Page 1

Digi International Inc.

11001 Bren Road East

Minnetonka, MN 55343

877 912-3444 or 952 912-3444

http://www.digi.com

XBee®/XBee-PRO® ZB RF Modules

ZigBee RF Modules by Digi International

Models: XBEE2, XBEEPRO2, PRO S2B

Hardware: S2 and S2B

Firmware Versions:

- 20xx - Coordinator - AT/Transparent Operation

- 21xx - Coordinator - API Operation

- 22xx - Router - AT/Transparent Operation

- 23xx - Router - API Operation

- 28xx - End Device - AT/Transparent Operation

- 29xx - End Device - API Operation

90000976_D

11/5/2009

Page 2

XBee®/XBee‐PRO®ZBRFModules

© 2009 Digi International, Inc. All rights reserved

Nopartofthecontentsofthismanualmaybetransmittedorreproducedinany

formorbyanymeanswithoutthewrittenpermissionofDigiInternational,Inc.

®isaregisteredtrademarkoftheZigBeeAlliance.

ZigBee

XBee®andXBee‐PRO®areregisteredtrademarksofDigiInternational,Inc.

Technical Support: Phone: (866) 765-9885 toll-free U.S.A. & Canada

(801) 765-9885 Worldwide

8:00 am - 5:00 pm [U.S. Mountain Time]

Live Chat: www.digi.com

Online Support: http://www.digi.com/support/eservice/login.jsp

Email: rf-experts@digi.com

©2009DigiInternational,Inc. 2

Page 3

XBee®/XBee‐PRO®ZBRFModules

Contents

Overview 6

What's New in 2x7x 6

Firmware 6

Manual 7

Key Features 8

Worldwide Acceptance 8

Specifications 9

Mechanical Drawings 10

SIF Header Interface 11

Mounting Considerations 11

Pin Signals 12

EM250 Pin Mappings 13

Design Notes 13

Power Supply Design 13

Recommended Pin Connections 13

Board Layout 14

Electrical Characteristics 16

RF Module Operation 17

Serial Communications 17

UART Data Flow 17

Serial Buffers 17

Serial Flow Control 18

Serial Interface Protocols 19

Modes of Operation 21

Idle Mode 21

Transmit Mode 21

Receive Mode 22

Command Mode 22

Sleep Mode 23

XBee ZigBee Networks 24

Introduction to ZigBee 24

ZigBee Stack Layers 24

Networking Concepts 24

Device Types 24

PAN ID 25

Operating Channel 26

ZigBee Application Layers: In Depth 26

Application Support Sublayer (APS) 26

Application Profiles 26

Coordinator Operation 27

Forming a Network 27

Channel Selection 28

PAN ID Selection 28

Security Policy 28

Persistent Data 28

XBee ZB Coordinator Startup 28

Permit Joining 29

Resetting the Coordinator 29

Leaving a Network 30

Replacing a Coordinator (Security Disabled Only)

30

Example: Starting a Coordinator 31

Example: Replacing a Coordinator (security dis-

abled) 31

Router Operation 31

Discovering ZigBee Networks 31

Joining a Network 32

Authentication 32

Persistent Data 32

XBee ZB Router Joining 32

Permit Joining 34

Joining Always Enabled 34

Joining Temporarily Enabled 34

Router Network Connectivity 34

Leaving a Network 36

Resetting the Router 37

Example: Joining a Network 37

End Device Operation 37

Discovering ZigBee Networks 37

Joining a Network 38

Parent Child Relationship 38

End Device Capacity 38

Authentication 38

Persistent Data 38

Orphan Scans 39

XBee: ZB End Device Joining 39

Parent Connectivity 40

Resetting the End Device 40

Leaving a Network 40

Example: Joining a Network 41

Channel Scanning 41

Managing Multiple ZigBee Networks 41

PAN ID Filtering 42

Preconfigured Security Keys 42

Permit Joining 42

Application Messaging 42

Data Transmission, Addressing, and Routing 43

©2009DigiInternaitonal,Inc. 3

Page 4

XBee®/XBee‐PRO®ZBRFModules

Contents

Addressing 43

64-bit Device Addresses 43

16-bit Device Addresses 43

Application Layer Addressing 43

Data Transmission 43

Broadcast Transmissions 44

Unicast Transmissions 44

Data Transmission Examples 46

RF Packet Routing 48

Link Status Transmission 48

AODV Mesh Routing 49

Many-to-One Routing 51

Source Routing 52

Encrypted Transmissions 55

Maximum RF Payload Size 56

Throughput 56

ZDO Transmissions 56

ZigBee Device Objects (ZDO) 57

Sending a ZDO Command 57

Receiving ZDO Commands and Responses 57

Transmission Timeouts 59

Unicast Timeout 59

Extended Timeout 59

Transmission Examples 60

Security 62

Security Modes 62

ZigBee Security Model 62

Network Layer Security 62

Frame Counter 63

Message Integrity Code 63

Network Layer Encryption and Decryption 63

Network Key Updates 64

APS Layer Security 64

Message integrity Code 64

APS Link Keys 64

APS Layer Encryption and Decryption 65

Network and APS Layer Encryption 65

Trust Center 65

Forming and Joining a Secure Network 65

Implementing Security on the XBee 66

Enabling Security 66

Setting the Network Security Key 66

Setting the APS Trust Center Link Key 66

Enabling APS Encryption 66

Using a Trust Center 67

XBee Security Examples 67

Example 1: Forming a network with security

(pre-configured link keys) 67

Example 2: Forming a network with security (obtaining keys during joining) 68

Network Commissioning and Diagnostics 69

Device Configuration 69

Device Placement 69

Link Testing 69

RSSI Indicators 70

Device Discovery 70

Network Discovery 70

ZDO Discovery 70

Joining Announce 70

Commissioning Pushbutton and Associate LED

71

Commissioning Pushbutton 71

Associate LED 72

Managing End Devices 74

End Device Operation 74

Parent Operation 74

End Device Poll Timeouts 75

Packet Buffer Usage 75

Non-Parent Device Operation 76

XBee End Device Configuration 76

Pin Sleep 76

Cyclic Sleep 78

Transmitting RF Data 81

Receiving RF Data 81

IO Sampling 82

Waking End Devices with the Commissioning

Pushbutton 82

Parent Verification 82

Rejoining 82

XBee Router/Coordinator Configuration 83

RF Packet Buffering Timeout 83

Child Poll Timeout 83

Transmission Timeout 83

Putting it all Together 84

Short Sleep Periods 84

Extended Sleep Periods 84

Sleep Examples 84

©2009DigiInternaitonal,Inc. 4

Page 5

XBee®/XBee‐PRO®ZBRFModules

Contents

XBee Analog and Digital IO Lines 86

IO Configuration 86

IO Sampling 86

Queried Sampling 88

Periodic IO Sampling 88

Change Detection Sampling 88

RSSI PWM 88

IO Examples 89

API Operation 90

API Frame Specifications 90

API Examples 92

API UART Exchanges 93

AT Commands 93

Transmitting and Receiving RF Data 93

Remote AT Commands 93

Source Routing 94

Supporting the API 94

API Frames 94

AT Command 94

AT Command - Queue Parameter Value 95

ZigBee Transmit Request 95

Explicit Addressing ZigBee Command Frame 97

Remote AT Command Request 99

Create Source Route 100

AT Command Response 101

Modem Status 101

ZigBee Transmit Status 102

ZigBee Receive Packet 103

ZigBee Explicit Rx Indicator 104

ZigBee IO Data Sample Rx Indicator 105

XBee Sensor Read Indicator 106

Node Identification Indicator 108

Remote Command Response 109

Over-the-Air Firmware Update Status 110

Route Record Indicator 111

Many-to-One Route Request Indicator 112

Sending ZigBee Device Objects (ZDO) Commands with the API 113

Sending ZigBee Cluster Library (ZCL) Commands with the API 115

Sending Public Profile Commands with the API

117

XBee Command Reference Tables 118

Module Support 128

X-CTU Configuration Tool 128

Customizing XBee ZB Firmware 128

Design Considerations for Digi Drop-In Net-

working 128

XBee Bootloader 128

Programming XBee Modules 129

Serial Firmware Updates 129

Invoke XBee Bootloader 129

Send Firmware Image 129

SIF Firmware Updates 130

Writing Custom Firmware 130

Regulatory Compliance 130

Enabling GPIO 1 and 2 130

Detecting XBee vs. XBee-PRO 131

Ensuring Optimal Output Power 131

Improving Low Power Current Consumption

132

XBee (non-PRO) Initialization: 13 2

When sleeping (end devices): 132

When waking from sleep (end devices): 132

Appendix A:Definitions 133

Appendix B: Agency Certifications 135

Appendix C:Migrating from ZNet 2.5 to XBee ZB

143

Appendix D:Additional Information 144

©2009DigiInternaitonal,Inc. 5

Page 6

1.Overview

This manual describes the operation of the XBee/XBeePRO ZB RF module, which consists of ZigBee firmware

loaded onto XBee S2 and S2B hardware, models: XBEE2,

XBEEPRO2 and PRO S2B. The XBee/XBee-PRO ZB RF

Modules are designed to operate within the ZigBee

protocol and support the unique needs of low-cost, lowpower wireless sensor networks. The modules require

minimal power and provide reliable delivery of data

between remote devices.

The modules operate within the ISM 2.4 GHz frequency band and are compatible with the

following:

• XBee RS-232 Adapter

• XBee RS-485 Adapter

• XBee Analog I/O Adapter

• XBee Digital I/O Adapter

• XBee Sensor

• XBee USB Adapter

•XStick

• ConnectPort X Gateways

• XBee Wall Router.

The XBee/XBee-PRO ZB firmware release can be installed on XBee ZNet or ZB modules. The XBee

ZB firmware is based on the EmberZNet 3.x ZigBee PRO Feature Set mesh networking stack, while

the XBee ZNet 2.5 firmware is based on Ember's proprietary "designed for ZigBee" mesh stack

(EmberZNet 2.5.x). ZB and ZNet 2.5 firmware are similar in nature, but not over-the-air

compatible. Devices running ZNet 2.5 firmware cannot talk to devices running the ZB firmware.

What's New in 2x7x

Firmware

XBee/XBee-PRO ZB firmware includes the following new features (compared with 2x6x):

• Using Ember stack version 3.4.1.

• Support for the PRO S2B with temperature compensati on and an overvoltage chec k. Within 15

seconds of the supply voltage exceeding 3.9V, the API will emit a 0x08 modem status (Overvoltage) message, and then the AT/API versions will do a watchdog reset.

• ZDO passthru added. If AO=3, then ZDO requests which are not supported by the stack will

be passed out the UART.

• An attempt to send an oversized packet (256+ bytes) will result in a Tx Status message with

a status code of 0x74.

• End devices have two speed polling. 7.5 seconds is the slow rate, which switches to the fast

rate to trasact with its parent. When transactions are done, it switches back to the slow rate.

• A new receive option bit (0x40) indicates if the packet came from an end device.

• If the extended timeout option is enabled, then use it because end devices need more time

than routers to ack their packets.

• An option bit (0x01) was added to disable APS retries.

• If an end device has not had its polls answered for 5 secs, it will leave and attempt to rejoin

the network.

• XBee S2B has a new TP command which returns the temperature compensation sensor reading in units if Celsius degrees.

• The PP command returns the power dBm setting when PL4 is selected.

• The PO command sets the slow polling rate on end devices. Range is 1-0x1770 in units of 10

msec (10 msec to 60 sec). Default is 0 which invokes a 100 msec delay.

©2009DigiInternational,Inc. 6

Page 7

XBee®/XBee‐PRO®ZBRFModules

• Rejoining now can proceed without a NR or NRO command after a Mgmt_Leave_req is processed.

• Command ranges were changed for the SC, IR, and LT commands.

• A PAN Id corruption problem was fixed.

See the 2x7x release notes for a complete list of new features and bug fixes at www.digi.com/

support.

Manual

The XBee/XBee-PRO/S2B ZB 2x7x manual includes the following corrections over the 2x6x

manual:

• Descriptions and specification for th e PRO S2B.

• SIF Header Interface, pin 8 relabeled as pin 10.

• Pin mappings for pins 22 and 24 updated.

• New modem status codes were added.

• Corrections to the ZigBee Receive Packet description.

• Description changes for the SC, PL, PP, AO, IR, %V, and PO commands.

• Updates to Appendix B.

©2009DigiInternational,Inc. 7

Page 8

XBee®/XBee‐PRO®ZBRFModules

High Performance, Low Cost

XBee

• Indoor/Urban: up to 133’ (40 m)

• Outdoor line-of-sight: up to 400’ (120 m)

• Transmit Power: 2 mW (3 dBm)

• Receiver Sensitivity: -96 dBm

XBee-PRO (S2)

• Indoor/Urban: up to 300’ (90 m), 200' (60

m) for International variant

• Outdoor line-of-sight: up to 1 mile (1600

m), 2500' (750 m) for International variant

• Transmit Power: 50mW (17dBm), 10mW

(10dBm) for International variant

• Receiver Sensitivity: -102 dBm

XBee-PRO (S2B)

• Indoor/Urban: up to 300’ (90 m), 200' (60

m) for International variant

• Outdoor line-of-sight: up to 1 mile (1600

m), 2500' (750 m) for International variant

• Transmit Power: 68mW (18dBm), 10mW

(10dBm) for International variant

• Receiver Sensitivity: -102 dBm

Advanced Networking & Security

Retries and Acknowledgements

DSSS (Direct Sequence Spread Spectrum)

Each direct sequence channel has over

65,000 unique network addresses available

Point-to-point, point-to-multipoint

and peer-to-peer topologies supported

Self-routing, self-healing and fault-tolerant

mesh networking

Low Power

XBee

• TX Peak Current: 40 mA (@3.3 V)

• RX Current: 40 mA (@3.3 V)

• Power-down Current: < 1 uA

XBee-PRO (S2)

• TX Peak Current: 295mA (170mA for

international variant)

• RX Current: 45 mA (@3.3 V)

• Power-down Current: < 10 uA

XBee-PRO (S2B)

• TX Peak Current: 205mA (117mA for

international variant)

• RX Current: 47 mA (@3.3 V)

• Power-down Current: < 10 uA

Easy-to-Use

No configuration necessary for out-of box

RF communications

AT and API Command Modes for

configuring module parameters

Small form factor

Extensive command set

Free X-CTU Software

(Testing and configuration software)

Free & Unlimited Technical Support

Key Features

Worldwide Acceptance

FCC Approval (USA) Refer to Appendix A for FCC Requirements.

Systems that contain XBee®/XBee-PRO® ZB RF Modules inherit Digi Certifications.

ISM (Industrial, Scientific & Medical) 2.4 GHz frequency band

Manufactured under ISO 9001:2000 registered standards

XBee®/XBee-PRO® ZB RF Modules are optimized for use in US, Canada, Europe,

Australia, and Japan (contact Digi for complete list of agency approvals).

©2009DigiInternational,Inc. 8

Page 9

XBee®/XBee‐PRO®ZBRFModules

Specifications

SpecificationsoftheXBee®/XBee‐PRO®ZBRFModule

Specification XBee XBee-PRO (S2) XBee-PRO (S2B)

Performance

Indoor/Urban Range up to 133 ft. (40 m)

Outdoor RF line-of-sight

Range

Transmit Power Output

RF Data Rate 250,000 bps 250,000 bps 250,000 bps

Data Throughput up to 35000 bps (see chapter 4) up to 35000 bps (see chapter 4) up to 35000 bps (see chapter 4)

Serial Interface Data Rate

(software selectable)

Receiver Sensitivity

Power Requirements

Supply Voltage 2.1 - 3.6 V 3.0 - 3.4 V 2.7 - 3.6 V

Operating Current

(Transmit, max output

power)

Operating Current

(Receive))

Idle Current (Receiver off) 15mA 15mA 15mA

Power-down Current

General

Operating Frequency

Band

Dimensions 0.960” x 1.087” (2.438cm x 2.761cm) 0.960 x 1.297 (2.438cm x 3.294cm) 0.960 x 1.297 (2.438cm x 3.294cm)

Operating Temperature -40 to 85º C (industrial) -40 to 85º C (industrial) -40 to 85º C (industrial)

Antenna Options

Networking & Security

Supported Network

Topologies

Number of Channels 16 Direct Sequence Channels 14 Direct Sequence Channels 15 Direct Sequence Channels

Addressing Options

Agency Approvals

United States (FCC Part

15.247)

Industry Canada (IC) IC: 4214A-XBEE2 IC: 1846A-XBEEPRO2 IC: 1846A-PROS2B

Europe (CE) ETSI ETSI ETSI

Australia C-Tick C-Tick C-Tick

Up to 300 ft. (90 m), up to 200 ft (60 m)

international variant

up to 400 ft. (120 m)

2mW (+3dBm), boost mode enabled

1.25mW (+1dBm), boost mode

disabled

1200 bps - 1 Mbps

(non-standard baud rates also

supported)

-96 dBm, boost mode enabled

-95 dBm, boost mode disabled

40mA (@ 3.3 V, boost mode

enabled)

35mA (@ 3.3 V, boost mode

disabled)

40mA (@ 3.3 V, boost mode

enabled)

38mA (@ 3.3 V, boost mode

disabled)

o

< 1 uA @ 25

ISM 2.4 GHz ISM 2.4 GHz ISM 2.4 GHz

Integrated Whip, Chip, RPSMA, or

U.FL Connector

Point-to-point, Point-to-multipoint,

Peer-to-peer, and Mesh

PAN ID and Addresses, Cluster IDs

and Endpoints (optional)

FCC ID: OUR-XBEE2 FCC ID: MCQ-XBEEPRO2 FCC ID: MCQ-PROS2B

C < 10 uA @ 25oC < 10 uA @ 25oC

Up to 1 mile (1600 m), up to 2500 ft

(750 m) international variant

50mW (+17 dBm)

10mW (+10 dBm) for International

variant

1200 bps - 1 Mbps

(non-standard baud rates also

supported)

-102 dBm -102 dBm

295mA (@3.3 V)

170mA (@3.3 V) international variant

45 mA (@3.3 V) 47 mA (@3.3 V)

Integrated Whip, Chip, RPSMA, or U.FL

Connector

Point-to-point, Point-to-multipoint, Peerto-peer, and Mesh

PAN ID and Add resses, Cluster IDs a nd

Endpoints (optional)

Up to 300 ft. (90 m), up to 200 ft (60 m)

international variant

Up to 1 mile (1600 m), up to 2500 ft (750 m)

international variant

63mW (+18 dBm)

10mW (+10 dBm) for International variant

1200 bps - 1 Mbps

(non-standard baud rates also supported)

205mA (@3.3 V)

117mA (@3.3 V) internation al variant

Integrated Whip, Integrated PCB, RPSMA,

or U.FL Connector

Point-to-point, Point-to-multipoint, Peer-topeer, and Mesh

PAN ID and Addresses, Cluster IDs and

Endpoints (optional)

©2009DigiInternational,Inc. 9

Page 10

XBee®/XBee‐PRO®ZBRFModules

SpecificationsoftheXBee®/XBee‐PRO®ZBRFModule

Specification XBee XBee-PRO (S2) XBee-PRO (S2B)

Japan R201WW07215215 R201WW08215142

RoHS Compliant Compliant Compliant

Mechanical Drawings

MechanicaldrawingsoftheXBee®/XBee‐PRO®ZBRFModules(antennaoptionsnotshown)

MechanicalDrawingsfortheRPSMAVari a n t

.

©2009DigiInternational,Inc. 10

Page 11

XBee®/XBee‐PRO®ZBRFModules

SIF Header Interface

The XBee/XBee-PRO ZB modules include a SIF programming header that can be used with

Ember's programming tools to upload custom firmware images onto the XBee module. The SIF

header orientation and pinout are shown below.

A male header can be populated on the XBee that mates with Ember's 2x5 ribbon cable. The male

header and ribbon cables are available from Samtec:

2x5 Male Header - FTSH-105-01-F-DV-K

2x5 Ribbon Cable - FFSD-05-D-12.00-01-N

Mounting Considerations

The XBee modules were designed to mount into a receptacle (socket) and therefore does not

require any soldering when mounting it to a board. The XBee-PRO Development Kits contain RS232 and USB interface boards which use two 20-pin receptacles to receive modules.

XBee‐PROModuleMountingtoanRS‐232InterfaceBoard.

The receptacles used on Digi development boards are manufactured by Century Interconnect.

Several other manufacturers pro vide compar able mounting sol utions; however, Digi currently uses

the following receptacles:

• Through-hole single-row receptacles -

Samtec P/N: MMS-110-01-L-SV (or equivalent)

• Through-hole single-row receptacles -

Mill-Max P/N: 831-43-0101-10-001000

• Surface-mount double-row receptacles -

Century Interconnect P/N: CPRMSL20-D-0-1 (or equivalent)

©2009DigiInternational,Inc. 11

Page 12

XBee®/XBee‐PRO®ZBRFModules

• Surface-mount single-row receptacles -

Samtec P/N: SMM-110-02-SM-S

Digi also recommends printing an outline of the module on the board to indicate the orientation the

module should be mounted.

Pin Signals

XBee®/XBee‐PRO®ZBRFModulePinNumber

(topsidesshown‐shieldsonbottom)

PinAssignmentsfortheXBee‐PROModules

Pin # Name Direction Description

1 VCC - Power supply

2 DOUT Output UART Data Out

3 DIN / CONFIG

4 DIO12 Either Digital I/O 12

5 RESET

6 RSSI PWM / DIO10 Either RX Signal Strength Indicator / Digital IO

7 DIO11 Either Digital I/O 11

8 [reserved] - Do not connect

9DTR

10 GND - Ground

11 DIO4 Either Digital I/O 4

12 CTS

13 ON / SLEEP

14 VREF Input

15 Associate / DIO5 Ei ther Associated Indicator, Digital I/O 5

16 RTS

17 AD3 / DIO3 Either Analog Input 3 or Digital I/O 3

18 AD2 / DIO2 Either Analog Input 2 or Digital I/O 2

19 AD1 / DIO1 Either Analog Input 1 or Digital I/O 1

20

(Low‐assertedsignalsaredistinguishedwithahorizontallineabovesignalname.)

Input UART Data In

Input Module Reset (reset pulse must be at least 200 ns)

/ SLEEP_RQ/ DIO8 Either Pin Sleep Control Line or Digital IO 8

/ DIO7 Ei ther

/ DIO6 Either

AD0 / DIO0 / Commissioning

Button

Output Module Status Indicator or Digital I/O 9

Either Analog Input 0, Digital IO 0, or Commissioning Button

Clear-to-Send Flow Control or Digital I/O 7. CTS, if enabled, is

an output.

Not used on this module. For compatibility with other XBee

modules, we recommend connecting this pin to a voltage

reference if Analog sampling is desired. Otherwise, connect to

GND.

Request-to-Send Flow Control, Digital I/O 6. RTS, if e nabled, is

an input.

• Signal Direction is specified with respect to the module

• See Design Notes section below for details on pin co nnections.

©2009DigiInternational,Inc. 12

Page 13

XBee®/XBee‐PRO®ZBRFModules

EM250 Pin Mappings

The following table shows how the EM250 pins are used on the XBee.

EM250 Pin Number XBee Pin Number Other Usage

13 (Reset) 5 Connected to pin 8 on 2x5 SIF header.

19 (GPIO 11) 16

20 (GPIO 12) 12

21 (GPIO 0)

22 (GPIO 1)

24 (GPIO 2)

25 (GPIO 3) 13

26 (GPIO 4 / ADC 0) 20 Connected to pin 9 on 2x5 SIF header.

27 (GPIO 5 / ADC 1) 19 Connected to pin 10 on 2x5 SIF header.

29 (GPIO 6 /ADC 2) 18

30 (GPIO 7 / ADC 3 17

31 (GPIO 8) 4

32 (GPIO 9) 2

33 (GPIO 10) 3

34 (SIF_CLK) Connected to pin 6 on 2x5 SIF header.

35 (SIF_MISO) Connected to pin 2 on 2x5 SIF header.

36 (SIF_MOSI) Connected to pin 4 on 2x5 SIF header.

37 (SIF_LOAD) Connected to pin 7 on 2x5 SIF header.

40 (GPIO 16) 7

41 (GPIO 15) 6

42 (GPIO 14) 9

43 (GPIO 13) 11

15

XBee

Tied to ground (module identification)

XBee-PRO (S2)

Low-asserting shutdown line for output power compensation circuitry.

XBee-PRO (S2B)

Used to communicate with Temp Sensor and control Shutdown for low power mode.

XBee

Not connected. Configured as output low.

XBee-PRO (S2)

Powers the output power compensation circuitry.

XBee-PRO (S2B)

Used to communicate with Temp Sensor and control Shutdown for low power mode.

Design Notes

The XBee modules do not specifically require any external circuitry or specific connections for

proper operation. However, there are some general design guidelines that are recommended for

help in troubleshooting and building a robust design.

Power Supply Design

Poor power supply can lead to poor radio performance especially if the supply voltage is not kept

within tolerance or is excessively noisy. To help reduce noise a 1uF and 8.2pF capacitor are

recommended to be placed as near to pin1 on the PCB as possible. If using a switching regulator

for your power supply, switching frequencies above 500kHz are preferred. Power supply ripple

should be limited to a maximum 250mV peak to peak.

Recommended Pin Connections

The only required pin connections are VCC, GND, DOUT and DIN. To support serial firmware

updates, VCC, GND, DOUT, DIN, RTS, and DTR should be connected.

©2009DigiInternational,Inc. 13

Page 14

XBee®/XBee‐PRO®ZBRFModules

All unused pins should be left disconnected. All inputs on the radio can be pulled high with 30k

internal pull-up resistors using the PR software command. No specific treatment is needed for

unused outputs.

For applications that need to ensu re th e l owe st sleep current, inputs should never be left floating.

Use internal or external pull-up or pull-down resistors, or set the unused I/O lines to outputs.

Other pins may be connected to external circuitry for convenience of operation including the

Associate LED pin (pin 15) and the Commissioning pin (pin 20). The Associate LED pin will flash

differently depending on the state of the module to the network, and a pushbutton attached to pin

20 can enable various join functions without having to send UART commands. Please see the

commissioning pushbutton and associate LED section in chapter 7 for more details. The source

and sink capabilities are limited to 4mA for all pins on the modu le.

The VRef pin (pin 14) is not used on this module. For compatibility with other XBee modules, we

recommend connecting this pin to a voltage reference if analog sampling is desired. Otherwise,

connect to GND.

Board Layout

XBee modules do not have any specific sensitivity to nearby processors, crystals or other PCB

components. Other than mechanical considerations, no special PCB placement is required for

integrating XBee radios except for those with integral antennas. In general, Power and GND tr aces

should be thicker than signal traces and be able to comfortably support the maximum currents.

The radios are also designed to be self sufficient and work with the integrated and external

antennas without the need for additional ground planes on the host PCB. However, considerations

should be taken on the choice of antenna and antenna location. Metal objects that are near an

antenna cause reflections and may reduce the ability for an antenna to efficiently radiate. Using an

integral antenna (like a wire whip antenna) in an enclosed metal box will greatly reduce the range

of a radio. For this type of application an external antenna would be a better choice.

External antennas should be positioned away from metal objects as much as possible. Metal

objects next to the antenna or between transmitting and receiving antennas can often block or

reduce the transmission distance. Some objects that are often overlooked are metal poles, metal

studs or beams in structures, concrete (it is usua lly reinforced with metal rods), metal enclosures,

vehicles, elevators, ventilation ducts, refrigerators and microwave ovens.

Wire Whip Antennas should be straight and perpendicular to the ground plane and/or chassis. It

should reside above or away from any metal objects like batteries, tall electrolytic capacitors or

metal enclosures. If the antenna is bent to fit into a tight space, it should be bent so that as much

of the antenna as possible is away from metal. Caution should be used when bending the antenna,

since this will weaken the solder joint where the antenna connects to the module. Antenna

elements radiate perpendicular to the direction they point. Thus a vertical antenna emits across

the horizon.

Embedded or Chip Antennas should not have any ground planes or metal objects above or below

the module at the antenna location. For best results the module should be in a plastic enclosure,

instead of metal one. It should be placed at t he edge of the PCB to which it is mounted. The

ground, power and signal planes should be vacant immediately below the antenna section (See

drawing for recommended keepout area).

©2009DigiInternational,Inc. 14

Page 15

XBee®/XBee‐PRO®ZBRFModules

©2009DigiInternational,Inc. 15

Page 16

XBee®/XBee‐PRO®ZBRFModules

Electrical Characteristics

DCCharacteristicsoftheXBee/XBee‐PRO

Symbol Parameter Condition Min Typical Max Units

VIL Input Low Voltage All Digital I nputs - - 0.2 * VCC V

V

IH

V

OL

V

OH

II

IN

I

OHS

I

OHH

I

OLS

I

OLH

I

OH + IOL

Input High Voltage All Digital Inputs 0.8 * VCC - - V

Output Low Voltage VCC >= 2.7 V - - 0.18*VCC V

Output High Voltage VCC >= 2.7 V 0.82*VCC - - V

Input Leakage Current

Output source current (standard)

Output source current (high

current)

Output sink current (standard

Output sink current (high current) RSSI/PWM, DIO10, DIO4 digital outputs 8 mA

Total output current for all I/O pins All digital outputs 40 mA

= VCC or GND, all inputs, per pin

V

IN

All digital outputs except

RSSI/PWM, DIO10, DIO4

- - 0.5uA uA

4mA

RSSI/PWM, DIO10, DIO4 digital outputs 8 mA

All digital inputs except

RSSI/PWM, DIO10, DIO4

4mA

©2009DigiInternational,Inc. 16

Page 17

2.RFModuleOperation

DIN (data in)

DIN (data in)

DOUT (data out )

DOUT (data out)

Serial Communications

The XBee RF Modules interface to a host device through a logic-level asynchronous serial port.

Through its serial port, the module can communicate with any logic and voltage compatible UART ;

or through a level translator to an y se rial devic e (for e xample: through a RS-232 or USB int erface

board).

UART Data Flow

Devices that have a UART interface can connect directly to the pins of the RF module as shown in

the figure below.

SystemDataFlowDiagraminaUART‐interfacedenvironment

(Low‐assertedsignalsdistinguishedwithhorizontallineoversignalname.)

Serial Data

Data enters the module UART through the DIN (pin 3) as an asynchronous serial signal. The signal

should idle high when no data is being transmitted.

Each data byte consists of a start bit (low), 8 data bits (least significant bit first) and a stop bit

(high). The following figure illustrates the serial bit pattern of data passing through the module.

UARTdatapacket0x1F(decimalnumberʺ31ʺ)astransmittedthroughtheRFmodule

ExampleDataFormatis8‐N‐1(bits‐parity‐#ofstopbits)

Serial communications depend on the two UAR Ts (the microcontroller's and the RF module's) to be

configured with compatible settings (baud rate, parity, start bits, stop bits, data bits).

The UART baud rate, parity, and stop bits settings on the XBee module can be configured with the

BD, NB, and SB commands respectively. See the command table in chapter 10 for details.

Serial Buffers

The XBee modules maintain small buffers to collect received serial and RF data, which is illustrated

in the figure below. The serial receive buffer collects incoming serial characters and holds them

until they can be processed. The serial transmit buffer collects data that is received via the RF link

that will be transmitted out the UART.

©2009DigiInternational,Inc. 17

Page 18

XBee®/XBee‐PRO®ZBRFModules

Serial

Receiver

Buffer

RF TX

Buffer

Transmitter

RF Switch

Antenna

Port

Receiver

Serial Transmit

Buffer

RF RX

Buffer

Processor

DIN

DOUT

CTS

RTS

TInternalDataFlowDiagram

Serial Receive Buffer

When serial data enters the RF module through the DIN Pin (pin 3), the data is st ored in the serial

receive buffer until it can be processed. Under certain conditions, the module may not be able to

process data in the serial receive buffer immediately. If large amounts of serial data are sent to

the module, CTS

Cases in which the serial receive buffer may become full and possibly overflow:

1.If the module is receiving a continuous stream of RF data, the data in the serial receive buffer

will not be transmitted until the module is no longer receiving RF data.

2.If the module is transmitting an RF data packet, the module may need to discover the destination address or establish a route to the destination. After transmitting the data, the module

may need to retransmit the data if an acknowledgment is not received, or if the transmission is

a broadcast. These issues could delay the processing of data in the serial receive buffer.

flow control may be required to avoid overflowing the serial receive buffer.

Serial Transmit Buffer

When RF data is received, the data is moved into the serial tr ansmit buffer and se nt out the UAR T.

If the serial transmit buffer becomes full enough such that all data in a received RF packet won’t fit

in the serial transmit buffer, the entire RF data packet is dropped.

Cases in which the serial transmit buffer may become full resulting in dropped RF

packets

1. If the RF data rate is set higher than the interface data rate of the module, the module

could receive data faster than it can send the data to the host.

2. If the host does not allow the module to transmit data out from the serial transmit buffer

because of being held off by hardware flow control.

Serial Flow Control

The RTS and CTS module pins can be used to provide RTS and/or CTS flow control. CTS flow

control provides an indication to the host to stop sending serial data to the module. RTS flow

control allows the host to signal the module to not send data in the serial transmit buffer out the

uart. RTS

CTS Flow Control

If CTS flow control is enabled (D7 command), when the serial receive buffer is 17 bytes away from

being full, the module de-asserts CTS

serial data. CTS

and CTS flow control are enabled using the D6 and D7 commands.

(sets it high) to signal to the host device to stop sending

is re-asserted after the serial receive buffer has 34 bytes of space.

©2009DigiInternational,Inc. 18

Page 19

XBee®/XBee‐PRO®ZBRFModules

RTS Flow Control

If RTS flow control is enabled (D6 command), data in the serial transmit buffe r will not be sent out

the DOUT pin as long as RTS

for long periods of time to avoid filling the serial transmit buffer. If an RF data packet is received,

and the serial transmit buffer does not have enough space for all of the data bytes, the entire RF

data packet will be discarded.

Note: If the XBee is sending data out the UART when RTS

could send up to 5 characters out the UART after RTS

Serial Interface Protocols

The XBee modules support both transparent and API (Application Programming Interface) serial

interfaces.

Transparent Operation

When operating in transparent mode, the modules act as a serial line replacement. All UART data

received through the DIN pin is queued up for RF transmission. When RF data is received, the data

is sent out through the DOUT pin. The module configuration parameters are configured using the

AT command mode interface.

Data is buffered in the serial receive buffer until one of the following causes the data to be

packetized and transmitted:

• No serial characters are received for the amount of time determined by the RO (Packetization

Timeout) parameter. If RO = 0, packetization begins when a character is received.

• The Command Mode Sequence (GT + CC + GT) is received. Any character buffered in the

serial receive buffer before the sequence is transmitted.

• The maximum number of characters that will fit in an RF packet is received.

RF modules that contain the following firmware versions will support Transparent Mode:

20xx (AT coordinator), 22xx (AT router), and 28xx (AT end device).

is de-asserted (set high). The host device should not de-assert RTS

is de-asserted (set high), the XBee

is de-asserted.

API Operation

API operation is an alternative to transparent operati on. The fr ame-bas ed API ext ends th e lev el to

which a host application can interact with the networking capabilities of the module. When in API

mode, all data entering and leaving the module is contained in frames that define operations or

events within the module.

Transmit Data Frames (received through the DIN pin (pin 3)) include:

• RF Transmit Data Frame

• Command Frame (equivalent to AT commands)

Receive Data Frames (sent out the DOUT pin (pin 2)) include:

• RF-received data frame

• Command response

• Event notifications such as reset, associate, disassociate, etc.

The API provides alternative means of configuring modules and routing data at the host

application layer. A host application can send data frames to the module that contain address and

payload information instead of using command mode to modify addresses. The module will send

data frames to the application containing status packets; as well as source, and payload

information from received data packets.

The API operation option facilitates many operations such as the examples cited below:

-> Transmitting data to multiple destinations without entering Command Mode

->Receive success/failure status of each transmitted RF packet

-> Identify the source address of each received packet

RF modules that contain the following firmware versions will support API operation: 21xx (API

coordinator), 23xx (API router), and 29xx (API end device).

©2009DigiInternational,Inc. 19

Page 20

XBee®/XBee‐PRO®ZBRFModules

A Comparison of Transparent and API Operation

The following table compares the advantages of transparent and API modes of operation:

Simple Interface All received serial data is transmitted unless the module is in command mode.

Easy to support It is easier for an application to support transparent operation and command mode

Easy to manage data

transmissions to multiple

destinations

Received data frames

indicate the sender's

address

Advanced ZigBee

addressing support

Advanced networking

diagnostics

Remote Configuration

Transparent Operation Features

API Operation Features

Transmitting RF data to mu ltiple remotes only requires changing the address in the API frame. This

process is much faster than in transparent operation where the app lication must e nter AT command

mode, change the address, exit command mode, and then transmit data.

Each API transmission can return a transmit status frame indicating the success or reason for

failure.

All received RF data API frames indicate the source address.

API transmit and receive frames can expose ZigBee addressing fields including source and

destination endpoints, cluster ID and profile ID. This makes it easy to support ZDO commands and

public profile traffic.

API frames can provide indication of IO samples from remote devices, and node identifica tion

messages.

Set / read configuration commands can be sent to remote devices to configure them as needed

using the API.

As a general rule of thumb, API firmware is recommended when a device:

• sends RF data to multiple destinations

• sends remote configuration commands to manage devices in the network

• receives IO samples from remote devices

• receives RF data packets from multiple devices, and the application needs to know which

device sent which packet

• must support multiple ZigBee endpoints, cluster IDs, and/or profile IDs

• uses the ZigBee Device Profile services.

If the above conditions do not apply (e.g. a sensor node, router, or a simp le application), then AT

firmware might be suitable. It is acceptable to use a mixture of devices running API and AT

firmware in a network.

©2009DigiInternational,Inc. 20

Page 21

XBee®/XBee‐PRO®ZBRFModules

16-bit Network

Address Discovery

Data Discarded

Successful

Transmi ssion

Yes

No

New

Transmission

16-bit Network

Add ress D iscovered?

Route Known?

Rou te Dis covered ?

16-bit Network

Address Known?

Rou te Discovery

Transmit Data

Idle Mode

No

Yes

No No

Yes Yes

Modes of Operation

Idle Mode

When not receiving or transm itting data, the RF modu le is in Idle Mode. The module shifts into the

other modes of operation under the following conditions:

• Transmit Mode (Serial data in the serial receive buffer is ready to be packetized)

• Receive Mode (Valid RF data is received through the antenna)

• Sleep Mode (End Devices only)

• Command Mode (Command Mode Sequence is issued)

Transmit Mode

When serial data is received and is ready for packetization, the RF module will exit Idle Mode and

attempt to transmit the data. The destination address determines which node(s) will receive the

data.

Prior to transmitting the dat a, th e m o dul e en su re s th at a 1 6-bi t n e twork address and route to the

destination node have been established.

If the destination 16-bit network address is not known, network address discovery will take place.

If a route is not known, route discovery will take place for the purpose of establishing a route to

the destination node. If a module with a matching network address is not discovered, the packet is

discarded. The data will be transmitted once a route is established. If route discovery fails to

establish a route, the packet will be discarded.

Tra n smitModeSequence

©2009DigiInternational,Inc. 21

Page 22

XBee®/XBee‐PRO®ZBRFModules

When data is transmitted from one node to another, a network-level acknowledgement is

transmitted back across the established route to the source node. This acknowledgement packet

indicates to the source node that the data packet was received by the destination node. If a

network acknowledgement is not received, the source node will re-transmit the data.

It is possible in rare circumstances for the destination to receiv e a data packet, but for the source

to not receive the network acknowledgment. In this case, the source will retransmit the data,

which could cause the destination to receive the same data packet multiple times. The XBee

modules do not filter out duplicate packets. The application should include provisions to address

this potential issue

See Data Transmission and Routing in chapter 4 for more information.

Receive Mode

If a valid RF packet is received, the data is transferred to the serial transmit buffer.

Command Mode

To modify or read RF Module parameters, the module must first enter into Command Mode - a

state in which incoming serial characters are interpreted as commands. Refer to the API Mode

section in chapter 9 for an alternate means of configuring modules.

AT Command Mode

To Enter AT Command Mode:

Send the 3-character command sequence “+++” and observe guard times before and after the

command characters. [Refer to the “Default AT Command Mode Sequence” below.]

Default AT Command Mode Sequence (for transition to Command Mode):

• No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

• Input three plus characters (“+++”) within one second [CC (Command Sequence Character)

parameter = 0x2B.]

• No characters sent for one second [GT (Guard Times) parameter = 0x3E8]

Once the AT command mode sequence has been issued, the module sends an "OK\r" out the

DOUT pin. The "OK\r" characters can be delayed if the module has not finished transmitting

received serial data.

When command mode has been entered, the command mode timer is started (CT command), and

the module is able to receive AT commands on the DIN pin.

All of the parameter values in the sequence can be modified to reflect user preferences.

NOTE: Failure to enter AT Command Mode is most commonly due to baud rate mismatch. By default,

the BD (Baud Rate) parameter = 3 (9600 bps).

To Send AT Commands:

Send AT commands and parameters using the syntax shown below.

Figure2‐01.SyntaxforsendingATCommands

To read a parameter value stored in the RF module’s register, omit the parameter field.

The preceding example would change the RF module Destination Address (Low) to “0x1F”. To store

the new value to non-volatile (long term) memory, subsequently send the WR (Write) command.

For modified parameter values to persist in the module’s registry after a reset, changes must be

saved to non-volatile memory using the WR (Write) Command. Otherwise, parameters are

restored to previously saved values after the module is reset.

©2009DigiInternational,Inc. 22

Page 23

XBee®/XBee‐PRO®ZBRFModules

Command Response

When a command is sent to the module, the module will parse and execute the command. Upon

successful execution of a command, the module returns an “OK” message. If execution of a

command results in an error, the module returns an “ERROR” message.

Applying Command Changes

Any changes made to the configuration command registers through AT commands will not take

effect until the changes are applied. For example, sending the BD command to change the baud

rate will not change the actual baud r ate until changes are applied. Changes can be applied in one

of the following ways:

• The AC (Apply Changes) command is issued.

• AT command mode is exited.

To Exit AT Command Mode:

1. Send the ATCN (Exit Command Mode) command (followed by a carriage return).

[OR]

2. If no valid AT Commands are received within the time specified by CT (Command Mode

Timeout) Command, the RF module automatically returns to Idle Mode.

For an example of programming the RF module using AT Commands and descriptions of each configurable parameter, please see the Command Reference Table chapter.

Sleep Mode

Sleep modes allow the RF module to enter states of low power consumption when not in use. The

XBee RF modules support both pin sleep (sleep mode entered on pin transition) and cyclic sleep

(module sleeps for a fixed time). XBee sleep modes are discussed in detail in chapter 6.

©2009DigiInternational,Inc. 23

Page 24

3.XBeeZigBeeNetworks

Introduction to ZigBee

ZigBee is an open global standard built on the IEEE 802.15.4 MAC/PHY. ZigBee defines a network

layer above the 802.15.4 layers to support advanced mesh routing capabilities. The ZigBee

specification is developed by a growing consortium of companies that make up the ZigBee

Alliance. The Alliance is made up of over 300 members, including semiconductor, module, stack,

and software developers.

ZigBee Stack Layers

The ZigBee stack consists of several layers including the PHY, MAC, Network, Application Support

Sublayer (APS), and ZigBee Device Objects (ZDO) layers. Technically, an Application Framework

(AF) layer also exists, but will be grouped with the APS layer in remaining discussions. The ZigBee

layers are shown in the figure below.

A description of each layer appears in the following table:

ZigBee Layer Description

PHY Defines the physical operation of the ZigBee device

MAC Manages RF data transactions between neighboring

Network Adds routing capabilities that allows RF data packets

APS (AF) Application layer that defines various addressing

ZDO Application layer that provides device and service

including receive sensitivity , channel reje ction, outpu t

power, number of channels, chip modulation, and

transmission rate specifications. Most ZigBee

applications operate on the 2.4 GHz ISM band at a

250kbps data rate. See the IEEE 802.15.4

specification for details.

devices (point to point). The MAC includes services

such as transmission retry and acknowledgment

management, and collision avoidance techniques

(CSMA-CA).

to traverse multiple devices (multiple "hops") to route

data from source to destination (peer to peer).

objects including profiles, clusters, and endpoints.

discovery features and advanced network

management capabilities.

Networking Concepts

Device Types

ZigBee defines three different device types: coordinator, router, and end device.

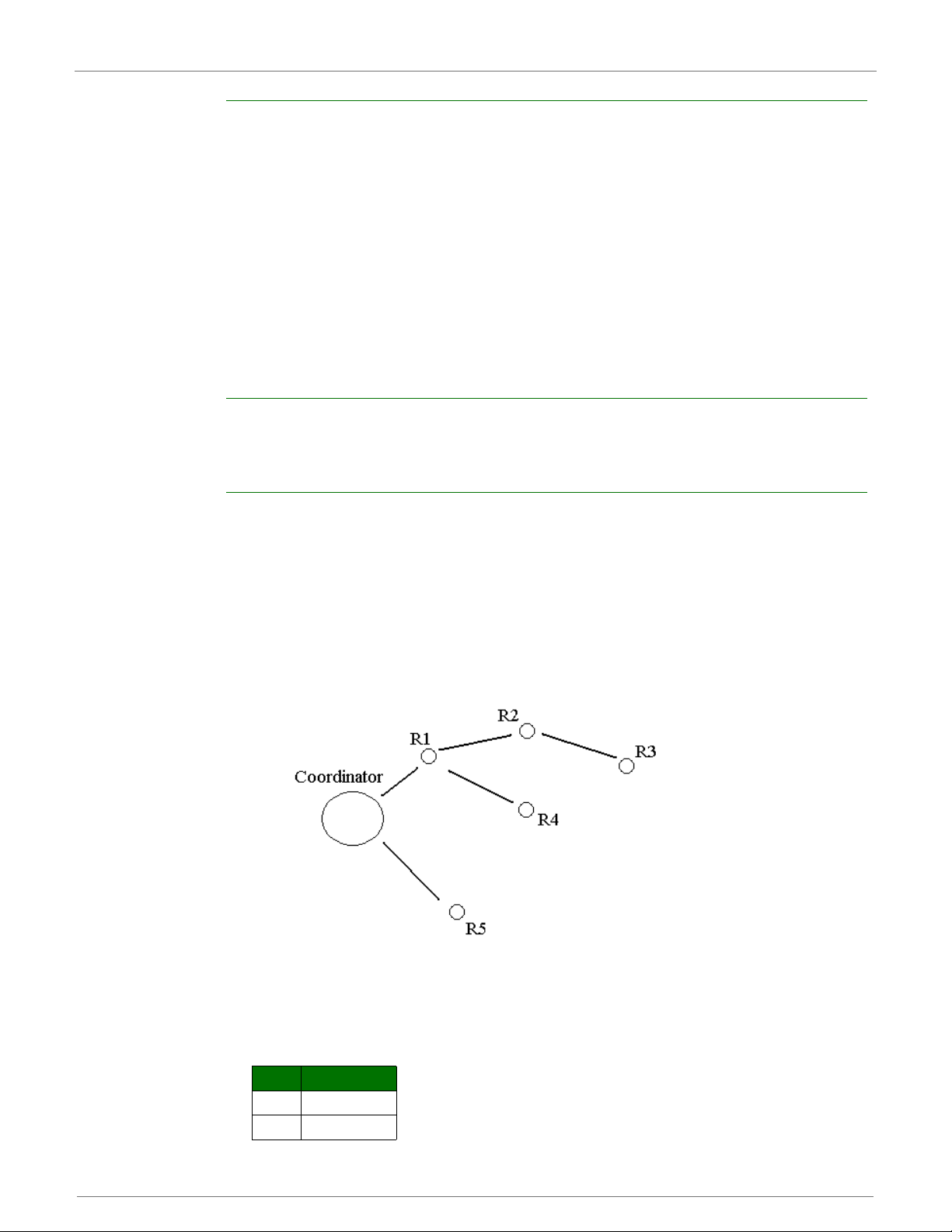

Node Types / Sample of a Basic ZigBee Network Topology

A coordinator has the following characteristics: it

• Selects a channel and PAN ID (both 64-bit and 16-bit) to start the network

• Can allow routers and end devices to join the network

• Can assist in routing data

• Cannot sleep--should be mains powered

• Can buffer RF data packets for sleeping end device children.

©2009DigiInternational,Inc. 24

Page 25

XBee®/XBee‐PRO®ZBRFModules

A router has the following characteristics: it

• Must join a ZigBee PAN before it can transmit, receive, or route data

• After joining, can allow routers and end devices to join the network

• After joining, can assist in routing data

• Cannot sleep--should be mains powered.

• Can buffer RF data packets for sleeping end device children.

An end device has the following characteristics: it

• Must join a ZigBee PAN before it can transmit or receive data

• Cannot allow devices to join the network

• Must always transmit and receive RF data through its parent. Cannot route data.

• Can enter low power modes to conserve power and can be battery-powered.

An example of such a network is shown below:

In ZigBee networks, the coordinator must select a P AN ID (64-bi t and 16-bit ) and channel to start

a network. After that, it behaves essentially like a router. The coordinator and routers can allow

other devices to join the network and can route data.

After an end device joins a router or coordinator, it must be able to transmit or receive RF data

through that router or coordinator. The router or coordinator that allowed an end device to join

becomes the "parent" of the end device. Since the end device can sleep, the parent must be able

to buffer or retain incoming data packets destined for the end device until the end device is able to

wake and receive the data.

PAN ID

ZigBee networks are called personal area networks or P ANs. Each network is defined with a unique

PAN identifier (P AN ID ). Thi s i den ti fie r is common among all devices of the same network. ZigBee

devices are either preconfigured with a PAN ID to join, or they can discovery nearby networks and

select a PAN ID to join.

ZigBee supports both a 64-bit and a 16-bit PAN ID. Both PAN IDs are used to uniquely identify a

network. Devices on the same ZigBee network must share the same 64-bit and 16-bit PAN IDs. If

multiple ZigBee networks are operating within range of each other, each should have unique PAN

IDs.

The 16-bit PAN ID is used as a MAC layer addressing field in all RF data transmissions between

devices in a network. However, due to the limited addressing space of the 16-bit PAN ID (65,535

possibilities), there is a possibility that multiple ZigBee networks (within range of each other)

could use the same 16-bit PAN ID . To resolve potential 16-bit PAN ID conflicts, the ZigBee Alliance

created a 64-bit PAN ID.

The 64-bit PAN ID (also called the extended PAN ID), is intended to be a unique, non-duplicated

value. When a coordinator starts a network, it can either start a network on a preconfigured 64-bit

PAN ID, or it can select a random 64-bit PAN ID. The 64-bit PAN ID is used during joining; if a

device has a preconfigured 64-bit PAN ID, it will only join a network with the same 64-bit PAN ID.

Otherwise, a device could join any detected PAN and inherit the PAN ID from the network when it

joins. The 64-bit PAN ID is included in all ZigBee beaco ns and is used in 16-bit PAN ID conflict

resolution.

©2009DigiInternational,Inc. 25

Page 26

XBee®/XBee‐PRO®ZBRFModules

Routers and end devices are typically configured to join a network with any 16-bit PAN ID as long

as the 64-bit PAN ID is valid. Coordinators typically select a random 16-bit PAN ID for their

network.

Since the 16-bit PAN ID only allows up to 65,535 unique values, and since the 16-bit PAN ID is

randomly selected, provisions exist in ZigBee to detect if two networks (with different 64-bit PAN

IDs) are operating on the same 16-bit PAN ID. If such a conflict is detected, the ZigBee stack can

perform PAN ID conflict resolution to change the 16-bit PAN ID of the network in order to resolve

the conflict. See the ZigBee specification for details.

To summarize, ZigBee routers and end devices should be configured with the 64-bit PAN ID of the

network they want to join. They typically acquire the 16-b it PAN ID when they join a network.

Operating Channel

ZigBee utilizes direct-sequ ence s pread spectru m modulation and oper ates on a fixe d channel. The

802.15.4 PHY defines 16 operating channels in the 2.4 GHz frequency band. XBee modules

support all 16 channels and XBee-PRO modules support 14 of the 16 channels.

ZigBee Application Layers: In Depth

This section provides a more in-depth look at the ZigBee application stack layers (APS, ZDO)

including a discussion on ZigBee endpoints, clusters, and profiles. Much of the material in this

section can introduce unnecessary details of the ZigBee stack that are not required in many cases.

Skip this section if

• The XBee does not need to interoperate or talk to non-Digi ZigBee devices

• The XBee simply needs to send data between devices.

Read this section if

• The XBee may talk to non-Digi ZigBee devices

• The XBee requires network management and discovery capabilities of the ZDO layer

• The XBee needs to operate in a public application profile (smart energy, home automation,

etc.)

Application Support Sublayer (APS)

The APS layer in ZigBee adds support for application profiles, cluster IDs, and endpoints.

Application Profiles

Application profiles specify various device descriptions including required functionality for various

devices. The collection of device descriptions forms an application profile. Application profiles can

be defined as "Public" or "Private" profiles. Private profiles are defined by a manufacturer whereas

public profiles are defined, developed, and maintained by the ZigBee Alliance. Each application

profile has a unique profile identifier assigned by the ZigBee Alliance.

Examples of public profiles include:

• Home Automation

• Smart Energy

• Commercial Building Automation

The Smart Energy profile, for example, defines various device types including an energy service

portal, load controller, thermostat, in-home display, etc. The Smart Energy profile defines required

functionality for each device type. For example, a load controller must respond to a defined

command to turn a load on or off. By defining standard communication protocols and device

functionality, public profiles allow interoperable ZigBee solutions to be developed by independent

manufacturers.

Digi XBee ZB firmware operates on a private profile called the Digi Drop-In Networking profile.

However, the API firmware in the module can be used in many cases to talk to devices in public

profiles or non-Digi private profiles. See the API Operations chapter for details.

©2009DigiInternational,Inc. 26

Page 27

XBee®/XBee‐PRO®ZBRFModules

Clusters

A cluster is an application message type defined within a profile. Clusters are used to specify a

unique function, service, or action. For example, the following are some clusters defined in the

home automation profile:

• On/Off - Used to switch devices on or off (lights, thermostats, etc.)

• Level Control - Used to control devices that can be set to a level between on and off

• Color Control - Controls the color of color capable devices.

Each cluster has an associated 2-byte cluster identifi er (cluster ID). The cluster ID is inc luded in all

application transmissions. Clusters often have associated request and response messages. For

example, a smart energy gateway (service portal) might send a load control event to a load

controller in order to schedule turning on or off an appliance. Upon executing the event, the load

controller would send a load control report message back to the gateway.

Devices that operate in an application profile (private or public) must respond correctly to all

required clusters. For example, a light switch that will operate in the home automation public

profile must correctly implement the On/Off and other required clusters in order to interoperate

with other home automation devices. The ZigBee Alliance has defined a ZigBee Cluster Library

(ZCL) that contains definitions or various general use clusters that could be implemented in any

profile.

XBee modules implement various clusters in the Digi private profile. In addition, the API can be

used to send or receive messages on any cluster ID (and profile ID or endpoint). See the Explicit

Addressing ZigBee Command API frame in chapter 3 for details.

Endpoints

The APS layer includes supports for endpoints. An endpoint can be thought of as a running

application, similar to a TCP/IP port. A single device can support one or more endpoints. Each

application endpoint is identified by a 1-byte value, ranging from 1 to 240. Each defined endpoint

on a device is tied to an application profile. A device could, for example, implement one endpoint

that supports a Smart Energy load controller, and another endpoint that supports other

functionality on a private profile.

ZigBee Device Profile

Profile ID 0x0000 is reserved for the ZigBee Device Profile. This profile is implemented on all

ZigBee devices. Device Profile defines many device and service discovery features and network

management capabilities. Endpoint 0 is a reserved endpoint that supports the ZigBee Device

Profile. This endpoint is called the ZigBee Device Objects (ZDO) endpoint.

ZigBee Device Objects (ZDO)

The ZDO (endpoint 0) supports the discovery and management capabilities of the ZigBee Device

Profile. A complete listing of all ZDP services is included in the ZigBee specification. Each service

has an associated cluster ID.

The XBee ZB firmware allows applications to e asily send ZDO messages to devices in the networ k

using the API. See the ZDO Transmissions section in chapter 4 for details.

Coordinator Operation

Forming a Network

The coordinator is responsible for selecting the channel, PAN ID (16-bit and 64-bit), security

policy, and stack profile for a network. Since a coordinator is the only device type that can start a

network, each ZigBee network must have one coordinator. After the coordinator has started a

network, it can allow new devices to join the network. It can also route data packets and

communicate with other devices on the network.

To ensure the coordinator starts on a good channel and unused PAN ID, the coordinator performs

a series of scans to discover any RF activity on different channels (energy scan) and to discover

©2009DigiInternational,Inc. 27

Page 28

XBee®/XBee‐PRO®ZBRFModules

any nearby operating PANs (PAN scan). The process for selecting the channel and PAN ID are

described in the following sections.

Channel Selection

When starting a network, the coordinator must select a "good" channel for the net work to oper ate

on. To do this, it performs an energy scan on multiple channels (frequencies) to detect energy

levels on each channel. Channels with excessive energy levels are removed from its list of

potential channels to start on.

PAN ID Selection

After completing the energy scan, the coordinator scans its list of potential channels (remaining

channels after the energy scan) to obtain a list of neighboring PANs. To do this, the coordinator

sends a beacon request (broadcast) transmission on each potential channel. All nearby

coordinators and routers (that have already joined a ZigBee network) will respond to the beacon

request by sending a beacon back to the coordinator. The beacon contains information about the

PAN the device is on, including the PAN identifiers (16-bit and 64-bit). This scan (collecting

beacons on the potential channels) is typically called an active scan or PAN scan.

After the coordinator completes the channel and PAN scan, it selects a random channe l and

unused 16-bit PAN ID to start on.

Security Policy

The security policy determines wh ich devices are allowed to join the network, and which device(s)

can authenticate joining devices. See chapter 5 for a detailed discussion of various security

policies.

Persistent Data

Once a coordinator has started a network, it retains the following information through power cycle

or reset events:

•PAN ID

•Operating channel

• Security policy and frame counter values

• Child table (end device children that are joined to the coordinator).

The coordinator will retain this information indefinitely until it leaves the network. Wh en the

coordinator leaves a network and starts a new network, the previous PAN ID, operating channel,

and child table data are lost.

XBee ZB Coordinator Startup

The following commands control the coordinator network formation process.

Networkformationcommandsusedbythecoordinatortoformanetwork.

Command Description

ID Used to determine the 64-bit PAN ID. If set to 0 (default), a random 64-bit PAN ID will be selected.

SC Determines the scan channels bitmask (up to 16 channels) used by the coordinator when forming a

SD Set the scan duration period. This value determines how long the coordinator performs an energy scan or

ZS Set the ZigBee stack profile for the netw ork.

EE Enable or disable security in the network.

network. The coordinator will perform an energy scan on all enabled SC channels. It will then perform a

PAN ID scan and th en form the network on one of the SC channels.

PAN ID scan on a given cha nnel.

©2009DigiInternational,Inc. 28

Page 29

XBee®/XBee‐PRO®ZBRFModules

NK Set the network security key for the network. If set to 0 (default), a random network security key will be

KY Set the trust center link key for the network. If set to 0 (default), a random link key will be used.

EO Set the security policy for the network.

Once the coordinator starts a network, the network configuration settings and child table data

persist through power cycles as mentioned in the "Persistent Data" section.

When the coordinator has successfully started a network, it

These behaviors are configurable using the following commands:

Command Description

NJ Sets the permit-join time on the coordinator,

D5 Enables the Associate LED functionality.

LT Sets the Associate LED blink time when

If any of the command values in the network formation commands table changes, the coordinator

will leave its current network and start a new network, possibly on a different channel. Note that

command changes must be applied (AC or CN command) before taking effect.

used.

• Allows other devices to join the network for a time (see NJ command)

•Sets AI=0

• Starts blinking the Associate LED

• Sends an API modem status frame ("coordinator started") out the UART (API firmware only).

measured in seconds.

joined. Default is 1 blink per second.

Permit Joining

The permit joining attribute on the coordinator is configurable with the NJ command. NJ can be

configured to always allow joining, or to allow joining for a short time.

Joining Always Enabled

If NJ=0xFF (default), joining is permanently enabled. This mode should be used carefully. Once a

network has been deployed, the application should strongly consider disabling joining to prevent

unwanted joins from occurring.

Joining Temporarily Enabled

If NJ < 0xFF, joining will be enabled only for a number of seconds, based on the NJ parameter. The

timer is started once the XBee joins a network. Joining will not be re-enabled if the module is

power cycled or reset. The following mechanisms can restart the permit-joining timer:

• Changing NJ to a different value (and applying changes with the AC or CN commands)

• Pressing the commissioning button twice (enables joining for 1 minute)

• Issuing the CB command with a parameter of 2 (software emulation of a 2 button press enables joining for 1 minute).

Resetting the Coordinator

When the coordinator is reset or power cycled, it checks its PAN ID, operating channel and stack

profile against the network configuration settings (ID, CH, ZS). It also verifies the saved security

policy against the security configuration settings (EE, NK, KY). If the coordinator's PAN ID,

operating channel, stack profile, or security policy is not valid based on its network and security

configuration settings, then the coordinator will leave the network and attempt to form a new

network based on its network formation command values.

To prevent the coordinator from leaving an existing network, the WR command should be issued

after all network formation commands have been configured in order to retain these settings

through power cycle or reset events.

©2009DigiInternational,Inc. 29

Page 30

XBee®/XBee‐PRO®ZBRFModules

Leaving a Network

There are a couple of mechanisms that will caus e the coordinator to leav e its current P AN and start

a new network based on its network formation parameter values. These include the following:

• Change the ID command such that the current 64-bit PAN ID is invalid.

• Change the SC command such that the current channel (CH) is not included in the channel

mask.

• Change the ZS or any of the security command values (excluding NK).

• Issue the NR0 command to cause the coordinator to leave.

• Issue the NR1 command to send a broadcast transmission, causing all devices in the network

to leave and migrate to a different channel.

• Press the commissioning button 4 times or issue the CB command with a parameter of 4.

Note that changes to ID, SC, ZS, and security command values only take effect when changes are

applied (AC or CN commands).

Replacing a Coordinator (Security Disabled Only)

In rare occasions, it may become necessary to replace an existing coordinator in a network with a

new physical device. If security is not enabled in the network, a replacement XBee coordinator can

be configured with the PAN ID (16-bit and 64-bit) , channel, and stack profil e settings of a running

network in order to replace an existing coordinator.

NOTE: Having two coordinators on the same channel, stack profil e, and P AN ID (16-bit and 64-bit)

can cause problems in the network and should be avoided. When replacing a coordinator, the old

coordinator should be turned off before starting the new coordinator.

To replace a coordinator, the following commands should be read from a device on the network:

AT C o m m and Description

OP Read the operating 64-bit PAN

OI Read the operating 16-bit PAN

CH Read the operating channel.

ZS Read the stack profile.

Each of the commands listed above can be read from any device on the network. (These

parameters will be the same on all devi ces in t he network. ) Af ter re ading the se comman ds from a

device on the network, these parameter values should be programmed into the new coordinator

using the following commands.

AT C o m m and Description

ID Set the 64-bit PAN ID to match

II Set the initial 16-bit PAN ID to

SC Set the scan channels bitmask

ID.

ID.

the read OP value.

match the read OI value.

to enable the read operating

channel (CH command). For

example, if the operating

channel is 0x0B, set SC to

0x0001. If the operating channel

is 0x17, set SC to 0x1000.

©2009DigiInternational,Inc. 30

Page 31

XBee®/XBee‐PRO®ZBRFModules

ZS Set the stack profile to match the

Note: II is the initial 16-bit PAN ID. Under certain conditions, the ZigBee stack can change the 16bit PAN ID of the network. For this reason, the II command cannot be saved using the WR

command. Once II is set, the coordinator leaves the network and starts on the 16-bit PAN ID

specified by II.

read ZS value.

Example: Starting a Coordinator

1. Set SC and ID to the desired scan channels and PAN ID values. (The defaults should suffice.)

2. If SC or ID is changed from the default, issue the WR command to save the changes.

3. If SC or ID is changed from the default, apply changes (make SC and ID changes take effect)

either by sending the AC command or by exiting AT command mode.

4. The Associate LED will start blinking once the coordinator has selected a channel and PAN ID.

5. The API Modem Status frame ("Coordinator Started") is sent out the UART (API firmware only).

6. Reading the AI command (association status) will return a value of 0, indicati ng a successful

startup.

7. Reading the MY command (16-bit address) will return a value of 0, the ZigBee-defined 16-bit

address of the coordinator.

After startup, the coordinator will allow joining based on its NJ value.

Example: Replacing a Coordinator (security disabled)

1. Read the OP, OI, CH, and ZS commands on the running coordinator.

2. Set the ID, SC, and ZS parameters on the new coordinator, followed by WR command to save

these parameter values.

3. Turn off the running coordinator.

4. Set the II parameter on the new coordinator to match the read OI value on the old coordinator.

5. Wait for the new coordinator to start (AI=0).

Router Operation

Routers must discover and join a valid ZigBee network before they can participate in a ZigBee

network. After a router has joined a network, it can allow new devices to join the network. It can

also route data packets and communicate with other devices on the network.

Discovering ZigBee Networks

To discover nearby ZigBee networks, the router performs a PAN (or active) scan, just like the

coordinator does when it starts a network. During the PAN scan, the router sends a beacon

request (broadcast) transmission on the first channel in its scan channels list. All nearby

coordinators and routers operating on that channel (that are already part of a ZigBee network)

respond to the beacon request by sending a beacon back to the router. The beacon contains

information about the PAN the nearby device is on, including the PAN identifier (PAN ID), and

whether or not joining is allowed. The router evaluates each beacon received on the channel to

determine if a valid PAN is found. A router considers a PAN to be valid if the PAN:

• Has a valid 64-bit PAN ID (PAN ID matches ID if ID > 0)

• Has the correct stack profile (ZS command)

• Is allowing joining.

If a valid PAN is not found, the router performs the PAN scan on the next channel in its scan

channels list and continues scanning until a valid network is found, or until all channels have been

©2009DigiInternational,Inc. 31

Page 32

XBee®/XBee‐PRO®ZBRFModules

scanned. If all channels have been scanned and a valid PAN was not discovered, all channels will

be scanned again.

The ZigBee Alliance requires that certified solutions not send beacon request messages too

frequently . To meet certification requirements, the XBee firmware attempts 9 scans per minute for

the first 5 minutes, and 3 scans per minute thereafter. If a valid PAN is within range of a joining

router, it should typically be discovered within a few seconds.

Joining a Network

Once the router discovers a v alid network, it sends an association request to the device that sent a

valid beacon requesting a join on the ZigBee network. The device allowing the join then sends an

association response frame that either allows or denies the join.

When a router joins a network, it receives a 16-bit address from the device that allowed the join.

The 16-bit address is randomly selected by the device that allowed the join.

Authentication

In a network where security is enabled, the router must then go through an authentication

process. See the Security chapter for a discussion on security and authentication.

After the router is joined (and authenticated, in a secure network), it can allow new devices to join

the network.

Persistent Data

Once a router has joined a network, it retains the following information through power cycle or

reset events:

•PAN ID

•Operating channel

• Security policy and frame counter values

• Child table (end device children that are joined to the coordinator).

The router will retain this information indefinitely until it leaves the network. When the router

leaves a network, the previous PAN ID, operating channel, and child table data are lost.

XBee ZB Router Joining

When the router is powered on, if it is not already joined to a valid ZigBee network, it immediately

attempts to find and join a valid ZigBee network.

Note: The DJ command can be set to 1 to disable joining. The DJ parameter cannot be written wit h

WR, so a power cycle always clears the DJ setting.

©2009DigiInternational,Inc. 32

Page 33

XBee®/XBee‐PRO®ZBRFModules

The following commands control the router joining process.

Command Description

ID Sets the 64-bit PAN ID to join. Setting ID=0 allows the router to join any

64-bit PAN ID.

SC Set the scan channels bitmask that determines which channels a router

SD Set the scan duration, or time that th e router will listen for beacons on

ZS Set the stack profile on the device.

EE Enable or disable security in the network. This must be set to match the

KY Set the trust center link key. If set to 0 (default), t he link key is expect ed to

will scan to find a valid network. SC on the router should be se t to match

SC on the coordinator. For example, setting SC to 0x281 enables

scanning on channels 0x0B, 0x12, and 0x14, in that order.

each channel.

EE value (security policy) of the coordinator.

be obtained (unencrypted) during joining.

Once the router joins a network, the network configuration settings and child table data persist

through power cycles as mentioned in the "Persistent Data" section previously. If joining fails, the

status of the last join attempt can be read in the AI command register.

If any of the above command values change, when command register changes are applied (AC or

CN commands), the router will leave its current network and attempt to discover and join a new

valid network.

When a ZB router has successfully joined a network, it:

• Allows other devices to join the network for a time

•Sets AI=0

• Starts blinking the Associate LED

• Sends an API modem status frame ("associated") out the UART (API firmware only).

©2009DigiInternational,Inc. 33

Page 34

XBee®/XBee‐PRO®ZBRFModules

These behaviors are configurable using the following commands:

Command Description

NJ Sets the permit-join time on

D5 Enables the Associate LED

LT Sets the Associate LED blink

Permit Joining

The permit joining attribute on the router is configurable with the NJ command. NJ can be