Page 1

NS7520 Hardware Reference

90000353_D

Page 2

Page 3

NS7520 Hardware Reference

Part number/version: 90000353_D

Release date: March 2006

www.digi.com

Page 4

©2001-2006 Digi International Inc.

Printed in the United States of America. All rights reserved.

Digi, Digi International, the Digi logo, the Making Device Networking Easy logo, NetSilicon, a Digi

International Company, NET+, NET+OS and NET+Works are trademarks or registered trademarks of Digi

International, Inc. in the United States and other countries worldwide. All other trademarks are the

property of their respective owners.

Information in this document is subject to change without notice and does not represent a committment

on the part of Digi International.

Digi provides this document “as is,” without warranty of any kind, either expressed or implied, including,

but not limited to, the implied warranties of, fitness or merchantability for a particular purpose. Digi may

make improvements and/or changes in this manual or in the product(s) and/or the program(s) described

in this manual at any time.

This product could include technical inaccuracies or typographical errors. Changes are made periodically

to the information herein; these changes may be incorporated in new editions of the publication.

Digi International

11001 Bren Road East

Minnetonka, MN 55343 U.S.A.

United States: +1 877 912-3444

Other locations: +1 952 912-3444

www.digi.com/support/

www.digi.com

Page 5

Contents

Chapter 1: About the NS7520..................................................1

NS7520 Features ......................................................................... 2

Key features and operating modes of the major NS7520 modules........ 2

NS7520 module block diagram......................................................... 5

Operating frequency .................................................................... 6

Chapter 2:

Packaging ................................................................................. 8

Pinout detail tables and signal descriptions........................................11

Chapter 3:

ARM Thumb concept ...................................................................30

CPU performance.......................................................................30

Working with ARM exceptions ........................................................31

Pinout and Packaging ............................................7

System bus interface............................................................12

Chip select controller........................................................... 16

Ethernet interface MAC................................ ........ ....... ....... ... 18

“No connect” pins ...............................................................21

General-purpose I/O ............................................................21

System clock and reset .........................................................24

System mode (test support)....................................................25

JTAG test (ARM debugger) .....................................................26

Power supply .....................................................................28

Working with the CPU......................................... 29

Summary of ARM exceptions ...................................................32

Exception priorities.............................................................. 32

iii

Page 6

Exception vector table.......................................................... 33

Detail of ARM exceptions....................................................... 34

Entering and exiting an exception (software action) ......................37

Hardware Interrupts....................................................................39

FIRQ and IRQ lines............................................................... 39

Interrupt controller.............................................................. 39

Interrupt sources................................................................. 40

Chapter 4:

BBus Module ...........................................................43

BBus masters and slaves...............................................................44

Cycles and BBus arbitration...........................................................44

Address decoding .......................................................................45

Chapter 5:

SYS Module.............................................................47

Signal description....................................................................... 48

JTAG support............................................................................48

ARM debug...............................................................................49

System clock generation (NS7520 clock module) .................................. 49

External oscillator vs. internal PLL circuit...................................49

NS7520 clock module block diagram.......................................... 50

Using the external oscillator.......................................................... 50

External oscillator mode hardware configuration ..........................51

Using the PLL circuit ...................................................................52

PLL mode hardware configuration ............................................ 52

Setting the PLL frequency.............................................................54

PLL Settings register: Setting the PLL frequency on bootup..............54

PLL Control register: Setting the PLL frequency with the PLL Control

register............................................................................ 57

Reset circuit sources...................................................................59

NS7520 bootstrap initialization....................................................... 60

iv

Chapter 6: GEN Module

.............................................................61

Module configuration................................................................... 62

GEN module hardware initialization.................................................62

GEN module registers ..................................................................63

Page 7

System Control register.........................................................63

System Status register ..........................................................68

Software Service register.......................................................70

Timer Control registers .........................................................70

Timer Status registers...........................................................73

PORTA Configuration register.................................................. 74

PORTC Configuration register.................................................. 77

Interrupts ................................................................................ 80

Interrupt controller registers ..................................................81

Chapter 7:

Memory Controller Module................................. 85

About the MEM module ................................................................86

MEM module hardware initialization................................................. 86

Pin configuration.................................................................86

MEM module configuration ............................................................88

Setting the chip select address range ........................................88

Memory Module Configuration register.......................................90

Chip Select Base Address register.............................................93

Chip Select Option Register A ................................................. 97

Chip Select Option Register B.................................................101

Static memory (SRAM) controller ...................................................102

Single cycle read/write........................................................103

Burst cycles......................................................................104

NS7520 DRAM address multiplexing.................................................105

Using the internal multiplexer................................................105

Using the external multiplexer...............................................108

DRAM refresh...........................................................................109

FP/EDO DRAM controller .............................................................109

Single cycle read/write........................................................110

FP/EDO DRAM burst cycles ....................................................111

SDRAM ...................................................................................111

NS7520 SDRAM interconnect .................................. ....... ....... .. 1 12

SDRAM A10/AP support ........................................................116

Command definitions...........................................................117

Memory timing fields — SDRAM ...............................................118

BSIZE configuration.............................. ....... ........ ....... ....... .. 1 18

SDRAM Mode register..................... ....... ....... ........ ....... ....... .. 1 19

v

Page 8

SDRAM read cycles.............................................................. 1 20

SDRAM write cycles............................................... ....... .......122

Peripheral page burst size ...........................................................124

Chapter 8:

DMA Module.......................................................... 127

DMA module ............................................................................128

Fly-by operation transfers.....................................................128

Memory-to-memory operation................................................129

DMA buffer descriptor ................................................................130

DMA channel assignments ............................................................133

DMA channel registers ................................................................134

Address map.....................................................................134

Buffer Descriptor Pointer register ...........................................136

DMA Control register ........ ........ ....... ....... ........ ....... ....... ....... 1 36

DMA Status/Interrupt Enable register .......................................142

Ethernet transmitter considerations................................................144

Ethernet receiver considerations ...................................................145

External peripheral DMA support....................................................145

Signal description...............................................................146

External DMA configuration ...................................................146

Memory-to-memory mode.....................................................146

DMA controller reset ..................................................................147

Chapter 9:

Ethernet Module .................................................. 149

Ethernet front-end (EFE) .............................................................150

Transmit and receive FIFOs ...................................................151

EFE transmit processing .......................................................151

EFE receive processing.........................................................151

Receive buffer descriptor selection .........................................152

External CAM filtering ................................................................153

MAC module ............................................................................154

MAC module block diagram ...................................................154

DMA channel assignments ............................................................156

EFE configuration......................................................................156

Ethernet General Control register (EGCR) bit definitions ................158

Ethernet General Status register (EGSR) bit definitions..................164

vi

Page 9

Ethernet FIFO Data register...................................................167

Ethernet Transmit Status register............................................169

Ethernet Receive Status register.............................................174

MAC Configuration Register 1.................................................178

MAC Configuration Register 2.................................................180

Back-to-Back Inter-Packet-Gap register.....................................184

Non-Back-to-Back Inter-Packet-Gap register...............................185

Collision Window/Collision Retry register ..................................186

Maximum Frame register ......................................................187

PHY Support register...........................................................188

Test register.....................................................................189

MII Management Configuration register .....................................191

MII Management Command register..........................................193

MII Management Address register ............................................194

MII Management Write Data register ........................................195

MII Management Read Data register .........................................196

MII Management Indicators register..........................................197

SMII Status register .............................................................198

Station Address registers ......................................................198

Station Address Filter register................................................201

Register hash table.............................................................202

Chapter 10:

Serial Controller Module .................................209

Supported features....................................................................210

Bit-rate generator .....................................................................211

Serial protocols ........................................................................212

UART mode .............................................................................212

SPI mode ................................................................................213

FIFO management ................ ........ ....... ....... ........ ....... ....... .. 2 14

General-purpose I/O configurations ................................................222

Serial port performance..............................................................223

Configuration...........................................................................223

Serial Channel registers ..............................................................225

Serial Channel 1, 2 Control Register A ......................................225

Serial Channel 1, 2 Control Register B ......................................231

Serial Channel 1, 2 Status Register A........................................235

Serial Channel 1, 2 Bit-Rate registers .......................................244

vii

Page 10

Serial Channel 1, 2 FIFO registers............................................254

Serial Channel 1, 2 Receive Buffer Gap Timer .............................255

Serial Channel 1, 2 Receive Character Gap Timer.........................256

Serial Channel 1,2 Receive Match register..................................258

Serial Channel 1, 2 Receive Match MASK register..........................258

Chapter 11:

Electrical Characteristics............................... 261

DC characteristics .....................................................................262

Recommended operating conditions.........................................262

Input/Output characteristics .................................................263

Pad pullup and pulldown characteristics....................................263

Absolute maximum ratings ....................................................265

AC characteristics .....................................................................265

AC electrical specifications ...................................................265

Oscillator Characteristics...................................................... .......267

Timing Diagrams ................................... ....... ........ ....... ....... .......269

Timing_Specifications............... ...........................................269

Reset_timing ....................................................................270

SRAM timing .....................................................................271

SDRAM timing....................................................................281

FP DRAM timing .................................................................289

Ethernet timing .................................................................296

JTAG timing......................................................................298

External DMA timing............................................................300

Serial internal/external timing...............................................303

GPIO timing......................................................................305

viii

Index

Page 11

Using This Guide

Using This Guide

Review this section for basic information about the guide you are using, as

well as general support and contact information.

About this guide

This guide provides information about the NS7520 32-bit networked

microprocessor. The NS7520 is part of the NET+ARM line of SoC (System-onChip) products, and supports high-bandwidth applications for intelligent

networked devices.

The NET+ARM family is part of the NET+Works integrated product family, which

includes the NET+OS network software suite.

Who should read this guide

This guide is for hardware developers, system software developers, and

applications programmers who want to use the NS7520 for development.

To complete the tasks described in this guide, you must:

Understand the basics of hardware and software design, operating

systems, and microprocessor design.

Understand the NS7520 architecture.

ix

Page 12

What’s in this guide

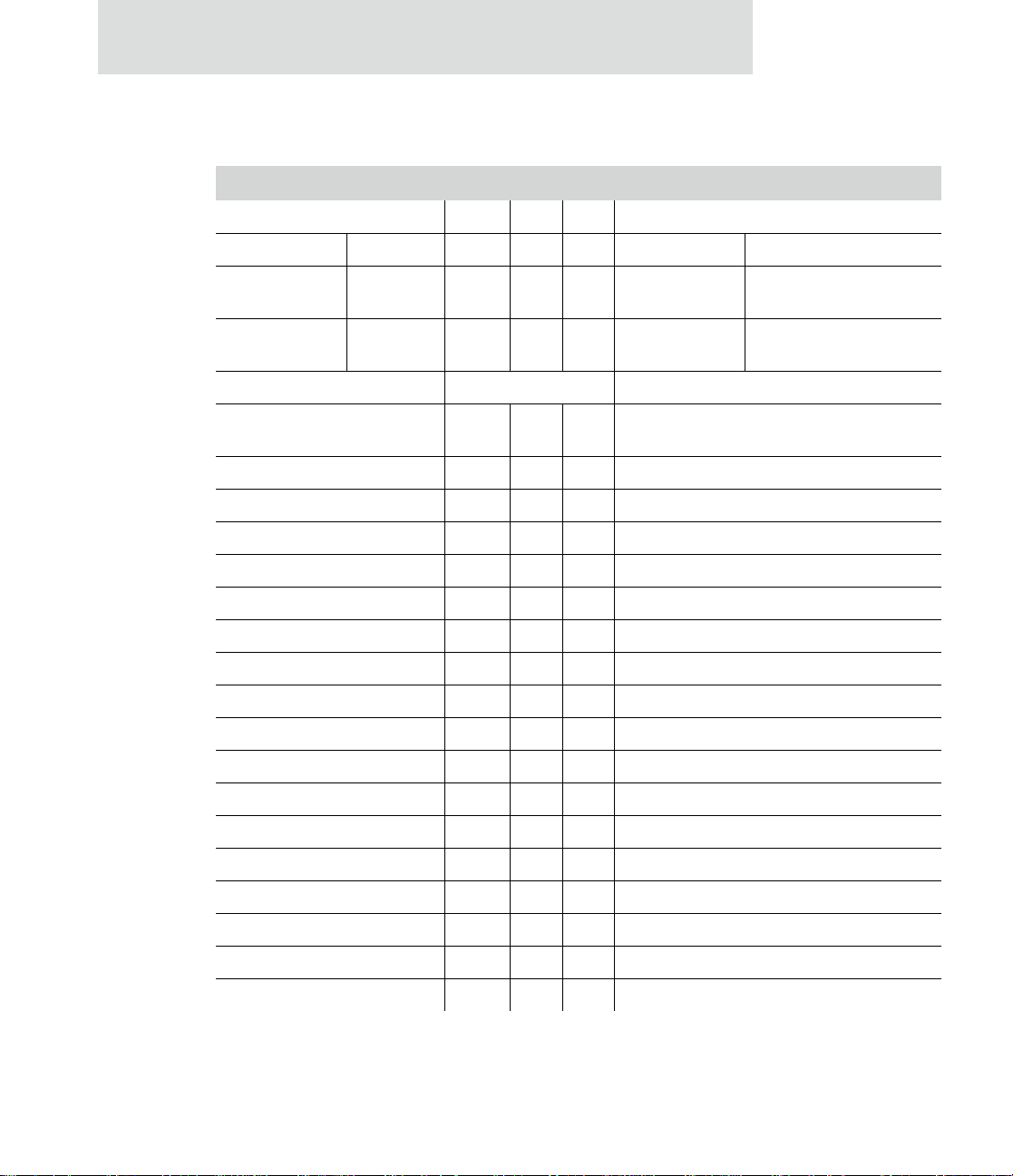

This table shows where you can find specific information in this guide:

To read about See

NS7520 key features Chapter 1, "About the NS7520"

NS7520 ball grid array assignments & packaging Chapter 2, "Pinout and Packaging"

NS7520 CPU and ARM Thumb concept Chapter 3, "Working with the CPU"

BBus functionality Chapter 4, "BBus Module"

System functionality Chapter 5, "SYS Module"

General (GEN) module functionality Chapter 6, "GEN Module"

How the NS7520 can be configured to interface

with different types of memory devices

DMA controller, supported DMA channels, and

internal and external DMA transfers

Ethernet controller module Chapter 9, "Ethernet Module"

Serial channels A and B Chapter 10, "Serial Controller Module"

NS7520 timing information and diagrams Chapter 11, "Electrical Characteristics"

Conventions used in this guide

This table describes the typographic conventions used in this guide:

This convention Is used for

italic type Emphasis, new terms, variables, and document titles.

monospaced type

_ (underscore) Defines a signal as being active low.

‘b Indicates that the number following this indicator is in binary radix

Filenames, pathnames, and code examples.

Chapter 7, "Memory Controller Module"

Chapter 8, "DMA Module"

‘d Indicates that the number following this indicator is in decimal radix

‘h Indicates that the number following this indicator is in hexadecimal radix

x

NS7520 Hardware Reference, Rev. D 03/2006

Page 13

Related documentation

NS7520 Jumpers and Components provides a hardware description of the NET+Works

Development Board, and includes information about jumpers, connectors, switches,

and interface configurations, as well as development board diagrams.

Review the documentation CD-ROM that came with your development kit for

information on third-party products and other components.

See the NET+OS software documentation for information appropriate to the chi p you

are using.

Documentation updates

Digi occasionally provides documentation updates on the Web site

(www.digi.com/support).

Be aware that if you see differences between the documentation you received in your

package and the documentation on the Web site, the Web site content is the latest

version.

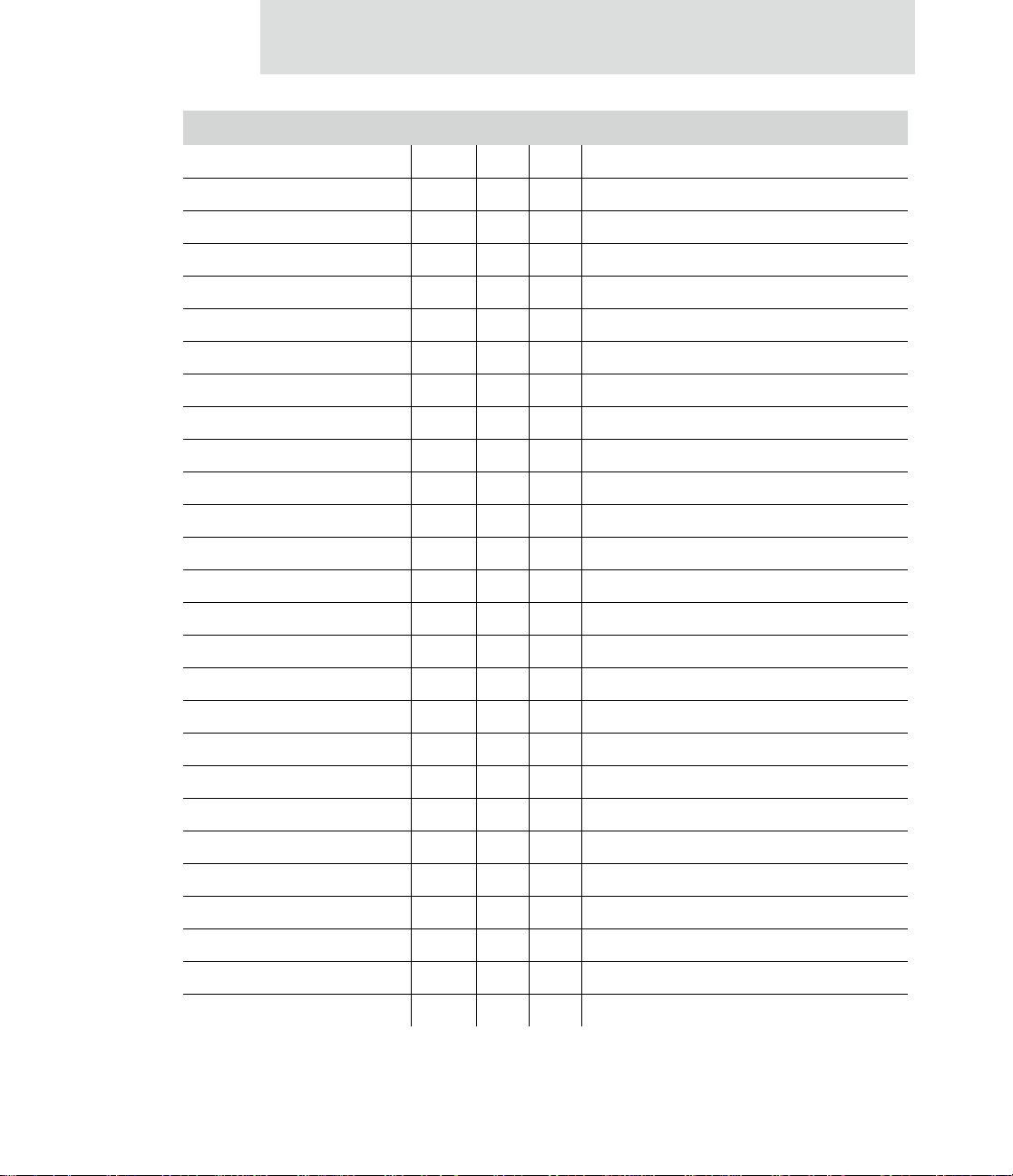

Customer support

To get help with a question or technical problem with this product, or to make

comments and recommendations about our products or documentation, use the

contact information listed in this table:

For Contact information

Technical support United States: +1 877 912-3444

Other locations: +1 952 912-3444

www.digi.com/support

www.digi.com

www.digi.com

xi

Page 14

Page 15

About the NS7520

CHAPTER 1

This chapter provides an overview of the NS7520. The NS7520 is a high-

performance, highly integrated, 32-bit system-on-a-chip ASIC designed for use in

intelligent networked devices and Internet appliances. The NS7520 is based on the

standard architecture in the NET+ARM family of devices.

NET+ARM is the hardware foundation of the NET+Works family of integrated hardware

and software solutions for device networking. These comprehensive platforms

include drivers, popular operating systems, networking software, development tools,

APIs, and complete development boards.

1

Page 16

NS7520 Features

NS7520 Features

The NS7520 can support most any networking scenario, and includes a 10/100 BaseT

Ethernet MAC and two independent serial ports (each of which can run in UART or SPI

mode).

The CPU is an ARM7TDMI (ARM7) 32-bit RISC processor core with a rich complement of

support peripherals and memory controllers, including:

Glueless connection to different types of memory; for example, flash,

SDRAM, EEPROM, and others.

Programmable timers

13-channel DMA controller

External bus expansion module

16 general-purpose I/O (GPIO) pins

Key features and operating modes of the major NS7520 modules

CPU core

13-channel DMA controller

2

– ARM7 32-bit RISC processor

– 32-bit internal bus

– 32-bit ARM mode and 16-bit Thumb mode

– 15 general-purpose 32-bit registers

– 32-bit program counter (PC) and status register

– Five supervisor modes, one user mode

– Two channels dedicated to Ethernet transmit and receive

– Four channels dedicated to two serial modules’ transmit and receive

– Four channels for external peripherals (only two channels — either 3 and 5

or 4 and 6 — can be configured at one time)

– Three channels available for memory-to-memory transfers

– Flexible buffer management

NS7520 Hardware Reference, Rev. D 03/2006

Page 17

About the NS7520

General-purpose I/O pins

– 16 programmable GPIO interface pins

– Four pins programmable with level-sensitive interrupt

Serial ports

– Two fully independent serial ports (UART, SPI)

– Digital phase lock loop (DPLL) for receive clock extractions

– 32-byte transmit/receive FIFOs

– Internal programmable bit-rate generators

– Bit rates 75–230400 in 16X mode

– Bit rates 1200 bps–4 Mbps in 1X mode

– Flexible baud rate generator, external clock for synchronous operation

– Receive-side character and buffer gap timers

– Four receive-side data match detectors

Power and operating voltages

– 500 mW maximum at 55 MHz (all outputs switching)

– 418 mW maximum at 46 MHz (all outputs switching)

– 291 mW maximum at 36 MHz (all outputs switching)

– 3.3 V — I/O

– 1.5 V — Core

Integrated 10/100 Ethernet MAC

– 10/100 Mbps MII-based PHY interface

– 10 Mbps ENDEC interface

– Support for TP-PMD and fiber-PMD devices

– Full-duplex and half-duplex modes

– Optional 4B/5B coding

– Station, broadcast, and multicast address detection filtering

– 512-byte transmit FIFO, 2 Kbyte receive FIFO

– Intelligent receive-side buffer size selection

www.digi.com

3

Page 18

NS7520 Features

Programmable timers

– Two independent timers (2μs–20.7 hours)

– Watchdog timer (interrupt or reset on expiration)

– Programmable bus monitor or timer

Operating frequency

– 36, 46, or 55 MHz internal clock operation from 18.432 MHz quartz crystal

or crystal oscillator

– f

= 36, 46, or 55 MHz (grade-dependent)

MAX

– System clock source by external quartz crystal or crystal oscillator, or clock

signal

– Programmable PLL, which allows a range of operating frequencies from 10

to f

MAX

– Maximum operating frequency from external clock or using PLL

multiplication f

Bus interface

MAX

– Five independent programmable chip selects with 256 Mb addressing per

chip select

– All chip selects support SRAM, FP/EDO DRAM, SDRAM, flash, and EEPROM

without external glue

– Supports 8-, 16-, and 32-bit peripherals

– External address decoding and cycle termination

– Dynamic bus sizing

– Internal DRAM/SDRAM controller with address multiplexer and

programmable refresh frequency

– Internal refresh controller (CAS before RAS)

4

– Burst-mode support

– 0–63 wait states per chip select

– Address pins that configure chip operating modes; see "NS7520 bootstrap

initialization" on page 60.

NS7520 Hardware Reference, Rev. D 03/2006

Page 19

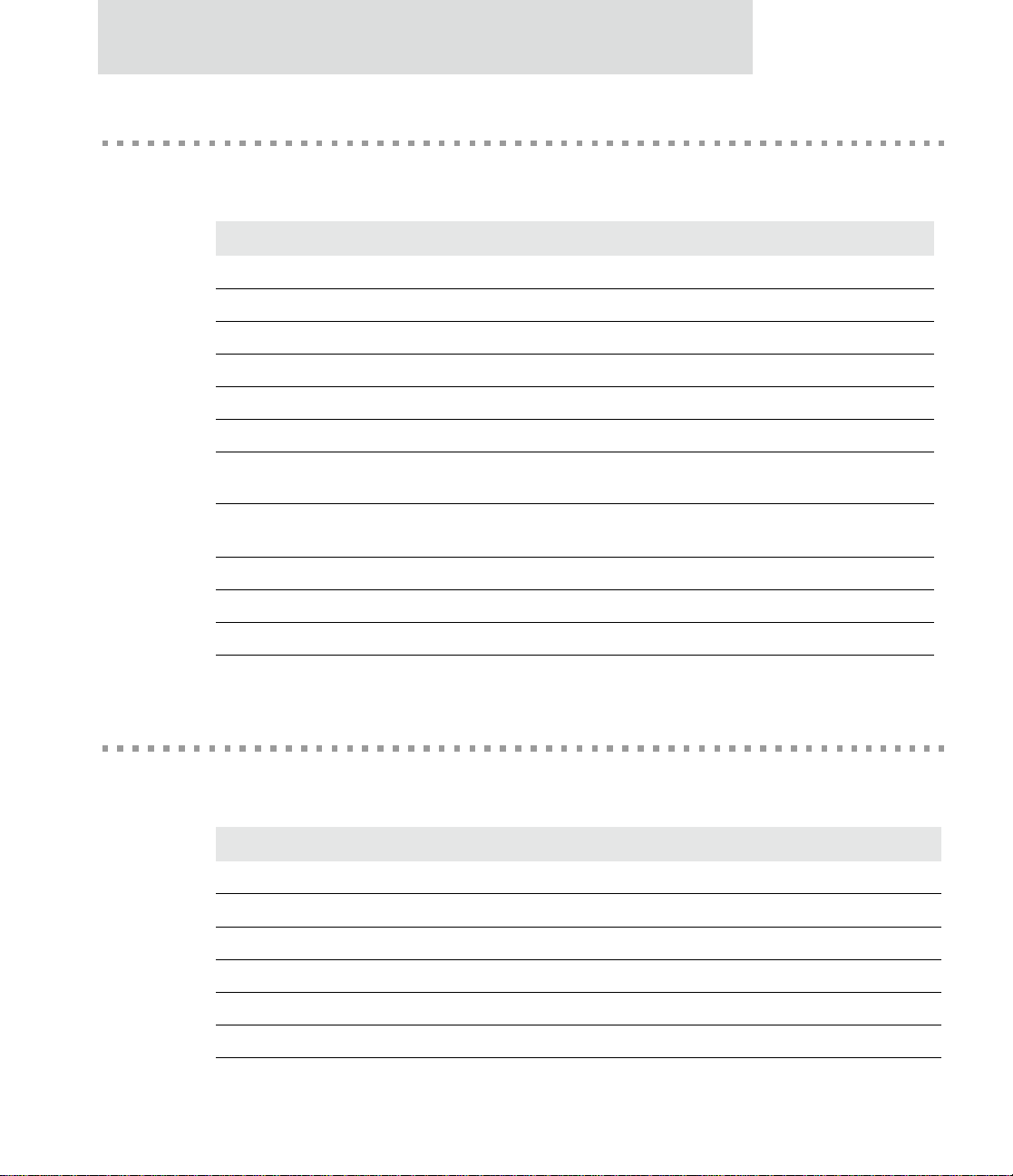

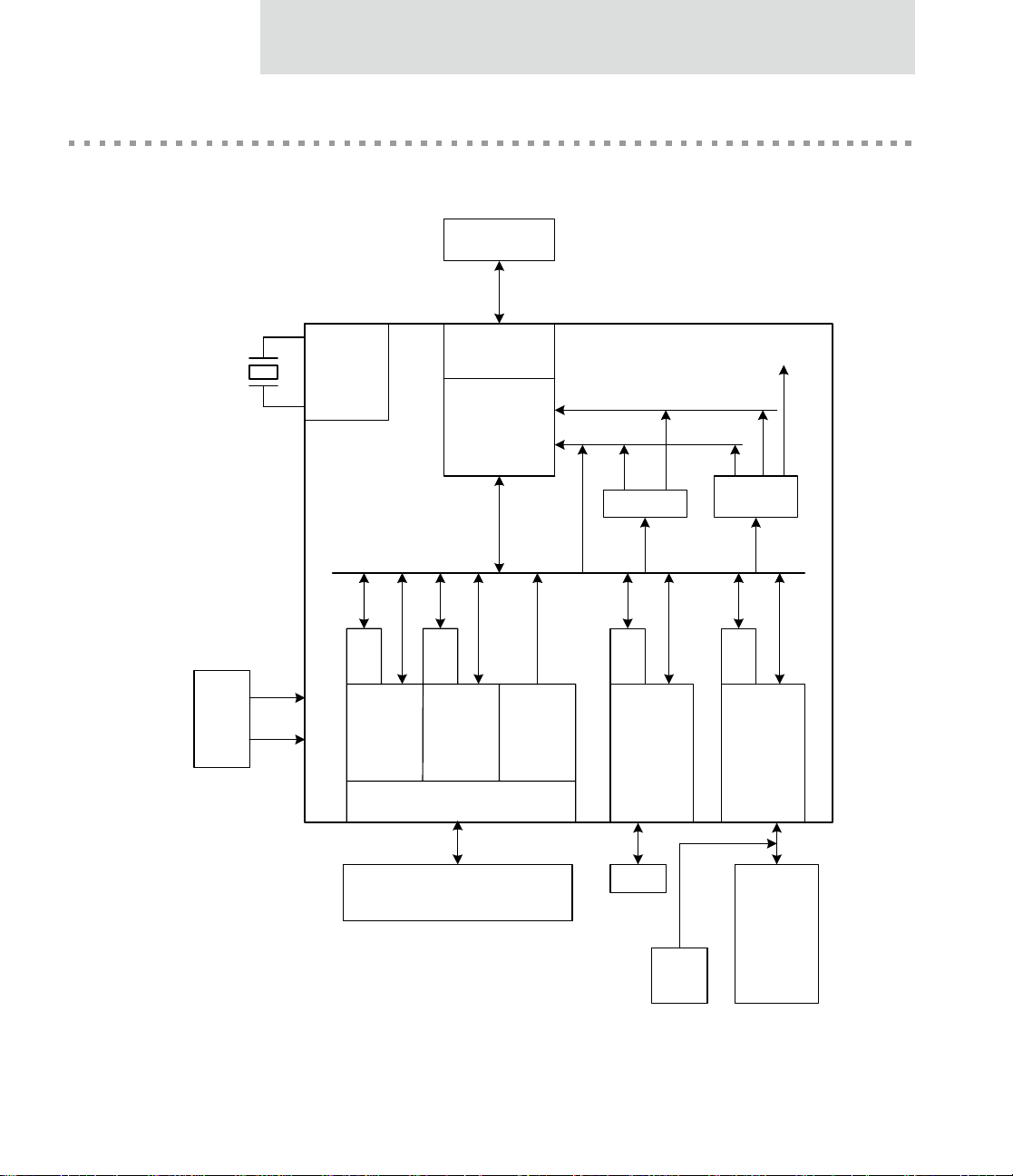

NS7520 module block diagram

Figure 1 is an overview of the NS7520, including all the modules.

About the NS7520

Debugger

Power

3.3V

1.5V

PLL

System

Clock

BBUS

D

M

A

Serial-A

UART

SPI

JTAG Debug

ARM7TDMI

D

M

A

Serial-B

UART

SPI

16 GPIO

Interface

4

level

interrupt

inputs

FIRQ

IRQ

NS7520

2 timers

D

M

A

Ethernet

controller

802.3

compliant

Reset

Watchdog

timer

D

M

A

External

memory

controller

Address bus

Serial transceivers and other

devices

Figure 1: NS7520 overview

MII

Boot

config

www.digi.com

Memory

devices

Flash

SRAM

FP DRAM

SDRAM

5

Page 20

Operating frequency

Operating frequency

The NS7520 is available in grades operating at three maximum operating frequencies:

36 MHz, 46 MHz, and 55 MHz. The operating frequency is set during bootstrap

initialization, using pins A[8:0]. These address pins load the PLL settings register on

powerup reset. A[8:7] determines IS (charge pump current); A[6:5] determines FS

(output divider), and A[4:0] defines ND (PLL multiplier). Each bit in A[8:0] can be set

individually.

See "Setting the PLL frequency," beginning on page 54, for more detailed

information.

6

NS7520 Hardware Reference, Rev. D 03/2006

Page 21

Pinout and Packaging

CHAPTER 2

The NS7520 can be used in any embedded environment requiring networking

services in an Ethernet LAN. The NS7520 contains an integrated ARM RISC processor,

10/100 Ethernet MAC, serial ports, memory controllers, and parallel I/O. The NS7520

can interface with another processor using a register or shared RAM interface. The

NS7520 provides all the tools required for any embedded networking application.

7

Page 22

Packaging

Packaging

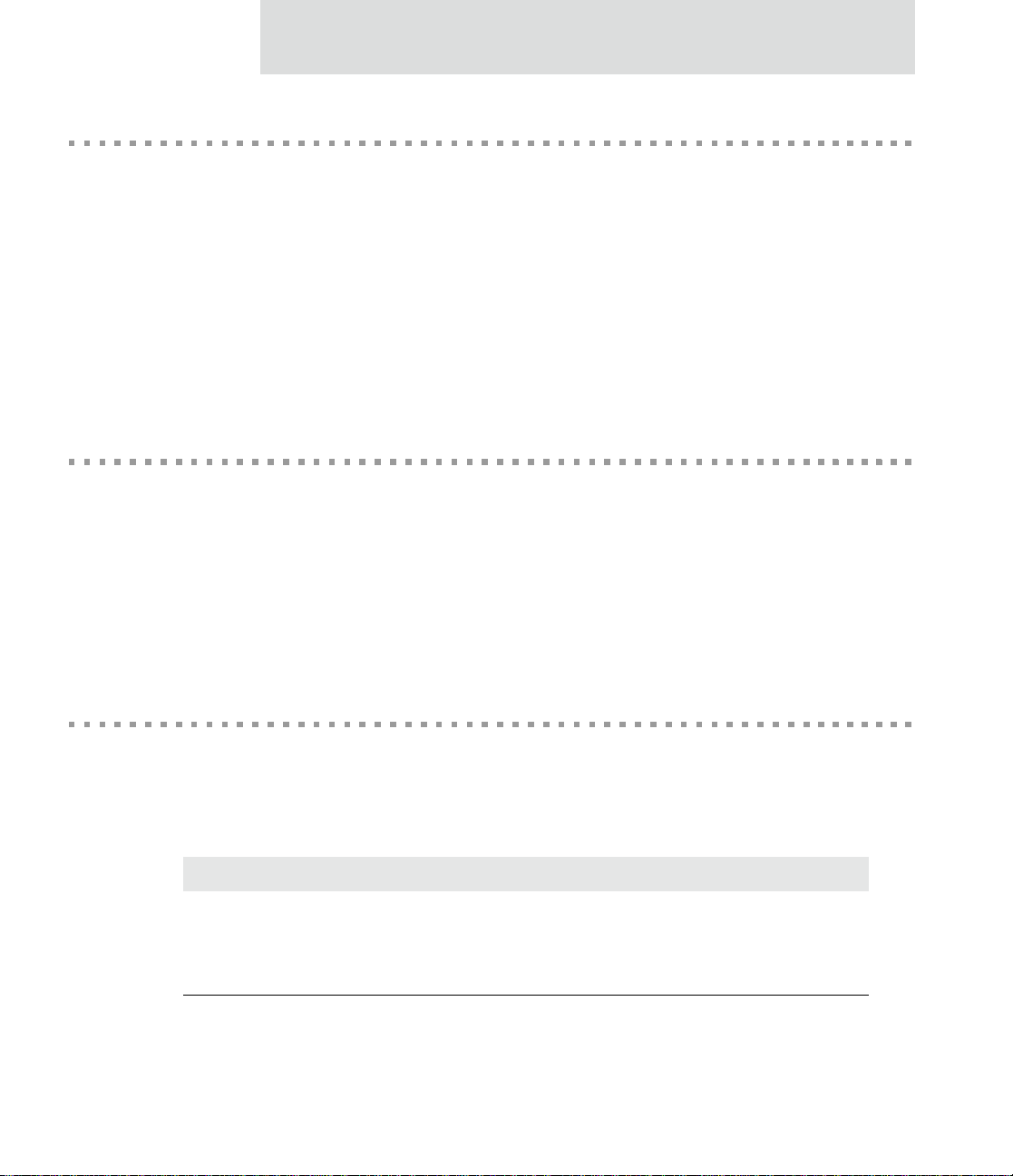

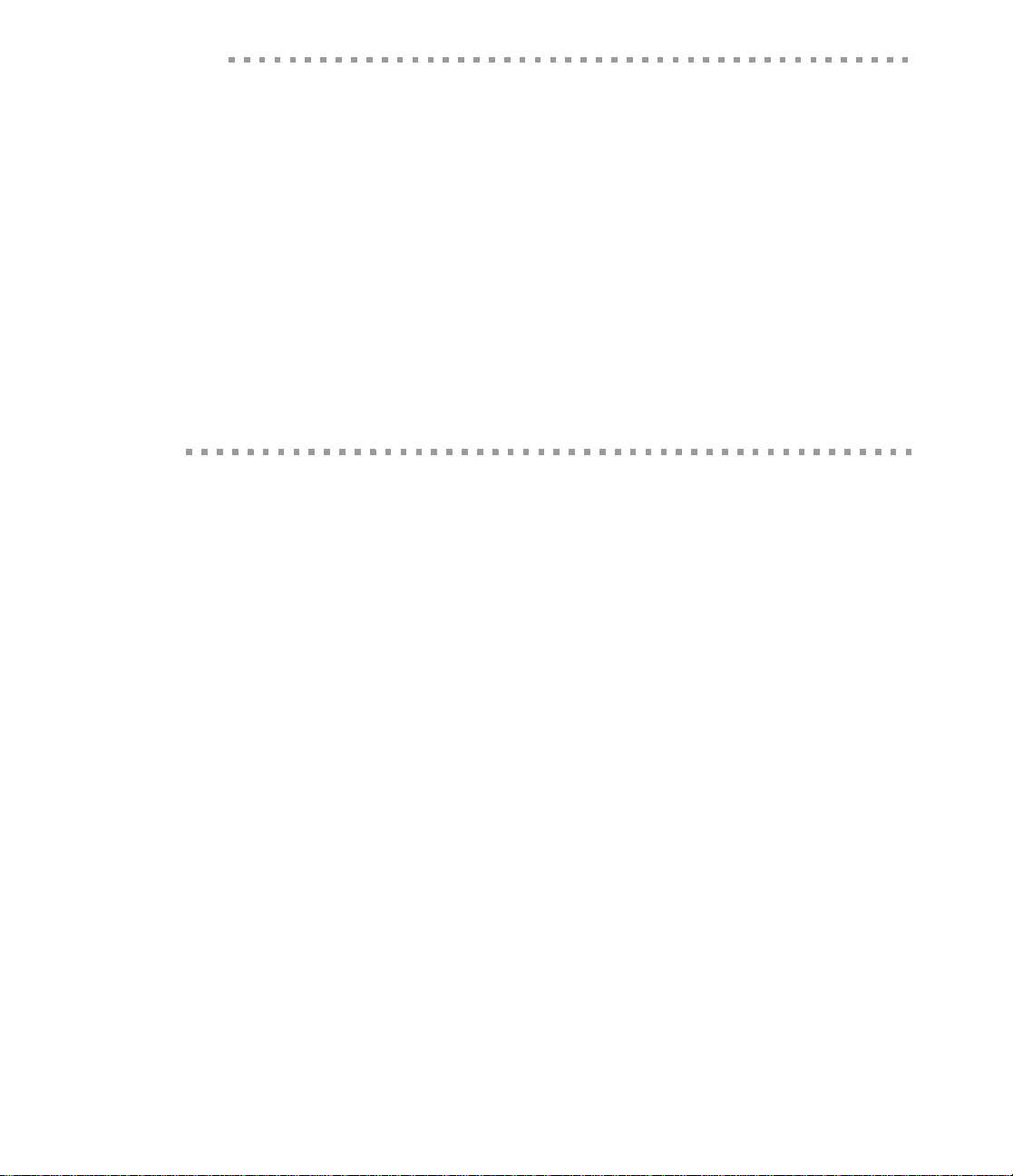

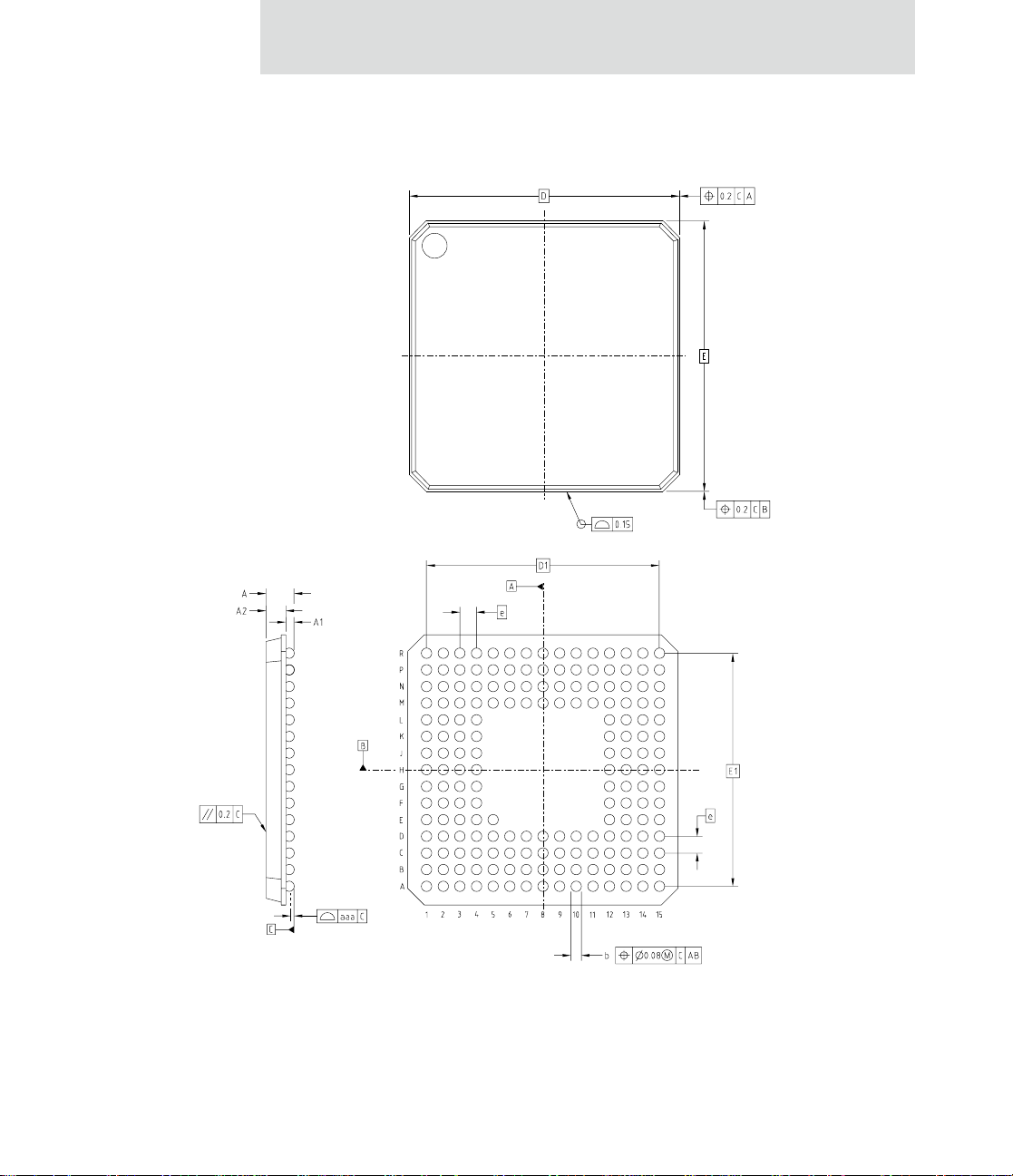

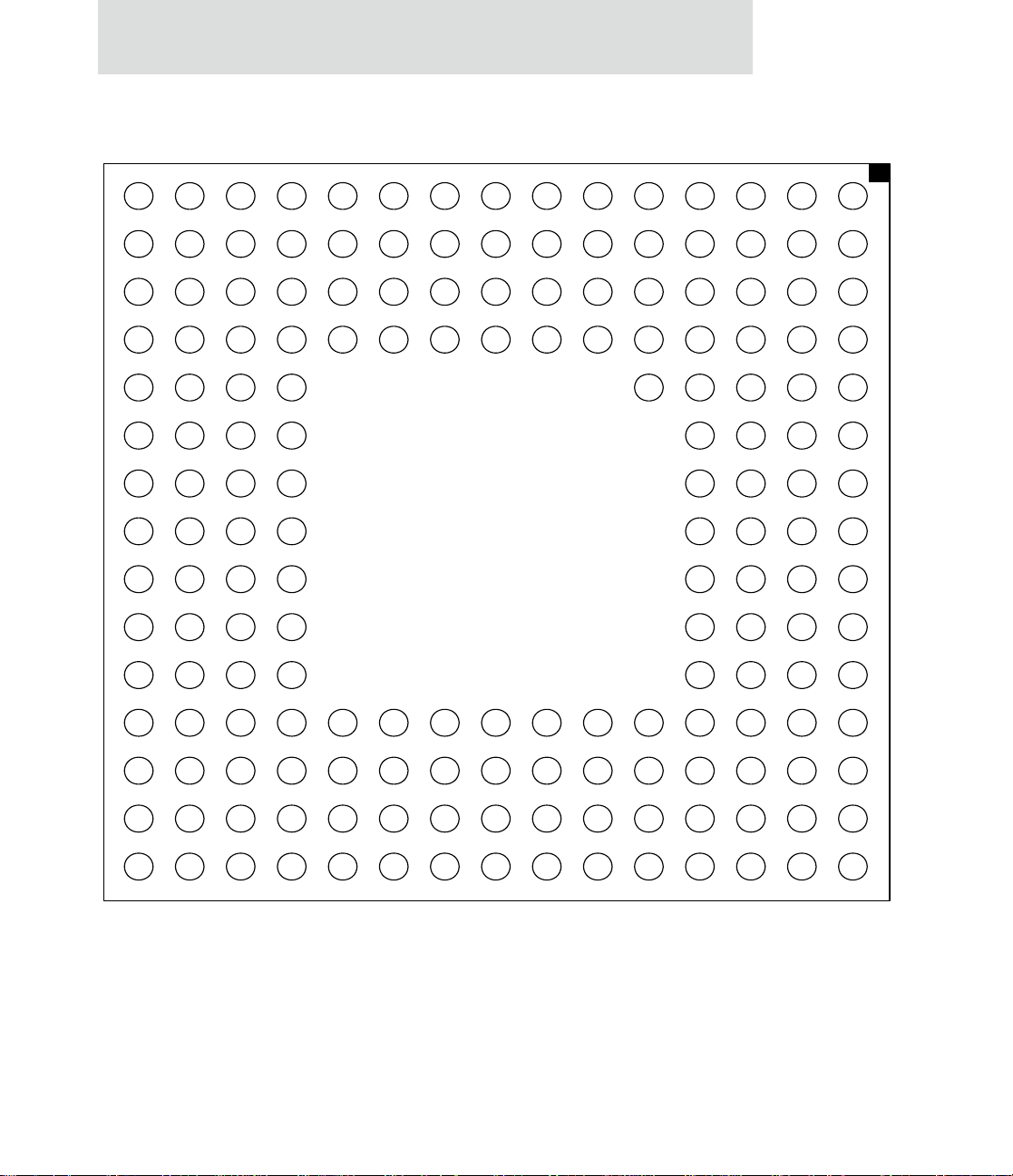

Table 1 provides the NS7520 packaging dimensions. Figure 2 shows the pinout and

NS7520 dimensions. Figure 3 shows the NS7520 BGA layout.

Symbol Min Nom Max

A——1.4

A1 0.35 0.40 0.45

A2——0.95

b 0.45 0.50 0.55

D 13.0 BSC

D1 11.2 BSC

E 13.0 BSC

E1 11.2 BSC

e 0.8 BSC

aaa 0.1

Table 1: NS7520 packaging dimensions

8

NS7520 Hardware Reference, Rev. D 03/2006

Page 23

177 PFBGA

Pinout and Packaging

Figure 2: NS7520 pinout and dimensions

www.digi.com

9

Page 24

Packaging

R

P1

R1

A0

A3

R2

P2

A6

GNDPY1

R3

P3 B3

VCCPY2

A7

R4

P4

GNDPY2

A8

P5

R5

VCCPY3

VDDC01

GNDPY11

RESV2+

XTALB2

A10

R6

A13

A15

R7

A17

GNDPY3

R8

A19

R9

VSSC01

A22

R10

P10

A26/0WE_ A27/0OE_

A24

P11

R11

NC2

R12

NC4

RESV1-

P13

R13

NC6

R14

P14

NC5

VSSOSC1

P15

R15

TCK

P6

P7

P8

P9

P

N

N1

D31

N2

A1

N3

VCCPY1

N4

A4

N5

A9

N6

A12

N7

A16

N8

A20

N9

A23

N10

N11

NC3

N12

XTALB1

N13

OSCVCC1

N14

TDI

N15 L15

PLLTST_

M

M1

D30

M2

VCCPY4

M3

A2

M4

A5

M5

A11

M6

A14

M7

A18

M8

GNDPY4

M9

A21

M10

A25

M11

NC1

M12

TMS

M13

TDO

M14

TRST_

M15

BISTEN_

L

L1

L2

D28

L3

D29

L4

D27

L12

PLLVSS

L13

SCANEN_

L14

VDDC02

PLLVDD

E

K

K1

D23

D20

K2 D2

D24

D22

K3

D21

D25

K4

VCCPY5

GNDPY5

H

J

H1

J1

D14

D17

H2 C2

J2

D16

D12

H3

J3

D19

D13

H4

J4

D15

D18

F

G

G1

GNDPY13

G2

D10

G3

G4

D9

D11

F1

F2

F3

F4

E1

D8

E2

D7

E3

D6

E4

VCCPY8

E5

GUIDE PIN

NS7520, 177 PFBGA

Top View, Balls Facing Down

V1.0

K12

XTAL2

K13

VSSC02

K14

XTAL1

K15

GNDPY12

J12

PORTA4

J13

PORTA6

PORTA7

J15

PORTA5

H12

H13

PORTA1

H14

VCCPY6

H15

PORTA3

G12

PORTA0

G13

PORTC7

G14

PORTC6

G15

GNDPY6

PORTC4

PORTC3

VCCPY7

PORTC5

F12

F13

F14

F15

E12

PORTC1

E13

GNDPY7

E14

PORTC0

E15

PORTC2

C

D

D1

D5

GNDPY8

D3 A3

OSCVCC2

D1

D4

D2

CAS2_

D5

CS2_

CS0_

D6

RW_

WE_

D7

BR_

BG_

D8

TEA_

TA_

D9

BE1_

BE3_

D10

C10

MDC

TXCLK

D11

C11

GNDPY14

TXD1

C12

D12

RXCRS

RXCLKPORTA2

D13

C13

VDDC04

VSSC04

C14

D14

VDDC03

RXD3

C15

D15

RXDV

RXER

B

B1

C1

D3D26

D4

B2

D0

VSSOSC2

C3

CAS1_

C4

B4

CS4_

C5

B5

CS1_

C6

B6

OE_

C7

B7

BUSY_

B8

C8

VCCPY10

B9

C9

BE0_

B10

MDIO

B11

TXD2

B12

TXEN

B13

RXD0

B14

VSSC03

B15

RXD2

A

A1

CAS3_

A2

CAS0_

VCCPY9

A4

CS3_

A5

GNDPY9

A6

BCLK

A7

GNDPY10

A8

TS_

A9

BE2_

A10

RESET_

A11

TXD0

A12P12

TXD3

A13

TXER

A14J14

TXCOL

A15

RXD1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Figure 3: NS7520 BGA layout

10

NS7520 Hardware Reference, Rev. D 03/2006

Page 25

Pinout detail tables and signal descriptions

Each pinout table applies to a specific interface and contains the following

information:

Column Description

Signal The pin name for each I/O signal. Some signals have multiple function modes and

are identified accordingly. The mode is configured through firmware using one or

more configuration registers.

Pin The pin number assignment for a specific I/O signal.

U next to the pin number indicates that the pin is a pullup resistor (input

current source).

D next to the pin number indicates that the pin is a pulldown resistor (input

current sink).

No value next to the pin indicates that the pin has neither a pullup nor

pulldown resistor.

See Figure 28, "Internal pullup characteristics," on page 264 and Figure 29,

"Internal pulldown characteristics," on page 264 for an illustration of the

characteristics of these pins. Use the figures to select the appropriate value of the

complimentary resistor to drive the signal to the opposite logic state. For those

pins with no pullup or pulldown resistor, you must select the appropriate value per

your design requirements.

Pinout and Packaging

_ An underscore (bar) indicates that the pin is active low.

I/O The type of signal — input, output, or input/output.

OD The output drive strength of an output buffer. The NS7520 uses one of three

drivers:

2 mA

4 mA

8 mA

Notes:

NO CONNECT as a description for a pin means do not connect to this pin.

The 177th pin (package ball) is for alignment of the package on the PCB.

www.digi.com

11

Page 26

Pinout detail tables and signal descriptions

System bus interface

Symbol Pin I/O OD Description

BCLK A6 O 8 Synchronous bus clock

External bus Other External bus Other

ADDR27 CS0OE_ N10 U I/O 4 Addr bit 27 Logical AND of CS0_

ADDR26 CS0WE_ P10 U I/O 4 Addr bit 26 Logical AND of CS0_

External bus External bus

ADDR25 M10 U I/O 4 Remainder of address bus (through

ADDR24 R10 U I/O 4

ADDR23 N9 U I/O 4

ADDR22 R9 U I/O 4

ADDR21 M9 U I/O 4

and OE_

and WE_

ADDR0)

ADDR20 N8 U I/O 4

ADDR19 P8 U I/O 4

ADDR18 M7 U I/O 4

ADDR17 R7U I/O 4

ADDR16 N7 U I/O 4

ADDR15 R6 U I/O 4

ADDR14 M6 U I/O 4

ADDR13 P6 U I/O 4

ADDR12 N6 U I/O 4

ADDR11 M5 U I/O 4

ADDR10 P5 U I/O 4

ADDR9 N5 U I/O 4

ADDR8 R4 U I/O 4

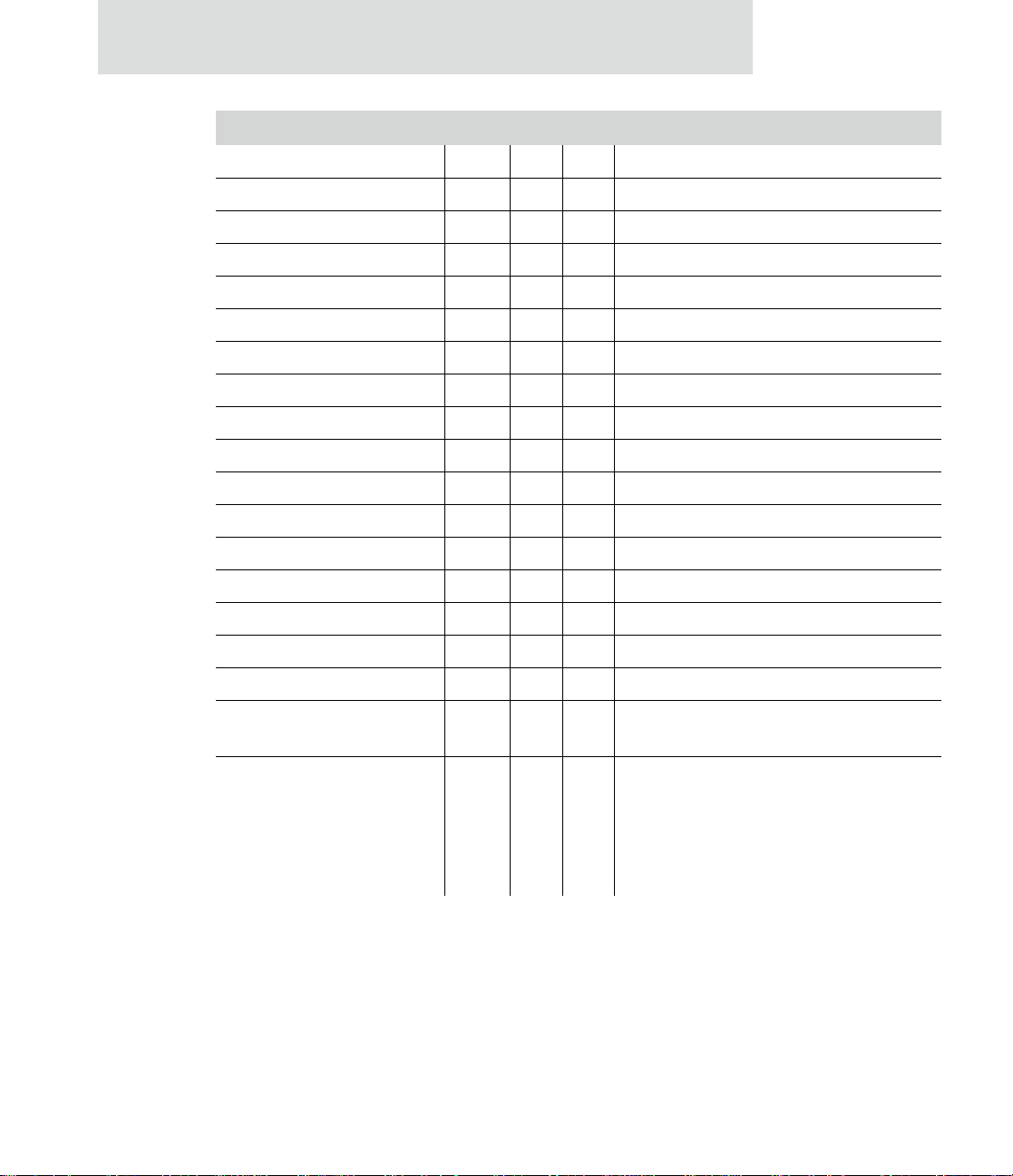

Table 2: System bus interface pinout

12

NS7520 Hardware Reference, Rev. D 03/2006

Page 27

Symbol Pin I/O OD Description

ADDR7 R3 U I/O 4

ADDR6 R2 U I/O 4

ADDR5 M4 U I/O 4

ADDR4 N4 U I/O 4

ADDR3 R1 U I/O 4

ADDR2 M3 U I/O 4

ADDR1 N2 U I/O 4

ADDR0 P1 U I/O 4

DATA31 N1 I/O 4 Data bus

DATA30 M1 I/O 4

DATA29 L3 I/O 4

DATA28 L2 I/O 4

DATA27 L4 I/O 4

DATA26 L1 I/O 4

Pinout and Packaging

DATA25 K3 I/O 4

DATA24 K2 I/O 4

DATA23 K1 I/O 4

DATA22 J2 I/O 4

DATA21 J3 I/O 4

DATA20 J1 I/O 4

DATA19 H3 I/O 4

DATA18 H4 I/O 4

DATA17 H1 I/O 4

DATA16 H2 I/O 4

DATA15 G4 I/O 4

DATA14 G1 I/O 4

DATA13 G3 I/O 4

Table 2: System bus interface pinout

www.digi.com

13

Page 28

Pinout detail tables and signal descriptions

Symbol Pin I/O OD Description

DATA12 G2 I/O 4

DATA11 F4 I/O 4

DATA10 F2 I/O 4

DATA9 F3 I/O 4

DATA8 E1 I/O 4

DATA7 E2 I/O 4

DATA6 E3 I/O 4

DATA5 D1 I/O 4

DATA4 C1 I/O 4

DATA3 B1 I/O 4

DATA2 D4 I/O 4

DATA1 D3 I/O 4

DATA0 C2 I/O 4

BE3_ D9 I/O 2 Byte enable D31:D24

BE2_ A9 I/O 2 Byte enable D23:D16

BE1_ C9 I/O 2 Byte enable D15:D08

BE0_ B9 I/O 2 Byte enable D07:D00

TS_ A8 U I/O 4 DO NOT USE

TA_ D8 U I/O 4 Data transfer acknowledge

Table 2: System bus interface pinout

14

Add an external 820 ohm pullup to 3.3 V.

Add an external 820 ohm pullup to 3.3 V.

TA_ is bidirectional. It is used in input

mode to terminate a memory cycle

externally. It is used in output mode for

reference purposes only.

NS7520 Hardware Reference, Rev. D 03/2006

Page 29

Pinout and Packaging

Symbol Pin I/O OD Description

TEA_ C8 U I/O 4 Data transfer error acknowledge

Add an external 820 ohm pullup to 3.3 V.

TEA_ is bidirectional. It is used in input

mode to terminate a memory cycle

externally. It is used in output mode for

reference purposes only.

RW_ D6 I/O 2 Transfer direction

BR_ D7 NO CONNECT

BG_ C7 NO CONNECT

BUSY_ B7 NO CONNECT

Table 2: System bus interface pinout

Signal descriptions

Mnemonic Signal Description

BCLK Bus clock Provides the bus clock. All system bus interface

signals are referenced to the BCLK signal.

ADDR[27:0] Address bus Identifies the address of the peripheral being

addressed by the current bus master. The address

bus is bi-directional.

DATA[31:0] Data bus Provides the data transfer path between the

NS7520 and external peripheral devices. The data

bus is bi-directional.

Recommendation: Less than x32 (S)DRAM/SRAM

memory configurations. Unconnected data bus

pins will float during memory read cycles. Floating

inputs can be a source of wasted power.

For other than x32 DRAM/SRAM configurations,

the unused data bus signals should be pulled up.

TS_ Transfer start NO CONNECT

BE_ Byte enable Identifies which 8-bit bytes of the 32-bit data bus

are active during any given system bus memory

cycle. The BE_ signals are active low and

bi-directional.

Table 3: System bus interface signal description

www.digi.com

15

Page 30

Pinout detail tables and signal descriptions

Mnemonic Signal Description

TA_ Transfer acknowledge Indicates the end of the current system bus

memory cycle. This signal is driven to 1 prior to

tri-stating its driver.

TA_ is bi-directional.

TEA_ Transfer error

RW_ Read/write indicator Indicates the direction of the system bus memory

BR_ Bus request NO CONNECT

BG_ Bus grant NO CONNECT

BUSY_ Bus busy NO CONNECT

Table 3: System bus interface signal description

Chip select controller

acknowledge

Indicates an error termination or burst cycle

termination:

In conjunction with TA_ to signal the end of a

burst cycle.

Independently of TA_ to signal that an error

occurred during the current bus cycle. TEA_

terminates the current burst cycle.

This signal is driven to 1 prior to tri-stating its

driver.

TEA_ is bi-directional. The NS7520 or the external

peripheral can drive this signal.

cycle. RW_ high indicates a read operation; RW_

low indicates a write operation. The RW_ signal is

bi-directional.

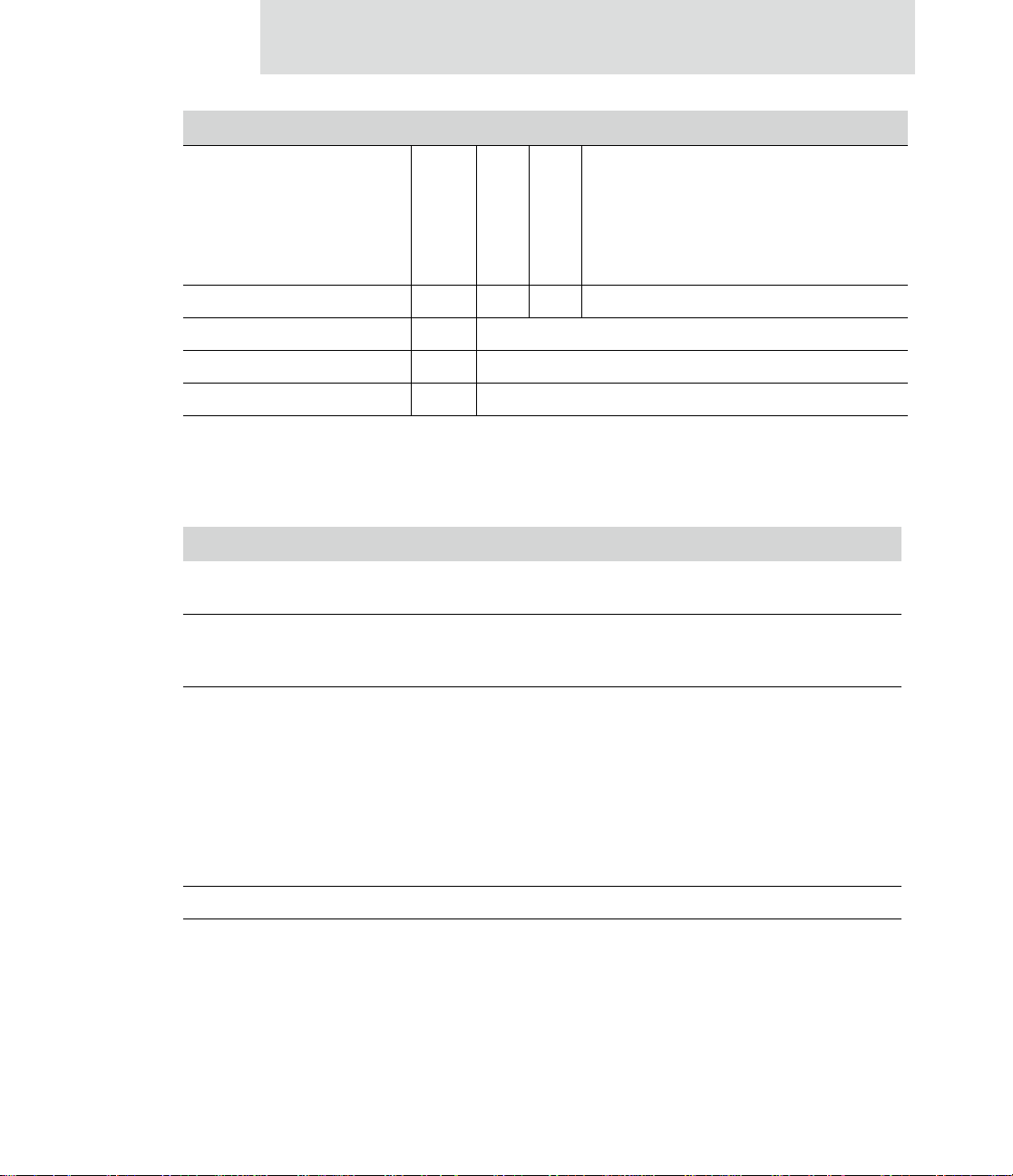

The NS7520 supports five unique chip select configurations:

Symbol Pin I/O OD Description

CS4_ B4 O 4 Chip select/DRAM RAS_

CS3_ A4 O 4 Chip select/DRAM RAS_

CS2_ C5 O 4 Chip select/DRAM RAS_

CS1_ B5 O 4 Chip select/DRAM RAS_

Table 4: Chip select controller pinout

16

NS7520 Hardware Reference, Rev. D 03/2006

Page 31

Pinout and Packaging

Symbol Pin I/O OD Description

CS0_ D5 O 4 Chip select (boot select)

CAS3_ A1 O 4 FP/EDO DRAM column strobe

D31:D24/SDRAM RAS_

CAS2_ C4 O 4 FP/EDO DRAM column strobe

D23:D16/SDRAM CAS_

CAS1_ B3 O 4 FP/EDO DRAM column strobe

D15:D08/SDRAM WE_

CAS0_ A2 O 4 FP/EDO DRAM column strobe

D07:D00/SDRAM A10(AP)

WE_ C6 O 4 Write enable for NCC Ctrl’d cycles

OE_ B6 O 4 Output enable for NCC Ctrl’d cycles

Table 4: Chip select controller pinout

Signal descriptions

Mnemonic Signal Description

CS0_

CS1_

CS2_

CS3_

CS4_

Chip select 0

Chip select 1

Chip select 2

Chip select 3

Chip select 4

Unique chip select outputs supported by the

NS7520. Each chip select can be configured to

decode a portion of the available address space

and can address a maximum of 256 Mbytes of

address space. The chip selects are configured

using registers in the memory module.

A chip select signal is driven low to indicate the

end of the current memory cycle. For FP/EDO

DRAM, these signals provide the RAS signal.

Table 5: Chip select controller signal description

www.digi.com

17

Page 32

Pinout detail tables and signal descriptions

Mnemonic Signal Description

CAS0_

CAS1_

CAS2_

CAS3_

WE_ Write enable Active low signal that indicates that a memory

OE_ Output enable Active low signal that indicates that a memory read

Table 5: Chip select controller signal description

Ethernet interface MAC

Column address strobe

signals

Activated when an address is decoded by a chip

select module configured for DRAM mode. The

CAS_ signals are active low and provide the

column address strobe function for DRAM devices.

The CAS_ signals also identify which 8-bit bytes of

the 32-bit data bus are active during any given

system bus memory cycle.

For SDRAM, CAS[3:1]_ provides the SDRAM

command field. CAS0_ provides the

auto-precharge signal.

For non-DRAM settings, these signals are 1.

write cycle is in progress. This signal is activated

only during write cycles to peripherals controlled

by one of the chip selects in the memory module.

cycle is in progress. This signal is activated only

during read cycles from peripherals controlled by

one of the chip selects in the memory module.

Note:

In this table, GP designates general-purpose.

Symbol Pin I/O OD Description

MII ENDEC MII ENDEC

MDC GP output D10 O 2 MII

MDIO GP output B10 U I/O 2 MII data State of UTP_STP bit

TXCLK C10 I TX clock

Table 6: Ethernet interface MAC pinout

18

ENDEC values for general-purpose output and TXD refer to bits in the

Ethernet General Control register. ENDEC values for general-purpose input

and RXD refer to bits in the Ethernet General Status register.

State of (LPBK bit XOR

management

clock

NS7520 Hardware Reference, Rev. D 03/2006

(Mode=SEEQ))

Page 33

Pinout and Packaging

Symbol Pin I/O OD Description

TXD3 GP output A12 O 2 TX data 3 State of AUI_TP[0] bit

TXD2 GP output B11 O 2 TX data 2 State of AUI_TP[1] bit

TXD1 GP output D11 O 2 TX data 1 Inverted state of PDN

bit, open collector

TXD0 TXD A11 O 2 TX data 0 Transmit data

TXER GP output A13 O 2 TX code error State of LNK_DIS_ bit

TXEN B12 O 2 TX enable

TXCOL A14 I Collision

RXCRS D12 I Carrier sense

RXCLK C12 I RX clock

RXD3 GP input D14 I RX data 3 Read state in bit 12

RXD2 GP input B15 I RX data 2 Read state in bit 15

RXD1 GP input A15 I RX data 1 Read state in bit 13

RXD0 RXD B13 I RX data 0 Receive data

RXER GP input C15 I RX error Read state in bit 11

RXDV GP input D15 I RX data valid Read state in bit 10

Table 6: Ethernet interface MAC pinout

Signal descriptions

The Ethernet MII (media independent interface) provides the connection between the

Ethernet PHY and the MAC (media access controller).

Mnemonic Signal Description

MDC MII management clock Provides the clock for the MDIO serial data

channel. The MDC signal is an NS7520 output.

The frequency is derived from the system

operating frequency per the CLKS field setting (see

the CLKS field in Table 69: "MII Management

Configuration register bit definition" on page 191).

Table 7: Ethernet interface MAC signal description

www.digi.com

19

Page 34

Pinout detail tables and signal descriptions

Mnemonic Signal Description

MDIO Management data IO A bi-directional signal that provides a serial data

TXCLK T ransmit clock An input to the NS7520 from the external PHY

channel between the NS7520 and the external

Ethernet PHY module.

module. TXCLK provides the synchronous data

clock for transmit data.

TXD3

TXD2

TXD1

TXD0

Transmit data signals Nibble bus used by the NS7520 to drive data to the

external Ethernet PHY. All transmit data signals are

synchronized to TXCLK.

In ENDEC mode, only TXD0 is used for transmit

data.

TXER Transmit coding error Output asserted by the NS7520 when an error has

occurred in the transmit data stream.

TXEN Transmit enable Asserted when the NS7520 drives valid data on

the TXD outputs. This signal is synchronized to

TXCLK.

COL Transmit collision Input signal asserted by the external Ethernet PHY

when a collision is detected.

CRS Receive carrier sense Asserted by the external Ethernet PHY whenever

the receive medium is non-idle.

RXCLK Receive clock An input to the NS7520 from the external PHY

module. The receive clock provides the

synchronous data clock for receive data.

RXD3

RXD2

RXD1

RXD0

Receive data signals Nibble bus used by the NS7520 to input receive

data from the external Ethernet PHY. All receive

data signals are synchronized to RXCLK.

In ENDEC mode, only RXD0 is used for receive

data.

RXER Receive error Input asserted by the external Ethernet PHY when

RXDV Receive data valid Input asserted by the external Ethernet PHY when

Table 7: Ethernet interface MAC signal description

20

the Ethernet PHY encounters invalid symbols from

the network.

the PHY drives valid data on the RXD inputs.

NS7520 Hardware Reference, Rev. D 03/2006

Page 35

“No connect” pins

Pin Description

Pinout and Packaging

R13 Tie to V

P12 Tie to V

N12 XTALB1: Tie to V

R15 XTALB2: NO CONNECT

M11 NO CONNECT

P11 NO CONNECT

N11 NO CONNECT

R12 NO CONNECT

R14 NO CONNECT

P13 NO CONNECT

Table 8: “No connect” pins

General-purpose I/O

GPIO

signal

PORTA7 TXDA J14 U I/O 2 Channel 1 TXD

Serial

signal

CC

CC

Other

signal

CC

Pin I/O OD

Serial channel

description

Other

description

PORTA6 DTRA_ DREQ1_ J13 U I/O 2 Channel 1

DTR_

PORTA5 RTSA_ J15 U I/O 2 Channel 1

RTS_

PORTA4 RXCA/

RIA_/

OUT1A_

J12 U I/O 2 Pgm’able Out/

Channel 1

RXCLK/

Channel 1 ring

signal/Channel

1 SPI clock

(CLK)

Table 9: GPIO pinout

www.digi.com

DMA channel

3/5 Req

21

Page 36

Pinout detail tables and signal descriptions

GPIO

signal

Serial

signal

Other

signal

Pin I/O OD

Serial channel

description

Other

description

PORTA3 RXDA DACK1_ H15 U I/O 2 Channel 1 RXD DMA channel

3/5 ACK

PORTA2 DSRA_ AMUX H12 U I/O 2 Channel 1

DSR_

PORTA1 CTSA_ DONE1_

(O)

PORTA0 TXCA/

DONE1_ (I) G12 U I/O 2 Pgm’able Out/

OUT2A_/

DCDA_

H13 U I/O 2 Channel 1

CTS_

Channel 1

DCD/Channel 1

DRAM addr

mux

DMA channel

3/5 DONE_Out

DMA channel

3/5 DONE_In

SPI enable

(SEL_)/Channel

1 TXCLK

PORTC7 TXDB G13 U I/O 2 Channel 2 TXD GEN interrupt

out

PORTC6 DTRB_ DREQ2_ G14 U I/O 2 Channel 2

DTR_

PORTC5 RTSB_ REJECT_ F15 U I/O 2 Channel 2

DMA channel

4/6 Req

CAM reject

RTS_

PORTC4 RXCB/RIB_/

OUT1B_

RESET_ F12 U I/O 2 Pgm’able Out/

Channel 2

RXCLK/

Channel 2 ring

RESET output

See Note 1

following this

table.

signal/Channel

2 SPI clock

(CLK)

PORTC3

RXDB LIRQ3/

DACK2_

F13 U I/O 2 Channel 2 RXD Level sensitive

IRQ/DMA

2

channel 4/6

ACK

PORTC2

DSRB_ LIRQ2/

RSPF_

E15 U I/O 2 Channel 2

DSR_

Level sensitive

IRQ/CAM

2

request

PORTC1

CTSB_ LIRQ1/

DONE2_

(O)

E12 U I/O 2 Channel 2

CTS_

Level sensitive

IRQ/DMA

channel 4/6

2

DONE_out

Table 9: GPIO pinout

22

NS7520 Hardware Reference, Rev. D 03/2006

Page 37

Pinout and Packaging

GPIO

signal

PORTC02TXCB/

Serial

signal

OUT2B_/

DCDB_

Other

signal

LIRQ0/

DONE2_(I)

Serial channel

Pin I/O OD

E14 U I/O 2 Pgm’able Out/

description

Channel 2

DCD/Channel 2

SPI enable

(SEL_)/Channel

2 TXCLK

Other

description

Level sensitive

IRQ/DMA

channel 4/6

DONE_in

Table 9: GPIO pinout

Notes:

1 RESET output indicates the reset state of the NS7520. PORTC4 persists beyond

the negation of RESET_ for approximately 512 clock cycles if the PLL is dis abled.

When the PLL is enabled, PORTC4 persists beyond the negation of RESET_ to

allow for PLL lock for 100 microseconds times the ratio of the VCO to XTALA.

Note that this GPIO is left in output mode active following a hardware

RESET.

2 *PORTC[3:0] pins provide level-sensitive interrupts. The inputs do not need to

be synchronous to any clock. The interrupt remains active until cleared by a

change in the input signal level.

Signal descriptions

See Chapter 6, "GEN Module," for signal and configuration information for PORTA and

PORTC.

www.digi.com

23

Page 38

Pinout detail tables and signal descriptions

System clock and reset

Symbol Pin I/O OD Description

XTALA1 K14 I ARM/system oscillator circuit

XTALA2 K12 O

PLLVDD (1.5V) L15 P PLL clean power

PLLVSS L12 P PLL return

RESET_ A10 I System reset

Table 10: System clock pinout

Signal descriptions

The NS7520 has three clock domains:

System clock (SYSCLK)

Bit rate generation and programmable timer reference clock (XTALA1/2)

System bus clock (BCLK)

The SYS module provides the NS7520 with these clocks, as well as system reset and

backup resources.

Mnemonic Signal Description

XTALA1

XTALA2

PLLVDD

PLLVSS

RESET_ System reset Resets the NS7520 hardware.

Table 11: Clock generation and reset signal d escription

24

Oscillator input

Oscillator output

Clean PLL power

Connect directly to the

GND plane

NS7520 Hardware Reference, Rev. D 03/2006

A standard parallel quartz crystal or crystal

oscillator can be attached to these pins to provide

the main input clock to the NS7520.

Power and ground for PLL circuit.

Page 39

Pinout and Packaging

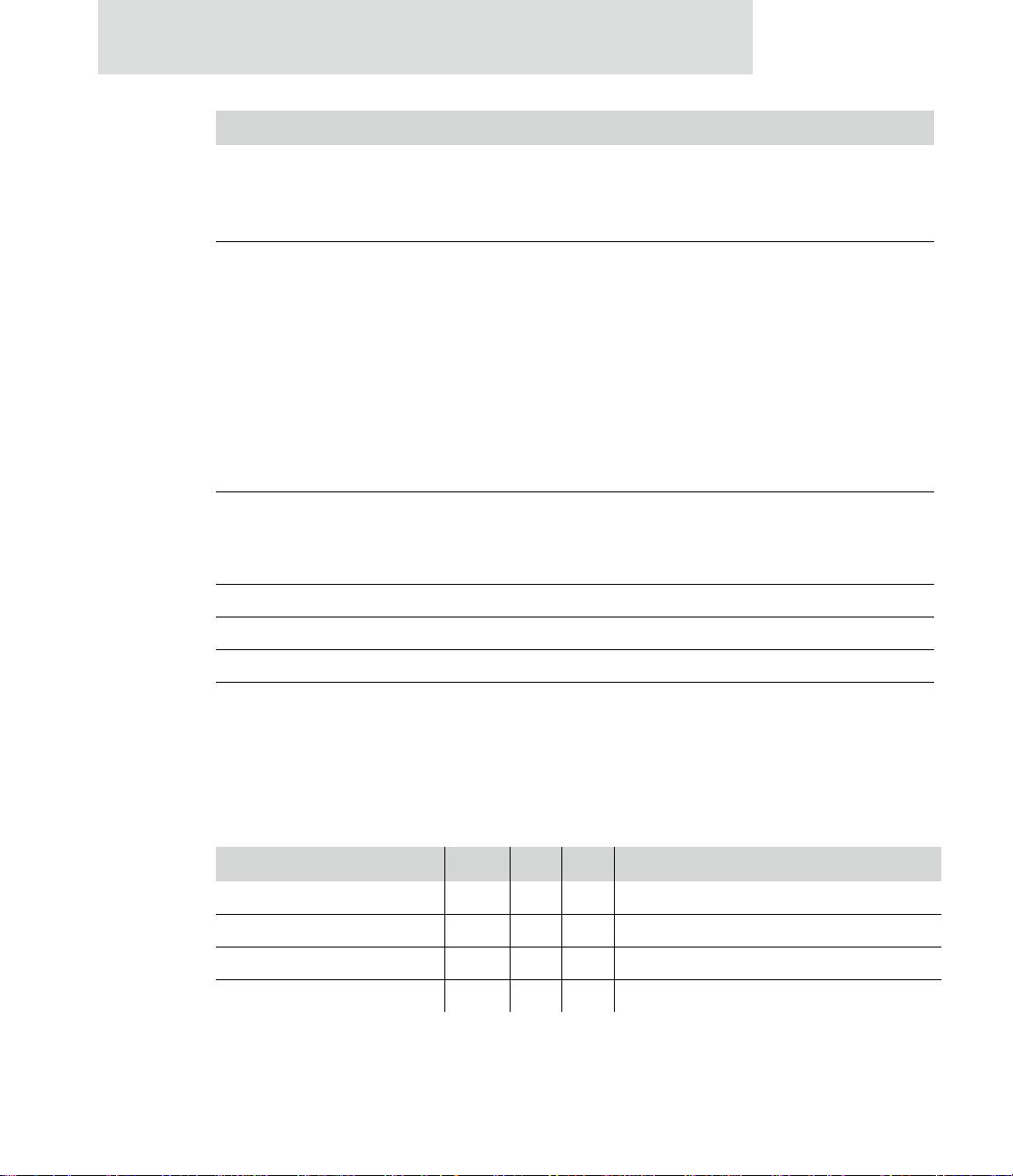

This figure shows the timing and specification for RESET_ rise/fall times:

tF tR

tF max = 18ns

V in = 2.0V to 0.8V

System mode (test support)

PLLTST_, BISTEN_, and SCANEN_ primary inputs control differen t test modes for both

functional and manufacturing test operations. See Chapter 5, "SYS Module," for more

information.

Symbol Pin I/O OD Description

PLLTST_ N15 I Encoded with BISTEN_ and SCANEN_

BISTEN_ M15 I Encoded with PLLTST_ and SCANEN_

SCANEN_ L13 I Encoded with BISTEN_ and PLLTST_

Table 12: System mode and system reset pinout

tR max = 18ns

V in = 0.8V to 2.0V

Add an external pullup to 3.3V or

pulldown to GND.

Add an external pullup to 3.3V or

pulldown to GND.

Add an external pullup to 3.3V or

pulldown to GND.

www.digi.com

25

Page 40

Pinout detail tables and signal descriptions

JTAG test (ARM debugger)

JTAG boundary scan allows a tester to check the soldering of all signal pins and tristate all outputs.

Symbol Pin I/O OD Description

TDI N14 U I Test data in

TDO M13 O 2 Test data out

TMS M12 U I Test mode select

TRST_ M14 I Test mode reset

TCK P15 I Test mode clock

Table 13: JTAG test pinout

Requires external termination when not

being used (see Figure 4, "TRST_

termination," on page 27 for an

illustration of the termination circuit on

the development PCB).

Add an external pullup to 3.3V.

Signal descriptions

Mnemonic Signal Description

TDI Test data in TDI operates the JTAG standard. Consult the

TDO Test data out TDO operates the JTAG standard. Consult the

TMS Test mode select TMS operates the JTAG standard. Consult the

Table 14: ARM debugger signal description

26

JTAG specifications for use in boundary-scan

testing. These signals meet the requirements of the

Raven and Jeeni debuggers.

JTAG specifications for use in boundary-scan

testing. These signals meet the requirements of the

Raven and Jeeni debuggers.

JTAG specifications for use in boundary-scan

testing. These signals meet the requirements of the

Raven and Jeeni debuggers.

NS7520 Hardware Reference, Rev. D 03/2006

Page 41

Pinout and Packaging

Mnemonic Signal Description

TRST_ Test mode reset TRST_ operates the JTAG standard. Consult the

JTAG specifications for use in boundary-scan

testing. These signals meet the requirements of the

Raven and Jeeni debuggers.

TCK Test mode clock TCK operates the JTAG standard. Consult the

JTAG specifications for use in boundary-scan

testing. These signals meet the requirements of the

Raven and Jeeni debuggers.

Table 14: ARM debugger signal description

NS7520

Figure 4: TRST_ termination

www.digi.com

TRSTNS7520

27

Page 42

Pinout detail tables and signal descriptions

Power supply

Signal Pin Description

Oscillator VCC (3.3V) N13, C3 Oscillator power supply

Core VCC (1.5V) R8, L14, C14, C13 Core power supply

I/O VCC (3.3V) E4, K4, M2, N3, P3, R5, H14, F14, B8, A3I/O power supply

GND D2, F1, J4, P4, P7, M8, P9, R11, K15,

G15, E13, D13, B14, C11, A7, A5, B2,

P2, P14, K13

Ground

Table 15: Power supply pinout

See the DC and AC electrical specifications in Chapter 11, "Electrical Characteristics,"

for more information.

28

NS7520 Hardware Reference, Rev. D 03/2006

Page 43

Working with the CPU

CHAPTER 3

The CPU uses an ARM7TDMI core processor, which provides high performance while

maintaining low power consumption and small size. This chapter describes the ARM

Thumb concept and provides an overview of ARM exceptions and hardware interrupts.

29

Page 44

ARM Thumb concept

ARM Thumb concept

The ARM7TDMI processor uses a unique architectural strategy known as Thumb, which

makes the processor ideally suited to high-volume applications with memory

restrictions or applications for which code density is an issue.

Thumb code’s primary attribute is a super-reduced instruction set. The ARM7TDMI

processor has essentially two instruction sets:

Standard 32-bit ARM set

16-bit Thumb set

Thumb’s 16-bit instruction length allows it to approach twice the density of standard

ARM code while retaining most of the ARM’s performance advantage over a

traditional 16-bit processor using 16-bit registers. Thumb code operates on the same

32-bit register set as the ARM code, but consumes only 65% of the same code

compiled in ARM mode.

Thumb instructions operate with the standard ARM register configuration, allowing

interoperability between ARM and Thumb states. Each 16-bit Thumb instruction has a

corresponding 32-bit ARM instruction with the same effect on the processor model.

Thumb architecture provides a Thumb instruction decoder in front of the standard

32-bit ARM processor. The Thumb instruction decoder basically remaps each 16-bit

Thumb instruction into a 32-bit standard ARM instruction. The Thumb instruction set

typically requires 30% more instructions to perform the same task as 32-bit

instructions, but the Thumb instruction can fit twice as many instructions in the code

space. The net result is a 35% decrease in overall code density.

CPU performance

The ARM7TDMI core does not contain cache, and runs as fast as instructions can be

fetched. The performance rating for the ARM RISC depends on system bus speed and

cycle time. Performance is also affected by the size of the system bus and the type of

code (ARM or Thumb) being executed.

30

NS7520 Hardware Reference, Rev. D 03/2006

Page 45

Working with the CPU

The ARM instruction set yields a 0.9 Dhrystone (2.1) rating MIPS/MHz of instruction

executions; the Thumb instruction set yields 0.75 Dhrystones MIPS/MHz. The MHz

rating reflects the rate at which instructions can be fetched from external flash

memory, as shown in this table:

System bus

size Code style RISC speed

Thumb mode

16-bit Thumb 25 MHz 25 MHz 1 120 ns N/A

16-bit Thumb 25 MHz 25 MHz 0 80 ns N/A

16-bit Thumb 36 MHz 36 MHz 3 125 ns N/A

16-bit Thumb 46 MHz 46 MHz 4 109 ns N/A

16-bit Thumb 55 MHz 55 MHz 5 108 ns N/A

ARM mode

32-bit ARM 36 MHz 36 MHz 3 125 ns 6.8

32-bit ARM 46 MHz 46 MHz 4 109 ns 8.6

32-bit ARM 55 MHz 55 MHz 5 108 ns 10.4

System bus

speed

Wait

states

Instruction

cycle time

Dhrystone

rating

Table 16: ARM performance

Working with ARM exceptions

Exceptions occur when the normal flow of a program is halted temporarily; for

example, to service an interrupt from a peripheral. Each ARM exception causes the

ARM processor to save some state information, then jump to a location in low

memory (referred to as the vector table; see "Exception vector table" on page 33).

Before an exception can be handled, the current processor state must be preserved

so the original program can resume when the handler routine has finished.

www.digi.com

31

Page 46

Working with ARM exceptions

Summary of ARM exceptions

The ARM processor can be interrupted by any of seven basic exceptions:

Reset exception. After a reset condition, the ARM7TDMI saves the current

values of the PC (program counter) and CPSR (Current Processor Status

register).

Undefined exception. The ARM7TDMI takes the undefined instruction trap

when it finds an instruction it cannot handle.

SWI instruction. The ARM7TDMI uses the software interrupt instruction

(SWI) to enter supervisor mode, usually to request a specific supervisor

instruction.

Abort exception. An abort exception indicates that the current memory

access cannot be completed. There are two types of abort exception:

– Prefetch. Occurs during an instruction prefetch.

– Data. Occurs during a data operand access.

IRQ. An interrupt request (IRQ) exception is a normal interrupt serviced by

the ARM7TDMI controller.

FIRQ. A fast interrupt request (FIRQ) exception supports a data transfer or

channel process. An FIRQ interrupt is generated only by the GEN module

timers and watchdog timer.

Exception priorities

Several exceptions can occur at the same time. If this happens, a fixed-priority

system determines the order in which they are handled:

Highest priority

1 Reset

2 Data abort

3 FIRQ

4 IRQ

5 Prefetch abort

6 Undefined instruction, SWI

Lowest priority

32

NS7520 Hardware Reference, Rev. D 03/2006

Page 47

Not all exceptions can occur at the same time, however.

Undefined instructions and SWIs are mutually exclusive, as they each

correspond to particular (non-overlapping) decoding of the current

instruction.

If a data abort occurs at the same time as FIRQ and the FIRQ is enabled

(that is, the CPSR F flag is clear), the data abort takes priority. ARM7TDMI

enters the data abort handler and immediately goes to the FIRQ vector. A

normal return from FIRQ causes the data abort handler to resume

execution.

Placing data abort at a higher priority than FIRQ is necessary to ensure

that the transfer error does not escape detection. The time for this

exception entry should be added to worst-case FIRQ latency

calculations.

Exception vector table

All exceptions result in the ARM processor vectoring to an address in low memory,

using the exception vector table. The exception vector table always exists and always

starts at base address 0.

Working with the CPU

Vector

address

’h0 RESET Reset vector; for initialization and startup

’h4 Undefined Undefined instruction encountered

’h8 SWI Software interrupt; used for entry point into the kerne l

’hC Abort (prefetch) Bus error (no response or error) fetching instructions

’h10 Abort (data) Bus error (no response or error) fetching data

’h14 Reserved Reserved

’h18 IRQ Interrupt from ARM7TDMI interrupt controller

’h1C FIRQ Fast interrupt from ARM7TDMI controller

Vector Description

Table 17: Exception vector table

www.digi.com

33

Page 48

Working with ARM exceptions

All internal ARM7TDMI internal peripherals are presented to the CPU using the IRQ or

FIRQ interrupt inputs. The ARM can mask various ARM7TDMI peripheral interrupts at

the global level, using the ARM7TDMI interrupt controller. The ARM also can mask

interrupts at the micro-level, using configuration features with the peripheral

modules.

All IRQ interrupts are disabled when the I bit is set in the ARM CPSR. When the I bit is

cleared, those interrupts enabled in the ARM7TDMI interrupt controller can assert the

IRQ input to the ARM processor.

The ARM processor sets the I bit automatically when entering an interrupt service

routine (ISR), which disables recursive interrupts. The ISR’s first task is to read the

Interrupt Status register, which identifies all active sources for the IRQ interrupt.

Firmware sets the priorities for servicing interrupts at bootup, using the bits defined

in the Interrupt Status register.

Detail of ARM exceptions

Reset exception

A reset exception is the highest priority exception. When the ARM7TDMI is held in

reset, the processor abandons the executing instruction and cont inu es to fetch

instructions from incrementing word addresses.

When the ARM7TDMI is removed from reset, the processor performs these steps:

1 Overwrites R14_svc and SPSR_svc (Saved Processor Status register) by copying the

2 Forces the CPSR M field to 10011 (supervisor mode), sets the I and F bits in the

3 Forces the PC to fetch the next instruction from address ’h00.

4 Resumes execution in ARM state.

Undefined exception

When the ARM7TDMI encounters an instruction it cannot handle, it takes the

undefined instruction trap. The undefined instruction trap can extend either the

Thumb or ARM instruction set by software emulation.

34

current values of the PC and CPSR into them. The values of the saved PC and

SPSR are not defined.

CPSR, and clears the CPSR T bit (back to ARM mode).

NS7520 Hardware Reference, Rev. D 03/2006

Page 49

Working with the CPU

After emulating the failed instruction, t h e trap handler should execute the following

instruction irrespective of the state (Thumb or ARM):

MOVS PC, R14_und.

This instruction restores the PC and CPSR, and returns to the instruction following the

undefined instruction.

SWI exception

An SWI is used for entering supervisor mode, usually to request a particular supervisor

function. An SWI handler should return by executing this instruction irrespective of

the state (ARM or Thumb):

MOVS PC, R14_SVC.

This instruction restores the PC and CPSR, and returns to the instruction following the

SWI.

Abort exception

An abort indicates that the current memory access cannot be completed, and is

signaled by the external ABORT input. The ARM7TDMI checks for the abort exception

during memory access cycles.

There are two types of abort exception:

Prefetch abort. Occurs during an instruction prefetch. If a prefetch abort

occurs, the prefetch instruction is marked as invalid but the exception is

not taken until the instruction reaches the head of the pipeline. If the

instruction is not executed (for example, if a branch occurs while the

instruction is in the pipeline), the abort does not take place.

Data abort. Occurs during a data operand access. If a data abort occurs, the

action taken depends on the instruction type:

– Single data transfer instructions (LDR, STR) write back modified base

registers; the abort handler must be aware of this.

– A swap instruction (SWP) is aborted as though it had not been executed.

– Block data transfer instructions (LDM, STM) complete. If write-back is set,

the base is updated. If the instruction would have overwritten the base with

data (that is, the base is in the transfer list), the overwriting is prevented.

All register overwriting is prevented after an abort is indicated, which

means that

R15 (always the last register to be transferred) is preserved in an

aborted LDM instruction.

www.digi.com

35

Page 50

Working with ARM exceptions

The abort mechanism allows the implementation of a demand-paged virtual memory

system. In this type of system, the processor is allowed to generate arbitrary

addresses. When the data at an address is unavailable, the memory management unit

(MMU) signals an abort. The abort handler must then work out the cause of the abort,

make the requested data available, and retry the aborted instruction. The

application program needs no knowledge of the amount of memory available to it,

and its state is not affected by the abort.

The handler executes one of the following instructions, irrespective of the state (ARM

or Thumb), after fixing the cause of the abort:

For a prefetch abort: SUBS PC, R14_abt, #4

For a data abort: SUBS PC, R14_abt, #8

IRQ exception

An IRQ exception is a normal interrupt sourced by the ARM7TDMI interrupt controller.

IRQ has a lower priority than FIRQ, and is masked out when an FIRQ sequence is

entered. IRQ can be disabled at any time by setting the I bit in CPSR to 1; this can be

done only from privileged (non-user) mode.

The IRQ handler should leave the interrupt by executing the following instruction

irrespective of the state (ARM or Thumb):

FIRQ exception

An FIRQ exception supports a data transfer or channel process. In ARM state, FIRQ has

enough registers to remove the need for register saving, which minimizes context

switching overhead.

Only two peripherals can generate an FIRQ interrupt: the GEN module built-in timers

and the GEN module watchdog timer.

The FIRQ handler should leave the interrupt by executing the following instruction

irrespective of the state (ARM or THUMB):

The FIRQ interrupt can be disabled by setting the CPSR F flag to 1, only in non-user

mode. If the F flag is clear, the ARM7TDMI checks for a low level on the output of the

FIRQ synchronizer at the end of each instruction.

36

SUBS PC, R14_irq, #4.

SUBS PC, R14_firq, #4.

NS7520 Hardware Reference, Rev. D 03/2006

Page 51

Entering and exiting an exception (software action)

The ARM7TDMI performs specific steps when handling exceptions.

Entering an exception

When handling an exception, ARM7TDMI does this:

1 Preserves the address of the next instruction in the appropriate Link register.

– If the exception has been entered from the ARM state, the address of the

next instruction is copied into the Link register. The addr ess is either

current

"Exception entry/exit by exception type" on page 38.)

– If the exception has been entere d from Thumb state, the value written into

the Link register is the current PC offset by a value that lets the program

continue from the correct place on return from the exception.

The exception handler does not need to determine from which state the

exception was entered. With an SWI, for example,

returns to the next instruction whether executed in ARM or Thumb state.

PC + 4 or PC + 8, depending on the exception. (See Table 18:

Working with the CPU

MOVS PC, R14_SVC always

2 Copies the CPSR into the appropriate SPSR.

3 Forces the CPSR mode bits to a value that depends on the exception.

4 Forces the PC to fetch the next instruction from the relevant exception vector.

5 Sets the I (for IRQ interrupts) or F (for FIRQ interrupts) bits to disable interrupts

to prevent unmanageable nesting of exceptions .

Note:

If the processor is in Thumb state when an exception occurs, it

automatically switches into ARM state when the PC is loaded with the

exception vector address.

Exiting an exception

On completion, ARM7TDMI does this:

1 Moves the Link register, minus the offset where appropriate, to the PC. The

offset value varies depending on the type of exception.

2 Copies the SPSR back to the CPSR.

3 Clears the interrupt disable flags, if they were set on entry.

www.digi.com

37

Page 52

Working with ARM exceptions

Note:

An explicit switch back to Thumb state is never needed. Restoring the

CPSR from the SPSR automatically sets the T bit to the value it held

immediately before the exception.

Exception entry/exit summary

In the variable

R14_x, R14 is the Link register; _x is the previous state of the

processor.

Return/

exception Return instruction

BL

RESET NA NA NA 4

UNDEF

SWI

ABORT P

ABORT D

IRQ

FIRQ

MOV PC, R14

MOVS PC, R14_und

MOVS PC, R14_svc

SUBS PC, R14_abt, #4

SUBS PC, R14_abt, #8

SUBS PC, R14_irq, #4

SUBS PC, R14_firq, #4

Previous state

ARM R14_x

PC+4 PC+2 1

PC+4 PC+2 1

PC+4 PC+2 1

PC+4 PC+4 1

PC+8 PC+8 3

PC+4 PC+4 2

PC+4 PC+4 2

Previous state

Thumb R14_x Notes

Table 18: Exception entry/exit by exception type

Notes:

1

2 Where PC is the address of the instruction that was not executed since FIRQ or

3 Where PC is the address of the load or store instruction that generated the data

4 The value saved in R14_svc upon reset is unpredictable.

38

Where PC is the address of the BL/SWI/undefined in stru ction fetch th at had the

prefetch abort. BL is a branch with link instruction.

IRQ took priority.

abort.

NS7520 Hardware Reference, Rev. D 03/2006

Page 53

Hardware Interrupts

Two wires that go into the ARM7 CPU core can interrupt the processor:

IRQ (normal interrupt)

FIRQ (fast interrupt)

Although the interrupts are basically the same, FIRQ can interrupt IRQ.

FIRQ and IRQ lines

The FIRQ line adds a simple, two-tier priority scheme to the interrupt system. Most

sources of interrupts on the ARM7TDMI come from the IRQ line. The only potential

sources for FIRQ interrupts in the ARM7TDMI come from the two built-in timers and

the watchdog timer; there is no way to generate an FIRQ signal externally. These

timers are controlled by registers in the GEN module (see "Timer Control registers,"

beginning on page 70):

The built-in timers are controlled using the Timer Control registers

(’hFFB0 0010/18). The corresponding bit in the Interrupt Enable register

must be set for either IRQ or FIRQ to function.

Working with the CPU

The watchdog timer is controlled using the System Control register

(’hFFB0 0000).

Interrupt controller

Interrupts come from many different sources on the ARM7TDMI, and are managed by

the interrupt controller within the GE N module. Interrupts can be enable d or disabled

on a per-source basis using the Interrupt Enable register (’hFFB0 0030), which serves

as a mask for the interrupt sources and ultimately controls whether an interrupt from

an ARM7TDMI module can reach the IRQ line.

There are two read-only registers in the interrupt controller:

Interrupt Status Register Raw . Indicates the source of an ARM7TDMI

interrupt regardless of the state of the Interrupt Enable register. All

interrupts that are active in their respective module will be visible in the

Interrupt Status Register Raw.

www.digi.com

39

Page 54

Hardware Interrupts

Interrupt Status Register Enabled. Identifies the current state of all

interrupt sources that are enabled. This register is defined by performing a

logical AND of the Interrupt Status Register Raw and the Interrupt Enable

register. All bits in the Interrupt Status Register Enabled are ORed together.

The output is fed directly to the IRQ line, which then interrupts the ARM.

Interrupt sources

Each interrupt source is enabled and disabled within its respective module (and

submodule) within the NS7520 ASIC. The interrupt controller in the GEN module,

however, does not latch any of the interrupt signals.

Note:

Interrupt causes are latched in their respective submodule until cleared.

Interrupt sources include the following:

DMA interrupts. All [13] DMA channels, including the four sub-channels of

the Ethernet receiver, have five possible interrupt sources. See Chapter 8,

"DMA Module."

Ethernet receive and transmit interrupts. There are three interrupts for

Ethernet receive and four interrupts for Ethernet transmit; all interrupts

are part of the Ethernet General Status register. These interrupts are used

only when the Ethernet receiver and transmitter are in interrupt mode

rather than DMA mode. See Chapter 9, "Ethernet Module."

Serial interrupts. The Serial Channel Status register has many interrupt

sources. See Chapter 10, "Serial Controller Module."

Watchdog timer interrupts. When the watchdog timer expires, the system

can generate either an IRQ interrupt, an FIRQ interrupt, or a system reset.

The interrupt type and length of the timer are configured using the GEN

module System Control register. The watchdog is strobed using the Software

Service register. See Chapter 6, "GEN Module."

Timer 1 and Timer 2 interrupts. Tw o types of interrupts can be generated

by Timers 1 and 2. The interrupt type is configured in the Timer Control

register; the interrupt itself is contained within the Timer Status register.

See Chapter 6, "GEN Module."

40

NS7520 Hardware Reference, Rev. D 03/2006

Page 55

Working with the CPU