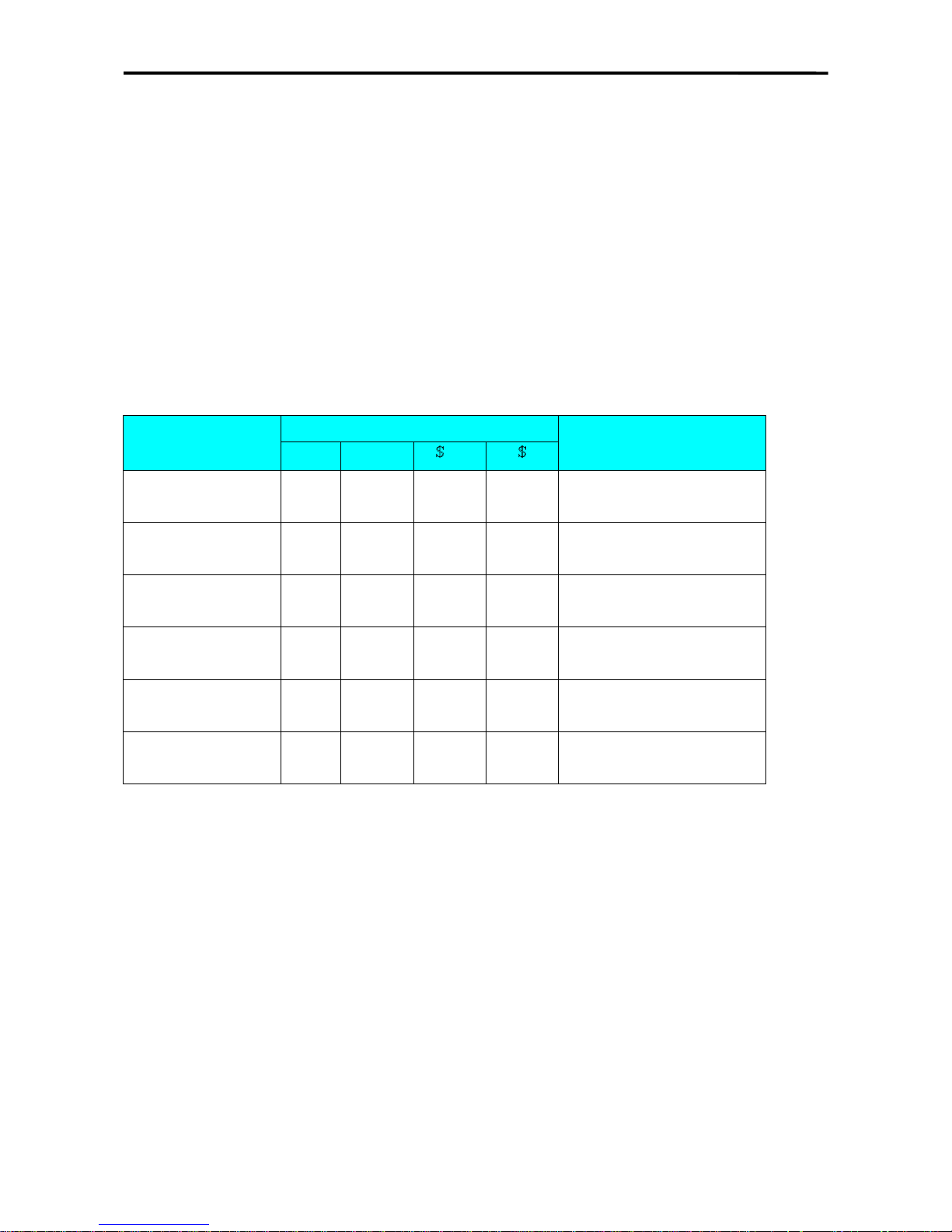

4.2.1 Customer SPEC Setting

To change setting of the Customer SPEC if there are some SPEC setting in it need to be alter.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[1][4][1] SPEC 000

XXX

(setting)

XXX

(former)

Enter [1][4][1] while depressing

[Rezero].

XXX:SPEC data

[]

SPEC 001 XXX XXX

[]key only increase specification

count, it does not update SPEC data.

[]

SPEC 000 XXX XXX

[]key only decrease specification

count, it does not update SPEC data.

[1][7]

[X]

SPEC 000

SPEC 017

017

XXX

XXX

XXX

It goes to a designed specification

count.

(000~441 is enabled)

[>>] SPEC 017 XXX XXX

[>>] key select SPEC data.

Move cursor right.

[<<] SPEC 017 XXX XXX

[<<] key select SPEC data.

Move cursor left.

[1]

[*]

SPEC 017

SPEC 018

001

XXX

XXX

XXX

[C] SPEC 018 000 XXX Clear the enter data.

[PLU]

* Note 1

Z1.0 RESET SALES DAILY

Store the updated specification and

escape to Z mode.

* Remark: The Weight in the display window will display the SPEC number. The Unit Price

window will display the new value setting entered. The Total Price window will

display the old value setting. The selection you have made will be highlighted in the

dot matrix display. Please use [] to increase spec count, [] to decrease spec count,

[*] to store a new value and [PLU] to save spec setting.

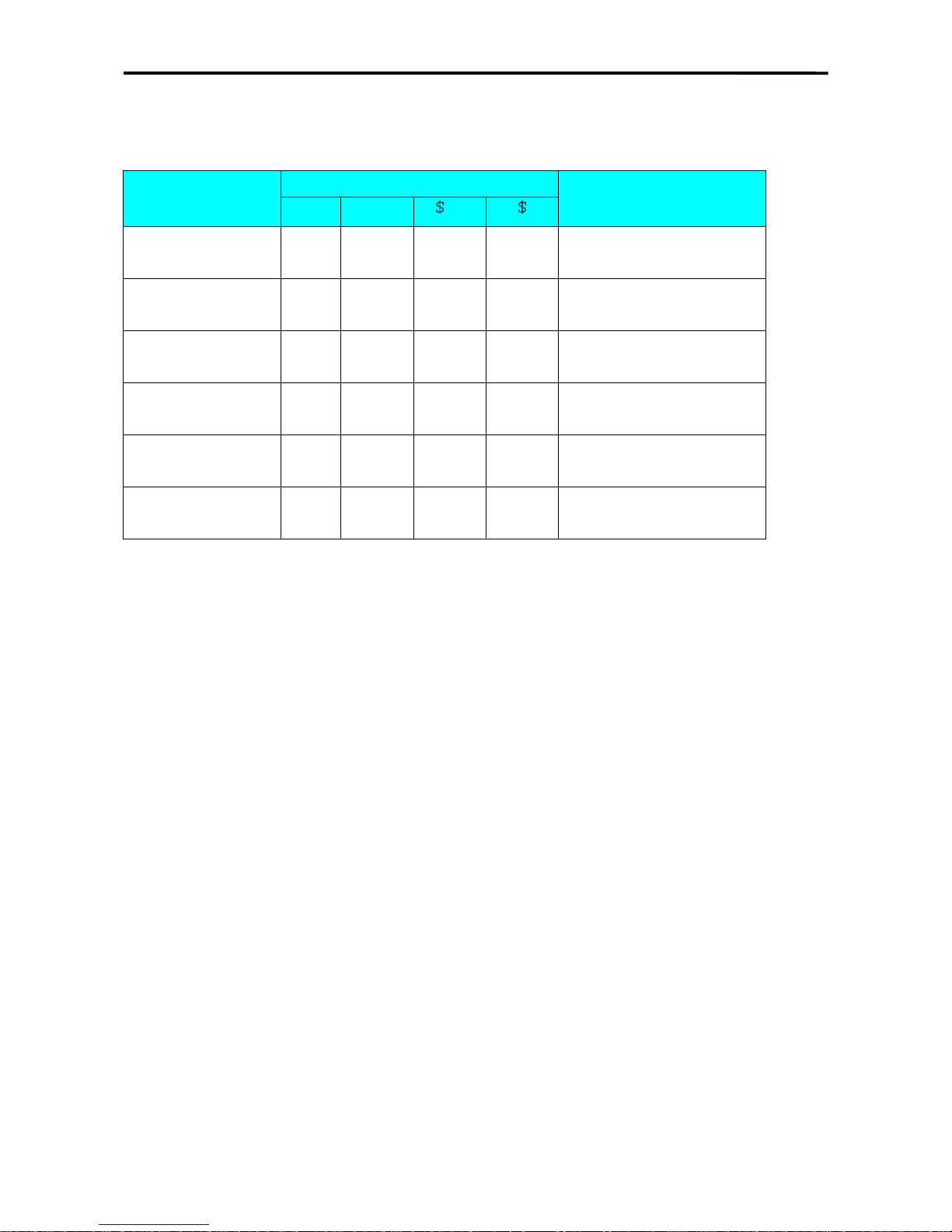

4.2.2 Weight & Measurement SPEC Setting

Page 35

SM 100 SOFTWARE SETTING

33

To change the setting of the Weight & Measurement SPEC if there are some SPEC need to alter.

(Please turn on the span switch when using this process)

OPERATION

DISPLAY

REMARK

PT kg

/kg

Press SPAN

SWITCH

Z1.0 RESET SALES DAILY SPAN SWITCH is on(ENABLE).

[Rezero]+[1][4][2] SPEC 600

XXX

(setting)

XXX

(former)

Enter [1][4][2] while depressing

[Rezero].

XXX:SPEC data

[]

SPEC 601 XXX XXX

[]key only increase specification

count, it does not update SPEC data.

[]

SPEC 600 XXX XXX

[]key only decrease specification

count, it does not update SPEC data.

[6][1][5]

[X]

SPEC 600

SPEC 615

615

XXX

XXX

XXX

It goes to a designed specification

count.

(600~709 is enabled)

[>>] SPEC 615 XXX XXX

[>>] key select SPEC data.

Move cursor right.

[<<] SPEC 615 XXX XXX

[<<] key select SPEC data.

Move cursor left.

[1]

[*]

SPEC 615

SPEC 616

001

XXX

XXX

XXX

[*] key to update specification,

increase specification count.

[2] SPEC 616 002 XXX

[C] SPEC 616 000 XXX Clear the enter data.

[PLU]

* Note 1

Z1.0 RESET SALES DAILY

Store the updated specification and

escape to Z mode.

Note 1: If press [T] key, it does not store the updated specification and escape to Z mode.

* Remark: The Weight in the display window will display the SPEC number. The Unit Price

window will display the new value setting entered. The Total Price window will

display the old value setting. The selection you have made will be highlighted in the

dot matrix display. Please use [] to increase spec count, [] to decrease spec count,

[*] to store a new value and [PLU] to save spec setting.

Page 36

SM100 ADJUSTMENT

34

5. ADJUSTMENT

5.1 PEEL SENSOR VOLTAGE AND LABEL SENSOR SENSITIVITY ADJUSTMENT

LOCATION OF PEEL AND LABEL SENSOR

Page 37

SM100 ADJUSTMENT

35

5.1.1 Peel Sensor Voltage

To set the peel sensor voltage if the peel sensor is not working normally in some situations like temperature

and humidity change.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[5][1][5] PEEL PFD 0.5 0.0

Enter [5][1][5] while depressing

[Rezero].

/kg window displays label paper

peel sensor voltage, window

displays new setting value.

[T] Z1.0 RESET SALES DAILY [T] key to exit.

5.1.2 Label Sensor Sensitivity

When the label came out three or more when feeding or printing, the sensitivity of the sensor need to be

adjusted to sense the gap between the label better. There is a variable resistor near the sensor. Adjust it to

increase or decrease the sensitivity. Clockwise is to increase the sensitivity and anti-clockwise is to decrease

the sensitivity.

Adjust here for sensor

Page 38

SM100 ADJUSTMENT

36

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[5][1][6] GAP PFD 2.0 3.1

Enter [5][1][6] while

depressing [Rezero].

/kg window displays

label paper gap sensor

voltage, window

displays new setting

value.

[T] Z1.0 RESET SALES DAILY [T] key to exit.

Page 39

SM100 ADJUSTMENT

37

5.2 ADJUSTMENT OF PRINTING POSITION

This function is used to adjust the print position on label.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[5][1][4] ADJ PFD 0 0

Enter [5][1][4] while depressing

[Rezero].

/kg window display old setting,

window display new setting.

[1][0] ADJ PFD 0 10

To move up the point position on

label, enter the new value by numeric

key (Ex. 10 dots).

[1][0][]

ADJ PFD 0

10

If you want to move down the print

position, please enter the new value

by numeric key (Ex. 10dots), and

then press [−

] key.

[PLU] 0.000 0.000 0.00 0.00

Save the feed setting.

[T] Z1.0 RESET SALES DAILY

If you want to exit without saves the

setting, press [T] key to exit.

PRINTING TOO HIGH CORRECT POSITION PRINTING TOO LOW

(ADJUST DOWNWARD) (ADJUST UPWARD)

Page 40

SM100 ADJUSTMENT

38

5.3 VOLTAGE CHECKPOINT

There are several voltage checkpoints on the PCB boards. Below are some reference voltage points that are

commonly use.

VOLTAGE POINT VOLTAGE PURPOSE

VCC 3.3 V Provide voltage for most of the IC

VTH 24 V Provide voltage mainly to the thermal head

VBB 3 V Provide backup voltage for the RAM IC

HVcc 5 V

The tolerance of all the voltage is about ± 5% except V

TH

is +2% and -5%

Page 41

SM100 INTERFACE

39

6. INTERFACE

6.1 PC INTERFACE

SM 100 can be connect to PC through Ethernet interface and RS232C. See below for the connection

method.

CONFIGURATION OF PC ETHERNET CARD

Window version client driver

Any Ethernet cards can be used for PC running the Window version client driver

Windows 98

My Computer →

Control Panel → Network→TCP/IP of Ethernet card (Select Properties)

IP address : 192.168.1.XXX ------ XXX - can be any number. But preferable 100 to 255.

Submask : 255.255.255.0

Above IP address is use as a standard address to use for SM 100 Ethernet communication.

If whatever reason, the IP address had to be change, it may do so. But the scale IP address had to be

change at the SM 100 scale also so that they are within the same network. Eg. If the computer IP

address is 192.168.1.XXX, the SM 100 scale IP address has to be change to 192.168.1.XXX. The last

three digits of the IP address should not be similar within the computer and scales at all time. As can

see the first three set of number of the IP address of the computer and scale must be the same.

Page 42

SM100 INTERFACE

40

Before setting the SPEC setting of the scale, please check below.

6.2 SCALE ETHERNET ADDRESS

The main board have a Scale Ethernet Address that is set during production. This address is a

hardware setting for Ethernet communication. But when changing a new main board, the new main

board did not have any this address. If the scale is using Ethernet communication, a Scale Ethernet

Address is needed apart from software IP address. Please take note that the Scale Ethernet Address

can only input once after saving. Please view and note down the Scale Ethernet Address of the old

main board before changing the new main board. Below procedure is to view and input the Scale

Ethernet Address. Please turn on the span switch before proceed.

KEY TO PRESS DISPLAY OPERATION

PT kg

/kg

Go to Z mode Z1.0 RESET SALES Daily At Z mode

[REZERO] +

[0][6][1][2]

ETHER NET ……. ……. Viewing of Ethernet address

For new main board, it can

act as input of the address if

the address shown ……..

Else it would not let you to

input

.

[0][0][0][6][C][0]

[0][0][0][0][2]

[4]

ETHER NET 0006C 0000024 For input only. Enter

Ethernet address e.g.

0006C 0000024

[PLU] Z1.0 RESET SALES Daily Save address and escape to Z

mode. After saving it will

not be able to input again.

[T] Z1.0 RESET SALES Daily Escape to Z mode without

saving.

Power off the scale

Turn off the power and do

the memory clear process.

* IMPORTANT : Please take note that this is a one time setting. It cannot be change after setting

it. Please check the old address and input accordingly. As same internal Ethernet

address in a network may conflict during communication.

6.3 SCALE IP ADDRESS

Page 43

SM100 INTERFACE

41

This is to set the IP address for PC communication using Ethernet for specific IP address. It should

not be confused with the Scale Ethernet Address as above. The Scale Ethernet Address is mainly for

hardware and Scale IP Address is for software. The software when communicating to the scale must

specify the same IP address on the scale else it will give error. The default is 192.168.000.000 where

the last three digit will change when SPEC 135 change. Please turn on the span switch before

proceed.

KEY TO PRESS DISPLAY OPERATION

PT kg

/kg

Go to Z mode Z1.0 RESET SALES Daily At Z mode

[REZERO] +

[0][4][1][6]

SCALE IP ……. ……. Input or viewing of IP

address

[1][9][2][1][6][8]

[0][0][1][0][1][6]

SCALE IP 192168 001016 Enter IP address e.g.

192.168.001.016

( The last 3 digits cannot be

input as it will change when

SPEC 135 change)

[PLU] Z1.0 RESET SALES Daily Save address and escape to Z

mode

[T] Z1.0 RESET SALES Daily Escape to Z mode without

saving.

Page 44

SM100 INTERFACE

42

6.4 CONNECTION METHOD

6.4.1 RS232C Interface with PC

PC Scale

* Note : Only 1 scale can be connect in this method.

SPEC setting on scale

:

SPEC 48 Scale number (For 4 line / RS232C port)

Enter number between 1 to 999,999

SPEC 51 Baud rate for SIO (RS232C port)

0 1200 2 4800 4 19200

1 2400 3 9600 5 38400

6 76800

SPEC 52 Data length for SIO (For RS232C port)

0 7 bit 1 8 bit

SPEC 53 Parity for SIO (For RS232C port)

0 None 1 Odd 2 Even

SPEC 54 Stop bit for SIO (For RS232C port)

0 1 bit 1 2 bits

6.4.2 Ethernet Connection (Ethernet Interface)

Com 1 / Com 2 RS232C Port

Page 45

SM100 INTERFACE

43

Scale #1 Scale #2 Scale #3 Scale #4 Scale #5

PC

HUB

SPEC setting on scale :

SPEC 49 CLIENT / SERVER INTERFACE

0 No interface 3 Not used

1 Ethernet - Coaxial Cable 4 4 lines, RS485 (For future use)

2 Ethernet - Twisted Cable

SPEC 50 CLIENT / SERVER

0 Client 2 Back-up server

1 Server / Workstation

SPEC 135 PORT NUMBER

* Enter number from 1 to 254

Page 46

SM100 INTERFACE

44

6.5 WIRE CONFIGURATION

6.5.1 Ethernet Wire - Straight Cable and Crossover Cable

Straight cable is for Client / Server connection. Crossover cable is for Hub to Hub

connection. (Some models of the hub do not need crossover cable for hub to hub connection.

Please refer to the hub operation manual if in doubt)

Telephone Modular Plug (Category 5) -

Preferable type : CviLux CJP3 / CviLux CJP4 (with insert bar)

CABLE TYPE -

Cable type : 4 pair 100MHz Cat.5 AWG 24 or 26 UTP / FTP / STP.

Preferable type : Cat. 5 AWG 24 or 26 FTP / Cat. 5 AWG 24 or 26 STP

(Recommended for CISPR 22B conformance)

PIN CONFIGURATION

1 8

SM 100 HUB

8 1

Solder to braid wire of the Ethernet

wire if using plug without insert bar

1 8

SM 100 HUB

8 Solder the braid wire of the Ethernet 1

wire if using plug with insert bar

STRAIGHT CONNECTION

CROSSOVER CONNECTION

SCALE HUB HUB HUB

PIN SIGNAL SIGNAL PIN PIN SIGNAL SIGNAL PIN

1 TX+ TX+ 1 1 TX+ TX+ 3

2 TX- TX- 2 2 TX- TX- 6

3 RX+ RX+ 3 3 RX+ RX+ 1

6 RX- RX- 6 6 RX- RX- 2

5,7,8 N.A. N.A. 5,7,8 5,7,8 N.A. N.A. 5,7,8

Page 47

SM100 INTERFACE

45

6.5.2 RS232C Wire

PC (9 PIN) TO SCALE RS232C PORT

6.5.3 Cash Drawer Connector

SM-100 uses normal phone mike plug to connect cash drawer and the scale.

Plug in the scale Connector of Cash Drawer

Pin Output

Input Pin

1 Not used.

Not used 1

2 + 8 V

Voltage + 2

3 GDD

GDD 3

4 Not used.

Not used 4

RS-232

PC

Pin

Pin

1

Not used

Not used 1

2 RXD TXD 2

3

TXD

RXD 3

4 DTR Not used 4

5 GND GND 5

6 DSR Not used 6

7 DTR Not used 7

8 DSR Not used 8

9 Not used Not used 9

RS232C Port9 Pin PC COM Port9 Pin

1 pin

4 pin

1 pin

4 pin

Page 48

SM 100 MISCELLANEOUS

46

7. MISCELLANEOUS

7.1 MODE CHANGE

To toggle between R, X, S, Z and Password mode.

OPERATION

DISPLAY

REMARK

PT kg

/kg

0.000 0.000 0.00 0.00 Weight mode.Lamp R turns on.

[MODE],[MODE]

(within 3 seconds)

XMODE

Enter X mode.Lamp X turns on.

[MODE] S1

PLU FILE

Enter S mode.Lamp S turns on.

[MODE] Z1.0 RESET SALES DAILY Enter Z mode.Lamp Z turns on.

[MODE] PWD X 0 SET

Enter Password Set mode.Lamp X

flicker

[MODE] 0.000 0.000 0.00 0.00 Back to Weight mode.Lamp R turns on.

** The “X ” mark on the X, S, Z and R mean the indicator light is on. When in Passwomode, the

indicator light will be blinking.

7.2 SPAN SWITCH STATUS

To check the status of the span switch.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[2][8][4] STE16 VX.XX S-OFF

Enter [2][8][4] while depressing

[Rezero].

Z1.0 RESET SALES DAILY Exit after 3 seconds.

7.3 CLEAR ALL PLU DATA

To clear all the PLU data only, the span switch status must be on.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[2][3][0] CLEAR PLU FILE

Enter [2][3][0] while depressing

[Rezero].

* CLEAR PLU Y--C N--T Enter C for Yes, Enter T for No..

C(T) Z1.0 RESET SALES DAILY Back to Z mode

7.4 THERMAL HEAD USAGE

Page 49

SM 100 MISCELLANEOUS

47

To check how many time the thermal head had been printing.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][8][2][3] PRINTER USAGE 5

Display thermal printer usage

condition(meter).

[T] Z1.0 RESET SALES DAILY [T] key to exit.

7.5 IP ADDRESS

To check and modify the scale IP address.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1][6] SCALE IP 19216800 0000 Display the scale IP address.

[1][9][2][0][0]

[9][1][0] [0]

SCALE IP 19200910 0000

Modify the IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

7.6 SERVER IP ADDRESS

To check and modify the server IP address.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1]7] SERVER IP 25525525 5000 Display the server IP address.

[1][9][2][0][0]

[9][1][0] [0]

SCALE IP 19200910 0000

Modify the server IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

7.7 SUBNET MASK

Page 50

SM 100 MISCELLANEOUS

48

To check and modify the subnet mask.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[0][4][1]8] SERVER IP 25525525 5000 Display the server IP address.

[1][9][2][0][0]

[9][1][0] [0]

SCALE IP 19200910 0000

Modify the server IP address.

[#] ----------

Save the new IP address.

Press [T] key to exit.

7.8 MAC ADDRESS

To check the MAC address.

Please turn on the span switch before proceed.

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode Z1.0 RESET SALES

DAILY Z mode.

Lamp Z turns on.

[Rezero]+[0][6][1]2]

ETHERN

ET

0006C071 96BE

Display the

MAC address.

[T] Z1.0 RESET SALES DAILY Press [T] key to exit.

7.9 SERIAL NO

To check the serial NO..

OPERATION

DISPLAY

REMARK

PT kg

/kg

Go to Z mode

Z1.0 RESET SALES DAILY

Z mode.

Lamp Z turns on.

[Rezero]+[1][1][1] SCALE S/N 05386686 Display the serial NO..

[T] Z1.0 RESET SALES DAILY Press [T] key to exit.

8.0 ASCII CHARACTER

Below are the common use of characters of ASCII code in HEX value. Please enter the hex value

when entering commodity name, advertisement, shop name, clerk name, special message,

ingredient, text etc. when using the SM-100.

A B C D E F G H I J K L M

Page 51

SM 100 MISCELLANEOUS

49

41 42 43 44 45 46 47 48 49 4A 4B 4C 4D

N O P Q R S T U V W X Y Z

4E 4F 50 51 52 53 54 55 56 57 58 59 5A

a b c d e f g h i j k l m

61 62 63 64 65 66 67 68 69 6A 6B 6C 6D

n o p q r s t u v w x y z

6E 6F 70 71 72 73 74 75 76 77 78 79 7A

0 1 2 3 4 5 6 7 8 9 ! @ #

30 31 32 33 34 35 36 37 38 39 21 40 23

$ % ^ & * ( )

: ; " '

+ <

24 25 5D 26 2A 28 29 3A 3B 22 27 2B 3C

> = / ?

·

,

Space

3E 3D 2F 3F 2E 2C 20

Page 52

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 1 of 32

TITLE

REVISION NO.

ISSUED DATE

:

:

:

SM-100 SPECIFICATION LIST

0

17 August, 2004

Rev.

No.

Modification Details

Software

Version

0 First Release 1.00

Page 53

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 2 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

CUSTOMER SPECIFICATION [REZERO] + [1][4][1]

00 Item Barcode

X

0 F1F2 CCCCC XCD XXXX CD 13 F1X2 CCCCCC XXXX CD

All are 13 digits non-PLU

barcode unless

otherwise stated.

#1 13 digits PLU

barcode

#2 8 digits PLU barcode

#3 8 digits non-PLU

barcode

1 F2 CCCCCC XCD XXXX CD 14 F1F2 CCCC XCD XXXXX CD

2 F1F2 CCCCC 0 XXXX CD 15 F2 CCCCC XCD XXXXX CD

3 F1F2 CCCCCC XXXX CD 16 F1F2 CCC XXXXXXX CD

4 F1F2 CCCCC XXXXX CD 17 F1F2 CC XXXXXXXX CD

5 F2 CCCCCC XXXXX CD 18 CCC WWWW PPPPP CD

6 F2 CCCCC XXXXXX CD 19 No Barcode

7 F1F2 CCCCCCCCCC CD #1 20 F1F2 CCCCC PCD XXXX CD

8 F1F2 CCCC XXXXXX CD

9 F1F2 CCCCC CD #2

10 F2 CC XXXX CD #3

11 No Barcode

12 F1X2 CCCCC XCD XXXX CD

01 Right Side Data of Item Barcode

X

0 Quantity 4 Original Price

# Related to SPEC153.

1 Price 5 Weight / Quantity

2 Weight 6 Unit Price

3 User Programmable # 7 Unit Price after discount

02 Right Side Price Data of Item Barcode

X

0 Price before Tax 1 Price after Tax

Effective when SPEC1 =

1

03 Flag Data F1 and F2 for 13 Digits Non-PLU Barcode

X

Enter value from range 0 to 99

04 Flag Data F1 and F2 for 13 Digits PLU Barcode

X

Enter value from range 0 to 99

05 Flag Data F2 for 8 Digit Non-PLU Barcode

X

Enter value from range 0 to 9

06 Flag Data F1 and F2 for 8 Digit PLU Barcode

X

Enter value from range 0 to 99

07 Total Barcode

X

0 F1F2 CCCCC XCD XXXX CD 12 F1X2 CCCCC XCD XXXX CD

All are 13 digits non-PLU

barcode unless

otherwise stated.

#1 13 digits PLU

barcode

#2 8 digits PLU barcode

#3 8 digits non-PLU

barcode

1 F2 CCCCCC XCD XXXX CD 13 F1X2 CCCCCC XXXX CD

2 F1F2 CCCCC 0 XXXX CD 14 F1F2 CCCC XCD XXXXX CD

3 F1F2 CCCCCC XXXX CD 15 F2 CCCCC XCD XXXXX CD

4 F1F2 CCCCC XXXXX CD 16 F1F2 CCC XXXXXXX CD

5 F2 CCCCCC XXXXX CD 17 F1F2 CC XXXXXXXX CD

6 F2 CCCCC XXXXXX CD 18 CCC WWWW PPPPP CD

7 F1F2 CCCCCCCCCC CD #1 19 No Barcode

8 F1F2 CCCC XXXXXX CD 20 F1F2 CCCC PCD XXXX CD

9 F1F2 CCCC CD #2

10 F2 CC XXXX CD #3

11 No Barcode

08 Left Side Data of Total Label

X

0 Scale No. 3 Clerk No.

1 Last Accumulated Item Code 4 Fixed No.

2 Receipt No.

09 Fixed Data for Left Side Data of Total Barcode

X

Enter value from range 0 to 9 999 999 999

10 Flag Data F0, F1 and F2 for Total Barcode

X

Enter value from range 0 to 999

Page 54

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 3 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

11 Right Side Data of Total Barcode

X

0 Quantity 2 Weight

1 Price

12 Total Barcode Print on Receipt

X

0 No 1 Yes

13 Print Readable Character of F1 for Item and Total Barcode (for EAN only)

W

0 No Print 1 Print

14 Printing Position for Advertisement Message

X

0 First Line 2 Above

1 Below 3 Not Used

15 Turnover Printing for Advertisement Message

0 No 1 Yes

16 Exit from “Change” Mode within Specified Interval

X

0 No 3 10 sec

1 3 sec 4 15 sec

2 6 sec

17 Order of the Month, Day and Year for Print

X

0 MM/DD/YY 2 YY/MM/DD

1 DD/MM/YY 3 Not Used

18 1 or 2 Line(s) Commodity Name on Receipt

X

0 2 Lines

2 No Print

1 1 Line

19 Label Printing by Clerk Key

X

0 No Print 2 Print without Accumulated

1 Print with Accumulation

20 Total Label Printing

X

0 No Print 1 Print

21 Printing Operator Name on Receipt and Label

X

0 Code 1 Name

22 Receipt Paper Width

W

0 60 mm 2 50 mm

1 40 mm

23 Manual Price Entry for Printing or Accumulating

X

0 Allow 1 Inhibit

24 Default Label Format for Item Printing

X

0 T1 (A)

12 S (T7)

Formats in ( ) are for U1

and CA only.

F1 to F8 are Free

Format.

1 T2 (B)

13 A (T8)

2 T3 (C)

14 B (T9)

3 T4 (U2)

15 C (T10)

4 T5 (U3)

16 F1 (F1)

5 T6 (U4)

17 F2 (F2)

6 T7 (U5)

18 F3 (F3)

7 T8 (U6)

19 F4 (F4)

8 T9 (U7)

20 F5 (F5)

9 T10 (U8)

21 F6 (F6)

10 T11 (T5)

22 F7 (F7)

11 T12 (T6)

23 F8 (F8)

Page 55

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 4 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

25 Default Label Format for Total Printing

X

0 T1 (A)

12 S (T7)

Formats in ( ) are for U1

and CA only.

F1 to F8 are Free

Format.

1 T2 (B)

13 A (T8)

2 T3 (C)

14 B (T9)

3 T4 (U2)

15 C (T10)

4 T5 (U3)

16 F1 (F1)

5 T6 (U4)

17 F2 (F2)

6 T7 (U5)

18 F3 (F3)

7 T8 (U6)

19 F4 (F4)

8 T9 (U7)

20 F5 (F5)

9 T10 (U8)

21 F6 (F6)

10 T11 (T5)

22 F7 (F7)

11 T12 (T6)

23 F8 (F8)

26 Shop Name Printing on Label

X

0 No Print 1 Print

27 Forced Tare Function

X

0 Disable 1 Enable

28 Peel Sensor Function in Prepack Mode

X

0 Disable 1 Enable

29 Continuous Print for Label in Prepack Mode

X

0 Inhibit 1 Allow

30 Selection of CDV

W

0 Inhibit 1 Allow

For SF only.

31 CDV Type

W

0 CDV 1 Tear-off

For SF only.

32 CDV Modulus

W

0 Modulus 10 1 Modulus 11

For SF only.

Effective when SPEC30

and 31 = 1.

33 On Spot Correction

X

0 Allow 1 Inhibit

34 Search Correction

W

0 Allow 1 Inhibit

35 Move Back Correction

X

0 Allow 1 Inhibit

36 Past Sales Data Correction

0 Allow 1 Inhibit

37 Label Print Density

X

0 Low 2 High-mid

1 Mid 3 High

38 Receipt Print Density

X

0 Low 2 High-mid

1 Mid 3 High

39 Calling of PLU

X

0 Manual 2 Time-out

Related to SPEC40.

1 Auto

40 PLU Digits for Auto PLU Calling/Time-out Calling

X

0 3 Digits / 0.5 sec 2 5 Digits / 1.5 sec

Effective when SPEC39

= 1.

1 4 Digits / 1.0 sec 3 6 Digits / 2.0 sec

Page 56

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 5 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

41 Unit Price of Weigh PLU Can Use for Price of Non-weigh PLU and Vice Versa

X

0 Allow 1 Inhibit

Effective when SPEC643

= 0.

42 Unit Price Override

X

0 Allow 1 Inhibit

43 Main Usage for Commodity Name, Shop Name and Special Message

X

0 Receipt 1 Label

Always set to 0 for SM-

200.

44 Tare Override

X

0 Allow 1 Inhibit

45 Item Printing

X

0 Allow 1 Inhibit

46 Default Data of Printing Shop Name Number for Label

X

Enter value from range 0 to 32

47 Default Data of Printing Shop Name Number for Receipt

X

Enter value from range 0 to 32

48 Setting of Scale Number

X

Enter value from range 0 to 999 999

49 Type of Client / Server Interface

X

0 No Interface 3 Not Used

Related SPECs for

Ethernet I/F are

SPEC50, 135, 214.

1

Ethernet (Coaxial Cable) 4 4-Lines (RS-485)

2 Ethernet (Twisted Pairs)

50 Setting of Client / Server

X

0

Client 2 Backup Server

Related SPECs for S/C

setting are SPEC61, 150,

163, 165, 187, 194, 208,

229, 252, 253, 254, 255,

265, 276.

1 Server / Workstation

51 Baud Rate of SIO (RS-232C Port)

X

0 1 200 bps 4 19 200 bps

Apply to both RS-232C

and RS-485 ports setting

for SM-300.

Related SPECs are

SPEC48, 52, 53, 54, 60,

134.

1 2 400 bps 5 38 400 bps

2 4 800 bps

6 76 800 bps

3 9 600 bps

52 Data Length of SIO (RS-232C Port)

X

0 7 Bits 1 8 Bits

Apply to both RS-232C

and RS-485 ports setting

for SM-300.

53 Parity Bit of SIO (RS-232C Port)

X

0 None 2 Even

Apply to both RS-232C

and RS-485 ports setting

for SM-300.

1 Odd

54 Stop Bit of SIO (RS-232C Port)

X

0 1 Bit 1 2 Bits

Apply to both RS-232C

and RS-485 ports setting

for SM-300.

55 Baud Rate of Multi-drop SIO (RS-485 / 4-Lines Port)

W

0 1 200 bos 3 9 600 bps

Related SPECS are

SPEC48, 56, 57, 58, 59,

134.

1 2 400 bps 4 19 200 bps

2 4 800 bps 5 38 400 bps

56 Data Length of Multi-drop SIO (RS-485 / 4-Lines Port)

W

0 7 Bits 1 8 Bits

Page 57

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 6 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

57 Parity Bit of Multi-drop SIO (RS-485 / 4-Lines Port)

W

0 None 2 Even

1 Odd

58 Stop Bit of Multi-drop SIO (RS-485 / 4-Lines Port)

W

0 1 Bit 1 2 Bits

59 Multi-drop SIO (RS-485 / 4-Lines Port) Select Job

W

0 No Operation 2 Pick ‘N’ Pay #2

#1 Either SPEC59 or 60

can be selected at any

one time.

#2 For SF only.

1 FIS 3000 #1

60 SIO (RS-232C Port) Select Job

W

0 No Operation 3 Point ‘N’ Shop

Apply for both RS-232C

and RS-485 ports setting

for SM-300.

#1 Refer to SPEC59’s

comments #1.

#2 For SM-300 only

1 FIS 30000 #1 4 Barcode Scanning

2 FL-1 5 Video Control #2

61 Floating Clerk

W

0 Inhibit 1 Allow

62 Receipt Free Format

W

0 Disable 1 Enable

Exclude AA.

63 SM-90 and DI-10 RS-232C Communication

W

0 No 1 Yes

64 Enable Password Mode

X

0 Allow 2 Allow Multi Password

1 Inhibit

65 Report Printing in Daily and Term Transaction Clea

r

X

0 Inhibit 1 Allow

66 Pack Quantity Function Key Enable

X

0 Allow 1 Inhibit

67 Advertisement Function Key Enable

X

0 Allow 1 Inhibit

68 Fixed Total Price Discount Function Key Enable

X

0 Allow 1 Inhibit

69 Total Price Percentage Discount Function Key Enable

X

0 Allow 1 Inhibit

70 Fixed Unit Price Function Key Enable

X

0 Allow 1 Inhibit

71 Fixed Unit Price Percentage Function Key Enable

X

0 Allow 1 Inhibit

72 Pack Date Function Key Enable

X

0 Allow 1 Inhibit

73 Minus Pack Date Function Key Enable

X

0 Allow 1 Inhibit

74 Sell by Date Function Key Enable

X

0 Allow 1 Inhibit

75 Unit Symbol Function Key Enable

0 Allow 1 Inhibit

Page 58

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 7 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

76 Quantity Set Function Key Enable

0 Allow 1 Inhibit

77 Price Change Function Key Enable

0 Allow 1 Inhibit

78 Refund Item Function Key Enable

X

0 Allow 1 Inhibit

79 Shop Name Function Key Enable

X

0 Allow 1 Inhibit

80 Logo Function Key Enable

X

0 Allow 1 Inhibit

81 Print Select Function Key Enable

X

0 Allow 1 Inhibit

82 Print of Place of Production on Label

X

0 Inhibit 1 Allow

83 Selection of Markdown

X

0 No Markdown 2 Total Price Markdown

1 Unit Price Markdown 3 Unit and Total Price Markdown

84 Sub-total Function Key Enable

X

0 Allow 1 Inhibit

85 Grand Total Function Key Enable

X

0 Allow 1 Inhibit

86 Label Sensor Gap Value

W

Enter value range from 0 to 255

87 Label Type

X

0 Gap 1 No Gap

88 Sell by Date Title Print out

W

0 Inhibit 1 Allow

For AA only.

89 ASCII Code Entry in S Mode

W

0 Inhibit 1 Allow

For AA only.

90 Sub-total Markdown

X

0 No Markdown 1 Markdown

91 Printer Speed for Receipt

X

0 Slow 2 High

1 Normal

92 Printer Speed for Label

X

0 Slow 2 High

1 Normal

Printer Strode

W

0 Single 2 Not Used

1 Double

93 Print Second Receipt

X

0 No Print 3 3 sec Delay

1 Continuous Print 4 User Select

2 1 sec Delay

94 Position of Currency Symbol (on Label)

X

0 Before Price 1 After Price

Page 59

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 8 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

95 Receipt Printing with Dual Copy

W

0 Inhibit 1 Allow

96 Advertisement Message on All Label

X

0 Inhibit 1 Allow

97 Manual Print in Prepack Mode for Weigh Item

X

0 Inhibit 1 Allow

98 Quantity and Unit Symbol Print Out for Non-weigh Item in Manual Mode

X

0 Allow 1 Inhibit

99 Unit Print Out for Non-weigh Item in Manual Mode

W

0 Inhibit 1 Allow

100 Discount in PLU Programming

W

0 Allow 1 Inhibit

101 Zero Suppress for Date and Time

X

0 Disable 1 Enable

102 Discount Presentation in Receipt

W

0 Discounted Unit Price and

Original Price

1 Original Unit Price and Price

103 Unit Price Assignment Function Key for PLU

0 Enable 1 Disable

104 Discount Price Rounding Method

X

0 Rounding 2 Cut Up

1 Cut Down

105 Fixed Total Price Markdown Function Key Enable

X

0 Allow 1 Inhibit

106 Total Price Percentage Markdown Function Key Enable

X

0 Allow 1 Inhibit

107 Fixed Unit Price Markdown Function Key Enable

X

0 Allow 1 Inhibit

108 Fixed Unit Price Percentage Markdown Function Key Enable

X

0 Allow 1 Inhibit

109 Source of Sell by Date

X

0 Real Time Clock 1 Packed Date

110 Year Type

W

0 Standard 1 Japanese / Taiwan

For AA and TW only.

111 Price Symbol on Receipt

W

0 No Print 2 Yen

For AA only.

1 Kanji Yen

112 Default Data of Printing Special Message Number for Receipt

X

Enter value range from 0 to 16

113 Label Logo Printing Status

X

0 No Print 3 Logo 3

1 Logo 1 4 Logo 4

2 Logo 2

Page 60

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 9 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

114 Receipt Logo Printing Status

0 No Print 4 Logo 3

1 Logo 1 5 Logo 4

2 Logo 2 6 Logo 1, 2, 3 and 4

3 Logo 1 and 2

115 Type of Entry for Used by Date and Sell by Date

W

0 By Day 1 By Hour

For NICHII only.

116 Barcode Printing in First Label for Dual Label Printout

W

0 Print 1 No Print

For NICHII only.

117 Zero Minutes Printing

W

0 No Print 1 Print

For NICHII only.

118 Both Price before and after Discount

W

0 Price before and after Discount 1 Price befor e Discount only

For NICHII only.

119 Unit Symbol Printout in Receipt

X

0 Depend on PLU Programming 2 No Print

For AA only.

1 Japanese PCS

120 PLU Number Print

X

0 No Zero Suppress 1 Zero Suppress

121 Thick Japanese Character Printout

W

0 Thick Character 1 Thin Character

For AA only.

122 Prepare Mode after Power On

W

0 Manual Mode 1 Prepack Mode

Always set to 0 for SM-

200.

123 Printing Thank You Message on Receipt

W

0 Enable 1 Disable

124 PLU Unit Price after Discount

X

0 Unit Price after Discount 1 Unit Price Discount Amount

125 Position of Special Message on Receipt

X

0 Bottom 1 Top

126 Function Keys Protection for Self-service

W

0 No Protection 2 Partial Protection

1 Full Protection

127 Printing of Checksum for Item Barcode

0 Disable 1 Enable

128 Setting of Host Number (For SM-15 Multi-drop)

W

Enter value between 0 to 99

For IR only.

129 Type of Host to be Communicated

W

0 Standalone 2 POS ECR

For IR only.

Use with SPEC128.

1 TMR ECR

130 Selection of Print Item on Prepack Total Label

X

0 Based on Status on Item Label 1 Based on Status on Manual Total

Label

131 Print PLU Setting Quantity in Manual Mode

X

0 No 1 Yes

Effective when SPEC98

= 0.

132 Receipt Total Report

W

0 No 1 Yes For DM only.

Page 61

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 10 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

133 Change All PLU Default Format when Default SPEC Change

X

0 Yes 1 No

134 Host Communication

W

0 No Operation 1 Enable

Host Communication

0 RS-232C 1 RS-485

135 Port Number

X

Enter value from range 1 to 254

136 One or Two Touch for Self-service Operation

X

0 One Touch 1 Two Touches

137 Centering of Ingredient Data

X

0 Yes 1 No

138 Permanent Price or Discount Price Change via Function Key

X

0 No Update to PLU 1 Update to PLU

139 Number of Digits for Teraoka Code

W

0 2 Digits 1 3 Digits

140 AA Message Size

W

0 24 x 24 1 16 x 16

For AA only.

141 Year Format

X

0 YY 1 YYYY

142 Selection of Day Display for Sell by Date

X

0 Disable 1 Enable

143 Peel Sensor Trigger Voltage

W

0 High 1 Low

144 Display Prepack Quantity Balance

W

0 Enable 1 Disable

145 Print Select Function Across the Board

X

0 Disable 1 Enable

146 Label Format 1, 2 Function Key Enable

X

0 Inhibit 1 Allow

Exclude AA.

147 Prepack Non-add Function Key Enable

0 Inhibit 1 Allow

Exclude AA.

148 FIS3000 Code

W

0 SM-80/90 FIS3D 1 SM-25 FIS3D

149 Main Group Function Key Enable

0 Inhibit 1 Allow

Exclude AA.

150 Preset Key Assignment for Client

0 Local Assign 1 Central Assign

151 Change Sell by Date or Used by Date when Packed Date Changed

0 No 1 Yes

152 Sell by Date or Sell by Time for Individual PLU

0 Disable 1 Enable

153 User Programmable Right Side Data for Item Barcode

X

0 With Identification Digit 1 Without Identification Digit

Page 62

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 11 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

154 Keysheet Letter Size

W

0 Small Letter 1 Capital Letter

For FL & AS only.

155 Test Print on Receipt

W

0 No Print 1 Print

For SD only.

156 Image Copy from Free Format

X

0 Disable 1 Enable

157 Training Mode

W

0 Disable 1 Enable

Exclude DEC.

158 FSD Price and Image

W

0 Disable 1 Enable

For U1 only.

159 ½ and ¼ Key Function

W

0 Disable 1 Enable

160 Twisted Pair Cable for Ethernet

W

0 Shield 1 Unshielded

Not in used.

161 Discount Label Format

W

0 Enable 1 Disable

For SD only.

162 Item Code Function Key Enable

0 Enable 1 Disable

163 Transaction Data Store in Client Memory

0 Disable 1 Enable

164 Maximum Label Length

W

0 120 mm 1 240 mm

165 Update Report for Client / Server System

0 Yes 1 No

166 Average Price and Weight Label Function

X

0 Disable 1 Enable

167 Label Date Title Print

X

0 No Print 1 Print

Exclude AA.

168 GB Code

W

0 GB Code 1 Shift GB Code

For CN and MS only.

169 Print PLU Setting Unit in Manual Mode

0 No 1 Yes

170 User Specification (REZERO + 141) Accessible from Z Mode Only

W

0 No 1 Yes

171 Euro Mode

X

0 Disable 1 Enable

172 Dual Declarations

X

0 No 1 Yes

For U1 only.

173 Mask 7-segment Display in X, S and Z Mode

W

0 No 1 Yes

For double display types

only.

174 Fixed Clerk Assign to Preset Key 8, 16, 24 and 32

W

0 Clerk Keys 1 Function Keys

For bench type only.

Page 63

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 12 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

175 30 lb to 15 kg Conversion

W

0 Disable 1 Enable

For UK only.

176 Discount Time on Daily Basis

X

0 No 1 Yes

177 Weight Check Function

W

0 No 1 Yes

178 Unit Price Override per PLU

X

0 No 1 Yes

179 Black Bar Sensing Label

X

0 Normal 1 Black Bar Sensing

180 Scroll Message Group

0 Disable 1 Enable

181 Continuos Label

X

0 Disable 1 Enable

182 Character Size for Barcode Data

X

0 Large 1 Small

183 PLU Clear after 10 seconds Time-out

W

0 No 1 Yes

184 Duplicate Unit and Total Price on Label

W

0 No Print 1 Print

Effective when SPEC158

= 1.

185 Weigh PLU Can Use for Non-weigh PLU and Vice Versa Function Key Enable

0 Disable 1 Enable

186 Print $ and Weight Unit on Label

X

0 No Print 1 Print

187 Clear Total Data by Server

0 Both Server and Client 1 Server

188 Tare Decimal Point Left Shift for SM-25 FIS3D

W

0 No 1 Yes

189 PLU Auto Delete

0 No Delete 2 30 Days

1 15 Days 3 90 Days

190 Swap Weight and Unit Price on Receipt

W

0 No 1 Yes

191 Default Item Code Equals to PLU Numbe

r

X

0 No 1 Yes

192 Nutrition Template

W

0 Standard 3 Standard Condensed

For U1 and CA only.

1 Simplified 4 Tabulated

2 Simplified Condensed 5 Tabulated Extra Condensed

193 Nutrition Adjustment Feed

X

Enter value from range 0 to 255

For U1 and CA only.

194 Server IP Address

X

Enter a value between 1 to 254

For Client scale only.

Page 64

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 13 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

195 Weight Print for Non-weigh Item

X

0 No 1 Yes

196 Scale File

0 Disable 1 Enable

197 Print Format of Month

X

0 Number 2 3 Alphabetic

1 2 Alphabetic

198 FSD Saving Calculation

W

0 Net Value 1 Cent Off

For U1 only.

199 FIS3000 Time Out

W

0 2 sec 2 32 sec

1 8 sec

200 PLU Call Up Range

0 Disable 1 Enable

201 Sell by Date for Manual Mode

0 Programmed Sell by Date 1 Zero Sell by Date

202 Printing of Item Label when Barcode Data Overflow

X

0 Print 1 No Print

203 Preset Keys Pages

X

0 1 Page 2 3 Pages by Shift Key

1 3 Pages by Toggle

204 Reference PLU Function Key Enable

0 Inhibit 1 Allow

205 Print Function Key Enable

W

0 Inhibit 1 Allow

206 Print Barcode when Right Side Data Overflow

0 No print 1 Print Barcode Digits

207 Weight Decimal Point Position for Barcode and Label Printing

W

0 Same as SPEC607 1 0.000

Effective when SPEC607

= 2.

208 Network Time Out

X

0 3 sec 2 x4

1 x2 3 x10

209 FSD Calculation

W

0 Unit Price 1 Price Percentage Off

For U1 only.

210 PLU Repeat Function Key Enable

0 Inhibit 1 Allow

211 Pick ‘N’ Pay Protocol

W

0 Old 1 New

For SF only.

212 Department Number for Pick ‘N’ Pay

W

Enter a value between 1 to 99

For SF only.

213 Flag Code Function Key Enable

0 Inhibit 1 Allow

214 DHCP Function

0 Disable 1 Enable

Page 65

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 14 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

215 Centering of Special Message

X

0 Yes 1 No

216 JIS Code Table

W

0 New 1 Old

For AA only.

217 Default Label Format 2 for Item Printing

0 Not Used 5 F5

1 F1 6 F6

2 F2 7 F7

3 F3 8 F8

4 F4

218 Zero Unit Price for Unit Price Change Function Key

0 Inhibit 1 Allow

219 Numeric Key Entry Reset

X

0 3 sec 2 Disable

For AA only.

1 5 sec

220 Item Barcode Right Side Data Dependent on Unit

W

0 Disable 1 Enable

Effective when SPEC1 =

0 or 2.

221 Receipt with Tax Information Function Key Enable

W

0 Inhibit 1 Allow

222 Open Cash Drawer without Sales Function Key Enable

X

0 Inhibit 1 Allow

223 Negative Unit Price Function

W

0 Disable 1 Enable

224 FIS3000 Wire Type

W

0 4 wires 1 2 wires

225 Prepack Grand Total for Individual PLU

0 Yes 1 No

226 Reverse Calculation of ITF Check Digit

X

0 No 1 Yes

227 Unit Price Override Password Function

0 Inhibit 1 Allow

Effective when SPEC178

= 1.

228 Individual PLU Total Transaction

X

0 No 1 Yes

229 Preset Key Group

0 Disable 1 Enable

Effective when SPEC150

= 1.

230 Auto Print after PLU Call

X

0 No 1 Yes

231 Zero Unit Price for PLU and Unit Price Override

X

0 Inhibit 1 Allow

232 Feed for Continuous Label

X

0 No 1 Yes

233 Time Format

X

0 24 Hours 1 12 Ho urs (AM/PM)

Page 66

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 15 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

234 Sub-total and Grand Total Barcode

X

0 Based on Item Barcode 1 Based on Total Barcode

235 Mask Barcode Last Human Readable Check Digit

X

0 No 1 Yes

236 Character Generator for Korea

W

0 Old 1 New

For KE only.

237 Half-key Function

0 Inhibit 1 Allow

238 FIS3000 Free Format Unit

X

0 mm 2 SM-25 Dots

1 Dots

239 Cheque and Credit Payment Function Key

X

0 Inhibit 1 Allow

240 Voucher Payment Function Key

0 Inhibit 1 Allow

241 PLU Code for IR POS and TMR

0 6 Digits 1 7 Digits

242 Discount without Limit Function Key

0 Inhibit 1 Allow

243 Concatenate Commodity Name Display

W

0 No 1 Yes

244 Enable PLU Price Change Flag

0 No 1 Yes

245 Print Sell by Date or Used by Date when Date Equals Packed Date

X

0 Yes 1 No

246 Print First and Check Digits Outside Barcode

X

0 No 1 Yes

247 Print Packed date

X

0 Manual and Prepack Mode 2 Prepack Mode

1 Manual 3 No Print

248 Print Sell by Date

X

0 Manual and Prepack Mode 2 Prepack Mode

1 Manual Mode 3 No Print

249 Print Used by Date

X

0 Manual and Prepack Mode 2 Prepack Mode

1 Manual Mode 3 No Print

250 Centering Shop Name on Label

X

0 No 1 Yes

251 Shop Name on Receipt

X

0 Top 1 Bottom

252 Auto Reconnect when Server Down

0 Disable 2 Every 3 min

1 Every 2 min 3 Every 15 min

Page 67

Specification List SM-100 V2.00 26 December, 2006

2

nd

R&D Dept, SHANGHAI TERAOKA ELECTRONIC CO., LTD. 16 of 32

SPEC

NO.

SPECIFICATION DESCRIPTION SM-100

253 Client Auto PLU Update

0 Update / Delete Existing PLU 3 Update All Server PLU

1 Update / Delete All Sever PLU 4 Disable

2 Update Existing PLU

254 Auto Update of Client Off-line Report

0 Disable 1 Enable

255 Retry Ethernet Communication

0 2 times 1 5 times

256 Display Price with Tax after Clerk Key Press

W

0 Yes 1 No

For AA only.

257 Change Place Name to PLU via Function Key

0 No 1 Yes

For AA only.

258 Beef Labeling

X

0 No 1 Yes

259 Auto Print Sub-total Label in Prepack

X

0 No 1 Yes

260 Beef Labeling : Print Country

X

0 Code 1 Name

261 External Rewinder

0 Disable 1 Enable

262 Selection of Receipt / Label

W

0 Label 1 Receipt

Always set to 1 for SM-

200.

263 FSD Net Value Minimum

W

0 Off 1 On

For U1 only.

264 Print Ingredient Data on Next Label

X

0 Disable 1 Enable

265 Client Using Local Free Format Label

0 No 1 Yes

266 FSD Weight

W

0 Back Computed (Single Range) 2 Exact Weight

For U1 only.

1 Back Computed (Dual Range)